BCM2000

Bock Compressor Management

Operating instructions BCM2000

D

GB

F

E

engineering for a better world GEA Refrigeration Technologies

09794-05.2012-DGbFEI

1

Foreword

Dear Customer,

The BCM 2000 (Bock Compressor Management) has been developed by Bock. It constitutes a compact compressor monitoring unit with logical, simple functions. The unit can be used for early detection

of faults, to reduce damage and failures, and thus to increase the operating reliability and service life

of your refrigerating compressor or refrigerating machine. The unit has been designed and certifi ed

only for Bock hermetic compressors. It is located in the terminal box (instead of the motor protection

trigger device). All possible monitoring functions are connected and have been activated and tested in

the factory. Only the control voltage has to be connected and the unit integrated in the machine control

safety chain for it to be ready to operate.

Bock Kältemaschinen GmbH

Postfach 11 61

D-72632 Frickenhausen

Benzstr. 7

D-72636 Frickenhausen

Fon: +49 7022 9454-0

Fax: +49 7022 9454-137

mail@bock.de

www.bock.de

All we ask of you:

Please read the information summarised for you in

this manual before starting work.

It contains important instructions for safety, control, initial

commissioning and troubleshooting. In addition you will

fi nd information on spare parts and accessories.

Some instructions are identifi ed by special symbols:

WARNING! This symbol is used to indicate

that inaccurate compliance or total failure

to comply with the instructions could cause

injury to persons or damage to the compressor or refrigerating machine.

This symbol indicates important additional

instructions which you should observe

during your work.

The high quality standard of Bock compressors is guaranteed also by on-going further development of the design,

features and accessories. This could possibly result in

nonconformities between this present manual and your

unit. Please understand that it is not possible for any

claims to be derived from the details, illustrations and

descriptions.

Your team at

Bock Kältemaschinen GmbH

D

GB

F

E

GEA Bock GmbH

GEA Bock GmbH

Benzstraße 7

72636 Frickenhausen

Germany

Telephone +49 7022 9454 0

Fax +49 7022 9454 137

bock@gea.com

www.bock.de

2

GEA Bock GmbH

09794-05.2012-DGbFEI

3

D

GB

F

E

09794-05.2012-DGbFEI

Contents

Contents Page

Foreword 2

Safety instructions 4

Technical data 4

Structure / functions 4

Standart settings 6

Adjustable setting 6

Sensor details 6

Electrical connection 7

- General 7

- Connecting the unit 7

- Integration of additional switching and control components 9

Checking functions 9

Activating or bridging certain monitoring functions 10

Reset button 11

Error messages - information messages - emergency operation 11

- Temperature displays

- Oil pressure displays

- Compressor displays 1 3

- Surge guard displays 1 3

- Service displays 1 3

Spare parts and accessories 14

Troubleshooting 15

Legend:

LED on or ashes

LED off

12

12

D

Structure / functions

The BCM 2000 is used solely for monitoring the operation of BOCK refrigerating compressors. All

monitoring parameters have been coordinated exactly to the compressor connected up in the factory.

Incoming signals are detected as status, information or error messages and processed to release,

shutdown and reporting functions. The unit does not exercise any regulating function.

GB

F

E

Product description

Safety

Work on the BCM 2000 may only be carried out by persons whose technical training, skills and

experience together with their knowledge of pertinent regulations means that they are capable of

assessing the work to be carried out and detecting any possible dangers.

Safety instructions

CAUTION HIGH-VOLTAGE CURRENT!

Only qualied electricians are allowed to handle the unit.

The monitoring unit BCM 2000 is mounted in the compressor connection box. Although the

motor connection is covered, the machine must be disconnected from the mains before and

during all work and when testing the machine, otherwise there is a risk of injuries.

National safety regulations, accident prevention regulations, technical rules and other

specications must be observed.

Compare the voltage and frequency details with the data for the local electricity mains.

The unit may only be connected to the mains when the data coincide.

The terminals of the control unit must not come into contact with the mains voltage,

otherwise the unit and the monitoring sensors will be destroyed.

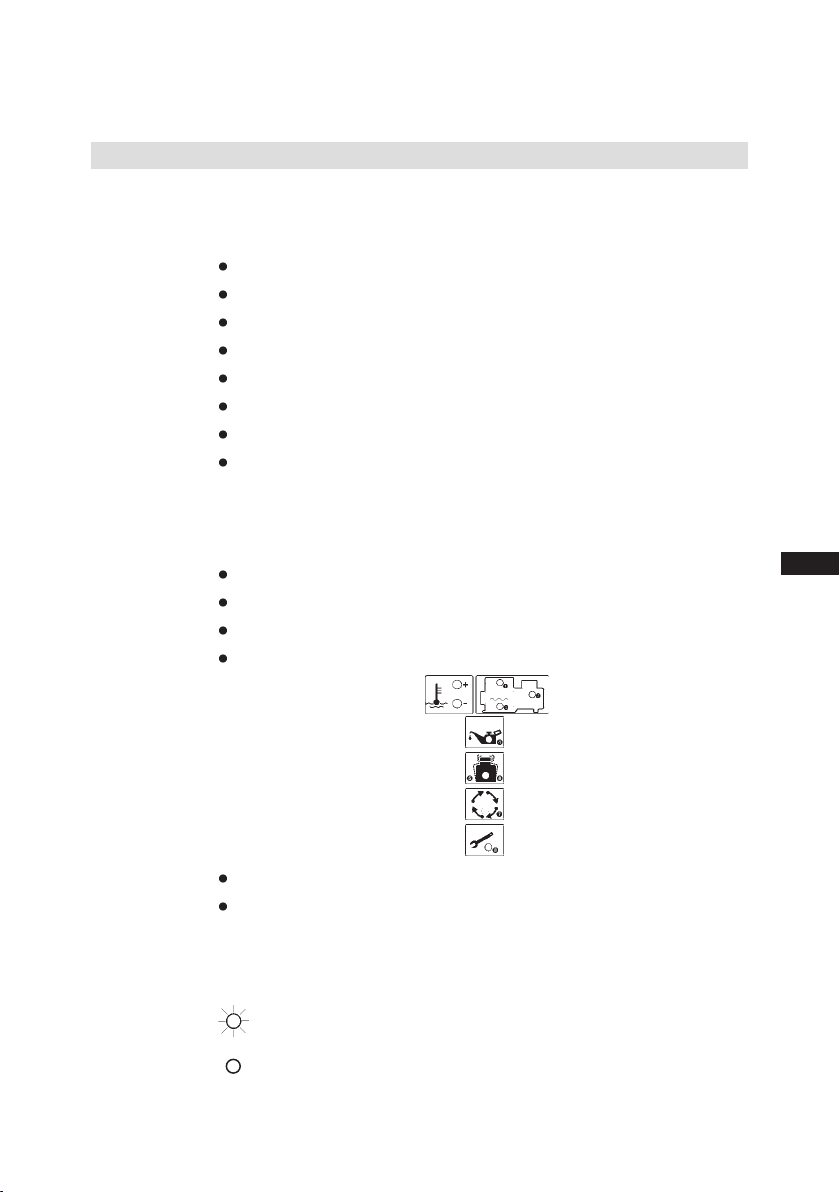

Technical data

Connection voltage: AC 230 V + 10% 50/60 Hz

tol. ambient temperature: -30°C … +60°C

Relay: AC 250 V, 3A, 750 VA ind.

B

Connection terminals:

- on power supply section up to 1,5 mm²

- on control section up to 0,25 mm²

B

C

Structure / functions

4

L = 100

B = 60

H = 52

C

09794-05.2012-DGbFEI

5

D

GB

F

E

09794-05.2012-DGbFEI

Product description

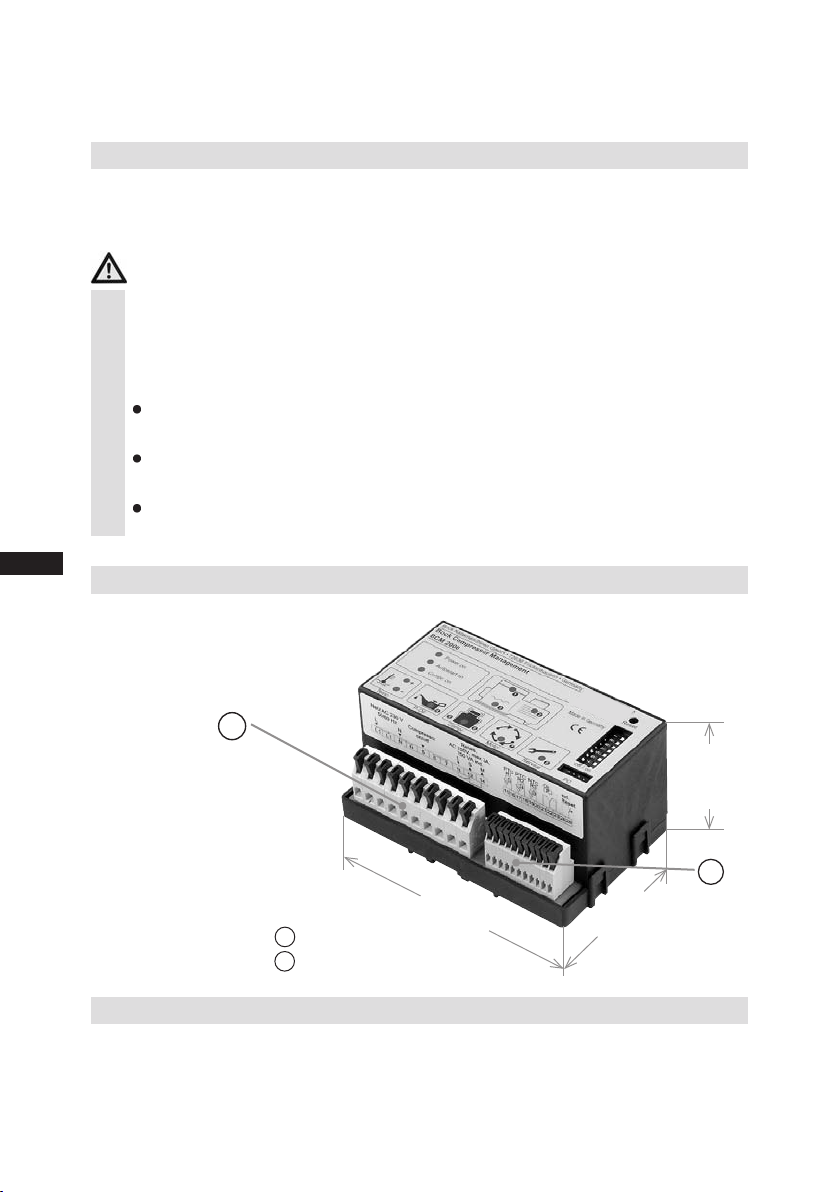

Structure / functions

The BCM 2000 is used solely for monitoring the operation of BOCK refrigerating compressors. All

monitoring parameters have been coordinated exactly to the compressor connected up in the factory.

Incoming signals are detected as status, information or error messages and processed to release,

shutdown and reporting functions. The unit does not exercise any regulating function.

The unit has three main components:

A

- Electronic section B - Power supply section C - Control section

Altogether the unit has 8 monitoring functions: motor winding temperature, compressed gas temperature, oil temperature, oil pressure, liquid detection during start-up, compressor rotation detection,

surge guard, recommended oil change.

A

B

C

12

11

4

910

65

15

14

13

8

7

2

3

1

A

B

C

12

11

4

910

65

15

14

13

8

7

2

3

1

Item No. Designation Function

1 Mains voltage LED green for mains voltage

2 Compressor operation LED green for compressor operation

3 Automatic compressor start LED yellow for automatic compressor release. Com

pressor starts after a delay via the machine

control or lube oil pre-heating

4 Motor winding temperature LED red when temperature too high

5 Compressed gas temperature LED red when temperature too high

6 Oil temperature LED red when temperature too low

Compressor is enabled for starting only

when the lube oil is pre-heated to +25°C,

but at the latest after 30 min.

7 Temperature display + LED red comb. with item 4 / 5 / 6

8 Temperature display - temperature too high (+) or too low (-)

9 Oil pressure LED red when oil pressure too low

Delay: approx. 90 s

10 Liquid detection LED red for liquid hammers during start-up

10 Compressor rotation detection LED red when compressor does not start although

motor supplied with power

11 Surge guard LED yellow for more than 12 starts per hour

Compressor continues to operate, no stop

12 Recommended oil change LED yellow after a certain interval has been exceeded

Compressor continues to operate, no stop

13 Reset button Reset to operating function

14 Bridging switch Activates or bridges individual functions

15 PC interface For reading

}

Standard settings

Monitoring Procedure Value

Motor temperature Compressor switched off at motor overtemperature 130° C

Reset release when cooled down after motor overtemperature 120° C

Oil temperature Automatic release after the oil has pre-heated 25° C

1)

1)

or automatic release after maximum pre-heating time 30 min

Automatic shut-down of the compressor at oil overtemperature 120° C

Automatic release when cooled down after oil overtemperature 95° C

Automatic shut-down of the compressor at oil undertemperature 17° C

Discharge gas Shut-down of the compressor at hot gas overtemperature 140° C

temperature Reset release when cooled down after hot gas overtemperature 130° C

Oil differential Minimum value for oil differential pressure 0,65 bar

pressure Shut-down of the compressor when differential pressure too low 0,6 bar

2)

2)

Shut-down delay time when differential pressure too low 90s

A

A

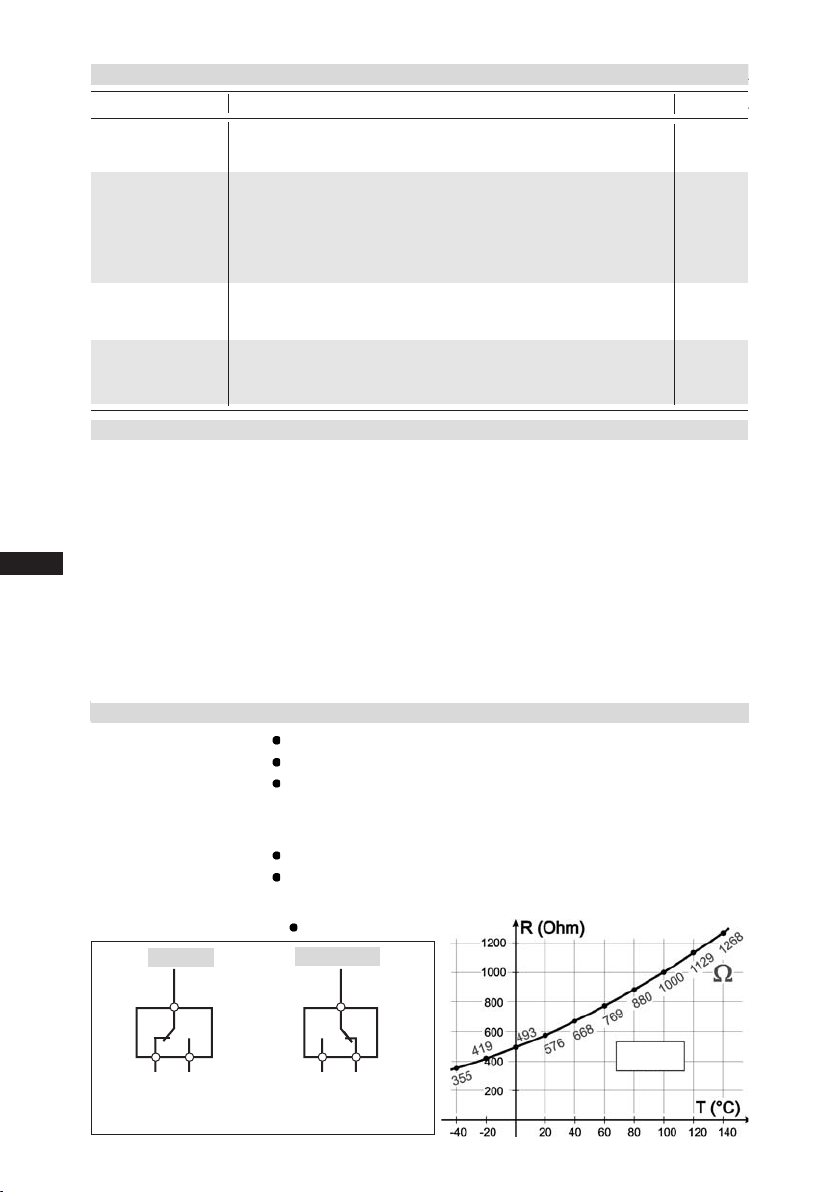

Sensor details

Discharge gas tem-

PTC sensor switching at 140 °C.

perature sensor: Resistance range 20 - 100 Ω at 15 - 50°C (value for each sensor).

Functioning principle: only slight change in resistance when heated up

below the switching point temperature, but in the switching point range

the resistance value suddenly changes by several kOhm.

Oil temperature sensor: Sensor KTY84-130 (see diagram: resistance temperature curve)

Functioning principle: resistance value changes according to the

change in oil temperature

Differential pressure switch:

∆P Reed contact, IP 65

Switching current: 30 mA, switching power: max.

30 VA; Ambient temperature: -30 … +70°C

brown

red

orange

L+

∆P good

red

orange

L+

∆P bad

brown

Adjustable settings

All the errors saved in BCM 2000 (up to 170) incl. the operating hours counter total can be read out

with a PC, the reading program on CD-ROM and the cable. In addition, the following trigger settings

can be changed on the spot depending on the prevailing conditions:

Out-of-step: Compressor blocked after every standart shut-down: 180 s

D

GB

F

E

Variable time range: 0 - 255 s

For rack operation, set this position to “0” or hide with bypass switch 7,

see pos. 7 in the chapter “error messages – information messages –

emergency operation.

Oil pressure error time: Shut-down delay (standart setting): 90 s

Variable time range: 15 - 90 s

Rotation detection: Vibration factor (standart setting): 2

Variable time range: 0 - 40

KTY84-130

6

09794-05.2012-DGbFEI

7

D

GB

F

E

09794-05.2012-DGbFEI

orange

brown

red

C

B

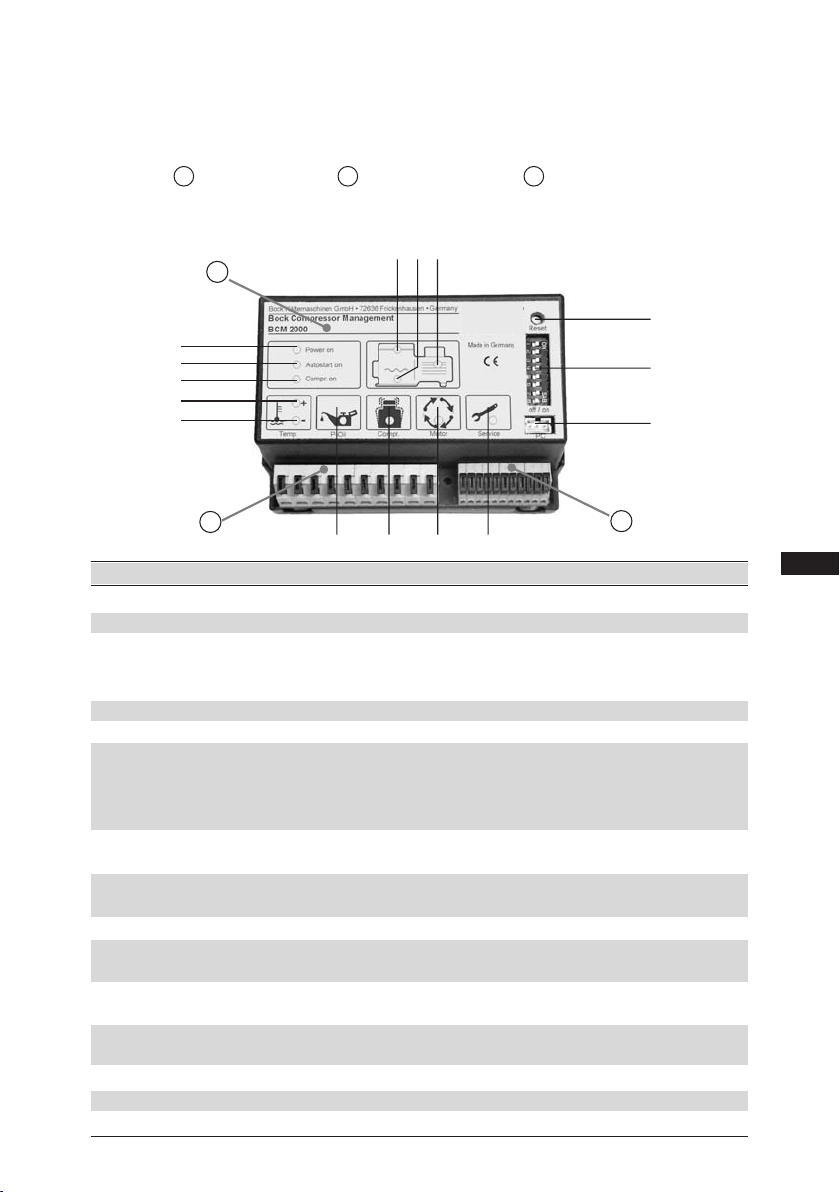

Connecting the unit

PTC

compressed gas

temperature sensor

PTC

motor winding

temperature sensor

oil temperature

sensor

oil pressure

sensor

oil sump

heating E1

brown

red

orange

Electrical connection

Electrical connection

General

The unit has two different connection blocks:

1) Power supply section

B

2) Control section

C

The power supply section is for connection to the machine mains voltage. It is to be integrated in the

machine control by the refrigerating engineer (qualifi ed engineer). The unit is to be integrated in fi rst

position of the safety chain. The power supply at L1-N should be identical with the switching voltage

at relay contacts 11, 12 and 14.

The control section is used for connection of the individual monitoring functions. These are normally

ready wired in the factory and prefabricated ready for operation so that no additional work is necessary here.

The whole control section (terminals 15 - 25) and all monitoring sensors, probes and

corresponding connections must not have any contact with mains voltage. Otherwise

the BCM 2000 and sensor components will be destroyed.

Electrical connection

Connecting the unit

B

C

E1 Oil sump heater

F1 Control fuse

K1.1 Auxiliary contactor

K2T Delay relay 10-60 min.,

Connection facility for external

collective error message

F Safety chain with regulating unit (thermostat)

Kx Compressor load contactor or protection

combination with motor protection switches

S1 Switch for control voltage Off / On

Electrical connection of the unit is to be carried out by a qualied electrician accor-

ding to the circuit diagramm.

Comply with the local safety regulations.

Always disconnect the machine from the power supply before and during working

on the machine.

Compare the voltage and frequency details on the nameplate with the details for

the electricity mains. Unit may only be connected up when these coincide.

D

GB

F

E

Electrical connection

ca. 10 - 40 min.

orange

brown

red

10-60 min

8

09794-05.2012-DGbFEI

9

D

GB

F

E

09794-05.2012-DGbFEI

Checking functions

Integration of additional switching and control components

• Auxiliary contactor K1.1

An auxiliary contactor K1.1 is provided to protect the contacts in the unit (max. tol. load AC

250 V / 3 A / 750 VA ind.)

• Delay relay K2T

A delay relay K2T 10 - 60 min is to be superposed so that various operating interruptions are

not indicated as fault (adjustment range approx. 10 to 60 minutes, settling time 40 min.)

• Oil sump heating E1

The compressor oil sump heater E1 is to be connected up in combination with the oil tempera-

ture function. The oil sump heater should already be running during the evacuation phase.

If the oil temperature is under +25°C,

the compressor is blocked and the

oil sump heater is running.

For oil temperatures exceeding +25°C, but at the latest after 30 min. pre-heating

heater

time the compressor is released for operation and the oil sump

switches off.

Checking the functions

General

The unit is mounted in the compressor terminal box. All monitoring sensors are connected and their

functions have been checked. A separate function check is not necessary. The following function

checks can be carried out when spare parts have been supplied or as part of troubleshooting:

Function check for compressed gas/winding/oil temperature

Function check for oil pressure

Procedure for checking the compressed gas / winding / oil temperature functions

1 Disconnect from the mains

Disconnect the temperature sensor (terminal 15, 17 or 19)

Important! Every sensor must be checked individually!

2 Insert wire bridge L1 - 5

3 Apply mains voltage

The 2 corresponding LEDs must light up after 30 s delay

4 Disconnect from the mains, remove the wire bridge (see no. 2), connect sensor (see no. 1)

5 Apply mains voltage

Unit ready

Activation / bridging the monitoring functions

Procedure for checking the oil pressure function

1 Disconnect from the mains

Disconnect the sensor (terminal 22)

2 Insert wire bridge L1 - 5

3 Apply mains voltage

The corresponding LED must light up after approx. 90 s delay

4 Disconnect from the mains, remove the wire bridge (see no. 2), connect sensor (see no. 1)

5 Apply mains voltage

Unit ready

D

GB

F

E

Activating or bridging individual monitoring functions

General

Each of the 8 possible functions can be individually activated or

bridged. The works setting is always „activated“. Every function

is numbered and allocated to the function switch with the same

number. The adjustment of the function switch is only activated

after quitting with the reset button for safety reasons. The adjustment can be made when the compressor is running or at a standstill.

No safety functions work in bridged state. Therefore use only for

emergency operation. LED ashes until function is activated again.

Bridge function

(e.g. service display)

Switch setting to the left (off)

Activate function

(e.g. service display)

Switch setting to the right (on)

Reset

LED ashes

Reset

LED off

Reset button

Function switches

Compressor starts up or continues through the machine

control

Compressor starts up or continues through the machine

control; exception: longer

power failure. operation only

released after lube oil has

pre-heated

10

09794-05.2012-DGbFEI

11

D

GB

F

E

09794-05.2012-DGbFEI

Reset, messages, emergency operation

Reset

General

Every message can be quit with reset. The procedure can be

repeated as often as necessary.

Caution! First rectify the fault, then release the compressor. After quitting the fault with the reset button,

the compressor starts up again without any delay

Quit fault (e.g. oil fault)

Compressor starts up immediately. Exception: longer

Reset

LED on LED off

power failure. operation only

released after lube oil has preheated

Reset button

Fault messages - information messages - emergency operation

General

The unit has 8 monitoring functions. These are divided into:

- 5 fault messages (compressor shutdown when triggered)

- 2 information messages (compressor not shutdown when triggered)

- 1 status message (compressor automatically released when triggered)

There are two possibilities for reactivating the messages:

a) reset to initial function (using reset button)

b) bridging the functions (emergency operation using function switch)

The unit can save several approx. 170 fault messages.

The device can save up to 170 error messages. The saved error messages can

be read via the PC interface with the special interface cable (accessory, article no.

06988) and the Bock reading program (accessory, article no. 06992).

CAUTION! Remedy fault rst, then release compressor!

No protection functions available in bridged status. Therefore only use

for emergency operation! LED ashes until function activated again.

Function switches

Reset button

Messages and emergency operation

D

GB

F

E

Display a) Reset to initial function b)

operation - no safety function)

Fault message

Compressed gas temperature

1

too high. LED ON / Compressor

OFF

Fault message

Winding temperature too high.

2

LED ON / Compressor OFF

Status message

Oil temperature too low.

3

LED ON / Compressor OFF

Possible after cooling down

to operating temperature

Reset

Compressor starts up immedi-

ately.

LED OFF

Possible after cooling down

to operating temperature

Reset

Compressor starts up immedi-

ately.

LED OFF

Reset not possible

Compressor starts automa-

tically after preheating the

lube oil to +25°C, but at

the latest after 30 min.

pre-heating time

LED - OFF / Compressor - ON

Function bridged (emergency

Possible without cooling down

to operating temperature

+

Reset

Switch 1 Off

Compressor starts up through

machine control. LED ashes

Possible without cooling down

to operating temperature

+

Reset

Switch 2 Off

Compressor starts up through

machine control. LED ashes

+

Reset

Switch 3 Off

Compressor starts up through

machine control. LED ashes

12

Status message

Oil temperature too high.

3

LED ON / Compressor OFF

Reset not possible

Compressor starts automa-

tically after cooling down.

LED - OFF / Compressor - ON

+

Reset

Switch 3 Off

Compressor starts up through

machine control. LED ashes

09794-05.2012-DGbFEI

13

D

GB

F

E

09794-05.2012-DGbFEI

Messages and emergency operation

Display a) Reset to initial function b)

operation - no safety function)

Fault message

Reset

Oil pressure too low

4

LED ON / Compressor OFF

Fault message

Combined function 1:

Liquid at start

5

LED ON / Compressor OFF

Fault message

Combined function 2:

Compressor not turning.

6

LED ON / Compressor OFF

Information message

Compressor starts up immedi-

ately.

LED OFF

Reset

Compressor starts up

immediately.

LED OFF

Reset

Compressor starts up

after fault eliminated.

LED OFF

12 starts per hour

exceeded

Function bridged (emergency

+

Reset

Switch 4 Off

Compressor starts up through

machine control. LED ashes

+

Reset

Switch 5 Off

5 + 6 are bridged. Compressor

starts up through machine control.

starts up through machine control.

LED ashes

+

Reset

Switch 6 Off

Only 6 is bridged. Compressor

LED OFF

Engine monitoring by winding temperature feeler

Surge op. too high

7

LED ON / Compressor ON

Information message

Recommended oil change

8

LED ON / Compressor ON

Reset

LED OFF

Reset to „0“

Counting starts again

Reset

LED OFF

Reset to „0“

Evaluation starts again

+

Reset

Switch 7 Off

Compressor starts up through

machine control. LED ashes

+

Reset

Switch 8 Off

Compressor starts up through

machine control. LED ashes

D

GB

F

E

Spare parts and accessories

Spare parts and accessories

General

The basic BCM 2000 unit is designed and programmed in the factory to work with the corresponding compressor. This guarantees the best possible functional reliability. When spare parts are

required, we must know the compressor type and machine number before delivering an individual

unit to ensure that it will function properly.

Overview of spare parts / accessories

Item. Designation Art. No.

1 Electronic compressor protection

Bock - BCM 2000, 230 V~ 06950

consisting of:

basic unit with microprocessor

for all possible functions, display with individual

function displays, adjusting switches for the various

functions, reset button, interface for PC

connection, power supply section, control section for

the individual functions

2b

2 Oil pressure monitoring ∆P

2 a: Delta-P screw-on part ¾“ 16 UNF 06990

(to version ID 17)

2 b: INT 250 - circuit part with lead 06989

2 c: Delta-P screw-on part M20x1,5 50225

(starting from version ID 18)

2a, 2c

3 Oil temperature monitoring

NTC screw-on temperature sensor 06947

Thread NPTF 1/8“ with lead

Lead colour: black

4 Compressed gas temperature monitoring

PTC screw-on temperature sensor 06033

Thread NPTF 1/8“ with lead

Lead colour: red-brown

5 Interface lead

for PC connection 06988

6 CD with read-out program 06992

14

09794-05.2012-DGbFEI

15

D

GB

F

E

09794-05.2012-DGbFEI

Troubleshooting

What to do, when ….

Display Possible fault causes or information message

> Check control fuse and voltage at terminals

L and N on the BCM 2000

Control voltage is ON

but no LED lights up

> Interruption (open contact) in the safety chain.

Check all integrated switches and units for continuity

LED „power on“ and „compressor on“

light up but the compressor does not turn

Fault message

> discharge end temperature too high

> Suction gas overheating too high

> Condensing temperature too high

> Bypass from pressure to suction side

1 = compressed gas temp. too high

LED ON / Compressor OFF

Fault message > Motor overload

> Undervoltage

> Control error

> Winding short, short circuit, accidental ground

> Two-phase mode

2 = winding temperature too high > Motor cooling insuffi cient

LED ON / Compressor OFF > Extremely unequal phase load

Status message

> Oil sump heating not working

> Pre-heating phase too short

Operation released at +25°C, but at the latest

3 = Oil temperature too low after 30 min. pre-heating time

LED ON / Compressor OFF

> Oil sensor is not screwed as far as it will go into the Fault

message screw-in sleeve

> Not enough oil

> Liquid coolant in compressor / in oil

> Dirt in machine / in oil

> Oil pump defect

4 = Oil pressure too low > Inadequate oil return

LED ON / Compressor OFF > Unsuitable oil grade

> Damage to bearings or power plant, wear

What to do, when ... ?

D

GB

F

E

Troubleshooting

Display Possible fault causes or information message

Fault message

> Refrigerant or oil displaced in the machine

> Check electric valve, solenoid in liquid pipe for

function and leaks

5 = liquid at start

Fault message > One or all power supply phases not connected.

> For parallel operation: Sensor possibly affected by

the operation of an adjacent compressor

(–> bypass function).

Fault message 6 is displayed although the compressor

is running:

6 = compressor not turning > Operating vibrations too low. Vibration sensor cannot

LED ON / Compressor OFF detect the compressor running due to the exception-

ally quiet operation.

> Adjust the sensor’s sensitivity (Bock service software

required for this). This position can also be temporarily

shut down without the service software by tripping

DIP switch 6. Multiple monitoring of this position

ensures that the compressor is fully monitored.

Information message > More than 12 start-ups per hour

> Faulty control or setting

> Insufcient refrigerant

> Condenser pressure control fault

> Evaporator icing

7 = Surge op. too high > E-valve problem

LED ON / Compressor ON > SL lter or dryer contaminated

Information message

> Oil change is recommended

> Filter or dryer change can be associated with

this message

8 = Recommended oil change

LED ON / Compressor ON

16

09794-05.2012-DGbFEI

17

D

GB

F

E

09794-05.2012-DGbFEI

Standard Paragraph Designation Value

EN 60730 2.2.15 Purpose of control unit: Motor protection device

6.2.6 Type of controlled load: pilot load

6.4 Reset characteristic: not automatic: type 3BH

automatic: type 3C

Software class A

Device protection class

Relevant standards

Fault memory:

The Bock BCM 2000 (v1.4) software provides the possibility of exporting the complete fault

memory of the BCM 2000 to a text le thus making a backup of it.

Procedure for backing up the fault memory:

1. A voltage of 230 V must be applied between L1 and N of the BCM 2000.

2. The BCM 2000 must be connected to a PC using the special cable.

3. Start the BCM 2000 software and wait until the fault report is read out.

4. On the “Diagnostics” screen, there is the “Export” button next to the “Retrieve” button which

makes a new readout of the BCM 2000 possible when clicked.

5. The BCM 2000 software creates a text le (“Export File”) when the “Export” button is clicked.

6. Select the destination where the text le should be saved. Input lename and conrm with

“Save”. The name of the backup le should contain the machine number, type and date.

Example: AN022334A014-HGX8-2830-4S-01012006.txt

Excellence Passion Integrity Responsibility GEA-versity

GEA Group is a global engineering company with multi-billion euro sales and operations in more

than 50 countries. Founded in 1881, the company is one of the largest providers of innovative

equipment and process technology. GEA Group is listed in the STOXX Europe 600 Index.

D

GB

F

E

GEA Refrigeration Technologies

GEA Bock GmbH

Benzstraße 7, 72636 Frickenhausen, Germany

Telephone: +49 7022 9454-0, Fax: +49 7022 9454-137

bock@gea.com, www.bock.de

18

09794-05.2012-DGbFEI © GEA Group AG. All rights reserved.

09794-05.2012-DGbFEI

Loading...

Loading...