GEA Steam jet heaters User Manual

87GEA Wiegand GmbH 76275 Ettlingen · Germany · Tel.: +49 7243 705-0

www.gea-wiegand.com Fax: +49 7243 705-330 · E-mail: info.gewi.de@geagroup.com

Steam jet heaters for vessels

APPLICATION

Steam jet heaters are used to heat all kinds

of liquids in vessels. Heating is achieved by

means of direct condensation of steam. The

steam condensate mixes with the liquid.

MODE OF OPERATION

The steam jet emerging from the motive

nozzle accelerates the liquid present in its

vicinity and in the mixing nozzle, and condenses (see also “General information on jet

pumps”,

o

| abl1).

In this way a controlled flow is produced.

Furthermore, the whole content of the vessel is set in motion and the heat transferred

to the liquid is evenly distributed throughout the vessel.

All the heaters are provided with a threaded

connection for an air pipe. Normally it is not

necessary to operate with air supply. However, the admission of air greatly intensifies

the movement of the circulating liquid; it

can also assists in avoiding condensation

hammers and rattling that may occur when

starting with a cold liquid.

If air is to be supplied, a corresponding line

with installed regulation valve has to be connected (see fig. 1). Depending on the application, atmospheric air which is sucked in by

the heater itself is sucient.

To operate the steam jet heater, a steam

overpressure of at least 1.5 bar is necessary

to overcome the static pressure of the liquid

and to achieve the minimum speed at which

no disturbing noise is produced.

The heaters described can also be used for

operating with low pressure steam (special

construction).

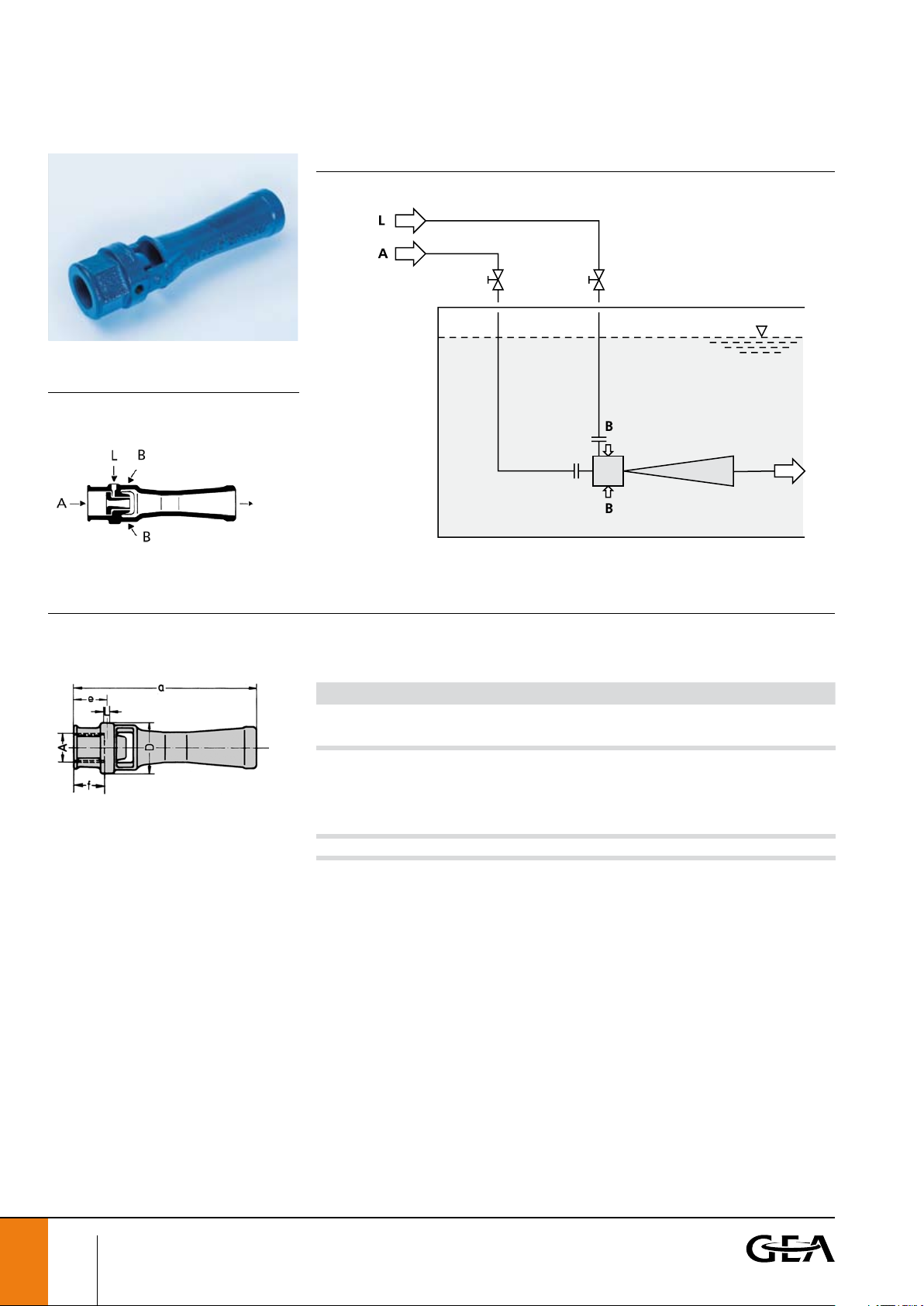

FIG. 1

A Motive steam

B Liquid

L Air

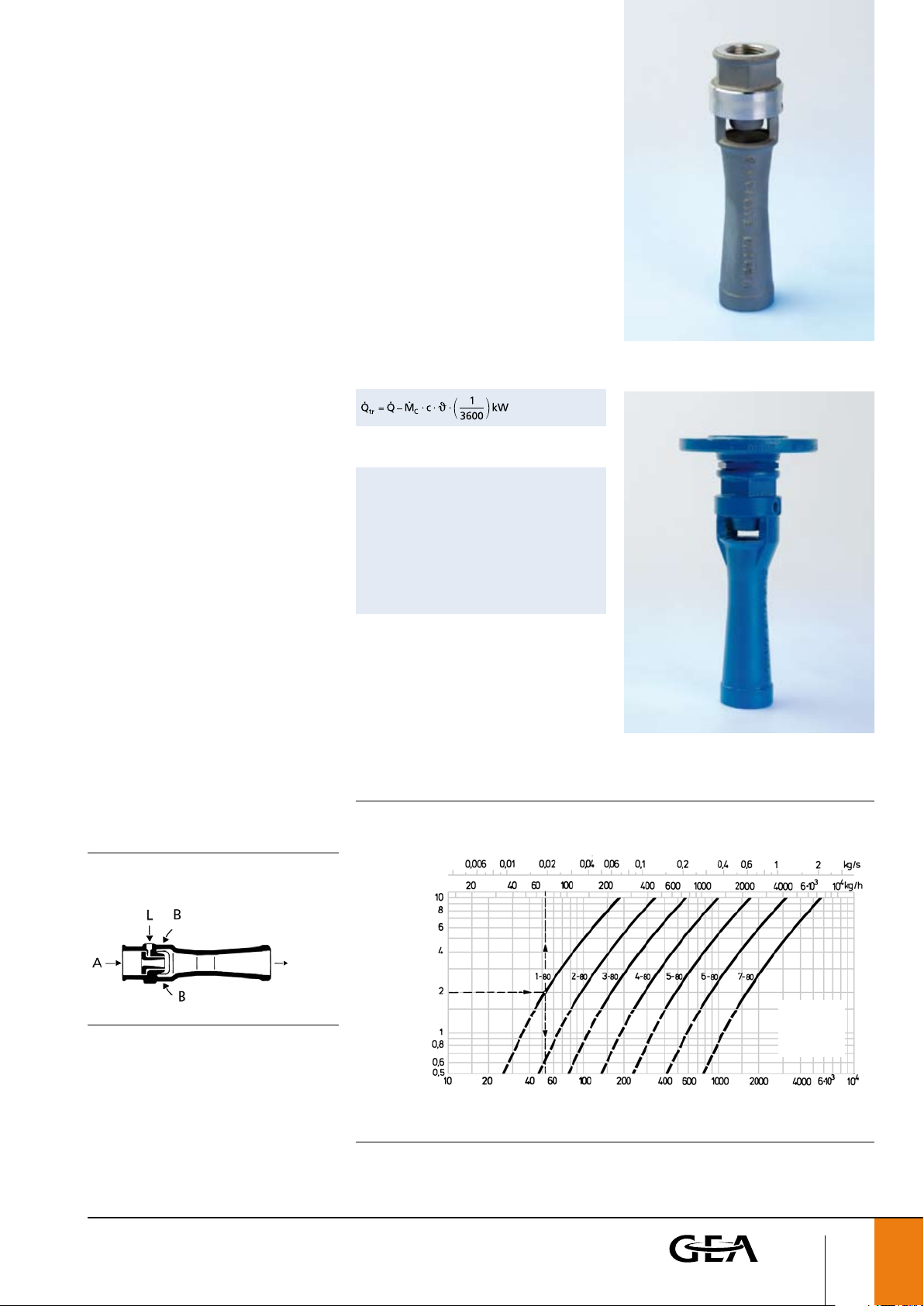

PERFORMANCE CHART

On the bottom scale, the chart in fig. 2 gives

the heat flow in kW for each size. This is the

heat content of the inflowing steam. However, the heat actually transferred to the liquid

is less. It is reduced by the heat contained in

the condensate.

The condensate flow produced by the condensation of the inflowing steam is given on

the top scale. With the aid of this scale and

the temperature ϑ of the heated liquid, the

heat flow actually transferred is calculated

as follows:

Whereas:

œtr Transferred heat flow in kW

œ Heat flow in kW = Enthalpy of the

inflowing steam

Ø

Condensate flow in kg/h

C

c Specific heat capacity of the condensate

in kJ/kg °C (water = 4.2)

ϑ Temperature of the heated water in °C

EXAMPLE

GIVEN:

A steam quantity of approx. 70 kg/h

is required to heat a vessel.

Steam at 2 bar g is available.

SOLUTION: The chart in fig. 2 shows that size

1-80 matches the example.

FIG. 2

Steam consumption Ø

or condensate ØC in kg/h or kg/s resp.

D

Construction with thread

Construction with flange

Steam pressure in bar g

Heat flow œ in kW ¥ Enthalpy of the inflowing steam

Performance chart for steam jet heaters, size 1 to 7, construction series 80, for water

Steam jet

heaters,

sizes 1–7,

series 80

aw1 09

GEA Wiegand GmbH 76275 Ettlingen · Germany · Tel.: +49 7243 705-0

www.gea-wiegand.com Fax: +49 7243 705-330 · E-mail: info.gewi.de@geagroup.com

88

Steam jet heaters for vessels

Steam jet heater with thread, type 18.1

A Motive steam

B Liquid

L Air

EXAMPLE OF INSTALLATION : STEAM JET HEATER WITH THREAD, TYPE 18.1

FIG. 3

FIG. 4

CONNECTIONS, DIMENSIONS AND WEIGHTS

STEAM JET HEATER WITH THREAD, TYPE 18.1

Size 1-80 2-80 3-80 4-80 5-80 6-80 7-80

Nominal diameter A G 3/4 G 1 G 1 1/2 G 1 1/2 G 2 G 3 G 4

L G 1/8 G 1/8 G 1/4 G 1/4 G 1/4 G 3/8 G 3/8

Dimensions in mm a 170 220 265 345 400 520 610

D 52 60 75 85 100 125 160

e 35 40 40 40 50 75 80

f 20 25 24 24 30 33 40

Weight in kg 1 2 3 5 7 12 21

STANDARD CONSTRUCTIONS:

I Housing: cast iron EN-GJL-200 (GG20), motive nozzle: red brass

II Housing: cast iron EN-GJL-200 (GG20), motive nozzle: stainless steel

III Housing: cast stainless steel (1.4581), motive nozzle: stainless steel

Thread according to DIN ISO 228

SPECIAL CONSTRUCTIONS are possible in most of the usual materials.

Please indicate size, type and material with your order.

For inquiries please use our questionnaire.

aw1 09

Loading...

Loading...