Page 1

s

t

d

i

u

q

i

L

o

V

a

l

u

e

Mineral Oil Separators

®

Westfalia Separator

Technical Data | OSE 5, OSE 10, OSE 20, OSE 40, OSE 80, OSE 120

®

with Westfalia Separator

unitrolplus system

eagleclass

GEA Mechanical Equipment / GEAWestfalia Separator Group

Page 2

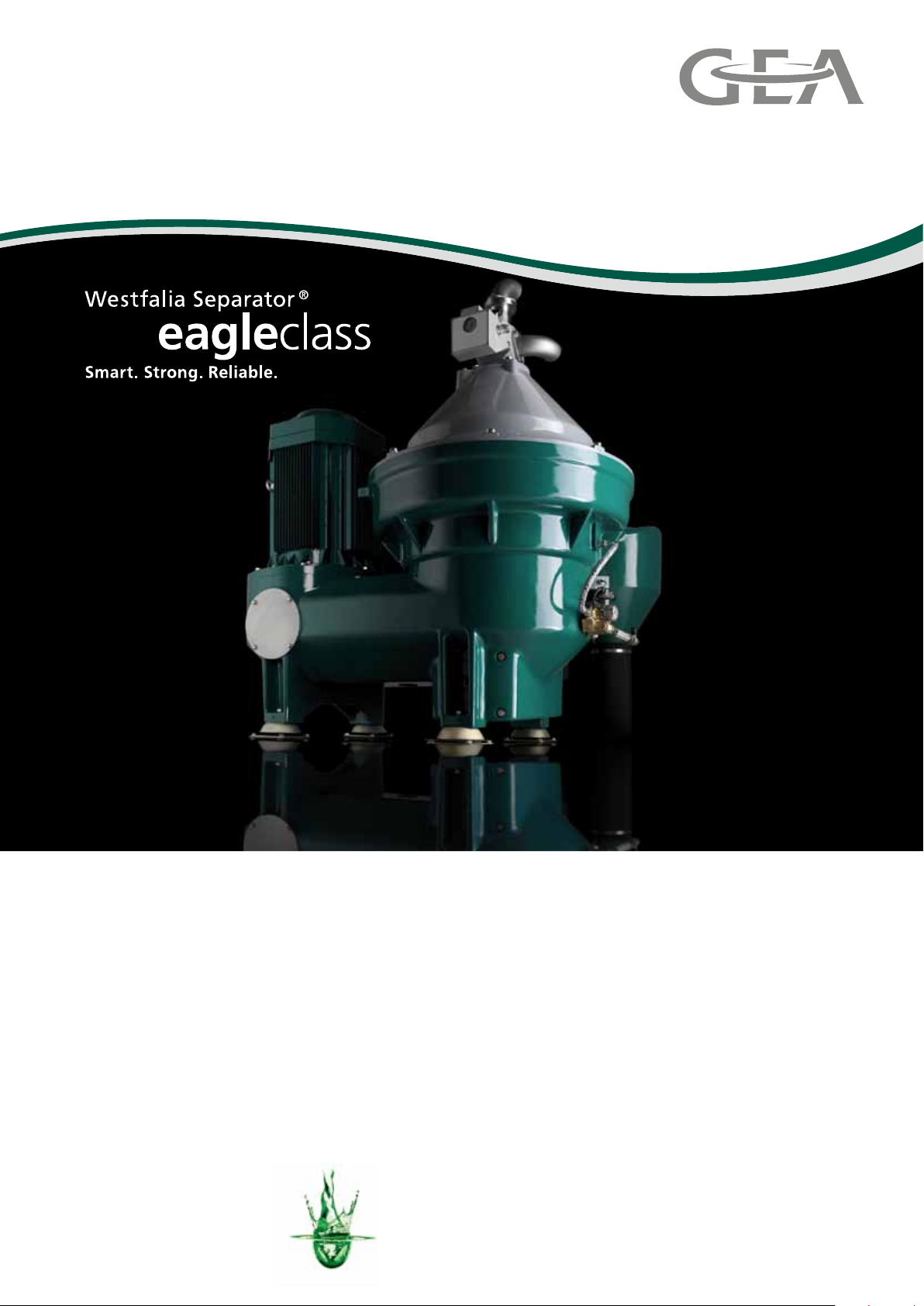

Operating Principles and Constructional Features

Mineral oil separators Westfalia Separator® eagleclass

13

1

OSE… - 0136 - 067

OSE… - 0196 - 067

3 4

6

7

8

5

2

9

10

11

12

14

15

15

16

Dirty oil feed / displacement water feed

Clean oil discharge

Pressure gauge

Pressure transmitter

WMS sensor

SMS sensor

Solenoid valve (circulation)

Sensing liquid line

Centripetal pump, sensing liquid

Centripetal pump, clean oil

Separating disc

Sludge holding space

Dirty water discharge

Sludge discharge

Operating water discharge

Operating water feed

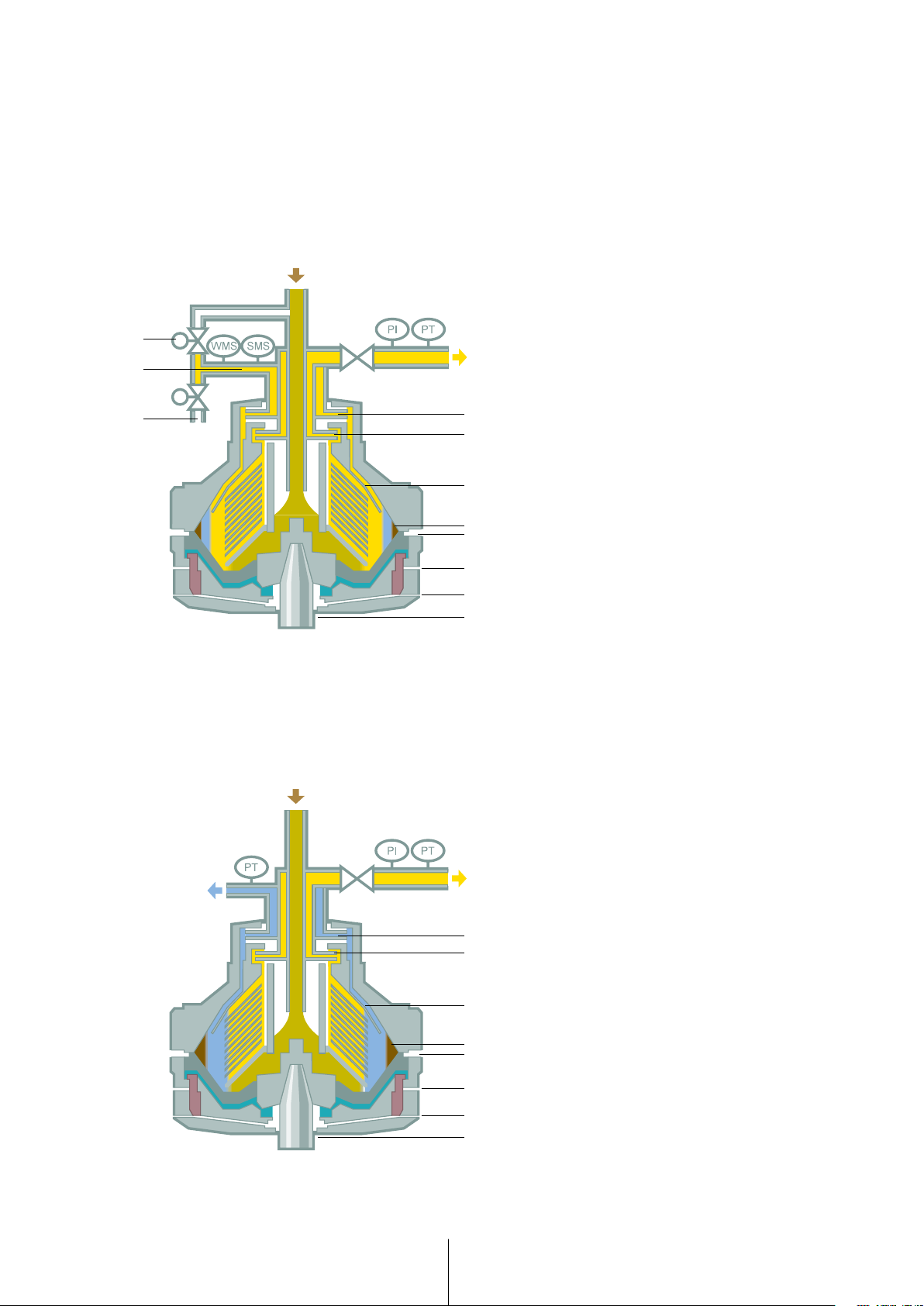

1

3 4

5

6

2

7

8

9

10

11

12

12

13

OSE… - 91 - 067

Dirty oil feed / displacement water feed

Clean oil discharge

Pressure gauge

Pressure transmitter

Pressure transmitter

Dirty water discharge

Centripetal pump, dirty water

Centripetal pump, clean oil

Separating disc

Sludge holding space

Sludge discharge

Operating water discharge

Operating water feed

2

Page 3

The Westfalia Separator® eagleclass separators are

®

equipped with a Westfalia Separator

system for gentle product treatment. This results

in optimum separating efficiency and higher

specific capacities. The patented Westfalia Separator

hydrostop system of the Westfalia Separator

eagleclass separators enables controlled bowl ejec-

tions to be carried out at full operating speed.

soft stream inlet

®

®

Separators OSE… - 0136 - 067 /

OSE… - 0196 - 067 with new

®

Westfalia Separator

The centrifuges are equipped with a self-cleaning

disc-type bowl. They are employed for clarification

and purification in fuel oil (up to a density of

1.01 g / ml) and lube oil treatment plants. The oil

is conveyed to the centrifuge by means of a separate

pump. The feed (1) is via a closed line system. The

clean oil is discharged under pressure (2) by means

of a centripetal pump (10). The centri fuges operate

without regulating rings.

unitrolplus system

New Westfalia Separator®

unitrolplus system

The separators with new Westfalia Separator®

unitrolplus system are provided with two monitoring

systems:

Water Monitoring System – WMS

Sludge Monitoring System – SMS

Water Monitoring System (WMS)

The small volume of liquid (8) which is branched off

via the separating disc (11) and the sensing liquid

pump (9) is monitored by the WMS sensor (5). If the

WMS sensor registers water, the solenoid valve (10)

opens and the water flows off through the dirty

water discharge (13). As soon as the WMS sensor

detects a change

of oil, the solenoid valve (10) closes and

portion

the solenoid valve (7) opens intermittently. The

sensing liquid flow (8) is recycled into the feed (1).

brought about by an increased pro-

Sludge Monitoring System (SMS)

A small amount of product (8) is diverted via

the separating disc (11). It is conveyed by the

sensing liquid pump (9) through the SMS sensor (6)

and is fed back into the feed line (1) of the centrifuge.

If this flow of sensing liquid is interrupted by solids

accumulated in the sludge space (12), the SMS sensor

(6) transmits a pulse

matic ejection program is initiated. The control and

monitoring

“round-the-clock”.

unit guarantees unsupervised operation

to the control unit and the auto-

Separators OSE… - 91 - 067

The separators are equipped with a self-cleaning

disc-type bowl. They are employed for clarification

and purification in fuel oil (fuel oil up to a density

of 0.991 g / ml) and lube oil treatment plants. The

product (1) is fed in through a system of closed

lines. The heavy liquid phase (6) is pressure

discharged by means of a centripetal pump (7). The

clean oil (2) is also discharged by means of a

centripetal pump (8). The centrifuges operate with

regulating rings for the heavy phase.

Frame, hood and drive

The separators are of enclosed design and meet the

requirements of the classification societies. The

separators are driven by a -phase AC motor. Power

is transferred to the bowl spindle via a centrifugal

clutch and a flat belt. All bearings are splash-

lubricated from a central oil bath.

3

Page 4

Materials of construction

Frame: grey cast iron

Hood: Silumin

Main bowl parts: stainless steel

Standard equipment

-phase AC motor

Rubber cushions with welding plates

Flexible feed and discharge lines

Pressure gauge

Pressure transmitter clean oil discharge

Valve block for operating, filling and

displacement water

set of commissioning parts

Ejection monitoring

Motor temperature monitoring

Additional equipment

(available at extra cost, must comply with the

specification of GEA Westfalia Separator Group)

Motor control

Control unit for automatic operation

Pump

Prestrainer

Preheater

Automatic steam valve

Shut-off valve

Controls for electric heaters

Set of tools

Set of spare parts

Vibrocontrol

Product temperature monitoring

Flow indicator

/ way valve

Page 5

Mineral Oil Separators Westfalia Separator® eagleclass

5

Page 6

Technical Data

®

Mineral Oil Separators Westfalia Separator

Operating principles and constructional features

Technical data OSE 5 OSE 10 OSE 20 OSE 40 OSE 80 OSE 120

3-phase AC motor

Rating (50 Hz) up to 4 kW up to 4 kW up to 7.5 kW up to 18.5 kW up to 30 kW –

Rating (60 Hz) up to 4.6 kW up to 4.6 kW up to 8.6 kW up to 21 kW up to 35 kW up to 60 kW

Speed at 50 Hz 3000 rpm 3000 rpm 3000 rpm 3000 rpm 1500 rpm –

Speed at 60 Hz 3600 rpm 3600 rpm 3600 rpm 3600 rpm 1800 rpm 1800 rpm

Type IMV1 IMV1 IMV1 IMV1 IMV1 IMV1

Type of protection IP55 IP55 IP55 IP55 IP55 IP55

Centripetal pump 1 bar 1 bar 1 – 2 bar 2 bar 2 bar 2 – 3 bar

Weights and shipping data

Separator with

bowl and motor

Weights 150 kg 205 kg 320 kg 1060 kg 1620 kg 2500 kg

Case dimensions

(L x B x H) 1100 x 600 x 1000 mm 1280 x 700 x 1030 mm 1300 x 870 x1030 mm 1800 x1000 x1400 mm 1800 x1050 x1600 mm 2000 x1500 x 2100 mm

Shipping volume 0.66 m

Dimensions

A 760 mm 846 mm 1005 mm 1283 mm 1611 mm 1778 mm

B 401 mm 544 mm 550 mm 737 mm 867 mm 1190 mm

C 759 mm 880 mm 1009 mm 1288 mm 1503 mm 1942 mm

Capacities, for optimum throughputs refer to table of capacities.

3

0.92 m

3

1.17 m

3

2.5 m

3

3.0 m

eagleclass

3

6.0 m

3

Function

Continuous treatment of fuel and lube oils.

Application

Mainly on board of ships, in power stations, industry

and oilfield.

The information contained in this brochure merely

serves as a non-binding description of our products

and is without guarantee.

Binding information, in particular relating to capacity

data and suitability for specific applications, can only be

provided within the framework of concrete inquiries.

®

Westfalia

and Westfalia Separator ® are registered

trademarks of GEA Mechanical Equipment GmbH.

Printed on chlorine-free bleached paper

www.kabutz.de

TD_WS-11-04-0005 EN

Printed in Germany

Subject to modification

Dimensions in mm

C

B

A

GEA Mechanical Equipment

GEA Westfalia Separator Group GmbH

Werner-Habig-Straße 1 · 59302 Oelde (Germany)

Phone +49 2522 77-0 · Fax +49 2522 77-1778

www.westfalia-separator.com

Loading...

Loading...