Page 1

C

GE Consumer Service T raining

TECHNICAL SER VICE GUIDE

Monogram® Wall-Mounted

and Island Hoods

MODEL SERIES:

ZV750

ZV850

PUB # 31-9043 03/00

Page 2

!

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

CAUTION

To avoid personal injury, disconnect power before servicing this

product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used

to complete a path to ground are removed for service, they must

be returned to their original position and properly fastened.

GE Consumer Service Training

Technical Service Guide

Copyright © 2000

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

Page 3

Table of Contents

Hood Nomenclature ............................................................................................ 2

Features ...............................................................................................................3

Installation Highlights.........................................................................................3

Controls ...............................................................................................................5

Use and Care Information .................................................................................. 8

Halogen Lamp Assembly Replacement ............................................................ 9

Filter Replacement ..............................................................................................9

Component Access/Duct Cover Removal......................................................... 9

Control PCB Replacement ................................................................................. 10

Entry/Display Assembly Replacement .............................................................. 11

Filter Microswitch Replacement1 ......................................................................11

Fuse Replacement .............................................................................................. 12

Glass Visor Replacement ...................................................................................12

Motor & Blower Assembly Replacement .......................................................... 13

Motor Capacitor Replacement ........................................................................... 14

Transformer Replacement.................................................................................. 15

Triac Replacement ..............................................................................................16

Troubleshooting .................................................................................................. 17

Schematic & Strip Circuits .................................................................................18

Model ZV750 Illustrated Parts Breakdown ....................................................... 22

Model ZV850 Illustrated Parts Breakdown ....................................................... 24

Warranty Information..........................................................................................27

– 1 –

Page 4

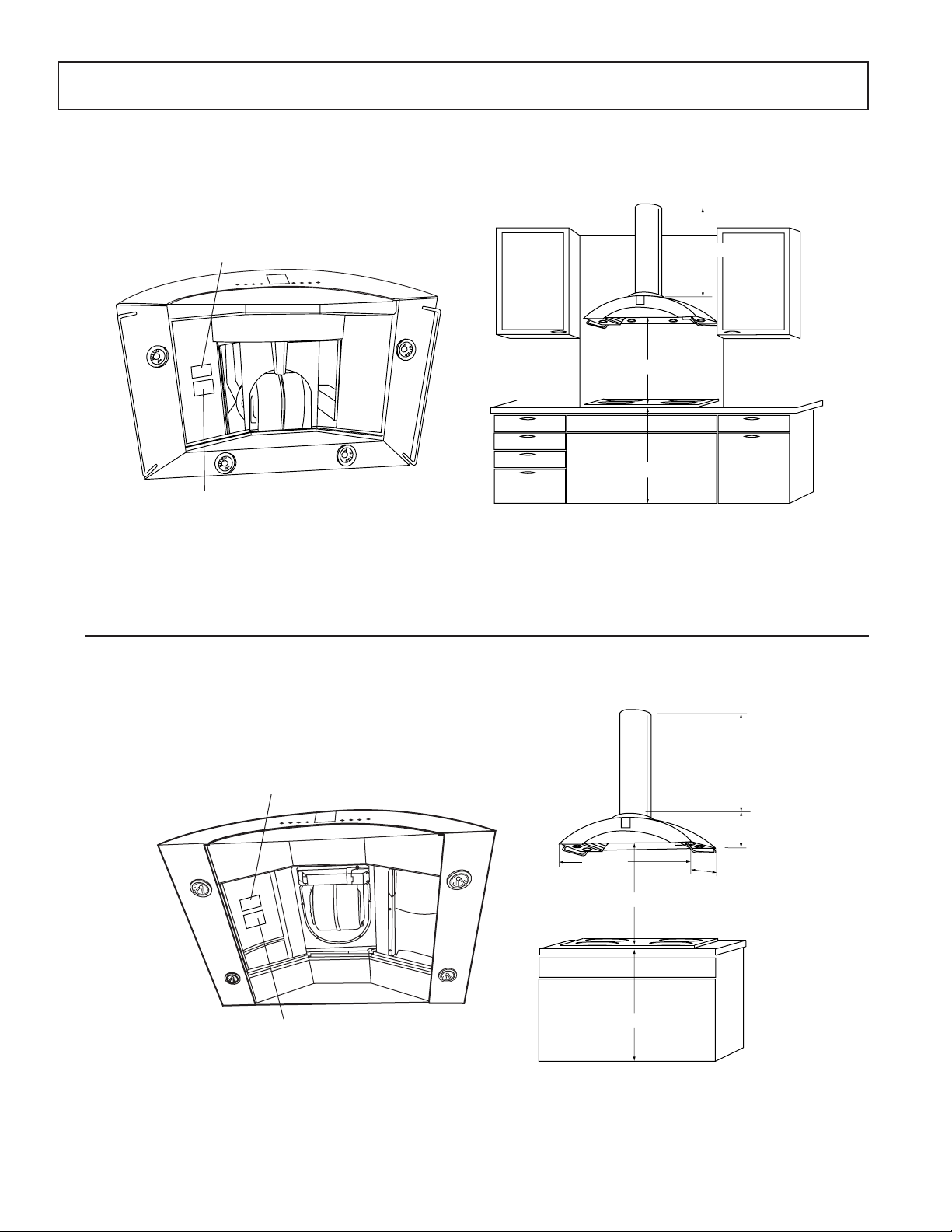

Hood Nomenclature

*

7

ZV750

Nomenclature

25-1/2" Recommended

36" Min.

Mini Manual

Locator Label

ZV750Y1: Early model wall-mounted hood.

ZV750Y2: Later model wall-mounted hood with motor

mount similar to Island-mounted hood.

Height to Ceiling*

GEA0002

ZV850

Height

to Ceiling

Nomenclature

8-1/4"

35-3/8"

25-1/2" Recommended

Mini Manual

Locator Label

*Duct covers are available as necessary accessory kits to accomodate installations with 8-, 9-, or 10-foot ceilings.

36" Reference

27-1/2"

GEA00028

– 2 –

Page 5

Features

Stainless Steel Finish

36-Inch Width

350 CFM V ertical Exhaust Blower Rating

Electronic T ouchpad Controls

4 Halogen Lamps

3 Removable Filters with 30-Hour Filter Cleaning Reminder

6-Inch Round Duct

Model ZV750 W all Mount

Model ZV850 Island Mount

Installation Highlights

Mount Dimensions and Clearances

(See Hood Nomenclature)

The vent hood must be installed at least 24 inches and not more than 30 inches above the cooking surface.

25-1/2 inches is recommended to ensure that the duct cover meets the ceiling. The cooking surface should

be at least 36 inches above the floor .

Electrical Wiring

WARNING: Remove house fuse or open circuit breaker before beginning installation. Do not use an

extension cord or adapter plug with this appliance. Follow national electrical codes or prevailing local codes

and ordinances.

Electrical Supply

The vent hood must be supplied with 120V, 60Hz electrical power, and connected to an individual, properly

grounded branch circuit, protected by a 15- or 20-ampere circuit breaker or time delay fuse.

• Wiring must be 2-wire with ground.

• If electrical supply does not meet the above requirements, call a licensed electrician before proceeding.

• Route wiring as close to the installation location as possible, in the ceiling or soffit.

• Connect the wiring to the house wiring in accordance with local codes.

– 3 –

Page 6

Grounding Instruction

in

n

WARNING: The improper connection of the equipment-grounding conductor can result in a risk of electric

shock. Check with a qualified electrician if you are in doubt whether the appliance is properly grounded.

The grounding conductor must be connected to a metal ground, permanent wiring system, or an

equipment-grounding terminal or lead on the hood.

Exhaust Ducting

The hood uses 6-inch metal ducting to exhaust fumes. Refer to the vent hood installation instructions for

details of the maximum permissable lengths to be used for duct runs to outdoors. Do not exceed the

maximum permissable equivalent length total of 100 feet for a range hood.

Flexible 6-inch metal ducting may be used. When flexible ducting is used, all equivalent feet values of

components must be doubled. The flexible metal duct should be straight and smooth and extended as

much as possible. Do not use flexible plastic ducting.

Note: Any home ventilation system, such as a ventilation hood, may interrupt the proper flow of combustion air and exhaust required by fireplaces, gas furnaces, gas water heaters, and other naturally vented

systems. To minimize the chance of interruption of such naturally vented systems, follow the heating

equipment manufacturer’s guidelines and safety standards such as those published by NFPA and ASHRAE.

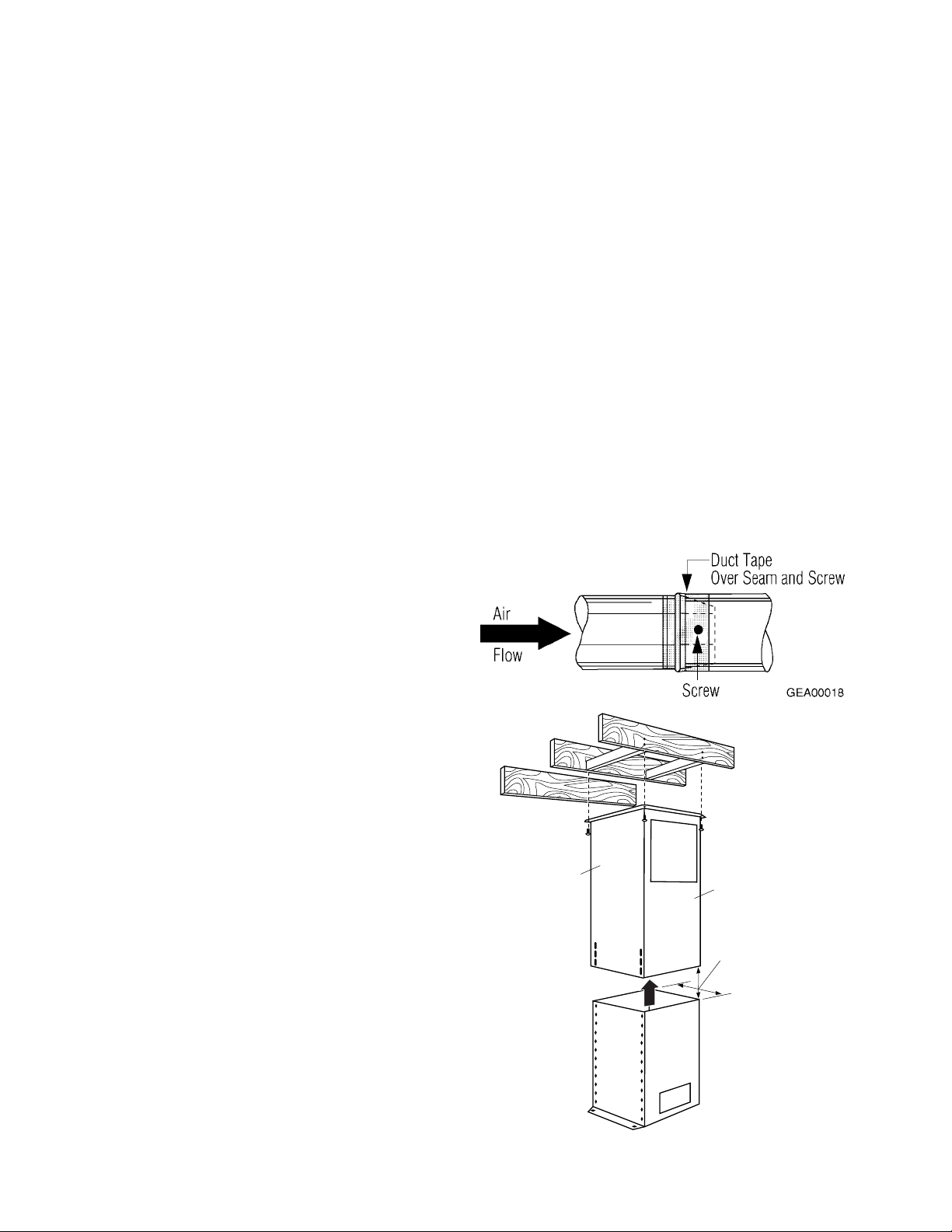

Install all ductwork by making joint connections

in the direction of the air flow as illustrated.

Secure the joints with sheetmetal screws. Wrap

the joints with duct tape for an airtight seal.

Model ZV 850

This model is installed using 1 of 3 installation

kits (for 8-, 9-, or 10-foot ceilings). The upper

support frame (shown at right) is secured to the

ceiling joists and/or cross framing with 4 screws.

The support frame must be level and square.

The lower support frame slips into the upper

frame and can be adjusted up or down to the

desired height. It is secured with 8 screws and

washers.

Upper

Support

Frame

Lower

Support

Frame

Front

Of

Hood

Support

Frame

Opening

Check Level

Both Directio

– 4 –

GEA00116

Page 7

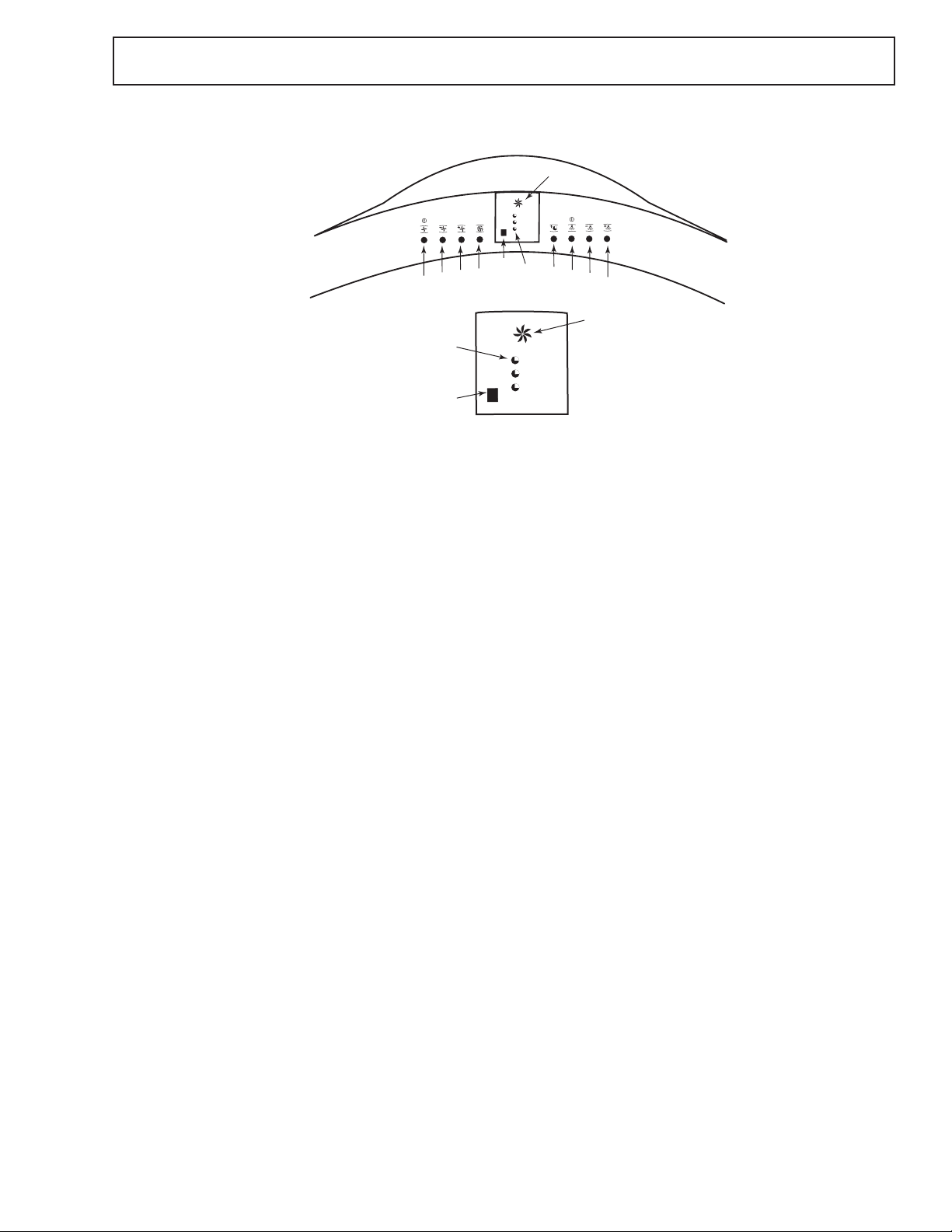

CONTROLS CONFIGURATION

4

Fan Keypad Operation

Controls

4

3

2

1

10

9

11

9

10

5

6

7

8

11

05

10

20

GEA0001

1. ON/OFF Switch - T urns electrical power to motor on and off. Remembers the last fan speed used.

2. Decrease Speed - Decreases current fan speed (4 speeds).

3. Increase Speed - Increases current fan speed (4 speeds).

4. High Speed - Maximum fan speed (350 cfm).

5. Delayed Shut-off - Choose 5-, 10-, or 20-minute shutdown time by pushing this button. Time is

indicated by illumination of Delay Shut-off Indicators (10).

Hood Lights Keypad Operation

6. Light ON/OFF - T urns electrical power to light on and off. Remembers the last light level used.

7. Decrease Brightness - Dims lights in 6 light levels.

8. Increase Brightness - Brightens lights in 6 light levels.

Display LEDs

9. Filter Cleaning Reminder Indicator - Lights after 30 hours of “on” time to remind you to clean the

metal grease filters. The light blinks until the filters are replaced. The timer reset s automatically.

10. Delayed Shut-off Indicators - Indicates delayed time setting. The fan will shut of f automatically at the

end of the delayed time setting.

11. Fan Operating Symbol - When illuminated, indicates that the fan is in operation even if the noise of

the fan cannot be heard.

– 5 –

Page 8

ELECTRONIC HOOD CONTROL DESCRIPTION

6

C

T

5

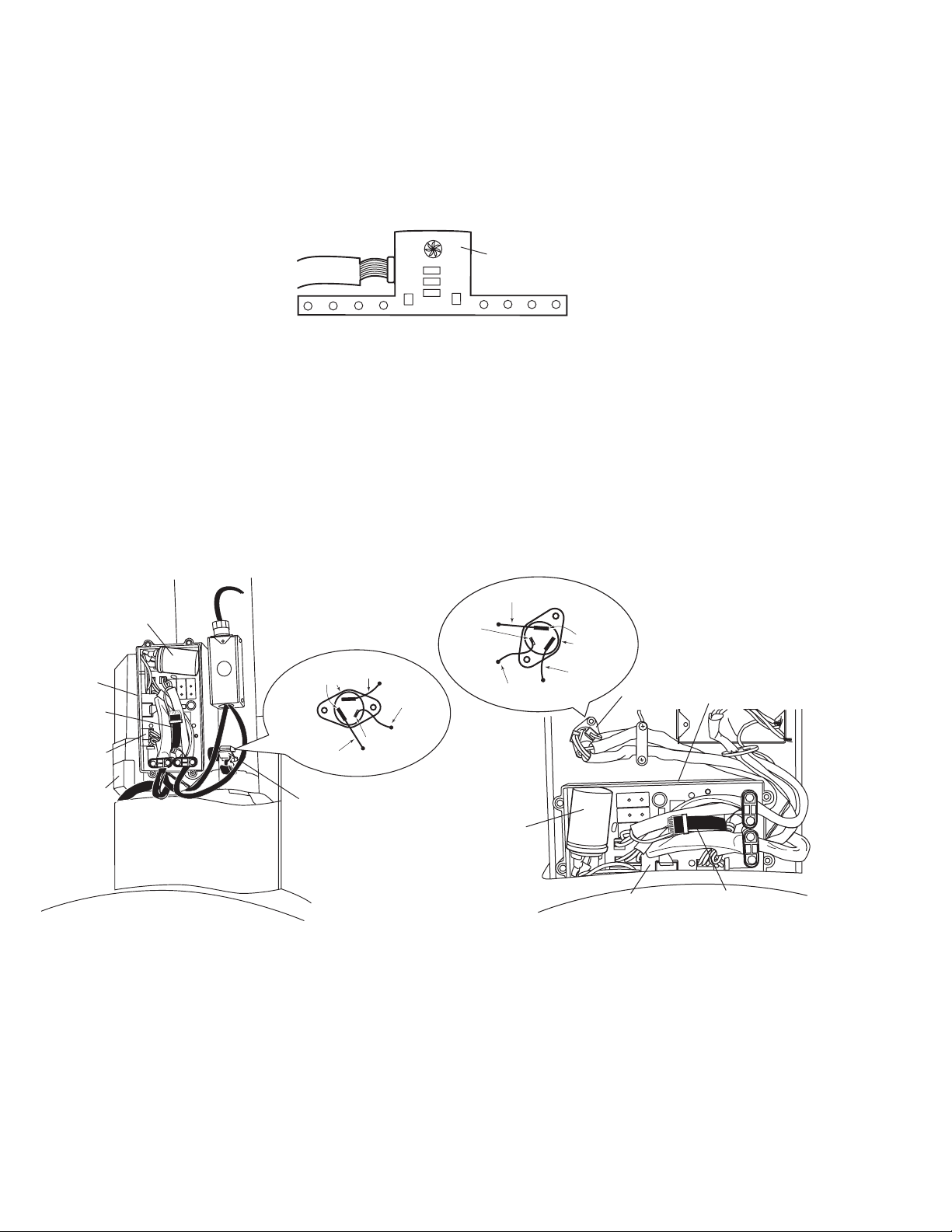

The electronic hood control system consists of the following parts: Entry/Display Assembly; Control PCB;

Triac; Fuse Holder; Motor Cap acitor; Transformer; Halogen Lamps; Filter Microswitch; and Induction Fan Motor.

CAUTION: Components are electrically HOT on the electronic control when voltage is connected to the

hood even though the ON/OFF switch is in the OFF position.

Entry

Control

Enclosure

GEA0001

1. ENTRY/DISPLAY ASSEMBLY

The replacement assembly WB27X10345 has 3 Printed Circuit Boards (PCB) mounted in a plastic enclosure with 8 push buttons and a ribbon cable. The three PCBs are Fan Touch Control PCB, Lamp Touch

Control PCB, and Display PCB.

Note: Before replacing the assembly, check the operation of the other hood components by plugging the

new Entry/Display Assembly cable into connector CN5 on the Control PCB. If the unit does not work,

replace the control board first and then recheck whether the existing Entry/Display assembly is OK. The

harness in the hood can be used instead of the one supplied with the assembly by carefully removing the

five screws from the enclosure assembly and unplugging the cable.

Black Box

Fuse Holder

ontrol PCB

ransformer

Motor Capacitor

Note: Mini Manual

on Control PCB

Cover.

1/4"

Terminals

Brown

Triac

Black

3/16"

Terminal

Orange

Brown

3/16"

Terminal

Orange

Motor

Capacitor

1/4"

Terminals

Black

Triac

Control PCB

ZV750 ZV850

Note: Mini Manual

on Control PCB

Cover.

Black Box

Fuse Holder

GEA0001

2. CONTROL PCB

This PCB has an AC to DC power supply, microprocessor, and fan relays and is located in the black box in

the hood chimney area.

Note: The 5 green connectors are locking type. Use a small flat blade screwdriver to unlock as follows:

Insert screwdriver in the center of the space between the plug and connector receptacle on the PCB. Push

down on the screwdriver handle to pivot blade about 5 degrees and pull out the plug at the same time.

TO CHECK OPERATION OF CONTROL PCB:

Check that all 6 connectors are locked in place, no leads are broken, and connector solder joints are not

broken on PCB copper tracks.

– 6 –

Page 9

3. TRIAC

E

7

The triac controls the four hood lamps and is mounted in a box in the chimney area. T riac has an isolated

case, which is mounted to the chimney with two screws.

Note: Triac wire connection must be correct or lamp flickering could occur. Triac can be checked for electrical short by removing the black lead and measuring the resistance between the two 1/4" terminals (terminals with black and brown wires). Resistance should be greater than 1M ohm.

4. FUSE HOLDER

The fuse holder is an in-line type, which is in series with 12V AC from the transformer and is located in the

blackbox. An open fuse may be caused by a lamp failing or a wrong wattage lamp.

Note: The fuse is 5 x 20 mm and rated at (8) A, 250V AC (GE part number WB02X10584).

5. MOTOR CAPACITOR

The start/run capacitor is mounted in the black box and plugs into the Control PCB connector CN3.

ntry/Display Assembly Filter Microswitch

AA

4 Lamps

Fan Motor

Lamps (4)

ZV750 ZV850

Transformer

Fan Motor

Motor mtg.-4 Hex Screws

(Use 9/32" Socket With Extension)

Entry/Display Assembly

A

A

Filter

Microswitch

6. TRANSFORMER

The transformer provides 12V AC to the hood lamps and the Control PCB power supply. It is attached by

four screws from the top of the chassis. The transformer is located next to the black box in Model ZV750

and above the grease filter in Model ZV850.

7. HALOGEN LAMPS

The 4 halogen lamps are the push-in type and rated at 12V AC/20W. The equivalent GE lamp is a

Q20MR16/C/CG40 - BAB.

GEA0001

8. FILTER MICROSWITCH

The microswitch is mounted in the filter area. When filters are removed, the microswitch causes the red

display light to blink continously. The red display light will also turn “on” after 30 hours of fan operation to

remind the user to clean the filters. Make sure the filter is seated properly when installed, or the filter light

will blink. NOTE: If electrical power is lost, the timer automatically resets to 0.

9. INDUCTION F AN MOT OR ASSEMBL Y

The motor is a 4-speed, start/run capacitor, induction type rated at 120V AC/1.7A. Motor stator winding

resistances:

Orange-Red = 17 ohms Blue-White = 8.5 ohms

Blue-Black = 17 ohms Black-White = 8.5 ohms

– 7 –

Page 10

Use and Care Information

9

N

f

b

u

If the consumer has any questions that the service person cannot answer, refer them to the GE Answer

Center (800.626.2000).

Care and Cleaning Stainless Steel Hood

WARNING: Before servicing or cleaning the unit, switch power off at the service panel and lock the

service panel to prevent power from being switched on accidentally. If the service panel cannot be

locked, fasten a tag or prominent warning label to the panel.

Metal Grease Filter

Note: To remove filters, push them back and down

using the knob.

ote:

To remove

ilters push them

ack and down

sing the knob.

Clean the grease filter after 30 hours of “on” time. A

signal light will alert you when 30 hours have passed.

Remove the grease filters and wash them either by

hand or in the dishwasher using

nonabrasive soap.

GEA0001

Note: If electrical power is lost, the timer automatically resets to 0.

For proper operation, be sure to use the lower set of

filter channels to assure that the microswitch is set.

Hood Surface

To clean the hood surface, use hot soapy water, then rinse and dry. For greasy soil, use an all-purpose

cleaning spray such as Fantastik

steel cleaner such as Bon-Ami®, Cameo®, or Barkeepers Friend®. Always scrub lightly and with the grain.

Do not use steel wool pads or other abrasive cleaners; they will scratch the surface.

®

brand or Formula 409® brand. For hard to clean soil, use a stainless

– 8 –

Page 11

Halogen Lamp Assembly Replacement

7

5

Service

Manual

Envelope

Triac

Junction

Box

Transformer

Black Box

(Control PCB)

ZV750 GEA00006

1. Remove the ring nut by turning it counter clockwise.

2. Grasp the bulb on the edges and pull it

straight out.

3. Remove 3 filters from the fan housing.

4. Remove 2 screws and lamp protection

from the hood.

5. Disconnect wires from lamp socket.

CAUTION: Replace the lamp with the same

size bulb. These 12-volt, 20-watt halogen bulbs

are available at specialty lighting stores. Ask for

GE bulb or equivalent: Q20 MR16/FL 40°–BAB.

Note: When reinstalling, ensure that all electrical

connections are securely fastened.

Filter Replacement

(Access to lighting and wiring)

1. Grasp knob and push filter back into rear

recess to release front edge of filter from track.

2. Pull front edge of filter down.

3. Pull filter toward you to remove.

GEA0000

Component Access/Duct Cover Removal

Model ZV750, Wall-Mounted Hood

Note: A ladder or step stool is needed for the

following procedure.

1. Remove 2 screws from the top duct cover at

the ceiling and slide the top cover down (see

illustration).

2. Lift and remove both duct covers. Set covers

aside.

GEA0000

– 9 –

Page 12

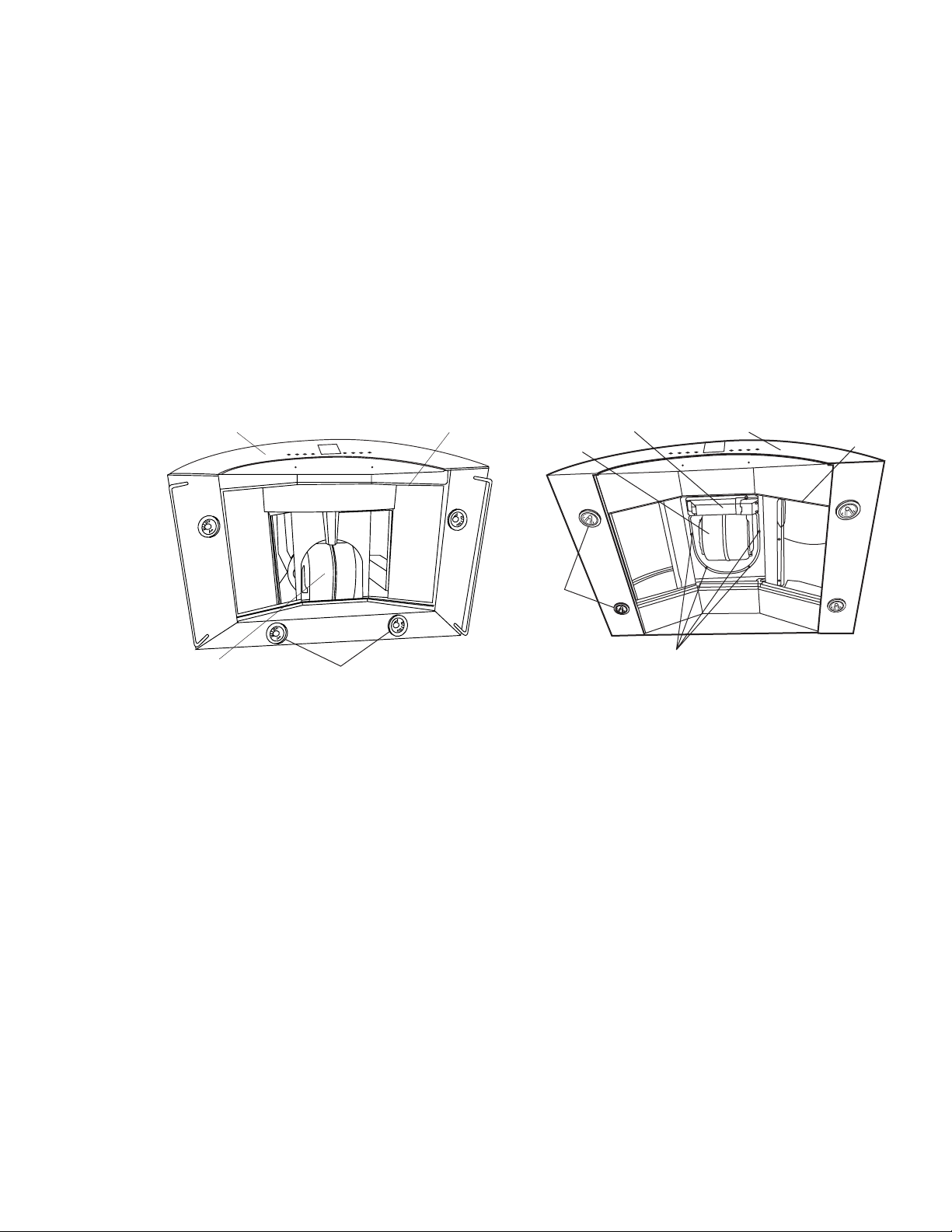

Component Access/Duct Cover Removal

er

7

B

Model ZV850, Island Hood

WARNING: Stop screw must be installed in one

of the support frame holes. Failure to do so may

cause personal injury or damage to duct cover.

1. Lift the lower duct cover up into the upper duct

cover (see illustration).

2. Remove the stop screw from the service

manual envelope.

3. Install stop screw in 1 of the holes provided in

the support frame to secure the lower duct

cover.

Note: Return the stop screw to the service manual

envelope when service is complete.

Control PCB Replacement

Install Stop

Screw In One

of 3 Holes

Provided

Triac

Bottom

Duct

Cover

AC Pow

Junction

Box

Service

Manual

Envelope

Black Box (Control PCB)

GEA00002

Motor Capacitor

lack Box

Control PCB

Motor

Capacitor

Control PCB

Black Box

ZV850ZV750

GEA0011

1. Access black box (refer to Component Access/Duct Cover Removal).

2. Disconnect motor capacitor connection from terminal CN3.

3. Disconnect entry/display assembly cable from terminal CN5.

4. Disconnect filter microswitch and triac connector from terminal CN4A.

5. Disconnect transformer and fuse connector from terminal CN4B.

6. Replace control PCB with new control PCB.

Note: When reinstalling, ensure that all electrical connections are securely fastened.

– 10 –

Page 13

Entry/Display Assembly Replacement

E

7

9

5

ntry/Display Assembly Filter Microswitch

Transformer

Fan Motor

AA

4 Lamps

Fan Motor

Lamps (4)

Motor mtg.-4 Hex Screws

(Use 9/32" Socket With Extension)

ZV750 ZV850

1. Remove 3 filters from hood.

2. Remove 2 screws (A) from hood and entry/display assembly .

3. Remove entry/display assembly from hood.

4. Remove the pusher bracket holding the display in place on

the face of the hood.

5. Remove the entire display .

Entry/Display Assembly

A

A

Filter

Microswitch

GEA0001

Entry

Control

Enclosure

GEA0001

Note: When reinstalling, ensure that all electrical connections are securely fastened, and the pusher

bracket and 2 screws are installed correctly. Check to be sure that the push buttons move freely through

the front surface of the control panel.

Filter Microswitch Replacement

Filter Microswitch

A

B

Note: Model ZV750Y1 is shown; Model ZV750Y2 and later , and Model ZV850 have only one filter

microswitch.

1. Disconnect electrical power to hood assembly .

2. Remove 2 screws (A) and filter microswitch bracket (B) from fan.

3. Remove 2 screws (C) and microswitch box from bracket.

4. Remove microswitch (D) from microswitch box and cover.

5. Disconnect wires from microswitch.

6. Replace microswitch with new microswitch.

C

D

GEA0002

Note: When reinstalling, ensure that all electrical connections are securely fastened.

– 11 –

Page 14

Fuse Replacement

9

B

lack Box

Fuse Holder

1. Access black box (refer to Component Access/

Duct Cover Removal).

2. Remove 4 screws and cover from black box.

3. Remove cap and fuse from fuse holder.

4. Replace fuse with new fuse.

Fuse Holder

ZV850ZV750

Black Box

GEA0011

WARNING: The fuse is a 5 x 20 mm and is rated

at 8 amps, 250V AC. Replace with fuse of the

same rating only (GE part number WB02X10584).

Glass Visor Replacement

Note: Model ZV750 hood has 1 glass visor and the

ZV850 has 2 glass visors.

1. Remove the plastic screws from the range hood.

2. Remove glass visor(s) from hood.

GEA00032

– 12 –

Page 15

Motor & Blower Assembly Replacement

F

M

1

B

d

s

Mounting Screw

GEA00121

Model ZV750

Note: This procedure requires that the unit be

removed from the wall.

ZV750

Entry/Display Assembly

Wire Shield/Wire Guide

Filter Microswitch

1. Remove duct cover (refer to Component

Access/Duct Cover Removal).

2. Disconnect power supply and exhaust ducting.

Note: Two people are required to perform the

next step.

3. While an assistant supports the hood, remove

2 lower mounting screws and the hood from

the wall.

4. Remove 4 screws (A) from the exhaust

opening.

5. Remove the black box cover ( 4 screws).

6. From the black box, remove the following:

a. 2 wire restraints (2 screws each)

b. wires from motor to Control PCB

(unplug terminal CN1)

c. ground wire

7. Remove green ground wires from ground

post.

8. Remove the blower assembly from the

hood (4 screws).

9. Remove the split ring from around the motor

wires and turn the plug sideways to remove.

an

otor

A

A

Lamps (4)

Change

Lamps

A

A

GEA0001

Note: Test motor before reinstallation.

Motor Capacitor

Note: When reinstalling, ensure that all

electrical connections, including ground

connections, are securely fastened.

lack Box

Control PCB

ZV750

Groun

Wire

GEA00117

– 13 –

Page 16

Motor & Blower Assembly Replacement

4

4

7

B

Model ZV850

1. Raise duct cover (refer to Component

ZV850

Access/Duct Cover Removal).

2. Remove filters (refer to Filter Replacement).

3. Remove the black box cover (4 screws).

Transformer

Entry/Display Assembly

4. From the black box, remove the following:

a. 2 wire restraints (2 screws each)

Fan Motor

b. wires from motor to Control PCB

(unplug terminal)

c. ground wire

5. Remove green ground wires from ground

post.

6. Remove retaining bracket and wire guide

(3 screws and split ring).

7. Remove the blower assembly from the

Lamps

Motor mtg.-4 Hex Screws

(Use 9/32" Socket With Extension)

hood (4 screws).

Note: When reinstalling, ensure that all electrical connections, including ground

connections, are securely fastened.

Filter

Microswitch

Change

Lamps

GEA0000

Motor Capacitor Replacement

Motor Capacitor

lack Box

Control PCB

Motor

Capacitor

Control PCB

1. Access black box (refer to Component Access/Duct Cover Removal).

2. Remove 4 screws and cover from black box.

3. Unplug connector from control PCB connector CN3 and remove motor capacitor from black box.

4. Replace motor capacitor with new motor capacitor.

Black Box

ZV850ZV750

GEA0011

Note: When reinstalling, ensure that all electrical connections are securely fastened.

– 14 –

Page 17

1

Transformer Replacement

8

T

B

(

lack Box

Control PCB)

ransformer

Service

Manual

Envelope

Transformer

Junction

Box

Triac

ZV750 ZV850

Note: Model ZV750 transformer is located above

the hood; Model ZV850 transformer is located

inside the hood.

1. Access transformer (refer to Component

Access/Duct Cover Removal).

2. Remove 2 screws and cover from transformer.

3. Loosen 4 screws and remove 5 wires from

transformer.

Note: Model ZV750 transformer does not have

an external ground wire; Model ZV850 trans former has an internal green ground wire

attached to the lower ground screw.

4. Remove the 2 screws, nuts, and the

transformer from the hood assembly.

5. Replace the transformer with a new transformer.

Note: When reinstalling, ensure that all electrical

connections are securely fastened.

ZV750

GEA0011

GEA0003

– 15 –

Page 18

6

C

T

Triac Replacement

Brown

Motor Capacitor

Black Box

Fuse Holder

ontrol PCB

ransformer

1/4"

Terminals

Brown

Triac

ZV750 ZV850

Black

Orange

3/16"

Terminal

1. Access triac (refer to Component Access/

Duct Cover Removal).

Note: The triac is located on the right side of

Model ZV750 and on the front of Model ZV850.

See Electronic Hood Control Description for

ZV850 diagram.

3/16"

Terminal

Orange

Motor

Capacitor

1/4"

Terminals

Black

Triac

Control PCB

Black Box

Fuse Holder

GEA0001

2. Remove 2 screws and the triac cover from

the hood.

3. Unplug 3 connectors from the triac.

4. Remove 2 screws and the triac from the hood.

5. Replace the triac with a new triac.

Note: When reinstalling, ensure that all electrical

connections are securely fastened and in the

correct location (ref. – mini manual).

– 16 –

Page 19

Troubleshooting

N

SERVICE DIAGNOSTIC FLOWCHART

WARNING

POWER MUST BE DISCONNECTED

BEFORE SERVICING THE APPLIANCE

REMOVE

TRIAC

ORANGE

LEAD

YES

YES

DONE

YES

ORDER/

INSTALL

TRIAC

YES

FAN

OK?

LIGHTS

OK?

LIGHTS

ALWAYS

ON?

NO

LIGHTS

ON?

NO

NO

NO

HOOD

LIGHTS

FLICKERING?

NO

NO

NO

RED DISPLAY

YES

FIX/

ORDER

MOTOR

YES

CHECK/MODIFY

TRIAC

CONNECTIONS

HOOD

LIGHTS

FLICKERING?

ORDER/INSTALL

NO

PUSH BUTTONS STUCK?

NO

PUSH BUTTONS STUCK?

NO

LIGHT

BLINKING?

FAN BLADES

BLOCKED?

CONTROL

YES

REMOVE/

RE-SEAT

RIGHT

FILTER

NO

• CHECK FM CAP (CN3)

NO

• UNPLUG CN1, CHECK

FM RESISTANCE

• FM OK?

YES

INSPECT

PCB IN

BLACKBOX

NOTE #1

YES

PCBs

YES

HOOD

DONE

ORDER/INSTALL

ENTRY/DISPLAY

ASSEMBLY

& CONTROL

PCBs

OK?

NO

HOOD CONTROL

DEAD?

TRANSFORMER

ORDER/

INSTALL

YES

UNSTICK/ADJUST

NOTE #2

YES

ORDER/INSTALL

ENTRY/DISPLAY

SUBASSEMBLY

YES

YES

DONE

TRANSFORMER

INSPECT

PCB IN

BLACKBOX

NOTE #1

YES

HOOD

OK?

ORDER/INSTALL

ENTRY/DISPLAY

ASSEMBLY

& CONTROL

PCBs

~

120V AC

=

AT

PRIMARY?

NO

NO

FIX

WIRING

DONE

YES

WIRING

DONE

YES

RED DISPLAY

NO

NO

FIX

YES

NO

REMOVE

RIGHT

FILTER

LIGHT

BLINKING?

RED DISPLAY

LIGHT

BLINKING?

~

120V AC

=

AT HOOD?

~

=

12V AC

AT CONNECTOR

(CN4B) IN

BLACKBOX?

FUSE IN

BLACKBOX

OK?

REPLACE

UNIT NOW

OK?

NO

YES

YES

NO

YES

CHECK/ADJUST

MICROSWITCH

NO

DONE

Check parts in the black box as follows:

ote #1 —

All six connectors are locked in place and no leads are broken.

Connector solder joints are not broken on PCB copper side.

Fuse is OK.

Capacitor (12.5uf 250VAC); Check that cap, is not open or shorted by using VOM.

Loosen and re-position entry/display assembly as follows:

Note #2 —

Loosen (2) screws on under surface of hood

Loosen (2) screws on assembly pusher plate

Check for button protrusion through the hood

holes and that buttons have movement

GEA00012

– 17 –

Page 20

CONTROL PCB

3

4

E

CN1

CN2

LINE

120V

GND

AC

NEUT.

CN3 CN5

CN4BCN4A

BLACK

GREEN

WHITE

Schematic & Strip Circuits

WARNING

POWER MUST BE DISCONNECTED

BEFORE SERVICING THE APPLIANCE

BLACK

WHITE

TRANSFORMER

120V

CN2

CN1

MOTOR

RELAYS

BROWN

12VAC

EMI

FILTER

8A250V - 5X20MM

FUSE

BROWN

(2) BLUE

GREY

RED

CN4B

LOW VOLTAGE

POWER SUPPLY

MICROPROCESSOR

CIRCUIT

GREY

WHITE

ISOLATED

TRIAC

ORANGE

BLUE

A1

A2

G

BLACK

MOTOR

FM WIRING

ORANGE

RED

BLUE

WHITE

BLACK

17 OHMS

8.5 OHMS

8.5 OHMS

MICROPROCESSOR

BLACK

WHITE

CIRCUIT

RED

BLUE

ORANGE

M

GREEN

CN3

WHITE

12.5 F

MOTOR

250V AC

CAPACITOR

CN4A

CN5

FAN TOUCH PCB

WHITE

VIOLET

FILTER

MICROSWITCH

ZV850 AND ZV750Y2

LIGHT TOUCH PCB

DISPLAY

PCB

G TO TRIAC GAT

CN4A

VIOLET

GEA0006

FILTER

MICROSWITCHES

(ZV750)*

4 LAMPS

12V AC

20W

GEA0001

– 18 –

Page 21

STRIP CIRCUITS

1

G

4

E

E

M

G

2

3

MOTOR CAPACITOR

OTOR CAPACITOR FM WINDIN

12.5 F 250 VAC

MICROPROCESSOR

CIRCUIT

MICROPROCESSOR

CIRCUIT

WHITE BLU

CN3

FILTER MICROSWITCH

WHITE

VIOLET

CN4A

WHITE

VIOLET

CN4A

ZV850 AND ZV750Y2

GREY

ZV750Y1

FILTER

MICROSWITCH

FILTER

MICROSWITCH

RED

GEA0002

G TO TRIAC GAT

GEA00024

G TO TRIAC GAT

GEA0006

GREEN

BROWN

BLUE

MICROPROCESSOR

12 VAC

CIRCUIT

MOTOR

M

8A250V - 5X20MM

FUSE

ORANGE

CN4A

BLACK

BLUE

ORANGE

BROWN

(2) BLUE

WHITE

RED

MOTOR

CN1

TRIAC

A1

G

RELAYS

ISOLATED

TRIAC

A2

MOTOR

BLACK

BLUE

NOTE: SEE

SCHEMATIC

FOR WINDIN

RESISTANCE

GEA0002

GEA0002

– 19 –

Page 22

STRIP CIRCUITS

5

1

D

N

FAN

LINE

20V

GND

AC

NEUT.

MOTOR

GREEN

MOTOR CAPACITOR

12.5 F 250 VAC

M

WHITE

BLACK

BLUE

BLACK

GREEN

WHITE

WHITE

ORANGE

CN3

RED

CN2

CN1

LAMPS

EMI

FILTER

MOTOR

RELAYS

FAN TOUCH PCB

MICROPROCESSOR

CIRCUIT

CN5

DISPLAY

PCB

LIGHT TOUCH PCB

GEA0002

120V

TRANSFORMER

CN4B

LOW VOLTAGE

POWER SUPPLY

FAN TOUCH PCB

BLACK

WHITE

LINE

EUT.

CN2

CN2

8A250V - 5X20MM

FUSE

12 VAC

MICROPROCESSOR

CIRCUIT

CN5

DISPLAY

PCB

BROWN

(2) BLUE

ORANGE

CN4A

LIGHT TOUCH PCB

A1

G

BLUE

ISOLATE

TRIAC

A2

GEA00026

BLACK

– 20 –

Page 23

Notes

– 21 –

Page 24

Model ZV750 Illustrated Parts Breakdown

– 22 –

Page 25

Model ZV750 Illustrated Parts Breakdown

Reference # Description Part #

9 GREASE FIL TER WB02X10396

14 CONDENSER WB17X10001

26 LAMP BULB WB08X10014

29 MONOGRAM LOGO WB02X10353

37 KNOB WB03X10002

48 MOTOR & BLOWER ASM WB26X10071

56 CONNETION AIR OUTLET WB07X10005

57 NON-RETURN FLAP WB02X10397

64 BOTTON BRACKET WB03X10003

73 GLASS VISOR WB07X10007

77 PLEXIGLASS WB02X10642

118 BOTTOM DUCT WB38X10022

119 UPPER DUCT WB38X10023

133 IMPLEMENT HOLDER WB03X10092

144 WIRE STOP PIN WB02X10398

166 PRINTED CIRCUIT BOARD WB27X10004

170 FUSE WB02X10646

171 FUSE HOLDER WB02X10647

195 BRACKET WB02X10399

199 CERAMIC INSULA TION BASE WB02X10400

200 DICHROIC LAMP PROTECTION WB08X10001

202 REFLECTOR STOP WB02X10401

203 BLOCKING WB07X10006

208 TRANSFORMER WB17X10002

223 SWITCH BUTTON WB03X10001

227 DISPLA Y CONTROL ASSY WB27X10364

250 RING NUT WB01X10002

252 MICROSWITCH BOX WB07X10003

253 MICROSWITCH WB24X10001

254 MICROSWITCH BOX COVER WB07X10004

479 TRIAK WB02X10402

500 INSTALLATION HARDWARE WB02X10655

999 MINI-MANUAL 31-20762

999 TEMPLATE 49-8818

999 USE & CARE MANUAL 49-8964-1

999 INSTALLATION INSTRUCTION 49-8990

– 23 –

Page 26

Model ZV850 Illustrated Parts Breakdown

– 24 –

Page 27

Model ZV850 Illustrated Parts Breakdown

Reference # Description Part #

9 GREASE FIL TER WB02X10396

14 CONDENSER WB17X10001

26 LAMP BULB WB08X10002

29 MONOGRAM LOGO WB02X10645

48 MOTOR & BLOWER ASM WB26X10068

56 CONNECTION AIR OUTLET WB07X10005

57 NON-RETURN FLAP WB02X10397

64 BUTTON BRACKET WB03X10084

73 GLASS VISOR WB07X10007

77 PLEXIGLASS WB02X10642

118 BOTTOM DUCT 8 FT.CEIL. WB38X10028

118 BOTTOM DUCT 9 FT.CEIL. WB38X10030

118 BOTTOM DUCT 10 FT.CEIL. WB38X10032

1 1 9 UPPER DUCT 8 FT.CEIL. WB38X10029

1 1 9 UPPER DUCT 9 FT.CEIL. WB38X10031

1 1 9 UPPER DUCT 10 FT.CEIL. WB38X10033

133 IMPLEMENT HOLDER WB03X10085

166 PRINTED CIRCUIT BOARD WB27X10004

170 FUSE WB02X10646

171 FUSE HOLDER WB02X10647

195 BRACKET WB02X10399

199 CERAMIC INSULA TION BASE WB02X10400

200 DICHROIC LAMP PROTECTION WB08X10001

203 BLOCKING BRACKET WB07X10339

208 TRANSFORMER WB17X10002

223 SWITCH BUTTON WB03X10001

227 DISPLA Y CONTROL ASSY WB27X10345

250 RING NUT WB01X10002

252 MICROSWITCH BOX WB07X10003

253 MICROSWITCH WB24X10001

254 MICROSWITCH BOX COVER WB07X10004

479 TRIAC WB02X10402

500 INSTALLATION HARDWARE WB02X10581

999 MINI MANUAL 31-20753-1

999 TEMPLATE 49-8776

999 USE & CARE MANUAL 49-8964-1

999 INSTALL INSTR 49-8970

– 25 –

Page 28

Notes

– 26 –

Page 29

Warranty Information

MONOGRAM ® HOOD W ARRANTY

Sales slip or cancelled check is required as proof of original

purchase date to obtain service under warranty.

WHAT IS

COVERED

WHAT IS

NOT

COVERED

FULL ONE-YEAR W ARRANTY

For one year from date of original purchase, we will provide, free of charge, parts and

service labor in your home to repair or replace any part of the hood that fails because

of a manufacturing defect.

This warranty is extended to the original purchaser and any succeeding owner for products

purchased for ordinary home use in the 48 mainland states, Hawaii, and W ashington, D.C.

In Alaska the warranty is the same except that it is LIMITED because you must p ay to ship

the product to the service shop or for the service technician’s travel costs to your home.

All warranty service will be provided by our Factory Service Centers or by our authorized

Customer Care® servicers during normal working hours.

Should your appliance need service during warranty period or beyond, call 800.444.1845.

• Service trips t o your home to teach you

how to use the product.

Read your Use and Care material.

If you then have any questions about

operating the product, please contact your

dealer or our Consumer A ffairs office at

the address below, or call, toll-free:

GE Answer Center®

800.626.2000

consumer information service

• Replacement of house fuses or resetting

of circuit breakers.

• Replacement of the replaceable filters.

• Damage to the product caused by

accident, fire, floods, or acts of God.

• Failure of the product if it is used for other

than its intended purpose or used

commercially .

• Improper installation.

If you have an installation problem, contact

your dealer or installer . Y ou are responsible

for providing adequate electrical, gas,

exhausting and other connecting facilities

as described in the Installation Instructions

provided with the product.

WARRANTOR IS NOT RESPONSIBLE

FOR CONSEQUENTIAL DAMAGES.

Some states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation or exclusion may not apply to you. This warranty gives you specific

legal rights, and you may also have other rights which vary from st ate to state.

To know what your legal rights are in your state, consult your local or state consumer affairs

office or your state’s Attorney General.

Warrantor: General Electric Company. If further help is needed concerning this warranty,

write to: Manager—Consumer Affairs, GE Appliances, Louisville, KY 40225.

– 27 –

Page 30

Consumer

Services

GE Answer

Center®

800.626.2000

In-Home

Repair

Service

800.444.1845

For Customers

with Special

Needs…

800.626.2000

Whatever your question about any Monogram

information service is available to help. Your call—and your question—will be answered

promptly and courteously . And you can call any time. GE Answer Center® service is

open 24 hours a day, 7 days a week.

A GE Consumer Service professional will provide expert repair service, scheduled at a

time that’s convenient for you. Many GE Consumer Service company-operated locations offer you service today or tomorrow , or at your convenience (7:00 a.m. to 7:00

p.m. weekdays, 9:00 a.m. to 2:00 p.m. Saturdays). Our factory-trained technicians know

your appliance inside and out—so most repairs can be handled in just one visit.

GE offers, free of charge, a brochure to assist in planning

a barrier-free kitchen for persons with limited mobility .

Consumers with impaired hearing or speech who have

access to a TDD or a conventional teletypewriter may call

800.TDD.GEAC (800.833.4322) to request information

or service.

®

major appliance, GE Answer Center®

Service

Contracts

800.626.2224

Parts and

Accessories

800.626.2002

You can have the secure feeling that GE Consumer Service will still be there after your

warranty expires. Purchase a GE contract while your warranty is still in effect and you’ll

receive a substantial discount. With a multiple-year contract, you’re assured of future

service at today’s prices.

Individuals qualified to service their own appliances can have parts or accessories sent

directly to their home. The GE p art s system provides access to over 47,000

parts…and all GE Genuine Renewal Parts are fully warranted. VISA, MasterCard and

Discover cards are accepted.

User maintenance instructions cover procedures intended to be performed by

any user . Other servicing generally should be referred to qualified service

personnel. Caution must be exercised, since improper servicing may cause

unsafe operation.

– 28 –

Loading...

Loading...