Page 1

Installation

Instructions

30" Chimneg Vent Hood

For Model:

ZV830

30" (76,2 cm)

Hotte aspirante

Instructions d'installation

Pour IQModUle •

ZV830

La section fran_aise commence _ la page 21

Campana de ventilaci6n

de chimenea de 30" (76,2 cm)

Instrucciones de instalaci6n

PQrQIVlodelo:

ZV830

La secci6n en espaSol empieza en la p_gina 41

149-so5121

01-08 JR

Page 2

Safetg Information

READ AND SAVE THESE INSTRUCTIONS

BEFORE YOU BEGIN

Read these instructions completely and carefully.

• IMPORTANT- Savetheseinstructionsfor

localinspector'suse.

•IM PORTANT-Observeallgoverningcodes

and ordinances.

• Note to Installer - Besure to leave these

instructions with the Consumer.

• Note to Consumer- Keepthese instructions

with your Owner's Manual for future reference.

• Skill Level -Installation of this appliance requires

basic mechanical and electrical skills.

• Completion Time - I to 3 Hours.

• Proper installation isthe responsibility of the installer.

Product failure due to improper installation is not

covered under the warranty.

ForMonogram localserviceingour area,call 1.800.444.1845.

For Monogram service in Canada, call 1.800.561.3344.

For Monogram Parts and Accessories, call 1.800.626.2002.

CAUTION:

Due to the weight and size of these vent hoods and

to reduce the risk of personal injury or damage to the

product, TWO PEOPLEAREREQUIREDFORPROPER

INSTALLATION.

WARNING:

To reduce the risk of fire or electrical shock, do not

use this range hood with any external solid-state speed

control device. Any such alteration from original factory

wiring could result in damage to the unit and/or create

an electrical safety hazard.

TOREDUCETHERISKOFFIRE,USEONLYMETALDUCTWORK.

WAR N IN G:TOREDUCETHERISKOFFIRE,

ELECTRICALSHOCK OR INJURY TO PERSONS, OBSERVE

THE FOLLOWING:

A. Use this unit only in the manner intended

by the manufacturer. If you have any questions,

contact the manufacturer.

a.

Before servicing or cleaning the unit, switch

the power off at the service panel and lock the

service disconnecting means to prevent the power

from being switched on accidentally. When the

service disconnecting means cannot be locked,

securely fasten a prominent warning device,

such as a tag, to the service panel.

CAUTION: FOR GENERAL VENTILATING

USE ONLY.DO NOT USE TO EXHAUST HAZARDOUS

MATERIALS,EXPLOSIVEMATERIALSOR VAPORS.

WAR N IN G:TOREDUCETHERISKOFFIRE,

ELECTRICALSHOCK OR INJURY TO PERSONS, OBSERVE

THE FOLLOWING:

Installation work and electrical wiring must be done

by qualified person(s)in accordance with all applicable

codes and standards, including fire-rated construction.

Sufficient air is needed for proper combustion

and exhausting of gases through the flue (chimney)

of fuel burning equipment to prevent back-drafting.

Follow the heating equipment manufacturer's

guidelines and safety standards, such as those

published by the National Fire Protection Association

(NFPA),the American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE)and the local

code authorities.

• When cutting or drilling into walls or ceilings, do not

damage electrical wiring and other hidden utilities.

• Ducted systems must always be vented

to the outdoors.

Local codes vary. Installation of electrical connections

and grounding must comply with applicable codes.

In the absence of local codes, the vent should be

installed in accordance with National Electrical Code

ANSI/NFPA70-1990 or latest edition.

CAUTION: TO reduceriskoffireand to

properly exhaust air, be sure to duct air outside-do not

vent exhaust air into spaces within walls or ceilings or

into attics, crawl spaces or garages.

Page 3

Design Information

CONTENTS

Design Information

Product Dimensions and Clearances ....................................................3

Installation Options ........................................................................................3

Installation Preparation

Advance Planning, Ductwork, Framing ................................................4

Power Supply ....................................................................................................4

Duct Fittings ......................................................................................................5

Tools and Materials Required ....................................................................6

Remove the Packaging ................................................................................6

Determine Installation Height ..................................................................7

Wall Mount Installation Heights ..............................................................7

Check Installation Hardware ......................................................................8

Installation-Vented to the Outside

Ductwork, Wiring Locations ......................................................................9

Step 1, Install Framing for Hood Support ............................................9

Step 2, Install Hood Mounting Screws................................................10

Step 3, Install Duct Bracket ......................................................................10

Step/4, Mount the Hood ............................................................................10

Step 5, Connect Ductwork ........................................................................11

Step 6, Connect Electrical ........................................................................12

Step 7, Install Duct Covers........................................................................12

Step 8, Install Filters ....................................................................................13

Step 9, Finalize Installation ......................................................................13

Installation--Recirculating

Ductwork, Wiring Locations ....................................................................1/4

Step 1, Install Framing for Hood Support ..........................................1/4

Step 2, Install Hood Mounting Screws................................................15

Step 3, Install Duct Bracket ......................................................................15

Step/4, Mount the Hood ............................................................................15

Step 5, Size and Cut Duct Piece ............................................................16

Step 6, Connect Electrical ........................................................................17

Step 7, Install Duct Covers........................................................................17

Step 8, Install Filters ....................................................................................18

Step 9, Finalize Installation ......................................................................18

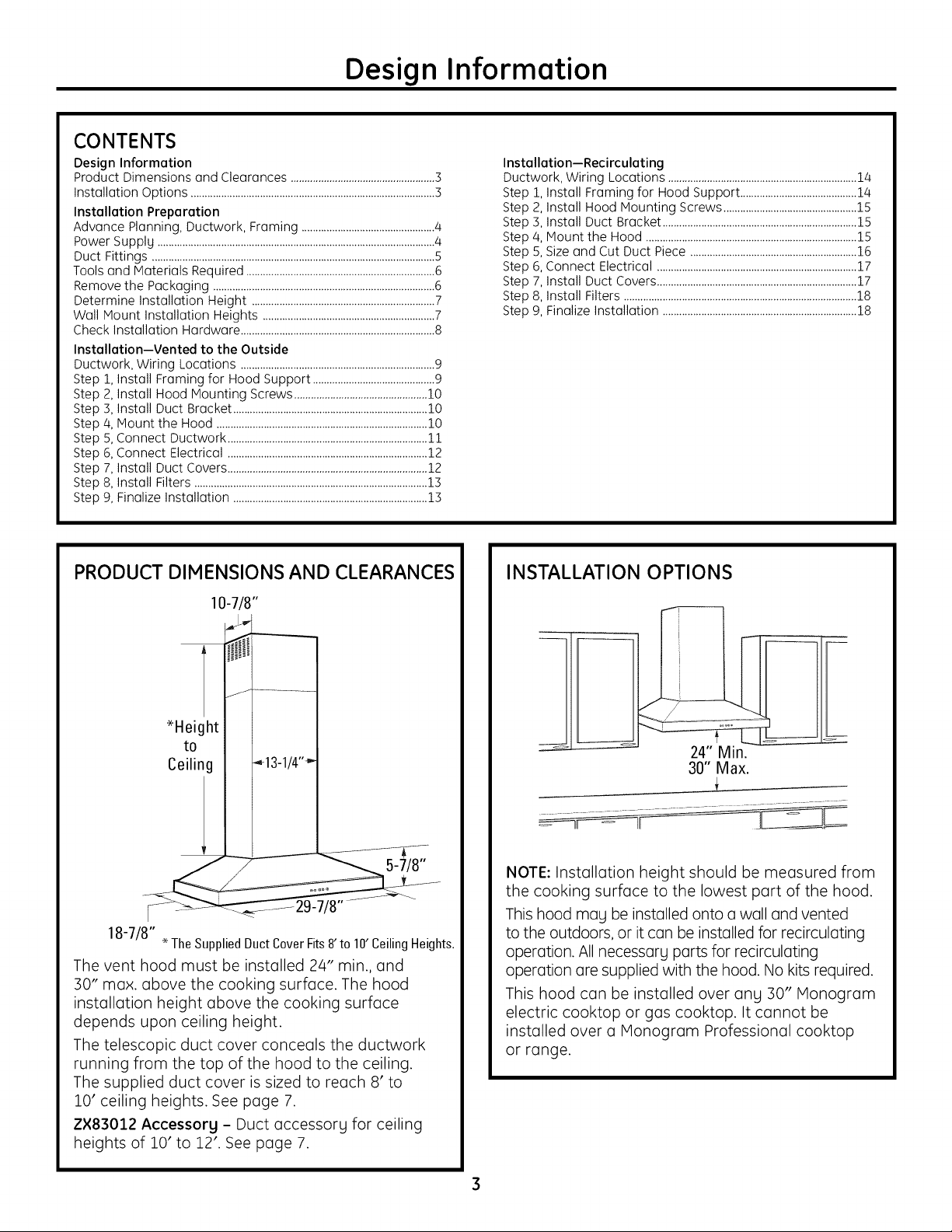

PRODUCT DIMENSIONS AND CLEARANCES

10-7/8"

t

:H ghte,.i:gii .13lJ,-1

18-7/8". TheSuppliedDuct CoverFits8'to 10'CeilingHeights.

The vent hood must be installed 2/4" min., and

:30" max. above the cooking surface. The hood

installation height above the cooking surface

depends upon ceiling height.

The telescopic duct cover conceals the ductwork

running from the top of the hood to the ceiling.

The supplied duct cover is sized to reach 8' to

10' ceiling heights. See page 7.

Z×83012 Accessorg - Duct accessorg for ceiling

heights of 10' to 12'. See page 7.

INSTALLATION OPTIONS

NOTE: Installation height should be measured from

the cooking surface to the lowest part of the hood.

This hood mag be installed onto a wall and vented

to the outdoors, or it can be installed for recirculating

operation. All necessarg parts for recirculating

operation are supplied with the hood. No kits required.

This hood can be installed over ang :30" Monogram

electric cooktop or gas cooktop. It cannot be

installed over a Monogram Professional cooktop

or range.

Page 4

Installation Preparation

ADVANCEPLANNING

• Determinethe exact location of the vent hood.

• Planthe route for venting exhaustto the outdoors.

• Usethe shortest and straightest duct route possible.For

satisfactory performance, duct run should not exceed 100 ft.

equivalent length for any duct configurations.

• Referto "Duct Fittings"chart on page 5to compute the

maximum permissiblelengthfor duct runsto the outdoors.

CAUTION:To reduce riskof fire and to properly

exhaust air,be sure to duct air outside-do not vent exhaust

air into spaceswithin walls or ceilingsor into attics, crawl

spacesor garages.

WARNING: TO REDUCE THE RISK OF FIRE,

USE ONLY METAL DUCTWORK.

• Installa wall cap with damper or roofcap at the exterior

opening.Orderthe wall or roof cap and any transition

neededin advance.

Wall Framing for Adequate Support

• Thisvent hood is heavy.Adequate structural support must

be provided in alltypes of installations.The hood must be

securedto vertical studs in the wall, orto a horizontal

support.

• The vent hood should be on sitebefore finalframing and

wall finishing.Thiswill help to accurately locatethe duct

work and electricalservice.

• Installation will be easierif the vent hood isinstalled before

the cooktop and countertop are installed.

ACCESSORYDUCT COVER

Thishood isshippedwith a decorative duct cover for ceiling

heights of 7'11" to 10'.TheZX83012duct cover accessory

isavailableto reachceiling heights between 10'1" and 12'.

Theaccessoryshould be ordered withthe hood and be

on sitebefore installation begins.

POWERSUPPLY

IMPORTANT- {Pleaseread carefullg)

WARNING:FORPERSONALSAFETY,

THISAPPLIANCEMUSTBEPROPERLYGROUNDED.

Removehouse fuse or open circuit breaker before beginning

installation.

Donot usean extension cord or adapter plug withthis

appliance. Follow National electricalcodes orprevailing local

codes and ordinances.

Electrical supplg

Thesevent hoods must be suppliedwith 120V,60Hz,and

connected to an individual,properly grounded branch circuit,

and protected by a 15 or 20 amp circuit breaker or time

delay fuse.

• Wiring must be 2 wire with ground.

• Ifthe electricalsupply doesnot meet the above

requirements,call a licensedelectrician before proceeding.

• Routehousewiring ascloseto the installation location as

possible,inthe ceiling or back wall. Referto Wiring Locations

on page 9.

• Connectthe hood wiring to the housewiring in accordance

with localcodes.

Grounding instructions

Thegrounding conductor must be connectedto a grounded

metal, permanent wiring system, or an equipment-grounding

terminal or leadon the hood.

WARNING:The improper connection of the

equipment-grounding conductor can resultin a risk of

electric shock.Checkwith a qualifiedelectrician or service

representative if you are in doubt whether the appliance is

properly grounded.

CAUTION:Automatically Operated Device-

Toreducethe risk of injury disconnect from power supply

before servicing.This unit isequipped with an integral

disconnecting switch located insidethe blower housing.

4

Page 5

Installation Preparation

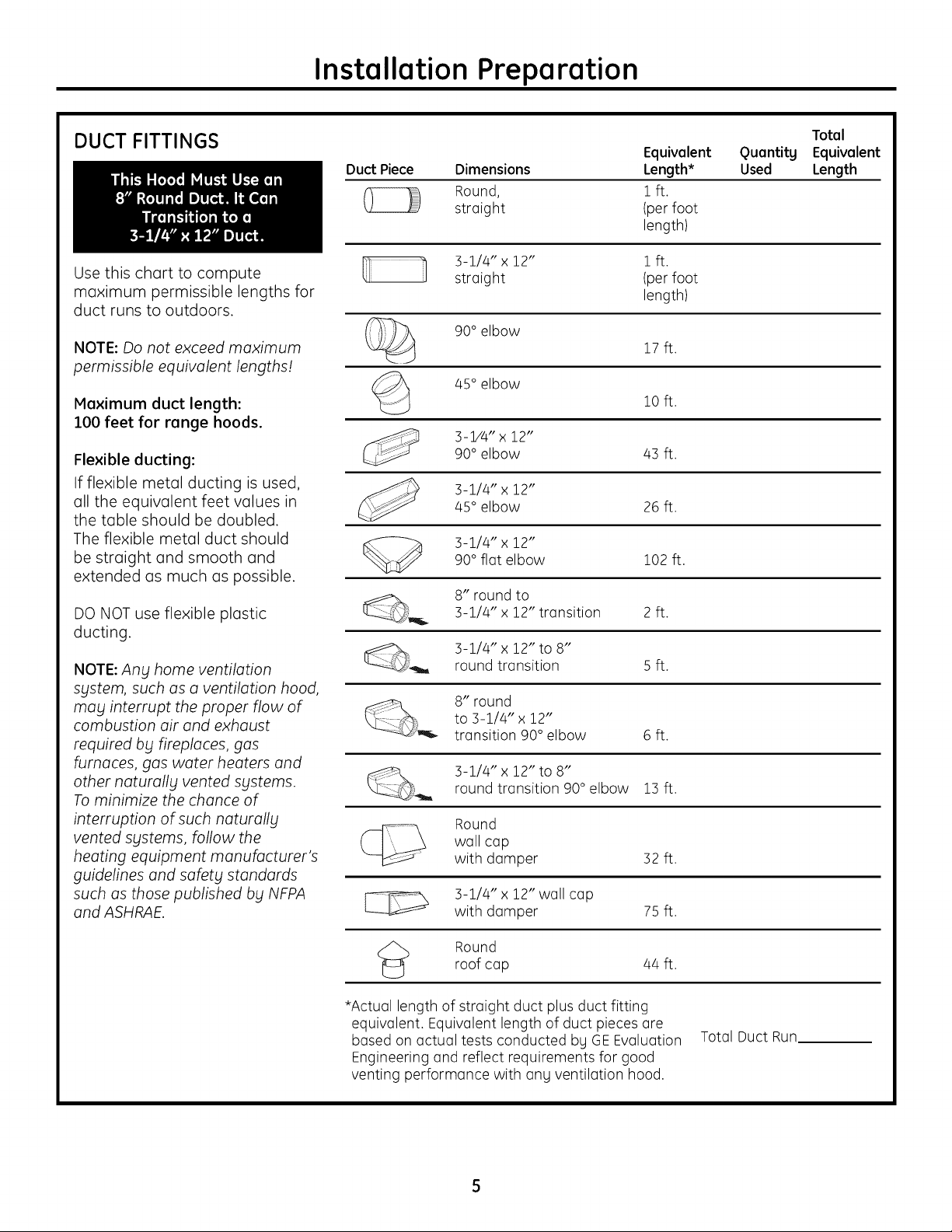

DUCT FITTINGS

Use this chart to compute

maximum permissible lengths for

duct runs to outdoors.

NOTE: Do not exceed maximum

permissible equivalent lengths!

Maximum duct length:

100 feet for range hoods.

Flexible ducting:

If flexible metal ducting is used,

all the equivalent feet values in

the table should be doubled.

The flexible metal duct should

be straight and smooth and

extended us much us possible.

Duct Piece Dimensions

Round,

straight

3-1/4" x 12" 1 ft.

straight (per foot

90° elbow

45° elbow

3-1/4" x 12"90° elbow 43 ft.

3-1/4" x 12"

45° elbow 26 ft.

90° flat elbow 102 ft.

3-1/4" x 12"

Equivalent

Length*

1ft.

(per foot

length)

length)

17 ft.

10 ft.

Quantity

Used

Total

Equivalent

Length

DO NOT use flexible plastic

ducting.

NOTE: Ang home ventilation

sgstem, such as a ventilation hood,

may interrupt the proper flow of

combustion air and exhaust

required by fireplaces, gas

furnaces, gas water heaters and

other naturallbl vented systems.

To minimize the chance of

interruption of such naturally

vented sgstems, follow the

heating equipment manufacturer's

guidelines and safety standards

such as those published bbl NFPA

and ASHRAE.

_,_ 8" round to3-1/4" x 12" transition 2 ft.

3-1/4" x 12" to 8"

round transition 5 ft.

8" round

to 3-1/4" x 12"

transition 90° elbow 6 ft.

3-1/4" x 12" to 8"round transition 90° elbow 13 ft.

Round

wall cap

with damper 32 ft.

F---_I----X 3-1/4" x 12" wall cap

L_x_

<_ Round

*Actual length of straight duct plus duct fitting

equivalent. Equivalent length of duct pieces are

based on actual tests conducted by GE Evaluation

Engineering and reflect requirements for good

venting performance with any ventilation hood.

with damper 75ft.

roof cap /4/4ft.

Total Duct Run

Page 6

Installation Preparation

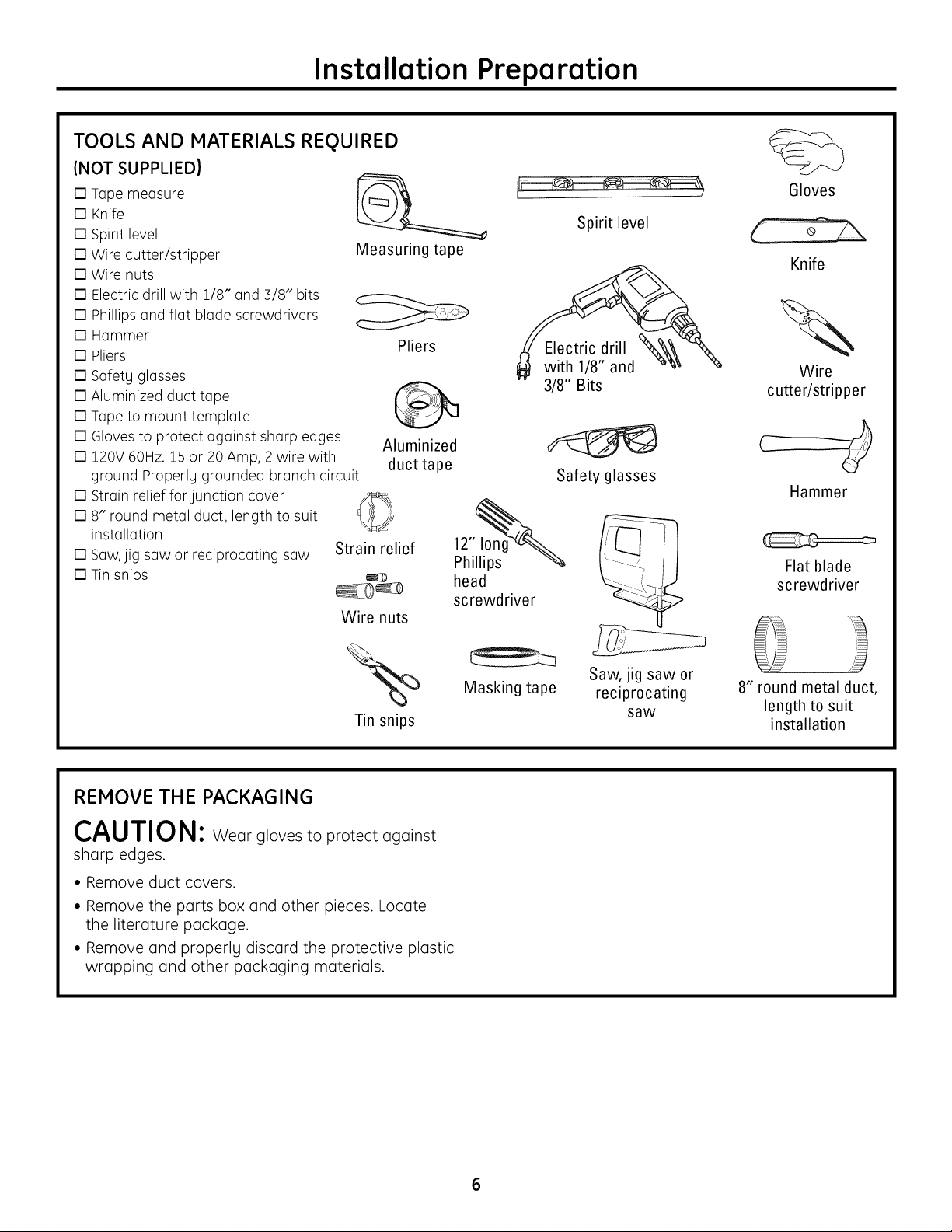

TOOLS AND MATERIALS REQUIRED

(NOT SUPPLIED)

[] Tape measure

[] Knife

[] Spirit level

[] Wire cutter/stripper

[] Wire nuts

[] Electric drill with 1/8" and 3/8" bits

[] Phillips and flat blade screwdrivers

[] Hammer

[] Pliers

[] Safetg glasses

[] Aluminized duct tape

[] Tape to mount template

[] Gloves to protect against sharp edges

[] 120V 60Hz. 15 or 20 Amp, 2 wire with

ground Properlg grounded branch circuit

[] Strain relief for junction cover

[] 8" round metal duct, length to suit

installation

[] Saw,jig saw or reciprocating saw

[] Tin snips

Measuring tape

Strain relief

Wire nuts

Pliers

Aluminized

ducttape

head

screwdriver

Spirit level

Electric drill

with 1/8" and

3/8" Bits

Safety glasses

Gloves

Knife

Wire

cutter/stripper

Hammer

Flat blade

screwdriver

Tin snips

REMOVE THE PACKAGING

CAUTION: Wear gloves to protect against

sharp edges.

• Remove duct covers.

• Remove the parts box and other pieces. Locate

the literature package.

• Remove and properlg discard the protective plastic

wrapping and other packaging materials.

Masking tape

Saw, jig saw or

reciprocating

saw

8" round metal duct,

length to suit

installation

Page 7

Installation Preparation

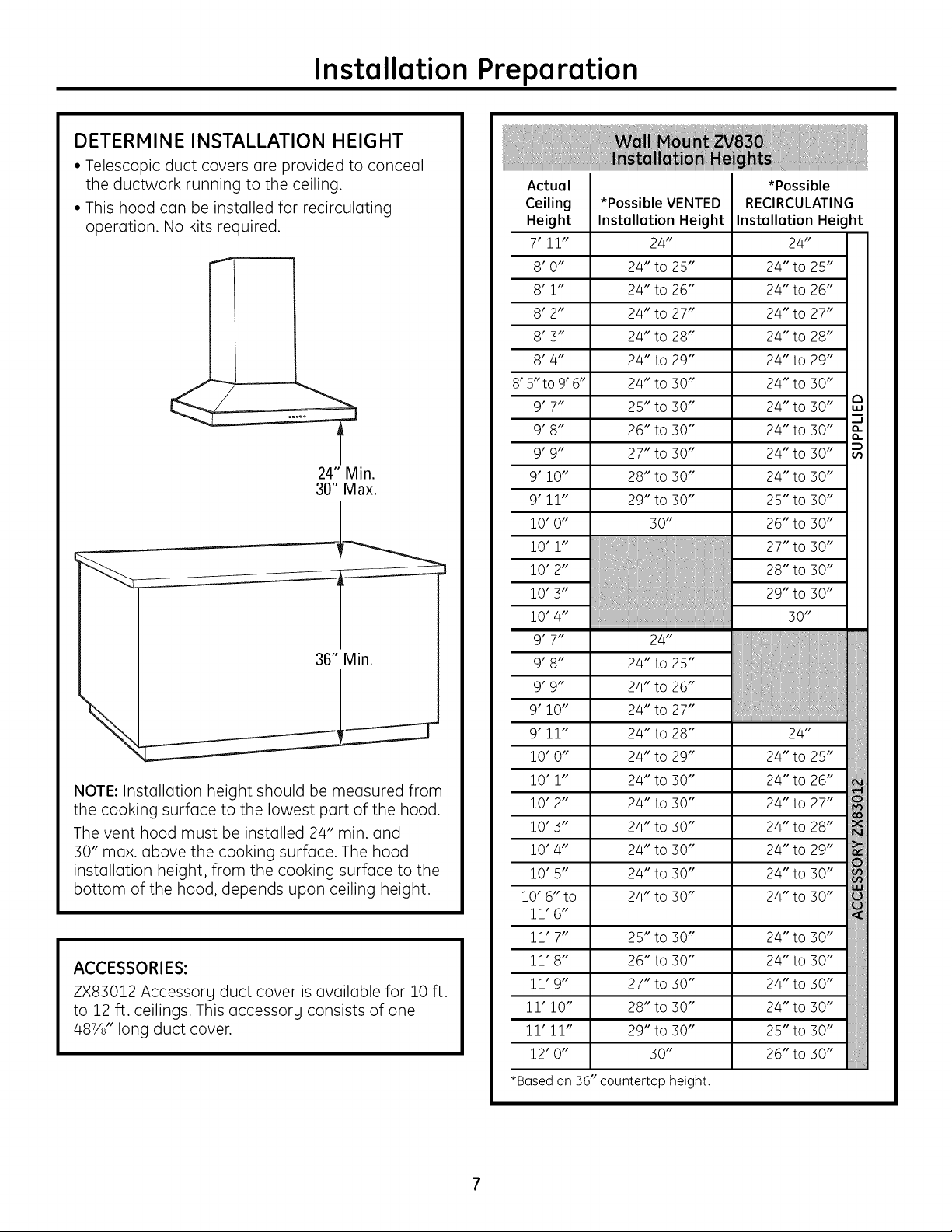

DETERMINE INSTALLATION HEIGHT

• Telescopic duct covers are provided to conceal

the ductwork running to the ceiling.

• This hood can be installed for recirculating

operation. No kits required.

24" Min.

30" Max.

36" Min.

NOTE: Installation height should be measured from

the cooking surface to the lowest part of the hood.

The vent hood must be installed 2/4" min. and

30" max. above the cooking surface. The hood

installation height, from the cooking surface to the

bottom of the hood, depends upon ceiling height.

ACCESSORIES:

ZX83012 Accessory duct cover is available for 10 ft.

to 12 ft. ceilings. This accessory consists of one

487/8" long duct cover.

Actual

Ceiling

Height

7'11"

8'0"

8'1"

8'2"

8'3"

8'4"

8' 5"to 9' 6"

9'7"

9'8"

9'9"

9' 10"

9'11"

10' O"

10' 1"

10'2"

i0'3"

10' 4"

9'7"

9'8"

9'9"

9' 10"

9'11"

10'0"

10' 1"

10'2"

i0'3"

10' 4"

10' 5"

10' 6"to

11'6"

11'7"

11'8"

11'9"

11' 10"

11' 11"

12'0"

*BQsed

on 36" countertop height.

*Possible VENTED

Installation Height

24"

24" to 25"

24" to 26"

24" to 27"

24" to 28"

24" to 29"

24" to 30"

25" to 30"

26" to 30"

27" to 30"

28" to 30"

29" to 30"

30"

24"

24" to 25"

24" to 26"

24" to 27"

24" to 28"

24" to 29"

24" to 30"

24" to 30"

24" to 30"

24" to 30"

24" to 30"

24" to 30"

25" to 30"

26" to 30"

27" to 30"

28" to 30"

29" to 30"

30"

24"

24" to 25"

24" to 26"

24" to 27"

24" to 28"

24" to 29"

24" to 30"

24" to 30"

24" to 30"

24" to 30"

24" to 30"

24" to 30"

25" to 30"

26" to 30"

Page 8

Installation Preparation

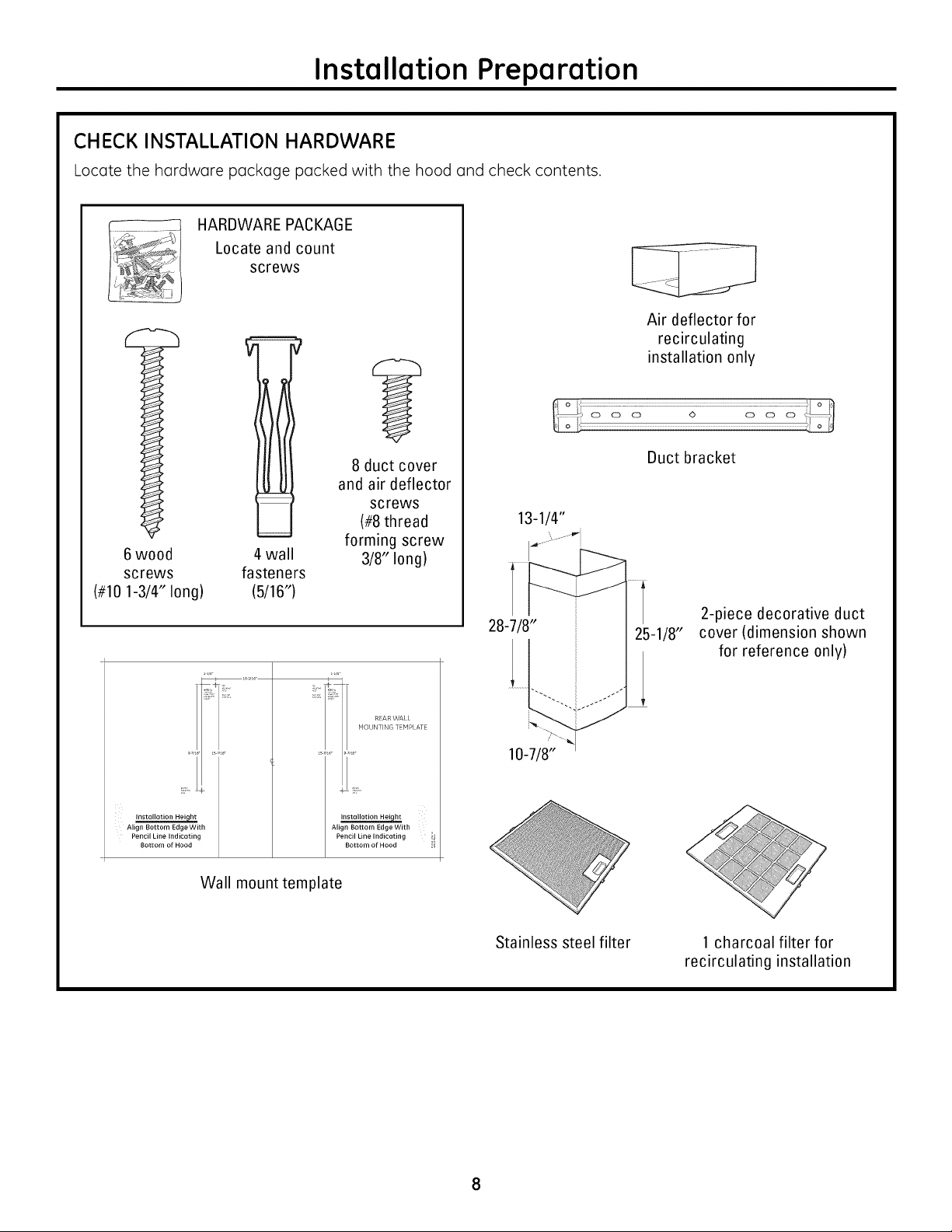

CHECK INSTALLATION HARDWARE

Locate the hardware package packed with the hood and check contents.

HARDWARE PACKAGE

Locate and count

screws

d

Air deflector for

recirculating

installation only

6wood

screws

(#10 1-3/4" long)

Installation Height

Align Bottom Edge With

Pencil Line Indicating

Bottom of Hood

4 wall

fasteners

(5/16")

Wall mount template

8 duct cover

and air deflector

screws

(#8 thread

forming screw

3/8" long)

REAR WALL

HOUNTING TEMPLATE

Installation Hei ht

Align Bottom Edge With

Pencil Line Indicating

Bottom of Hood

Duct bracket

13-1/4"

2-piece decorative duct

cover (dimension shown

for reference only)

Stainless steel filter 1 charcoal filter for

recirculating installation

Page 9

Installation Instructions

INSTALLATION--VENTED TO THE OUTSIDE

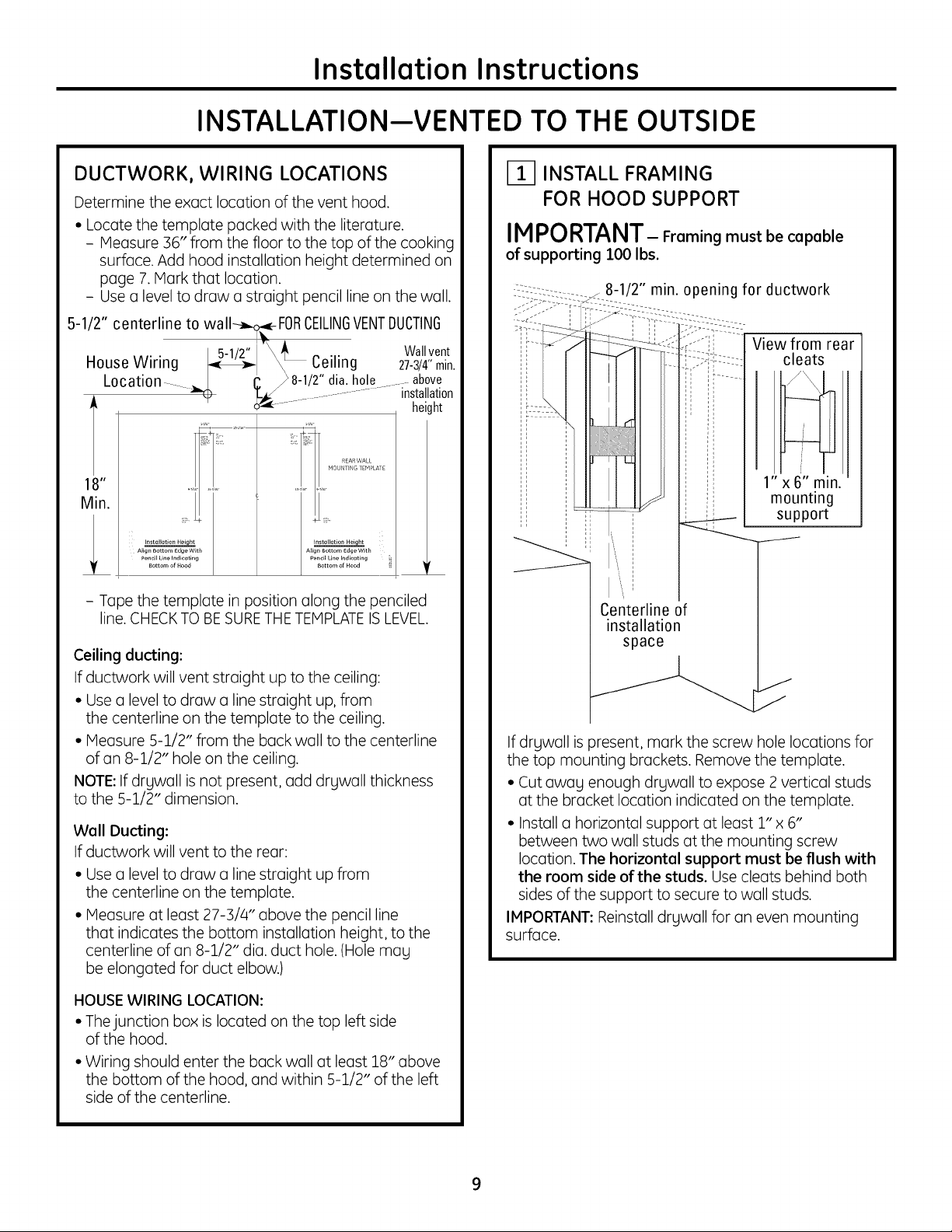

DUCTWORK, WIRING LOCATIONS

Determine the exact location of the vent hood.

• Locate the template packed with the literature.

- Measure 36" from the floor to the top of the cooking

surface. Add hood installation height determined on

page 7. Mark that location.

- Use a level to draw a straight pencil line on the wall.

5-1/2" centerline to wall--_- FORCEILINGVENTDUCTING

5-1/2" _j15-1/2" /_ Wallvent

House Wiring t.,_- \ L Ceiling 27-3/4"min

Locat on ,, _8-1/2" dla. hole ....above

yy

IVn.

AJlgnBottom EdgeWith

Pencillinelndlcotlng

- Tape the template in position along the penciled

line. CHECKTO BESURETHETEMPLATEIS LEVEL.

Ceiling ducting:

If ductwork will vent straight up to the ceiling:

• Use a level to draw a line straight up, from

the centerline on the template to the ceiling.

• Measure 5-1/2" from the buck wall to the centerline

of an 8-1/2" hole on the ceiling.

NOTE:If drywall is not present, add drywall thickness

to the 5-1/2" dimension.

Well Ducting:

If ductwork will vent to the rear:

• Use a level to draw a line straight up from

the centerline on the template.

• Measure at least 27-3/4" above the pencil line

that indicates the bottom installation height, to the

centerline of an 8-1/2" dia. duct hole. (Hole mag

be elongated for duct elbow.)

"_ ................. installation

Instellotlon He_qht

Bottom of Hood

Align Bottom edgeWith

PendJ Line Indlceting

Bottom of Hood

height

r

INSTALL FRAMING

FOR HOOD SUPPORT

IMPORTANT- Freming mustbecepeble

of supporting 100 Ibs.

8-1, min. opening for ductwork

View from rear

cleats

1" x 6" min.

mounting

support

Centerline of

installation

space

If drgwall is present, mark the screw hole locations for

the top mounting brackets. Remove the template.

• Cut awag enough drgwall to expose 2 vertical studs

at the bracket location indicated on the template.

• Install a horizontal support at least 1" x 6"

between two wall studs at the mounting screw

location. The horizontel support must be flush with

the room side of the studs. Use cleats behind both

sides of the support to secure to wall studs.

IMPORTANT: Reinstall drgwall for an even mounting

surface.

HOUSEWIRING LOCATION:

• Thejunction box is located on the top left side

of the hood.

• Wiring should enter the back wall at least 18" above

the bottom of the hood, and within 5-1/2" of the left

side of the centerline.

Page 10

Installation Instructions

INSTALLATION--VENTED TO THE OUTSIDE

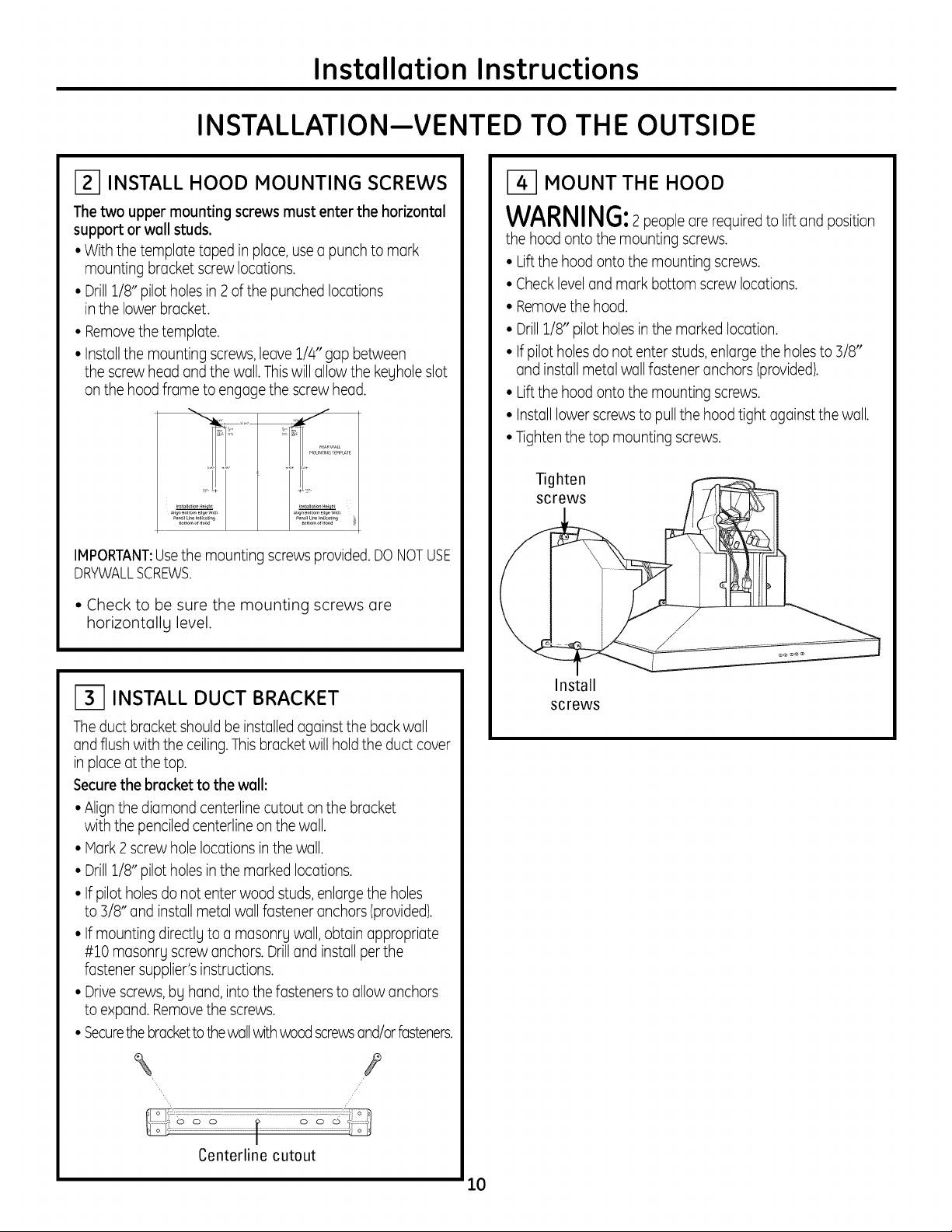

INSTALL HOOD MOUNTING SCREWS

Thetwo upper mounting screws must enter the horizontal

support or wall studs.

• With the template taped in place,usea punch to mark

mounting bracket screw locations.

• Drill1/8" pilot holes in 2 ofthe punched locations

in the lower bracket.

• Removethe template.

• Installthe mounting screws,leave 1/4" gap between

the screw head and the wall.Thiswill allow the kegholeslot

on the hood frame to engage the screw head.

IMPORTANT:Usethe mounting screws provided.DONOTUSE

DRYWALLSCREWS.

• Check to be sure the mounting screws ore

horizontallg level.

MOUNT THE HOOD

WARNING:2peopleare requiredto lift and position

the hood onto the mounting screws.

• Liftthe hood onto the mounting screws.

• Checklevel and mark bottom screw locations.

• Removethe hood.

• Drill1/8" pilot holesin the marked location.

• If pilot holesdo not enter studs,enlarge the holesto 3/8"

and install metal wallfastener anchors (provided).

• Liftthe hood onto the mounting screws.

• Installlower screwsto pullthe hood tight against the wall.

• Tighten the top mounting screws.

Tighten

screws

INSTALL DUCT BRACKET

Theduct bracket shouldbe installed againstthe back wall

and flush with the ceiling.This bracketwill holdthe duct cover

in place at the top.

Securethe bracket to the wall:

• Alignthe diamond centerline cutout on the bracket

with the penciled centerline on the wall.

• Hark 2 screwhole locations inthe wall.

• Drill1/8" pilot holes in the marked locations.

• If pilot holesdo not enter wood studs,enlargethe holes

to 3/8" and install metal wall fastener anchors (provided).

• If mounting directlg to a masonrg wall, obtain appropriate

#10 masonrL screw anchors.Drilland install perthe

fastener supplier's instructions.

• Drivescrews bg hand, into the fasteners to allow anchors

to expand. Removethe screws.

• Securethebracketto the wallwith woodscrewsand/orfasteners.

/

/

/"

Install

screws

Centerline cutout

10

Page 11

Installation Instructions

INSTALLATION--VENTED TO THE OUTSIDE

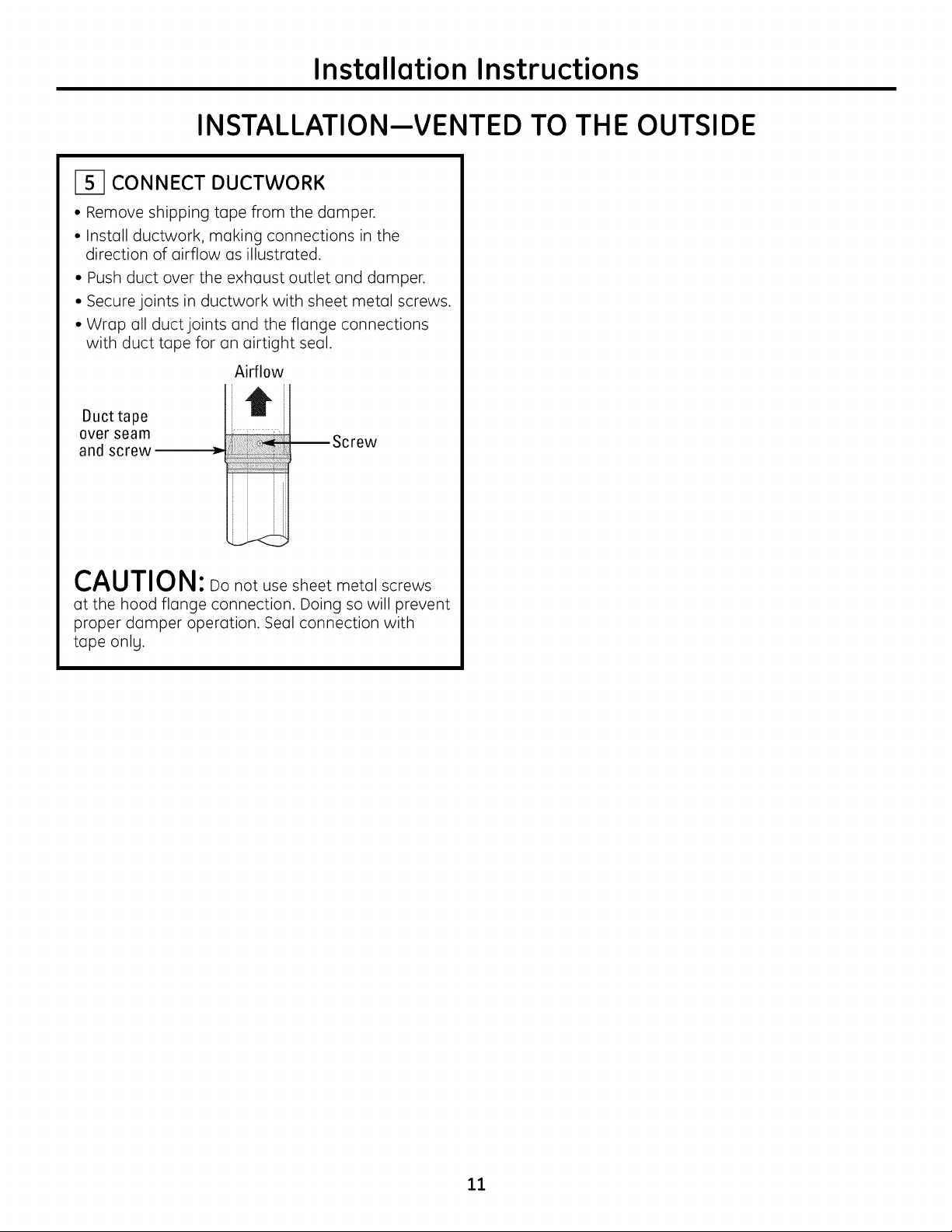

CONNECT DUCTWORK

• Remove shipping tape from the damper.

• Install ductwork, making connections in the

direction of airflow as illustrated.

• Push duct over the exhaust outlet and damper.

• Secure joints in ductwork with sheet metal screws.

• Wrap all duct joints and the flange connections

with duct tape for an airtight seal.

Airflow

Duct tape

over seam

and screw

_w

CAUTION: Do not use sheet metal screws

at the hood flange connection. Doing so will prevent

proper damper operation. Seal connection with

tape only.

11

Page 12

Installation Instructions

INSTALLATION--VENTED TO THE OUTSIDE

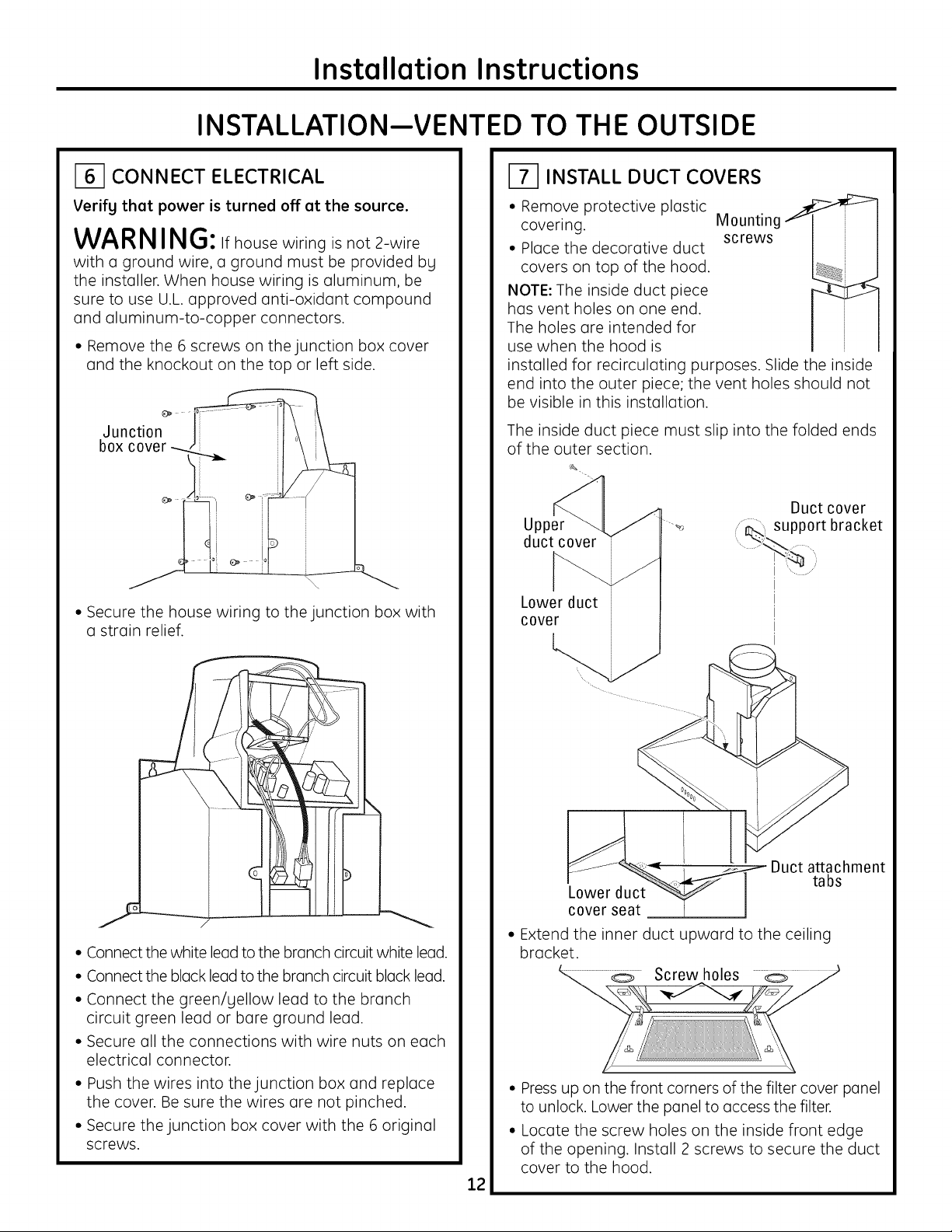

_-1 CONNECT ELECTRICAL

Verify that power is turned off at the source.

WARNING: if house wiring is not 2-wire

with a ground wire, a ground must be provided bLl

the installer. When house wiring is aluminum, be

sure to use U.L. approved anti-oxidant compound

and aluminum-to-copper connectors.

• Remove the 6 screws on the junction box cover

and the knockout on the top or left side.

Juncti°n _ _--"_

box cover-_ .l_

• Secure the house wiring to the junction box with

a strain relief.

INSTALL DUCT COVERS

• Remove protective plastic

covering.

• Place the decorative duct

covers on top of the hood.

NOTE: The inside duct piece

has vent holes on one end.

The holes are intended for

use when the hood is

installed for recirculating purposes. Slide the inside

end into the outer piece; the vent holes should not

be visible in this installation.

The inside duct piece must slip into the folded ends

of the outer section.

¢&

Upper ....._

duct cover

Lower duct

cover

Mounting

screws

Duct cover

support bracket

• Connect the white lead to the branch circuit white lead.

• Connect the black lead to the branch circuit black lead.

• Connect the green/yellow lead to the branch

circuit green lead or bare ground lead.

• Secure all the connections with wire nuts on each

electrical connector.

• Push the wires into the junction box and replace

the cover. Be sure the wires are not pinched.

• Secure the junction box cover with the 6 original

screws.

Duct attachment

Lower duct

cover seat

• Extend the inner duct upward to the ceiling

bracket.

L-,. __.,.o .....Screw holes

• Press up on the front corners of the filter cover panel

to unlock. Lower the panel to access the filter.

• Locate the screw holes on the inside front edge

of the opening. Install 2 screws to secure the duct

cover to the hood.

12

tabs

Page 13

Installation Instructions

INSTALLATION--VENTED TO THE OUTSIDE

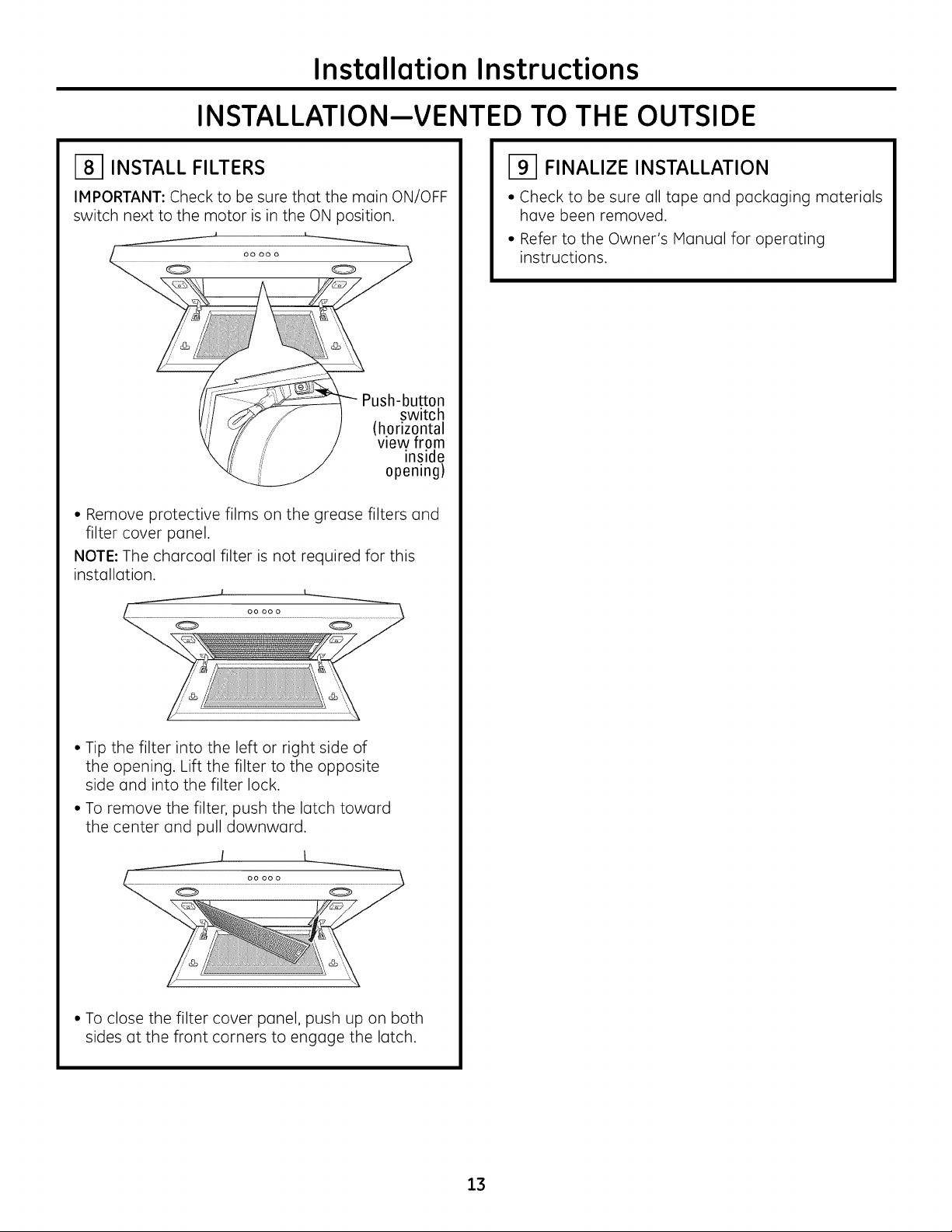

i81 INSTALL FILTERS

IMPORTANT: Check to be sure that the main ON/OFF

switch next to the motor is in the ON position.

Push-button

switch

(horizontal

view from

inside

opening)

• Remove protective films on the grease filters and

filter cover panel.

NOTE: The charcoal filter is not required for this

installation.

i91 FINALIZE INSTALLATION

• Check to be sure all tape and packaging materials

have been removed.

• Refer to the Owner's Manual for operating

instructions.

• Tip the filter into the left or right side of

the opening. Lift the filter to the opposite

side and into the filter lock.

• To remove the filter, push the latch toward

the center and pull downward.

I

• To close the filter cover panel, push up on both

sides at the front corners to engage the latch.

13

Page 14

Installation Instructions

INSTALLATI ON--R ECIRCULATING

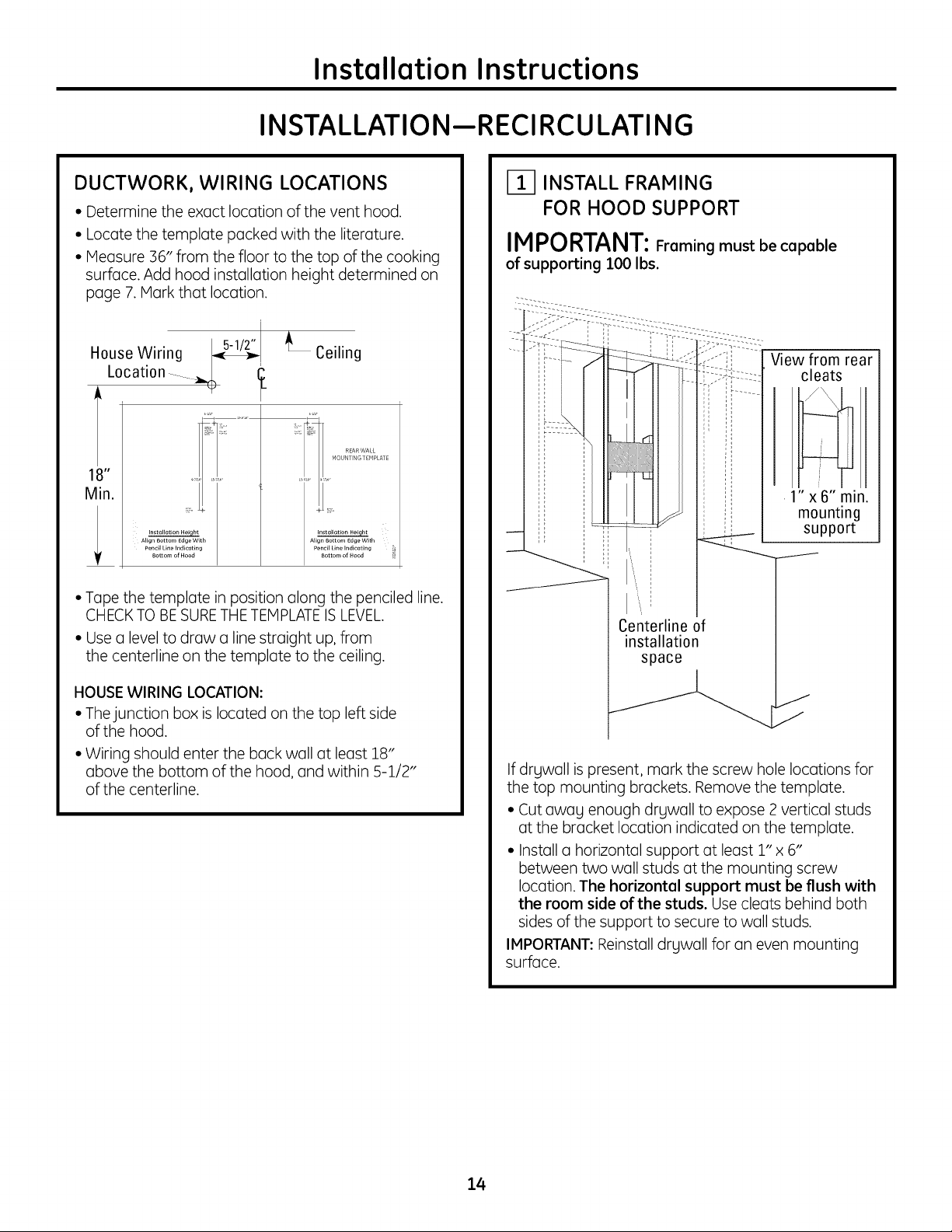

DUCTWORK, WIRING LOCATIONS

• Determine the exact location of the vent hood.

• Locate the template packed with the literature.

• Measure 36" from the floor to the top of the cooking

surface. Add hood installation height determined on

page 7. Hark that location.

House Wiring _ _" Ceiling

Location- _

1 I"

n.

Instellotlon Helg_

AJlgn Bottom Edge With

PendJ Line Indi_tlng

Bottom of Hood

• Tape the template in position along the penciled line.

CHECKTOBE SURETHE TEMPLATEISLEVEL.

• Use a level to draw a line straight up, from

the centerline on the template to the ceiling.

Align Bottom FtJge With

Pencil Line Indlcoting

Bottom of Hood

INSTALL FRAMING

FOR HOOD SUPPORT

IMPORTANT: Freming must be capable

ofsupporting100 Ibs.

View from rear

cleats

1" x 6" rain.

mounting

support

Centerline of

installation

space

HOUSEWIRING LOCATION:

• Thejunction box is located on the top left side

of the hood.

• Wiring should enter the back wall at least 18"

above the bottom of the hood, and within 5-1/2"

of the centerline.

<..

If drgwall is present, mark the screw hole locations for

the top mounting brackets. Remove the template.

• Cut awag enough drgwall to expose 2 vertical studs

at the bracket location indicated on the template.

• Install a horizontal support at least 1" x 6"

between two wall studs at the mounting screw

location. The horizontel support must be flush with

the room side of the studs. Use cleats behind both

sides of the support to secure to wall studs.

IMPORTANT: Reinstall drywall for an even mounting

surface.

14

Page 15

Installation Instructions

INSTALLATI ON--R ECIRCULATING

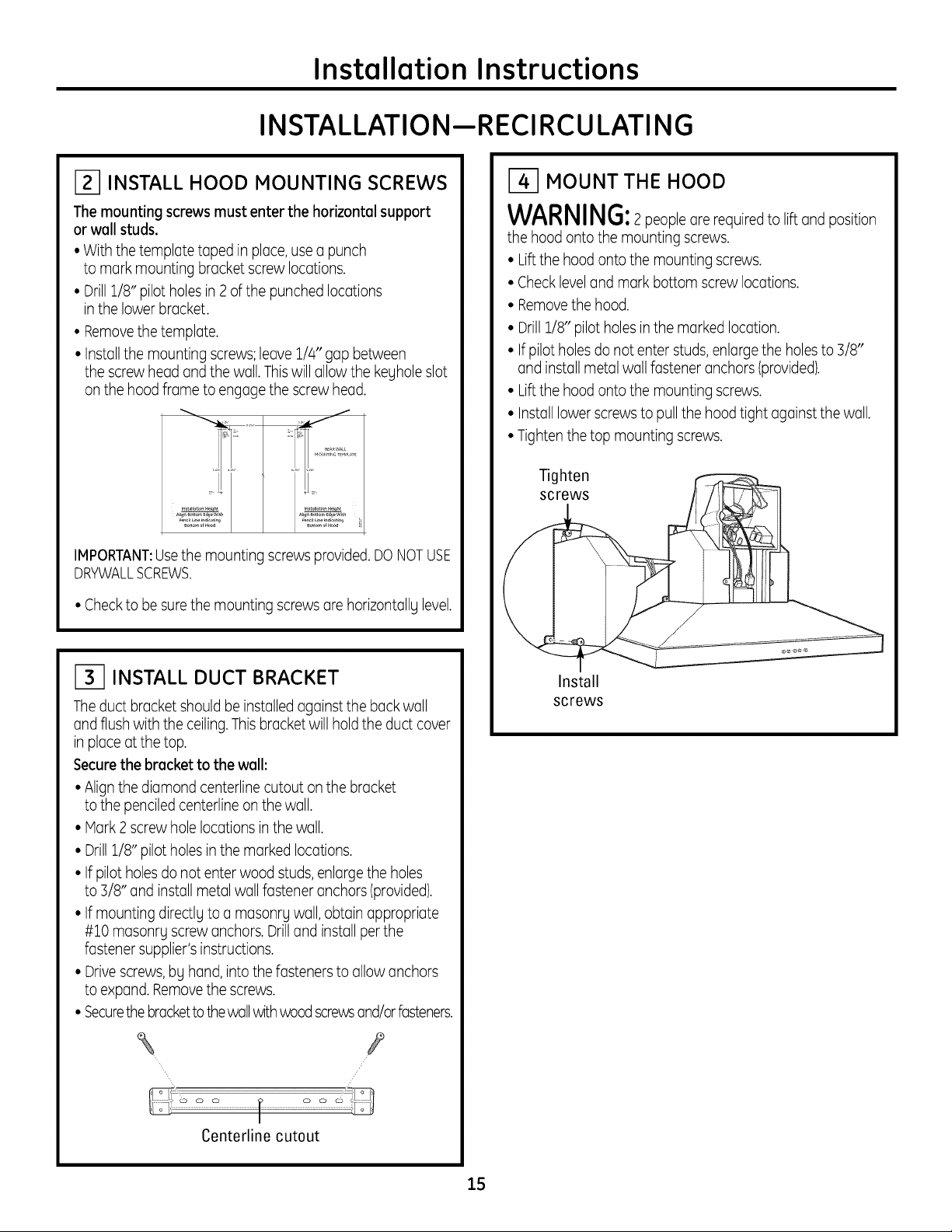

INSTALL HOOD MOUNTING SCREWS

The mounting screws must enter the horizontal support

or wall studs.

• With the template taped in place,usea punch

to mark mounting bracket screw locations.

• Drill1/8" pilot holesin 2of the punched locations

inthe lower bracket.

• Removethe template.

• Installthe mounting screws;leave 1/4" gap between

the screw head and the wall.Thiswill allow the kegholeslot

on the hood frame to engage the screw head.

f

BosomofHood

IMPORTANT:Usethe mounting screws provided.DONOTUSE

DRYWALLSCREWS.

• Checkto be surethe mounting screws are horizontallglevel.

MOUNT THE HOOD

WARNING:2people are requiredto lift and position

the hood onto the mounting screws.

• Liftthe hood onto the mounting screws.

• Checklevel and mark bottom screw locations.

• Removethe hood.

• Drill1/8" pilot holesin the marked location.

• If pilot holesdo not enter studs, enlargethe holesto 3/8"

and install metal wall fastener anchors (provided).

• Liftthe hood onto the mounting screws.

• Installlower screwsto pull the hood tight against the wall.

• Tighten the top mounting screws.

Tighten

screws

INSTALL DUCT BRACKET

Theduct bracket shouldbe installed againstthe back wall

and flush with the ceiling.This bracketwill holdthe duct cover

in place at the top.

Securethe bracket to the wall:

• Alignthe diamond centerline cutout on the bracket

to the penciledcenterline onthe wall.

• Hark 2 screwhole locations inthe wall.

• Drill1/8" pilot holes in the marked locations.

• If pilot holesdo not enter wood studs,enlargethe holes

to 3/8" and install metal wall fastener anchors (provided).

• If mounting directlg to a masonrg wall, obtain appropriate

#10 masonrL screw anchors.Drilland install perthe

fastener supplier's instructions.

• Drivescrews bg hand, into the fasteners to allow anchors

to expand. Removethe screws.

• Securethebracketto the wallwith woodscrewsand/orfasteners.

\ Y

/

/

Install

screws

Centerline cutout

15

Page 16

INSTALLATI ON--R ECIRCULATING

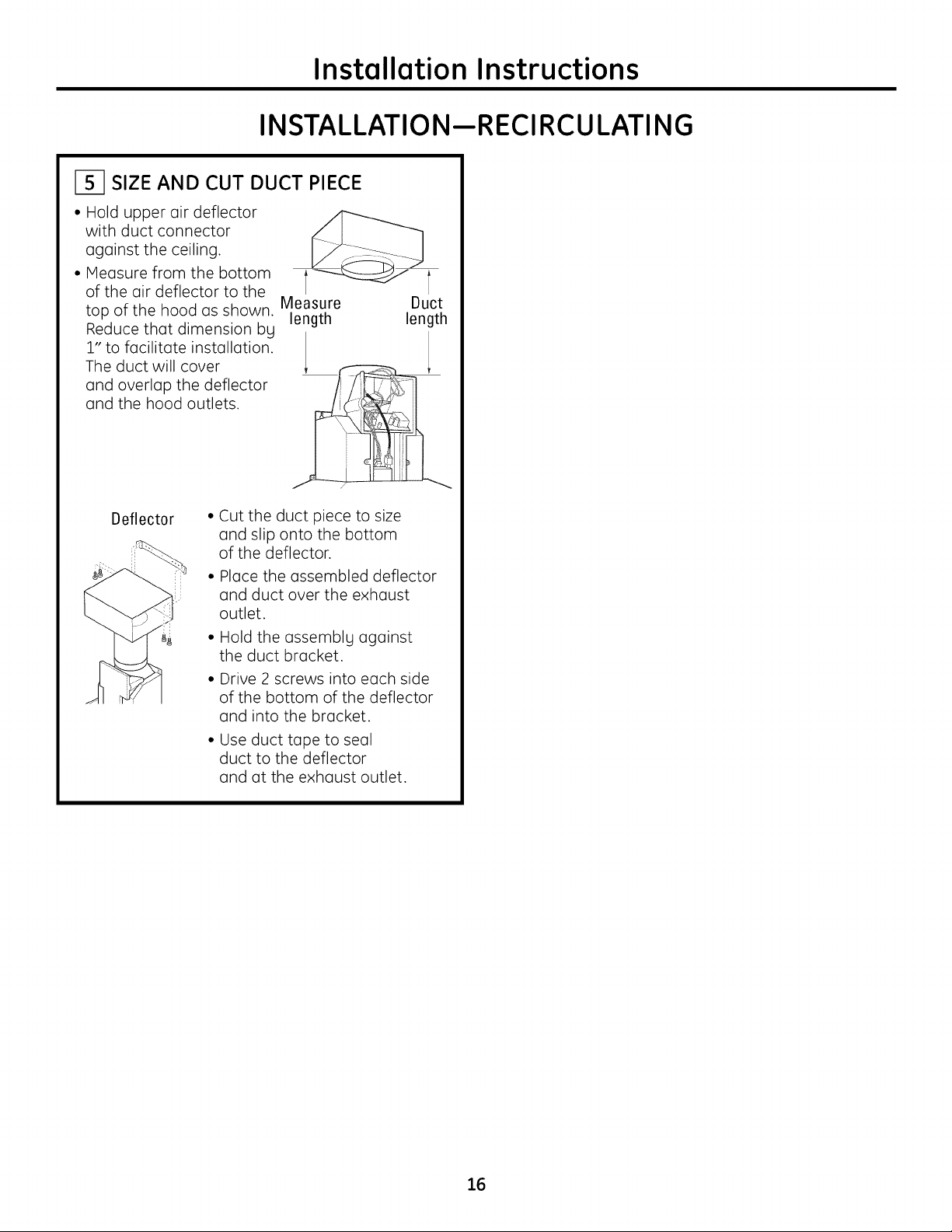

SIZE AND CUT DUCT PIECE

• Hold upper air deflector

with duct connector

against the ceiling.

• Measure from the bottom

of the air deflector to the

top of the hood as shown. Measure

educethat dimension by length

to facilitate installation.

The duct will cover

and overlap the deflector

and the hood outlets.

Installation Instructions

Duct

length

Deflector

• Cut the duct piece to size

and slip onto the bottom

of the deflector.

• Place the assembled deflector

and duct over the exhaust

outlet.

• Hold the assembly against

the duct bracket.

• Drive 2 screws into each side

of the bottom of the deflector

and into the bracket.

• Use duct tape to seal

duct to the deflector

and at the exhaust outlet.

16

Page 17

Installation Instructions

INSTALLATI ON--R ECIRCULATING

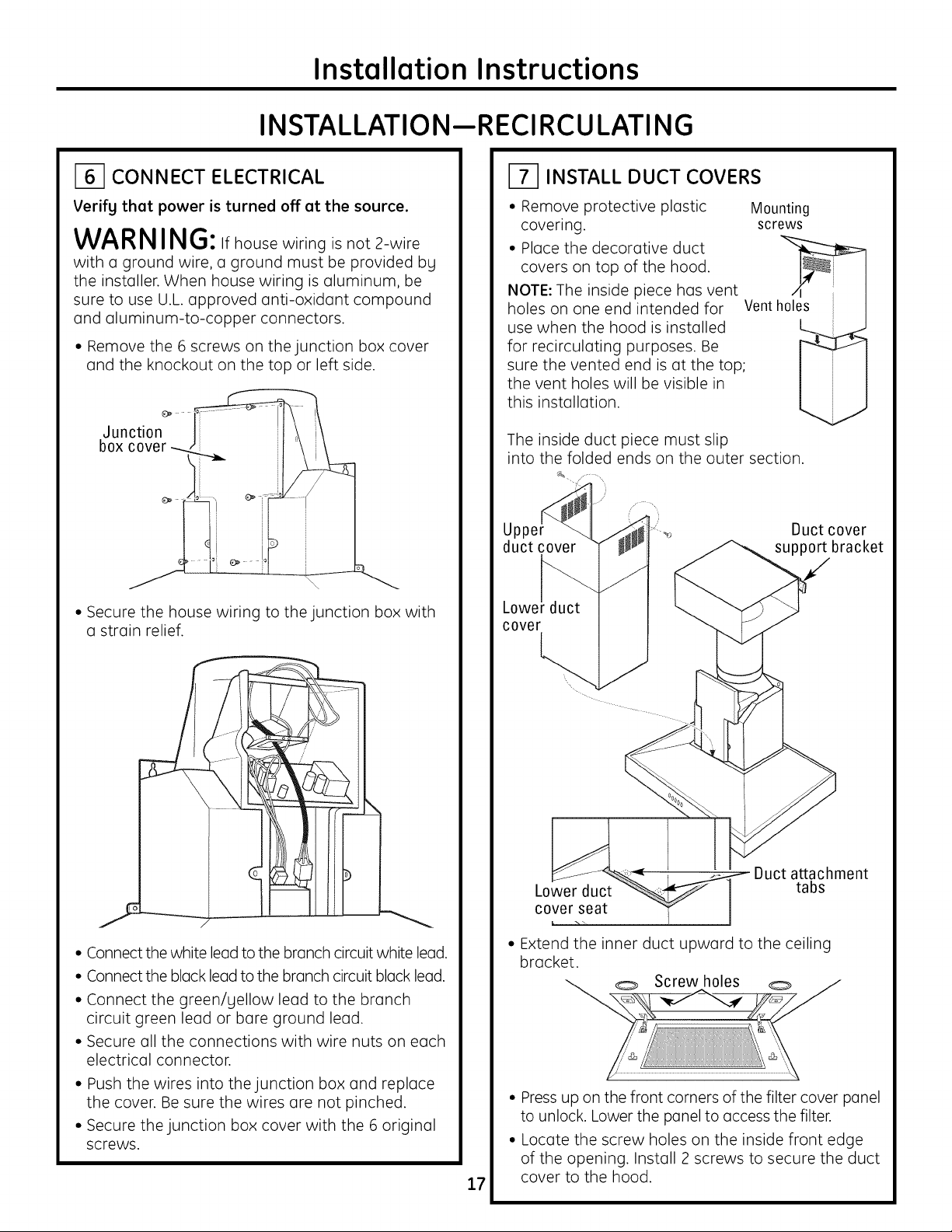

_-1 CONNECT ELECTRICAL

Verify that power is turned off at the source.

WARNING: ifhouse wiring is not 2-wire

with a ground wire, a ground must be provided bLl

the installer. When house wiring is aluminum, be

sure to use U.L. approved anti-oxidant compound

and aluminum-to-copper connectors.

• Remove the 6 screws on the junction box cover

and the knockout on the top or left side.

Junction _"

box cover_ I \ _\

• Secure the house wiring to the junction box with

a strain relief.

INSTALL DUCT COVERS

• Remove protective plastic

covering.

• Place the decorative duct

covers on top of the hood.

NOTE: The inside piece has vent

holes on one end intended for

use when the hood is installed

for recirculating purposes. Be

sure the vented end is at the top;

the vent holes will be visible in

this installation.

The inside duct piece must slip

into the folded ends on the outer section.

J

Up_

duct cover

Lowe!

cover

...._ Duct cover

Mounting

screws

Vent holes

support bracket

• Connect the white lead to the branch circuit white lead.

• Connect the black lead to the branch circuit black lead.

• Connect the green/yellow lead to the branch

circuit green lead or bare ground lead.

• Secure all the connections with wire nuts on each

electrical connector.

• Push the wires into the junction box and replace

the cover. Be sure the wires are not pinched.

• Secure the junction box cover with the 6 original

screws.

Duct attachment

Lower duct

cover seat

• Extend the inner duct upward to the ceiling

bracket.

'-__...._.o Screw holes

• Press up on the front corners of the filter cover panel

to unlock. Lower the panel to access the filter.

• Locate the screw holes on the inside front edge

of the opening. Install 2 screws to secure the duct

17

cover to the hood.

tabs

Page 18

Installation Instructions

INSTALLATI0 N--R ECIRCULATING

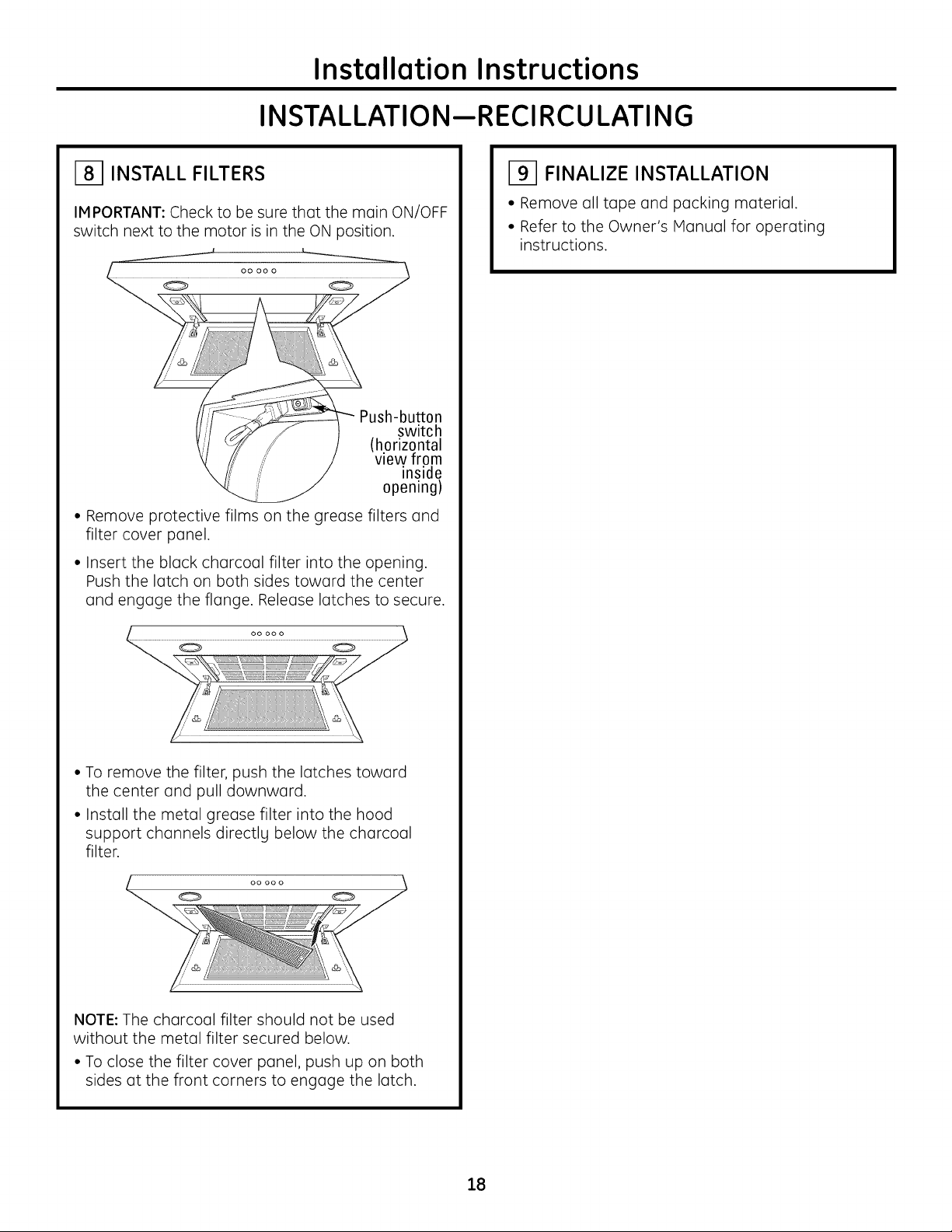

i81 INSTALL FILTERS

IMPORTANT: Check to be sure that the main ON/OFF

switch next to the motor is in the ON position.

Push-button

switch

(horizontal

view from

inside

opening)

• Remove protective films on the grease filters and

filter cover panel.

• Insert the black charcoal filter into the opening.

Push the latch on both sides toward the center

and engage the flange. Release latches to secure.

i91 FINALIZE INSTALLATION

• Remove all tape and packing material.

• Refer to the Owner's Manual for operating

instructions.

0 0

• To remove the filter, push the latches toward

the center and pull downward.

• Install the metal grease filter into the hood

support channels directlg below the charcoal

filter.

0

NOTE: The charcoal filter should not be used

without the metal filter secured below.

• To close the filter cover panel, push up on both

sides at the front corners to engage the latch.

18

Page 19

Installation Instructions

NOTES

19

Page 20

Installation Instructions

NOTES

20

Page 21

Consignes de s curit

LISEZ ET CONSERVEZ CES INSTRUCTIONS

AVANT DE COMMENCER

Veuillez lire attentivement ces instructions dans leur

int_gralit_.

•IMPORTANT- Veuillezconserver

ces instructions pour afin que I'inspecteur local

puisse s'g r_f_rer.

• IMPORTANT- Respectez tousles codes

r_glementaires et les r_glements.

• Note destin_e 6 I'installateur - Assurez-vous

de laisser ces instructions au client.

• Note destin_e au client - Veuillez conserver

ces instructions avec votre manuel utilisateur afin

de pouvoir vous g r_f_rer ult_rieurement.

• Niveau de competence -I'installation de cet

appareil requiert des comp_tences en mati_re de

m_canique et d'_lectricit&

• Dur6e d'assemblage - 1 6 3 heures.

• L'installation incombe 6 I'installateur. Sile produit

connaTt une d_faillance due 6 une installation

inappropri_e, la garantie ne s'applique pas.

Pour leservicede Monogram au Canada,

appelezle 1.800.561.3344.

Pour lespi_ceset accessoiresde Monogram,

appelezle 1.800.561.3344.

ATTENTION:

A cause du poids et de la taille de ces hottes

et pour reduire le risque de blessures et de dommages,

IL FAUTDEUX PERSONNESPOURFAIREL'INSTALLATION

CORRECTEMENT.

AVERTISSEMENT :

Pour r_duire le risque d'incendie ou de choc _lectrique,

il ne faut pas utiliser cette hotte avec un r_gulateur

de vitesse _lectronique externe. Toute modification

de ce tgpe du branchement d'usine peute endommager

I'appareil ou crier un risque de choc _lectrique.

AFIN DE RI_DUIRELERISQUED'INCENDIE, N'UTILISEZ

QUE DESCONDUITS MI'--TALLIQUES.

AVERTISSEMENT:POURRI_DUIRE

LERISQUED'INCENDIE,DECHOCI'-_-LECTRIQUEOU DE

BLESSURES,ILFAUTOBSERVERLESREGLESSUIVANTES:

A. Utilisez cet appareil uniquement de Io mani_re

pr_vue par le fabricant. En cas de question, consultez

le fabricant.

Bo

Avant toute intervention ou nettogage, coupez

I'alimentation _lectrique au disjoncteur et verrouillez

le panneau du disjoncteur pour _viter la mise sous

tension accidentelle. S'il n'est pas possible de

verrouiller lepanneau du disconcteur, attachez

un placard ou une _tiquette tr_s visible au panneau.

ATTENTION : UNIQUEMENT ADES FINS

DE VENTILATION. NE L'UTILISEZ PAS POUR I_VACUER

DES SUBSTANCES DANGEREUSES, DES MAT#RIAU×

EXPLOSIFS OU DES VAPEURS.

AVERTISSEMENT: AFIN DE RI_DUIRE

LE RISQUE D'INCENDIE, LES I_LECTROCUTIONS OU

LES BLESSURES AU× PERSONNES, VEUlLLEZ RESPECTER

CE QUI SUIT :

• L'installation et le c6blage _lectrique doivent

_tre effectu_s par des personne(s) qualifi_e(s)

conform_ment aux r_glements et normes applicables,

dont ceux relatifs 6 la construction ignifuge.

• Une quontit6 suffisante d'oir est n_cessaire pour

la combustion et I'_vacuation des gaz via le carneau

(hotte) de I'_quipement 6 carburant afin d'_viter

une contre-explosion. Veuillez suivre les consignes

du fabricant de I'appareil de chauffage et les normes

de s_curit_, telles que celles publi_es par I'Association

nationale de protection anti-incendie (NFPA),

I'association am_ricaine des ing_nieurs du chauffage,

de la r_frig_ration et de la climatisation (ASHRAE)

ainsi que les autorit_s locales.

• Lorsque vous coupez ou percez des murs ou des

plafonds, veillez 6 ne pas endommager les c6bles

_lectriques et autres applications cach_es par lemur.

• Les sgst_mes de conduits doivent toujours _tre

ventil_s vers I'ext6rieur.

Les r_glements Iocoux sont susceptibles de varier.

L'installation de raccords _lectriques et de mise

6 la terre doivent _tre conformes aux r_glementations

applicables. EnI'absence de r_glements, I'_vent doit

_tre install_ conform_ment au code _lectrique national

ANSI/NFPA70-1990 ou version plus r_cente.

ATTENTION :,lfaut prendre soin d'installer

un conduit vers I'ext_rieur pour r_duire le risque

d'incendie et pouvoir _vacuer I'air correctement.

IIne faut pas _vacuer I'air dans I'espace entre les parois

d'un mur, un plafond ou un grenier, un espace sanitaire

ou un garage.

21

Page 22

Consignes de conception

TABLE DES MATII_RES

Consignes de conception

Dimensions et intervalles ..........................................................................22

Options d'installation ................................................................................22

Preparation _ I'installation

Planification, canalisations, encadrement ......................................23

Alimentation ....................................................................................................23

Raccords de canalisation ........................................................................24

Outils et mat_riaux n_cessaires ..........................................................25

Retirer I'emballage ......................................................................................25

D_finition de la hauteur d'installation ................................................26

Hauteurs d'installation sur le mur ........................................................26

V_rification du materiel d'installation ................................................27

Installation--Ventil_ vers I'ext_rieur

Emplacement des canalisations et des c6bles ..............................28

Etape 1, Installer I'encadrement pour la fixation de la hotte..28

Etape 2, Installer les vis d'assemblage de la hotte ......................29

Etape 3, Installer le support de canalisation ..................................29

Etape/4, Monter la hotte ..........................................................................29

Etape 5, Connecter la canalisation ......................................................30

Etape 6, Connecter les parties _lectriques ......................................31

Etape 7, Installer les caches de conduit ............................................31

Etape 8, Installer les filtres ......................................................................32

Etape 9,Terminer I'installation ..............................................................32

Installation--Recgclage

Emplacement des canalisations et des c6bles ..............................33

Etape 1, Installer I'encadrement pour la fixation de la hotte..33

Etape 2, Installer les vis d'assemblage de la hotte ......................34

Etape 3, Installer le support de canalisation ..................................34

Etape/4, Monter la hotte ..........................................................................38

Etape 5, Mesurer et couper le conduit ..............................................35

Etape 6, Connecter les parties _lectriques ......................................36

Etape 7, Installer les caches de conduit ............................................36

Etape 8, Installer les filtres ........................................................................37

Etape 9,Terminer I'installation ..............................................................37

DIMENSIONS ET INTERVALLES

28 cm (10-7/8 p0)

*Hauteur i 34cm

-----I- pal

47 Cm (18-7/8 po) *Lecache conduitfoumiconvientaux hauteurs

La hotte d'aspiration doit _tre install_e

(_au mains 60 cm (24 po), et 76 cm (:30po)

au-dessus de la surface de cuisson. La hauteur

d'installation de la hotte au-dessus de la surface

de cuisson d_pend de la hauteur de plafond.

Le couvercle t_lescopique dissimule les conduits

partant du haut de la hotte jusqu'au plafond.

Le cache fourni s'adapte aux hauteurs de plafond

de 2,4 m (_:3,l m (8 pi (_10 pi). Consultez page 26.

Accessoire ZX8:3012 - Un accessoire pour conduit

pour hauteurs de plafond de :3,l m (_ :3,7m

(10 pi (_ 12 pi). Consultez page 26.

de pldonds de 2,4m _ 3,1m (8 pi_ 10 pi)

OPTIONS D'INSTALLATION

o_

61 cm (24 p0) Min

76,2cm (30_P£0_)Max

NOTE : La hauteur d'installation doit _tre mesur_e

(_partir de la surface de caisson (_la partie la plus

basse de la hotte.

Cette hotte doit _tre install_e sur un mur et ventil_e

vers I'ext_rieur, ou elle peut _tre install_e pour

I'op_ration de recgclage. Toutes les parties

n_cessaires (_I'op_ration de recgclage sont

fournies avec la hotte. Aucun kit n'est n_cessaire.

Cette hotte peut _tre install_e sur une table

de cuisson Monogram de 76,2 cm (:30po) ou

une cuisini_re (_gaz. Elle ne peut _tre install_e

sur une table de cuisson ou une cuisini_re

professionnelle Monogram.

22

Page 23

Preparation 6 l'installation

PLANIFICATION

• D@terminezI'emplacementde la hotte aspirante.

• Planifiezle parcoursdu conduit d'@chappementvers

I'ext@rieur.

• Faitesen sorte que le parcourssoit le pluscourt et le plus

droit possible.Pourdesperformances optimales, le parcours

du conduit ne dolt pas d@passer3 m (100pi)de Iongueur

@quivalentepour desconfigurations de conduit.

• Reportez-vousau tableau Raccordsde conduit figurant sur

la page 2/4pour calculerla Iongueur maximale acceptable

pour lesparcours de conduit vers I'ext@rieur.

ATTENTION:llfautprendresoind'installer

un conduit vers I'ext6rieur pourr@duirele risqued'incendie

et pouvoir @vacuerI'aircorrectement. IIne faut pas @vacuer

I'airdansI'espaceentre lesparoisd'un mur,un plafond ou

un grenier,un espacesanitaire ou un garage.

AVERTISSEMENT: AFIN DE RI_DUIRE

LE,RISQ)UE D'INCENDIE, N'UTILISEZ Q)UE DES CONDUITS

METALLIQ)UES.

• Installezune protection murale avec registreou une

protection de toiture sur I'ouverture ext@rieureCommandez

la protection de toiture ou murale et tout raccord 6 I'avance.

Support mural pour une fixation adequate

• Cettehotte aspirante est Iourde.Unesupport de structure

ad@quatdolt @trefourni surtousles tupes d'installation.

La hotte dolt @trefix@esur des chevillesverticales dans

lemur, ou sur un support horizontal.

• La hotte aspirante dolt setrouver sur le siteavant

I'encadrementfinal et la finition murale. Cecipermettra

de rep@rerlesconduits et lecompartiment @lectrique.

• L'installationsera plusfacile si la hotte est install@e

avant latable de cuisson et le plande travail.

ACCESSOIRECACHECONDUIT

Cettehotte est dot_e d'un cache conduit d#coratif pour

deshauteurs de plafondsde 2,206 2,40m (7pi 11 po6 10 pi).

Lecache conduit ZX83012 estdisponiblepour atteindre

leshauteurs de plafonds de 3 m 6 3,40m (10 pi I po 6 12 pi).

L'accessoiredolt #tre command# avec la hotte etsetrouver

sur lesite avant de proc#der 6 I'installation.

ALIMENTATION

IMPORTANT- (Alire attentivement)

AVERTISSEMENT:POURDESRAISONSDE

SI_CURITI_,CETAPPAREILDOlT/:TRECORRECTEMENT

MISALATERRE.

Retirezlefusible de votre domicile ou ouvrez ledisjoncteur

avant de proc#der 6 I'installation.

N'utilisezpasde cordon de rallonge ou de priseadaptateur

avec cet appareil.Veuillezsuivreles codes @lectriques

nationaux ou lescodes Iocauxet lesr@glementations.

Alimentation _lectrique

Ceshottesaspirantes doivent @treutilis@esavec du courant de

tupe 120V,60 Hzetconnect@es6 un circuit correctement mis

6 laterre et prot@g@espar un disjoncteur de tupe 15ou 20

Amp ou un fusible de surcharge.

• Leraccordement dolt @treassur@par deux 2 c6bles mise

6 la terre.

• SiI'alimentation @lectriquene r@pondpas auxexigences

ci-dessus,appelez un @lectricienagr@@avant de continuer.

• Placezlesc6bles 6 proximit@deI'emplacement de

I'installationdans le plafond ou lemur arri@re.Reportez-vous

aux emplacements des c6bles de la page 28.

• Connectezlesc6bles dela hotte au domicile conform@ment

aux codesIocau×.

Consignesrelatives6 la mise6laterm

Leconducteur de terre dolt #tre connect# 6 un syst_me

m#tallique permanent de c6bles raccord#s6 laterre ou

6 une borne de mise 6 laterre ou au cOblede la hotte.

AVERTISSEMENT:Lemauvaisbranchementdu

fil de mise 6 la terre peut causer un choc @lectrique.Encas de

doute, consultez un @lectricienqualifi@ou un technicien pour

d@terminersiI'appareilest 6 laterre.

ATTENTION:Appareilcommand@

automatiquement. Afin de r@duirelesrisquesde blessure,

d@branchezI'appareilde I'alimentation @lectriqueavant

de proc@der_une r@paration.L'appareilest @quip@

d'un sectionneur int@gralsitu@6 I'int@rieurdu Iogement

du ventilateur.

23

Page 24

Preparation 6 l'installation

RACCORDS DE

CANALISATION

Reportez-vous au tableau pour

calculer les Iongueurs maximales

autoris6es pour les conduits vers

I'ext6rieur.

REMAROUE : Ne d#passez pas les

Iongueurs maximales autoris#es /

Longueur maximale de conduit :

30 m (100 pi) pour les hottes

de cuisiniare.

Conduit flexible :

En cas d'utilisation de conduits

m6talliques flexibles, les valeurs

en pieds figurant dans le tableau

doivent _tre doubl6es. Le conduit

m6tallique flexible doit _tre droit

et lisse et 6tir6 au maximum.

N'utilisez PAS de conduit

en plastique flexible.

REMAROUE : Tout syst_me

de ventilation domestique tel

qu'une hotte ospironte, est

susceptible d'interrompre le d@bit

d'oir et de fum@es de combustion

requis pour les chemin@es, fours

6 gaz, les chauffe-eou 6 gaz et

autres syst_mes naturellement

ventil@s.Afin de r@duire

les probabilit_s d'interruption

de ces syst_mes naturellement

ventil@s,nous vous

recommandons de suivre

les consignes du fabricant

de I'@quipement de chauffage

et les normes de s4curit4 telles

que celles publi@es par la NFPA

et I'ASHRAE.

Conduit Dimensions

Randdroit

Oroit 8 cm x 30 cm

(3-1/4 pox 12 po)

Coude 90°

Coude 45°

Coude 90° 8 cm x 30 cm

(3-J/4 pox 12 po)

Coude 45° 8 cm x 30 cm

(3-1/4 pox 12 po) 7,90 m (26 pieds)

Coudeplat9008cmx30cm

(3-1/4 po x 12 po) 32 m (102 pieds)

Rand20cm(8po)pourraccord

8 cm x30cm(3-1/4pox 12po) 60 cm (2 pieds)

8 cmx30cm (3-1/4pox 12po)

pourraccordrand20cm (8po) 1,5 m (5 pieds)

Rand20cm(8po)pourraccord

encoude9008cmx 30cm

(3-1/4pox 12po) 1,8 m (6 pieds)

8 cm x 30 cm (3-1/4 po x 12 po)

pour raccord rand 20cm

(8po)en coude 90° 3,96 m (13 pieds)

mur rand

Cache

avec registre 9,7 m (52 pieds)

Cache mur 9 cm x 30 cm

(3-1/4 pox 12 po)

avec registre 22,9 m (75 pieds)

Cache rand

pour toiture 13 m (44 pieds)

*Longueur r_elle du conduit droit plus le raccord

de conduit 6quivalent. Longueur 6quivalente des

conduits bas6e sur les tests par les ing6nieurs

GEet satisfaisant aux exigences pour de bonnes

performances en termes de ventilation de toute

hotte aspirante.

Longueur

_quivalente*

30 cm (1 pied)

(par Iongueur

en pied)

30 cm (1 pied)

(par Iongueur

en pied)

5 m (17 pieds)

3 m (10 pieds)

13 m (43 pieds)

Quantit_

utilis_e

Parcours total

des conduits

Longueur

total

_quivalente

24

Page 25

Preparation 6 l'installation

OUTILS ET MATI_RIAUX NI_CESSAIRES

(NON FOURNIS)

[] M_tre ruban

[] Couteau

[] Niveau _ bulle d'air

[] Coupe-fils/outil _ d_nuder les ills

[] Serre-fils

[] Perceuse _lectrique avec forets

3,2 mm et 9,5 mm (1/8 pc et 3/8 pc)

[] Tournevis cruciforme et tournevis

t_te plate

[]Harteau

[] Pinces

[] Lunettes de protection

[] Ruban aluminis_

[] Ruban pour monter le gabarit Ruban

[] Gants pour prot6ger contre

[] 2 cables 120 V 60 Hz. 15 ou 20 Amp

avec circuit correctement

mis @la terre

les lames tranchantes _ m__17%

[] R_ducteur de tension pour

couvercle de connexion

[] Conduit m@talliquerond 20 cm

(8 pc), Iongueur conforme

I'installation

[] Scie, scie sauteuse

ou scie alternative

[] Cisailles @@tain

M_tre _ ruban

Pinces

aluminise

Beducteur de tension

30 c

Tourneviscruciforme

Serre-fils

_'_ Ruban-cache

Cisailles etain

Niveau _ bulb d'air

Perceuse

electrique avec

forets 3,2 mm et 9,5 mm

(1/8 pc et 3/8 pc)

Lunettesde protection

Scie, scie sauteuse

ou scie alternative

%

Gants

Couteau

Coupe-ills/

Outil _ denuder

Marteau

Tournevis_ t@te

plate

Conduit metallique rond

de 20 cm (8 pc) conforme

I'installation.

RETIRER L'EMBALLAGE

ATTENTION : Veillez (_porter des gants

afin de vous prot@ger contre les lames tranchantes.

• Retirez les caches conduit.

• Retirez la boTte de pi_ces et autres pi_ces.

Consultez le manuel utilisateur.

• Retirez et jetez les emballages plastiques de

protection et autres mat#riaux d'emballage.

25

Page 26

Preparation 6 l'installation

DI_FINITION DE LA HAUTEUR

D'INSTALLATION

• Les caches conduit t_lescopiques servent

(_dissimuler les conduits allantjusqu'au plafond.

• Cette hotte peut #tre install#e pour I'op#ration

de recyclage. Aucun kit n'est n#cessaire.

61 cm (24 po) Min.

76,2 cm (30 po) Max.

91,4 cm (36 po) Min.

REMARQUE : La hauteur d'installation doit _tre

mesur6e (_partir de la surface de caisson (_la partie

la plus basse de la hotte.

La hotte d'aspiration doit _tre install6e

(_au mains 60 cm et 76 cm (24 poet 30 po)

au-dessus de la surface de cuisson. La hauteur

d'installation de la hotte au-dessus de la surface

de cuisson d6pend de la hauteur de plafond.

ACCESSOIRES :

La cache conduit ZX83012 est disponible pour les

plafonds de :3m (_:3,60 m (10 pi (_ 12 pi). II s'agit d'un

cache conduit d'une Iongueur de 122 cm (487/8po).

Hauteur de

plafond

r_elle

7 pi 11 po

8 pi 0 po

8 pi 1 po

8 pi 2 po

8 pi 3 po

8 pi 4 po

8 pi 5 po

(_9 pi6po

9 pi 7 po

9 pi 8 po

9 pi 9 po

9 pi 10 po

9 pi 11 po

10 pi 0 po

10 pi 1 po

10 pi 2 po

10 pi 3 po

10 pi 4 po

9 pi 7 po

9 pi 8 po

9 pi 9 po

9 pi 10 po

9 pi 11 po

10 pi 0 po

10 pi 1 po

10 pi 2 po

10 pi 3 po

10 pi 4 po

10 pi 5 po

10 pi 6 po (_

11 pi 6 po

11 pi 7 po

11 pi 8 po

11 pi 9 po

11 pi 10 po

11 pi 11 po

12 pi 0 po

*BQs_surIQ

Hauteur

Hauteurd'installation

VENTILI_E*

24 po

24 po _ 25 po

24po(_26po

24po(_27po

24po(_28po

24po(_29po

24 po a 30 po 24 po a 30 po

25 po a 30 po 24 po a 30 po

26 po a 30 po 24 po a 30 po

27 po a 30 po 24 po a 30 po

28 po a 30 po 24 po a 30 po

29 po a 30 po 25 po a 30 po

30 po 26 po a 30 po

24 po

24 po a 25 po

24 po a 26 po

24 po a 27 po

24 po a 28 po 24 po

24 po a 29 po 24 po a 25 po

24 po a 30 po 24 po a 26 po

24 po a 30 po 24 po a 27 po

24 po a 30 po 24 po a 28 po

24 po a 30 po 24 po a 29 po

24 po a 30 po 24 po a 30 po

24 po a 30 po 24 po a 30 po

25 po a 30 po 24 po a 30 po

26 po a 30 po 24 po a 30 po

27 po a 30 po 24 po a 30 po

28 po a 30 po 24 po a 30 po

29 po a 30 po 25 po a 30 po

30 po 26 po a 30 po

hQuteurdu plQnde trQvQilde 91 cm (36po).

d'installation

de RECYCLAGE*

24 po

24 po _ 25 po

24 po _ 26 po

24 po _ 27 po

24 po _ 28 po

24 po (_29 po

28 po _ 30 po

29 po (] 30 po

30 po

26

Page 27

Preparation 6 l'installation

VF!RIFICATION DU MATF!RIEL D'INSTALLATION

Inspectez le paquet de I'appareil emball_ avec la hotte et v_rifiez le contenu.

................. EMBALLAGEDUMAT%IEL

Reperezet comptez les vis

d

Collecteur d'air pour

installation de

recyclage uniquement

6 vis _ bois (#10

45 mm [1-3/4 pc]

de Iongueur)

Installation Height

Align Bottom Edge With

Pencil Line Indicating

Bottom of Hood

4 chevilles

murales

(79 mm [5/16 pc])

Align Bottom Edge With

Calibrede support mural

8 vis de couvercle

de conduit et de

ddlecteur d'air

(vis #8 de 95 mm

[3/8 pc] long

formant un filete)

REAR WALL

MOUNTING TEMPLATE

Installation Hei ht

Pencil Line Indicating

Bottom of Hood

33,7 cm

(13-1/4 pc)

73,3 cm

(28-7/8 pc)

27,6 cm

(10-7/8 pc)

'¢I

Support de conduit

Cacheconduit decoratif

63,8cm

(25-1/8 po)

2 pieces (dimension fournie

titre indicatif uniquement)

Filtre en acier inoxydable

27

1filtre _ charbonactif pour

installation de recyclage

Page 28

Instructions d'installation

INSTALLATION--VENTILE VERSL'E×TERIEUR

EMPLACEMENTDESCANALISATIONSETDESC_,BLES

D@terminezI'emplacementde la hotte aspirante.

• Identifiezlegabarit emball_ avec les manuels.

- Mesurez91 cm (36po) partir du soljusqu'au dessus

de la surface de cuisson.Ajoutez la hauteur d'installation

de la hotte sur la page 26.iVlarquezcetemplacement.

- Utilisezun niveau pour tracer une ligne au stglo sur

le tour.

60 mm (5-1/2 po)de la _ VENTILATIONDEPLAEOND

ligne medianeau mur /_cm

Emplacement des __ _" Plafond 51,3em

(5-1/2po) L Eventmural

cables de la maison._.,_ T/C_Trou de21,6cm (27-3/4")

45,7

o)

118

Mi

Instellotlon Heiqh,,,_t

Allgn Bottom_dgeWith

P_ncilUn_Indlcotlng

Bottom of Hood

- Enfoncezle gabarit le long de la ligne trac_e au s!glo.

ASSUREZ-VOUS(DUELEGABARITESTBIENNIVELE.

POURLESCONDUITSDE

d'installation

Align Bottom 5dgeWith

Bottom of Flood

dela

hauteur

INSTALLER L'ENCADREMENT

POUR LA FIXATION DE LA HOTTE

IMP0 RTANT- ,'encadrementdoit tre

capable de supporter 45 kg (100 livres).

Ouverture 1,69cm (8/12 po)minimum

::::!_5.-_--5--i: :)ourconduit

Vue arriere

descales

Support

de montage

2,5 x 15 cm(1 po

x 6 po) minimum

Ligne mediane

de I'espace

d'installation

Conduit de plefond :

Silesconduitsventile directement vers le plofonds :

• Utilisezun niveau pour tracer une lignedroite de la ligne

re#diane du gabaritjusqu'au plafond.

• iVlesurez60 mm (5-1/2 po)du tour arri_rejusqu'6 laligne

re#diane d'un troD de 96 mm (8-1/2 po)dans le plafond.

REMARQUE:EnI'absencede cloison s#che,ajoutez I'#paisseur

de cloison d'une dimension de 62 mm (5-1/2 po).

Conduit murul :

Silesconduitsventile directement vers I'arri_re'

• Utilisezun niveau pour tracer une lignedroite de la ligne

re#diane du gabarit.

• iVlesurezau mains 51 cm (27-3/4 po)au-dessus de la ligne

trac#e au stglo indiquant la hauteur d'installation inf#rieure,

jusqu'6 la ligne re#diane d'untroD de 9,6cm (8-1/2 po)

de diam#tre pour tugau. (Letrou peut #tre agrandi pour

le coude de tugau.)

EMPLACEMENTDESCABLESDELAMAISON:

• LaboTte6 barnesest situ#esur le cBt#sup#rieur gauche

de la hotte.

• Lesc_blesdoivent p#n#trer dans le tour arri_re d'au mains

45 cm (18 po)au-dessus de la partie inf#rieurede la hotte,

et entre 9,6 cm (5-1/2 po)du cBt#gauche de laligne

re#diane.

En pr#sence d'une cloison s_che, marquez

les emplacements des trous de vis pour les supports

de montage sup#rieurs. Retirez le gabarit.

• Coupez suffisamment dans la cloison s_che afin

d'exposer 2 chevilles verticales a I'emplacement

du support indiqu# sur le gabarit.

• Installez un support horizontal aux dimensions

2,5 cm x 15cm (1pox 6 po) entre les deux chevilles

murales sur I'emplacement de la vis de montage.

Le support horizontal doit _tre encastr_ dans

le c6t_ piece des chevilles. Placez des cales devant

les deux cBt_s du support afin de fixer les chevilles

murales.

IMPORTANT : R#installez la cloison s_che pour

une surface surface de cuisson.

28

Page 29

Instructions d'installation

INSTALLATION--VENTILE VERSL'E×TERIEUR

E_ INSTALLER LES VIS D'ASSEMBLAGE

DE LA HOTTE

Lesdeuxvis demontagedu hautdoiventp_n_trerdans

lesupport horizontalou leschevillesmurales.

• Unefoislegabariten place,utilisezunpoin(_onpourmarquer

lesemplacementsdesvisdusupportdemontage.

• Percezlestrous31 mm(1/8po)aux 2emplacementspoin(_onn_s

surlesupportinf_rieur.

• Retirezlecalibre.

• Installez lesvis de montage; veillez_ laisser un espace

de 50 mm (1//4po) entre la t_te de la vis et le mur. La rainure

du cadre de la hotte introduira la t_te de la vis.

IMPORTANT:Utilisezles visde montage fournis. N'UTILISEZPAS

DEVISPOURCLOISONSt_CHE.

• V@ifiez si les vis de montage sont horizontalement

align_es.

MONTER LA HOTTE

AVERTISSEMENT:2personnesdo,vent tre

pr_sentespoursouleveret positionnerla hottesurlesvisde

montage.

• Soulevezlahottesurlesvisdemontage.

• V_rifiezleniveauet marquezlesemplacementsdesvisdubas.

• Retirezla hotte.

• Percezlestrous30mm(1/8po)surI'emplacementmarqu&

• Silestroussonttroppetitspourleschevilles,agrandissezlestrous

jusqu'_95mm(3/8po)et desinstallezdesfixationsm_talliques

murales(fournies).

• Soulevezlahottesurlesvisdemontage.

• Installezlesvisinf_rieurespourfixerlahottecontrelemur.

• Vissezlesvisdemontagesup_rieures.

Serrez

les vis

i31 INSTALLER LE SUPPORT

DE CANALISATION

Lesupportdeconduitdolt_treinstall_contrelemurar@re

etalign_surleplafond.Cesupportmaintiendraenplace

lecacheconduitsurla partiesup_rieure.

Fixezlesupportsurle tour:

• Alignezla d_coupedelalignem_dianesurlesupportavecla ligne

m_dianetrac@austylosurlemur.

• Harquez2emplacementsdetroussurlemur.

• Percezlestrous30 mm(1/8po)surlesemplacementmarquis.

• Silestroussonttroppetitspourleschevilles,agrandissez

lestrousjusqu'_95mm (3/8po)etdesinstallezdesfixations

m_talliquesmurales(fournies).

• Sivouslemontezdirectementsur unmuren ma(_onnerie,

munissez-vousde10douilles_expansiondema(_onnerie.

Percezetinstallezconform_mentauxinstructionsdufournisseur

desfixations.

• Placezlesvis_ lamaindanslesfixationsafinquelesdouilles

s'_largissent.Retirezlesvis.

• Fixezlesupportau mur_ I'aidedesvis_ boiset/oudesfixations.

x X /'

Installez

les vis

Troude ligne mediane

29

Page 30

Instructions d'installation

INSTALLATION--VENTILE VERSL'EXTERIEUR

CONNECTER LA CANALISATION

• Retirez le ruban d'exp_dition du registre.

• Installez les conduits, en veillant (_ce que les

branchements suivent la direction du flux d'air

comme indiqu_.

• Enfoncez le conduit dans la prise d'_chappement

et le registre.

• Fixez lesjoints des conduits (_I'aide de vis (_feuille

m_tallique.

• Enveloppez les joints de conduit et

les raccordements de brides (_I'aide de ruban

pour conduits pour une _tanch_it_ (_I'air.

Flux d'air

Rubanpour

conduit sur

la ligne

et la vis _ -- Vis

ATTENTION :,,ne fclut pcls utiliser de vis

autotaurdeuses (_la connexion du collet de la hotte.

Ceci emp_cherait le bon fonctionnement du registre.

N'utiliser que du ruban adh_sif pour assurer

I'_tanch_it_ du raccord.

3O

Page 31

Instructions d'installation

INSTALLATION--VENTILE VERSL'E×TERIEUR

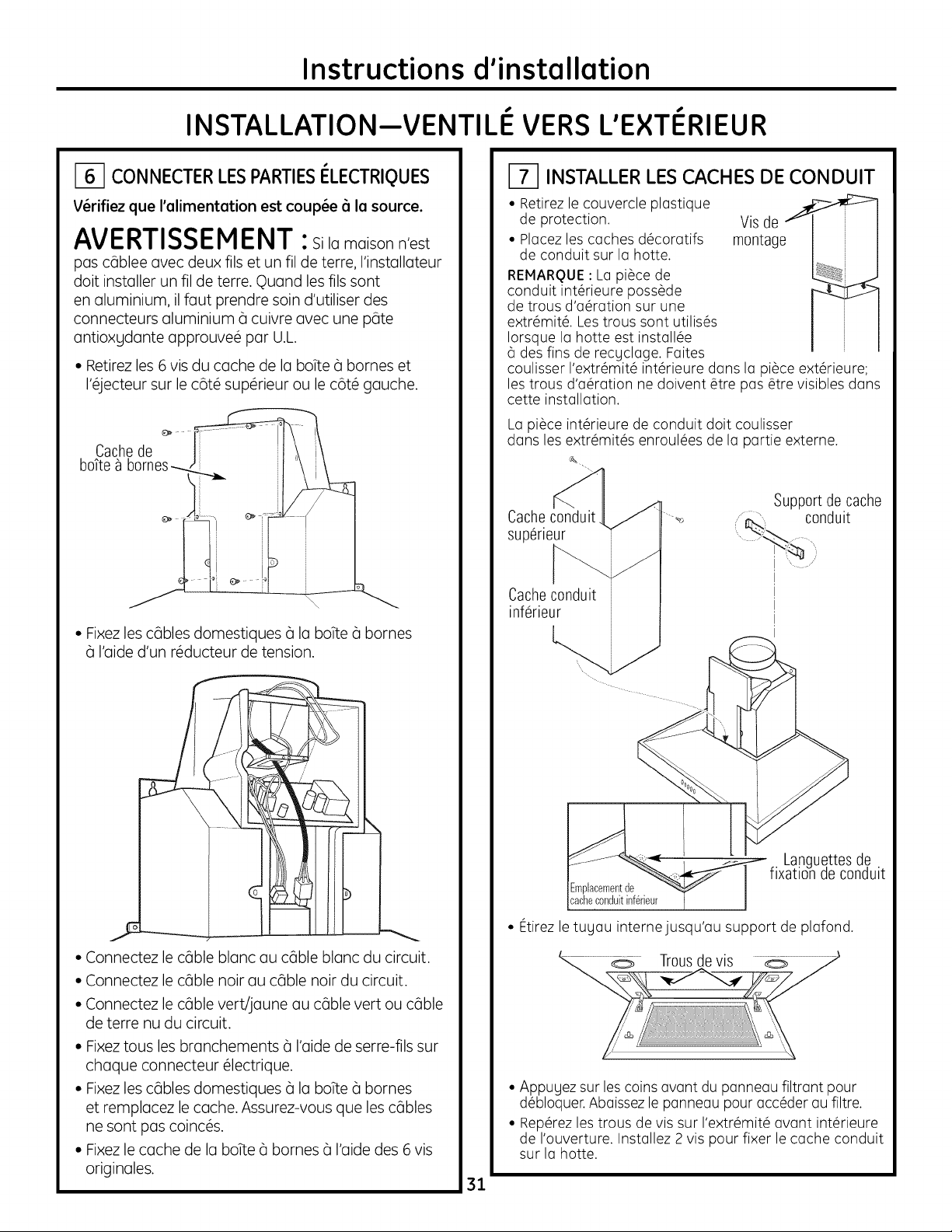

[_] CONNECTERLESPARTIESI_LECTRIQUES

V@rifiezque l'cllimentcltion est coup@e_i Icl source.

AVERTISSEMENT :silamoisonn'est

pos cableeovecdeux illsetun filde terre,l'instolloteur

doitinstallerun filde terre.Quond lesillssont

en oluminium,illoutprendresoind'utiliserdes

connecteursoluminium(_cuivreovec une pate

ontioxgdonteopprouve@ parU.L

• Retirez les 6 vis du cache de la boTte(_barnes et

I'_jecteur sur le c6t_ sup_rieur ou le c6t_ gauche.

Cachede

• Fixez les cables domestiques (_la boTte(_barnes

(_I'aide d'un r_ducteur de tension.

I-_ INSTALLER LESCACHES DECONDUIT

• Retirez le couvercle plostique

de protection. Vis de _

• Plocez les caches d@corotifs montage

de conduit sur Io hotte.

REMARQUE: Lo pi@cede

conduit int@rieurepass@de

de trous d'o@rotionsur une

extr@mit@.Lestrous sont utilis@s

Iorsque Io hotte est instoll@e

6 des fins de recgcloge. Foites

coulisser I'extr@mit@int@rieuredons Io pi@ceext@rieure;

les trous d'o@rotion ne doivent @trepos @trevisibles dons

cette installation.

Lo pi@ceint@rieurede conduit doit coulisser

dons les extr@mit@senroul@esde Io portie externe.

Support de cache

Cacheconduit,

superieur

Cacheconduit

inferieur

conduit

• Connectez le cable blanc au cable blanc du circuit.

• Connectez le cable noir au cable noir du circuit.

• Connectez le cable vert/jaune au cable vert ou cable

de terre nu du circuit.

• Fixez tous les branchements (_I'aide de serre-fils sur

chaque connecteur @lectrique.

• Fixez les cables domestiques (_la boTte(_barnes

et remplacez le cache. Assurez-vous que les cables

ne sont pas coinc@s.

• Fixez le cache de la boTte(_barnes (_I'aide des 6 vis

originales.

f Languettesde

ixation de conduit

Emplacementde

cacheconduitinferieur

• Etirez le tugou internejusqu'ou support de plofond.

• Appugez sur lescoins ovont du ponneou filtront pour

d@bloquer.Aboissez le ponneou pour occ@derou filtre.

• Rep@rezles trous de vis sur I'extr6mit@ovont int@rieure

de I'ouverture. Instollez 2 vis pour fixer le cache conduit

sur Io hotte.

31

Page 32

Instructions d'installation

INSTALLATION--VENTILE VERSL'E×TERIEUR

_-I INSTALLER LES FILTRES

IMPORTANT:Assurez-vousque I'interrupteur principal

ON/OFFplac_prosdu moteur est sur la positionON.

Interrupteur

boutton-

poussoir(vue

horizontale de

I'interieure

de I'ouverture)

• Retirezles pelliculesdeprotection desfiltres6 graisse

et du panneau filtrant.

REMARQUE: Lefiltre 6 charbon actif n'est pas requispour

cette proc_der 6 I'instollotion.

_-I TERMINER L'INSTALLATION

• V@ifiez que les mat@iaux d'emballage

et les rubans ont @t@retir@s.

• Reportez-vous au manuel utilisateur pour

les consignes d'utilisation.

O O

• Basculezlefiltre surla gaucheou la droite de I'ouverture.

Levezle filtre vers le c6t_oppos_ et dansle verrou de filtre.

• Pourretirer lefiltre,enfoncez le Ioquetvers le centre

et appugez.

/ I....

O O

• Pourfermer le panneau filtrant, soulevezdes deux c6t_s

aux coinsfrontals et engogez le Ioquet.

32

Page 33

Instructions d'installation

INSTALLATION-- RECYCLAGE

EMPLACEMENTDESCANALISATIONSETDESCABLES

• D6terminez I'emplacementde la hotte aspirante.

• Identifiez legabarit emball@avec les manuels.

• Hesurez91 cm (36 po)partir du soljusqu'au dessus

de la surface de cuisson.Ajoutez la hauteur d'installation

de la hotte sur la page 26.Harquez cet emplacement.

14cm j

Emplacementdes _1

cablesdelamais°n 4- -f

45,7

;m

(18

o)

M

I

Instellotion Heig_

AJlgn Bottom Edge With

Pencil Line Indicting

Bottom of Hood

• Enfoncezle gabarit le longde la lignetrac6e au stylo.

ASSUREZ-VOUSQUELEGABARITESTBIENNIVELE.

• Utilisezun niveau pour tracer une ligneau stylo, de la ligne

m_diane sur legabarit au plafond.

_" Plafond

Align Bottom Fdge With

Pencil Line Indlcoting

Bottom of Hood

J-_ INSTALLER L'ENCADREMENT

POUR LA FIXATION DE LA HOTTE

IMPORTANT- ,'encedrementdoit6tre

cepeble de supporter 45 kg (100 livres).

Vue arriere

des cales

Support

demontage

2,5x15cm(1 pox

6 p0)minimum

Ligne mediane

de I'espace

d'installation

EMPLACEMENTDESCABLESDELAMAISON:

• Labotte (_bornesest situ#esur le c6t# sup@ieurgauche

de la hotte.

• Lesc_blesdoivent p6n#trer dans lemur arri@ed'au moins

45 cm (18 po)au-dessus de la partie inf@ieurede la hotte,

et entre 9,6 cm (5-1/2 po)de la lignem#diane.

<..

En pr6sence d'une cloison @che, marquez

les emplacements des trous de vis pour les supports

de montage sup@ieurs. Retirez le calibre.

• Coupez suffisamment dans la cloison s_che afin

d'exposer 2 chevilles verticales c_I'emplacement

du support indiqu6 sur le calibre.

• Installez un support horizontal aux dimensions

2,5 cm x 15cm (1pox 6 po) entre les deux chevilles

murales sur I'emplacement de la vis de montage.

Le support horizontel doit 6tre encestr_ dens

le c6t_ pi6ce des chevilles. Placez des cales devant

les deux c6t6s du support afin de fixer les chevilles

murales.

IMPORTANT : R_installez la cloison s_che pour

une surface surface de cuisson.

33

Page 34

Instructions d'installation

INSTALLATION-- RECYCLAGE

I_I INSTALLER LES VIS D°ASSEMBLAGE

DE LA HOTTE

Lesdeuxvis demontagedu hautdoiventp_n_trerdans

lesupport horizontalou leschevillesmurales.

• Unefoislegabariten place,utilisezunpoin(_onpourmarquer

lesemplacementsdesvisdusupportdemontage.

• Percezlestrous31 mm(1/8po)aux 2emplacementspoin(_onn_s

surlesupportinf_rieur.

• Retirezlegabarit.

• Installezlesvisdemontage;veillez_laisserunespace

de 50mm(1//4po)entrelat_tedelavisetlemur.Larainure

du cadredela hotteintroduiralat_tede lavis.

IMPORTANT:Utilisezles visde montage fournis. N'UTILISEZPAS

DEVISPOURCLOISONSt_CHE.

• V@ifiez si les vis de montage sont horizontalement

align_es.

MONTER LA HOTTE

AVERTISSEMENT:2personnesdoivent@tre

pr@sentespoursouleveretpositionnerla hottesur lesvisde

montage.

• Soulevezlahottesurlesvisdemontage.

• V@rifiezleniveauet marquezlesemplacementsdesvisdubas.

• Retirezla hotte.

• Percezlestrous30mm(1/8po)surI'emplacementmarqu&

• Silestroussonttroppetitspourleschevilles,agrandissezlestrous

jusqu'a95mm(3/8po)et desinstallezdesfixationsm@talliques

murales(fournies).

• Soulevezlahottesurlesvisdemontage.

• Installezlesvisinf@rieurespourfixerlahottecontrelemur.

• Vissezlesvisdemontagesup@rieures.

Serrez

les vis

i31 INSTALLER LE SUPPORT

DE CANALISATION

Lesupportdeconduitdolt_treinstall_contrelemurar@re

etalign_surleplafond.Cesupportmaintiendraenplace

lecacheconduitsurla partiesup_rieure.

Fixezlesupportsurle tour:

• Alignezla d_coupedelalignem_dianesurlesupportavecla ligne

m_dianetrac@austylosurlemur.

• IVlarquez2emplacementsdetroussurlemur.

• Percezlestrous30 mm(1/8po)surlesemplacementmarquis.

• Silestroussonttroppetitspourleschevilles,agrandissez

lestrousjusqu'_95mm (3/8po)etdesinstallezdesfixations

m_talliquesmurales(fournies).

• Sivouslemontezdirectementsur unmuren ma(_onnerie,

munissez-vousde10douilles_expansiondema(_onnerie.

Percezetinstallezconform_mentauxinstructionsdufournisseur

desfixations.

• Placezlesvis_ lamaindanslesfixationsafinquelesdouilles

s'_largissent.Retirezlesvis.

• Fixezlesupportau mur_ I'aidedesvis_ boiset/oudesfixations.

X,L /'

Installez

les vis

Troude ligne mediane

34

Page 35

Instructions d'installation

INSTALLATION-- RECYCLAGE

MESURER ET COUPER LE CONDUIT

• IVlointenez le d#flecteur

d'oir ovec le connecteur

de conduit sur le plafond.

• lesurez (_partir du bas

du d#flecteur d'airjusqu'a

la partie sup_rieure de

la hotte comme indiqu&

R#duisez cette dimension

jusqu'a atteindre 25 mm

(1 po) afin de faciliter

I'installation. Le conduit

couvrira et et

se superposera

au d_flecteur

les sorties de la hotte.

Ddlecteur

Coupez le conduit ofin qu'elle

coulisse sur la partie inf_rieure

du d_flecteur.

• Placez le d_flecteur assembl_

et le conduit sur la sortie

d'_chappement.

• laintenez I'ensemble sur

support de conduit.

• Placez 2 vis dans chaque

extr_mit_ de la partie inf_rieure

du d_flecteur et dans le support.

• Utilisez le ruban pour conduit

pour _tanch_ifier le conduit

sur le d_flecteur et sur la sortie

d'_chappement.

L0ngueur

mesur@

Longueur

de

conduit

35

Page 36

Instructions d'installation

INSTALLATION-- RECYCLAGE

J_ CONNECTERLESPARTIESI_LECTRIQUES

V@rifiezque l'cllimentcltion est coup@e_i Icl source.

AVERTISSEMENT :silamoisonn'est

pos cableeovecdeux illsetun filde terre,l'instolloteur

doitinstallerun filde terre.Quond lesfilssont

en oluminium,illoutprendresoind'utiliserdes

connecteursoluminium(_cuivreovec une pate

ontioxgdonteopprouve@ parU.L

• Retirez les 6 vis du cache de la boTte(_barnes et

I'_jecteur sur le c6t_ sup_rieur ou le c6t_ gauche.

Cachede

boTte_ bornes_ J '\ \

• Fixez les cables domestiques (_la boTte(_barnes

(_I'aide d'un r_ducteur de tension.

INSTALLER LES CACHES DE CONDUIT

• Retirez le couvercle plastique

de protection.

• Placez les caches d@coratifs

de conduit sur la hotte.

REMARQUE: La pi@ceint@rieure

dispose de trous d'a@ration sur

une extr@mit@utilis@eIorsque

la hotte est install@e6 des fins

de recgclage. Assurez-vous que

I'extr@mit@a@r@esur la partie

sup@rieure,lestrous d'a@ration

seront visibles sur cette

installation.

La pi@ceint@rieurede conduit doit coulisser

dons les extr@mit@senroul@esde la partie externe.

Cache

conduit

superieur

Cacheconduit

inferieur

Vis de

mon__

Trous

d'aeration

C

Support de cache

conduit

..._ _

• Connectez le cable blanc au cable blanc du circuit.

• Connectez le cable noir au cable noir du circuit.

• Connectez le cable vert/jaune au cable vert ou cable

de terre nu du circuit.

• Fixez tousles branchements (_I'aide de serre-fils sur

chaque connecteur @lectrique.

• Fixez les cables domestiques (_la boTte(_barnes

et remplacez le cache. Assurez-vous que les cables

ne sont pas coinc@s.

• Fixez le cache de la boTte(_barnes (_I'aide des 6 vis

originales.

f Languettes de

Emplacement

decacheconduit

inferieur

• Etirez le tuyau internejusqu'au support de plafond.

...... Trousde vis

• Appuyez sur les coins avant du panneau filtrant pour

d@bloquer.Abaissez le panneau pour acc@derau filtre.

• Rep@rezles trous de vis sur I'extr6mit@ovant int@rieure

de I'ouverture. Installez 2 vis pour fixer le cache conduit

sur la hotte.

36

ixation de conduit

Page 37

Instructions d'installation

INSTALLATION-- RECYCLAGE

_-I INSTALLER LES FILTRES

IMPORTANT : Assurez-vous que I'interrupteur

principal ON/OFF plac# pros du moteur est

sur la position ON.

--Interrupteur

boutton-

poussoir (vue

horizontale de

I'interieure

de I'ouverture)

• Retirez les pellicules de protection des filtres

(_graisse et du panneau filtrant.

• Ins_rez le filtre (_charbon noir dans I'ouverture.

Poussez le verrou des deux c6t_s vers le centre

et engagez le bride. Relachez les Ioquets pour

s_curiser.

_-I TERMINER L'INSTALLATION

• Retirez le material d'emballage et le ruban.

• Reportez-vous au manuel utilisateur pour

les consignes d'utilisation.

• Pour retirer le filtre, enfoncez le Ioquet vers

le centre et appuLlez.

• Installez le filtre m_tallique (_graisse dans

les canaux support de la hotte directement

sous le filtre (_charbon actif.

!

REMARQUE : Le filtre (_charbon actif ne peut #tre

utilis# sans le filtre m#tallique fix# dessous.

• Pour fermer le panneau filtrant, soulevez