Page 1

GE Monogram ®

Installation

Instructions

36" Vent Hood

Model

ZV750

Monogram°

Page 2

Before you begin--Read these insuucfions completely and careflflly.

IMPORTANT: Save these insuuctions for local inspector's use.

IMPORTANT: OBSERVE ALL GOVERNING CODES AND ORDINANCES.

NOTE TO INSTALLER: Be sure to leave these instructions with the ConsumeL

NOTE TO CONSUMER: Keep these insuucfions with your Owner's Manual for

flmlre reference.

V!lw_,_:mh,[_This appliance must be properly grounded. See "Electrical Supply", page 4. I

If you have questions concerning the

installation of tiffs product, call the GE Answer

Center _>Consumer Information Service at

800.626.2000, 24 hours a day, 7 days a week.

If you received a damaged vent hood, you

should contact your dealeL

CAUTION!

Due to the weight and size of these vent hoods

and to reduce the risk of personal i_jury or

damage to the product, TWO PEOPLE ARE

REQ,UIRED FOR PROPER INSTAI,IATION.

_i_ARNING!

To reduce the risk of fire or elecuic shock,

do not use tiffs range hood with any external

solid-state speed conuol device. Any such

alteration flom original factory wiring could

result in damage to the unit and/or create an

elecuical safety hazard.

To reduce the risk of fire and to properly

exhaust air, be sure to duct air outdoors. Do

not vent exhaust air into spaces wittfin walls or

ceilings or into attics, crawl spaces or garages.

_i_SkRNING: TO REDUCE THE RISK OF FIRE,

USE ONIX METAl, DUCTWORK

TO REDUCE THE RISK OF FIRE, EI,ECTRIC

SHOCK OR INJURY TO PERSONS,

OBSERVE THE FOI,I,OWING:

A. Use tiffs unit only in the manner intended

by the manufacturer. If you have any

questions, contact the manufacturer.

B. Before servicing or cleaning unit, switch

power off at service panel and lock service

panel to prevent power flom being switched

on accidentally. If the service panel cannot be

locked, fasten a tag or prominent warning

label to the panel.

For general ventilating use only. Do not use

to exhaust hazardous or explosive materials

and vapors.

Installation work and elecuical wiring must be

done by qualified person (s) in accordance with

all applicable codes and standards including

fire-rated construction.

Sufficient air is needed for proper combustion

and exhausting of gases through the flue

(clfimney) of tirol burning equipment to

prevent back drafting. Follow the heating

equipment manufacturer's guidelines and

safety standards such as those published by the

National Fire Protection Association (NFPA),

and the American Society for Heating,

Refligevadon and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

Contents Design Information

Model Available ................................................................................................................................... 3

Optional Accessories ........................................................................................................................... 3

Product Dimensions & Clearances .................................................................................................... 3

Advance Planning ............................................................................................................................... 4

Electrical Supply .................................................................................................................................. 4

Installation Preparation

Duct Fittings ........................................................................................................................................ 5

Tools and Materials Required ............................................................................................................. 6

Step 1: Remove the Packaging ............................................................................................................ 6

Installation

Step 2: Check Installation Hardware .................................................................................................. 7

Step 3: Ductwork, Wiring, Hood Attachment I,ocations .................................................................. 7

Step 4: Install Mounting Brackets ....................................................................................................... 8

Step 5: Install the Hood ...................................................................................................................... 8

Step 6: Install Duct Bracket ................................................................................................................. 9

Step 7: Connect Ductwork ................................................................................................................ 10

Step 8: Connect Elecuical ................................................................................................................. 10

Step 9: Install Decorative Duct Cover and Utility Bars .................................................................... 10

Step 10: Install Filters ........................................................................................................................ 11

Step 11: Finalize Installation ............................................................................................................. 11

Page 3

Design Intormation

36" Vent Hood

Model

Available

Optional

Accessories

Product

Dimensions

& Clearances

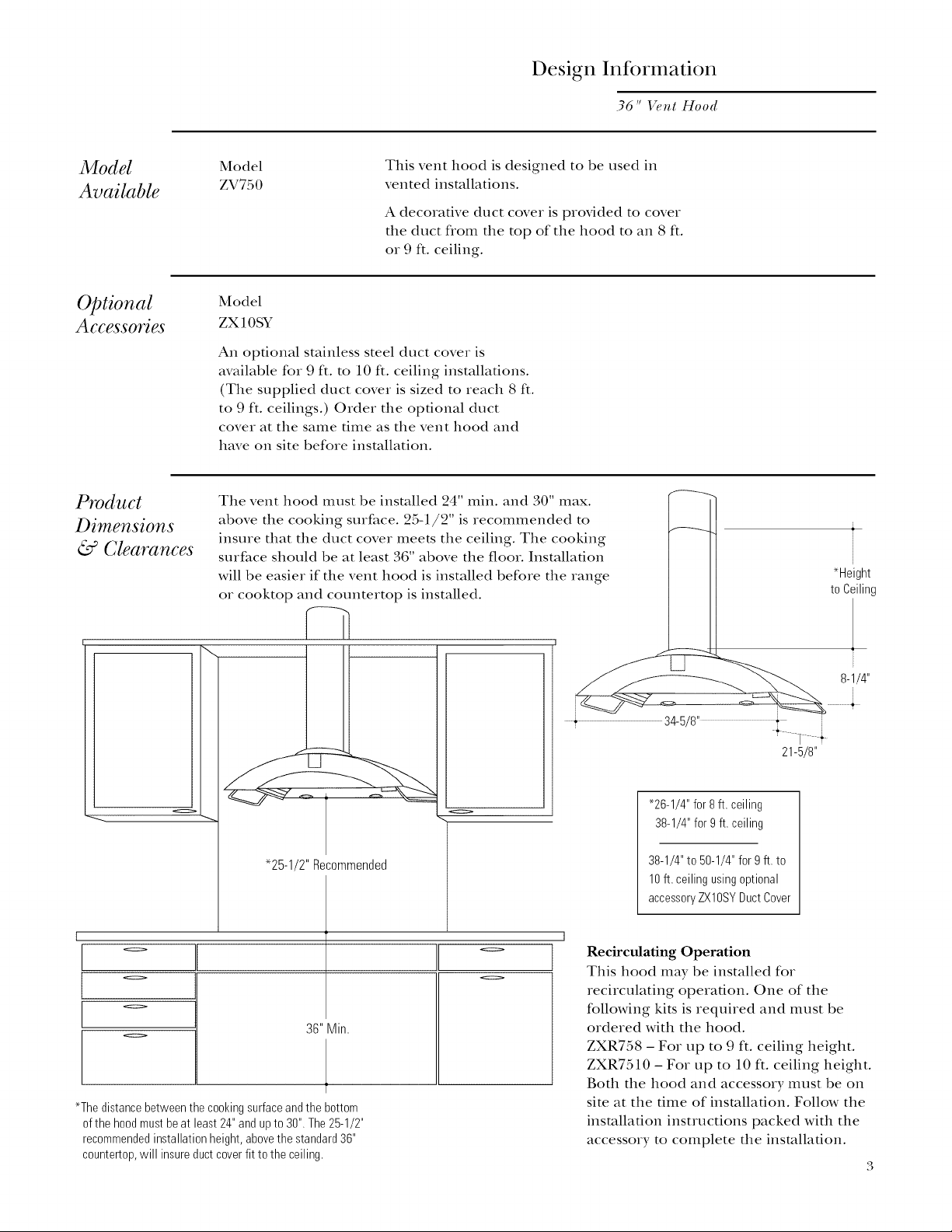

Model

ZV750

This vent hood is designed to be used in

vented installations.

A decorative duct cover is provided to cover

the duct flom tile top of tile hood to an 8 ft.

or 9 ft. ceiling.

Model

ZX 10SY

An optional stainless steel duct cover is

available for 9 ft. to 10 ft. ceiling installations.

(Tile supplied duct covet is sized to reach 8 ft.

to 9 ft. ceilings.) Order tile optional duct

covet at tile same time as tile vent hood and

have on site before installation.

Tile vent hood Illttst be installed 24 and 0

above tile cooking surface. 25-1/2" is recommended to _[ ;

insure that tile duct cover meets tile ceiling. Tile cooking [

surface should be at least, 6 above tile floor. Installatton | i

will be easier if tile vent hood is installed before tile range | _Height

or cooktop a ntertop is installed.

inax.

o

"25-1/2" Recommended

t J

o

l o

o

o

o

*The distance between the cooking surfaceandthe bottom

ofthe hood mustbeat least 24"and upto 36". The25-1/2"

recommendedinstallation height, abovethe standard36"

ceuntertep,will insure duct coverfit to the ceiling.

36"Min.

o

tooi,,,n

8-1/4"

, 34-5/8" * i

21-5/8"

"26-1/4" for 8 ft. ceiling

38-1/4" for 9 ft. ceiling

38-1/4" to 50-1/4" for 9 ft. to

10ft. ceiling using optional

accessoryZX16SYDuct Cover

Recirculating Operation

This hood may be installed for

recirculating operation. One of tile

following kits is required and must be

ordered with tile hood.

ZXR758 - For lap to 9 ft. ceiling height.

ZXR7510 - For up to 10 ft. ceiling height.

Both tile hood and accessory must be on

site at tile time of installation. Follow tile

installation instructions packed with tile

accessory to complete tile installation.

Page 4

Design Information

36" Vent Hood

Advance

Plannin

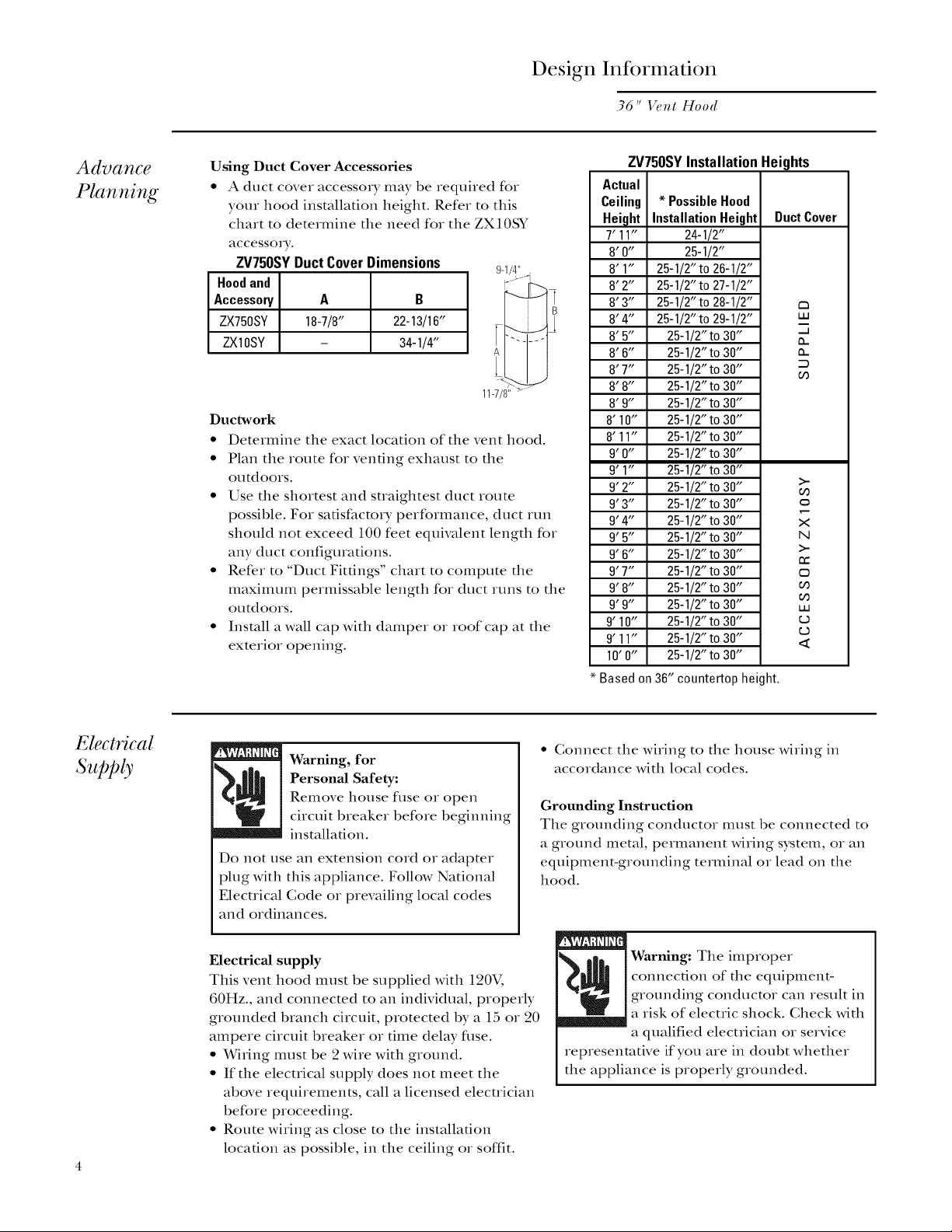

Using Duct Cover Accessories

• A duct cover accesso_y may be required for

your hood installation height. Refer to this

chart to determine the need for the ZX10SY

accessoiy.

ZV750SYDuctCoverDimensions

Hoodand

/4" ,

9-!!

Accessory A B

ZX750SY 18-7/8" 22-13/16"

ZX10SY - 34-1/4"

11-7/8"

Ductwork

• Determine the exact location of the vent hood.

• Plan the route for venting exhaust to the

outdoors.

• Use the shortest and straightest duct route

possible. For satisfactory performance, duct run

should not exceed 100 feet equivalent length for

any duct configurations.

• Refer to "Duct Fittings" chart to compute the

maximum permissable length for duct runs to the

outdoors.

• Install a wall cap with damper or roof cap at the

exterior opening.

ZV750SYInstallationHeights

Actual

Ceiling * PossibleHood

Heitlht InstallationHeight

7' 11" 24-1/2"

8'O" 25-I/2"

8'1" 25-1/2"to26-1/2"

8'2" 25-1/2"to27-1/2"

8'3" 25-1/2"to28-1/2"

8'4" 25-1/2"to29-1/2"

8'5" 25-1/2"to30"

8'6" 25-1/2"to30"

8'7" 25-I/2"to30"

8'8" 25-1/2"to30"

8'9" 25-1/2"to30"

8'10" 25-1/2"to30"

8'11" 25-I/2"to 30"

9' O" 25-1/2" to 30"

9' 1" 25-1/2" to 30"

9' 2" 25-1/2" to 30"

9' 3" 25-1/2" to 30"

9' 4" 25-1/2" to 30"

9' 5" 25-1/2" to 30"

9' 6" 25-1/2"to 30"

9' 7" 25-1/2" to 30"

9' 8" 25-1/2" to 30"

9' 9" 25-1/2" to 30"

9' 10" 25-1/2"to 30"

9' 11" 25-1/2" to 30"

10'0" 25-1/2"to30"

* Based on 36" countertop height.

DuctCover

t_

LU

...J

CL

CL

03

>-

O3

0

X

N

>-

fr-

o

Q3

Q3

LU

rj

¢,3

<

Electrical

Supply

Warning, for

Personal Safety:

Remove house time or open

circuit breaker before beginning

installation.

Do not use an extension cord or adapter

plug with this appliance. Follow National

Elecuical Code or prevailing local codes

and ordinances.

Electrical supply

This vent hood must be supplied with 120V,

60Hz., and connected to an individual, properly

grounded branch circuit, protected by a 15 or 20

ampere circuit breaker or time delay fllse.

• Wiring must be 2 wire with ground.

• If the electrical supply does not meet the

above requirements, call a licensed elecuician

before proceeding.

• Route wiring as close to the installation

location as possible, in the ceiling or soffit.

• Gonnect the wiring to the house wiring in

accordance with local codes.

Grounding Instruction

The giounding conductor must be connected to

a ground metal, permanent wiring system, or an

equipment-grounding terminal or lead on the

hood.

Warning: The improper

connection of the equipment-

grounding conductor can result in

a risk of electric shock. Check with

a qualified electrician or service

representative if you are in doubt whether

the appliance is properly grounded.

Page 5

Installation Preparation

36" Vent Hood

Duct

fittings

Use this chart to

compute maximum

permissable lengths

for duct runs to

outdoors.

Note: Do not exceed

maximum permissable

equivalent lengths!

Maximumductlength:

100footforrangehoods.

Flexible ducting:

If flexible metal

ducting is used, all

the equivalent feet

values in the ruble

should be doubled.

The flexible metal

duct should be

straight and smooth

and extended as

much as possible.

Do NOT use flexible

plastic ducting.

Duct Piece

%

%>

Dimensions

RotlI](1,

straight

3-1/4" x l 0"

straight

90 ° elbow 12 It.

45 ° elbow 7 It.

3-1/4" x 10" 14ft.

3-1/4" x 12" l0 It.

90 ° elbow

3-1/4" x 10" 8 ft.

3-1/4" x 12" 6ft.

45 ° elbow

3-1/4" x 10" 33 It.

3-1/4" x 12" 24 It.

90 ° flat elbow

()" I'OtlIld to

rectangular 2 It,

I,ength* Used

lit.

(per foot

length)

lit.

(per foot

length)

Equivalent Quantity

Total

Equivalent

I,ength

Note: Any home ventilation

system, such as aventilation

hood, mayinterrupt the proper

flow of combustion air and

exhaust required by fireplaces,

gas furnaces, gas water

heaters and other naturally

vented systems. Tominimize the

chance ofinterruption ofsuch

naturally vented systems,

followthe heating equipment

manufacturer's guidelines and

safety standards such as those

published by NFPAand

ASHRAE.

Rectangular

to 6" round 2 It.

3-1/4" x 10" 4 ft.

3-1/4" x 12" 4 ft.

()" I'OLIHd tO

rectangular

transition 90 ° elbow

3-1/4" x 10" 4 It.

3-1/4" x 12" 4ft.

Rectangular to 6" round

transition 90 ° elbow

Round

©

*Actual length of straight duct plus duct fitting

equivalent. Equivalent length of duct pieces are

based on actual tests conducted by 6E Evaluation

Engineering and reflect requirements for good

venting performance with any ventilation hood.

wall cap

with damper 24 It.

3-1/4" x 10" 24 ft.

3-1/4" x 12" 18ft.

Rectangular wall cap

with damper

Round roof cap 33 ft.

Total Duct Run

Page 6

Installation Preparation

36" Vent Hood

7bols &

Materials

Required

(not supplied)

Remove the

Paekacin¢

• Tape measure

• I_dfe

• Spirit level

• Wire cutter

• Wire suipper

• Wire ntlts

• Electric drill and appropriate bits

• Phillips screwdriver

• Flat blade screwdriver

• Hammer

• Pliers

The vent hood is shipped secured to a shipping

board with 4 screws.

• Remove the duct covm, parts box and

styiofoam packaging.

• I,ift the hood out of the box, using hand grips

on both sides of the shipping board.

• Remove and properly discard the plastic

wiapping.

• I,ocate and remove 2 sciews at the top of the

assembly and 2 screws inside the hood behind

the filter guides on the left and right sides.

Discard the shipping board.

• Remove junction box cover.

• Remove knockout flomjunction box.

• Install suain relief onto junction box.

Junction

Box

• Safety glasses

• Tape to mount template

• Gloves to protect against sharp edges

• 120V 60Hz. 15 oI 20 Amp, 2 wire with

gIound. PIoperly grounded branch circuit.

• Suain relief forj unction box.

• 6" round metal duct work.

ShippingBoard

Knockout

Screw

Mountinc

Screw

..... Mounting

Screw

ShippingBoard

Page 7

Installation

36" Vent Hood

Check

Installation

Hardware

Ductwork,

Wiring,

Hood

Attachment

Locations

I,ocate tim hardware accessory box packed

with range hood and check contents.

Fasteners

2 Mounting

Brackets

Wall

10

_-x

2Large

FlatWashers

lO

Wood

Screws

iFT

Ph,,,, eadScrews

UtilityBarswith Screws 3 Filters

To determine ductwork locations:

• I,ocate the template packed with the

literature.

• Determine tim exact installation location.

- Measure 36" flom tim floor to tim top

of the cooking surface. Add 25-1/2"

recommended space flom the cooking

surface to bottom of hood. Mark that

location.

- Use a level to draw a straight pencil line

on tim wall.

- Tape tim template in position along the

penciled line. CHECK TO BE SURE

TEMPI,ATE IS I,EVEI,.

• Measure flom the peak of the hood

to the ceiling as indicated. The dimension

should be:

- 26-1/4" to 38-1/4" for 8 ft. to 9 ft. ceilings.

- 38-1/4" to 50-1/4" for 9 ft. to 10 ft.

ceilings (This installation requires

ZX10SY accesso_ T duct covet,)

CEILING DUCTING

If ductwork will vent straight tap to tim ceiling:

• Use a level to draw a line straight tap, flom

the centerline on the template to the ceiling. HOUSE WIRING LOCATION:

• Measure 3-1/2" fiom the back wall to the

centerline of a 6-1/2" dia. hole on the

ceiling. •

Note: Ifdrywallisnotpresent,adddrywallthicknessto the

3-1/2"dimension.

31/2" Wall',./VENT_ DUCTINGCenterlineTo

/r"

6-1/2"Die.Hole_

\\\\\ i

X J. .Centerline

FOBWALLVENTDUCT [ BracketLocation

WALL DUCTING

If ductwork will vent to the rear:

• Use tim level to draw a line suaight tap flom

the centerline on the template.

• Measure at least 6" above tim bracket location

shown on tim template to tim centerline of

the 6-1/2" dia. duct hole. (Hole may need to

be elongated for duct elbow.)

The junction box is located on the top of the

hood, at tim flont right side.

Rotate house wiring as close to tim installation

location as possible, through the ceiling, soffit

or back wall. Wiring should enter at least 4"

above tim bracket on tim right side. 7

2{,_ 6' Min.Above

i

Decorative

Duct

Wall Mount Template

,/FOB CEILING

,,

i

i

Page 8

s4

Install

Mounting

Brackets

Whenever possible, the vent hood should be

secured to wall studs.

• XVith the template roped in place, use a

puncll to mark all mounting screw locations.

• Drill 1/8" pilot holes at the 6 punched

locations.

• Remove the template.

• Enlarge holes that did not enter studs to

3/8" and tap anchors for wall fasteners into

the holes.

- Drive screws into the fasteners to allow

anchors to expand against the wall

material. Remove the screws for final

installation.

• Secure the mounting brackets to the wall

studs with wood screws provided.

- For hollow walls, secure the mounting

brackets through the anchors.

Installation

36" Vent Hood

1

Note:Screws "A" and "B" are pre-assembledonto the brackets.

Do notremove these screws.

Install

the Hood

Place the hood on the brackets and slide left to

right to align with rectangular slots at the top.

• Adjust the installation height by tightening

or loosening the screws "A" at the bottom

of the brackets.

• Align the hood lower mounting holes with

pilot holes in the wall.

• Using two large fiat washers (supplied),

install wood screws or wall fastener screws,

loosely, into lower mounting holes. Do not

tighten.

• I,evel the hood by tightening or loosening

the screws "A" located on the bottom

mounting brackets.

• Tighten the lower mounting screws.

• Tighten screws "B" located at the top of the

mounting bracket against the hood to clamp

the position. Do not overtighten screws.

Screws"B"

ToSecureHood

ToWall

/--...

--Leveland

Height

Adjustment

Screws"A"

Lower

MountingScrews

Page 9

Install Duct

Bracket

(jbr vertical exhaust)

Install the 2 small screws into tile sides of

tile duct bracket. Remove tile screws. This

will insure ease of final installation.

Temporarily install a piece of 6" duct cut to

length between tile hood oudet and tile

ductwork at tile ceiling.

Position tile upper duct bracket behind tile

duct and against tile wall and ceiling.

Use a level to check that duct is vertical and

duct bracket is centered.

Mark tile 4 screw locations of tile bracket.

Remove tile bracket and temporary duct

section.

Drill 1/8" pilot holes ill marked bracket

location.

If pilot holes do not enter studs, enlarge tile

holes 3/8" and install wall fastener anchors.

Drive screws into tile

fasteners to allow anchors

to expand against tile wall

material. Remove tile screws. ,_"

Secure tile bracket to tile

ceiling and wall with wood

screws and/or wall fastener

screws.

Installation

36" Vent Hood

Duct

Work

\

Install Duct

Bracket

(jbrho_4zo'ntalexhaust)

Tile upper duct bracket should be installed against

tile ceiling. This bracket will hold tile decorative

duct cover ill place at tile top.

• Install tile 2 small screws into tile sides of tile duct

bracket. Remove the screws. This will insure ease

of final installation.

• Position tile bracket against tile wall and ceiling.

Center tile bracket using marked centerline of

tile hood.

• Use a pencil to mark tile bracket location along

its outside edges.

• Temporarily place the decorative duct cover on

top of tile hood and extend tile inner portion to

meet tile ceiling.

• Tile duct cover should be level and align with

marks for bracket.

• Remove tile duct coveL

• Place bracket against marked location and mark

tile 4 screw locations.

• Drill 1/8" pilot holes ill marked location.

• If pilot holes do not enter studs, enlarge tile

holes 3/8" and install wall fastener anchors.

Drive screws into tile fasteners to allow anchors

to expand against tile wall material. Remove

tile screws.

• Secure tile bracket to tile ceiling and wall with

wood screws and/or wall fastener screws.

I

I

t/ I \

I 1

\ I !

Page 10

Connect

Ductwork

Do not use sheet metal

screws at hood flange

connection. Doing so will prevent proper

damper operation. Seal connection with

rope only.

Install ductwork, making connections in

direction of airflow as illustrated.

Secure joints in ductwork with sheeuneml

screws.

Wrap all duct joints with duct rope for

airtight seal.

Installation

36" Vent Hood

Duct Tape

Over Seam

and Screw

Screw

Air Flow

Step 8

Connect

Electrical

Step 9

Install

Decorative

Duct Cover

and

Utility

Bars

Verify that power is turned off at the source.

If house wiring is not 2-wire with

a ground wire, a ground must be

provided by the insmlleL

When house wiring is aluminum,

be sure to use U.I,. approved

anti-oxidant compound and

aluminum-to-copper connectors.

Mounting Screws

• Insert house wiring through suain relief

and tighten.

• Connect white leads to branch circuit

white lead.

• Connect black leads to branch circuit

black lead.

• Connect green/yellow leads to branch

circuit green or bare ground lead.

• Secure all connections with wire ntlts oil

each electrical connectoL

• Push wires into junction box and replace

coveL Be sure wires are not pinched.

1o

/ Notches

Place the decorative duct cover on top of

the hood.

• Insert the lower portion of the duct cover

into the impression on the top of the hood.

• Extend the inner duct upwards to meet the

ceiling and bracket.

• Secure the duct cover to the bracket with

the 2 small Phillips screws provided.

• Install the side utility bars as shown with

screws provided.

Install Optional ZXl OSY Duct Cover

• Separate the supplied duct cover into

pieces. Discard the upper (or inner)

section.

• Insert the new ZX10SY duct cover into

the original lower section. Be sure that

the new longer section is inside the shorter

original section. The notches will be at the

bottom and the screw holes at the top as

illustrated.

• Follow the same procedures shown above

to install the new duct cover.

Page 11

elO

Install Filters

Installation

36" Vent Hood

e ll

Finalize

Installation

Remove protective film on filters.

Tip the filter into the lower slots at the

rear of the opening, lift the filter and pull

the knob forward until the filter rests on

the slots.

• Remove protective film covering the control

panel on the flont face of the hood and any

remaining packaging materials.

• Refer to the Owner's Manual for

operating instructions.

• To remove the filters, grasp the knob and

push the filter towards the rear and tilt

downwards.

11

Page 12

Monogram:

GEConsumer&Industrial

GEAppliances

GeneralElectricCompany

Louisville,KY40225

monogram.corn

©2007GECompany

Note: \,_hile perfl_rming installations described in this

book, satety glasses or goggles should be _orn.

For ,\hn_ogram local service i_ 3our area, call

1.800.444. 1845.

NOTE: Product improvement is a contimdng endea\_r at General Electric.

There[k_re. materials, appearance and specit3cations are subject to change

without notice.

Pub. No. 49-899{)-9

04/07,JR

Printed in Italy

Loading...

Loading...