Page 1

installation

®

Instr ct

Island Vent Hoods

Models:

ZV421

ZV541

Page 2

SafetyInformation

READ AND SAVE THESE INSTRUCTIONS

BEFORE YOU BEGIN

Read these instructions completelg and carefullg.

"IMPORTANT- Savetheseinstructionsfor

local inspector's use.

"IMPORTANT- Observeallgoverningcodes

and ordinances.

. Note to Installer - Besure to leave these

instructions with the Consumer.

. Note to Consumer - Keep these instructions

with gour Owner's Manual for future reference.

* Skill Level -Installation of this appliance requires

basic mechanical and electrical skills.

. Completion Time - i to 3 Hours.

. Proper installation isthe responsibilitg of the installer.

Product failure due to improper installation is not

covered under the warrantg.

ForMonogram localserviceingour area,call 1.800.4443845.

For Monogram service in Canada, call 1.800.561.3344.

For Monogram Parts and Accessories, call 1.800.626.2002.

CAUTION:

Due to the weight and size of these vent hoods and

to reduce the risk of personal injurg or damage to the

product, THREE PEOPLEAREREQUIREDFORPROPER

INSTALLATION.

AWARNING:

To reducetheriskoffireorelectricalshock,do not

usethisrange hoodwithang externalsolid-statespeed

control device. Any such alteration from original factorg

wiring could result in damage to the unit and/or create

an electrical safetg hazard.

TO REDUCETHERISKOFFIRE,USEONLYMETALDUCTWORK.

WARNING: To REDUCE THE RISK OF

FIRE, ELECTRICAL SHOCK OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

A. Use this unit onlg in the manner intended

bg the manufacturer. If gou hove ang questions, con-

tact the manufacturer.

B.

Before servicing or cleaning the unit, switch

the power off at the service panel and lock the ser-

vice disconnecting means to prevent the power from

being switched on accidentallg. When the service dis-

connecting means cannot belocked, securelg fasten

a prominent warning device,

such as a tag, to the service panel.

ACAUTION: FORGENERALVENTILATING

USE ONLY. DO NOT USE TO E×HAUST HAZARDOUS

MATERIALS,E×PLOSIVEMATERIALS OR VAPORS.

AWARNING: TO REDUCE THE RISK OF

FIRE, ELECTRICAL SHOCK OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

. Installation work and electrical wiring must be done

bg qualified person(s)in accordance with all applicable

codes and standards, including fire-rated construction.

* Sufficient air is needed for proper combustion

and exhausting of gases through the flue (chimneg)

of fuel burning equipment to prevent back-drafting.

Follow the heating equipment manufacturer's guide-

lines and safetg standards, such as those published

bg the National Fire Protection Association (NFPA),

the American Societg for Heating, Refrigeration and

Air Conditioning Engineers (ASHRAE)and the local

code authorities. When applicable, install any makeup

(replacement) air system in accordance with local

building code requirements. Visit GEAppliances.com

for available makeup air solutions,

* When cutting or drilling into walls or ceilings, do not

damage electrical wiring and other hidden utilities.

* Ducted systems must always be vented

to the outdoors.

Local codes vary. Installation of electrical connections

and grounding must comply with applicable codes.

In the absence of local codes, the vent should be

installed in accordance with National Electrical Code

ANSI/NFPA70-1990 or latest edition.

A CAUTION: TO reduceriskoffireand to

properlyexhaustair,be suretoductairoutside-donot

ventexhaustairintospaceswithinwallsorceilingsor

intoattics,crawlspacesorgarages.

49 80209 5

Page 3

Consignes de S@curit_

LISEZ ETCONSERVEZ

AVANT DE COMMENCER

Lisez ces instructions enti_rement et attentivement.

CES INSTRUCTIONS

B.

"IMPORTANT- Conservezces instructions

pour I'inspecteur 61ectrique local.

" IMPORTANT- Respecteztouslescodeset

r_glementsen vigueur.

. Remarque pour I'installateur - Assurez-vous

de remettre ces instructions 5 I'utilisateur.

Remarque pour I'Utilisateur - Conservez ces

instructions avec votre notice d'utilisation pour toute

r6f@ence future.

Niveau de comp@tence - L'installation de cet

appareil demande des connaissances de base en

m6canique et en 61ectricit_.

@

D@lai d'ex@cution - 1 6 3 heures.

@

L'installateur est responsable de I'installation

correcte de I'appareil. La panne de I'appareil due a

une mauvaise installation n'est pas couverte par la

garantie.

Pour les services Ioceux Monogram dans votre secteur,

appelez le 1.800.444.1845.

Pour lesservicesMonogram au Canada, appelezle

1.800.561.3344.

Pour les Pi_ces et Accessoires Monogram, appelez

1.800.626.2002.

A M ISE EN GA RD E :UNIQUEMENT

POUR UNE I:VACUATIONDE TYPE GI:NI_RALN'UTILISEZ

PAS CET APPAREILPOUR F!VACUERDES SUBSTANCES

OU DES VAPEURS NOCIVES OU EXPLOSIVES.

AAVERTISSEMENT : POURR_DU,RE

LERISQUED'INCENDIE, DECHOC I_LECTRIQUEOU DE

BLESSURECORPORELLE,SUIVEZLESINSTRUCTIONS

SUIVANTES:

. L'installation et le c(3blage 61ectrique doivent _tre

, Une quantit6 d'air suffisante est n6cessaire (3une

_,MISE EN GARDE :

A cause de la taille et du poids de ces hottes d'extraction

ainsi que pour r_duire le risque de blessure corporelle

ou de dommage au produit, TROIS PERSONNESSONT

REQUISESPOUR UNE INSTALLATION CORRECTE.

_AVERTISSEMENT :

Pour r6duire le risque d'incendie ou de choc 61ectrique,

n'utilisez pas cette hotte avec un dispositif de contr61e

de la vitesse 5 semi-conducteurs. Toute alt@ation du

c(3blage61ectrique d'origine peut endommager I'appareil

et/ou cr6er un risque 61ectrique.

POURREDUIRELERISQUED'INCENDIE,N'UTILISEZQUEDES

CONDUITSMErALLIQUES.

, Lorsque vous effectuez des d6coupes ou que vous

ZkAVERTISSEMENT: POURR_DU,RE

LE RISQUED'INCENDIE, DE CHOCELECTRIQUEOU DE

BLESSURECORPORELLE,SUIVEZLESINSTRUCTIONS

SUIVANTES:

A. Cet appareil doit uniquement _tre utilis6 aux fins

pr6vues par le fabricant. Sivous avez des questions,

contactez le fabricant.

_,MISE EN GARDE :Pourr@duire

le risque d'incendie et @vacuercorrectement l'air en

I'@vacuantvers I'ext@ieur-n'@vacuez pas I'air vers un

espace entre deux murs ou dans le plafond ou encore

dans un grenier, un vide sanitaire ou un garage.

Avant de r6parer ou de nettoger un appareil, coupez

I'alimentation 61ectriqueau niveau du tableau de

distribution et verrouillez le disjoncteur pour _viter

que I'alimentation 61ectrique ne soit accidentellement

r6tablie. Quand il n'est pas possible de verrouiller le

disjoncteur, attachez un moLlen d'avertissement, une

@iquette par exemple, au panneau de distribution.

effectu6s par une ou plusieurs personnes qualifi6es,

conform6ment (3tousles codes et toutes les normes

applicables, dont ceux concernant la r6sistance au feu

des constructions.

combustion et une _vacuation appropri6es des

gaz par le conduit d'_vacuation (chemin_e) de

1'6quipement (3combustible pour 6viter tout refoule-

ment. Suivez les directives et normes de s6curit6 du

fabricant de I'appareil chauffant, comme celles pub-

li6es par la National Fire Protection Association (NFPA),

par I'American Societg for Heating, Refrigeration and

Air Conditioning Engineers (ASHRAE)et par les auto-

rit6s locales. Le cos 6ch6ant, installez un sgst_me de

compensation d'air (remplacement) conform_ment

aux conditions des codes Iocaux du b(3timent. Visitez

le site GEApplionces.com pour connaTtre les solutions

offertes en mati@e de sLIst_me de compensation d'air.

percez un mur ou un plafond, n'endommagez pas le

c(3blage61ectrique ou tout autre r6seau d'alimentation

cach&

L'air des ventilateurs disposant de conduits d'a@ation

doit toujours @tre6vacu6 vers I'ext@ieur.

Les codes Iocaux peuvent varier. L'installation de

branchements 61ectriques et la mise (3la terre doivent

@treconformes aux codes en vigueur. Les6vacuations

doivent @treinstall6es conform@ment (3la derni@re@di-

tion du Code Electrique National ANSI/NFPA No

70-1990.

49 80209 5 3

Page 4

CONTENTS

Design Information

Design Information

Product Dimensions ............................................................................4

Duct Cover Accessories .....................................................................5

Product Clearances .............................................................................5

Advance Planning

Ductwork Planning .............................................................................6

Ceiling Framing for Support ............................................................6

Accessorg Frames and Duct Covers .........................................6

Mounting the hood without a support frame .......................6

Power Supplg ........................................................................................6

Installation Height ...............................................................................7

Duct Fittings ..........................................................................................8

Installation Preparation

Tools and Materials Required.........................................................9

Installation Instructions

Step !, Construct Ceiling Support .....................................11-13

2, Mount Template .................................................................14

Step

3, Sizeand Install Ductwork ..............................................14

Step

4, Install Support Frame and Duct Covers.................15

Step

5, Install Duct Transition and Damper ........................16

Step

6, Install Hood to Support...................................................16

Step

7, Connect Duct ......................................................................16

Step

8, Connect Electrical..............................................................17

Step

9, Install the Motor .................................................................17

Step

10,SlideDuct Cover Down ................................................18

Step

11,Install Filters.......................................................................18

Step

12,Install Rods.........................................................................18

Step

13,Install Supplied Duct Cover, Top Cover................19

Step

14,Finalize Installation .........................................................19

Step

15,Installation Checklist ....................................................19

Step

Remove the Packaging ....................................................................9

Parts, Hardware, Accessorg Packages .................................10

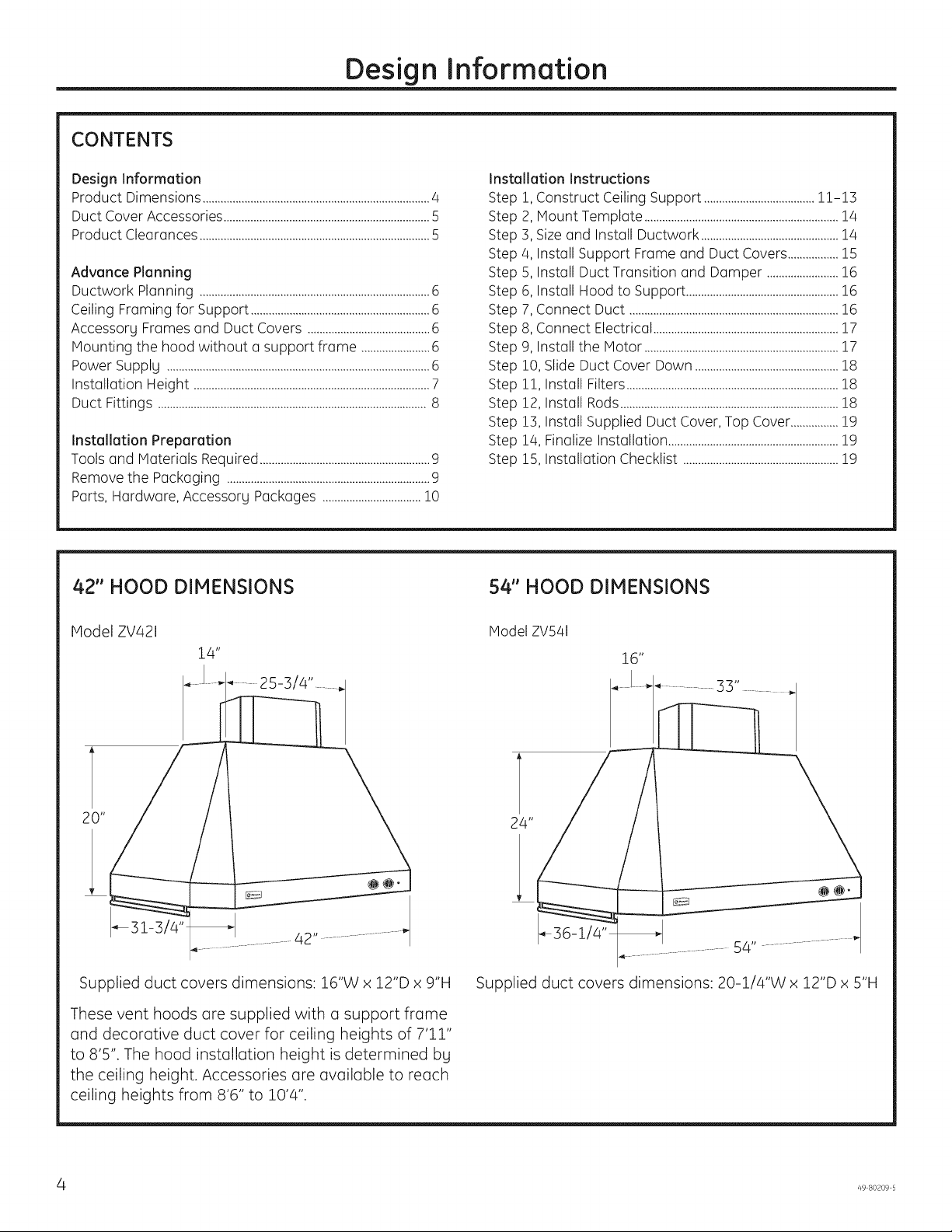

42" HOOD DIMENSIONS 54" HOOD DIMENSIONS

Model ZV421

14"

20"

Supplied duct covers dimensions: 16"W x 12"D x 9"H

These vent hoods are supplied with a support frame

and decorative duct cover for ceiling heights of 7'11"

to 8'5". The hood installation height is determined bg

the ceiling height. Accessories are available to reach

ceiling heights from 8'6" to 10'4".

Model ZV541

16"

/

......[............... 33" •.....

24"

_36-1/4"_ _ ....... 54 ......................

/

Supplied duct covers dimensions: 20-1/4"W x 12"D x 5"H

49 80209 5

Page 5

Design Information

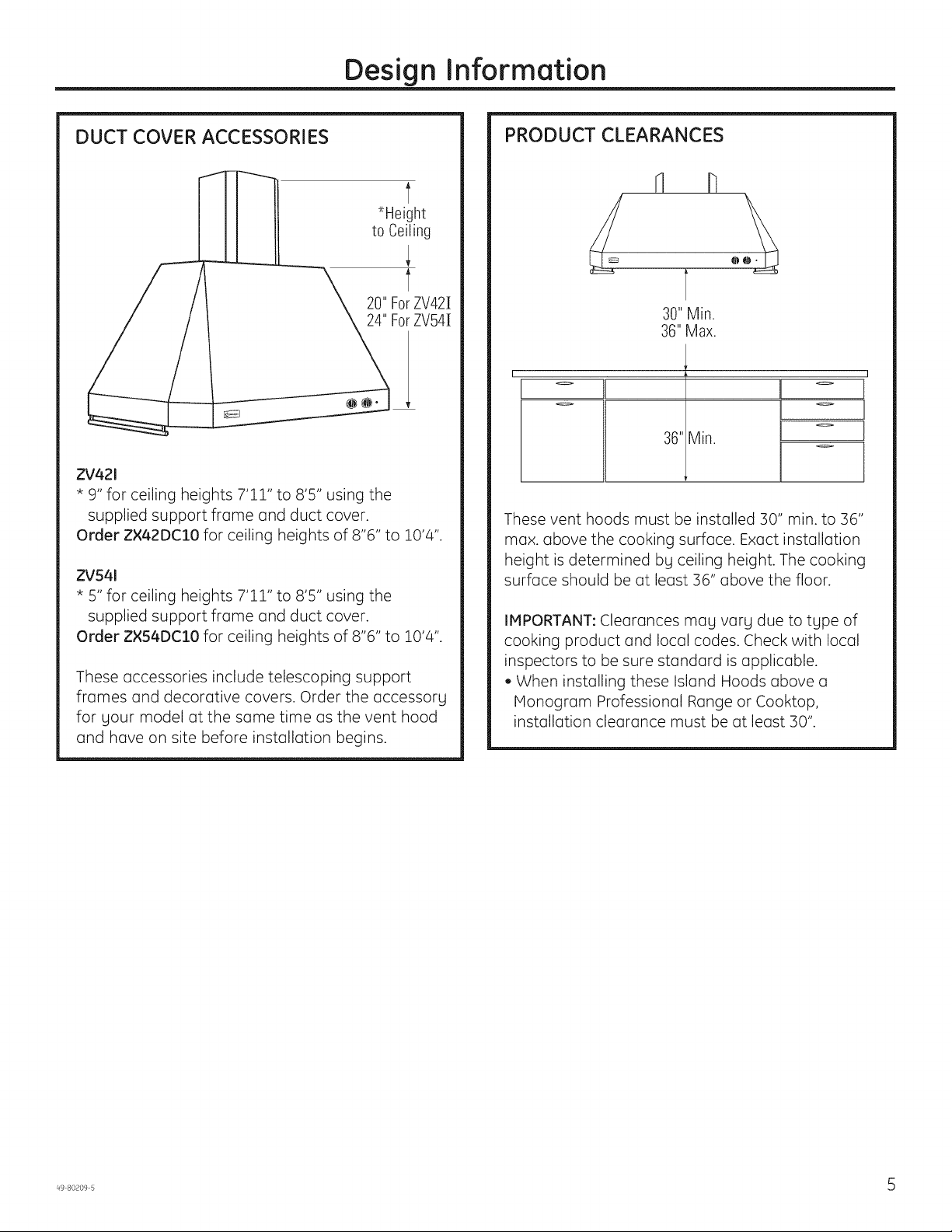

DUCT COVER ACCESSORIES

_]_ *Height

_L_3

ZV421

* 9" for ceiling heights 7'11" to 8'5" using the

supplied support frame and duct cover.

Order ZX42DC10 for ceiling heights of 8"6" to 10'4".

ZV541

* 5" for ceiling heights 7'11" to 8'5" using the

supplied support frame and duct cover.

Order ZX54DC10 for ceiling heights of 8"6" to 10'4".

These accessories include telescoping support

frames and decorative covers. Order the accessory

for your model at the same time as the vent hood

and have on site before installation begins.

to Ceiling

20" F0!ZV42I

ForZV54I

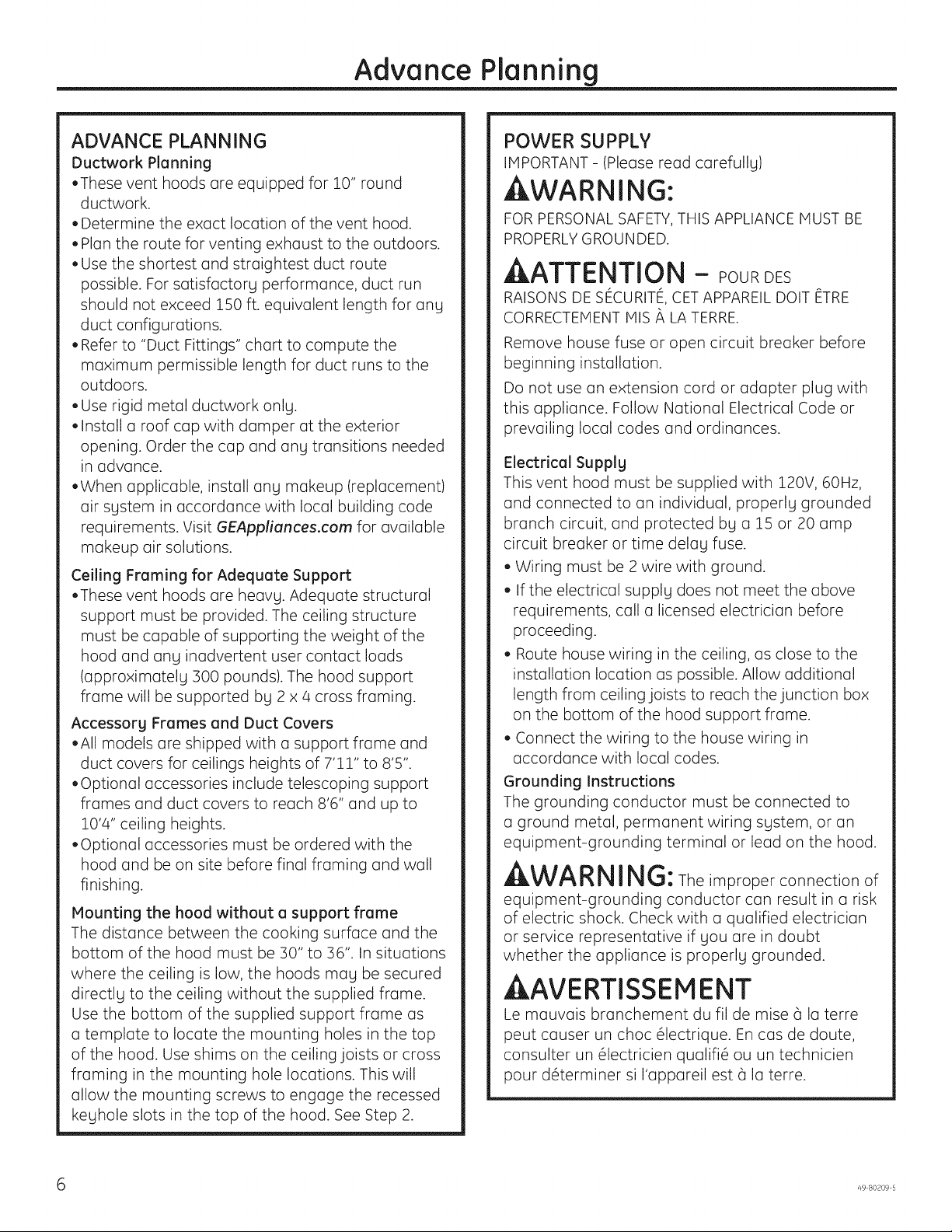

PRODUCT CLEARANCES

[

o

36" Min.

These vent hoods must be installed 30" min. to 36"

max. above the cooking surface. Exact installation

height is determined by ceiling height. The cooking

surface should be at least 36" above the floor.

IMPORTANT: Clearances may vary due to type of

cooking product and local codes. Check with local

inspectors to be sure standard is applicable.

, When installing these Island Hoods above a

Monogram Professional Range or Cooktop,

installation clearance must be at least 30".

o

o

o

Z_9 80209 5 5

Page 6

Advance Planning

ADVANCE PLANNING

Ductwork Planning

,These vent hoods are equipped for 10" round

ductwork.

, Determine the exact location of the vent hood.

, Plan the route for venting exhaust to the outdoors.

, Use the shortest and straightest duct route

possible. For sotisfoctorg performance, duct run

should not exceed 150 ft. equivalent length for ang

duct configurations.

, Refer to "Duct Fittings" chart to compute the

maximum permissible length for duct runs to the

outdoors.

, Use rigid metal ductwork onlg.

, Install o roof cop with damper at the exterior

opening. Order the cop and ang transitions needed

in advance.

,When applicable, install ong makeup (replacement)

air sgstem in accordance with local building code

requirements. Visit GEAppliances.com for available

makeup air solutions.

Ceiling Framing for Adequate Support

,These vent hoods are heavg. Adequate structural

support must be provided. The ceiling structure

must be capable of supporting the weight of the

hood and ong inadvertent user contact loads

(approximatelg 300 pounds). The hood support

frame will be supported bg 2 x 4 cross framing.

Accessorg Frames and Duct Covers

,All models ere shipped with a support frame and

duct covers for ceilings heights of 7'11" to 8'5".

,Optional accessories include telescoping support

frames and duct covers to reach 8'6" and up to

10'4" ceiling heights.

,Optional accessories must be ordered with the

hood and be on site before final framing and wall

finishing.

Mounting the hood without a support frame

The distance between the cooking surface and the

bottom of the hood must be 30" to 36". In situations

where the ceiling is low, the hoods meg be secured

directlg to the ceiling without the supplied frame.

Use the bottom of the supplied support frame as

a template to locate the mounting holes in the top

of the hood. Use shims on the ceiling joists or cross

framing in the mounting hole locations. This will

allow the mounting screws to engage the recessed

keghole slots in the top of the hood. See Step 2.

POWER SUPPLY

IMPORTANT - (Please read carefully)

-&WARNING:

FOR PERSONAL SAFETY,THIS APPLIANCE MUST BE

PROPERLYGROUNDED.

AATTENTION - POURDES

RAISONS DE SECURITE,CET APPAREIL DOIT ETRE

CORRECTEMENT MIS A LA TERRE

Remove house fuse or open circuit breaker before

beginning installation.

Do not use an extension cord or adapter plug with

this appliance. Follow National Electrical Code or

prevailing local codes and ordinances.

Electrical Supplg

This vent hood must be supplied with 120V, 60Hz,

and connected to an individual, properlg grounded

branch circuit, and protected bg a 15 or 20 amp

circuit breaker or time delag fuse.

, Wiring must be 2 wire with ground.

, If the electrical supplg does not meet the above

requirements, call a licensed electrician before

proceeding.

, Route house wiring in the ceiling, as close to the

installation location as possible. Allow additional

length from ceiling joists to reach the junction box

on the bottom of the hood support frame.

, Connect the wiring to the house wiring in

accordance with local codes.

Grounding Instructions

The grounding conductor must be connected to

a ground metal, permanent wiring sgstem, or an

equipment-grounding terminal or lead on the hood.

AWARN ING: The improper connectionof

equipment-grounding conductor can result in a risk

of electric shock. Check with a qualified electrician

or service representative if gou are in doubt

whether the appliance is properlg grounded.

AAVERTISSEMENT

Le mauvais branchement du fil de mise (_la terre

peut causer un choc 61ectrique. En cas de doute,

consulter un 61ectricien qualifi6 ou un technicien

pour d6terminer si I'appareil est (_la terre.

49 80209 5

Page 7

Advance Planning

INSTALLATIONHEIGHTREQUIREMENTS

• These vent hoods must be installed 30" min. and

36" max. above the cooking surface - regardless of

the ceiling height. Therefore, installation height of

the hood depends on the exact ceiling height of the

kitchen.

• Accessories are available for ceiling heights 8'6" and

up to 10'4".

Example: Hood installation height with 8 ft. ceilings.

8 ft. Ceiling 8 ft. Ceiling

9" s" II II

Supplied Supplied/

Duct Duct {_= ,,,,,_

Cover Cover t -

31" 31"

i

ZV421 ZV541

• Bothmodelsare shippedwith a supportframe and

ductcoverfor 7'11"to 8'5"ceilings.

• Ifthe ceiling height is 7'1r', the installationheight

abovethe cookingsurfacewillbe30".

• If the ceiling height is8'5%the hood installation height

will be 36".

DETERMINE INSTALLATION HEIGHT

1. Heasure the exact ceiling height.

2. Review the chart to determine the range

of hood installation heights that can be

accomplished with or without an accessorg kit.

Duct Cover t _i_ ....

,'"" L 20"forZV42I'"',,

/" / 24" for ZV54I ",,,

Ceiling

30" Min. and 36"Max.

Heicht

II II

3@"

to

Countertop

ACCESSORIES

ZX42DC10 - Optional Accessory for ZV421.

ZX54DC10 - Optional Accessory for ZV541.

Accessories for ceiling heights of 8'6" to 10'4".

Includes telescoping support frames and duct

cove rs.

Actual Chimney Length at

Ceiling Hood Insta!tgtion H_igh!

Height 30" 3r' 32 33 | 34' 35

10'4" 36 35 34 33

10'3" 36 35 34 33 32

I

10'2" 36 35 34 33 32 31

iO'i" 35 34 33 32 31 30

10' 34 33 32 31 30 29

9'11" 33 32 31 30 29 28

9'10" 32 31 30 29 28 27

9'9" 31 30 29 28 27 26

9'8" 30 29 28 27 26 25

9'7" 29 28 27 26 25 24

9'6" 28 27 26 25 24 23

9'5" 27 26 25 24 23 22

9'4" 26 25 24 23 22 21

9'3" 25 24 23 22 21 20

9'2" 24 23 22 21 20 19

9'1" 23 22 21 20 19 18

I

9' 22 21 20 19 18 17

8'11" 21 20 19 18 17 16

8'10" 20 19 18 17 16 15

8'9" 19 18 17 16 15

8'8" 18 17 16 15

8'7" 17 16 15

8'6" 16 15

8'5" 15

8'4" 9

8'3" 9

8'2" 9

8'1" 9

8' 9

7'11" 9

_,ctuat Chimney Length at Duct

:eiling Hood Insta,!tationHeight Cover

10'4" 28

10'3" 28 27 Order

10'2" 28 27 26 ZXS4DClO

10'1" 28 27 26 25 Use Long

10' 28 27 26 25 24 Support

9'lr' 28 27 26 25 24 23 and

9'10" 28 27 26 25 24 23 22 Duct Cover

9'9" 27 26 25 24 23 22 21

9'8" 26 25 24 23 22 21 20

9'7" 25 24 23 22 21 20 19

9'6" 24 23 22 21 20 19 18

9'5" 23 22 21 20 19 18 17

9'4" 22 21 20 19 18 17 16 Order

9'3" 21 20 19 18 17 16 15 ZX54DC10

9'2" 20 19 18 17 16 15 14 Use Short

9'2" 29 28 27 16 15 14 13 Support

9' 18 17 16 15 14 13 12 and

B'I 2" 27 26 25 24 23 22 Duct Cover

B'IO" 16 15 14 13 12

B'9" 15 14 13 12

B'8" 14 13 12

B'7" 13 12

B'6" 12

B'5" 5 Use

9'4" 5 Supplied

B3" 5 Support

B'2" 5_ and

B'2" 5 Duct Cover

9' 5

7'11" i 5

30" 3r' 32" 33 34' 35 J36" KitHeight

I

I

Duct

Cover

36" Kit

32

31 Order

30 ZX42DC10

29 Use Long

28 Support

27 and

26 Duct Cover

25

24

23

22

21 Order

20 ZX42DCI0

19 Use Short

18 Support

17 and

16 Duct Cover

15

I

2

Use

Supplied

Support

and

Duct Cover

49 80209 S 7

Page 8

DUCT FITTINGS

Use this chart to compute maximum

permissible lengths for duct runs to

outdoors.

For best results, use 10" diameter duct.

Note: Do not exceed maximum permissible

equivalent lengths!

Maximum recommended duct length

for these hoods: 150 feet

Flexible ducting:

If flexible metal ducting is used, all

the equivalent feet values in the table

should be doubled. The flexible metal

duct should be straight and smooth

and extended as much as possible.

Do NOT use flexible plastic ducting.

Advance Planning

to 8" round

10" round

Round, 1 ft.

straight (per foot

90° elbow 8" Dia. 52 ft.

%

45° elbow 8" Dia. 31 ft.

C_ Round 8" Dia. 99 ft.wall cap 10" Dia. 41 ft.

with damper

5 ft.

length)

10" Dia. 24 ft.

10" Dia. 14 ft.

Note: Ang home ventilation sgstem, such as a

ventilation hood, mug interrupt the proper flow of

combustion air and exhaust required bg fireplaces,

gas furnaces, gas water heaters and other

noturallg vented sgstems. To minimize the chance

of interruption of such naturallg vented sgstems,

follow the heating equipment manufacturer's

guidelines and safetg standards such as those

published bg NFPA and ASHRAE.When applicable,

install ang makeup (replacement) air sgstem in

accordance with local building code requirements.

Visit GEAppliances.cam for available makeup air

solutions.

*Hoods are supplied with a

10" round transition. A Iocallg

supplied transition is required

for other sizes.

Note: Outlet on top of hood is

8-!/8" x 8".

*Actuallengthofstraightductplusductfittingequivalent.

Equivalentlengthofductpiecesarebasedonactual

testsconductedbgGEEvaluationEngineeringandreflect

requirementsforgoodventingperformancewithang

ventilationhood.

roof cap 10" Dia. 56 ft.

Round 8" Dia. 136 ft.

Total Duct Run

49 80209 5

Page 9

Installation Preparation

TOOLS AND MATERIALS REQUIRED

(NOT SUPPLIED} 7/16" Pivoting

_sions

Duct tape

Pencil and tape measure

Wire cutter/ U

stripper

hex socket with 4"

Keg Hole Saw

Electric or batterg operated drill

and 3/16", bits, Phillips and Flat

Blade Screwdriver bits.

Safetg glasses

Spirit level

/

Sabersaw

or Sawsall

Step ladder

Carpenter's square

REMOVE THE PACKAGING

, Remove the parts packages and packing materials.

, Lift the hood out of the box.

IMPORTANT: Lift the hood bg grasping the

outside edges of the exhaust opening on the top.

" i Parts ,,

iParts/,

Pliers Metal Snips

J

Partsl

-,

10" round metal

Wire nuts

Flashlight

Phillips and flat

screwdrivers

duct, length to

suit installation.

©

Strain relief for

junction cover.

120V 60Hz. 15 or 20 Amp,

2-wire with ground. Properlg

grounded branch circuit.

Carefullg, lag the hood on its side. A support frame

is secured to the inside top of the hood. Remove

the attachment screws at the outside top. Discard

screws.

,Grasp the support

frame inside the

hood with both \

hands and

carefullg rotate

out of the open-

ing.

Be careful not to

scratch the hood,

\

i i

,,,,,/ Hood

7',' Mounted

' on Skid

J

, Place the hood on a protective surface to prevent

scratches and damage to the stainless steel finish.

Z_9 80209 5 9

Motor

ShippingCarton

,i", _

J

,The hood motor is shipped secured to the skid with

a screws. Locate and remove 2 screws on each side

of the motor. Discard the shipping skid and screws.

Page 10

Installation Preparation

PARTS PROVIDED

Locate the parts packed with the hood.

Allen Wrench

0000

Implement rods with standoffs

Transition with Damper

2-piece decorative duct cover

Support frame for 8 ft. ceiling

with 4 large pan head screws

installed on the bottom corners.

Duct collar

2Grease trags (3with 54" hood)

HAR DWAR E PACKAG E

Locate and check

contents. Screws

shown actual size.

Screws B

2 (!/8" x !-!/2")

Phillips

pan head

i_s "",

2Templates

screws.

if

Screws C:

8 blunt point

Phillips

screws

Screw F

Blower safetg screw and lock washer,

Phillips head Ivl6 x 16.

Note: Hardware appearance mag varg slightlg.

Screws A

4 (7/16")

hex head

wood

screws

T

Screws D

2 small

Phillips

head

screws

?

Screws E

2 Phillips

head wood

screws

2 Filters (3 with 54" hood)

EZ]3

Decorative top cover

ACCESSO RY PACKAG E

Check accessorg package.

Select the taller set for 9'6" to 10'8" ceilings.

Select the shorter set for 8'6" to 9'6" ceilings.

Discard unused set.

2 Sets of Duct Covers

I

i

S

"_- L_ J

2 Support Frames

with 8 height

adjustment

screws

i

4 Attachment Screws

0 49 80209 5

Page 11

Installation instructions

ISTEP 11 CONSTRUCT CEILING SUPPORT

Plan the Location of the Hood and Ductwork

, Use a plumb bob to check the location. The

countertop/cooktop below the hood must be centered

with the hood.

Ceiling

Hood

.......Ducting

Centerline

Front

i

31-3/4" ,:

Align With

Center of ................... i

Cooktop

i /j

_ Cooktop

_____________ Countertop

42" HoodSide View

, The hood should extend beyond the front and rear

edge of the cooking appliance.

, The duct in the ceiling must be centered over the

cooktop.

Ceil.ing

i Hood

i J.........Ducting

i'-l Centerline

Mp i , ,

1

Align With _36-1/4'i _"

I

Center of ................. i CooktoF

Cooktop _

........ Counter

54" Hood Side View

Ceiling Support Structure

, At the hood location, install 2 x 4 cross framing

between ceiling joists as shown. (2x4's are required to

support the weight of the hood.)

12-3/4" (42" Hood)

EXAMPLE A

17" (54" Hood)Install

Cross-Framing

Sgmmetricallg About -_

Duct/Cooktop Centerline

I

i

, Arrange cross framing in the ceiling to suit the exist-

ing structure.

, Your ceiling joists will be like one of the following

examples.

_'Cooktop

Outline

Top View - Ceiling Joists Parallel to Front of Hood

Page 12

Installation instructions

ISTEP iI CONSTRUCT CEILING SUPPORT

CONTINUED

EXAMPLE B

12-3/4" (42"

Hood) 17" (54"

Hoodt Install

16" Jois

Spacing

Cross-Framing

Sgmmetricallg

About Duct/ -_

Cooktop Centerline

2x4 Cross

\

Align duct

to center

of Cooktop

Top View - Ceiling Joists Run Perpendicular to Front of Hood

Cooktop

Outline

g

EXAMPLE C

Z2-3/z_" (42" Hood)

17" (54" Hood)Install Cross-Framin(

Sgmmetricallg About Duct/Cooktop

Centerline

16" Joist

Spacing

Top View - Ceiling Joists at Angle with Front of Hood

2x4 Cross

Framing

_'_ Align duct \

to center Cooktop

of Cooktop Outline

12 49 80209 5

Page 13

Installation instructions

ISTEP 11 CONSTRUCT CEILING SUPPORT

CONTINUED

, Secure each 2 x 4 block with at least four (4), #10

wood screws, 3" long (not supplied). Use 8 wood

screws total for the two supports.

, The cross framing must be accurately aligned to

assure correct positioning of the hood.

, The cross framing must be level in all directions.

Check with a spirit level and adjust if necessarg.

IMPORTANT: The ceiling structure must be capable

of supporting the weight of the hood (approximatelg

300 pounds) and ang inadvertent user contact loads.

The hood support frame will be supported bg the 2 x

4 cross framing.

Ductwork

, Use the shortest and straightest duct route possible.

For satisfactorg performance, duct run should not

exceed 150 feet equivalent length for ang duct

configuration.

, Refer to "Duct Fittings" chart to compute the

maximum permissible length for duct runs to the

outdoors.

, This vent hood must use 10" round rigid duct.

, Install the house ductwork to run horizontallg

between ceiling joists or straight up through the

roof.

2x 4 Min.

Cross Framing

Ceiling .,7 ':-

/8.......8-5

ThroughThe Ceiling

_zZZZZZ_

= i

= i

= =

i =

i

10"

Duct

VentStraight Up

(54" Hoo(

12-3/4"

(42"Hoo(

Height

Adjustmen

Screw Hole

Ceiling Joint

/

/

/

2x4

Finish the Ceiling

, Finish the ceiling surface. Be sure to mark location

of the ceiling joists and cross framing. Check to be

sure the ceiling is level, use shims if necessary.

Page 14

Installation instructions

ISTEP2J MOUNT TEMPLATE

. Select the template for gour hood size. _;_ !ff-_"_ F"

- Besure the template is oriented correctlg, [][][]

with the front of the hood.

"andAligntapetheintemplateplace,with the marks on the ceiling _ UI_

. Use a plumb to check to be sure the mount- ".

ing holes will provide parallel alignment with

. Center punch all hole locations.

. Drill pilot holes in the 4 screw locations. Use a

3/16" bit and drill approximatelg 1-1/2" deep.

. Drive 4 Hex head wood screws (Screws A)into

the center of the ceiling joists and cross fram-

the countertop below, cr ....

ing. Leave a 1/4" gap to allow the screw head

to engage the keghole slots on the support

frames.

, Cut the 10-1/2" duct opening through the

sheet rock.

STEP 31 SIZE AND INSTALL DUCTWORK

. Measure from house duct flange to bottom of

support frame. Subtract 4-3/8" for clearance to the

bottom of the support frame.

. Cut the 10" duct length to size.

. Secure duct to house ducting with sheet metal

screws.

. Seal all connections with duct tape.

. Attach the duct collar Iooselg, about 1" from the

bottom of the duct using Screws B.

l

i_-!l I" Duct

Duct::):1 14

.....................i...........

c°llar"i"-i-._:!::_'

•-;.......... : 4-3/8" Clearance

II/'

_o___ o, to Bottom of Fran

_4 49 80209 5

Page 15

Installation Instructions

STEP 4] INSTALL ACCESSORY (OR SUPPLIED) SUPPORT AND DUCT COVERS

Install Small Pan Hea

i'

/

/

Install

Safetg Screw

on Each Side

Screws on Each Side

Adjust

Frame to

nstallation

Height

/

Screws D

?

Screws E

iF

Install Stop

Screw \

Stop Screw

Storage Location

Install supplied support frame OR telescoping accessorg

frame

, Hang the supplied support frame or telescoping

accessory frame to the ceiling joists and cross

framing on the 4 hex head screws by engaging the

keyhole slots on the frame.

, Check to be sure the support frame is level, vertically

and horizontally.

, Tighten the hex head screws securely.

, Install safety screws, (Screws E)on each side of the

frame.

Adjust telescoping accessorg frame to length

, Remove the 8 frame adjustment screws. Adjust the

lower support up or down to the pre-determined

length. Reinstall and securelg tighten the 8

adjustment screws.

, Slide the top (inner) accessorg duct cover up and

over the frame. Secure the duct cover to the frame as

shown using Screws D.

, Locate and remove the safetg stop screw. Slide

bottom duct cover up and over the top duct cover.

Align bottom duct screw hole to the hole in the

frame. Hold the duct cover in place while installing

screw.

_L,/_V|lVl_: The stop screw

must be installed. Failure to do so could result in

personal injurg or damage to the duct cover. The stop

screw will prevent the lower duct from sliding down

while completing the installation.

APRUDENCE

II faut mettre en place la vis de but6e afin d'6viter des

blessures ou d'endommager I'enceinte du conduit. La

vis de but6e emp_che I'enceinte inf@ieure du conduit

de descendre pendant I'installation.

Secure house wiring

, Route house wiring through the ceiling and pull a

length to reach the hood junction box, approximatelg

6" below the support. Tape to the right side of the

support frame.

IMPORTANT: Again, check to be sure the support is

level in both directions. There is no wag to level the

hood after the hood is secured to the frame.

Page 16

Installation instructions

ISTEP5J

INSTALL DUCT TRANSITION

WITH DAMPER

Pads

i

/

Attachmen

Screws

Screws C

INPORTANT: Remove shipping tape from damper

and check that damper moves freelg.

, Place the transition piece over the hood exhaust

and secure with 4 Screws C provided.

, Use duct tape to seal the connection. Check to be

sure the damper moves freelg.

Duct

Transition

ISTEP6J INSTALL HOOD

Note: THREE PEOPLE ARE REQUIRED TO COMPLETE

THIS INSTALLATION!

/

Attachment /

Keyholes_

, Back out the hanging screws on the bottom of the

support frame to a 1/4" gap.

, Lift the hood up to the support frame. Carefullg

align the hood keghole to the screws on the support

frame. Slide the hood to engage the keghole slots.

, Tighten the screws.

Install

I-2Safetg I

I Screws

Screws C

, Install safetg screws into the top of the hood as

shown.

, Check hood level in both directions.

[STEP7J CONNECT DUCT

, Loosen duct collar and slide down to cover

gap between

transition and

house duct.

Tighten collar

screws and tape _. _...o:

alljoints.

, Seal all k

connections with

duct tape.

Note: Do not drive screws through this duct

connection. Doing so will prevent proper damper

operation.

Slide Duct

Collar Down

to Cover Gap

16 49 80209 5

Page 17

Installation Instructions

STEP 8 ! CONNECT ELECTRICAL

Verifg thot power is turned off ot the source.

WARNING: housewiringisnot2-wire

with o ground wire, o ground must be provided bg

the installer. When house wiring is aluminum, be

sure to use UL approved anti-oxidant compound

and aluminum-to-copper connectors.

ATTENTION - silec_blagede la

maison n'estpas du tgpe (_deu× filsavec un filde

terre, I'installateur dolt fournir un circuit de terre.

Quond les ills de Io moison sont en oluminium,

il prendre soin d'utiliser de Io p_te ontioxido-

tion opprouv6e par UL et des connecteurs pour

I'oluminium-cuivre.

STEP 91 INSTALL THE MOTOR

Outlet

;I

\

Attachment

Slot

/

€--

Spring

Clip

, Install strain relief onto the knockout of the

junction box.

, Insert house wiring through strain relief and tighten.

, Use wire nuts to connect incoming ground to green,

white to white and block to block.

, Push wires into junction box and replace cover. Be

sure wires ore not pinched.

IMPORTANT: Connector

ends ore designed to

mote onlg one wag.

Hatch flat and round

connectors us shown.

Attochment Screw

ond Wosher

©

Screw F

/_,

f--

Attachment Spring

Slot Clip

, From the inside of the hood, slip motor into the

attachment slot on the left.

, Rotate motor upwards until it snaps into the spring

clip on the right.

, Secure the motor to the hood with the machine

screw and lock washer (Screw is marked with red

point.)

, Plug blower cable into the connector on the blower.

¢ ....", ¢

, Plug cable at the top of the hood into the junction

box connector. Route cable so it won't be pinched

or damaged when the duct cover is lowered.

Page 18

installation instructions

ISTEP i0] SLIDE DUCT COVER DOWN

SKIP THIS STEP IF USING THE SUPPLIED DUCT

COVER

, Hold the duct cover in place and remove the

temporGrg stop screw. Return the screw to the

storage location for future use.

, Slide the lower duct cover down onto the hood.

t Remove \

Ductt _ _ \

Storage Location

STEP 11 INSTALL FILTERS

ISTEP 12] INSTALL RODS

, Use a flat blade screwdriver to install stand-offs

into the bottom of the hood.

, Align implement rod to stand-offs with the screw

hole towards the inside of the hood. Secure the rod

to the stand-offs with the supplied Allen wrench.

, Follow the same procedure on the opposite side.

Screw

Stand-offs

Into Hood

Wrench to /'

",,, Secure Rod /

\

\_to Stand-offsf

.\

J

Allen ....

/

, Place filter drip trags into the rear of the hood.

, Insert the filter into the upper opening and drop

into the trags.

, To remove the filters, grasp the knobs and push

the filter up and lift out.

18 49 80209 5

Page 19

Installation Instructions

STEP 13 INSTALL SUPPLIED DUCT

COVER AND TOP COVER

lnstall Duct

CoverScrew

iF

Screws O

, Install the supplied 2-piece duct cover over the

support frame (if using supplied frame). Snap ends

together.

, Secure duct covers to support frame with 2

Screws D.

, For o more finished appearance, a top cover is

supplied and should be installed whenever the top

of the hood is visible.

TIP:Place pieces

of tape over ends

of the cover to

prevent scratch-

ing the duct

cover. Remove

tape before

installing screws.

, Engage tabs into slots on each side at the top of

the hood. The covers should lag flat in the impres-

sion on top of the hood.

n EachSide

,,Tab.<

STEP 151 INSTALLATION CHECKLIST

Check Blower Safetg Screw

[] Ensure that blower safetg screw is securelg tight-

ened. See page 16, Step 9. If screw is missing, order

replacement ports bag.

Check Operating Sound and Proper Air-Flow

[] Turn blower to each speed setting and listen for

rattles and vibration. You should notice an audible

difference at each speed setting.

[] Check for foreign material in transition.

[] Check that blower screen is not damaged or pushed

into the blower impeller.

[] The damper should move freely. Listen for opening

and closing while turning the unit on and off.

[] Check that the damper is not damaged, does not

vibrate and that damper bumper pads are in place.

Order a damper replacement assembly if needed.

[] Check that ductwork is 10" round. If duct type is not

rigid and less than 10" round, inform the consumer

that performance will be reduced.

Check Lighting Function

[] Check that power cable is plugged into the junction

box on top of the hood.

[] Turn halogen lamps to each setting. Note change in

brightness at different settings.

[] Check that each lamp bezel is secure. Turn to the

right to tighten. Order replacement lamp bezel and

socket assemblies if needed.

/

ove

Screws C

, Install 2 Screws C to secure the cover to the hood

at the front and back.

Install Screws t\

Front and Back

[STEP 14] FINALIZE INSTALLATION

, Check all lamps to assure tightness in sockets.

, Turn power on at the circuit breaker.

, Refer to the Owner's Hanual for operating and

cleaning instructions.

Check appearance and installation

[] Use a spirit level to check that the hood is level.

Review installation instructions to determine source

of problem.

[] Top covers (if used) should lay flat in the recess on

top of the hood. Hake sure side tabs are engaged in

slots and the cover is secured with two screws.

[]

Clean the hood surfaces and all filters. See the

Owner's Hanual for cleaning instructions. They

should be free of construction debris such as

sawdust.

Page 20

Note: While performing instollotions described in this book,

sofetg glosses or goggles should be worn.

For Monogrom ®/oco/service in your oreo, co//

1.800.¢¢¢.18¢5.

Note: Product improvement is mcontinuing endemvor mt

Generol Electric. Therefore, moteriols, oppeoronce ond sped-

ficotions ore subject to chonge without notice.

149-80209-5 1

02-13 GE

Printed in Mexico

GE Appliances & Lighting

Applionces

Gener(]l Electric Comp(]ny

Louisville, KY/40225

GEApplionces.com

Loading...

Loading...