Page 1

GE Consumer Products

TECHNICAL SER VICE GUIDE

2003 Monogram

30-, 36-, and 48 in.

Stainless Steel Hoods

MODEL SERIES:

ZV30RS

ZV30SS

ZV30TS

ZV36RS

ZV36SS

ZV36TS

ZV48RS

ZV48SS

ZV48TS

Technical Consultant:

Tom Ledbetter

Cincinnati Zone

PUB # 31-9107 08/03

Page 2

!

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

W ARNING

To avoid personal injury, disconnect power before servicing this

product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used

to complete a path to ground are removed for service, they must

be returned to their original position and properly fastened.

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electr ic Company.

GE Consumer Products

Technical Service Guide

Copyright © 2003

– 2 –

Page 3

Table of Contents

Autotransformer - ZV30, ZV36, and ZV48...................................................................................10

Autotransformer - ZV30R, ZV36R, and ZV48R ..........................................................................15

Baffle Grease Filter and Drip Trays - ZV30, ZV36, and ZV48 ...................................................... 7

Control Features ...........................................................................................................................6

Data Location ................................................................................................................................4

Fan Motor - ZV30, ZV36, and ZV48 ..............................................................................................7

Fan Motor - ZV30R, ZV36R, and ZV48R ...................................................................................12

Fan Motor Indicator Light - ZV30, ZV36, and ZV48 .....................................................................11

Fan Motor Indicator Light - ZV30R, ZV36R, and ZV48R ............................................................15

Grease Baffles - ZV30R, ZV36R, and ZV48R ............................................................................12

Heat Lamp Panel - ZV30, ZV36, and ZV48...................................................................................7

Heat Lamp Panel - ZV30R, ZV36R, and ZV48R.........................................................................12

Heat Lamp Socket - ZV30, ZV36, and ZV48.................................................................................8

Heat Lamp Socket - ZV30R, ZV36R, and ZV48R.......................................................................12

Heat Lamp Switch - ZV30, ZV36, and ZV48 .................................................................................8

Heat Lamp Switch - ZV30R, ZV36R, and ZV48R .......................................................................13

Introduction....................................................................................................................................4

Nomenclature................................................................................................................................4

Illustrated Parts ...........................................................................................................................21

Rotary Switch - ZV30, ZV36, and ZV48 ......................................................................................10

Rotary Switch - ZV30R, ZV36R, and ZV48R..............................................................................14

Schematics.................................................................................................................................19

Surface Lights - ZV30, ZV36, and ZV48 .......................................................................................9

Surface Lights - ZV30R, ZV36R, and ZV48R .............................................................................13

Surface Light Sockets - ZV30, ZV36, and ZV48 ...........................................................................9

Surface Light Sockets - ZV30R, ZV36R, and ZV48R .................................................................14

Troubleshooting...........................................................................................................................16

Warranty........................................................................................................................................5

– 3 –

Page 4

Introduction

The 2003 Monogram S tainless S teel, 30-, 36- and 48 in.

Range Hood models are being introduced with a new

motor mount that allows for easy removal and

replacement of the fan motor .

Other features include:

• Baffle grease filters and drip trays to allow for quick

and easy cleaning.

• A four-setting light control.

• A four-setting fan control.

• An infrared heat lamp.

• A fan ON indicator light.

• Kitchen utensil rods, located on each side of the

hood used to hang and display cooking utensils,

pots and pans, or nonflammable decorative items.

Model ZV30

Model ZV30R

Nomenclature

To access the nomenclature and schematic

diagram, remove the left grease baffle.

Schematic

Nomenclature

Schematic

Nomenclature

– 4 –

Page 5

W arranty

Monogram Hood Warranty

Proof of original purchase date is needed to obtain service under warranty.

What Is Covered

Full One-Year Warranty

For one year from date of original purchase, we will provide, free of charge, parts and service labor in

your home to repair or replace any part of the hood that fails because of a manufacturing defect.

This warranty is extended to the original purchaser and any succeeding owner for products purchased

for ordinary home use in the mainland 48 states, Hawaii, and Washington, D.C. In Alaska, the warranty

is the same except that it is LIMITED because you must pay to ship the product to the service shop or

for the service technician’s travel costs to your home.

All warranty service will be provided by our Factory Service Centers or by our authorized Customer

®

Care

Servicers during normal working hours.

Should your appliance need service, during warranty period or beyond, call 800.444.1845.

What Is Not Covered

• Service trips to your home to teach you how to use the product.

• Replacement of home fuses or resetting of circuit breakers.

• Incidental or consequential damage caused by possible defects with this appliance.

• Replacement of the filters and light bulbs.

• Damage to the product caused by accident, fire, floods, or acts of God.

• Failure of the product if it is used for other than its intended purpose or used commercially .

• Improper installation.

If you have an installation problem, contact your dealer or installer . You are responsible for providing

adequate electrical, gas, exhausting, and other connecting facilities as described in the Installation

Instructions provided with the product.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and

you may also have other rights which vary from state to state.

To know what your legal rights are in your state, consult your local or state consumer affairs office or

your state’s Attorney General.

Warrantor: General Electrical Company. Louisville, KY 40225

– 5 –

Page 6

Control Features

1 - Light Control

The two surface lights are controlled using a 5position switch (OFF, 1, 2, 3, and HI). Turn the light

from OFF to HI to adjust the intensity of the light while

cooking.

2 - Fan Control

The fan speed is controlled using a 5-position switch

(OFF, 1, 2, 3, and HI). Turn the fan control speed

from OFF to HI as needed.

3 - Fan Indicator Light

The fan indicator light comes ON when the fan is

turned ON.

4 - Heat Lamp Control

The heat lamp is controlled by its own ON/OFF

rocker switch. Press the rocker switch for the

warming lamps to begin heating.

12

43

12

43

– 6 –

Page 7

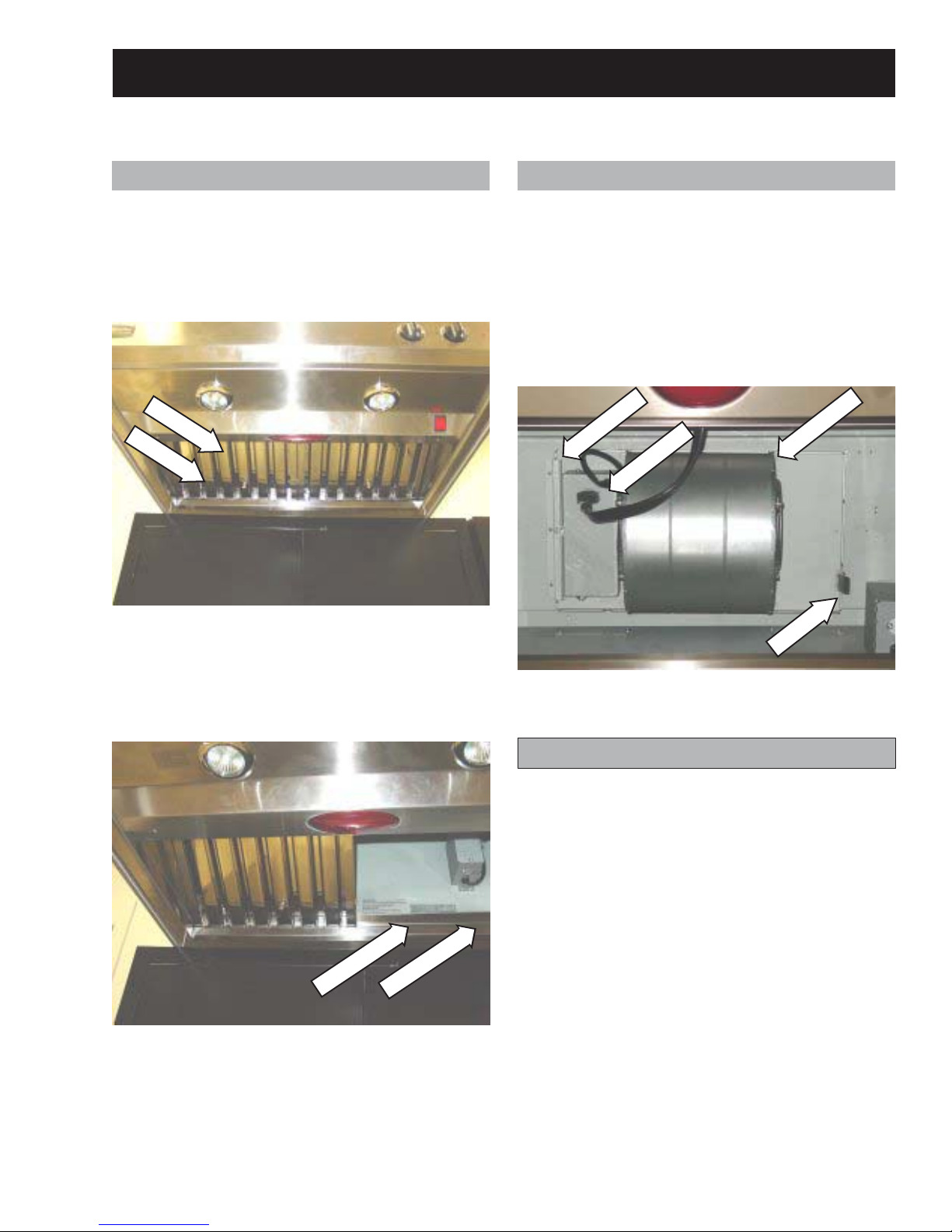

ZV30, ZV36, and ZV48 Components

Baffle Grease Filter and Drip T rays

Removal and Replacement

1. Grasp the 2 handle knobs. Slide the grease

filter forward and up until it clears the drip tray

and remove. Remove the drip trays.

Knob

Knob

Fan Motor

Removal and Replacement

1. Disconnect the electrical connector from the

fan motor.

2. Press back the motor mount retaining clip.

3. Slide the motor mount from the channel and

remove the fan motor .

Channel

Connector

Motor

2. Remove the 2 drip trays from drip tray

channel.

Drip Tray

Channel

Clip

Heat Lamp Panel

Removal and Replacement

WARNING: Heat lamp may be hot.

The bulb is a 120 volt, 175 watt, par-38 infrared

bulb. Part No. - WB08X10029.

1. Remove the heat lamp.

2. Remove the 2 screws from the heat lamp

panel, then lower the panel from the range

hood.

.

(Continued next page)

– 7 –

Page 8

Panel

Lamp

Screw

Screw

3. Disconnect the electrical connector and

remove the heat lamp panel.

Connector

Panel

Clamp

Clamp

3. Loosen the 2 wire retaining screws and

remove the wires from the heat lamp socket.

Socket

2 Screws

Heat Lamp Socket

Removal and Replacement

WARNING: Heat lamp socket may be hot.

T ech Tip: Use of a plastic putty knife or a taped

metal putty knife helps prevent scratching of

metal surfaces.

1. Remove the

2. Press the socket clamps in and pull the heat

lamp socket from the heat lamp panel.

Heat Lamp Panel.

Heat Lamp Switch

Removal and Replacement

1. Remove the

2. Press the switch clamps in and pull the

switch from the heat lamp panel.

3. Label and disconnect the 4 electrical

connectors from the heat lamp switch.

Heat Lamp Panel.

Clamps

Connectors

Switch

– 8 –

Page 9

Surface Lights

Removal and Replacement

WARNING: Surface light s may be hot.

The surface lights are 120 volt, 50 watt, par-16

halogen flood bulbs. Part No. WB08X10028.

1. Turn the trim ring counterclockwise until it falls

from the socket.

2. Remove the light from the socket.

Trim Ring

Trim Ring

4. Loosen the 2 wire retaining screws and

remove the wires from the surface light

socket.

Screw

Screw

Surface Light Sockets

Removal and Replacement

1. Remove the

2. Remove the

3. Press the socket clamps in and pull the

socket from the overhead light panel.

Heat Lamp Panel.

Surface Lights.

Clamp

Clamp

Socket

– 9 –

Page 10

Rotary Switch

Removal and Replacement

Note: The procedure to remove both the fan

rotary switch and the light rotary switch are

identical.

.

Note: Make sure the pin on the rotary switch is

aligned with the hole in the panel before installing

the nut.

1. Remove the

Heat Lamp Panel.

2. Pull the control knob from the rotary switch.

3. Remove the nut from the front of the rotary

switch

Nut

Switch

4. Reach behind the hood and pull the rotary

switch out to access the electrical

connectors.

5. Label and disconnect the 7 wires from the

rotary switch and remove the rotary switch.

Hole

Pin

Autotransformer

Removal and Replacement

1. Remove the

2. Remove the light switch control knob. (See

Rotary Switch.)

3. Remove the fan switch control knob. (See

Rotary Switch.)

4. Remove the 7 screws that hold the surface

light panel to the hood.

Heat Lamp Panel.

– 10 –

Page 11

5. Remove the 4 screws that hold the

autotransformer to the mounting bracket.

4 Screws

Bracket

6. Label and disconnect the 7 wires from the

autotransformer and remove the autotransformer.

Autotransformer

Socket

2 Terminal Lugs

3. Pull the indicator light socket from the red

indicator cap.

Cap

Fan Motor Indicator Light

Removal and Replacement

1. Remove the

2. Reach behind the hood and disconnect the 2

wires from the indicator light socket.

Heat Lamp Panel.

– 11 –

Page 12

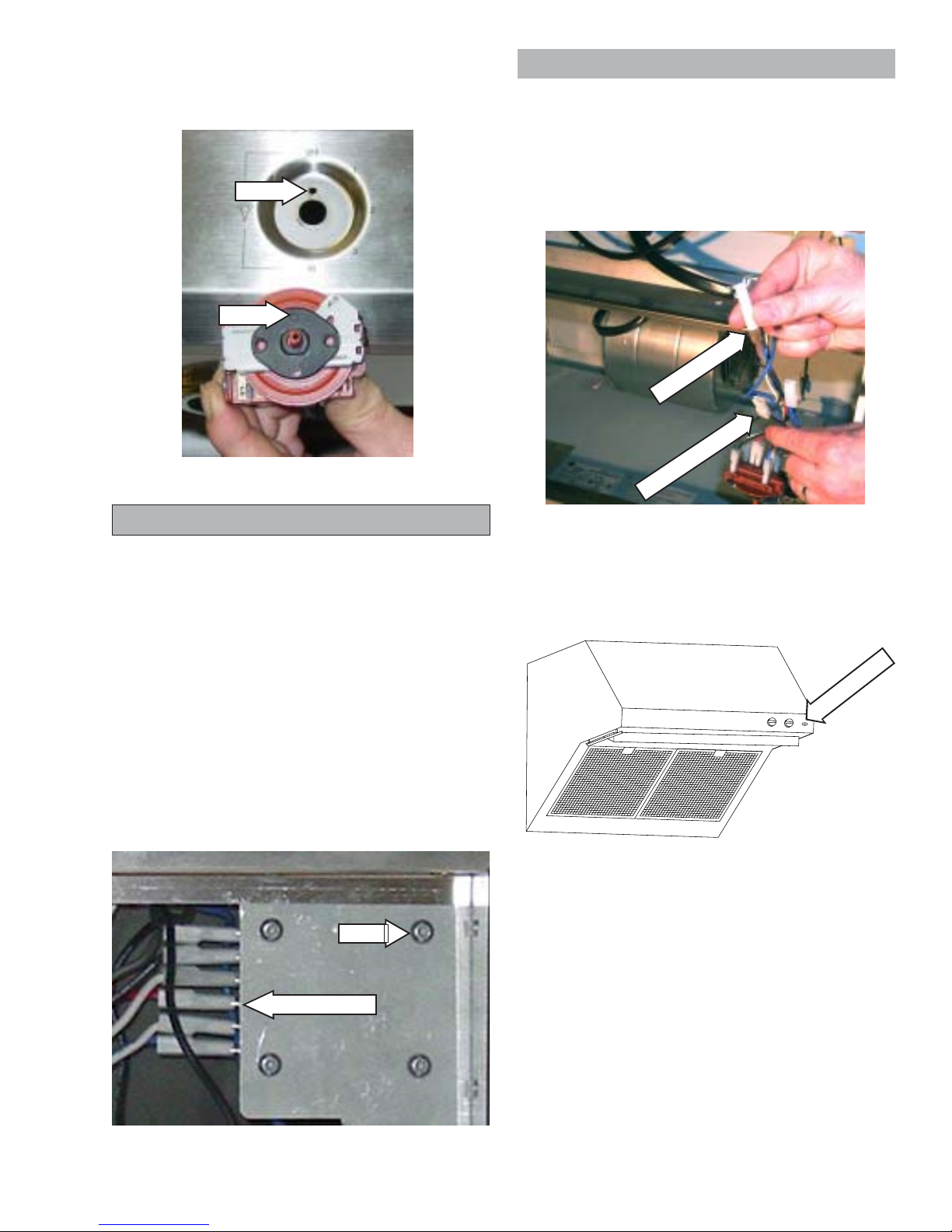

ZV30R, ZV36R, and ZV48R Component s

Grease Baffles

Removal and Replacement

1. Lift the tabs to release the baffles.

2. Remove the 2 baffles from the hood.

Tab

Fan Motor

Removal and Replacement

WARNING: Heat lamp may be hot.

Heat Lamp Panel

Removal and Replacement

WARNING: Heat lamp may be hot.

1. Remove the heat lamp.

2. Remove the 2 screws from the heat lamp

panel and lower the heat lamp panel from the

range hood.

screw

3. Disconnect the electrical connector and

remove the heat lamp panel.

screw

1. Disconnect the electrical connector from the

fan motor.

2. Press back the motor mount retaining clip.

3. Slide the motor mount from the channel and

remove the fan motor .

Clip

Disconnect

Heat Lamp Socket

Removal and Replacement

WARNING: Heat lamp socket may be hot.

1. Remove the

2. Press the socket clamps in and pull the heat

lamp socket from the heat lamp panel.

Heat Lamp Panel.

– 12 –

Page 13

Clamp

Clamp

3. Loosen the 2 wire retaining screws and

remove the wires from the heat lamp socket.

Clamps

4 Connectors

Switch

Surface Lights

Socket

2 Screws

Heat Lamp Switch

Removal and Replacement

1. Remove the

2. Press the switch clamps in and pull the

switch from the heat lamp panel.

3. Label and disconnect the 4 electrical

connectors from the heat lamp switch.

Heat Lamp Panel.

Removal and Replacement

WARNING: Surface light s may be hot.

1. Turn the trim ring counterclockwise until it falls

from the socket.

2. Remove the light from the socket.

Retainer

– 13 –

Page 14

Surface Light Sockets

Rotary Switch

Removal and Replacement

1. Remove the

Heat Lamp Panel.

2. Remove the surface lights.

3. Press the socket clamps in and pull the

socket from the surface light panel.

Clamp

Clamp

Socket

Removal and Replacement

Note: The procedure to remove both the fan

rotary switch and the light rotary switch are

identical.

1. Remove the

Heat Lamp Panel.

2. Pull the control knob off the rotary switch.

3. Remove the nut from the front of the rotary

switch.

Nut

4. Loosen the 2 wire retaining screws and

remove the wires from the overhead light

socket.

Screw

Screw

4. Reach behind the hood and pull the rotary

switch out to access the electrical

connectors.

5. Label and disconnect the 7 terminal lugs from

the rotary switch and remove the rotary

switch.

Connectors

Switch

6. Label and disconnect seven terminal lugs

from the rotary switch.

– 14 –

Page 15

Note: Make sure the pin on the rotary switch is

aligned with the hole in the panel before installing

the nut.

Fan Motor Indicator Light

Removal and Replacement

Hole

Pin

Autotransformer

Removal and Replacement

1. Remove the

2. Remove the light switch control knob. (See

Rotary Switch.)

Heat Lamp Panel.

1. Remove the

Heat Lamp Panel.

2. Reach behind the hood and disconnect the 2

wires from the indicator light socket.

Socket

2 Terminal Lugs

3. Pull the indicator light socket from the red

indicator cap.

3. Remove the fan switch control knob. (See

Rotary Switch.)

4. Remove four screws from the

autotransformer.

5. Label and disconnect seven terminal lugs

from the autotransformer.

Screw

Terminal Lugs

Cap

– 15 –

Page 16

Troubleshooting

Single Fan Motor (Use schematic SE1ANB)

The fan

does not

work.

! Do the lights work?

Yes

! Is the circuit breaker open or fuse blown?

No

No

Yes

Reset the circuit

breaker or replace th e

fuse.

! With the lamp switch set to OFF, is 120

volts present between pin (a) and pin (e)

on the fan motor switch?

No

Repair faulty wiring.

Yes

Disconnect power and remove the wires from

termi na ls from (a) and (e) on the fan motor switch.

! Can you turn the fa n bl ad e by ha n d?

No

Replace the fan motor.

Yes

Isolate the fan motor swit ch.

! With the fan motor switch set to (1), is continuity present between pin (a) and pin (1) on the fan motor switch?

! With the fan motor switch set to (2), is continuity present between pin (a) and pin (2) on the fan motor switch?

! With the fan motor switch set to (3), is continuity present between pin (a) and pin (3) on the fan motor switch?

! With the fan motor switch set to (HI), is continuity present between pin (a) and pin (4) on the fan motor switch?

! With the fan motor switch set to (1), is continuity present between pin (e) and pin (5) on the fan motor switch?

! With the fan motor switch set to (2), is continuity present between pin (e) and pin (5) on the fan motor switch?

! With the fan motor switch set to (3), is continuity present between pin (e) and pin (5) on the fan motor switch?

! With the fan motor switch set to (HI), is continuity present between pin (e) and pin (5) on the fan motor switch?

Yes

Isolate the fan motor swit ch.

! Is the resistence between the white wire and the red wire leading from the fan motor switch approximately 2.5 ohms?

! Is the resistence between the white wire and the grey wire leading from the fan motor switch approximately 4.7 ohms?

! Is the resistence between the white wire and the black wire leading from the fan motor switch approximately 8.3 ohms?

! Is the resistence between the white wire and the blue wire leadi ng from the fan motor switch approximately 14.2 ohms?

Yes

No

Replac e the fan m o tor

betw e en the terminal board

No

and the fan motor switch.

switch.

Repair faulty wiring

Locate the fan motor capacitor.

! Is the resistence between the brown wire and the yellow wire approximately 18.1 ohms?

Yes

Replace the capacitor. If the motor

fails to operate replace the motor.

Replace the fan motor.

No

Note: On dual motor models, if one of the

capacitors is open, or if the wires and/or

connections to the capacitor are open, the motors

will run slower than normal. If both capacitors are

open, then both motors will hum.

– 16 –

Page 17

Fan Motor Indicator Light

The fan

does not

work.

! D o the lig hts work?

Yes

! W ith the lamp sw itch set to OFF, is 120

volts present between pin (a) and pin (e)

on the fan moto r switch?

Yes

Disconnect power and remove the wires from

terminals from (a) and (e) on the fan motor switch.

! Can you turn the fan blade by hand?

Yes

Isolate the fan motor switch.

! W ith th e fan moto r switch set to (1), is con tinuity p resent bet ween pin (a) and pin (1) on the f an motor switch?

! W ith th e fan moto r switch set to (2), is con tinuity p resent bet ween pin (a) and pin (2) on the f an motor switch?

! W ith th e fan moto r switch set to (3), is con tinuity p resent bet ween pin (a) and pin (3) on the f an motor switch?

! W ith th e fan moto r switch set to (H I), is co ntinuity pr esent between pin (a) and pin (4) on the f an motor switch?

! W ith th e fan moto r switch set to (1), is con tinuity p resent bet ween pin (e) and pin (5) on the f an motor switch?

! W ith th e fan moto r switch set to (2), is con tinuity p resent bet ween pin (e) and pin (5) on the f an motor switch?

! W ith th e fan moto r switch set to (3), is con tinuity p resent bet ween pin (e) and pin (5) on the f an motor switch?

! W ith th e fan moto r switch set to (H I), is co ntinuity pr esent between pin (e) and pin (5) on the f an motor switch?

Yes

Isolate the fan motor switch.

! I s the resistence b etween th e white wire and the red w ire leadi ng from th e fan mo tor switch approximately 2.5 ohms?

! I s the resistence b etween th e white wire and the grey wire leading from the fan mo tor switc h approxim ately 4.7 ohms?

! I s the resistence b etween th e white wire and the black wire lea ding fro m the fan motor switch appro ximately 8.3 ohms?

! I s the resistence b etween th e white wire and the blue wire lea ding from the fan motor switc h appro ximately 14.2 ohms?

Yes

Locate the fan motor capa citor.

! I s the resistence b etween th e brown w ire and the yello w wire approximate ly 18.1 o hms?

Yes

Replace the capacitor. If the motor

fails to operate replace t he motor.

! Is the circuit breaker open or fuse blown?

No

No

No

No

Repai r faulty w iring.

Replac e the fan m otor.

Yes

Reset the cir cu it

breaker or replace the

fuse.

Replace the fan motor.

No

No

No

Replace the fan motor

switch.

Repai r faulty w iring

between the terminal board

and the fan motor switch.

Heat Lamp

! Is the circuit breaker open or fuse blown?

! Does the heat lamp bulb have continuity?

! Is 120 volts present between pin (4) and pin (1) on the heat lamp switch?

! Is continuity present between pin (2) on the heat lamp switch and terminal (L) on the heat lamp socket?

! Is continuity present between pin (5) on the heat lamp switch and terminal (N) on the heat lamp socket?

The heat

lamp does

not work.

No

Yes

Yes

Yes

Replace the heat lamp switch.

If the problem persists, replace

the heat lamp socket.

Yes

No

Reset the circuit

breaker or replace the

fuse.

Replace the lamp bulb.

No

Repair faulty wiring.

No

Repair faulty wiring.

– 17 –

Page 18

Surface Lights

One or both

of the

surface

lights do

not work .

! Is the circuit breaker open or fuse

blown?

Yes

Reset the circuit

breaker or replace the

fuse.

No

! Does the lamp bulb have continuity?

Repl a c e th e l amp bulb.

No

Yes

! With the lamp switch set to OFF, is 120 volts prese n t between pi n

(e) on the lamp switch and pin (6) on the autotransformer?

No

Repair faulty wiring.

Yes

Isolate the lamp switch.

! With the lamp switch set to (1), is continuity present between pin (a) and pin (1) on the lamp switch?

! With the lamp switch set to (2), is continuity present between pin (a) and pin (2) on the lamp switch?

! With the lamp switch set to (3), is continuity present between pin (a) and pin (3) on the lamp switch?

! With the lamp switch set to (HI), is continuity present between pin (a) and pin (4) o n the lamp switch?

! With the lamp switch set to (1), is continuity present between pin (e) and pin (5) on the lamp switch??

! With the lamp switch set to (2), is continuity present between pin (e) and pin (5) on the lamp switch?

! With the lamp switch set to (3), is continuity present between pin (e) and pin (5) on the lamp switch?

! With the lamp switch set to (HI), is continuity present between pin (e) and pin (5) o n the lamp switch?

Yes

! Is continuity present between pin (5) on the lamp switch and pin (1) on the autotransformer?

! Is continuity present between pin (4) on the lamp switch and pin (6) on the autotransformer?

! Is continuity present between pin (3) on the lamp switch and pin (5) on the autotransformer?

! Is continuity present between pin (2) on the lamp switch and pin (4) on the autotransformer?

! Is continuity present between pin (1) on the lamp switch and pin (3) on the autotransformer?

No

Yes

No

Repair faulty wiring.

Repl ace the

lamp switch.

Isolat e the lamp switc h.

! Is continuity present between pin (1) and pin (2) on the autotransformer?

! Is the resistence between pin (1) and pin (3) on the autotransformer approximately 3.2 ohms?

! Is the resistence between pin (1) and pin (4) on the autotransformer approximately 3.9 ohms?

! Is the resistence between pin (1) and pin (5) on the autotransformer approximately 4.4 ohms?

! Is the resistence between pin (1) and pin (6) on the autotransformer approximately 5.0 ohms?

Yes

! Is continuity present between lamp switch pin (a) and terminal (L) on both lamp sockets?

! Is continuity present between autotransformer pin (2) and terminal (N) on both lamp sockets?

Yes

Replace the faulty

lamp socket.

No

No

Replace the

autotransformer.

Repair faulty wiring.

– 18 –

Page 19

Schematics

All ZV30 and ZV36 - RSF1SS, SSF1SS, and TSF1SS Models

WARNING: Power must be disconnected before servicing the appliance.

– 19 –

Page 20

All ZV48 - RSF1SS, SSF1SS, and TSF1SS Models

WARNING: Power must be disconnected before servicing the appliance.

– 20 –

Page 21

Illustrated Parts

ZV30, ZV36, and ZV48 - SSF1SS Models

– 21 –

Page 22

ZV30, ZV36, and ZV48 - SSF1SS Models

VIEW

NUMBER

13 W B 02X10872 JUNCTION BOX COV E R 1

19 WB27X10669 CAPACITOR 1

23 WB02X10869 FILTER, BAFFLE 2

31 WB08X10028 120V 50W HALOGEN BULB 2

32 WB08X10030 LAMPHOLDER 2

84 WB20X10026 TRANSFORMER 1

87 W B 02X10871 DUCT TRANSITION W/ DAM P E R 1

103 WB38X10069 BLOWER ASSEMBLY 1

105 WB08X10032 LAMPHOLDER SUPPORT 2

117 WB08X10033 INDICATOR LIGHT 1

CATALOG

NUMBER

DESCRIPTION QUANTITY

133 W B 07X10607 HALOGE N LAM P P A NE L 30" 1

225 WB02X10832 MONOGRAM LOGO 1

226 WB01X10070 CLIP LOGO 2

234 WB24X10110 SWITCH, MOTOR/LAMP 2

236 WB03X10163 KNOB ASSEMBLY 2

291 W B 07X10608 HEA T LAMP P A NE L 30" 1

315 WB02X10870 GREASE TRAY 30" 2

512 W B 24X10111 HEA T-LAMP ROCKER SW ITCH 1

539 W B 02X10873 UTENSIL ROD-TAPER 30" 2

565 W B 08X10029 120V 175W INFRARE D LAM P 1

573 WB08X10031 BEZEL LAMP 2

574 WB01X10196 HARDWARE BAG 1

999 49-80150 USE & CARE M ANUA L 1

999 49-80151 INSTALL INSTRUCTION 1

– 22 –

Page 23

ZV30, ZV36, and ZV48 - TSF1SS Models

– 23 –

Page 24

ZV30, ZV36, and ZV48 - TSF1SS Models

VIEW

NUMBER

13 W B02X10872 JUNCTION BOX COVE R 1

19 WB27X10669 CAPACITOR 1

23 WB02X10869 FILTER, BAFFLE 2

31 W B 08X10028 120V 50W HALOGEN B ULB 2

32 WB08X10030 LAMPHOLDER 2

84 WB20X10026 TRANSFORMER 1

87 WB02X10871 DUCT TRANSITION W/DAMPER 1

103 WB38X10069 BLOWER ASSEMBLY 1

105 WB08X10032 LAMPHOLDER SUPPORT 2

117 WB08X10033 INDICATOR LIGHT 1

CATALOG NUMBER DES CRIPTION QUANTITY

133 WB07X10613 HALOGEN LAM P PA NE L 30" 1

225 WB02X10832 MONOGRAM LOGO 1

226 WB01X10070 CLIP LOGO 2

234 WB24X10110 SWITCH, MOTOR/LAMP 2

236 WB03X10163 KNOB ASSEMBLY 2

291 WB07X10608 HEAT LAMP PANE L 30" 1

315 WB02X10870 GREAS E TRA Y 30" 2

512 WB24X10111 HEAT-LAMP ROCKE R SWITCH 1

539 WB02X10873 UTENSIL ROD-TAPER 30" 2

565 WB08X10029 120V 175W INFRARED LAM P 1

573 WB08X10031 BEZEL LAMP 2

574 WB01X10196 HARDWARE BAG 1

999 49-80150 USE & CARE M ANUAL 1

999 49-80151 INSTALL INSTRUCTIONS 1

– 24 –

Page 25

ZV30, ZV36, and ZV48 - RSF1SS Models

– 25 –

Page 26

ZV30, ZV36, and ZV48 - RSF1SS Models

VIEW

NUMBER

13 WB02X10872 JUNCTION BOX COVER 1

19 WB27X10669 CAPACITOR 1

23 WB02X10897 FILTER, BAFFLE 2

31 W B08X10028 120V 50W HALOGEN BULB 2

32 WB08X10030 LAMPHOLDER 2

58 WB07X10660 SHELF 1

84 WB20X10026 TRANSFORMER 1

87 WB02X10871 DUCT TRANSITION W/DAMPER 1

103 WB38X10069 BLOWER ASSEMBLY 1

105 WB08X10032 LAMPHOLDER SUPPORT 2

117 WB08X10033 INDICATOR LIGHT 1

CATALOG

NUMBER

DESCRIPTION QUANTITY

209 WB61X10004 BACK SPLASH 1

225 WB01X10070 CLIP LOGO 1

225 WB02X10832 MONOGRAM LOGO 1

234 WB24X10110 SWITCH, MOTOR/LAMP 2

236 WB03X10163 KNOB ASSEMBLY 2

291 WB 07X10608 HEA T LAMP PA NEL 30" 1

315 WB02X10899 GREASE TRAY 30" 2

512 WB24X10111 HEAT-LAMP ROCKER SWITCH 2

539 WB02X10900 UTENSIL ROD-TAPER 30" 2

565 WB 08X10029 120V 175W INFRARED LAMP 1

573 WB08X10031 BEZEL LAMP 2

574 WB01X10211 HARDWARE BAG 1

999 49-80152 USE & CARE 1

999 49-80150-1 INSTALLATION 1

– 26 –

Page 27

Notes

– 27 –

Page 28

Notes

Loading...

Loading...