72R-1000

9/05

ZTX Series Automatic Transfer Switches

40-400 Amps

GE Zenith Controls

Operation and Maintenance Manual

e

Page

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1ii

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Equipment Inspection and Storage . . . . . . . . .11

Final Equipment Inspection . . . . . . . . . . . . . . .11

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Power Connections . . . . . . . . . . . . . . . . . . . . . .12

Engine Start Control Connections . . . . . . . . .13

Exerciser Option . . . . . . . . . . . . . . . . . . . . . . . .14

Functional Test . . . . . . . . . . . . . . . . . . . . . . . . .15

Jumper Positions . . . . . . . . . . . . . . . . . . . . . . . . .6

Control Interface . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Indicator LED’s . . . . . . . . . . . . . . . . . . . . . . . . .17

Pushbuttons . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Using the Keypad Controls . . . . . . . . . . . . . . . .18

Automatic Generator Exerciser . . . . . . . . . . . .19

In-Phase Monitor Operation . . . . . . . . . . . . .110

Page

Example Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Partial Coverage Systems . . . . . . . . . . . . . . . . .11

Total Coverage Systems . . . . . . . . . . . . . . . . . . .11

Typical Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Power Circuit Schematic . . . . . . . . . . . . . . . . . .12

Power Panel Layout . . . . . . . . . . . . . . . . . . . . . .12

Interconnect Plug . . . . . . . . . . . . . . . . . . . . . . .12

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . .13

Standard Transition 40-200 Amps . . . . . . . . . .13

Standard Transition 225-400 Amps . . . . . . . . .14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Table of Contents

Authorized Service

For GE parts and service, call: 773 299-6600

Introduction

GE Zenith Transfer Switches are used to provide a continuous source of power for lighting and other critical loads by automatically transferring from source 1 power to source 2 power in the event that source 1 voltage falls below preset limits.

Voltage sensing and system control is performed via a state-of-the-art microcontroller located on the cabinet door.

It is designed to give highly accurate control of the transfer switch system.

All GE Zenith transfer switches are designed for use on emergency or standby systems, and are rated for total system or

motor loads. Transfer switches are UL Listed under Standard 1008 and CSA Certified under Standard C22.2 No. 178 and

IEC Listed under Standard 947.

NOTES: A protective device such as a molded case circuit breaker or fused

disconnect switch MUS

T be installed on both sources of incoming

power for circuit protection and as a disconnection device.

All references made within this manual about the term “S1” or

“Source 1” relate to a Normal Power Source. All references made

about the term “S2” or “Source 2” relate to an Emergency

or Alternative Power Source.

■■

GE Zenith Controls 1

■■

ZTX Operation and Maintenance Manual (72R-1000)

Each GE Zenith transfer switch is factory wired and

tested. A complete information package is furnished

with each switch which includes:

a. Sequence of operation.

b. Description and operation of

all accessories supplied.

c. Power panel connection diagram

and schematic.

d. Description and identification of

all customer field connections.

Installation of GE Zenith transfer switches includes:

a. Mounting the transfer switch cabinet.

b. Connection of all Normal, Emergency,

and Load cables or bus bars.

c. Connection of external control

circuits as required.

Mounting

Enough room should be allowed to open the cabinet doors

fully for inspection and servicing of the switch per NEC and

local codes.

Installation

DANGER

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

The safe operation of your switch is GE Zenith’s focus.

The proper storage, installation, operation and maintenance will help increase the life of the switch.

Equipment Inspection

and Storage

Once you have received the transfer switch, inspect

it for any damage. This includes damage to the enclosure, power panel, control panel and wiring harness. If

any damage is found or suspected, file a claim as soon as

possible with the carrier and notify the nearest

GE Zenith

representative.

Before installation, it is necessary to store the transfer

switch in a clean dry place, protected from dirt and

water. Provide ample air circulation and heat, if

necessary, to prevent condensation.

5% to 95%

(non-condensing)

-30°C to

+75°C

(-22°F to

+167°F)

-20°C to +65°C

(-4°F to +149°F)

Operating

Storage Temperature

Temperature (Ambient): Humidity

CAUTION

Due to hazardous voltage and current, GE Zenith rec-

ommends that a

GE Zenith Certified technician or a

qualified electrician must perform the

installation and maintenance of the switch.

Final Equipment Inspection

Prior to energizing the transfer switch:

1. Remove any debris incurred, with a vacuum,

due to shipment or installation.

WARNING

Do not use a blower since debris may

become lodged in the electrical and

mechanical components and cause damage.

2. Verify that all cabled connections are correct.

3. Check engine start connections and verify

the correct connection of all control wires.

4. Check the lug torque values of the power

connections.

NOTE

: Lug torque values are specified

in the power panel manual.

5. Make sure that all covers and barriers are

installed and properly fastened.

NOTE: Power panels ship from GE Zenith

in the Normal Position.

CAUTION

Before drilling conduit entry holes or any

accessory mounting holes, cover and protect

the switch and control panel to prevent dirt

and metal fragments from entering the

mechanical and electrical components.

Failure to do so may result in

damage and malfunction of the switch.

NOTE: When lifting the switch using a spreader bar,

height H must be equal to half of distance D.

■■

2 GE Zenith Controls

■■

ZTX Operation and Maintenance Manual (72R-1000)

OR

S

Y

S

3N3

3

r

ON

T

Y

ON

T

A

OR

Install

load

cables

first.

Tip!

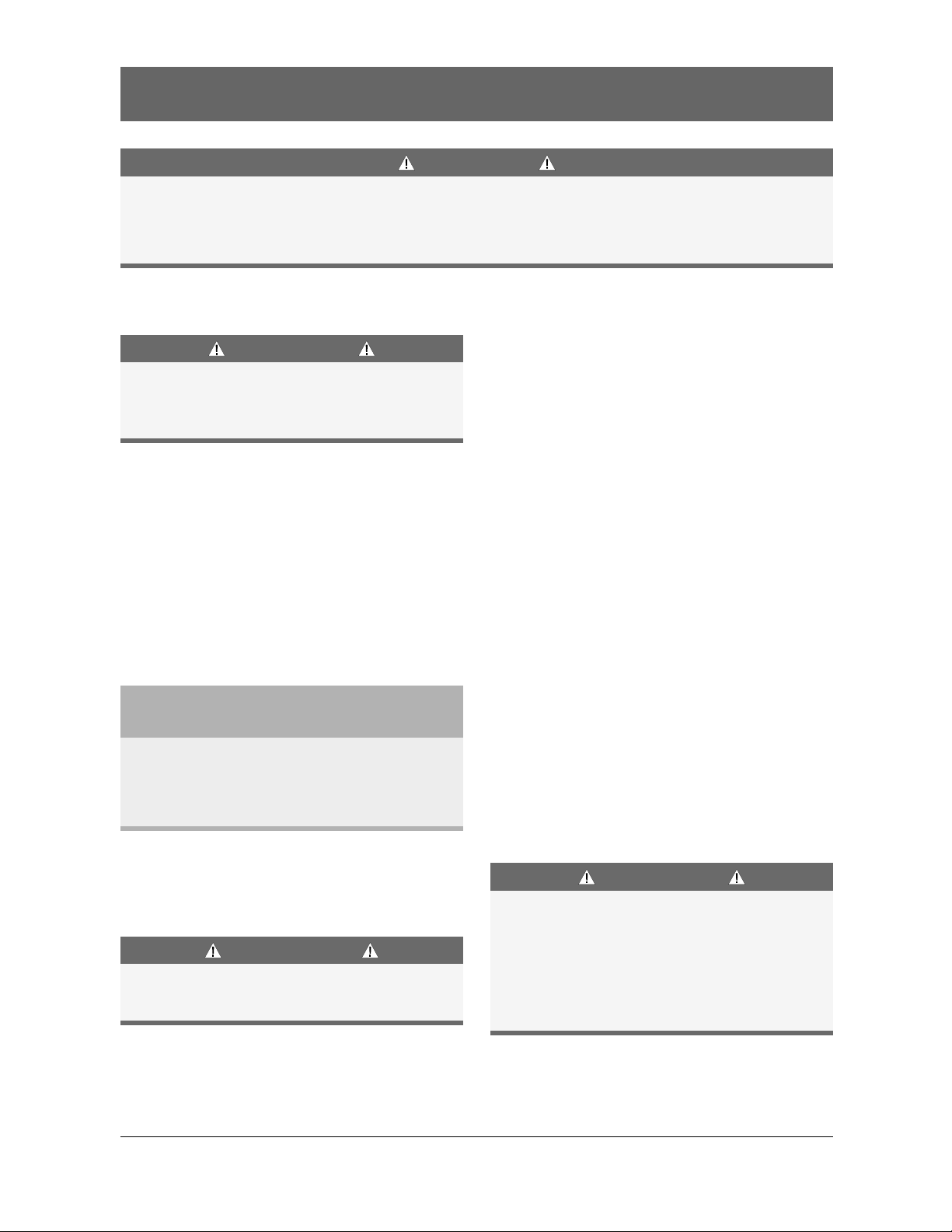

Table 1

Screw Type Terminals for External Power Connections

Switch Size

(Amps)

40

80

100

150

Utility, Generator and Load Terminals

1 #8 to 3/0 AWG

Cable Per Pole Range of Wire Sizes

1 #8 to 3/0 AWG

1 #8 to 3/0 AWG

1 #8 to 3/0 AWG

Fully Rated Neutral Bar (When Required)

3 #8 to 1/0 AWG

No. of Cables Range of Wire Sizes

3 #8 to 1/0 AWG

3 #8 to 1/0 AWG

3 #8 AWG to 300 MCM

200, 225, 250*

300, 400

1 #6 AWG to 250 MCM

1 #4 AWG to 600 MCM

3 #6 AWG to 300 MCM

3 #4 AWG to 300 MCM

* IEC Rating Only

Installation

(cont’d)

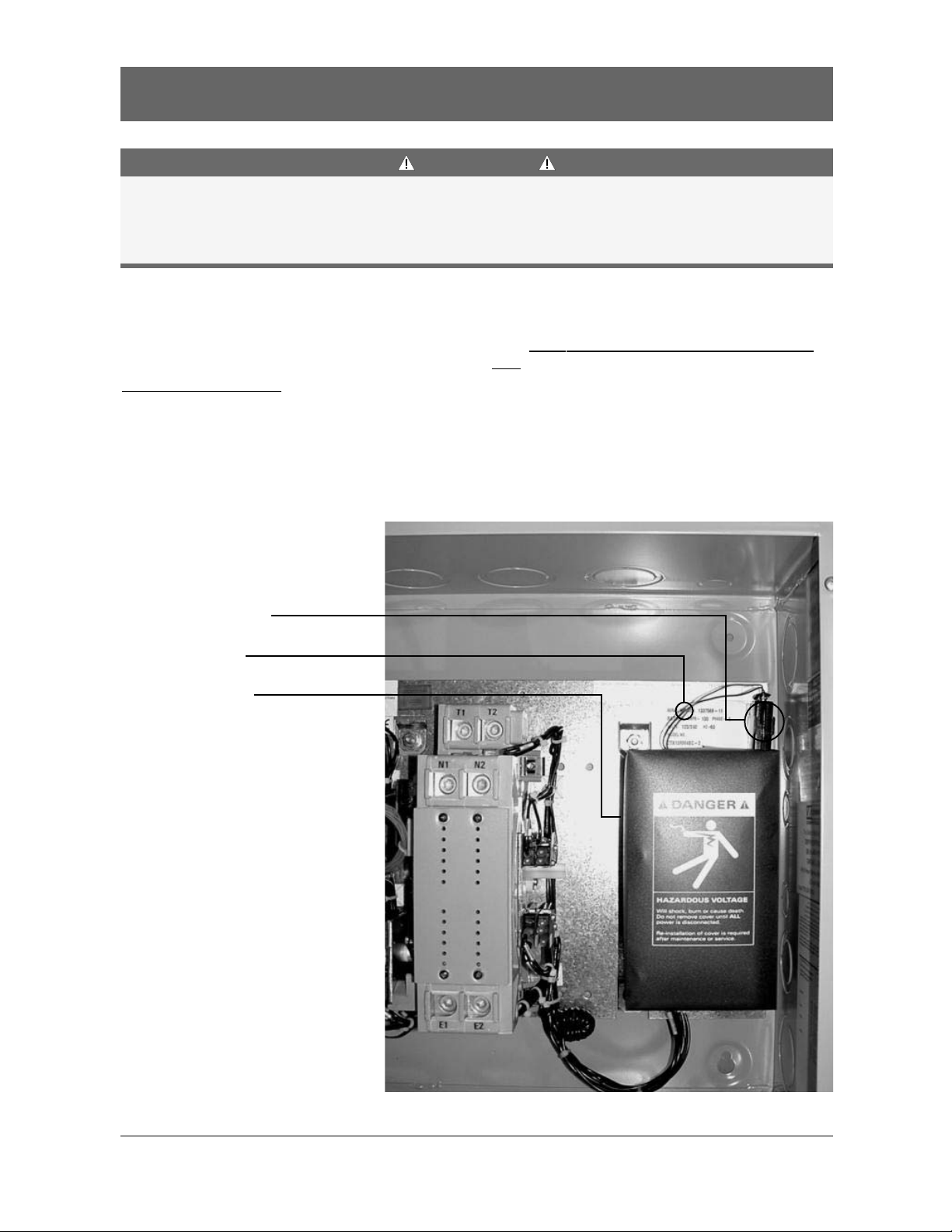

Figure 1 - Power Panel

Power Connections

GE Zenith transfer switches are supplied with UL listed

solderless screw type terminals as standard for the

Normal, Emergency and Load power connections.

Table 1 lists the number and sizes of cable lugs supplied

as standard for each switch amp rating.

DANGER

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

Connect the Normal, Emergency, and Load conductors

to the clearly marked terminals on the transfer switch.

Remove surface oxides from cables by cleaning with a

wire brush. Verify that all connections are correct before

tightening the lugs. All cable lug connections must be

tightened to the proper torque values as shown in Table 2.

NOTE: Do not run cables or wiring behind

front-connected transfer switches.

TERMINALS

TILIT

TERMINAL

LOAD

T

I

ERA

ILIT

SWITCH

POSITION

INDICAT

E

TI

ERA

GENERAT

TERMINAL

T = Load N = Utility E = Generato

NER

■■

GE Zenith Controls 3

■■

ZTX Operation and Maintenance Manual (72R-1000)

Installation

(cont’d)

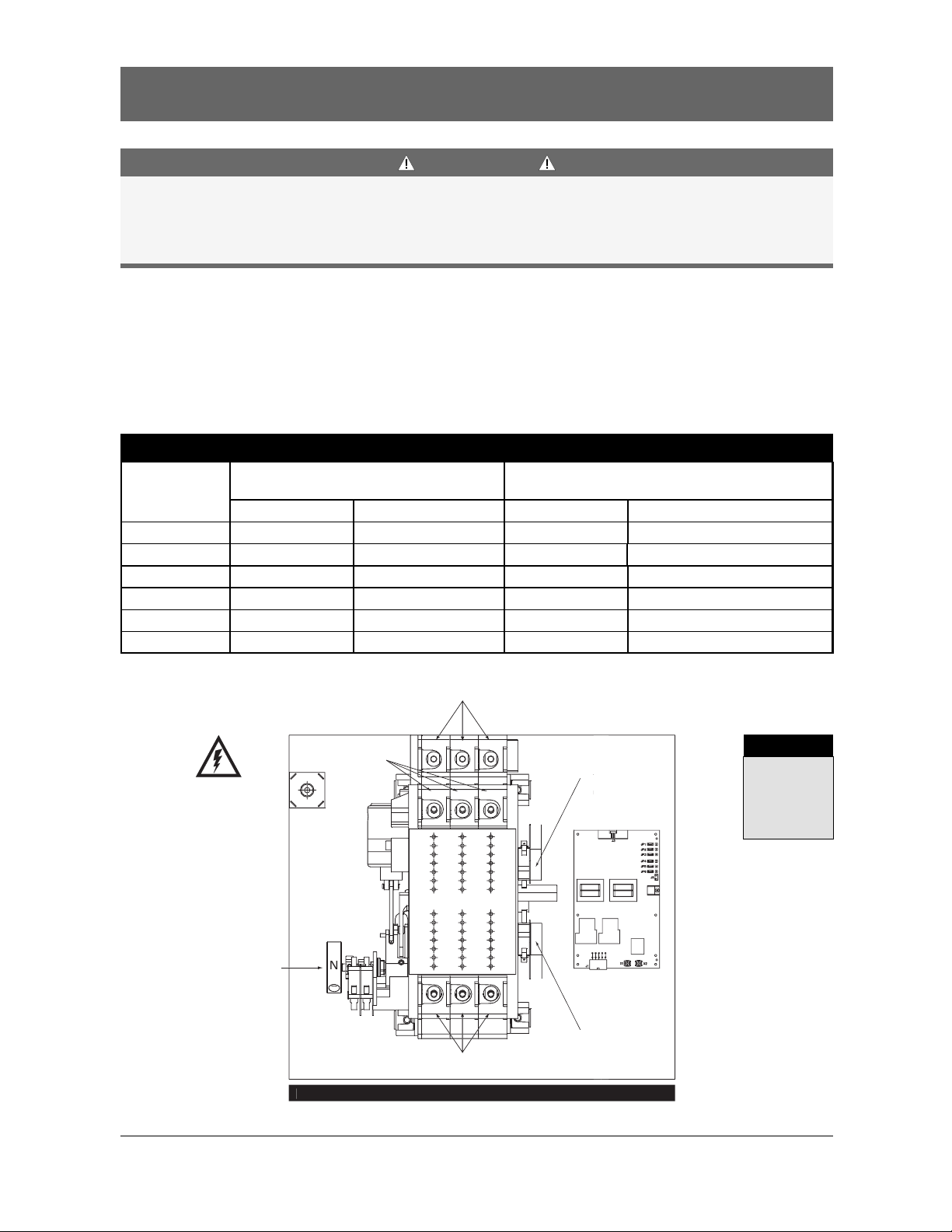

Control Connections

Connecting Engine Start may cause Generator to

start. Before connecting, turn Generator OFF.

With the Generator breaker open and the Generator

control switch off, install the Generator start connections.

Note:

N = Utility Position

E = Generator Position

Manual operation is possible for maintenance purposes only.

Manual operation of the switch can be checked before it

is operated electrically.

With all power off, insert a Phillips screwdriver or equivalent

size tool into the manual operator socket and operate

the transfer switch between the Utility and Generator

positions. The transfer switch should operate smoothly

without binding. Return the switch to the Utility position,

remove the screwdriver.

Figure 4

Table 2

Tightening Torque for Lugs

Socket Size

Across Flats

Torque

Lb. - In. Lb. - Ft.

451/8 4

1005/32 8

1203/16 10

1507/32 12

2001/4 17

2755/16 23

3753/8 31

5001/2 42

6009/16 50

The engine-start terminals are clearly identified by a

label on the microcontroller backplate. In the case of

manual transfer switches, or in other applications not

requiring the microprocessor, clearly marked terminal

blocks are provided in the upper left corner of the control

panel for the engine start control wires.

Terminals for field connections to the A3 Emergency

auxiliary contacts and the A4 Normal auxiliary contacts

are also provided. These terminals are clearly marked

and appear on the side of the power panel. On 400 amp

metal frame units these terminals appear on the bracket

above the operator handle.

DANGER

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

Figure 3

g

SERIAL NUMBER:

RA

TING

: VOLTS -

AMPS -

SYSTEM VOLTS:

MODEL NUMBER:

HZ -

PHASE -

GE Zenith Controls

Figure 2

JP

Battery

Connection

■■

4 GE Zenith Controls

■■

ZTX Operation and Maintenance Manual (72R-1000)

Installation

(cont’d)

DANGER

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

ATTENTION!

This applies only to the switches with the RM4-CAT

exerciser option:

Only after ATS installation, connect a commercial-grade

alkaline 9V battery to the MX60 controller via the harness connected to the controller. The battery should be

placed in the holder installed just above the controller.

The battery is used to maintain the exerciser function in

the event of power outage. The battery should be

replaced at least once a year. If the battery is not

installed and/or replaced as recommended, an

exerciser set from the front panel will lose its settings

during power outages and the exerciser will not work.

Note: Batter

y life if reduced if neither source is available. Typical battery life when both sources are

unavailable is 21 days.

Should the battery connection become disconnected

in shipping, take the controller cover off and plug the

harness into the receptacle in the top right corner of

the MX controller as shown in figure 2 and 5. Reinstall

the cover and connect the battery.

Battery and Holder

Battery Harness

MX60 Controller

(Under Cover)

Figure 5

■■

GE Zenith Controls 5

■■

ZTX Operation and Maintenance Manual (72R-1000)

Functional Test

Functional testing of the automatic transfer switch

(ATS) is described in this section. Before proceeding,

read and understand all instructions and review the

operation of all accessories provided.

To begin the test, close the Utility source circuit breaker.

Referring to Figure 7, the controller will illuminate the

Utility Available LED when proper voltage is sensed. If

the ATS mechanism is set on S1, the S1 position LED

will also light.. Verify the phase to phase voltages at the

Utility line terminals.

Next, close the Generator source breaker and start the

engine generator. The S2 (Generator) Available LED

will illuminate when proper voltage and frequency levels

are sensed. After both sources have been verified, shut

down the engine generator, and put the generator’s start

control in the automatic position. Complete the visual

inspection of the transfer switch, and replace the cabinet

cover (or close the cabinet door).

Simulate a utility outage by opening the S1 Utility side

breaker. The delay to engine start timer (P) begins its

timing cycle. After the P timer has completed its timing

cycle, the engine start contacts close to start the generator.

When generator voltage and frequency reach the preset

restore points (see Table 4) the S2 Available LED illumi-

nates. Simultaneously, the delay to generator timer (W)

begins its timing cycle. When the W time delay is completed the ATS will transfer to Generator, the S1 position

LED goes off, and the S2 position LED illuminates.

Reclose the Utility breaker to retransfer to utility. The

delay to utility timer (T) begins its timing cycle (Table

3). When the T timer has completed its timing cycle, the

ATS will transfer. The optional S2 position LEDs go off,

and the S1 position LED illuminates. The delay engine

stop timer (U) begins its timing cycle. The generator

runs unloaded for the duration of the U timing cycle.

When the timer completes its timing cycle, the generator

will stop. The S2 Available LED goes off.

Installation

(cont’d)

Table 3

DANGER

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

ATS Timing Cycle

Action P Timer W Timer T Timer U Timer

P - 5 sec. W - 20 sec. T - 5 min. U - 5 min.

S1 Fail or Time Delay Time Delay Time Delay Time Delay

Test or S2 Start S2 Stable S1 Stable S2 Stop

Exerciser

Transfer to S2 Retransfer to S1 Engine Cool-Down

S1 returns or Test/Exerciser Ends

Table 4

Preset Settings

Utility Generator

S1 Fail Voltage 80% Nominal Line Voltage S2 Fail Voltage 80% Nominal Line Voltage

S1 Restore 90% Nominal Line Voltage S2 Restore Voltage 90% Nominal Line Voltage

S1 Fail Frequency 80% S2 Fail Frequency 90%

S1 Restore Frequency 90% S2 Restore Frequency 95%

Timers

P Timer W Timer T Timer U Timer

P - 5 sec. W - 20 sec. T - 5 min. U - 5 min.

■■

6 GE Zenith Controls

■■

ZTX Operation and Maintenance Manual (72R-1000)

Installation

(cont’d)

DANGER

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

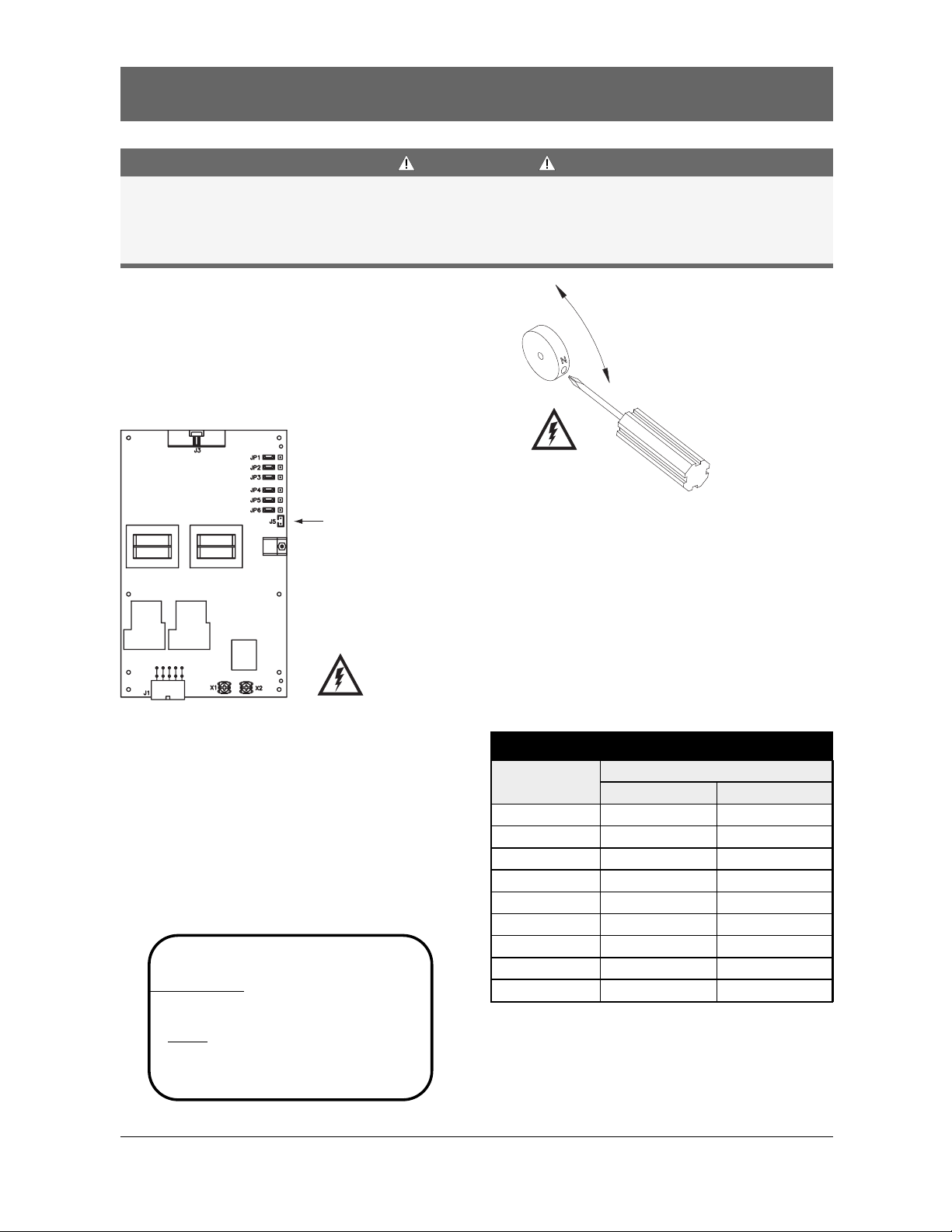

System Voltage Settings

ZTX controller boards are preconfigured to the system

voltages specified at the time of order. Exact system voltages are normally set at the factory, however, depending on the actual application and system nominal voltage, ZTX control boards are capable of being adjusted

slightly, to meet different source characteristics for

voltage as well as frequency. (See Table 5)

Figure 6 (on right) shows the variations each of the 3

basic types of controllers can be adjusted to within its

nominal voltage range. Position Jumpers JP1 and JP2,

as needed for voltage. Position JP3 for frequency.

As with any other Jumper setting, always remove power

completely from the controller before making changes.

Note: Do not change voltage Jumper positions

without consulting service or technical support.

Arbitrarily changing voltage jumpers can adversely

affect ATS operation.

Type 1 Type 2 Type 3 Type 4 Frequency

120V 208 - 240VAC 380 - 416VAC 440 - 480VAC

JP1 JP2 JP1 JP2 JP1 JP2 JP1 JP2 JP3

B B 208 A B 380 B B 440 B A 50 Hz A

- - 220 B A 416 A B 480 A A 60 Hz B

- - 240 A A - - - - - - - -

Table 5

Figure 6

Voltage / Frequency Selection Jumper Settings

240/480

JP1

JP2

BA

208/416

JP1

JP2

BA

50Hz

JP3

BA

120/380

JP1

JP2

BA

220/440

JP1

JP2

BA

60Hz

JP3

BA

■■

GE Zenith Controls 7

■■

ZTX Operation and Maintenance Manual (72R-1000)

Control Interface

Pushbuttons

TEST - Pressed and held for 1 second Simulates

a power outage, starts the Generator and

transfers the ATS to S2.

EXER SET - Sets an Automatic Exerciser

BYPASS TIMER - Pressed while E is blinking

bypasses any remaining countdown Timer

CANCEL - Depending on the current state of ATS

operation, ends specific functions or indications

A

B

D

C

E

G H IF

Indicator LEDs

S1 (Utility) Available Green LED. When on, indicates source is acceptable.

S1 (Utility) Position Green LED. When on, indicates ATS is connected to Utility

S2 (Generator) Available Red LED. When on, indicates source is acceptable.

S2 (Generator) Position Red LED. When on, indicates ATS is connected to Generator.

Timing/In-phase Amber LED. When blinking, indicates the ATS is timing a Delay

When on steady, indicates the ATS is waiting for both

sources to synchronize with each other.

Figure 7

A

B

C

D

E

F

G

H

I

DANGER

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

Using the Keypad Controls

TEST KEY

The TEST KEY initiates a transfer sequence to S2 and

holds the ATS in that mode until either the CANCEL

key is pressed or, a situation arises to cause the ATS to

go back to S1(ie, S2 actually fails).

In order to perform a TEST, the ATS must be on S1 and

S1 must qualify as a "good source" by being above the

FAIL thresholds for both Voltage and Frequency (see

Table 2).

Once the TEST KEY is pressed for at least 1 Sec, the

ATS will begin the Timer Sequence (see figure 5),

attempt to start S2 generator source, and if S2

qualifies as a "good source", transfer the load to S2.

(There is no P-Time in a test)

The TEST key is typically used to perform a system

operational or maintenance test or, to purposely cause

and hold the Load off of S1. If during the TEST, S2

fails and S1 is available, the TEST will be cancelled and

the Load will be immediately retransferred to S1.

EXER SET

Whenever it is required to have a regular test

performed automatically on a repeating basis, the

Automatic Exerciser function can be setup using

this key.

Depending on the jumper settings shown in Figure 8,

the ATS can be programmed to perform a repeating 7,

14, 21 or 28 day exercise at a particular time of day.

To initiate an Automatic Exercise, the EXER SET key

is pressed and held for at least 1 Sec. at the desired

exercise time. The ATS will begin the Timer Sequence,

attempt to start S2 generator source and if S2 qualifies

as a good source, transfer the Load to S2 for the duration of the Generator Run-Time. After the Generator

Run-time has expired, the timing sequence will restart

and the Load will be transferred back to S1, after Ttime, ending by running the U-time and finally ending

the call for S2.

■■

8 GE Zenith Controls

■■

ZTX Operation and Maintenance Manual (72R-1000)

Control Interface

(cont’d)

DANGER

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

TIMER BYPASS

This key is used to bypass (truncate), any of the running

timers shown in Table 3. Whenever the Timing/

Inphase LED is blinking, pressing the TIMER BYPASS

will end that particular delay and cause the ATS controller to immediately jump to the next sequence step.

Note: The BYPASS key cannot be used to truncate an

In-phase transfer sequence, or the P-Timer.

CANCEL

The CANCEL key performs 3 different cancel actions

depending on the ATS current state of operation:

1. If the ATS is currently performing a TEST,

the CANCEL key will cancel the test.

2. If an Automatic Exerciser has been set, pressing and holding the CANCEL key for 10 Sec.

will cancel (and remove), the set exercise

3. If after in-phase monitor has passed 1 minute,

waiting for sources to synchronize, will cause

transfer immediatly (which may result in an

out-of-phase transfer).

■■

GE Zenith Controls 9

■■

ZTX Operation and Maintenance Manual (72R-1000)

Control Interface

(cont’d)

Figure 8

Automatic Generator Exerciser

The ZTX automatic generator Exerciser can perform a

pre-scheduled repeating test of the generator and/or

the ATS mechanism depending on which jumpers are

selected on the controller board. Additionally, the ATS

can be preset to perform the exercise every 7, 14, 21

or 28 days. Regardless of which interval is selected, all

exercisers have a preset run-duration of 10 minutes.

Selection of the exerciser interval is through three

jumpers located on the controller board as shown in

Figure 6. The Exerciser comes from the factory preset

at 28 days and is not active. To change the exerciser

interval, remove power from the controller completely,

and move the jumpers at positions jp4 and jp5 to match

the selected repeat-cycle from the configurations shown

in Figure 7.

Selecting Exerciser with or without Load Transfer

The Exerciser function can be programmed to perform

either a Load-transfer or a non-Load transfer. Selecting

either is done by changing the Jumper JP6 as shown in

Figure 8. To change between a Load-transfer or no-Load

transfer, remove power from the controller completely

and move the jumper at position JP6.

Setting and Canceling an Exerciser

In order to set an automatic Exerciser, choose the exerciser interval and whether a Load-transfer or no-Load

transfer is desired as stated above. An exercise can only

be set if S1 is available and the ATS (and Load), is on S1

source.

To establish an Exerciser

At the exact time desired, press and hold the EXER SET

key for at least 1 second. The ATS will immediately start

an initial exercise by attempting to start the generator,

running through the Timers (figure 3) and will either

only start the generator, or, will start the generator and

transfer the Load from S1 to S2, for the time duration

of the exerciser interval, 10 minutes. Once the Exercise

is completed, the ATS will continue the timing sequence

and retransfer the Load back to S1, cool down the generator and terminate until the next scheduled interval

time. Any time an Exerciser has been established and is

scheduled, the S2 Available and S2 position LEDs quickly blink approximately every 4 seconds as a reminder.

However, if S2 source becomes available during the time

DANGER

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

the ATS is waiting for the next impending exercise, the

ATS will not show a blinking indication but instead will

show the S2 Available LED as solidly on to indicate the

true condition of S2. Any Exercise event can be prematurely canceled by pressing the CANCEL key.

Note: pressing the CANCEL key in the middle of an

scheduled event does not cancel a set Exerciser, but

only cancels the current event.

To completely clear an already-set Exerciser

A set Exerciser can be completely cleared out of

memory by pressing and holding the CANCEL key

for at least 10 Seconds causing the blink indication

to stop.

If S2 fails to meet the criteria for a good source,

during an Exercise attempt, the Controller will

continue to hold the P-contacts closed for the

duration of the Runtime timer then wait for the next

scheduled exercise. If S2 fails during an Exercise, the

Controller will abort that exercise and wait till then

next scheduled exercise.

Automatic Exerciser Jumper Settings

7 Day

JP4

JP5

BA

21 Day

JP4

JP5

BA

14 Day

JP4

JP5

BA

28 Day

JP4

JP5

BA

JP6

JP6

BA

No Load

Load

■■

10 GE Zenith Controls

■■

ZTX Operation and Maintenance Manual (72R-1000)

Control Interface

(cont’d)

In-Phase Monitor

ZTX ATS senses when the sources are as far out as 2 Hz

or as close as .01Hz in frequency differential of each

other and transfers the load to and from either source

in-phase. If turned on, R50 In-Phase monitor tracks the

frequency of both the Utility and Generator sources

allowing a smooth, synchronous transfer of the load,

which is especially beneficial where conveyors, pumps

and other motor loads are involved. ZTX indicates it is

waiting for the sources to synchronize by holding the

Timer/In-Phase LED on. When both sources have synchronized, the ATS will transfer the Load (within 20° of

each other, if sources are within 2Hz differential), and

the Timer/In-Phase LED will turn off. If the sources fail

to synchronize, after 1 minute, the controller will blink

the Timer/In-Phase LED once, alerting the operator

that the In-Phase monitor function can be bypassed by

pressing the CANCEL key, causing an immediate transfer (see Cancel Key function). If the CANCEL key is

not pressed, the ZTX will continue to wait for an inPhase condition to occur.

In a typical ATS application, one source is on the utility

and one source is a backup system such as a gas or

diesel generator. Because sources have a slight

frequency difference, sources come in and out of phase.

If ZTX In-Phase Monitor is on, The ZTX ATS Controller

monitors both sources and transfers the Load at the

ideal time to minimize back-EMF conditions.

DANGER

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

In the case of both sources coming from the same

source, or, one configured as WYE and the other as

DELTA, the frequency difference is fixed at the same

frequency or fixed but 30 degrees out of phase.

In those cases, In-Phase Monitor can be turned off.

In-Phase Monitor is turned on as default from the

factory. To turn In-Phase Monitor OFF or ON, take

the following steps:

Turn In-Phase Monitor OFF:

1. Remove all power, (both S1 and S2) from

the controller. Wait at least 20 seconds.

2. From the keypad, hold both the BYPASS and

CANCEL keys down while energizing either

source. If In-Phase Monitor was on, the Timer

/ In-phase LED will flash once for 1 second,

then go out. The In-Phase Monitor is now off.

Turn In-Phase Monitor ON:

1. Remove all power, (both S1 and S2) from

the controller. Wait at least 20 seconds.

2. From the keypad, hold both the BYPASS and

CANCEL keys down while energizing either

source. If In-Phase Monitor was off, the

Timer/In-Phase LED will light and remain lit

until the keys are released. The In-Phase

Monitor is now on.

Timer / In-phase LED

Figure 9

■■

GE Zenith Controls 11

■■

ZTX Operation and Maintenance Manual (72R-1000)

Example Systems

Partial Coverage System

Total Coverage System

Figure 9

Figure 10

Loads

Utility

Source

Utility Panel

Transfer Switch

Generator

Circuit

Breaker

Distribution Panel

Source

Loads

Utility

Source

Circuit

Breaker

Transfer Switch

Circuit

Breaker

Main

Breaker

Panel

Generator

Source

All Loads

■■

12 GE Zenith Controls

■■

ZTX Operation and Maintenance Manual (72R-1000)

Typical Diagrams

OM

3

3

0

Power Circuit Schematic 40-240 Amps

Power Panel Layout Interconnect Plug

Figure 11

Figure 12

Figure 13

C

PTIONAL

N

1

■■

GE Zenith Controls 13

■■

ZTX Operation and Maintenance Manual (72R-1000)

Replacement Parts

3

Standard Transition — 40 to 200 Amps

TAG DESCRIPTION

VOLTAGE

CN/CE Solenoid

Solenoid Plunger and Link

SCN/SCE Coil Cutout Switch

A3/A4 Auxiliary Contacts

120

208

220

240

380/416

440/480

K-2207

K-2208

K-2208

K-2228

K-2212

K-2209

ALL 57P-1030

120-480V L-3078

L-3078

SCN/SCE

Coil Cutout Switch

600V L-4027

BR

Rectifier

ALL PS-5076

40 TO 200 AMPS

Figure 14

Table 7

BR

CN/CE

SP+L

A

SCN/SCE

■■

14 GE Zenith Controls

■■

ZTX Operation and Maintenance Manual (72R-1000)

Replacement Parts

(cont’d)

Standard Transition - 225 to 400 Amps

ge

g

n

d

s

*

*

00

g

,2,

,2,

Size

#4-6

#4-6

s

6B

E

SEPo

h

4

s

er

6

#

Figure 15

Table 8

BR

CN/CE

T1 T2 T3 TN

E1 E2 E3 EN

N1 N2 N3 NN

SN

A4

SE

A3

Ta

1,2,3 N

E 1

3 N

T 1

3 N

CN/C

N/

A3/A

Descriptio

Cable Connection Lu

Wire

lenoid

sition Sense Limit Switc

Auxiliary Contact

Rectifi

Recommende

as Spare

225, 250

-2701

6-250 MCM

il Volt

08/220/240 K-224

Stock Numbers by Ampera

260, 300

-2701

00 MCM

L-3078

PS-507

4

-2701

00 MCM

■■

GE Zenith Controls 15

■■

ZTX Operation and Maintenance Manual (72R-1000)

Troubleshooting

Symptom Possible Cause Corrective Action

S1 or S2 Available LED not lit Sources either fully or partially unacceptable Check for under voltage

S1 or S2 breakers open Check for missing phase (s)

Check for under frequency

ATS will not retransfer Load T - Timer has not expired

back to Utility Automatic Exerciser is in process

S1 Utility fully or partially unacceptable

ATS does not transfer Load to S2 S2 Generator fully or partially unacceptable Set motor-saver to dropout below

(generator) Motor loads on system creating enough back- ATS Fail setpoint

EMF to keep missing phase from falling below

Fail setpoint.

S2 Generator will not start X1 or X2 not connected Check Generator Start wiring

S2 Generator will not shut down U - Timer not expired Wait for U timer to expire

Automatic Exerciser in process

All LEDs off Keypad connector unplugged at Controller

Both source breakers open

ATS will not transfer in-phase In-Phase monitor not on Turn on In-Phase monitor

Frequency difference between S1 and Adjust Generator governor to hold

S2 greater than 2Hz. freqency closer to Utility

ATS will not retain a Battery dead or missing Replace battery with a fresh industrial

Set Automatic Exerciser grade Alkaline battery

Timer/In-Phase LED constantly on Both sources locked in frequency or one Turn In-Phase monitor off

source greater than 20° out of phase

S1 and S2 LEDs Blinking Phase Rotation Mis-match between sources Rewire sources to be same rotation

S1 Position LED Blinking SN limit switch bad or intermittent Check connection or SN limit switch

S2 Position LED Blinking SE Limit switch bad or intermittent Check connection or SE limit switch

Both S1 and S2 Positioin Solenoid bad or disconnected Requires CANCEL key to clear LEDs Blinking ATS contactor in mid-position check Solenoid

Requires CANCEL key to clear Check both limit switches

Service must be performed by qualified personnel.

DANGER

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

Table 9

A Product of GE Consumer & Industrial

General Electric Company

830

West 40

th

Street, Chicago, IL

60609 USA

773 299-6600, Fax: 773 247-7805

www.geelectrical.com

g

GE Zenith Controls

Loading...

Loading...