g

62R-2000C

7/02

ZTX SERIES

40-400 Amps

GE Zenith Controls

Operation and Maintenance Manual

Page

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1ii

How to Remove the Cover . . . . . . . . . . . . . . . . . . .11

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Equipment Inspection and Storage . . . . . . . .12

Final Equipment Inspection . . . . . . . . . . . . . .12

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Power Connections . . . . . . . . . . . . . . . . . . . . .13

Engine Start Control Connections . . . . . . . . .14

RM4 Exerciser Option . . . . . . . . . . . . . . . . . .15

Functional Test . . . . . . . . . . . . . . . . . . . . . . . .16

RMF Control Interface . . . . . . . . . . . . . . . . . . . . . .17

Optional Indicator LED’s . . . . . . . . . . . . . . . .17

Optional Pushbuttons . . . . . . . . . . . . . . . . . . .17

Automatic Transfer Generator Testing . . . . . .18

Transfer Generator Testing . . . . . . . . . . . . . . .18

LED Diagnostic Flash Codes . . . . . . . . . . . . . .18

Automtic Generator Exerciser . . . . . . . . . . . .19

Selecting Exercisor without Transfer . . . . . . .19

Selecting Exercisor with Transfer . . . . . . . . . .19

Page

Engine Controller Accesoory Board . . . . . . . . . . .110

Example Systems . . . . . . . . . . . . . . . . . . . . . . . . . .11

Partial Coverage Systems . . . . . . . . . . . . . . . . .11

Total Coverage Systems . . . . . . . . . . . . . . . . . .11

Typical Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . .12

Power Circuit Schematic . . . . . . . . . . . . . . . . .12

Power Panel Layout . . . . . . . . . . . . . . . . . . . . .12

Interconnect Plug . . . . . . . . . . . . . . . . . . . . . .12

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . .13

General Troubleshooting . . . . . . . . . . . . .13, 14

Table of Contents

Introduction

GE Zenith Transfer Switches are used to provide a continuous source of power for lighting and other critical loads by

automatically transferring from the normal source of power to an emergency source of power in the event that the normal source voltage falls below preset limits.

Voltage sensing and system control is performed via a state-of-the-art microcontroller located on the cabinet door. It is

designed to give highly accurate control of the transfer switch system.

All GE Zenith transfer switches are designed for use on emergency or standby systems, and are rated for total system or

motor loads. Transfer switches are UL Listed under Standard 1008 and CSA Certified under Standard C22.2 No. 178 and

IEC Listed under Standard 947.

NOTE

: A protective device such as a molded care circuit breaker or fused

disconnect switch MUST be installed on both sources of incoming

power for circuit potection and as a disconnection device.

Authorized Service

For GE parts and service, call: 773 299-6600

■■

GE Zenith Controls 1

■■

ZTX Operation and Maintenance Manual (62

R-2000)

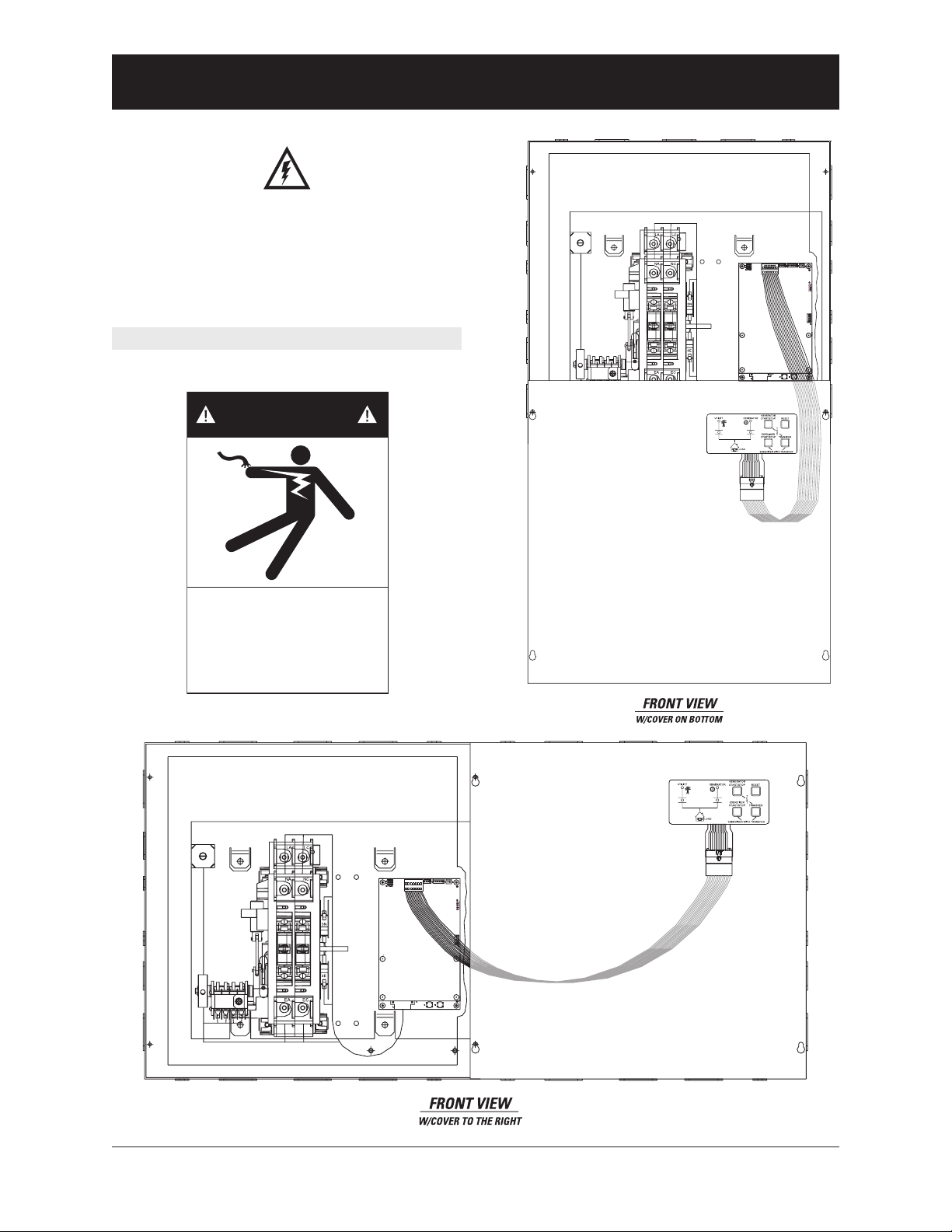

How to Remove the Cover

Loosen but do not remove four cover screws. Lift cover

off the four screws and hang on two screws (2 bottom

or 2 right-hand). See Figure i and ii.

This will prevent damage to the cable. The cable may

also be disconnected at the controller or keypad.

Figure i

Figure ii

NOTE: Reattach cable before installing cover.

DANGER

HAZARDOUS VOLTAGE

Will shock, burn or cause death.

Do not remove cover until ALL

power is disconnected.

Re-installation of cover is required

after maintenance or service.

■■

2 GE Zenith Controls

■■

ZTX Operation and Maintenance Manual (62

R-2000)

Each GE Zenith transfer switch is factory wired and

tested. A complete information package is furnished

with each switch which includes:

a. Sequence of operation.

b. Description and operation of

all accessories supplied.

c. Power panel connection diagram

and schematic.

d. Description and identification of

all customer field connections.

Installation of GE Zenith transfer switches includes:

a. Mounting the transfer switch cabinet.

b. Connection of all Normal, Emergency,

and Load cables or bus bars.

c. Connection of external control

circuits as required.

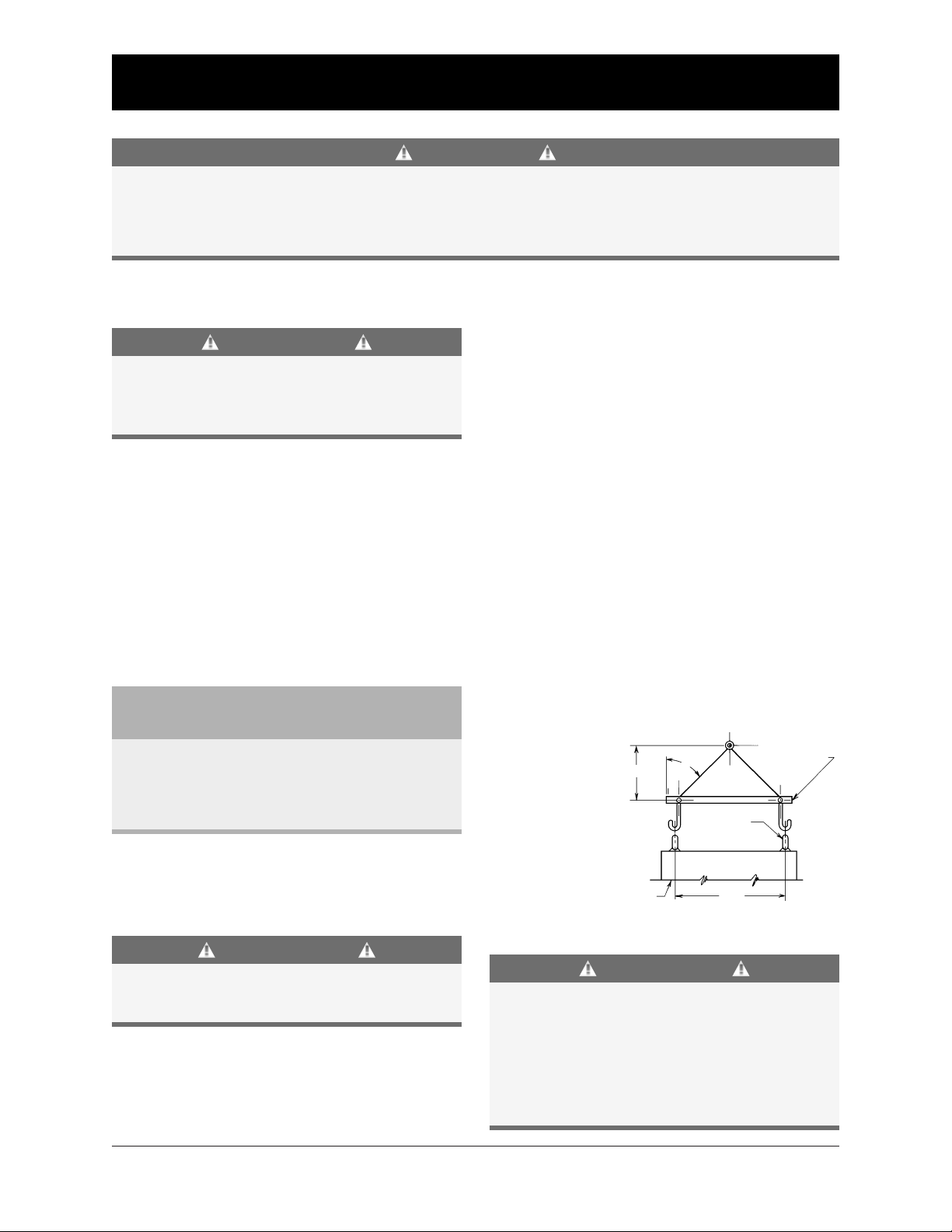

Mounting

Adequate lifting means must be used to mount the transfer

switch into place. The recommended method for moving

the transfer switch using the lifting eyes, where supplied,

and a spreader bar is

illustrated here.

Enough room should

be allowed to open

the cabinet doors

fully for inspection

and servicing of the

switch per NEC and

local codes.

Installation

DANGER

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

The safe operation of your switch is GE

Zenith’s focus.

The proper storage, installation, operation and maintenance will help increase the life of the switch.

Equipment Inspection

and Storage

Once you have received the transfer switch, inspect

it for any damage. This includes damage to the enclosure, power panel, control panel and wiring harness. If

any damage is found or suspected, file a claim as soon as

possible with the carrier and notify the nearest

GE Zenith

representative.

Before installation, it is necessary to store the transfer

switch in a clean dry place, protected from dirt and

water. Provide ample air circulation and heat, if necessary, to prevent condensation.

5% to 95%

(non-condensing)

-30°C to

+75°C

(-22°F to

+167°F)

-20°C to +65°C

(-4°F to +149°F)

Operating

Storage Temperature

Temperature (Ambient): Humidity

CAUTION

Due to hazardous voltage and current, GE Zenith rec-

ommends that a

GE Zenith Certified technician or a

qualified electrician must perform the

installation and maintenance of the switch.

Final Equipment Inspection

Prior to energizing the transfer switch:

1. Remove any debris incurred, with a vacuum,

due to shipment or installation.

WARNING

Do not use a blower since debris may

become lodged in the electrical and

mechanical components and cause damage.

NOTE: Lug torque values are specified

in the power panel manual.

5. Make sure that all covers and barriers are

installed and properly fastened.

NOTE: Power panels ship from GE Zenith

in the Normal Position.

CAUTION

Before drilling conduit entry holes or any

accessory mounting holes, cover and protect

the switch and control panel to prevent dirt

and metal fragments from entering the

mechanical and electrical components.

Failure to do so may result in

damage and malfunction of the switch.

D

CABINET

LIFTING EYES

SPREADER BAR

H

45°

NOTE: When lifting the switch using a spreader bar,

height H must be equal to half of distance D.

2. Verify that all cabled connections are correct.

3. Check engine start connections and verify

the correct connection of all control wires.

4. Check the lug torque values of the power

connections.

■■

GE Zenith Controls 3

■■

ZTX Operation and Maintenance Manual (62

R-2000)

Install

load

cables

first.

Tip!

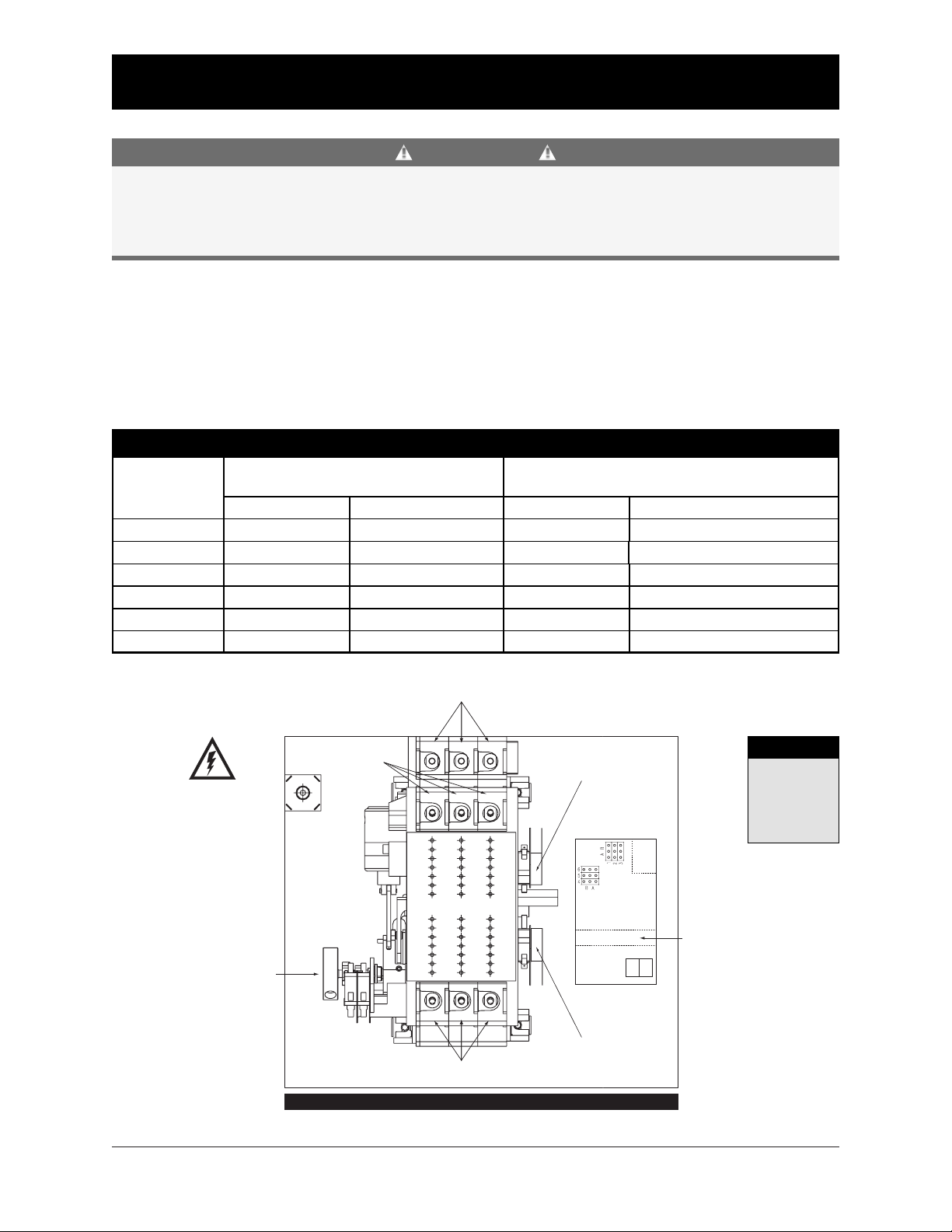

Table 1

Screw Type Terminals for External Power Connections

Switch Size

(Amps)

40

80

100

150

Utility, Generator and Load Terminals

1 #8 to 3/0 AWG

Cable Per Pole Range of Wire Sizes

1 #8 to 3/0 AWG

1 #8 to 3/0 AWG

1 #8 to 3/0 AWG

Fully Rated Neutral Bar (When Required)

3 #8 to 1/0 AWG

No. of Cables Range of Wire Sizes

3 #8 to 1/0 AWG

3 #8 to 1/0 AWG

3 #8 AWG to 300 MCM

200, 225, 250*

300, 400

1 #6 AWG to 250 MCM

1 #4 AWG to 600 MCM

3 #6 AWG to 300 MCM

3 #4 AWG to 300 MCM

* IEC Rating Only

Installation

(cont’d)

Figure 2 - Power Panel

Power Connections

GE Zenith transfer switches are supplied with UL listed

solderless screw type terminals as standard for the

Normal, Emergency and Load power connections.

Table 1 lists the number and sizes of cable lugs supplied

as standard for each switch amp rating.

DANGER

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

Connect the Normal, Emergency, and Load conductors

to the clearly marked terminals on the transfer switch.

Remove surface oxides from cables by cleaning with a

wire brush. Verify that all connections are correct before

tightening the lugs. All cable lug connections must be

tightened to the proper torque values as shown in Table 2.

NOTE

: Do not run cables or wiring behind

front-connected transfer switches.

TERMINALS

LOAD

UTILITY

TERMINALS

BR

T1 T2 T3

N1 N3

N2

OPTIONAL A4 CONTACT

OPERATES WHEN IN

UTILITY POSITION

JP

Exerciser

CONTROLLER

SWITCH

POSITION

INDICATOR

N

E3

E2

E1

GENERATOR

TERMINALS

T = Load N = Utility E = Generator

ENGINE

START

OPTIONAL A3 CONTACT

OPERATES WHEN IN

GENERATOR POSITION

OPTIONAL ENGINE CONTROLS

OR AIR CONDITION DISCONNECT

OR 3 PHASE BOARD

3 AND 4 POLE ONLY

■■

4 GE Zenith Controls

■■

ZTX Operation and Maintenance Manual (62

R-2000)

Installation

(cont’d)

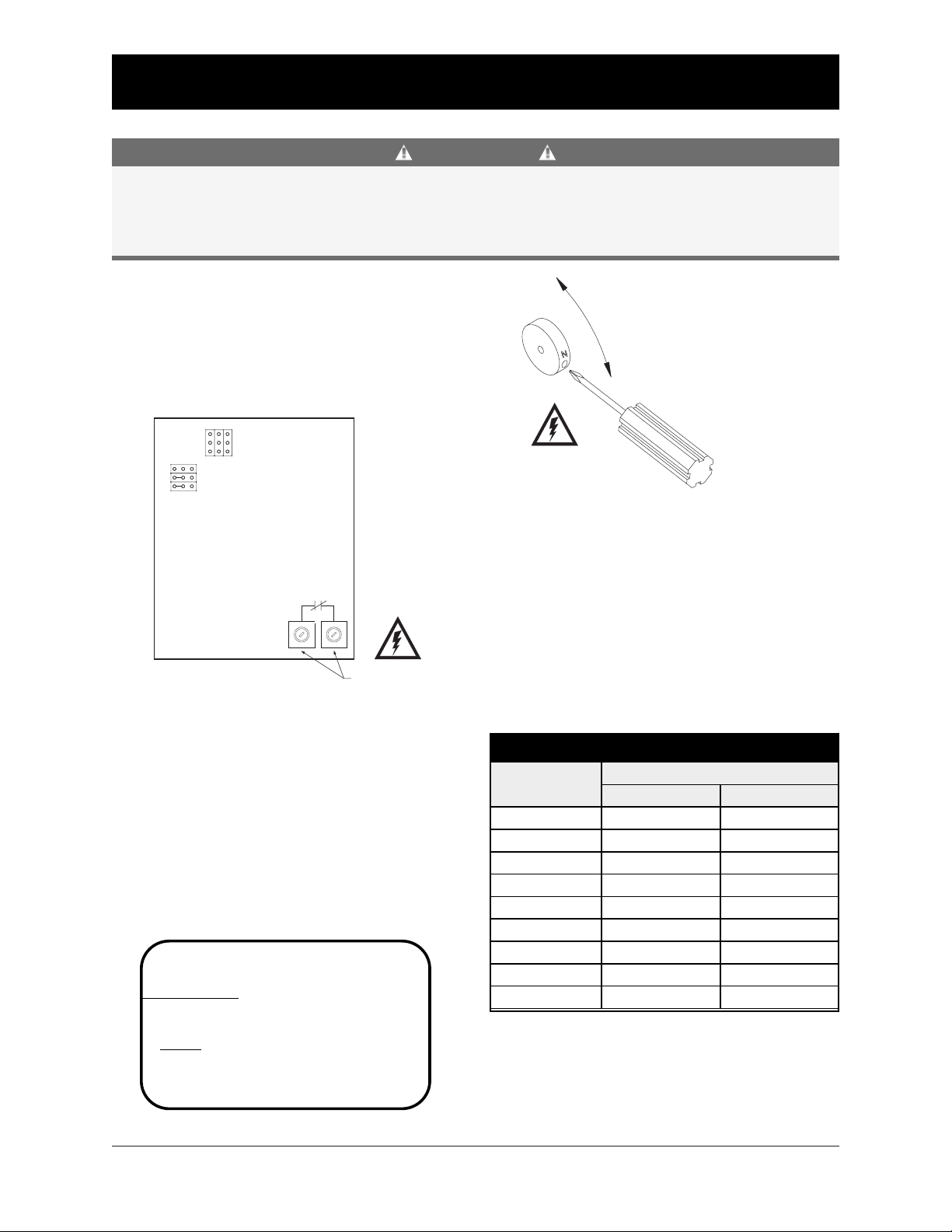

Control Connections

Connecting Engine Start may cause Generator to

start. Before connecting, turn Generator OFF.

With the Generator breaker open and the Generator

control switch off, install the Generator start connections.

Note:

N = Utility Position

E = Generator Position

Manual operation is possible for maintenance purposes only.

Manual operation of the switch can be checked before it

is operated electrically.

With all power off, insert a Phillips screwdriver or equivalent

size tool into the manual operator socket and operate

the transfer switch between the Utility and Generator

positions. The transfer switch should operate smoothly

without binding. Return the switch to the Utility position,

remove the screwdriver.

Figure 3

Figure 4

Table 2

Tightening Torque for Lugs

Socket Size

Across Flats

Torque

Lb. - In. Lb. - Ft.

451/8 4

1005/32 8

1203/16 10

1507/32 12

2001/4 17

2755/16 23

3753/8 31

5001/2 42

6009/16 50

The engine-start terminals are clearly identified by a

label on the microcontroller backplate. In the case of

manual transfer switches, or in other applications not

requiring the microprocessor, clearly marked terminal

blocks are provided in the upper left corner of the control

panel for the engine start control wires.

Terminals for field connections to the A3 Emergency

auxiliary contacts and the A4 Normal auxiliary contacts

are also provided. These terminals are clearly marked

and appear on the side of the power panel. On 400 amp

metal frame units these terminals appear on the bracket

above the operator handle.

DANGER

HAZARDOUS VOLTAGE

(Can Cause Severe Injury or Death)

Turn OFF all power before installation, adjustment, or removal of transfer switch or any of its components.

Figure 3

g

SERIAL NUMBER:

RA

TING

: VOLTS -

AMPS -

SYSTEM VOLTS:

MODEL NUMBER:

HZ -

PHASE -

GE Zenith Controls

JP

AB

B

Exerciser

123

A

6

5

4

CONTROLLER

Close to Start

Opens to Stop

Engine Start

Contact Output

Contact Rating

28Vdc @ 5 amps

Loading...

Loading...