Page 1

GE Monogram ®

Installation

Instructions

Stainless Steel

Built-In

Refrigerators

Models

ZISS3b'D SS, ZISS3b'N SS

ZISS42D SS, ZISS42N SS

ZISS48D SS, ZISS48N SS

Page 2

Contents

Before you begin - Read these instructions completely and carefully.

IMPORTANT - Save these instructions for local inspector's use.

IMPORTANT- OBSERVE ALL GOVERNING CODES AND ORDINANCES.

Note to Installer - Be sure to leave these instructions with the Consumer.

Note to Consumer - Keep these instructions with your Use and Care Book for future reference.

fl?11? This appliance must be properly grounded. See "Grounding the Refrigerator," page 6. I

Cet appareil doit 6tre correctement mis _ la terre.

Consulter <<Mise _ terre du r6frig6rateur >_,page 6.

If you have a question concerning the installa-

tion of this product, call the GE Answer

Center :'_Consumer Information Service at

800.626.2000, 24 hours a day, 7 days a week.

If you received a damaged refrigerator, you

should immediately contact your dealer or

builder

Proper installation is the responsibility of the

installer. Product failure due to improper

installation is not covered under the GE

Appliance Warranty. See the Use & Care

Guide for warranty information.

For Monogram local service in your area,

1-800-444-1845.

For Monogram Service in Canada,

1-800-880-3030.

For Monogram Parts and Accessories, call

1-800-626-2002.

Design Information

Flush or Semi-Flush Enclosure Installations ................................................................................... 3

Enclosure Cutout and Product Dimensions ................................................................................... 3

Installation Examples ........................................................................................................................ 4

Installation Preparation

Product Dimensions & Clearances .................................................................................................. 5

Water Connection Location, Electrical ........................................................................................... 5

Accessories ......................................................................................................................................... 5

Grounding the Refrigerator ............................................................................................................. 6

Tools Required .................................................................................................................................. 7

Materials Required ............................................................................................................................ 7

Hardware Supplied ........................................................................................................................... 7

Optional Hardware ........................................................................................................................... 7

Flooring .............................................................................................................................................. 7

Step 1: Remove Packaging ................................................................................................................ 7

Installation Instructions

Step 2: Install Water Line ................................................................................................................. 8

Step 3: Install Side Panels ................................................................................................................ 9

Step 4: Roll Refrigerator into Opening ........................................................................................... 9

Step 5: Level Refrigerator ............................................................................................................... 10

Step 6: Secure Refrigerator Case Trim to Side Panels ................................................................. 10

Step 7: Connect Water Supply ........................................................................................................ 11

Step 8: Connect Power .................................................................................................................... 11

Step 9: Mount Top Grill Panel ....................................................................................................... 11

Step 10: Arrange Interior ............................................................................................................... 12

Step 11: Set Temperature Controls ................................................................................................ 12

Step 12: Start Icemaker ................................................................................................................... 12

Step 13: Install Toekick ................................................................................................................... 13

Problem Solving .............................................................................................................................. 15

• Use this appliance only for its intended

purpose.

• Immediately repair or replace electric service

cords that have become flayed or damaged.

• Unplug the refrigerator before cleaning or

making repairs.

• Repairs should be made by a qualified service

technician.

• I1 ne faut utiliser cet appareil que pour l'usage

pour lequel il a _t_ construit.

• I1 faut r_parer ou remplacer imm_diatement

tout cordon d'alimentation _lectrique

effiloch_ ou endommag_.

• D_brancher le r_ffig_rateur avant le nettoyage

ou route intervention.

• Les r_parations doivent _tre faites par un

technicien qualifi_.

Page 3

Design Information

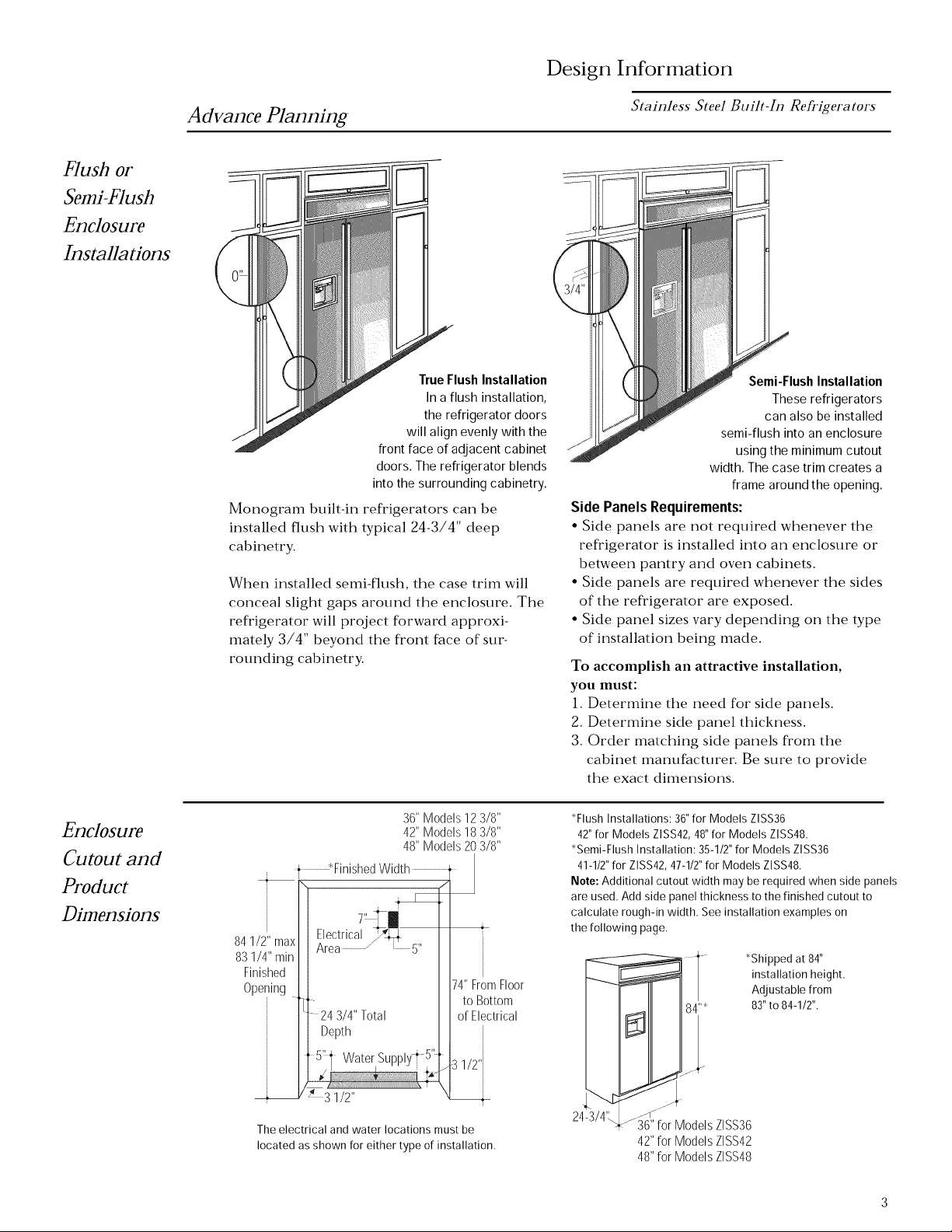

Flush or

Semi-Flush

Enclosure

Installations

Advance Planning

I

i

True Flush Installation

In a flush installation,

the refrigerator doors

will align evenly with the

front face of adjacent cabinet

doors. The refrigerator blends

into the surrounding cabinetry.

Monogram built-in refrigerators can be

installed flush with typical 24-3/4" deep

cabinetry.

When installed semi-flush, the case trim will

conceal slight gaps around the enclosure. The

refrigerator will project forward approxi-

mately 3/4" beyond the front face of sur-

rounding cabinetry.

Stainless Steel Built-In Refrigerators

Semi-Flush Installation

These refrigerators

can also be installed

semi-flush into an enclosure

using the minimum cutout

width. The case trim creates a

frame around the opening.

Side PanelsRequirements:

• Side panels are not required whenever the

refrigerator is installed into an enclosure or

between pantry and oven cabinets.

• Side panels are required whenever the sides

of the refrigerator are exposed.

• Side panel sizes vary depending on the type

of installation being made.

To accomplish an attractive installation,

you must:

1. Determine the need for side panels.

2. Determine side panel thickness.

3. Order matching side panels from the

cabinet manufacturer. Be sure to provide

the exact dimensions.

Enclosure

Cutout and

Product

Dimensions

36" Models 12 3/8"

42" Models 18 3/8"

48" Models 20 3/8"

, ¢Finished Width

84 1/2" max Electrical _ ,,

83 1/4" min ]I Area / 5

Finished II

Opening tit

lit 24 3/4" Total

II Depth

_t 5"1 Water Supply i 5't

_Y ; 3 1/2"

The electrical and water locations must be

located as shown for either type of installation.

/

74"FromFloor

to Bottom

of Electrical

1/2'i

*Flush Installations: 36" for Models ZLSS36

42" for Models ZLSS42, 48" for Models ZLSS48.

*Semi-Flush Installation: 35-1/2" for Models ZISS36

41-1/2" for ZISS42, 47-1/2" for Models ZISS48.

Note: Additional cutout width may be required when side panels

are used. Add side panel thickness to the finished cutout to

calculate rough-in width. See installation examples on

the following page.

*Shipped at 84"

installation height.

Adjustable from

83"to 84-1/2".

24-3/4'L

36"for ModelsZISS36

42"for ModelsZISS42

48"for ModelsZISS48

Page 4

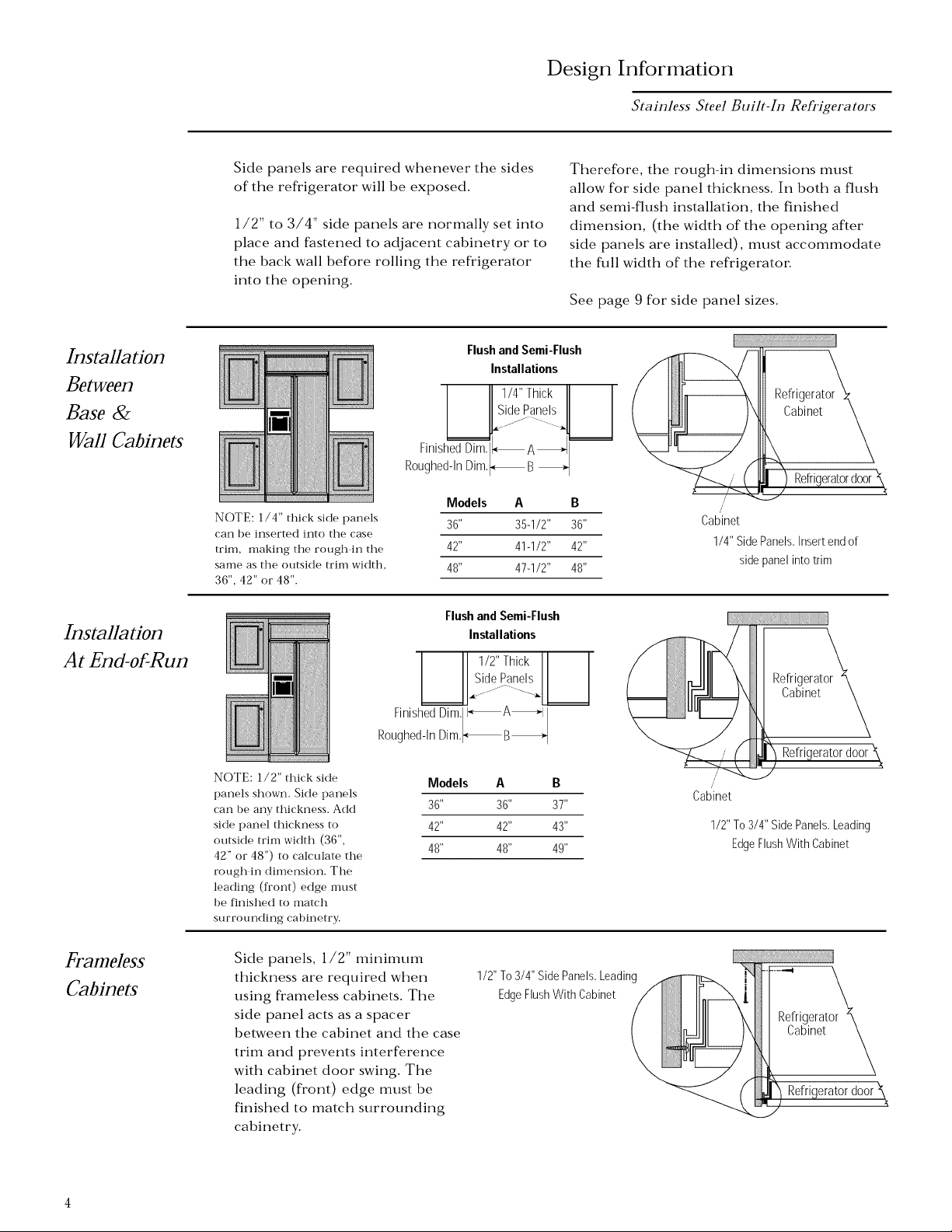

Design Information

Stainless Steel Built-In Refrigerators

Installation

Between

Base c_

Wall Cabinets

Installation

At End-of-Run

Side panels are required whenever the sides

of the refrigerator will be exposed.

1/2" to 3/4" side panels are normally set into

place and fastened to adjacent cabinetry or to

the back wall before rolling the refl'igerator

into the opening.

Flushand Semi-Flush

I IISidePanels II I

Finished Dim, I_A_

Roughed-In Dim,_B

Models A B

NOTE: 1/4" thick side panels

can be inserted into the case

trim, making the rough in the

same as the outside trim width,

36", 42" or 48".

Finished Dim, I_, A_-I

Roughed-In Dim,_B_

NOTE: 1/2" thick side

panels shown. Side panels

can be any thickness. Add

side panel thickness to

outside trim width (36",

42" or 48") to calculate the

rough in dimension. The

leading (front) edge nmst

be finished to match

surrounding cabinetry.

36" 35-1/2" 36" Cabinet

42" 41-1/2" 42"

48" 47-1/2" 48"

Flushand Semi-Flush

Installations

1/2" Thick

IISideoPanelsII I

[_lJ" ..... _ll I

Models A B

36" 36" 37"

42" 42" 43"

48" 48" 49"

Installations

1/4" Thick

jjJ - ._

Therefore, the rough-in dimensions must

allow for side panel thickness. In both a flush

and semi-flush installation, the finished

dimension, (the width of the opening after

side panels are installed), must accommodate

the full width of the refrigerator

See page 9 for side panel sizes.

!i) Refrigerat°r_

Cabinet

/

/

1/4" Side Panels,Insertend of

side panel into trim

Refrigeratordoor

Refrigerator'_

\ Cabinetk

i_, Refrigeratordoor\

/

Cabinet

1/2" To 3/4" SidePanels,Leading

EdgeFlush With Cabinet

Frameless

Cabinets

Side panels, 1/2" minimum

thickness are required when

using frameless cabinets. The

side panel acts as a spacer

between the cabinet and the case

trim and prevents interference

with cabinet door swing. The

leading (front) edge must be

finished to match surrounding

cabinetry.

1/2" To 3/4" SidePanels,Leading

EdgeFlush With Cabinet /

erator

Page 5

Installation Preparation

Stainless Steel Built-In Refrigerators

Product

Dimensions

Clearances

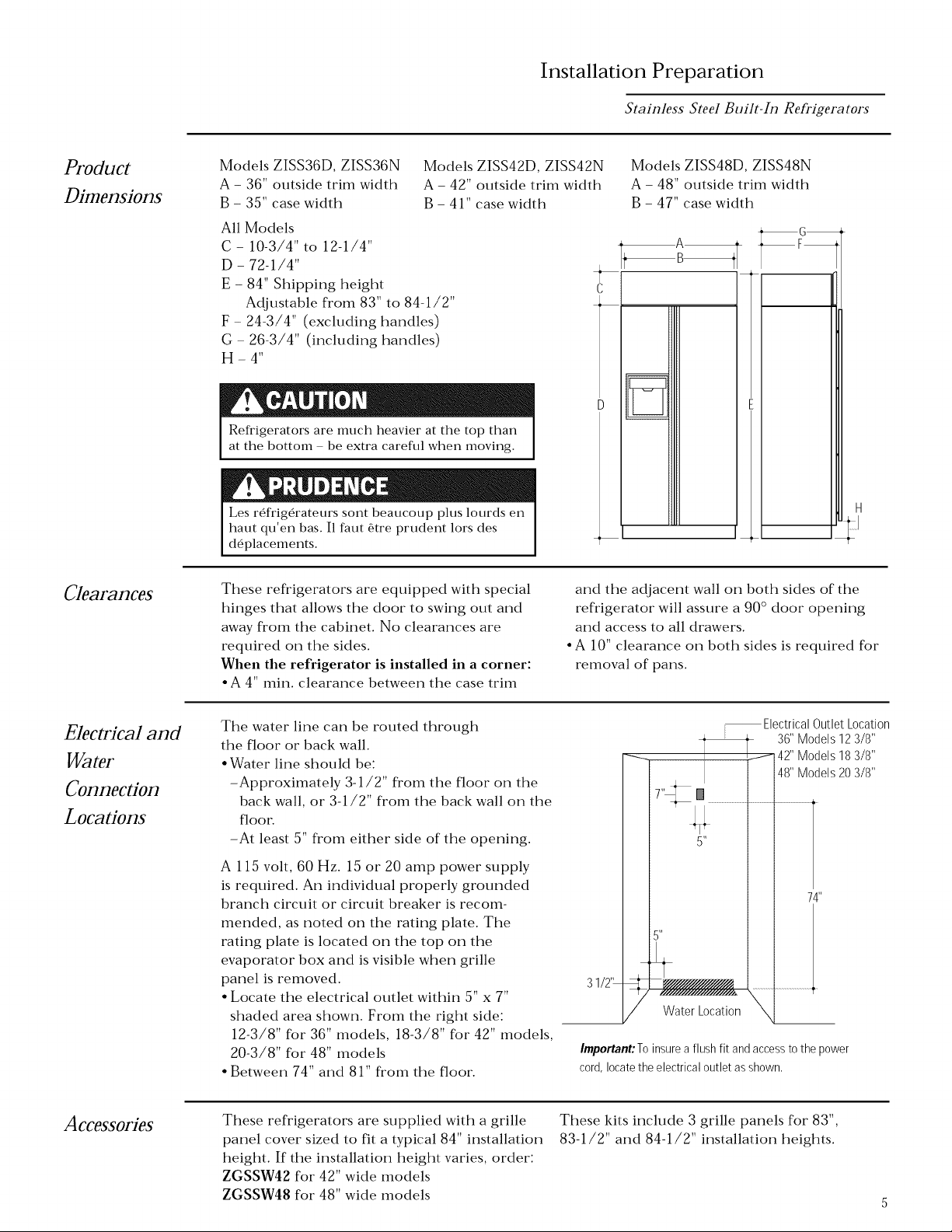

Models ZISS36D, ZISS36N Models ZISS42D, ZISS42N

A - 36" outside trim width A - 42" outside trim width

B - 35" case width B - 41" case width

All Models

C - 10-3/4" to 12-1/4"

D - 72-1/4"

E - 84" Shipping height

Adjustable from 83" to 84-1/2"

F - 24-3/4" (excluding handles)

G - 26-3/4" (including handles)

H-4"

Refrigerators are much heavier at the top than

at the bottom be extra careflfl when moving.

Les r_frig_rateurs sont beaucoup plus lourds en

haut qu'en bas. I1 faut _tre prudent lors des

d_placements.

These refrigerators are equipped with special

hinges that allows the door to swing out and

away from the cabinet. No clearances are

required on the sides.

When the refrigerator is installed in a corner:

* A 4" min. clearance between the case trim

and the adjacent wall on both sides of the

refrigerator will assure a 90 ° door opening

and access to all drawers.

• A 10" clearance on both sides is required for

removal of pans.

Models ZISS48D, ZISS48N

A - 48" outside trim width

B - 47" case width

T

C

_G

_F_

I

Electrical and

Water

Connection

Locations

Accessories

The water line can be routed through

the floor or back wall.

• Water line should be:

-Approximately 3-1/2" from the floor on the

back wall, or 3-1/2" from the back wall on the

floor.

-At least 5" from either side of the opening.

A 115 volt, 60 Hz. 15 or 20 amp power supply

is required. An individual properly grounded

branch circuit or circuit breaker is recom-

mended, as noted on the rating plate. The

rating plate is located on the top on the

evaporator box and is visible when grille

panel is removed.

• Locate the electrical outlet within 5" x 7"

shaded area shown. From the right side:

12-3/8" for 36" models, 18-3/8" for 42" models,

20-3/8" for 48" models

• Between 74" and 81" from the floor.

These refrigerators are supplied with a grille

panel cover sized to fit a typical 84" installation

height. If the installation height varies, order:

ZGSSW42 for 42" wide models

ZGSSW48 for 48" wide models

-- ElectricalOutletLocation

36"Models123/8"

42"Models183/8"

48"Models203/8"

74"

31/2'_

Water Location \

Important:To insurea flush fit and accessto the power

cord, locate the electrical outlet as shown,

These kits include 3 grille panels for 83",

83-1/2" and 84-1/2" installation heights.

Page 6

Installation Preparation

Stainless Steel Built-In Refrigerators

Grounding

the

Refrigerator

IMPORTANT- (Please read careflflly)

FOR PERSONAL SAFETY, THIS APPLI-

ANCE MUST BE PROPERLY GROUNDED.

The power cord of this appliance is equipped

with a three-prong (grounding) plug which

mates with a standard three-prong (ground-

ing) wall receptacle to minimize the possibil-

ity of electric shock hazard from this appli-

ance.

Have the wall outlet and circuit checked by a

qualified electrician to make sure the outlet

is properly grounded.

Where a standard 2-prong wall outlet is

encountered, it is your personal responsibil-

ity and obligation to have it replaced with a

properly grounded 3-prong wall outlet.

Use of Adapter plug

Because of potential hazards under certain

conditions, we strongly recommend against

use of an adapter plug. However, if you still

elect to use an adapter, where local codes

permit, a TEMPORARY CONNECTION, may

be made to a properly grounded 2-prong wall

outlet by use of a UL listed adapter available

at most hardware stores.

The larger slot in the adapter must be

aligned with the larger slot in the wall outlet

to provide proper polarity in the connection

of the power cord.

Attaching the adapter ground terminal to

a wall outlet cover screw does not ground

the appliance unless the cover screw is

metal, and not insulated, and the wall

outlet is grounded through the house

wiring. You should have the circuit

checked by a qualified electrician to make

sure the outlet is properly grounded.

DO NOT, UNDER ANY CIRCUMSTANCES,

CUT OR REMOVE THE THIRD (GROUND)

PRONG FROM THE POWER CORD.

When disconnecting the power cord from

the adapter, always hold the adapter in place

with one hand and pulling the power cord

with the other hand. If this is not done, the

adapter ground terminal is very likely to

break with repeated use.

Should the adapter ground terminal break,

DO NOT USE the appliance until a proper

ground has again been established.

Use of Extension Cords

Because of potential safety hazards under

certain conditions, we strongly recommend

against the use of an extension cord. How-

ever, if you still elect to use an extension

cord, it is absolutely necessary that it be a UL

listed 3-wire grounding type appliance

extension cord having a grounding type plug

and outlet and that the electrical rating of

the cord be 15 amperes (minimum) and

120 volts.

FICHE D'ADAPTATION

(Fiches d'adaptation non permises au

Canada)

Page 7

Installation Preparation

Stainless Steel Built-In Refrigerators

Tools

Required

Materials

• Tinsnips to cut banding

• Stepladder

• Bucket

• Level

• 1-1/2" open-end wrench

• Side panels to match cabinetry

• 2x4, 36", 42" or 48" long, for Anti-Tip support, see page 10

Required

Hardware

Supplied

• Special velcro adhesive strips for 1/4" side panels

• 1/4-1/4 union with nuts

• Water filter bypass plug

Hardware • Water shut-off valve

Recommendations

Flooring

For proper installation, this refrigerator must

be placed on a level surface of hard material

that is at the same height as the rest of the

flooring. This surface should be strong

enough to support a fully loaded refrigerator

• Appliance Hand Truck

• Tubing cutter

• 7/16" open-end wrench

• #2 Phillips screwdriver

• Stubby Phillips screwdriver

NOTE: Protect the finish of the flooring. Cut

a large section of the cardboard carton and

place under the refrigerator where you are

working.

• Drill and appropriate bits

• 7/16" socket with 3" extension

for ratchet

• Safety glasses

SteI1

melllOVe

Packaging

Refrigerator is much heavier at the top than at

the bottom be careflfl when moving. When

using a hand truck, handle from side only.

Le r_ffig_rateur est beaucoup plus lourd en

haut qu'en bas. I1 faut 6tre prudent lots des

d6_placements. Si un diable est utilis_, il faut

soulever le r_frig_rateur sur le c6t_ seulement.

• Remove outer carton.

-Careflflly cut banding at the top and

bottom.

° Slide out back corner posts (2).

° Slide carton off top of cabinet.

NOTE: IT IS NOT NECESSARY TO LAY

CABINET DOWN IN ORDER TO REMOVE

SKID!

° To remove skid, remove the four 7/16" bolts

and their brackets.

° There are support blocks on the bottom of

the cabinet and door: They must be removed

before sliding unit off skid or damage will

OCCtlF,

• Careflflly, tilt cabinet and slide blocks out

from beneath cabinet, slide unit off skid.

° Remove toekick from the fresh food com-

partment, set aside for later installation.

7/16" Bolt

,/

f

f

DO NOT ATTEMPT TO ROLL UNIT OFF

SKID.

IL NE FAUT PAS ESSAYERDE FAIRE

ROULER LE Rt_FRIGt_RATEURPOUR

L'ENLEVER DE LAYPALETTE.

Page 8

Install

Water

Line

Installation

= 11

When connecting a GE Reverse

Osmosis Water System to your

refrigerator, the only approved

installation is with a GE RVKIT.

If the water supply to the refrigera-

tor is from a Reverse Osmosis Water

System AND the refrigerator also has

a water filter, use the refrigerator's

filter bypass plug. Using the

refrigerator's water filtration

cartridge in conjunction with the

RO filter can result in hollow ice

cubes and slower water flow from the

water dispenser.

If you use the bypass Plug and want a light shield without

the filter opening, order a replacement solid light shield:

For 36" Models Order WR17X3025

For 42" Models Order WR02X8967

For 48" Models Order WR17X3433

To Remove

Stainless Steel Built-In Refrigerators

-V

Lors du raccordement au r_frig_rateur

du syst_me GE de purification de l'eau

par osmose inverse.e, seule l'installation

avec un ensemble GE RVKIT est

approuv_e.

Si le r_frig_.rateur es aliment6_ en eau

partir d'un syst_me de filtration d'eau par

osmose invers_e, et si le r_frig_rateur

comporte _galement un filtre a eau,

utiliser le bouchon du circuit de

d_rivation du filtre du r_frig_rateur. Si la

cartouche de filtration d'eau du

r_frig_rateur est utilis_e en conjonction

avec le syst_me de filtration par osmose

invers_e, on peut observer une r_duction

du d_bit d'eau au point de puisage, et la

production de cubes de glace creux.

• A cold water supply is required for automatic

icemaker operation. The water pressure

must be between 40 and 120 p.s.i.

• Route 1/4" OD copper tubing between

house cold water line and the water connec-

tion location.

• Copper tubing should be long enough to

extend to the front of the refrigerator. Allow

enough to accommodate bend leading into

the water valve.

Shut off the main water supply.

Turn on the nearest faucet long enough to

clear the line of water.

Install a shut-off valve between the icemaker

water valve and cold water pipe in a basement

or cabinet. The shut-off valve should be

located where it will be easily accessible.

NOTE: It is best to install the valve into a

vertical water pipe. If you install the valve into

a horizontal water pipe, make the connection

at the top or side, rather than at the bottom,

to avoid drawing off any sediment from the

water pipe.

• Drill a 1/4" hole in the water pipe.

• Fasten the shut-off valve to the pipe with

pipe clamp.

• Tighten the clamp screws until the sealing

washer begins to swell. Do not over tighten.

"Place a compression nut and ferrule (sleeve)

onto the end of the tubing and connect it to

the shut-off valve. Make sure the tubing is

flflly inserted into the valve and ferrule is

tightened.

° Floor_

CopperTubing4

Washer

SaddleType

Inlet End

Shuto?ve_

Pipe Clamp

Packin_

Outlet Valve

Compression Nut

/

\

Ferrule

(Sleeve)

• Turn on the main water supply and flush

debris from the line. Run about a quart of

water through the tubing into a bucket. Shut

off water supply at the shut-off valve.

NOTE: Saddle type shut-off valves are in-

cluded in many water supply kits. Before

purchasing, make sure a saddle type valve

complies with your local plumbing codes.

NOTE: Commonwealth of Massachusetts

Plumbing Codes 248CMR shall be adhered

to. Saddle valves are illegal and use is not

permitted in Massachusetts. Consult with

your licensed plumber.

Page 9

Installation

Stainless Steel Built-In Refrigerators

Install

Side

Panels

• Side panels are required whenever the sides

of the refrigerator will be exposed and when

installed between frameless cabinets. See

pages 3 and 4.

• Side panels are not required when the

refrigerator is installed into an enclosure.

• Side panel installation will be determined by

the design of the side panel you have previ-

ously chosen.

• Side panels must be installed plumb.

Illustration/z,

1/4" Side Panels-

Insertendof side

panel into case trim,

Fastenwith Velcro

strips included,

TopView

Standard 4" high toekick or trim to fit, Height

mayvary dependingon application,

Illustration C

1/2" to 3/4" Side

Panels- Recessed

front edge of side

panel, Fastento

adjacent cabinet,

23-9/16"

84"

2-9/16"

234/16"

ill .................t

84"

• If you choose to use 1/4" side panels, they

should be inserted into the case trim as

illustrated. Fasten the panels to the refrigera-

tor with velcro strips (provided) before setting

refrigerator in place. See illustration A.

° 1/2" to 3/4" side panels are normally set into

place and fastened to adjacent cabinetry or

the back wall before rolling the refrigerator

into the opening. See illustrations B and C.

Illustration B

1/2" to 3/4" Side

Panels- Leading

edgeof sidepanel is

flushwith cabinet

front, Fastento the

backwall usinga

cleat,

24-3/4"

) 3-3/4"

Top View

Standard 4" high toekick or trim to fit,

Height mayvary depending on application,

Roll

Refrigerator

Into Opening

@

Top View

Standard 4" high toekick or trim to fit,

Height mayvary depending on application,

2 5/16

• The cardboard protective pad should be

beneath the refrigerator.

° Gently push refrigerator into opening with

hands against front corners.

° Roll refrigerator into the opening until it is

flush with adjacent cabinets.

Page 10

Level

Refrigerator

SteI6

Secure

Refrigerator

Case Trim,

to Side Panel

All models have 4-point leveling. The front is

supported by leveling legs, the rear is

supported by wheels.

• To level the back of the refrigerator,

turn the 7/16" hex nut located above the

front wheels. Turn to raise or lower the

refrigerator.

° For front leveling, use a 1-1/2" open-end

wrench.

• Adjust carefully, the refrigerator should be

level and plumb with cabinetry, and should

align with toekick height.

ANTI-TIP PRECAUTIONS

The refrigerator is heavy at the top and must be

secured to prevent the possibility of tipping

forward.

PRECAUTIONS CONTRE LES

BASCULEMENTS

Le r_frig6_rateur est beaucoup plus lourd en

haut et il faut le maintenir en place pour 6_viter

la possibilit6_ de son basculement vers l'avant.

Installation

Stainless Steel Built-In Refrigerators

HexNut

RearWheels

Block.....

OPTION 1

To prevent the refrigerator from tipping

over, you must:

• Install a wood block, the full width of the

refrigerator. Secure the block with wood

screws penetrating at least 3/4" into wall

studs.

OPTION 2

When using 1/2" to 3/4" side panels, the

front flange of the case trim should be

attached to the side panel.

• Open freezer door to access case trim.

• Drill hole in flange and drive screw

through the flange, into the side panel.

Follow the same procedure on the fresh

food side.

OR

If refrigerator is installed between cabinets

with no side panels or in a custom enclosure,

install a spacer block as shown.

• Open freezer door to access case trim.

• Drill hole in trim and drive screw through

the trim and into the spacer block.

• Follow the same procedure for fresh food

side.

SideView

m

Stud_Rerrigerator Cabinet_

SideView

10

Page 11

st7

Connect

Water

Supply

SteI 8

Connect

Installation

Stainless Steel Built-In Refrigerators

Check to be sure that refrigerator power cord

is not plugged into the wall outlet.

• Locate and bring copper tubing to the front

of the cabinet.

• The copper tubing should be just long

enough to reach the coupling. Excess tubing

length could interfer with door closing or

toekick installation.

• Slip a 1/4-1/4 union nut (provided) over

both ends of the copper tubing at the right

front leg of the refrigerator and couple the

lines.

• Turn on the water to check for leaks.

° Connect the refrigerator power cord plug

to properly grounded receptacle, accessible

through the top right side of the hood

opening.

Power

SteI9

Mount

Top Grille

Pand

The matching grille panel is sized for an

84" installation height.

° The refrigerator is shipped with the top

case trim secured at 84" installation height.

To raise or lower case trim to other installa-

tion heights:

° Loosen 2 screws on both sides and raise the

case trim to meet soffit height or to the top

of adjacent cabinets.

° Tighten all 4 screws.

° Mount the grille panel by dropping into

slots on the case trim.

If installation height is more or less than 84",

order ZGSSW42 or ZGSSW48 optional grille

panel kit which accommodates 83", 83-1/2"

and 84-1/2" heights.

TopCase Trim

RaiseToI

Installation

Height

1-1/2"

min,

gap

/

(

,\

\

/

/

.7

j-

/

J

/

Important: Maintain 1-1/2" min,gap between top of

doors and bottom of grille panel,

11

Page 12

Arrange

Interior

Installation

Stainless Steel Built-In Refrigerators

• Remove internal packing materials.

• The freezer compartment shelves are turned

upside down for shipping. They must be

removed and turned right side up. To

remove shelf packing, apply upward pressure

on the inverted shelf with one hand and hold

in place. Remove packing with other hand.

Grip shelf with both hands, lower shelf front

and remove from cabinet. Turn shelf right

side up and install in desired location.

• In the fresh food section, remove packing on

each side of shelves.

° Remove tape from all shelves.

° Set Fresh Food control at "5".

° Set Freezer control at "5".

Temperature

Controls

Start

Icemaker

IMPORTANT: Allow 24 hours for tempera-

tures to stabilize before making adjustments.

° Lower the feeler arm to the ON position

and the icemaker will begin operation

automatically.

• Discard the first few batches of ice cubes to

be sure that any remaining impurities in the

water line will be flushed out.

NOTE: During operation, you will hear the

hum of the motor, movement of the cube

ejector, humming or clicking of the water

valve, and ice falling into the bin. These

sounds are normal.

n

It

12

Page 13

Installation

Stainless Steel Built-In Refrigerators

Install

Toekick

• A standard toekick is supplied. Install with 2

screws provided, adjust to desired height and

tighten screws.

°A custom toekick can be installed to match or

complement the surrounding cabinetry.

°A standard toekick is supplied with all

models. If a custom toekick is to be installed,

use the supplied toekick as a template to cut

out notches around hinges and waterline

tubing.

°For 1/2" to 3/4" thick custom toekicks,

additional material should be removed and

cut away. This will allow the water and

electrical umbilical tube to rotate smoothly

when the door is fully opened.

StandardToekick(Packedwith Product)

L

1/4"ThickCustomToekick

D

1/2"to3/4"ThickCustomToekickRemoveAdditionalMaterial

13

Page 14

14

Page 15

Installation

Stainless Steel Built-In Refrigerators

Problem

Solving

Alignment of doors

Door alignment is usually assured when the

refrigerator is leveled. If doors are not aligned

after leveling the unit, call for service.

Operation of Refrigerator

If the refrigerator does not operate after

checking the installation instructions:

• Check to be sure power cord is plugged in

the wall outlet.

• Check to be sure that fuse or circuit breaker

is turned on.

If any of these problems persist:

Call for Monogram local service in your area,

1-800-444-1845.

In Canada, call 1-888-880-3030.

Cleaning the Stainless Steel Refrigerator

Stainless Steel has some unique cleaning

characteristics. In order to keep your

refrigerator looking like new, we suggest

cleaning it with Stainless Steel Magic or a

similar product.

Stainless Steel Magic is available at Ace, True

Value, Home Depot, Servistar, HWI and other

leading stores. It is also available through GE

Parts by calling 1-800-626-2002. Order part

number WX 10X 15.

15

Page 16

Monogram;

General Electric Company

Louisville, KY40225

Note: While performing installations described in this book,

safety glasses or goggles should be worn.

To obtain specific information concerning any

MonoglT_m product o1"service, call GE Answer Center _'

consumer #1formation service at 800.626.2000--any

dme, ct:_y o1"night.

For Monogram loc:_l service m yo_u are:_, c:_fi

1 800 444 1845.

NOTE: Product improvement is a continuing endeavor at General

Electric. Theaefoae, materials_ appearance and specifications are subject

to change without notice.

Pub. No. 49 60060 1

Dwg. No. 197r)1310PO02

¢) 1999 GE Appliances

(N.r). 459A) 12/99

70602 04

Loading...

Loading...