Page 1

GE Monogram ®

36" Bottom Mount

Refrigerators

Custom

Options Guide

and

Installation

Instructions

With Custom Panel Dimensions

These Monogram refrigerators are

designed to be customized with decorator

door and grille panels. Field installed

panels are required.

Factory installed trim will accommodate

1/4" thick custom panels or optional

Lexan ® and stainless steel panel kits.

Optional trim kits allow an even broader

range of custom appearance options.

Read this bo&_t carefully to accomplish the

desired appearance and to insure a troub_ free

instaUation.

This booklet contains information and

illustrations to demonstrate custom

possibilities. Custom door and grille panel

sizes vary to accommodate the kit being

used. Dimensions for each application are

included and can be faxed or sent to the

and Trim Kit Installation Instructions

Models:

ZIC36N RH

ZIC36N LH

cabinet manufacturer so that the panels can

be constructed accurately.

Page 2

Before you begin - Readthese instructions completely and carefully.

IMPORTANT- Savethese instructions for local inspector's use.

iMPORTANT- OBSERVEALL GOVERNINGCODESAND ORDINANCES.

Note to Installer - Be sure to leave these instructions with the Consumer.

Note to Consumer - Keepthese instructions with your Use and Care Book for future reference.

:t I This appliance musthe properlygrounded.See "Grounding the Refrigerator,"page12.

p_j._l_ Cet appareil dolt_tre correctementmisa la terre.

Ifyou have a question concerning the installation of this

product, call the GEAnswer Center® Consumer

Information Service at 800.626.2000,24hours a day,

7 days a week.

ifyou received a damaged refrigerator, you should

immediately contact your dealer or builder.

Proper installation is the responsibility of the installen

Product failure due to improper installation is not

covered under the GEAppliance Warranty. Seethe

Use & Care Guidefor warranty information.

ForMonogramlocal service in yourarea,

1-800-444-1845.

ForMonogramservice in Canada,

1-888-880-3030

ForMonogramParts andAccessories,call

1-800-626-2002.

Contents DesignInformation

Flushor Semi-Flush Enclosure Installations ...............................................................................................................................3

Enclosure Cutout and ProductDimensions .................................................................................................................................3

Installation Examples,Between Base & Wall Cabinets ...........................................................................................................4

Installation at End-of-Run ...............................................................................................................................................................4

FramelessCabinets ..........................................................................................................................................................................4

Accessory PanelKits .......................................................................................................................................................................4

Models Available ..............................................................................................................................................................................5

Advance Planning Exterior Appearance Options.......................................................................................................................5

Trim KitDescriptions ........................................................................................................................................................................6

Consulter. Mise aterre de re_frige_rateerii, page 12.

• Use this appliance only for its intended purpose,

• Immediately repair or replace electric service

cords that have become frayed or damaged,

• Unplug the refrigerator before cleaning or making

repairs.

• Repairs should be madeby a qualified service

technician.

• II nefaat utiliser cet appareil que pour I'usage

pour leqael il a 6t6 constrait,

• II faut rGparer oa remplacer immGdiatement tout

cordon d'alimentation 61ectriqueeffiloch6 ou

endommag&

• OGbrancher le rGfrigGrateuravant le nettoyage ou

route intervention,

• Les rGparations doivent _tre faites par un

technicien qualifi&

CustomPanel Dimensions

Product and Cutout Information ....................................................................................................................................................7

1/4"Thick CustomPanels or Panels Secured to 1/4"thick backing ........................................................................................8

3/4"Thick Panelswith Supplied Handle, ZKTC36Lor ZKTC36R..............................................................................................9

3/4"Thick Panelswith CustomHandle .......................................................................................................................................10

Side Panel or Filler Options ..........................................................................................................................................................11

Installation Instructions..........................................................................................................................................................12-17

TrimKits

ZGC2TrimKit, Grille Panel FrameAdjustment ..........................................................................................................................18

ZKHC1Trim Kit(for 1/4"Panels), Support for Custom Handles.........................................................................................19-21

ZKTC36L/ZKTC36RTrim Kit,3/4"Custom Panels..................................................................................................................22-27

ZKHTClTrim Kit (for 3/4" Panels),Support for Custom Handles ......................................................................................28-31

ZKHCSS1Trim Kit (for 1/4"Panels),Tubular Stainless Steel Handles .............................................................................32-35

ZKHTCSS1Trim Kit (for 3/4"Pane]s),Tabular Stainless Steel Handles ...........................................................................36-38

ZFClTrim Kit, for side to side installation ..................................................................................................................................39

Page 3

Design Information

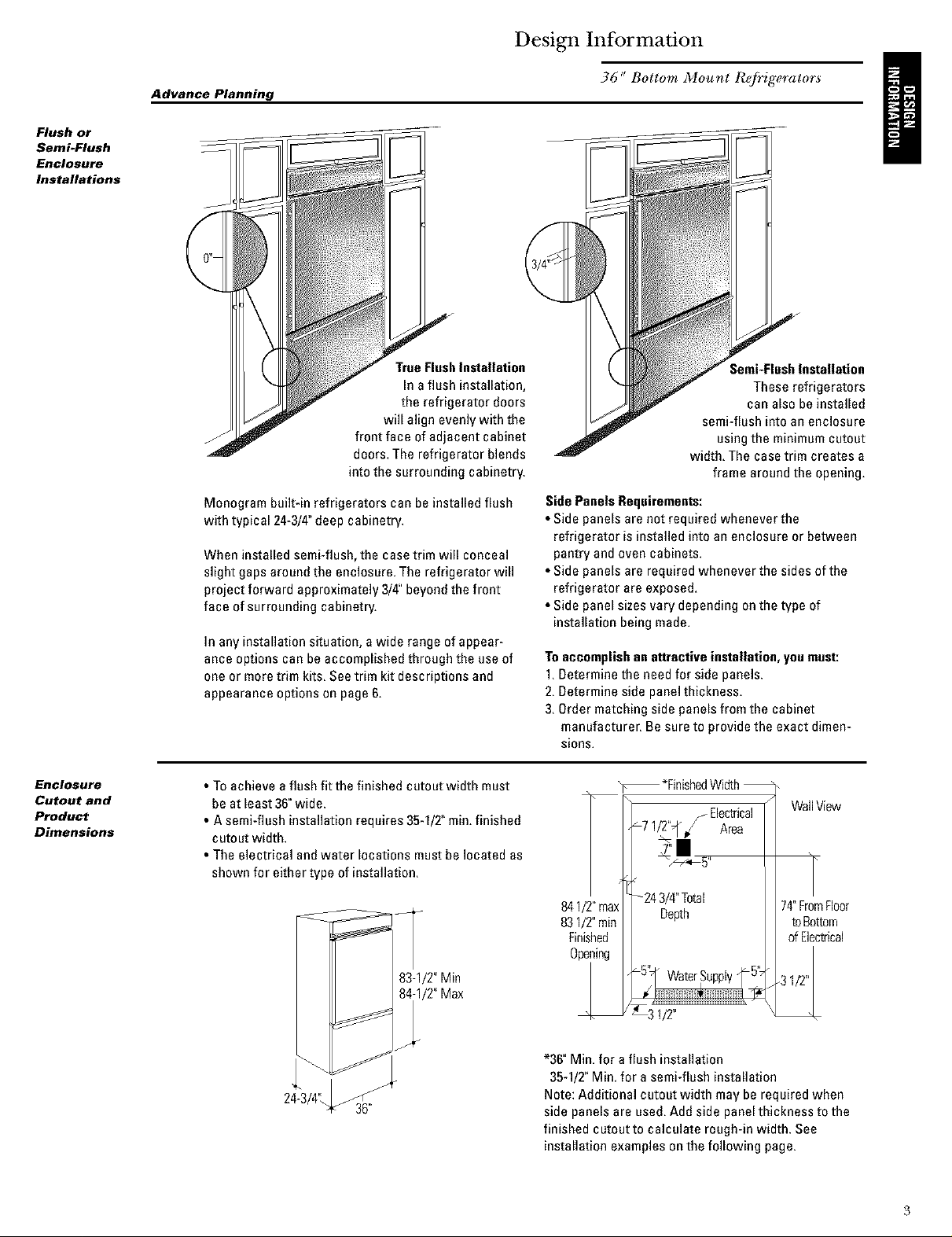

Flush or

Semi-Flush

Enclosure

Installations

Advance Planning

Monogram built-in refrigerators can be installed flush

with typical 24-3/4"deep cabinetry.

When installed semi-flush, the case trim will conceal

slight gaps around the enclosure. The refrigerator will

project forward approximately 3/4" beyondthe front

face of surrounding cabinetry.

In any installation situation, a wide range of appear-

ance options can be accomplished through the use of

one or more trim kits. See trim kit descriptions and

appearance options on page 6.

f

True FlushInstallation

In a flush installation,

the refrigerator doors

will align evenly with the

front face of adjacent cabinet

doors. The refrigerator blends

into the surrounding cabinetry.

36" Bottom Mount ReJi_igerators

I

;emi-FlushInstallation

These refrigerators

can also be installed

semi-flush into an enclosure

using the minimum cutout

width. The case trim creates a

frame around the opening.

SidePanels Requirements:

• Side panels are not required whenever the

refrigerator is installed into an enclosure or between

pantry and oven cabinets.

• Side panels are required whenever the sides of the

refrigerator are exposed.

• Side panel sizes vary depending on the type of

installation being made.

Toaccomplishan attractive installation, you must:

1.Determine the need for side panels.

2. Determine side panel thickness.

3. Order matching side panels from the cabinet

manufacturer. Be sure to provide the exact dimen-

sions.

Enclosure

Cutout and

Product

Dimensions

• To achieve a flush fit the finished cutout width must

be at least 36"wide.

• A semi-flush installation requires 35-1/2" rain.finished

cutout width.

• The electrical andwater locations must be located as

shown for either type of installation.

83-1/2"Min

_/2" Max

24-3/4'_

36"

*FinishedWidth

Electrical

_7 1/_q" / Area

WallView

!|

5

841/2"max

831/2"min

Finished

Opening

*36" Min. for aflush installation

35-1/2"Min. for asemi-flush installation

Note: Additional cutout width may be required when

side panels are used. Add side panel thickness to the

finished cutout to calculate rough-in width. See

installation examples on the following page.

-24 3/4"Total

Depth

_ 1/2"

74"FromFloor

toBottom

ofElectrical

Page 4

Design Information

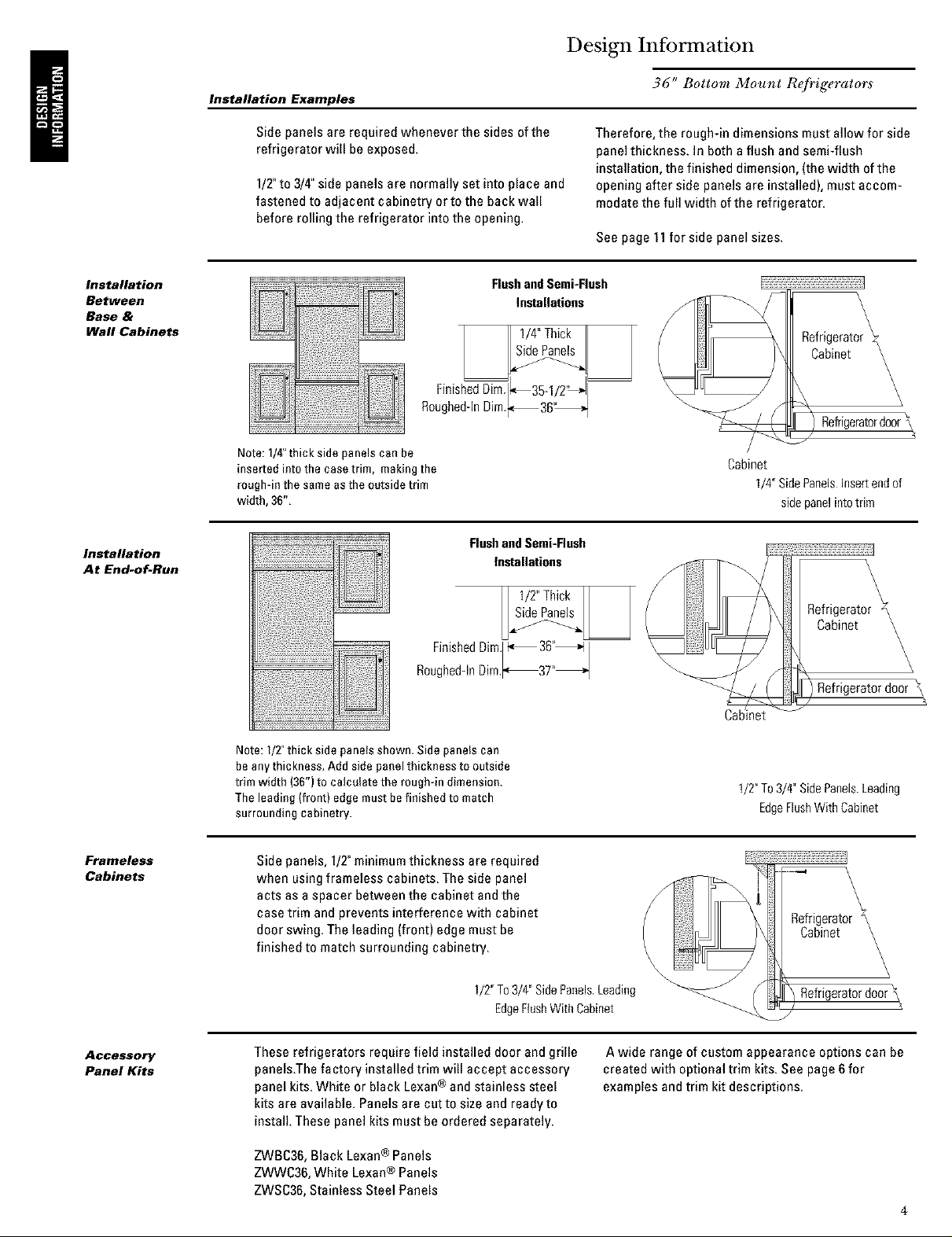

Installation

Between

Base &

WaH Cabinets

Installation Examples

Side panels are required whenever the sides ofthe

refrigerator will be exposed.

1/T to 3/4" side panels are normally set into place and

fastened to adjacent cabinetry orto the back wall

before rolling the refrigerator into the opening.

Note: 1/4"thick side panels can be

inserted into the ease trim, making the

rough-in the same as the outside trim

width, 36",

36" Bottom Mount R@ig_rators

Therefore, the rough-in dimensions must allow for side

panelthickness. In both aflush and semi-flush

installation, the finished dimension, (the width ofthe

opening after side panels are installed), must accom-

modatethe full width of the refrigerator.

See page 11for side panel sizes.

FlushandSemi-Flush

Installations

I II1/4"TNckII I

FinishedDim._35-_ /2"_1

Roughed-InDim._36'_

/_tLy

Cabinet

1/4"SidePanelsInsertendof

sidepanelintotrim

Installation

At End-of-Run

Framaless

Cabinets

FlushandSemi-Flush

. . . 3 _1

FmmhedDml._ 6_,_

Roughed-InRim._37"_

Note: I/2" thick side panels shown. Side panels can

beany thickness, Add side panel thickness to outside

trim width (36")to calculate the rough-in dimension.

The leading (front) edge must befinished to match

surrounding cabinetry.

Side panels, 1/2"minimumthickness are required

when using frameless cabinets. The side panel

acts as a spacer between the cabinet and the

case trim and prevents interference with cabinet

door swing. The leading (front} edge must be

finished to match surrounding cabinetry.

1/2"To3/4"SidePanels.Leading

II1/TThickII I

EdgeFlushWithCabinet

\

Refrigerator

Cabinet

)Refrigeratordoor \

Cabinet

1/2"To3/4"SidePanelsLeading

EdgeFlushWithCabinet

\

\

\

RefrigeratorY\

Cabinet \

Refrigeratordoor\

\

\

\

\

\

\

\

\

\,

Accessory

Panel Kits

These refrigerators require field installed door and grille

panels.Thefactory installed trim will accept accessory

panel kits. White or black Lexan® and stainless steel

kits are available. Panels are cut to sizeand ready to

install. These panel kits must be ordered separately.

ZWBC36,Black Lexan® Panels

ZWWC3g,White Lexan® Panels

ZWSC36,Stainless Steel Panels

Awide range of custom appearance options can be

created with optional trim kits. See page 6 for

examples and trim kit descriptions.

4

Page 5

Design Information

36" Bottom Mount Re/_igerator

Models

available

Advance

planning

exterior

appearance

options

ZIC36NRH

36"wide model with handle onthe left side,the door

swings left to right.

These refrigerators are designed to be customized with

decorator door and grille panels. Field installed custom

door and grille panels are required for these models.

Factory installed trim will accommodate 1/4"thick

custom panels, Lexan® or stainless steel panel kits.

Door and grille panel sizesvary to accommodate the kit

being used. Sizes are provided inthis booklet,

Caution: Maximum panel weight for fresh food door is

50pounds and 30 pounds for freezer drawer panel,

Side panels must be used whenever the sides ofthe

refrigerator will beexposed. Side panel sizes vary

depending onthe installation.

3/4"thick custom panels-Withouttrim kits

A raised panel design, screwed or glued to a 1/4"thick

backing can be used. Seepage 8 for panel sizes and

clearances.

ZIC36NLH

36"wide model with handle on the right side, the door

swings right to left.

Youshould:

1.Select the appearance option.

2. Order the trim kit for that option.

3. Order the custom door and grille panels from the

cabinet manufacturer. The exact dimension for each

trim kit application is provided in this booklet. Find

and pull out the page for your application and fax or

send itto the cabinet manufacturer. The cabinet

manufacturer must havethis information to

construct the panels accurately.

4. Determine the final installation situation and order

matching side panels.

i

5

Page 6

Design Information

36" Bottom Mount R@ig_rator

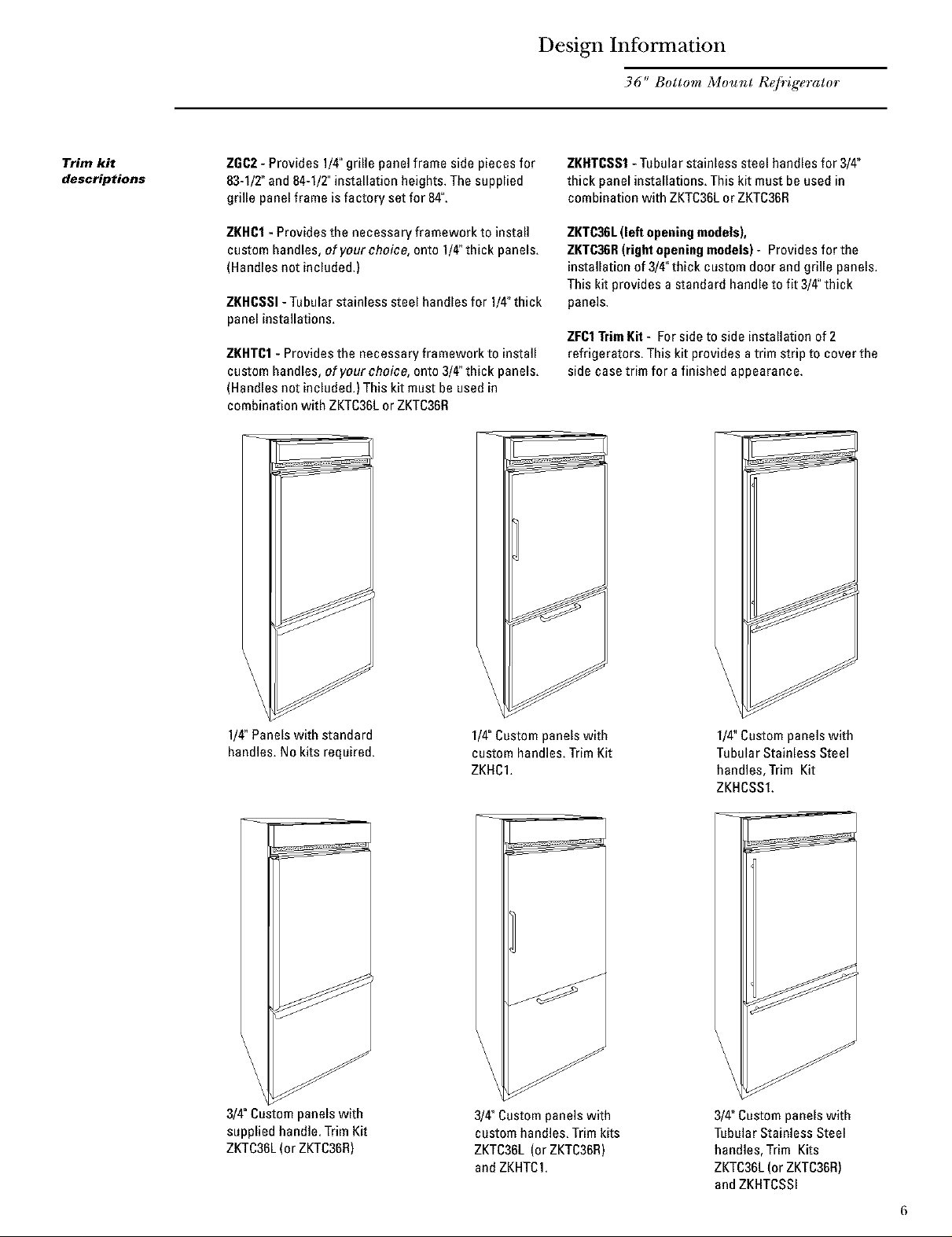

Trim kit

descriptions

ZGC2- Provides 1/4"grille panel frame side pieces for

83-1/2"and 84-1/2"installation heights. The supplied

grille panelframe is factory set for 84".

ZKHCI - Provides the necessary framework to install

custom handles, of your choice, onto 1/4"thick panels.

(Handles not included.)

ZKHCSSI-Tabular stainless steel handles for 1/4"thick

panel installations.

ZKHTC1- Provides the necessary framework to install

custom handles, of your choice, onto 3/4"thick panels.

(Handles not included.) This kit must be used in

combination with ZKTC36LorZKTC36R

ZKHTCSS1- Tubular stainless steel handles for 3/4"

thick panel installations. This kit must beused in

combination with ZKTC36Lor ZKTC36R

ZKTC36L(left openingmodels),

ZKTC36R(right openingmodels)- Provides for the

installation of 3/4"thick custom door and grille panels.

This kit provides a standard handle to fit 3/4"thick

panels.

ZFC1TrimKit - For sideto side installation of 2

refrigerators. This kit provides a trim strip to cover the

side case trim for a finished appearance.

1/4"Panelswith standard

handles. No kits required.

3/4"Custom panels with

supplied handle. Trim Kit

ZKTC36L(or ZKTC36R)

1/4"Custompanels with

custom handles. Trim Kit

ZKHC1.

_ Custompanels with

custom handles, Trim kits

ZKTC36L (or ZKTC36H)

andZKHTC1,

1/4"Custompanels with

TubularStainless Steel

handles, Trim Kit

ZKHCSS1.

3/4" Custom panels with

Tubular Stainless Steel

handles, Trim Kits

ZKTC36L(or ZKTC36H)

andZKHTCSSI

6

Page 7

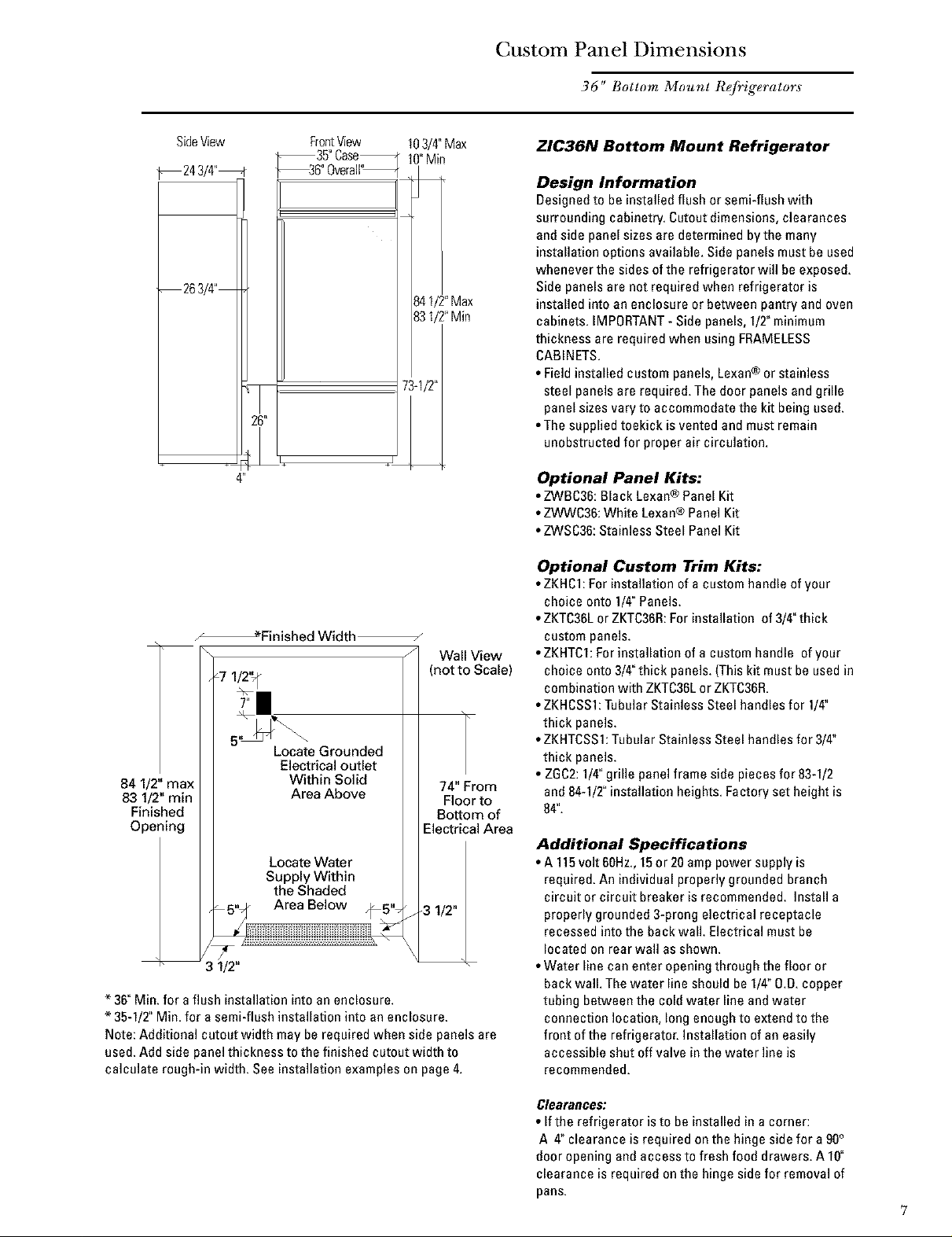

Custom Panel Dimensions

36" Bottom Mount ReJi_igerators

SideView

243/4"_

_26 3/4"

FrontView 103/4"Max

35"Case_ 10"Min

_6" 0verall'_

841/2"Max

831/2"Min

H/2"

26"

_Finished Width _

Wall View

(not to Scale)

Locate Grounded

Electrical outlet

84 1/2" max

83 1/2" min

Finished

Opening

1/2"

* 36"Min. for aflush installation into an enclosure.

* 35-1/2"Min. for a semi-flush installation into an enclosure.

Note: Additional cutout width may be required when side panels are

used. Add side panel thickness to the finished cutout width to

calculate rough-in width. See installation examples on page 4.

Within Solid

Area Above

Locate Water

Supply Within

the Shaded

_iiii \

74" From

Floor to

Bottom of

Electrical Area

3 1/2"

ZIC36N Bottom Mount Refrigerator

Design Information

Designedto be installed flush or semi-flush with

surrounding cabinetry. Cutout dimensions, clearances

and side panel sizes are determined by the many

installation options available. Side panels must be used

whenever the sides of the refrigerator will be exposed.

Side panels are not required when refrigerator is

installed into an enclosure or between pantry andoven

cabinets. IMPORTANT- Side panels, 1/2"minimum

thickness are required when usingFRAMELESS

CABINETS.

• Field installed custom panels, Lexan® or stainless

steel panels are required. The door panels and grille

panel sizes vary to accommodate the kit being used.

• The supplied toekick is vented and must remain

unobstructed for proper air circulation.

Optional Panel Kits:

• ZWBC36:Black Lexan® Panel Kit

• ZWWC36:White Lexan® Panel Kit

• ZWSC36:Stainless Steel PanelKit

Optional Custom Trim Kits:

• ZKHCl: For installation of a custom handle of your

choice onto 1/4"Panels.

• ZKTC36Lor ZKTC36R:For installation of 3/4"thick

custom panels.

• ZKHTCI: Forinstallation of a custom handle of your

choice onto 3/4"thick panels. (This kit must be used in

combination with ZKTC36LorZKTC36R.

• ZKHCSSI: Tubular Stainless Steel handles for 1/4"

thick panels.

• ZKHTCSSI:Tubular Stainless Steel handles for 3/4"

thick panels.

• ZGC2:1/4"grille panel frame side pieces for 83-1/2

and 84-1/2" installation heights. Factory set height is

84".

Additional Specifications

• A 115volt 6OHz.,15or 20 amp power supply is

required. An individual properly grounded branch

circuit or circuit breskeris recommended. Install a

properly grounded 3-prong electrical receptacle

recessed into the back wall. Electrical must be

located on rear wall as shown.

• Water line can enter opening through the floor or

back wall. The water line should be 1/4"O.D.copper

tubing between the cold water line and water

connection location, long enough to extend to the

front of the refrigerator. Instagation of an easily

accessible shut off valve in the water line is

recommended.

Clearances:

• If the refrigerator is to be installed in a corner:

A 4" clearance is required onthe hinge side for a 90°

door opening and access to fresh food drawers. A 10"

clearance is required on the hinge side for removal of

pans.

7

Page 8

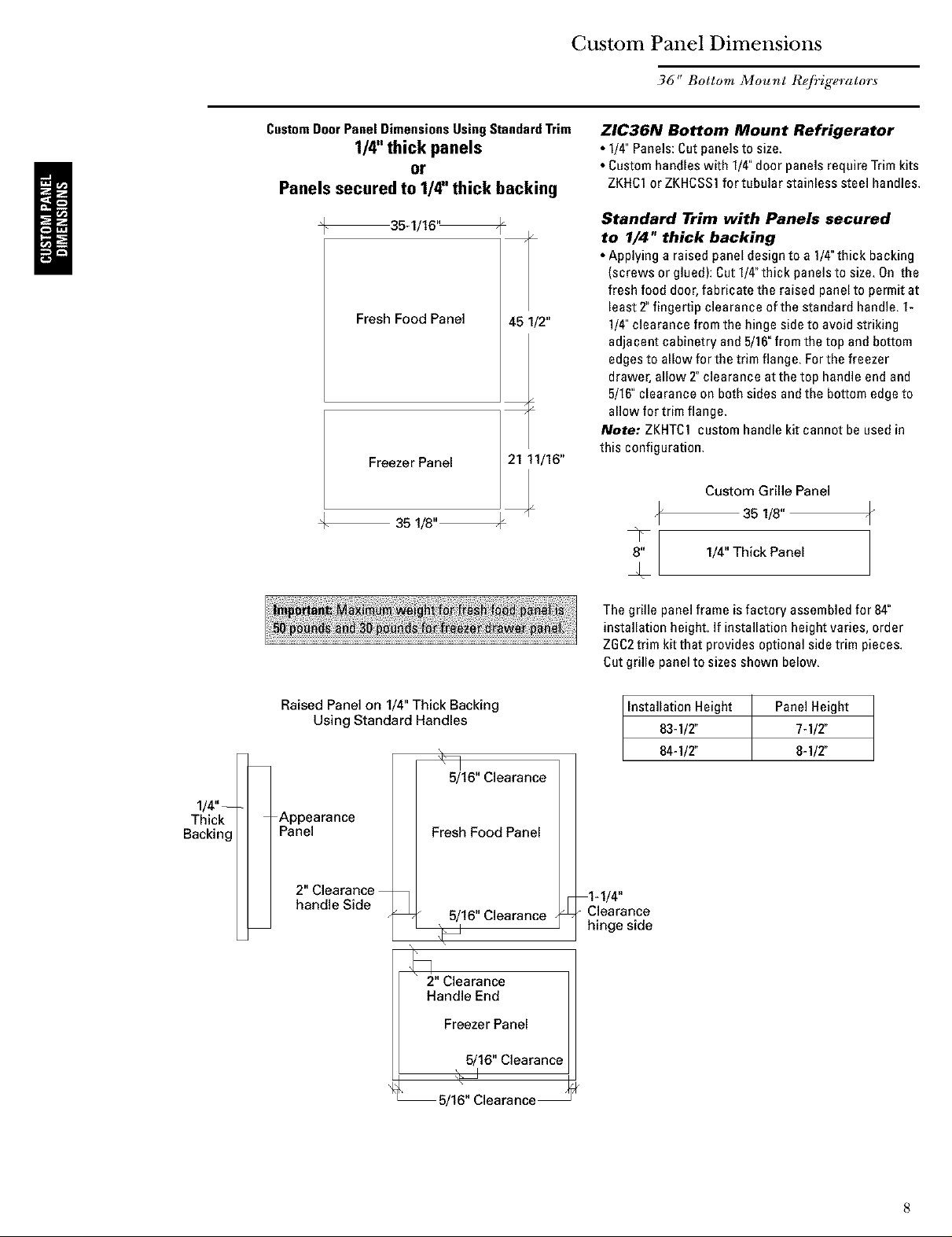

Custom Panel Dimensions

36" Bottom Mount ReJi_igerators

CustomDoorPanel DimensionsUsingStandardTrim

1/4" thick panels

or

Panels secured to 1/4" thick backing

@ 35-1/16 _

Fresh Food Panel 45 1/2"

Freezer Panel

+

35 1/8"

21 11/16"

¢

ZIC36N Bottom Mount Refrigerator

• 1/4"Panels:Cutpanels to size

• Custom handles with 1/4 door panels require Trim kits

ZKHC1orZKHCSSl for tubular stainless steel handles

Standard Trim with Panels secured

to 1/4" thick backing

• Applying a raised panel design to a 1/4"thick backing

(screws or glued): Cut1/4"thick panels to size On the

fresh food door,fabricate the raised panel to permit at

least 2, fingertip clearance of the standard handle 1-

1/4 clearance from the hinge side to avoid striking

adjacent cabinetry and 5/16 from the top and bottom

edgesto allow for the trim flange For the freezer

drawer, allow 2"clearance at the top handle endand

5/16 clearance on both sides andthe bottom edge to

allow for trim flange

Note: ZKHTCl custom handle kit cannot be used in

this configuration

Custom Grille Panel

35 1/8"

8" 1/4" Thick Panel

1/4"-

Thick

Backing

Raised Panel on 1/4" Thick Backing

Using Standard Handles

-Appearance

Panel

2anC/_ar_i_tCee2_

5/16" Clearance

Fresh Food Panel

5/16" Clearance •

2" Clearance

Handle End

Freezer Panel

8/16" Clearance

The grille panel frame isfactory assembled for 84"

installation height If installation height varies, order

ZGC2trim kit that provides optional side trim pieces

Cut grille panel to sizes shown below

Installation Height PanelHeight

83-1/2' 7-1/2"

84-1/2" 8-1/2"

1-1/4"

Clearance

hinge side

5/16" Clearance

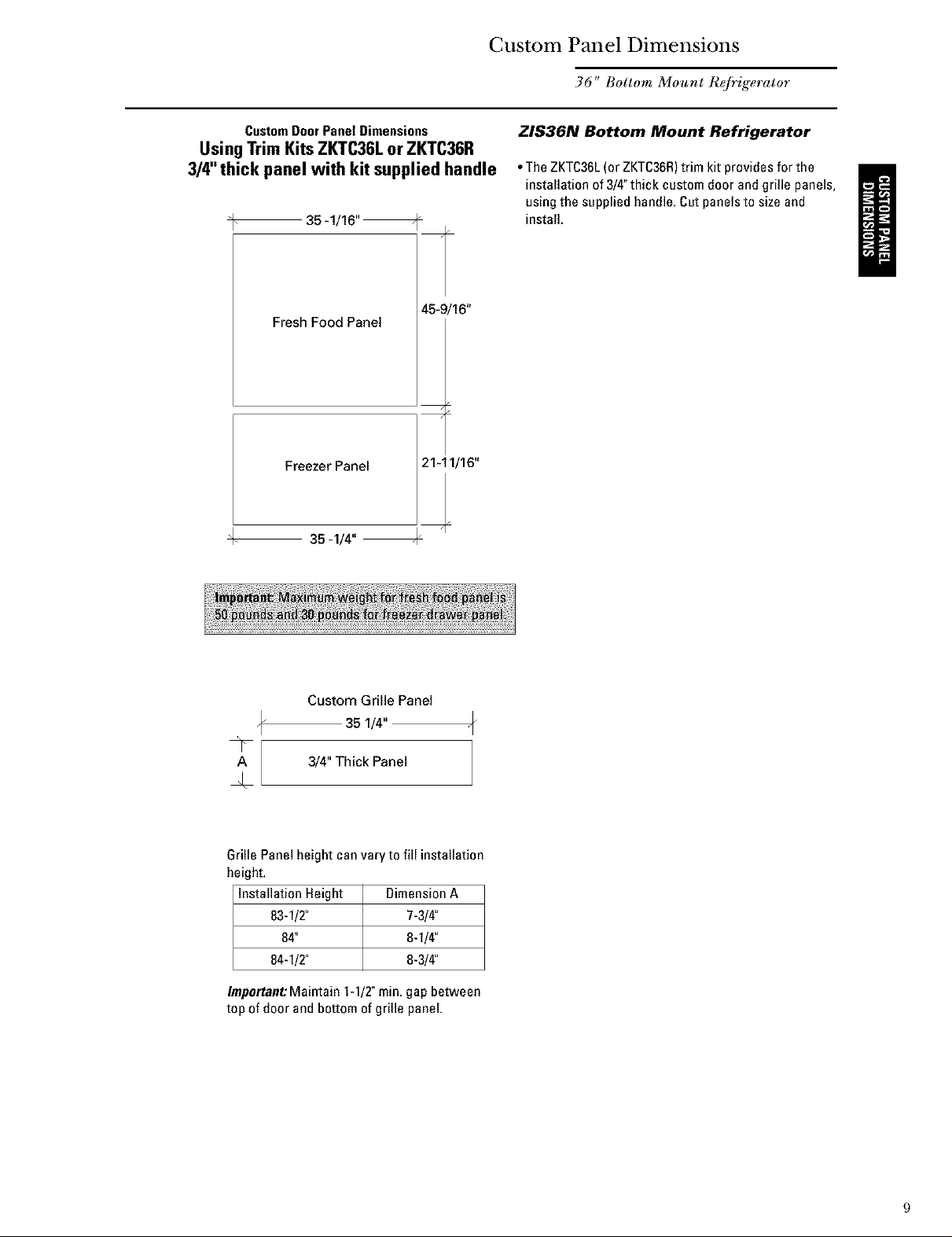

Page 9

Custom Panel Dimensions

36" Bottom Mount Refrigerator

CustomDoorPanel Dimensions

UsingTrim KitsZKTC36Lor ZKTC36R

3/4" thick panel with kit supplied handle

35-1/16"

Fresh Food Panel

+

Freezer Panel

35 4/4"

45-9/16"

/

/

2141/16"

ZIS36N Bottom Mount Refrigerator

• TheZKTC36L(or ZKTC36R)trim kit provides for the

installation of 3/4"thick custom door andgrille panels,

using the supplied handle. Cat panels to size and

install.

Custom Grille Panel

35 1/4"

A 3/4" Thick Panel

J.

Grille Panel height can vary to fill installation

height,

Installation Height Dimension A

83-1/2" 7-3/4"

84" 8-1/4"

84-1/2" 8-3/4"

Important:Maintain 1-1/2"min, gap between

top of door and bottom of grille panel,

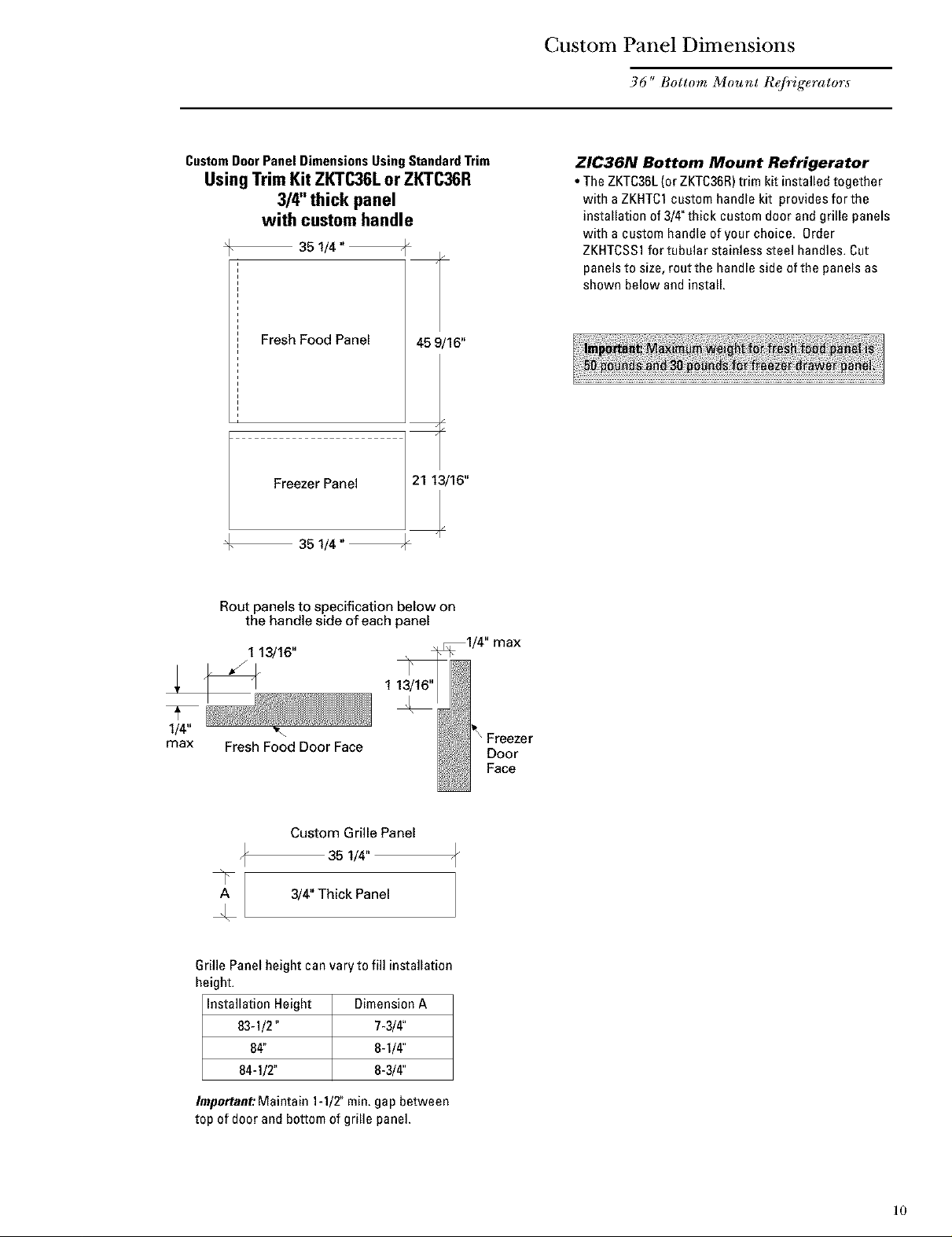

Page 10

Custom Panel Dimensions

36" Bottom Mount Refrigerators

CustomDoor PanelDimensionsUsingStandardTrim

Using Trim Kit ZKTC36L or ZKTC36R

3/4" thick panel

with custom handle

4F 35 1/4 "

Fresh Food Panel 45 9/16"

Freezer Panel

+

Rout panels to specification below on

the handle side of each panel

35 1/4"

ZIC36N Bottom Mount Refrigerator

• The ZKTC36L(or ZI(TC36R)trim kit installed together

with aZKHTC1custom handle kit provides for the

installation of 3/4"thick custom door and grille panels

with a custom handle of your choice, Order

ZKHTCSS1for tubular stainless steel handles. Cut

panelsto size, rout the handle side of the panels as

shown below and install.

1 13/16"

1/4"

max

Fresh Food Door Face

A 3/4" Thick Panel

\

Custom Grille Panel

35 1/4"

&

Grille Panel height can vary to fill installation

height.

Installation Height Dimension A

83-1/2" 7-3/4"

84" 8-1/4"

84-1/2" 8-3/4"

Important:Maintain 1-1/T min. gap between

top of door and bottom of grille panel.

1 13/16"

Door

Face

10

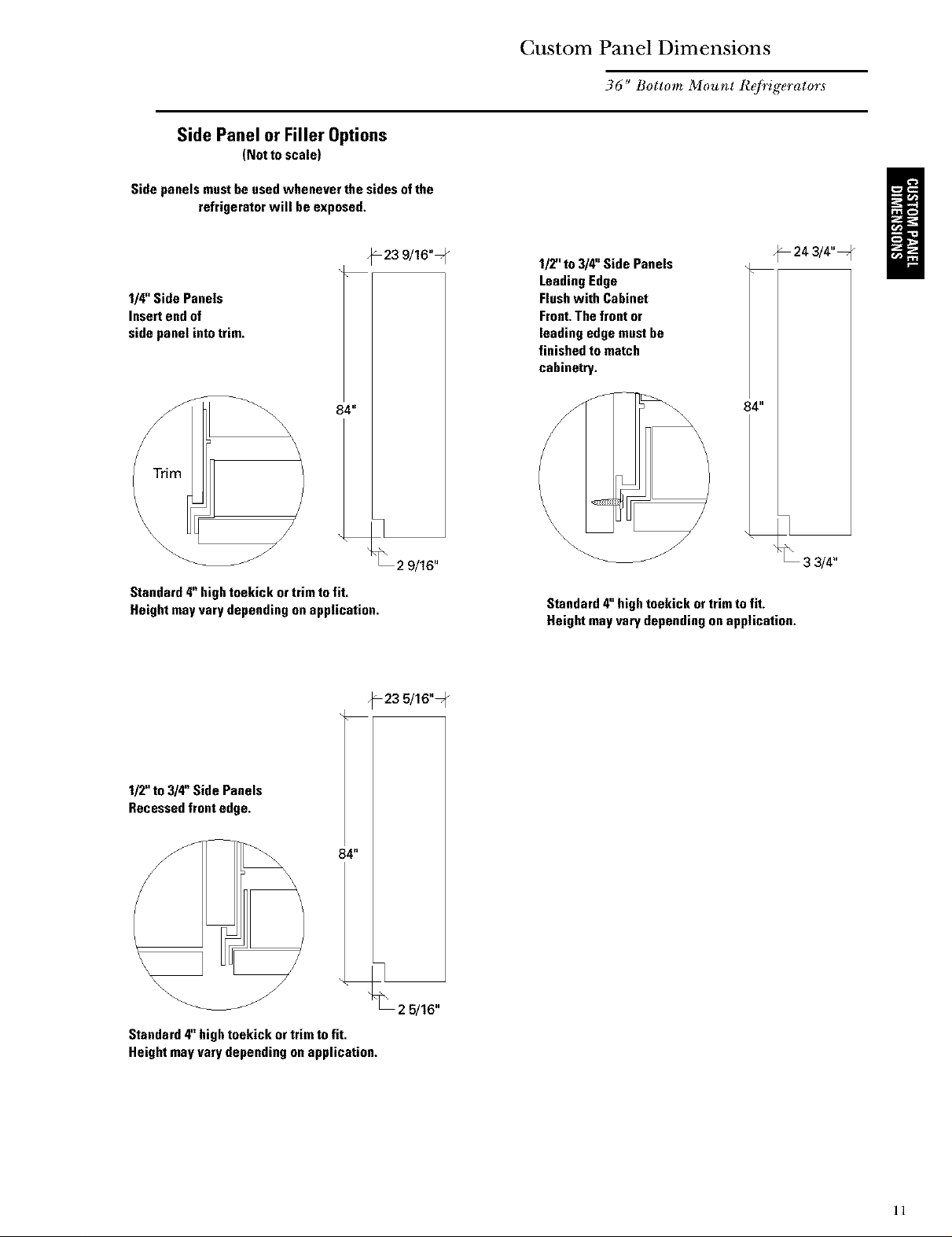

Page 11

Side Panel or Filler Options

(Notto scale)

Side panelsmast heused whenever the sides ofthe

refrigerator will beexposed.

Custom Panel Dimensions

36" Bottom Mount Refrigerators

114"Side Panels

Insertendof

side panel intotrim,

84"

\\\\

Standard4"hightoekick ortrim to fit,

Height may varydependingonapplication.

_23 9/16"7

-23 5/16" q_

1/2" to3/4"Side Panels

_24 3/4"=

LeadingEdge

Flushwith Cabinet

Front.Thefront or

leadingedge mastbe

finishedto match

cabinetry.

84"

\

Standard4"hightoekick ortrim tofit.

Height mayvarydependingonapplication.

112"to 3/4" Side Panels

Recessedfrontedge.

84"

Standard4"hightoekick or trim tofit.

Heightmayvarydependingonapplication.

25/16"

11

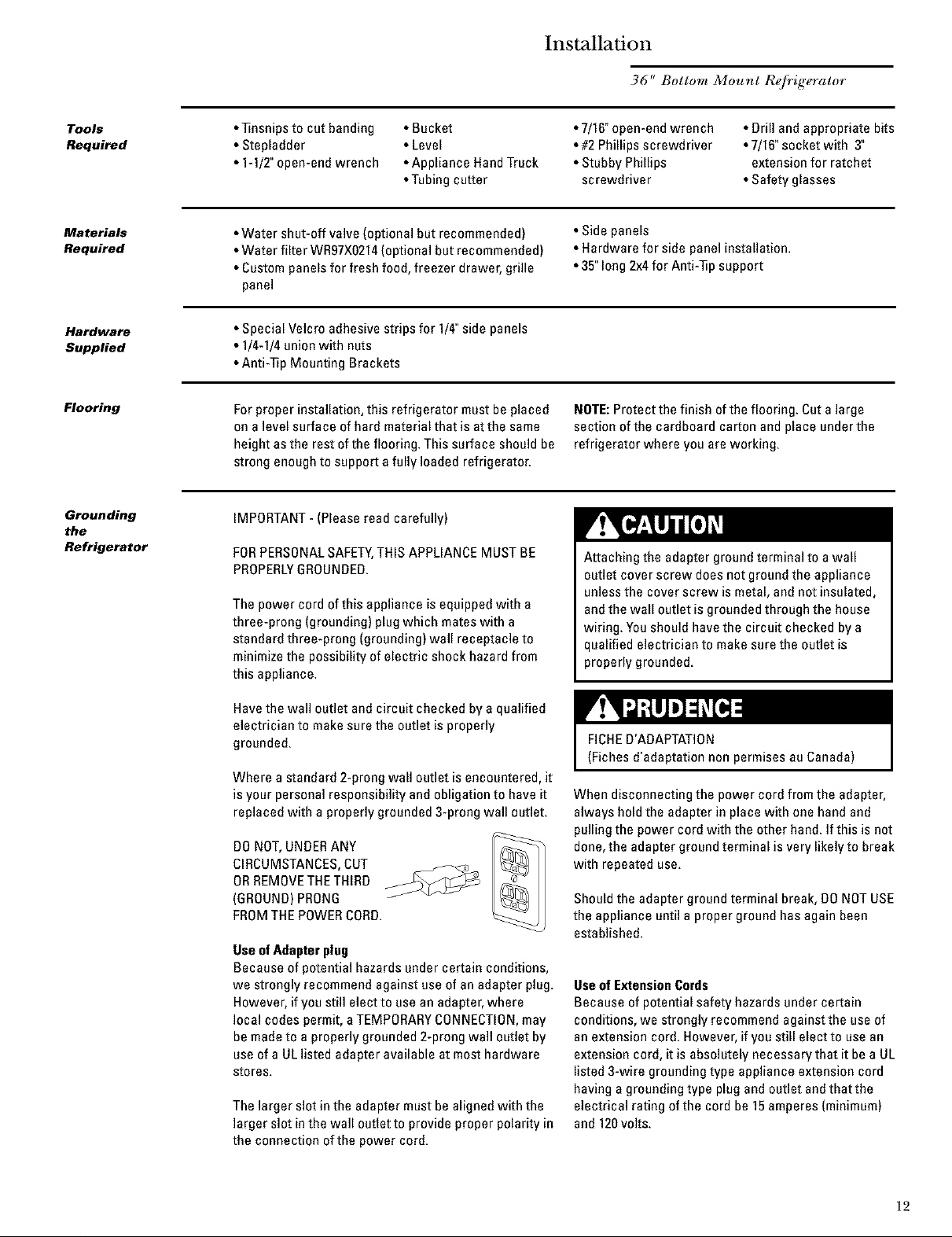

Page 12

Installation

36" Bottom Mount R@ig_rator

Tools

Required

Materials

Required

Hardware

Supplied

Flooring

Grounding

the

Refrigerator

• Tinsnips to cut banding

• Stepladder

• 1-1/2"open-end wrench

• Bucket

• Level

• Appliance Hand Truck

• Tubing cutter

• Water shut-off valve (optional but recommended)

• Water filter WR97XO214(optional but recommended)

• Custom panels for fresh food, freezer drawer, grille

panel

• Special Velcro adhesive strips for 1/4"side panels

• 1/4-1/4union with nuts

• Anti-Tip Mounting Brackets

Forproper installation, this refrigerator must be placed

on alevel surface of hard material that is atthe same

height asthe rest of the flooring. This surface should be

strong enough to support a fully loaded refrigerator.

IMPORTANT- (Please read carefully)

FORPERSONALSAFETY,THIS APPLIANCE MUST BE

PROPERLYGROUNDED.

The power cord of this appliance is equipped with a

three-prong (grounding) plug which mates with a

standard three-prong (grounding) wall receptacle to

minimize the possibility of electric shock hazard from

this appliance.

• 7/15"open-end wrench

• #2 Phillipsscrewdriver

• Stubby Phillips

screwdriver

• Drill and appropriate bits

• 7/16"socket with 3"

extension for ratchet

• Safety glasses

• Side panels

• Hardware for side pane] installation.

• 35"long 2x4for Anti-'tip support

NOTE:Protectthe finish ofthe flooring. Cut a large

section of the cardboard carton and place under the

refrigerator where you are working.

Attaching the adapter ground terminal to a wall

outlet cover screw does not ground the appliance

unless the cover screw is metal, and not insulated,

andthe wall outlet is grounded through the house

wiring. Youshould have the circuit checked by a

qualified electrician to make sure the outlet is

properly grounded.

Havethe wall outlet and circuit checked bya qualified

electrician to makesure the outlet is properly

grounded.

Where a standard 2-prong wall outlet is encountered, it

is your personal responsibility and obligation to have it

replaced with a properly grounded 3-prong wall outlet.

DO NOT,UNDERANY

CIRCUMSTANCES,CUT

ORREMOVETHETHIRD

(GROUND)PRONG

FROMTHEPOWERCORD.

Useof Adapterplug

Because of potential hazards under certain conditions,

we strongly recommend against use of an adapter plug.

However, if you still elect to use an adapter, where

local codes permit, aTEMPORARYCONNECTION,may

be made to a properly grounded 2-prong wall outlet by

use of a UL listed adapter available at most hardware

stores.

The larger slot in the adapter must be aligned with the

larger slot in the wall outlet to provide proper polarity in

the connection of the power cord.

FICHED'ADAPTAT]ON

(Fiches d'adaptation non permises au Canada)

When disconnecting the power cord from the adapter,

always hold the adapter in place with onehand and

pulling the power cord with the other hand. If this is not

done,the adapter ground terminal is very likely to break

with repeated use.

Should the adapter ground terminal break, DONOTUSE

the appliance until a proper ground has again been

established.

Useof ExtensionCords

Because of potential safety hazards under certain

conditions, we strongly recommend against the use of

an extension cord. However, if you still elect to use an

extension cord, it is absolutely necessary that it be a UL

listed 3-wire grounding type appliance extension cord

having a grounding type plug andoutlet and that the

electrical rating of the cord be 15amperes (minimum)

and 120volts.

12

Page 13

Step 1

Remove

Packaging

Refrigerator is much heavier at the top than at the

bottom- be careful when moving. When using a

hand truck, handle from side only.

Le r6frig6rateur est beaucoup plus Iourd en haut

qu'en has.II faut _tre prudent Iors des

d6placements. Si un diane est utilis6, il faut

soulever le r6frig6rateur sur le cOt6 aeulement.

• Removeouter carton.

- Carefully cut banding atthe top and bottom.

• Slide out back corner posts (2).

• Slide carton off top of cabinet.

NOTE:IT IS NOT NECESSARYTO LAYCABINETDOWN

IN ORDERTOREMOVESKID!

• Toremove skid, removethe four 7/16"bolts and their

brackets.

• There are support blocks on the bottom ofthe cabinet

anddoor. They must be removed before sliding unit off

skid or damage will occur.

DONOTATTEMPTTOROLLUNIT OFFSKID.

Installation

36" Bottom Mount Refrigerator

7/1B"Bolt

/

• Carefully, tilt cabinet and slide blocks out from

beneath cabinet, slide unit off skid.

• Removetoekick from the fresh food compartment, set

aside for later installation.

IL NE EAUTPASESSAYERDEFAIREROULERLE

REFRIGI_RATEURPOURL'ENLEVERDEkAY PALETTE.

Step2

_s_H

Wa_rLme

• A cold water supply is required for automatic

icemaker operation. The water pressure must be

between 20 and 120p.a.i.

• Route 1/4"ODcopper tubing between house cold

water line and the water connection location.

• Copper tubing should be long enoughto extend to the

front ofthe refrigerator. Allow enough to accommo-

date bend leading into the water valve.

Shutoffthe mainwater supply.

Turn onthe nearest faucet long enough to clear the line

ofwater.

• install a shut-off valve between the icemaker water

valve and cold water pipe in a basement or cabinet.

The shut-off valve should be located where it will be

easily accessible.

NOTE:It is best to install the valve into a vertical water

pipe. If you install the valve into a horizontal water pipe,

makethe connection at the top or side, rather than at

the bottom, to avoid drawing off any sediment from the

water pipe.

• Drill a 1/4"hole in the water pipe.

• Fasten the shut-off valve to the pipe with pipe clamp.

• Tighten the clamp screws until the sealing washer

begins to swell. Do not over tighten.

• Place a compression nut and ferrule (sleeve} onto the

endof the tubing and connect it to the shut-off valve.

Make sure the tubing isfully inserted into the valve

andferrule is tightened.

• Turn onthe main water supply and flush debris from

the line. Run about a quart of water through the tubing

into a bucket. Shut off water supply at the shut-off

valve.

Floor

CopperTubingJ

SaddleType dnlet End

ShutoffValve

Packing.Nut

ionNut

0utletValve \

Ferrule

(Sleeve}

NOTE: Saddle type shut-off valves are included in

manywater supply kits. Before purchasing, make sure

asaddle type valve complies with your local plumbing

codes,

• Install optional water filter in the water line near the

refrigerator. A water filter is recommended in areas

where water supply contains sand or particles.

Installation instructions are packed with the filter.

13

Page 14

Installation

36" Bottom Mount ReJi_igerator

Step 3

Install

Side Panels

• Side panels are not required when the refrigerator is

installed into an enclosure. Skip this step if you are

installing into an enclosure,

• Side panels are required whenever the sides ofthe

refrigerator will be exposed and when installed

between frameless cabinets. See pages 3and 4.

• Side panel installation will be determined by the

design of the side panel you have previously chosen,

• Side panels must be installed plumb.

Illustration A I

Cabinet

1/4"Side panels - Insert end of side panel into case

trim. Fasten with Velcro strips provided.

Illustration C

• If you choose to use 1/4"side panels, they should be

inserted into the case trim as illustrated. Fasten the

panelsto the refrigerator with Velcro strips (provided)

before setting refrigerator in place. See illustration A.

• 1/2"to 3/4"side panels are normally set into place and

fastened to adiacent cabinetry or the back wall before

rolling the refrigerator into the opening. Seeillustra-

tions B and C.

Illustration B

--- \

\

\

Refrigerator

Cabinet

\

\

Refrigeratordoor\

1/2"to 3/4" Side Panels - Leading edge of side panel is

flush with cabinet front. Fastento the back wall using a

cleat,

\

1/2"to 3/4" Side Panels - Recessed front edge of side

panel. Fasten to adiacent cabinet.

14

Page 15

Installation

36" Bottom Mount R@ig_rator

Step 4

Install

Anti-Tip

Brackets

!_i_r,111kqh_[€llANTI-TIP PRECAUTIONS

he refrigerator is heavy at the top and mustbe

ecured topreventthe possibilityof tippingforward.

PRECAUTIONSCONTRELESBASCULEMENTS

Le r(_frigerateurest beaucoupplusIourd en hautet

ilfaut le maintenir enplace poureviter la

possibilitede sonbasculementversI'avant

• Mount brackets provided using #12or #14wood

screws located 83-1/Z from the finished floon

• Screws must protrude at least one inch into vertical

wall studs.

• Attach a 35"long 2x4 block to brackets as shown,

Roll RefrigeratorIntoOpening

• Gently push refrigerator into opening with hands

against front corners, The cardboard protective pad

should be beneath the refrigerator,

• Roll refrigerator into the opening until it is flush or

semi-flush with adiacent cabinets.

83-1/2"

From

Floor

to

Bottom

ofWood

Block

SideView SideView

_Mounting Bracket

_83q/2" FromFloor

_-- _ WoodScrewsMountedinto

VerticalWoodStuds

Important Note: When the refrigerator is installed under a

soffit or if there is not enough height for this method of

security, use Step 6 as an alternate. The refrigerator must

be secured to prevent tipping.

Step 5

Level

Refrigerator

Step 6

Secure

Refrigerator

to Sides

All models have 4-point leveling. The front is supported

byleveling legs,the rear is supported by wheels.

• Adjust rear wheels beneath the refrigerator to iuat

barely touch the 2x4 block.

• Turn the 7/16"hex nut located above the front wheels.

Turnto raise or lower the refrigerator.

• For front leveling legs, use a 1-1/2"open-end wrench.

• Adjust carefully, the refrigerator should be level and

plumb with cabinetry, and should align with toekick

height.

Noter Whenever possible,

perform this step for

additional anti*tip security.

This step can be used as an

alternate to Step 4, Anti*Tip

bracket installation,

whenever brackets cannot be

used.

When using 1/2"to 3/4" side panels, the front flange of

the case trim is attached to the side panel.

• Openfresh food door to access case trim.

• Drill hole intrim slightly below fresh food opening.

Drive screw through the trim andinto the side panel.

• Follow the same procedure on the opposite side.

HexNI

RearWheets

LevelingLeg

OR

_J

If refrigerator is installed between cabinets with no

side panels or in a custom enclosure, install a spacer

block as shown.

• Openfresh food door to access case trim.

• Drill hole intrim slightly below fresh food opening and

drive screw through the trim and into the spacer

block.

• Follow the same procedure on the opposite side.

15

Page 16

Installation

36" Bottom Mount R@ig_rator

Step 7

Connect

Water

Supply

Step 8

InstaH 1/4"

doorpane_

Checkto be sure that refrigerator power cord is not

plugged into the wall outlet.

• Locate and bring copper tubing to the front of the

cabinet.

• The copper tubing should be just long enough to

reach the coupling. Excesstubing length could interfer

with drawer closing or toekick installation.

• Slip a 1/4-1/4union nut(provided) over both ends of

the copper tubing at the right front leg of the refrigera-

tor and couple the lines.

• Turn on the water to check for leaks.

If you are using3/4"thick custom panels, SKIPTHIS

STEP.See CustomPanel Dimensions pagesfor panel

sizes with ZKTC36Lor ZKTC36Rtrim kit and other kits.

Referto trim kit installation instructions in this booklet.

Freshfood doorpanel:

• Opendoor to 90°stop. Removethe Phillips head

screws from the aluminum trim door handle.

• Remove handle. Retain all screws.

• Slide custom panel into the door trim.

• Replace door handles and secure with original

screws,

I

_k

i

Freezerdrawer panel:

• Slide freezer drawer out about half way.

• Removethe Phillips head screws from the aluminum

trim door handle.

• Lift off handle. Retain screws.

• Slide custom panel into

the drawer trim.

• Replace the drawer handle

and secure with

original screws.

Remove

4 Screws

.I

Install

Original

Screws

16

Page 17

Installation

36" Bottom Mount ReJi'igerator

Step 9

Connect

power

Step 10

Mount

Top Grille

Panel

• Connect refrigerator power cord plug to a properly

grounded receptacle, accessible through the top lelt

side ofthe grille opening.

• Checkto make sure power to refrigerator is on by

opening refrigerator door to see if interior lights are

on.

If you are using 3/4"thick custom panels, SKIPTHIS

STEP. SeeDimensions and Specifications for grille

panel sizes. Order ZKTC36Lor ZKTC36Rand follow the

installation instructions packed with the kit.

The grille panel frame isfactory assembled for an 84"

installation height. If installation height varies, order

ZGC2trim kit which provides optional sidetrim pieces

for 83-1/2"and 84-1/2"heights.

Cut 1/4"thick custom panel to fit the frame,

35-1/8"wide, 8"deep (for an 84" installation).

Toinsert customgrille panel into the frame:

• Removescrews (2 on each top corner) and "L"

brackets on each side.

• Slide panelinto the frame and reassemble.

• Mount the grille panel by dropping into slots on the

case trim.

Top

Case

Trim

RaiseTot

Installation

Height

Step 11

Install

Toekick

• Forshipping purposes, the top case trim is secured at

84"installation height.

Toraise casetrim to 84-1]2"orto lower to 83-1/2"

installation height:

• Loosen 2screws on both sides and raise the top or

lower case trim to meet soffit height or to the top of

adjacent cabinets.

•]]ghten all 4 screws.

J

_iln/.2"

/

g

Important Maintain 1-1/2" min gapbetween top of doors and

bottom of panel frame

• A standard toekick is supplied. Install with 2 screws

provided, adiust to desired height and tighten screws.

Important:The vented toekick must remain unobstructed

for proper air circulation and operation.

17

Page 18

This kit provides optional side trim pieces for the

original grille panel frame to fit 83-1/2" and 84-1/2"

installation heights.

Tochange grille panel size:

• Determine the installation height by measuring the

enclosure from the floor to the underside of soffit.

When there is no soffit, measure to the top ofthe

adjacent cabinets.

• Adjust refrigerator case trim to desired height. See

Product installation.

• Select the side trim pieces for your installation height.

A. Locate original grille panel frame supplied with the

refrigerator.

• Remove8 screws (two on each corner) and "L"

brackets asillustrated.

B.Select correct set of side trim pieces (2 sets

provided).

• Secure new side trim pieces to original bottom trim.

ZGC2 Trim Kit

Grille panel.f_'ame adjustment

E.Mount the assembled panel by dropping into slots on

the case trim.

J

[12_ _Barrel_ Discard

_uts r SideTrim

Pieces

C.Removebarrel nuts from original sidetrim pieces (2

each side).

• Reinstall the barrel nuts on the new side trim pieces

you have selected. Discard original sidetrim.

@

_q9

D.Slide custom panel into front slots.

• Secure the top trim piece to the frame with "L"

brackets andscrews.

ImportantrMaintain 1-1/2" rain, gap between top of door

and bottom of grille panel.

18

Page 19

ZKHCI Trim Kit (for 1/4" Panels)

Support Jbr custom handles

Step 1

Remove

handles

Toolsand materials required:

• #2 Phillipsscrewdriver

• Drill and appropriate bits

• Custom door panels

• Custom Handles

• Safety glasses

Paris List."

A, Fresh food door extrusion {for left hand models}

B, Fresh food door extrusion {for right hand models}

C. Freezerdrawer extrusion

This kit provides the necessary framework to install

custom handles, of your choice, onto 1/4"thick custom

panels. (Handles not included.) The extrusions in this kit

allow the custom handles to be secured to the door

structure, rather than the door panels.

• Select fresh food extrusion for your model, discard

other fresh food extrusion.

Freshfood door:

• Open doorto 90°, Removethe screws from the full

length aluminum handle,

• Retain screws. Discard handle,

Freezerdrawer:

• Slidethe freezer drawer open, about half way.

• Removescrews from thefull-width aluminum handle.

Retain screws. Discard handle.

Righthand door swing models are illustrated in these

instructions, Follow these instructions for left hand

models,

Remove

4Screws

19

Page 20

Step 2

Locate

handle

positions

ZKHC1 Trim Kit (for 1/4" Panels)

!i!_iii!ii_i_iiii!_!_iiiiii!iii_i_i_!:!ij_ii!ii_!i!ii!i!

\

\

\

Support Jbr custom handles

3/4 Min

1-1/2"Max

Freshfood door:

• Slide custom panel into the door trim.

• Temporarily secure the new handle extrusion to the

door using at least 2 screws,

• The custom handles must belocated 3/4"to 1-1/Z

from the edge of the extrusion,

Install

• Determine the desired location of the custom handle

and mark centedinea of the screw holes

• Drill 1/16 pilot hole through the panel until it starts

into the aluminum extrusion This will markthe

matching location for drilling the clearance hole when

assembling the handle, panel and extrusion

Freezerdrawer:

• Slide custom panel into the freezer drawer trim

• Temporarily secure the new handle extrusion to the

drawer using at least 2 screws

• The handle must belocated 3/4" to 11/2 from the

edge of the extrusion

• Determine the location of the custom handle and

carefully mark centerlines of the screw holes

• Drill 1/16"pilot hole through the panel until it starts

into the aluminum extrusion Thiswill mark the

matching location for drilling clearance holes when

assembling the handle, panel andextrusion

20

Page 21

Step 3

Assemble

panel,

extrusion and

handle

Decorator--/ !

DoorPanel

Handle_/ / 3/4" Min.

_"Max.

_Extrusion

ZKHCI Trim Kit (for 1/4" Panels

Support,/or custom handles

Screw

Decorator _" !

Door_-/

Panel

÷1

Freshfood (leer: Freezerdrawer:

• Removethe door extrusion and custom panel. • Removethe handle extrusion and panel.

• Drill 1/16"pilot hole through extrusion. • Drill 1/16"pilot hole through extrusion.

• Drill clearance holes through the panel and extrusion. • Drill clearance holes through the panel and extrusion.

• Assemble the door panel, extrusion and custom handle. "Assemble the door panel, extrusion and custom

• Install screw(s) long enough to pass through the handle.

extrusion, door panel and into the handle. • Install screws(s) long enough to pass through the

• Slide the assembly into the door frame until the new extrusion, door panel and into the handle.

extrusion fits firmly against the steel door. • Slidethe assembly intothe drawer trim until the new

• Reinstall original screws into the door extrusion, extrusion fits firmly against the steel drawer.

• Reinstall original screws into the extrusion.

21

Page 22

ZKTC36L/ZKTC36R Trim Kit

3/4" Custom Panels

Kit Contents

Righthand door swing models are illustrated in these

instructions. Follow these instructions for left hand

models.

Toolsand materials

required:

• #2 Phillips screwdriver

• Drill and appropriate

bits

• Custom door panels

• Patty knife

• Safety glasses

PartsList

A. Toptrim

B.Fresh Food Handle

C,Hinge side trim

D Bottom trim

E.Freezer Handle

ESide Trim

G.Side Trim

H.Bottom trim

l, Support brackets for

custom panels

J. 4-3/8" screws for

support brackets

(2O)

K, Grille support

panel and screws

H

(0)

L Wood screws #6

1/2"flat head

screws (30)

This kit provides for the installation of 3/4"thick custom

door and grille pane]s. Handles are included and must

replace the supplied handles,

F

G

K

Note: if you are using

custom handles, see

ZKHTC1 installation

instructions. For tubular

stainless steel handles, see

ZKHTCSS1 installation

instructions.

22

Page 23

ZKTC36L/ZKTC36R Trim Kit

3/4" Custom Panels

Step 1

Remove

handles

and trim

Freshfood door:

• Open doorto 90°

• Removethe Phillips head screws from the full length

handle, remove handle.

• Openthe doorfully to stop.

• Removethe screws from the aluminum trim, top

bottom, hinge and handle side.

• Retain screws. Discard original trim and handle.

Freezerdrawer:

• Slidethe drawer fully open.

• Lift out top and bottom freezer

baskets,

• There are 2 sets of 4 screws on

the inside of the drawer door,

insert putty knife behind screw

cover and snap off. Retain screw

covers.

• Loosen all screws.

• Carefully, lift off entire drawer

door.

• Place door on a protected surface,

front side down. Take care not to

bend switch plate onthe bottom of

the door.

• Removelight switch plate by

backing out 3 Phillips head

screws. Retain switch plate and

screws.

*Turn the drawer over,front side

up. Removetrim on both sides,

bottom and handle. Retain all

screws.

..--"

Drawer Slides

.

Inside Freezer Drawer

Atta chmentScrews

&==A

Light Switch Plate

T T _

FrontFace Freezer Drawer

LightSwitch Plate

23

Page 24

ZKTC36L/ZKTC36R Trim Kit

3/4" Custom Panels

Step 2

Install

3/4" trim

FreshFoodDoor:

• Attach the new 3/4"trim pieces on the top, hinge side

and bottom using original screws.

FreezerDrawer:

• Attach the new 3/4"trim pieces on the bottom and

both sides.

Front FaceFreezer Drawer

Step 3

Apply panel

support

brackets

• Position support bracket on the back side ofthe fresh

food panel, 14-5/16"from the hinge side. Secure

support bracket to panel with screws provided.

• Position support bracket on the back side ofthe

freezer drawer panel,14-5/16"from the right side.

Secure support bracket to pane] with screws

provided.

1 L 1

BackSideFreshFoodPanel

Side

114-5/16"_ BottomEdge

BackSideFreezerDrawerPanel

-L14-5/16"_ BottomEdge

24

Page 25

ZKTC36L/ZKTC36R Trim Kit

3/4" Custom Panels

Step 4

Install

panels

FreshFoodPanel:

• Place the 3/4"thick panel on the bottom trim with

support bracket tabs inserted into slots. Push the

panel back against the steel door, flush with hinge

side trim.

• Open the door fully.

• Carefully drill 4starter holes using a small drill bit,

through the backside of the trim at the top.

• Install original screws through the trim and into the

panel to secure the panelto the door.

• Drill 4 starter holes through the hinge side and 4

through the bottom trim. Install original screws.

Freezerpanel:

• Place the 3/4"thick panel onto the door with the

support bracket tabs inserted into slots. Thesides of

the panel should be flush with trim on both sides.

• Turn door over, panel side down. Attach the panel to

the sides and bottom by installing screws through the

back of the trim and into the wood panel.

• Reinstall lightswitch plate to the bottomtrim with

original screws.

/ /"

/

Insert support bracket tabs

into slots on bottom trim

Inside Freezer Drawer

/"

LightSwitch Plate

25

Page 26

ZKTC36L/ZKTC36R Trim Kit

3/4" Custom Panels

Step 5

Install

handles

Step 6

Adjust

grille

panel height

• Install new fresh food door handle using original

screws.

• Place assembled drawer door onto freezer slides.

• Tighten screws and snap on screw covers.

• Install new freezer drawer handle with original

screws.

• For shipping purposes, the top case trim is secured at

the 84"installation height.

• Loosen 2 screws on both sides ofthe case trim and

raise or lower trim to meet soffit height, from 83-1/2"to

84-1/2".

• Tighten all 4 screws.

Important: Maintain 1-1/Z' min. gap between top of door

and bottom of grille panel,

Install

4Screws

Top

Case

_im

Installation

Height

Step 7

Secure 3/4"

panel to

grille panel

support

• Secure the grille panel support to the back side of the

3/4" custom panel with #6 screws,

• Be sure the lip ofthe support is over the top of the

wood panel.

PanelSupport

J

f_

f

26

Page 27

ZKTC36L/ZKTC36R Trim Kit

3/4" Custom Panels

Step 8

Install

grille panel

• Install four of the six larger undercut screw so that the

top of the screws are 1/16"from the surface of the

support.

• Attach the assembled panelto the refrigerator by

inserting the four protruding screws into the brackets

on each side of the grille opening.

27

Page 28

ZKHTC1 Trim Kit (For 3/4" Panels)

Support,/or Custom Handles

Kit Contents

Righthand door swing models are illustrated in these

instructions. Follow these instructions for left hand

models.

Toolsand materials required:

• #2 Phillips screwdriver

• Drill and appropriate bits

• Custom door panels

• Custom handles

• Safety glasses

Note:This kitmust beused incombination with ZKTC36L

or ZKTC36Rtrim kitfor 3/4"paneltrim.

Part List:

A. Fresh food handle extrusion (for left hand models)

B.Fresh food handle extrusion (for right hand models)

C. Freezerdrawer extrusion

This kit provides the necessary framework to install

custom handles, of your choice, onto 3/4"thick

decorator door panels. (Handles not included.) The

door extrusions allow the custom handles to be

secured to the door structure, rather than the door

panels.

• Select fresh food handle extrusion for your model,

discard other fresh food extrusion.

Before

you begin

3/4" custom door panels must be routed to accommo-

date these door handle extrusions. Routthe panels as

illustrated, 1/4"deep, and 1-13/16"wide onthe handle

side of the fresh food panel and the top end of the

freezer panel.

Referto installation instructions for ZKTC36Lor

ZKTC36Htrim kit for 3/4"custom panels:

• Follow Step 1 to remove the standard aluminum trim.

• Follow Steps 2 and 3 to attach new 3/4"trim pieces

andto install panel support brackets.

FreshFoodPanel

FreezerDrawerPanel

,U1-13/16"

1/4" Max._ BackSide

HandleSide

Important: Optimal final appearance depends on careful

routing depth, Do not exceed 1/4" routing depth

Handle

End

28

Page 29

Step 1

Temporarily

mount door

pane_

Freshfood door:

• Place the prepared 3/4"custom door panels on the

bottomtrim with support bracket tabs inserted into trim

slots.

• Pushthe panel back against the steel door, making

surethe panel is flush with the hinge side trim.

• Secure the panel to the trim temporarily bydriving 2

screws through the backside of the trim atthe top.

• Slidethe handle extrusion in between the panel and

steel door.

• Temporarily secure the extrusion to the door with 2

screws.

NoterThe freezer drawer door should be removed as shown

in the installation instructions for the ZKTC36 kit. Follow the

instructions in Step 1to remove the door.

ZKHTC1 Trim Kit (For 3/4" Panels)

Support,/or Custom Handles

I

Insert support bracket tabs

into slots on bottom trim

Inside Freezer Drawer

%,

Freezerdrawer:

• Place the prepared 3/4"custom panel onthe bottom

trim with support bracket tabs inserted into the trim

slots.The panel should beflush with trim on both sides.

• Secure the panel to the trim temporarily bydriving one

screw through the back side of each sidetrim.

• Temporarily mountthe assembled drawer door onto the

drawer slides. This will help to determine the handle

location.

Note: Be careful not to bend light switch plate on the

bottom of the door.

• Slidethe handle extrusion in between the panel and

steel door.

• Temporarily secure the extrusion to the door with 2

screws.

29

Page 30

ZKHTC1 Trim Kit (For 3/4" Panels)

Support jbr Custom Handles

Step 2

Locate

position

of handles

Freshfood door:

• Determine the locationof the custom handles

and carefully mark centerlines ofthe screw

holes.The handles must be located 3/4" to

1-1/Z from the edge of the extrusion.

• Drill 1/16"pilot hole through the panel until it

starts into the aluminum extrusion. This will

mark the matching location for drilling a

clearance hole when assembling the

extrusion, panel and handle.

FreezerDrawer:

• Follow the same procedures as for the fresh

food door.

3/4" Min.

1-1/2"Max.

/" \

Step 3

Assemble

panel,

extrusion and

handle

Freshfood door:

• Removethe handle extrusion, the 2 temporary

screws and custom panel.

• Drill 1/16"pilot hole through extrusion.

• Drill clearance holes through the panel and

extrusion.

• Assemble the panel, extrusion and custom handle.

• Install screw(s) long enoughto passthrough the

extrusion, door panel andinto the handle.

Freezerdrawer:

• Removethe handle extrusion and entire assembled

drawer door.

• Remove panel from drawer door.

• Drill clearance holes through the panel and

extrusion.

• Assemble the panel, extrusion and custom handle.

• Install screw(s) long enoughto passthrough the

extrusion, door panel andinto the handle.

Screw\. I

I

I

1-f/2" Max.

3O

Page 31

Step 4

Mount

assembled

panels

ZKHTC1 Trim Kit (For 3/4" Panels)

Support,/br Custom Handles

Install

4Screws

J_ _J

Fresh food door:

• Place assembled panel ontothe bottom trim with

support bracket tabs inserted into slots.

• Pushthe panel back against the steel door with

handle extrusion flush to handle side of the door.

• Open doorfully to stop.

• Install original screws atthe top, hinge side and

handle side.

Freezerdrawer:

• Mount assembled door with panel onto freezer slides.

• Install original screws along the top handle extrusion.

31

Page 32

ZKHCSSI Trim Kit (For 1/4" Panels)

Tubular Stainless Steel Handles

Right hand door swing models are illustrated in these

instructions. Follow these instructions for left hand

models.

Note: It is best that 2 people install this kit,

Toolsand materials required:

• #2Phillips screwdriver

• Drill and appropriate bits

• Customdoor & drawer panels

• Safety glasses

• Center punch

• Masking tape

• Hammer

• Pencil

• 1/2"thick 12"x 12"rain. piece of plywood to protect

floor when drilling

• For stainless steel panels, wear glovesto protect

against sharp edges.

Parts List:

A. Handle extrusion(for left hand models)

B. Handle extrusion (for right hand models)

C.Freezer handle extrusion.

D. Freshfood and freezer door handles

E.6 Spacer rings (for Stainless Panels ONLY)

(4 required, 2 extra)

E4 Handle standoffs

G.6 Screws for mounting handle standoffs

(4 required, 2 extra)

H. 6Set screws (4 required, 2 extra)

I.3/32"Allen wrench for set screws

This kit provides for the installation of Stainless Steel

handles on 1/4"thick decorator door panels. The door

extrusions allow these custom handles to besecured

to the door structure, rather than to the custom panels.

• Select fresh food extrusion for your model, discard

other fresh food extrusion.

B

C

F

zzm

Step 1

Remove

handles

Freshfood door:

• Openfresh food door to 90%Removethe

screws from the full-length handle.

• Retain screws, discard handle.

Freezerdrawer:

• Slidethe drawer open about halfway.

• Carefully removethe Phillips head screws

from the top trim. Lift off handle.

• Retain screws, discard handle.

Remove

4 Screws

..

.I

32

Page 33

ZKHCSSI Trim Kit (For 1/4" Panels)

Tubular Stainless Steel Handles

Step 2

Match

handle

extrusions

to handle

See Step 2A

for Stainless

Steel panels

• Cut a piece of corrugated to use as a pad to protect

the panelfinish. Use 1/2"thick section of plywood to

protect flooring when drilling.

• Place custom panels on the pad, appearance side

down.

Freshfeed door:

• Onthe back side of the panel - at the handle side,

measure and mark 1/4"below thetop edge of the

panelwith a pencil.

• Slip panels into new extrusion on the handle side of

the panels.

• Align the extrusion at the pencil mark, 1/4"below the

top of the panel.

• Tape the extrusion to the panel to prevent movement.

• Center punch and drill 1/8"pilot holes through the

holes in the extrusion and into the panel.

• Turn panel over. Onthe appearance side, use 9/32"bit

to enlarge clearance hole.

Freezerdrawer:

• Lay panel onthe pad, appearance side down.

• Slip panel into the new extrusion onthe handle end.

• The panel should be even with both endsof the

extrusion. Tape panel to extrusion to prevent

movement.

• Center punch and drill 1/8"pilot holes through the

holes inthe extrusion and into the panel.

• Turn panel over. Onthe appearance side, use 9/32"bit

to enlarge clearance hole.

IMPORTANT'. Hole locations must be exact to accept

handle standoff and handle assembly,

Decorator

Door--/

Panel

_Extrusion

I

I

33

Page 34

ZKHCSSI Trim Kit (For 1/4" Panels)

Tubular Stainless Steel Handles

Stop 2A

Step 3

Install

standoffs

onto handles

Ifyon are installing those handlesonto Stainless

Steel Panels:

Use extreme caution if youare drilling through

stainless steel panels. Stainless steel panels must be

handled gently. Do not kneel on stainless steel panels.

Itwill leavea permanent dent. Donot remove protec-

tive plastic covering until final installation.

Freshfood door:

• Place supplied filler panel (corrugated) onfloor to use

asa pad.

• Onthe back side of the panel - at the handle side,

measure and mark 1/4"below thetop edge of the

panel.

• Slip panel into the new extrusion, flush against inner

edge, on the handle side.

• Align extrusion to pencil mark as shown in Step2.

Mark each screw hole location with pencil.

• Place a handle standoff onto attachment posts along

the handle. Position the set screw hole onthe

standoff to point to the floor.

• Install set screws into the bottom of each standoff,

using the Allen wrench provided. The standoff should

betight against the handle.

• Tape extrusion to panel to prevent movement.

• Place panel on plywood section, appearance side

down. Be sure plywood is clean without nicks and

burrs. Center punch at each screw hole location.

• Drill 1/8"pilot hole. Use 9/32"bit to enlarge clearance

hole.

• Measure and cut a 2"wide strip, top to bottom off the

corrugated panels. This will allow roomfor spacer

rings between the stainless panel and extrusion.

Freezerdrawer:

• Place supplied filler panel (corrugated) on floor to use

as a pad.

• Onthe back side of the panel - at the handle end,

slip panel into the new extrusion, even end to end.

• Mark each screw hole location with pencil.

• Follow the same procedure as for fresh food door.

Step 4

Install

handles

and panels

See Step 4A

for stainless

steel panels

Freshfood door:

• Slide panel into the door trim. Leave about 4" ofthe

panel exposed to allow room to install the handle

extrusion.

• Place extrusion onto the back side of the panel, install

mounting screws through the extrusion and just

through the panel.

• Drive screw part way through the top standoff, then

part way through the bottom standoff.

• Drive both screws until the handle is tight against the

panel.

• Removetape.

• Slidethe assembled panel into the door trim until the

extrusion fits firmly against the steel door. Reinstall

original screws into the extrusion.

Freezerdrawer:

• Slide panel into the drawer trim. Leave about 4"of the

panel exposed to allow room to install the handle

extrusion.

• Place extrusion onto the panel, install mounting

screws through the extrusion and just through the

panel.

• Drive screw part way through one standoff, then part

way through the other standoff.

• Drive both screws until the handle is tight against the

panel.

• Removetape.

• Slidethe assembled panel down until the extrusion

fits firmly against the top of the drawer. Reinstall

original screws into the extrusion.

Decorator

D°°iPanel=_

sciw

J

34

Page 35

Step 4A

Install

handles and

panels

ZKHCSSI Trim Kit (For 1/4" Panels)

Tubular Stainless Steel Handles

Screw

Stp_n,e;_iat_ SRP__ - Extrusi°n

Handle_--;

• Crimp top and bottom edges of corrugated.

• Slide corrugated into door and drawer trim, Leave

about 1/4"gapbetween edge of corrugated and

hinge side trim ofthe door and 1/4"gap above bottom

trim ofthe drawer,

• Place extrusion onto panel. Use a pencil to punch

hole in tape covering spacer rings and align with

screw holes

• Install mounting screws through the extrusion and

panel

• Drive screw part way through the top standoff, then

Note: Panels have a protective plastic covering. Peel

away just enough to allow panel to slide into trim and to

clear handle mounting screws. The plastic covering will

keep the panels clean during the installation process.

Be sureto maintain 1/4"gap between corrugated and

hinge side or bottom trim.

Freshfeed deer:

• Slide panels into the door trim. Leaveabout 4" ofthe

panel exposed to allow room to install the handle

extrusion,

• Place a spacer ring over each ofthe 2 screw holes

part way through the bottom standoff

• Drive both screws until the handles are tight against

the panel

• Slide the assembly into the door trim until the

extrusion fits firmly against the steel door

• Reinstall original screws into the door extrusion

Freezerdrawer:

• Follow the same procedure to install spacer ring,

mounting screws and handle to extrusion as de-

scribed for fresh food panel

• Slide the assembly down into the door trim until the

extrusion fits firmly against the steel drawer

• Reinstall original screws into the door extrusion

on the extrusion. Usetape to hold in place,

Raised Panel on 1/4"Thick Backing:

A raised panel design secured to a 1/4"thick backing

RaisedPanelon 1/4"Thick Backing

UsingStandardHandles

(screwed or glued) can be used with this handle kit.

• Cutthe 1/4"thick panels to size, _]

• Fabricate the raised panel to allow 14/4" clearance 1/4" __Appearance

from the hinge side ofthe fresh food panel to avoid Thick Panel

striking adjacent cabinetry, Backing

• Allow 5/16"clearance atthe other edges to allow for _ 5/16"

thetrim flange, [_ Clearance ,

• Total panel thickness should notexceed 3/4", u handleSide

• Countertops adjacent to the refrigerator installation r

should be mitered 45°, 5/16"

Clearance

HandleEnd

Note: Longer Screws, obtained locally, will be required to

accommodate panel thickness. Use stainless steel

#10_32x1-1/4" truss Phillips head screws.

5/1ffClearance

FreshFoodPanel

5/1ff Clearance

FreezerPanel

5!1651earance

5/16"Clearance

1-1/4"

Clearance

hingeside

35

Page 36

ZKHTCSSI for 3/4" panels

Tubular Stainless Steel Handles

Kit

Contents

Right hand door swing models are illustrated in these

instructions. Follow these instructions for left hand

models.

This kit provides for the installation of Stainless Steel

handles on3/4"thick decorator door panels. The door

extrusions allow these custom handles to be secured

to the door structure, rather than to the custom panels.

• Select fresh food extrusion for your model, discard

other fresh food extrusion.

Toolsand materials required:

• #2 Phillips screwdriver

• Drill and 1/8",9/32" bits

• Custom door panels

• Safety glasses

• Center punch

• Masking tape

• Hammer

• Pencil

Paris List:

A. Handle extrusion (for left hand models)

B.Handle extrusion (for right hand models)

C. Freezerdrawer handle extrusion

D.2Stainless tubular handles

E.4 Handle standoffs

E6 Screws for handle standoffs

(4 required, 2 extra)

G.6 Set screws (4 required, 2 extra)

H.3/3Z Allen wrench for set screws

This kit must be used in combination with ZKTC36,trim

kit.

Note:It is best that 2people install this kit.

Before

you begin:

• 3/4" custom panels must be routed to accommo-

datethese handle extrusions. Routthe panels

asillustrated, 1/4"deep, and 1-13/16"wide, top

to bottom on the handle side.

• Follow the instructions inthe ZKTC36R(or

ZKTC36L)to install trim onto the fresh food and

freezer drawer. Discard the handles supplied

with that kit.

• Continue the instructions inthe ZKTC36R(or

ZKTC36L)trim kit to install support brackets to

the bottom of the fresh food and freezer panels.

FreshFoodPane[

FreezerDrawerPane[

Handle

End

÷

Handle Side

IMPORTANT:Optional final appearance depends on

careful routing depth. Do not exceed 1/4"routing depth.

36

Page 37

ZKHTCSS1 for 3/4" Panels

Tubular Stainless Steel Handles

Step 1

Match Handle

Extrusions

to Panels

• Cut a piece of corrugated to use as a padto protect

the pane] finish. Additional material maybe required

to protect flooring when drilling.

• Place custom panels onthe pad, appearance side

down.

Nete: If panels are wood, besure to note which end is

the top sothat wood grain is in the correct direction on

both panels.

FreshFoodPanel:

Select fresh food handle extrusion for your model, left

or right side extrusion.

• Place extrusion against the handle side of the fresh

food panel.

• Align the extrusion evenlywith the top and bottom of

the panel.

• Tape the extrusion to the panel to prevent movement.

• Center punch and drill 1/8"pilot holes through the

holes in the extrusion and into the panel.

• Turn panel over. Onthe appearance side, use9/32" bit

to enlarge clearance hole.

FreezerPanel:

• Place extrusion against the handle end of the freezer

drawer panel.

• Align the extrusion evenly, side to side.

• Tapethe extrusion to the panel to prevent movement.

• Center punch and drill 1/8"pilot holes throughout the

holes in the extrusion and into the panel.

• Turn panel over. Onthe appearance side, use9/32" bit

to enlarge clearance holes.

AlignExtrusionEven

With Panel

Extrusion

EvenWith

Panel

Note,"Hole locations must be exactto accept handle

standoff and handle assembly.

Step 2

Install

Standoffs

onto Handles

• Place a handle standoff on each attachment post on

the handle. Position the screw hole on the standoff

to point to the floor.

• Install set screws into the bottom of each standoff,

using the Allen wrench provided. The standoff

should betight against the handle.

_Screw

_Wrench

37

Page 38

ZKHTCSS1 For 3/4" Panels

Tubular Stainless Steel Handles

Step 3

Install

mounting

screws

and handles

Step 4

Install

Assembled

Panels

FreshFoodPanel:

• Start mounting screws through the extrusion and iust

through the custom panel.

• Stand panelup on the hinge side and hold to access

the appearance side. Place handle against mounting

screws on the appearance side, drivetop screw from

the back ofthe extrusion partially into the standoff.

• Drive second screw partially into the standoff,

alternate back to the top until the handle istight

against the door.

FreezerDrawer Panel:

• Follow the same procedureto assemble handle to

panel,

It is best thet 2 people perform this step.

FreshFoodPanel:

• Place assembled panel onto the bottom door trim

with support bracket tabs inserted into slots.

• Push and hold the panel back against the steel door

with door handle extrustion flush to the handle side

of the door.

• Reinstall original screws into the door extrusion.

• Open the door fully to stop.

• Instag screws atthe top, and hinge side.

Note:The freezer drawer panel should be removed

as shown in the installation instructions for the

ZKTC36kit. Follow the instructions in Step 1to

remove the door.

FreezerDrawer Panel:

•Place the assembled pane] onto the bottom trim

with support brackets inserted into slots. The panel

should beflush with trim on both sides.

• Secure the panel to the trim at the bottom and both

sides.

• Mount the assembled drawer panel onto the freezer

slides. Tighten all screws.

• Install 4screws into the top of the handle extrusion

and into the door.

Install

4Screws

38

Page 39

ZFC1 Trim Kit

For the ultimate in convenience, install two refrigerators

side to side.

This trim kit includes 6 foam spacer pads to fill the gap

between the refrigerator side case trims. Forafinished

appearance, a trim strip is provided to conceal the case

trim ofthe two refrigerators.

Ifyou are installing into an enclosure, provide a 72"wide

opening. If you are installing where the sides of the

refrigerators will be exposed, allow additional width for

any side panels used.

• Apply foam spacer pads evenly to the side of one

refrigerator as shown.

Side to Side Installation

J

D a_I

• Slide second refrigerator into position.

• Check to besure both refrigerators are level. If they

are not level, anobvious gap can be seenbetween

the side trims. Adjust leveling legs if needed. Slight

gaps will be concealed with the trim strip.

• Open both fresh food doors to access side trim.

• The U-shape trim will overlap the side case trim of

both refrigerators.

• Set the top case trim (see page 17)to installation

height.

• Hold trim strip against top end of case, at the point

where case overlaps to the bottom of case trim. See

illustration.

• Mark length with a pencil.

• Trim excess length.

• Starting at the top, press trim strip over case trims of

both refrigerators.

• Continue pressing about half way down. Slide open

freezer drawers and continue pressing trim until you

reach the bottom of the strip.

D D.

n s j

CaseTrim

39

Page 40

Note: While performing installationsdescribed in this book,

safety glasses or goggles should be worn,

"l_ obtain spec!fic i_zJbrmation cor_cernin E l_r_y

Monogram product or service, caa GE Ar_sw_ Cente_

consumer b_lbrmatior_ service at 800.626.2000-a_y

time, day or nik,ht.

bbr Monogram '_' Ncal semice ir_your area, caa

1-800-444-1845.

Note: ProdHct improvement is a continuing endeavor at

General Electric. Therefore, materials, appearance and

specifications are su!_iect to change without notice.

Q Monogram

Genera[ Electric Compa_V

Louisville, KY40225

Pub. No. 49-60000-3

7999GEAppliances

Printed in U.S.A.(N0381) 3/99

5A 95020-02

Loading...

Loading...