Page 1

Design Guide with

Installation

Instructions

30" Built-In

Bottom-Freezer, 2-Dr(]wer

Refrigerator

monogram.tom

Page 2

Safety information

BEFORE YOU BEGIN

Readthese instructions completely and carefully.

. IMPORTANT- Savetheseinstructions

for local inspector's use.Observe all governing codes

and ordinances.

. Note to Installer - Be sure to leave these

instructions with the Consumer.

. Note to Consumer - Keep these instructions

with your Owner's Manual for future reference.

,Skill Level - Installation of this refrigerator requires

basic mechanical, carpentry and plumbing skills. Proper

installation is the responsibility of the installer. Product

failure due to improper installation is not covered under

the GEAppliance Warranty. Seethe Owner's Manual for

warranty information.

For Monogram local service in your area, call

1.800.444.1845.

For Monogram Parts and Accessories, call

1.800.626.2002.

www.monogram.com

A WARNING:

Thisappliancemust be properlygrounded.

See "GroundingtheRefrigerator,"page 5.

If you received a damaged refrigerator, you should

immediately contact your dealer or builder.

A CAUTION:

Due totheweightand sizeofthisrefrigerator,and to

reducetheriskofpersonalinjuryordamage tothe

product-TWO PEOPLE ARE REQUIRED FOR PROPER

INSTALLATION.

A WARNING:

. Theserefrigeratorsaretop-heavyand must

be securedto preventthepossibilityoftipping

forward.Anti-tipprotectionisrequired.See page 14

for details.

. Usethis appliance only for its intended purpose.

. Immediately repair or replace electric service cords

that become frayed or damaged.

. Turn off the circuit breaker to disconnect power

before cleaning or making repairs.

. Repairs should be made by a qualified service

technician.

WARN ING-R6OOaRefrigerant

Warning: This appliance contains isobutane refrigerant,

R6OOa,a natural gas with highenvironmental

compatibility.However it isalso combustible. Please

adhere to the warnings below:

1)When handling, installing and operating the appliance,

careshould betaken to avoid

damage to the refrigerant tubing.

2) Servicingshallbe performed by factory-authorized service

personneland component parts shall be replacedwith

manufacturer-authorized replacement components.

21)Refrigeration products contain refrigerants, which

under federal law must be removed prior

to product disposal.

41Keepventilation openings in the appliance enclosures or

inthe built-in structure clear of obstruction.

51Donot usemechanical devicesor other means

to accelerate the defrosting process.

61Donot damage refrigerant circuit.

7) Do not use electrical appliances insidethe

food storage compartment of the appliance.

CONTENTS

Design Guide

Cabinet Enclosure Dimensions ............3

Refrigerator Dimensions..........................4

The Installation Space..............................5

Grounding the Refrigerator ....................5

Dimensions and Clearances ..................3

Integrated Handles

115° Door Swing ........................................6

Integrated Handles

90° Door Swing ............................................7

Professional Handles

1!5 ° Door Swing ........................................8

Professional Handles

90° Door Swing ............................................9

SSPanel Accessory & Dimension ....10

3/8" Custom Panel Dimensions ........11

Installation Instructions

Tools, Hardware, Materials ..................12

Step 1, Remove Packaging ..................13

Step 2, Install Anti-tip Bracket............1/4

Step 3, Thread Water Line ..................1/4

Step 4, Connect Power ..........................1/4

Step 5, Remove Toekick and Vent....15

Step 6,Slide Unit into Enclosure ......15

Step 7,Connect Water Line ................15

Step 8, Level Refrigerator ....................16

Step 9, Install Toekick and Vent........16

Step !0, Reverse Door Swing......17,18

Step !!, Adjust Door Swing ................18

Step 12,Attach Hinge Guard ..............18

Step 13, Install Door and Drawer

Panels..........................................19

Step 14, Start Icemaker ........................20

Badge Templates ....................................21

Page 3

Design Guide

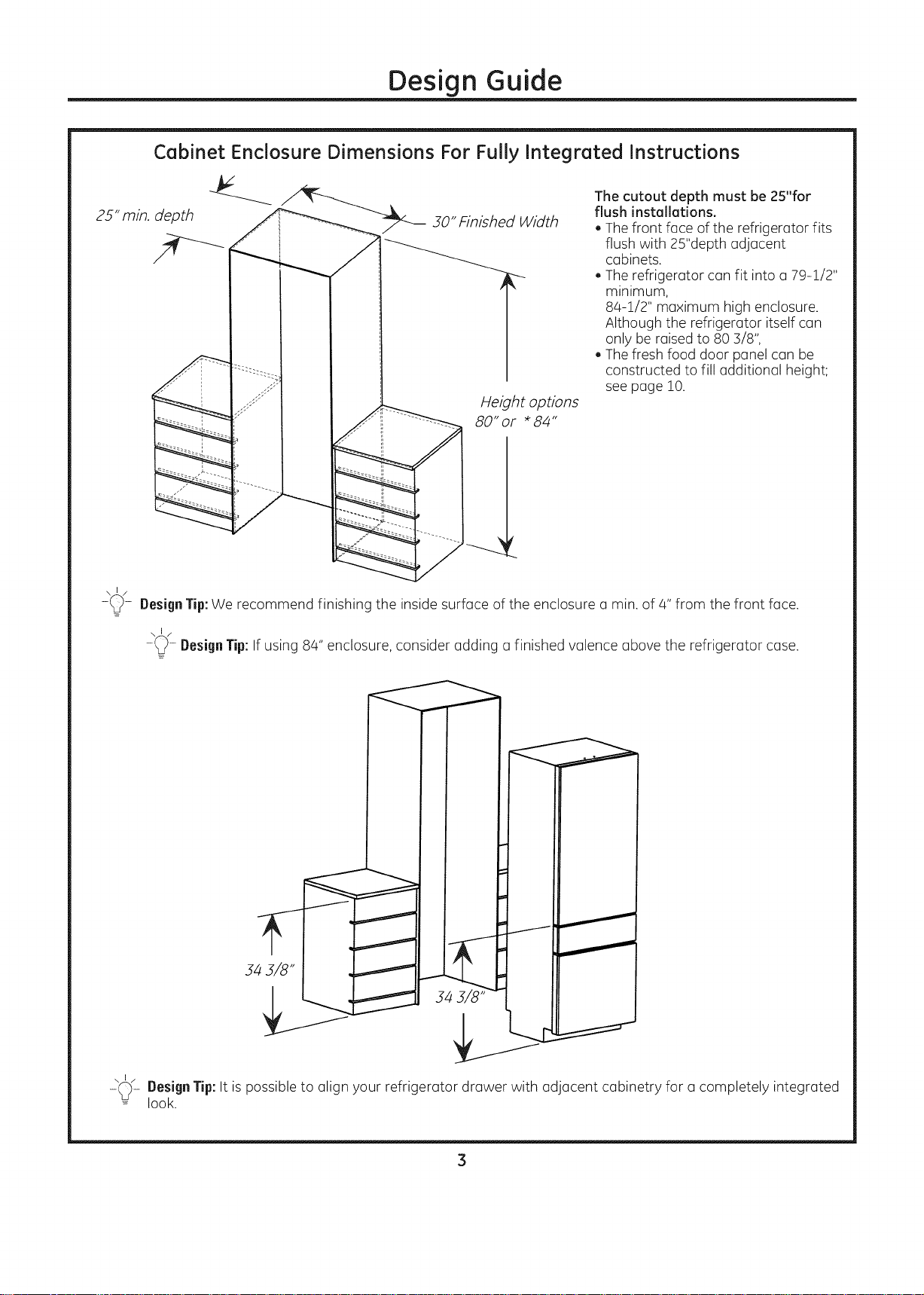

Cobinet Enclosure Dimensions For Fully Integroted instructions

25" min. depth _ YO"Finished Width

Height options

80" or * 84"

The cutout depth must be 25"for

flush instollotions.

Thefront face of the refrigerator fits

flush with 25"depth adjacent

cabinets.

The refrigerator can fit into a 79-1/2"

minimum,

84-1/2" mGximum high enclosure.

Although the refrigerator itself cGn

only be rGisedto 80 3/8",

Thefresh food door pGnel can be

constructed to fill GdditionGI height;

see pGge 10.

ZOo- Design Tip: We recommend finishing the inside surface of the enclosure a min. of 4" from the front face.

=-

-'(_f- Design Tip: If using 84" enclosure, consider adding a finished valence above the refrigerator case.

ZOo- Design Tip: possible align your refrigerator adjacent cabinetry a completely integrated

look.

It is to drawer with for

3

Page 4

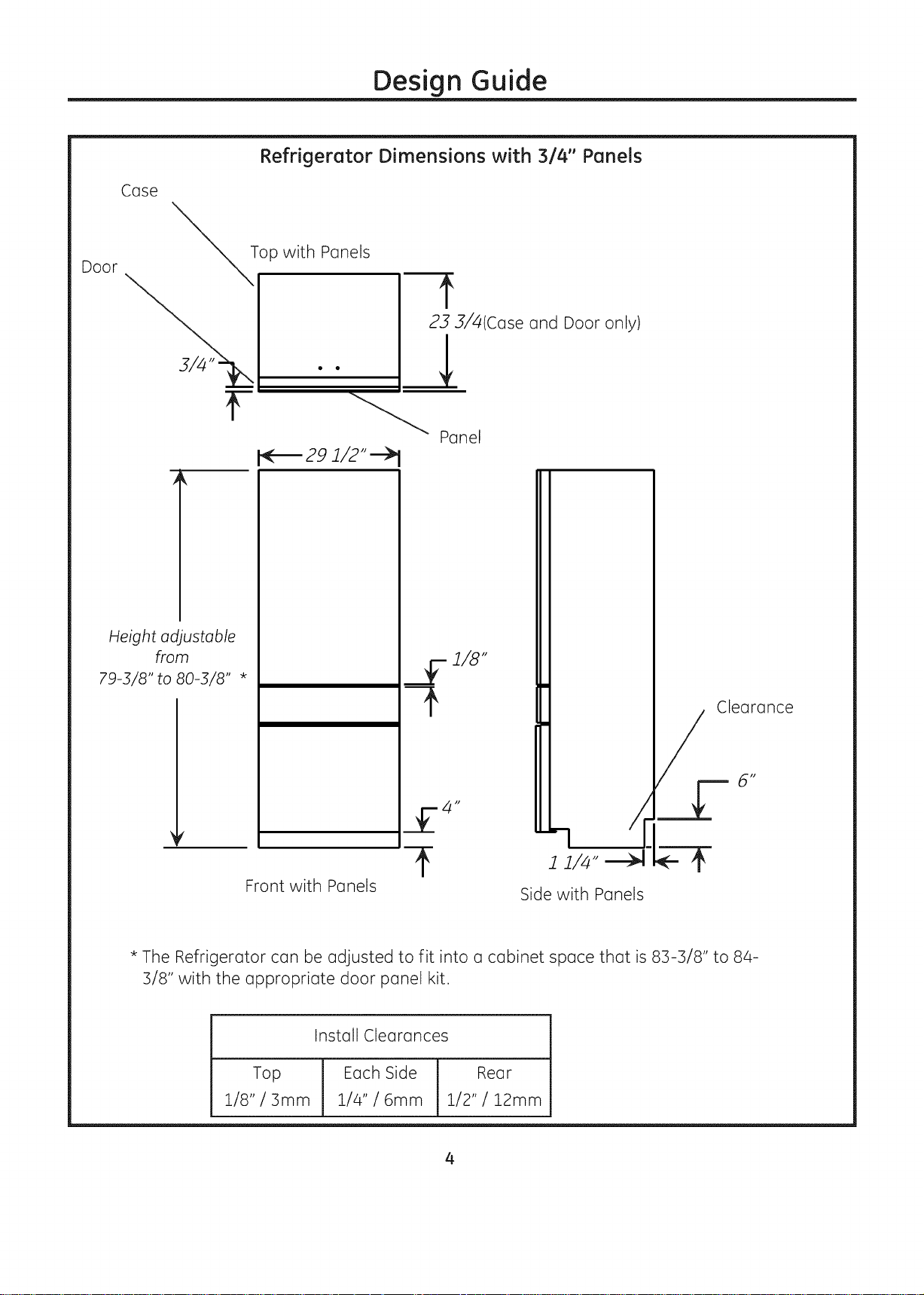

Case

Design Guide

Refrigerotor Dimensions with 3/4" Ponels

Door

J_

Height adjustable

from

79-3/8" to 80-3/8" *

Top with Panels

(Caseand Door only)

• o

Panel

I_ 291/2" _

Clearance

/

_____ 6"

Front with Panels

* The Refrigerator can be adjusted to fit into a cabinet space that is 83-3/8" to 84-

3/8" with the appropriate door panel kit.

install Clearances

Top Each Side Rear

1/8" / 3mm 1/4" / 6mm 1/2"/12mm

Side with Panels

4

Page 5

Design Guide

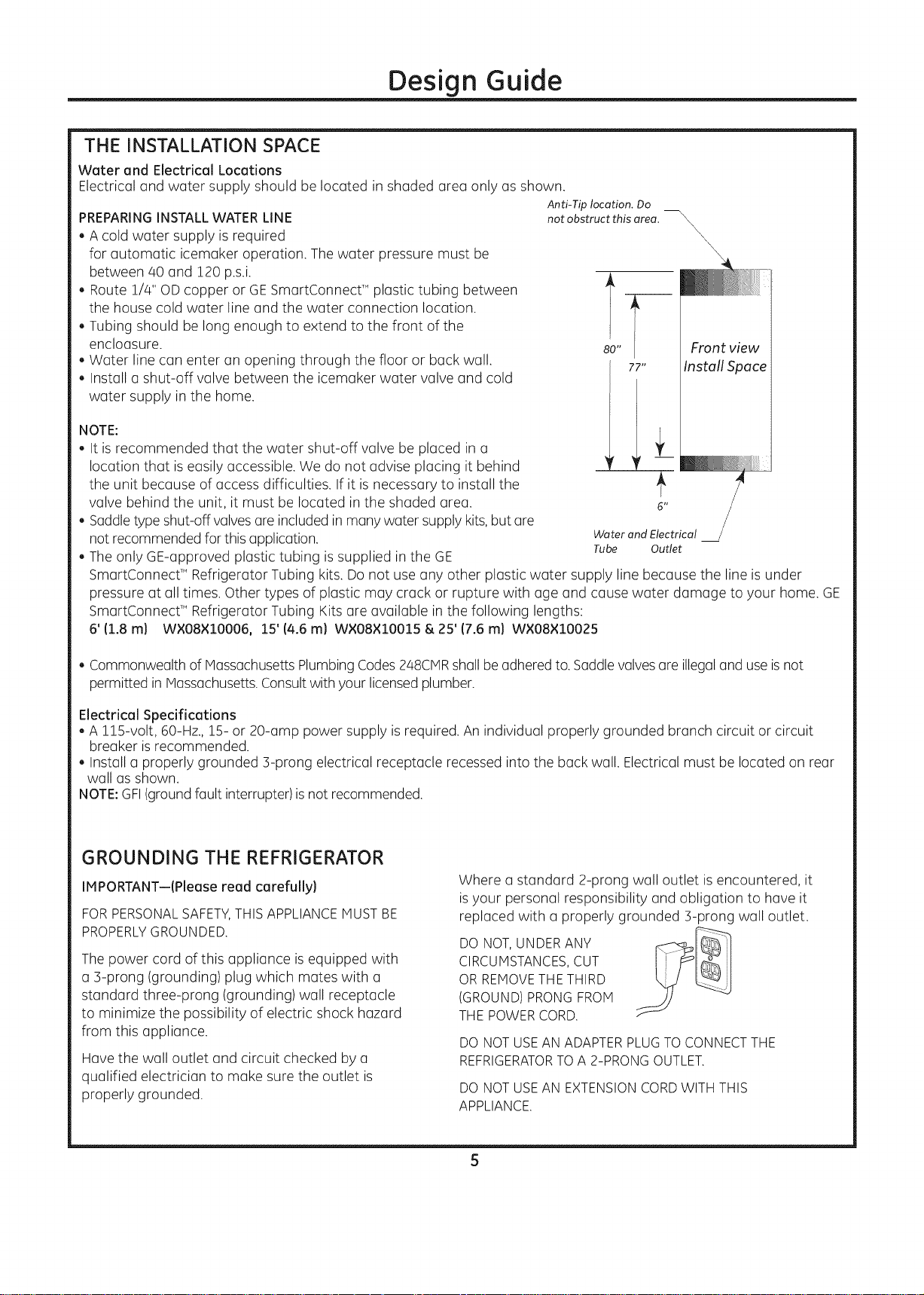

THE INSTALLATION SPACE

Water and Electrical Locations

Electrical and water supply should be located in shaded area only as shown.

Anti-Tip location. Do

PREPARINGINSTALLWATERLINE notobstructthisarea. _

. A cold water supply is required

for automatic icemaker operation. The water pressure must be

between 40 and 120 p.s.i.

. Route 1/4" OD copper or GE SmartConnecf" plastic tubing between

the house cold water line and the water connection location.

. Tubing should be long enough to extend to the front of the

encloasure, so"

. Water line can enter an opening through the floor or back wall.

. Install a shut-off valve between the icemaker water valve and cold

J_--

77"

water supply in the home.

NOTE:

. It is recommended that the water shut-off valve be placed in a

location that is easily accessible. We do not advise placing it behind

the unit because of access difficulties. If it isnecessary to install the

valve behind the unit, it must be located in the shaded urea.

. Saddletype shut-off valves are included in many water supply kits,but are

not recommended for this application.

. The only GE-approved plastic tubing is supplied in the GE

Water and Electrical /

Tube Outlet

SmartConnecf" Refrigerator Tubing kits. Do not use any other plastic water supply line because the line is under

pressure at all times. Other types of plastic may crack or rupture with age and cause water damage to your home. GE

SmartConnecf _Refrigerator Tubing Kits are available in the following lengths:

6'(1.8m) WXO8XIO006, 15'(4.6m) WXO8X10015 & 25'(7.6m) WXO8X10025

\\

Front view

Install Space

+

6"

. Commonwealth of Massachusetts PlumbingCodes 248CMRshall be adhered to. Saddle valves are illegaland use isnot

permitted in Massachusetts.Consultwith your licensedplumber.

Electrical Specifications

. A 1!5-volt, 60-Hz.,15- or 20-amp power supply is required. An individual properly grounded branch circuit or circuit

breaker isrecommended.

. Install a properly grounded ]-prong electrical receptacle recessed into the back wall. Electrical must be located on rear

wall as shown.

NOTE:GFI(ground fault interrupter)is not recommended.

GROUNDING THE REFRIGERATOR

IMPORTANT--(Please read carefully}

FOR PERSONAL SAFETY, THIS APPLIANCE MUST BE

PROPERLY GROUNDED.

The power cord of this appliance isequipped with

a 3-prong (grounding) plug which mates with a

standard three-prong (grounding) wall receptacle

to minimize the possibility of electric shock hazard

from this appliance.

Have the wall outlet and circuit checked by a

qualified electrician to make sure the outlet is

properly grounded.

Where a standard 2-prong wall outlet isencountered, it

isyour personal responsibility and obligation to have it

replaced with a properly grounded :3-prong wall outlet.

DO NOT,UNDERANY _1 _]-_

CIRCUMSTANCES,CUT

ORREMOVETHETHIRD

(GROUND)PRONGFROM

THE POWERCORD.

DO NOT USEAN ADAPTER PLUG TO CONNECT THE

REFRIGERATORTO A 2-PRONG OUTLET.

DO NOT USEAN EXTENSION CORD WITH THIS

APPLIANCE.

5

Page 6

Design Guide

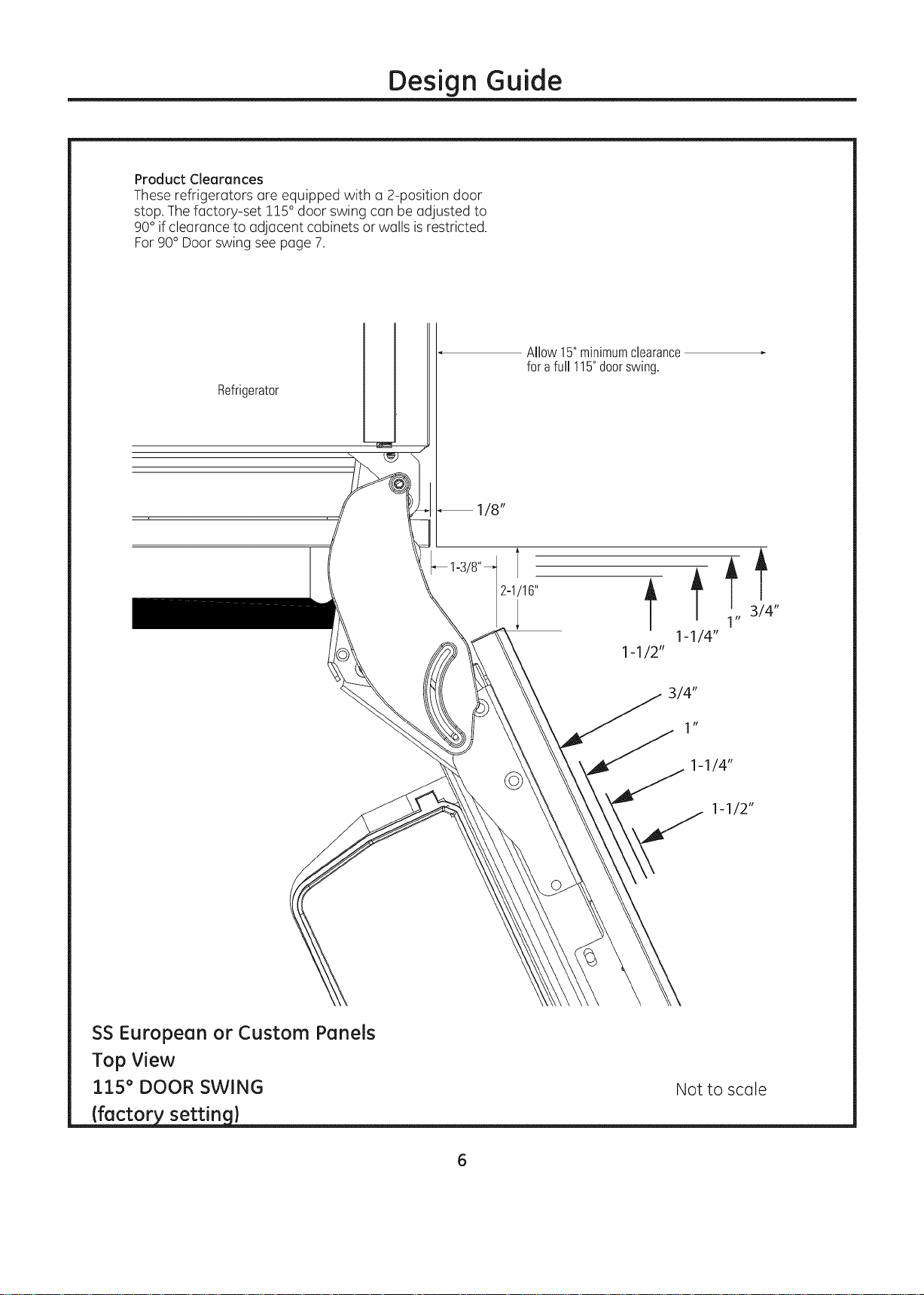

Product Cleoronces

These refrigerators ere equipped with e 2-position door

stop. Thefactory-set 115°door swing con be adjusted to

90° if clearance to udjacent cabinets or wells isrestricted.

For90° Door swing see pege 7.

Refrigerator

Allow 15"minimumclearance

fora full 115°doorswing.

2-1/16"

©

1-1/4"

1-1/2"

SS Europeon or Custom Ponels

Top View

115 ° DOOR SWING Not to scale

(foctor settin }

6

Page 7

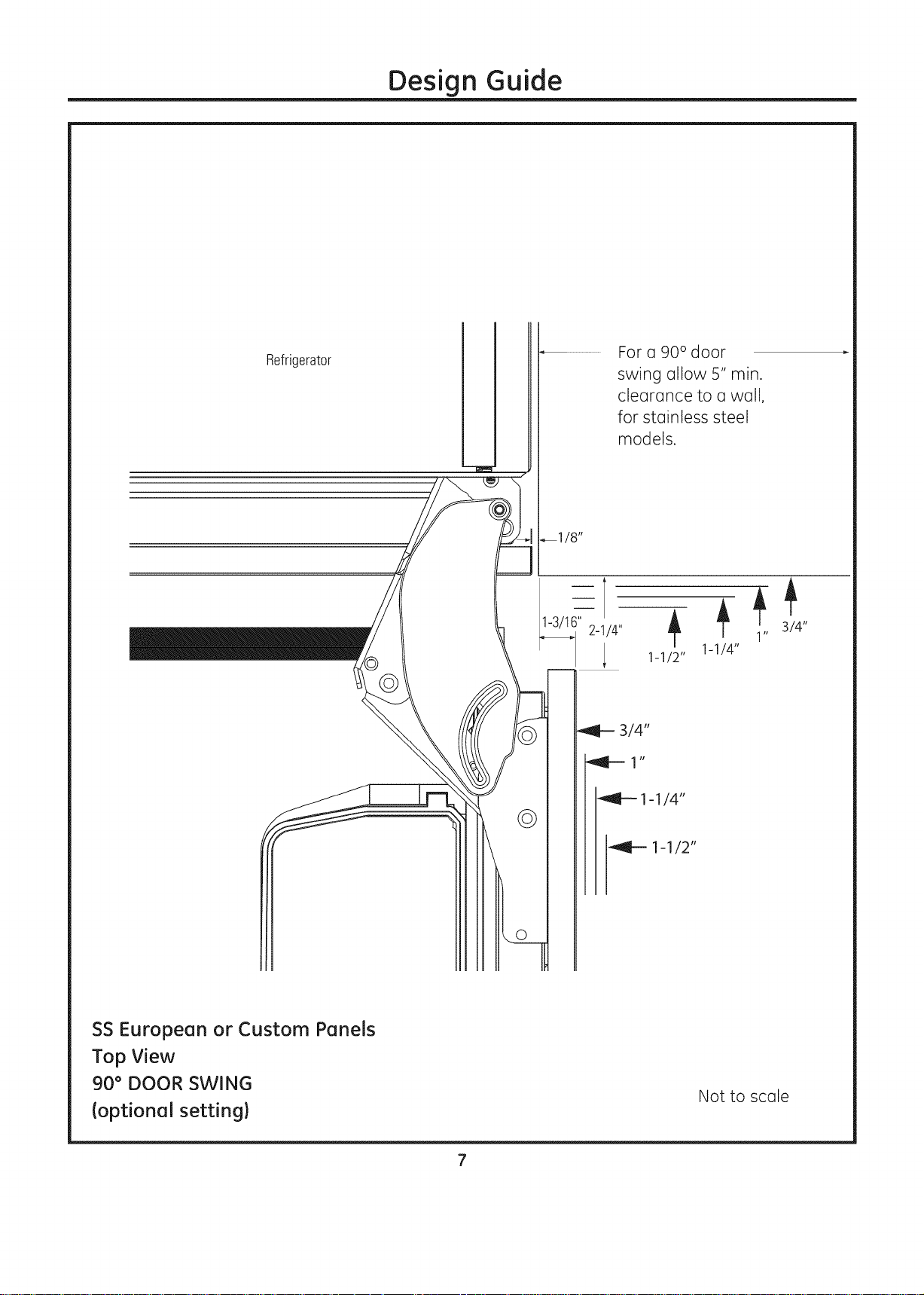

Design Guide

Refrigerator

_1/8"

For a 90 ° door

swing allow 5" min.

clearance to a wall,

for stainless steel

models.

2-1/4" _ 1-1/4"

1-1/2"

3/4"

•'_--- I"

3/4"

1 H

SS Europeon or Custom Ponels

Top View

90 ° DOOR SWING

(optionol setting}

I -I/4"

©

1-1/2"

0

Not to scale

Page 8

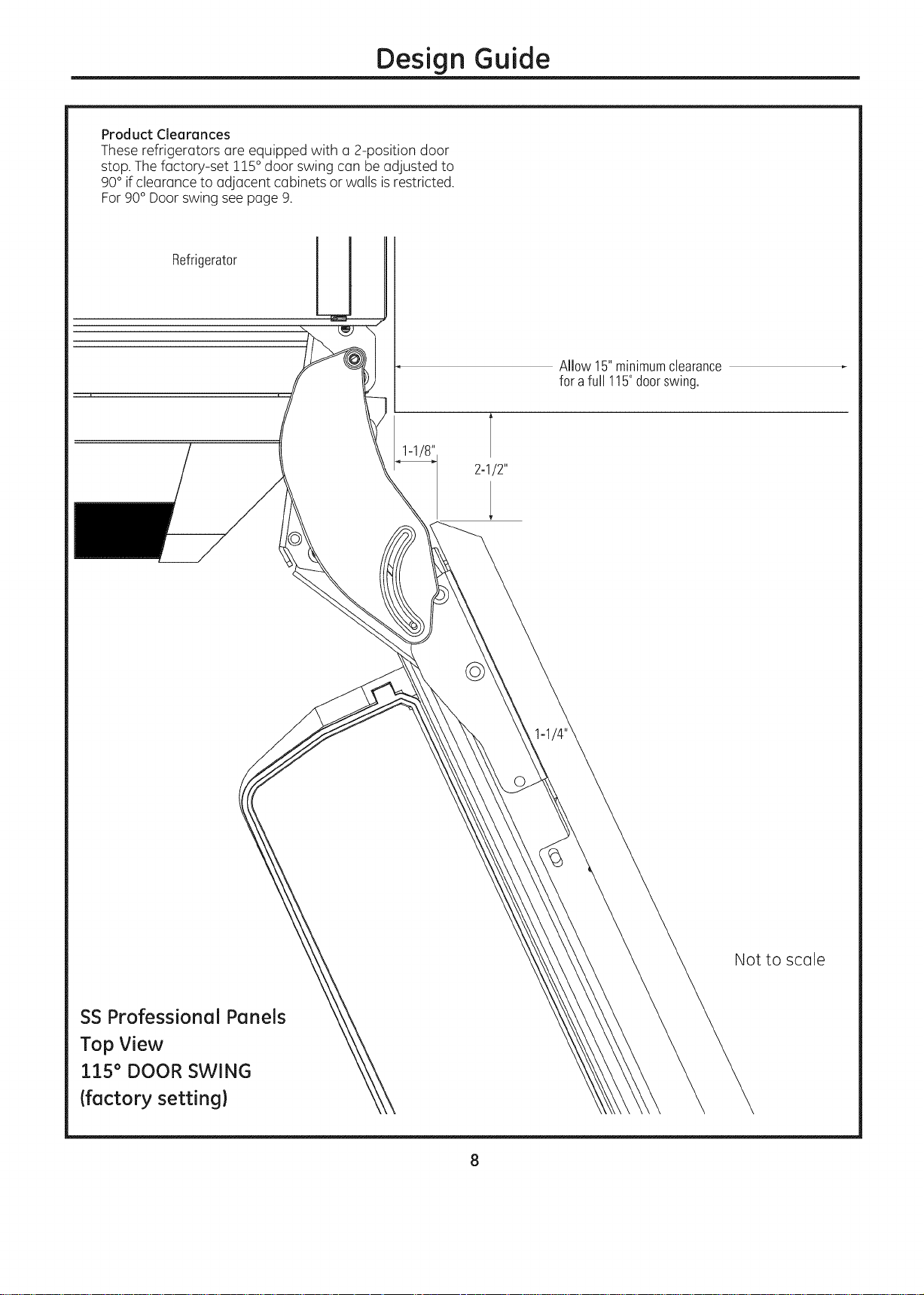

Design Guide

Product Clearances

These refrigerators ore equipped with o 2-position door

stop. ThefGctory-set 1!5 °door swing con be adjusted to

90° if clearance to adjacent cabinets or walls isrestricted.

For 90° Door swing see page 9.

Refrigerator

Allow 15"minimumclearance

fora full 115°doorswing.

2-I/2"

SS Professional Panels

Top View

115 ° DOOR SWING

(factory setting)

Not to scGle

8

Page 9

Refrigerator

Design Guide

For a 90° door

swing allow 5" min.

clearance to a wall,

for stainless steel

models.

2-9/16"

SS Professional Panels

Top View

90 ° DOOR SWING

(optional settingi

Not to scale

9

Page 10

Design Guide

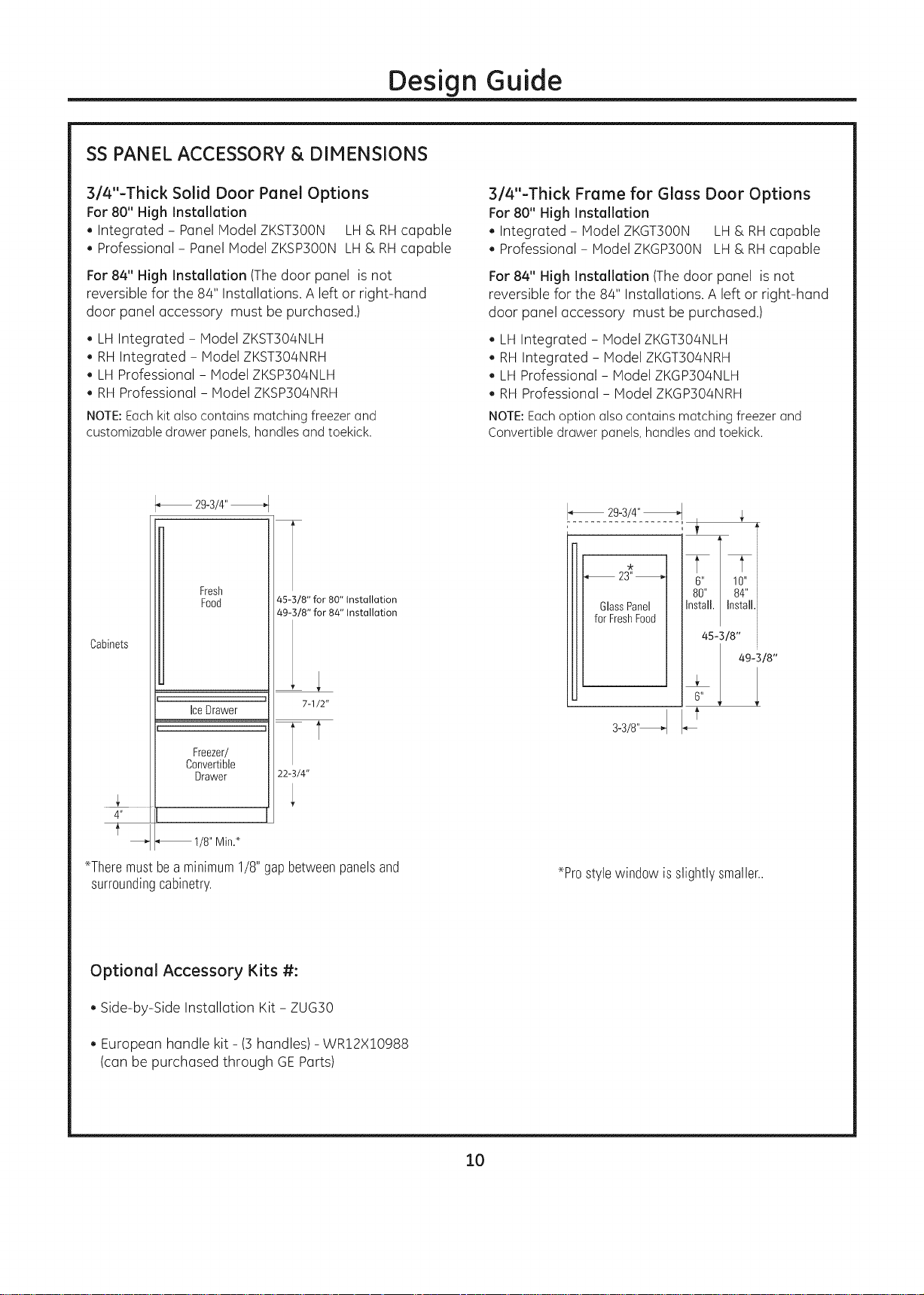

SS PANEL ACCESSORY & DIMENSIONS

3/4"-Thick Solid Door Panel Options

For 80" High Installation

. Integrated - Panel Model ZKST3OON LH & RH capable

. Professional- Panel Model ZKSP3OON LH & RH capable

For 84" High Installation (The door panel is not

reversible for the 84" Installations. A left or right-hand

door panel accessory must be purchased.)

, LH Integrated - Model ZKST304NLH

, RH Integrated - Model ZKST304NRH

, LH Professional - Model ZKSP304NLH

, RH Professional - Model ZKSP304NRH

NOTE:Each kit also contains matching freezer and

customizable drawer panels, handles and toekick.

2g-3/4" _

Fresh

Food

Cabinets

45-3/8" for 80" Installation

49-3/8" for 84" Installation

3/4"-Thick Frame for Glass Door Options

For 80" High Installation

, Integrated - Model ZKGT3OON LH & RH capable

, Professional - Model ZKGP3OON LH & RH capable

For 84" High Installation (Thedoor panel is not

reversible for the 84" Installations. A left or right-hand

door panel accessory must be purchased.

, LH Integrated - Model ZKGT304NLH

, RH Integrated - Model ZKGT304NRH

, LH Professional- Model ZKGP304NLH

, RH Professional - Model ZKGP304NRH

NOTE:Each option also contains matching freezer and

Convertible drawer panels, handles and toekick.

_29-3/4"_

_. 23"_

GlassPanel

for FreshFood

T

UlO" i

4s-318"

A

49-3/8"

IceDrawer

7-1/2"

t

Freezer/

Convertible

Drawer

4"

I

f

_Theremustbea minimum1/8"gapbetweenpanelsand

surroundingcabinetry.

Optional Accessory Kits #:

. Side-by-Side Installation Kit - ZUG30

. European handle kit - (3 handles) - WR12X10988

(can be purchased through GEParts)

1/8"Minf

T

3-3,8. If

_Prostylewindow isslightlysmaller..

10

Page 11

Design Guide

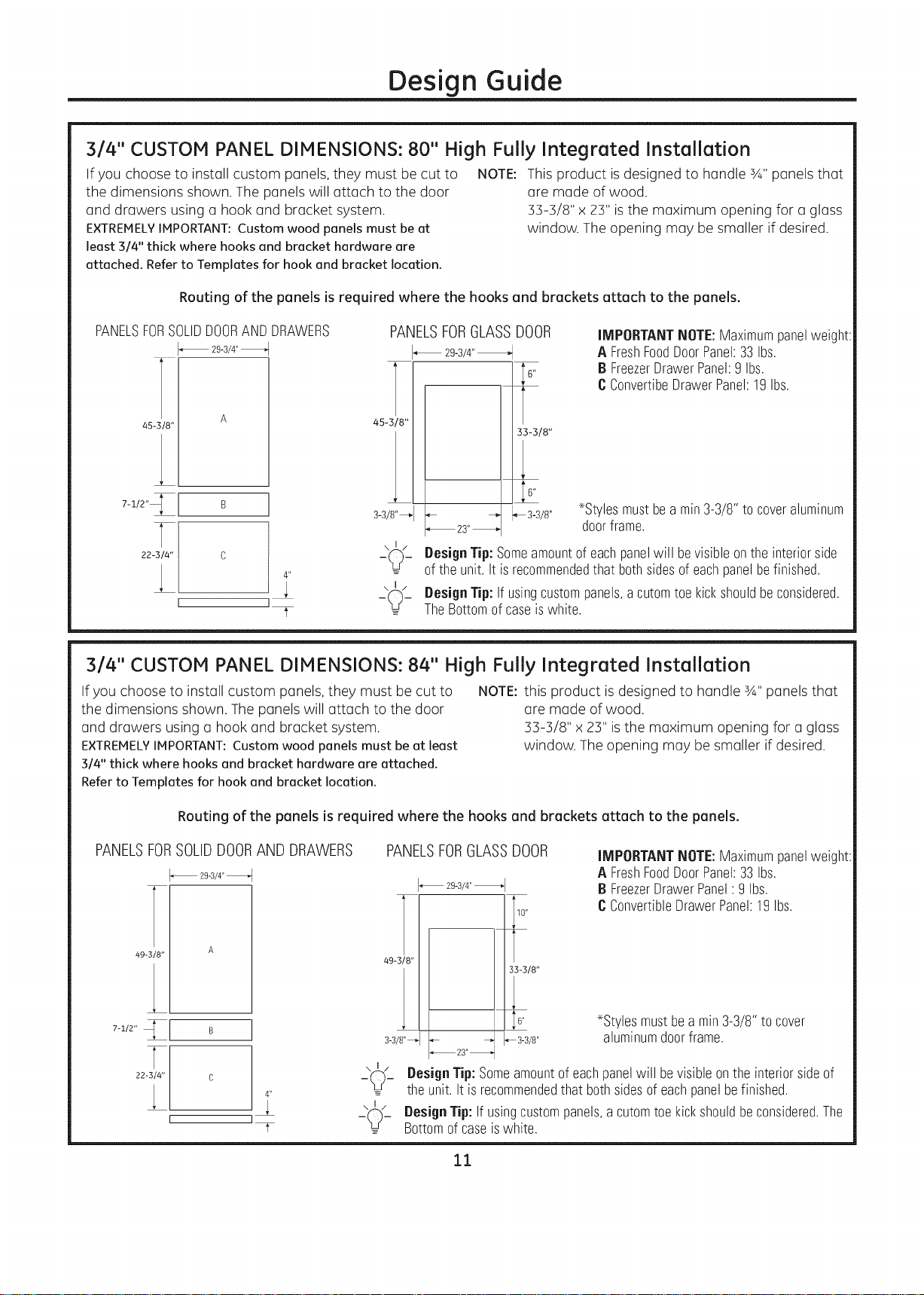

3/4" CUSTOM PANEL DIMENSIONS: 80" High Fully Integrated Installation

If you choose to install custom panels, they must be cut to

the dimensions shown. The panels will attach to the door

and drawers using a hook and bracket system.

EXTREMELY IMPORTANT: Custom wood panels must be at

least 3/4" thick where hooksand brocket hardwore ore

attached. Referto Templotes for hookond brocket location,

Routing of the panels is required where the hooks end brackets attach to the panels.

NOTE:

This product is designed to handle 3A"panels that

are made of wood.

33-3/8" x 23" is the maximum opening for a glass

window. The opening may be smaller if desired.

PANELSFORSOLIDDOORANDDRAWERS

29-3/4'

45-3/8"

7-!/2"q_ B

22-3/4"

A

4"

PANELSFORGLASSDOOR

I'- 29-3/4"

6"

45-3/8"

3-3/8"_1 1_3-3/8"

Design Tip: Someamountofeachpanelwill bevisibleontheinteriorside

ofthe unit.It isrecommendedthat bothsidesof eachpanelbefinished.

33-3/8"

"

IMPORTANTNOTE:Maximumpanelweight:

A FreshFoodDoorPanel:33Ibs.

B FreezerDrawerPanel:9 Ibs.

CC0nvertibeDrawerPanel:19Ibs.

_Stylesmustbea min3-3/8"to coveraluminum

doorframe.

Design Tip: If usingcustompanels,acutomtoe kickshouldbeconsidered.

TheBottomof caseis white.

3/4" CUSTOM PANEL DIMENSIONS: 84" High Fully Integrated Installation

If you choose to install custom panels, they must be cut to

the dimensions shown. The panels will attach to the door

and drawers using a hook and bracket system.

EXTREMELYIMPORTANT: Custom wood panels must be at least

3/4" thick where hooks ond brocket hardwore ore ottached.

Refer to Templates for hook ond brocket location,

NOTE: this product is designed to handle sA"panels that

are made of wood.

33-3/8" x 23" is the maximum opening for a glass

window. The opening may be smaller if desired.

Routing of the panels is required where the hooks and brackets attach to the panels.

PANELSFORSOLIDDOORAND DRAWERS

I_ 29-3/4"

49-3/8" A

7-!/2" _ B

22-3/4" C

4"

PANELSFORGLASSDOOR

IMPORTANTNOTE:Maximumpanelweight:

A FreshFoodDoorPanel:33Ibs.

I_ 29-3/4" _1

B FreezerDrawerPanel:9 Ibs.

CConvertibleDrawerPanel:19Ibs.

49-3/8"

33-3/8"

_Stylesmustbea min3-3/8" to cover

3-3/8"

3-3/8"

aluminumdoorframe.

Design Tip: Someamountofeachpanelwill bevisibleonthe interiorsideof

theunit. It is recommendedthat both sidesof eachpanelbe finished.

[lesion Tip: If usingcustompanels,acutomtoekickshouldbeconsidered.The

Bottomof caseiswhite.

11

Page 12

Installation Instructions

TOOLS REQUIRED

,5/32" Allen wrench

, Utility knife

. Stepl(]dder

. Bucket

. Level

. Appli(]nce h(]nd truck

. Tubing cutter

.7/16" open-end wrench

.1-5/16" open-end wrench

. #2 Phillips screwdriver

. Drill (]nd bit set

.5/16" socket

. S(]fety gl(]sses

. Pliers

.3/8" r(]tchet

. Torx T-20, T-30 wrench

HARDWARE SUPPLIED

. Anti-tip br(]cket & screws

. P(]nel mounting br(]ckets

. Door p(]nel templates- Pub # 31-/46543

. W(]ter filter - P(]rt # GSWF

. Dryw(]ll Anchors (]nd screws

MATERIALS REQUIRED

.1/4" copper w(]ter line tubing or GESm(]rtConnect T"

Refriger(]tor Tubing kits

. W(]ter shut-off v(]lve

. Custom p(]nels for fresh food door, freezer dr(]wer

(]nd Convertible dr(]wer

. Velcro w/(]dhesive if using custom toekick.

FLOORING

Forproper inst(]ll(]tion, this refriger(]tor must be

pl(]ced on (] level surf(]ce of h(]rd m(]teri(]l th(]t is (]t

the same height as the rest of the flooring. This

surf(Ice should be strong enough to support (] fully

Io(]ded refriger(]tor, or (]pproxim(]tely 1,200 Ibs.

NOTE:Protect the finish of the flooring. Cut (] I(]rge

section of the c(]rdbo(]rd c(]rton (]nd pl(]ce under

the refriger(]tor where you (ire working.

12

Page 13

Installation Instructions

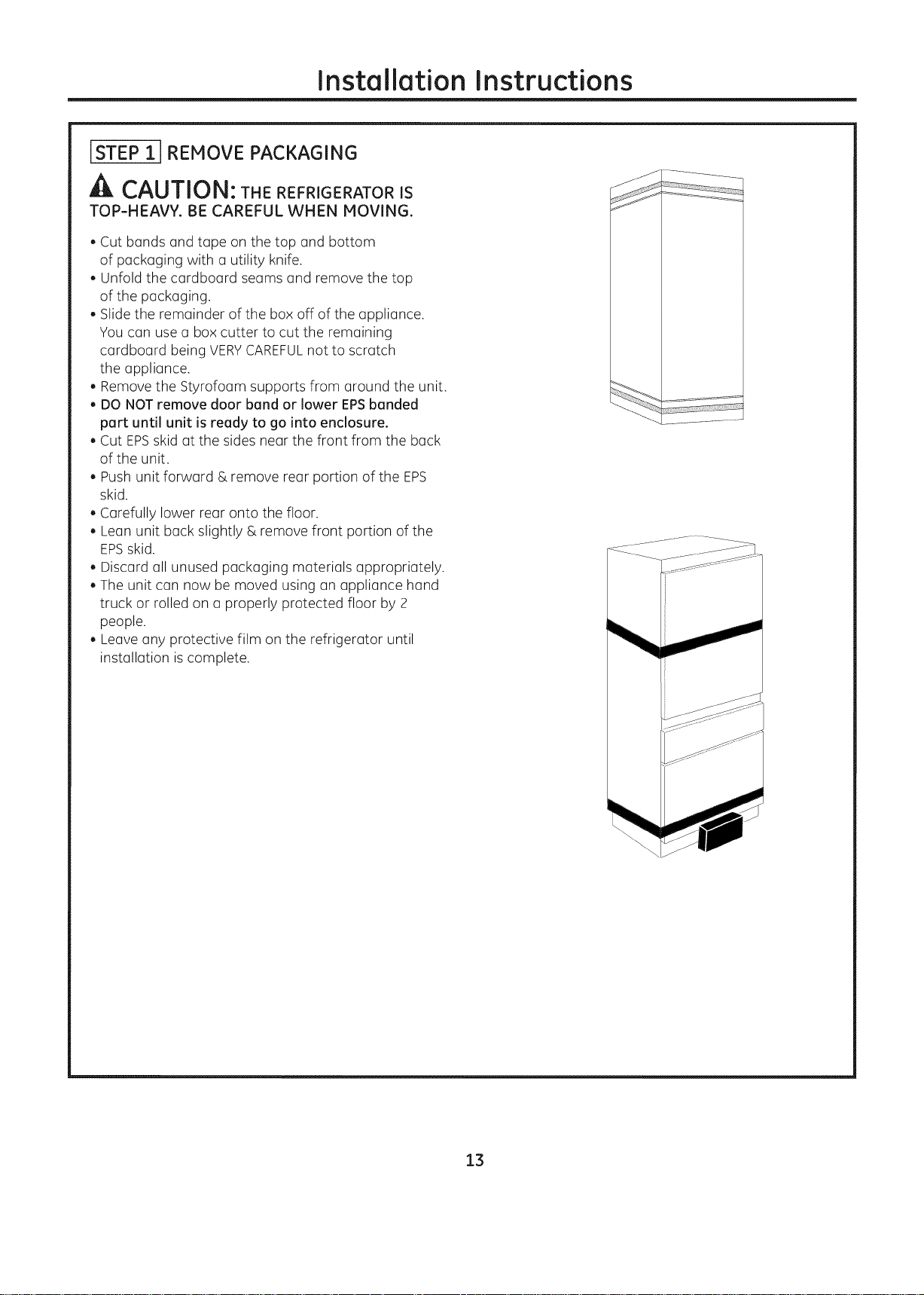

[STEP 1] REMOVE PACKAGING

A CAUTION: THEREFRISERATORiS

TOP-HEAVY. BE CAREFUL WHEN MOVING.

Cut bands and tape on the top and bottom

of packaging with o utility knife.

Unfold the cardboard seams and remove the top

of the packaging.

Slide the remainder of the box off of the appliance.

You can use a box cutter to cut the remaining

cardboard being VERYCAREFULnot to scratch

the appliance.

Remove the Styrofoam supports from around the unit.

DO NOT remove door bend or lower EPSbanded

pert until unit is reedy to go into enclosure.

Cut EPSskid at the sides near the front from the back

of the unit.

Push unit forward & remove rear portion of the EPS

skid.

Carefully lower rear onto the floor.

Lean unit back slightly & remove front portion of the

EPSskid.

Discard all unused packaging materials appropriately.

The unit can now be moved using an appliance hand

truck or rolled on a properly protected floor by 2

people.

Leave any protective film on the refrigerator until

installation is complete.

13

Page 14

Installation Instructions

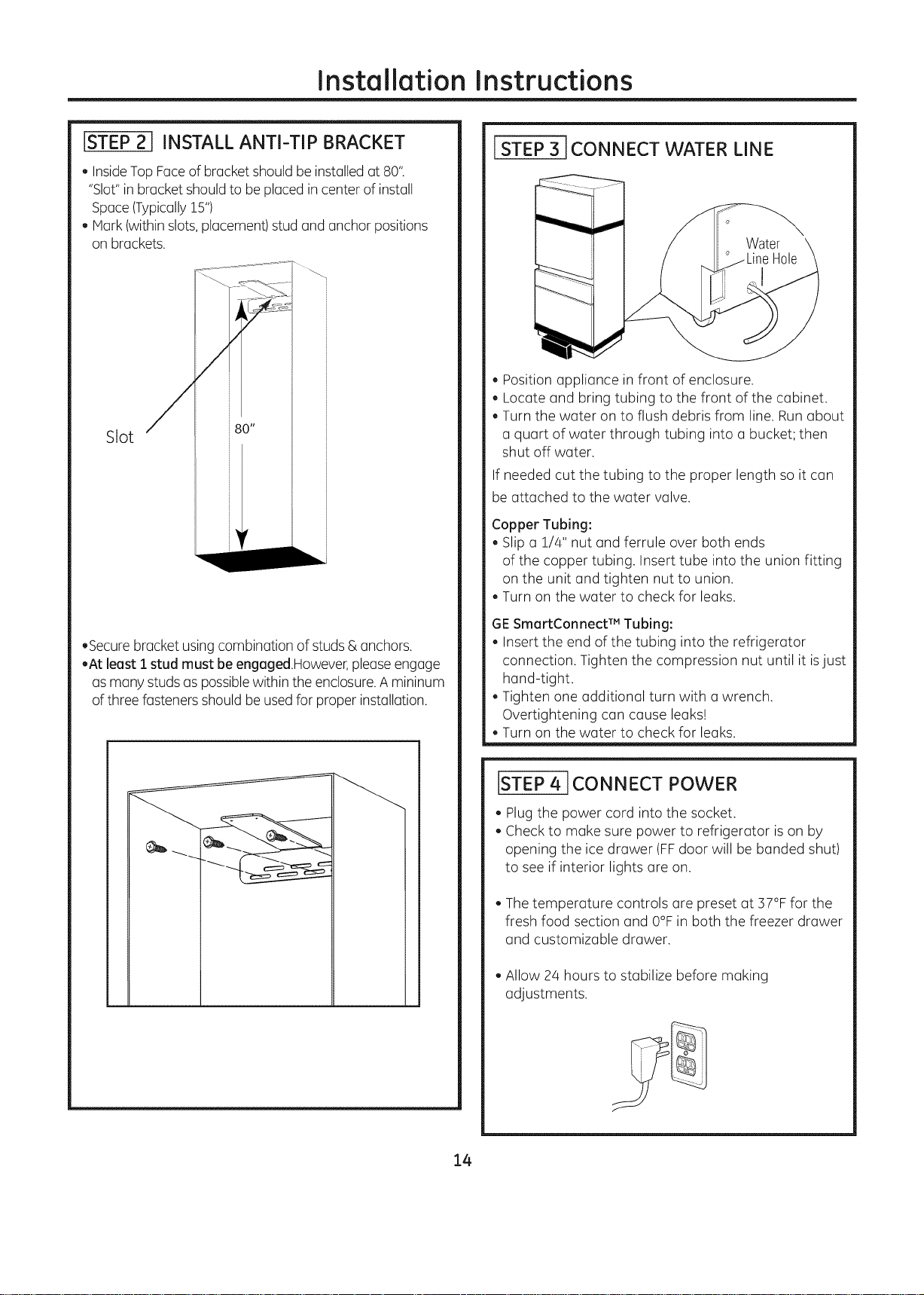

ISTEP 21 INSTALL ANTI-TIP BRACKET

. InsideTop Faceof bracket should be installed at 80"

"Slot"in bracket should to beplaced in center of install

Space(Typically!5")

, Mark (withinslots, placement)stud and anchor positions

on brackets.

Slot

80 _l

I

iSTEP 3 i CONNECT WATER LINE

. Position appliance in front of enclosure.

. Locate and bring tubing to the front of the cabinet.

, Turn the water on to flush debris from line. Run about

a quart of water through tubing into a bucket; then

shut off water.

If needed cut the tubing to the proper length so it can

be attached to the water valve.

Copper Tubing:

, Slip a 1/4" nut and ferrule over both ends

of the copper tubing. Insert tube into the union fitting

on the unit and tighten nut to union.

, Turn on the water to check for leaks.

•Securebracket usingcombination of studs & anchors.

,At least 1 stud must be engaged.However, please engage

as many studs as possiblewithin the enclosure.A mininum

of three fasteners should be usedfor proper installation.

GE SmartConnect TM Tubing:

, Insert the end of the tubing into the refrigerator

connection. Tighten the compression nut until it isjust

hand-tight.

, Tighten one additional turn with a wrench.

Overtightening can cause leaks!

, Turn on the water to check for leaks.

[STEP 4 CONNECT POWER

, Plug the power cord into the socket.

, Check to make sure power to refrigerator is on by

opening the ice drawer (FFdoor will be banded shut)

to see if interior lights are on.

, The temperature controls are preset at 37°F for the

fresh food section and 0°Fin both the freezer drawer

and customizable drawer.

, Allow 2/4hours to stabilize before making

adjustments.

14

Page 15

Installation Instructions

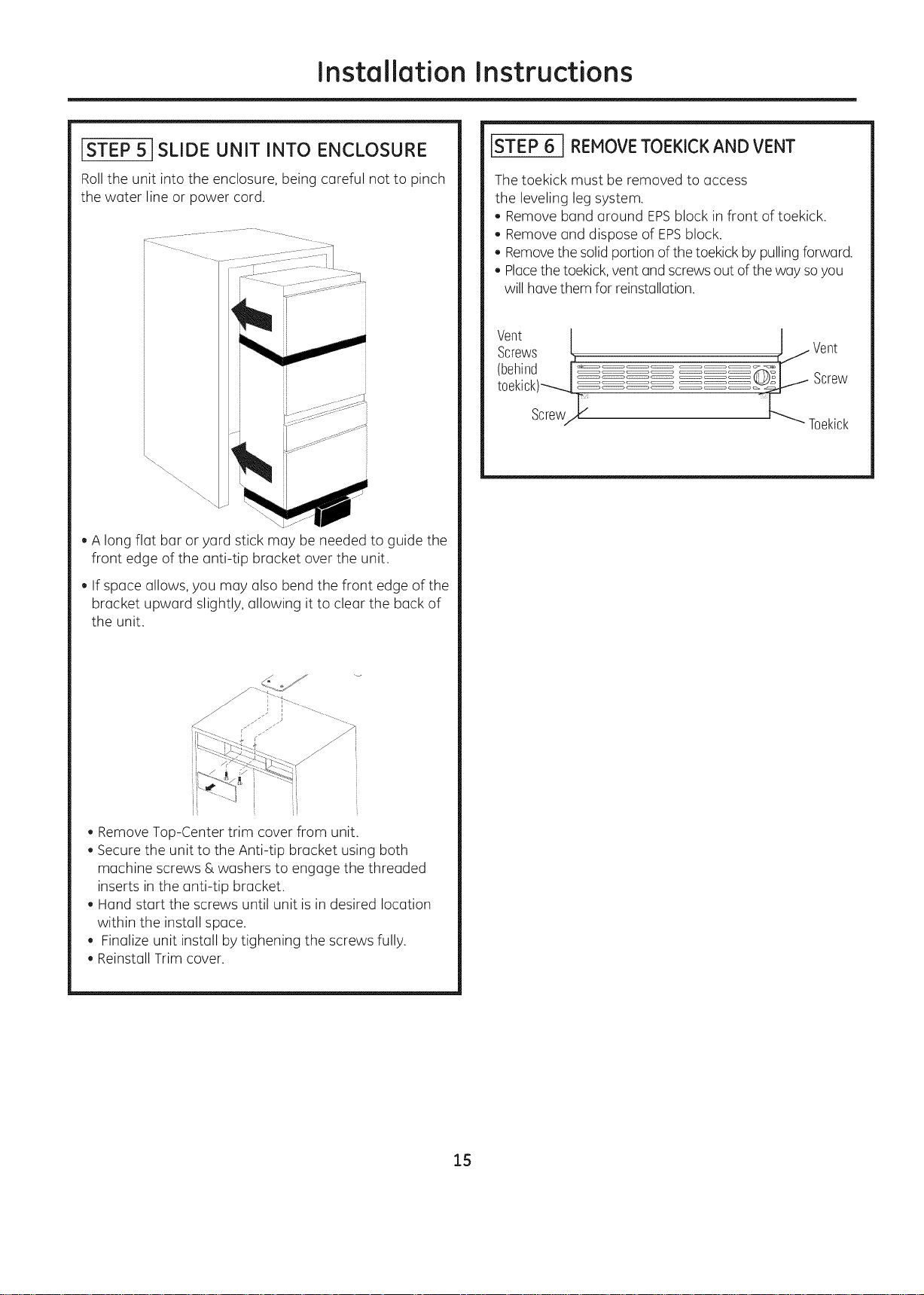

[STEP 5] SLIDE UNIT INTO ENCLOSURE

Rollthe unit into the enclosure, being c(]reful not to pinch

the w(]ter line or power cord.

i

, A long flat bar or y(]rd stick may be needed to guide the

front edge of the anti-tip bracket over the unit.

STEP 6 ] REMOVETOEKICKAND VENT

The toekick must be removed to access

the leveling leg system.

Remove b(]nd (]round EPSblock in front of toekick.

Remove (]nd dispose of EPSblock.

Removethe solid portion of the toekick by pullingforw(]rd.

Pl(]cethe toekick, vent (]nd screws out of the w(]y soyou

will h(]vethem for reinst(]ll(]tion.

Vent /

Screws L

(behind I._....

t0el<icl<)--_

Screw/Y

_,_ Vent

Q_ Screw

_] -_"T0el<ick

, If space allows, you may also bend the front edge of the

bracket upw(]rd slightly, (]llowing it to cle(]r the b(]ck of

the unit.

i i ..........

.J

J

. Remove Top-Center trim cover from unit.

Secure the unit to the Anti-tip br(]cket using both

machine screws & w(]shers to engage the threaded

inserts in the (]nti-tip bracket.

Hand start the screws until unit is in desired Ioc(]tion

within the install space.

Finalize unit install by tighening the screws fully.

Reinst(]ll Trim cover.

15

Page 16

Installation Instructions

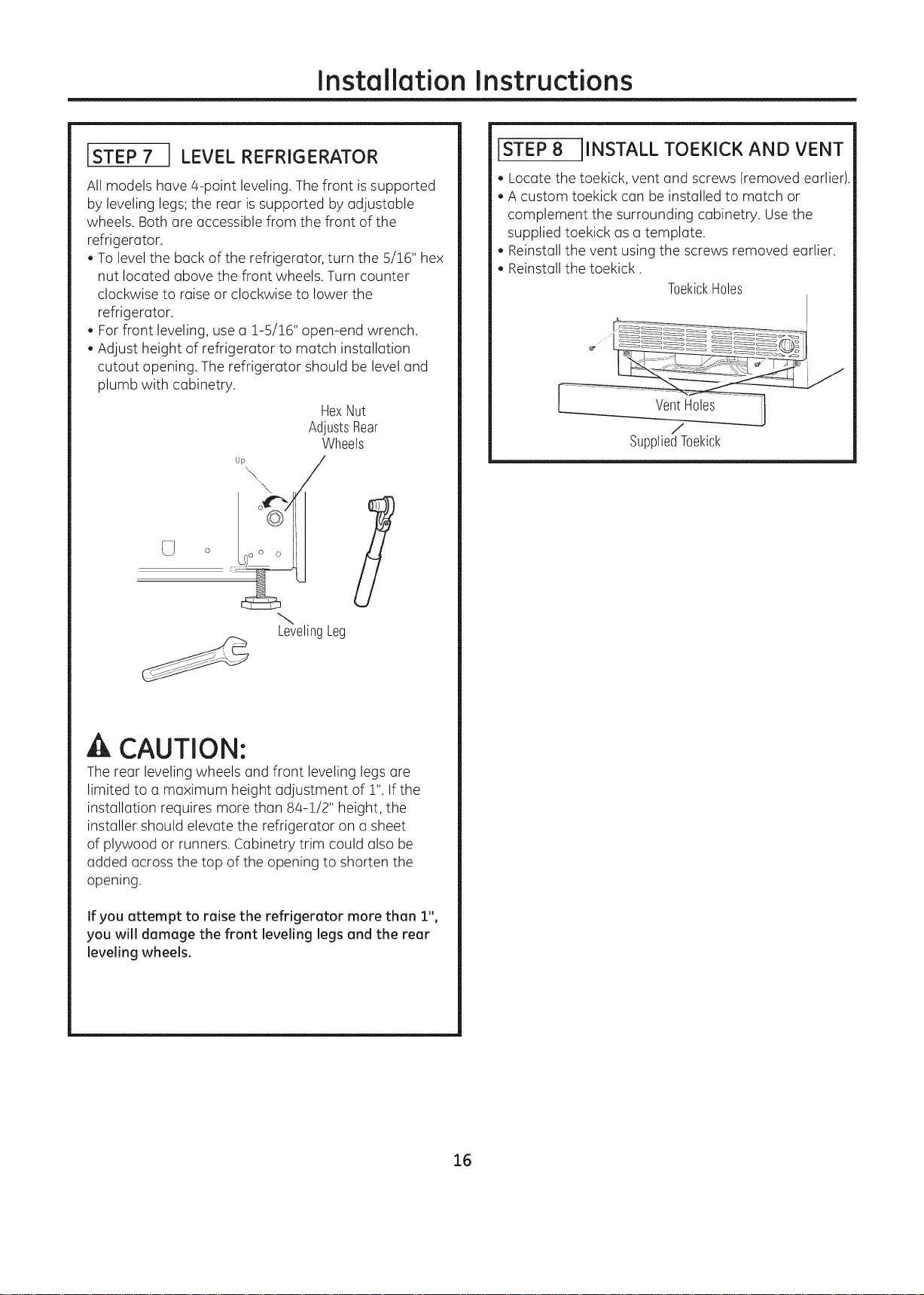

[STEP 7 I LEVEL REFRIGERATOR

All models have 4-point leveling. The front is supported

by leveling legs; the rear is supported by adjustable

wheels. Both are accessible from the front of the

refrigerator.

. To level the back of the refrigerator, turn the 5/16" hex

nut located above the front wheels. Turn counter

clockwise to raise or clockwise to lower the

refrigerator.

. For front leveling, use a !-5/16" open-end wrench.

. Adjust height of refrigerator to match installation

cutout opening. The refrigerator should be level and

plumb with cabinetry.

HexNut

AdjustsRear

Wheels

°P\_'_/IO°

STEP 8 INSTALL TOEKICK AND VENT

. Locate the toekick, vent and screws (removed earlier).

. A custom toekick can be installed to match or

complement the surrounding cabinetry. Usethe

supplied toekick as a template.

. Reinstall the vent using the screws removed earlier.

. Reinstall the toekick.

T0el<icl<Holes

/

SuppliedT0ekick

LevelingLeg

CAUTION'.

The rear leveling wheels and front leveling legs are

limited to a maximum height adjustment of 1". If the

installation requires more than 84-1/2" height, the

installer should elevate the refrigerator on a sheet

of plywood or runners. Cabinetry trim could also be

added across the top of the opening to shorten the

opening.

If you attempt to raise the refrigerator more than 1",

you will damage the front leveling legs and the rear

leveling wheels.

16

Page 17

Installation Instructions

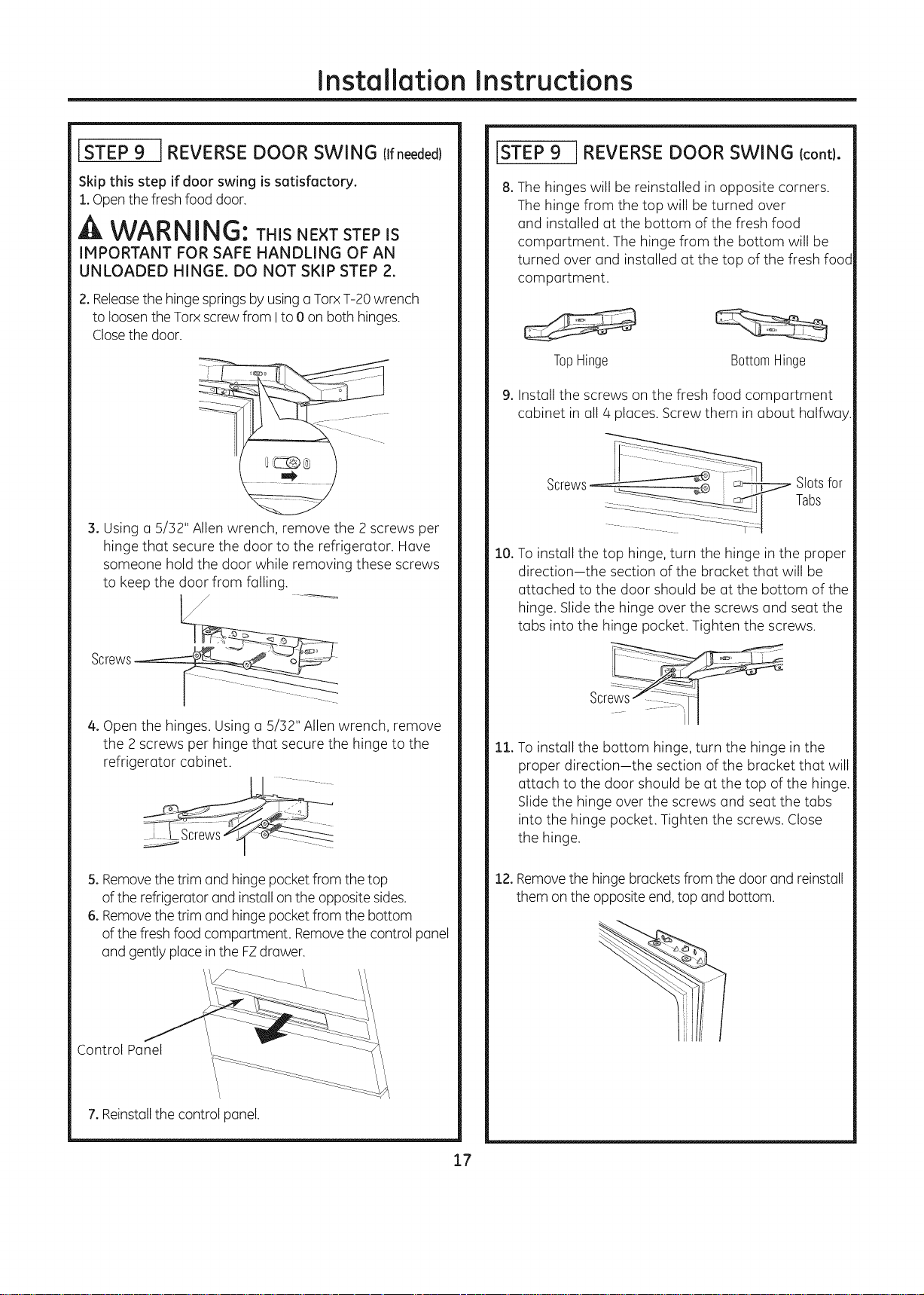

STEP 9 REVERSE DOOR SWING Ilfneeded)

Skip this step if door swing is satisfactory.

1.Open the fresh food door.

WARNING: THISNEXTSTEPIs

IMPORTANT FOR SAFE HANDLING OF AN

UNLOADED HINGE. DO NOT SKIP STEP 2.

2. Releosethe hinge springs by using o TorxT-20 wrench

to loosenthe Torx screw from Ito 0 on both hinges.

Closethe door.

3. Using o 5/32" Allen wrench, remove the 2 screws per

hinge thot secure the door to the refrigerotor. Hove

someone hold the door while removing these screws

to keep the door from foiling.

STEP 9 REVERSE DOOR SWING Icont).

8. The hinges will be reinstolled in opposite corners.

The hinge from the top will be turned over

ond instolled ot the bottom of the fresh food

comportment. The hinge from the bottom will be

turned over ond instolled ot the top of the fresh fooc

comportment.

TopHinge BottomHinge

9. Install the screws on the fresh food comportment

cubinet in oil/4 Dluces.Screw them in ubout hulfwuy.

Slotsfor

Tabs

i0. To install the top hinge, turn the hinge in the proper

direction-the section of the bracket thot will be

attached to the door should be at the bottom of the

hinge. Slide the hinge over the screws und seot the

tubs into the hinge pocket. Tighten the screws.

Screws

4. Open the hinges. Using o 5/32" Allen wrench, remove

the 2 screws per hinge thot secure the hinge to the

refrigerotor cobinet.

5. Removethe trim ond hingepocket from the top

of the refrigerotor ond instoll on the opposite sides.

6. Removethe trim ond hingepocket from the bottom

of the fresh food comportment. Removethe control ponel

ond gently ploce in the FZdrower.

Control Ponel

11.To install the bottom hinge, turn the hinge in the

proper direction-the section of the bracket thot will

attach to the door should be at the top of the hinge.

Slide the hinge over the screws ond seat the tubs

into the hinge pocket. Tighten the screws. Close

the hinge.

12.Removethe hinge brockets from the door and reinstoll

them on the opposite end, top ond bottom.

7. Reinstollthe control ponel.

17

Page 18

Installation Instructions

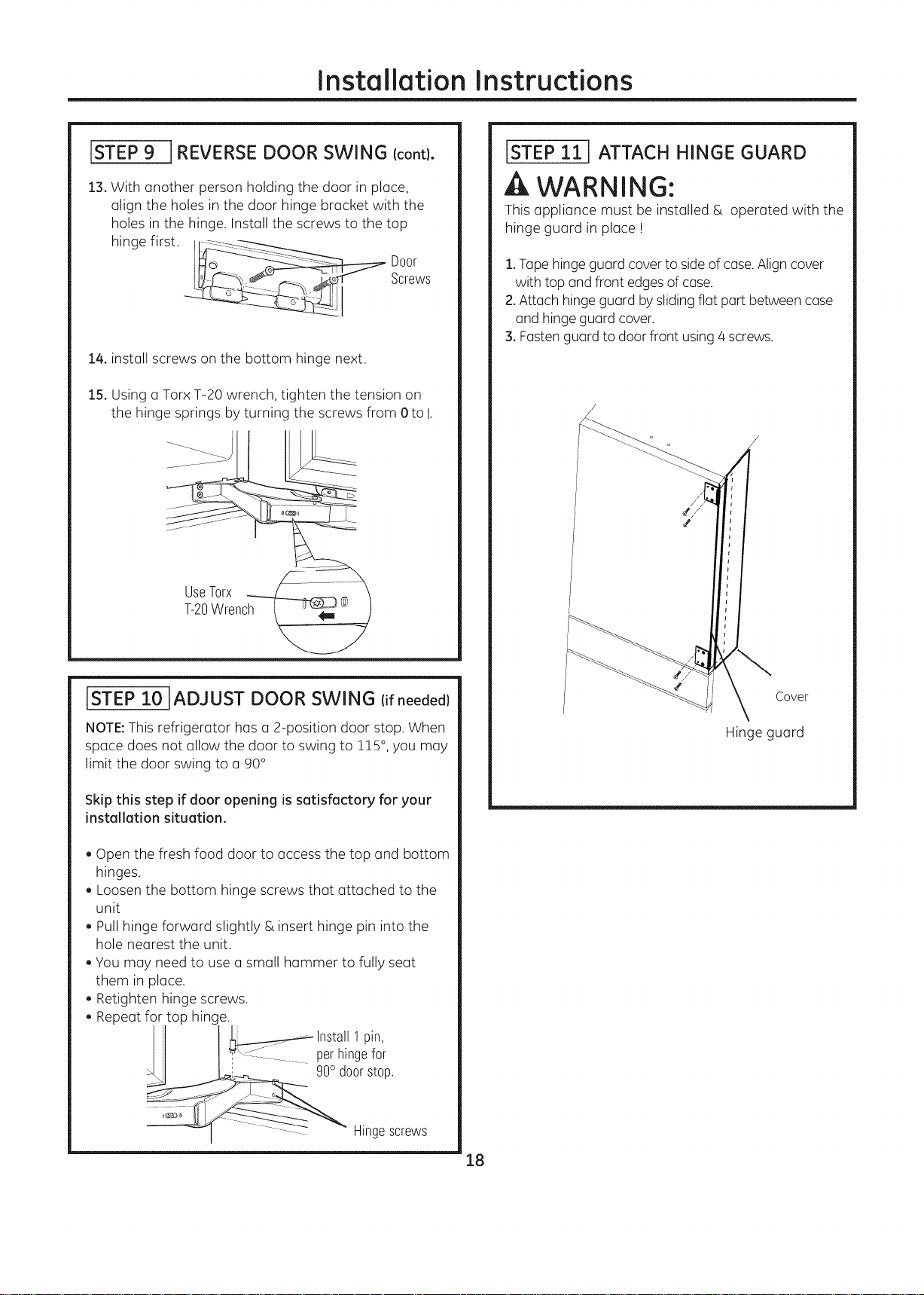

ISTEP 9 JREVERSE DOOR SWING (cont).

13.With another person holding the door in place,

align the holes in the door hinge bracket with the

holes in the hinge. Install the screws to the top

hinge first.

Screws

Door

14.install screws on the bottom hinge next.

15. Using a Torx T-20 wrench, tighten the tension on

the hinge springs by turning the screws from 0 to I.

STEP 11 ATTACH HINGE GUARD

WARNING:

This appliance must be installed & operated with the

hinge guard in place !

1.Tapehinge guard cover to sideof case.Align cover

with top and front edges of case.

2.Attach hinge guard bysliding flat part between case

and hinge guard cover.

3. Fastenguard to door front using 4 screws.

T-20Wrenc_

STEP 10 ADJUST DOOR SWING (if needed)

NOTE:This refrigerator has a 2-position door stop. When

space does not allow the door to swing to 1!5 °,you may

limit the door swing to a 90°

Skip this step if door opening is satisfactory for your

installation situation.

. Open the fresh food door to access the top and bottom

hinges.

. Loosen the bottom hinge screws that attached to the

unit

. Pull hinge forward slightly & insert hinge pin into the

hole nearest the unit.

.You may need to use a small hammer to fully seat

them in pk]ce.

. Retighten hinge screws.

. Repeat for top hinge.

, ....... perhingefor

_lnstall 1pin,

%0 doorstop.

Cover

Hinge guard

Hingescrews

18

Page 19

Installation Instructions

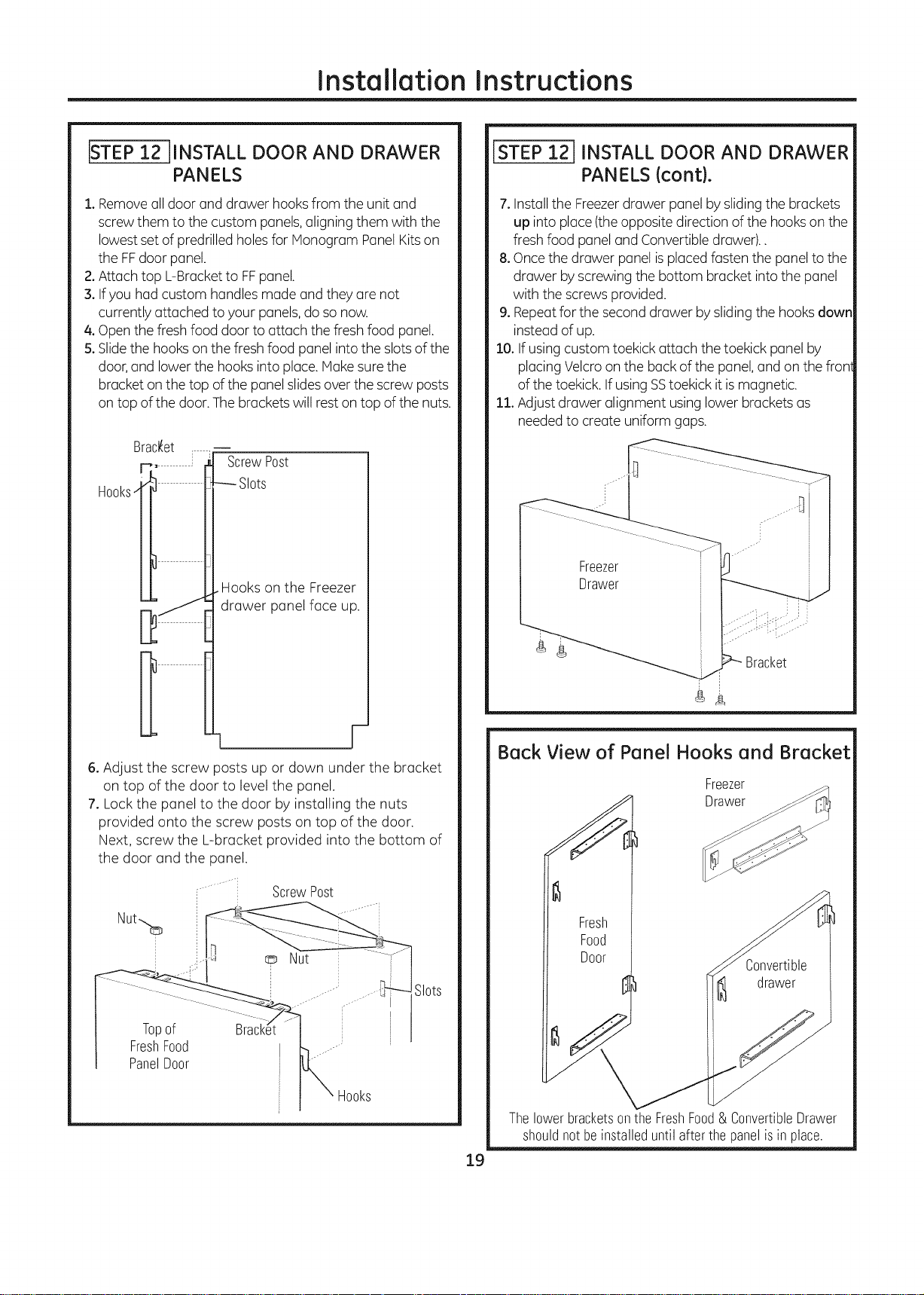

STEP 12 ]INSTALL DOOR AND DRAWER

PANELS

1. Removeall door and drawer hooksfrom the unit and

screw them to the custom panels,aligning them with the

lowest set of predrilled holesfor ivlonogram Panel Kitson

the FFdoor panel.

2.Attach top L-Bracketto FFpanel.

3. Ifyou had custom handlesmade and they are not

currently attached to your panels,do so now.

4. Open the fresh food door to attach the fresh food panel.

5.Slidethe hookson the freshfood panel into the slotsof the

door,and lower the hooks into place. Hake surethe

bracket on the top of the panel slidesoverthe screw posts

on top of the door. The brackets will rest on top ofthe nuts.

Bracl(et . --

ScrewPost

Hooks _ Slots

•Hooks on the Freezer

drawer panel face up.

[STEP 121 INSTALL DOOF AND DRAWER

PANELS {cont}.

7. Installthe Freezerdrawer panel by sliding the brackets

up into place (the opposite direction of the hooks onthe

fresh food panel and Convertible drawer)..

8. Oncethe drawer panel is placed fasten the panel to the

drawer byscrewing the bottom bracket into the panel

with the screws provided.

9. Repeatfor the second drawer by sliding the hooks dow_

instead of up.

10. If using custom toekick attach the toekick panel by

placingVelcro on the back of the panel,and on the fron

of the toekick. Ifusing SStoekick it is magnetic.

11.Adjust drawer alignment using lower brackets as

neededto create uniform gaps.

Freezer

Drawer -----_ _.....

6. Adjust the screw posts up or down under the bracket

on top of the door to level the panel.

7. Lock the panel to the door by installing the nuts

provided onto the screw posts on top of the door.

Next, screw the L-bracket provided into the bottom of

the door and the panel.

[ ScrewPost

Slots

PanelDoor

Hooks

_-- Bracket

Back View of Panel Hooks and Bracket

Freezer

Drawer

Fresh

Food

Door

Thelowerbracketsonthe FreshFood& ConvertibleDrawer

shouldnotbe installeduntilafter the panelis inplace•

19

Convertible

drawer

Page 20

Installation Instructions

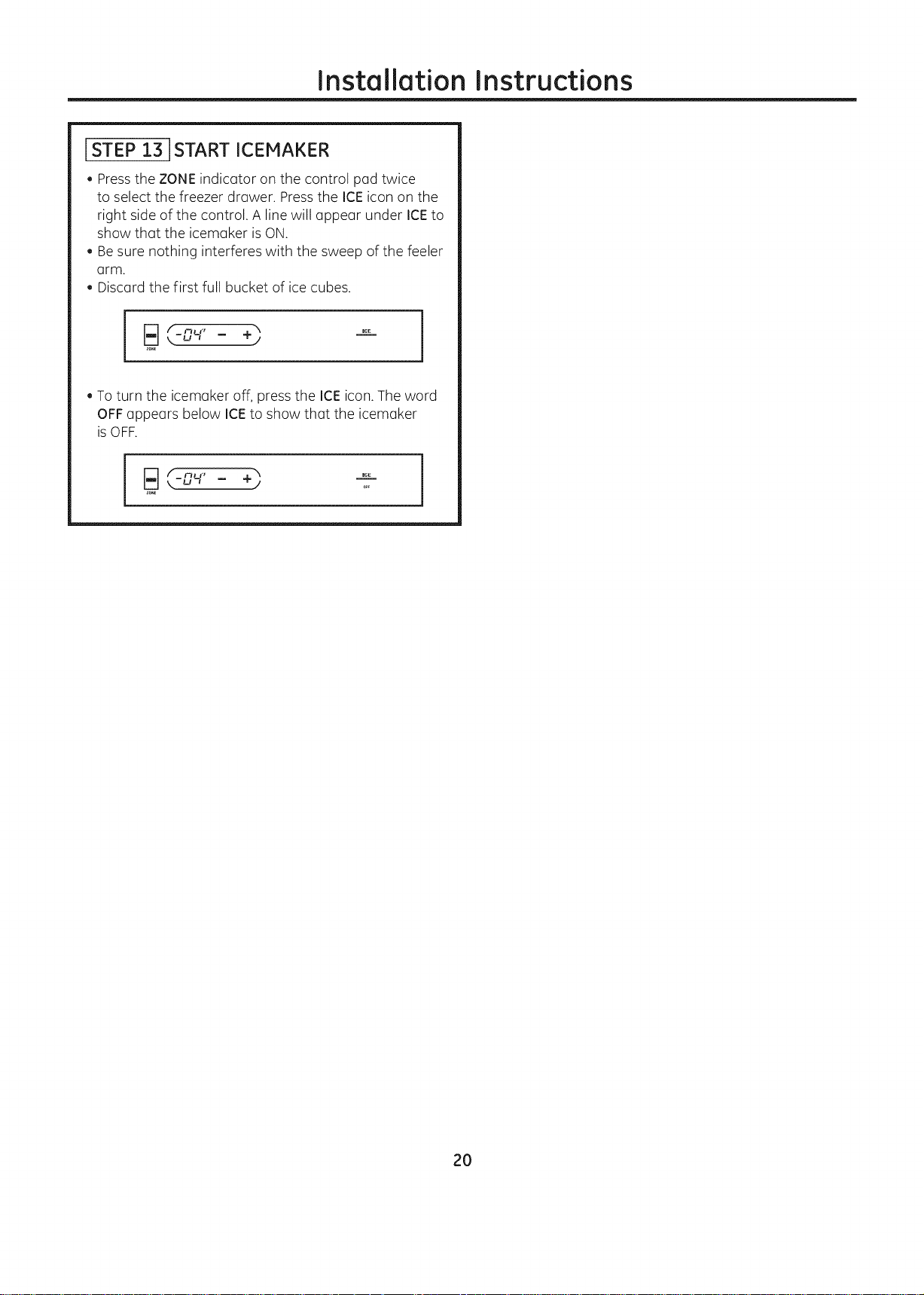

[STEP 13 ]START ICEMAKER

. Pressthe ZONE indicator on the control pod twice

to select the freezer drGwer. Pressthe ICE icon on the

right side of the control. A line will appear under ICEto

show that the icemaker is ON.

, Be sure nothing interferes with the sweep of the feeler

arm.

, Discard the first full bucket of ice cubes.

1

. To turn the icemaker off, press the ICE icon. The word

OFF appears below ICE to show that the icemaker

is OFF.

i

2O

Page 21

Installation Instructions

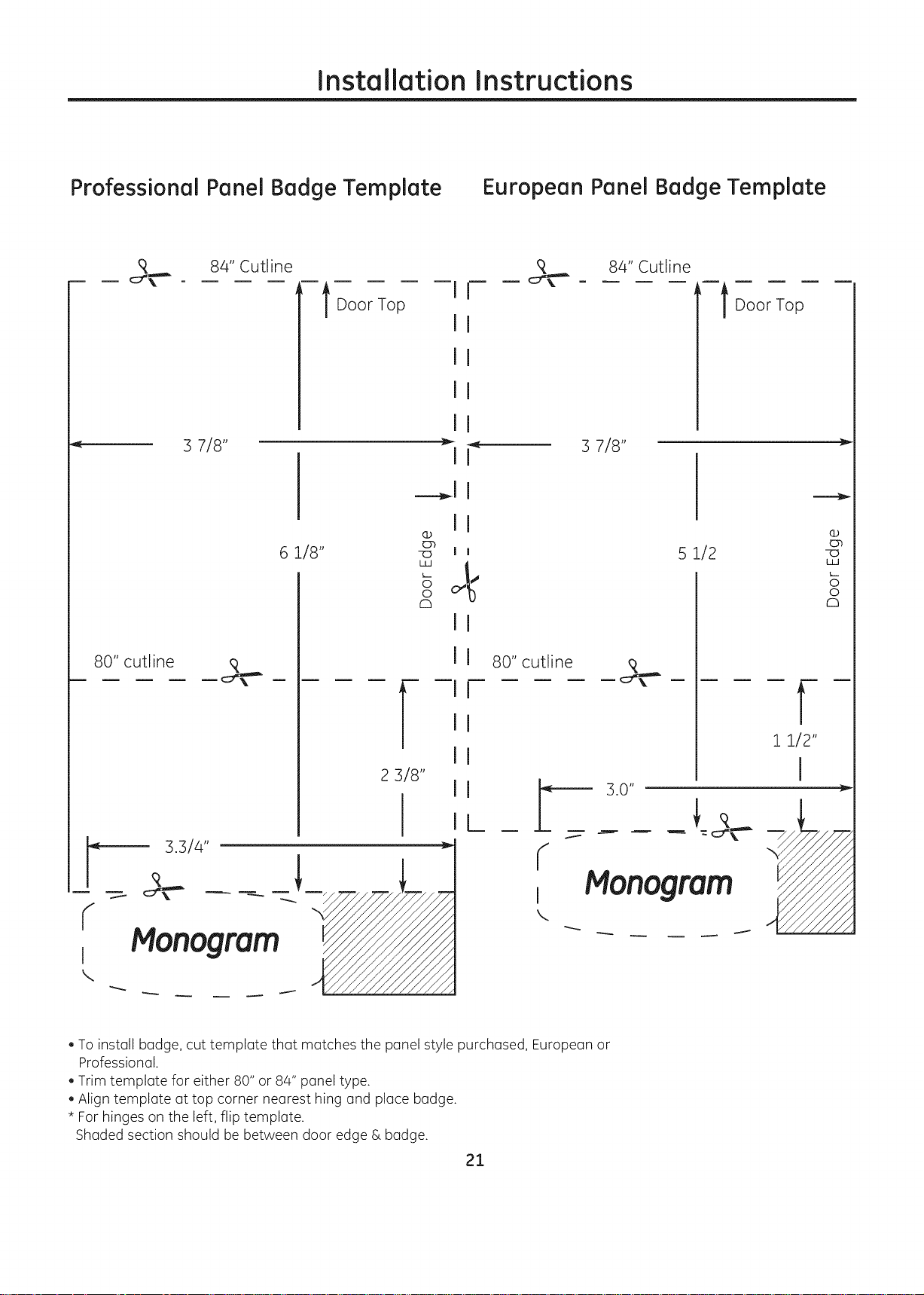

Professional Panel Badge Template European Panel Badge Template

84" Cutline _ 84" Cutline

i Door Top '--I Door Top

80" cutline

3 7/8"

6 1/8"

_< 3 7/8" _"

I

Oh

I I

-0

Iii

0

0

a

5 1/2

RD

LLJ

rh

(u

[D)

0

0

80" cutline

F m

11/2"

I

[

I

¢

I

\

. To install badge, cut template that matches the panel style purchased, European or

Professional.

. Trim template for either 80" or 84" panel type.

. Align template at top corner nearest hing and place badge.

* For hinges on the left, flip template.

Shaded section should be between door edge & badge.

21

Monogram

Page 22

Notes

22

Page 23

Notes

23

Page 24

Pub. No. 51-46542-5

Part No. !97D8!25P002

04-12 GE

NOTE:While performing installations described in this book,

safety glasses or goggles should be worn.

For Monogram _'local service in your area, call

1.800.¢¢¢.1845.

NOTE:Product improvement is a continuing endeavor

at General Electric. Therefore, materials, appearance and

specifications are subject to change without notice.

GE Consumer & Industriel

Appliances

General Electric Companu

Louisville, KY40225

GEApptiances.com

Page 25

Consignes de S curit

AVANT DE COMMENCER

Lisez ces instructions enti_rement et attentivement.

. IMPORTANT- Conservezces instructionspour

I'inspecteur local. Respectez tousles codes et r#glements

en vigueur.

. Remarque pour I'lnstallateur - Assurez-vous de

remettre ces instructions au Client.

. Remarque pour I'Utilisateur - Conservez ces

instructions avec votre notice d'utilisation pour toute

r#f#rence future.

.Niveau de competence - Uinstallation de ce

r#frig#rateur demande des connaissances de base en

mTcanique, en menuiserie et en plomberie. L1nstallateur

est responsable de I'installation correcte de I'appareil. La

panne de I'appareil due (3une mauvaise installation n'est

pas couverte par la garantie GE Electrom#nagers.

Consultez le manuel d'utilisation pour toute information

sur la garantie.

Pour les services Iocaux Monogram® dans votre secteur,

appelez le 1.800.444.1845.Pour les Pi_ces et Accessoires

Monogram, appelez 1.800.626.2002.

www.monogram.com

A AVERTISSEMENT:

Cet appareil dolt 6tre correctement connect# a la terre. Se

r#f#rer (_la section <<Mise(_la terre du r#frig#rateur >>(_la

page 5.

Sile r#frig#rateur requ est endommag#, contactez

imm#diatement votre vendeur ou votre installateur.

A MISE EN GARDE :

A cause de la taille et du poids de ce r#frig@ateur ainsi que

pour r#duire le risque de blessure corporelle ou de

dommage au produit, DEUXPERSONNESSONTREOUISES

POURUNEINSTALLATIONCORRECTE.

A AVERTISSEMENT:

. Le haut de ces r#frig@ateurs est Iourd et ils doivent

6tre fix#s pour @iter toute possibilit# de basculement

vers I'avant. Une protection anti-basculement est

requise. Voir page 14 pour de plus amples informations

.. N'utilisez cet appareil qu'aux fins pr@ues

.. R#parez ou remplacez imm#diatement tout cordon

#lectrique us# ou endommag#.

. Coupez I'alimentation #lectrique du r#frig#rateur au

niveau du disjoncteur avant tout nettoyage ou

r#paration.

, Les r#parations doivent _tre effectu#es par un

technicien de service qualifi#.AVERTISSEIVlENT-

Frigorig#ne R600a

AVERTISSEMENT- Frigorig ne

R6OOa

Avertissement: Cetappareil contient un fluide frigorig#ne

isobutane, R600a,un gaz naturel d'une grande compatibilit#

environnementale. IIs'agit toutefois d'un combustible.

Veuillezrespecter les avertissements suivants:

i) Lorsde la manipulation, de I'installation et de I'utilisation

de cet appareil, prenezsoin de ne pas endommager les

tubes de circulation du fluide frigorig#ne..

2) L'entretiendoit @reeffectu# parun technicien de service

autoris# par le fabricant. Lespi#ces seront remplac#es

par des pi#ces recommand#es par lefabricant.

3) Les appareils r#frig#rants contiennent des fluides

frigorig#nes qui conform#ment _ la I#gislation f#d#rale

doivent #tre retir#s avant la mise au rebut de I'appareil.

41N'obstruezpas les #vents dans I'enceinte pr@ue pour

I'appareil.

51N'utilisezpas d'appareils ouautres moyens m#caniques

pour acc#l#rer le processusde d#givrage.

61N'endommagez pasle circuit du fluide frigorig#ne.

71N'utilisezpas d'appareils #lectriquesdans le

compartiment r#frig#rateur decet appareil.

TABLE DES MATIERES

Guide de conception

Dimensions de I'enceinte ....................26

Dimensions du r#frig#rateur ............27

Emplacement pour le r#frig#rateur 28

Mise (_la terre du r#frig#rateur ........26

Dimensions et d#gagements ............27

Poign#es int#gr#es pour ouverture de la

porte (_115° ..............................................29

Poign#es int#gr#es pour ouverture de la

porte a 90° ................................................30

Poign#es professionnelles pour ouverture

de la porte (_115° ..................................31

Poign#es professionnelles pour ouverture

de la porte a 90°......................................32

Accessoires et dimensions des panneaux

en acier inoxydable ................................33

Dimensions d'un panneau sur mesure de

sApo ..............................................................34

Instructions d'installation

Outils, quincaillerie, mat@iaux ........35

Etape i, retrait de I'emballage ........36

Etape 2, installation de la patte anti-

basculement ..............................................37

Etape 3, passage du tuyau d'eau ....37

Etape 4, branchement de

I'alimentation #lectrique ......................37

Etape 5, positionnement de I'appareil

dans son enceinte ..................................38

Etape 6, installation de la plinthe et de

I'#vent ..........................................................38

Etape 7, mise (_niveau du

r#frig#rateu ................................................39

Etape 8, installation de la plinthe et de

I'#vent ..........................................................39

25

Etape 9, installation de la plinthe et de

I'#vent ........................................................../40

Etape 10,r#glage de I'ouverture de

porte ......................................................40, 4!

Etape 11,installation de la protection

de charni#re ..............................................41

Etape 12,installation des panneaux

de porte et de tiroirs ............................../42

Etape 13,mise en marche de la

machine a glaqons ................................43

Gabarits ......................................................../4/4

Observation ................................................/45

Page 26

Guide de conception

Dimensions de I'enceinte pour instructions d'installation du r_frig_rateur encastr_

L'ouverture d_coup_e doit avoir une

25" min. depth _ 30" Finished Width

Height options

80" or * 84"

profondeur minimale de 25 pc pour

un montage sans renfoncement.

. La face avant du r6frig6rateur doit

_tre au m_me niveau que les

meubles adjacents avec une

profondeur de 25 pc.

. Le r6frig_rateur peut s'int6grer dans

une enceinte d'une hauteur entre 79

1/2pc et 84 1/2po.Toutefois, le

r6frig_rateur peut seulement _tre

sur61ev6a une hauteur de 80-3/8 pc.

. Le panneau du compartiment

r6frig6rateur peut _tre fabriqu6 de

faqon _ couvrir la hauteur

suppl6mentaire; voir page 10.

ZOqgonseil deconception.Nous recommandons de faire terminer la surface interieure de I'enceinte & une

=- distance minimale de 4 pc de la face avant.

Z_-gonseil deconception.Si une enceinte d'une hauteur de 84 pc est utilisee, pensez & utiliser une

bordure de finition au-dessus de la cuve du refrigerateur.

ZOqgonseil de II est le tiroir du le meuble fini

completement encastre.

conception. possible d'aligner refrigerateur

26

avec

adjacent

pour

un

Page 27

Cuve

Guide de conception

Dimensions du r_frig6rateur avec des panneaux de 3A po

Porte

Jk

Height adjustable

from

79-3/8" to 80-3/8" *

Dessus Gvec pGnneGux

)k

23 3/4'(Cuve et porte seulement)

• •

}--

Panneau

<-_ 29 1/2"--->

Degagement

f

Av(]nt (]vec p(]nne(]ux

* Le refrigerateur peut _tre adapte pour s'encastrer dans une enceinte de 83-

3/8 po & 84-3/8 po avec le jeu de panneaux de porte appropri&

Degagements pour I'installation

Dessus Chaque c6te Arriere

1/8po/3mm 1/4po / 6mm 1/2po / 12mm

11

27

Page 28

Guide de conception

ENCEINTE POUR LE RI FRIGI RATEUR

Emplacement des branchements _lectriques et des branchements 6 l'alimentation d'eau.

Les alimentations 61ectrique et en eau doivent _tre plac6es dans les parties gris6es comme indiqu6 sur le sch6ma ci-

contre.

PRI_PARATIONDEL'INSTALLATION

DU TUYAU D'EAU

, Une alimentation d'eau froide est requise pour faire fonctionner la

machine 6 glaqons automatique, La pression de I'alimentation d'eau

doit rester dans une gamme de pression entre 40 et 120 p.s.i.

, Faites passer le tuyau d'!/4 po en cuivre ou le tuyau en plastique GE

SmartConnect TM entre la conduite d'eau froide du domicile et le

raccord de branchement d'eau.

, Letuyau doit _tre suffisamment long pour atteindre I'avant du

r6frig@ateur. Pr6voyez une Iongueur de tuyau suffisante pour

prendre en compte la courbe menant au raccord 6 la conduite d'eau.

, Letuyau d'eau peut passer par une ouverture dans le sol ou dans le

mur du fond.

, Installez un robinet entre le robinet de la machine 6 glaqons et le

tuyau d'alimentation en eau froide du domicile.

REMARQUE:

, Le robinet doit _tre plac6 dans un endroit facilement accessible. II

n'est pas recommand_ de le placer derri@e I'appareil 6 cause de

I'acc_s difficile. S'ilest n6cessaire d'installer un robinet derri@e

I'appareil, il doit _tre install6 dans les zones gris6es du sch6ma.

, Les robinets de type vanne 6 6trier sont souvent inclus dans les

trousses de branchement de I'alimentation d'eau, mais ne sont pas recommand6s pour cette application.

, Les seuls tuyaux en plastique autoris_s par GEsont fournis avec la trousse de tuyauterie pour r6frig@ateur GE

SmartConnect TM. N'utilisez pas d'autres tuyaux d'alimentation d'eau en plastique, cette ligne _tant sous pression en

permanence. Certains types de plastique peuvent se fissurer ou se rompre avec le vieillissement et causer des d6gats

d'eau dans votre maison. Lestrousses de tuyauterie pour r6frig@ateur GESmartConnect TM sont disponibles dans les

Iongueurs suivantes:

6 pi (1,8 m) W×08×10006, 15 pi (4,6 m} W×08×10015 & 25 pi (7,6 m) W×08×10025

, L'installation seraconforme aux codesde plomberie 248CiVlRdu Commonwealth du IVlassachusetts.L'utilisation de robinets-

vannes 6 @tierest interdite au Massachusetts.DemandezI'avisde votre plombier qualifi&Emplacement pour lapatte anti-

basculement. N'obstruezpas cette zone.Branchement 61ectriqueetbranchement 6 I'alimentation d'eau.Vuede face de

I'enceinted'installation

Caract_ristiques _lectriques

, Une alimentation 61ectrique de 115 volts, 60 Hz et de 15 6 20 amp@es est demand6e. L'utilisation d'un circuit de

d@ivation individuel correctement mis 6 la terre ou d'un disjoncteur est recommand6e.

, Installez un bottier 61ectrique 6:3 fiches correctement branch6 6 la terre et encastr6 dans lemur du fond. La prise

_lectrique doit _tre situ6e sur le mur du fond comme indiqu&

REMARQUE:L'utilisation d'un disjoncteur de fuite de terre n'est pas recommand6e.

Anti-Tip location. Do

not obstruct this area.

80"

77"

_F

Water and Electrical

Tube Outlet

\Xx

Front view

Install Space

+

6"

MISE/ , LA TERRE DU RI FRIGI RATEUR si une prise murale standard 2-broches, il est de votre

IMPORTANT--(#, life attentivement)

POUR DES RAISONS DE SECURITE, CET APPAREIL DOlT

ETRECORRECTEMENT MIS A LA TERRE.

Le cordon d'alimentation de cet appareil est 6quip6

d'une fiche 6 trois broches (pour une mise 6 la terre)

qui s'adapte 6 la prise decourant standard 6 3

broches (pour une mise 6 la terre) pour minimiser les

risques de chocs 61ectriques par cet appareiI.Faites

v@ifier la prise murale et le circuit _lectrique par un

61ectricien qualifi6 pour s'assurer que le syst_me est

correctement mis 6 la terre.

Dans le cas d'une prise biphas_e, I'installateur a la

responsabilit6 et I'obligation de la remplacer par une

prise triphas6e correctement mise 6 la terre.

responsabilit6 personnelle et I'obligation de la faire

remplacer par une prise murale 6 3 broches mise 6 la

terre.

NECOUPEZPASOU N'ENLEVEZ _---_-_/

PAS,sousAUCUNPRUFXTE I

LATROISIEMEBROCHE DE [.i / [_ I

MISEA LA TERRE DU

CORDON D'ALIMENTATION.

N'UTILISEZ PAS D'ADAPTATEUR POUR BRANCHER LE

REFRIGERATEUR/_ UNE PRISE BIPHASEE.

N'UTILISEZ PAS DE RALLONGE AVEC CET APPAREIL.

28

Page 29

Guide de conception

D_gagements

Ces r6frig6rateurs sont 6quip_s d'une but6e de porte 6

deux positions. L'ouverture de porte r6gl6e en usine 6

115° peut _tre r6duite 6 90° si les d6gagements par

rapport aux meubles ou murs adjacents sont

restreints.Ouverture de la porte 6 90°, voir page 7

Refrigerator

Allow 15"minimumclearance

fora full 115° doorswing.

2-1/16"

©

Panneaux europ_ens en acier

inoxydable ou sur mesureCoupe

horizontaleOUVERTURE DE PORTE A Non a I'echelle

@ s I "

:1.15ire la e d uslne}

29

Page 30

Guide de conception

Refrigerator

_1/8"

For a 90 ° door

swing allow 5" min.

clearance to a wall,

for stainless steel

models.

2-1/4" _ 1-1/4"

1-1/2"

3/4"

•'_--- I"

3/4"

1 "

Panneaux europ6ens en acier

inoxydable ou sur mesureCoupe

horizontaleOUVERTURE DE PORTE

90°(r_glages en option}

I -I/4"

©

1-1/2"

0

Non & I'echelle

3O

Page 31

Guide de conception

D_gagements

Ces r6frig6rateurs sont 6quip6s d'une but6e de porte (3

deux positions. L'ouverture de porte r6gl6e en usine (3

115° peut _tre r6duite (390° si lesd6gagements par

rapport aux meubles ou murs adjacents sont

restreints.Ouverture de la porte (390°,voir page 9

Refrigerator

Allow 15"minimumclearance

fora full 115°doorswing.

Panneaux europ_ens en

acier inoxydable ou sur

mesureCoupe

horizontaleOUVERTURE DE

PORTE A 115°ir_glage

d'usine}

Non a I'echelle

31

Page 32

Refrigerator

Guide de conception

For (] 90° door

swing GIIow 5" min.

clearance to (] wall,

for stainless steel

models.

2-g/16"

Panneaux europ_ens en acier

inoxydable ou sur mesureCoupe

horizontaleOUVERTURE DE

PORTE #, 90°(r_glages en option}

Non & I'echelle

32

Page 33

Guide de conception

ACCESSOIRES ET DIMENSIONS DES PANNEAU× EN ACIER INOXYDABLE

Option : panneau de porte massif de sA pc

d'_paisseur

Pour une installation d'une hauteur de 80 pc

, Encastr6 -ivlod_le de panneau ZKST300N,possibilit6 de

poign6e 6 gauche ou 6 droite

, Professionnel -ivlod_le de panneau ZKSP300N,possibilit6

de poign6e 6 gauche ou 6 droite

Pour une installation d'une hauteur de 88 pc (Lepanneau

de porte n'est pas r_versible pour les installations 6 84 pc. II

est n6cessaire d'acheter un autre accessoire de panneau de

porte pour poign6e 6 gauche ou 6 droite.)

, Encastr6 avec poign6e gauche - ivlod_leZKST304NLH

, Encastr_ avec poign6e droite - ivlod_le ZKST304NRH

, Professionnel avec poign6e gauche -ivlod_le ZKSP304NLH

, Professionnel avec poign6e droite -ivlod_le ZKSP304NRH

REMARQUE:Chaquetrousse contient _galementdespanneaux,

despoign_eset uneplinthe assortispour le cong_lateuret letiroir

convertible.

2g-3/4"_

Fresh

Food

Cabinets

IceDrawer

45-3/8" for 80" Installation

49-3/8" for 84" Installation

7-1/2"

t

Freezer/

Convertible

Drawer

22-3/4"

Option : Cadre de sA pc d'_paisseur pour

porte en verre

Pour une installation d'une hauteur de 80 pc

, Encastr6 - ModUleZKGT300N,possibilit6 de poign6e 6

gauche ou 6 droite

• Professionnel -ivlod_le ZKGP300N,possibilit6 de

poign6e 6 gauche ou 6 droite

Pour une installation d'une hauteur de 84 pc (Le

pannequ de porte n'est pus r_versiblepou, r res

installations a 8q pc. est n6cessaire d'acneter un autre

accessoire de panneau de porte pour poign6e 6 gauche

ou 6 droite.)

, Encastr6 avec poign6e gauche - ModUle ZKGT304NLH

Encastr6 avec poign6e droite - ivlod_le ZKGT304NRH

Professionnel avec poign6e gauche -ivlod_le

ZKGP304NLH

Professionnel avec poign6e droite -ivlod_le

ZKGP304NRH

REMARQUE: Chaque option contient @galement des panneaux

des poign@es et une plinthe assortis pour le cong@lateur et le

tiroir convertible.

I_ 29-3/4"

_. 23"_

GlassPanel

for FreshFood

80" 84" i

Install Install.J

45-3/8"

49-3/8"

T

I

f

1/8" Min.X

_11doit y avoir und_gagementminimumd'1/8pc entre/es

panneauxetles meublesdecuisineadjacent.

Accessoires en option #:

,, Trousse d'installation c6te-6-c6te -ZUG30

,, Trousse poign_e europ6enne -(3 poign6es)-

WR12X10988 (peut @re achet6e aupr_s du

service GE Parts)

_LesfenatresdetypeProsontIdgbrementplus

petites..

33

Page 34

Guide de conception

DIMENSIONS D'UN PANNEAU SUR MESURE DE 3A po Installation totalement

encastr_e de 80 po de hauteur

En Gasd'installation de panneaux sur mesure, ceux-ci

:loivent @trecoup6s aux dimensions indiqu6es. Les

oanneaux se fixeront 6 la porte et aux tiroirs 6 I'aide d'un

Syst_me de crochets et de pattes.

TRESIMPORTANT:panneaux en bois sur mesure doit 6tre

d'au moins 3 14 "d'_paisseur o6 les crochets et le

rnat6riel de fixation sont attaches Reportez-vous 6 des

rnod_les pour le crochet et le lieu de fixation.

L'insertion des panneaux est requise 16o6 il y a presence de crochets et de fixations install_s aux panneaux

REMARQUE:Ce produit est conqu pour _tre utilis_ avec des

panneaux en bois de sApo.Dimensions

maximales de I'ouverture pour une vitre en

verre : 33-3/8 po x 23 po. L'ouverture peut _tre

plus petite si vous le souhaitez.

PANNEAUXPOURPORTESETTIROIRS

MASSIFS

_,29-3/4"_

PANNEAUXPOURPORTEEN VERRE

I_ 29-3/4"_

6"

45-318" T

33-3/8"

REMAROUEIMPORTANTE:Poids

maximaldupanneau:

A Panneaudeportedu compartiment

rdfrigdrateur: 33livres(15kg).

B Panneaudu tiroir congd/ateur: 8

livres(4kg).

CPanneaudu tiroir convertible: 18

livres(9kg).

L

7-1/2"_

i

22-3/4"

1

DIMENSIONS D'UN

PANNEAU SUR MESURE DE sA po: Installation totalement

3-3/8"_ 23" _3-3/8"

Consei/deconception.Linepartie dechaquepanneausaravisibleducot#

intdrieurdeI'appareiLIIestrecommand#quala finitionsoit faite dechaque

cot#dupanneau.

4 _,

Conseildeconception.Encasd'utilisationdepanneauxsurmesure,il est

importantdepenser_une plinthe surmesure.Lehasde lacuveestde

couleurblanche.

encastr_e de 84 po de hauteur

En cas d'installation de panneaux sur mesure, ceux-ci

doivent @trecoup6s aux dimensions indiqu6es. Les

panneaux se fixeront 6 la porte et aux tiroirs 6 I'aide d'un

syst_me de crochets et de pattes.

TRESIMPORTANT:panneaux en bois sur mesure doit 6tre

d'au moins 3 / 4 "d'_paisseur o6 les crochets et le

mat6riel de fixation sont attach6s Reportez-vous 6 des

mod61es pour le crochet et le lieu de fixation.

L'insertion des panneaux est requise 16o6 il y a presence de crochets et de fixations install_s aux panneaux

PANNEAUXPOURPORTESETTIROIRS

MASSIFS

_29-3/4"_

PANNEAUXPOURPORTEEN VERRE

REMAROUE:Ceproduit est conqu pour _tre utilis_ avec des

29-3/4"-_,

7

49-3/8"

49-?/8"

*Lesstylesdoivent#tred'aumoins3-3/8po pour

recouvrirle cadredeporte enaluminium.

panneaux en bois de sA po.Dimensions

maximales de I'ouverture pour une vitre en

verre :33-3/8 pox 23 po. L'ouverture peut _tre

plus petite si vous le souhaitez.

REMAROUEIMPORTANTE:Poids

maximaldupanneau:

10"

33-3/8"

A Panneaudeporteducompartiment

rdfrigdrateur: 33 livres(15kg)

B Panneaudu tiroir congdlateur:

9 livres(4kg)

CPanneaudu tiroir convertible:

19livres(9 kg)

7-1/2" __

22-3/4"

1

l

1

*Lesstylesdoivent#tred'aumoins3-3/8po

B

C

4"

m

t

3-3/8"----_ --_ _--3-3/8"

ZO'_ Consei/deconception.Une2artiedechaquepanneausara visibleducot#intdrieur

deI'appareil.II estrecommand#quala finition soit faite dechaquecot#dupanneau.

_ Conseildeconception.Encasd'utilisationdepanneauxsurmesure,ilest important

depenser_uneplinthesurmesure.Lehasde la cuveestdecouleurblanche.

23"----_

34

pourrecouvrirle cadredeporteenaluminium.

Page 35

Instructions d'installation

OUTILS REOUIS

, CI6 Allen de 5/32 po

Couteau 6 lame r#tractable

Escabeau

Seau

, Niveau

, Diable

, Coupe-tube

, CI# anglaise de 7/16 po

, CI# anglaise de 1-1/4 po

, Tournevis Phillips cruciforme #2

, Perceuse et jeu de forets

, Douille 5/16 po

, Lunettes de s#curit#

, Pinces

, Cliquet 3/8 po

, Torx T-20, T-30 cl#

QUINCAILLERIE FOURNIE

, Patte anti-basculement et vis

, Pattes de montage des panneaux

, Gabarits de panneau de porte - Pub # 31-46543

, Filtre 6 eau - Piece # GSWF

, Brides d'ancrage et vis pour cloison s_che

I QUIPEMENT REQUIS

, Tuyau d'alimentation d'eau en cuivre d' 1Apo ou

trousse pour r#frig#rateur GESmartConnect TM

, Robinet d'arr_t d'eau

, Panneaux sur mesure pour la porte du

compartiment r#frig#rateur, pour le tiroir

cong_lateur et pour le tiroir convertible

, Velcro avec c6t# adh#sif pour la plinthe sur mesure.

SOL

Pour obtenir une installation correcte, le r_frig#rateur

doit _tre plac# sur une surface horizontale en

mat#riau dur qui est au m_me niveau que le reste du

sol. Cette surface doit _tre suffisamment solide pour

supporter le poids d'un r#frig#rateur rempli, soit

environ 1,200 livres (550 kg).

REMARQUE:Prot#gez la finition du sol. D#coupez un

grand morceau de carton et placez-le sous le

r#frig#rateur sur I'aire de travail.

35

Page 36

Instructions d'installation

I_TAPE 1 RETRAIT DE L'EMBALLAGE

A MISE EN GARDE: LEHAUTDE

VOTRE RIeFRIGERATEUR EST LOURD. FAITES

ATTENTION EN LE DEPLA(_ANT.

. Coupez les courroies et le ruban adh6sif sur le haut et

sur le bas de I'emballage 6 I'aide d'un couteau 6 lame

r6tractable.

. D6pliez le carton d'emballage et retirez le haut de

I'emballage.

. Retirez le reste de I'emballage en lefaisant glisser de

I'appareil. Vous pouvez utilisez un couteau polyvalent

pour retirer le reste du carton d'emballage EN

PRENANTSOIN de ne pas rayer I'appareil.

. Retirez les supports en Styrofoam de I'appareil.

. NEretirez PASla courroie maintenant la porte ou la

partie inf_rieure avant que I'appareil ne soit pr_t 6

_tre install_ darts son enceinte.

. D6coupez la palette en PSEsur les c6t6s avant par

I'arri@e de I'appareil.

. PoussezI'appareil vers I'avant et retirez la pattie

arri@e de la palette en PSE.

. Posezcloucement I'arri@e de I'appareil sur le sol.

. Penchez I_g@ement I'appareil vers I'arri@e et retirez la

partie avant de la palette en PSE.

. Mettez correctement au rebut les mat@iau×

d'emballage non-utilis6s.

• II est maintenant possible pour 2 personnes de

d6placer I'appareil 6 I'aide clucliable ou de le faire

fouler jusqu'6 un emplacement au sol correctement

prot6g6.

. Laisseztout film protecteur sur le r6frig@ateur jusqu'6

la fin de I'installation.

36

Page 37

Instructions d'installation

I_TAPE2 INSTALLATION DE LA PATTE

ANTI-BASCULEMENT

, LGpartie sup@ieureinterne de la patte anti-basculement

dolt @reinstall6e a une hauteur de 80 po. LG<<fente >>

dans la patte dolt @replac_e au centre de I'espace

dlnstallation (typiquement !5 po)

, Morquez (auniveaudes fentes)les positionsdes montants

et desancrages sur les )attes.

Fente

,Fixez la patte en utilisant les montants et des ancrages.

,Au mains un des montants doit @reutilis_.Toutefois,

utilisezautant de montants possiblesau sein de

I'ouverture.Au mains trois fixations doivent @reutilis6es

pour une installation correcte.

80 II

i_TAPE3 CONNECT CONDUITE D'EAU

Ouvertum

pourletwau

, Placez I'appareil devant I'enceinte.

, Localisez et amenez le tuyau vers I'avant du meuble

de cuisine.

, Ouvrez le robinet d'eau pour 61iminerles d_bris dans

le tuyau. Faites couler environ ! litre d'eau dans le

tuyau, recueillez I'eau dans un seau puis fermez le

rob_net.

Si besoin est.,co%0ezle tuyau a la Iongueur requise

pour qu'il pu_sseetre connect6 au roblnet d'eau.

Tuyeu en cuivre:

e 1

Faites passer un _crou et un.embout d'¼ po par-

dessus les deux extr6mit6s du tuyau en cuivre.

Ins@ezle tuyau dans le raccord union sur I'appareil

et serrez '6crou.

, Ouvrez le robinet d'eau pour v@ifier I'absence de

fuites.

Tuyau GESmartConnectTM:

, Ins@ezI'extr6mit6 moul6e du tube dans le raccord

du r6frig@ateur. Serrez 1'6croude compression (3la

main.

, Serrez un tour suppl_mentaire avec la cl6. Des fuites

peuvent survenir si 1'6crouest trap serf6 !

, Ouvrez le robinet d'eau pour v6rifier I'absence de

fuites.

II_TAPE41 BRANCHEMENT DE

L'ALIMENTATION f_LECTRI(DUE

, Branchez le cordon d'alimentation dans la prise.

, V@ifiez que le r6frig@ateur soit bien branch6 en

ouvrant le bac @glaqons (la porte FFsera ferm6e par

une courroie) pour v@ifier que leslumi@res

int@ieures sont allum6es.

, Lescommandes de temp@ature sont pr@6gl6es sur

37°F(3°C)pour le r6frig@ateur et sur O°F(-!8°C) pour

le tiroir du compartiment de cong61ation et du tiroir

convertible.

, Attendez 24 heures que la temp@ature se stabilise

avant de faire les r6glages.

37

Page 38

Instructions d'installation

{I_TAPES] POSITIONNEHENT DE

L'APPAREIL DANS SON ENCEINTE

Faites rouler I'appareil dans son enceinte, en s'assurant

de ne pas accrocher letuyau d'eau ou le cable

d'alimentation.

:Z]_ .......................... IT:::

................;]1:;;:::7;:;;; ] I

Une Iongue barre plate ou une r_gle de trente-six

pouces sera peut-_tre n6cessaire pour guider le bord

avant de la patte anti-basculement par-dessus

I'appareil.

S'ily a assez de place, vous pouvez 16g@ement courber

le bord avant de la patte vers le haut, permettant ainsi le

passage de I'appareil.

I_TAPE6 INSTALLATIONDELA PLINTHEET

DEL'I_VENT

La p inthe doit _tre enlev6 pour acc6der 6 la legstyle

nlve ement

Retirez la pattie pleine de la plinthe en la tirant vers

I'avant.

,Placez la plinthe, 1'6ventet les vis 6 1'6cart pour une

r6installation future.

Faites passer le tuyau d'eau par I'appareil jusqu'6 ce

qu'il sorte par I'avant.

Fixezle tuyau au sol 6 I'aide de ruban adh6sif en

attendant que I'appareil soit plac6 dans I'enceinte.

Visde l !jEvent

I_vent

(derribrela I_..... _

plinthe)_ Vis

Vis _ "_" Plinthe

Retirez la protection de la garniture de I'appareil.

FixezI'appareil 6 la patte anti-basculement 6 I'aide des

vis de m6canique et des rondelles pour enfiler les

douilles filet6es dans la patte anti-basculement.

Commencez 6 visser les vis 6 la main jusqu'6 ce que

I'appareil soit dans la position d6sir6e dans I'enceinte.

Finalisez I'installation en serrant lesvis compl_tement.

,R6installez la protection de la garniture.

38

Page 39

Instructions d'installation

IETAPE71 MISEANIVEAUDU

RI_FRIGERATEUR

Tous les modules poss_dent quatre points de mise 6

niveau. L'avc]ntest soutenu par des pieds de mise 6

niveau, I'arri6re par des roulettes r6glables. Les deux

sont accessibles par I'avant du r6frig6rateur

, Pour mettre c_nivec]u I'arri6re du r6frig6rateur, tournez

1'6crouhexagonal de 5/16 po situ6 (]u dessus des

roulettes (]vant. Tournez dans le sens des aiguilles

d'une montre pour rehc]usser le r6frig6rateur et dc]ns

le sens inverse des (]iguilles d'une montre pour

I'abaisser.

. Pour mettre I'avant de niveau, utilisez une cl6 plate de

11Apo.

R_glez I(] hauteur du r6frig6rateur pour correspondre

(_I'ouverture d6coup6e pour I'instc]llation. Le

r6friq6rateur doit 6tre de nivec]u et dk]plomb avec les

meu]ales(]lentours.

Verslehaut .pour le rdglagedes

._oo(_l f roulettesarribre

o o o o

Ecrouhexagonal

[I_TAPE 8] INSTALLATION DE LA

PLINTHE ET DE L'EVENT

. Localis,ez la plinthe, 1'6ventet lesvis (retir6s

pr6c6demment}.

. bne plinthe sur mesure peut _tre install6e pour _tre

assortie ou pour completer les meubles alentours.

Utilisez la plinthe fournie comme module pour

d_couper la forme.

. R_installez 1'6vent6 I'aide des vis retir6es

pr6c6demment.

. R6installez la plinthe.

Plinthefournie

Piedderaise_niveau

A MISE EN GARDE:

Lesroulettes arri6re et les pieds (]vant de mise (_niveau

sont limit6s 6 un r6glage d'une hauteur maximale de 1

po. Si I'installc]tion demande une hauteur sup6rieure (3

84 V2po, I'installateur doit sur61everle r6frig6rateur c_

I'aide d'une plaque de contreplaqu6 ou des patins. II est

6galement possible d'ajouter une moulure de meuble

sur le haut de I'ouverture pour r6duire cette derni_re.

Toute tentetive de sur_l_vetion du r_frig_rateur de

plus d'l po ve endommager les pieds event et les

roulettes erri_re de raise 0 niveeu.

39

Page 40

Instructions d'installation

I TAPE 91 INVERSION DE L'OUVERTURE

DE PORTE (sin_cessclJre)

Sautez cette _tape si I'ouverture de la porte est

satisfaisante.

1.Ouvrez la porte du refrig_rateur.

A AVERTISSEM ENT: L' TAPESU,VA.TE

EST IMPORTANTE POUR LA MANIPULATION EN TOUTE

SI_CURITE_D'UNE CHARNII_RE NON CHARGI_E NE SAUTEZ PAS

L'I_TAPE 2.

2. Lib_rezlesressorts deI(]charniere en utilisant une cleTorx

T-20 pour desserrer Ic]visTorx de k] position 1 6 k] position

0 sur lesdeux charnieres.

21.A I'aide d'une cle hexagonale de type Allen de 5/32

po, retirez les deux vis _e chaque charniere qui

maintiennent I(] ports sur le refrig_rateur. Demondez

6 quelqu'un detenir la porte pendant que vous

retlrez ces vis pour 6viter que la porte ne tombe.

ETAPE

9JINVERSION DE L'OUVERTURE

DE PORTE {suite)

8. Lescharnieres seront installees dans les coins

opposes. La charniere superieure sera retournee et

installee sur le bus du compartiment refrig_rateur. La

charniere inferieure sera retournee et installee sur le

hc]utdu compc]rtiment refrigerateur.

Charnibresupdrieure Charnibreinfdrieure

9. Installez les vis sur la cuve du compc]rtiment

refrigerateur (]ux 4 endroits. Vissez-lesjusqu'(_ mi-

course.

Vis

10. Pour installer la charniere supeneure, placez la

charniere dans le bon sens -la partie du support

qui sera fix_e (_la porte doit _tre sur le bas de la

charniere. Fc]itesglisser la charniere sur lesvis et

plc]cez les I(]nguettes dans le compc]rtiment de I(]

charniere. Serrez les vis.

Fentes

/anguettes

Vis

4. Ouvrez les charnieres. A I'aide d'une cle hexagonale

de type Allen de 5/32 po, retirez les deux vis de

chaque charniere qui maintiennent I(] charniere sur

I(]cuve du refrigerateur.

I

5.RetirezI(]garniture et lecompartiment decharniere du

haut du refrig_rateur et installez-lessur le c6t6 oppose.

6.Retirezla garniture et lecompc]rtiment de charniere du

bas du compartiment r_frigerateur. Retirezletableau de

commc]nde et pk]cez-le delicatement duns le tiroir FZ.

/ f ...............

Tableau de

commc]nde

11. Pour installer la charniere inf_rieure, placez la

charniere dans le bon sens - I(]partie du support qui

sera fix6 6 la porte doit _tre sur le haut de la

charniere.Faites glisser I(] charniere sur lesvis et

placez les languettes duns le compc]rtiment de I(]

charniere. Serrez les vis. Fermez I(]charniere.

12.Retirezles supports de la charniere de I(]porte et

reinstallez-lessur lec6t6 oppose,en hc]utet en bus.

7. Reinstallezletableau de commc]nde.

4O

Page 41

Instructions d'installation

[I_TAPE9J INVERSION DE L'OUVERTURE

DE PORTE {suite}

13. Avec I'aide cl'une deuxi_me personne pour maintenir

la porte en place, alignez les trous clans le support de

la chami_re de porte avec ceux clans la charnl_re.

Placez d'abord les vis clans la chami_re sup6deure.

_ Visde

. . ._ _ porte

r

14. Installez ensuite les vis sur la charni_re inf6rieure.

15.A I'aide d'une cl_ Torx T-20, resserrez la tension sur

les ressorts de la charni_re en tournant lesvis de la

position 0 a la position 1.

II_TAPE :I.:I.]INSTALLATION DE LA

PROTECTION DE

CHARNIi_RE

A AVERTISSEblENT:

Cet appareil doit _tre install_ et utilis6 avec la

protection de charni6re en place !

1.S6curisezla protection de charni6re au c6t6 du caisson

avec du ruban. Alignezlecouvercle avec les rebords

sup6rieur et le devant du caisson.

2. Fixezla protection de charni6re en glissant la pattie

plate entre lecaisson et le couvercle.

3. Fixezla protection sur I'avantde laporte 6 I'aidedes 4

vis.

o

[I_TAPE 101RI_GLAGE DE L'OUVERTURE

DE PORTE (si n_cessaire)

REMARQUE:Cer6frig6rateur poss_de 2 buttes de position

d'ouverture, q)uand I'espace ne permet pas I'ouverture de

la porte (_!!5 °,vous pouvez limiter I'ouverture de porte (_

90°,

Ignorez cette _tape si I'ouverture de la porte est

satisfaisente pour I'installation.

, Ouvrez la porte du compartiment r_frig_rateur pour

exposer les charni_res sup6rieure et int6rieure.

, Desserrez les vis de la charni_re inf6rieure fix6es (_la

cuve

, Tirez la charni_re 16q_rement vers vous et ins_rez I'axe

de la charni_re dan_ le trou le plus proche de I'appareil.

, Vous pouvez utiliser un petit mart_,, _?.cur les mettre en

place correctement.

, Resserrez les vis de la charni_re.

, R_p_tez cette proc6dure pour

, Repeat for top hinge.

la charniere

_ supOrieure,Installation

: ...... d'unaxeparcharniere

:........ pourun,e ouverturede

a

80i.s°e c arnibre

"V,d h

couvercle

Protection de

charniere

41

Page 42

Instructions d'installation

I_TAPE 12]

INSTALLATION DES

PANNEAU× DE PORTE ET DE

TIROIRS

1.Retireztousles crochets des pores et des tiroirs de

I'appareilet vissez-lessurles panneuux sur mesure, en les

alignant sur lestrous pr#perc_s lesplusbas pour les

panneaux Monogram sur le panneau de porte FF.

2.Fixezle support en Lsup@ieuruu panneau FF.

3.Sivous avezfuit fabriquer des poign#essur mesure et

qu'ellesne sont pusencore fix#es uux punneuux, fuites-le

muintenunt.

4. Ouvrezla porte du r#frig@ateur pour suspendre le panneuu

appropri_. , , , ,

5.Fgjtesglisser lescrochets du panneau ae la porte au

r@rig@ateurduns lesfentes de la porte ettaites descendre

lescrochets duns la bonne position. Assurez-vousque la

patte sur le haut du panneau seglissepar-dessus lesvis

relieusessur le haut de la porte. Lesputtes reposeront sur le

dessusdes6crous.

Patt_

Visrelieuse

Crochets, _ Fentes

.Crochets sur le

panneau du tiroir

cong#luteur vers le

haut.

[I_TAPE12] INSTALLATION DES

PANNEAU× DE PORTE ET DE TIROIRS

(suite)

.

Installezlespanneaux de tiroir cong_lateur en ins@ant

lespattes en remontant vers le haut. (dunsla direction

oppos_eaux crochets du panneau de la porte du

r_frig@ateuret du tiroir convertible).

.

Lorsquele panneau du tiroir est en place,fixez-le au tiroir

en vissant la patte inf@ieureau panneau (_I'aidedesvis

fournies.

.

R#p@ezla procedure pour le deuxi_metiroir en fuisant

glisserlescrochets vers le bus plut6t que vers le haut.

10.

Sivous utilisezune plinthe sur mesure,fixez le panneau

de la plinthe en plaqant le Velcroau dos du panneau et

sur le devant de la plinthe. Sivous utilisezune plinthe en

acier inoxydable,il sera aimant#.

11.

AjustezI'alignement du tiroir enutilisant lespattes

inf@ieuressi n6cessairepour cr@r un d6gagement

uniforme.

jj .'"

Tiroir

congd/ateur

,--i

_-- Patte

F

6. Ajustez lesvis reli(

sous la putte sur le haut de la porte pour mettre le

panneuu de niveuu.

7. Verrouillez le punneuu sur la porte en plaqant les

6crous fournis sur les vis relieuses sur le dessus de la

porte.Ensuite, vissez la putte inf@ieure en L uu bus de

la porte et du panneau.

_usesvers le haut ou vers le bus

• Visrelieuse

Vue de I'arri6re des crochets et de la

patte du panneau

Tiroir

congdateur

Portedu

compartiment

rdfrigdrateur

Tiroir

convertible

Lessupportsinfdrieurssur laportedurdfrigdrateuret surle

tiroir convertiblenedoiventpus8treinstalldsavantles

panneaux.

42

Page 43

Instructions d'installation

I_TAPE 13 MISE EN MARCHE DE LA

MACHINE A GLA(_ONS

. Appuyez deux fois sur le voyant ZONEsur le panneau de

commande pour s61ectionner le tiroir cong61ateur.

Appuyez sur I'ic6ne ICE(gluqon) sur le c6t6 droit des

commandes. Une ligne apparaitra sous ICE(Glaqon) pour

indiquer que la machine 6 glaqons est activ6e.

. V6rifiez que rien n'interf_re avec le d6placement du bras

de d6tection.

. Jetez le premier bac de glaqons.

Ic......LE

i

. Pour arr6ter la machine a glaqons, appuyez sur I'ic6ne

ICE(glaqon). Le mot OFF(arr6t/apparaitra sous ICE

(Glaqon/pour indiquer que la machine a glaqons est

d6sactiv6e.

.... ,,,-u _ - +)

43

Page 44

Instructions d'installation

ModUle Profession Badge Groupe ModUle europ_en Badge Groupe

80" Ligne de

decoupe

84" Ligne de decoupe

3 7/8"

6 1/8" I i 5 1/2

i En Haut

84" Ligne de decoupe

'--i En Haut

< 3 7/8"

I

o _

4"

80"

Ligne de

o dec0upe o

m m

[

2 3/8"

I

3.3/4" >

, Pour installer insigne, module de d6coupe qui correspond au style du panneou ochet6, europ6en ou professionnel.

, Trim mod61epour soit 80 "ou 84" type de panneau.

, aligner le gobarit dans le coin sup6rieur le plus proche badge Hing et le lieu.

* Pour lescharni6res sur la gauche, un mod61eflip.

Section ombrog6e dolt 6tre compris entre bard de Io porte et badge.

L _ _ _._ = _

r

\

Monogram

I

44

Page 45

Observations

45

Page 46

Pub. No. 31-46542-3

Part No. 197D8125P002

04-12 GE

REMARQUE:II est recommand6 de porter des lunettes de

s6curit6 ou des lunettes #tanches Iors de I'installation de cet

appareil.

Pour les services Iocaux Monogram@ dons votre

secteur, oppelez le 1.800./444.1845.

REMARQUE:Au sein de General Electrics, nous nous

efforqons toujours d'am61iorer nos produits. Ainsi, les

mat6riau×, I'aspect et les sp6dfications peuvent @tre

modifi6s sans pr@avis.

GE Consumer & Industrial

Appliances

General Electric Compang

Louisville, KY80225

GEApptiances.com

Page 47

Informaci6n sabre Seguridad

ANTES DE COMENZAR

Lea estas instrucdones en su totalidad y atentamente.

. IMPORTANTE - Conserveestasinstrucciones

para usa del inspector local. Cumpla con todos los

c6digos y ordenanzas gubernamentales.

, Nota para el Instalador - AsegQrese que el

Comprador conserve estas instrucciones.

. Note pare el Consumidor- Guarde estas

instrucciones con su Manual del Propietario para

referencia future.

,Nivel de habilidod - LGinstalacian de este

dispositivo requiere un nivel basico de habilidades de

mecanica, carpinter[a y plomer[a. Lo correcta

instalacian del producto es responsabilidad del

instalador. Sise producen fallas en el producto debido a

una instalacian inadecuada, la Garant[a del Producto de

GEno cubrir6 las mismas. Para obtener informacian

sabre la garant[a, consulte el Manual del Propietario.

Pare acceder el servicio local de Monogram, Ilome al

1.800.444.1845.

Pare acceder a Piezas y Accesorios de Monogram,

Ilome al 1.800.626.2002.

www.monogrom.com

A ADVERTENCIA:

Esteelectrodom_stico deber6 estar conectado a tierra de

forma adecuada.Consulte "C6mo Conectar a Tierra el

Refrigerador", p6gina 5.

Si el refrigerador que recibi6 est6 dahado, se deber6

comunicar de inmediato con su vendedor o contratista.

A PRECAUCI6N:

Debido al peso y tamaho de este refrigerador, y a fin de

reducir el riesgo de lesiones personales o dahos sabre el

producto--SE DEBER_,CONTARCON DOSPERSONAS

PARAUNA INSTALACI(DNADECUADA.

A ADVERTENCIA:

* Estosrefrigeradores presentan inestabilidad y se

deberan asegurar a fin de evitar posibles inclinaciones

hacia adelante. Se requiere contar con protecci6n anti-

volcaduras. Para mas detalles, consulte la pagina 14.

. Use este electrodomastico s61opara su prop6sito

original.

. De forma inmediata, repare o reemplace los cables del

servicio elactrico que sufran da_os o peladuras.

. Antes de realizar su limpieza o hacer reparaciones,

apague el disyuntor para desconectar la corriente.

. Cualquier reparaci6n deber6 ser realizada por un

t6cnico calificado del servicio.

A ADVERTEN Ci A-Refrigero nte

R600o

Advertendo: Esteelectrodom_stico cuente con

refrigemnte isobuteno, R6OOa,un gas natural con alto

nivel de competibilided medioembientel. Sin embargo,

tembi_n es inflemeble. Sesolidte el cumplimiento de los

siguientes edvertendes:

1}AI mover, insteler y operer el electrodom_stico, se

deber6 tenet cuidedo de eviter de_er le tuberie del

refrigerente.

2) Elservicio t_cnico deber6 set reelizedo par personal

eutorizedo del servido dele f6brice, y los com.ponentes

podr6n ser reemplezedos par componentes de

reemplezo euton'zedos par el febdcente.

3) Los productos de refrigered6n cuenten con

retrigerentes, los cueles de ecuerdo con le lay federal

deber6n set eliminedos antes de descerter e|producto.

4) Mentenge los ebertures de ventiled6n en el especio de

proteca%n del electrodom_stico o en le estructum

mcorporede libres de obstrucd6n.

5) No use dispositivos mec6nicos u otros medias peru

ecelerer el proceso de descongelemiento.

6} No de_e el circuito del refdgemnte.

7) No use dispositivos el_ctricos dentro del

cgmpe_imiento de elmecenemiento de comide del

electrodom_stico.

CONTENIDOS

Guie de Diseffo

Dimensiones del Gabinete de

Protecci6n ..................................................../48

Dimensiones del Refrigerador ............/49

ElEspacio de Instaluci6n ....................50

Conexi6n a Tierra del Refrigerador 50

Dimensiones y Espacio Libre..............50

Manijas Integradas con Giro de Puerta de

1150 ..............................................................51

HanUas Integradas con Giro de Puerta de

900 ..................................................................52

ManUasProfesionales con Giro de Puerta

de 1150 ........................................................53

ManUas Profesiona[es con Giro de Puerto

de 900 ..........................................................54

Accesorioy Dimensi6n de[ Pane[ SS. 55

Dimensiones de[ Pane[ a Medida

de 3/4". .........................................................56

Instrucciones de Instalaci6n

Herramientas, Equipo, Materiales....57

Paso1, Retire el Envoltorio ..................58

Paso2, Instale el Soporte Anti-

Volcaduros ..................................................59

Paso3, Inserte el Suministro de

Agua ..............................................................59

Paso4, Conecte la Corriente ............59

Paso5, Deslice la Unidad en el Espacio Puerta y el Caj6n ....................................64

de Protecci6n ............................................60

Paso6, Retire el Tope de Piey la

Ventilaci6n ..................................................60

Paso7, Nivele el Refrigerador ..........61