GE ZGP48 Series, ZGP304 Series, ZGP36 Series, ZGP30 Series Installation Instructions Manual

Page 1

Installation

Instructions

Convert Natural Gas to LP Gas Operation

Convert LP Gas to Natural Gas Operation

WARNING: This conversion

must be performed by a qualified installer

or gas supplier in accordance with the

manufacturer’s instructions and all codes

and requirements of the authority having

jurisdiction. Failure to follow instructions

could result in serious injury or property

damage. The qualified agency performing

this work assumes responsibility for the

conversion.

WARNING: The rangetop, as

shipped from the factory, is set for use with its

intended gas. If you wish to use your rangetop

with the alternate gas, you must first

replace the orifices and convert the pressure

regulator.

WARNING: The following

adjustments must be made before turning

on the burner. Failure to do so could result in

serious injury. Be sure pressure regulator has

been converted as described in Step 2.

TOOLS YOU NEEDED FOR CONVERSION

Safety Glasses

Small Flat-Head Screwdriver

(2 to 2.4 mm or 3/32” tip size,

60 mm long)

Crescent Wrench

1/4” and 7mm Nutdrivers

7/16” (11 mm)

Open End Wrench

Small Pliers

1/2” Deepwell

Socket Wrench

Philips

Screwdriver

1

ORIFICE HOLDER

The range orifice holder is located behind the front

access panel at the bottom of the range. Remove

the door(s) (See instructions on Page 10) and the

screws on the top and

bottom of the front access

panel. Remove the front

access panel to access the

orifice holder.

Additional orifices may

be present. Use only the

orifices specified in the

instructions for your range

or rangetop.

2

CONVERT THE REGULATOR(S)

Disconnect all electrical power at the main circuit

breaker or fuse box.

A. Shut off the gas supply by closing the manual

shut-off valve on the unit or by the wall.

B. Move the range out in order to access the

rear of the unit.

C. Remove the range back to access the regulator(s)

-

(1) on 30” & 36” ranges and (2) on 48” ranges.

D. Convert the pressure regulator(s):

• Unscrew the cap with plunger.

• Place your thumb against flat side of the

plunger and press down to snap the plunger

out of the cap.

• Carefully look at the plunger to locate the NAT

or LP position.

• Turn the plunger over so that the desired gas

is showing

near the

bottom.

• Snap the

plunger back

into the cap.

• Screw the cap

back onto the

regulator.

E. Reverse these steps to reassemble the

pressure regulator.

DOWN

FOR OFF

NAT

LP

LP

NAT

LP

NAT

NAT

LP

Gasket

Cap

Plunger

LP Position

NAT.

Position

Pressure Regulator

3

CHANGE BURNER ORIFICES

INSTALLATION TIP: First remove

all orifices and then start

replacing them. This will help to

prevent the possibility that some

may not be replaced.

A. Remove the burner grates,

burner caps and burner heads.

B. Loosen the top burner orifices using

a 7 mm nut driver. Use small

pliers to carefully lift out the

orifices.

The main orifice is located

low in the center of the

burner, while the simmer

orifice is located higher beside the center of the

burner.

IMPORTANT: Find your model number below.

Read each orifice label to identify and install them

in the exact locations shown.

A. Return the unused orifices to the holder.

Reattach the holder and the instruction sheet

with screw in the original storage location.

B. Replace the burner heads, caps and top

grates

. On range models, replace rear vent trim.

Burner Cap

Burner

Head

Spark

Igniter

Burner Base

Main

Orifice

Simmer

Orifice

ZGP304 SIMMER ORIFICES

A 34SL or 51SN orifice will

be used on all burners.

ZGP364, ZGP366, ZGP484, ZGP486

SIMMER

ORIFICES

A 34SL or 51SN

orifice will be

used on all

burners.

Use 108XL or

190XN orifices for

all burners.

MAIN

ORIFICES

4 CHANGE GRILL ORIFICE (if present)

Locate the 1–1/2” long Grill orifice.

Select the proper orifice size for your gas and

burner from the conversion chart.

A. Remove the grill cover, grates

and grate frame. Lift the

radiant baffle straight up and

off.

B. Remove the 2 hex head

screws from the top of the

igniter.

• Remove one screw from

each side of the burner

surround.

• Lift out the surround.

C. Carefully push the igniter

aside and under the

burner. Do not pull or

pinch the wire.

Remove 4 burner

attachment screws,

2 at the front and

2 at the back. Slide

the burner assembly

toward the back and

out of the gas inlet.

D. Use a 1/2” deep well

socket to remove and

replace the orifice .

Reverse these steps to

re-assemble the grill. Be

sure to place the unused

orifice in the holder for

possible future use.

Remove

2 hex

head

screws

Surround

Screws

Burner

Surround

Igniter

Burner

Assembly

Front of Range

Capillary

Front of Range

5

CHANGE GRIDDLE ORIFICE

(if present)

Locate the 3/4” long griddle orifice.

Select the proper orifice size for your gas

and burner from the conversion chart.

A. Lift off the griddle flue cover. Remove the 2

inside clamping screws.

B. Lift out the cast-

iron grease trough.

Slide the griddle

toward the rear

and out of the

hold-down tabs

along the bottom.

C. Carefully lift and

hold the griddle

while pulling

additional length

of the capillary

from the entry

hole. Stand the

griddle on end in the grease sump.

D. Remove the 2

hold-down screws

at the rear of the

burner.

Pull the burner

straight back

toward the rear

and out of the gas inlet.

E. Use a 1/2” deepwell

socket to remove

and replace the

orifice.

Reverse these steps

to reassemble the

griddle. Push excess

capillary back into the entry hole. Place the

unused orifice in the holder for possible

future use.

Griddle Flue Cover

Clamping Screws

Leveling Screws

NOTE: Remove

the 2 screws

positioned on

the inside only.

Do not remove

the outermost

screws—they

are for leveling.

Back of Range

6A

CHANGE MAIN BAKE BURNER

ORIFICE

Locate the 3/4” long bake burner orifice.

Select the proper orifice size for your gas and burner

from the conversion chart.

A. Remove the oven door and set aside in a

safe location.

B. Remove the 2 oven bottom hold-down

screws from the rear of the cover.

C. Slide the oven bottom forward and set

aside.

D. Remove the burner diffuser screw.

E. Lift the front of the burner diffuser up

slightly and slide it forward to disengage

the clips at the rear. Set the burner diffuser

aside.

Hold-Down Screws

Oven

Bottom

Diffuser screw

Clips

31-10766-1 11-10 GE

1

Front Access Cover

ZGP304 MAIN ORIFICES

A 84XL or 126HXN

orifice will be used

on these three

burners.

Use a 108XL or

190XN orifice

for the right

front burner.

Page 2

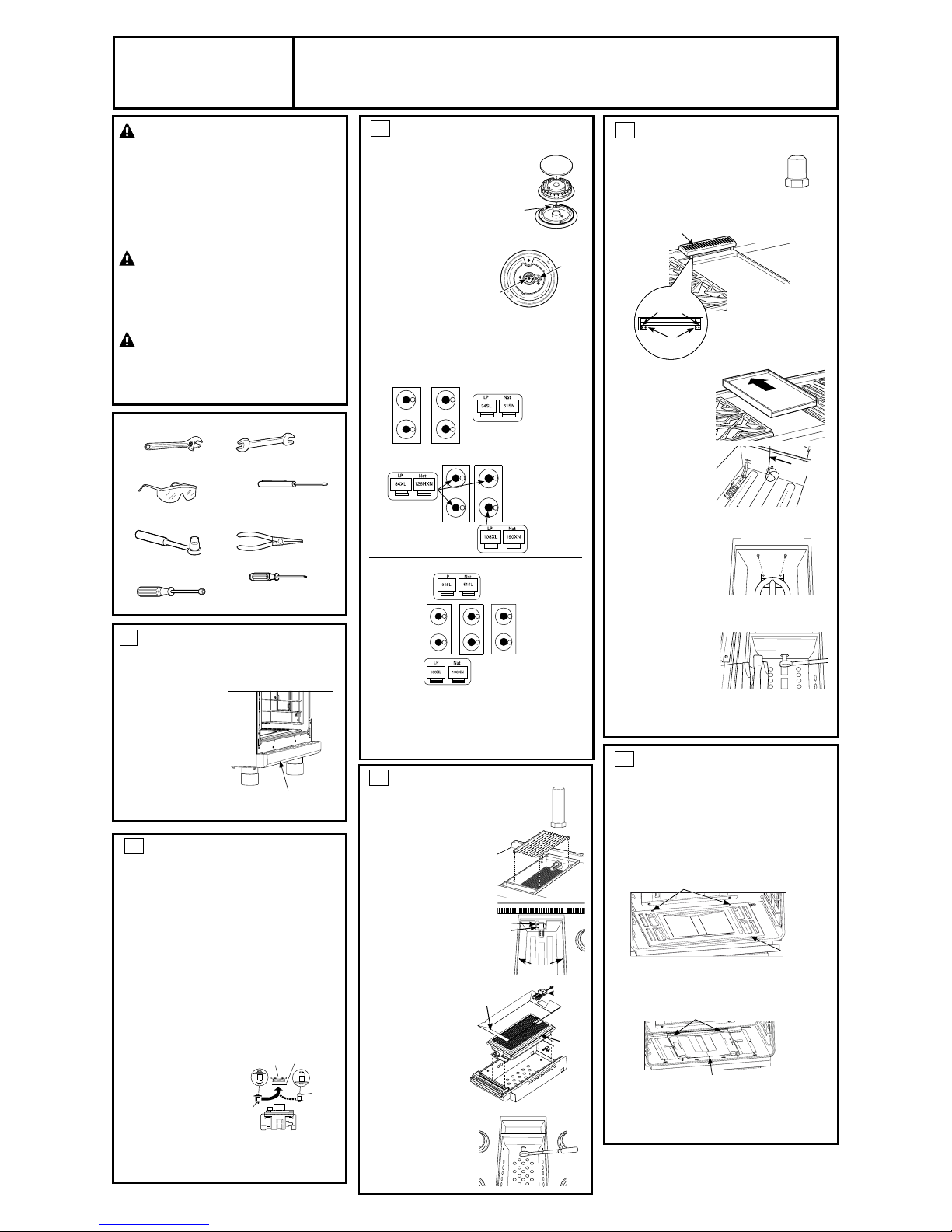

BURNER OUTPUT RATINGS: BTU/HR

7

CHANGE MAIN/COMPANION

BROIL BURNER ORIFICE

Locate the broil burner orifice.

Select the proper orifice size for your gas and

burner from the conversion chart.

The rear cover should still be removed from

converting the regulator(s). Refer to section 2 for details if it is not.

A. Remove the 2 broil duct cover retension

screw. Lift up and slide out to remove.

B. Loosen and remove the broil supply tube

nut from the broil orifice holder.

C.

Using an adjustable wrench and a 7/16” (11

mm) box end wrench to loosen and remove

and replace the broil orifice.

D. Reverse these steps to reassemble the

griddle.Push excess capillary back into the

entry hole.Place the unused orifice in the

holder for possible future use.

6A

CHANGE MAIN BAKE BURNER

ORIFICE (Cont.)

F. Remove the 2 burner retention screws.

G.

Lift the front of the burner up slightly and slide

forward setting aside (careful not to damage

the igniter.)

H. Use a 1/2” deepwell socket to remove and

replace the orifice.

I. Reverse these steps to reassemble the

griddle. Push excess capillary back into the

entry hole. Place the unused orifice in the

holder for possible future use.

Burner retention

screws

Burner

6B

CHANGE COMPANION BAKE

BURNER ORIFICE (if present)

Locate the 3/4” long bake burner orifice.

Select the proper orifice size for your gas and

burner from the conversion chart.

A. Remove the oven door and set aside in a

safe location.

B. Remove the 2 oven bottom hold-down

screws from the rear of the cover.

C. Slide the oven bottom forward and set

asside.

D. Remove the burner diffuser screw.

E. Lift the front of the burner diffuser up

slightly and slide it forward to disengage

the clips at the rear. Set the burner diffuser

aside.

F. Remove the 3 burner retension screws (1 in

front and 2 at the rear)

G. Lift the front of the burner up slightly and

slide leftward to remove.

H. Use a 1/2” deep-

well socket to

remove and replace the orifice.

I. Reverse these

steps to reassemble the

griddle.Push

excess capillary

back into the entry hole.Place the unused

orifice in the holder for possible future use.

Hold-Down

Screws

Oven

Bottom

Diffuser Screw

Clips

Burner

Retension

Screws

Remove

screws

8

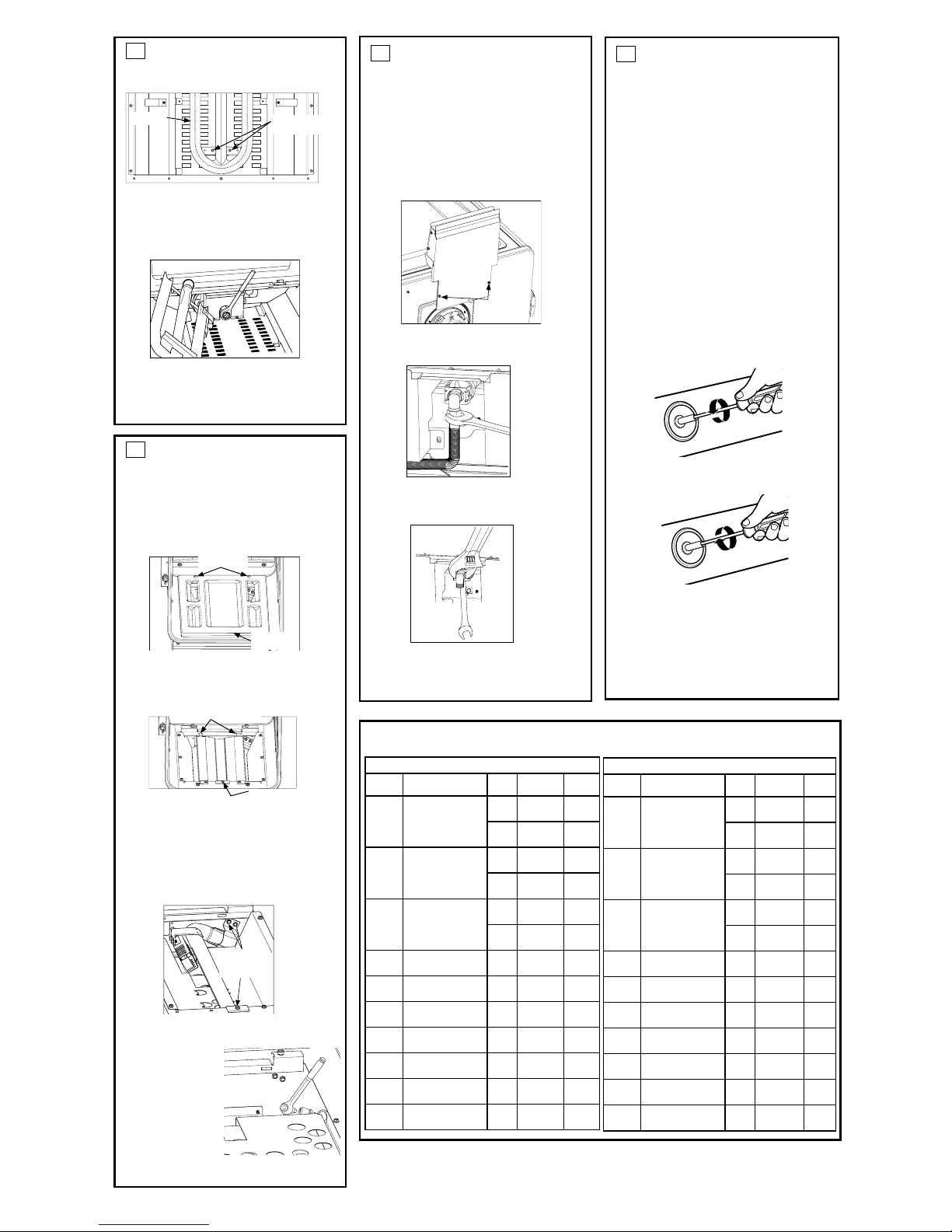

ADJUST BURNER FLAMES

Normally, burners do not need further

adjustment. Make adjustments only when

necessary.

A. Turn on the gas. Plug in electrical cord.

B. Turn all burners on highest setting and

check the flames. They should be blue in

color. When using LP gas, the flames may

have some yellow tipping at the ends of the

flame. Foreign particles in the gas line may

cause an orange flame at first, but this will

soon disappear.

C. Turn the burner knob to “LO” while

observing the flame.

Adjust the setting of the upper row of flames

using the valve bypass screw as follows:

Adjustments must be made with two other

burners in operation on a medium setting.

This prevents the upper row of flames from

being set too low, resulting in the flame

being extinguished when other burners are

turned on.

D. To adjust the flame, remove the knobs. Insert

a small flat-blade screwdriver into the hole

in the center of the valve stem to engage

screw.

• If the flames are too small or flutter, turn the

screw counterclockwise.

• If the flames are too large, turn the screw

clockwise.

E. Make the adjustment by slowly turning the

screw until flame appearance is correct.

2

NG (Natural) Gas, 5” W.C.P.

MODEL BURNER

BTU

RATE

ORIFICE

SIZE

ID

ZGP48

ZGP36

ALL SURF. Main 16,800

0.075”

(1.90mm)

190XN

BURNERS Simmer 1,200

0.002”

(0.51mm)

51SL

ZGP304

RF BURNER

Main 16,800

0.075”

(1.90mm)

190XN

Simmer 1,200

0.002”

(0.51mm)

51SN

ZGP304

RR, LR, LF

Main

Simmer

8,800

0.050”

(1.26mm)

126HXN

1,200

0.002”

(0.51mm)

51SN

ALL GRILL 15,000

0.0689”

(1.75mm)

0.069

ALL GRIDDLE 18,000

0.076”

(1.93mm)

0.076

ZGP48/

ZGP36

BAKE MAIN 24,500

0.0886”

(2.25mm)

0.089

ZGP30 BAKE MAIN 23,500

0.0866”

(2.20mm)

0.087

ZGP48 BAKE COMPANION 10,500

0.0531”

(1.35mm)

0.053

ALL BROIL MAIN 12,500

0.063”

(1.60mm)

160

ZGP48 BROIL COMPANION 9,000

0.052”

(1.32mm)

132

LP (Propane) Gas, 10” W.C.P.

MODEL BURNER

BTU

RATE

ORIFICE

SIZE

ID

ZGP48

ZGP36

ALL SURF. Main 13,800

0.043”

(1.08mm)

108XL

BURNERS Simmer 1,200

0.013”

(0.34mm)

34SL

ZGP304

RF BURNER

Main 13,800

0.043”

(1.08mm)

108XL

Simmer 1,200

0.013”

(0.34mm)

34SL

ZGP304

RR, LR, LF

Main

Simmer

7,900

0.033”

(0.84mm)

84XL

1,200

0.013”

(0.34mm)

34SL

ALL GRILL 14,000

0.047”

(1.19mm)

0.047

ALL GRIDDLE 16,000

0.047”

(1.19mm)

0.047

ZGP48/

ZGP36

BAKE MAIN 23,000

0.055”

(1.397m)

0.055

ZGP30 BAKE MAIN 21,500

0.0531”

(1.35mm)

0.053

ZGP48 BAKE COMPANION 10,000

0.0374”

(0.95mm)

0.037

ALL BROIL MAIN 11,500

0.041”

(1.04mm)

104

ZGP48 BROIL COMPANION 9,000

0.0360”

(0.91mm)

91

Page 3

5

CHANGEZ L’ORIFICE DE LA

PLAQUE CHAUFFANTE (si installé)

Saisissez-vous de l’orifice de la plaque

chauffante de (19 mm) 3/4” longueur.

Sélectionnez le type de gaz.

LP

—

.047, NAT—.076

A.

Soulevez le couvercle d’aération de la plaque

chauffante. Retirez les 2 vis intérieures de fixation.

B.

Soulevez les

lèchefrites en fonte.

Faite glisser la

plaque chauffante

vers l’arrière et hors

des languettes de

maintien le long de

la partie inférieure.

C.

Soulevez

délicatement la

plaque chauffante

tout en la maintenant.

Tirez la longueur

excédentaire de tube

capillaire par le trou d’entrée. Posez la plaque

chauffante debout sur

la lèchefrite.

D. Retirez les 2 vis de

maintien à l’arrière

du brûleur.

Tirez le brûleur

directement vers

l’arrière et détachez-le de l’arrivée du gaz.

E. Utilisez une clé à

douille d’1/2 po pour

retirer et réinstaller

l’orifice.

Inversez la procédure

pour remonter la

plaque chauffante.

Repoussez la longueur excédentaire de tube

capillaire dans le trou d’entrée. Placez l’orifice

non utilisé sur le possible pour une possible

utilisation ultérieure.

Consignes

d’installation

Conversion du gaz naturel au propane

Conversion du propane au gaz naturel

AVERTISSEMENT : Cette

conversion doit être effectuée par un plombier ou

un fournisseur de gaz qualifié conformément aux

consignes du fabricant et aux réglementations et

aux normes en vigueur afin d’éviter toute blessure

ou dommage matériel. L’agence en charge de

l’installation assume la responsabilité de la

conversion.

AVERTISSEMENT : La table de

cuisson telle qu’elle est livrée depuis l’usine est

conçue pour être utilisée avec le gaz adéquat.

Si vous souhaitez l’utiliser avec un autre type de

gaz, vous devez d’abord remplacer les orifices et

convertir le régulateur de pression.

AVERTISSEMENT : Vous devez

procédez aux réglages suivants avant d’allumer le

brûleur afin d’éviter toute blessure grave. Assurezvous que le régulateur de pression ait été converti

comme indiqué lors de l’étape 2.

OUTILS DONT VOUS AUREZ BESOIN

POUR LA CONVERSION

Lunettes protectrices

Petit tournevis à tête plate

(pointe de 2 à 2,4 mm ou

3/32”, 60 mm de longueur)

Clé à molette

Tournevis à douille

7 mm et 1/4”

7/16” (11 mm)

Open End Wrench

Petites pinces

Clé à douille 1/2”

(12,7 mm)

Tournevis

cruciforme

1

SUPPORT D’ORIFICE

Le support d’orifice de la cuisinière est situé sur le

panneau d’accès frontal et au fond de la cuisinière.

Retirez les portes (voyez les instructions à la page

10) et les vis supérieures et inférieures du panneau

d’accès frontal. Retirez

le panneau frontal pour

accéder au support

d’orifice.

Des orifices additionnels

peuvent être présents.

Utilisez uniquement les

orifices mentionnés aux

instructions pour votre

cuisinière ou plaque de

cuisson.

2

CONVERTIR LE RÉGULATEUR

Débranchez l’électricité sur le disjoncteur

ou la boîte à fusible du circuit principal.

A. Coupez le gaz en fermant le robinet de

fermeture sur l’appareil ou le mur.

B. Déplacez la cuisinière de manière à pouvoir

accéder à l’arrière de l’appareil.

C.

Enlevez le panneau arrière pour pouvoir

accéder aux régulateurs - (1) sur les cuisinières

de 76 et 91 cm (30 et 36 po) et (2) cuisinières de

121 cm (48 po).

D.

Convertissez le régulateur de pression:

• Dévissez le bouchon avec la ventouse.

• Placez votre doigt contre la partie plate du piston

et appuyez pour sortir la ventouse du bouchon.

• Observez attentivement le piston pour repérer la

position NAT ou LP.

• Retournez le piston de sorte que le type de gaz

souhaité

apparaisse à

côté du bas.

• Replacez le

piston dans le

bouchon.

• Vissez le

bouchon sur le

régulateur.

E. Inversez ces étapes pour réassembler le

régulateur de pression.

DOWN

FOR OFF

NAT

LP

LP

NAT

LP

NAT

NAT

LP

Joint

Bouchon

Piston

Position LP

(propane)

Position NAT

(gaz naturel)

Régulateur de pression

3 CHANGEZ LES ORIFICES DU BRÛLEUR

CONSEIL D’INSTALLATION :

Commencez par retirer tous

Orifices, puis replacez-les. Vous

éviterez ainsi tout oubli.

A. Retirez les grilles du brûleur,

les chapeaux et les têtes.

B. Desserrez les orifices

du brûleur du haut à l’aide

d’un tournevis à douille 7 mm.

Utilisez de petites pinces

pour soulever les orifices

délicatement.

L’orifice principal est situé

assez bas au centre

du brûleur, tandis que

l’orifice de mijotage est placé plus haut dans le

centre du brûleur.

IMPORTANT : Veuillez trouver le numéro de

modèle ci-dessous. Lisez chacune des étiquettes

des orifices afin de les identifier et de les placer

dans les emplacements indiqués.

A.

Replacez les orifices non utilisés sur le support. Fixez

le support à nouveau et la fiche d’instruction avec la

vis dans le lieu de rangement d’origine.

B.

Replacez les têtes des brûleurs, les chapeaux

et les grilles supérieures. Sur les cuisinières, replacez

la plaque d’aération arrière.

Chapeau de brûleur

Tête de

brûleur

Allumeur

d’étincelles

Base du brûleur

Orifice

principal

Orifice de

mijotage

ORIFICES DE MIIJOTAGE ZGP304

Un orifice de type 34SL ou 51SN

sera utilisé sur tous les brûleurs.

ZGP364, ZGP366, ZGP484, ZGP486

ORIFICES DE

MIIJOTAGE

Un orifice de type

34SL ou 51SN sera

utilisé sur tous les

brûleurs.

Utilisez un orifice 108XL

ou 190XN pour le brûleur

situé devant à droite.

ORIFICES

PRINCIPAUX

4

CHANGEZ L

’ORIFICE DU

GRILL

(si installé)

Localisez l’orifice du grill d’une longueur

de 1–1/2” (4 cm).Sélectionnez le type

de gaz. LP

—

.047, NAT—.067

A. Retirez le couvercle du grill,

les grilles et le cadre. Enlevez

le déflecteur de rayonnement.

B. Retirez les 2 vis à tête

hexagonale du haut de

l’allumeur.

• Retirez 1 vis de

chagne côte du

dispositif de protection

du brûleur.

• Soulevez le dispositif

de protection.

C. Poussez avec

précaution sur

l’allumeur sur le côté et

sous le brûleur.

Ne tirez ou ne coincez

pas le câble.

Retirez les 4 vis de

fixation du brûleur, 2

à l’avant et 2 autres à

l’arrière. Faites glisser le

brûleur vers l’arrière et

à l’extérieur de l’arrivée

du gaz.

D. Utilisez une clé à

douille 1/2” pour retirer

et réinstaller l’orifice .

Inversez la procédure pour

remonter le grill. Assurezvous de placer l’orifice

non utilisé sur le support

pour pouvoir l’utiliser

ultérieurement.

Retirez

les deux

vis à tête

hexagonale

Vis du

dispositif de

protection

Boîtier du

brûleur

Allumeur

Brûleur

Partie avant de la cuisinière

Avant de la cuisinière

Couvercle d’aération de la plaque chauffante

Vis de maintien

Vis de mise de niveau

NOTE : Retirez

seulement les 2 vis de

fixation sur l’intérieur.

Ne retirez pas les vis les

plus à l’extérieur—elles

sont utilisées pour la

mise de niveau.

Arrière de la cuisinière

6A

REMPLACEMENT DU BRÛLEUR DE

CUISSON DU FOUR LATÉRAL (si présent)

Repérez l’orifice de 19 mm (3/4 po) de long du

brûleur de cuisson du four.

Choisissez la dimension d’orifice adéquate selon

votre type de gaz et de brûleur au diagramme de

conversion.

A. Retirez la porte du four et placez-la dans un

endroit sûr.

B. Retirez les deux fonds du four fixés à l’aide de vis

et situés à l’arrière du panneau.

C.

Glissez le fond du four vers l’avant puis déposez-le

tout près.

D.

Retirez les deux vis du diffuseur de brûleur.

E.

Soulevez légèrement la partie frontale du diffuseur du brûleur et glissez-le vers l’avant pour

déclencher les fixations arrière. Mettez le diffuseur de côté.

Hold-Down Screws

Oven

Bottom

Diffuser screw

Clips

31-10766-1 11-10 GE

1

Panneau d’accès frontal

Tube

capillaire

ORIFICES PRINCIPAUX ZGP304

Un orifice de

type 84XL ou

126HXN sera

utilisé sur ces

trois brûleurs.

Utilisez des

orifices 108XL ou

190XN sur tous

les brûleurs.

Page 4

PUISSANCES NOMINALES DE SORTIE DU BRÛLEUR : BTU/HR

7

REMPLACEMENT DE L’ORIFICE

DU BRÛLEUR DE CUISSON DU

FOUR LATÉRAL

Repérez l’orifice brûleur de cuisson du four.

Choisissez la dimension d’orifice adéquate

selon votre type de gaz et de brûleur au diagramme de conversion.

Le panneau arrière doit être retiré des régulateurs de conversion. Consultez l’article

2 pour obtenir tous les détails si celui-ci est

toujours en place.

A. Retirez les deux vis de retenue du cou-

vercle de conduit du gril

B. Retirez les deux vis de retenue du cou-

vercle de conduit du gril

C.

Utilisez une clé à ouverture variable et une

douille de 11 mm (7/16 po) pour dévisser,

retirer et replacer l’orifice du gril.

D. Inversez ces étapes pour rassembler la

plaque chauffante. Poussez l’excès du

tube capillaire dans l’orifice d’entrée.

Placez l’orifice inutilisé dans le support

pour une utilisation future..

6A

REMPLACEMENT DU BRÛLEUR DE

CUISSON DU FOUR LATÉRAL

(suite)

F.

Retirez les trois vis de retenue du brûleur (1 à

l’avant et deux à l’arrière).

G.

Soulevez légèrement la partie frontale du brûleur

et glissez-le vers la gauche pour le retirer.

H.

Utilisez une douille profonde de 12,7 mm (1/2

po) pour retirer et replacer l’orifice.

I.

Inversez ces étapes pour rassembler la plaque

chauffante. Poussez l’excès du tube capillaire

dans l’orifice d’entrée. Placez l’orifice inutilisé

dans le support pour une utilisation future.

Vis de retenue

du brûleur

Brûleur

6B

REMPLACEMENT DU BRÛLEUR DE

CUISSON DU FOUR LATÉRAL (si présent)

Repérez l’orifice de 19 mm (3/4 po) de long du

brûleur de cuisson du four.

Choisissez la dimension d’orifice adéquate selon

votre type de gaz et de brûleur au diagramme de

conversion.

.

A. Repérez l’orifice de 19 mm (3/4 po) de long

du brûleur de cuisson du four.

B.

Retirez la porte du four et placez-la dans un

endroit sûr.

C. Glissez le fond du four vers l’avant puis

déposez-le tout près..

D. Retirez les deux vis du diffuseur de brûleur.

E. Soulevez légèrement la partie frontale

du diffuseur du brûleur et glissez-le vers

l’avant pour déclencher les fixations arrière. Mettez le diffuseur de côté.

F. Retirez les trois vis de retenue du brûleur (1

à l’avant et deux à l’arrière).

G. Soulevez légèrement la partie frontale du

brûleur et glissez-le vers la gauche pour le

retirer.

H. Utilisez une

douille profonde

de 12,7 mm (1/2

po) pour retirer et

replacer l’orifice.

I.

Inversez ces

étapes pour rassembler la plaque

chauffante. Poussez l’excès du tube capillaire dans l’orifice

d’entrée. Placez l’orifice inutilisé dans le

support pour une utilisation future.

Vis serre-tôle

Fond du

four

Vis du diffuseur

Fixations

Vis de retenue

du brûleur

Retirez

les vis

8

AJUSTEZ LES FLAMMES DU

BRÛLEUR

Les brûleurs ne requièrent normalement aucun

ajustement. Ne procédez à des ajustements que

si cela s’avère nécessaire.

A. Allumez le gaz. Branchez le cordon

d’alimentation.

B. Allumez les brûleurs au maximum et vérifiez

les flammes. Elles devraient être bleues. Si

vous utilisez du propane, la pointe de flammes

devrait être jaune. La présence d’objets

étrangers dans le tuyau d’alimentation en

gaz devraient donner une couleur orange à

la flamme au début. L’orange disparaît par la

suite.

C. Tournez le bouton du brûleur sur “LO” (feu

doux) tout en observant la flamme.

Ajustez le réglage de la première rangée de

flammes avec la vis de dérivation de vanne de

la manière suivante :

Vous pouvez procédez à des ajustements sur

deux autres brûleurs en marche sur un réglage

moyen. La rangée supérieure des flammes est

ainsi réglée sur un niveau qui n’est pas trop

faible, ce qui pourrait provoquer l’extinction de la

flamme lorsque d’autres brûleurs sont allumés.

D. Pour ajuster la flamme, retirez les boutons.

Introduisez un tournevis à tête plate dans le

trou au centre du piston de la vanne pour

engager la vis.

• Si les flammes sont trop petites ou vacillent,

tournez la vis dans le sens inverse des aiguilles

d’une montre.

• Si les flammes sont trop grandes, tournez la vis

dans le sens des aiguilles d’une montre.

E. Procédez à l’ajustement en tournant

doucement la vis jusqu’à ce que l’aspect de la

flamme soit le bon.

2

Gaz naturel, avec P.C. de 12,7 cm (5 po)

MODÈLE

BRÛLEUR

PUIS-

SANCE

BTU

DIMENSION

ORIFICE

ID

ZGP48

ZGP36

BRÛLEURS Princ.

16,800

0,075”

(1,90mm)

190XN

TOUTES SURFACES

Mijoter

1,200

0.002”

(0,51mm)

51SL

ZGP304

BRÛLEUR AD

Princ.

16,800

0.075”

(1,90mm)

190XN

Mijoter

1,200

0.002”

(0,51mm)

51SN

ZGP304

AD, GD, AG

Princ.

Mijoter

8,800

0.050”

(1.,26mm)

126HXN

1,200

0.002”

(0,51mm)

51SN

ALL FOUR

15,000

0.0689”

(1,75mm)

0.069

ALL TABLE DE CUISSON

18,000

0.076”

(1,93mm)

0.076

ZGP48/

ZGP36

CUISSON - PRINCIPAL

24,500

0.0886”

(2,25mm)

0.089

ZGP30

CUISSON - PRINCIPAL

23,500

0.0866”

(2,20mm)

0.087

ZGP48

CUISSON - POUR LATÉRAL

10,500

0.0531”

(1,35mm)

0.053

ALL GRIL PRINCIPAL

12,500

0,063”

(1.60mm)

160

ZGP48

GRIL - FOUR LATÉRAL

9,000

0,052”

(1.32mm)

132

Gaz propane, avec P.C. de 25,5 cm (10 po)

MODÈLE

BRÛLEUR

PUIS-

SANCE

BTU

DIMENSION

ORIFICE

ID

ZGP48

ZGP36

BRÛLEURS Princ.

13,800

0.043”

(1,08mm)

108XL

TOUTES SURFACES

Mijoter

1,200

0.013”

(0,34mm)

34SL

ZGP304

BRÛLEUR AD

Princ.

13,800

0.043”

(1,08mm)

108XL

Mijoter

1,200

0.013”

(0,34mm)

34SL

ZGP304

AD, GD, AG

Princ.

Mijoter

7,900

0.033”

(0,84mm)

84XL

1,200

0.013”

(0,34mm)

34SL

ALL FOUR

14,000

0.047”

(1,19mm)

0.047

ALL TABLE DE CUISSON

16,000

0.047”

(1,19mm)

0.047

ZGP48/

ZGP36

CUISSON - PRINCIPAL

23,000

0.0551”

(1,397mm)

0.055

ZGP30

CUISSON - PRINCIPAL

21,500

0.0531”

(1,35mm)

0.053

ZGP48

CUISSON - POUR LATÉRAL

10,000

0.0374”

(0,95mm)

0.037

ALL GRIL PRINCIPAL

11,500

0.041”

(1,04mm)

104

ZGP48

GRIL - FOUR LATÉRAL

9,000

0.0360”

(0,91mm)

91

Page 5

5

CAMBIE EL ORIFICIO DE LA

PLANCHA

(si corresponde)

Ubique el orificio de la plancha de 3/4”

de longitud. Seleccione el tipo de gas.

LP—.047, NAT—.076

A. Levante la tapa de ventilación de

la plancha. Retire los 2 tornillos interiores de

apriete.

B. Retire la canaleta

para grasa de

hierro fundido.

Deslice la plancha

hacia atrás y fuera

de las lengüetas

de sujeción a lo

largo de la parte

inferior.

C. Con cuidado

levante y sostenga

la plancha mientras

agrega longitud

desde el capilar al orificio de entrada.

Sostenga la plancha en el extremo del cárter

para grasa.

D. Retire los 2 tornillos

de sujeción en la

parte trasera del

quemador.

Quite el quemador

empujando hacia

atrás y afuera de la entrada de gas.

E. Use la llave de cubo

larga de 1/2” para

retirar y reemplazar

el orificio.

Realice los pasos

hacia atrás para

volver a ensamblar

la plancha. Vuelva a colocar el capilar

excesivo nuevamente en el orificio de

entrada. Coloque el orificio no utilizado en el

soporte para posibles usos futuros.

Instrucciones

de instalación

Conversión de gas natural a gas LP

Conversión de gas LP a gas natural

ADVERTENCIA: Esta conversión

debe efectuarla un instalador calificado o un

proveedor de gas de acuerdo con las instrucciones

del fabricante y con todos los códigos y

requerimientos de la autoridad competente.

No seguir estas instrucciones puede provocar

lesiones graves o daños a la propiedad. La agencia

calificada a cargo de este trabajo asume la

responsabilidad de la conversión.

ADVERTENCIA: La estufa, como

se envía de fábrica, se encuentra configurada

para funcionar con una clase de gas determinada.

Si desea utilizar su estufa con otro gas, primero

deben reemplazar los orificios y convertir el

regulador de presión.

ADVERTENCIA: Los siguientes

ajustes deben realizarse antes de encender el

quemador. No hacerlo puede provocar una lesión

grave. Asegúrese de que el regulador de presión se

haya convertido como se describe en el Paso 2.

HERRAMIENTAS NECESARIAS PARA

LA CONVERSIÓN

1

SOPORTE DE ORIFICIOS

El retenedor del orificio de la estufa se encuentra

detrás del panel de acceso frontal en la base de la

estufa. Retire la(s) puerta(s) (Consulte las instrucciones

en la página 10) y los tornillos

en la parte superior e inferior

del panel de acceso frontal.

Retire el panel de acceso

frontal para lograr acceso al

retenedor del orificio.

Podría haber orificios

adicionales presentes.

Use únicamente los

orificios especificados en

las instrucciones para su

estufa u hornilla.

2

CONVIERTA EL REGULADOR

Desconecte el suministro de energía desde

el interruptor de circuitos o la caja de

fusibles.

A. Corte el suministro de gas cerrando la válvula

de apagado manual de la unidad o de la pared.

B. Mueva la estufa para lograr acceso a la parte

posterior de la unidad.

C. Retire la parte posterior de la estufa para

lograr acceso al regulador(es) - (1) en estufas

de 30” y 36” y (2) en estufas de 48”.

.

D.

Convierta el regulador de presión:

• Desenrosque la tapa del émbolo.

• Coloque el pulgar contra el lado plano del

émbolo y presione hacia abajo para remover el

émbolo de la tapa.

•

Mire bien el émbolo para ubicar la posición NAT o LP.

• Dé vuelta el émbolo para que el gas deseado se

vea cerca de la

parte inferior.

•

Vuelva a colocar

el émbolo en la

tapa.

• Enrosque la

tapa dentro del

regulador.

E. Reverse estos

pasos para volver a armar el regulador de

presión.

DOWN

FOR OFF

NAT

LP

LP

NAT

LP

NAT

NAT

LP

Junta

Tapa

Émbolo

Posición LP

Posición NAT.

Regulador de presión

3

CAMBIE LOS ORIFICIOS DE LOS

QUEMADORES

CONSEJO DE INSTALACIÓN:

Primero quite todos los orificios

y luego comience a colocarlos

de nuevo. Esto lo ayudará a

evitar la posibilidad de que

algunos no vuelvan a colocarse.

A. Quite las rejillas de los

quemadores, las tapas de los

quemadores y cabezales de

los quemadores.

B. Afloje los orificios del

quemador superior utilizando

una llave de tuercas de 7 mm.

Utilice alicates pequeños para

quitar los orificios con mucho

cuidado.

El orificio principal se encuentra en la parte inferior del

centro del quemador, mientras que el orificio de fuego

lento se encuentra más arriba al lado del centro del

quemador.

IMPORTANTE: Busque el número de modelo a

continuación. Lea cada etiqueta de los orificios para

identificarlos e instalarlos en las ubicaciones precisas

que se muestran.

A. Coloque los orificios sin usar de vuelta en el

soporte. Vuelva a instalar el soporte y la hoja

de instrucciones con el tornillo en la ubicación

de almacenamiento original.

B. Reemplace los cabezales, las tapas y las

rejillas superiores. En los modelos de cocina,

reemplace el reborde de ventilación trasero.

Tapa del quemador

Cabezal del

quemador

Encendedor

por chispa

Base del

quemador

Orificio

principal

Orificio

de fuego

lento

ZGP304 ORIFICIOS DE FUEGO LENTO

Un orificio 34SL o 51SN se utiliza

en todos los quemadores..

ZGP364, ZGP366, ZGP484, ZGP486

ORIFICIOS

DE FUEGO

LENTO

Un orificio 34SL

o 51SN se utiliza

en todos los

quemadores.

Utilice orificios 108XL

o 190XN en todos los

quemadores.

ORIFICIOS

PRINCIPALES

4

CAMBIE EL ORIFICIO DE LA

PARRILLA

(si corresponde)

Ubique el orificio de parrilla de 1–1/2” de

longitud. Seleccione el tipo de gas. LP—.047,

NAT

—

.067

A. Quite la tapa de la parrilla, las

rejillas y el armazón de la rejilla.

Levante el deflector radiante

hacia arriba y afuera.

B. Quite los 2 tornillos de cabeza

hexagonal de la parte superior

del encendedor.

• Saque un tornillo de

cada lado del marco

del quemador.

• Levante el marco.

C. Cuidadosamente,

empuje el encendedor

hacia un costado

debajo del quemador.

No hale del cable ni lo

pellizque.

Saque 4 tornillos de

sujeción del quemador,

2 en el frente y 2 en la

parte trasera. Deslice

la ensambladura del

quemador hacia atrás

y fuera de la entrada de

gas.

D. Utilice una llave

de cubo larga de

1/2” para sacar y

reemplazar el orificio. Invierta

estos pasos para volver a

montar la parrilla.

Asegúrese de colocar el

orificio sin usar en el soporte

para posibles usos futuros.

Quite los

2 tormillos

de cabeza

hexagonal

Tornillos del

marco

Marco del

quemador

Encendedor

Ensambladura

del quemador

Frente de la cocina

Frente de la cocina

Tapa de ventilación de la plancha

Tornillos de

apriete

Tornillos de

nivelación

NOTA: Retire

los 2 tornillos

posicionados sólo en

la parte interior. No

retire los tornillos más

alejados—cumplen la

función de nivelar.

Trasera de la cocina

6A

CAMBIE EL ORIFICIO DEL

QUEMADOR DE HORNEAR PRINCIPAL

Localice el orificio del quemador de hornear

de ¾” de largo.

Seleccione el tamaño de orificio correcto para su gas

y quemador en la tabla de conversión.

A.

Retire la puerta del horno y coloque a un

lado en un lugar seguro.

B.

Retire los dos tornillos de sostienen la base

del horno de la parte trasera de la cubierta.

C.

Glissez le fond du four vers l’avant puis déposez-le

tout près.

D.

Retirez les deux vis du diffuseur de brûleur.

E. Levante el frente del difusor del quemador

ligeramente y deslice hacia adelante para

liberar los ganchos en la parte posterior.

Coloque el difusor del quemador a un lado.

Tornillos retenedores

Base del

horno

31-10766-1 11-10 GE

1

Cubierta de acceso frontal

Tornillo del difusor

Ganchos

Capilar

Gafas de seguridad

Destornillador plano

pequeño (2 a 2.4 mm o

3/32” de tamaño de punta,

60 mm de largo)

Llave Crescent

Llave de tuercas

de 7 mm y 1/4”

Alicates

pequeños

Llave de cubo larga de 1/2”

Destornillador

de estrella

Tirón con final

abierto de 11mm

y 7/16”

ORIFICES PRINCIPAUX ZGP304

Un orifice de type

84XL ou 126HXN

sera utilisé sur ces

trois brûleurs.

Utilisez des

orifices 108XL ou

190XN sur tous

les brûleurs.

Page 6

CALIFICACIONES DE SALIDA DEL QUEMADOR: BTU/HR

7

CAMBIE EL ORIFICIO DEL

QUEMADOR ASADOR

PRINCIPAL/ACOMPAÑANTE

Localice el orificio del quemador asador.

Seleccione el tamaño correcto de orificio para

su gas y quemador en la tabla de conversión.

La cubierta posterior deberá continuar retirada de la conversión del regulador(es). Consulte

la sección 2 para los detalles si no es así.

A. Retire los dos tornillos de retención de la

cubierta del ducto del asador. Levante y

deslice para quitar.

B. Afloje y retire la tuerca del tubo de sumi-

nistro del asador que se encuentra en el

retenedor del orificio del asador.

C.

Use una llave ajustable y una llave estriada

de 7/16” (11 mm) para aflojar, quitar y reemplazar el orificio del asador.

D. Inversez ces étapes pour rassembler la

plaque chauffante. Poussez l’excès du

tube capillaire dans l’orifice d’entrée.

Placez l’orifice inutilisé dans le support

pour une utilisation future..

6A

CAMBIE EL ORIFICIO DEL

QUEMADOR DE HORNEAR

PRINCIPAL

(cont.)

F. Retire los dos tornillos de retención del

quemador.

G.

Levante el frente del quemador ligeramente y

deslice hacia adelante para ponerlo a un lado

(con cuidado de no dañar la ignición).

H. Use una llave de copa de 1/2” para retirar

y reemplazar el orificio.

I. Reverse estos pasos para re-ensamblar la

plancha. Empuje la capilaridad excesiva

de nuevo en el orificio de entrada. Coloque

el orificio no utilizado en el retenedor para

posible uso futuro.

Tornillos de

retención del

quemador

Quemador

6B

CAMBIE EL ORIFICIO DEL

QUEMADOR DE HORNEAR

ACOMPAÑANTE

(sI LO HAy)

Localice el orificio quemador de hornear de ¾”

de largo.

Seleccione el tamaño correcto de orificio para su

gas y quemador en la tabla de conversión.

A. Repérez l’orifice de 19 mm (3/4 po) de long

du brûleur de cuisson du four.

B.

Retirez la porte du four et placez-la dans un

endroit sûr.

C. Deslice la base del horno hacia el frente y

coloque a un lado.

D. Retire el tornillo del difusor del quemador.

E. Levante el frente del difusor del difusor del que-

mador ligeramente y deslice hacia adelante

para liberar los ganchos en la parte posterior.

Coloque el difusor del quemador a un lado.

F. Retire los tres tornillos de retención del

quemador (1 al frente y 2 atrás).

G. Levante el frente del quemador ligera-

mente y deslice hacia adelante para quitar.

H. Use una llave

de copa de 1/2”

para retirar y

reemplazar el

orificio.

I.

Reverse estos pasos para re-ensamblar la plancha.

Empuje la capilaridad excesiva de nuevo en el orificio de

entrada. Coloque el orificio no utilizado en el

retenedor para posible uso futuro.

Tornillos retenedores

Fond du

four

Tornillo del difusor

Ganchos

Tornillos de retención

del quemador

Retirez

les vis

8

AJUSTE LAS LLAMAS DEL

QUEMADOR

Normalmente, los quemadores no necesitan

nuevos ajustes. Realice los ajustes sólo cuando

sea necesario.

A. Encienda el gas. Enchufe el cable eléctrico.

B. Encienda todos los quemadores en la

configuración más alta y controle las

llamas. Tienen que ser de color azul.

Cuando utilice gas LP, las llamas pueden

tener puntas amarillas. Partículas extrañas

en la línea de gas pueden provocar una

llama anaranjada al comienzo, pero esto

desaparecerá rápidamente.

C. Gire la perilla del quemador de la estufa a

“LO” (bajo) mientras observa la llama.

Ajuste la configuración de la hilera

superior de las llamas utilizando el tornillo

de derivación de válvula de la siguiente

manera:

Los ajustes deben efectuarse con otros

dos quemadores que funcionen en una

configuración media. Este procedimiento

evita que la hilera superior de las llamas sea

demasiado baja, lo que provoca que la llama

se apague cuando los otros quemadores se

encienden.

D. Para ajustar la llama, quite las perillas.

Introduzca un destornillador pequeño

de lados planos a través del orificio en

el centro del vástago de la válvula para

enganchar el tornillo.

• Si las llamas son demasiado pequeñas o se

agitan, gire el tornillo en sentido contrario a

las agujas del reloj.

• Si las llamas son demasiado grandes, gire

el tornillo en sentido de las agujas del reloj.

E. Realice el ajuste girando el tornillo

lentamente hasta que la apariencia de la

llama sea la correcta.

2

Gas NG (Natural), 5” W.C.P.

MODELO

QUEMADOR

CALIFI-

CACIÓN

BTU

TAMAÑO

ORIFICIO

ID

ZGP48

ZGP36

Principal

QUEMADORES TODA

16,800

0.075”

(1.90mm)

190XN

SUPERFICIE

Fuego lento

1,200

0.002”

(0.51mm)

51SL

ZGP304

Principal

QUEMADOR RF

16,800

0.075”

(1.90mm)

190XN

Fuego lento

1,200

0.002”

(0.51mm)

51SN

ZGP304

Principal

RR, LR, LF

Fuego lento

8,800

0.050”

(1.26mm)

126HXN

1,200

0.002”

(0.51mm)

51SN

Todos PARILLA

15,000

0.0689”

(1.75mm)

0.069

Todos PLANCHA

18,000

0.076”

(1.93mm)

0.076

ZGP48/

ZGP36

HORNEAR PRINCIPAL

24,500

0.0886”

(2.25mm)

0.089

ZGP30

HORNEAR PRINCIPAL

23,500

0.0866”

(2.20mm)

0.087

ZGP48

HORNEAR

ACOMPAÑANTE

10,500

0.0531”

(1.35mm)

0.053

Todos ASAR PRINCIPAL

12,500

0.063”

(1.60mm)

160

ZGP48

ASAR ACOMPAÑANTE

9,000

0.052”

(1.32mm)

132

LP (Propane) Gas, 10” W.C.P.

MODELO

QUEMADOR

CALIFI-

CACIÓN

BTU

TAMAÑO

ORIFICIO

ID

ZGP48

ZGP36

Principal

QUEMADORES TODA

13,800

0.043”

(1.08mm)

108XL

SUPERFICIE

Fuego lento

1,200

0.013”

(0.34mm)

34SL

ZGP304

Principal

QUEMADOR RF

13,800

0.043”

(1.08mm)

108XL

Fuego lento

1,200

0.013”

(0.34mm)

34SL

ZGP304

Principal

RR, LR, LF

Fuego lento

7,900

0.033”

(0.84mm)

84XL

1,200

0.013”

(0.34mm)

34SL

ALL

PARILLA

14,000

0.047”

(1.19mm)

0.047

ALL

PLANCHA

16,000

0.047”

(1.19mm)

0.047

ZGP48/

ZGP36

HORNEAR PRINCIPAL

23,000

0.055”

(1.397mm)

0.055

ZGP30

HORNEAR PRINCIPAL

21,500

0.0531”

(1.35mm)

0.053

ZGP48

HORNEAR

ACOMPAÑANTE

10,000

0.0374”

(0.95mm)

0.037

ALL

ASAR PRINCIPAL

11,500

0.041”

(1.04mm)

104

ZGP48

ASAR ACOMPAÑANTE

9,000

0.0360”

(0.91mm)

91

Loading...

Loading...