Page 1

Installation

Instructions

30", 36" and 48"

All Gas Professional Ranges

Pour toutes les cuisini_res

professionnelles au gaz

de 30" (76 cm), 36" (91 cm)

et de 48" (121 cm)

Instructions d'installation

La section fran9aise commence 6 la page 27

Estufas profesionales

completamente a gas

de 30", 36"y 48"

Instrucciones de instalaci6n

La secci6n en espafiol empieza en la p6gina 51

[31-i0755-i]

ii-i0GE

Page 2

Installation Instructions

BEFORE YOU BEGIN

Read these instructions completely and carefully.

• IMPORTANT Save theseinstructionsfor

localinspector'suse

• IMPORTANT Observeallgoverningcodes

and ordinances

• Note to Installer - Be sure to leave these

instructions with the Consumer.

• Note to Consumer - Keep these instructions

with your Owner's Manual for future reference.

• Completion Time - i to 3 hours.

• Proper installation is the responsibility of the installer.

Product failure due to improper installation is not

covered under the warranty. See Owner's Manual for

warranty information.

-4,WARNING:

This appliance must be properly grounded. Follow

directions in "Electric Supply" of this manual. Failure to

do so may result in electric shock.

For Monogram local service in your area,

1.800.444.1845.

For Monogram Service in Canada,call 1.800.561.3344.

For Monogram Parts and Accessories, call

1.800.626.2002.

If you received a damaged range, you should contact

your dealer.

In the Commonwealth of Massachusetts:

• This product must be installed by a licensed plumber

or gas fitter.

• When using ball type gas shut off valves, they shall be

T-handle type.

• A flexible gas connector, when used, must not exceed

3 feet.

-4,WARNING:

All ranges con tip. Injury could result. Install the

supplied Anti-Tip Bracket provided. See instructions

in this manual or with the bracket.

If sold outside the U.S.and Canada:

_4,WARNING: ifyouwish to use this product

with Liquefied Petroleum (LP}gas containing greater

than 10% butane, you must purchase the butane

conversion kit #WB28K10589. To order, please call

1.888.664.8403 or 1.787.276.4051. Failure to do so

may result in carbon monoxide or fire hazard.

Vent hood Combinations:

A suitable overhead vent hood is required for models

with a grill and is recommended for all other models.

• Install a hood with at least 1200 CFM above o 48"

wide range.

• Install a hood with at least 600 CFM above o 30" or

36" range.

Due to the high heat capacity of this unit, particular

attention should be paid to the hood and ductwork

installation to assure it meets local building codes.

-4,WARNING:

Clearances to horizontal surfaces above the range,

measured to the cooking surface are below. Failure to

comply may result in fire hazard.

• Installations without a hood require 48" minimum to

combustibles.

• A custom hood installation with exposedhorizontol

combustibles surfaces must have an Auto-On

feature.

• For other installations with a hood, refer to hood

installation instructions for specific hood clearances.

,CAUTION:

These ranges weigh up to 700 pounds. Some

disassembly will reduce the weight considerably. Due

to the weight and size of the range and to reduce the

risk of personal injury or damage to the product:

TWO PEOPLEAREREQUIREDFORPROPER

INSTALLATIONOF 36" AND 30" RANGES.

THREEPEOPLEARE REQUIREDFORPROPER

INSTALLATIONOF 48" RANGES.

Leak testing of the appliance shall be conducted

according to the manufacturer's instructions.

Installation must conform with local codes. In the

absence of local codes, the range must comply

with the National Fuel Gas Code, ANSIZ22.K1/NFPA

5/4,latest edition and National Electrical Code ANSI/

NFPA 70 latest addition. In Canada, installation must

conform with the current Natural Gas Installation Code,

CAN/CGA-B1/49.1 or the current Propane Installation

Code, CAN/CGA-B1/49.2,and with local codes where

applicable. This range has been design-certified by CSA

International according to ANSI Z21.1, latest edition

and Canadian Gas Association according to CAN/CGA-

1.1 latest edition.

Page 3

Design Information

CONTENTS

Design Information

Models Available ......................................................................3

Backsplash Accessories .......................................................3

Product Dimensions and Clearances .......................4-7

Tools and Materials Required .........................................8

Installation Preparation

Power Supply Locations .....................................................9

Installation Instructions

Step 1, Remove Packaging ..............................................10

Step 2, Move Range Indoors ...........................................11

Step 5, Install Anti-Tip Device .........................................12

Step 4, Connect Range to Gas .......................................15

Step 5, Connect Electrical .................................................15

MODELS AVAILABLE

These Monogram ranges are factory set for either

natural gas or LPgas. Order the model for your

installation situation.

48" Natural Gas Models:

ZGP484NG - 4 gas burners, grill and griddle

ZGP486NR - 6 gas burners and grill

ZGP486ND - 6 gas burners and griddle

48" LP Gas Models:

ZGP484LG - 4 gas burners, grill and griddle

ZGP486LR - 6 gas burners and grill

ZGP486LD - 6 gas burners and griddle

Step

6, Roll Range into Position ....................................14

Step

7, Level the Range ....................................................15

Step

8, Replace Oven Doors ............................................15

9, Check Burners ........................................................16

Step

10, Check Operation of

Step

Oven Bake Burners ...........................................16

Step

11, Adjusting the Bake Burner

at Shutter ..............................................................16

Step 12, Check Operation of

Oven Broil Burner ..............................................17

Finalize Installation ..............................................................17

Installation Checklist ...........................................................17

Accessories ..............................................................................18

Accessory Installation ................................................19-21

Gas Conversion .............................................................22-26

36" Natural Gas Models:

ZGP366N - 6 gas burners

ZGP364NR - 4 gas burnersand grill

ZGP364ND - 4 gas burnersand griddle

36" LP Gas Models:

ZGP366L - 6 gas burners

ZGP364LR - 4 gas burners and grill

ZGP364LD - 4 gas burners and griddle

30" Natural Gas Model: ZGP304N

30" LP Gas Model: ZGP304L

BACKSPLASH ACCESSORIES

All models require 12" minimum clearance to a

vertical combustible surface at the rear. If clearance

is less than 12", the entire surface of the buck wall

above and the full width of the range must be

protected by u bucksplash. The backsplash must be

constructed of non-combustible material, such as

metal, ceramic tile, brick, marble or other stone.

Two Backsplash Accessories Available:

• The 12" high stainless steel backsplash accessory

is available. Use this backsplosh in combination

with a custom, non-combustible backsplash built

beyond the 12" height. The combined height of

the backsplash accessory and the custom

backsplash must reach the bottom of a hood,

or when there is no hood, to 48" above the

cooking surface.

• An adjustable 30" to 36" high backsplash with

shelf is also available. This bocksplash fills in the

space between the top of the range and the

bottom of the hood. The shelf is positioned so that

heat lamps from the bottom of o Monogram

professional hood are directed towards the shelf.

12" High Bocksplosh

ZX12B48PSS,for 48" wide ranges

ZX12B36PSS,for 36" wide ranges

ZX12B30PSS,for 30" wide ranges

30"to 36" Adjust(]ble Height

Bocksplosh With Shelf

ZXADJBA8PSS,for 48" wide r(]nges

ZXADJB36PSS,for 36" wide r(]nges

ZXADJB30PSS,for 30" wide ranges

Page 4

Design Information

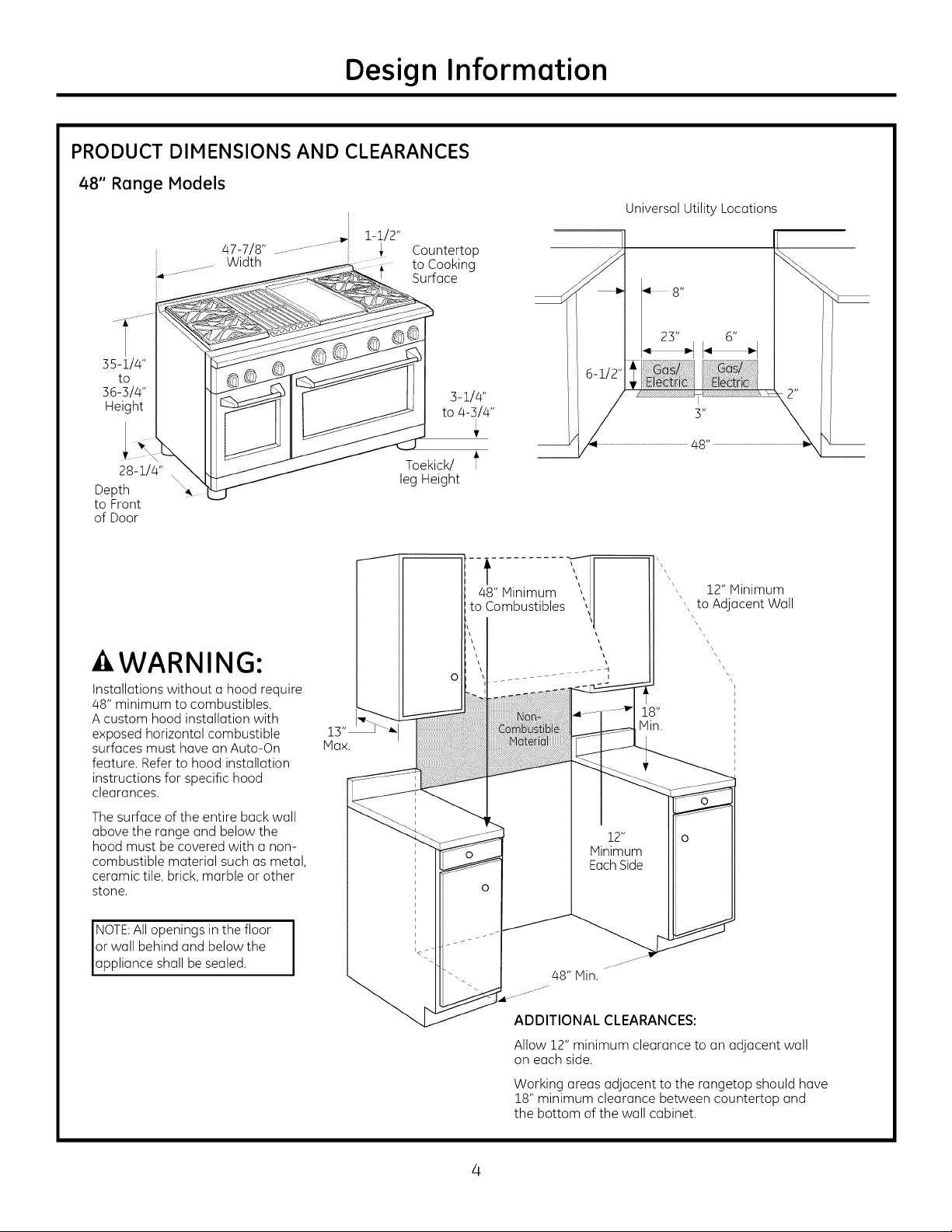

PRODUCT DIMENSIONS AND CLEARANCES

48" Range Models

Countertop

to Cooking

Surface

35-i/4"

to

36-3/4"

Height

to 4-3/4"

Universal Utility Locations

3-1/4"

28-1/4"

Depth

to Front

of Door

-AWARNING:

Installations without a hood require

48" minimum to combustibles.

Acustom hood installation with

exposed horizontal combustible

surfaces must have an Auto-On

feature. Refer to hood installation

instructions for specific hood

clearances.

The surface of the entire back wall

above the range and below the

hood must be covered with a non-

combustible material such as metal,

ceramic tile, brick, marble or other

stone.

Toekick/ _'

leg Height

--_,-

48" Minimum

to Combustibles

\

', 12" Minimum

', to Adjacent Wall

18"

Hin.

i

i

NOTE:All openings in the floor I

or wall behind and below the

app iance sha be sea ed.

I

48" Hin.

ADDITIONAL CLEARANCES:

Allow 12" minimum clearance to an adjacent wall

on each side.

Working areas adjacent to the rangetop should have

18" minimum clearance between countertop and

the bottom of the wall cabinet.

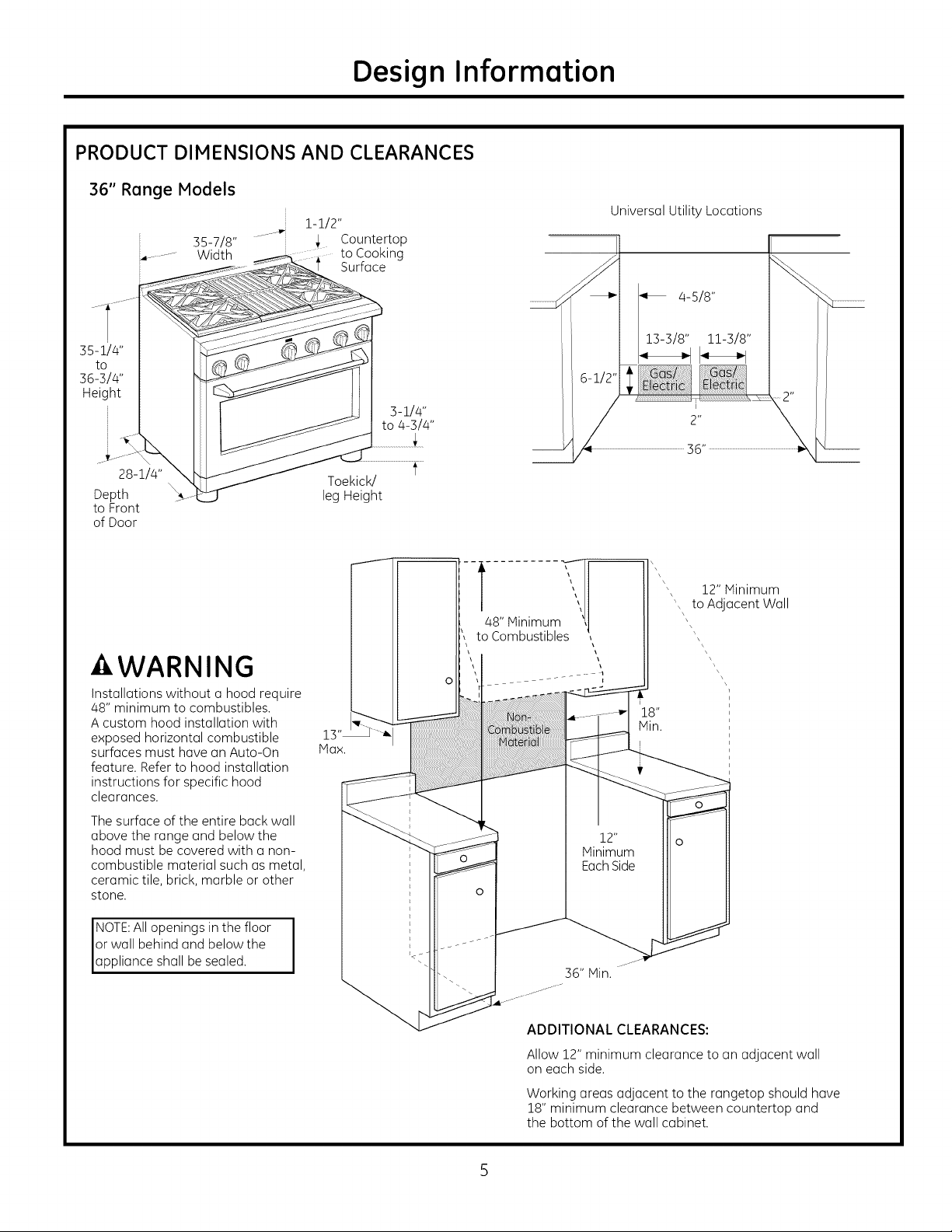

Page 5

Design Information

PRODUCT DIMENSIONS AND CLEARANCES

36" Range Models

1-1/2"

s5-7/8"

Width

35-i/4"

to

36-3/4"

Height

, Countertop

to Cooking

Surface

to 4-3/4"

3-1/4"

Universal Utility Locations

4-s/8"

13-3/8" 11-3/8"

28-1/4"

Depth

to Front

of Door

WARNING

Installations without a hood require

48" minimum to combustibles.

A custom hood installation with

exposed horizontal combustible

surfaces must have an Auto-On

feature. Refer to hood installation

instructions for specific hood

clearances.

The surface of the entire back wall

above the range and below the

hood must be covered with a non-

combustible material such as metal,

ceramic tile, brick, marble or other

stone.

Toekick/

leg Height

f

....t..........

48" Minimum

to Combustibles

i

18"

Min.

I

\

', 12" Minimum

', to Ad acent Wall

\

NOTE:All openings in the floor I

or wall behind and below the

app iance sha be sea ed.

I

36" Min.

ADDITIONAL CLEARANCES:

Allow 12" minimum clearance to an adjacent wall

on each side.

Working areas adJacent to the rangetop should have

18" minimum clearance between countertop and

the bottom of the wall cabinet.

5

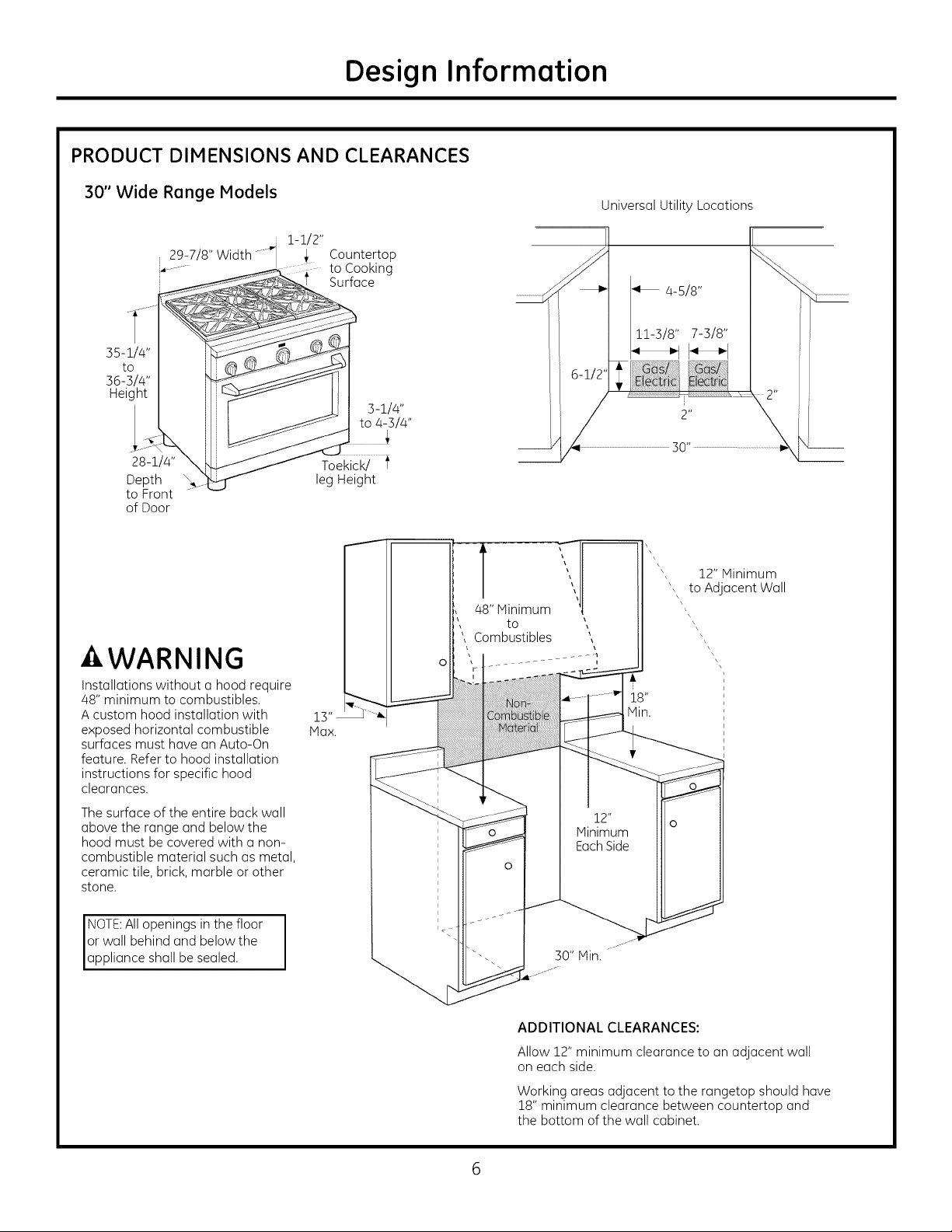

Page 6

Design Information

PRODUCT DIMENSIONS AND CLEARANCES

30" Wide Range Models

29-7/8" Width Countertop

,......... to Cooking

:i Surface

35-1/4"

to

36-314"

Height

28-1/4"

Depth

to Front

of Door

to 4-314"

Toekick/ f

leg Height

3-114"

Universal Utility Locations

4-5/8"

11-3/8" 7-3/8"

\

\\

12" Minimum

\\

to Ad acent Wall

to

AWARNING

Installations without a hood require

48" minimum to combustibles.

A custom hood installation with

exposed horizontal combustible

surfaces must have an Auto-On

feature. Refer to hood installation

instructions for specific hood

clearances.

The surface of the entire back wall

above the range and below the

hood must be covered with a non-

combustible material such as metal,

ceramic tile, brick, marble or other

stone.

NOTE:Allopenings in the floor

or wall behind and below the

app iance sha be sea ed.

13"

Max.

18"

Hin.

30" Hin.

ADDITIONAL CLEARANCES:

Allow 12" minimum clearance to an adJacent wall

on each side.

Working areas adJacent to the rangetop should have

18" minimum clearance between countertop and

the bottom of the wall cabinet.

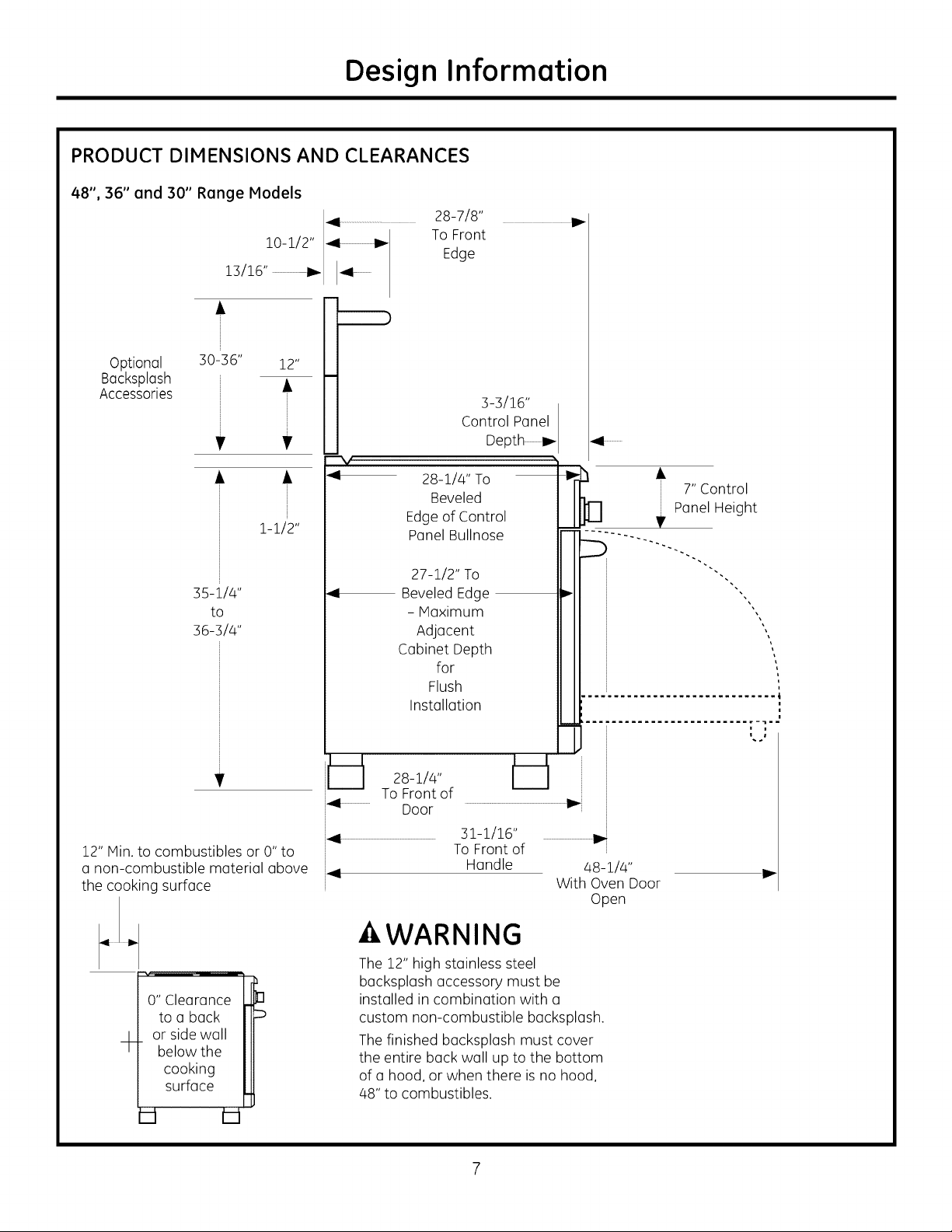

Page 7

Design Information

PRODUCT DIMENSIONS AND CLEARANCES

48% 36" and 30" Range Models

28-7/8"

i0-i/2" = .............................im-

13/16" m- 4

A

Optional 30-36" 12"

Backs@ash A

Accessories

To Front

Edge

3-3116"

Control Panel

Depth I_

i-i/2"

3s-zI4"

to

36-3/4"

V

12" Hin. to combustibles or 0" to

a non-combustible material above

the cooking surface

28-1/4" To

Beveled

Edge of Control

Panel Bullnose

27-1/2" To

Beveled Edge

- Haximum

Adjacent

Cabinet Depth

for

Flush

Installation

28-i/4"

4 Door I_

i4t To Front of

i4

i

To Front of

31-i/16"

Handle

With Oven Door

7" Control

Panel Height

........................... --In J

J

i j

p.

48-i/4"

D,-

Open

i

i

m

|

- WARNING

The 12" high stainless steel

backsplash accessory must be

installed in combination with a

custom non-combustible backs@ash.

The finished backsplash must cover

the entire back wall up to the bottom

of a hood, or when there is no hood,

48" to combustibles.

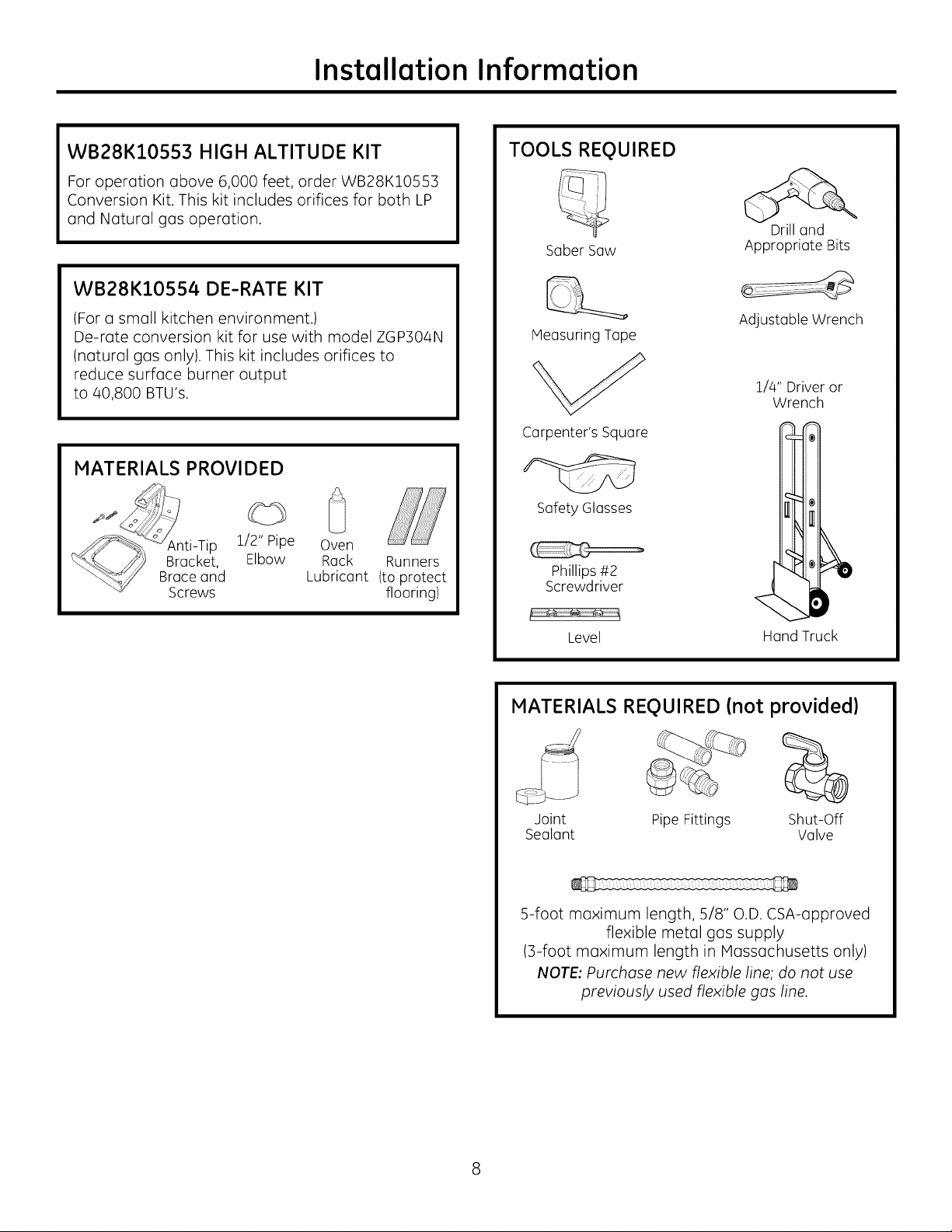

Page 8

Installation Information

WB28K10553 HIGH ALTITUDE KIT

For operation above 6,000 feet, order WB28K10553

Conversion Kit. This kit includes orifices for both LP

and Natural gas operation.

WB28K10554 DE-RATE KIT

(For a small kitchen environment.)

De-rate conversion kit for use with model ZGPBO4N

(natural gas only). This kit includes orifices to

reduce surface burner output

to/40,800 BTU's.

MATERIALS PROVIDED

1/2" Pipe

Elbow

'd

Oven

Rack Runners

Lubricant (to protect

flooring)

TOOLS REQUIRED

Saber Saw

Measuring Tape

Carpenter's Square

Safety Glasses

Phillips#2

Screwdriver

Drill and

Appropriate Bits

Adjustable Wrench

i/4" Driver or

Wrench

Level Hand Truck

MATERIALS REQUIRED (not provided)

Joint Pipe Fittings Shut-Off

Sealant Valve

5-foot maximum length, 5/8" O.D. CSA-approved

flexible metal gas supply

(3-foot maximum length in Massachusetts only)

NOTE: Purchase new flexible line; do not use

previously used flexible gas line.

Page 9

POWER SUPPLY LOCATIONS

Installation Preparation

Gas Supply:

•The natural gas models are designed to operate at

S" water column pressure. For proper operation, the

pressure of the natural gas supplied to the regulator

must be between 7" and 13" water column.

•The LP models are designed to operate at 10" water

column pressure. For proper operation, the pressure

of the LP gas supplied to the regulator must be

between 11" and 13" water column.

•Locate the pipe stub on the back wall or floor as

illustrated in "Dimensions and Clearances." Use

S-foot maximum length, 5/8" O.D. flexible gas supply

line (3-foot in Massachusetts).

Electric Supply:

Your range must be electrically grounded in

accordance with local codes, in accordance with

National Electrical Code (ANSI/NFPA 70, latest

edition). In Canada, electrical grounding must be in

accordance with the current CSA C22.1 Canadian

Electrical Code Part 1. See Electrical Connections in this

section.

-4,CAUTION

Do not attempt to operate the oven if this range of

this range during a power failure.

Page 10

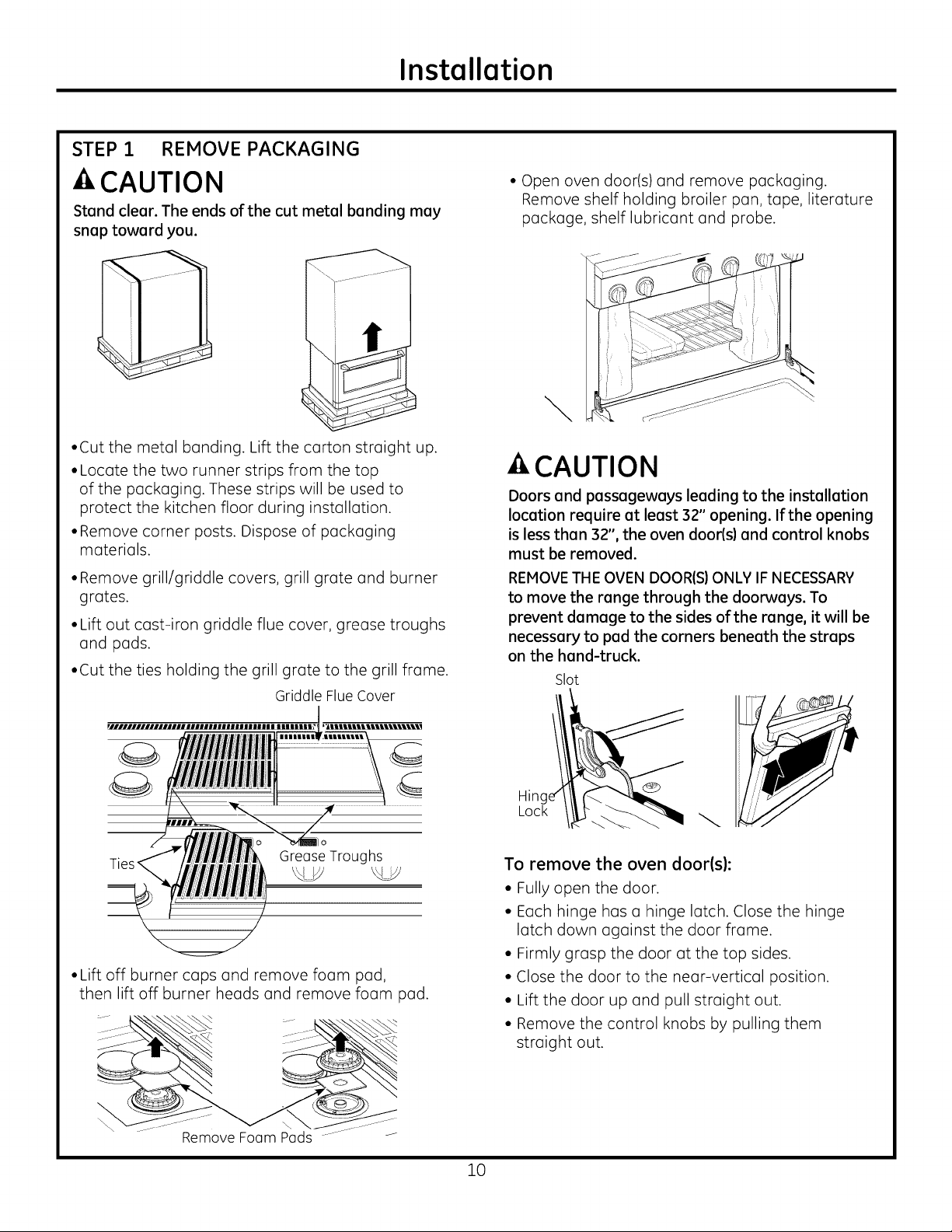

STEP 1 REMOVE PACKAGING

Installation

CAUTION

Stand clear. The ends of the cut metal banding may

snap toward you.

•Cut the metal banding. Lift the carton straight up.

•Locate the two runner strips from the top

of the packaging. These strips will be used to

protect the kitchen floor during installation.

•Remove corner posts. Dispose of packaging

materials.

•Remove grill/griddle covers, grill grate and burner

grates.

•Lift out cast-iron griddle flue cover, grease troughs

and pads.

•Cut the ties holding the grill grate to the grill frame.

Griddle Flue Cover

• Open oven door(s) and remove packaging.

Remove shelf holding broiler pan, tape, literature

package, shelf lubricant and probe.

\

-4,CAUTION

Doors and passageways leading to the installation

location require at least 32" opening. If the opening

is less than 32", the oven door(s) and control knobs

must be removed.

REMOVETHE OVEN DOOR(S)ONLY IF NECESSARY

to move the range through the doorways. To

prevent damage to the sides of the range, it will be

necessary to pad the corners beneath the straps

on the hand-truck.

Slot

GreaseTroughs

•Lift off burner caps and remove foam pad,

then lift off burner heads and remove foam pad.

Remove Foam Pods

Hin(

Lock

To remove the oven door(s):

• Fully open the door.

• Each hinge has a hinge latch. Close the hinge

latch down against the door frame.

• Firmly grasp the door at the top sides.

• Close the door to the near-vertical position.

• Lift the door up and pull straight out.

• Remove the control knobs by pulling them

straight out.

10

Page 11

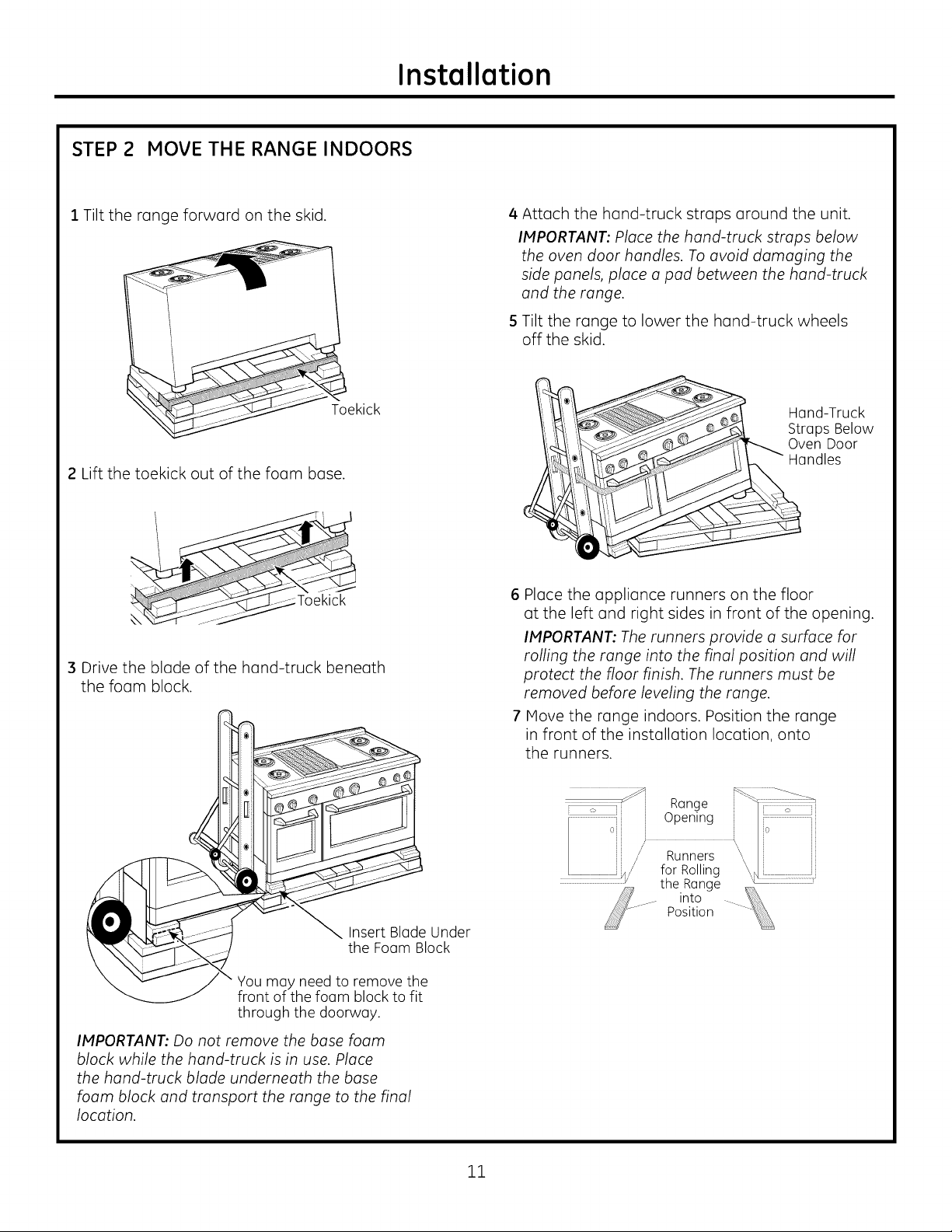

STEP 2 MOVE THE RANGE INDOORS

Installation

1 Tilt the range forward on the skid.

__Toekick

2 Lift the toekick out of the foam base.

/ _i_iii¢_i¢,_i_

3 Drive the blade of the hand-truck beneath

the foam block.

4 Attach the hand-truck straps around the unit.

IMPORTANT: Place the hand-truck straps below

the oven door handles. To avoid damaging the

side panels, place a pad between the hand-truck

and the range.

5 Tilt the range to lower the hand-truck wheels

off the skid.

Hand-Truck

Strops Below

Oven Door

Handles

6 Place the appliance runners on the floor

at the left and right sides in front of the opening.

IMPORTANT: The runners provide a surface for

rolling the range into the final oosition and will

protect the floor finish. The runners must be

removed before leveling the range.

7 IVlove the range indoors. Position the range

in front of the installation location, onto

the runners.

Insert Blade Under

the Foam Block

You may need to remove the

front of the foam block to fit

through the doorway.

IMPORTANT: Do not remove the base foam

block while the hand-truck is in use. Place

the hand-truck blade underneath the base

foam block and transport the range to the final

location.

11

Page 12

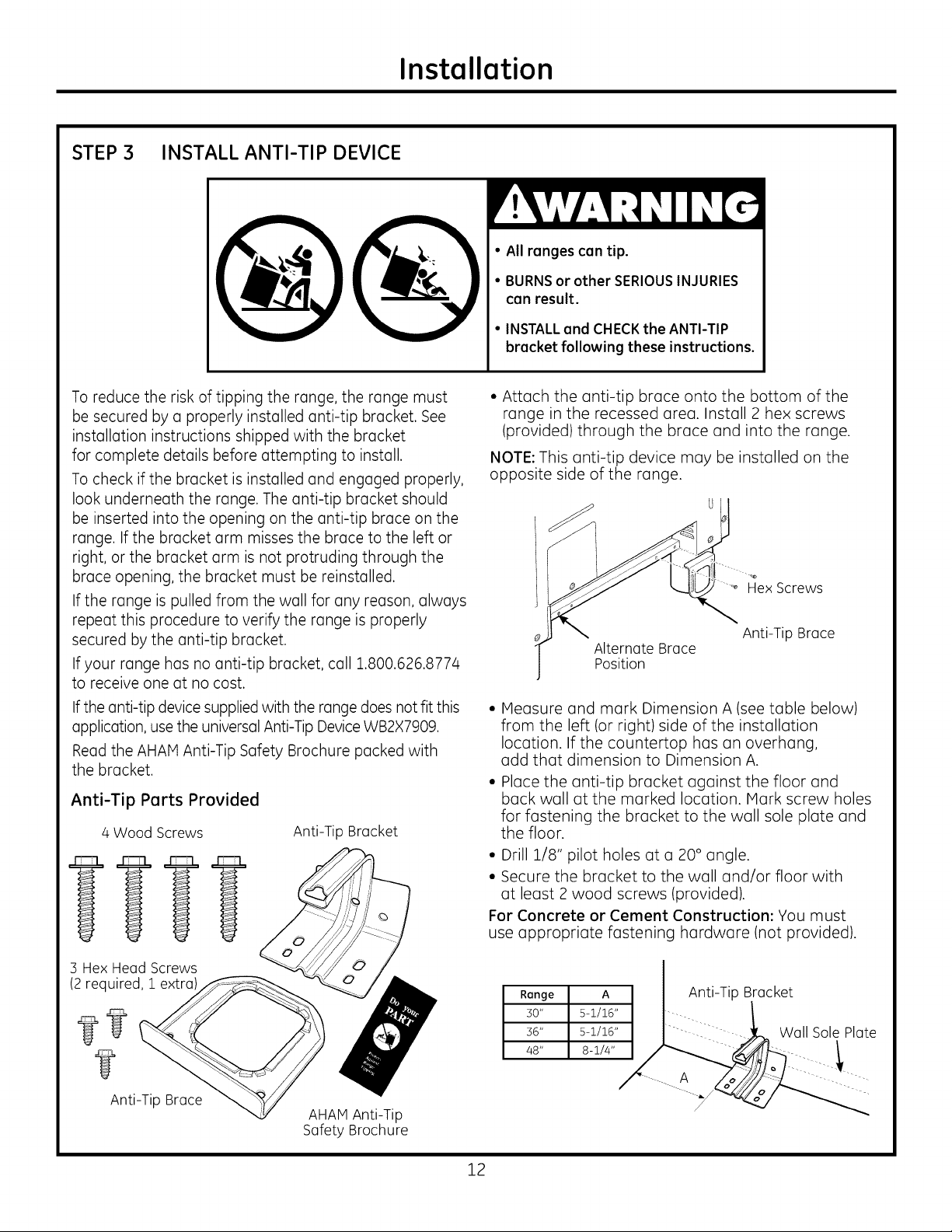

STEP 3 INSTALL ANTI-TIP DEVICE

Installation

• All ranges can tip.

• BURNSor other SERIOUSINJURIES

can result.

INSTALLand CHECKthe ANTI-TIP

bracket following these instructions.

To reduce the risk of tipping the range, the range must

be secured by a properly installed anti-tip bracket. See

installation instructions shipped with the bracket

for complete details before attempting to install.

To check if the bracket is installed and engaged properly,

look underneath the range. The anti-tip bracket should

be inserted into the opening on the anti-tip brace on the

range. If the bracket arm misses the brace to the left or

right, or the bracket arm is not protruding through the

brace opening, the bracket must be reinstalled.

If the range is pulled from the wall for any reason, always

repeat this procedure to verify the range is properly

secured by the anti-tip bracket.

If your range has no anti-tip bracket, call 1.800.626.8774

to receive one at no cost.

Ifthe anti-tip device supplied with the range does not fit this

application, use the universal Anti-Tip Device WB2X7909.

Read the AHAI Anti-Tip Safety Brochure packed with

the bracket.

Anti-Tip Parts Provided

4 Wood Screws

Anti-Tip Bracket

• Attach the anti-tip bruce onto the bottom of the

range in the recessed area. Install 2 hex screws

(provided) through the brace and into the range.

NOTE: This anti-tip device may be installed on the

opposite side of the range.

_e

Hex Screws

Anti-Tip Brace

Alternate Brace

Position

• Measure and mark Dimension A (see table below)

from the left (or right) side of the installation

location. If the countertop has an overhang,

add that dimension to Dimension A.

• Place the anti-tip bracket against the floor and

back wall at the marked location. Hark screw holes

for fastening the bracket to the wall sole plate and

the floor.

• Drill 1/8" pilot holes at a 20° angle.

• Secure the bracket to the wall and/or floor with

at least 2 wood screws (provided).

For Concrete or Cement Construction: You must

use appropriate fastening hardware (not provided).

3 Hex Head Screws

(2 required, 1 extra)

??

?

Anti-Tip Brace

AHAM Anti-Tip

Safety Brochure

12

Range

30"

36"

48"

I

A I Anti-Tip Bracket

5-1/16" e

8-1/4"

5-1/16"_

Page 13

Installation

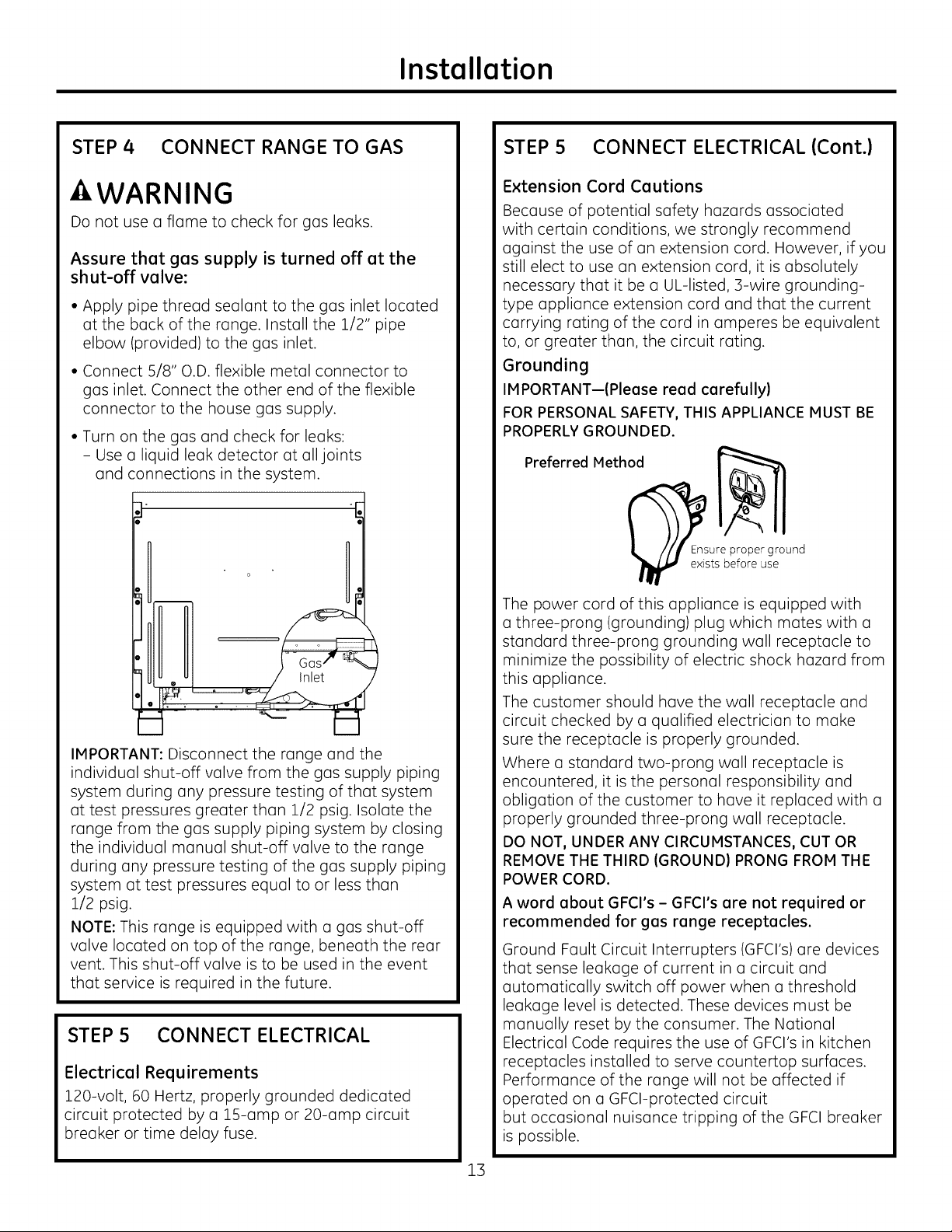

STEP4 CONNECT RANGE TO GAS

AWARNING

Do not use a flame to check for gas leaks.

Assure that gas supply is turned off at the

shut-off valve:

• Apply pipe thread sealant to the gas inlet located

at the back of the range. Install the 1/2" pipe

elbow (provided) to the gas inlet.

• Connect 5/8" O.D. flexible metal connector to

gas inlet. Connect the other end of the flexible

connector to the house gas supply.

• Turn on the gas and check for leaks:

- Use a liquid leak detector at alljoints

and connections in the system.

or,

STEP 5 CONNECT ELECTRICAL (Cont.}

Extension Cord Cautions

Because of potential safety hazards associated

with certain conditions, we strongly recommend

against the use of an extension cord. However, if you

still elect to use an extension cord, it is absolutely

necessary that it be a UL-listed, 3-wire grounding-

type appliance extension cord and that the current

carrying rating of the cord in amperes be equivalent

to, or greater than, the circuit rating.

Grounding

IMPORTANT--IPlease read carefully)

FOR PERSONAL SAFETY, THIS APPLIANCE MUST BE

PROPERLY GROUNDED.

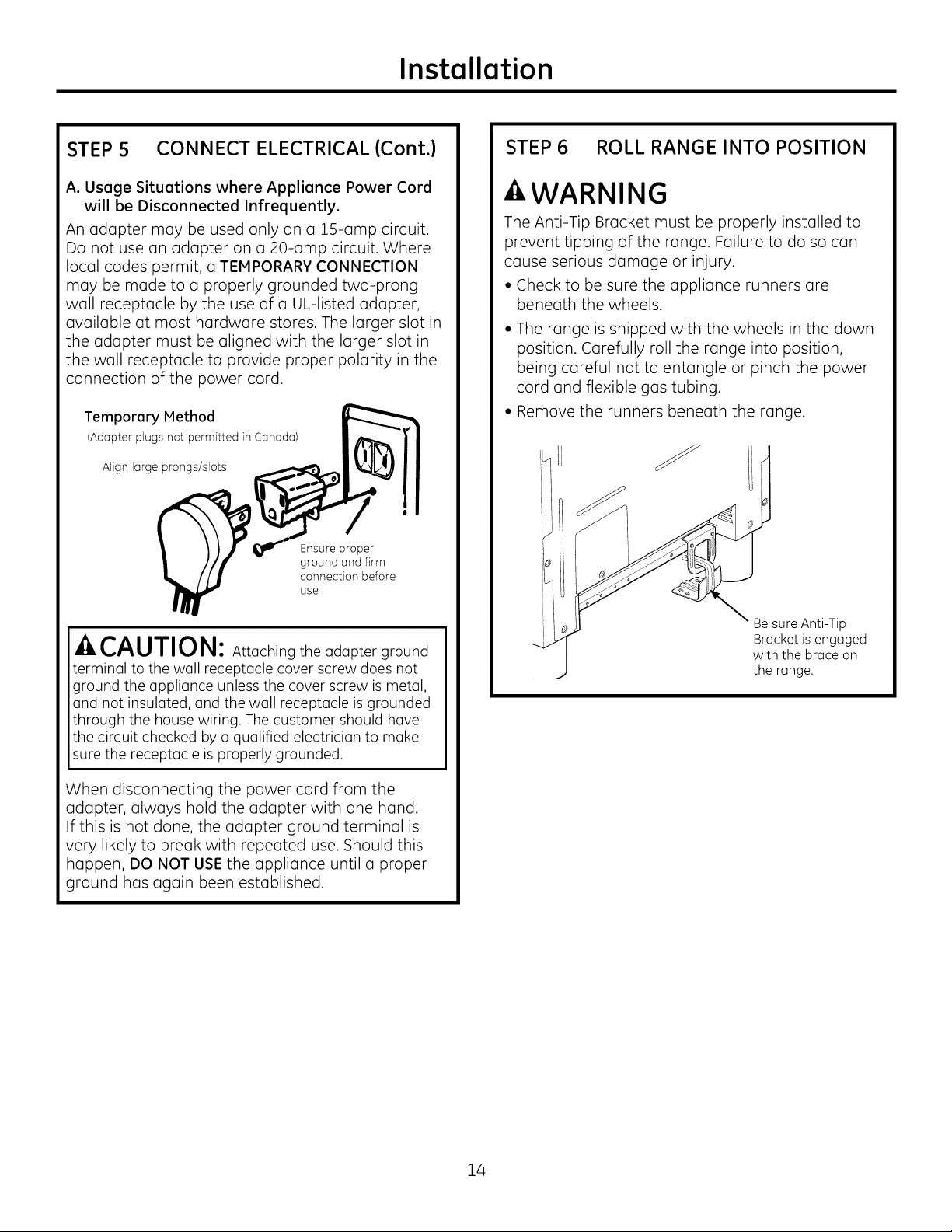

Preferred Method

Ensure proper ground

exists before use

IMPORTANT: Disconnect the range and the

individual shut-off valve from the gas supply piping

system during any pressure testing of that system

at test pressures greater than 1/2 psig. Isolate the

range from the gas supply piping system by closing

the individual manual shut-off valve to the range

during any pressure testing of the gas supply piping

system at test pressures equal to or less than

1/2 psig.

NOTE: This range is equipped with a gas shut-off

valve located on top of the range, beneath the rear

vent. This shut-off valve is to be used in the event

that service is required in the future.

STEP 5 CONNECT ELECTRICAL

Electrical Requirements

120-volt, 60 Hertz, properly grounded dedicated

circuit protected by a 15-amp or 20-amp circuit

breaker or time delay fuse.

The power cord of this appliance is equipped with

a three-prong (grounding) plug which mates with a

standard three-prong grounding wall receptacle to

minimize the possibility of electric shock hazard from

this appliance.

The customer should have the wall receptacle and

circuit checked by a qualified electrician to make

sure the receptacle is properly grounded.

Where a standard two-prong wall receptacle is

encountered, it is the personal responsibility and

obligation of the customer to have it replaced with a

properly grounded three-prong wall receptacle.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG FROM THE

POWER CORD.

A word about GFCI's - GFCI's are not required or

recommended for gas range receptacles.

Ground Fault Circuit Interrupters (GFCI's) are devices

that sense leakage of current in a circuit and

automatically switch off power when a threshold

leakage level is detected. These devices must be

manually reset by the consumer. The National

Electrical Code requires the use of GFCI's in kitchen

receptacles installed to serve countertop surfaces.

Performance of the range will not be affected if

operated on a GFCI-protected circuit

but occasional nuisance tripping of the GFCI breaker

is possible.

13

Page 14

Installation

STEP 5 CONNECT ELECTRICAL(Cont.)

A. Usage Situations where Appliance Power Cord

will be Disconnected Infrequently.

An adapter may be used only on a 1S-amp circuit.

Do not use an adapter on a 20-amp circuit. Where

local codes permit, a TEMPORARY CONNECTION

may be made to a properly grounded two-prong

wall receptacle by the use of a UL-listed adapter,

available at most hardware stores. The larger slot in

the adapter must be aligned with the larger slot in

the wall receptacle to provide proper polarity in the

connection of the power cord.

Temporary Method

(Adapterplugsnot permitted inCanada)

Align large prongs/slots

Ensure proper

ground and firm

connection before

use

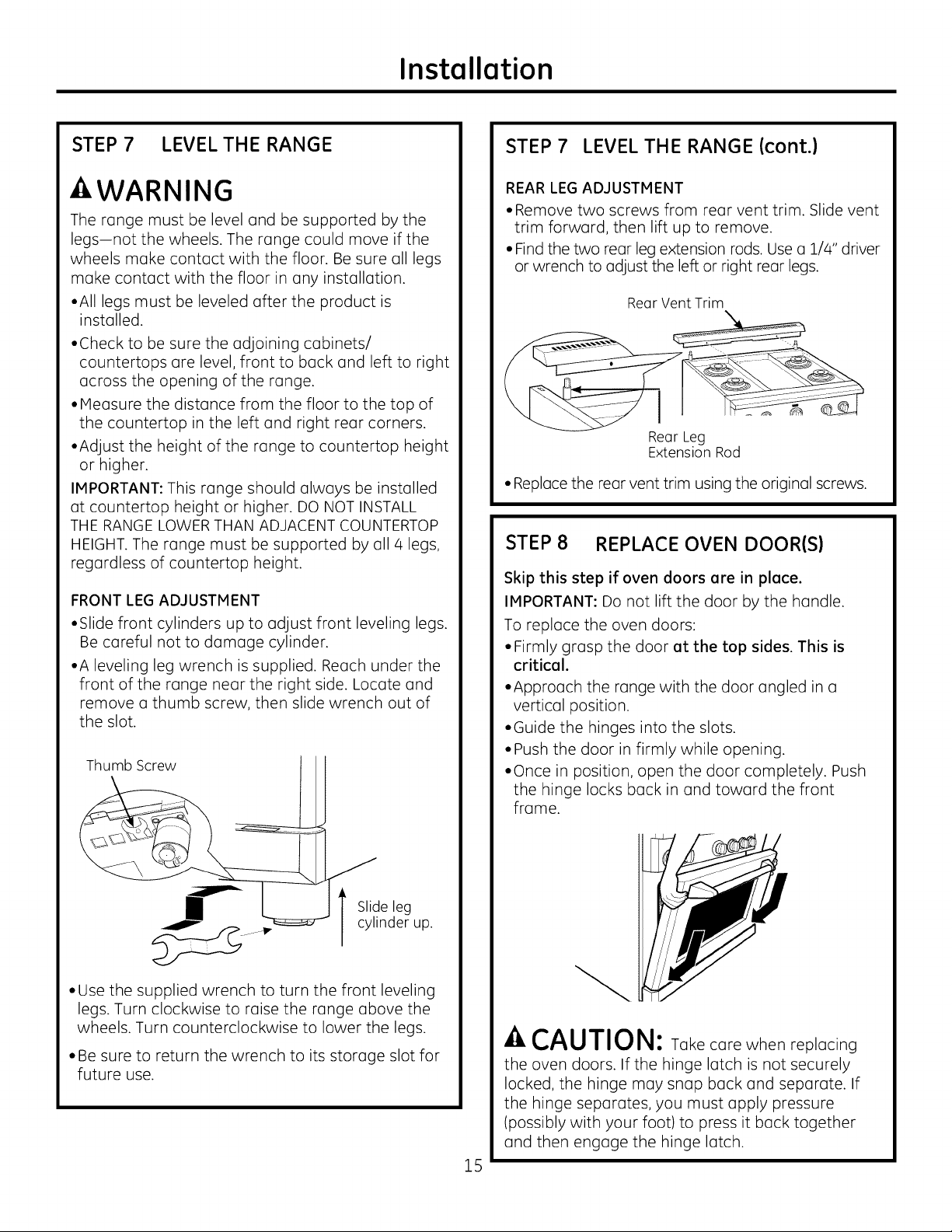

STEP 6 ROLL RANGE INTO POSITION

-4,WARNING

The Anti-Tip Bracket must be properly installed to

prevent tipping of the range. Failure to do so can

cause serious damage or injury.

• Check to be sure the appliance runners are

beneath the wheels.

• The range is shipped with the wheels in the down

position. Carefully roll the range into position,

being careful not to entangle or pinch the power

cord and flexible gas tubing.

• Remove the runners beneath the range.

u

-4,CAUTION: Attaching the adapter ground

terminal to the wall receptacle cover screw does not

ground the appliance unless the cover screw is metal,

and not insulated, and the wall receptacle is grounded

through the house wiring. The customer should have

the circuit checked by a qualified electrician to make

sure the receptacle is properly grounded.

When disconnecting the power cord from the

adapter, always hold the adapter with one hand.

If this is not done, the adapter ground terminal is

very likely to break with repeated use. Should this

happen, DO NOT USE the appliance until a proper

ground has again been established.

Be sure Anti-Tip

Bracket isengaged

with the brace on

the range.

14

Page 15

Installation

STEP 7 LEVEL THE RANGE

WARNING

The range must be level and be supported by the

legs-not the wheels. The range could move if the

wheels make contact with the floor. Be sure all legs

make contact with the floor in any installation.

•All legs must be leveled after the product is

installed.

•Check to be sure the adjoining cabinets/

countertops are level, front to back and left to right

across the opening of the range.

•Measure the distance from the floor to the top of

the countertop in the left and right rear corners.

•Adjust the height of the range to countertop height

or higher.

IMPORTANT: This range should always be installed

at countertop height or higher. DO NOT INSTALL

THE RANGE LOWER THAN ADJACENT COUNTERTOP

HEIGHT. The range must be supported by all 4 legs,

regardless of countertop height.

FRONT LEG ADJUSTMENT

•Slide front cylinders up to adjust front leveling legs.

Be careful not to damage cylinder.

•A leveling leg wrench is supplied. Reach under the

front of the range near the right side. Locate and

remove a thumb screw, then slide wrench out of

the slot.

Thumb Screw

STEP 7 LEVEL THE RANGE (cont.}

REAR LEG ADJUSTMENT

• Remove two screws from rear vent trim. Slide vent

trim forward, then lift up to remove.

• Find the two rear leg extension rods. Use o 1/4" driver

or wrench to adjust the left or right rear legs.

Rear Vent Trim

Rear Leg

Extension Rod

• Replace the rear vent trim using the original screws.

STEP 8 REPLACE OVEN DOORIS}

Skip this step if oven doors are in place.

IMPORTANT: Do not lift the door by the handle.

To replace the oven doors:

• Firmly grasp the door at the top sides. This is

critical.

• Approach the range with the door angled in a

vertical position.

• Guide the hinges into the slots.

• Push the door in firmly while opening.

• Once in position, open the door completely. Push

the hinge locks back in and toward the front

frame.

Slide leg

cylinder up.

• Use the supplied wrench to turn the front leveling

legs. Turn clockwise to raise the range above the

wheels. Turn counterclockwise to lower the legs.

• Be sure to return the wrench to its storage slot for

future use.

-ACAUTION: Take cure when replacing

the oven doors. If the hinge latch is not securely

locked, the hinge may snap back and separate. If

the hinge separates, you must apply pressure

(possibly with your foot) to press it back together

and then engage the hinge latch.

IS

Page 16

Installation

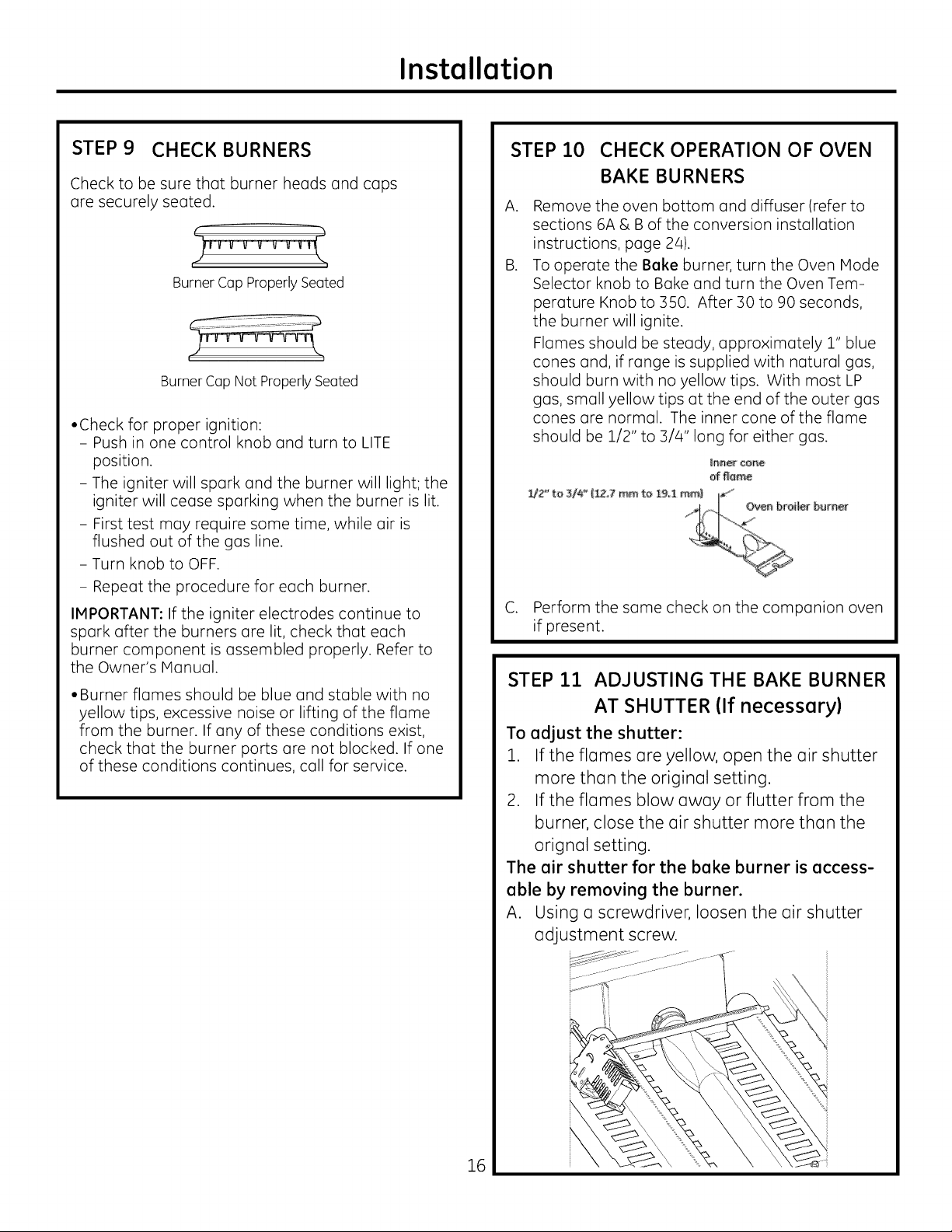

STEP9 CHECK BURNERS

Check to be sure that burner heads and caps

are securely seated.

Burner Cap Properly Seated

Burner Cap Not Properly Seated

•Check for proper ignition:

- Push in one control knob and turn to LITE

position.

- The igniter will spark and the burner will light; the

igniter will cease sparking when the burner is lit.

- First test may require some time, while air is

flushed out of the gas line.

- Turn knob to OFF.

- Repeat the procedure for each burner.

IMPORTANT: If the igniter electrodes continue to

spark after the burners are lit, check that each

burner component is assembled properly. Refer to

the Owner's Manual.

•Burner flames should be blue and stable with no

yellow tips, excessive noise or lifting of the flame

from the burner. If any of these conditions exist,

check that the burner ports are not blocked. If one

of these conditions continues, cull for service.

STEP 10 CHECK OPERATION OF OVEN

BAKE BURNERS

A.

Remove the oven bottom and diffuser (refer to

sections 6A & B of the conversion installation

instructions, page 24).

B.

To operate the Bake burner, turn the Oven Mode

Selector knob to Bake and turn the Oven Tem-

perature Knob to 350. After 30 to 90 seconds,

the burner will ignite.

Flames should be steady, approximately 1" blue

cones and, if range is supplied with natural gas,

should burn with no yellow tips. With most LP

gas, small yellow tips at the end of the outer gas

cones ore normal. The inner cone of the flame

should be 1/2" to 3/4" long for either gas.

C. Perform the same check on the companion oven

if present.

STEP II ADJUSTING THE BAKE BURNER

AT SHUTTER (If necessary)

To adjust the shutter:

1. If the flames ore yellow, open the air shutter

more than the original setting.

2. If the flames blow away or flutter from the

burner, close the air shutter more than the

orignol setting.

The air shutter for the bake burner is access-

able by removing the burner.

A. Using o screwdriver, loosen the air shutter

adjustment screw.

16

Page 17

Installation

STEP 11 ADJUSTING THE BAKE BURNER

AT SHUTTER (Cont.)

B. Hake the air shutter adjustment.

C. Retighten the air shutter screw.

D. Check that the inner cone of the flame is

between 1/2" and 3/4" (12.7 mm and

19.1 mm)long.

After confirming correct burner operation,

replace oil ports.

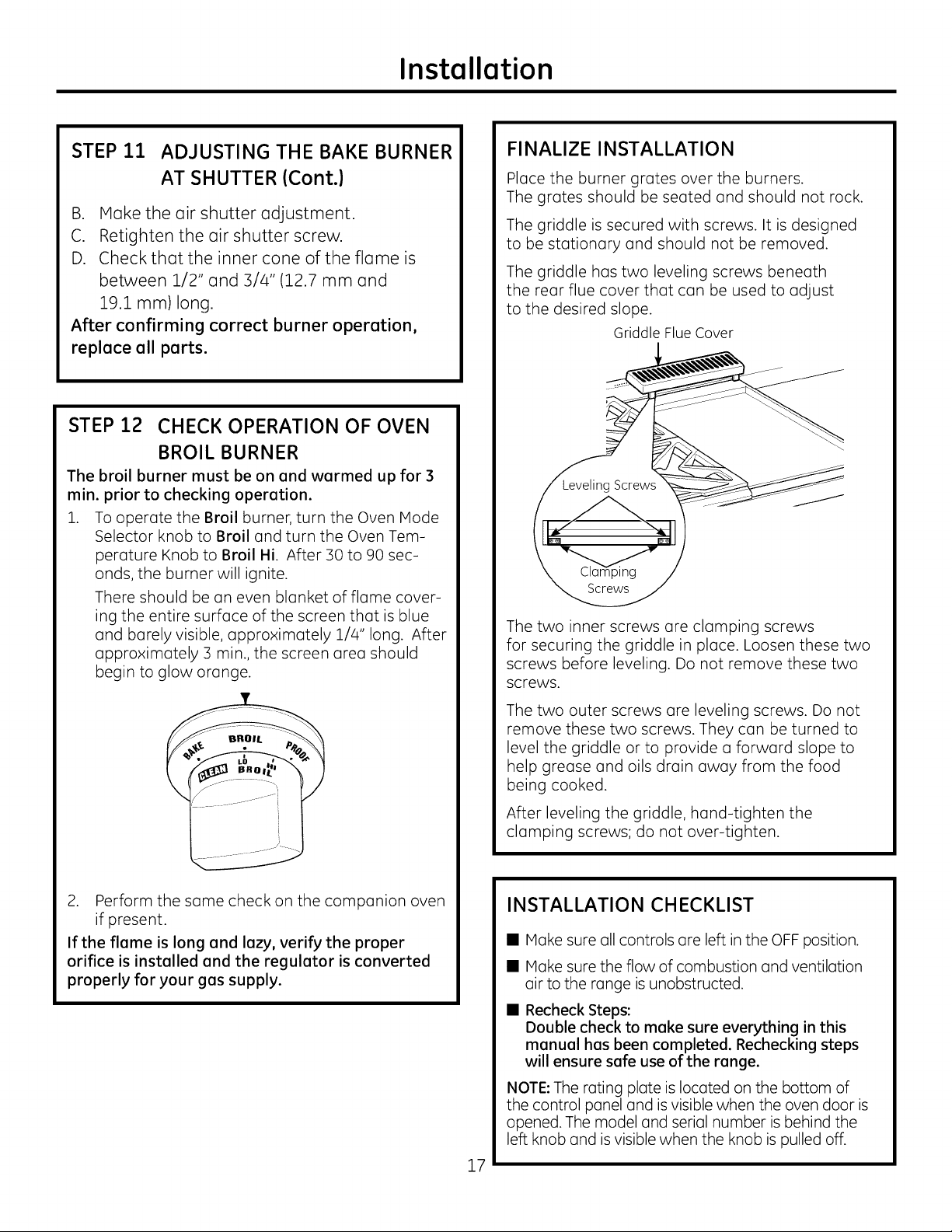

STEP 12 CHECK OPERATION OF OVEN

BROIL BURNER

The broil burner must be on and warmed up for 3

min. prior to checking operation.

1. To operate the Broil burner, turn the Oven IVlode

Selector knob to Broil and turn the Oven Tem-

perature Knob to Broil Hi. After 30 to 90 sec-

onds, the burner will ignite.

There should be on even blanket of flame cover-

ing the entire surface of the screen that is blue

and barely visible, approximately 1/4" long. After

approximately 3 min., the screen area should

begin to glow orange.

FINALIZE INSTALLATION

Place the burner grates over the burners.

The grates should be seated and should not rock.

The griddle is secured with screws. It is designed

to be stationary and should not be removed.

The griddle has two leveling screws beneath

the rear flue cover that con be used to adJust

to the desired slope.

Griddle Flue Cover

_Leveling Screws

The two inner screws ore clamping screws

for securing the griddle in place. Loosen these two

screws before leveling. Do not remove these two

screws.

................. JJ_i

2. Perform the some check on the companion oven

if present.

If the flame is long and lazy, verify the proper

orifice is installed and the regulator is converted

properly for your gas supply.

The two outer screws ore leveling screws. Do not

remove these two screws. They con be turned to

level the griddle or to provide o forward slope to

help grease and oils drain away from the food

being cooked.

After leveling the griddle, hand-tighten the

clamping screws; do not over-tighten.

INSTALLATION CHECKLIST

• Make sure oll controls ore left in the OFF position.

• IVlokesure the flow of combustion and ventilation

air to the range is unobstructed.

• Recheck Steps:

Double check to make sure everything in this

manual has been completed. Rechecking steps

will ensure safe use of the range.

NOTE:The rating plate is located on the bottom of

the control panel and is visible when the oven door is

opened. The model and serial number is behind the

left knob and is visible when the knob is pulled off.

17

Page 18

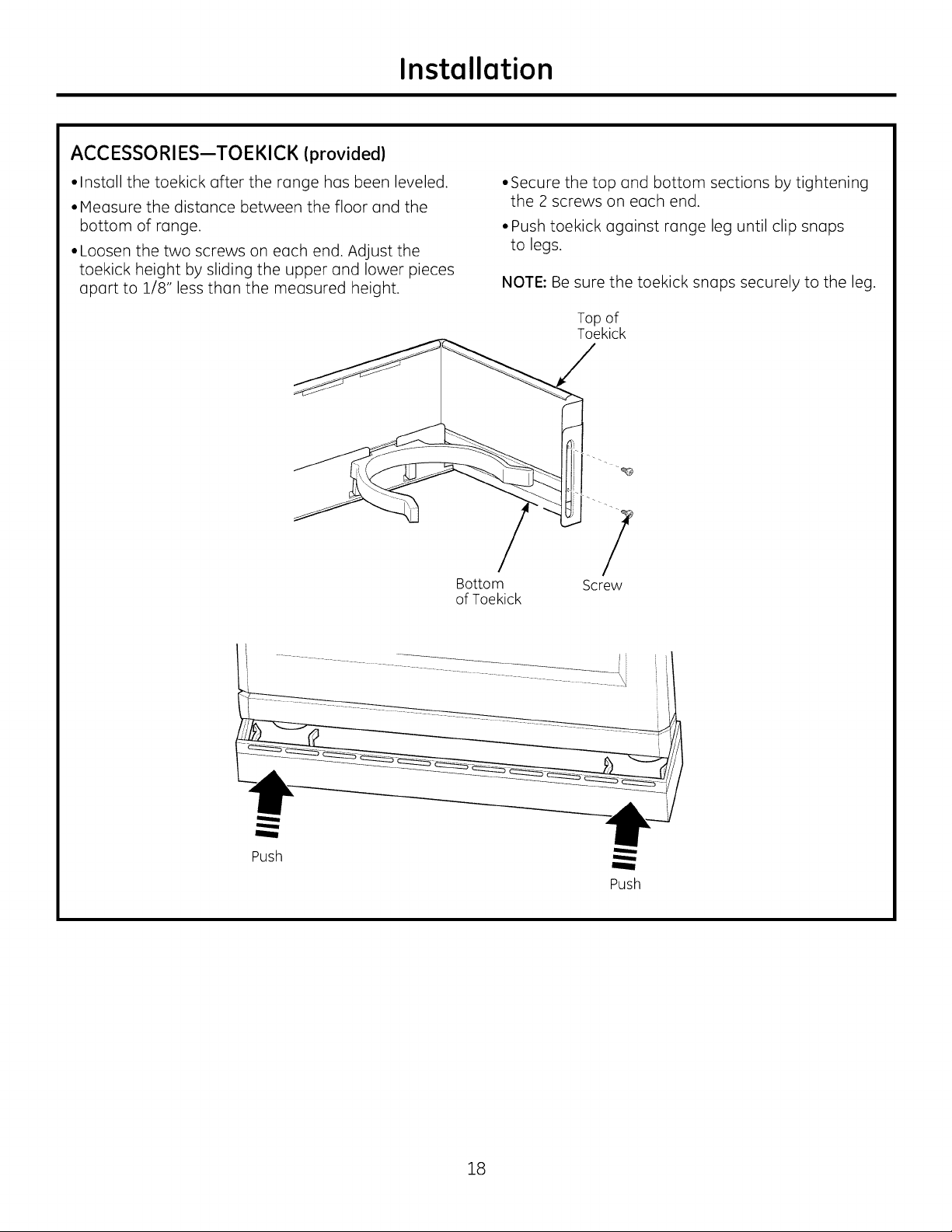

ACCESSORIES--TOEKICK (provided)

Installation

•lnstoll the toekick ofter the ronge hos been leveled.

•Meosure the distonce between the floor ond the

bottom of ronge.

•Loosen the two screws on eoch end. Adjust the

toekick height by sliding the upper ond lower pieces

oport to 1/8" less thon the meosured height.

•Secure the top ond bottom sections by tightening

• Push toekick ogoinst ronge leg until clip snops

NOTE: Be sure the toekick snaps securely to the leg.

Bottom

of Toekick

the 2 screws on eoch end.

to legs.

Top of

Toekick

/

Screw

Push

Push

18

Page 19

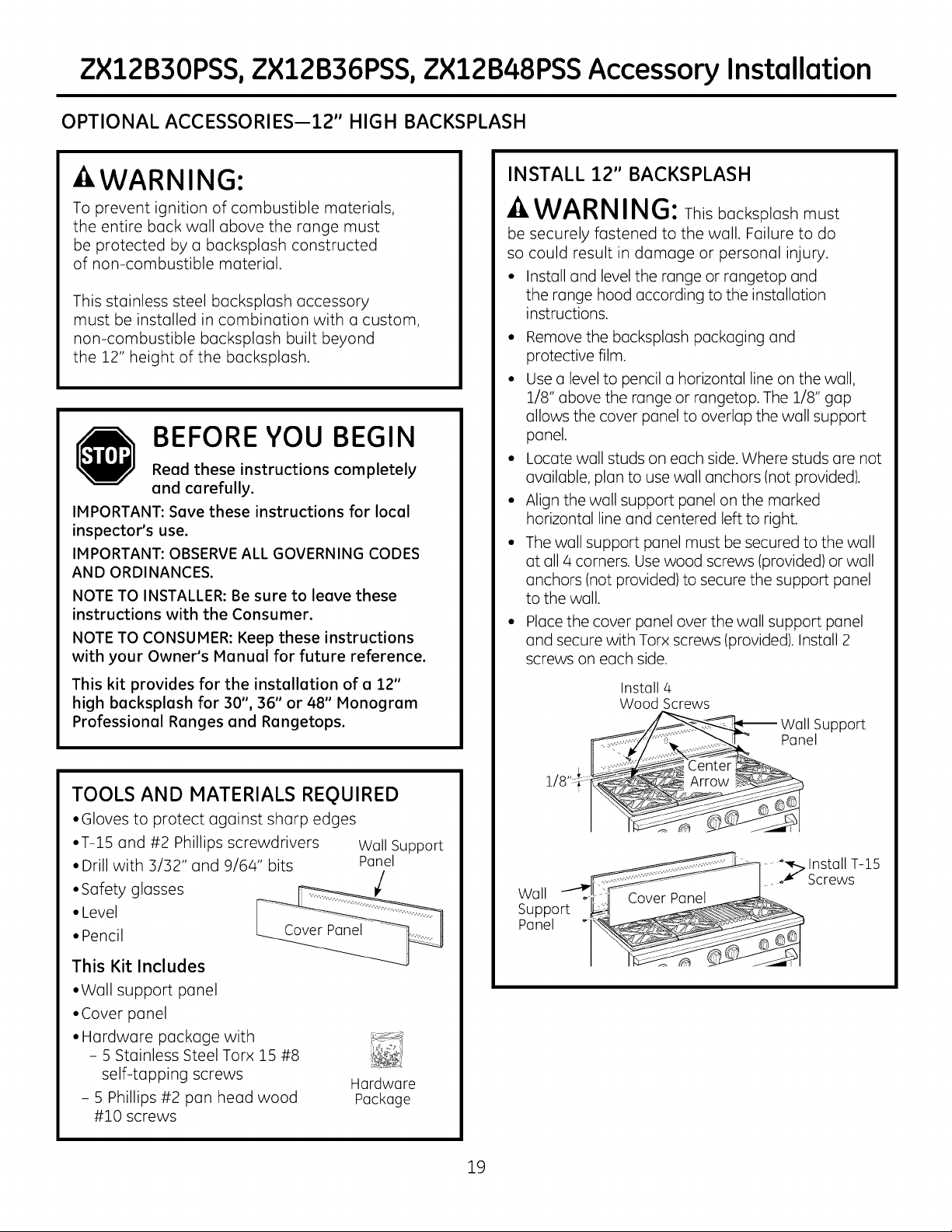

ZX12B30PSS, ZX12B36PSS, ZX12B48PSS Accessory Installation

OPTIONAL ACCESSORIES--12" HIGH BACKSPLASH

AWARNING:

To prevent ignition of combustible materials,

the entire back wall above the range must

be protected by a bocksplosh constructed

of non-combustible material.

This stainless steel backsplash accessory

must be installed in combination with a custom,

non-combustible backsplash built beyond

the 12" height of the bocksplosh.

BEFORE YOU BEGIN

Read these instructions completely

and carefully.

IMPORTANT: Save these instructions for local

inspector's use.

IMPORTANT: OBSERVE ALL GOVERNING CODES

AND ORDINANCES.

NOTE TO INSTALLER: Be sure to leave these

instructions with the Consumer.

NOTE TO CONSUMER: Keep these instructions

with your Owner's Manual for future reference.

INSTALL 12" BACKSPLASH

-AWARNING: Thisbocksploshmust

be securelyfastenedtothe wall.Failuretodo

so couldresultindamage or personalinjury.

• Installand leveltherangeorrangetopand

therange hood accordingtotheinstallation

instructions.

• Remove the backsplash packaging and

protective film.

• Use a level to pencil a horizontal line on the wall,

1/8" above the range or rangetop. The 1/8" gap

allows the cover panel to overlap the wall support

panel.

• Locate wall studs on each side. Where studs are not

available, plan to use wall anchors (not provided).

• Align the wall support panel on the marked

horizontal line and centered left to right.

• The wall support panel must be secured to the wall

at all 4 corners. Use wood screws (provided) or wall

anchors (not provided) to secure the support panel

to the wall.

Place the cover panel over the wall support panel

and secure with Torx screws (provided). Install 2

screws on each side.

This kit provides for the installation of a 12"

high backsplash for 30", 36" or 48" Monogram

Professional Ranges and Rangetops.

TOOLS AND MATERIALS REQUIRED

•Gloves to protect against sharp edges

•T-15 and #2 Phillips screwdrivers

• Drill with 3/32" and 9/64" bits

•Safety glosses

• Level

•Pencil

This Kit Includes

•Wall support panel

•Cover panel

• Hardware package with

- 5 Stainless Steel Torx 15 #8

self-tapping screws

- 5 Phillips #2 pan head wood

#10 screws

Wall Support

Panel

Hardware

Package

Wall

Support

Panel

Install 4

Wood Screws

Support

Panel

"°.'_'7Install T-15

o_" Screws

Cover Panel

19

Page 20

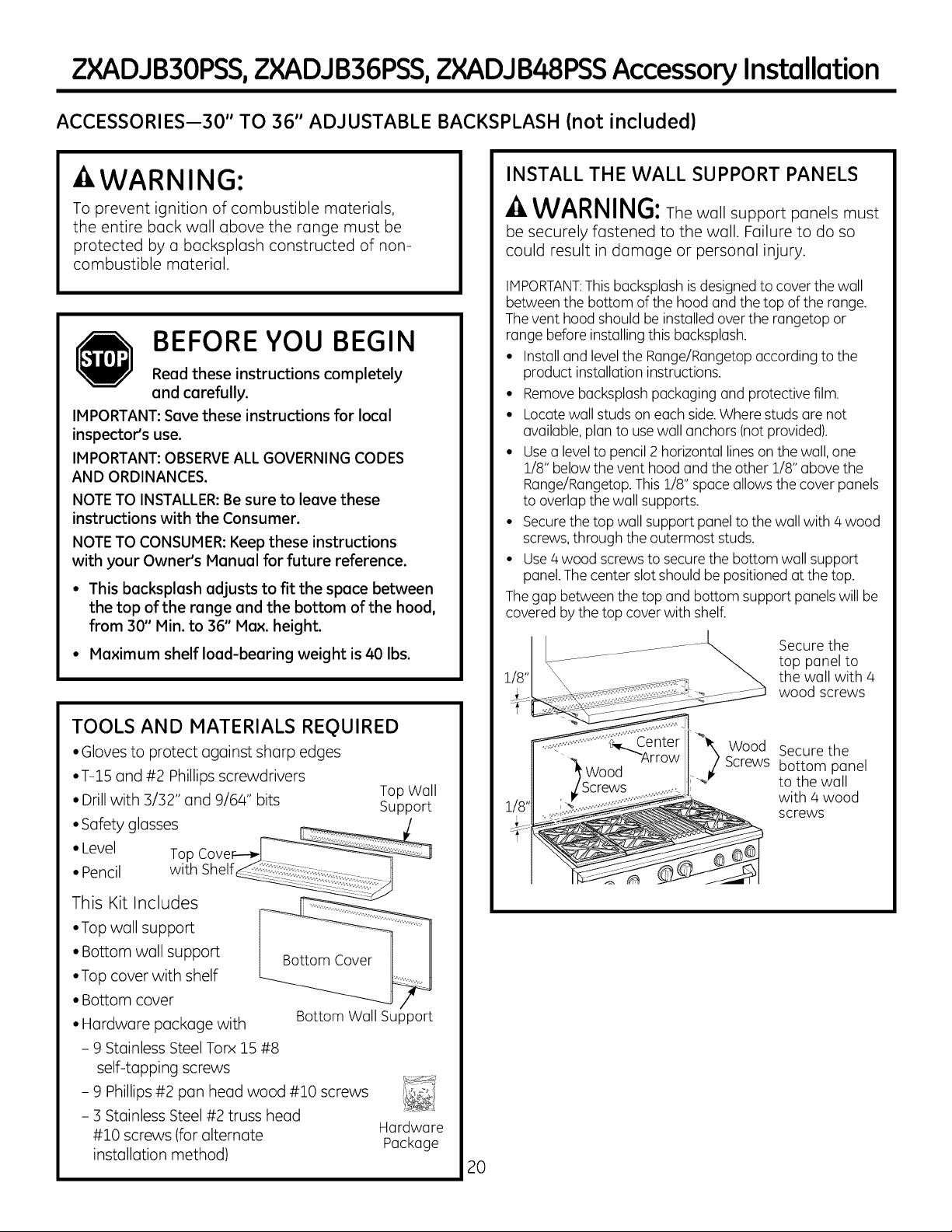

ZXADJB30PSS,ZXADJB36PSS,ZXADJB48PSSAccessory Installation

ACCESSORIES--30" TO 36" ADJUSTABLE BACKSPLASH (not included)

WARNING:

To prevent ignition of combustible materials,

the entire back wall above the range must be

protected by a backsplash constructed of non-

combustible material.

BEFOREYOU BEGIN

Read these instructions completely

and carefully.

IMPORTANT: Save these instructions for local

inspectoCs use.

IMPORTANT: OBSERVEALL GOVERNING CODES

AND ORDINANCES.

NOTE TO INSTALLER: Be sure to leave these

instructions with the Consumer.

NOTE TO CONSUMER: Keep these instructions

with your Owner's Manual for future reference.

• This backsplash adjusts to fit the space between

the top of the range and the bottom of the hood,

from 30" Min. to 36" Max. height.

• Maximum shelf load-bearing weight is 40 Ibs.

INSTALL THE WALL SUPPORT PANELS

WARNING: The wall support panels must

be securely fastened to the wall. Failure to do so

could result in damage or personal injury.

IMPORTANT:Thisbacksplash isdesigned to cover the wall

between the bottom of the hood and the top of the range.

Thevent hood should be installed over the rangetop or

range before installing this backsplash.

• Installand level the Range/Rangetop according to the

product installation instructions.

• Removebacksplash packaging and protective film.

• Locatewall studs on each side.Where studs are not

available, plan to usewall anchors (notprovided).

• Usealevel to pencil 2 horizontal lines on the wall, one

1/8" below the vent hood and the other 1/8" above the

Range/Rangetop.This 1/8" space allows the cover panels

to overlapthe wall supports.

• Securethe top wall support panel to the wall with/4 wood

screws,through the outermost studs.

• Use/4wood screws to secure the bottom wall support

panel.Thecenter slot should be positioned at the top.

Thegap between the top and bottom support panels will be

covered bythe top cover with shelf.

Secure the

top panel to

the wall with/4

wood screws

TOOLS AND MATERIALS REQUIRED

•Gloves to protect against sharp edges

•T-15 and #2 Phillips screwdrivers

• Drill with 3/32" and 9/6/4" bits

•Safety glasses

• Level Top

• Pencil with Shelf

This Kit Includes

•Top wall support

•Bottom wall support

•Top cover with shelf

• Bottom cover

• Hardware package with

- 9 Stainless Steel Torx 15 #8

self-tapping screws

- 9 Phillips #2 pan head wood #10 screws

- 3 Stainless Steel #2 truss head

#10 screws (for alternate

installation method)

Bottom Wall Support

Top Wall

Support

Hardware

Package

20

Wood

Wood

Screws

Secure the

bottom panel

to the wall

with/4 wood

screws

Page 21

ZXADJB30PSS,ZXADJB36PSS,ZXADJB48PSSAccessory Installation

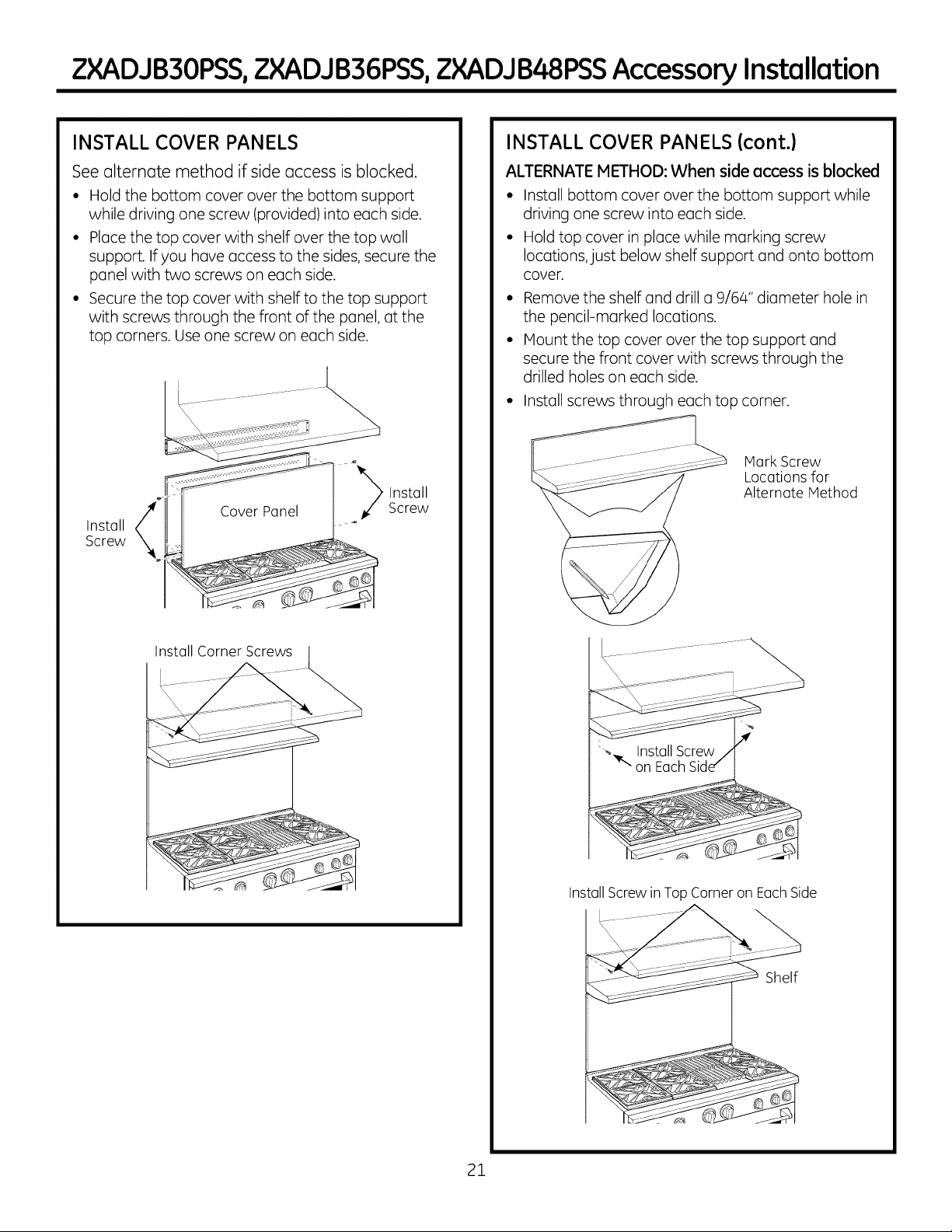

INSTALL COVER PANELS

See alternate method if side access is blocked.

• Hold the bottom cover over the bottom support

while driving one screw (provided)into each side.

• Place the top cover with shelf over the top wall

support. Ifyou have access to the sides, secure the

panel with two screws on each side.

• Secure the top cover with shelf to the top support

with screws through the front of the panel, at the

top corners. Use one screw on each side.

Install

Screw

Install

Screw

INSTALL COVER PANELS (cont.)

ALTERNATE METHOD: When side access is blocked

• Install bottom cover over the bottom support while

driving one screw into each side.

• Hold top cover in place while marking screw

locations, just below shelf support and onto bottom

cover.

• Remove the shelf and drill a 9/64" diameter hole in

the pencil-marked locations.

• Mount the top cover over the top support and

secure the front cover with screws through the

drilled holes on each side.

Instoll screws through eoch top corner.

Hark Screw

Locations for

Alternate Hethod

Install Corner Screws

i

InstallScrew inTop Corner on Each Side

Shelf

21

Page 22

IInstallat.ion 1 Convert Natural Gasto LPGasOperation

nstruCtlOns Convert LPGasto Natural GasOperation

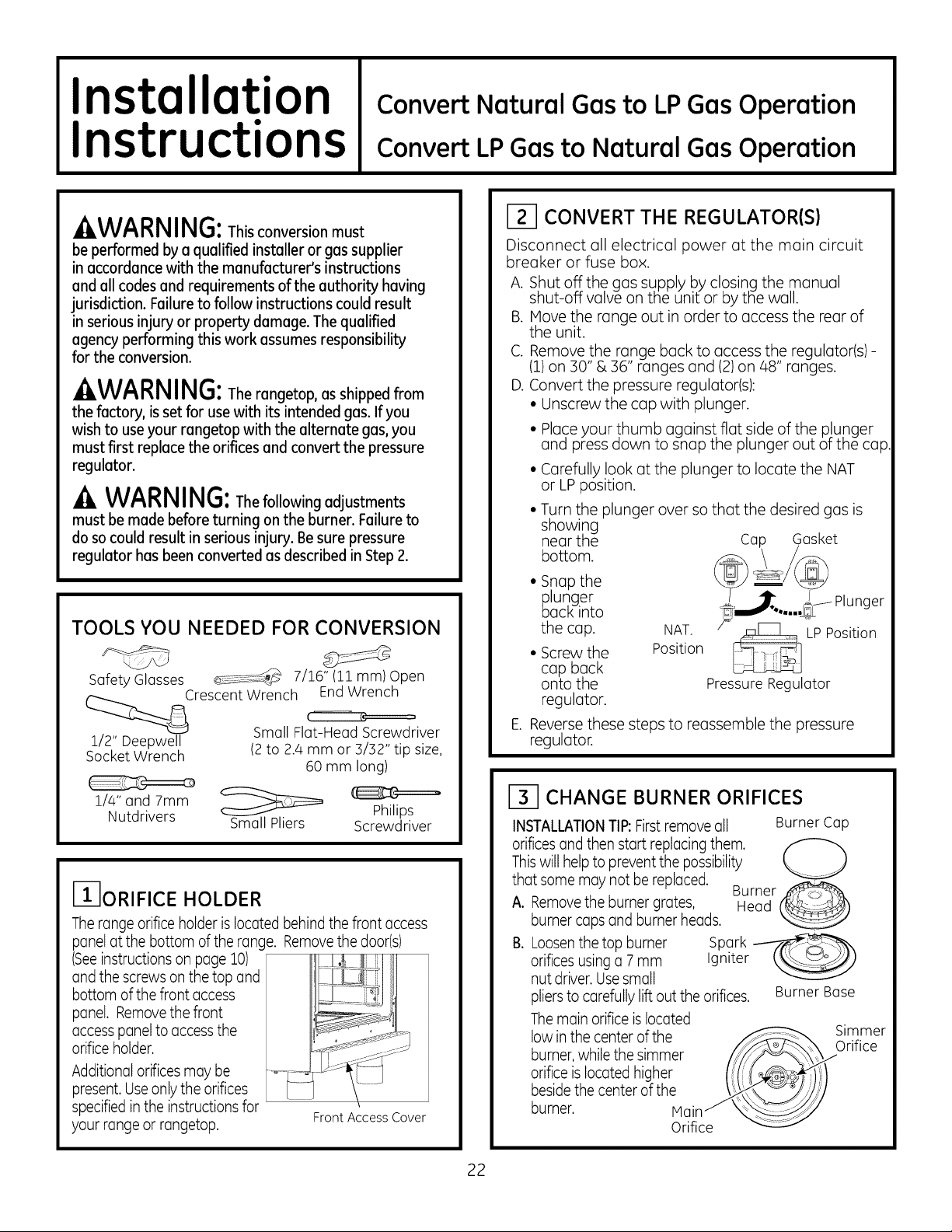

-AWARNING:This conversion must

be performed by a qualified installer or gas supplier

in accordance with the manufacturer's instructions

and all codes and requirements of the authority having

jurisdiction. Failure to follow instructions could result

in serious injury or property damage. The qualified

agency performing this work assumes responsibility

for the conversion.

_AWARNING:The rangetop, as shipped from

the factory, is set for use with its intended gas. If you

wish to use your rangetop with the alternate gas,you

must first replace the orifices and convert the pressure

regulator.

-A WARNING:Thefollowing adjustments

must be made before turning on the burner. Failure to

do socould result in serious injury. Be sure pressure

regulator has been converted asdescribed in Step2.

TOOLS YOU NEEDED FOR CONVERSION

Safety Glosses 7/16" (ii mm) Open

1/2" Deepwell

Socket Wrench (2 to 2.4 mm or :3/32" tip size,

Crescent Wrench End Wrench

Small Flat-Head Screwdriver

60 mm long)

_-I CONVERT THE REGULATOR(S)

Disconnect all electrical power at the main circuit

breaker or fuse box.

A. Shut off the gas supply by closing the manual

shut-off valve on the unit or by tl_e wall.

B. Move the range out in order to access the rear of

the unit.

C. Remove the range back to access the regulator(s) -

(i) on 30" & 36" ranges and (2)on 48" ranges.

D. Convert the pressure regulator(s):

• Unscrew the cap with plunger.

• Place your thumb against flat side of the pJupger

and press down to snap the plunger out of the cap.

• Carefully look at the plunger to locate the NAT

or LPposition.

• Turn the plunger over so that the desired gas is

showing

near the

bottom.

• Snap the

lunger

ack into

the cap.

• Screw the

cap back

onto the

regulator.

E. Reverse these steps to reassemble the pressure

regulator.

Position

NAT. /_

Cap Gasket

_ _--_ Plunger

_" .... 'L_r-

Pressure Regulator

Position

i/4" and 7mm

Nutdrivers

Small Pliers Screwdriver

Philips

FI-IORIFICE HOLDER

Therange orifice holder is located behind the front access

panel at the bottom of the rance. Removethe door(s)

(Seeinstructions on page 10)

and the screws on the top and

bottom of the front access

panel. Removethe front

access panel to accessthe

orifice holder.

Additional orifices may be

present.Useonly the orifices

specifiedin the instructions for

your range or rangetop. Front Access Cover

CHANGE BURNER ORIFICES

INSTALLATIONTIP:First remove all Burner Cap

orificesand then start replacing them.

Thiswill help to prevent the possibility

that some may not be replaced.

A. Removethe burner grates, Head

burner caps and burner heads.

B. Loosenthe top burner Spark

orifices using a 7 mm Igniter

nut driver. Usesmall

pliersto carefully lift out the orifices. Burner Bose

Themain orifice is located

low in the center of the

burner,while the simmer

orifice is located higher

besidethe center of the

burner.

Orifice

22

Burner

Simmer

Orifice

Page 23

Installation Instructions for Gas Conversion

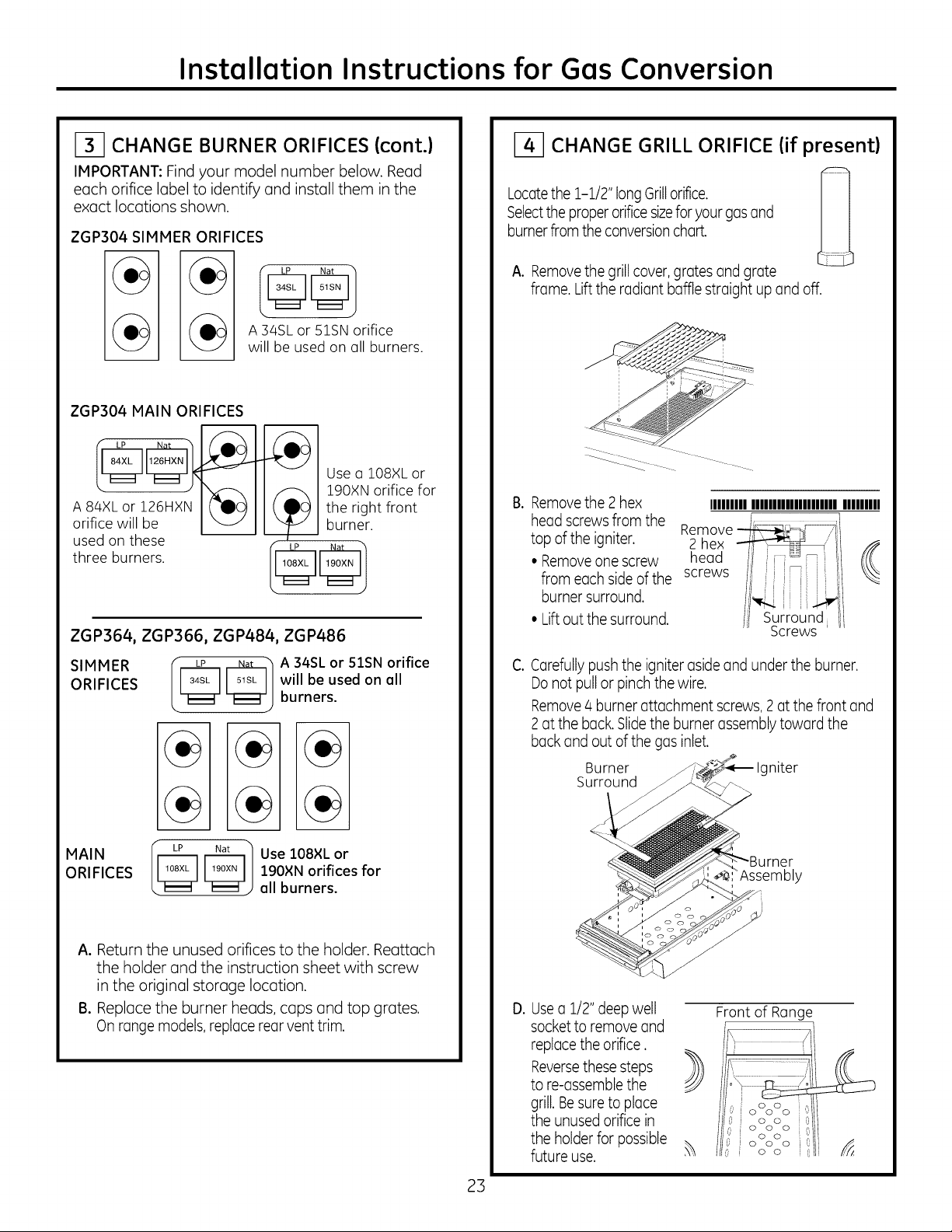

CHANGE BURNER ORIFICES (cont.)

IMPORTANT: Find your model number below. Read

each orifice label to identify and install them in the

exact locations shown.

ZGP304 SIMMER ORIFICES

A 34SL or 51SN orifice

will be used on all burners.

ZGP304 MAIN ORIFICES

Use o 108XL or

190XN orifice for

Aor_cXeLjir,,I_6HXN I _ I L _,

used on these

three burners.

ZGP364, ZGP366, ZGP484, ZGP486

ORIFICES

SIMMER I_

/

the right front

burner.

A 34SL or 51SN orifice

will be used on oll

burners.

E_ CHANGE GRILL ORIFICE (if present)

Locatethe 1-1/2" longGrillorifice.

Selectthe properorificesizeforyour gasand

burner from the conversionchart.

A. Removethe grill cover,grates and grate

frame. Lift the radiant baffle straight up and off.

Z]

iiiiiiiiii

B. Removethe 2 hex

head screwsfrom the

top of the igniter.

• Removeone screw

from each sideof the

burner surround.

• Lift out the surround.

C. Carefullypush the igniter asideand under the burner.

Donot pull or pinch the wire.

Remove4 burner attachment screws,2at the front and

2 at the back. Slidethe burner assembly toward the

back and out of the gas inlet.

Burner niter

Surround

IIIIIIIII IIIIIIIIIIIIIIIIIIII IIIIIIIII

f

Screws '

<

MAIN

ORIFICES

A. Return the unused orifices to the holder. Reattach

the holder and the instruction sheet with screw

in the original storage location.

B. Replace the burner heads, caps and top grates.

On range models,replace rear vent trim.

I@@l Use 108×L or

190×N orifices for

oll burners.

23

D°

Usea 1/2" deep well

socket to remove and

replacethe orifice.

Reversethese steps )]]

to re-assemble the

grill.Besureto place

the unused orifice in

the holder for possible

future use.

"Assembly

Front of Ronge

\ /

y

'j o°o°o

;°o%°

0 i o o

Y

j o o

Page 24

Installation Instructions for Gas Conversion

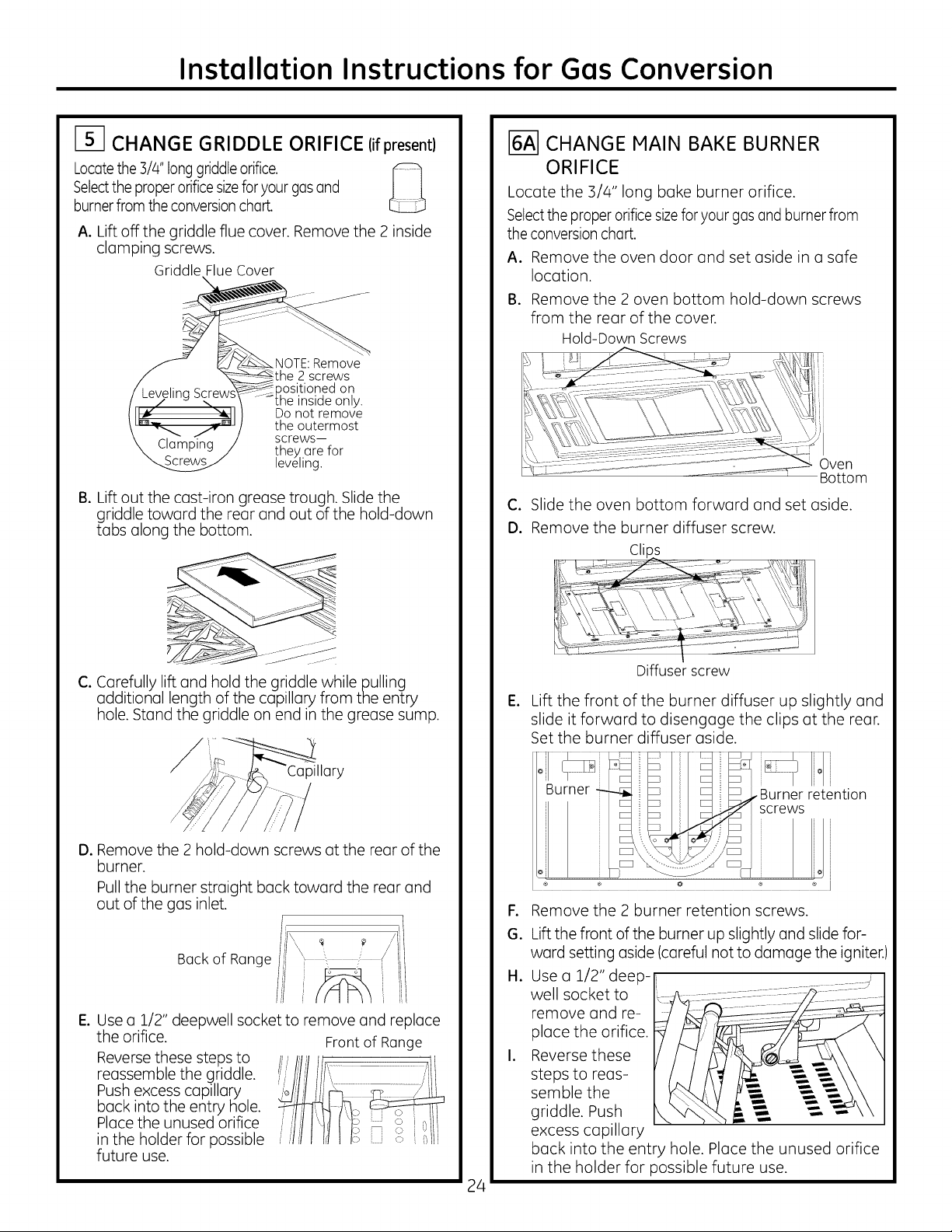

I _ I CHANGE GRIDDLE ORIFICElifpresent}

Locatethe 314"longgriddleorifice.

Selectthe properorificesizeforyour gasand

burnerfrom the conversionchart.

A. Lift off the griddle flue cover. Remove the 2 inside

clamping screws.

Griddle Flue Cover

/_posi.tioped on

/_\ -{he inside only.

Ill#" "_11I Do not remove

\,_....._ j_ii the outermost

\ C'lNmn_nN / s,crews--

\ '_'"v"'_ / theK are for

B. Lift out the cast-iron grease trough. Slide the

griddle toward the rear and out of the hold-down

tabs along the bottom.

leveling.

CHANGE MAIN BAKE BURNER

ORIFICE

Locate the 3/4" long bake burner orifice.

Selectthe proper orifice sizeforyour gas and burner from

the conversion chart.

A. Remove the oven door and set aside in a safe

location.

B. Remove the 2 oven bottom hold-down screws

from the rear of the cover.

Hold-Down Screws

Bottom

C. Slide the oven bottom forward and set aside.

D. Remove the burner diffuser screw.

CNp# ,_

C. Carefully lift and hold the griddle while pulling

additional length of the capillary from the entry

hole. Stand the griddle on end in the grease sump.

D. Remove the 2 hold-down screws at the rear of the

burner.

Pull the burner straight back toward the rear and

out of the gas inlet.

Back of Range

E. Use a 1/2" deepwell socket to remove and replace

the orifice. Front of Range

Reverse these steps to

reassemble the griddle.

Push excess capillary

back into the entry hole.

Place the unused orifice

in the holder for possible

future use.

ix \, i_

I

Diffuser screw

E. Lift the front of the burner diffuser up slightly and

slide it forward to disengage the clips at the rear.

Set the burner diffuser aside.

® ® o @ @

Remove the 2 burner retention screws.

F°

G.

Lift the front of the burner up slightly and slide for-

ward setting aside (careful not to damage the igniter.)

H°

Use a 1/2" deep-

well socket to

............... zZ-ZE Z-Z Z-ZEZ ..... /

remove and re-

place the orifice.

Reverse these

steps to reas-

semble the

griddle. Push

excess capillary

back into the entry hole. Place the unused orifice

in the holder for possible future use.

24

...... )

Page 25

Installation Instructions for Gas Conversion

i6--_CHANGE COMPANION BAKE BURNER

ORIFICE (if present)

Locate the 3/4" long bake burner orifice.

Select the proper orifice size for your gas and burner

from the conversion chart.

A. Remove the oven door and set aside in a safe

location.

B. Remove the 2 oven bottom hold-down screws

from the rear of the cover.

Hold-Down

C. Slide the oven bottom forward and set asside.

D. Remove the burner diffuser screw.

i-_ CHANGE MAIN/COMPANION BROIL

BURNER ORIFICE

Locate the broil burner orifice.

Select the proper orifice size for your gas and

burner from the conversion chart.

The rear cover should still be removed from

converting the regulatoris). Refer to section 2 for

details if it is not.

A. Remove the 2 broil duct cover retension screw.

Lift up and slide out to remove.

Remove

screws

B°

Loosen and remove the broil supply tube nut

from the broil orifice holder.

Diffuser Screw

E. Lift the front of the burner diffuser up slightly and

slide it forward to disengage the clips at the rear.

Set the burner diffuser aside.

R Remove the 3 burner

retension screws (1 in

front and 2 at the rear)

G. Lift the front of the

burner up slightly and

slide leftward to re-

move.

H. Use a 1/2" deepwell

socket to remove and

replace the orifice.

I. Reverse these steps to

reassemble the griddle.

Push excess capillary

back into the entry

hole.Place the unused

orifice in the holder for

possible future use.

! I

C°

Using an adjustable wrench and a 7/16" (11 mm)

box end wrench to loosen and remove and re-

place the broil orifice.

//

/

/

/

D°

Reverse these steps to reassemble the griddle.

Push excess capillary back into the entry hole.

Place the unused orifice in the holder for pos-

sible future use.

25

Page 26

Installation Instructions for Gas Conversion

ADJUST BURNER FLAMES

Normally, burners do not need further adjustment.

Hake adjustments only when necessary.

A. Turn on the gas. Plug in electrical cord.

B. Turn all burners on highest setting and check

the flames. They should be blue in color. When

using LPgas, the flames may have some yellow

tipping at the ends of the flame. Foreign particles

in the gas line may cause on orange flame at first,

but this will soon disappear.

C. Turn the burner knob to "LO" while observing the

flame.

Adjust the setting of the upper row of flames using

the valve bypass screw as follows:

Adjustments must be made with two other burners

in operation on a medium setting. This prevents the

upper row of flames from being set too low, resulting

in the flame being extinguished when other burners

are turned on.

D. To adjust the flame, remove the knobs. Insert a small

fiat-blade screwdriver into the hole in the center of

the valve stem to engage screw.

• If the flames are too small or flutter,

turn the screw counterclockwise.

• If the flames are too large, turn the screw

clockwise.

E. Make the adjustment by slowly turning the screw

until flame appearance is correct.

HODEL

ZGP48

ZGP36

ZGP304

ZGP304

ALL

ALL

ZGP48/

ZGP36

ZGP30

ZGP48

ALL

ZGP48

BURNER OUTPUT RATINGS: BTU/HR

NG (Natural) Gas, 5" W.C.P. LP (Propane) Gas, 10" W.C.P.

BURNER BTU ORIFICE SIZE ID MODEL BURNER BTU ORIFICE SIZE ID

RATE RATE

ALL SURF. Main 16,800 0.075" (1.90mm) 190XN ZGP48 ALL SURF. Main 13,800 0.043" (1.08mm) 108XL

BURNERS Simmer 1,200 0.002" (0.51mm) 51SL ZGP36 BURNERS Simmer 1,200 0.013"(0.34mm) 34SL

RFBURNER ZGP304 RFBURNER

RR,LR,LF Simmer 1,200 0.002" (0.51mm) 51SN ZGP304 RR,LR,LF Simmer 1,200 0.013"(0.34mm) 34SL

GRILL 15,000 0.0689"(1.75mm) 0.069 ALL GRILL 14,000 0.047"(1.19mm) 0.047

GRIDDLE 18,000 0.076" (1.93mm) 0.076 ALL GRIDDLE 16,000 0.047"(1.19mm) 0.047

BAKEMAIN 0.0886" ZGP48/ BAKEMAIN 0.0571"

BAKEMAIN 23,500 0.0866"(2.20mm) 0.087 ZGP30 BAKEMAIN 21,500 0.0531"(1.35mm) 0.053

BAKECOMPANION 10,500 0.0531"(1.35mm) 0.053 ZGP48 BAKECOMPANION 10,000 0.0374"(0.95mm) 0.037

BROIL MAIN 12,500 0.063" (1.60mm) 160 ALL BROIL MAIN 11,500 0.041"(1.04mm) 104

BROILCOMPANION 9,000 0.052" (1.32mm) 132 ZGP48 BROILCOMPANION 9,000 0.0360"(0.91mm) 91

Main 16,800 0.075" (1.90mm) 190XN Main 13,800 0.043"(1.08mm) 108XL

Simmer 1,200 0.002" (0.51mm) 51SN Simmer 1,200 0.013"(0.34mm) 34SL

Main 8,800 0.050" (1.26mm) 126HXN Main 7,900 0.033"(0.84mm) 84XL

24,500 0.089 23,000 0.055

(2.25mm) ZGP36 (1.35mm)

place the label beneath the control panel. Forrangetops, placethe label on the bottom of the unit.

I ncethe conversion is complete ond checked,fill out the conversion label ond affix the label neor the rating label. Forranges,

I

Page 27

Consignes d'installation

AVANT DE COMMENCER

Lisezattentivement I'ensemble desconsignes.

• IMPORTANT- Conservezcesconsignes,ellespeuvent

vous_treutilespourtouteinspectiondevotreinstallation

"IM PORTANT- Respecteztouteslesnormesainsique

lesrecommandationspreconiseesparlesautoritescompetentes

• Remarque _]I'attention de I'installateur- Apres

intervention,assurez-vousd'avoirremiscesinstructionsc)

I'utilisateur

• Remarque _]I'attention de I'utilisateur- Conservez

cesinstructionsaveclemanueldeI'utilisateurpourtoute

consultationulterieure

• Temps d'installation - 1 _ 3 heures.

• IIincombe_I'installateurdeveiller_ labonneinstallation.Toute

ddaillanceduproduitdue_ uneinstallationnonconformene

c_OUrraCtrecouvertepar lagarantie.Pourtout compl_ment

'information,reportez-vousaumanueldeI'utilisateur.

AVERTISSEMENT:

CetappareildoitCtrecorrectementmis_ laterre.Veuillezsuivre

lesdirectivesdonn_es_lasection<<Alimentationelectrique>>

dupresentmanuel.Lenon-respectdecesdirectivespourrait

occasionnerunchoc_lectrique.

Pourcontacterleservicede d@annageMonogramleplusproche

dechezvous,veuillezappelerle1.800.444.18/45.

.Pourcontacterleserviceded@annageMonogramduCanada,

veuillezappelerlenum@ro1.800.561.33/44.

Pourcontacterleserviced'accessoiresetdepiecesdetachees

Monogram,veuillezappelerle1.800.626.2002.

Sivousrecevezunecuisiniereddaillante,veuillezcontactervotre

revendeur.

Dansle Commonwealthof Massachusetts(Communaut_du

Massachusetts):

• Ceproduitdoit¢treinstall_parunplombierouuntechniciengaz

agree.

• Sivousutilisezdesrobinetsd'arrCtgaz,ceux-cidoiventCtre

detype1//4detour.

• Sivousutilisezunraccord8 gazflexible,celui-cinedoispas

mesurerplusde3 pieds(100cm).

Dispositions de hotte

d'extraction:

Une hotte d'aspiration appropri_e est n6cessairepour les

modules (] barbecue et est recommand6e pour tous les

autres modules.

• Installezunehottedisposantd'unecapacit6d'6vacuation

d'au moins1200CFM(piedscubesparminute ou 35 m@tres

cubes/m)aunedistancede/48"(122cm)delatablede cuisson.

• Installezunehottedisposantd'unecapacit6d'6vacuation

d'au moins600CFM(ou18 m@trescubes/m)au-dessus

d'unetablede cuissondetype30"(76cm)ou36"(91cm).

Cetappareilproduisantune importantequantit6dechaleur,

vousdevezporteruneattentiontoute particulierea rinstallation

de lahotteetdelaconduited'a6rationafindevousassurerqu'elle

r@ondaux normesdeconstructionenvigueurdansvotre r6gion.

AVERTISSEMENT :

IIfaut pr@oirlesdegagementsci-dessousparrapportauxsurfaces

horizontalesquisetrouventau-dessusdelacuisiniere.Lenon-

respectdecetteconsignepourraitpresenterunrisqued'incendie.

• Pourlesinstallationsd@ourvuesdehotte,pr@oyezunespace

minimumde/48"(122cm)entreI'appareilettout@l@ment

inflammablesitueau-dessusdecelui-ci.

• IIestpossibled'installerunehottespeciale_proximited'elements

horizontauxinflammablesdanslamesureoOcelle-cidispose

d'unefonctiondemiseenmarcheautomatique.

• Pourobtenirlesspecificationsrelativesauxespacesd'autres

installationspourvuesd'unehotte,veuillezvousreporteraux

instructionsfourniesaveccelle-ci.

-4,ATTENTION : Cescuisinierespesentplusde

300kg.Afind'@itertoutrisquede blessureoud'endommagement

deI'appareilet comptetenudupoidsetdelatailledelacuisiniere:

DEUXPERSONNESSONTNECESSAIRESPOURUNEINSTALLATION

ADEQUATEDESCUISINIERES30"(76cm)et36"(91cm).

TROISPERSONNESSONTNECESSAIRESPOURUNEINSTALLATION

ADEQUATEDESCUISINIERES/48"(121CM).

AVERTISSEMENT :

Touteslescuisinierespeuventserenverseraurisquedeprovoquer

degravesblessures.Installezlesupportantibasculementfourni

conformementauxinstructionsfigurantdanscemanuelou@celles

fourniesaveclesupport.

SiI'articleestvendu6 I'ext rieurdes

oudu Canada"

_-/kAVERTISSEMENT:sivoussouhaitezutiliserce

produitavecun gazde p_trole liqu_fi_(GPL)qui contient plusde

10% debutane,vousdevezacheterun n_cessairedeconversion

au butanen°WB28K10589.Pourcommander,veuillezcomposer

le 1.888.664.8403ou le1.787.276.4051.Lenon-respectdecette

consignepourrait presenterun risqued'incendieoud'intoxication

au monoxydedecarbone.

Veuillezvousreporterauxconsignesdufabricantpourdetecter

la pr6sencedefuites.

L'installationdoitrespecterlesnormesenvigueurdansvotre

region.EnI'absencedecelles-ci,lacuisinieredoit@treinstall@

suivantladerniereeditionducodenationalpourlesappareils

augaz,ANSIZ223.!/NFPA54,et laderniereeditiondela norme

americainepourlesappareilselectriquesANSI/NFPA70.Au

Canada,I'installationdoit respecterlaIoienvigueurspecifieepar

la normecanadienneCAN/CGA-B!49.!pourlesappareilsau

gaznatureloulanormeCAN/CGA-B!49.2pourlesappareilsau

propaneenvigueur,etsesloisquientrentdanssondomaine

d'application.Cettecuisinierea eteco%ueetcertifi@eCSAetdans

lerespectdeladerniereeditiondelanormeANSIZ2!.!, ainsique

I'Associationcanadiennedugazet danslerespectdeladerniere

_ditiondelanormeCAN/CGA-!.!.

27

Page 28

Caract ristiques

TABLE DES MATII_RES

Caract_ristiques

IVlod_les disponibles ............................................................28

Accessoires du dosseret ...................................................28

Dimensions du produit et espaces requis ........29-32

Outils et mat#riel requis ..................................................33

Preparation de I'installation

Emplacement des alimentations ..................................34

Consignes d'installation

I_tape 1, Sortez I'appareil de son emballage ...........35

I_tape 2, D#placez la cuisini_re 0 I'int#rieur .............36

I_tape 3, Installez le support anti-basculement ....37

I_tape 4, Raccordez la cuisini_re

6 I'alimentation en gaz ...................................38

MODI_LES DISPONIBLES

Les cuisini_res Monogram sont congues en usine

pour fonctionner au gaz naturel ou au goz propane.

Commandez le module correspondont _ votre

installation domestique.

ModUles au gaz naturel 48" 1122 cm):

ZGP484NG- 4 brOleurs6 gaz, grill et plaque chauffante

ZGP486NR- 6 brOleurs 6 gazet grill

ZGP486ND - 6 brOleurs 6 gazet plaque chauffante

Mod@les au gaz propane 48" (121 cm) :

ZGP484LG- 4 brOleurs 6 gaz,grill et plaque chauffante

ZGP486LR - 6 brOleurs 6 gazet grill

ZGP486LD - 6 brOleurs 6 gazet plaque chauffante

I_tape 5, Branchez lacuisini_re 6 laprise#lectrique......38

I_tape 6, Placez la cuisini_re dans sa position

en la fuisant rouler ............................................39

I_tape 7, Ajustez le niveau de la cuisini_re ...............40

I_tape 8, R#instullez les portes du four .......................40

I_tape 9, V#rifiez les br01eurs ...........................................41

I_tape 10, V#rifiez le fonctionnement

des br01eurs de cuisson du four ..............41

I_tape 11, R#glez le br01eur de cuisson

depuis le valet d'obturation .............41, 42

I_tape 12, V#rifiez le fonctionnement du br01eur

du gril du four ...................................................42

Terminez I'installation ........................................................42

Liste de v#rification pour I'instullation .......................42

Accessoires ..............................................................................43

Installation des accessoires ...................................44-46

Conversion de la cuisini_re pour le gaz ............47-51

Mod@les au gaz naturel 36" (91 cm):

ZGP366N - 6 brOleurs6 goz

ZGP364NR - 4 br01eurs (_gaz et grill

ZGP364ND - 4 br01eurs 6 gaz et plaque chouffonte

Mod@les au propane 36" (91 cm):

ZGP366L - 6 br01eurs (_gaz

ZGP364LR - 4 br01eurs (_gazet grill

ZGP364LD - 4 br01eurs 6 gozet plaque chauffante

Mod@le au propane :30" (76 cm) : ZGP304N

Mod@les au gaz naturel 30" (76 cm) : ZGP304L

DOSSERET

Tous les modules requi_rent au minimum 12"

(30 cm) d'espace de s6paration arri@re avec route

surface inflammable. S_cet espoce est int#rieur

0 12" (30 cm), la totalit@ de Io surface du mur se

trouvant derri@re et au-dessus de la cuisini@re doit

@tre prot@g6e par un dosseret. Le dosseret doit #tre

fabriqu# (_I'oide d'une mati@re ignifuge comme le

m@td, la tuile en c@ramique, la 5rique, le morbre

ou tout autre pierre.

Deu× dosserets sont disponibles :

• II existe un dosseret de 12" (30 cm) en acier

inoxydable. Utilisez ce dosseret coupl@ 0 un

dosseret sp@cial et ignifuge mont@ au-dessus

du premier. Lo hauteur des deux dqsserets

combin6s doit atteindre la pattie int#rieure

de Io hotte, ou en I'absence de hotte, la hauteur

totale (_portir de.la surface de cuisson doit

otteindre les 48" (122 cm).

• Iexist un dosseret adjustable de Z0" (76cm) - 36"

(91cm). Cedosseret comble I'espace entre

le dessus de la cuisini%re et a partie inf#rieure

de la hotte. L'#tag%re est congue pour que les

ampoules d'une hotte professionnelle Monogram

soient orient%es vers elle.

_ Dosseretde30cm,48 cm (12")dehauteur

28

ZX12B48PSS,pour lescuisini_resde 121cm (48")

ZX12B:36PSS,pour lescuisini_resde 91cm (36")

ZX12BZOPSS,pour lescuisini_resde 76cm (50'1

Dosseret(_hauteurr@glageavec@tagere

76cm-91cm (30"-36")

ZXADJB48PSS,pourlescuisinieresde121cm(48")

ZXADJB36PSS,pourlescuisinieresde91cm(361

ZXADJB30PSS,pourlescuisinieresde76cm(301

Page 29

Caract ristiques

DIMENSIONS DU PRODUIT ET ESPACES DE SI_PARATION

ModUles de cuisini_re 121 cm (48")

1-1/2"

47-7/8" (117,15 cm) ...._"

de largeur ....... travail

i (3,8cm) Plan de

a surface

de cuisson

Emplacements de raccord universels

_______2

(82'0,32cm)

23" 6"

35-1/4"(88,26cm)

to

363/4"(90,8cm)

dehauteur

28-1/4"

(70,48 cm)

Profondeur

jusqu% I'avant

de la porte

.4,AVERTISSEMENT:

Pour les installations d#pourvues

de hotte, pr#voyez au minimum un

espace de 48" (122 cm) entre I'appareil

et toute mati@e inflammable. IIest

possible d'installer une hotte sp#ciale

proximit# d'#l#ments horizontaux

inflammables dans la mesure o@celle-

ci dispose d'une fonction de mise en

marche automatique. Pour obtenir les

sp#cifications d'espace pour d'autres

installations pourvues d'une hotte,

veuillez vous reporter aux instructions

fournies avec celle-ci.

La totalit@ de la surface du mur arri@e

ainsi que la surface se trouvant

au-dessus de la table de cuisson

doit _tre faite d'une mati@e ignifuge

comme le m#tal, la tuile en c#ramique,

la brique, le marbre ou tout autre

pierre.

3-1/4" (6,98 cm)

4-3/4" (8,25 cm)

Plinthe/ _'

Hauteur de pied

to

--I-

A48" (122 cm)

inflammable

6-1/2"

(13,97 cm)

_,,

(7_8cm)

-- (121 cm)

\\

\\ 30 cm (12")au moins

, par rapport au mur

18"

45,7 cm) Hin.

48" (121 cm) min.

2" (5 cj)

adjacent.

NOTE:Toutes les ouvertures dans

le plancher ou le mur derri@e ou en

dessous de I'appareil doivent #tre

scell_s.

ESPACES SUPPLI_MENTAIRES :

Pr@voyezun espace minimum de 30 cm (12") par rapport au

mur adjacent sur chaque c6t@.

Les espaces de transit autour de la table de cuisson doivent

@tres@par@espar un espace d'au moins 45,7 cm (18") entre

le plan de travail et le bas du placard mural.

29

Page 30

Caract ristiques

DIMENSIONS DE L°APPAREIL ET ESPACES

ModUles de cuisini_re 91 cm (36") Caract_ristiques

35-7/8" :_ 1-1/2"

Largeur ....."_

de {86,67 cm) , travail

(3,8 cm) Plan de

6 surface

de cuisson

Emplacements de raccord universels

b

35-1/4"(88,26cm)

to

36-3/4"(90,8cm)

de hauteur

3-1/4" (6,98 cm)

4-3/4" (8,25 cm)

28-1/4" Plinthe/

Profondeur Hauteur de pied

jusqu'6 I'avant

de la porte

-&AVERTISSEMENT:

Pour les installations d_pourvues

de hotte, pr#voyez au minimum un

espace de 48" (122 cm) entre I'appareil 13" " "-

et toute mati_re inflammable. II est (33 cm) max

possible d'installer une hotte sp#ciale

6 proximit# d'#l#ments horizontaux

inflammables dans la mesure at] celle-

ci dispose d'une fonction de mise en

marche automatique. Pour obtenir les

sp#cifications d'espace pour d'autres

installations pourvues d'une hotte,

veuillez vous reporter aux instructions

fournies avec celle-ci.

La totalit# de la surface du mur arri_re

ainsi que la surface se trouvant

au-dessus de la table de cuisson

dolt #tre faite d'une mati_re ignifuge

comme

le m_tal, la tuile en c_ramique,

la brique, le marbre ou tout autre

pierre.

#_-_ _ 4-5/8" (8,57 cm)

/13-3/8 '' 11-3/8"

(37,02 cm) (26,98 cm)

6-1/2"

(13,97cm)

to

-- 36"

f

#,48" (122 cm) ',

de toute mat6riau

inflammable

\\

\

\

\

2" ('5cm)

(91 cm)

\\

\

\

', 30 cm (12") au

', mains par rapport

' au mur adjacent.

18"

(45,7 cm) iVtin.

Minimum 12"

(30,4cm)de

chaque

36"

(76 cm) Min.

2" (5 cm)

le plancher ou lemur derriere ou en

dessous de I'appareil doivent #tre

INOTE :Toutes les ouvertures dans

scell_s.

ESPACES SUPPLI_MENTAIRES :

Pr_voyez un espace minimum de 30 cm (12") par rapport

au mur adjacent sur chaque c6t_.

Les espaces de travail autour de la table de cuisson doivent

_tre s_par_es par un espace d'au mains 45,7 cm (18") entre

le plan de travail et le bas du placard mural.

30

Page 31

Caract ristiques

DIMENSIONS DE L°APPAREIL ET ESPACES

ModUles de cuisini_re 76 cm (30")

1"

(2,5cm) Plan de

_, 6 surface

35-1/4" (88,26cm)

to

36-3/4"(90,8cm)

de hauteur

28-1/4"

(70,48 cm)

Profondeur

jusqu'6 l'avant

de la porte

_-d cuisson

Hauteur de

travail

I/I 3-1/4" (6,98 cm)

II! to

4-3/4" (8,25 cm)

Plinthe/ 1

pied

Emplacements de raccord universels

11-3/8" 7-3/8"

(26,98 (ll_8L_tm)

\

', 30 cm (12") au

', moins par rapport

, au mur adjacent.

Zl,AVERTISSEHENT:

Pour les installations d_pourvues

de hotte, pr_voyez au minimum un ,_..---'7_-_

espace de 48" (122 cm) entre 13,,_ --i,I

I'appareil et toute mati_re inflammable. (33 cm) max.

IIest possible d'installer une hotte

sp#ciale a proximit# d'#l#ments

horizontaux inflammables dans

la mesure oOcelle-ci dispose

d'une fonction de mise en marche

automatique. Pour obtenir les

sp#cifications d'espace pour d'autres

installations pourvues d'une hotte,

veuillez vous reporter aux instructions

fournies avec celle-ci.

La totalit_ de la surface du mur arri@e

ainsi que la surface se trouvant

au-dessus de la table de cuisson

dolt _tre faite d'une mati@e ignifuge

comme

le m#tml, la tuile en c#ramique,

la brique, le marbre ou tout autre

pierre.

le plancher ou lemur derriere ou en

dessous de I'appareil doivent #tre

NOTE :Toutes les ouvertures dans

scell#s.

18"

(45,7 cm) Min.

30"

........(76 cm) Min.

ESPACES SUPPLI_MENTAIRES:

Pr_voyez un espace minimum de 30 cm (12") par rapport

au mur adjacent sur chaque c6t_.

Les espaces de transit autour de la table de cuisson doivent

@tres@par@espar un espace d'au moins 45,7 cm (18") entre

le plan de travail et le bas du placard mural.

31

Page 32

Caract ristiques

DIMENSIONS DE L°APPAREIL ET ESPACES

ModUles de cuisini_re 76 cm (30"), 91 cm (36") et 121 cm (48")

28-7/8" (68,89 cm) I_

jusqu'au bord

avant

3-3/16" Profondeur

du panneau de

commande 7,14 cm;

Dosseret

en option

10-1/2" (24,13 cm) = .............................I_

13/16" (2 cm) I_ 4

A

12"

30-36" (:30cm)

(76-91 cm) li,

V v

41 ................

A A

1-1/2"

(3,8 cm)

35-1/4" (88,26 cm)

6

36-3/4" (89,53 cm)

V

30,5 cm (12") min par rapport

aux mat@iaux inflammables ou 0

par rapport aux mat@iaux

ignifuges au-dessus de la surface

de cuisson

28-1/4" (70,48 cm)

jusqu'au bord

en biseau du chanfrein

)

7" Hauteur du panneau

de commande (17,78 cm)

arrondi du panneau

de commande

27-1/2" (67,31 cm)

I)-

par rapport au

borden biseau -

Profondeur

maximum

du placard

..............................

adjacent pour

un encastrement

parfait

j41 28-1/4"(70,96 cm)jusqu'6 I_

I'avant de la porte

_4t 31-1/16" (78 58 cm) I_

j jusqu'6 I'avant de la poign6e

i

J4 48-1/4" (121,28 cm)

( avec la porte du four ouverte

J

i j

i

i

m

i

AVERTISSEMENT :

Le un dosseret de 12" (30 cm) en acier

inoxydable dolt @treinstall@avec un

dosseret ignifuge personnalis@.

Le dosseret fini dolt recouvrir la totalit6

du mur arri@rejusqu'au bas de la hotte,

ou en I'absence de hotte, 48" (121cm)

aux mat@riaux inflammables.

32

Page 33

Consignes d'installation

KIT HAUTE ALTITUDE WB28K10553

Pour une utilisution 5 une altitude sup#rieure 5 900

m (6000 pieds), commundez le kit de conversion

WB28K10553. Ce kit comprend des orifices pour

un fonctionnement au gaz naturel et au propane.

KIT DE RI_DUCTION DES

CARACTI_RISTIQUES NOMINALES

WB28K10554

(For a small kitchen environment.)

Kit de conversion de r#duction des curuct#ristiques

nominales pour le module ZDP304N (gaz nuturel

uniquement). Ce kit comprend des orifices pour

r#duire la puissance du brOleur de surface au

niveau de 40,000 BTU.

MATI_RIEL FOURNI

Coude de

raccordement Lubrifiant

de tuyau pour grille

(12,7 mm) 1/2" de four

Support

antid@apant,

#querre et vis

Cules

(pour

prot#ger

le sol)

OUTILS NI_CESSAIRES

Perceuse et

Scie sauteuse

M_tre

Equerre de maqon

Lunettes protectrices

Tournevis cruciforme

2

Niveau Diable

forets adapt#s

CI#anglaise

Tournevis ou cl6 5

molette 1/4" (0.63 cm)

MATI_RIEL NI_CESSAIRE (non fourni)

33

Scellant Raccords de tuyau Clapet de

ajoint fermeture

Tuyau m6tallique flexible d'alimentation de gaz

agr## CSA de 1,58 cm de diam@tre et d'une

Iongueur maximale de 1,5 m (5 pieds)(Longueur

maximum de 90 cm (3 pieds) dans

le Massachusetts uniquement)

REIVlAROUE: procurez-vous un tuyau flexible neuf,

n'utilisez pas un tuyau ayant d6j5 #t# utilis&

Page 34

Preparation de I'installation

EMPLACEMENT DES ALIMENTATIONS

Alimentation de gaz :

•Les modules (]u g(]z n(]turel ont #t# conqus pour

fonctionner (_une pression de 5" (12,7 cm) colonne

d'eau. Pour un fonctionnement optimal,

la pression du gaz naturel qui alimente le

r6gulateur doit se situer entre 7" (17,8 cm) et 13" (33

cm) colonne d'eau.

•Les modules ou propone ont St# congus pour