Page 1

GE Monogram

Installation

Instructions

Component

Cooktop

System

®

Models

ZEW145

ZGW124

ZGW125

ZEW155

ZEW166

ZEW176

www.monogram.com

Page 2

Before you begin—Read these instructions completely and carefully.

IMPORTANT: Save these instructions for local inspector’s use.

IMPORTANT: OBSERVE ALL GOVERNING CODES AND ORDINANCES.

NOTE TO INSTALLER: Be sure to leave these instructions with the Consumer.

NOTE TO CONSUMER: Keep these instructions with your Owner’s Manual for future

reference.

WARNING

This appliance must be properly grounded. See “Electrical Supply”, page 13.

For Monogram local service in your area,

1-800-444-1845.

If you received a damaged component, you

should contact your dealer.

For Monogram service in Canada,

1-888-880-3030.

For Monogram Parts and Accessories, call

1-800-626-2002.

CAUTION: FOR PERSONAL SAFETY,

REMOVE HOUSE FUSE OR CIRCUIT

BREAKER BEFORE BEGINNING

INSTALLATION.

These appliances must be supplied with the

proper voltage and frequency, as listed on

page 18. Connect to an individual, properly

grounded branch circuit breaker or time delay

fuse. Proper electrical ratings should be

verified with listing on product’s rating plate.

Installation of these components require basic

mechanical skills. Proper installation is the

responsibility of the installer.

other naturally vented systems. To minimize

the chance of interference with such naturally

vented systems, follow the heating equipment

manufacturer’s guidelines, and local codes.

Also follow the guidelines in ASHRAE

Standard 62-1989, “Ventilation for Acceptable

Indoor Air Quality”, section 5.8. When

following these guidelines, be sure to test for

proper airflow direction into the draft hood of

a naturally vented gas furnace or water heater.

This can be checked by striking a match,

Wiring must conform to the requirements of

the National Electrical Code. If the electric

supply provided does not meet the specifications, call a licensed electrician.

blowing it out, and while it is still smoking,

holding it near the draft hood relief opening.

If smoke is drawn into the opening, vent flow

is in the proper direction. If the ASHRAE

Standard 62 guidelines are not satisfied, a

WARNING:

Any home ventilation system, such as a

positive supply of outside air may have to be

supplied.

cooktop with a downdraft mechanism, may

interfere with the proper flow of exhaust

products or combustion air required by gas

furnaces, gas water heaters, fireplaces, or

In the absence of local codes, the gas cooktop

must comply with the National Fuel Gas Code,

ANSI Z223.1, latest edition.

Contents

2

Models Available .................................................. 3

Product Dimensions ........................................ 3, 4

Installation Accessories........................................5

Advance Planning ................................................ 5

Installation Options .............................................5

Installation Rules ................................................. 5

Installation Location............................................ 6

Tools & Materials Required ................................ 7

Cutout Information .................................... 7, 8, 9

Venting Options ................................................. 10

Ductwork Advance Planning ............................. 10

Optional Ductwork Arrangement .................... 10

Determine Ductwork Location .........................11

Install Blower Assembly .....................................11

Finalize Ductwork .............................................. 11

Duct Fittings ....................................................... 12

Gas Supply Location ..........................................13

Electrical Supply ................................................13

Step 1: Apply Gasket Strip .................................14

Step 2: Remove Knobs, Gates ............................ 14

Step 3: Joining Multiple Cooktops ...... 14, 15, 16

Step 4: Secure Cooktop(s) to Countertop ....... 16

Step 5: Connect Gas ...........................................17

Step 6: Connect Electrical .......................... 17, 18

Electrical Power Requirements .....................18

Finalize Installation............................................ 19

Page 3

Design Information

14-1/2"

21-5/16"

2-1/4"

5-1/2"

Shipped With

Discharge On

Left Side

Component Cooktop System

Models

Available

Product

Dimensions

Monogram Component Cooktop System

offers cooking flexibility with modular

cooktops in a variety of cooking technologies

to meet any cooking need.

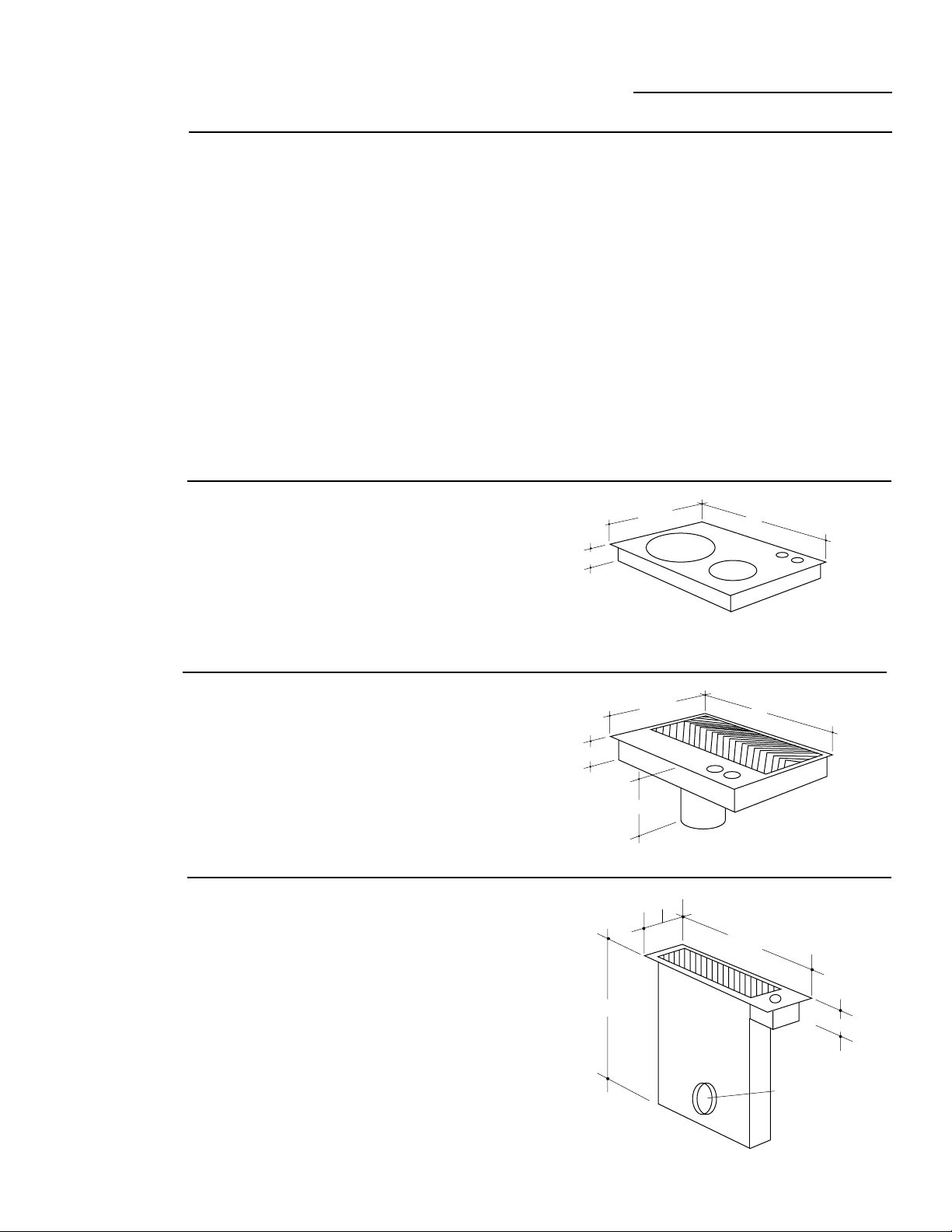

ZEW145

Radiant Cooktop Component

ZEW155

Updraft Grill Cooktop Component,

ZEW166

Downdraft Grill Cooktop Component

ZEW176

Downdraft Vent Component

ZEW145

Radiant Cooktop Component

(240 and 208 volt, dual rated)

Parts supplied:

• 44" flexible conduit

• One joiner strip

• Two sets clamping screws

• One chassis support brace

ZGW124

Gas Cooktop Component,

with right hand controls

ZGW125

Gas Cooktop Component,

with left hand controls

JXBA55 blower motor assembly is supplied

for the downdraft vent and downdraft grill.

JXBC55 optional outdoor cover accessory

may be ordered for installation of blower and

motor assembly on an outside wall.

15-1/2"

*3-1/4"

*Allow additional 1" depth for clearance

of flexible conduit

21"

ZEW155

Updraft Grill Cooktop Component

(240 volt)

Parts supplied

• Grease collection jar

• 48" flexible conduit

• One joiner strip

• Two sets clamping screws

• One chassis support brace

ZEW176

Downdraft Vent Component

Install next to gas or radiant components.

(Cannot be installed next to an updraft grill)

(120 volt)

Parts supplied:

• 48" flexible conduit

• Two downdraft joiner strips

• One downdraft endcap

• JXBA55 blower motor assembly

NOTE: The downdraft plenum is shipped with the discharge

outlet on the left side. It can be changed to the right side.

5-3/8"

16-3/8"

10"

21"

3

Page 4

Design Information

Component Cooktop System

Product

Dimensions

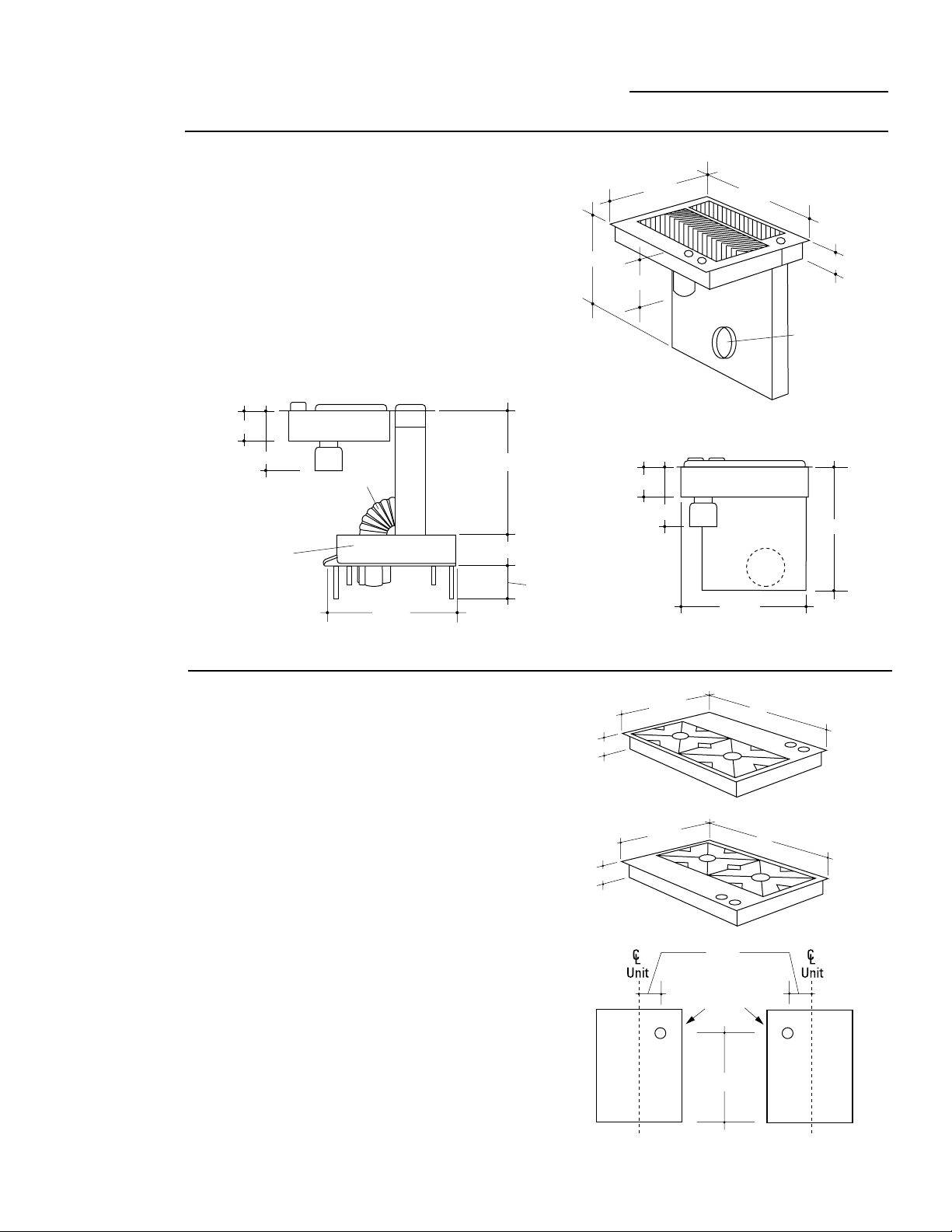

ZEW166

Downdraft Grill Cooktop Component

(240 volt)

Parts supplied:

• Grease collection jar

• 48" flexible conduit

• One set clamping screws

• One downdraft joiner strip

• JXBA55 blower motor assembly

NOTE: The downdraft plenum is shipped with the discharge

outlet on the left side. It can be changed to the right side.

5-3/8"

10"

Blower

Motor

Assembly

6"

90°

Elbow

14-1/2"

3-1/4"

17-1/2"

Adjustable

5" to 8"

14-1/2"

21-1/2"

10"

5-3/8

21-5/16"

5-3/8"

Shipped With

Discharge On

Left Side

10"

14-1/2"

16-3/4"

Front View, Downdraft Grill With Blower Motor Assembly Left Side View, Downdraft Grill

ZGW124

Gas Cooktop Component,

with right hand controls

3-1/4"

15-1/2"

ZGW125

Gas Cooktop Component,

with left hand controls

15-1/2"

Parts supplied with each:

• 1/2" inlet pipe

• Pressure regulator

3-1/4"

• One joiner strip

• Two sets clamping screws

• One chassis support brace

NOTE: Gas components are designed for natural

gas operations and cannot be converted to LP

4-7/16"

Top View

Countertop

Cutout

operation.

Gas

If installation includes a drawer beneath gas

cooktop, make allowance for gas inlet pipe.

Inlet

Pipe

17-1/8"

Gas inlet extends 1-1/4" from bottom.

ZGW124

Right Hand

Controls

21"

21"

Gas

Inlet

Pipe

ZGW125

Left Hand

Controls

4

Page 5

Design Information

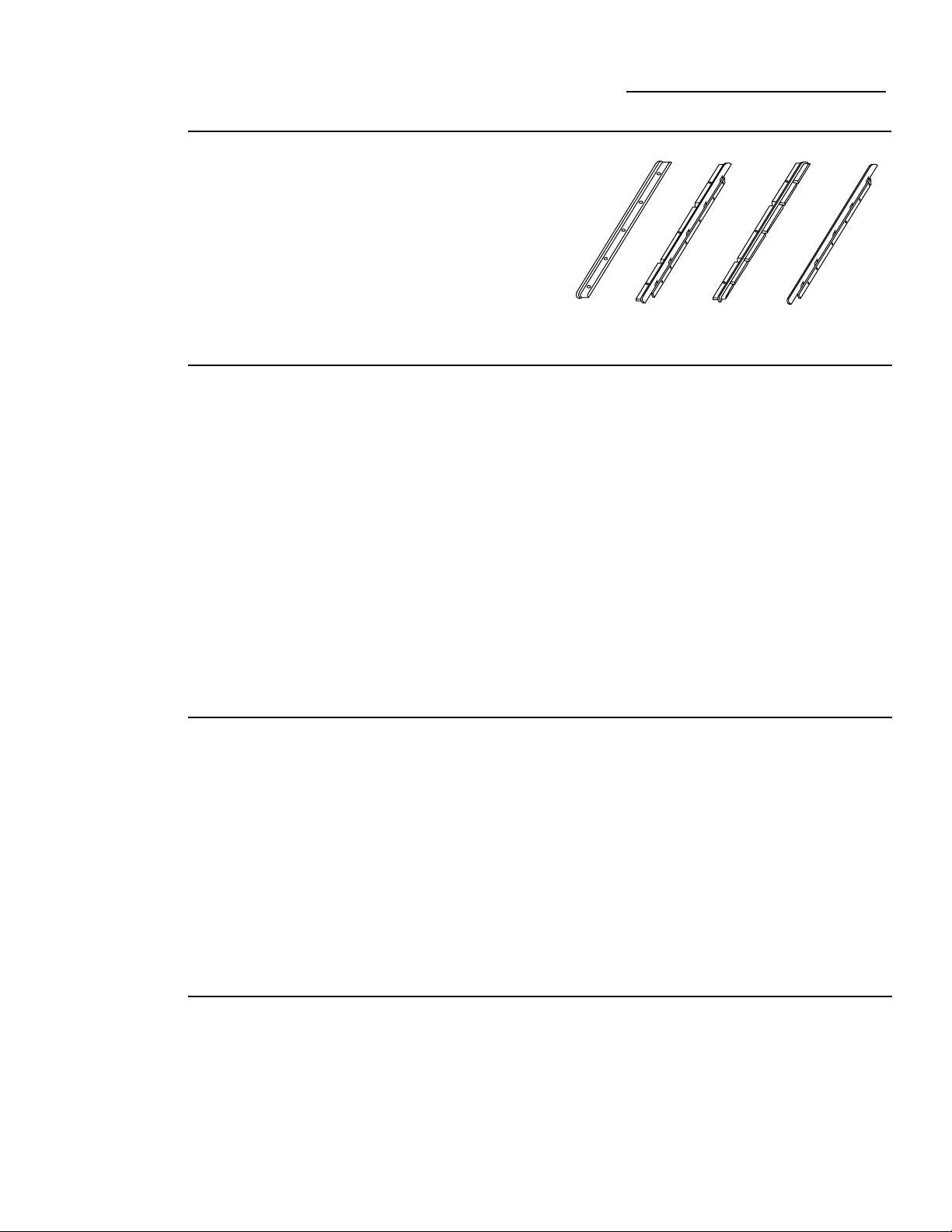

End Cap Downdraft Joiner Downdraft

Joiner End Cap

Component Cooktop System

Installation

Accessories

Provided

Advance

Planning

Joiner strips and end caps are included to

provide a finished look to any modular

cooktop arrangement.

• Consider base cabinet storage arrangements

to accommodate the downdraft blower/

motor assembly.

–The downdraft plenum assembly will occupy

the cabinet below the cooktop. Drawers

cannot be installed below the downdraft

vent or downdraft grill components. The

blower may be installed in the cabinet or

located downstream from the plenum in

the duct run.

–Shorter length drawers may be installed

below gas components, allowing for gas

inlet clearance.

• Do not cut holes for ductwork locations until

components are on-site, with countertop in

place, and all pre-planned locations are

confirmed.

• Always pre-plan electrical and gas

connections to be accessible at the time of

installation.

• Consider the distance to power supply, cable

length and bending restrictions before

cutting holes.

• Gas components are not convertible to liquid

propane operation.

• In the absence of local codes, the gas cooktop

must comply with the National Fuel Gas

Code, ANSI Z223.1, latest edition.

UL, A.G.A. approved.

Installation

Options

Installation

Rules

• Multiple gas and electric components can be

combined to form one custom cooking

arrangement.

–Multiple electric components can operate

from a single junction box, if local codes

permit.

–Multiple gas components can operate from

a manifold, as permitted by local codes.

• Updraft components can be vented

according to normal exhausting methods.

• The downdraft vent and grill blower assembly

may be vented downwards to the left or right

sides or through the floor. See page 11.

• Never vent a cooktop into an interior space always to the outdoors.

• The updraft grill requires an overhead vent

with at least 300 CFM.

• DO NOT install an updraft grill component

next to a downdraft vent.

–The motor blower assembly can be

mounted in the cabinet or under the floor.

The blower will fit between floor joists on

16" centers.

–The plenum on the downdraft grill and

vent is shipped with the discharge on the

left side. It can be changed to discharge

from the right side.

• JXBC55 optional outdoor cover accessory

may be ordered for installation of blower

and motor assembly on an outside wall.

• DO NOT install a downdraft vent behind a

cooktop.

• DO NOT install a gas or grill cooktop where

the knobs are between the heated area and

the downdraft vent.

5

Page 6

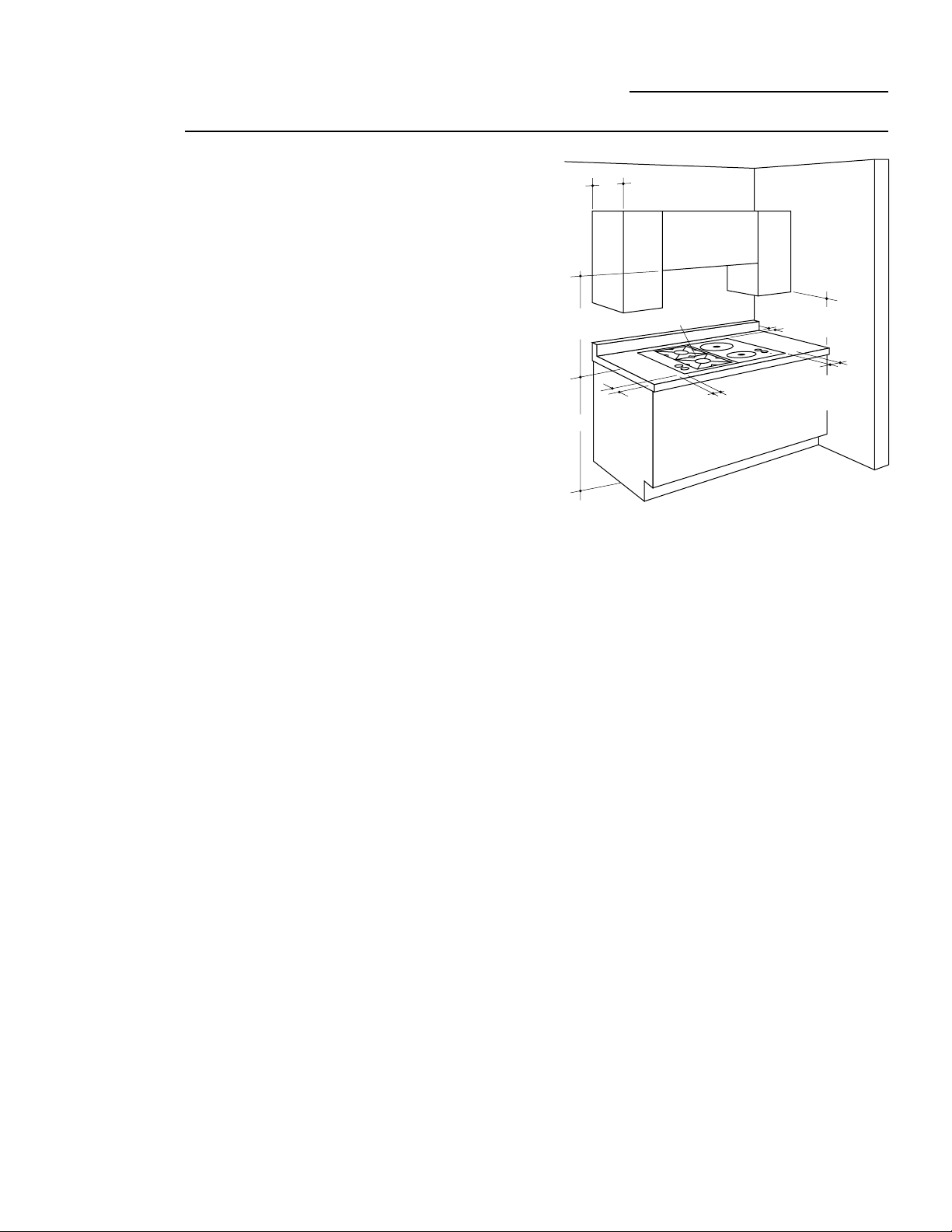

Cabinetry

13"

Max

*1" Min.

to Wall

*2" Min.

to Front

Edge

36"

18"

Min.

**1" Min.

to Wall

* Gas in side to side orientation

requires 2" min. to rear wall.

** Gas requires 2" min. to side wall.

One or

More

Component

Cooktops

30"

Min.

*1" Min.

to wall

Component Cooktop System

Installation

Location

• Whenever possible, avoid placing cabinetry

directly above the cooking surface.

• If cabinetry is used above the cooking

surface:

–Use cabinets no more than 13" deep.

–Maintain 30" minimum clearance between

cooktop(s) and unprotected cabinets

directly above the cooktop.

–If clearance is less than 30", protect cabinet

bottoms with flame-retardant millboard at

least 1/4" thick or gypsum board at least

3/16" thick covered with 28 gauge sheet

steel or .02" thick copper.

–Clearance between cooktop and protected

cabinetry must not be less than 24".

–Working areas next to the cooktops should

have 18" minimum clearance between the

countertop and the cabinet bottom.

EXCEPTION: Installation of a listed

microwave oven or cooking appliance over the

cooktop(s) shall conform to the installation

instructions packed with that appliance.

• Installation must conform with local codes.

Clearances:

• When installed electric components require

the following clearances:

– 2" min. from front of cooktop to front edge

of countertop,

–1" min. from back of cooktop to rear wall,

–1" min. from side of cooktop to side wall.

Gas components require:

–2" min. from back of cooktop to rear wall,

–2" min. from side of cooktop to side wall.

6

Page 7

Cabinetry

Component Cooktop System

Tools &

Materials

Required

(Not supplied)

Cutout

Information

• Carpenter’s square

• Measuring tape

• Saw

• #2 Phillips head screwdriver bit socket

• Phillips screwdriver

• 1/4" nutdriver

• 5/16" nutdriver

• 7/16" and 5/16" socket and ratchet wrench

• Pencil

• Scissors

• Level

• Hole saw

• 6" 90° elbow

• Duct work to suit the installation.

4" Minimum Between Cutouts

4"

For Gas Components:

• Pipe wrench

• Gas line to reach installation location

• Gas resistant pipe joint sealant.

• Manual gas line shut-off valve

• 3/4" NPT x 3/4" I.D. or 1/2" NPT x 1/2"

I.D. flare union adapter

• 1/2" NPT x 3/4" I.D. or 1/2" I.D. flare union

adapter

• 5 foot AGA certified flexible metal appliance

connector, 3/4" x 1/2" I.D. to match gas

supply line.

–If required by local codes, use solid pipe

with fittings.

NOTE: Use new flexible line. DO NOT use old,

previously used flexible line.

4" Minimum Between Cutouts

4

Front to Back Orientation

• Minimum clearance is 4" between cooktops

in separate cutouts. This clearance does not

apply when multiple component cooktops

are installed in one cutout.

Find Dimension A in chart below and on the

following page.

1-7/8" Min. to

Rear Wall (2-7/8" for gas)

19-1/2"

1-3/4" Min.

to Side Wall

(2-3/4"

for Gas)

A

2-1/2" Min.

Front to Back Orientation

1-3/4" Min.

to Side Wall

Cut the opening as shown above. Measure

carefully when cutting countertop, making

sure sides are parallel and front and rear cuts

are perpendicular to sides.

• The front and rear of the opening must clear

support rails of the cabinet.

• The cutout depth (front to back) is 19-1/2"

for all components.

(2-3/4"

for Gas)

Side to Side Orientation

NOTE: Do not install a downdraft vent in a side to side

orientation behind a gas or radiant component. This

would require the user to reach over a heated surface

to access the control.

1-3/4" Min. to Rear Wall

(2-3/4" for gas)

A

1-7/8" Min.

to Side Wall

19-1/2"

(2-7/8"

for Gas)

2-1/2" Min.

Side to Side Orientation

1-7/8" Min.

to Side Wall

(2-7/8"

for Gas)

A

Radiant 14-1/2"

Gas 14-1/2"

Updraft grill 15-3/8"

Downdraft Grill 20-3/4"

Downdraft Vent 5-1/8"

7

Page 8

Cabinetry

Component Cooktop System

Cutout

Information

(Continued)

If your configuration is not shown in the previous

charts, use the following chart to calculate your cutout

Component/Connector Model/Name Width Quantity Sub Total Width

ZEW145 Radiant Cooktop

Component 14-1/2"

ZGW124

ZGW125 Gas Component 14-1/2"

ZEW166 Downdraft Grill

Component 20-3/4"

ZEW155 Updraft Grill

Component 15-3/8"

Downdraft Vent

ZEW176 Component 5-1/8"

Connection between

two cooktops (including

updraft grill and non-vent

Joiner Strip side of downdraft grill) 3/4"

size. For each of the following components, add the

dimensions given.

Cutout

Information:

Multiple

Components

Example

Connection between

cooktop and

Downdraft downdraft vent or vent

Joiner Strip side of downdraft grill 1/4"

Provide finished look to

Cooktop and component cooktop

Downdraft arrangement. Do not

Vent End count as part of

Caps cutout width. 0" 0"

Total Cutout Width

A = 14-1/2" + 3/4" + 14-1/2" + 1/4" + 5-1/8" + 1/4" + 14-1/2" = 49-7/8" Total

*

*Endcaps Do Not

Add to Cutout

A

8

Page 9

Cabinetry

Component Cooktop System

Cutout

information:

multiple

component

units

If multiple components will be attached together, determine dimension A from the

following:

Unit 1 Unit 2 Unit 3 Unit 4 Unit 5 A

Radiant Radiant 29 -3/4"

RH Gas RH Gas

LH Gas LH Gas

Radiant Updraft 30-5/8"

Grill

RH Gas

LH Gas

Updraft Updraft 31-1/2"

Grill Grill

Downdraft Radiant 19-7/8"

Vent*

RH Gas

Downdraft Radiant 35-1/2"

Grill

RH Gas

Radiant Downdraft Radiant 34-5/8"

Vent*

LH Gas RH Gas

Downdraft Radiant Radiant 50-3/4"

Grill

RH Gas RH Gas

LH Gas

Radiant Downdraft Radiant Downdraft Radiant 54-3/4"

Vent* Vent*

Downdraft Radiant LH Gas Downdraft Radiant 55-1/4"

Vent* Vent*

RH Gas RH Gas

Radiant Downdraft Downdraft Radiant 55-5/8"

Vent* Grill*

LH Gas RH Gas

*See “Venting rules” concerning placement of knobs in relation to downdraft vent.

If your configuration is not shown, refer to following page.

9

Page 10

Venting

Options

Ductwork

Through Floor Between Joists Through Floor & Under Joists

Multiple cooktops and downdraft vent units

may be used in a single arrangement.

• Plan the route for venting exhaust to the

outdoors.

• Ductwork must be vented to outdoors - never

to a crawl space, attic or other enclosed space.

• Duct should be located between floor joists or

wall studs whenever possible.

• Blower and motor assembly can be installed

on an outside wall. JXBC55 optional outdoor

cover accessory is required and must be

ordered with each downdraft venting unit.

• Every downdraft vent and downdraft grill

must have it’s own, separate duct run.

Component Cooktop System

Direct To Outdoors

Inside Wall

To Roof

With JXBC55 Mounted

On Outside Wall

Ductwork

Advance

Planning

Optional

Ductwork

Arrangement

• Use the shortest and straightest duct run

possible.

–Duct run for Downdraft Grill Component,

ZEW166, should not exceed equivalent

length of 100 feet.

–Duct run for Downdraft Vent, ZEW176,

should not exceed equivalent length of

150 feet.

–Refer to “Duct Fittings” chart to calculate

equivalent length for various duct

configurations.

6" PVC duct should be used when installing

under a concrete slab.

• Use recommended wall caps with damper.

Do not use laundry type wall caps.

• Ductwork must be vented to the outside.

• Each cooktop blower system requires a

separate duct system.

NOTE: Local building code must be followed for installation and in

specifying approved type and schedule of PVC duct used.

• The downdraft blower system is designed for

use with 3-1/4" x 10" ductwork. It can be

transitioned to 6" round.

• Ductwork MUST be vented to the outside –

never into a crawl space, attic or other

enclosed space.

10

Page 11

Determine

Ductwork

Ductwork

Component Cooktop System

Location

6" 90° Elbow

(not Supplied)

Discharge left side (not to scale)

To accurately locate the ductwork holes in the

cabinet floor:

• Place all components into the cutout,

arranged in the exact position they will be

installed.

• Place a 90° elbow over the discharge outlet

and into the blower motor assembly.

• Position the transition duct on the end of the

blower motor assembly.

• Mark the location and remove the

components and blower motor assembly.

• Cut holes and install ductwork connections.

• The discharge on the plenum is located on

the left side. To change to the right side,

remove 2 screws on each side of the plenum

below the cooktop flange. Rotate the plenum

and re-install screws.

6" 90° Elbow

(not Supplied)

Discharge right side (not to scale)

6" 90° Elbow

(not Supplied)

Discharge through the

floor (not to scale).

Install

Blower

Assembly

Finalize

Ductwork

Install blower

• The blower can be mounted in the cabinet or

under the floor. The blower will fit between

floor joists on 16" centers.

• For installation where the blower is mounted

inside the cabinet, attach the mounting

supports to the bottom corners of the blower

housing. (The motor is on the bottom side,

the 6" round opening is the top side).

• If the blower is installed under the floor,

attach the mounting supports to the top

corners (the side with the 6" round opening).

NOTE: Do not drill additional holes in the blower.

• Install ductwork, making connections in the

direction of airflow as shown.

• Secure all joints with sheetmetal screws.

• Wrap joints with duct tape for airtight seal.

• Install a wall cap with damper or roof cap at

exterior opening.

Adjust mounting supports

• Adjust the height of the mounting supports

by sliding the two halves up or down. With

supports at desired length, install bolts and

nuts into the supports.

• Secure the blower to the cabinet floor or

between floor joist with screws provided.

Duct Tape

Over Seam

and Screw

Airflow

Screw

11

Page 12

Ductwork

Component Cooktop System

Duct

fittings

Use copies of this

form to compute

maximum

permissable lengths

for duct runs to

outdoors.

ZEW166 Downdraft Grill

Component maximum

equivalent length is

100 feet.

ZEW176 Downdraft Vent

Component maximum

equivalent length is

150 feet

Note:

Do not exceed maximum

permissable equivalent lengths!

Flexible ducting:

If flexible metal

ducting is used, all

the equivalent length

values in the table

should be doubled.

The flexible metal

duct should be

straight and smooth

and extended as

much as possible.

Do NOT use flexible

plastic ducting.

CAUTION:

Any home ventilation system, such

as a cooktop with a downdraft

exhaust mechanism, may interrupt

the proper flow of combustion air

and exhaust required by fireplaces,

gas furnaces, gas water heaters

and other naturally vented

systems. To minimize the chance

of interruption of such naturally

vented systems, follow the heating

equipment manufacturer’s

guidelines and safety standards

such as those published by NFPA

and ASHRAE.

Equivalent Quantity Equivalent

Duct Piece Dimensions Length* Used Length

1 ft.

6" round, (per foot

straight length)

1 ft.

3-1⁄4" x 10" (per foot

straight length)

6"

90° elbow 15 ft.

6"

45° elbow 9 ft.

3-1⁄4" x 10"

90° elbow 15 ft.

3-1⁄4" x 10"

45° elbow 9 ft.

3-1⁄4" x 10"

90° flat elbow 20 ft.

6" round

to 3-1⁄4" x 10"

transition 1 ft.

3-1⁄ 4" x 10"

to 6" round

transition 5 ft.

6" round to

3-1⁄ 4" x 10"

transition

90° elbow 5 ft.

3-1⁄ 4" x 10" to 6"

round transition

90° elbow 15 ft.

6" round

wall cap

with damper 30 ft.

3-1⁄ 4" x 10"

wall cap

with damper 30 ft.

6" round

roof cap 26 ft.

6" round

roof vent 24 ft.

* Actual length of straight duct plus duct fitting

equivalent. Equivalent length of duct pieces are based

on actual tests conducted by GE Evaluation Engineering and reflect requirements for good venting

performance with any downdraft cooktop.

Total Duct Run

Total

12

Page 13

Gas and Electrical Supply

ZGW124

ZGW125

ZEW145

ZEW155

ZEW166

Component Cooktop System

Gas

Supply

Location

Electrical

Supply

• Gas components are designed to operate on

natural gas at 4" water column pressure.

These cooktops are supplied with 1/2" NPT

male gas connections. The connection for

models with right hand controls is on the

bottom right corner, and left hand control

models on the left corner.

• Gas components cannot be converted to LP

gas operation.

• Make gas connection through the rear wall,

or on the cabinet floor at the rear.

• For rigid connection, locate pipe stub:

–4-7/16" from center line of appliance,

–on the back wall, at least 12" below

countertop,

–on the floor, 2-1/2" forward of the back of

the countertop cutout.

For flexible connection, locate pipe stub on

floor or back wall in a convenient location.

• Install a manual shut-off valve in the gas line

in an easily accessible location.

The radiant component operates on 240/208

volt, 60 Hz. Updraft grill and downdraft grill

components operate on 240 volt, 60 Hz. Gas

and downdraft vent components operate on

120 volt, 60 Hz. from a separate junction box.

A dedicated circuit, protected by a time delay

fuse or circuit breaker is required for

cooktops. The downdraft vent requires an

appliance circuit with a time delay fuse of

circuit breaker.

4-7/16"

4-7/16"

12"

Min.

L.H. Gas Unit

R.H. Gas Unit

Gas Supply Options

Important: 12" min. is specified to allow space for shut-off valve

if supply is opted to enter from rear.

Note: Both left and right-controlled gas components are

illustrated together in order to compare their supply rough-in

locations.

2-1/2"

from Rear Edge

of Cutout

• If local codes permit, more than one cooktop

can be used on the same branch circuit. See

local codes or the National Electrical Code

for circuit demand loads.

WARNING: DO NOT USE AN EXTENSION

CORD WITH THESE APPLIANCES.

ZGW124/ZGW125

ZEW176

13

Page 14

Installation

Component Cooktop System

Step

1

Apply

Gasket Strip

Step

2

Remove

Knobs,

Gates

Step

3

Joining

Apply foam tape (supplied) on top surface of

countertop along all edges of the cutout.

• Turn all control knobs to OFF position.

• Carefully remove knobs by lifting straight up.

• Remove all grates, burner caps and vent

covers from components.

• Remove tape covering screw holes on the

downdraft grill.

Multiple

Cooktops

Remove

These Nuts

Cooktop

Joiner Strip

• Lay cooktops upside down on a clean flat

work surface.

• Remove endcaps on sides to be joined by

removing three nuts with a 5/16" nutdriver.

Discard nuts.

• Attach joiner strip to first cooktop by

tightening flanged nuts (supplied) over the

flanges.

Attach chassis support brace to equal-height

cooktops

• When attaching gas to gas, gas to radiant,

radiant to radiant or grill to grill, place

support brace as shown.

• Remove one screw from the center of each

cooktop chassis.

• Position brace and tighten screws.

• Repeat these steps for three cooktops.

• Place the two cooktops into the countertop

cutout.

• Slide the cooktops together so that the slots

in the joiner strip are engaged by the studs.

There should be no gaps between cooktops

and joiners. Press together firmly to assure a

tight fit.

• Place flanged nuts in end of 5/16" nutdriver.

Start nuts on studs and tighten from below.

14

Page 15

Installation

Front of Countertop

Downdraft

Endcap

Component Cooktop System

Joining

Multiple

Cooktops

(Continued)

Attach chassis support brace to different

height cooktops

• When attaching grill to radiant or gas, place

the support brace as shown.

• Remove one screw from the center of each

cooktop chassis.

• Position brace and tighten screws.

• Repeat these steps for three cooktops.

Downdraft

Joiner Strip

Joining Cooktop to Downdraft Vent

• Remove all grates, knobs, burner caps and drip

pans.

• Lay cooktop upside down.

• Remove endcap on side of cooktop to be joined

by removing three nuts with a 5/16" nutdriver.

Gas or

Halogen

Grill

Remove

These Nuts

Important: Pre-tap holes in downdraft joiner and

endcaps by driving supplied screws through

holes and then backing out before installation.

This will make the joining process easier.

• Replace endcap with downdraft joiner strip

using the same three nuts.

–If the vent is to be installed at the end of

the countertop opening, attach downdraft

endcap to that side.

• Place the downdraft vent and cooktop into the

cutout.

• Remove two screws from the front of cooktop

chassis. Drive the two screws into holes below

the downdraft vent flange as shown. Use a

phillips screwdriver bit socket.

• If downdraft vent is installed at the end of the

cutout, secure the downdraft endcap to the

countertop by driving two phillips head screws

as shown.

• To finalize installation, proceed to “Securing

cooktop(s) to countertop.

• If additional cooktop(s) are to be installed,

proceed to “Joining additional cooktop to

downdraft vent or downdraft grill.”

15

Page 16

Joining

Multiple

Cooktops

(Continued)

Installation

Component Cooktop System

Front of Countertop

Front of Countertop

Step

4

Secure

Cooktop(s)

to Countertop

Joining additional cooktop to downdraft vent

or to downdraft grill

• Remove endcap on the side of the next

cooktop to be joined.

• Pre-tap holes in downdraft joiner and

endcaps by driving supplied screws through

holes and then backing out before

installation. This will make the joining

process easier.

• Attach downdraft joiner strip to cooktop.

• Loosen screws on hold-down brackets at

each end of cooktop. Extend the bracket to

reach the underside of the countertop.

Tighten screws.

• Drive a long screw (2 lengths are provided)

through the bracket until screw is tight

against the bottom of the countertop.

• Place cooktop next to downdraft vent in the

cutout.

• Drive two phillips head screws into pretapped holes. Use a phillips screwdriver bit

socket.

• To install additional vent or cooktop(s),

refer to “Joining Multiple Cooktops.”

16

Page 17

Installation

3-Pin Connector

Component Cooktop System

Step

5

Connect

Gas

Step

6

Connect

Electrical

• Install the supplied pressure regulator in gas

supply line as close to the cooktop inlet as

possible. Allowances for ventilation ducting

may be required.

–The regulator should be installed with the

arrow pointing in the direction of gas flow.

• Install a manual gas shut-off valve where it

will be easily reached. Be sure the user knows

where and how to shut off the gas supply.

• Appropriate flare union adapters are

required at each end of a flexible connector.

• Turn on the gas and check for leaks. Use a

liquid leak detector at all connections in the

system. A pressure test fitting is located on

the pressure regulator.

NOTE: If local codes permit, use 5 foot AGAcertified flexible metal gas supply line. 3/4" or 1/2"

I.D. to match gas supply line.

Do not use old, previously used flexible line.

Connect electrical to downdraft vent

• Connect the 3-pin plastic plug from the

blower/motor assembly to the 3-pin plastic

socket on the underside of the vent controls.

• Fasten the wire box on the conduit over the

plug and onto the bottom of the control box

with screws provided.

CAUTION

Do not use a flame to

check for leaks.

1-1/4"

Regulator

Solid Piping

or Flexible

Connector

Shut-Off

Valve

Pipe Stub

The blower conduit is long enough to reach

the vent connection when installed in the

cabinet below. The conduit will also reach

some blower installations below the cabinet

floor.

• If the blower conduit is not long enough to

reach the vent connection, the leads can be

extended.

To add conduit length:

• Install an appropriate junction box near the

blower.

• Remove the wire box from the end of the

blower conduit.

• Cut the leads approximately 3" from the

plug.

• Cut a length of electrical cable to reach the

junction box. Use 14 gauge min. electrical

cable (or conform to local codes).

• Attach the wire box and plug to one end of

the cable. Connect opposite end of cable to

blower leads in the junction box.

Vent

Electrical Box

(with vent)

Power Cable

(not included

with vent)

Junction Box

(not included

with vent)

To Blower

17

Page 18

Installation

White

Black

Red

White or

Gray

Black

Branch Circuit Cooktop

3-Conductor Branch Circuit

Bare or

Green

+120V AC

-120V AC

Neutral

Component Cooktop System

Step

6

Connect

Electrical

(Continued)

3-Conductor branch circuit:

• Connect red lead to branch circuit red lead.

• Connect black lead to branch circuit black

lead.

• Connect bare or green conductor and white

lead * of the cooktop to branch circuit

neutral lead, which is white or gray.

4-Conductor branch circuit:

• Connect red lead to branch circuit red lead.

• Connect black lead to branch circuit black

lead.

• Break connection between cooktop white

lead to bare or green conductor.

• Connect cooktop white lead* to branch

circuit neutral lead, which is white or gray.

• Ground unit by connecting bare conductor

of cooktop to branch circuit bare or green

lead (ground lead).

The frames of these appliances are grounded

to neutral.

4-Conductor Branch Circuit

Branch Circuit Cooktop

+120V AC

Neutral

-120V AC

DND

Red

White or

Gray

Black

Bare or

Green

Red

White

Black

Bare or

Green

Electrical

Power

Requirements

* Updraft grill has no white neutral wire.

Connect only black, red and bare wires as

shown.

Model Voltage Frequency AMPS KW

ZGW124 120 60 Hz 1.0 ––

ZGW125 120 60 Hz 1.0 ––

ZEW145 208 60 Hz 11.0 2.3

ZEW145 240 60 Hz 12.7 3.0

ZEW155 240 60 Hz 7.3 1.8

ZEW166 240 60 Hz 13.5 3.3

ZEW176 120 60 Hz 1.8 ––

18

Page 19

Installation

Component Cooktop System

Finalize

Installation

Install downdraft vent filter

• Place filter into the opening and on top of

the supports.

• Place grille over the filter.

Electric Components:

Push in and turn each knob to high position.

Make sure each element heats up.

Gas Components:

(Electrical connections should be complete).

• Plug power cord into outlet.

• Assemble burner(s) as shown.

• Check for proper ignition:

–Push in control knob and turn 90° to HIGH

position.

• First test may require some time, while air is

flushed out of the gas line.

–Turn knob to OFF.

–Repeat the procedure for each burner.

Filter

Grille Removed

Control Knob

Burner

Grate

Burner Cap

Trim Ring

CAUTION

the burners until all burner parts

are in place.

Do not operate

19

Page 20

Monogram.

General Electric Company

Louisville, KY 40225

Note: While performing installations described in this book,

safety glasses or goggles should be worn.

For Monogram local service in your area, call

1-800-444-1845.

NOTE: Product improvement is a continuing endeavor at General

Electric. Therefore, materials, appearance and specifications are subject

to change without notice.

Pub. No. 49-8834-2

Dwg. No. 164D3333P076

®

Printed in USA

(N.D. 237) 8/01

953-0559-000 - Rev. 1

Loading...

Loading...