Page 1

GE Monogram ®

Installation

Instructions

30" Convection

Built-In Ovens

Models

7_2T8 575YS5

7_,T8 5 7DYSB

Zk2T85 713YBB

7__,7"857"WY_7

7_,T8 375YS5

7_2T837l)YSB

7_2T837BYBB

7__,7"837"WY_7

Page 2

IV!'llW:lH OlIO[,1

Before you begin--Read these instructions completely and carefldly.

IMPORTANT: Save these instructions for local inspector's use,

IMPORTANT: OBSERVE ALL GOVERNING CODES AND ORDINANCES.

NOTE TO INSTALLER: Be sure to leave these instructions with the

Coilsuiner.

NOTE TO CONSUMER: Keep these instructions with your Use and Care

Book tor flttttI'e referet/ce.

This appliance must he properly grounded. See "Electrical Supply", page 9. ]

Contents

If you have questions concerning the installa-

tion of"this product, call the (;E Answer

Center #_Consumer Information Service at

800.626.2000, 24 hours a day, 7 days a week.

If you received a damaged oven, you should

conutct your dealer.

CAUTION:

• This oven should be installed by a qualified

installer or service technician.

• Never use the oven tor warming or heating a

room. Prolonged use of the oven without

adequate ventilation can be hazardous.

Proper installation is tile responsibility of the

installer. Product fi_ilut'e due to improper installation

is not covered under tile (;E Appliance V',_lrranty. See

tile [Tse K"Care Guide tor warranty intormation.

Check with local utilities for electrical codes which

apply in your area. Local codes vary. Installation,

electrical connections and grounding must comply

with applicable codes. In tile absence of local codes,

the oven should be installed in accordance with

National Electrical Code ANSI/NFPA 70-1990.

Design Information

Models Available .................................................................................................................................. 3

Dimensions and Clearances ............................................................................................................... 3

Cabinet Style Options ......................................................................................................................... 4

Cabinetry

Tools and Materials req uired ............................................................................................................. 5

Framed Cabinet, Double Oven .......................................................................................................... ,_

Framed Cabinet, Single Oven ............................................................................................................ 6

Fram eless Cabin ets .............................................................................................................................. 7

Installation

Provide Oven Supports ....................................................................................................................... 8

Install Oven Supports .......................................................................................................................... 8

Step 1: Remove the Packaging ............................................................................................................ 8

Electrical Supply .................................................................................................................................. 9

Step 2: Install.]traction Box ................................................................................................................ 9

208V Electrical Supply ....................................................................................................................... 10

Step 3: Remove Oven Doors ............................................................................................................. 11

Step 4: Rotate Cable through Ctttt)ttt ............................................................................................... l l

Step 5: Secm'e Oven to Cabinet ........................................................................................................ l 1

Step 6: Replace the Oven Door ........................................................................................................ 12

Step 7: Cmmect Electrical ................................................................................................................. 19

Cabinetry Modification Suggestions

Determine Need for Fillet" Panels ..................................................................................................... 13

Fillet" Panel Construction .................................................................................................................. 13

(',tit Rail for Fillet" Panel .................................................................................................................... 14

(:tit Appearance Panel ...................................................................................................................... 14

Determine Location of Cleats ........................................................................................................... 14

Cut and Secm'e Cleats tit Fillet" Panel ............................................................................................... 15

Secm'e Rail to Appearance Panel ..................................................................................................... 15

Secure Assembled Fillet" Panel to Cabinet ....................................................................................... 15

Page 3

Design hdbrmation

30" Built-I_ Co_vectio_ Ove_s

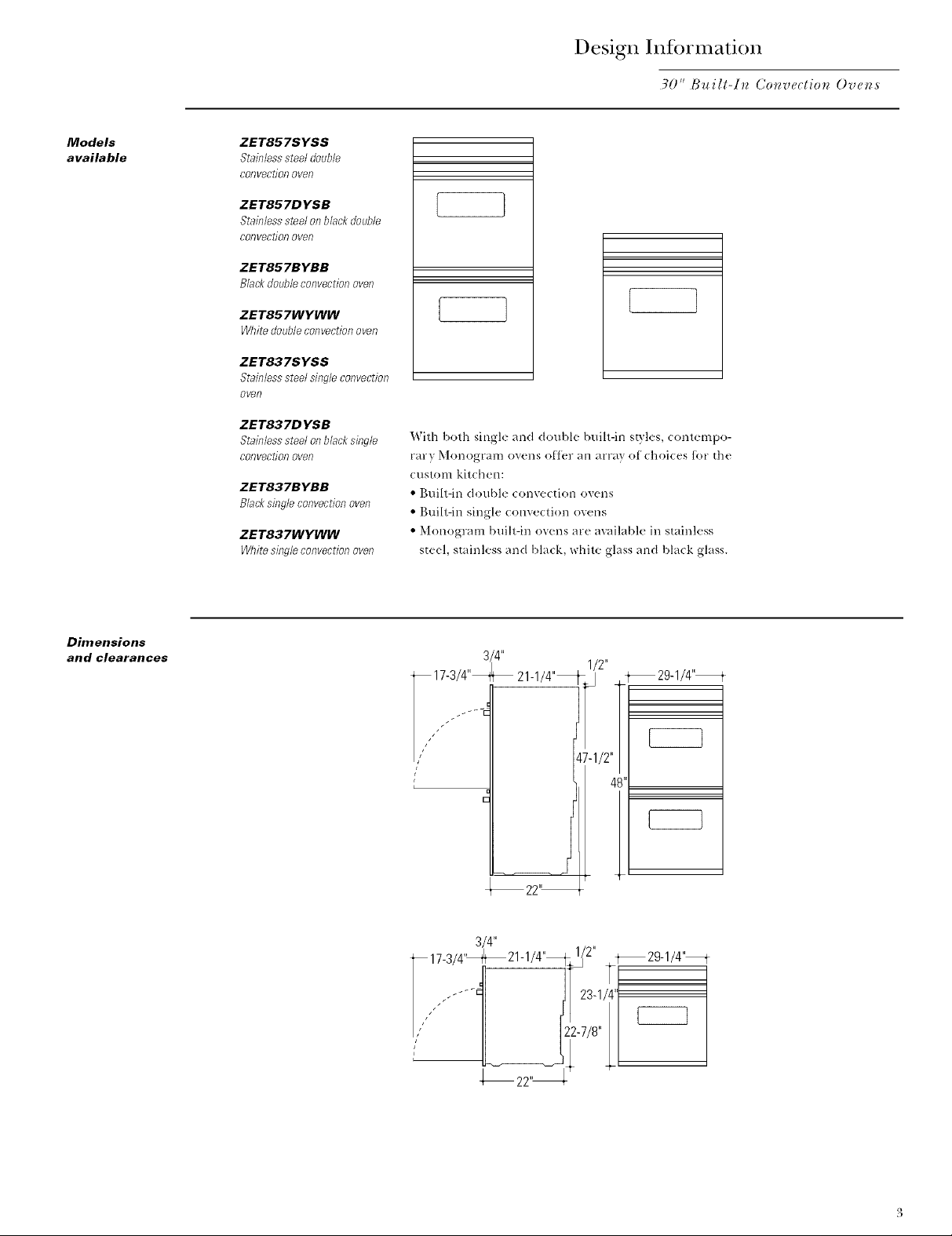

Models

available

ZET857S YSS

Stainlesssteel double

convection oven

ZETa57D YSB

Stainlesssteel on blackdouble

convection oven

ZET857BYBB

Blackdoubleconvectionoven

ZET85 7WYWW

Whitedoubleconvectionoven

ZETa37S YSS

Steinlesssteel singleconvection

even

ZET837D YSB

Stainlesssteel on blacksingle

convection oven

ZET837BYBB

B/a_ singleconvectionoven

ZET837WYWW

Whitesingleconvectionoven

I }

With both single and double built-in styles, contempo-

rary Monogram ovens ottbr an array of choices for the

custom kitchen:

• Built-in double convection ovens

• Built-in single convection ovens

• Monogram built-in ovens are available in stainless

steel, stainless and black, white glass and black glass.

Dimensions

and clearances

7-3/4"

3/4"

_ 17-3/4"_L 21-1/4"--

i

L

22'_

/2" --29-1/4"--

23-

:-7/8

Page 4

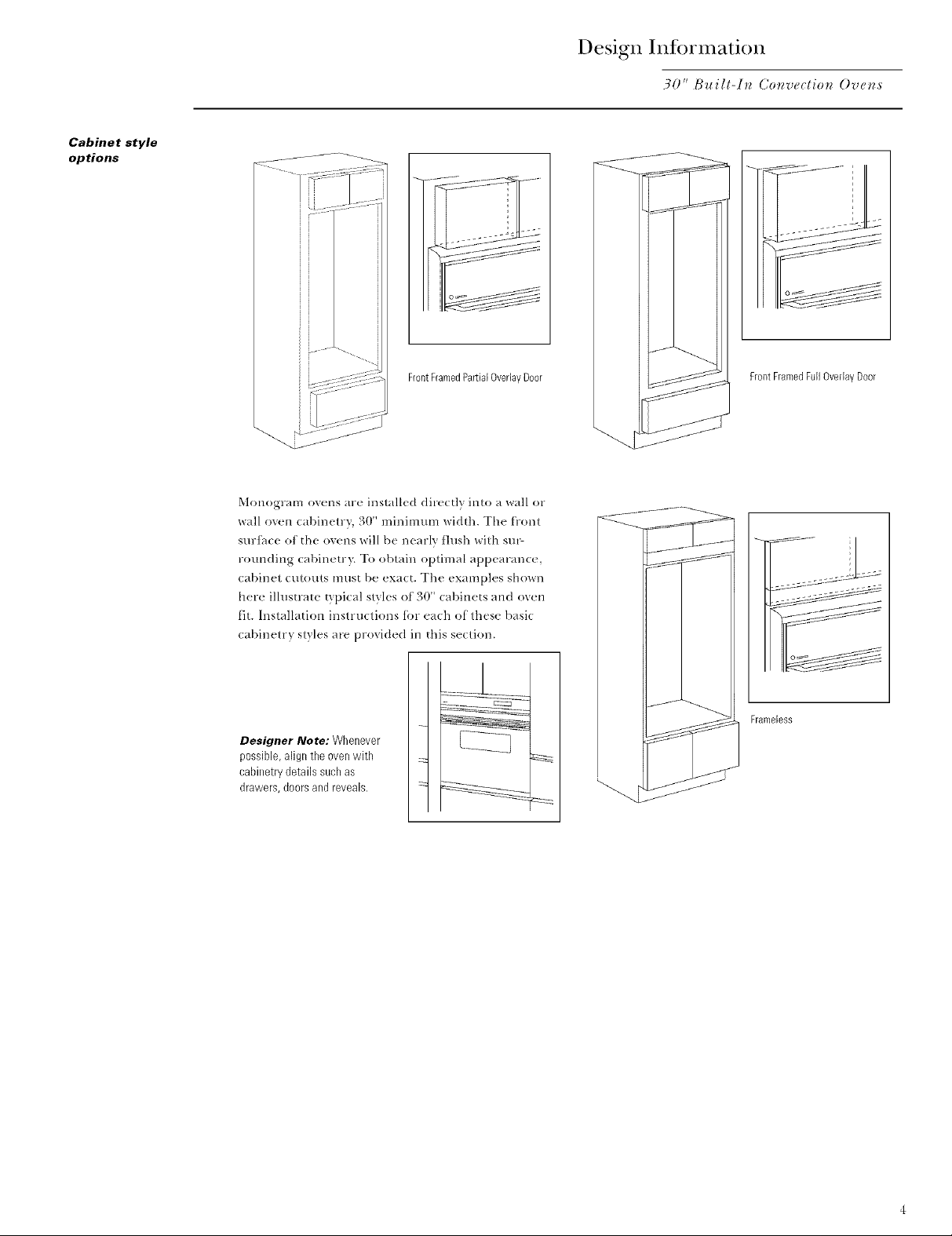

Cabinet style

options

Design hdbrmation

30" Built-I_ ( o_vectio_ Ove_,_

FrontFramedPartial OverlayDoor

Monogram ovens are installed directly into a wall 01-

wall oven cabinetry, 30" minimum width. The fl-ont

sm-tilce of the ovens will be nearly tlush with sur-

rounding cabinetry. To obtain optimal appearance,

cabinet cutouts must be exact. The examples shown

here illustrate typical styles of 30" cabinets and oven

fit. Installation instructions tot each of these basic

cabinetry styles are provided in this section.

Designer Note: Whenever

possible,alignthe ovenwith

cabinetry detailssuchas

drawers,doorsand reveals.

f_

FrontFramedFuji Overlay Door

Framebss

Page 5

Cabinetry

30" t_uill-I_ ( o_veclio_ Ove_s

Tools and

materials

required

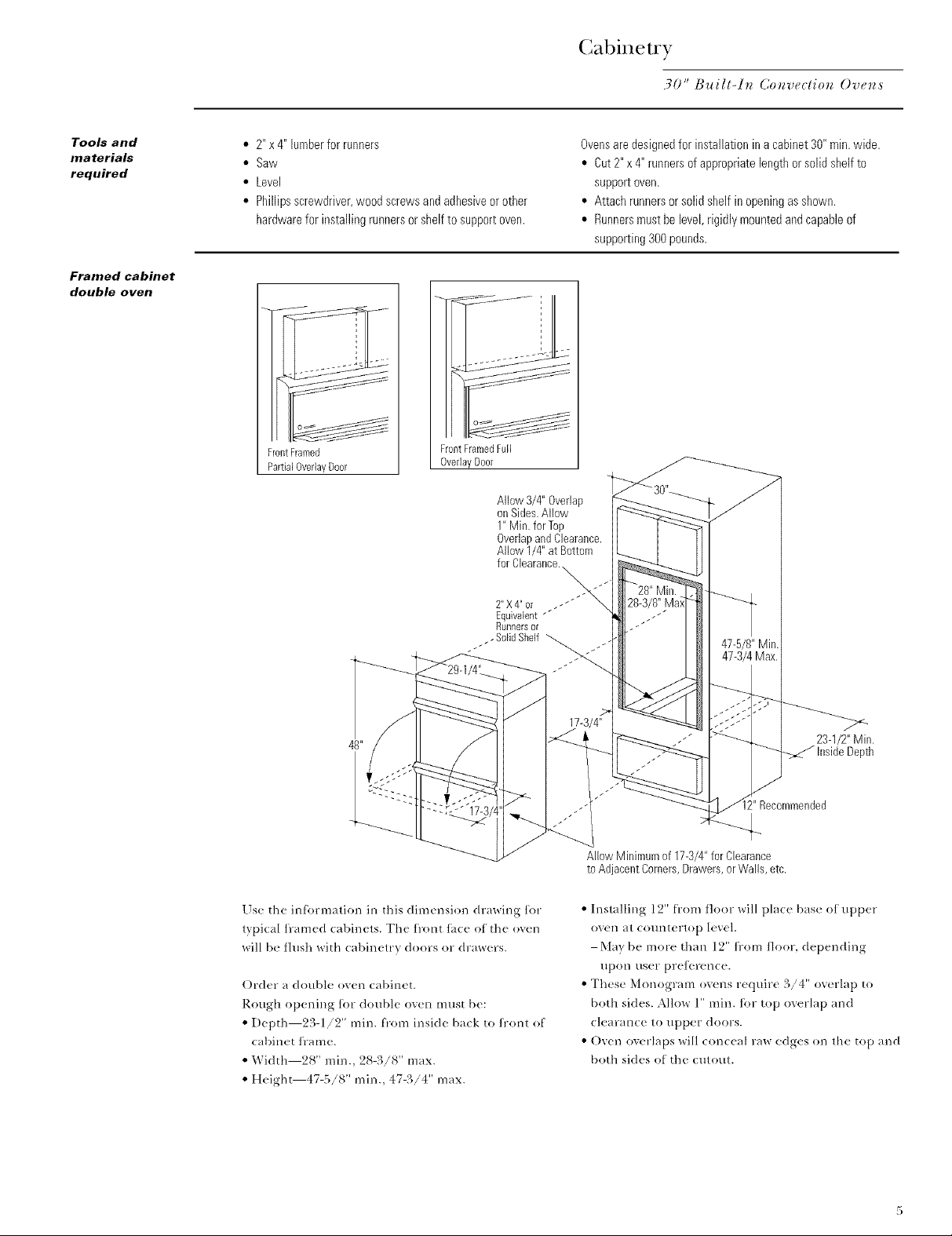

Framed cabinet

double oven

• 2"x 4" lumberfor runners

• Saw

• Level

• Phillips screwdriver,wood screws and adhesiveor other

hardware for installing runnersor shelfto support oven.

FrontFramed

PartialOverlayDoor

FrontFramedFull

Overlay Door

Allow 3/4" Overlap

onSides.Allow

1"Min. for Top

OverlapandClearance.

Allow 1/4" at Bottom

for Clearance.

Ovensare designedfor installation ina cabinet 30" rain.wide.

• Out2" x4" runners of appropriate length or solid shelf to

support oven.

• Attach runnersor solid shelf in opening as shown.

• Runnersmust be level, rigidly mountedand capable of

supporting 3(}0pounds.

Use the inlormation in this dimension drawing tor

typical trained cabinets. The tvont titce of"the oven

will be f]ush with cabinetry doors or drawers.

Order a double oven cabinet.

Rough opening for double oven must be:

• I)epth--23-1i2" min. fiom inside back to tront of

cabinet fl-ame.

• Width--28" rain., 28-3/8" max.

• Height--47-5/8" rain., 47-3/4" max.

23-1/2"Min.

_"Recommended

Allow Minimumof 17-3/4"for Clearance

to AdjacentCorners,Drawers,orWalls, etc.

• Installing 12" from floor will place base of upper

i)verl at cotnlteltop level.

-May be more than 12" from floor, depending

upon user preference.

• These Monogram ovens require 3/4" overlap to

both sides. Allow 1" rain. fbr top overlap and

clearance to upper doors.

• t)ven overlaps will conceal raw edges on the top and

both sides of the cutout.

Page 6

Framed cabinet

single oven

Cabinetry

30" Buill-I_ ( o_vr'clio_ Ovr'_s

FrontFramed

PartialOvedayDoor

23-1/4"

FrontFramed

Full Overlay Door

Allow 3/4" Overlap

onSides.Allow

1"Min. forTop

OverlapandClearance.

Allow 1/4" at Bottom

2"x4" or

Eq_

or SolidShelf

Allow Minimumof 17-3/4"for Clearance

to AdjacentCorners,Drawers,orWails, etc.

23-I/2" Min.

InsideDepth

Use the inlormation in this dimension drawing tor

typical h-amed cabinets. The h-ont li_ce of the oven

will be flush with cabinetry doors or drawers.

Order a single oven cabinet.

Rough opening tot single oven must be:

• I)epth--23-1/2" rain. fl-om inside back to fi-ont of

cabinet hame.

• Width--28" rain., 28-3/8" max.

• Height--23" max.

• 34" h'om floor is recommended to bring oven

door to countertop height when opened.

• All Monogram ovens require 3/4" overlap on both

sides. Allow 1"rain. tot top overlap and clearance to

upper doors.

• Oven overlaps will conceal rmv edges on top and both

sides of cutout.

Single ovens can be installed below a countertop. Use

the cutout dimensions shown on this page. If the

cabinets being used have an opening that is tuller than

the maximum dim_ nsions shown, filler panels can be

made to fill the gaps. See Cabinet1T Modifications

Suggestions on page 13 tot more infbrmation.

Page 7

Frameless

cabinets

Cabinetry

30" Buill-I_ ( o_veclio_ Ove_s

_3O"f

J

Frameless

Trim Strip or Upper Cabinet Shelf

With Finished Ends like Cabinet

Sides. 1" Min. Deep for Oven

Flange Overlap and

Cabinet Depth 23-1/2" Min.

FromInside Backto

of Cabinet Frame or Side

Panel,Excluding Doors

or Drawer Fronts.

3/4" 0

Shelf Cut Back Flushwith 0

Front of Side Panel

See page 9.

O0

Double Ovens

47-5/8" Min.

Single Ovens

23" Min.

FabricateFiller

Panelif Necessary,Similar

to DrawerFrontor

UpperCabinetDoors

or OrderAdditional

DrawerFront

1/2" Cleatsto

HoldOvenMounting

Screws,MeasureOven

to FindExactLocations.

FinishTrimStrip1/4"Min.

DeepforClearance.

ToObtainInstallationHeight

fromFloorit maybeNecessary

to InstallaLowerFillerPanel.

Use the inlormation in this dimension drawing %r

typical h-ameless cabinets. The h-ont t_me of the oven

will be f]ush with cabinetry doors or drawers.

Whenever possible, order 30" h-am_less cabinet with

the cutout sized to fit the oven. If yon are using stock

cabinets, additional finished fillet- pieces may be

required to covet openings.

Rough opening tot single and double ovens:

• I)epth--23-1/2" rain. liom inside back to flont of

cabinet or side panel, excluding doors or drawer

tionts.

• Width--28" rain.

- Frameless cabinet cutout width may be up to

28-3/4". Add 1/2" cleats to the sides, flush with

the tiont edge of the side panels to accept

mounting screws.

• Height--tot double oven 47-5/8" rain.

• Height--tor single oven 23" min.

Both single and double ovens require 3/4" overlap

around edges of opening on both sides. Allow 1/2"

tor top overlap.

• Allow 1/8" clearance between top of oven and

cabinet door ol- panel and 1/8" between bottom of

oven and cabinet drawer.

• Installation of double oven requires a total height ot"

48-1/4" including clearances at top and bottom.

• Installation of single oven requires a total height

of 23-1/2" including clearances.

Page 8

Installation

30" Built-I_ ( o_vectio_ Ove_L_

Provide

oven supports

Install

oven supports

The ovens may be supported by either a solid bottom

OY 2 X 4 YunneFs,

• The support must be level and rigidly monnted,

flush with the bottom edge of the cutout.

• The entire weight of the oven is supported by 2 x 4

runners or the solid floor and must be capable of

supporting 300 lbs. for double ovens and 200 lbs. 24"

for single ovens.

Levelwith Bottom

Edgeof CutoutandFlush

Interior !

with CabinetFront

Cabinet Interior J

3/4" Min. 4,_-Width_l_- Cabinet /

Sheeting(Plywood Depth ] (

or WaferBoard _ _._

SourcedonSite) __-

__ _ II % asrlequlrea

--Tp__..------._ He_ht ,

3/4" She_ [__"_ _

(PlywoodorWafer _ '_ '"_--

BoardSourced _ I[

on Site)

/_ 2"x4"or

; /x \\

' _ 'i

i

i

i

t

i

i

i

i

i

i

i

i

i

i

i

i

i

_25"_

30"

EquivalentRunners

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

Step 1

Remove

the

Packaging

Ifa solid bottom is used:

• Cut two pieces of 3/4" thick sheeting, to tit inside

cabinet depth and awfilable inside cabinet height.

If there is no interfbrence below the cutout, such as

drawer r-nnners, the sheeting can rest on the floor.

Secure the sheeting strips or pieces to the cabinet

walls with screws. Lay 2 x 4 or solid bottom on top

of the sheeting and drive screws through the top

and into the sheeting.

• Remove the carton, plastic covering, and styrofbam

side/corner posts.

• To prevent damage to the floor, do not renlove the

sl}rofl)an_ base until the oven is ready to be

installed.

• Remove oven contents, shelves and packaging.

• Be sure to remove protective tape ti'om the door

latch pin.

RemoveTape/_

FromLatchPin

Page 9

Installation

30" Built-I_ ( o_vedion Ovens

Electrical

supply

• Junction box

• Electrical cable--3-conductor or 4-conductorwire--as required

by local codes

• U.L.listed conduit connector

• Wire cutters and wire stripper

Note: Do notusean extension

cordwith theseappliances.

Donot shortentheflexible power

cable.

Electrical Shock Hazard

• The electrical power to the oven

branch circuit must be shut off while

line connections are being made.

• Use copper wiring only.

• Electrical ground is required on this

appliance. The fl-ee end of the green wire (the

ground wire) must be connected to a suitable

ground.

This wire must remain grounded to the oven.

• If cold water pipe is interrupted by plastic, non-

metallic gaskets, union connections or other

insulating materials, I)O NOT use tbr grounding.

These Monogram built-in ovens require a separate,

properly grounded 3-wire 120/208 or 120/240 volt, 60

Hz power supply, protected by a time delay ltrse or

circuit breaker. Ovens are supplied with a flexible

power cahle, which must be attached to a junction

box. The cable length is 53" tor both single and

double conventional ovens.

I)ouble ovens are rated 6.3 KW at 240 volt, and 5.1 KW

at 208 w)lt.

Single ovens are rated 3.3 KW at 240 volt, and 2.8 KW

at 208 volt.

• DO NOT grotmd to a gas pipe.

• DO NOT have a fuse in the NEUTI_M+ oi"

GROUNI)ING circuit. A fl:se in the NEI ?Tl0LkI+or

GROUNI)ING circuit could result in an electrical

shock.

• Check with a qualified electrician if you are in

doubt as to whether the appliance is properly

grounded.

Failure to tbllow these instructions could result in

serious i:_iury ol- death.

Step 2

Install

junction

box

The conduit is located in the center at the top rear of

the oven.

FoI" dotlble oven:

• Locate and install the junction box within reach of

the power cable.

- Through the leli or right of cabinet wall into

a(!iacent cabinet.

- or, below the cutout tloor.

- or, above the cutout, into the top cabinet.

For single oven:

• Locate and install the junction box within reach of

the power cable.

- Below the cutout [loot.

- Or, through the left or right of cabinet wall into

a(!iacent cabinet.

- or, above the cutout, into the top cabinet.

DoubleOven:

LocateJunctionBox

in one ofthe locations

¢7-5/8" "n

23"

Min.

Single Oven:

LocateJunction Box

in one of the locations

Page 10

Installation

30" Built-I_ ( o_vection Ove_s

208V

Electrical

supply

Single ovens,

double ovens-

(upper oven)

_ Th_se OX_ llS aye pF_-wh-_ d _)t- connec-

]tion lo 24¢) volt, 60 Hz., suppl). If connecting

to a 208 _olt supply modifications must be made.

to _l 2'08 vol

To connect to 208 volt circuit:

• Remove the access panel(s) located on the back of

the ovens.

• Loosen the first and second screws ill the terminal

block as shown.

If connecting to a 208 volt, 60 Hz., supply, a jumper

mtlst be tlsed across two tetmitlals.

• For double ovens, there are lwojumpers, one fin- the

upper oven, one for the lower oven.

• For single ovens there is one jumper.

LoosenScrews

Jumper

Jumper Tighten Screws

• Remove the jumper and place between the fh-st and

second screws, tighten the screws to hold the

jumper in place.

• Replace the access panel(s).

Double ovens-

(lower oven)

I)ouble ovens-Lower

JumperL00 n

o

Jumper

Jumper Tighten Screws

Loosen Screws

10

Page 11

Installation

30" Built-b_ ( o_vectio_ Ove_,_

Step 3

Remove

Oven

Door(s)

Step 4

Route

cable

through

cutout

Caution: Donotlift theovenorovendoorwitb handle.

Caution: Oven{s)areveryheavy.2peopleare requiredto lift oven(s)

into the opening.Ovenshavesidebandies.Graspsidehandlewith one

handand intoovenopeningwith otber band.Lift theovento the

cabinetopening,verycarefully.

Locked

Ne Latch

• ()pen the door lttlly.

• Push hinge latches up to lock hinges in open

position.

• (;rasp each side of door and pull the door straight

out and away fi-om tlle oven.

• I.ay the oven door on packaging to prevent

scratching.

Step 5

Secure

oven

to cabinet

With oven in front of cabinet opening:

• Insert power cable into cabinet opening.

• Lift the oven into opening while continuing to rived

the cable in the direction of" the installed junction

box. Be sure the cable does not get pinched between

the back of the oven and cabinet wall.

• Slide oven into cabinet opening.

• I)rill 3/32" pilot holes into cabinet flame through

mounting holes in oven fl'ont li-ame.

• Secure oven to cabinet with screws fllrnished.

-Single ovens, use 2 screws, one on each side.

-I)ouhle ovens, use 4 screws, 2 on each side.

crews provided. Failur_ to do so could

ause the oven to mo_ or tip dtlFing tlse

tnd result ill p_rsonal il_iur }.

ShippingBase

(DO ©

/

] 1

Page 12

Installation

30" Built-I. ( o_vectio. Ove.s

Step 6

Replace the

oven door

Step 7

Connect

electrical

• Grasp door th-n:ly on both sides,

• Slide the hinge slots ill the bottom of the cloor over

the hinges.

• Push tile cloor all the way in against oven.

• ()pen the door thlly and push hinge latches down,

as illustrated, on both sides to secure.

• (;lose the door and open slowly to be sure it moves

smoothl>

Electrical Shock Hazard

• Electrical ground is required on this

appliance.

• I)o Not connect to the electrical

supply until appliance is

permanently grounclecl.

• Disconnect power to the junction box beli>re

making the electrical connection.

• This appliance must be connected to a grounded,

metallic, permanent wiring system, or a grounding

connector shoulcl be connected to tile grounding

terminal or wire lead on the appliance.

Failure to do so could result in a fire, personal

mjnry or electrical shock.

Junct:on Branch Circuit

Red Black

White.

Bareo

Green

Wires

CaNe UL-Listed

FromOven ConduitConnector

• When connecting to a 3-conductor branch circuit:

-Connect oven recl lead to branch circuit recl leacl.

-Connect oven |alack lead to branch circuit black

lead.

-Connect oven bare copper conductor and white

lead to branch circuit neutral lead (white or gray).

• When connecting to a 4-conductor branch circuit:

-Connect oven recl lead to branch circuit recl leacl.

-Connect oven |alack lead to branch circuit black

lead.

-Break connection between oven white lead and

oven bare copper cl)t)dtlctor.

-Connect oven white lead to branch circuit neutral

lead (white or gray).

-Connect oven bare copper conductor to branch

circuit grouncl lead (green or bm-e copper).

Note: Usecopperwire only.

Junction Branch Circuit

Red

Barn or

Green CaNe UL Listed

Wires From Oven Conduit Connector

White

Wires

12

Page 13

Installation

30" Built-I_ ( o_vectio_ Ove_s

Determine

need for

rifler panels

If dae cabinets being used have an opening that is

taller than the maximmn dimensions indicated tbr

the ovens, filler panels can be made to till the gaps.

Stock filler strips are usually awdlable or fbr larger

gaps order an extra drawer fl-ont. I)rawer honts are

recommended because they will match tl_e cabinetry

and have finished edges. Any cut edges will be seen

and should be finished.

Frameless cabinets usually come with a fl-ont panel

covering the opening. Fox-the optimum finished look,

this panel can be removed and used to construct filler

panels.

The oven support floor and supports should be

installed at the required locations.

If there is a gap belween the oven support floor and

the bottom of the opening, a bottom filler panel

should be constructed to fill the gap.

Measure from the oven support floor to the top of"the

opening. If the opening height is larger than the

maximmn cutout height, a filler panel should be

constructed to fill the gap.

FillerPanel

Overlaps

Slightly like

DoorsAbove

FillerPanel

Overlaps

[awer Shelf

Slightly

Filler panel

construction

We suggest that the filler" panel be constructed using

4 pieces:

• Appearance panel to match doors and drawers.

• A fail which will be covered by the oven overlaps

and conceal any slight gap between the top or

bottom of the oven and the start of the filler- panel.

The fhce of the rail should be made of finished

matching material; the cut edges and ends do not

need to be finished.

• Cleats which will be used to secure the filler panel

and rail to the cabinet. One for each side.

Cleals

/

_Screws

'_ Screws

\

Cleats

Top FillerPanel

Appearance Panel

_J

Rail

BottomFillerPanel

Rail

\

\

AppearancePanel

Cleats

Scraws_

Screws_]_:_

Cleats

/

13

Page 14

Cabinetry Modification Suggestions

30" Buill-I_ ( o_vedio_ Ovens

Cut rail

for filler

panel

Cut appearance

panel

Cut the rail out of linished material:

• Tile width should match cabinet opening width.

• Tile height of tile top rail should be enough to

securely attach the rail to dae appearance panel,

plus 1/4" oven trim overlap.

• Tile height of tile bottom rail should be enough to

securely attach the rail to tile appearance panel,

plus 7/8" oven trim overlap.

• Tile height of both the top and bottom rails should

be a_!justed depending upon the height of the gap

to be filled or to enhance appearance.

Else drawer fl-onts for appearance panels or cut

finished material and finish raw edges.

• The appearance panel width should match drawer

fronts or doors.

• Make the appearance panel appropriate height to

fill the gap above or below the oven, allowing for

reveals and overlaps to match existing drawers or

dooYs,

TopRail

Lengthto Match

CabinetCutoutOpening

BottomRail

Lengthto Match

Cabinet Cutout Opening

Width toMatch

drawers ordoors

Determine

location

of cleats

_ FramedCabinet _'

Appearance Panel

MarkCorners

with Pencil

InsideFront

of Cabinet

• To find the exact position of the cleats, place the

appearance panel onto tile cabinet in desired

position and align to match tile other drawers and

dooI's.

Frameless Cabinet

with Pencil

InsideFront

of Cabinet

• Use a pencil to mark tile back side of tile panel

where it meets the cabinet corners.

f 4

Page 15

Cut and

secure cleats

to filler panel

TopFiller Panel

Cabinetry Modification Suggestions

30" Buill-I_ ( o_vedio_ Ove_L_

BottomFiller Panel

Secure rail

to appearance

panel

Appearance

Panel

Cle{

For the top filler panel:

• Cut 2 cleats octt of 3/4" thick material, approxi-

mately 1-1/4" wide.

• Cut tile cleats to a length leaving apwoximately

1/2" at tile bottom of the appearance panel to

attach tile rail.

• l'osition the outside edge and top of" the cleat

against tile corner pencil marks.

• Secure the cleat to tile appearance panel with

SC f'ews.

Note: Tl_escrewssl_ouidhe longenoughto securethe cleats to tl_e

filler panelwitl_outpenetratingtile appearanceside.

Cleats Cleats

TopFiller Panel

Appearance

Panel

Cleat

For the bottom filler panel:

• (;tat 2 cleats out of" 3/4" thick material, approxi-

mately 1-1/4" wide.

• (;tit the cleats to a length leaving approximately

1/2" at tile top of the filler panel to attach the rail.

• Position the outside edge ancl bottom of" the cleat

against the corner pencil marks.

• Secure the cleat to tile appearance panel with

sciews.

Note: if appearancepanelis verynarrow,cleats can beattached to

tile rail.

%ttom Filler Panel

Secure

assembled

filler panel

to cabinet

Screws _ ScrewsRail

Appearances/Panel

• l'lace rail against cleats ancl flush with the outsicle

edges of the cleats. Secure with wood screws. If the

appearance panel is very narro_: cleats can be

attached to the rail.

Framed Cabinet

/

FillerPanel

Cleats\

/ Cleats

/

Attach

WithScrews

InsideFrontofCabinet

Screws \\ Screws

Cleats AppearancePanel Cleats

Rail _::_

Note: Thescrewsshould beions enoughto secure rail to tl_efiller

panelwitllout penetratingtl_efinished face of tile filler panel.

Frameless Cabinet

Cleats

Cleats

Attach

With Screws

InsideFrontof Cabinet

)

• I lace filler panel in proper position. To attain

proper relationship to ac[jacc nt ch-awers ancl doors

you may need to space tile filler panel ottt fiom the

cabinet face!edges clsing ch-awer bumpers or other

spacers.

15

Page 16

Monogram:

General Electric Company

Louisville, KY 40225

NOTI_]: While performing installationsdescribed inthis book,

safetyglassesor gogglesshouldbe worn.

Monog'*zzm product or s_n,ice, call (;l" Answer Ck _zl_r_"_

.nzsumer i_/b_w_alio_z _i_ _.al _f)f). 626.2000 a_O'

lim_< da3 oz _ligfiL

For Mo_uNram local s_.rvice i_z youz a_va, _all

l 800444 1845.

N()TE: P) oduct imp]ovemenl is a conlimfing ende tvol at (;ene]al

Elecl_ic Therefore, materials, appearance and specificalioiJs are

sul!lect to cl_J_ge witho_l J_<_ice

Pub No 49-8791

Dwg No 164DS333P046

© 1997 (;E Appliances

(ND 521) 3/97

Loading...

Loading...