Page 1

Installation

Instructions

30", 36" and 48"

Professional Ranges

Cuisinières professionnelles

de 30’’ (76 cm) 36" (91 cm)

et de 48" (121 cm)

Instructions d’installation

La section française commence à la page 24

31-10689

04-08 JR

Cocinas profesionales

de 30", 36" y 48"

Instrucciones de instalación

La sección en español empieza en la página 46

Page 2

Installation Instructions

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•

IMPORTANT— Save these instructions for

local inspector’s use.

•

IMPORTANT— Observe all governing

codes and ordinances.

• Note to Installer — Be sure to leave these

instructions with the Consumer.

• Note to Consumer — Keep these instructions

with your Owner’s Manual for future reference.

• Completion Time — 1 to 3 hours.

• Proper installation is the responsibility of the

installer. Product failure due to improper

installation is not covered under the warranty.

See Owner’s Manual for warranty information.

WARNING:

This appliance must be properly grounded.

See ”Electric Supply.

For Monogram local service in your area,

1.800.444.1845.

For Monogram Ser

1.800.561.3344.

For Monogram Parts and Accessories, call

1.800.626.2002.

If you r

contact your dealer.

In the Commonwealth of Massachusetts:

•

• When using ball type gas shut off valves, they

•

eceived a damaged range, you should

This product must be installed by a licensed

plumber or gas fitter.

shall be T-handle type.

A flexible gas connector

exceed 3 feet.

”

vice in Canada, call

, when used, must not

WARNING:

. Install the

y could r

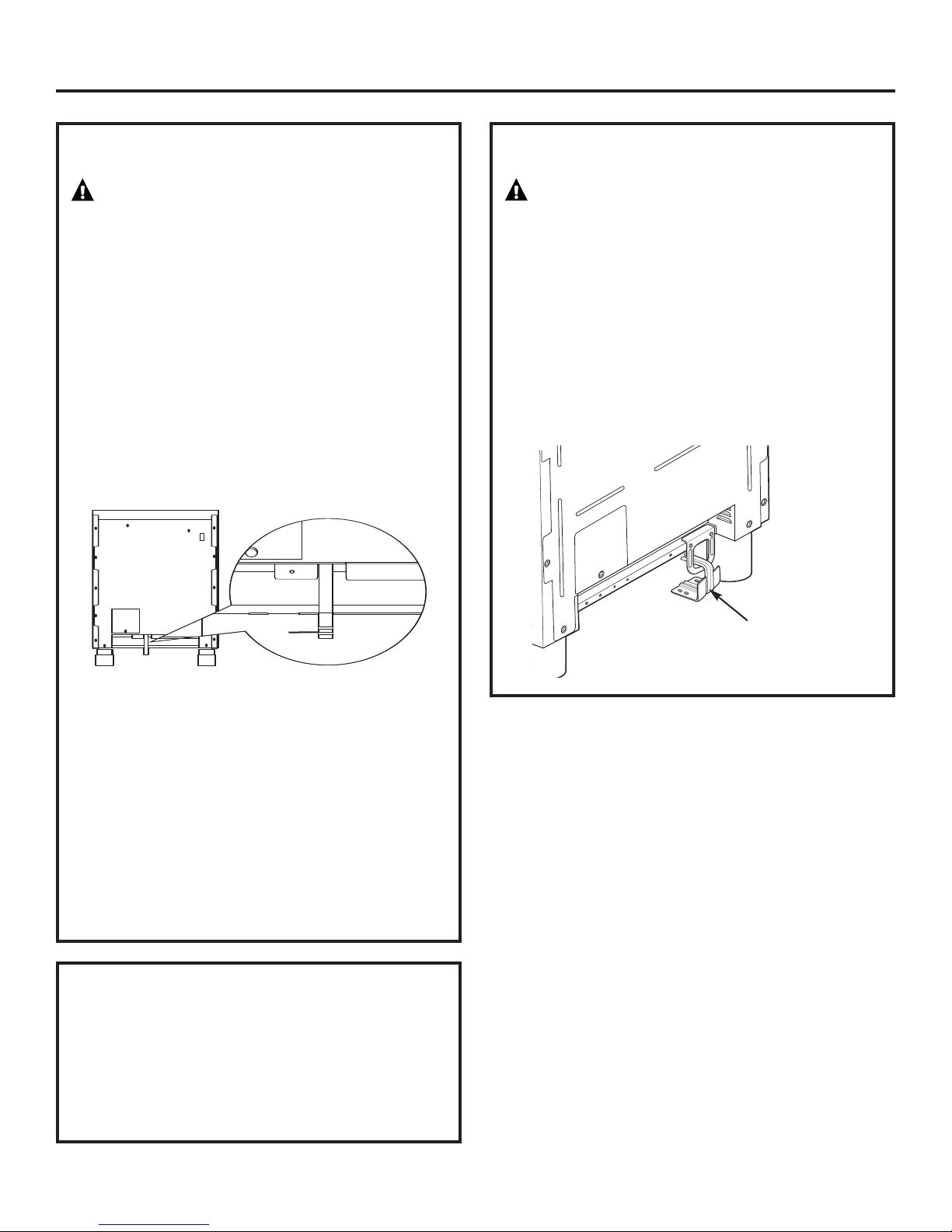

All ranges can tip

supplied Anti-Tip Bracket provided. See instructions

in this manual or with the bracket.

. Injur

esult

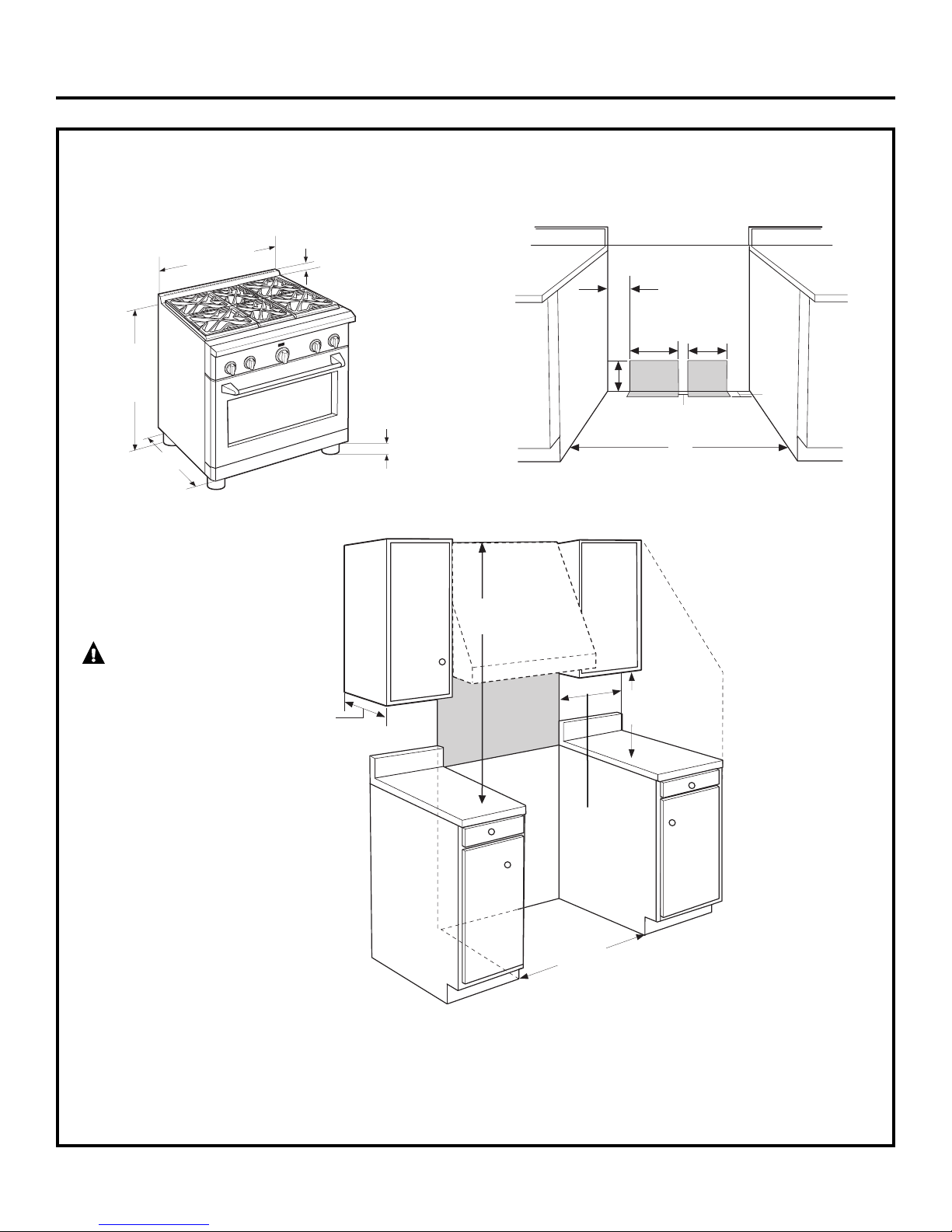

Vent hood Combinations:

It is recommended that these ranges be installed

in conjunction with a suitable overhead vent hood.

• Install a hood with at least 1200 CFM above a 48"

wide range.

• Install a hood with at least 600 CFM above a 30”

or 36” range.

Due to the high heat capacity of this unit, particular

attention should be paid to the hood and ductwork

installation to assure it meets local building codes.

WARNING:

Clearances to horizontal surfaces above the range,

measured to the cooking surface:

• Installations without a hood require 48” minimum

to combustibles.

• A custom hood installation with exposed

horizontal combustibles surfaces must have

an Auto-On feature.

• For other installations with a hood, r

installation instructions for specific hood

clearances.

efer to hood

CAUTION:

These ranges weigh up to 700 pounds. Some

disassembly will reduce the w

Due to the weight and size of the range and to

reduce the risk of per

the product:

TWO PEOPLE ARE REQUIRED FOR PROPER

ALLATION OF 36" AND 30" RANGES.

INST

THREE PEOPLE ARE REQUIRED FOR PROPER

ALLATION OF 48" RANGES.

INST

Leak testing of the appliance shall be conducted

according to the manufacturer’s instructions.

Installation must conform with local codes. In the

absence of local codes, the range must comply with

the National Fuel Gas Code, ANSIZ223.1/NFPA 54,

latest edition and National Electrical Code

ANSI/NFPA 70 latest addition. In Canada, installation

must conform with the current Natural Gas

Installation Code, CAN/CGA-B149.1 or the current

Propane Installation Code, CAN/CGA-B149.2, and

with local codes where applicable. This range has

been design-certified by CSA International according

to ANSI Z21.1, latest edition and Canadian Gas

Association according to CAN/CGA-1.1 latest edition.

sonal injury or damage to

eight considerably.

2

Page 3

Design Information

CONTENTS

Design Information

Models Available......................................................................3

Backsplash Accessories ......................................................3

Product Dimensions and Clearances........................4-7

Tools and Materials Required .......................................... 8

Installation Preparation

Power Supply Locations ..............................................9, 10

MODELS AVAILABLE

These Monogram ranges are factory set for either

natural gas or LP gas. Order the model for your

installation situation.

48" Natural Gas Models:

ZDP484NG – 4 gas burners, grill and griddle

ZDP486NR – 6 gas burner

ZDP486ND – 6 gas burners and griddle

48" LP Gas Models:

ZDP484L

ZDP486LR – 6 gas burner

ZDP486LD – 6 gas burners and griddle

G – 4 gas burners, grill and griddle

s and grill

s and grill

Installation Instructions

Step 1, Remove Packaging ..............................................11

Step 2, Move Range Indoors ..........................................12

Step 3, Install Anti-Tip Device ........................................13

Step 4, Connect Range to Gas........................................14

Step 5, Connect Electrical ................................................14

Step 6, Roll Range into Position ....................................14

Step 7, Level the Range ....................................................15

Step 8, Replace Oven Doors............................................15

Step 9, Check Burners ........................................................16

Finalize Installation ..............................................................16

Installation Checklist ..........................................................16

Accessories..............................................................................17

Accessory Installation ................................................18–20

Gas Conversion ............................................................21-23

36" Natural Gas Models:

ZDP366N – 6 gas burners

ZDP364NR – 4 gas burners and grill

ZDP364ND – 4 gas burners and griddle

36" LP Gas Models:

ZDP366L – 6 gas burner

ZDP364LR – 4 gas burner

ZDP364LD – 4 gas burners and griddle

s

s and grill

30" Natural Gas Model: ZDP304N

30" LP Gas Model: ZDP304L

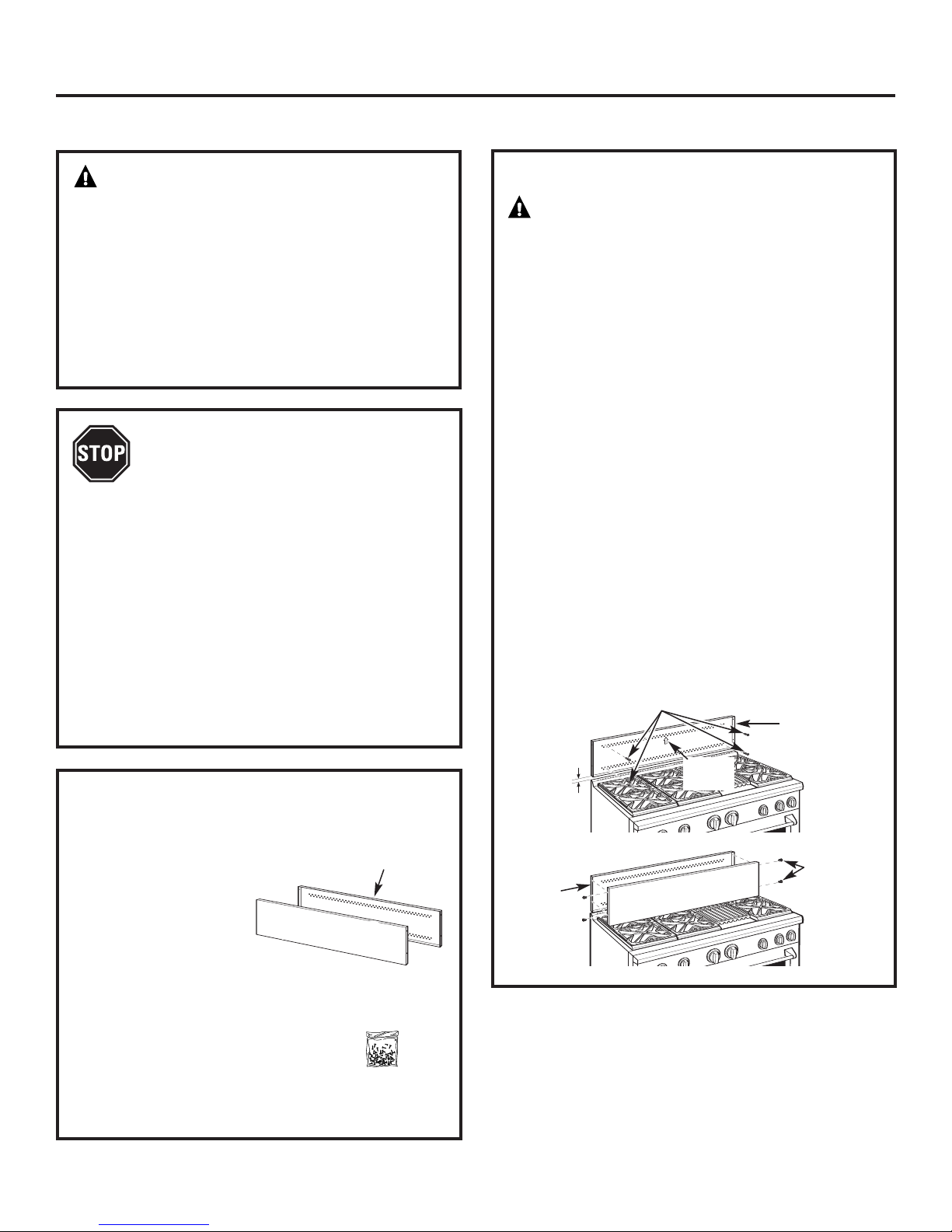

BACKSPLASH ACCESSORIES

All models require 12" minimum clearance to a

vertical combustible surface at the rear. If clearance

is less than 12”, the entire surface of the back wall

above and the full width of the range must be

protected by a backsplash. The backsplash must be

constructed of non-combustible material, such as

metal, ceramic tile, brick, marble or other stone.

Two Backsplash Accessories Available:

• The 12" high stainless steel backsplash accessory

is available. Use this backsplash in combination

with a custom, non-combustible backsplash built

beyond the 12” height

the backsplash accessory and the custom

backsplash must reach the bottom of a hood,

or when there is no hood, to 48” above the

cooking surface.

. The combined height of

An adjustable 30" to 36" high backsplash with

•

shelf is also available. This backsplash fills in the

space betw

bottom of the hood. The shelf is positioned so that

heat lamps from the bottom of a Monogram

ofessional hood are directed towards the shelf.

pr

een the top of the range and the

12" High Backsplash

ZX12B48PSS, for 48" wide ranges

ZX12B36PSS, for 36" wide ranges

ZX12B30PSS, for 30" wide ranges

30" to 36" Adjustable Height

Backsplash With Shelf

ZXADJB48PSS

ZXADJB36PSS

ZXADJB30PSS, for 30" wide ranges

, for 48" wide ranges

, for 36" wide ranges

3

Page 4

4

Design Information

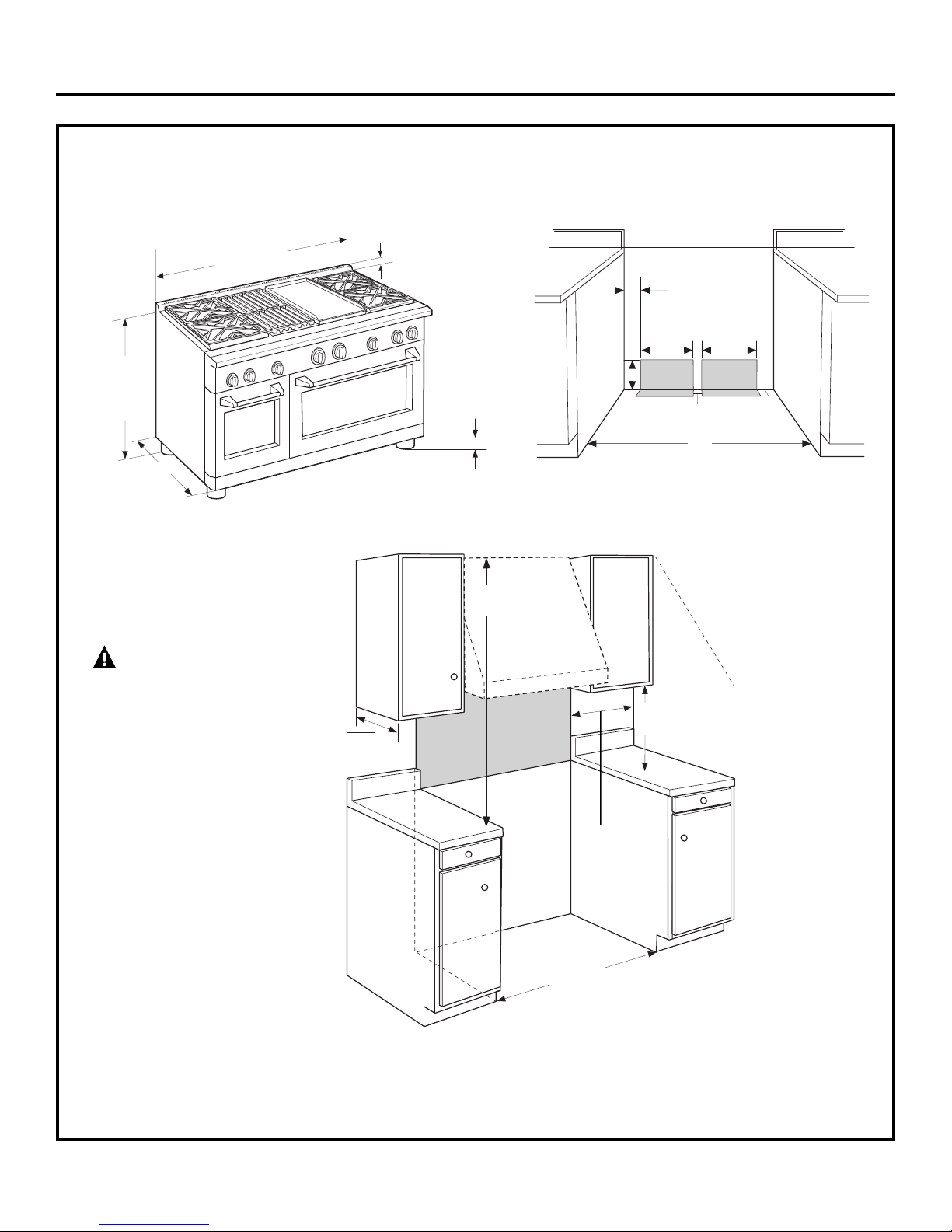

PRODUCT DIMENSIONS AND CLEARANCES

48" Range Models

Toekick/leg

Height

3-1/4”

to 4-3/4”

1”

35-1/4”

to

36-3/4”

Height

47-7/8” Width

28-1/4”

13”

Max.

12” Minimum

Each Side

48” Min.

ADDITIONAL CLEARANCES:

Allow 12" minimum clearance to an adjacent wall

on each side.

Working areas adjacent to the rangetop should have

18" minimum clearance between countertop and

the bottom of the wall cabinet.

12” Minimum

to Adjacent Wall

WARNING:

Installations without a hood require

48” minimum to combustibles.

A custom hood installation with

exposed horizontal combustible

surfaces must have an Auto-On

feature. Refer to hood installation

instructions for specific hood

clearances.

The surface of the entire back wall

above the range and below the

hood must be covered with a noncombustible material such as metal,

ceramic tile, brick, marble or other

stone.

Non-Combustible

Material

48”

8”

14”

2”

16”

Gas/

Electric

Electric

6-1/2”

2”

Universal Utility Locations

Depth

to Front

of Door

Countertop

to Cooking

Surface

48” Minimum

to Combustibles

18”

Min.

Page 5

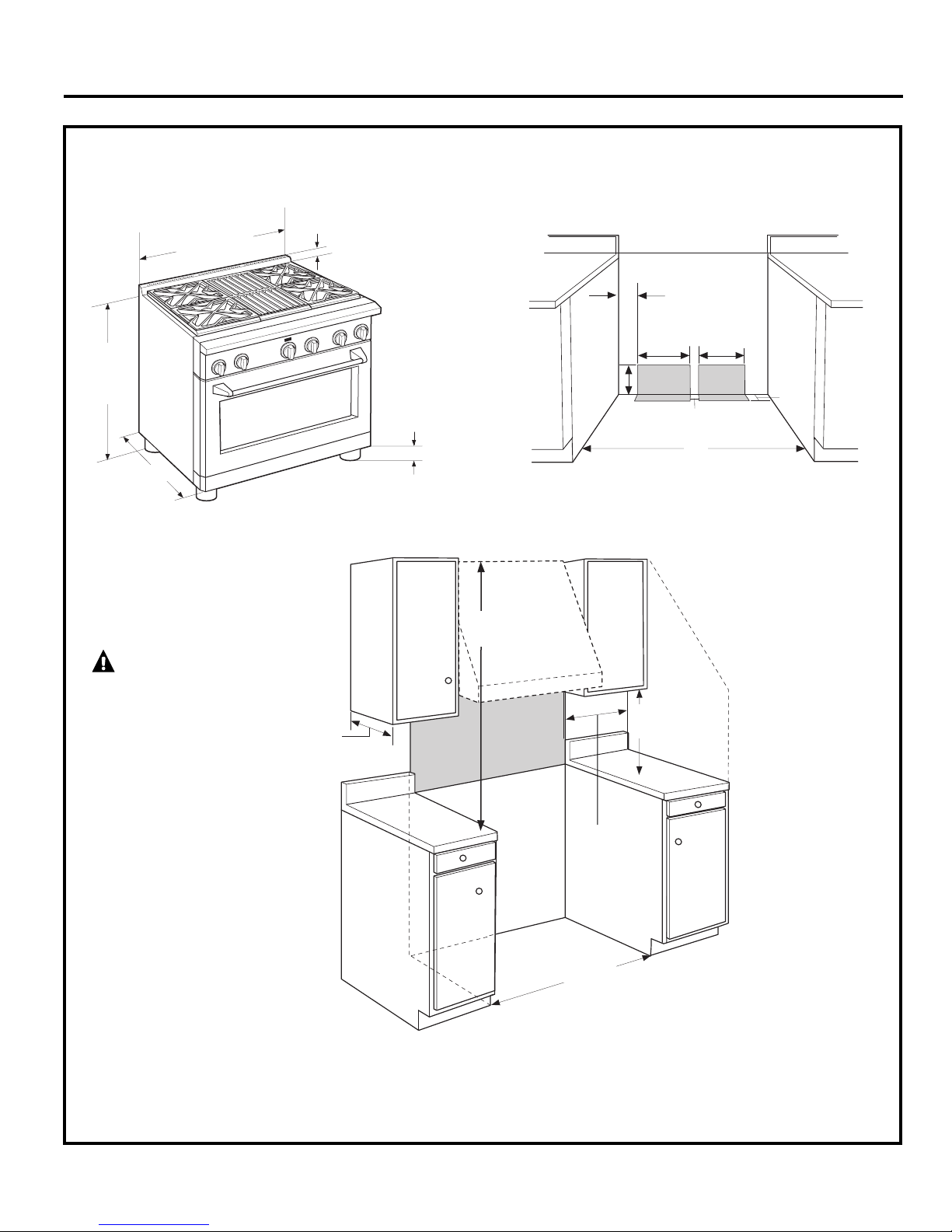

PRODUCT DIMENSIONS AND CLEARANCES

36" Range Models

Design Information

5

3-1/4”

to 4-3/4”

1”

35-1/4”

to

36-3/4”

Height

35-7/8” Width

28-1/4”

13”

Max.

36” Min.

ADDITIONAL CLEARANCES:

Allow 12" minimum clearance to an adjacent wall

on each side.

Working areas adjacent to the rangetop should have

18" minimum clearance between countertop and

the bottom of the wall cabinet.

WARNING:

Installations without a hood require

48” minimum to combustibles.

A custom hood installation with

exposed horizontal combustible

surfaces must have an Auto-On

feature. Refer to hood installation

instructions for specific hood

clearances.

The surface of the entire back wall

above the range and below the

hood must be covered with a noncombustible material such as metal,

ceramic tile, brick, marble or other

stone.

Non-Combustible

Material

36”

4-5/8”

13-3/8”

2”

11-3/8”

Gas/

Electric

Electric

6-1/2”

2”

Universal Utility Locations

12” Minimum

Each Side

12” Minimum

to Adjacent Wall

48” Minimum

to Combustibles

Depth

to Front

of Door

Toekick/leg

Height

Countertop

to Cooking

Surface

18”

Min.

Page 6

6

Design Information

PRODUCT DIMENSIONS AND CLEARANCES

30" Wide Range Models

13”

Max.

3-1/4”

to 4-3/4”

1”

35-1/4”

to

36-3/4”

Height

30” Min.

ADDITIONAL CLEARANCES:

Allow 12" minimum clearance to an adjacent wall

on each side.

Working areas adjacent to the rangetop should have

18" minimum clearance between countertop and

the bottom of the wall cabinet.

28-1/4”

30”

4-5/8”

11-3/8”

2”

7-3/8”

Gas/

Electric

Electric

6-1/2”

2”

WARNING:

Installations without a hood require

48” minimum to combustibles.

A custom hood installation with

exposed horizontal combustible

surfaces must have an Auto-On

feature. Refer to hood installation

instructions for specific hood

clearances.

The surface of the entire back wall

above the range and below the

hood must be covered with a noncombustible material such as metal,

ceramic tile, brick, marble or other

stone.

Universal Utility Locations

Non-Combustible

Material

12” Minimum

Each Side

12” Minimum

to Adjacent Wall

48” Minimum

to Combustibles

Depth

to Front

of Door

Toekick/leg

Height

29-7/8” Width

Countertop

to Cooking

Surface

18”

Min.

Page 7

Design Information

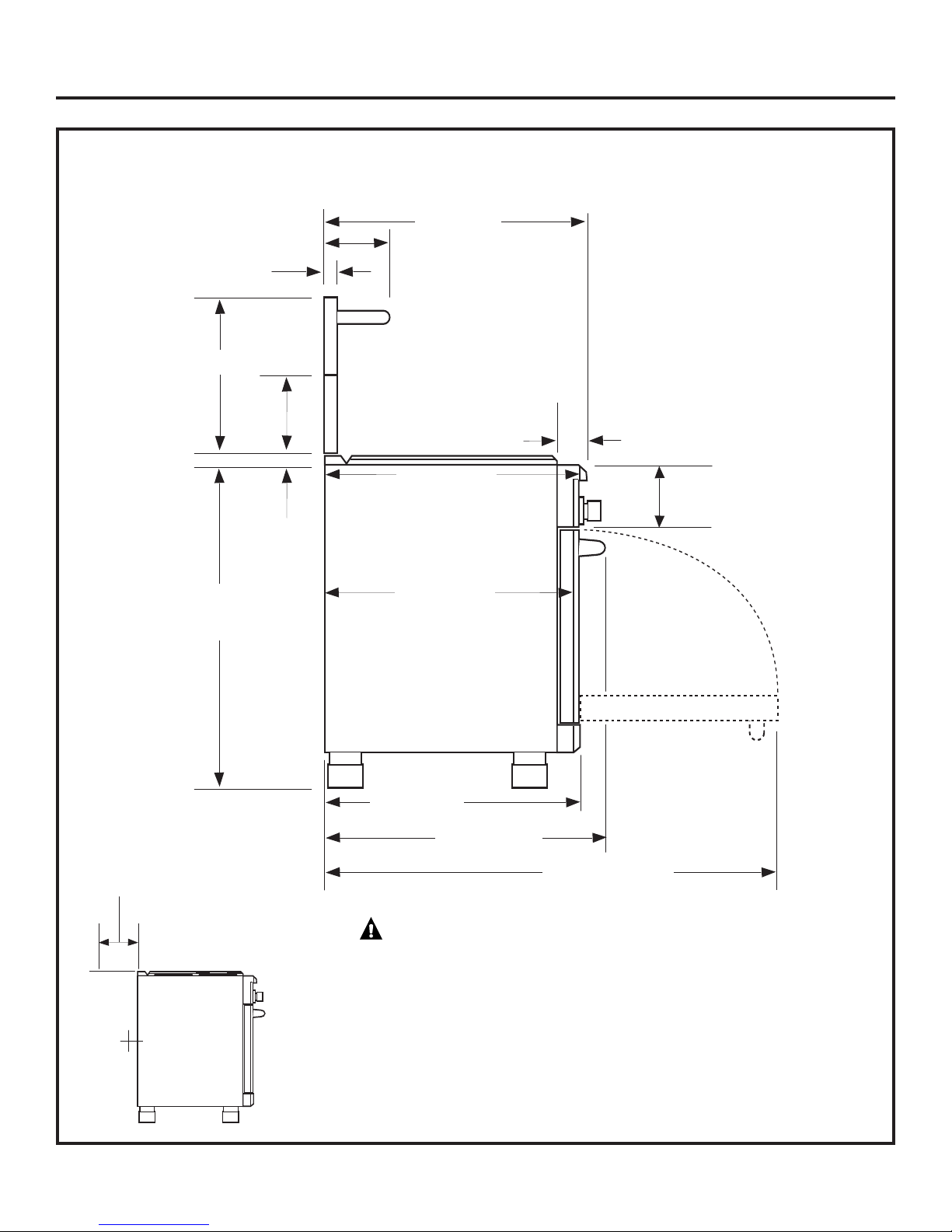

PRODUCT DIMENSIONS AND CLEARANCES

48", 36" and 30" Range Models

28-7/8”

10-1/2”

13/16”

To Front Edge

Optional

Backsplash

Accessories

12" Min. to combustibles or 0" to

a non-combustible material above

the cooking surface

30-36”

35-1/4”

to

36-3/4”

12”

1”

28-1/4” To

Beveled

Edge of Control

Panel Bullnose

27-1/2” To

Beveled Edge –

Maximum

Adjacent Cabinet

Depth for

Flush Installation

28-1/4”

To Front of Door

To Front of Handle

3-3/16”

Control Panel

Depth

7” Control Panel

Height

31-1/16”

48-1/4”

With Oven Door Open

0” Clearance

to a back or

side wall below

the cooking

surface

WARNING:

The 12” high stainless steel

backsplash accessor

installed in combination with a

custom non-combustible backsplash.

The finished backsplash must cov

the entire back wall up to the bottom

of a hood, or when ther

48” to combustibles.

y must be

er

e is no hood,

7

Page 8

Installation Information

WB28K10553 HIGH ALTITUDE KIT

For operation above 3,000 feet, order WB28K10553

Conversion Kit. This kit includes orifices for both LP

and Natural gas operation.

WB28K10554 DE-RATE KIT

(For a small kitchen environment.)

De-rate conversion kit for use with model

ZDP304N (natural gas only). This kit includes

orifices to reduce surface burner output

to 40,800 BTU’s.

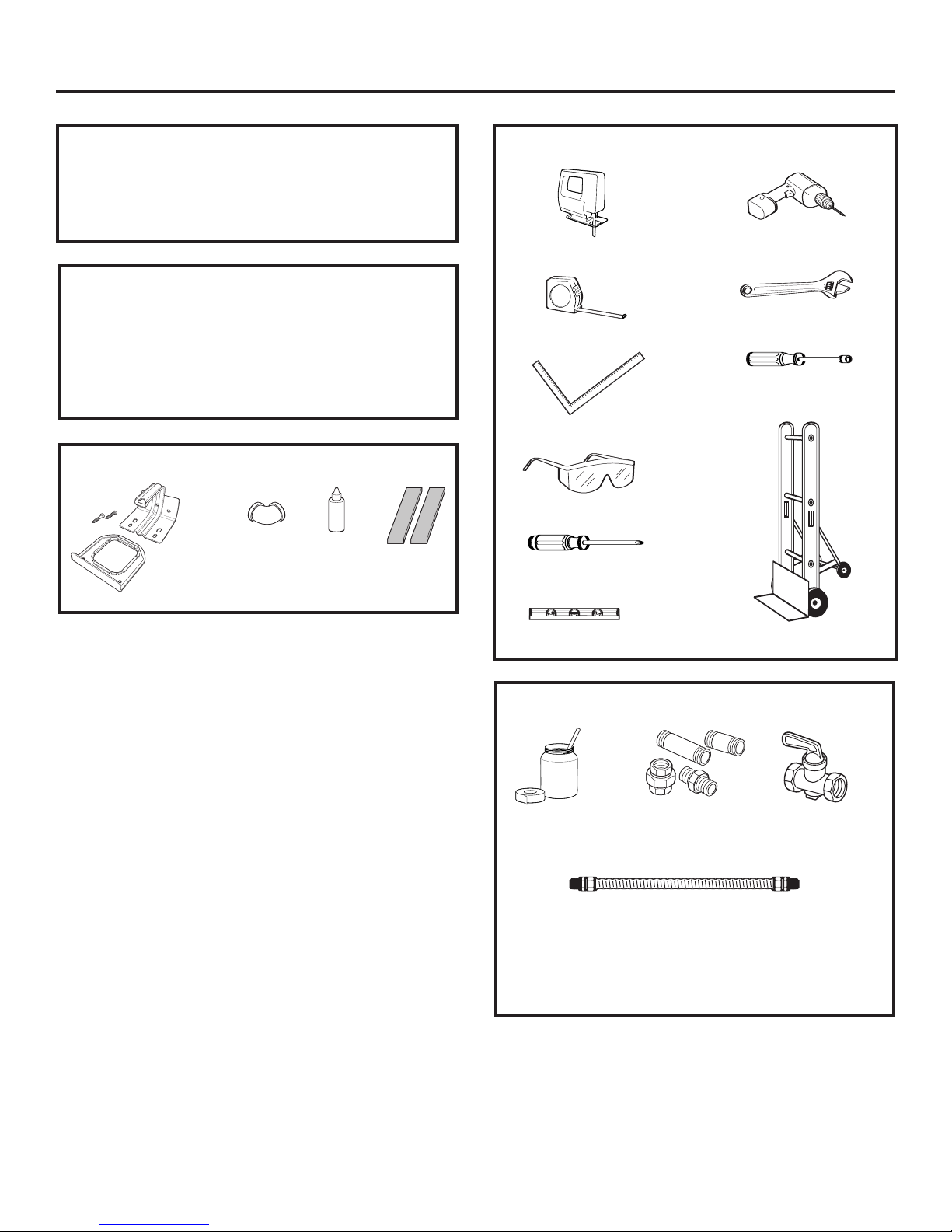

MATERIALS PROVIDED

Anti-Tip

Bracket, Brace

and Screws

1/2” Pipe

Elbow

Oven Rack

Lubricant

Runners

(to protect

flooring)

TOOLS REQUIRED

Saber Saw

Measuring Tape

Carpenter’s Square

Safety Glasses

Phillips #2 Screwdriver

rill and

D

Appropriate Bits

Adjustable Wrench

1/4” Driver or Wrench

Level

Hand Truck

MATERIALS REQUIRED (not provided)

Joint

Sealant

Pipe Fittings

5-foot maximum length, 5/8" O.D. CSA-approved flexible

metal gas supply

(3-foot maximum length in Massachusetts only)

NOTE: Pur

chase new flexible line; do not use

eviously used flexible gas line.

pr

Shut Off Valve

8

Page 9

Installation Preparation

POWER SUPPLY LOCATIONS

Gas Supply:

•The natural gas models are designed to operate

at 5" water column pressure. For proper operation,

the pressure of the natural gas supplied to the

regulator must be between 7" and 13" water

column.

•The LP models are designed to operate at 10"

water column pressure. For proper operation,

the pressure of the LP gas supplied to

the regulator must be between 11"

and 13" water column.

•A 1/2" elbow is provided for connection

to the range gas inlet, located at the rear

and near the floor.

•Locate the pipe stub on the back wall or floor

as illustrated in “Dimensions and Clearances.”

Use 5-foot maximum length, 5/8" O.D. flexible

gas supply line (3-foot in Massachusetts).

•Install a manual shut-off valve in the gas line

(not provided), in an easily accessible location.

Make sure the homeowner knows where

and how to shut off the gas supply to the range.

Electric Supply:

These ranges must be supplied with 208/240 volt,

60 Hz., and connected to an individual, properly

grounded branch circuit protected by a circuit

breaker or time delay fuse (50 amp for 48" ranges,

30 amp for 36" and 30" ranges). The receptacle

must be a NEMA 14-50R device to accept the

4-prong plug supplied with the range.

If the electrical service provided does not meet

the above specifications, it is recommended that

a licensed electrician install an approved outlet.

Locate the electric supply as illustrated

•

in “Dimensions and Clearances.”

WARNING

The range is equipped for use with an electrical

supply which uses a separate gr

(4 wire system).

If this range must be connected to an electrical

system which utilizes a single conductor for ground

and neutral (3 wire system), the grounding jumper

at the terminal block must be connected.

The gr

of the terminal block.

ounding jumper is located to the right

ounding conductor

The access plate

is on the back

of the range.

See 3-wir

9

er cord installation on the next page.

e pow

Page 10

Installation Preparation

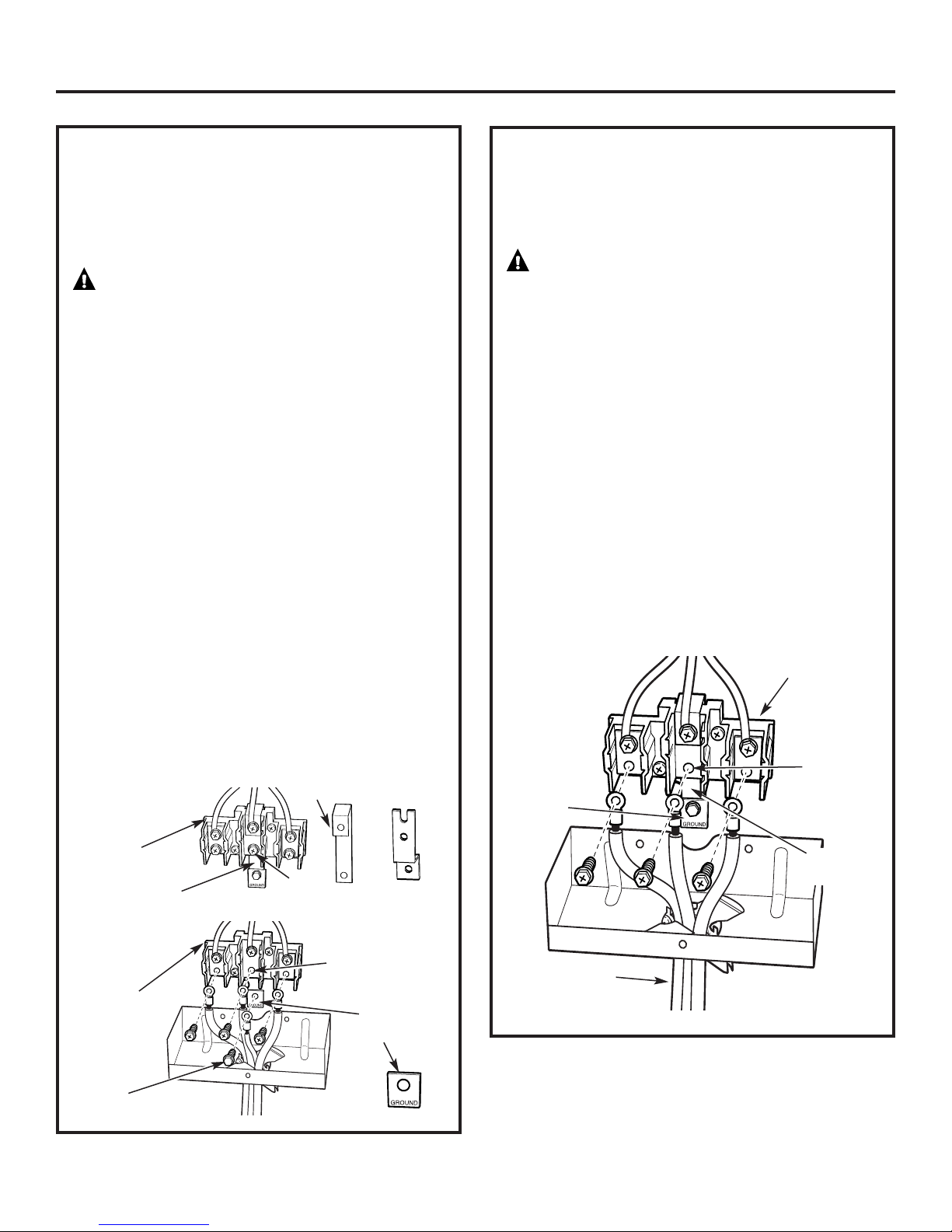

4-WIRE POWER CORD INSTALLATION

NOTE: A 4-wire cord is connected to the range

at the factory. Use the following steps to change

an existing installation from a 3-wire cord back

to a 4-wire cord.

WARNING

The neutral wire of the supply circuit must

be connected to the neutral terminal located

in the lower center of the terminal block.

The power leads must be connected

to the lower left and the lower right

terminals of the terminal block. The 4th

grounding lead must be connected to

the frame of the range with the ground

plate and the ground screw.

•Remove the 3 lower terminal screws from

the terminal block. Remov

and ground plate and r

•

Remov

THE GR

•Insert the one ground scr

ground wire terminal ring, through the ground

plate and into the frame of the range.

•Insert the 3 terminal screws (removed earlier)

thr

into the low

Be certain that the center wire (white/neutral)

is connected to the center low

of the terminal block. Tighten scr

into the terminal block.

Before

e the ground strap. DO

OUND STRAP OR ANY SCREWS.

ough each power cord terminal ring and

er terminals of the terminal block.

Terminal

Block

ound Strap

Gr

e the gr

etain them.

ew into the power cord

Neutral

Terminal

ound screw

NOT DISCARD

er position

ews securely

Ground Strap

or

3-WIRE POWER CORD INSTALLATION

NOTE: A 4-wire cord is connected to the range

at the factory. Use the following steps to change

the range to a 3-wire cord.

WARNING

The neutral or ground wire of the power cord

must be connected to the neutral terminal located

in the center of the terminal block. The power leads

must be connected to the lower left and the lower

right terminals of the terminal block.

Remove the ground strap (located at the right

•

side of the terminal block) and connect between

the center low

to the frame of the range.

•Remove the 3 low

the terminal block. Insert the 3 terminal screws

through each power cord terminal ring and

into the lower terminals

Be certain that the center wire (white/neutral)

is connected to the center lower position

of the terminal block. Tighten scr

into the terminal block.

NOT remove the ground strap connection.

DO

Ground

Plate

er portion of the terminal block

er terminal screws from

of the terminal block.

ews securely

Terminal Block

(appearance

may vary)

Neutral

Terminal

ound

Gr

Strap

er

t

Af

erminal

T

Block

Ground

Screw

Neutral T

Ground Plate

(grounding to

range)

er

minal

Power Cord

10

Page 11

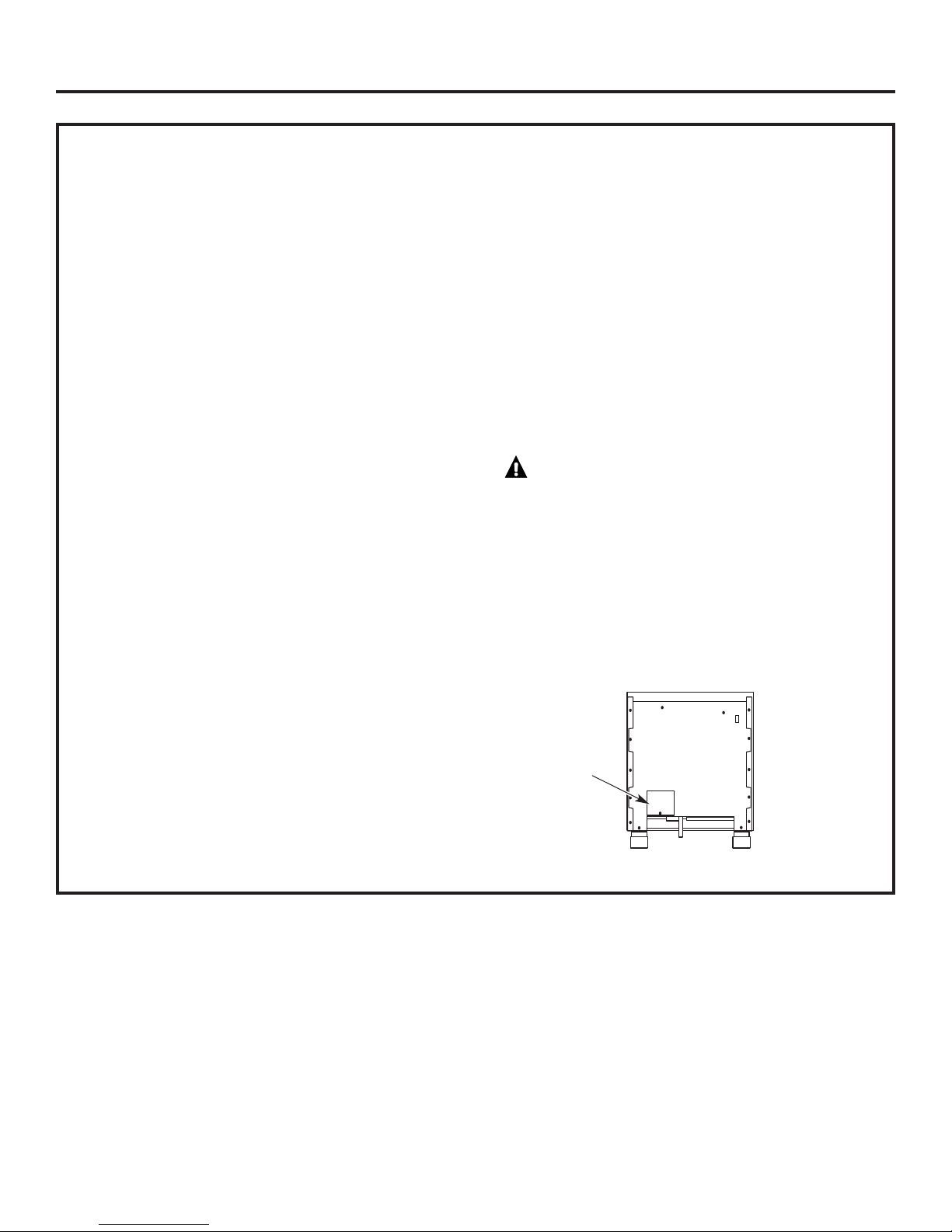

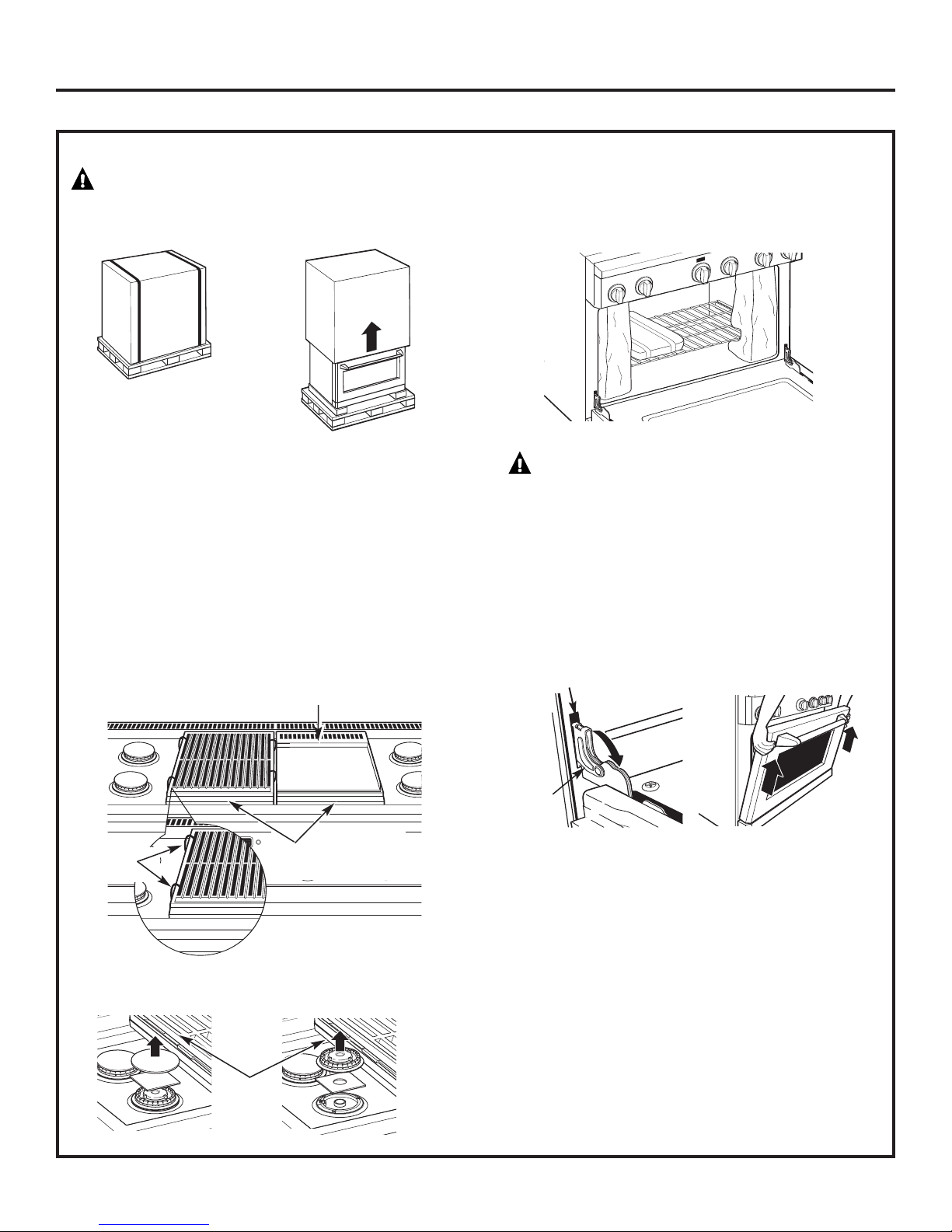

Installation

STEP 1

REMOVE PACKAGING

CAUTION

Stand clear. The ends of the cut metal banding may

snap toward you.

•Cut the metal banding. Lift the carton straight up.

•Locate the two runner strips from the top

of the packaging. These strips will be used to

protect the k

•Remove corner posts. Dispose of packaging

materials.

•Remove grill/griddle covers, grill grate and burner

grates.

•Lift out cast-iron griddle flue cover, grease troughs

and pads.

•Cut the ties holding the grill grate to the grill frame.

itchen floor during installation.

Griddle Flue Cover

• Open oven door(s) and remove packaging.

Remove shelf holding broiler pan, tape, literature

package, shelf lubricant and probe.

CAUTION

Doors and passageways leading to the installation

location require at least 32" opening. If the opening

is less than 32", the oven door(s) and control knobs

must be remov

REMOVE THE OVEN DOOR(S) ONLY IF NECESSARY to

move the range through the doorways. To prevent

damage t

necessary to pad the corners beneath the straps

on the hand-truck.

Slot

ed.

o the sides of the range, it will be

ies

T

Lift off burner caps and r

•

then lift off burner heads and remove foam pad.

Remove Foam Pads

Grease Troughs

e foam pad,

emov

Hinge

Lock

To remove the oven door(s):

• Fully open the door

• Each hinge has a hinge latch. Close the hinge

latch down against the door frame.

• Firmly grasp the door at the top sides.

• Close the door to the near

• Lift the door up and pull straight out

• Remove the control knobs by pulling them

straight out

.

.

tical position.

er

-v

11

.

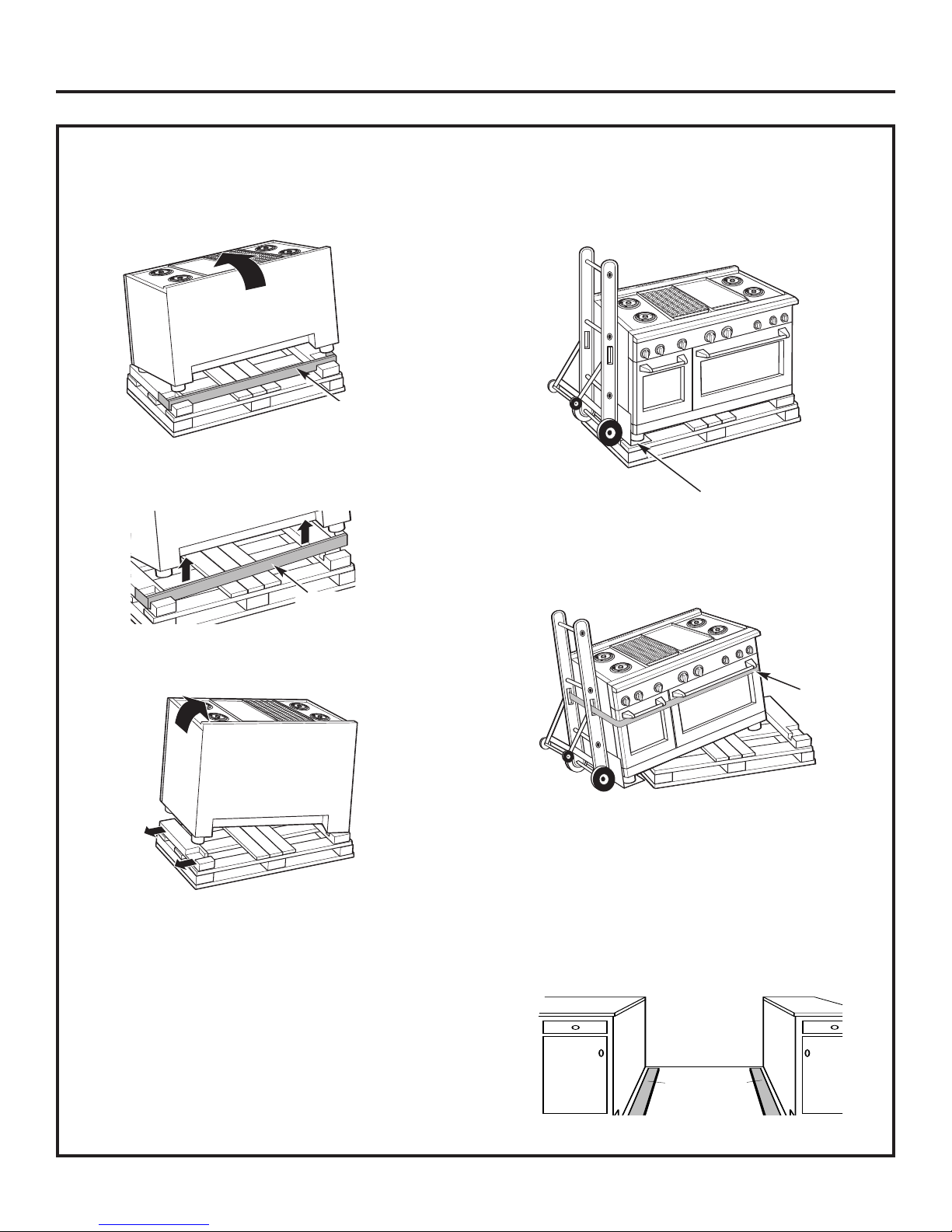

Page 12

Runners

To Support

Leveling Legs

Range

Opening

Installation Preparation

STEP 2

MOVE THE RANGE INDOORS

1 Tilt the range forward on the skid.

2 Lift the toek

ick out of the foam base.

Toekick

Toekick

4 Slide the blade of the hand-truck beneath

the front and back legs.

Insert Blade Under

the Range Legs

IMP

ORTANT

:

Place the hand-tr

uck straps below

the oven door handles.

5 Tilt the range to lower the hand-truck wheels

off the skid.

3 Tilt the range to one side and remove the foam block.

e the range indoor

6 Mov

s. Position the range

in front of the installation location.

7 Place the appliance runners on the floor

at the left and right sides of the opening.

unners provide a surface for rolling

The r

the range into the final position and will protect

the floor finish. The runners must be removed

e leveling the range.

befor

Range

Opening

Runners

for Rolling

the Range

into Position

12

Hand-Truck

Straps Below

Oven Door

Handles

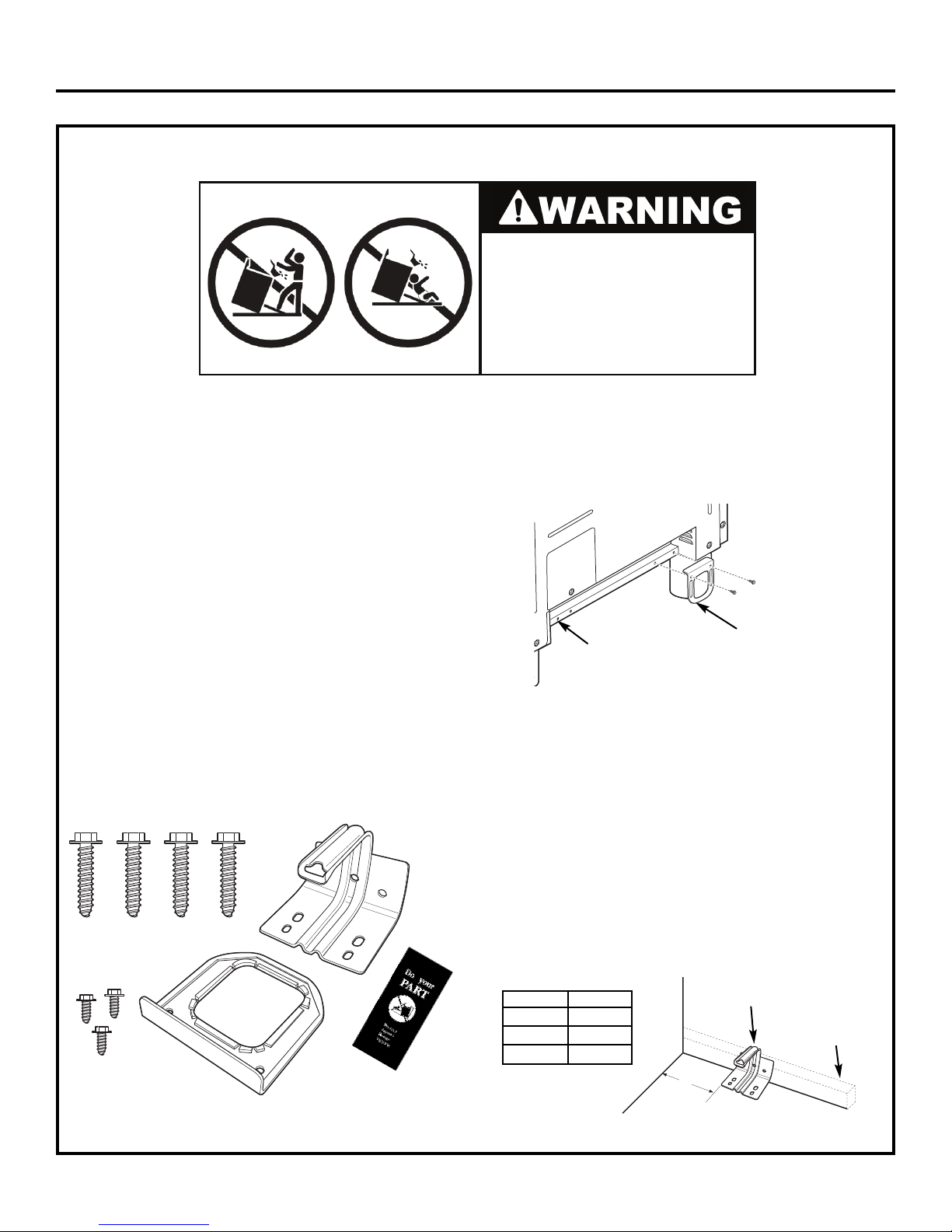

Page 13

INSTALL ANTI-TIP DEVICE

STEP 3

Installation

13

Anti-Tip Parts Provided

• Attach the Anti-Tip Brace onto the bottom

of the range in the recessed area. Install 2 hex

screws (provided) through the brace and into

the range.

NOTE: This Anti-Tip device may be installed on the

opposite side of the range.

Alternate Brace

Position

Hex Screws

Anti-Tip Brace

• Measure and mark Dimension A (see table below)

from the left (or right) side of the installation

location. If the countertop has an overhang,

add that dimension to Dimension A.

• Place the Anti-Tip Bracket against the floor

and back wall at the marked location. Mark screw

holes for fastening the bracket to the wall sole plate

and the floor.

• Drill 1/8" pilot holes at a 20° angle.

• Secure the bracket to the wall and/or floor with

at least 2 wood screws (provided).

For Concrete or Cement Construction: You must

use appropriate fastening hardware (not provided).

Anti-Tip Bracket

Anti-Tip Brace

4 Wood Screws

AHAM Anti-Tip

Safety Brochure

3 Hex Head Screws

(2 required, 1 extra)

To reduce the risk of tipping the range, the range

must be secured by a properly installed anti-tip bracket.

See installation instructions shipped with the bracket

for complete details before attempting to install.

To check if the bracket is installed and engaged properly,

carefully tip the range forward. The bracket should stop

the range within 4 inches. If it does not, the bracket must

be reinstalled.

If the range is pulled from the wall for any reason,

always repeat this procedure to verify the range

is properly secured by the anti-tip bracket.

If your range has no anti-tip bracket, call 1.800.626.8774

to receive one at no cost.

If the Anti-Tip device supplied with the range does not fit this

application, use the universal Anti-Tip device WB2X7909.

Read the AHAM Anti-Tip Safety Brochure packed

with the bracket.

Anti-Tip Bracket

A

Wall Sole Plate

Range A

30” 5-1/16”

36” 5-1/16”

48” 8-1/4”

• All ranges can tip.

• BURNS or other SERIOUS INJURIES

can result.

• INSTALL and CHECK the ANTI-TIP

bracket following these instructions.

Page 14

Installation

STEP 4

CONNECT RANGE TO GAS

WARNING

Do not use a flame to check for gas leaks.

Assure that gas supply is turned off

at the shut-off valve:

• Apply pipe thread sealant to the gas inlet located

at the back of the range. Install the 1/2" pipe

elbow (provided) to the gas inlet.

• Connect 5/8" O.D. flexible metal connector

to gas inlet. Connect the other end of the flexible

connector to the house gas supply.

Turn on the gas and check for leaks:

•

– Use a liquid leak detector at all joints

and connections in the system.

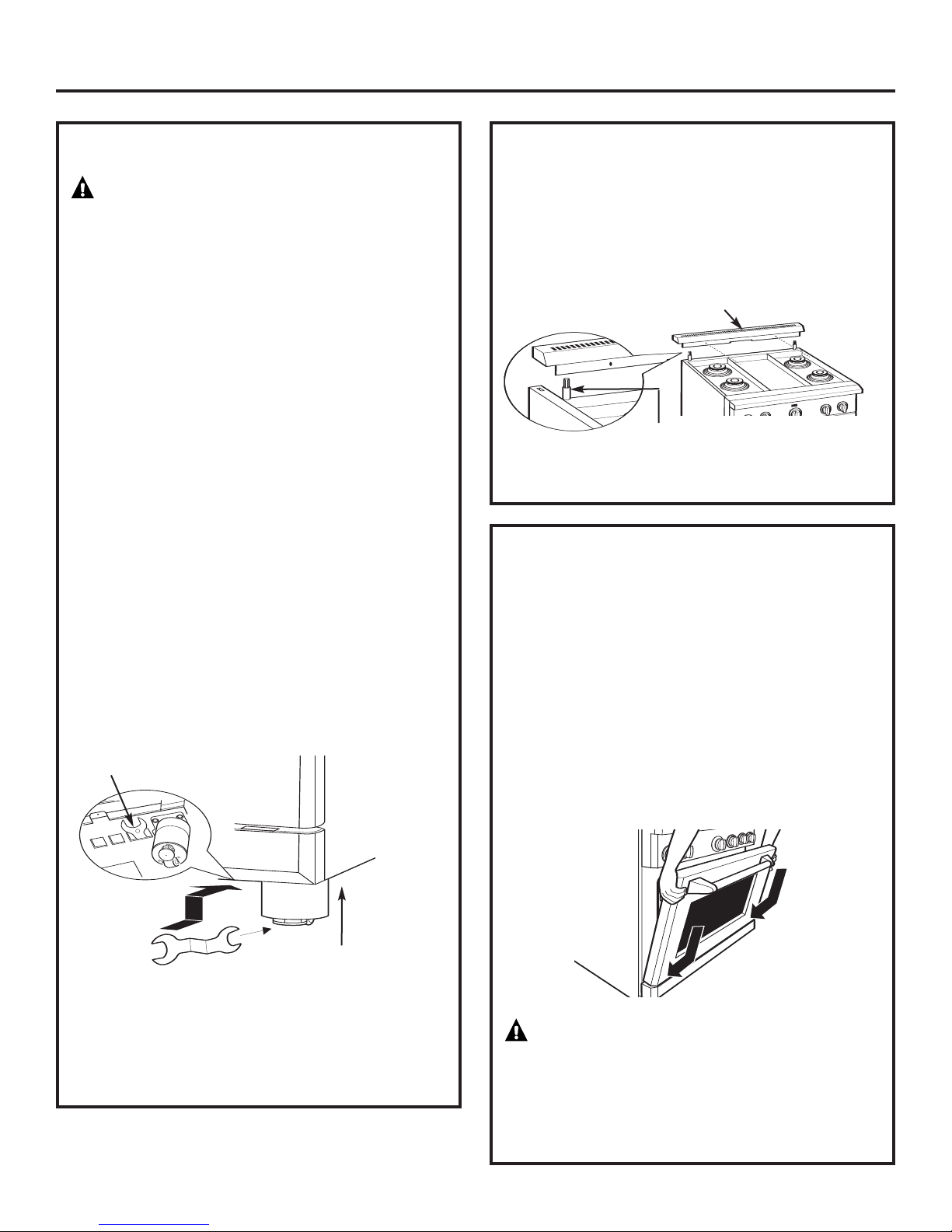

STEP 6

ROLL RANGE INTO POSITION

WARNING

The Anti-Tip Bracket must be properly installed

to prevent tipping of the range. Failure to do so

can cause serious damage or injury.

• Check to be sure the appliance runners are

beneath the wheels.

• The range is shipped with the wheels in the down

position. Carefully roll the range into position,

being car

cord and flexible gas tubing.

emove the runners beneath the range.

• R

eful not to entangle or pinch the power

Gas

Inlet

IMPORTANT: Disconnect the range and the

individual shut-off valve from the gas supply piping

system during any pressure testing of that system

at test pr

range fr

the individual manual shut-off valve to the range

during any pressure testing of the gas supply piping

system at test pr

1/2 psig.

NO

valve located on top of the range, beneath the rear

vent. This shut-off valve is to be used in the event

that ser

STEP 5

• Plug power cord into properly grounded

receptacle.

• Verify that power is connected by opening

the oven door or press the button on the left side

of the control panel to illuminate the accent

lighting.

essures greater than 1/2 psig. Isolate the

om the gas supply piping system by closing

es equal to or less than

essur

TE:

This range is equipped with a gas shut

ed in the future.

vice is r

equir

CONNECT ELECTRICAL

-off

Be sure Anti-Tip

Bracket is engaged

with the brace

on the range.

14

Page 15

Installation

STEP 7

LEVEL THE RANGE

WARNING

The range must be level and be supported

by the legs—not the wheels. The range could move

if the wheels make contact with the floor. Be sure all

legs make contact with the floor in any installation.

•All legs must be leveled after the product is

installed.

•Check to be sure the adjoining cabinets/

countertops are level, front to back and left

to right across the opening of the range.

•Measure the distance from the floor to the top

of the countertop in the left and right rear corners.

•Adjust the height of the range to countertop height

or higher

IMP

at countertop height or higher. DO NOT INSTALL

THE RANGE LOWER THAN ADJACENT COUNTERTOP

HEIGHT

regardless of countertop height.

FRONT LEG AD

•Slide front cylinders up to adjust front leveling

legs. Be car

•A leveling leg wrench is supplied. Reach under

the fr

and remove a thumb screw, then slide wrench out

of the slot.

Thumb Screw

.

ORTANT

:

This range should alw

. The range must be supported by all 4 legs,

JUSTMENT

eful not to damage cylinder.

ont of the range near the right side. Locate

ays be installed

STEP 7

REAR LEG ADJUSTMENT

•Remove two screws from rear vent trim. Slide vent

trim forward, then lift up to remove.

•Find the two rear leg extension rods. Use a 1/4"

driver or wrench to adjust the left or right rear legs.

•Replace the rear vent trim using the original screws.

STEP 8

Skip this step if oven doors are in place.

IMPORTANT:

To replace the oven doors:

•Firmly grasp the door at the top sides.

This is critical.

•Approach the range with the door angled

in a v

•Guide the hinges into the slots.

•Push the door in firmly while opening.

•Once in position, open the door completely.

Push the hinge locks back in and toward

the front frame.

LEVEL THE RANGE (cont.)

Rear Vent Trim

Rear Leg

Extension Rod

REPLACE OVEN DOOR(S)

Do not lift the door by the handle.

ertical

position.

•Use the supplied wrench to turn the front leveling

urn clock

legs. T

wheels. Turn counterclockwise to lower the legs.

•Be sure to return the wrench to its storage slot

for future use.

wise to raise the range abov

Slide leg

cylinder up.

e the

CAUTION: Take care when replacing

the ov

locked, the hinge may snap back and separate.

If the hinge separates, you must apply pr

(possibly with your foot) to pr

and then engage the hinge latch.

en door

15

s. If the hinge latch is not secur

ess it back together

ely

essure

Page 16

Installation

STEP 9

Check to be sure that burner heads and caps

are securely seated.

•Check for proper ignition:

– Push in one control knob and turn to LITE

position.

– The igniter will spark and the burner will light;

the igniter will cease spark

is lit.

– First test may require some time, while air

is flushed out of the gas line.

– Turn knob to OFF.

– Repeat the procedure for each burner.

IMPORTANT: If the igniter electrodes continue

to spark after the burners are lit, check that

each burner component is assembled properly.

Refer to the Owner’s Manual.

•Burner flames should be blue and stable with no

yellow tips, excessive noise or lifting of the flame

om the burner. If any of these conditions exist,

fr

check that the burner ports are not blocked.

If one of these conditions continues, call for

service.

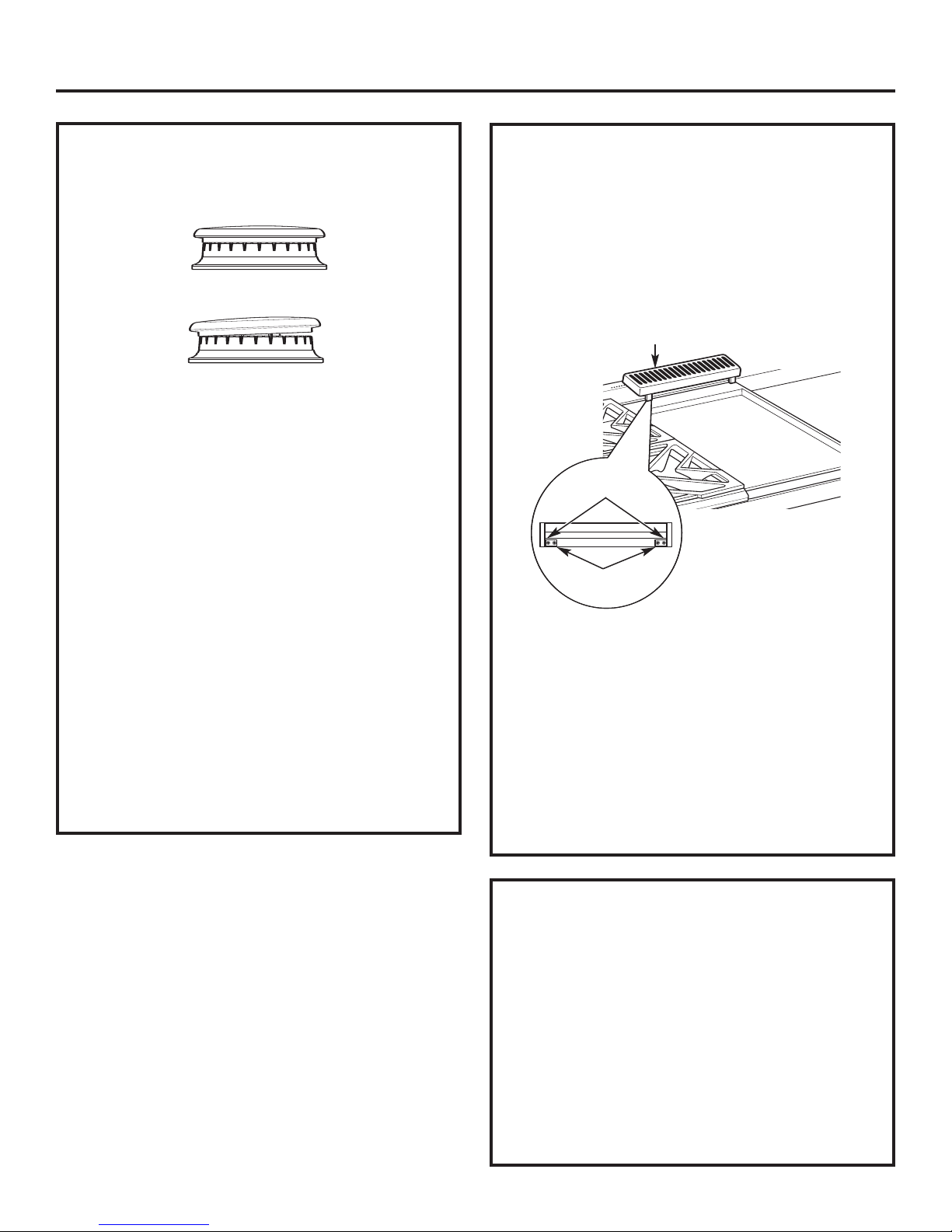

CHECK BURNERS

Burner Cap Properly Seated

Burner Cap Not Properly Seated

ing when the burner

FINALIZE INSTALLATION

Place the burner grates over the burners.

The grates should be seated and should not rock.

The griddle is secured with screws. It is designed

to be stationary and should not be removed.

The griddle has two leveling screws beneath

the rear flue cover that can be used to adjust

to the desired slope.

Griddle Flue Cover

Leveling Screws

Clamping Screws

The tw

securing the griddle in place. Loosen these two

screws before leveling. Do not remove these two

screws.

The two outer scr

remove these two screws. They can be turned to

level the griddle or to provide a forward slope to

help grease and oils drain away from the food

being cooked.

After leveling the griddle, hand-tighten

the clamping screws; do not over-tighten.

o inner screws are clamping scr

ews are lev

eling scr

ews for

ews. Do not

INSTALLATION CHECKLIST

❑ Make sure all controls are left in the OFF position.

e the flow of combustion and ventilation

❑ Mak

❑ Recheck Steps:

NOTE:

of the control panel and is visible when the oven door

is opened. The model and serial number is behind

the left knob and is visible when the knob is pulled off

16

e sur

air to the range is unobstructed.

ything in this

er

e ev

e sur

Double check t

manual has been completed. Rechecking steps

will ensure safe use of the range.

The rating plate is located on the bottom

o mak

.

Page 17

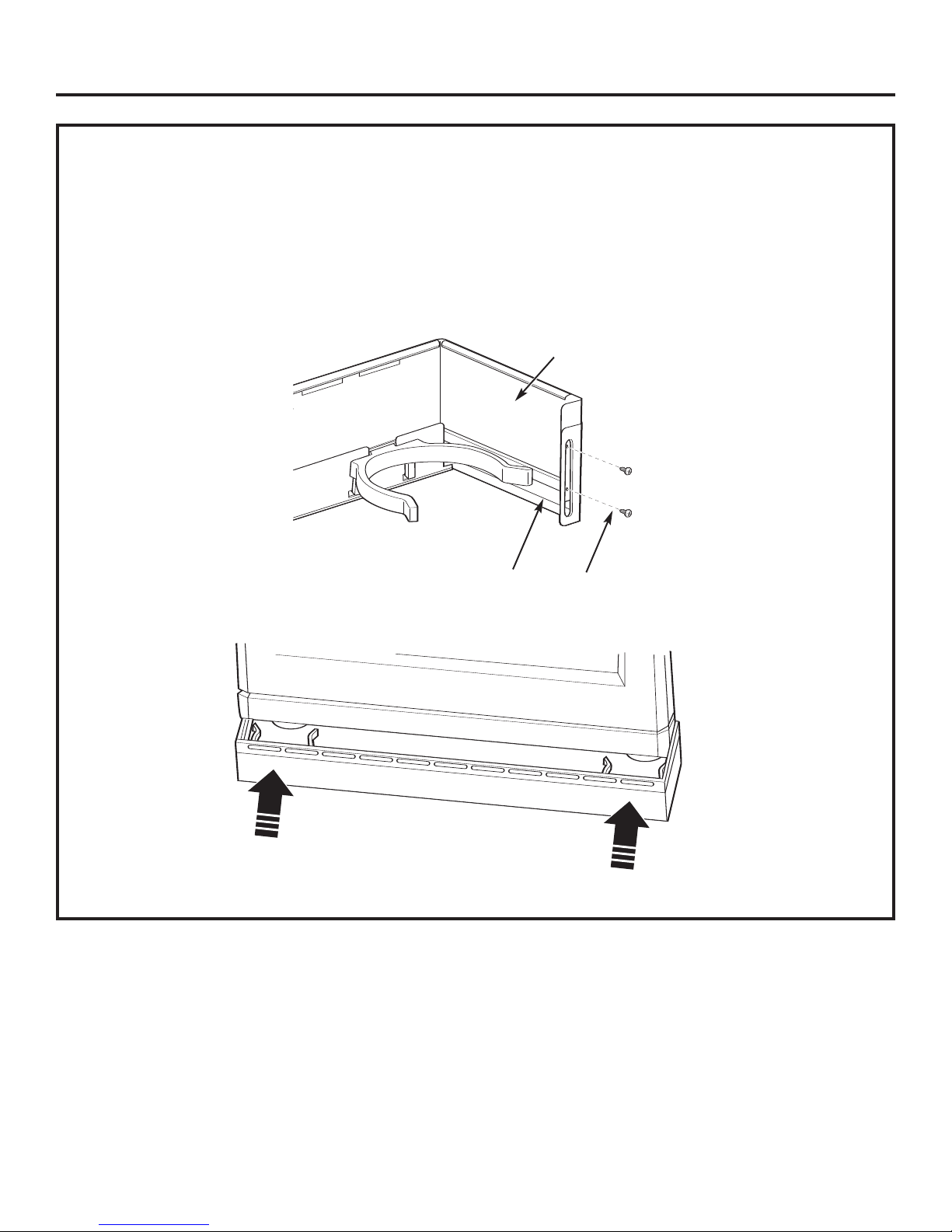

ACCESSORIES—TOEKICK (provided)

Installation

•Install the toekick after the range has been leveled.

•Measure the distance between the floor

and the bottom of range.

•Loosen the two screws on each end. Adjust

the toekick height by sliding the upper and lower

pieces apart to 1/8" less than the measured height.

•Secure the top and bottom sections by tightening

the 2 screws on each end.

•Push toekick against range leg until clip snaps

to legs.

NOTE: Be sure the toekick snaps securely to the leg.

Top of

Toekick

Bottom

of Toekick

Screw

Push

Push

17

Page 18

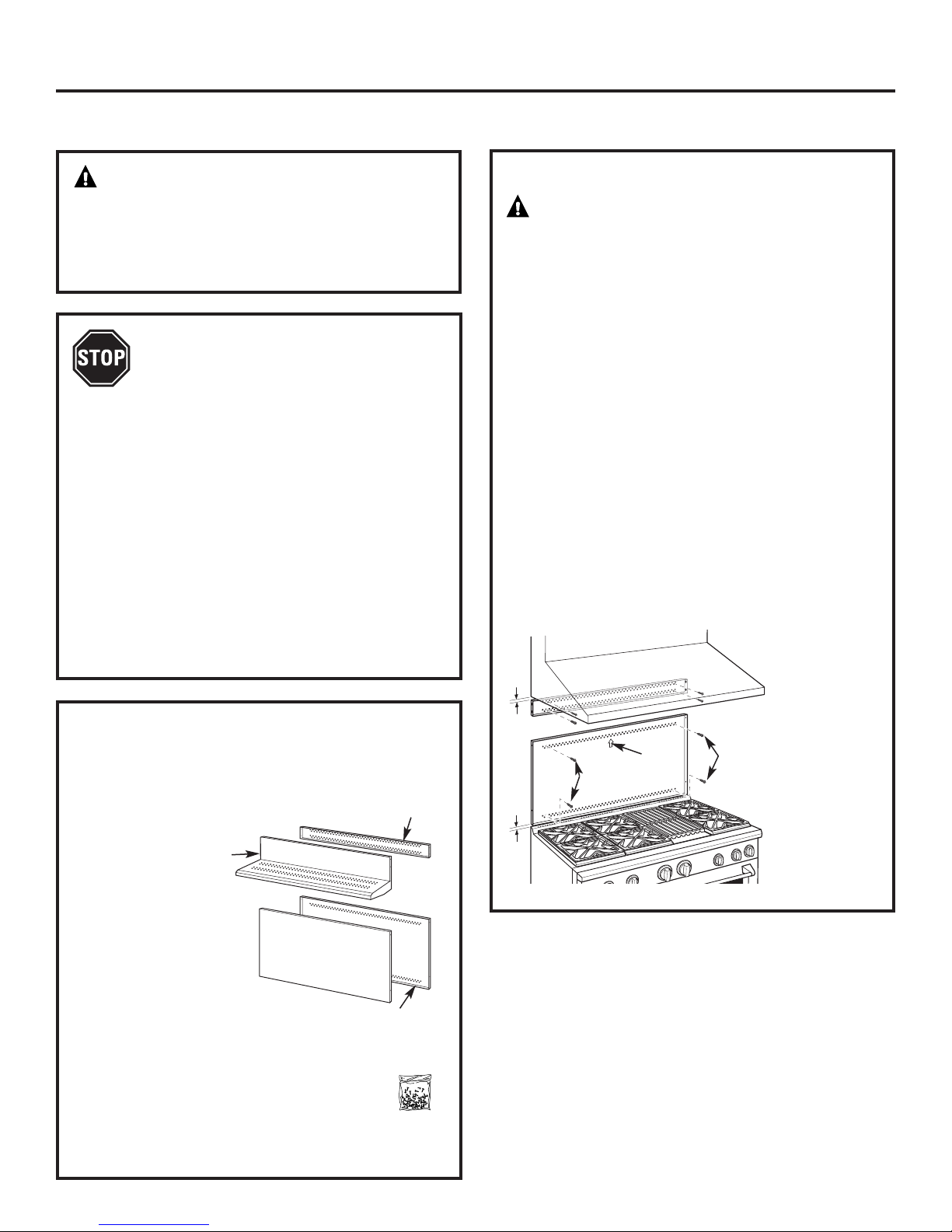

ZX12B30PSS, ZX12B36PSS, ZX12B48PSS Accessory Installation

OPTIONAL ACCESSORIES—12" HIGH BACKSPLASH

WARNING:

To prevent ignition of combustible materials,

the entire back wall above the range must

be protected by a backsplash constructed

of non-combustible material.

This stainless steel backsplash accessory

must be installed in combination with a custom,

non-combustible backsplash built beyond

the 12" height of the backsplash.

BEFORE YOU BEGIN

Read these instructions completely

and carefully.

IMPORTANT: Save these instructions for local

inspector’s use.

IMPOR

AND ORDINANCES

NO

instructions with the Consumer.

NOTE TO CONSUMER: Keep these instructions

with your Owner’s Manual for f

This kit pr

backsplash for 30", 36" or 48" Monogram

Professional Ranges and Rangetops.

TOOLS AND MATERIALS REQUIRED

•

• T-15 and #2 Phillips screwdrivers

• Drill with 3/32" and 9/64" bits

•

• Level

• Pencil

TANT: OBSERVE ALL GOVERNING CODES

.

TE TO INSTALLER: Be sure to leave these

uture refer

ovides for the installation of a 12" high

es to pr

Glov

Safety glasses

otect against sharp edges

Wall Support

Panel

Cover Panel

ence.

INSTALL 12" BACKSPLASH

WARNING: This backsplash must

be securely fastened to the wall. Failure to do

so could result in damage or personal injury.

• Install and level the range or rangetop and the

range hood according to the installation

instructions.

• Remove the backsplash packaging and

protective film.

• Use a level to pencil a horizontal line on the wall,

1/8" above the range or rangetop. The 1/8" gap

allows the cover panel to overlap the wall support

panel.

• Locate wall studs on each side. Where studs are not

ailable, plan to use wall anchors (not provided).

av

• Align the wall support panel on the marked

horizontal line and centered left to right

• The wall support panel must be secured to the wall

at all 4 corner

anchors (not provided) to secure the support panel

to the wall.

• Place the cover panel over the wall support

panel and secure with Torx screws (provided).

Install 2 screws on each side.

1/8″

all

W

Support

Panel

s. Use wood screws (provided) or wall

Install 4 Wood

Screws

Center

Arrow

Cover Panel

.

Wall Support

Panel

Install T-15

Screws

This Kit Includes

• Wall support panel

er panel

Cov

•

dware package with

Har

•

x 15 #8

or

– 5 Stainless S

self-tapping screws

– 5 Phillips #2 pan head w

#10 screws

teel T

ood

dwar

Har

Package

e

18

Page 19

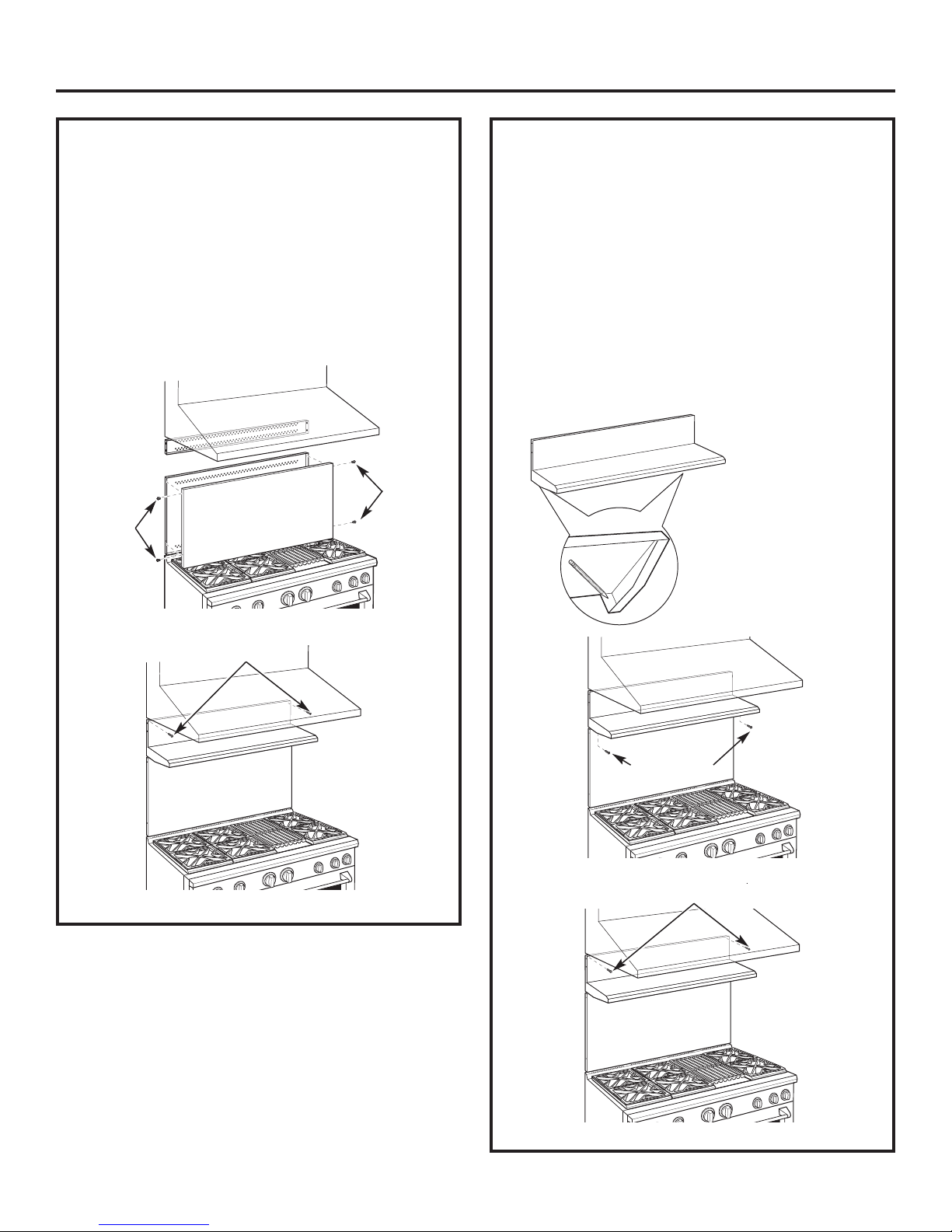

ZXADJB30PSS, ZXADJB36PSS, ZXADJB48PSS Accessory Installation

ACCESSORIES—30" TO 36" ADJUSTABLE BACKSPLASH (not included)

WARNING:

To prevent ignition of combustible materials,

the entire back wall above the range must

be protected by a backsplash constructed

of non-combustible material.

BEFORE YOU BEGIN

Read these instructions completely

and carefully.

IMPORTANT: Save these instructions for local

inspector’s use.

IMPORTANT: OBSERVE ALL GOVERNING CODES

AND ORDINANCES

TE TO INSTALLER

NO

instructions with the Consumer.

NOTE T

with your Owner’s Manual for future reference.

• This backsplash adjusts to fit the space between

• Maximum shelf load-bearing weight is 40 lbs.

O CONSUMER: Keep these instructions

op of the range and the bottom of the hood,

the t

from 30" Min. to 36" Max. height.

.

: Be sure to leave these

INSTALL THE WALL SUPPORT PANELS

W

ARNING:

must be securely fastened to the wall. Failure to

do so could result in damage or personal injury.

IMPORTANT: This backsplash is designed to cover the wall

between the bottom of the hood and the top of the range.

The vent hood should be installed over the rangetop or

range before installing this backsplash.

• Install and level the Range/Rangetop according

to the product installation instructions.

• Remove backsplash packaging and protective film.

• Locate wall studs on each side. Where studs are not

available, plan to use wall anchors (not provided).

• Use a level to pencil 2 horizontal lines on the wall,

one 1/8" below the vent hood and the other 1/8" above

the Range/Rangetop. This 1/8" space allows the cover

panels to overlap the wall supports.

• Secure the top wall support panel to the wall with 4 wood

screws, through the outermost studs.

• Use 4 wood screws to secure the bottom wall support

panel. The center slot should be positioned at the top.

The gap between the top and bottom support panels

will be covered by the top cover with shelf.

1/8″

The wall support panels

Secure the top

panel to the wall

with 4 wood

screws

TOOLS AND MATERIALS REQUIRED

• Gloves to protect against sharp edges

• T-15 and #2 Phillips screwdrivers

• Drill with 3/32" and 9/64" bits

Safety glasses

•

• Level

• Pencil

Top Cover

with Shelf

This Kit Includes

all suppor

op w

T

•

•

Bottom w

• Top cover with shelf

• Bottom cover

e package with

ar

dw

Har

•

– 9 Stainless Steel Torx 15 #8

self-tapping scr

– 9 Phillips #2 pan head w

– 3 Stainless Steel #2 truss head

#10 screws (for alternate

installation method)

t

all support

ews

Bottom Cover

Bottom Wall Support

ood #10 scr

Top Wall

Support

ews

Hardware

Package

19

1/8″

Center

Wood Screws

Arrow

Wood

Screws

Secure

the bottom panel

to the wall with

4 wood screws

Page 20

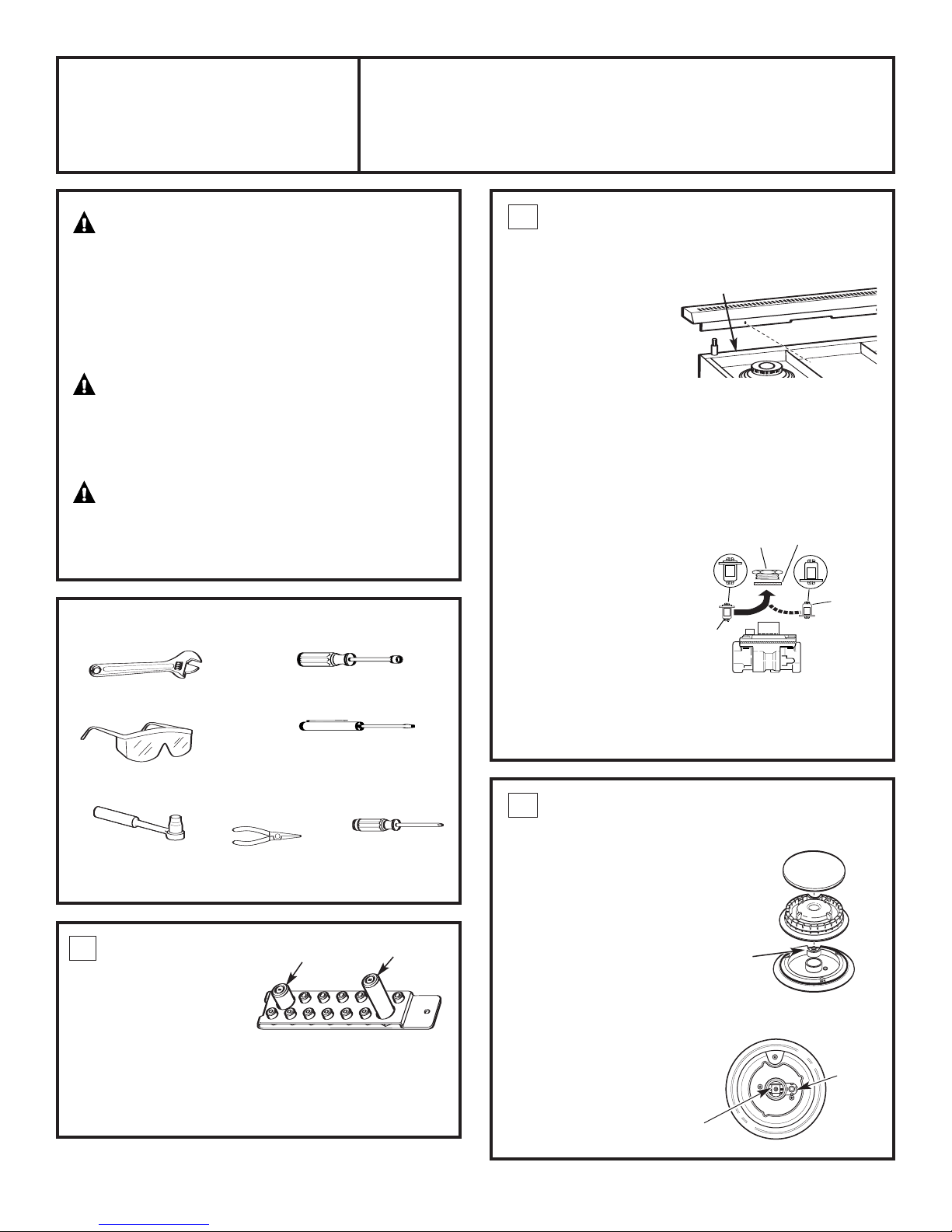

ZXADJB30PSS, ZXADJB36PSS, ZXADJB48PSS Accessory Installation

INSTALL COVER PANELS

See alternate method if side access is blocked.

• Hold the bottom cover over the bottom support

while driving one screw (provided) into each side.

• Place the top cover with shelf over the top wall

support. If you have access to the sides, secure

the panel with two screws on each side.

• Secure the top cover with shelf to the top

support with screws through the front of the panel,

at the top corners. Use one screw on each side.

Install

Cover Panel

Install

Screw

Screw

INSTALL COVER PANELS (cont.)

ALTERNATE METHOD: When side access is blocked

• Install bottom cover over the bottom support while

driving one screw into each side.

• Hold top cover in place while marking screw

locations, just below shelf support and onto bottom

cover.

• Remove the shelf and drill a 9/64" diameter

hole in the pencil-marked locations.

• Mount the top cover over the top support

and secure the front cover with screws through

the drilled holes on each side.

• Install screws through each top corner.

Mark Scr

for Alternate Method

ew Locations

Install Corner Screws

Install Screw

on Each Side

Install Screw in Top Corner on Each Side

Shelf

20

Page 21

DOWN

FOR OFF

N

AT

LP

LP

NAT

L

P

N

AT

N

AT

L

P

Installation Convert Natural Gas to LP Gas Operation

Instructions Convert LP Gas to Natural Gas Operation

2

WARNING: This conversion must

be performed by a qualified installer or gas supplier

in accordance with the manufacturer’s instructions

and all codes and requirements of the authority having

jurisdiction. Failure to follow instructions could result

in serious injury or property damage. The qualified

agency performing this work assumes responsibility

for the conversion.

WARNING: The rangetop, as shipped from

the factory, is set for use with its intended gas. If you

wish to use your rangetop with the alternate gas, you

must first replace the orifices and convert the pressure

regulator.

WARNING: The following adjustments must

be made before turning on the burner. Failure to do so

essure regulator

esult in serious injury. Be sur

could r

has been converted as described in Step 2.

TOOLS YOU NEEDED FOR CONVERSION

e pr

CONVERT THE REGULATOR

Disconnect all electrical power at the main circuit

breaker or fuse box.

A. Remove the rear vent

trim (on ranges only)

to access the

regulator. The

Rangetop regulator is

on the left bottom

corner.

B. Shut off the gas supply by closing the manual shut-off

valve in the unit or at the wall.

C.

Convert the pressure regulator:

• Unscrew the cap with plunger.

• Place your thumb against flat side of the plunger and

press down to snap the plunger out of the cap.

• Carefully look at the plunger to locate the NAT

or LP position.

• Turn the

plunger

over so

that the

desired gas

is showing

near the

bottom.

Range Regulator

NAT. Position

Cap

Gasket

Plunger

LP Position

Crescent Wrench

Safety Glasses

1/2” Deepwell

Socket W

1

ORIFICE HOLDER

ench

r

Small Pliers

1/4” and 7mm Nutdrivers

Small Flat-Head Screwdriver

(2 to 2.4 mm or 3/32” tip size,

60 mm long)

Griddle

Orifice

The range orifice holder

is located behind the front

access panel at the bottom

of the range.

The rangetop orifice holder

Burner Orifices

is located inside the range insulation cover.

. Use only the orifices

Additional orifices may be pr

specified in the instructions for your range or rangetop.

esent

Philips

Scr

ewdriver

Grill

Orifice

• Snap the plunger back into the cap

• Screw the cap back onto the regulator.

3

CHANGE BURNER ORIFICES

INSTALLATION TIP: First remove all

orifices and then star

t replacing them.

This will help to prevent the possibility

that some may not be replaced.

A. Remove the burner grates,

burner caps and burner heads.

B. Loosen the top burner

orifices using a 7 mm

nut driver. Use small

efully lift out the orifices.

s to car

plier

The main orifice is located

low in the center of the

burner, while the simmer

orifice is located higher

beside the center

of the burner

.

21

Pressure Regulator

.

Burner Cap

Burner

Head

Spark

Igniter

Burner Base

Simmer

Orifice

Main

Orifice

Page 22

Installation Instructions for Gas Conversion

3

CHANGE BURNER ORIFICES (cont.)

IMPORTANT: Find your model number below. Read

each orifice label to identify and install them in the

exact locations shown.

ZDP304 SIMMER ORIFICES

A 34SL or 51SN orifice

will be used on all burners.

ZDP304 MAIN ORIFICES

Use a 108XL

or 190XN orifice

A 84XL or

126HXN orifice

will be used

on these three

burners.

for the right

front burner.

4

CHANGE GRILL ORIFICE

Locate the 1–1/2” long Grill orifice.

Select for your gas type. LP

—

.047, NAT—.067

A. Remove the grill cover,

grates and grate frame. Lift

the radiant baffle straight

up and off.

B. Remov

e the 2 hex

head screws from

the top of the igniter.

• Remov

e one scr

ew

Remove 2

hex head

screws

from each side of

the burner surround.

• Lift out the surround.

(if present)

Surround

Screws

ZDP364, ZDP366, ZDP484, ZDP486

SIMMER

ORIFICES

MAIN

ORIFICES

A. Return the unused orifices to the holder. Reattach

the holder and the instruction sheet with screw

in the original storage location.

B. Replace the burner heads, caps and top grates

On range models, replace rear vent trim.

A 34SL or 51SN orifice

will be used on all

burners.

Use 108XL or

190XN orifices

for all burner

s.

C. Carefully push the

igniter aside and

Burner

Surround

Igniter

under

the burner.

Do not pull or pinch

the wire.

Remove 4 burner

Burner

Assembly

attachment screws,

2 at the fr

at the back

ont and 2

. Slide the

burner assembly

toward the back and

out of the gas inlet

D. Use a 1/2" deep well

.

Front of Range

socket to remove

eplace the orifice .

and r

Reverse these

steps to re-assemble

the grill. Be sure to

.

place the unused

orifice in the holder

for possible f

uture use.

22

Page 23

Installation Instructions for Gas Conversion

5

CHANGE GRIDDLE ORIFICE

Locate the 3/4” long Griddle orifice.

Select for your gas type. LP

—

.047, NAT—.076

A. Lift off

the griddle flue

cover. Remove

the 2 inside

clamping

Griddle Flue Cover

A

screws.

B. Use a pad or

piece of

carton to

protect

the adjacent

Leveling Screws

surface. Slide

the griddle

ard

tow

Clamping Screws

the rear

and out of

the hold-down tabs along

B

the bottom.

C. CAREFULLY lift and hold

the griddle. A thermostat

y is routed through

capillar

a clip. Gently lift the griddle

to one side and slip the

y out of the clip.

capillar

D. Lay the griddle

C

on the padded surface.

Do not disconnect or pull

on the capillary.

E. Remov

e the 2 burner

hold-down screws

at the rear of the burner.

• Pull the burner straight

back tow

ard the rear

D

and out of the gas inlet.

F. Use a 1/2" deep well socket

emove and replace

to r

the orifice.

(if present)

NOTE: Remove

the 2 screws

positioned on

the inside only.

Do not remove

the outermost

screws—they

are for leveling.

Capillary

6

ADJUST BURNER FLAMES

Normally, burners do not need further adjustment.

Make adjustments only when necessary.

A.

Turn on the gas. Plug in electrical cord.

B. Turn all burners on highest setting and check

the flames. They should be blue in color. When

using LP gas, the flames may have some yellow

tipping at the ends of the flame. Foreign particles

in the gas line may cause an orange flame at first,

but this will soon disappear.

C. Turn the burner knob to “LO” while observing the

flame.

Adjust the setting of the upper row of flames using

the valve bypass screw as follows:

Adjustments must be made with two other burners

in operation on a medium setting. This prevents

the upper row of flames from being set too low,

resulting in the flame being extinguished when

other burner

s are turned on.

D. To adjust the flame, remove the knobs. Insert a small

flat-blade screwdriver into the hole in the center

of the valve stem to engage screw.

• If the flames are too small or flutter,

turn the screw counterclockwise.

E

Back of Range

F

Reverse these steps to re-assemble the griddle. Push excess

capillary back into the entry hole. Route the thermostat

capillary so it is held by the clip. Place the unused orifice in

the holder for possible future use.

Once the conversion is complete and checked, fill out the conversion label and affix the label near the rating label. For ranges,

place the label beneath the contr

ol panel. For rangetops, place the label on the bottom of the unit

Front of Range

• If the flames are too large, turn the screw

clockwise.

E. Make the adjustment by slowly turning the screw

until flame appearance is correct.

.

23

Page 24

Consignes d’installation

AVANT DE COMMENCER

Lisez attentivement l’ensemble des consignes.

•

IMPORTANT — Conservez ces consignes,

elles peuvent vous être utiles pour toute

inspection de votre installation.

•

IMPORTANT — Respectez toutes les

normes ainsi que les recommandations

préconisées par les autorités compétentes.

• Remarque à l’attention de l’installateur —

Après intervention, assurez-vous d’avoir remis

ces instructions à l’utilisateur.

• Remarque à l’attention de l’utilisateur —

Conservez ces instructions avec le manuel

de l’utilisateur pour toute consultation ultérieure.

• Temps d’installation — 1 à 3 heures.

• Il incombe à l’installateur de veiller à la bonne

installation. T

à une installation non conforme ne pourra être

er

couv

d’information, reportez-vous au manuel

de l’utilisateur.

oute défaillance du produit due

te par la garantie. Pour tout complément

AVERTISSEMENT:

Cet appareil doit être correctement mis à la terre.

Reportez-vous à la section « Alimentation

électrique ».

Pour contacter le service de dépannage Monogram

le plus proche de chez vous, veuillez appeler

le 1.800.444.1845.

.Pour contacter le service de dépannage Monogram

du Canada, v

1.800.561.3344.

Pour contacter le service d’accessoires et de pièces

détachées Monogram, veuillez appeler

le 1.800.626.2002.

Si vous recevez une cuisinière défaillante, veuillez

contacter v

Dans le Commonwealth of Massachusetts

(Communauté du Massachusetts) :

• Ce produit doit être installé par un plombier

ou un technicien gaz agréé.

• Si vous utilisez des robinets d’arrêt gaz, ceux-ci

doivent être de type 1/4 de tour.

• Si vous utilisez un raccord à gaz flexible, celui-ci

ne dois pas mesurer plus de 3 pieds (100 cm).

euillez appeler le numéro

evendeur.

e r

otr

AVERTISSEMENT:

Toutes les cuisinières peuvent se renverser au risque

de provoquer de graves blessures. Installez le support

antibasculement fourni conformément aux instructions

figurant dans ce manuel ou à celles fournies av

le support.

ec

Dispositions de hotte

d’extraction:

Il est recommandé d’installer nos cuisinières avec une hotte

d’extraction suspendue.

• Installez une hotte disposant d’une capacité d’évacuation

d’au moins 1200 CFM (pieds cubes par minute ou 35

mètres cubes/m) à une distance de 48" (122 cm)

de la table de cuisson.

• Installez une hotte disposant d’une capacité d’évacuation

d’au moins 600 CFM (ou 18 mètres cubes/m) au-dessus

d’une table de cuisson de type 30’’ (76 cm) ou 36” (91 cm).

Cet appareil produisant une importante quantité de chaleur,

vous devez porter une attention toute particulière à

l'installation de la hotte et de la conduite d'aération afin

de vous assurer qu’elle répond aux normes de construction

en vigueur dans votre région.

AVERTISSEMENT:

Vous trouverez ci-dessous les espaces qui doivent être

respectés entre la surface de la table de cuisson et le

plafond ou encore toute surface horizontale se trouvant

au-dessus de la table de cuisson:

• Pour les installations dépourvues de hotte, prévoyez

un espace minimum de 48” (122 cm) entre l’appareil

et tout élément inflammable situé au-dessus de celui-ci.

• Il est possible d’installer une hotte spéciale à proximité

d’éléments horizontaux inflammables dans la mesure

où celle-ci dispose d’une fonction de mise en marche

automatique.

• Pour obtenir les spécifications relativ

d’autres installations pourvues d’une hotte, veuillez vous

reporter aux instructions fournies avec celle-ci.

es aux espaces

ATTENTION:ces cuisinièr

plus de 300 kg. Afin d'éviter tout risque de blessure

ou d’endommagement de l’appareil et compte tenu

du poids et de la taille de la cuisinièr

DEUX PERSONNES SONT NÉCESSAIRES POUR UNE

INSTALLATION ADÉQUATE DES CUISINIÈRES 76 cm

et 91 cm.

TROIS PERSONNES SONT NÉCESSAIRES POUR UNE

INSTALLATION ADÉQUATE DES CUISINIÈRES 121 CM.

Veuillez vous reporter aux consignes du fabricant pour détecter

la présence de fuites.

’installation doit r

L

égion. En l’

r

suivant la dernière édition du code national pour les appareils au

gaz, ANSIZ223.1/NFPA 54, et la dernière édition de la norme

américaine pour les appareils électriques ANSI/NFPA 70. Au

Canada, l’installation doit respecter la loi en vigueur spécifiée par

la norme canadienne CAN/CGA-B149.1 pour les appareils au gaz

naturel ou la norme CAN/CGA-B149.2 pour les appareils

au propane en vigueur, et ses lois qui entrent dans son domaine

application. Cette cuisinièr

d’

espect de la dernière édition de la norme ANSI Z21.1, ainsi que

le r

l’

Association canadienne du gaz et dans le respect de la dernière

édition de la norme CAN/CGA-1.1.

especter les normes en vigueur dans v

absence de celles-ci, la cuisinière doit être installée

e a été conçue et cer

24

e:

tifiée CS

es pèsent

e

otr

A et dans

Page 25

Caractéristiques

TABLE DES MATIÈRES

Caractéristiques

Modèles disponibles............................................................25

Accessoires du dosseret....................................................25

Dimensions du produit et espaces requis ........26-29

Outils et matériel requis .................................................. 30

Préparation de l'installation

Emplacement des alimentations ..........................31, 32

MODÈLES DISPONIBLES

Les cuisinières Monogram sont conçues en usine

pour fonctionner au gaz naturel ou au gaz propane.

Commandez le modèle correspondant à votre

installation domestique.

Modèles au gaz naturel 48” (122 cm) :

ZDP484NG – 4 brûleurs à gaz, grill et plaque chauffante

ZDP486NR – 6 brûleurs à gaz et grill

ZDP486ND – 6 brûleurs à gaz et plaque chauffante

Modèles au gaz propane 48” (121 cm):

ZDP484LG – 4 brûleurs à gaz, grill et plaque chauffante

ZDP486LR – 6 brûleurs à gaz et grill

ZDP486LD – 6 brûleurs à gaz et plaque chauffante

Consignes d’installation

Étape 1, Sortez l’appareil de son emballage ..........33

Étape 2, Déplacez la cuisinière à l’intérieur ............34

Étape 3, Installez le support anti-basculement ....35

Étape 4, Raccordez la cuisinière à l’alimentation en gaz 36

Étape 5, Branchez la cuisinière à la prise électrique ......36

Étape 6, Placez la cuisinière dans sa position

en la faisant rouler ............................................36

Étape 7, Ajustez le niveau de la cuisinière................37

Étape 8, Réinstallez les portes du four ......................37

Étape 9, Vérifiez les brûleurs ..........................................38

Terminez l’installation ........................................................38

Liste de vérification pour l’installation........................38

Accessoires..............................................................................39

Installation des accessoires ..................................40–42

Conversion de la cuisinière pour le gaz ............43-45

Modèles au gaz naturel 36” (91 cm):

ZDP366N – 6 brûleurs à gaz

ZDP364NR – 4 brûleurs à gaz et grill

ZDP364ND – 4 brûleur

s à gaz et plaque chauffante

Modèles au propane 36” (91 cm):

ZDP366L – 6 brûleurs à gaz

ZDP364LR – 4 brûleurs à gaz et grill

ZDP364LD – 4 brûleurs à gaz et plaque chauffante

Modèle au propane 30” (76 cm) : ZDP304N

Modèles au gaz naturel 30” (76 cm) : ZDP304L

DOSSERET

ent au minimum 12"

ous les modèles r

T

(30 cm) d’espace de séparation arrière avec toute

surface inflammable. Si cet espace est inférieur à

12” (30 cm), la totalité de la surface du mur se

trouvant derrière et au-dessus de la cuisinière doit

être protégée par un dosseret. Le dosseret doit être

fabriqué à l'aide d'une matièr

métal, la tuile en céramique, la brique, le marbre

ou tout autre pierre.

Deux dosserets sont disponibles:

• Il existe un dosseret de 12" (30 cm) en acier

inoxydable. Utilisez ce dosser

dosseret spécial et ignif

du premier. La hauteur des deux dosserets

combinés doit atteindre la partie inférieure

de la hotte, ou en l’absence de hotte, la hauteur

totale à partir de la surface de cuisson doit

atteindre les 48” (122 cm).

equièr

e ignif

et couplé à un

uge monté au-dessus

uge comme le

25

Il exist un dosser

•

(91cm). Ce dosser

le dessus de la cuisinière et la partie inférieure

de la hotte. L’étagère est conçue pour que les

ampoules d’une hotte professionnelle Monogram

soient orientées vers elle.

et adjustable de 30” (76cm) – 36”

et comble l’espace entr

et de 30cm, 48 cm (12") de hauteur

Dosser

ZX12B48PSS, pour les cuisinières de 121 cm (48")

ZX12B36PSS

ZX12B30PSS, pour les cuisinières de 76 cm (30")

Dosseret à hauteur réglage avec étagère 76 cm-91

cm (30"-36")

ZXADJB48PSS, pour les cuisinières de 121 cm (48")

ZXADJB36PSS

ZXADJB30PSS, pour les cuisinières de 76 cm (30")

, pour les cuisinièr

, pour les cuisinièr

e

es de 91 cm (36")

es de 91 cm (36")

Page 26

Caractéristiques

DIMENSIONS DU PRODUIT ET ESPACES DE SÉPARATION

Modèles de cuisinière 121 cm (48")

1”

lan de

P

ravail

t

surface

à

e cuisson

d

3-1/4” (6,98 cm)

4-3/4” (8,25 cm)

Plinthe/

Hauteur de pied

(13,97 cm)

to

35-1/4” (88,26 cm)

to

36-3/4” (90,8 cm)

de hauteur

28-1/4”

(70,48 cm)

Profondeur

jusqu'à l'avant

de la porte

47-7/8” (117,15 cm)

e largeur

d

(2,5 cm)

Emplacements de raccord universels

8”

(20,32 cm)

14”

6-1/2”

(35,56 cm)

Gaz/

Electricité

(40,64 cm)

Electricité

2”

(5 cm)

48”

(121 cm)

16”

2” (5 cm)

AVERTISSEMENT:

Pour les installations dépourvues

de hotte, prévoyez au minimum un

espace de 48’’ (122 cm) entre

l’appareil et toute matière

inflammable. Il est possible d’installer

une hotte spéciale à proximité

d’éléments horizontaux inflammables

dans la mesure où celle-ci dispose

d’une fonction de mise en marche

automatique. Pour obtenir les

spécifications d’espace pour d’autres

installations pourvues d’une hotte,

veuillez vous reporter aux instructions

fournies avec celle-ci.

La totalité de la surface du mur arrièr

ainsi que la surface se trouvant audessus de la table de cuisson doit être

faite d'une matière ignifuge comme

le métal, la tuile en céramique,

la brique, le marbre ou tout autre

e.

pierr

13"

(33 cm) max.

e

30 cm (12”) au moins

À 48” (122 cm)

de toute matériau

inflammable

Matériau ignifuge

Minimum 12”

(30,4 cm) de

chaque

48'' (121 cm) min.

CES SUPPLÉMENT

A

ESP

Prévoyez un espace minimum de 30 cm (12’’) par rapport au

mur adjacent sur chaque côté.

Les espaces de transit autour de la table de cuisson doiv

e séparées par un espace d’au moins 45,7 cm (18’’) entre

êtr

le plan de travail et le bas du placard mural.

(45,7 cm) Min.

par rapport au mur

adjacent.

18"

AIRES :

ent

26

Page 27

Caractéristiques

DIMENSIONS DE L’APPAREIL ET ESPACES

Modèles de cuisinière 91 cm (36’’) Caractéristiques

”

35-7/8”

Largeur

de (86,67 cm)

1

2,5 cm)

(

lan de

P

ravail

t

surface

à

e cuisson

d

mplacements de raccord universels

E

4-5/8” (8,57 cm)

35-1/4” (88,26 cm)

to

36-3/4” (90,8 cm)

de hauteur

28-1/4”

Profondeur

jusqu'à l'avant

de la porte

AVERTISSEMENT:

Pour les installations dépourvues

de hotte, prévoyez au minimum un

espace de 48’’ (122 cm) entre

l’appareil et toute matière

inflammable. Il est possible d’installer

une hotte spéciale à proximité

d’éléments horizontaux inflammables

dans la mesure où celle-ci dispose

d’une fonction de mise en marche

automatique. P

spécifications d’espace pour d’autres

installations pour

veuillez vous reporter aux instructions

fournies avec celle-ci.

La totalité de la surface du mur arrière

ainsi que la sur

dessus de la table de cuisson doit être

faite d'une matièr

le métal, la tuile en céramique,

la brique, le marbre ou tout autre

pierre.

our obtenir les

vues d’une hotte,

face se trouvant au-

e ignif

uge comme

3-1/4” (6,98 cm)

4-3/4” (8,25 cm)

Plinthe/

Hauteur de pied

13"

(33 cm) max.

to

À 48” (122 cm)

de toute matériau

inflammable

Matériau ignifuge

6-1/2”

(13,97 cm)

Minimum 12”

(30,4 cm) de

chaque

36”

(76 cm) Min.

13-3/8”

(37,02 cm)

Gaz/

Electricité

2” (5 cm)

36”

(91 cm)

18"

(45,7 cm) Min.

11-3/8”

(26,98 cm)

Electricité

2” (5 cm)

30 cm (12”) au moins

par rapport au mur

adjacent.

27

ESPACES SUPPLÉMENTAIRES:

oyez un espace minimum de 30 cm (12’’) par rapport

év

Pr

au mur adjacent sur chaque côté..

Les espaces de travail autour de la table de cuisson doivent

êtr

le plan de travail et le bas du placard mural.

ées par un espace d’

e sépar

au moins 45,7 cm (18’

’) entr

e

Page 28

Caractéristiques

DIMENSIONS DE L’APPAREIL ET ESPACES

Modèles de cuisinière 76 cm (30’’)

1”

(2,5 cm)

Plinthe/

Hauteur de pied

35-1/4” (88,26 cm)

to

36-3/4” (90,8 cm)

de hauteur

28-1/4”

(70,48 cm)

Profondeur

jusqu'à l'avant

de la porte

29-7/8”

(71,43 cm)

e largeur

d

lan de

P

ravail

t

surface

à

e cuisson

d

3-1/4” (6,98 cm)

to

4-3/4” (8,25 cm)

À 48” (122 cm)

de toute matériau

inflammable

Emplacements de raccord universels

4-5/8” (8,57 cm)

11-3/8”

6-1/2”

(13,97 cm)

(26,98 cm)

Electricité

Gaz/

(76 cm)

(16,82 cm)

Electricité

2” (5 cm)

30”

7-3/8”

2” (5 cm)

30 cm (12”) au

moins par rapport

au mur adjacent.

WARNING:

Pour les installations dépourvues

de hotte, prévoyez au minimum un

espace de 48’’ (122 cm) entre

l’appareil et toute matière

inflammable. Il est possible d’installer

une hotte spéciale à proximité

d’éléments horizontaux inflammables

dans la mesure où celle-ci dispose

d’une fonction de mise en mar

automatique. Pour obtenir les

spécifications d’espace pour d’autr

installations pourvues d’une hotte,

veuillez vous reporter aux instructions

fournies avec celle-ci.

La totalité de la sur

ainsi que la surface se trouvant audessus de la table de cuisson doit être

faite d'une matière ignifuge comme

le métal, la tuile en céramique,

la brique, le marbre ou tout autre

e.

pierr

face du mur arrière

che

es

13"

(33 cm) max.

18"

Matériau ignifuge

Minimum 12”

(30,4 cm) de

chaque

30”

(76 cm) Min.

(45,7 cm) Min.

ESPACES SUPPLÉMENTAIRES:

Prévoyez un espace minimum de 30 cm (12’’) par rapport au

mur adjacent sur chaque côté.

Les espaces de transit autour de la table de cuisson doivent

être séparées par un espace d’au moins 45,7 cm (18’’) entre

le plan de travail et le bas du placard mural.t.

28

Page 29

Caractéristiques

DIMENSIONS DE L’APPAREIL ET ESPACES

Modèles de cuisinière 76 cm (30’’), 91 cm (36’’) et 121 cm (48")

28-7/8” (68,89 cm)

10-1/2” (24,13 cm)

13/16” (2 cm)

jusqu'au bord avant

Dosseret

en option

30,5 cm min par rapport aux matériaux

inflammables ou 0 par rapport aux

matériaux ignifuges au-dessus de la

surface de cuisson

30-36”

35-1/4” (88,26 cm)

to

36-3/4” (89,53 cm)

12”

1”

3-3/16”Profondeur

du panneau de

commande (7,14 cm)

28-1/4” (70,48 cm)

jusqu'au bord

en biseau du chanfrein

arrondi du panneau

de commande

27-1/2” (67,31 cm)

par rapport au bord

en biseau –

Profondeur maximum

du placard adjacent

pour un encastrement

parfait

28-1/4” (70,96 cm)

jusqu'à l'avant de la porte

31-1/16”(78,58 cm)

jusqu'à l'avant de la poignée

7” Hauteur du panneau

de commande (17,78 cm)

48-1/4” (121,28 cm)

avec la porte du four ouverte

Espace par

rapport à un

mur arrière ou

latéral sous la

surface de

cuisson

AVERTISSEMENT:

Le un dosseret de 12" (30 cm) en acier

xydable doit êtr

ino

dosseret ignifuge personnalisé.

Le dosseret fini doit recouvrir la totalité

du mur arrièr

ou en l’absence de hotte, 121 cm aux

matériaux inflammables.

e installé av

e jusqu’au bas de la hotte,

29

ec un

Page 30

Consignes d’installation

KIT HAUTE ALTITUDE WB28K10553

Pour une utilisation à une altitude supérieure à 900

m (3000 pieds), commandez le kit de conversion

WB28K10553. Ce kit comprend des orifices pour

un fonctionnement au gaz naturel et au propane.

KIT DE RÉDUCTION DES

CARACTÉRISTIQUES NOMINALES

WB28K10554

(For a small kitchen environment.)

Kit de conversion de réduction des caractéristiques

nominales pour le modèle ZDP304N (gaz naturel

uniquement). Ce kit comprend des orifices pour

réduire la puissance du brûleur de surface au

niveau de 40,000 BTU.

MATÉRIEL FOURNI

OUTILS NÉCESSAIRES

Scie sauteuse

Mètre

Équerre de maçon

Lunettes protectrices

Tournevis cruciforme 2

erceuse et

P

forets adaptés

Clé anglaise

Tournevis ou clé à

molette 1/4" (0.63 cm)

Support

antidérapant,

équerre et vis

Coude de

raccordeme

nt de tuyau

(12,7 mm)

1/2”

Lubrifiant

pour grille

de four

Cales (pour

protéger

le sol)

Niveau

Diable

MATÉRIEL NÉCESSAIRE (non fourni)

Joint

Sealant

Raccords de tuyau

Tuyau métallique flexible d’alimentation de gaz agréé CSA

de 1,58 cm de diamètr

e et d’une longueur maximale de 1,5

m (5 pieds) (Longueur maximum de 90 cm (3 pieds) dans

le Massachusetts uniquement)

ez-vous un tuyau flexible neuf,

REMARQUE: pr

ocur

n’utilisez pas un tuyau ayant déjà été utilisé.

Couvre-joints

30

Page 31

Préparation de l’installation

EMPLACEMENT DES ALIMENTATIONS

Alimentation de gaz :

•Les modèles au gaz naturel ont été conçus pour

fonctionner à une pression de 5" (12,7 cm)

colonne d’eau. Pour un fonctionnement optimal,

la pression du gaz naturel qui alimente

le régulateur doit se situer entre 7" (17,8 cm)

et 13" (33 cm) colonne d’eau.

•Les modèles au propane ont été conçus pour

fonctionner à une pression de 10" (25,5 cm)

colonne d’eau. Pour un fonctionnement optimal,

la pression du propane qui alimente le régulateur

doit se situer entre 11" (27,9 cm) et 13" (33 cm)

colonne d’eau.

•Un coude 12,7 mm (1/2’’) est fourni pour

le raccordement de la cuisinière à l’arrivée du gaz,

située à l’arrière et à proximité du sol.

•Localisez l’embase du tuyau sur le mur arrière

ou le sol (voir “Dimensions de l’appareil

et espaces”). Utilisez le conduit d’alimentation

de gaz flexible (diamètre de 1,58 cm et longueur

de 1,5 m) (90 cm dans le Massachusetts).

•Installez un r

(non fourni) à un endr

ez-vous que le propriétair

Assur

où et comment fermer le robinet de gaz qui

alimente la table de la cuisinière.

obinet de fermeture sur le conduit

oit facile d’

accès.

e de la maison sait

Alimentation électrique :

Ces tables de cuisson doivent être alimentées par

du courant 208/240 volts, 60 Hz et branchées à un

circuit terminal correctement mis à la terre et dédié,

protégé par un disjoncteur ou un fusible (50 A pour

les cuisinières 121 cm, 91 cm et 76 cm). La prise

doit être de type NEMA 14-50R pour accepter

la fiche à 4 broches fournie avec la cuisinière.

Si le réseau électrique ne correspond pas

auxspécifications susdites, il est recommandé

de faire installer une prise agréée par un électricien

qualifié.

•Localisez la prise électrique comme indiqué dans

“Dimensions et espaces.

“

AVERTISSEMENT

La cuisinière est conçue pour être utilisée avec une

alimentation électrique utilisant un conducteur

de mise à la terre séparé (système à 4 fils).

Si cette cuisinière doit être branchée à un système

électrique utilisant un seul conducteur pour

le neutre (système à 3 fils), le cavalier de masse

et le bornier doivent être connectés. Le cav

de masse est situé sur la droite du bornier.

alier

La plaque

d’accès est

située à l’ar

de la cuisinière.

oir l’installation du cor

V

en page suivante.

31

rière

don d’alimentation 3 fils

Page 32

Préparation de l’installation

INSTALLATION DU CORDON

D’ALIMENTATION 4 FILS

REMARQUE: Un cordon à 4 fils est branché

à la cuisinière en usine. Suivez la procédure

suivante pour modifier l’installation existante

et passer du cordon 3 fils à un 4 fils.

AVERTISSEMENT

Le fil neutre du circuit d’alimentation doit être

branché à la borne neutre située au centre

inférieur du bornier. Les câbles d’alimentation

doivent être branchés aux bornes au bas

à gauche et au bas à droite du bornier. Le

quatrième fil de mise à la terre doit être branché

au cadre de la cuisinière avec la prise de terre

et la vis de mise à la terre.

•Retirez les 3 vis de la borne du bas du bornier.

Retirez la vis de mise à la terre et la prise de terre

et mettez-les de côté.

Retirez le conducteur de terre. NE JETEZ PAS LE

•

CONDUCTEUR OU LES VIS DE TERRE.

oduisez une vis de terre dans l’anneau de la

•Intr

borne du fil de terr

la prise de terre et dans le cadre de la cuisinièr

•Introduisez les 3 vis de la borne (r

précédemment) via chaque anneau de borne

du cordon d’alimentation et dans les bornes

inférieur

du centre (blanc/neutr

centrale inférieur

les vis sur le bornier.

Avant

Bornier

es du bornier

e du cordon d’alimentation, via

e.

etirées

. Veillez à ce que le fil

e) est branché à la position

e du bornier. Serrez correctement

Conducteur de terre

or

INSTALLATION DU CORDON

D’ALIMENTATION 3 FILS

REMARQUE: un cordon à 4 fils est branché à la

cuisinière en usine. Suivez la procédure suivante

pour modifier l’installation existante et passer

du cordon à 3 fils.

AVERTISSEMENT

Le fil neutre ou de garde du cordon d’alimentation

doit être branché à la borne neutre située au centre

inférieur du bornier. Les câbles d’alimentation

ent être branchés aux bornes au bas à gauche

doiv

et au bas à droite du bornier.

•Retirez le conducteur de terre (situé sur la droite

du bornier) et branchez entre la partie centrale

inférieur

•Retirez les 3 vis de la borne inférieure du bornier.

Introduisez les 3 vis de la borne (retirées

précédemment) via chaque anneau de borne

du cordon d’alimentation et dans les bornes

inférieures du bornier. Veillez à ce que le fil

du centre (blanc/neutre) est branché à la position

centrale inférieure du bornier. Serrez correctement

les vis sur le bornier.

NE retirez PAS le branchement du conducteur de terre.

e du bornier et le cadre de la cuisinière.

Prise

de terre

Bornier

(apparence

susceptible

de varier)

Borne

e

neutr

ne

Conducteur

e

r

de ter

ès

Apr

nier

Bor

Vis de mise

à la terre

Bor

neutre

Bor

ne neutr

e

Prise de terre

(mise à la

e vers la

r

ter

cuisinière)

32

Cordon

d’alimentation

Conducteur

re

de ter

Page 33

Installation

ÉTAPE 1

SORTEZ L’APPAREIL DE SON EMBALLAGE