Page 1

Professional

Ranges

48" N)lt_rd Gas Models

ZDP48N4 G

7d_)P48N6 R

ZDP48N6D

48" LP Gas Models

ZDP48L4 G

ZDP48L6R

ZDP48L6D

36" ;\')ttu_rll Gas Mode{s

ZDP36N6

ZDP36N4 £'

ZDP3&V4D

36" LP (;as Mode{s

ZDP36L6

ZDP36L4£'

ZDP36L4D

30" ;\;?tt,_rl[ Gas Model

ZDP3ON4

30" LP Gas Model

ZDP3OL4

Page 2

Before volx begimx--Read these instrlxctiom_ completely amid carefldh.

IMPORTANT: Save these h_strlxctions {i_r local inspector's ixse.

IMPOR'IANT: OBSERVE AIJL GOVERNING CODES AND ORDINANCES,

NOTE TO INSTALLER: Be slxre to ]e_x e these imxstr ixcti(m s _ i th the ((m sm_ er.

NOTE TO CONSUMER: Keep these h_ str Ixcti on s _ i th vom" ()x_ ixer's Mam_ Ixa] ti)r fmm'e

re{_relxce.

This appliance must be properly grounded, See _%leetrie Supply", page 7, ]

For Monogram ]Pea] service in yolxr area,

1-800-444-1845.

Fox" Monogram Service im_Canada,

Ca]] 1-888-880-3030.

For Mollogram Parts aF_d Accessories, ca]]

1-800-626-2002.

If volx received a damaged rm_ge, yolx sholdd

Insta]]ation of this range reqldres basic

el ectri cal, carpen try an d m echa_xi cal skill s.

Proper h_sta]]athm is the resp<msibilitv of the

im]sta]]er, f_ro(lixct thi]m'e (lixe to improper

h_sta]]atiol_ is not covered m_der the GE

Ap p]ian ce W_rran t_. See the ()_ ner's M aN_ixa]

for details.

contact VOlXrdealer.

in the Commonwealthof l_assachusetts:

• Thisproduct must be installed by a licensed plumber or gasfitter.

°When using baIItype gas shut off valves, they shall beT-handletype.

° A flexible gas connector, when used,must not exceed 3feet.

C(m.t#_¢ts

(:AUTION:

THESE RANGES SHOtJJLD BE INSTAI,I_ED

IN (:ON] [i N CTION WlTH A S [iITA BI _E

OVERHEAD VENT HOOD. Dixe to the high

h eat capaci ty of t hi s m_i t, p arti clx]ar atten ti o_]

sh (mid be paid to the h Pod am_d dlxct work

im_sta]]atiom_ to assm'e it meets Iota] bld]dim_g

codes.

Standard eountertop and island installations:

A 1200 CFM h Pod i s recom m ended ti)r 48"

r;H/ges.

A 600 CFM hood is recommended for 30" and

Hoods sholdd be 24" mh_. deep m_d the same

_idth as the cooktop.

(:beck local b_xi]dhxg codes for the proper

m eth od of gas rm_ ge hx sta]]ati om i x)ca] co des

varL Installation, electrical colmections mid

Models Available .........................................................3

Accessory Requirements ..........................................3

Models Dimensions and Clearances....................4,5

Advance Planning .......................................................6

Tools& Materials Required.......................................6

Power Supply Locations ............................................7

gro m_ di n g m _xst corn p]y _i t h app]i cab] e codes.

In the absence of ]Peal codes, the gas range

sho_dd be i_/sta]]ed i_ accordance _qth the

Nationa] F_xel Gas Code ANSI 223.1, ]atest

editiolx mxd Natiolm] E]ectHca] Code ANSI/

NFPA 70, latest edith)n.

(AiJTION:

These ran yes _ eigh _xp to 600 pomx ds. Sore e

disassembly _i]] red_xce the weight cow,sider-

ably. D_xe to the _eight mxd size of the rmxge

and to red_xce the risk of personal h_j_xry or

damage to the prod_xct, TWO PEOPI,E ARE

REQ[ _IRED FOR PROPER INSTAI,I,ATION.

i_staiiatio_

Step 1:RemovePackaging ........................................8

Step 2:Levelthe Range..............................................9

Step3: Install Anti-Tip Device ...................................9

Step4: Connect Rangeto Gas................................11

Step 5:install the RangeBackguard .....................11

Step6: Connect Electrical .......................................12

Step7: Slide Rangeinto Position ...........................12

Step8: Replace OvenDoors ...................................12

Step9: Assemble & Adjust Burners ......................13

Step 10:Adjustable Low Burner Settings .............13

Finalize installation ...................................................13

Page 3

Design Infi}rmafion

These rm]ges are tactorr set for either mttm'al

gas or liquid propam]e gas. Order the model

foF _ouI" iHsta]]ati(H] situati(H].

48" Natural (;as Models:

ZDP48N 4G

4 gas bl*rners, grill and grid<He

ZDP48N 6R

6 gas bm'n ers an d grill

ZDP48N 6D

36" Natural Gas Models:

ZDP36 N6

ZDP36N 4R

4 gas burn ers an d grill

ZDP36N4D

4 gas bl_rn ers an d gr]dd] e

36" Liquid Propane (;as Models:

ZDP3615

6 gas bm'n ers an d gri dd] e

48" Liquid Propane Gas Models:

ZDP481 AG

4 gas bl*rners, grill and grid<He

ZDP481 _6R

6 gas bm'n ers an d grill

ZDP481 _6D

6 gas bm'n ers an d gr]dd] e

ZDP361 _4R

4 gas bl_rn ers an d grill

ZDP361 _4D

4 gas bl_rn ers an d gr]dd] e

30" Natural Gas Model:

ZDP30N 4

30" Liquid Propane (;as Model:

ZDP30I _4

All m ode] s req u]re the in sta]]ati on of a bark-

guard. A bat kguard should be ordered at the

same time as the rm]ge. Both must be oil site

at the time of h]sta]]ation.

Order one baekguard for 48" Models:

ZXI B48

]-1/2" high bat kguard (reql*h'ed for island

im_sta]]at] on s or in sta]]ati on s wh ere back wall is

nun-combustible such as grit]% ceramic 6]e,

marble, etc.)

Order one backguard for 30" Models:

ZX1B; (• '3 )

1-1/2" high backgmwd (required for island

installations or im]sta]]atiuns _here back _%a]] is

non-combustible sltch as brick, ceramic tile,

marble, etc.)

ZX 1_B_ (

9" high backguard

ZX22B30

22" high backguard _qth _%arming shelf

ZX12B48

12" high backguard

ZX22B48

22" high bad<guard xqth x_armim_gshelf

(2 piece}

Order one backguaJ-d for 36" Models:

ZX1B;BC

1-l/2" high backguard (required for island

im]stall ati o]]s or im]stall ati orals _h ere back wall i s

non-combustible such as brick, ceramic die,

maH)Ie, etc.)

Z'_ *9" B{'

A / _D_ }

12"high ba(kguard

ZX22B36

_rd for

22" high backguard Mth _arming shelf

(2 piece)

Installation Note:

For a pp roxed im]stall ati (n ] s to m]oral-corn b i_sti b]e back _a]] m at eH a] s, c(n ] s_d t

material repi'eseutative to e_/sm'e that the material has appropriate resistance

to stai nin , an d/or discoloration.

12" kligh Backguard

(9" kiigh for 30" Models)

Island Installations only

Page 4

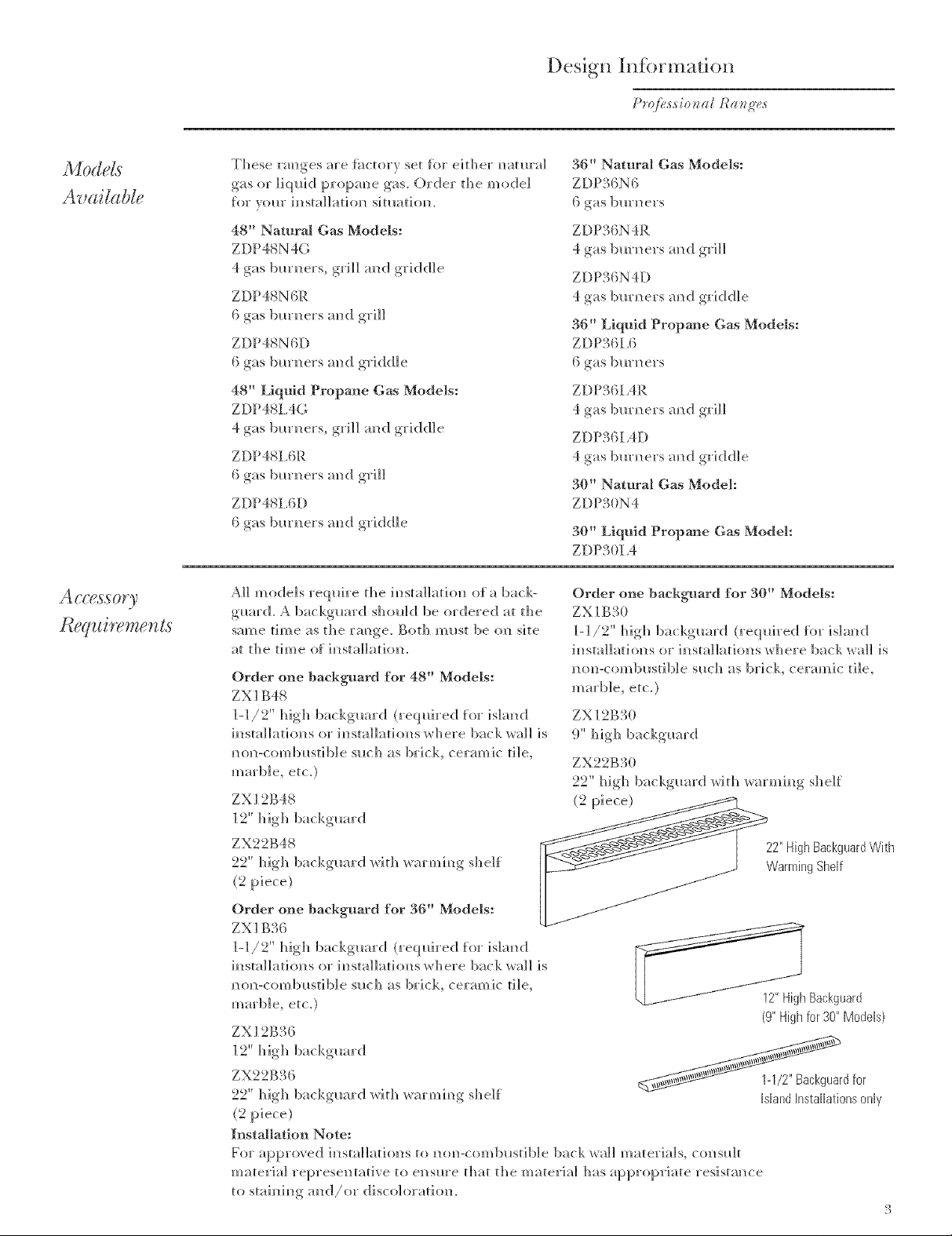

Prod_gct

U C[earm_c_,;s

Desigl, I!,formad<m

tb'@,,ssio_ag [:a*/g'es

35-1/4"-36-3/4"

28-1 _

3-1/4"_12'I

21-1/4" Shelf

48"'Wide Range Medems

29-1/16"

_ High

LowBack

47-7/8_

to Combustibles

36" Min.

35-1/4 36-3/4"

28-1/4" 35-7/8"

36"'Wide Range Modems

12"Min.to Combustibles

Without Backguardor0"

to Non-CombustibleWall

with 1-1/2" Backguard 36" Min.

1@ _Backguard

to

Combustibles

......O"Clearance

-0" Clearance

Aft MedMs

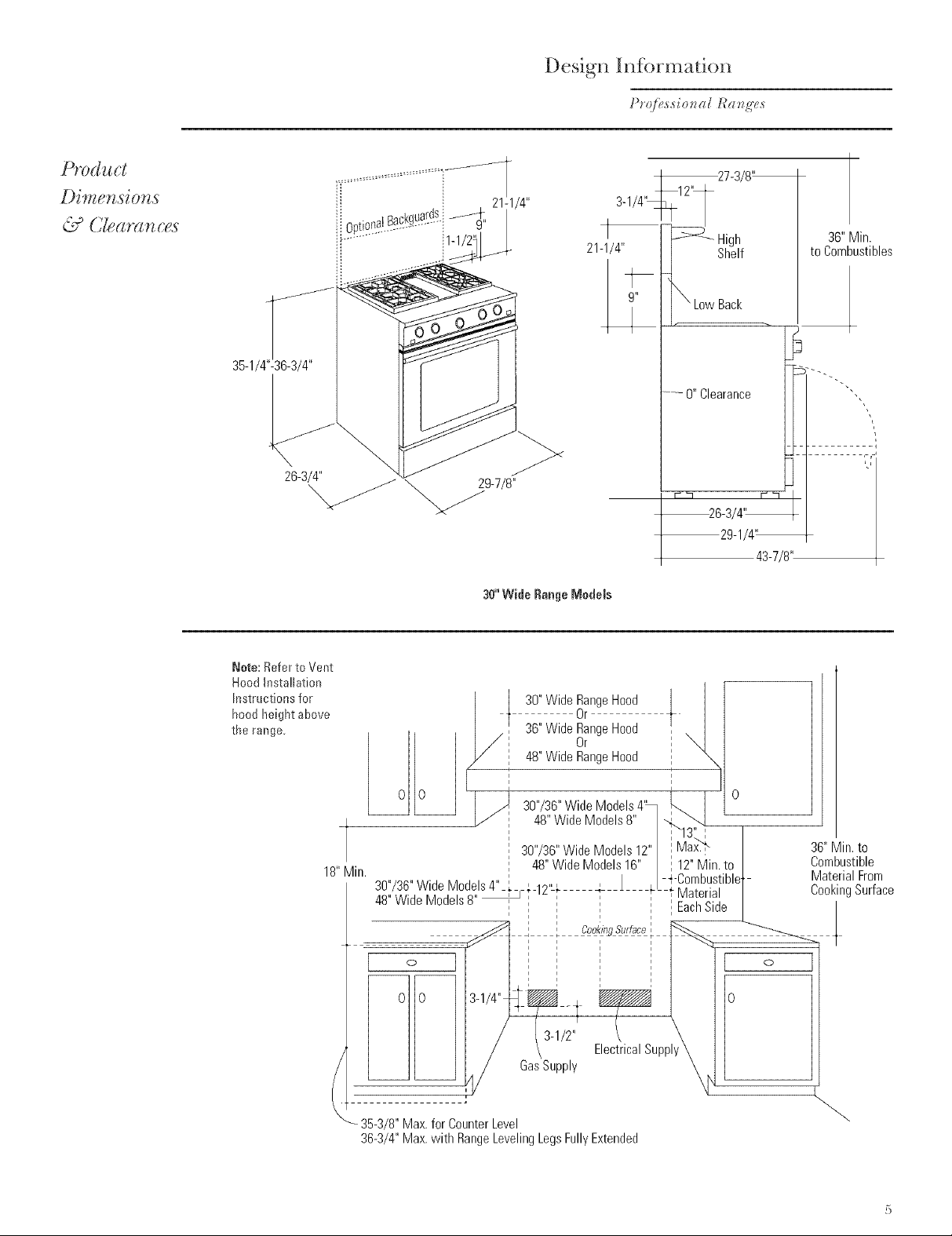

Page 5

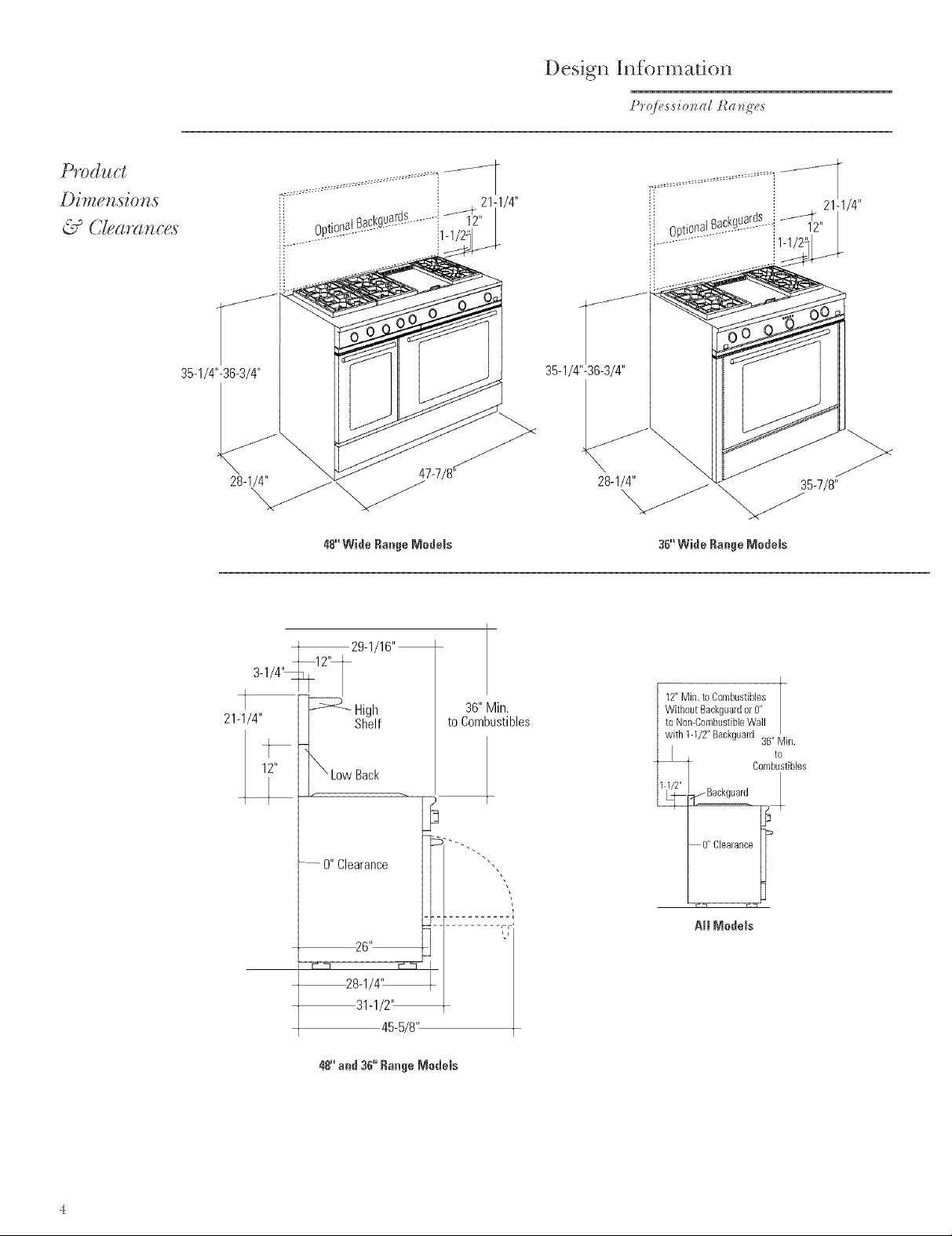

Desigl, Ii,fi rmatio ,

tb'r!i>,s,sio_lag _a _g'e,s

-_27-3/8"

(2earsn,ces

Note: Refer to Vent

Hood Installation

Instructions for

hood height above

the range.

-_ _ High

21-1/4" Shelf

........O"Clearance

30"'Wide Range Models

/ 30"Wide RangeHood ]

I t Or t

I//[ 36`'wideR_ngeH°°d [ _1

/P" 48"Wide RangeHood

I

36" Min.

to Combustibles

_ LowBack

43-7/8"

0"0 ' ] ' ' _-- 0

II I _ 4B,,WideModelsB,, ] .....Q_ _

18"Min. I 48" WideModels16" | 112"Min. to |

30"/36"Wide Model_ • 12,_# - J _ -_ C°_ebUaS[ible[

48"Wide Models8" I i ;'EachSide

o

0 I 3-1/2"

353/8 Max for CounterLevel

36-3/4"Max.with RangeLevelingLegsFullyExtended

, 30"/36"Wide Models4" I

l / I 13" , I

30"/36"Wide Models12" i Max,-'b"

I _ ' L_

ElectricalSupply

GasSupply

36"Min. to

Combustible

MaterialFrom

CookingSurface

/

Page 6

Design hKbrmadon

Advar ,ce

Refer to "Di men si]ms am]d CJearm] ce s" for

appropriate placement and necessary dear-

mices/1hem/ p]mmh]g the im]sta]]atiom

* Cab] m]etrv carol not be h] stall ed direcdv above

the range.

*We recom m era/d the imista]]ati]m of a ve]] t

hood above the sm'lhce.

-The vent hood mllst be at ]east 24" deep.

-The ve]/t hood mllst be the same/lidth as

the range.

-For 48" m ode] s, /t e recom m el/d th e veil t

hood bIo/ler be 1200 (FM.

-For 30" and 36" models, we recommend the

vent hood blower be 600 CFM.

*Working areas ai!jacent to the range sholl]d

have 18" mimlimllm c]earm]ce bettleen

com]tertop mid cabim]et bottom.

* CJearan ce bet11 eel/rm/ge an d side wall or

corn bllstib] e m ateH a] m list be at ]east ] 2" on

each side.

If the range is installed in an island:

*A]hal ]2" mh/. c]earm]ce at the back to

combllstib]e materials.

*A]]oll 36" mira above the cooking sm'fhce to

comb_lstib]e materials.

e For 48" m ode] s,/l e recom m el/d the ve]] t

hood b]o/l er be ] 200 CFM.

* For 30" am]d 36" m ode] s,/l e recom men d the

vent hood be 600 CFM.

* Installation mllst com/Jti_rm ttit]] local codes.

h] the abse_]ce of local codes, the rm]ge

must (omply/lit]i the Natio]]a] Fuel (;-as

('.ode, ANSI Z223A, latest edition.

A.G.A. approved.

7bots &-"

Req .tired:

* Measm'h]g tape

* Carpenter's sqllare

* Pipe and tittim]gs as reqLlired.

* Man ila] gas ]im/e sh m-off valve.

* (;as pressure regulator (supplied)

* i _arge flat-Made sere11 driver

* Pipe/l ten ch

* Drill an d appropriate bi ts

* Satety glasses

* Gas-res] start t pi pe.joi m]t sea]an t

* 5 foot, 5/8" AGA-certified flex]Me metal gas

supply line.

-If reqllh'ed bv local codes, ilse solid pipe

Note: Pro'chase role11flexible lim]e. DO NOT

[ISE OI_D, PREVIOI ISI5 [/SED FI_EXIBI_E

1_INE.

Page 7

Gas Supply:

*T1]e natm'al gas models are designed to

operate at 6" to 14" 1tater cohmm pressllre.

*The ]iqllid propane models are designed to

operate at ] ] to 14" /later cohmm pressure.

A reglllator is required at the LP. sollrce to

provide a maximum of 14"/later pressllre to

the range reglllator.

*These gas ranges are sLqsplied whh ]/2"

NPT fbmale gas com]ection located at the

lef[ rear C(]H/er_

*A 5/S" dia. metal flexible hue is

• For flexible connection, locate p] pe st ub on

t h e back _,lall as ill Llstrat ed.

-- [/se 54oot, 5/8" long flexible gas supply

line.

• For rigid com]ection, locate the pipe stub as

ill Llstrated.

• In] stall a m an ua] sh ut-off valve in t]]e gas

]h/e, h/ an easily accessible location.

Installation Preparation

Pr(b@ssional t¢ang'_,s

4" For 30"/36" Models

8" For 48" Models

12"

._..Gas Supply to Range

Wall ForGas

Supply

Flex Line

Electric Supply:

These ranges must be stlpphed/qtb 208/240

volt, 60 Hz., and com/ected to an individual,

properly groin/ded bran ch circuit protected

bv a circuit breaker or time delta' fllse (50

amp tbr 48" ranges, 30 amp tiw 36" ranges

and 25 amps Jtbr 30" ranges). The receptacle

must be a NEMA 14-50R devise to accept the

4-15ton g p]ug slqsp]] ed wit h the ran ge.

The range is eq ui pped for use with an

electrical slqsp]y tt hich Ilses a separate

groin]cling condllctor (4/1ire s}stem).

If this range mllst be comlected to an

e] ec tr] ca] svst em/l h]c h Ilti] ize s a s]n g]e

conductor for grom/d and nemral (3 wire

s}stem), the grom]ding,im/gser at the

terminal block mllst be connected. The

groin] di ng,i m//per is ]ocated beh]nd the

fl'on t kick pan eL

If the electrical service provided does not

meet the above specifications, it is recom-

mended that a licensed electrician install an

* [ x)cate the e] ectri c slqsp]y as i]] ustrated.

Green

/Black

TerminalBlock

To connect grounding jumper:

*Discon n ect restrai n ing dip h o]di n g j um per.

* (onnect green jm]/per to open term ina] on

ne utra] ( tl h]te) p or ti o]] of the term ina]

b]ock.

Page 8

Installation

Before moving the range indoors:

*Remove ulster carton and pa(k]ng material

from the shipping base.

LeftRearShipping

Screws

DoorHingeRoller

(Closed)

Un-Lock

Remove oven doors:

* Opel] t]_e door fu]]v an d h o]d d<_ ]].

* (lose die brass hinge latches to locked

positi<m on each side.

* C_aref u]]y, ]]ft am]d p i_]] t]_e dour m_ av fi'um t]_e

1"am/ge am] d o Ht uf t]/e _}'am e.

RangeMust

beUniformly

Supported

onBraces

The range is secm'ed to the skid _]th 2 bolts in

the fI'om]t am] 2 "]/' brackets <m the bottom

flmlge of the range back. Remove bu]ts and

"I/' brackets.

To simplify handling and to reduce the weight

of the range:

* Remove d_e grates and drm_ ers be]o_ d_e

knobs.

*Remuve grill mid griddle covers. DO NOT

ATTEMPT TO REMOVE A GRII _i_OR

GRIDDI _E ASSEM B1 _St

* Rein ove the broil er pan s/]i terat m'e pa_ kage

from h_side ovem_(s).

LevelingLeg:

Due to the _eight of these rm]ges, use a do]Iv

_ it]] soft _ h eel s to m uve t his rm_ ge.

* 1_fftt]]e ran ge on to the do]Iv all d m uve

in doors.

Page 9

H stallati(m

P*'@,ssio_vag t_a:_g'es

Step

36" and 48" Wide Models:

* Rein ove t]]e pail e] fl'om the rear of the

shippim/g pack. I.ay tile pa_]eI ore/tile floor

di rec t]v i]] t}'ol] t of th e ira/stall ati oil ]o cati oil.

Tile ram]ge shol_]d be p]aced on this pane] to

prevem]t damage to the floor.

All Models:

* Rein ove t h e ttl O str] pe t_x]m the ove]]

im]terior. Place the stripe oil the floor at the

]e_ am]d r]ght sides of t]]e ira/sta]]at] oil

]ocatJtm. These str]p s provi de a sIl]'%ce for

s]JdJm/g the range im/to the lira/a] posJtio]/ and

%1]] I.)I'evei]t damage to the {loot. The

]eve]im/g legs midst rest permamlei]t]y oil these

I'tlm]]] el" st]'] pc.

Note: Rear rm/ge ]evelim/g legs are n(]t acces-

sib] e at}er ira/sta]]ati oil.

* C_heck to be slate the a({ioim]]m]g cab]inlets/

col_m] tert op s are ]eveH I_'o_] t to ba(k am] d ]eft

to right across the opeiiiFlg of the rm]ge.

*Measl_re the distamlce [}'ore the floor to the

topofthecomltertopim] the]eflamldr]ght

]'e_]]" COH] e]'s.

,,_-'_---1 Range

| Opening |

[ II /// ToSupport

evehngLe

* A(]il_st the h eight of th e ramlge to corn] ter top

h eigh t or high er.

IMPORTANT: The rm]ge shol_]d a]/tays be

i_]sta]]ed at co_mtertop ]]eight or higher. DO

N OT IN STAI _i_THE RANGE I,OWER THAN

ADIACENT (O[/NTERTOP HE[(;HT.

_.AimRa,ges Ca, ]]p

i,jar_ Co,id Res,it

° m.stammA i-Tip

B_acRe_P_ovided

* See i.s_r.etio.s

The m]ti-tip bracket is deeiglied to be i_]sta]]ed

(]_/ top of the slide (framers)provided/lit]]

the rm/ge. Any other type of co]]str_ct]o_] may

req_ire special i_/sta]]atiol] tec]miq_es to

i_]sm'e ad eq _ate J_ste]]]_] g oJ_the a_]ti-ti p

bracket to the {]oor or flail.

*The bracket m_st be proper]v i_]sta]]ed to

pl'evei/t tippi_]g of the rm]ge.

*Read the AHAM A_]ti-Tip Satetv brochette

packed _r]t]_ t]_e prod_lct.

A]] Ra_]ges m_st I/ave an] m/ti-tip device

correctly i_]sta]]ed at cordi_]g to these

] _]st]'_lct] o_1S.

* If the rmlge is p_l]]ed o_*t J_'om the /la]] ii_r

a_]y reaso_], make s_re that the de_ice is

properly ei/gaged/the]] plashed back agai_/st

tile /la]] or i_/sta]]atio_] posJtio]].

* If the ai]ti-tip device is _]ot eilgaged, there is

a possible risk that the ra_lge ca_] tip over

a_/d cayuse ]_i_rY if yo_ or a ch]] d start d, s]t or

lean on m/ (]pe_/ door.

[41#10x2"woodscrews

Anti-Tip Bracket

AHAM Anti-Tip

SafetyBrochure

Page 10

SmallHolesForWood

Installations

Wood

Slide

Strip

Installatkm

tb'qik,s,sio,(d l,_a,g'e,s

SmallHoleForWood (2)WoodScrewsinto

Installations(2Total) BackWall

(2)LargeHolesFor \ (All Installations)

ConcreteInstallations

Back

Wall

Wood Construction:

* P]a(e th e b_'acket agai n st t h e back wail hi to the

righ t rea_" coH_ e_" of t]]e hi sta]]ati (m ] (>cad o_.

e See Dim eli si o]] A_ p usi ti om] the b_'acket the

coH'ect distance fl'om the Hght side. Mm'k the 2

small sc_'ew holes {_n" f;_stem_h_4 the b_'acket to

the {]uo_" and _'emove the b_'ackeL

eDH]] tv, o_ l/S" diameter" pilut holes,

e Fastem] the b_'acket sec m'e]v to the fl oo_" an d _ a]]

i_s]ng a]] 4 sc_'e_ s p_'ovided.

Concrete or Cement Construction:

Ha_'d_m'e Reqlfi_'ed (m)t sl_pp]ied) :

[2] sleeve am]ch(ws_ lag bolts am](] washe_'s.

• Place the bi'acket a_4ah]st die back _a]], into the

]'igh t ]'em" coH] e_"of t h e hi stall ati on ]ocati(m.

• See D] mem/ s]om] A_ positiui/ tile b_'acket the

cuH'ect dista_]ce fl'om the H gh t side. Mm'k the 2

]ai'ge holes for f;_stei]hig the b_'acket to the floor

am]d I'em ove the b_'ackeL

• D]']]] _'ecommeiided size holes %I" the haTdv, a_'e.

hi stall the s]eeve m]ch u_'s hi to the ho]es an d th eli

install the lag bolts t]]_'ough the b_'ackeL The

bo]ts must be p_'opeHy tigh te_] ed as _'ecum-

mei]ded fk)_" the ]_m'd',_ ai'e.

Faste_] the bTacket secm'e]v to the fi ooT.

DHve _ ood sc_'e_ s hi to the bark _ a]].

! 0

Page 11

Installation

Prqi_<ssio_la{ ]_a_zg'es

Connect

to Gas

A m am_I_a] sh la-off _a]_e m I_st be im_stall ed _1_ere

it _i]] be a_ cessib]e+

Assure that gas is turned off at the shut=off

valve,

* Remove a]] bllrn er/hanger scre_ s+

+ [ _ift an d rein ove a]] opem] top bl_rm]ers/h m]gers

to reveal the gas inlet location at the back of

+Pull the flexible metal gas line through the

back of the range an d in to the cooki n g area

m]til it meets the regular.

+ (:om]ect flexible metal connector to incoming

gas hne pipe stub.

+Tm'n on gas an d ch eck lot leaks:

-[Ise a liquid leak detector at all,joints and

con n ecti orals in t h e sxstem.

Flexor RigidGas

LineToRegub

Regulator

36"Models

Flexor RigidGas

LineToRegula

Regulator

30" Wide Models:

Rigid pipe is t;_ctory hi stall ed fl'om the

regl_]ator to the bottom rear of the range.

Flexible line may be used to connect to the

pipe stub+

A bad<guard is required fl>r a]] installations+

+ hi sert the backguard into the guide

cham_e]s on the back of the range+

+Secm+e the backguard to the range at the

rear _ ith th e 4 sh eetm eta] sere_ s pr ovi ded+

+h]sta]] 2 or 3 sc1+e_s thrtmgh the t}+om]tof

the rm_ge, dependh_g om__r_>_+ mode].

48"Models

FactoryInstalled

RigidGasLine

\

Regulator

30"Models

] ]

Page 12

Connect

Ix]stallafiox]

PIing power cord into properly grom/ded

* C_arefl_]]y, s]] de tbe rm]ge in to positi on.

-Be careh*] m]ot to em/tm]ge po/_ er cord m] d

gas flexible robing.

* Be slate the rig]It rear leg is engaged ira] the

s]o t of t b eim] stall ed all ti-ti p bracket,

* CJ_eck for proper bista]]at]om] by grasph]g the

range at the top front edge mid carefl_]]v

at tern p t t o ti]t tbe rm] ge Itbr t_ ard.

*(beck to be sm'e the from of the range is

level A({jl*st {i'(mt ]eve]im]g legs accordi_g]y:

* Replace tbe f}'on t kick pro]el by reversi ng tbe

procee(b_re described ira] Step ]1.

8t_ 8

R@lace

Ove, ,Door(,9

To replace the ()veil doors:

* Sh de t]] e b h] ge s h] to tb e op en h] gs. Th e

bhige s]loll]d rest ic_ the center of eatb

bil]ge roller.

* ()pe(] th e door fl_]]v an d m/] ock bin ge

latches.

( A[ ITION: Take care/_be]i rep]ach/g the

oven doors. If the bimlge latch is mlot secm'e]v

locked, the him/_ge may sm_p back mid sepa-

rate. If th e bim]ge separates, you m i_st apply

pressllre (possibly with yore" toot) to press it

back together and then engage the brass

hh_ge latch.

DoorHingeRoller

(Closed)

Un-Lock

]2

Page 13

kssemb[e

c A "

*Rep]a< e the bm'm]er bowels and bm'm]er caps.

*A<{justm en ts sh old d m_ot be req uired, m_l ess

vibration durim_g transit or variations im_local

gas supply make m in or a({j ustm en ts n e ces-

SaI'%

CA[JTION: Bm'm]er a<!jllstments mllst be made

by a q ilalifi e d t ech n ]c]an at th e ti m e of h] st all a-

don. Extreme care sholl]d be ilsed if a/]illst-

m e_]ts are m ade at_er h] sta]]at] on.

* Bm'mler flare es sh o u]d be b] lie am1d stab] e wi th

no ve]]o_l or ve]]o_l tips, excessive m]oise or

li}}in g of the flare e from the bm'n en If am]v of

these conditions exist, check that the air

shlltter or bm'ner ports are m]ot blocked. If

on e of these co_] diti o_]s con tin lies, a({j ust the

ah" shlltter as reqllh'ed.

-If t h e flam e is too yell o_l, th ere is in sllt}i cien t

ah" flow, adjllst the shmter com]terclock_ise

to h]crease ah" inlet.

-If the flame is nois', oi" tem]ds to ]]t_ m_av

_?'om the b m'n el, t here is too milch air+ Tm'n

the shlltter clockwise to re(blce air.

Installation

Pr:_:l>ssio_vag t_a:_g'es

_lgniter

lurner-

-Main Burner

Venturi(rear)

(e i

gniter- _ _ _- SimmerBurner

lurner- _ 'i)-venturi(rear)_ -AirShutter

MainBurner SimmerBurner

Venturi(front) Venturi(front)

Step

The open top bm'm]ers mid grill w_]ves l/ave an

adjllstab] e low setti ng. Each va4ve is in divi du-

ally tested m] d a({j listed before it ]s sh]p ped.

M]n oi" a/]j ustm en ts mav be requ]red (ble to

fl _lct_lati on s i_] ]oca] gas pressm'e. A (!j_lstm ell ts

to i_1crease oi" decrease gas tl o_l m av be

necessarv.

*Tm'n ]mob com]ter-cIockxlise to tile IJTE

* ()_]ce ]it, tm'n the knoll back to the "[.()W"

* Rein ove the k]] oh.

* In sert a thin-blade flat screwdriver in to the

valve sh all ( 3/ 3 2" b] ad e w] th recom -

* Grip die shaft _lit]/ pliers and mrn tile

Place the bm'ner grates h]to operating position.

Press corner of the grate to the cooktop. The

grates sh o_d d be seated an d sh o_l]d not rock.

Models equipped with grill and griddle:

*Tile grill mid grhkHe are secm'ed with screws at

the Jh'onL They are desig_]ed to be stathmarv

a_] d Sh o11] d _]ott/) be removed.

scre_ driver co m] ter-c] ock_ i set o ]o_l er the

flame, oi" c]ock_ise to increase the {Jame.

(AilTION: Do not mrn the {Jame so ]o_a that

it goes trot, cmlshlg the igniter to spark.

* When the desh'ed setth]g is made, replace

the k]]ob m]d tmq] bmmler off.

*The grhId]e has two leveling screxls beneath

the rear fi _le cover which can be _lsed to

a(]j ust to th e desired s]ope. The ce_] ter screw

is %I" shipping pro'poses o_]]y mid sho_dd be

rein oved.

]3

Page 14

Notcs

14

Page 15

Notes

15

Page 16

Pub.No.49-8814-5

Dwg.No.164D3333P058

(NO 728) 3/03

10658Rev 7

Note: While performing installations described in tills book,

safety glasses or goggles should be worn,

_Gr ,_lono_'_(t.i _ loc(d s(.l'.icc i. yo._ (_(.(_, c(dl

1-600-444- / 84 ).

Monogram;'

Webringgo_Jdthingstolife,

GEDmsunler Produc _u

General Electric [;onlpany

Louisville, KY40225

@2003 (@neralElectro Company

Loading...

Loading...