Page 1

Installation

I struct" n

30", 36" and 48"

Professional Ranges

Cuisini_res professionnelles

de 30" (76 cm), 36" (91 cm)

et de 48" (121 cm)

Instructions d'installation

La section fran_aise commence _ la page 24

Cocinus profesionales

de 30", 36"y 48"

Instrucciones de instalaci6n

La secci6n en espa_ol empieza en la p6gina 46

Page 2

Installation Instructions

BEFORE YOU BEGIN

Read these instructions completelg and corefullg.

•IMPORTANT- savetheseinstructionsfor

local inspector's use.

• IMPORTANT-Observeall governing

codes and ordinances.

• Note to Installer- Be sure to leave these

instructions with the Consumer.

• Note to Consumer - Keep these instructions

with gour Owner's Manual for future reference.

• Completion Time- 1to 3 hours.

• Proper installation is the responsibilitg of the

installer. Product failure due to improper

installation is not covered under the warrantg.

See Owner's Manual for warrantg information.

AWARNING:

This appliance must be properlg grounded.

See "Electric Supplg."

For Monogram local service in gour area,

1.800.444.1845.

For Monogram Service in Canada, call

1.800.561.3344.

For Monogram Parts and Accessories, call

1.800.626.2002.

If gou received a damaged range, gou should

contact gour dealer.

In the Commonwealth of Massachusetts:

• This product must be installed bg a licensed

plumber or gas fitter.

• When using ball tgpe gas shut off valves, theg

shall be T-handle tgpe.

• A flexible gas connector, when used, must not

exceed 3 feet.

- WARNING:

All ranges can tip. Injurg could result. Install the

supplied Anti-Tip Bracket provided. See instructions

in this manual or with the bracket.

Vent hood Combinations:

It is recommended that these ranges be installed

in conjunction with a suitable overhead vent hood.

• Install a hood with at least 1200 CFM above a 48"

wide range.

• Install a hood with at least 600 CFM above a 30"

or 36" range.

Due to the high heat capacitg of this unit, particular

attention should be paid to the hood and ductwork

installation to assure it meets local building codes.

- WARNING:

Clearances to horizontal surfaces above the range,

measured to the cooking surface:

• Installations without a hood require 48" minimum

to combustibles.

A custom hood installation with exposed

horizontal combustibles surfaces must have

an Auto-On feature.

For other installations with a hood, refer to hood

installation instructions for specific hood

clearances.

CAUTION:

These ranges weigh up to 700 pounds. Some

disassemblg will reduce the weight considerablg.

Due to the weight and size of the range and to

reduce the risk of personal injurg or damage to

the product:

TWO PEOPLEARE REQUIRED FORPROPER

INSTALLATION OF 36" AND 30" RANGES.

THREE PEOPLEARE REQUIRED FOR PROPER

INSTALLATION OF 48" RANGES.

Leak testing of the appliance shall be conducted

according to the manufacturer's instructions.

Installation must conform with local codes. In the

absence of local codes, the range must complg with

the National Fuel Gas Code, ANSIZ223.1/NFPA 54,

latest edition and National Electrical Code

ANSI/NFPA 70 latest addition. In Canada, installation

must conform with the current Natural Gas

Installation Code, CAN/CGA-B149.1 or the current

Propane Installation Code, CAN/CGA-B149.2, and

with local codes where applicable. This range has

been design-certified bg CSA International according

to ANSI Z21.1, latest edition and Canadian Gas

Association according to CAN/CGA-I.1 latest edition.

Page 3

Design Information

CONTENTS

Design Information

Models Available ......................................................................:3

Backsplash Accessories ......................................................3

Product Dimensions and Clearances ........................4-7

Tools and Materials Required ..........................................8

Installation Preparation

Power Supply Locations ..............................................9, 10

MODELS AVAILABLE

These Monogram ranges are factory set for either

natural gas or LP gas. Order the model for your

installation situation.

48" Natural Gas Models:

ZDP484NG - 4 gas burners, grill and griddle

ZDP486NR - 6 gas burners and grill

ZDP486ND - 6 gas burners and griddle

48" LP Gas Models:

ZDP484LG - 4 gas burners, grill and griddle

ZDP486LR - 6 gas burners and grill

ZDP486LD - 6 gas burners and griddle

Installation Instructions

Step 1, Remove Packaging ..............................................

Step 2, Hove Range Indoors ..........................................

Step 3, Install Anti-Tip Device ........................................

Step 4, Connect Range to Gas........................................

Step 5, Connect Electrical ................................................

Step 6, Roll Range into Position ....................................

Step 7, Level the Range ....................................................

Step 8, Replace Oven Doors ............................................

Step 9, Check Burners ........................................................

Finalize Installation ..............................................................

Installation Checklist ..........................................................

Accessories ..............................................................................

Accessory Installation ................................................18-20

Gas Conversion ............................................................21-23

36" Natural Gas Models:

ZDP366N - 6 gas burners

ZDP364NR- 4 gas burners and grill

ZDP364ND - 4 gas burners and griddle

36" LP Gas Models:

ZDP366L- 6 gas burners

ZDP364LR - 4 gas burners and grill

ZDP364LD - 4 gas burners and griddle

30" Natural Gas Model: ZDP304N

30" LP Gas ModeI:ZDP304L

1

2

3

.4

4

4

5

5

6

6

6

7

BACKSPLASH ACCESSORIES

All models require 12" minimum clearance to a

vertical combustible surface at the rear. If clearance

is less than 12", the entire surface of the back wall

above and the full width of the range must be

protected by a backsplash. The backsplash must be

constructed of non-combustible material, such as

metal, ceramic tile, brick, marble or other stone.

Two Backsplash AccessoriesAvailable:

• The 12" high stainless steel backsplash accessory

is available. Use this backsplash in combination

with a custom, non-combustible backsplash built

beyond the 12" height. The combined height of

the backsplash accessory and the custom

backsplash must reach the bottom of a hood,

or when there is no hood, to 48" above the

cooking surface.

• An adjustable 30" to 36" high backsplash with

shelf is also available. This backsplash fills in the

space between the top of the range and the

bottom of the hood. The shelf is positioned so that

heat lamps from the bottom of a Monogram

professional hood are directed towards the shelf.

12"HighBacksplash

ZX12B48PSS,for48" wideranges

ZX12B36PSS,for36" wideranges

ZX12B30PSS,for30" wideranges

30"to36" AdjustableHeight

BacksplashWith Shelf

ZXADJB48PSS,for 48"wide ranges

ZXADJB36PSS,for 36"wide ranges

ZXADJB30PSS,for 30"wide ranges

3

Page 4

Design Information

PRODUCT DIMENSIONS AND CLEARANCES

48" Range Models

I "

Countertop

_ .......47-7/8"Width to Cooking

.............. Surface

UniversalUtilityLocations

35-1/4"

to

36-3/4"

Height

28-1/4"

Depth

to Front

of Door

- WARNING:

Installations without a hood require

a8" minimum to combustibles.

Acustom hood installation with

exposed horizontal combustible

surfaces must have an Auto-On

feature. Referto hood installation

instructions for specific hood

clearances.

The surface of the entire back wall

above the range and below the

hood must be covered with a non-

combustible material such as metal,

ceramic tile, brick, marble or other

stone.

1% I1 i

3-1/4"

to 4-3/4"

Toel<icl</leg_'

Height

12"Minimum

', toAd acentWall

Max.

ADDITIONAL CLEARANCES:

Allow 12" minimum clearance to an adjacent wall

on each side.

Working areas adjacent to the rangetop should have

18" minimum clearance between countertop and

the bottom of the wall cabinet.

4

Page 5

Design Information

PRODUCT DIMENSIONS AND CLEARANCES

36" Range Models

1 "

35-7/8"Width

35-1/4"

to

36-3/4"

Height

Countertop

to Cooking

Surface

UniversalUtility Locations

28-1/4"

Depth

toFront

of Door

WARNING:

Installations without a hood require

48" minimum to combustibles.

A custom hood installation with

exposed horizontal combustible

surfaces must have an Auto-On

feature. Refer to hood installation

instructions for specific hood

clearances.

The surface of the entire back wall

above the range and below the

hood must be covered with a non-

combustible material such as metal,

ceramic tile, brick, marble or other

stone.

Toel<icl</leg

Height

12"Minimum

to Ac acentWall

48"Minimum

toCombustibles

Max.

ADDITIONAL CLEARANCES:

Allow 12" minimum clearance to an adjacent wall

on each side.

Working areas adjacent to the rangetop should have

18" minimum clearance between countertop and

the bottom of the wall cabinet.

5

Page 6

Design Information

PRODUCT DIMENSIONS AND CLEARANCES

30" Wide Range Models

29-7/8"Width

35-1/4"

to

36-3/4"

Height

28-1/4"

Depth

to Front

of Door

1 "

Countertop

to Cooking

Surface

Toel<icl</legf

Height

UniversalUtilityLocations

12"Minimum

\\

\\

to Ac acentWall

-&WARNING:

Installations without a hood require

/48"minimum to combustibles.

Acustom hood installation with

exposed horizontal combustible

surfaces must have an Auto-On

feature. Referto hood installation

instructions for specific hood

clearances.

The surface of the entire back wall

above the range and below the

hood must be covered with a non-

combustible material such as metal,

ceramic tile, brick, marble or other

stone.

30" Min.

ADDITIONAL CLEARANCES:

Allow 12" minimum clearance to an adjacent wall

on each side.

Working areas adjacent to the rangetop should have

18" minimum clearance between countertop and

the bottom of the wall cabinet.

Page 7

Design Information

PRODUCT DIMENSIONS AND CLEARANCES

48", 36" and 30" Range Models

28-7/8" ............................................................

10-1/2" _

13/16" _ 4

A

ToFrontEdge

Optional

Backsplash

Accessories

30-36"

35-1/4"

to

36-3/4"

v

,,

A

-='v_

,4 28-1/4"To

.

,4t

bl b1

4 ToFrontofDoor

3-3/16"

ControlPanel

Beveled

Edgeof Control

PanelBullnose

27-1/2"To

BeveledEdge

Maximum

AdjacentCabinet

Depthfor

FlushInstallation

28-1/4"

Depth I_-

4

7" ControlPanel

Height

V

u

u

u

12"Min.to combustiblesor 0" to

a non-combustiblematerialabove

thecookingsurface

0"Clearance

- toabackor

sidewall below

thecooking

surface

4 31-1/16"

ToFrontof Handle

48-1/4"

With OvenDoorOpen

WARNING:

The 12" high stainless steel

backsplash accessorg must be

installed in combination with a

custom non-combustible backsplash.

The finished backsplash must cover

the entire back wall up to the bottom

of a hood, or when there is no hood,

48" to combustibles.

Page 8

Installation Information

WB28K10553 HIGH ALTITUDE KIT

For operation above 3,000 feet, order WB28KlOS53

Conversion Kit. This kit includes orifices for both LP

and Natural gas operation.

WB28K10554 DE-RATE KIT

(For a smell kitchen environment.}

De-rate conversion kit for use with model

ZDP304N (natural gas onlg). This kit includes

orifices to reduce surface burner output

to 40,800 BTU's.

MATERIALS PROVIDED

1/2" Pipe OvenRack

Anti-Tip Elbow Lubricant

Bracket,Brace

andScrews

Runners

(toprotect

flooring)

TOOLS REQUIRED

SaberSaw

MeasuringTape

Carpenter'sSquare

SafetyGlasses

Phillips#2Screwdriver

Drilland

AppropriateBits

AdjustableWrench

1/4" DriverorWrench

Level

HandTruck

MATERIALS REQUIRED {not provided}

Joint PipeFittings Shut-0ffValve

Sealant

5-foot maximum length, 5/8" 0.D. CSA-approvedflexible

metal gas supply

(3-foot maximumlength in Massachusetts only)

NOTE: Purchasenew flexible line; do not use

previously used flexible gas line.

Page 9

POWER SUPPLY LOCATIONS

Installation Preparation

Gas Supplg:

•The natural gas models are designed to operate

at 5" water column pressure. For proper operation,

the pressure of the natural gas supplied to the

regulator must be between 7" and 13" water

column.

•The LP models are designed to operate at 10"

water column pressure. For proper operation,

the pressure of the LPgas supplied to

the regulator must be between 11"

and 13" water column.

• A 1/2" elbow is provided for connection

to the range gas inlet, located at the rear

and near the floor.

• Locate the pipe stub on the back wall or floor

as illustrated in "Dimensions and Clearances."

Use 5-foot maximum length, 5/8" O.D. flexible

gas supplg line (3-foot in Massachusetts).

• Install a manual shut-off valve in the gas line

(not provided), in an easilg accessible location.

Make sure the homeowner knows where

and how to shut off the gas supplg to the range.

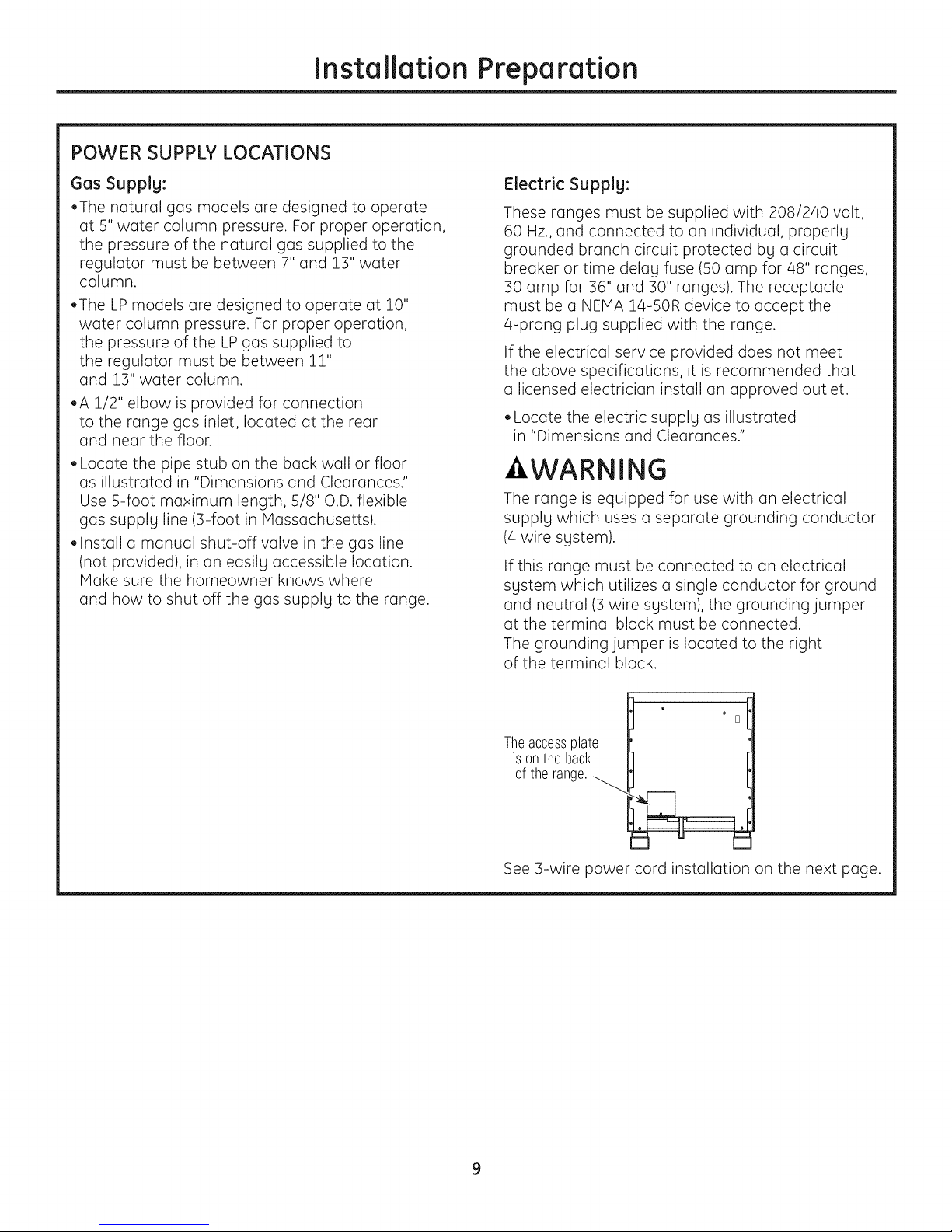

Electric Supplg:

These ranges must be supplied with 208/240 volt,

60 Hz., and connected to an individual, properlg

grounded branch circuit protected bU a circuit

breaker or time delag fuse (50 amp for 48" ranges,

50 amp for 56" and 50" ranges). The receptacle

must be a NEIVlA14-50R device to accept the

4-prong plug supplied with the range.

If the electrical service provided does not meet

the above specifications, it is recommended that

a licensed electrician install an approved outlet.

• Locate the electric supplg as illustrated

in "Dimensions and Clearances."

-&WARNING

The range is equipped for use with an electrical

supplg which uses a separate grounding conductor

(4 wire sgstem).

If this range must be connected to an electrical

sgstem which utilizes a single conductor for ground

and neutral (5 wire sgstem), the grounding jumper

at the terminal block must be connected.

The grounding jumper is located to the right

of the terminal block.

o

Theaccessplate

is onthe back

of the range._....

See 5-wire power cord installation on the next page.

o

D

Page 10

Installation Preparation

4-WIRE POWER CORD INSTALLATION

NOTE: A 4-wire cord is connected to the range

at the factory. Use the following steps to change

an existing installation from a 3-wire cord back

to a 4-wire cord.

- WARNING

The neutral wire of the supplg circuit must

be connected to the neutral terminal located

in the lower center of the terminal block.

The power leads must be connected

to the lower left and the lower right

terminals of the terminal block. The 4th

grounding lead must be connected to

the frame of the range with the ground

plate and the ground screw.

• Remove the 3 lower terminal screws from

the terminal block. Remove the ground screw

and ground plate and retain them.

• Remove the ground strap. DO NOT DISCARD

THE GROUND STRAP OR ANY SCREWS.

• Insert the one ground screw into the power cord

ground wire terminal ring, through the ground

plate and into the frame of the range.

• Insert the 3 terminal screws (removed earlier)

through each power cord terminal ring and

into the lower terminals of the terminal block.

Be certain that the center wire (white/neutral)

is connected to the center lower position

of the terminal block. Tighten screws securely

into the terminal block.

GroundStrap

3-WIRE POWER CORD INSTALLATION

NOTE: A 4-wire cord is connected to the range

at the factorg. Use the following steps to change

the range to a 3-wire cord.

WARNING

The neutral or ground wire of the power cord

must be connected to the neutral terminal located

in the center of the terminal block. The power leads

must be connected to the lower left and the lower

right terminals of the terminal block.

• Remove the ground strap (located at the right

side of the terminal block) and connect between

the center lower portion of the terminal block

to the frame of the range.

• Remove the 3 lower terminal screws from

the terminal block. Insert the 3 terminal screws

through each power cord terminal ring and

into the lower terminals of the terminal block.

Be certain that the center wire (white/neutral)

is connected to the center lower position

of the terminal block. Tighten screws securelg

into the terminal block.

DO NOT remove the ground strap connection.

TerminalBlock

aearance

mayvary)

Neutral

Terminal

Terminal or

Block

GroundStrap Neutral

After

Terminal

Block

Ground

Screw

Terminal

Plate

Ground

Strap

NeutralTerminal

GroundPlate

(groundingto

range)

10

Page 11

STEP 1 REMOVE PACKAGING

Installation

CAUTION

Stand clear. The ends of the cut metal banding may

snap toward gou.

•Cut the metal banding. Lift the carton straight up.

• Locate the two runner strips from the top

of the packaging. These strips will be used to

protect the kitchen floor during installation.

• Remove corner posts. Dispose of packaging

materials.

• Remove grill/griddle covers, grill grate and burner

grates.

• Lift out cast-iron griddle flue cover, grease troughs

and pads.

•Cut the ties holding the grill grate to the grill frame.

GriddleFlueCover

• Open oven door(s) and remove packaging.

Remove shelf holding broiler pan, tape, literature

package, shelf lubricant and probe.

\

- CAUTION

Doors and passagewags leading to the installation

location require at least 32" opening. Ifthe opening

islessthan 32",the oven door(s)and controlknobs

must be removed.

REMOVE THE OVEN DOOR(S) ONLY IFNECESSARY to

move the range throughthe doorwags. To prevent

damage tothe sidesofthe range,itwillbe

necessargto pad the cornersbeneath the straps

on the hand-truck.

;10t

G

Ties

• Lift off burner caps and remove foam pad,

then lift off burner heads and remove foam pad.

RemoveFoamPads

GreaseTroughs

Hinge

Lock

To remove the oven door(s):

• Fullg open the door.

• Each hinge has a hinge latch. Close the hinge

latch down against the door frame.

• Firmlg grasp the door at the top sides.

• Close the door to the near-vertical position.

• Lift the door up and pull straight out.

• Remove the control knobs bg pulling them

straight out.

11

Page 12

Installation Preparation

STEP2 MOVE THE RANGE INDOORS

1 Tilt the range forward on the skid.

Toekick

2 Lift the toekick out of the foam base.

, ,,J

3 Drive the blade of the hand-truck beneath

the foam block.

4 Attach the hand-truck straps around the unit.

IMPORTANT: Place the hand-truck straps below

the oven door handles. To avoid damaging the

side panels, place a pad between the hand-truck

and the range.

5 Tilt the range to lower the hand-truck wheels

off the skid.

Hand-Truck

StrapsBelow

OvenDoor

Handles

6 Place the appliance runners on the floor

at the left and right sides in front of the opening.

IMPORTANT" The runners provide a surface for

rolling the range into the final position and will

protect the floor finish. The runners must be

removed before leveling the range.

7 Move the range indoors. Position the range

in front of the installation location, onto

the runners.

You mayneed to remove the front

ofthe foamblockto fit through

the doorway.

IMPORTANT" Do not remove the base foam

block while the hand-truck is in use. Place

the hand-truck blade underneath the base

foam block and transport the range to the final

location.

Range

Opening

Runners

forRolling

the Range

Position

InsertBladeUnder

the FoamBlock

12

Page 13

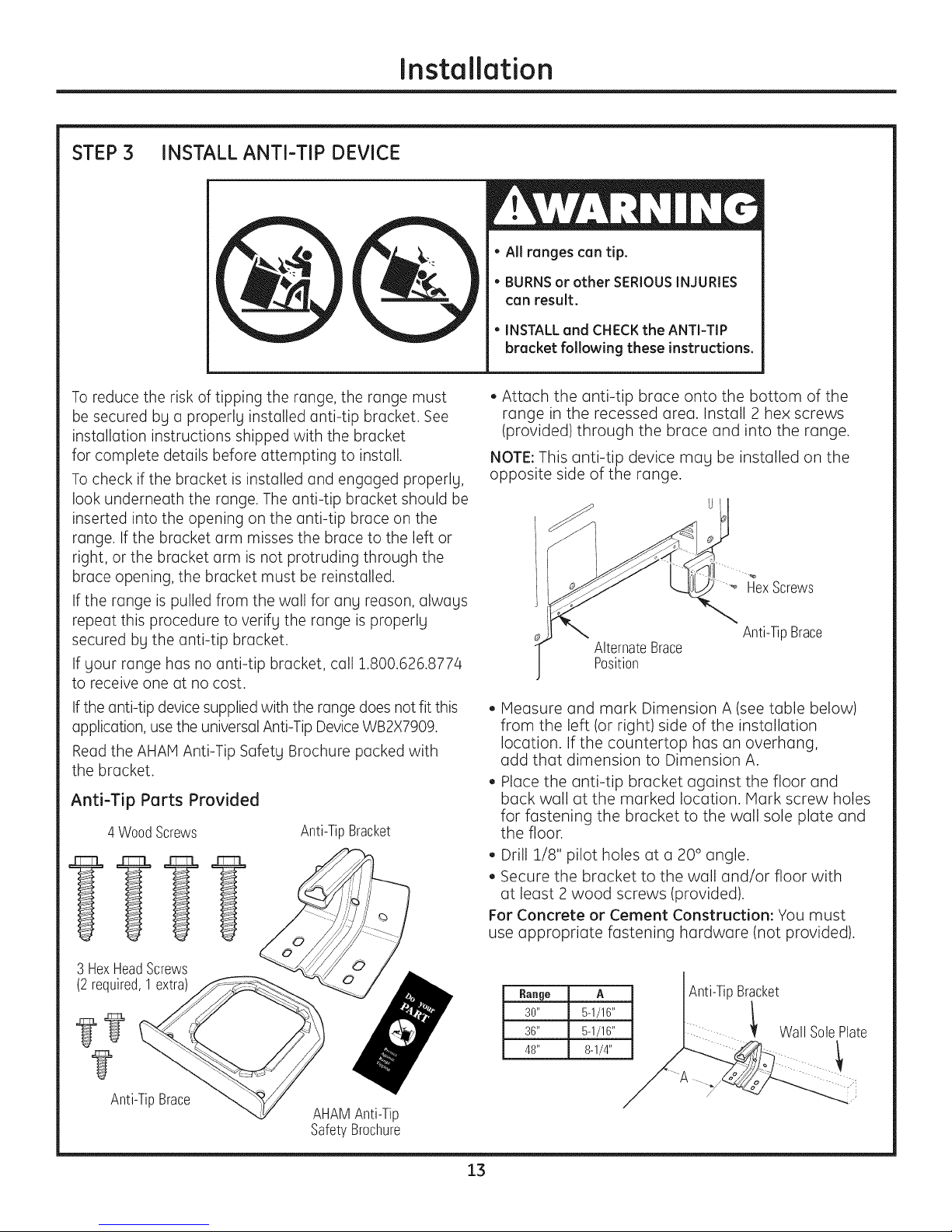

STEP 3 INSTALL ANTI-TIP DEVICE

Installation

• All ranges can tip.

• BURNSor other SERIOUSINJURIES

can result.

INSTALLand CHECKthe ANTI-TIP

bracket following these instructions.

To reduce the risk of tipping the range, the range must

be secured bg a properlg installed anti-tip bracket. See

installation instructions shipped with the bracket

for complete details before attempting to install.

To check if the bracket is installed and engaged properly,

look underneath the range. The anti-tip bracket should be

inserted into the opening on the anti-tip brace on the

range. If the bracket arm misses the brace to the left or

right, or the bracket arm is not protruding through the

brace opening, the bracket must be reinstalled.

If the range is pulled from the wall for ang reason, alwags

repeat this procedure to verify the range is properly

secured bg the anti-tip bracket.

If gour range has no anti-tip bracket, call 1.800.626.8774

to receive one at no cost.

Ifthe anti-tip device supplied with the range does not fit this

application, use the universal Anti-Tip Device WB2X7909.

Read the AHAP1Anti-Tip Safety Brochure packed with

the bracket.

Anti-Tip Parts Provided

4 WoodScrews

Anti-TipBracket

• Attach the anti-tip brace onto the bottom of the

range in the recessed area. Install 2 hex screws

(provided) through the brace and into the range.

NOTE: This anti-tip device mag be installed on the

opposite side of the range.

HexScrews

Anti-TipBrace

AlternateBrace

Position

• Measure and mark Dimension A (see table below)

from the left (or right) side of the installation

location. If the countertop has an overhang,

add that dimension to Dimension A.

• Place the anti-tip bracket against the floor and

back wall at the marked location. Mark screw holes

for fastening the bracket to the wall sole plate and

the floor.

• Drill 1/8" pilot holes at a 20 ° angle.

• Secure the bracket to the wall and/or floor with

at least 2 wood screws (provided).

For Concrete or Cement Construction: You must

use appropriate fastening hardware (not provided).

3 HexHeadScrews

(2 required,1extra)

Anti-TipBrace

AHAMAnti-Tip

SafetyBrochure

13

Range A Anti-TipBracket

30" 5-1/16" !

36" 5-1/16" Wall SolePlate

48" 8-1/4"

/

Page 14

Installation

STEP 4 CONNECT RANGE TO GAS

WARNING

Do not use a flame to check for gas leaks.

Assure that gas supplg is turned off

at the shut-off valve:

• Applg pipe thread sealant to the gas inlet located

at the back of the range. Install the l/2" pipe

elbow (provided) to the gas inlet.

• Connect 5/8" O.D. flexible metal connector

to gas inlet. Connect the other end of the flexible

connector to the house gas supplLI.

Turn on the gas and check for leaks:

- Use a liquid leak detector at all joints

and connections in the sLIstem.

STEP 6 ROLL RANGE INTO POSITION

AWARNING

The Anti-Tip Bracket must be properlLI installed

to prevent tipping of the range. Failure to do so

can cause serious damage or injurLI.

• Check to be sure the appliance runners are

beneath the wheels.

• The range is shipped with the wheels in the down

position. CarefullLI roll the range into position,

being careful not to entangle or pinch the power

cord and flexible gas tubing.

• Remove the runners beneath the range.

IMPORTANT: Disconnect the range and the

individual shut-off valve from the gas supplg piping

system during anLI pressure testing of that system

at test pressures greater than 1/2 psig. Isolate the

range from the gas supply piping system bLIclosing

the individual manual shut-off valve to the range

during any pressure testing of the gas supply piping

sLIstem at test pressures equal to or less than

1/2 psig.

NOTE: This range is equipped with a gas shut-off

valve located on top of the range, beneath the rear

vent. This shut-off valve is to be used in the event

that service is required in the future.

STEP 5 CONNECT ELECTRICAL

• Plug power cord into properlg grounded

receptacle.

• Verifg that power is connected bg opening

the oven door or press the button on the left side

of the control panel to illuminate the accent

lighting.

BesureAnti-Tip

Bracketisengaged

with thebrace

onthe range.

14

Page 15

Installation

STEP 7 LEVEL THE RANGE

AWARNING

The range must be level and be supported

by the legs-not the wheels. The range could move

if the wheels make contact with the floor. Be sure all

legs make contact with the floor in any installation.

• All legs must be leveled after the product is

installed.

• Check to be sure the adjoining cabinets/

countertops are level, front to back and left

to right across the opening of the range.

• Measure the distance from the floor to the top

of the countertop in the left and right rear corners.

• Adjust the height of the range to countertop height

or higher.

IMPORTANT: Thisrange should always be installed

atcountertopheightorhigher.DO NOT INSTALL

THE RANGE LOWER THAN ADJACENT COUNTERTOP

HEIGHT.The range must be supported by all4 legs,

regardlessofcountertopheight.

FRONT LEG ADJUSTMENT

• Slide front cylinders up to adjust front leveling

legs. Be careful not to damage cylinder.

• A leveling leg wrench is supplied. Reach under

the front of the range near the right side. Locate

and remove a thumb screw, then slide wrench out

of the slot.

ThumbScrew

STEP 7 LEVELTHE RANGE (cont.}

REAR LEG ADJUSTMENT

• Remove two screws from rear vent trim. Slide vent

trim forward, then lift up to remove.

• Find the two rear leg extension rods. Use a 1/4"

driver or wrench to adjust the left or right rear legs.

RearVent_im

RearLeg

ExtensionRod

• Replace the rear vent trim using the original screws.

STEP 8 REPLACE OVEN DOOR(S}

Skip this step if oven doors are in place.

IMPORTANT: Do not lift the door by the handle.

To replace the oven doors:

• Firmly grasp the door at the top sides.

This is critical.

• Approach the range with the door angled

in a vertical position.

• Guide the hinges into the slots.

• Push the door in firmly while opening.

• Once in position, open the door completely.

Push the hinge locks back in and toward

the front frame.

• Use the supplied wrench to turn the front leveling

legs. Turn clockwise to raise the range above the

wheels. Turn counterclockwise to lower the legs.

• Be sure to return the wrench to its storage slot

for future use.

Slideleg

cylinderup.

CAUTION: Take care when replacing

the oven doors.Ifthe hingelatchisnot securely

locked,the hinge may snap back and separate.

Ifthe hingeseparates,you must apply pressure

(possiblywithyour foot)topress itback together

and then engage the hingelatch.

15

Page 16

Installation

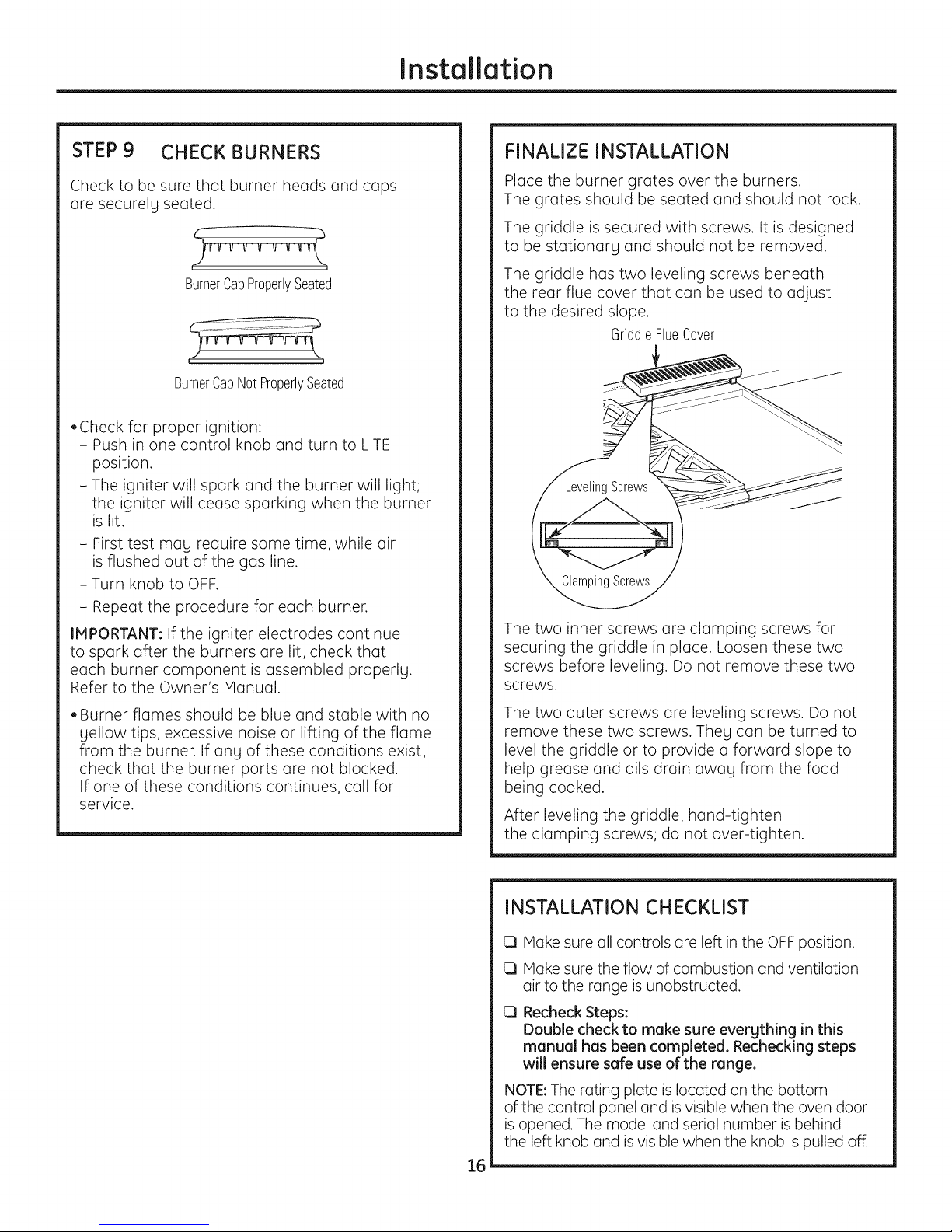

STEP9 CHECK BURNERS

Check to be sure that burner heads and caps

are securelg seated.

BurnerCapProperlySeated

i

BurnerCapNotProperlySeated

• Check for proper ignition:

- Push in one control knob and turn to LITE

position.

- The igniter will spark and the burner will light;

the igniter will cease sparking when the burner

is lit.

- First test mag require some time, while air

is flushed out of the gas line.

- Turn knob to OFF.

- Repeat the procedure for each burner.

IMPORTANT: Ifthe igniter electrodes continue

to spark after the burners are lit, check that

each burner component is assembled properlg.

Refer to the Owner's IVlanual.

FINALIZE INSTALLATION

Place the burner grates over the burners.

The grates should be seated and should not rock.

The griddle is secured with screws. It is designed

to be stationarg and should not be removed.

The griddle has two leveling screws beneath

the rear flue cover that can be used to adjust

to the desired slope.

GriddleFlueCover

_Screws

The two inner screws ore clumping screws for

securing the griddle in place. Loosen these two

screws before leveling. Do not remove these two

screws.

• Burner flames should be blue and stable with no

gellow tips, excessive noise or lifting of the flame

from the burner. If ang of these conditions exist,

check that the burner ports are not blocked.

If one of these conditions continues, call for

service.

The two outer screws are leveling screws. Do not

remove these two screws. They can be turned to

level the griddle or to provide a forward slope to

help grease and oils drain awag from the food

being cooked.

After leveling the griddle, hand-tighten

the clamping screws; do not over-tighten.

INSTALLATION CHECKLIST

Make sure all controls are left in the OFFposition.

Make sure the flow of combustion and ventilation

air to the range is unobstructed.

Recheck Steps:

Double check to make sure evergthing in this

manual has been completed. Rechecking steps

will ensure safe use of the range.

NOTE: The rating plate is located on the bottom

of the control panel and isvisible when the oven door

is opened. The model and serial number is behind

the left knob and isvisible when the knob is pulled off.

16

Page 17

ACCESSORIES--TOEKICK (provided)

Installation

• Install the toekick after the range has been leveled.

• Measure the distance between the floor

and the bottom of range.

• Loosen the two screws on each end. Adjust

the toekick height bg sliding the upper and lower

pieces apart to 1/8" less than the measured height.

oSecure the top and bottom sections bg tightening

the 2 screws on each end.

oPush toekick against range leg until clip snaps

to legs.

NOTE: Be sure the toekick snaps securelg to the leg.

Topof

Toekick

Bottom

ofToekick

Screw

Push

Push

17

Page 18

Z×12B30PSS,Z×12B36PSS,Z×12B48PSS AccessorgInstallation

OPTIONAL ACCESSORIES--12" HIGH BACKSPLASH

WARNING:

To prevent ignition of combustible materials,

the entire back wall above the range must

be protected bg a backsplash constructed

of non-combustible material.

This stainless steel backsplash accessorg

must be installed in combination with a custom,

non-combustible backsplash built begond

the 12" height of the backsplash.

BEFORE YOU BEGIN

Reed these instructions completelg

end cerefullg.

IMPORTANT: Sere these instructions for Iocel

inspector's use.

IMPORTANT: OBSERVE ALL GOVERNING CODES

AND ORDINANCES.

NOTE TO INSTALLER: Be sure to leeve these

instructions with the Consumer.

NOTE TO CONSUMER: Keep these instructions

with gour Owner's Menuel for future reference.

INSTALL 12" BACKSPLASH

-AWARNING: Thisbeckspleshmust

be securely fastened to the well. Failure to do

so could result in damage or personal injurg.

• Install and level the range or rangetop and the

range hood according to the installation

instructions.

• Remove the backsplash packaging and

protective film.

• Usea level to pencil o horizontal line on the wall,

1/8" above the range or rongetop. The 1/8" gap

allows the cover panel to overlap the wall support

panel.

• Locate wall studs on each side. Where studs ore not

available, plan to use wall anchors (not provided).

• Align the wall support panel on the marked

horizontal line and centered left to right.

• The wall support panel must be secured to the wall

at oil 4 corners. Use wood screws (provided) or wall

anchors (not provided) to secure the support panel

to the wall.

• Place the cover panel over the wall support

panel and secure with Torx screws (provided).

Install 2 screws on each side.

This kit provides for the instelletion of e 12" high

becksplesh for 30", 36" or 48" Monogrem

Professional Ranges end Rongetops.

TOOLS AND MATERIALS REQUIRED

• Gloves to protect against sharp edges

• T-15 and #2 Phillips screwdrivers Wall Support

Drill with :3/32" and 9/64" bits Panel

• Pencil

• SafetgLevelglasses

This Kit Includes

• Wall support panel

• Cover panel

• Hardware package with

- 5 Stainless Steel Torx 15 #8

self-tapping screws

- 5 Phillips #2 pan head wood

#10 screws

Hardware

Package

Wall

Support

Panel

Install4 Wood

Screws

Wall Support

Panel

.... _ InstallT-15

o_ Screws

CoverPanel

18

Page 19

ZXADJB30PSS,ZXADJB36PSS,ZXADJB48PSSAccessorg Installation

ACCESSORIES--30" TO 36" ADJUSTABLE BACKSPLASH (not included}

AWARNING:

To prevent ignition of combustible materials,

the entire back wall above the range must

be protected bg a backsplash constructed

of non-combustible material.

BEFORE YOU BEGIN

Read these instructions completely

and carefullg.

IMPORTANT: Save these instructions for local

inspector's use.

IMPORTANT: OBSERVEALL GOVERNING CODES

AND ORDINANCES.

NOTETO INSTALLER:Be sure to leave these

instructions with the Consumer.

NOTETO CONSUMER: Keep these instructions

with your Owner's Manual for future reference.

• This backsplash adjusts to fit the space between

the top of the range and the bottom of the hood,

from 30" Min. to 36" Max. height.

• Maximum shelf load-bearing weight is 40 Ibs.

INSTALL THE WALL SUPPORT PANELS

WARNING:Thewallsupportpanels

must be securel 9 fastened to the wall. Failure to

do so could result in damage or personal injurg.

IMPORTANT:Thisbacksplash isdesigned to cover the wall

between the bottom of the hood and the top of the range.

The vent hood should be installedover the rangetop or

range before installing this backsplash.

• Install and levelthe Range/Rangetop according

to the product installation instructions.

• Removebacksplash packaging and protective film.

Locatewall studson each side.Where studsare not

available, plan to usewall anchors (notprovided).

Usea levelto pencil2 horizontal lines on the wall,

one 1/8" below the vent hood and the other 1/8" above

the Range/Rangetop.This1/8" space allows the cover

panels to overlap the wall supports.

Securethe top wall support panel to the wall with 4wood

screws,through the outermost studs.

Use4 wood screwsto securethe bottom wall support

panel.The center slotshould be positioned at the top.

The gap between the top and bottom support panels

will be covered bUthe top cover with shelf.

Securethe top

paneltothe wall

with 4wood

screws

TOOLS AND MATERIALS REQUIRED

• Gloves to protect against sharp edges

• T-15 and #2 Phillips screwdrivers

• Drill with 3/32" and 9/64" bits

• Safetg glasses

• Level TopCover

• Pencil with Shelf

• Top wall support

• Bottom wall support

This Kit Includes

• Top cover with shelf

• Bottom cover

• Hardware package with

- 9 Stainless Steel Torx 15 #8

self-tapping screws

- 9 Phillips #2 pan head wood #10 screws

- 3 Stainless Steel #2 truss head

#10 screws (for alternate

installation method)

BottomWall Support

TopWall

Support

Hardware

Package

19

Wood

Screws

Secure

the bottompanel

to the wall with

4 woodscrews

Page 20

ZXADJB30PSS,ZXADJB36PSS,ZXADJB48PSSAccessorg Installation

INSTALL COVER PANELS

See alternate method if side access is blocked.

• Hold the bottom cover over the bottom support

while driving one screw (provided)into each side.

• Place the top cover with shelf over the top wall

support. If you have access to the sides, secure

the panel with two screws on each side.

Secure the top cover with shelf to the top

support with screws through the front of the panel,

at the top corners. Use one screw on each side.

Install

Screw

Install

Screw

INSTALL COVER PANELS {cont.)

ALTERNATE METHOD: When side access is blocked

• Install bottom cover over the bottom support while

driving one screw into each side.

• Hold top cover in place while marking screw

locations,just below shelf support and onto bottom

cover.

• Remove the shelf and drill a 9/64" diameter

hole in the pencil-marked locations.

• Mount the top cover over the top support

and secure the front cover with screws through

the drilled holes on each side.

Install screws through each top corner.

Marl<ScrewLocations

forAlternateMethod

InstallCornerScrews

"- InstallScrew

"'_ onEachSide

InstallScrewinTopCorneronEachSide

Shelf

2O

Page 21

I

stalJ ti

I

str ctJ

Convert Natural Gas to LP Gas Operation

Convert LP Gas to Natural Gas Operation

-AWARNING:Thisconversionmust

be performed bgo qualified installer or gas supplier

in accordance with the manufacturer's instructions

and all codesand requirements of the authority having

jurisdiction. Failure to follow instructions could result

in serious injury or property damage. Thequalified

agency performing this work assumes responsibility

for the conversion.

-AWARNING:The rangetop, as shipped from

the factorg, is set for usewith its intended gas. Ifgou

wish to use gour rangetop with the alternate gas, gou

must first replace the orifices end convert the pressure

regulator.

-AWARNING:Thefollowing adjustments

must bemode before turning on the burner. Failure to

do socould result in serious injurg. Be sure pressure

regulator has beenconverted as described in Step 2.

TOOLS YOU NEEDED FOR CONVERSION

r_ CONVERT THE REGULATOR

Disconnect all electrical power at the main circuit

breaker or fuse box.

A. Removethe rearvent RangeRegulator

trim (onrangesonly)

to accessthe

regulator.The

Rongetop_regulator is

on the left bottom

corner.

B. Shut off l_hegas supplLJby closingthe manual shut-off

vave inthe unit or at the wall.

C. Convertthepressureregulator:

• Unscrewthe copwith plunger.

• Placeyour thumb against flat sideofthe plunger and

pressdown to snapthe plunger out at the cap.

• Carefullylook at the plunger to locatethe NAT

or LPposition.

• Turnthe

plunger

overso

that the

desiredgas

isshowing

near the

bottom.

Position _ LPPosition

Cap G,asket

@=/@

_.. _JPlunger

CrescentWrench

SafetyGlasses

1/2" Deepwell

SocketWrench

SmallPliers Screwdriver

[_ ORIFICE HOLDER

Therange orifice holder

islocated behind the front

access panel at the bottom

of the range.

Therangetop orificeholder BurnerOrifices

islocated insidethe range insulation cover.

Additional orifices may bepresent. Useonly the orifices

specifiedin the instructions for your range or rangetop.

1/4"and7mmNutdrivers

r_

SmallFlat-HeadScrewdriver

(2to 2.4 mmor 3/32"tip size,

60mmlong)

Philips

Griddle Grill

Orifice Orifice

PressureRegulator

• Snapthe plunger back into the cap.

• Screwthe cap backonto the regulator.

[_ CHANGE BURNER ORIFICES

INSTALLATIONTIP:First removeall

orificesand then start replacingthem.

Thiswill helpto prevent the possibility

that some may not be replaced.

A.

Removethe burnergrates, Head

burner capsandburner heads.

B.

Loosenthe top burner Spark __

orificesusing a7mm Igniter

nut driver.Usesmall

pliersto carefully lift out the orifices. BurnerBase

Themain orificeislocated

low in the center of the

burner,while the simmer

orifice islocated higher

besidethe center

of the burner. Main

Orifice

BurnerCap

Burner

Orifice

21

Page 22

Installation Instructions for Gas Conversion

[_ CHANGE BURNER ORIFICES {cont.}

IMPORTANT: Find your model number below. Read

each orifice label to identify and install them in the

exact locations shown.

ZDP304 SIMMER ORIFICES

A 34SL or 52SN orifice

will be used on ell burners.

ZDP304 MAIN ORIFICES

Use a 108XL

or 190XN orifice

tt_LN°rorifice I/1OO) JI_,_y _d

will be used

on these three

burners.

forthe right

frontburner.

CHANGE GRILL ORIFICE (if present}

Locatethe 1-1/2" longGrillorifice.

Selectfor your gastype.LP--.047, NAT--.067

A. Removethe grill cover,

grates and grate frame. Lift

the radiant baffle straight

up andoff.

B. Removethe 2 hex

head screws from

the top of the igniter.

• Removeone screw

from eachside of

the burner surround.

• Lift out the surround.

lUUUU UUUUUUlIIIIIII UUUUl

Remove2--

hexhead--_ _ --,

screws I

i i / !

Surround

Screws

ZDP364, ZDP366, ZDP484, ZDP486

SIMMER

ORIFICES

MAIN

ORIFICES

A. Return the unused orifices to the holder. Reattach

the holder and the instruction sheet with screw

in the original storage location.

B. Replace the burner heads, caps and top grates.

On range models,replace rearvent trim.

I_ _I A 34SL or 51SN orifice

r

will be used on all

burners.

190×N orifices

Use 108×L or

forallburners.

C,

Cardully push the

igniter aside and

under

the burner.

Donot pullorpinch

the wire.

Remove4 burner

attachment screws,

2 at the front and 2

at the back. Slidethe

burner assembly

toward the back and

out of the gas inlet.

D°

Usea 1/2" deep well

socket to remove

and replacethe orifice.

Reversethese

stepsto re-assemble

the grill. Besureto

placethe unused

orifice in the holder

for possiblefuture use.

Burner Igniter

Surround

Assembly

Frontof Range

22

Page 23

Installation Instructions for Gas Conversion

[_ CHANGE GRIDDLE ORIFICE (if present}

Locatethe 3/4"longgriddleorifice.

Selectforyour gastype.LP--.047, NAT--.076 I t

A. Lift off the

griddle flue

cover. Remove

the 2 inside

clamping

screws.

B.

Lift out the

cast-iron

grease trough.

Slide the

griddle toward

the rear end

out of the

hold-down

tabs along the

bottom.

C.

Carefully lift and hold

the griddle while pulling

additional length of the

capillary from the entry

hole. Stand the griddle on

end in the grease sump.

D.

Remove the 2 hold-down

screws at the rear of the

burner.

Pull the burner straight

buck toward the rear and

out of the gas inlet.

E.

Use a 1/2" deepwell

socket to remove and

replace the orifice.

GriddleFlueCover

A

/

NOTE:Remove

2 screws

_ositionedon

insideonly.

Donotremove

the outermost

screws--they

arefor leveling.

Capillary

[_ ADJUST BURNER FLAMES

Normally, burners do not need further adjustment.

Hake adjustments only when necessary.

A. Turn on the gas. Plug in electrical cord.

B. Turn all burners on highest setting and check

the flames. They should be blue in color. When

using LPgas, the flames may hove some yellow

tipping at the ends of the flame. Foreign pc_rticles

in the gas line may cause tin orange flame at first,

but this will soon disappear.

C. Turn the burner knob to "LO" while observing the

flame.

Adjust the setting of the upper row of flames using

the valve bypass screw as follows:

Adjustments must be made with two other burners

in operation on a medium setting. This prevents

the upper row of flumes from being set too low,

resulting in the flume being extinguished when

other burners are turned on.

D. Toadjust the flume, remove the knobs. Insert c]small

flat-blade screwdriver into the hole inthe center

of the valve stem to engage screw.

• If the flames (Ire too small or flutter,

turn the screw counterclockwise.

B Backof Range E Frontof Range

Reverse these steps to reassemble the griddle.

Push excess capillary back into the entry hole.

Place the unused orifice in the holder for possible

future use.

• If the flumes are too large, turn the screw

clockwise.

E. Make the adjustment by slowly turning the screw

until flame (_ppec_ranceiscorrect.

I m

! Once the conversion iscomplete end checked,fill out the conversionlabelend affix the labelnearthe rating label.Forranges,

placethe label beneath the control panel.Forrongetops,placethe labelon the bottom of the unit.

23

Page 24

Consignes d'installation

AVANT DE COMMENCER

Lisez ettentivement I'ensemble des consignes.

•IMPORTANT-Conservezcesconsignes,

elles peuvent vous #tre utiles pour route

inspection de votre installation.

"IMPORTANT- Respectez toutes les

normes ainsi que les recommandations

pr6conis#es par les autorit6s comp6tentes.

• Remarque 6 l'attention de l'installateur-

Apr_s intervention, assurez-vous d'avoir remis

ces instructions (3 I'utilisateur.

• Remarque 6 I'attention de I'utilisateur-

Conservez ces instructions avec le manuel

de I'utilisateur pour route consultation ult@ieure.

• Temps d'installation - 1 6 3 heures.

• II incombe (3I'installateur de veiller (3la bonne

installation. Toute d6faillance du produit due

(3une installation non conforme ne pourra @re

couverte par la garantie. Pour tout compl#ment

d'information, reportez-vous au manuel

de I'utilisateur.

AVERTISSEMENT :

Cet appareil doit #tre correctement mis (3la terre.

Reportezovous (3la section <<Alimentation

#lectrique >>.

Pour contacter le service de d#pannage Monogram

le plus proche de chez vous, veuillez appeler

le 1.800.444.1845.

.Pour contacter le service de d#pannage Monogram

du Canada, veuillez appeler le num@o

1.800.561.3344.

Pour contacter le service d'accessoires et de pi@ces

d@ach#es Monogram, veuillez appeler

le 1.800.626.2002.

Si vous recevez une cuisini_re d#faillante, veuillez

contacter votre revendeur.

Dens le Commonwealth of Massachusetts

(Communaut_ du Massachusetts}:

• Ce produit doit #tre install# par un plombier

ou un technicien gaz agr##.

• Sivous utilisez des robinets d'arr#t gaz, ceux-ci

doivent #tre de tgpe 1/4 de tour.

• Sivous utilisez un raccord (3gaz flexible, celui-ci

ne dois pas mesurer plus de 3 pieds (100 cm).

AVERTISSEMENT :

Toutes les cuisini@espeuvent se renverserou risque

de provoquer de groves blessures. Instollezle support

ontibosculement fourni conform#ment oux instructions

figuront dons ce manuel ou (3cellesfournies avec

le support.

Dispositions de hotte

d'extracbon:

IIest recommend# d'installernos cuisini@esavec une hotte

d'extraction suspendue.

• Installezune hotte disposant d'une capacit# d'@acuation

d'au moins 1200 CFM(piedscubes par minute ou 35

m_tres cubes/m) (3une distance de 48 (122 cm)

de latable de cuisson.

• Installezune hotte disposant d'une capacit# d'@acuation

d'au moins 600 CFM(ou 18 m_tres cubes/m) au-dessus

d'une table de cuisson de tgpe 30" (76 cm) ou 36" (91 cm).

Cet ap.pareilproduisant une importante quant.it#de chaleur,

vous devez porter une attention toute particuli@e (3

Iinstallation de lahotte et de laconduite da#ration afin

de vous assurerqu'eller@ond aux normes de construction

en vigueur dens votre r#gion.

,AVERTISSEMENT :

Voustrouverez ci-dessous lesespaces qui doivent @re

respect#s entre la surface de latable de cuisson et le

plafond ou encore route surface horizontale setrouvant

au-dessus de la table de cuisson:

• Pourlesinstallations d@ourvues de hotte, pr@ogez

un espace minimum de 48" (122 cm) entre I'appareil

et tout #l#ment inflammable situ# au-dessus de celui-ci.

• IIestpossib!e d'installer une hotte sp#ciale (3proximit#

d'#l#ments horizontaux inflammables dans la mesure

o_ celle-cidisposed'une fonction de mise en marche

automatique.

• P.ourobtenir lessp#cifications relatives aux espaces

d'autres installations pourvues d'une hotte, veuillezvous

reporter aux instructions fournies avec celle-ci.

ZI,ATTENTION :Cescuisini resp_sent

plus de 300 kg. Afin d'#viter tout risque de blessure

ou d'endommagement de I'appareil et compte tenu

du poids et de la taille de la cuisini_re:

DEUX PERSONNESSONT NECESSAIRES,POUR UNE

INSTALLATION ADEQUATE DES CUISINIERES 30"

(76 cm) et 36" (91 cm).

TROIS PERSONNES SONT NECESSAIRESPOUR

UNE INSTALLATION ADEQUATE DES CUISINIERES

48" (121 CM).

Veuillezvousreporterauxconsignesdufabricantpour d_tecter

la presencedefuites.

L'installationdoit respecterlesnormesenvigueurdensvotre

r_gion.EnI'absencedecelles-ci,lacuisini_redoit @reinstall_e

suivantladerni_re_ditiondu codenationalpourlesappareilsau

gaz,ANSIZ223.1/NFPA54,etladerni_re6ditiondela norme

am@icainepour lesappareils_lectriquesANSI/NFPA70.Au

Canada,I'installationdoitrespecterlaIoienvigueursp_cifi6epar

la normecanadienneCAN/CGA-B149.1pourlesappareilsaugaz

natureloula normeCAN/CGA-B149.2pourlesappareils

au propaneenvigueur,etsesloisquientrentdensson domaine

d'application.Cettecuisini_rea_t6conqueetcertifi_eCSAet dens

lerespectdela derni_re_ditiondela normeANSIZ21.1,ainsique

I'Associationcanadiennedugazet denslerespectdeladerni_re

_ditiondelanorme CAN/CGA-I.1.

24

Page 25

Caract ristiques

TABLE DES MATII_RES

Caract_ristiques

IVlod_les disponibles ............................................................25

Accessoires du dosseret ....................................................25

Dimensions du produit et espaces requis ........26-29

Outils et mat#riel requis ..................................................30

Preparation de I'installation

Emplacement des alimentations ..........................31, 52

MODI_LES DISPONIBLES

Les cuisini_res Monogrom sont conques en usine

pour tonctionner au gaz naturel ou au gaz propane.

Commandez le mod61e correspondant _]votre

installation domestique.

ModUles au gaz naturel 48" (122 cm):

ZDP484NG- 4 brQleurs6 gaz,grill et plaque chauffante

ZDP486NR- 6 brQleurs 6 gaz et grill

ZDP486ND - 6 brQleurs 6 gaz et plaque chauffante

ModUles au gaz propane 48" (12:1 cm):

ZDP484LG- 4 brQleurs6 gaz,grill et plaque chauffante

ZDP486LR - 6 brQleurs 6 gaz et grill

ZDP486LD - 6 brQleurs 6 gazet plaque chauffante

Consignes d'installation

Etape 1, Sortez I'appareil de son emballage ..........33

Etape 2, D#placez la cuisini_re 6 I'int6rieur ............34

Etape 3, Installez le support anti-basculement ....35

Etape 4, Raccordezla cuisini_re6 I'alimentation

en gaz ........................................................................36

Etape 5, Branchez la cuisini_re 6 la prise #lectrique ......36

Etape 6, Placez la cuisini_re dans sa position

en la faisant rouler ............................................36

Etape 7, Ajustez le niveau de la cuisini_re ................37

Etape 8, R6installez les portes du four ......................37

Etape 9, V6rifiez les brQleurs ..........................................38

Terminez I'installation ........................................................38

Liste de v6rification pour I'installation ........................38

Accessoires ..............................................................................39

Installation des accessoires ..................................40-42

Conversion de la cuisini_re pour le gaz ............43-45

ModUles au gaz naturel 36" (9:1 cm):

ZDP366N - 6 brOleurs 6 gaz

ZDP364NR- 4 brQleurs 6 gazet grill

ZDP364ND - 4 brQleurs 6 gazet plaque chauffante

ModUles au propane 36" (9:1 cm):

ZDP366L- 6 brOleurs 6 gaz

ZDP364LR- 4 brQleurs 6 gazet grill

ZDP364LD - 4 brQleurs 6 gazet plaque chauffante

ModUle au propane 30" (76 cm) : ZDP304N

ModUles au gaz naturel 30" 176cm) "ZDP30aL

DOSSERET

Tousles modules requi_rent au minimum 12"

(30 cm) d'espace de s#paration arri6re avec toute

surface inflammable. Si cet espace est int#rieur _]

12" (30 cm), la totalit# de la surface du mur se

trouvant derri6re et au-dessus de la cuisini_re doit

#tre prot6g,#e par,un dosseret. Le dosseret dolt #tre

fabriqu6 (_l aide dune mati6re ignifuge comme le

m#tal, la tulle en c#ramique, la 5rique, le marbre

ou tout autre pierre.

Deux dosserets sont disponibles :

• IIexiste un dosseret de 12" (30 cm) en acier

inoxLIdable. Utilisez ce dosseret coupl# (_un

dosseret sp#cial et ignifuge mont# au-dessus

du premier. La hauteur des deux dosserets

combin6s doit atte)ndre la partie int6rieure

de la hotte, ou en Iabsence de hotte, la hauteur

totale 6 partir de la surface de cuisson doit

atteindre les 48" (122 cm).

• II exist un dosseret adjustable de 30" (76cm) - 36"

(91cm). Cedosseret comble I'espace entre

le dessus de la cuisini_re et la partie inf_rieure

de la hotte. L'_taq_re est conque pour que les

ampoules d'une hotte professionnelle Monogram

soient orient_es vers elle.

D0sseretde30cm,48cm(12")dehauteur

ZX12B48PSS,pourlescuisinieresde121cm(48")

ZX12B36PSS,pourlescuisinieresde91cm(36")

ZX12B30PSS,pourlescuisinieresde76cm(30")

D0sseretahauteurreglageavecetagere

76cm-91cm(30"-36")

ZXADJB48PSS,pourlescuisinieresde121cm(48")

ZXADJB36PSS,pourlescuisinieresde91cm(36")

ZXADJB30PSS,pourlescuisinieresde76cm(30")

2S

Page 26

Caract ristiques

DIMENSIONS DU PRODUIT ET ESPACES DE SI_PARATION

ModUles de cuisini_re 121 cm (48")

1 "

Plande

travail

surface

decuissen

3-1/4"(6,98cm)

to

4-3/4"(8,25cm)

35-1/4"(88,26cm)

to

36-3/4"(90,8cm)

dehauteur

47-7/8" 117,15cm) ....... _i

de argeur

(2,5cm)

Emplacementsderaccorduniversels

(82'0,32cm)

14" 16"

28-1/4"

(70,48cm)

Prefendeur

jusqu'8I'avant

dela porte

A AVERTISSEMENT".

Pour les installations d_pourvues

de hotte, pr_vouez au minimum un

espace de 48" (122 cm) entre

I'appareil et toute mati_re 13"

inflammable. II est possible d'installer (33 cm)max.

une hotte sp_ciale b proximit_

d'_l_ments horizontaux inflammables

duns la mesure o_ celle-ci dispose

d'une fonction de mise en marche

automatique. Pour obtenir les

specifications d'espace pour d'autres

installations pourvues d'une hotte,

veuillez vous reporter aux instructions

fournies avec celle-ci.

La totalit_ de la surface du mur arri_re

ainsi que la surface se trouvant au-

dessus de la table de cuisson dolt _tre

faite d'une mati_re ignifuge comme

le m@al,la tuile en c@amique,

la brique, le marbre ou tout autre

pierre.

Plinthe/ _'

Hauteurdepied

--i .........

inflammable

(121cm)

30cm(12")aumoins

parrapportaumur

adjacent.

18"

(45,7cm)Min.

48" (121cm)min.

ESPACES SUPPLI_MENTAIRES :

Pr@voyezun espace minimum de 30 cm (12'I par rapport au

mur adjacent sur chaque c6t@.

Lesespaces de transit autour de la table de cuisson doivent

@tres@par@espar un espace d'au moins/45,7 cm (!8") entre

le plan de travail et le bas du placard mural.

26

Page 27

Caract ristiq ues

DIMENSIONS DE L'APPAREIL ET ESPACES

Mod_les de cuisini_re 91 cm (36") Caract_ristiques

35-7/8" /25 cm_ D,o_,_

Largeur .............'',' 'tr'a'v'a_l_

de 86_67cm ......2..- , ,

I_, .... a surTace

35-1/4"(88,26cm) ___ _2_I

to

38-3/4"(90,8cm) __ 31/4" 898

dehauteur _ IJ I -, , , cm)

Profondeur _, _ J Hauteurdepied

jusqu'8I'avant

de laporte

I "

e cuisson

Emplacementsde raccorduniversels

I

4-5/8"(8,57cm)

13-3/8" 11-3/8"

(37,02cm) (26,98cm)

m a

6-1/2"

(13,97cm)

I

_4,AVERTISSEMENT:

Pour les installations d_pourvues

de hotte, pr_vouez au minimum un

espace de 48" (122 cm) entre

I'appareil et toute mati_re 13" " '-

inflammable. IIest possible d'installer (33 cm)max.

une hotte sp_ciale (_proximit_

d'_l_ments horizontaux inflammables

duns la mesure oQ celle-ci dispose

d'une fonction de mise en marche

automatique. Pour obtenir les

specifications d'espace pour d'autres

installations pourvues d'une hotte,

veuillez vous reporter aux instructions

fournies avec celle-ci.

La totalit_ de la surface du mur arri_re

ainsi que la surface se trouvant au-

dessus de la table de cuisson dolt _tre

faite d'une mati_re ignifuge comme

le m_tal, la tulle en c@amique,

la brique, le marbre ou tout autre

pierre.

Minimum12"

(30,4cm)de

chaque

38"

(76cm)Min.

\\

\

\

', 30cm (12")aumains

', par rapportaumur

, adjacent.

18"

(45,7cm)Min.

ESPACES SUPPLI_MENTAIRES :

Pr_voyez un espace minimum de 30 cm (12") par rapport

au mur adjacent sur chaque c6t&

Lesespaces de travail autour de la table de cuisson doivent

_tre s_par_es par un espace d'au mains 45,7 cm (18")entre

le plan de travail et le bas du placard mural.

27

Page 28

Caract ristiques

DIMENSIONS DE L'APPAREIL ET ESPACES

ModUles de cuisini_re 76 cm (30"}

1"

29-7/8" i (2,5cm) Plande

(71,43cm) "_

de largeur" _ travail

........ ...... asurface

35-1/4"(88,26cm)

to

36-3/4"(90,8cm)

dehauteur 3-1/4" (6,98cm)

4-3/4" (8,25cm)

28-1/4" Plinthe/ f

(70,48cm) Hauteurdepied

Profondeur

jusqu'8 I'avant

dela porte

Emplacementsde raccorduniversels

4-5/8"(8,57cm)

11-3/8" 7-3/8"

26,98cm (1682cm)

6-1/2"

(13,97cm)

to

30"

-- (76cm)

', 30 cm(12")au

', mainsparrapport

, aumuradjacent.

AVERTISSEMENT'.

Pour les installations d_pourvues

de hotte, pr_voyez au minimum un

espace de 48" (122 cm) entre

I'appareil et toute mati_re

inflammable. II est possible d'installer

une hotte sp_ciale b proximit_

d'_l_ments horizontaux inflammables

dans la mesure oOcelle-ci dispose

d'une fonction de mise en marche

automatique. Pour obtenir les

specifications d'espace pour d'autres

installations pourvues d'une hotte,

veuillez vous reporter aux instructions

fournies avec celle-ci.

La totalit_ de la surface du mur arri_re

ainsi que la surface se trouvant au-

dessus de la table de cuisson dolt _tre

faite d'une mati_re ignifuge comme

le m_tal, la tuile en c_ramique,

la brique, le marbre ou tout autre

pierre.

ESPACES SUPPLI_MENTAIRES:

Pr@voyezun espace minimum de 30 cm (!2") par rapport

au mur adjacent sur chaque c6t@.

Les espaces de transit autour de la table de cuisson doivent

@tres@par@espar un espace d'au mains/45,7 cm (!8") entre

le plan de travail et le bas du placard mural.

28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Instruccionesde instalaci6n

ANTES DE COMENZAR

Lea estas instrucciones por completo y con

detenimiento,

°IMPORTANTE- Guardeestas

instrucciones para el usa de inspectores locales.

•IMPORTANTE- cumplacon todoslos

c6digos g ordenanzas vigentes.

• Nota al instalador - AsegOrese de dejar estas

instrucciones con el consumidor.

• Nota al consumidor- IVlantenga estas

instrucciones con el Manual del propietario para

referencia futura.

• Tiempo de finalizaci6n - de ::1.a 3 horas.

• El instalador tiene la responsabilidad de efectuar

una instalaci6n adecuada. La Garantfa no cubre

las fallas del producto debido a una instalaci6n

incorrecta. Ver el Manual del propietario para

informaci6n sabre la garantia.

-4,ADVERTENCIA:

Esta unidad debe contar con una adecuada

conexi6n a tierra. Ver "Suministro el6ctrico".

Para servicio t6cnico local Monogram en su 6rea,

1.800.444.1845.

Para servicio t6cnico Monogram en Canad6, Ilame al

1.800.561.3344.

Para Piezas g accesorios Monogram, Ilame al

1.800.626.2002.

Si ha recibido una cocina daflada, usted debe

comunicarse con su vendedor.

En el Estado de Massachusetts:

o Este producto debe instalarlo un plomero

matriculado o un gasfitero.

Cuando use v61vulas esf@icas de apagado

de gas, deber6n ser del tipo de manija en T.

Si se usa una conexi6n flexible para gas,

6sta no debe superar los :3pies.

-AADVERTENCIA:

Todas las cocinas pueden volcarse. Pueden

producirse lesiones. Instale el soporte

anti-volcaduras provisto. Ver las instrucciones

en este manual o con el soporte.

Combinaciones de

capuchas de ventilaciBn:

Se recomienda qua estas cocinas se instalen en conjunto

con una adecuada capucha deventilaci6n a6ree.

• Instale una capucha de par Iomenos 1200 CFIVl

(piescObicos par minuto) sabre una cocina de 48"

de ancho.

Instale una capucha de par Iomenos 600 CFM

(piescObicos par minuto) sabre una cocina de 30"

o 36"deancho.

Debido a la elevada capacidad de calor de esta unidad,

debe prestarse especial atenci6n a la instalaci6n de la

capucha g de la red de conductos para garantizar que

cumpla con los c6digos de construcci6n locales.

-AADVERTENCIA:

Distancias respecto de superficies horizontales sabre la

cocina, medidas en relaci6n a la superficie de cocci6n:

Lasinstalaciones sin capucha requieren un minima

de 48" respecto de elementos combustibles.

Una instalaci6n de capucha a medida con superficies

expuestas horizontales combustibles debe contar con

una funci6n de encendido autom6tico.

Para otras instalaciones con una capucha, consulte

las instrucciones de instalaci6n de capuchas sabre

espacios espedficos para capuchas.

J

,PRECAUCION:

Estascocinas pesan hasta 700 Iibras.Desmontar

algunos elementos reducen su peso en forma

considerable. Debido al peso g tamaflo de la cocina

g para reducir elriesgo de lesiones personales o daflos

al producto:

SEREq)UIERENDOS PERSONASPARAUNA INSTALACION

ADECUADADELASCOCINASDE36"Y 30".

SEREq)UIERENTRESPERSONASPARAUNA INSTALACION

ADECUADADELASCOCINASDE48".

Elcontrol de p@didas del aparato deber6 realizarse segOn

las instrucciones del fabricante. La instalaci6n debe

cumplir con los c6digos locales. Sino existieran los

c6digos locales, la cocina debe cumplir con el C6digo de

GasCombustible Nacional, ANSIZ223.1/NFPA54, Oltima

edici6n, g con el C6digo EI6ctricoNacional ANSI/NFPA70,

Oltima incorporaci6n. En Canad6, la instalaci6n debe

cumplir con el C6digo de Instalaci6n de GasNatural

vigente, CAN/CGA-B149.1o elC6digo de Instalaci6n de

Propano vigente, CAN/CGA-B:149.2,g con losc6digos

locales,segOn corresponda. Esta cocina ha recibido la

certificaci6n de diseflo de CSAInternational de acuerdo

con ANSIZ21.1, Oltima edici6n, g de Canadian Gas

Association de acuerdo con CAN/CGA-I.1, Oltimaedici6n.

46

Page 47

Informaci6n de disefio

CONTENIDOS

Informad6n de disefio

Modelos disponibles ............................................................47

Requisitos de accesorios ..................................................47

Dimensiones g espacios del producto ................48-51

Herramientas g materiales requeridos ....................52

Preparaci6n para la instalaci6n

Ubicaciones del suministro de energ[a ..............5:3, 54

MODELOS DISPONIBLES

Estas cocinas Monogram se encuentran

configuradas de f6brica para gas natural o para

gas LR Solicite el modelo que se ajuste a su

situaci6n de instalaci6n.

Modelos a gas natural de 48":

ZDP484NG - 4 quemadores a gas, parrilla g plancha

ZDP486NR - 6 quemadores a gas g parrilla

ZDP486ND- 6 quemadores a gas g plancha

Modeios a gas LP de 48":

ZDP484LG - 4 quemadores a gas, parrilla g plancha

ZDP486LR - 6 quemadores a gas g parrilla

ZDP486LD - 6 quemadores a gas g plancha

Instrucciones de instalaci6n

Paso 1, Ouite el empaque ................................................55

Paso 2, Traslade la cocina al interior ..........................56

Paso :3,Instale el dispositivo anti-volcaduras ........57

Paso 4, Conecte la cocina al suministro de gas....58

Paso 5, Conecte la electricidad ......................................58

Paso 6, Coloque la cocina en su posici6n ................58

Paso 7, Nivele la cocina ....................................................59

Paso 8, Reemplace las puertas del horno ................59

Paso 9, Controle los quemadores ................................60

Finalice la instalaci6n ........................................................60

Lista de control de la instalaci6n ..................................60

Accesorios ................................................................................61

Instalaci6n de accesorios ........................................62-64

Conversi6n de gas ........................................................65-67

Modelos a gas natural de 36":

ZDP366N - 6 quemadores a gas

ZDP:364NR - 4 quemadores a gas g parrilla

ZDP:364ND - 4 quemadores a gas g plancha

Modelos a gas LP de 36":

ZDP366L- 6 quemadores a gas

ZDP364LR - 4 quemadores a gas y parrilla

ZDP364LD- 4 quemadores a gas y plancha

Modelo a gas natural de 30": ZDP304N

Modelo a gas LP de 30": ZDP304L

ACCESORIOS PARA SALPICADERO

Todos losmodelos requieren unespacio m[nimo de 12"

respecto de una superficie combustible vertical en la parte

trasera. Siel espacio es menor a 12",toda la superficie

de lapared trasera superior y elancho total de la cocina

deben protegerse mediante un salpicadero. Elsalpicadero

debe ester hecho de un material no combustible,

como metal, cer6mica, ladrillo,m6rmol u otra piedra.

Dos accesorios disponibles para salpicadero:

• Seencuentra disponible el accesorio para salpicadero

de acero inoxidable de 12"de altura. Utilice este

salpicadero en combinaci6n con un salpicadero

a medida no combustible construido m6s all6de la altura

de 12".La altura combinada del accesorio para

salpicadero g el salpicadero a medida debe alcanzar

la parte inferior de la capucha, o cuando no haga una

capucha, 48" sobre la superficie de cocina.

• Tambi6n seencuentra disponible un salpicadero con

estante de altura ajustable de 30"a 36". Estesalpicadero

Ilenael espacio ubicado entre la parte superior

de la cocina g laparte inferior de la capucha. Elestante

seencuentra ubicado de modo que las 16mparas

de calor de la parte inferior de la capucha Monogram

profesional se hallen dirigidas hacia el estante.

Salpicader0de12"dealtura

D(12B48PSS,parac0cinasde48"deanch0

b(12B36PSS,parac0cinasde36"deanch0

b(12B30PSS,parac0cinasde30"deanch0

Salpicader0conestantedealturaajustable

de30"a36"

ZXADJB48PSS,parac0cinasde48"deanch0

ZXADJB36PSS,parac0cinasde36"deanch0

ZXADJB30PSS,parac0cinasde30"deanch0

47

Page 48

Informaci6n de dise5o

DIMENSIONES Y ESPACIOS DEL PRODUCTO

Modelos de cocina de 48"

1"

_ Anchode47-7/8"

Mostradorde encimera

asuperficiedecocci6n

Ubicacionesdelos serviciospOblicos

35-1/4"

8

36-3/4"

dealtura

28-1/4"

Profundidad

hasta

elfrente

dela puerta

i ,ADVERTENCIA:

Lasinstalacionessin capucha

requierenun minimo dea8"respecto

de elementoscombustibles.Una

instalaci6ndecapucha a medida

consuperficiesexpuestashorizontales max.

combustiblesdebecontar con una

funci6n deencendidoautom6tico.

Consultelas instruccionesde

instalaci6nde lacapucha para

obtenerespaciosespecificos

de lascapuchas.

Lasuperficie de toda la pared trasera

sobre la cocina U por debajo

de la capucha debe cubrirse con un

material no combustible como metal,

cer6mica, ladrillo, m6rmol u otra

piedra.

3-1/4"

to 4-3/4"

Alturade la placa _'

deprotecci6n/pata

48"minimo

respecto

deelementos

combustibles

l HC%i1 i

12"mlnimorespectode

unaparedadyacente

ESPACIOS ADICIONALES:

Oeje un espacio minimo de 12" respecto de una pared

adgacente sobre cada lado.

Las 6reas de trabajo adyacentes a la estufa deben contar

con un espacio minimo de !8" entre el mostrador

de encimera U la parte inferior del gabinete de pared.

48

Page 49

Informaci6n de diseffo

DIMENSIONES Y ESPACIOS DEL PRODUCTO

Modelos de codna de 36"

Ubicacionesdelos serviciospOblicos

Anchode 38-7/8" Mostradordeencimera

35-1/4"

8

36-3/4"

dealtura

28-1/4"

Profundidad

hastael frente

dela puerta

AADVERTENCIA:

Lasinstalacionessincapucha

requierenun minimo de48"respecto

de elementoscombustibles.

Unainstalaci6nde capucha a medida

con superficiesexpuestashorizontales

combustiblesdebecontar con una

funci6n deencendidoautom6tico.

Consultelas instrucciones

de instalaci6nde la capucha para

obtenerespaciosespecificos

de lascapuchas.

La superficie de toda la pared trasera

sobre la cocina U por debajo

de la capucha debe cubrirse con

un material no combustible como

metal, cer6mica, ladrillo, m6rmol

u otra piedra.

asuperficiedecocci6n

Altura dela placa

deprotecci6n/pata

',

48"minimorespecto',

deelementos

combustibles

\\

', 12"minimorespecto

', deunaparedadyacente

\

12"minimo

sobrecadalado

ESPACIOS ADICIONALES:

Oeje un espacio minimo de !2" respecto de una pared

aduacente sobre cada lado.

Las 6reas de trabajo aduacentes a la estufa deben

contar con un espacio minimo de 18" entre el mostrador

de encimera U la parte inferior del gabinete de pared.

49

Page 50

Informaci6n de dise5o

DIMENSIONES Y ESPACIOS DEL PRODUCTO

Modelos de cocina de 30" de ancho

1"

Mostradordeencimera

asuperficiedecocci6n

Alturade la placa

de protecci6n/pata

35-1/4"

a

36-3/4"

dealtura

28-1/4"

Profundidad

hastael frente

dela puerta

Ancho

de29#/8"

Ubicacionesde losserviciospOblicos

4-5/S"

7-3/8"

I_1

t

', 12"minimorespectode

combustibles

', unaparedadyacente

-&ADVERTENCIA:

Lasinstalacionessin capucha

requierenun minimodea8"respecto

de elementoscombustibles.Una

instalaci6nde capucha a medida con

superficiesexpuestashorizontales

combustiblesdebecontar con una

funci6nde encendidoautom6tico.

Consultelas instrucciones

de instalaci6nde la capucha para

obtenerespaciosespecificos

de lascapuchas.

La superficie de toda la pared trasera

sobre la cocina g por debajo

de la capucha debe cubrirse con

un material no combustible como

metal, cer6mica, ladrillo, m6rmol

u otra piedra.

30"Min.

ESPACIOS ADICIONALES:

Deje un espacio minimo de 12" respecto de una pared

aduacente sobre cada lado.

Las 6reas de trabajo aduacentes a la estufa deben

contar con un espacio minimo de 18" entre el mostrador

de encimera g la parte inferior del gabinete de pared.

5O

Page 51

Informaci6n de dise5o

DIMENSIONES Y ESPACIOS DEL PRODUCTO

Modelos de cocinas de 48", 36" g 30"

10-1/2" -_

13/16" _ 4

A

hastael ladofrontal

28-7/8" ...........................

Accesorios

opcionalespara

salpicadero

30-36"

35-1/4"

a

36-3/4"

v

12"min.respectodemateriales

combustibleso 0" respectode

materialesnocombustiblessobre

lasuperficiedecocci6n

,,

A

3-3/16"

Profundidaddel

paneldecontrol

,4 28-1/4"hasta

el bordebiselado

.

del ladoredondeado

del paneldecontrol

27-1/2"hasta

el ladobiselado-