Page 1

GE Consumer & Industrial

Technical Service Guide

June 2009

Monogram

Professional Range

and Rangetops

ZDP486ND

ZDP486NR

ZDP484NG

ZDP364ND

ZDP364NR

ZDP366N

ZDP304N

31-9181

GE Appliances

General Electric Company

Louisville, Kentucky 40225

ZGU366N

ZGU364ND

ZGU364NR

ZGU486ND

ZGU484NG

ZGU486NR

Page 2

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by individuals possessing

adequate backgrounds of electrical, electronic, and mechanical experience. Any

attempt to repair a major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the interpretation

of this information, nor can it assume any liability in connection with its use.

WARNING

If the information in this manual is not followed exactly, fi re or explosion may

result causing property damage, personal injury or death. If you smell gas:

– Do not try to light any appliance.

– Do not touch any electrical switch; do not use any phone in the

building.

– Immediately call the gas supplier from a neighbor’s phone. Follow the

gas supplier’s instructions.

– If you cannot reach the gas supplier, call the fi re department.

WARNING

To avoid personal injury, disconnect power before servicing this product. If

electrical power is required for diagnosis or test purposes, disconnect the power

immediately after performing the necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to complete a

path to ground are removed for service, they must be returned to their original

position and properly fastened.

GE Consumer & Industrial

Technical Service Guide

Copyright © 2009

All rights reserved. This service guide may not be reproduced in whole or in part in any

form without written permission from the General Electric Company.

– 2 –

Page 3

Table of Contents

Back Panel ............................................................................................................................................................................ 47

Bake Element ......................................................................................................................................................................61

Broil Elements .....................................................................................................................................................................56

Component Locator Views ........................................................................................................................................... 27

Control Board Connector Locator .............................................................................................................................68

Control Features - Range ..............................................................................................................................................11

Control Features - Rangetop ....................................................................................................................................... 8

Control Panel .....................................................................................................................................................................30

Convection Bake Element .............................................................................................................................................57

Convection Fan Assembly ............................................................................................................................................58

Cooling Fan ..........................................................................................................................................................................48

Diagnostics and Service Information ......................................................................................................................71

Door Assembly ...................................................................................................................................................................51

Electronic Oven Control .................................................................................................................................................67

Factory Test Mode ..........................................................................................................................................................71

Gas Conversion Range and Rangetop ....................................................................................................................22

Glow-bar Igniter ...............................................................................................................................................................39

Griddle Assembly .............................................................................................................................................................35

Griddle Burner Igniter ..................................................................................................................................................... 37

Griddle Control ..................................................................................................................................................................37

Griddle Safety Valve ........................................................................................................................................................ 37

Grill and Griddle Ignition Systems ..........................................................................................................................38

Grill Assembly ....................................................................................................................................................................31

Grill Burner Igniter ............................................................................................................................................................ 33

Grill Control .........................................................................................................................................................................34

Grill Safety Valve ...............................................................................................................................................................33

Indicator Light Assembly .............................................................................................................................................46

Installation ..........................................................................................................................................................................19

Introduction ......................................................................................................................................................................... 5

LED Lights and Power Supply .................................................................................................................................... 45

Lock Assembly ...................................................................................................................................................................49

– 3 –

Page 4

Meat Probe Receptacle and Harness ......................................................................................................................63

Nomenclature - Range ................................................................................................................................................... 6

Nomenclature - Rangetop ............................................................................................................................................ 7

Optional Accessories .......................................................................................................................................................84

Oven Component Circuits .............................................................................................................................................81

Oven Components ...........................................................................................................................................................51

Oven Control Logic Board ..........................................................................................................................................60

Oven Light Assemblies ...................................................................................................................................................65

Oven Operational Notes ................................................................................................................................................ 25

Oven Racks ..........................................................................................................................................................................54

Oven Relay Board ..........................................................................................................................................................60

Oven Sensor, Sail, and Door Switch Test ................................................................................................................76

Oven TCO .............................................................................................................................................................................. 49

Oven Temperature Sensor............................................................................................................................................56

Range Components .........................................................................................................................................................47

Sail Switch ............................................................................................................................................................................49

Schematics and Wiring Diagrams ............................................................................................................................ 77

Side Access Panel ............................................................................................................................................................. 47

Spark Module .....................................................................................................................................................................43

Surface Burner ..................................................................................................................................................................41

Surface Burner Base .......................................................................................................................................................39

Surface Burner Igniter ....................................................................................................................................................40

Surface Burner Pan ........................................................................................................................................................40

Surface Burner Valve and Switch ............................................................................................................................42

Surface Component Circuits .......................................................................................................................................79

Surface Components ......................................................................................................................................................30

Task Light Switch ..............................................................................................................................................................46

Transformer .......................................................................................................................................................................44

Warranty-Range ............................................................................................................................................................... 86

Warranty-Rangetop ........................................................................................................................................................ 85

– 4 –

Page 5

Introduction

*Monogram introduces the new GE Monogram Professional Range and Rangetops. Their superior style

and performance parallel commercial units. Available in 48-, 36-, and 30-inch Ranges and 48- and 36-inch

Rangetop models -- these units feature electronic dial controls that combine the precision of modern digital

technology with the simplicity of traditional mechanical controls.

Authentic Professional appearance using premium-grade, 304 stainless steel with smoothly fi nished •

edges, large electronic control knobs, and heavy duty handles.

Sealed, dual-fl ame stacked burners deliver a full spectrum of heat settings, from an ultra-low 140°F •

simmer to an intense 18,000 BTUs.

Electronic ignition with automatic •

reignition ensures a continuous

fl ame which reignites automatically if

accidentally extinguished.

Reversible burner grates are fl at on one •

side and uniquely contoured on the other

to accommodate round-bottom woks.

Stainless steel and aluminum-clad griddle •

offers 18,000 BTUs of cooking power,

allowing fast and consistent heating

across the entire cooking surface.

Grill with infrared ceramic burner can •

be adjusted from 14,000 BTUs down to

approximately 10,000 BTUs.

Monogram Professional oven system •

combines European, reverse-air convection

technology and six heating elements in each

oven to provide superb baking results.

Main ("Caterer's") oven is uniquely sized to •

accommodate three full-sized sheet trays.

Companion ("Everyday") oven is just the right size for 9" x 13" casserole dishes.•

Halogen light columns provide a clear view, regardless of rack position.•

Heavy-duty, full-extension racks glide smoothly in and out on stainless steel ball bearings for easy •

access, and are designed to remain in the oven during the self-clean cycle.

LED task lights below the bullnose provide a functional and theatrical touch.•

Optional Fixed- (12 inch ) or adjustable-height (30 to 36-inch) backsplashes with shelf are available.•

Optional black knob kit available.•

*Features may vary by model.

– 5 –

Page 6

Model Number

Nomenclature - Range

Z D P 4 8 6 N D P S S

Monogram Product

Monogram Pro Range

Width

48 = 48-in. Range

36 = 36-in. Range

30 = 30-in. Range

Number of Surface Burners

4 = 4 Burners

6 = 6 Burners

Ta g

Nomenclature

Product Color

SS = Stainless Steel

Model Year Designator

Additional Cooking Surface

D = Griddle

R = Grill

G = Griddle and Grill

None = All Burner Model

Fuel Type

N = Natural Gas

L = Liquid Propane

Serial Number

The fi rst two numbers of the serial number

identify the month and year of manufacture.

Example: AS123456S = January, 2009

A - JAN 2009 - S

D - FEB 2008 - R

F - MAR 2007 - M

G - APR 2006 - L

H - MAY 2005 - H

L - JUN 2004 - G

M - JUL 2003 - F

R - AUG 2002 - D

S - SEP 2001 - A

T - OCT 2000 - Z

V - NOV 1999 - V

Z - DEC 1998 - T

The letter des ig nat ing

the year re peats every

12 years.

Example:

T - 1974

T - 1986

T - 1998

The nomenclature tag is located under the

front control panel on the left side. The model

and serial number are also on a tag located

on the bezel behind the left front knob.

The mini-manual is located at the bottom,

behind the access panel.

Mini-manual

– 6 –

Page 7

Model Number

Nomenclature - Rangetop

Z G U 4 8 6 N D P S S

Monogram Product

Monogram Gas Rangetop

Width

48 = 48-in. Range

36 = 36-in. Range

Number of Surface Burners

4 = 4 Burners

6 = 6 Burners

Nomenclature

Ta g

Product Color

SS = Stainless Steel

Model Year Designator

Additional Cooking Surface

D = Griddle

R = Grill

G = Griddle and Grill

Fuel Type

N = Natural Gas

L = Liquid Propane

Serial Number

The fi rst two numbers of the serial number

identify the month and year of manufacture.

Example: AS123456S = January, 2009

A - JAN 2009 - S

D - FEB 2008 - R

F - MAR 2007 - M

G - APR 2006 - L

H - MAY 2005 - H

L - JUN 2004 - G

M - JUL 2003 - F

R - AUG 2002 - D

S - SEP 2001 - A

T - OCT 2000 - Z

V - NOV 1999 - V

Z - DEC 1998 - T

The letter des ig nat ing

the year re peats every

12 years.

Example:

T - 1974

T - 1986

T - 1998

The nomenclature tag is located under the front

control panel on the left side. The model and serial

number are also on a tag located on the bezel behind

the left front knob.

The mini-manual is located on the bottom,

next to the gas inlet pipe.

Mini-manual

– 7 –

Page 8

Control Features - Rangetop

Design

information

(Not all features

are on all models.

Appearance may

vary.)

ZGU486NR, ZGU486LR–6 burners and grill

ZGU486ND, ZGU486LD–6 burners and griddle

ZGU484NG, ZGU484LG

4 burners, grill and griddle

ZGU364NR, ZGU364LR–4 burners and grill

ZGU364ND, ZGU364LD–4 burners and griddle

1

Bamboo Cutting Board

3

7

8

9

2

Grill and Griddle Covers

4

5

6

Number Feature

Feature Index Page

1 Bamboo Cutting Board

1 Bamboo Cutting Board 16

2 Grill and Griddle Covers

2 Grill and Griddle Covers ——

3 IR (Infrared) Grill

3 IR (Infrared) Grill 11, 12

4 Grill and Griddle Grease Troughs

4 Grill and Griddle Grease Troughs 15

5 Griddle 16

5 Griddle

6 Rangetop Burner Grates 15

6 Rangetop Burner Grates

7 Burner Location Indicator ——

7 Burner Location Indicator

8 LED Bullnose Task Lighting Control ——

8 LED Bullnose Task Lighting Control

9 Burner Control Knob with Lighted Bezel ——

9 Burner Control Knob with Lighted Bezel

ZGU366N, ZGU366L

6 gas burners

– 8 –

(Continued next page)

Page 9

Cooktop Controls

Electronic Ignition and Automatic Reignition

The range is equipped with electronic ignition which

eliminates the need for a standing pilot light.

The burners on this range will automatically relight if

the fl ame goes out.

All surface burner igniters will spark and make

clicking sounds when any burner is turned on or if

automatic reignition occurs. Do not touch any of the

burners when igniters are clicking.

Occasionally the burners may spark if excess wind

or a draft blows the fl ame away from the burner’s

fl ame sensor.

The griddle and IR (infrared) grill are equipped with

Glo-Bar igniters. The Glo-Bar remains energized

whenever the griddle or IR grill is in use to ensure

the burner always stays lit.

In case of a power outage, you can light the

surface burners on your cooktop with a match. Hold

a lighted match to the burner, then turn the knob

to the LOW position. Use extreme caution when

lighting burners this way.

After the burner ignites, turn the knob to adjust the

fl ame size.

To turn a burner off, turn the knob clockwise, as far

as it will go, to the OFF position.

Do not operate a burner for an extended period •

of time without cookware on the grate. The

fi nish on the grate may chip without cookware

to absorb the heat.

The indicator light on each bezel verifi es •

the burner is on. However, it should not be a

substitute for visually checking the fl ame at the

burner.

Dual-fl ame Stacked Burners

All surface burners on your range have two sets of

fl ames stacked one on top of the other; the dual-

fl ame burners have a lower (simmer) fl ame and a

upper (main) fl ame.

When a burner is turned on, the lower fl ame will

always light and stay on.

Lower Flame

Do not attempt to light the grill or griddle during

a power outage. The gas to these burners will

automatically shut off during a power outage.

To Light a Surface Burner

Push the control knob in and turn it

counterclockwise to the LITE position.

ON Indicator

Light

Upper Flame

Lower Flame

Simmering:

The stacked burner design provides a wide range

of heat settings with which to simmer. Depending

on the type and quantity of food, and pan size, the

fl ame can be adjusted to suit your specifi c need. The

lowest setting uses only the lower fl ame and can

maintain delicate foods at a safe 140°F.

Cooking:

Settings from LO to X-HI will use both upper and

lower fl ames. Use LO to HI for all purpose cooking.

Use HI or X-HI (highest setting) with larger diameter

cookware.

X-HI and HI are very high heat settings and are

intended to sear foods quickly and boil large

quantities of water.

(Continued next page)

– 9 –

Page 10

Using the IR Grill

Remove the cover before lighting the burner. The

cover must be removed when using the IR grill.

Set the control knob to PREHEAT. The longer the grill

is preheated, the darker the grill marks will be on the

food.

It may take up to 15 minutes to fully preheat the

grill.

After preheat, the control knob may be set to any

position between HI and LO.

Do not leave the grill unattended at any time.

Note: The grill will take approximately 45 seconds to

ignite. Unlike the surface burners, which use electric

igniters, the grill uses a Glo-Bar for ignition. It takes

approximately 45 seconds for the Glo-Bar to reach

temperature. Gas is only supplied to the grill once

the Glo-Bar reaches temperature.

Using the Griddle

To heat the griddle, push in the control knob and

turn to the desired Temperature setting. The light on

the bezel will glow to indicate the thermostat control

is working.

The griddle can be leveled. Remove the fl ue cover

by lifting it straight up. The two inner screws are

clamping screws for securing the griddle in place.

Loosen these two screws before leveling. Do not

remove these two screws.

The two outer screws are leveling screws. Do not

remove these two screws. They can be turned to

level the griddle or to provide a forward slope to

help grease and oils to drain away from the food

being cooked. After the fi rst few uses, you will be

able to judge the slope best suited for the foods

you are cooking and personal preference.

After leveling the griddle, tighten the clamping

screws to secure griddle in place. Hand tighten

screws; do not over-tighten.

The griddle is thermostatically controlled and can

be set to maintain any temperature from 200ºF to

450ºF.

Note: Unlike the surface burners, which use electric

igniters, the griddle uses a Glo-Bar for ignition. It

takes approximately 45 seconds for the Glo-Bar

to reach temperature. Gas is only supplied to the

griddle once the Glo-Bar reaches emperature.

Griddle flue cover

Leveling screws

Clamping screws

(Continued next page)

– 10 –

Page 11

Control Features - Range

Design

information

(Not all features

are on all models.

Appearance may

vary.)

ZDP486NR, ZDP486LR–6 burners and grill

ZDP486ND, ZDP486LD–6 burners and griddle

ZDP484NG, ZDP484LG

4 burners, grill and griddle

1

Bamboo Cutting Board

2

Toekick

6

4

9

10

11

5

3

Grill and Griddle Covers

7

8

13

14

15

16

ZDP364NR, ZDP364LR–4 burners and grill

ZDP364ND, ZDP364LD–4 burners and griddle

ZDP366N, ZDP366L

6 gas burners

ZDP304N, ZDP304L

17

12

Number Feature

1 Bamboo Cutting Board

Feature Index Page

1 Bamboo Cutting Board 37

2 Toekick

2 Toekick ——

3 Grill and Griddle Covers

3 Grill and Griddle Covers ——

4 Oven Vents

4 Oven Vents 17

5 IR (Infrared) Grill

5 IR (Infrared) Grill 12, 13

6 Grill and Griddle Grease Troughs

6 Grill and Griddle Grease Troughs 37

7 Griddle

7 Griddle 14

8 Cooktop Burner Grates 11, 36

8 Cooktop Burner Grates

9 Burner Location Indicator ——

9 Burner Location Indicator

10 LED Bullnose Task Lighting Control ——

10 LED Bullnose Task Lighting Bezel

11 Burner Control Knob with Lighted Bezel 11, 30

11 Burner Control Knob with Lighted Bezel

12 Oven Display 16

12 Oven Display

13 Mini-Knob

(to select PROBE, TIMER or Special Features) 16, 30

13 Mini-Knob (to select PROBE, TIMER, or Special Features)

14 Oven Mode Selector 16

14 Oven Mode Selector

15 Oven Temperature Knob 16

15 Oven Temperature Knob

16 Kitchen Timer 16, 28

Double oven model shown includes a small oven.

16 Kitchen Timer

17 Leveling System (4)

– 11 –

(Continued next page)

Page 12

Oven Control and Timer

1. Oven Mode Selector – Turn outer ring to select:

5

PROOF – Maintains a warm environment useful

for rising yeast-leavened products.

BAKE – Select for traditional baking.

CONV BAKE – Use for convection baking.

CONV ROAST – Use for convection roasting.

CONV BROIL – Use for convection broiling.

BROIL – Select for broiling.

CLEAN – Select for the self-cleaning function.

See the Self-Cleaning Oven section.

2. Temperature Knob – Turn to select:

Temperatures from 175°F to 550°F.

LOW BROIL – A lower broiling temperature is

automatically set.

HIGH BROIL – A higher broiling temperature is

automatically set.

CLEAN – The self-clean temperature is

automatically set.

4

1

3

2

The Oven Mode Selector (1) AND the Temperature

Knob (2) must be set together in one of the following

valid pairings:

Oven Mode Selector

BAKE

CONV BAKE

CONVECTION/ROAST

CONVECTION/BROIL

Temperature Knob

175º to 550°F

175º to 550°F

175º to 550°F

HIGH or LOW BROIL

1. Mini-Knob – Turn to select and push to enter

PROBE or TIMER settings. Also to adjust CLEAN cycle

time.

2. Timer Button – Push to select the kitchen

timer function. The timer does not control oven

operations.

3. Oven Display – Displays oven functions such as

oven and probe temperatures and kitchen timer.

BROIL

CLEAN

PROOF

HIGH or LOW BROIL

CLEAN

――

To cancel a feature, turn either the Oven Mode

Selector or the Temperature knob to OFF.

To cancel PROOF, turn the Oven Mode Selector to

OFF.

– 12 –

(Continued next page)

Page 13

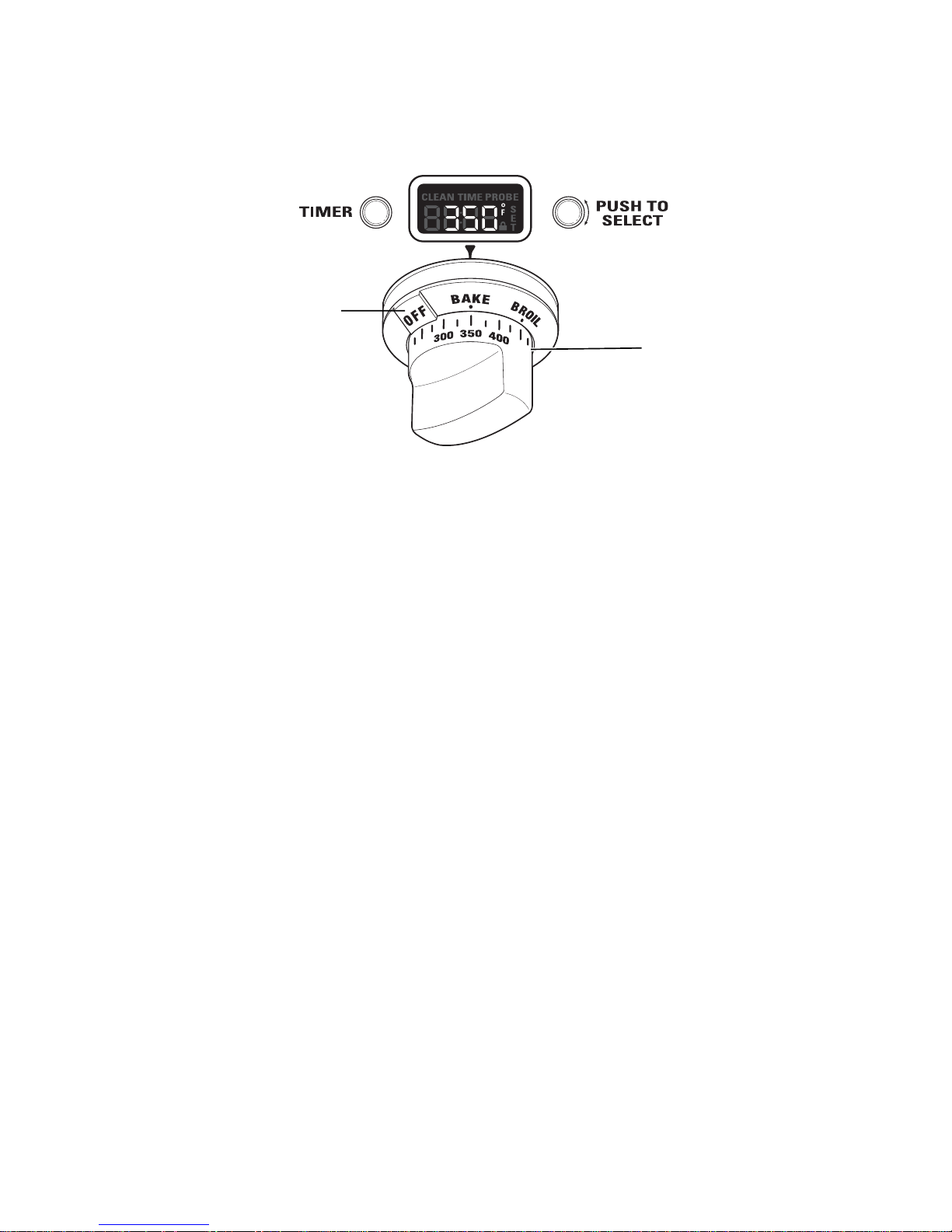

How to Set the Oven for Baking

Turn the Oven Mode Selector to 1. BAKE.

Using the Temperature knob, set the desired temperature, in 25°F increments, from 175°F to 550°F.2.

Oven Mode Selector

(Outer)

Oven Temperature Knob

(Inner)

The oven will now begin to preheat. The temperature display will begin at 100ºF and remain there until the

oven exceeds that temperature. From that point, the display will show the actual temperature.

The interior lights will turn on and stay on until the oven is turned off. The convection oven fan will turn on

temporarily during preheat. The control will beep when the oven is preheated and food can now be placed

inside the oven.

3. Turn the Oven Mode Selector and the temperature knob to OFF when baking is fi nished.

Note: A cooling fan will turn on to cool internal parts. This is normal, and the fan may continue to run even

after the oven is turned off.

Use the temperature probe when a precise internal temperature is important. See Owner's Manual.

– 13 –

(Continued next page)

Page 14

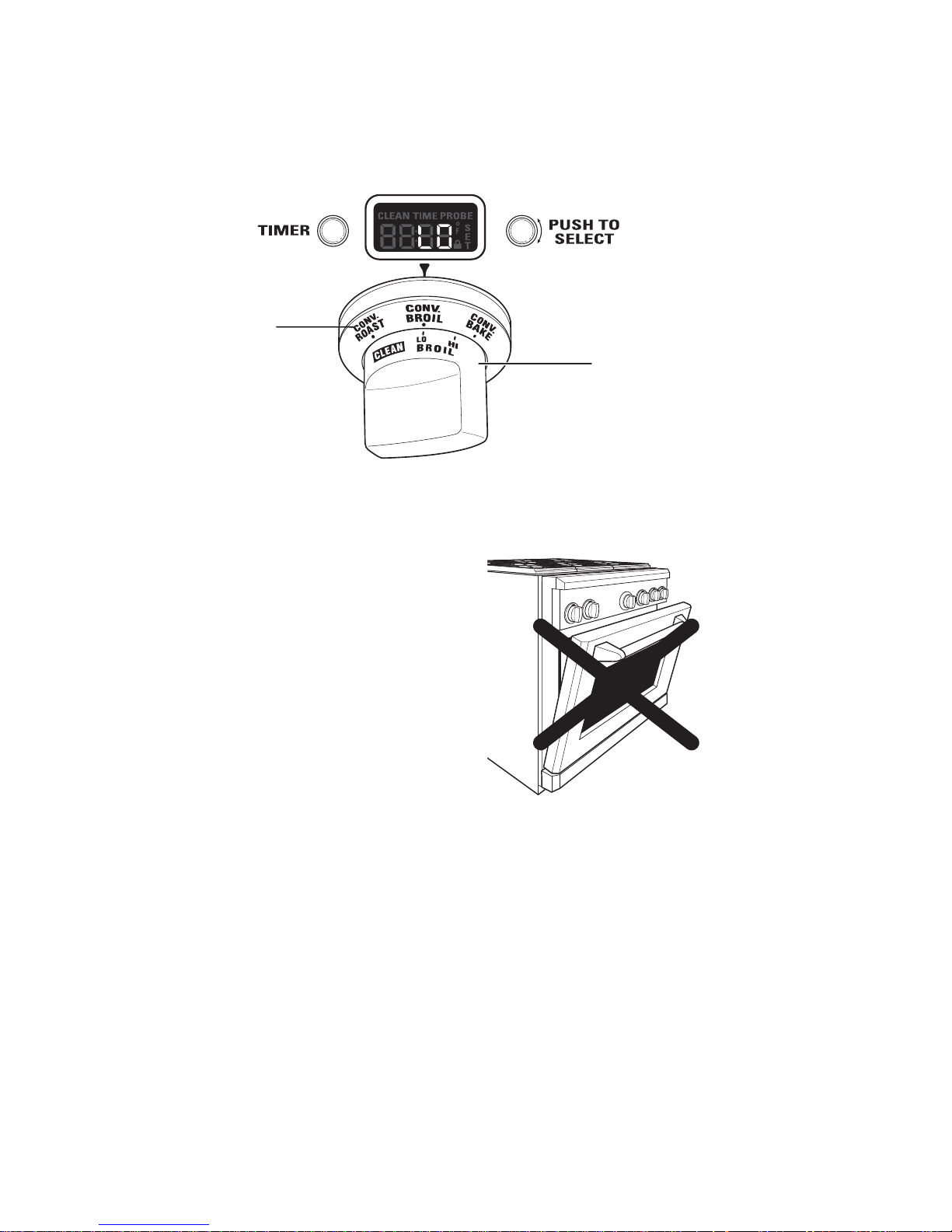

How to Set the Oven for Broiling and Convection Broiling

Turn the Oven Mode Selector to 1. BROIL or CONV BROIL.

Turn the Oven Temperature Knob to2. LO BROIL or HI BROIL. LO or HI will appear in the display.

Oven Mode Selector

(Outer)

Oven Temperature Knob

(Inner)

Note: Always broil with the door closed. If the door is left open, the display will scroll “CLOSE door” and the

elements will not turn on until the door is shut.

The oven interior lights will turn on and stay on until

the oven is turned off.

The convection fan will turn on when CONV BROIL is

selected.

Open door broiling is

not permitted.

3. When broiling is fi nished, turn the Oven Mode

Selector and the Temperature knob to OFF.

Note:

Broil will not work if the temperature probe is •

plugged in. Never leave your probe inside the oven

during a broil cycle.

A cooling fan will turn on to cool internal parts. This is normal, and the fan may continue to run even after •

the oven is turned off.

The broiler does not need to be preheated for most broiling. However, foods that cook quickly, such as thin

strips of meat or fi sh may require a short preheating period of approximately 5 minutes to allow the food to

brown. Turn the food only once during broiling.

– 14 –

(Continued next page)

Page 15

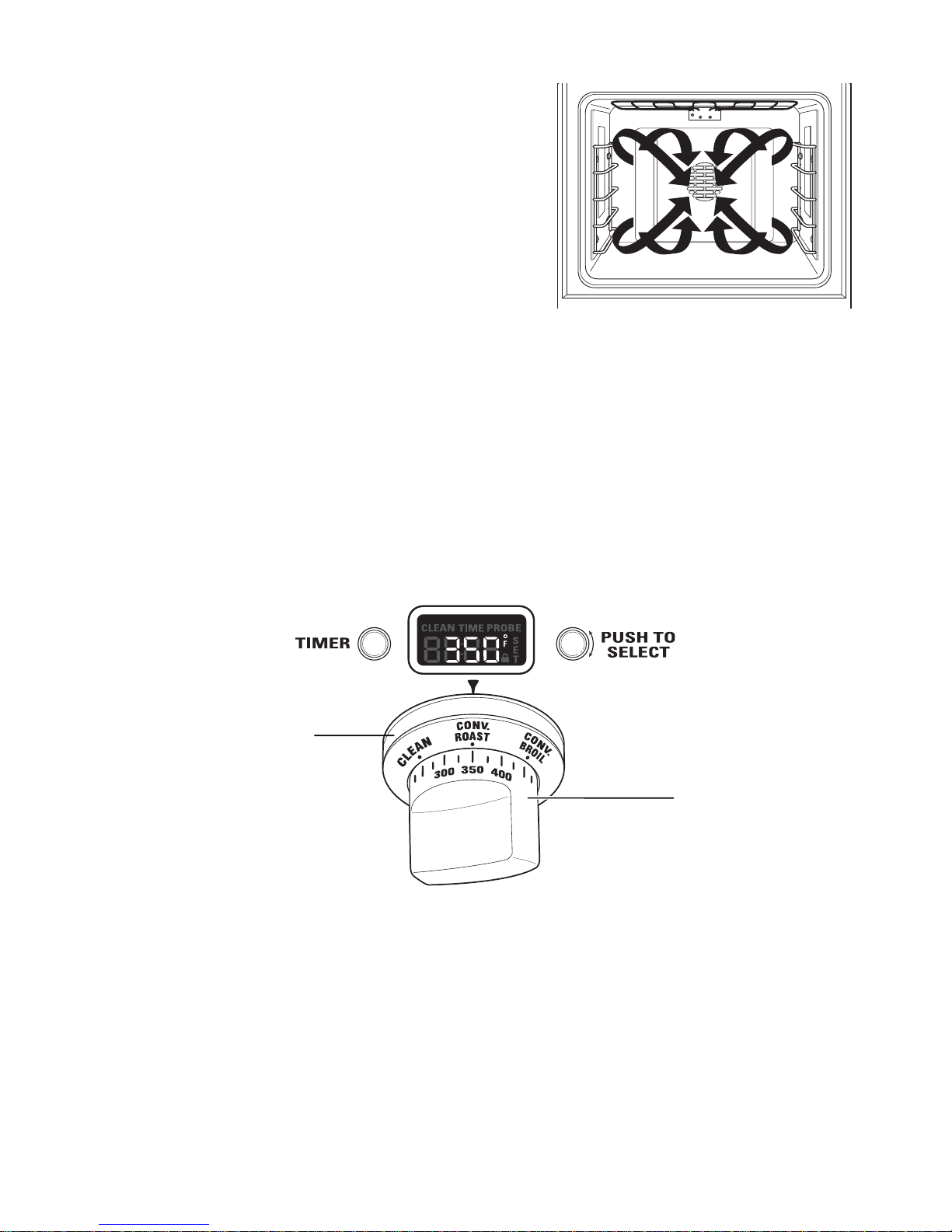

Introduction to Convection Cooking

The Monogram reverse-air convection system

consists of two dedicated heating elements

wrapped around the convection fan. After

preheating to the set temperature, all heat in CONV

BAKE mode comes from these two dedicated

elements. The convection fan periodically pauses,

then changes direction to best distribute hot air

throughout the oven. As a result, foods are evenly

cooked and browned―often in less time with

convection heat.

Note: The convection fan shuts off when the oven

door is opened.

How to Set the Oven for Convection Baking or Roasting

Convection Baking is ideal for evenly browned baked foods cooked on single or multiple racks. Select

Convection Roast to roast large, tender cuts of meat uncovered.

When set on CONV BAKE or CONV ROAST, the rear convection elements and the fan operate when the oven

is heating.

Turn the Oven Mode Selector to 1. CONV BAKE or CONV ROAST.

Using the Temperature knob, set the desired temperature, in 25°F increments, from 175°F to 550°F.2.

Oven Mode Selector

(Outer)

Oven Temperature Knob

(Inner)

The oven will now begin to preheat. The emperature display will begin at 100°F and remain there until the

oven exceeds that temperature. From that point , the display will show the actual temperature.

The interior lights will turn on and stay on until the oven is turned off. The convection oven fan will turn on

during preheat. The control will beep when the oven is preheated and food can be placed inside the oven.

3. Turn the Oven Mode Selector and the Temperature knob to OFF when convection cooking is fi nished.

Note: A cooling fan will turn on to cool internal parts. This is normal, and the fan may continue to run even

after the oven is turned off.

Use the temperature probe when a precise internal temperature is important. See Owner's Manual.

– 15 –

(Continued next page)

Page 16

How to Set the Oven for Proofi ng

How to Set the Oven for Cleaning

The proofi ng feature maintains a warm environment

which is useful for rising yeast-leavened dough.

Turn the Oven Mode Selector to 1. PROOF. The

display will show “PrF”. PROOF mode will not

operate when oven is above 125°F. The display

will scroll “too hot”. Allow the oven time to cool.

For best results, cover the dough with a cloth or with

greased plastic wrap.

Caution: See owner's Manual for Self-cleaning

safety precautions.

Turn the Oven Mode Selector to 1. CLEAN.

Turn the Temperature knob to 2. CLEAN.

The control automatically defaults to the

recommended clean cycle time of 5 hours. The

clean time may be adjusted to any time between

3 and 5 hours using the Mini-Knob. The display will

show the actual time remaining.

3. Push the Mini-Knob to start the CLEAN cycle. If

“CLOSE door” scrolls in the display, the self-clean

cycle has been selected but the door is not

closed. Close the oven door.

Mini-Knob

Turn to adjust

Push to select

Use rack position B or C in the large oven. Use rack

position B in the companion oven. See Owner's

Manual.

The proofi ng feature automatically provides the

optimum temperature (95°F) for the proofi ng

process; therefore the Temperature knob does not

affect the proof temperature.

The oven interior lights cycle on and off as

necessary to maintain optimum proof temperature

until the Oven Mode Selector has been turned to

OFF.

To avoid lowering the oven temperature and •

lengthening proofi ng time, do not open the oven

door unnecessarily.

Check bread products early to avoid over-•

proofi ng.

2. When proofi ng is fi nished, turn the Oven Mode

Selector to OFF.

The symbol will fl ash as the oven door is locked. It

will not be possible to open the oven door during the

clean cycle.

4. After the clean cycle is complete and the oven

has cooled, “End” will show in the display and

the will turn off. Turn the Oven Mode Selector

and the Temperature knob to OFF.

To interrupt a clean cycle, turn the Oven Mode

Selector and the Temperature knob to OFF. When

the oven has cooled to a safe temperature, the

symbol will turn off indicating the door may be

opened.

An interrupted clean cycle cannot be restarted until

after the oven is cool enough for the door to unlock.

– 16 –

(Continued next page)

Page 17

How to Set the Oven Timer

Oven Thermostat Adjustment

Note:

The timer is independent of all the other •

functions and does not control the oven.

Although the electronic control has a timer, it •

does not have a clock feature.

To set the timer:

Push the 1. TIMER button.

Turn the 2. Mini-Knob to adjust any length of time

up to 12 hours and push to select it.

Mini-Knob

Turn to adjust

Push to select

You may fi nd that your new oven cooks differently

than the one it replaced. Use your new oven for a

few weeks to become more familiar with it. If you

still think your new oven is too hot or too cold, you

can adjust the thermostat yourself.

On double oven models, use the main oven controls

to enter the mode and to select the adjustment.

To adjust the oven thermostat:

1. Push and hold the TIMER button and Mini-Knob

at the same time for 4 seconds until the display

shows “SF” (Special Features).

Mini-Knob

Turn to adjust

Push to select

On double oven models, each oven control has

its own timer function. Each timer can be set

independently.

The control will beep with 1 minute remaining and

the display will show seconds until the timer counts

down to :00. When the timer reaches :00, the control

will beep 3 times followed by one beep every 6

seconds until the Mini-Knob is pushed.

To cancel the timer:

Push the 1. TIMER button.

Turn the 2. Mini-Knob to :00 and push to select.

To adjust the timer after start:

Push the 1. TIMER button.

Turn the 2. Mini-Knob to a new desired time and

push to select.

Note: The timer cannot be used while the oven is

self-cleaning. (On double oven models, the timer for

the oven that is not in the self-cleaning mode may

be used.)

2. Turn the Mini-Knob counterclockwise until the

display scrolls “OFFSEt”. Push the Mini-Knob to

select the offset mode.

3. Turn the Mini-Knob to adjust the oven

thermostat up to 35°F hotter or (-) 35°F cooler in

1°F increments.

3A. On double oven models, you can adjust

the thermostat of the companion oven by

turning the Mini-Knob above the companion

oven. Use the main oven Mini-Knob to select

that adjustment.

4. Push the Mini-Knob to select your choice

and exit the mode. If you do not wish to save

changes, push the TIMER button to exit at any

time.

Note: This adjustment will only affect Bake,

Convection Bake and Convection Roast

temperatures; it does not affect broiling or selfcleaning temperatures. The adjustment will be

retained in memory after a power failure.

Do not use thermometers, such as those found in

grocery stores, to check the temperature setting of

your oven. These thermometers may vary 20–40

degrees.

– 17 –

(Continued next page)

Page 18

Sabbath Mode*

To set the Sabbath mode:

The Sabbath mode is designed for use on the Jewish

Sabbath and other Jewish holidays.

It can be used for baking only. It cannot be used for

any other cooking mode.

When the Sabbath feature is set, the oven light

and all audible beeps will be disabled. The feature

will also provide a random delay period, of

approximately 30 seconds to 1 minute, before the

oven will turn on once it is set to BAKE.

Push and hold the 1. TIMER button and Mini-Knob

at the same time for 4 seconds until the display

shows “SF” (Special Features).

Mini-Knob

Turn to adjust

Push to select

2. Turn the Mini-Knob clockwise until the display

scrolls “SAbbAtH.” Push the Mini-Knob to select

the Sabbath mode.

3. Once “SAbbAtH” is selected, the display will

scroll “SAbbAtH ON”.

The Sabbath setting will control both ovens. The

symbol will appear in both oven display windows

indicating the Sabbath mode is set. The symbol

indicates the oven is overheating.

For double oven models, use the main oven control

to set the Sabbath feature for both ovens.

To Cancel the Sabbath Mode:

Repeat steps 1, 2 and 3. The display will scroll

“SAbbAtH OFF”.

The oven temperature may be adjusted at any time

by turning the temperature knob. There is a random

delay before the oven elements respond.

*Certifi ed Sabbath Mode

– 18 –

Page 19

Installation

Installation information is for reference only. See the

Installation Instructions shipped with the product for

complete details and before attempting to install the

range or rangetop.

Caution: These ranges weigh up to 700 pounds.

Some disassembly will reduce the weight

considerably. Rangetops weigh up to 170 pounds.

Due to the weight and size of the range or rangetop,

and to reduce the risk of personal injury or damage

to the product:

TWO PEOPLE ARE REQUIRED FOR PROPER •

INSTALLATION OF 36" AND 30" RANGES AND 36"

AND 48" RANGETOPS.

THREE PEOPLE ARE REQUIRED FOR PROPER •

INSTALLATION OF 48" RANGES.

Gas Supply Range and Rangetop

The natural gas models are designed to operate at

5" water column pressure. For proper operation, the

pressure of the natural gas supplied to the regulator

must be between 7" and 13" water column.

The LP models are designed to operate at 10" water

column pressure. For proper operation, the pressure

of the LP gas supplied to the regulator must be

between 11" and 13" water column.

All models can be ordered to operate on NATURAL

or LP gas. Models ordered to operate on NATURAL

gas are shipped with an LP conversion kit. Models

ordered to operate on LP gas are shipped with a

NATURAL gas conversion kit.

High Altitude Conversion Kit - For operation

above 6,000 feet, order Part #WB28K10553. This

kit includes orifi ces for both LP and Natural gas

operation.

A manual shut-off valve in the gas line (not

provided), is to be installed in an easily accessible

location. Make sure the homeowner knows where

and how to shut off the gas supply to the range or

rangetop.

Range Electric Supply

These ranges must be supplied with 208/240 volt,

60 Hz., and connected to an individual, properly

grounded branch circuit.

This branch circuit is to be protected by a circuit

breaker or time delay fuse (50 amp for 48" ranges,

30 amp for 36" and 30" ranges).

The receptacle must be a NEMA 14-50R device to

accept the 4-prong plug supplied with the range.

If the electrical service provided does not meet

the above specifi cations, it is recommended that a

licensed electrician install an approved outlet.

Rangetop Electric Supply

These rangetops must be supplied with 120 volt,

60 Hz., and connected to a dedicated, properly

grounded branch circuit protected by a 15 amp

circuit breaker or time delay fuse.

The power cord of this appliance is equipped with

a three-prong (grounding) plug which mates with a

standard three-prong grounding wall receptacle to

minimize the possibility of shock hazard from this

appliance.

If the electrical service provided does not meet

the above specifi cations, it is recommended that a

licensed electrician install an approved outlet.

Backsplash Requirements

All models require 12" minimum clearance to a

vertical combustible surface at the rear. In a range

installation, if clearance is less than 12", the entire

surface of the back wall above and the full width

of the range must be protected by a backsplash.

In a rangetop installation, if clearance is less than

12", the entire surface of the back wall above the

countertop and the full width of the rangetop must

be protected by a backsplash. The backsplash must

be constructed of non-combustible material, such

as metal, ceramic tile, brick, marble or other stone.

WARNING: Installations without a hood require

48" minimum to combustibles. A custom hood

installation with exposed horizontal combustible

surfaces must have an Auto-On feature. Refer to

hood installation instructions for specifi c hood

clearances.

– 19 –

(Continued next page)

Page 20

Leveling the Range

WARNING:

All ranges can tip. Injury could result. Install the •

supplied Anti-Tip Bracket. See the instructions

included with the bracket.

3. Use the supplied wrench to turn the front

leveling legs. Turn clockwise to raise the range

above the wheels. Turn counterclockwise to

lower the legs.

4. Be sure to return the wrench to its storage slot

for future use.

The range must be level and be supported by •

the legs―not the wheels. The range could move

if the wheels make contact with the fl oor. Be

sure all legs make contact with the fl oor in any

installation.

Note:

All legs must be leveled after the product is •

installed.

Check to be sure the adjoining cabinets/ •

countertops are level, front to back and left to

right across the opening of the range.

Measure the distance from the fl oor to the top of •

the countertop in the left and right rear corners.

Adjust the height of the range to countertop •

height or higher.

IMPORTANT: This range should always be installed

at countertop height or higher. DO NOT INSTALL

THE RANGE LOWER THAN ADJACENT COUNTERTOP

HEIGHT. The range must be supported by all 4 legs,

regardless of countertop height.

Rear leg adjustment:

Remove two screws from rear vent trim. Slide 1.

vent trim forward, then lift up to remove.

Find the two rear leg extension rods. Use a 1/4-2.

in. driver or wrench to adjust the left or right rear

legs.

Rear Vent Trim

Rear Leg

Extension Rod

3. Replace the rear vent trim using the original

screws.

Range Toekick

Front leg adjustment:

Note: If toe kick is installed, pull to remove for

access to front leveling legs.

Slide front cylinders up to adjust front leveling 1.

legs. Be careful not to damage cylinder.

A leveling leg wrench is supplied. Reach under 2.

the front of the range near the right side. Locate

and remove a thumb screw, then slide wrench

out of the slot.

Thumb Screw

Slide leg

cylinder up.

A toe kick, that clips around the front leveling legs, is

supplied with each range. Customer use of the toe

kick is optional.

The toekick is installed after the range has been

leveled.

Toekick installation:

Measure the distance between the fl oor and the 1.

bottom of range.

2. Loosen the two screws on each end. Adjust the

toekick height by sliding the upper and lower

pieces apart to 1/8" less than the measured

height.

– 20 –

(Continued next page)

Page 21

3. Secure the top and bottom sections by

tightening the 2 screws on each end.

Top of

Toekick

Range Anti-Tip Device

WARNING: All ranges can tip. BURNS or other

SERIOUS INJURIES can result. INSTALL and CHECK

the ANTI-TIP bracket following these instructions.

To reduce the risk of tipping the range, the range

must be secured by a properly installed anti-tip

bracket. See installation instructions shipped with

the bracket for complete details before attempting

to install.

To check if the bracket is installed and engaged

properly, carefully tip the range forward. The

bracket should stop the range within 4 inches. If it

does not, the bracket must be reinstalled.

Bottom

of Toekick

Screw

4. Push toekick against range leg until clip snaps to

legs.

Note: Be sure the toekick snaps securely to the leg.

Push

Push

Push

Push

Rangetop Anti-Slide Bracket

If the range is pulled from the wall for any reason,

always repeat this procedure to verify the range is

properly secured by the anti-tip bracket.

If your range has no anti-tip bracket, call

1.800.626.8774 to receive one at no cost.

If the Anti-Tip device supplied with the range does

not fi t this application, use the universal Anti-Tip

device WB2X7909.

Read the AHAM Anti-Tip Safety Brochure packed

with the bracket.

Anti-Tip Parts Provided

4 Wood Screws

Anti-Tip Bracket

WARNING: All rangetops can slide out. Injury could

result. When properly installed, a hold-down strap

with screws secures the rangetop to the rear or side

cabinet walls. See the instructions included with the

bracket.

3 Hex Head Screws

(2 required, 1 extra)

Anti-Tip Brace

AHAM Anti-Tip

Safety Brochure

Hold-Down

Strap

Location and

Attachment

Back Wall

(Continued next page)

– 21 –

Page 22

Attach the Anti-Tip Brace onto the bottom of the

range in the recessed area. Install 2 hex screws

(provided) through the brace and into the range.

Gas Conversion Range and Rangetop

Note: This Anti-Tip device may be installed on the

opposite side of the range.

Hex Screws

Anti-Tip Brace

Alternate Brace

Position

Measure and mark Dimension A (see table 1.

below) from the left (or right) side of the

installation location. If the countertop has an

overhang, add that dimension to Dimension A.

Place the Anti-Tip Bracket against the fl oor and 2.

back wall at the marked location. Mark screw

holes for fastening the bracket to the wall sole

plate and the fl oor.

WARNING: This conversion must

be performed by a qualified installer or gas supplier

in accordance with the manufacturer’s instructions

and all codes and requirements of the authority having

jurisdiction. Failure to follow instructions could result

in serious injury or property damage. The qualified

agency performing this work assumes responsibility

for the conversion.

WARNING: The rangetop, as shipped from

the factory, is set for use with its intended gas. If you

wish to use your rangetop with the alternate gas, you

must first replace the orifices and convert the pressure

regulator.

WARNING: The following adjustments must

be made before turning on the burner. Failure to do so

could result in serious injury. Be sure pressure regulator

has been converted as described in Step 2.

TOOLS YOU NEEDED FOR CONVERSION

Crescent Wrench

Safety Glasses

1/4" and 7mm Nutdrivers

Small Flat-Head Screwdriver

(2 to 2.4 mm or 3/32" tip size,

60 mm long)

Drill 1/8" pilot holes at a 20° angle.3.

Secure the bracket to the wall and/or fl oor with 4.

at least 2 wood screws (provided).

For Concrete or Cement Construction: You must

use appropriate fastening hardware (not provided).

Anti-Tip Bracket

Wall Sole Plate

A

Range A

30" 5-1/16"

36" 5-1/16"

48" 8-1/4"

Philips

1/2" Deepwell

Socket Wrench

1

ORIFICE HOLDER

The range orifice holder

is located behind the front

access panel at the bottom

of the range.

The rangetop orifice holder

is located inside the range insulation cover.

Additional orifices may be present. Use only the orifices

specified in the instructions for your range or rangetop.

Small Pliers

Griddle

Orifice

Burner Orifices

Screwdriver

Grill

Orifice

– 22 –

Page 23

CONVERT THE REGULATOR

2

Disconnect all electrical power at the main circuit

breaker or fuse box.

A. Remove the rear vent

Range Regulator

trim (on ranges only)

to access the

regulator. The

Rangetop regulator is

on the left bottom

corner.

B. Shut off the gas supply by closing the manual shut-off

valve in the unit or at the wall.

Convert the pressure regulator:

C.

• Unscrew the cap with plunger.

• Place your thumb against flat side of the plunger and

press down to snap the plunger out of the cap.

• Carefully look at the plunger to locate the NAT

or LP position.

Gasket

• Turn the

plunger

over so

that the

desired gas

is showing

near the

bottom.

NAT. Position

Cap

LP

NAT

LP

NAT

Pressure Regulator

LP

LP Position

FOR OFF

DOWN

LP

NAT

NAT

Plunger

• Snap the plunger back into the cap.

• Screw the cap back onto the regulator.

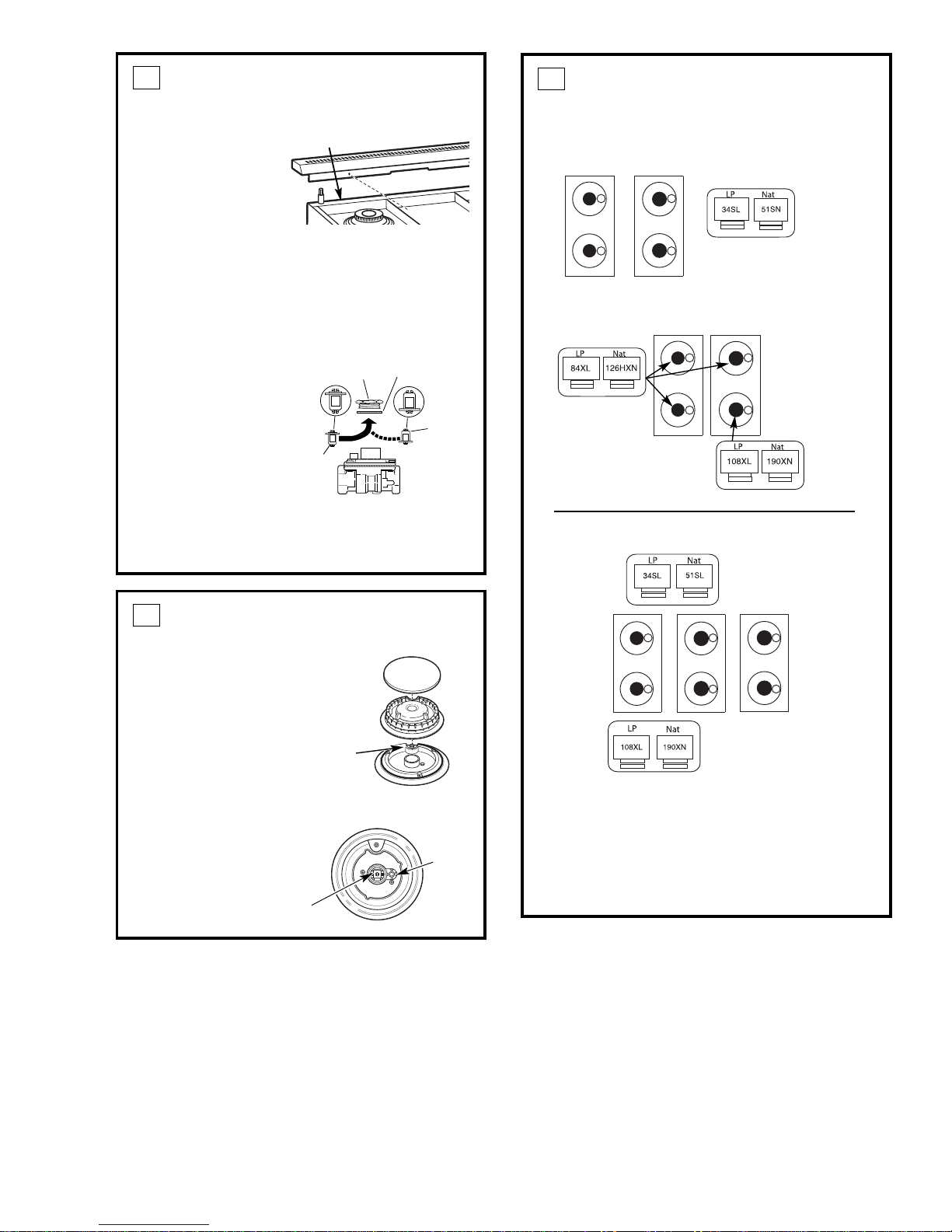

CHANGE BURNER ORIFICES (cont.)

3

IMPORTANT: Find your model number below. Read

each orifice label to identify and install them in the

exact locations shown.

ZDP304 SIMMER ORIFICES

A 34SL or 51SN orifice

will be used on all burners.

ZDP304 MAIN ORIFICES

Use a 108XL

A 84XL or

126HXN orifice

will be used

on these three

burners.

or 190XN orifice

for the right

front burner.

ZDP364, ZDP366, ZDP484, ZDP486

SIMMER

ORIFICES

A 34SL or 51SN orifice

will be used on all

burners.

CHANGE BURNER ORIFICES

3

INSTALLATION TIP: First remove all

orifices and then start replacing them.

This will help to prevent the possibility

that some may not be replaced.

A. Remove the burner grates,

burner caps and burner heads.

B. Loosen the top burner

orifices using a 7 mm

Burner

Head

Spark

Igniter

nut driver. Use small

pliers to carefully lift out the orifices.

The main orifice is located

low in the center of the

burner, while the simmer

orifice is located higher

beside the center

of the burner.

Main

Orifice

Burner Cap

Burner Base

Simmer

Orifice

MAIN

ORIFICES

Use 108XL or

190XN orifices

for all burners.

A. Return the unused orifices to the holder. Reattach

the holder and the instruction sheet with screw

in the original storage location.

B. Replace the burner heads, caps and top grates

On range models, replace rear vent trim.

.

– 23 –

(Continued next page)

Page 24

4

CHANGE GRILL ORIFICE

Locate the 1–1/2" long Grill orifice.

—

Select for your gas type. LP

.047, NAT—.067

A. Remove the grill cover,

grates and grate frame. Lift

the radiant baffle straight

up and off.

B. Remove the 2 hex

head screws from

the top of the igniter.

• Remove one screw

Remove 2

hex head

screws

from each side of

the burner surround.

• Lift out the surround.

C. Carefully push the

igniter aside and

Burner

Surround

under

the burner.

Do not pull or pinch

the wire.

Remove 4 burner

attachment screws,

2 at the front and 2

at the back. Slide the

burner assembly

toward the back and

out of the gas inlet.

D. Use a 1/2" deep well

socket to remove

and replace the orifice .

Reverse these

steps to re-assemble

the grill. Be sure to

place the unused

orifice in the holder

for possible future use.

(if present)

Surround

Screws

Front of Range

Igniter

Burner

Assembly

5

CHANGE GRIDDLE ORIFICE

(if present)

Locate the 3/4" long Griddle orifice.

Select for your gas type. LP

—

.047, NAT—.076

A. Lift off

the griddle flue

cover. Remove

the 2 inside

clamping

Griddle Flue Cover

A

screws.

B. Use a pad or

piece of

carton to

protect

the adjacent

Leveling Screws

surface. Slide

the griddle

toward

Clamping Screws

the rear

and out of

the hold-down tabs along

B

NOTE: Remove

the 2 screws

positioned on

the inside only.

Do not remove

the outermost

screws—they

are for leveling.

the bottom.

C. CAREFULLY lift and hold

the griddle. A thermostat

capillary is routed through

a clip. Gently lift the griddle

to one side and slip the

capillary out of the clip.

D. Lay the griddle

on the padded surface.

Do not disconnect or pull

C

Capillary

on the capillary.

E. Remove the 2 burner

hold-down screws

at the rear of the burner.

• Pull the burner straight

D

back toward the rear

and out of the gas inlet.

F. Use a 1/2" deep well socket

to remove and replace

the orifice.

E

Back of Range

F

Front of Range

Reverse these steps to re-assemble the griddle. Push excess

capillary back into the entry hole. Route the thermostat

capillary so it is held by the clip. Place the unused orifice in

the holder for possible future use.

– 24 –

(Continued next page)

Page 25

6

ADJUST BURNER FLAMES

Normally, burners do not need further adjustment.

Make adjustments only when necessary.

A. Turn on the gas. Plug in electrical cord.

B. Turn all burners on highest setting and check

the flames. They should be blue in color. When

using LP gas, the flames may have some yellow

tipping at the ends of the flame. Foreign particles

in the gas line may cause an orange flame at first,

but this will soon disappear.

C. Turn the burner knob to “LO” while observing the

flame.

Adjust the setting of the upper row of flames using

the valve bypass screw as follows:

Adjustments must be made with two other burners

in operation on a medium setting. This prevents

the upper row of flames from being set too low,

resulting in the flame being extinguished when

other burners are turned on.

D. To adjust the flame, remove the knobs. Insert a small

flat-blade screwdriver into the hole in the center

of the valve stem to engage screw.

• If the flames are too small or flutter,

turn the screw counterclockwise.

Oven Operational Notes

Certain modes, when selected, will automatically

enter into a preheat. The temperature knob is used

to set the desired temperature, in 25°F increments,

from 175°F to 550°F. The oven will now begin to

preheat. The temperature display will begin at

100ºF and remain there until the oven exceeds that

temperature. From that point, the display will show

the actual temperature.

The interior lights will turn on and stay on until the

oven is turned off. The convection oven fan will turn

on temporarily during preheat. The control will beep

when the oven is preheated and food can be placed

inside the oven.

Note: A cooling fan will turn on to cool internal

parts. This is normal, and the fan may continue to

run even after the oven is turned off.

Preheat Chart

Mode Preheat

Proof No

Bake Yes

Convection Bake Yes

Convection Roast Yes

Convection Broil No

Std Broil No

Clean No

Sabbath Mode No

Probe Usage Yes

• If the flames are too large, turn the screw

clockwise.

E. Make the adjustment by slowly turning the screw

until flame appearance is correct.

Note: Once the conversion is complete and checked,

fi ll out the conversion label and affi x the label near

the rating label. For ranges, place the label beneath

the control panel. For rangetops, place the label on

the bottom of the unit.

Preheat operation consists of multiple phases, •

which are time and/or temperature dependant.

Each phase of preheat utilizes combinations of

inner and outer bake, broil, and inner convection

elements. For example, one phase may use

inner convection and outer broil simultaneously.

Another phase may use inner broil and outer

bake simultaneously.

At the start of Preheat, the convection fan •

will delay running for 10 seconds. It will then

run CCW with no directional changes for the

remainder of Preheat.

– 25 –

Page 26

The convection fan will cycle on and off while •

cooking to best distribute hot air in the oven. The

convection fan shuts off when the oven door is

opened.

Different broil elements are used in each broil •

mode. There are 2 different broil modes, each

providing a HI and a LO setting.

The Convection Broil mode uses both the inside •

and outside broil elements and convection fan.

Broil will not work if the temperature probe is •

plugged in.

When using the probe, you can use the timer, •

but you cannot use timed oven operations.

In Convection Bake, both the inner and the outer •

convection elements cycle and the fan operates

whenever the oven is heating.

Convection Broil will not work if the temperature •

probe is plugged in. Never leave your probe

inside the oven during a broil cycle.

The Clean cycle can be set for a minimum of 3 •

hours and a maximum of 5 hours. The default

setting is 5 hours. The 5-hour set time consists

of 4 hours and 15 minutes of cleaning and 45

minutes of cool down. The door will unlock at an

approximate temperature of 450°F.

On double oven models, the ovens can be set to •

self clean in sequence. The fi rst oven set starts

the cycle. The second oven will start cleaning

as soon as the fi rst oven has cooled to 550°F (it

should already be below 550°F at the end of a

standard 5-hour clean since a 45 cool-down is

included in the time). If the fi rst oven clean cycle

is cancelled, the second oven will start cleaning

immediately or as soon as the fi rst oven cools

below 550°F.

Self-Clean will not work if the temperature probe •

is plugged in or if the Sabbath feature is set.

Proofi ng will not operate when oven is above •

125°F. The display will show “too hot”. Allow the

oven time to cool.

– 26 –

Page 27

Component Locator Views

Front of Range (48-in. range shown)

Task

Light

Switch

Rangetop

Control

Panel

Broil Element

Oven Door Gasket

Oven Door

Lights

Convection Fan

Lights

Broil Element

Lights

Convection Fan

Oven Door Gasket

Oven Door

– 27 –

(Continued next page)

Page 28

Rear of Range (48-in. range shown)

Level Leg Extension Rod

Sail Switch

Cooling Fan

Terminal Block

Regulator

Broil Element

Oven TCO

Convection Fan

Convection Element

Level Leg Extension Rod

Shutoff Valve

Sail Switch

Cooling Fan

Broil Element

Oven TCO

Convection Fan

Convection Element

Gas Inlet Pipe

– 28 –

(Continued next page)

Page 29

Rangetop ZGU484NG

LED Task

Lighting

Control

IR (Infrared) Grill

IR (Infrared) Grill Control

Knob with Lighted Bezel

Griddle

Griddle Control Knob

with Lighted Bezel

Burner Control Knob

with Lighted Bezel

Rangetop ZGU484NG (burner pans, top heat barriers, grill, and griddle removed)

(1 of 4)

Burner

Spark Module

Burner

Surface Burner Valve

Grill Burner Igniter

Grill Burner

Transformer

IR (Infrared) Grill Control

Burner

Griddle Burner

Griddle Burner Igniter

Burner

Surface Burner Valve

Griddle Control

– 29 –

Page 30

Surface Components

WARNING: Sharp edges may be exposed when

servicing. Use caution to avoid injury. Wear Kevlar

gloves or equivalent protection.

Control Panel

It is necessary to remove the control panel from the

range or rangetop chassis and place it in the service

position to access certain components.

To place the control panel in the service position:

Note: It will be necessary to pull the rangetop

approximately 10 inches out from its installation.

1. Remove left and right side grates, surface

burner knobs, grill and griddle control knobs.

2. On range models:

a. Remove the 2 Phillips-head screws that

attach the griddle control bezel to the

control panel.

b. Remove the 2 Phillips-head screws that

attach the griddle control to the manifold

bracket.

3. Remove the 2 Phillips-head screws within each

bezel that attach the bezel to the manifold

brackets.

4. Remove the T-15 Torx screws from the bottom

of the control panel.

5. Remove the Phillips-head screw at each front

corner that attaches the front of the side trim to

the control panel.

Bezel Screw

Control Screw

Control Screw

Bezel Screw

Note:

A ground wire at each end of the panel allows •

the panel to be lowered without falling.

Before lowering, protect the bottom of the front •

panel from scratches caused by the lock motor

arm (range models) or front frame edge.

If the range has a grill, use caution when •

lowering the control panel to prevent damage to

the switches mounted at the bottom of the grill

valve.

(Continued next page)

– 30 –

Page 31

6. On rangetops, remove the two 1/4-in. hex-head

screws and the Phillips-head screw (on each

side), from the back of the control panel fl ange.

7. Pull the control panel straight out from the

chassis, then carefully lower the control panel

onto a protective, supportive surface.

Grill Assembly

Note: The following describes the procedure to

remove the grill assembly.

To remove the grill:

Lift off the grill grate and grill frame.1.

Lift the grill baffl e straight up and remove it from 2.

the 4 support posts located on the side walls.

(See Control Features - Rangetop.)

Remove the two 1/4-in. hex-head screws that 3.

attach the igniter to the igniter bracket, then

place the igniter aside.

Remove the 2 Phillips-head screws that hold the 4.

refl ector trim in place.

Lift up and remove the trim and screen. 5.

Rangetop Control Panel in Service Position

– 31 –

(Continued next page)

Page 32

6. Remove the two 1/4-in. hex-head screws from

the front and the two 1/4-in. hex-head screws

from the rear of the grill burner.

Front of Grill Burner

Rear of Grill Burner

8. Remove the grill burner igniter. (See Grill Burner

Igniter.)

9. Place the control panel in the service position.

(See Control Panel.)

10. Remove the 2 Phillips-head screws and the

center trim, if applicable.

11. Remove the 2 Phillips-head screws from the

front and the 2 Phillips-head screws from the

rear of the grill burner box.

7. Lift up and maneuver the grill burner past the

igniter bracket.

Grill Burner Removed

Front of Grill Burner Box

Rear of Grill Burner Box

11. Lift up and remove the grill burner box.

– 32 –

Page 33

Grill Burner Igniter

Grill Safety Valve

Note: The following describes the procedure to

remove the grill burner igniter. The grill igniter

has a resistance value of 45 to 400 Ω at room

temperature.

To remove the grill burner igniter:

Remove the grill burner. (See 1. Grill Assembly.)

Note: In the following step, ensure that the spring

clip is captured and retained inside the grill burner

box.

Squeeze the ends of the spring clip and retract 2.

the clip from the harness access cutout on the

left side of the grill burner box.

Note: The following describes the procedure to

remove the grill safety valve. The grill safety valve

has a resistance value of 1 Ω or less.

To remove the grill safety valve:

Remove the grill assembly. (See 1. Grill Assembly.)

Remove the two 1/4-in. hex-head screws that 2.

attach the heat shield.

Heat Shield

3. Disconnect the wires from the valve.

Spring Clip

3. Pull the harness connector thru the cutout and

disconnect the igniter wire harness.

4. Remove the heat barrier.

Disconnect

Disconnect

Heat Barrier

5. Remove the 9/16-in. nut from the valve.

6. Remove the 1/4-in. hex-head screw that

attaches the valve to the valve bracket and

separate the valve from the gas tube and valve

bracket.

– 33 –

Page 34

Grill Control

The grill control is attached to the manifold bracket.

4. Using a ratchet wrench, remove the 1/4-in.

hex-head screw that attaches the control to the

manifold.

A switch bracket is attached to the control and

secures 2 switches. The front switch controls

the igniter and the rear switch controls the LED

indicator. When the Grill knob is turned to the

ON position, both switches close contacts. Both

switches can be replaced separately.

To remove the grill control switches:

Place the control panel in the service position.1.

(See Control Panel.)

Carefully press the 2 locking tabs away from 2.

the switches and remove the switches from the

switch bracket.

Mark and disconnect the wires from the 2 3.

switches.

5. Separate the control from the gas outlet tube

and manifold.

Caution: Ensure the control seal and the screw seal

are in place BEFORE installing the control.

Ta b

Ta b

To remove the grill control:

Remove the grill control switches. 1.

Remove the grill assembly. (See 2. Grill Assembly.)

Remove the 5/8-in. nut from the grill control gas 3.

outlet tube.

Note: Switch mounting bracket is a part of the valve

assembly.

Control Seal

Switch Mounting

Bracket

Screw Seal

– 34 –

Page 35

Griddle Assembly

Note: The following describes the procedure to

remove the griddle assembly.

To remove the griddle assembly:

Remove griddle fl ue cover and grease trough.1.

Caution: The griddle is heavy. Use care when lifting

and rotating the griddle to prevent damage to the

capillary.

4. Lift and rotate the griddle and remove the 2

Phillips-head screws and the retainer from the

bottom of the griddle.

Remove the (inner) clamping screws.2.

Note: It’s recommended to remove the griddle

completely when servicing the burner assembly.

The griddle control has a capillary that is positioned

securely to the underside of the griddle by a retainer

that is attached with 2 Phillips-head screws.

3. Push the griddle toward the back of the range to

release tabs from slots on the front of the range.

Retainer

Capillary

Note: When installing the retainer, ensure the

capillary is in direct contact with the bottom of the

griddle.

5. Remove the two 1/4-in. hex-head screws from

the back of the grill burner.

Ta b

Front of Range

Slot

(Continued next page)

– 35 –

Page 36

Note: In the following step, ensure that the spring

clip is captured and retained inside the griddle

burner box.

6. Squeeze the ends of the spring clip and retract

the clip from the harness access opening on the

right side of the griddle burner box.

7. Lift the burner and pull the igniter wiring and

harness connector through the opening.

8. Disconnect the igniter wire harness connector

and remove the two 1/4-in. hex-head igniter

screws.

13. Remove the 2 Phillips-head screws from the

front and the 2 Phillips-head screws from the

rear of the griddle burner box.

Front of Griddle Burner Box

Rear of Griddle Burner Box

Griddle Burner Removed

9. Remove the grease trough.

10. Remove the 4 Phillips-head screws that attach

the rear trim.

11. Place the control panel in the service position.

(See Control Panel.)

12. Remove the 2 Phillips-head screws and the

center trim, if applicable.

15. Lift the burner box while carefully guiding the

igniter wire harness connector and control

capillary through their openings.

– 36 –

Page 37

Griddle Burner Igniter

Griddle Control

The griddle burner igniter is attached to the right

side of the griddle burner with two 1/4-in. hexhead screws. It is necessary to remove the griddle

burner (See

Griddle Assembly.), to access the screws

and the igniter wire harness. The griddle igniter

has a resistance value of 45 to 400 Ω at room

temperature.

Griddle Safety Valve

Note: The following describes the procedure to

remove the griddle safety valve. The griddle safety

valve has a resistance value of 1 Ω or less.

To remove the griddle safety valve:

Place the control panel in the service position.1.

(See Control Panel.)

3. Disconnect the 2 wires from the valve.

4. Remove the heat barrier.

5. Remove the 9/16-in. nut from the valve.

The control utilizes a capillary that senses griddle

temperature and a switch that operates the LED

indicator light. When the griddle knob is turned to

the ON position, the control closes contacts that

start the ignition process. The LED switch contacts

also close and activate the LED indicator light. The

LED switch can be replaced separately.

On rangetops, the griddle control is attached to a

bracket that is held in place inside the front panel.

On ranges, the griddle control is attached to a

manifold bracket.

To remove the griddle control:

Remove the griddle, then remove the capillary 1.

retainer. (See Griddle Assembly.)

Note: On range models, it’s a tight fi t between the

manifold bracket and the front frame of the range.

Remove the 2 Phillips-head screws and the 2.

griddle control from the control bracket

(rangetops), or manifold bracket (ranges).

Disconnect (1 of 2)

Heat Barrier

6. Remove the two 5/16-in. hex-head nuts that

attach the valve to the chassis, then separate

the valve from the chassis and gas tube.

3. Place the cardboard insulator aside.

Cardboard Insulator

4. Slide the LED switch and switch plate off the

control shaft.

LED Switch

and Switch

Plate

(Continued next page)

– 37 –

Page 38

5. Slide the switch off the switch plate.

LED Switch

Grill and Griddle Ignition Systems

The grill and griddle burners are ignited by a glow-

bar ignition system. The igniter is a Norton style

rectangular glow-bar. The grill and griddle ignition

circuits consist of the control, an igniter, a hi limit

switch (griddle only), and a safety valve. These

components are wired in series for each cooking

function.

The most important points to know about the

ignition system are:

Switch Plate

6. Remove wires from the LED switch.

7. Remove wires from the control.

• THE IGNITER RESISTANCE DECREASES AS THE

IGNITER SURFACE TEMPERATURE INCREASES.

• THE SAFETY VALVE OPERATES BY CURRENT, NOT

VOLTAGE.

From a cold start, the igniter needs 30 to 60

seconds, with a minimum of 116 volts applied, to

reduce its electrical resistance enough to provide a

minimum of 2.9 amps of current fl ow in the series

circuit. This is the required current fl ow needed

for the safety valve to open and supply gas to the

burner.

The glow-bar should provide a steady current fl ow

of 3.4 to 3.6 amps (3.03 / 3.3 VAC) in the circuit. At

that point, the igniter temperature is 1800°F to

2500°F (982°C to 1371°C). The igniter will remain

energized at all times during burner operation. If

the igniter glows red but does not draw at least 2.9

amps, the fault is usually with the igniter, not the

valve.

Always check the gas shut-off valve located next to

the pressure regulator for a Not On condition.

8. Slide the capillary out of the griddle burner box.

– 38 –

Page 39

Glow-bar Igniter

Surface Burner Base

WARNING: The range and rangetop use rect-

angular Norton glow-bar igniters. They are NOT

INTERCHANGEABLE with cylindrical Carborundum

glow-bar igniters. The two types of glow-bar igniters

operate at different amperage and use different gas

valves.

Check the glow-bar circuit with a clamp-on

ammeter. If igniter glows red but circuit does not

draw at least 2.9 amps, the fault is likely with the

igniter, not the valve.

Note: If igniter glows, but ignition does not occur, be

sure the gas shut-off valve on the pressure regulator

is in the open position.

Slow ignition can be caused by one or more of the

following conditions:

Blockage of primary air intake: Inlet slots under 1.

bullnose (near LED light locations) must be open.

Blockage of secondary air intake holes: 2.

Examine grill and griddle burner boxes (galvanized box surrounding burner) and inspect the