Page 1

If you have questions, call 800.626.2000 or visit our website at: www.monogram.com

Monogram.

®

Installation

Instructions

Built-In Compactors

Models:

ZCG3500

ZCG3300

ZCG3100

Page 2

Before you begin—Read these instructions completely and carefully.

IMPORTANT: Save these instructions for local inspector’s use.

IMPORTANT: OBSERVE ALL GOVERNING CODES AND ORDINANCES.

NOTE TO INSTALLER: Be sure to leave these instructions with the Consumer.

NOTE TO CONSUMER: Keep these instructions with your Use and Care Book for future

reference.

This appliance must be properly grounded. See “Power Supply”, page 5.

Cet appareil doit être mis à la terre correctement. Voir la section « Alimentation

électrique » en page 5.

If you have a question concerning the

installation of this product, call the GE Answer

Center®Consumer Information Service at

800.626.2000, 24 hours a day, 7 days a week.

If you received a damaged compactor, you

should immediately contact your dealer or

builder.

2

Design Information

Models Available ......................................................................................................................................................................3

Dimensions and Clearances ....................................................................................................................................................3

Installation Preparation

Standard Appearance Panel Option ......................................................................................................................................4

Custom Panels ..........................................................................................................................................................................4

Option 1: 1/4" Thick Wood Panel ..........................................................................................................................................4

Option 2: 3/4" Thick Wood Panel ..........................................................................................................................................4

Option 3: 3/4" Thick Wood panel with Custom Handle........................................................................................................5

Power Supply ............................................................................................................................................................................5

Installation

Technical Data ..........................................................................................................................................................................6

Choosing the Location ............................................................................................................................................................6

Installation in a Corner ............................................................................................................................................................7

Level the Opening ....................................................................................................................................................................7

Step 1 Determine Toekick Depth ............................................................................................................................................8

Step 2 Adjust Movable Base ....................................................................................................................................................8

Step 3 Positioning the Compactor Backstop ..........................................................................................................................9

Step 4 Setting the Height ........................................................................................................................................................9

Step 5 Attach Tip-Over Brackets ............................................................................................................................................10

Step 6 Optional Custom Toekick ..........................................................................................................................................11

Step 7 Changing Front Panel ................................................................................................................................................12

Optional Custom Panels ........................................................................................................................................................13

NOTICE

• Compactor is shipped with ram in “Down” position.

Trash container compartment cannot be opened until

the ram is restored to normal “UP” position. See label

on compactor.

• Compactor has adjustable base to set toekick depth

to match cabinets. This adjustment must be made

prior to installing unit under countertop. See page 8.

• Compactor is designed for BUILT-IN applications

ONLY.

• Consideration must be given to provide adequate

clearances for installation and servicing.

• Do not use an extension cord or adaptor plug with

this appliance.

Proper installation is the responsibility of the installer.

Product failure due to improper installation is not covered

under the GE Appliance Warranty. See the Owner’s

Manual for warranty information.

For Monogram local service in your area, 800.444.1845

For Monogram Parts and Accessories, call 800.626.2002.

Contents

CAUTION

CAUTION

WARNING

AVIS

• À l’expédition, le bras de compression du compacteur se

trouve à la position « Down ». Il est impossible d’ouvrir le

compartiment du récipient à déchets tant que le bras de

compression ne revient pas à la position normale « UP ».

Lire l’étiquette sur le compacteur.

• Le compacteur est doté d’une base réglable permettant

d’adapter la profondeur du coup-de-pied à l’armoire. Ce

réglage doit être effectué avant de monter l’appareil sous le

comptoir. Voir la page 8.

• Le compacteur est conçu pour être ENCASTRÉ

SEULEMENT.

• Les dégagements appropriés doivent être prévus pour le

montage et l’entretien.

• N’utilisez pas de rallonge ou de fiche d’adaptation avec cet

appareil.

AVERTISSEMENT

MISE EN GARDE

Page 3

3

Design Information

Built-In Compactors

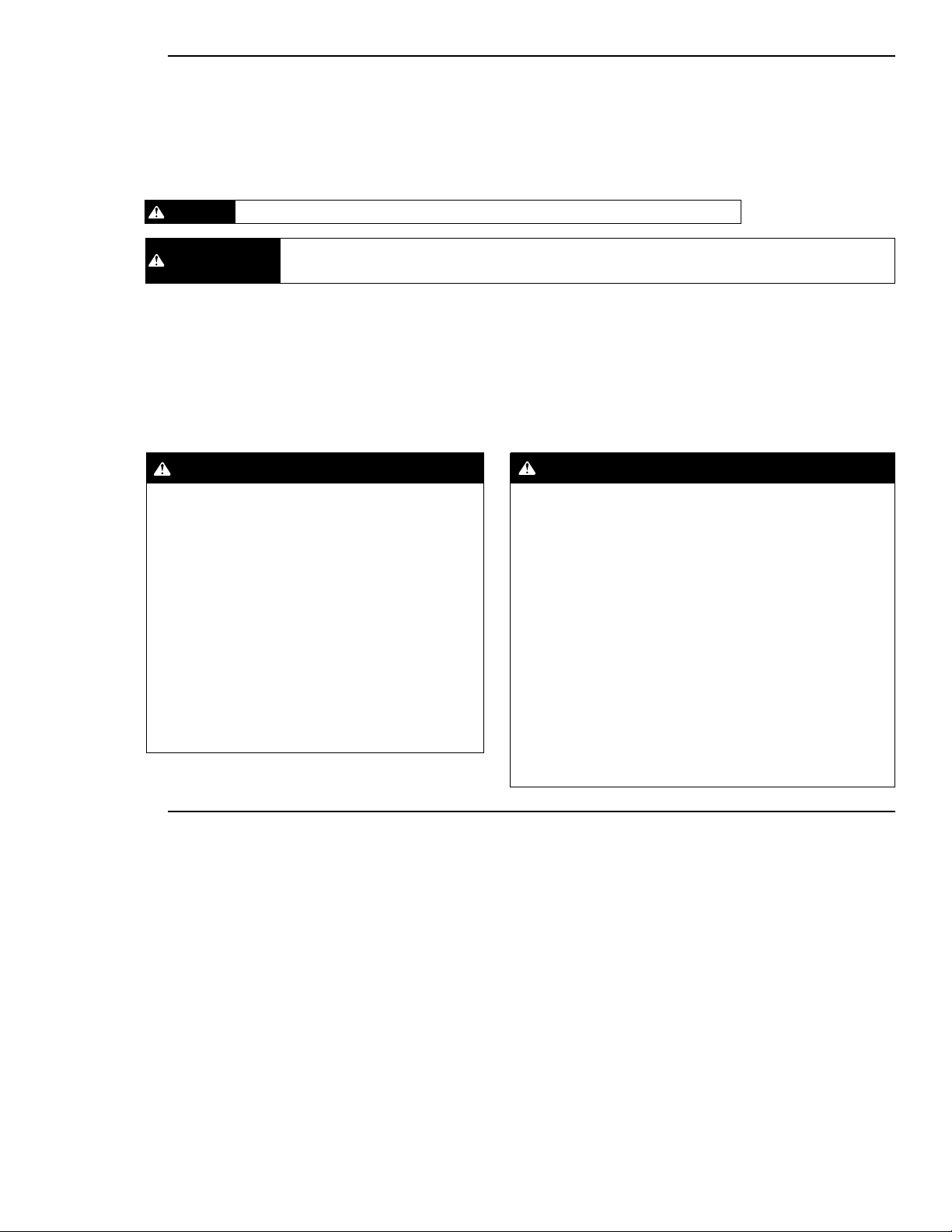

Models available

ZCG3500 SS

Stainless steel built-in

compactor

ZCG3300 WW

White built-in compactor

ZCG3100 BB

Black built-in compactor

Note: This compactor is

designed for built-in applications

only.

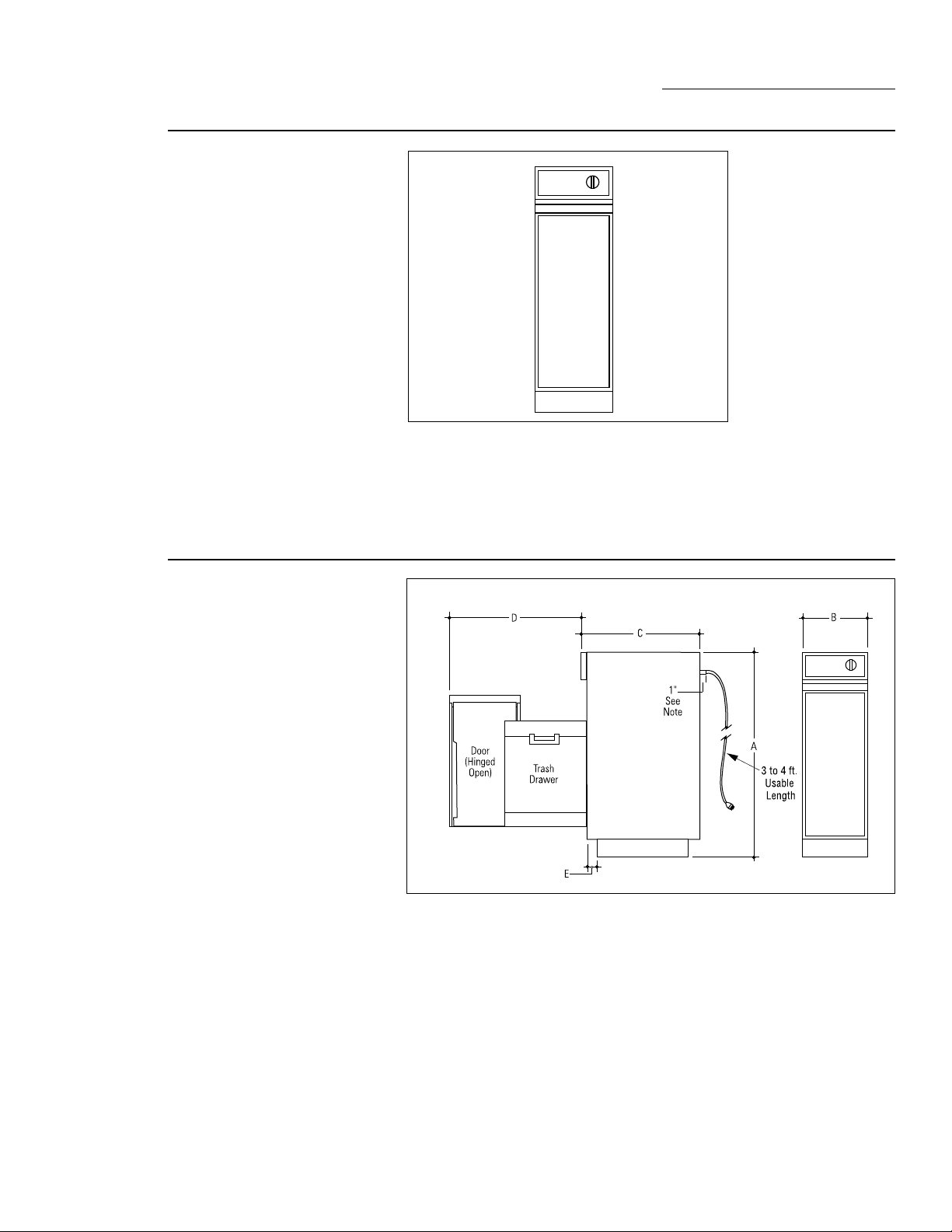

Dimensions and clearances

A – 34" (864 mm) adjustable to

35" (889 mm)

B – 12" (305 mm)

C – 20-1/4" (514 mm)

D – 22" (559 mm)

E – 2-3/4" to 4-1/4"

(70 mm to 108 mm)

base is adjustable from

front panel

Note: If cord is to be plugged

in directly behind compactor add

2-1/2" to overall depth in order

to allow proper clearance for the

electrical cord.

An extra touch of convenience for the custom kitchen,

the Monogram built-in compactor is a neat 12" wide.

This compactor offers design flexibility not found in

other models—an adjustable base allows the toekick

depth to match surrounding cabinetry.

Page 4

4

Standard

Appearance

Panel

Options

The Monogram compactor models ZCG3300

and ZCG3100 come with a white/black reversible

aluminum front drawer panel. Model ZCG3300 is

shipped with the white panel showing and model

ZCG3100 with the black side showing. The panels

on both models can be reversed to reveal the opposite

color side. The ZCG3500 comes with a stainless steel

wrapped panel.

Go to Step 7, page 12. Follow procedure A for

reversing door panel color if desired.

Monogram compactor models ZCG3300 and ZCG3100

are designed to accept a custom front drawer panel to

match the surrounding cabinetry.

You can:

• Install a 1/4" thick custom panel

• 3/4" thick custom panel

• 3/4" thick custom panel and custom handle

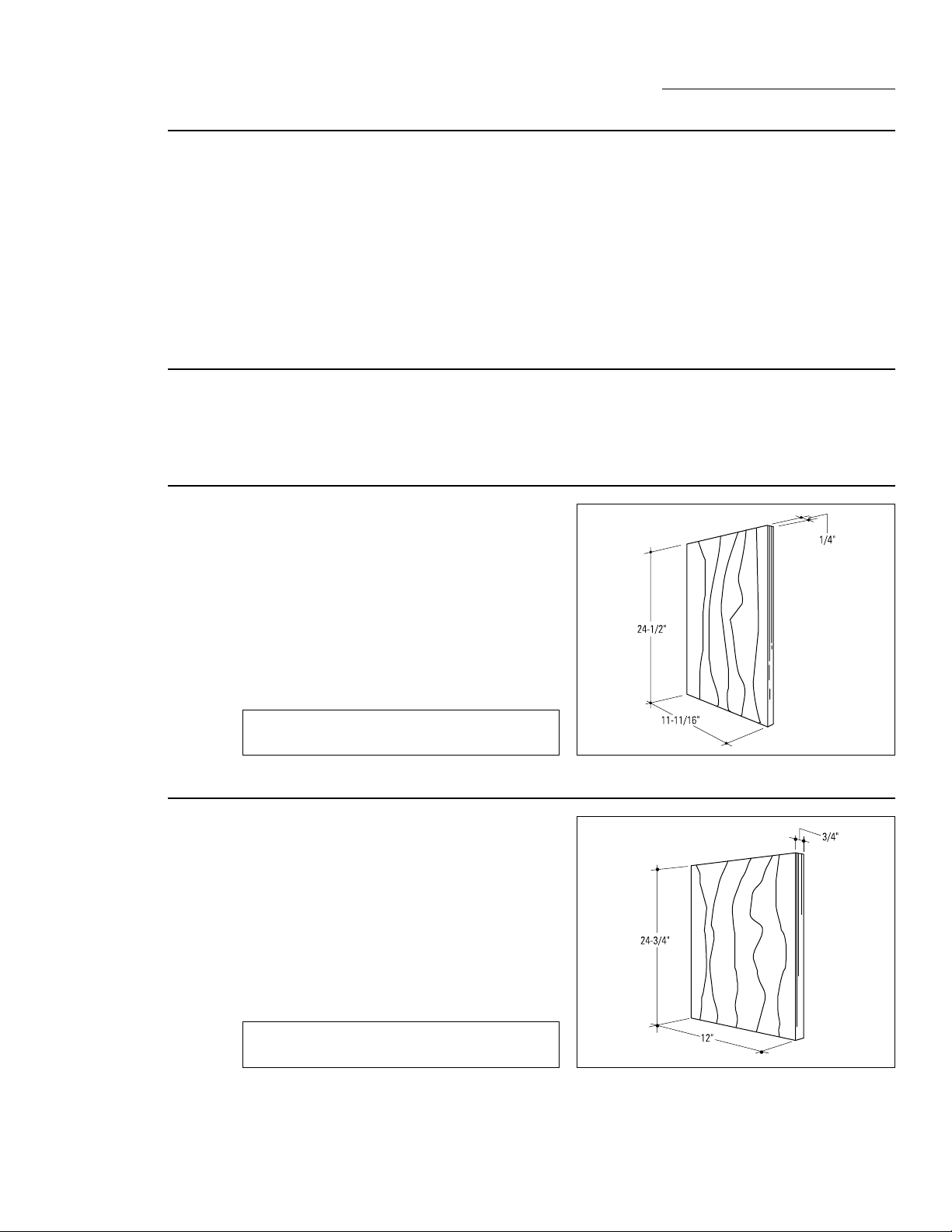

1/4" Thick Wood Panel

Go to Step 7, page 12. Follow procedure B for

installation.

• Cut panel 11-11/16" wide, 24-1/2" high.

The custom 1/4" thick panel replaces the

white/black aluminum panels and cardboard filler.

The custom panel will slide into the trim on the

drawer front, concealing raw cut edges.

3/4" Thick Wood Panel

• Cut panel 12" wide x 24-3/4" high.

The custom 3/4" thick panel replaces the

white/black aluminum panel. Cut edges will be

seen and must be finished for best appearance.

Both the trim and drawer front panel will be

removed to make this installation.

Note: 3/4" thick door panels, both raised and flat design,

should be constructed in the same manner as typical cabinet

doors. Order the 3/4" custom door panel from the cabinet

manufacturer. Be sure to provide the exact dimensions so

that the panel is constructed accurately.

Go to Step 7, page 12. Follow procedure C for

installation.

Installation Preparation

Built-In Compactors

Custom Panels

Option #1

Option #2

Page 5

5

3/4" Thick Wood Panel with custom handle

• Cut panel 12" wide x 25-13/16" high. A custom

handle, of your choice, can be installed onto the

3/4" wood panel, replacing the standard handle.

The cut edges of the custom panel can be seen

and must be finished for best appearance. The trim,

drawer front panel and the handle will be removed

to make this installation.

Note: 3/4" thick door panels, both raised and flat design,

should be constructed in the same manner as typical cabinet

doors. Order the 3/4" custom door panel from the cabinet

manufacturer. Be sure to provide the exact dimensions so

that the panel is constructed accurately. Order custom handle

to match cabinetry hardware.

Go to Step 7, page 14. Follow procedure D for

installation.

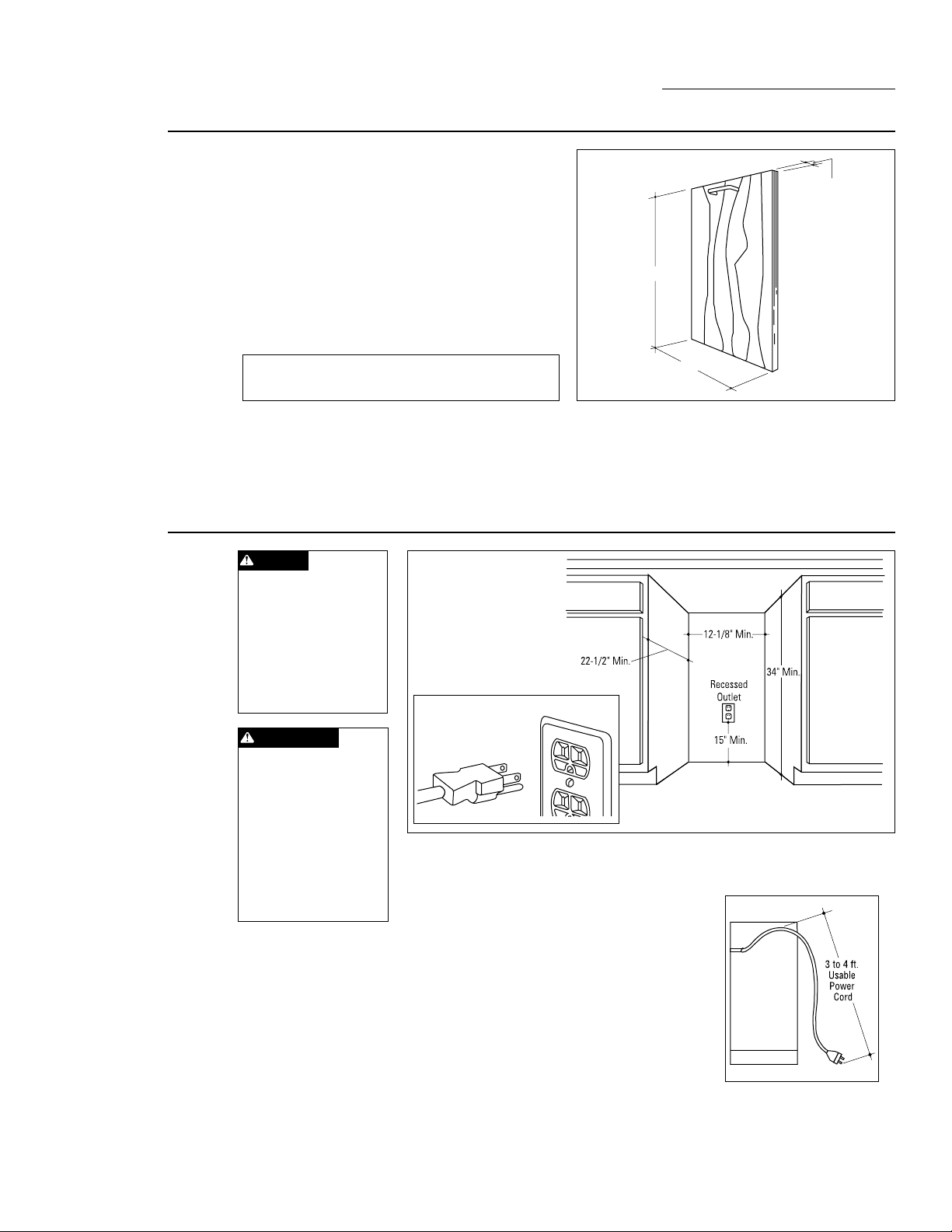

Follow national electrical codes

or prevailing local codes and

ordinances.

Note: The outlet location is critical for proper cord storage when

compactor is installed.

For personal safety, do not

use an extension cord or

adapter plug with this

appliance.

Do not, under any

circumstances, cut or remove

the third grounding prong

from the power cord.

Note: Usable power cord

length is 3 to 4 ft.

This appliance must be supplied with 120V, 60HZ

and connected to an individual, properly grounded

branch circuit protected by a 15 or 20 amp circuit

breaker or time delay fuse.

Install a 3-prong grounding type receptacle in the

rear wall of the cabinet opening.

25-13/16"

12"

3/4"

Pour votre sécurité

personnelle, n’utilisez pas

de rallonge ou de fiche

d’adaptation avec cet

appareil.

Ne coupez ou n’enlevez pas,

pour quelque motif que ce

soit, la troisième broche

de masse du cordon

d’alimentation.

CAUTION

CAUTION

MISE EN GARDE

CAUTION

Installation Preparation

Built-In Compactors

Option #3

Power supply

Page 6

6

Tools required:

•#2 Phillips head screwdriver

• Flat blade screwdriver

•Tape measure

•Spirit level

•10" long 2x4

•Adjustable wrench or slip

joint pliers

•Drill and 1/8" drill bit

Parts List:

•4 leveling feet caps

•4 Phillips head screws

• 2 Slotted head screws

•2 Tip-over brackets

•2 90° clips

Optional Materials

(not supplied):

•Custom front panel

• Custom handle

•Custom toekick board

•5 wood screws

Installation

Built-In Compactors

Technical data

Electric Power—120V, 60 HZ, 5 amp

Circuit Requirement—15 or 20 amp grounded outlet

Motor Horsepower—1/3

Compacting Force—5000# max.

Container volume—1.4 cu. ft.

Weight—135 lbs.

Cycle Time—70 sec. max., 12 sec. min.

Choosing the location

This compactor is designed as a built-in appliance

only. It may be located in any convenient space under

a countertop. DO NOT OPERATE FREE-STANDING

because the compactor will tip over when the drawer

is pulled out.

Page 7

7

Installation in a corner

If compactor is to be located in or near a corner of

base cabinets, a minimum of 2" clearance from the

corner is recommended. This is necessary to prevent

adjacent cabinet door handles from interfering with

the compactor drawer.

Do not install flooring material after compactor is

placed under the counter. This will limit ability to

service.

If there is an appreciable difference in floor height

between where the compactor is to be installed and

the floor of the kitchen, add runners of the minimum

height necessary to make floor level.

Installation

Built-In Compactors

Level the opening

Page 8

8

Step 1 Determine toekick depth

Place a section of the carton on the floor for

protection. Lay the compactor on its back, supporting

it with a piece of wood to prevent pressure on the

power cord.

Measure the toekick of an adjacent cabinet, from

the front of the cabinet door to the front of the

toekick (Dimension A).

Note: If a custom toekick board

is used, its thickness must be

accounted for in dimension “A”.

See step 6.

With the compactor laying on its back, locate the six

Phillips head screws on the bottom, positioned inside

of the movable base.

Loosen these six screws. Slide base to set dimensions

“A” as shown.

Tighten screws making sure base does not move.

Note: If an alternate toekick depth

dimension is required, follow the

procedure above and adjust the

base accordingly. The base can be

adjusted from 2-3/4" to 4-1/4" from

the compactor front panel.

Step 2 Adjust movable base

Installation

Built-In Compactors

Page 9

9

Step 3 Positioning the compactor backstop

A backstop should be installed to prevent the

compactor from “walking” back when the drawer

is closed.

Measure and mark 16" back from the front edge of

the cabinet toekick. Cut a 2x4, 10" long and anchor

to the floor.

Note: If using a custom toekick, add that

thickness to the 16" measurement.

Measure height “B” from the underside of the

countertop to the floor where the compactor

will be setting.

With the compactor still laying on its back, adjust

leveling feet to 1/16" less than the measurement

of “B”. Place the plastic leveling feet caps over the

leveling feet and stand compactor upright.

Installation

Built-In Compactors

Step 4 Setting the height

Page 10

Compactor Top

Countertop Overlap

Step 5 Attach tip-over brackets

Position tip-over brackets on the top of the

compactor. Match hole #3 of the bracket to the screw

hole on the compactor (the 3rd hole on the bracket

is the standard location). Attach tip-over bracket to

compactor with one slotted head screw on each side.

• Remove the compactor drawer for easier handling.

• Then position the compactor just in front of the

cabinet opening.

• PLUG POWER CORD INTO THE WALL

RECEPTACLE.

• Slide compactor back into cabinet opening.

Note: Make certain that the

leveling feet caps are on the

leveling feet and the power

cable is not under compactor.

The short leg of anti-tip bracket should be completely

under the lip of the countertop but not so far back

that the screws can’t be put in. If the bracket is not in

the proper location, pull the compactor back out far

enough to get to the top screws and reposition the

bracket to the appropriate hole.

Drill (4) 1/8" dia. x 1/2" deep pilot holes in the

underside of the countertop at the location of the

four holes in the short leg of the anti-tip bracket.

Caution: Do not drill up through the top of the countertop.

Secure anti-tip bracket to countertop with 4 Phillips

head screws (supplied) on each side.

10

Installation

Built-In Compactors

Page 11

Step 5

(continued)

If the countertop cannot be drilled into, slip the 90°

clips over the short leg of the bracket and screw into

the face of the cabinet.

11

To install custom toekick (not supplied) measure the

front of the compactor’s adjustable base and use those

dimensions to cut out your custom toekick. Secure as

appropriate to installation.

Note: The custom toekick should

be installed in such a manner that

it can be removed if service is

required.

Installation

Built-In Compactors

Step 6 Optional custom toekick

Page 12

12

Step 7

Changing

front panel

(ZCG3300 and

3100 only)

Remove compactor drawer by pulling it out until it

stops. Then lift the drawer to clear second stop and

remove drawer. Place drawer on its back.

Procedure A

Reverse color panel

Remove the two screws in the bottom edge of the

trim. Slide panel out, turn it over and slide back in.

Reinstall trim.

Procedure B

1/4" thick wood panel

Proceed as in “A” above, but discard the aluminum

color panel and cardboard spacer. Slide 1/4" panel

into trim. Reinstall trim.

Installation

Built-In Compactors

Optional

custom

panels

(ZCG3300 and

3100 only)

Procedure C

3/4" thick wood panel with supplied handle

• Pull the drawer out to stop position.

• Unlatch the drawer front by opening the clasp on

the right side.

• While supporting the weight of the drawer front,

remove the hinge pins on the left side.

Page 13

13

Procedure C (continued)

• Lay drawer front face down on a flat surface.

• Remove 9 screws which retain the front panel and

handle.

– Save handle and galvanized inner door.

– Discard front panel with side trim.

• Place galvanized inner door onto the back side of

the finished panel.

• Position the inner door 1/4" below the top of the

finished panel and center, left to right.

• Use the inner door as a template. Drill 3 pilot holes

in the top edge and 2 at the bottom, sized to match

screws being used. (Screws are not provided)

Caution: Select screw length carefully to avoid penetration of the

finished side.

• Lift the top edge of the inner door and slide the

handle between the inner door and the finished

panel. Align the screw holes of the inner door and

handle with pilot holes.

• Drive 2 screws loosely in the top. Align bottom holes,

and check to be sure that the inner door is centered

left to right over the finished panel. Drive 2 screws

at bottom.

• Drive last screw at top, tighten all screws.

• Replace drawer front to drawer by re-installing the

hinge pins. Swing door against drawer and secure

with side clasp.

• Slowly push the drawer closed and check alignment

of the panel.

Installation

Built-In Compactors

Page 14

14

Procedure D

3/4" thick wood panel with custom handle

• Pull the drawer out to stop position.

• Unlatch the drawer front by opening the clasp on

the right side.

• While supporting the weight of the drawer front,

remove the hinge pins on the left side.

• Lay drawer front face down on a flat surface.

• Remove 9 screws which retain the front panel and

handle.

– Save galvanized inner door.

– Discard front panel with side trim and handle.

• Place galvanized inner door onto the back side of

the finished panel.

• Position the inner door 1-5/16" below the top of the

finished panel and center, left to right.

• Use the inner door as a template. Drill 2 pilot holes

near the top and 2 at the bottom, sized to match

screws being used. (Screws are not provided)

• Drive 2 screws loosely into the bottom and 2 screw

into the top. Check to be sure the inner door is

centered left to right over the finished panel.

Tighten screws.

Caution: Select screw length carefully to avoid penetration of the

finished side.

Galvanized Inner Door

Back Side Finished Panel

C

L

1-5/16"

Galvanized Inner Door

Back Side Finished Panel

C

L

Installation

Built-In Compactors

Page 15

15

Procedure D (continued)

• Turn the panel over, appearance side up. Use

wood blocks to support the inner door and prevent

damage to the hinge and lock tabs.

• Drill pilot holes through the front of the custom

panel and through the metal panel to match the

chosen handles.

• Secure handle to wood panel with screws (not

supplied).

Installation

Built-In Compactors

• Replace drawer front to the drawer by re-installing

the hinge pins. Swing door against drawer and

secure with side clasp.

• Slowly push the drawer closed and check alignment

of the panel.

Page 16

Pub. No. 49-5778-4

Dwg. No. 165D4700P196

93042835C

10-03 JR

Note: While performing installations described in this book,

safety glasses or goggles should be worn.

For Monogram®local service in your area, call

800.444.1845.

Note: Product improvement is a continuing endeavor at

General Electric. Therefore, materials, appearance and

specifications are subject to change without notice.

GE Consumer Products

General Electric Company

Louisville, KY 40225

© 2003 General Electric Company

Monogram.

®

Loading...

Loading...