Page 1

Installation Instructions

Built-In Dishwasher

Ifyou have questions, call 800.GE.CARES1800.432.2737)or visit our Website at: GEAppliances.com.

In Canada, please call 1.800.561.3344or visit www.geappliances.ca

BEFOREYOU BEGIN

Readthese instructions completely and

carefully.

M PORTANT - Observeallgoverningcodesand

ordinances.

. Note to Installer - Be sure to leave these instructions for the

consumer's and local inspector's use.

. Note to Consumer - Keep these instructions with your

Owner's Manual for future reference.

. Skill Level - Installation of this dishwasher requires

basic mechanical, electrical and plumbing skills. Proper

installation is the responsibility of the installer. Product

failure due to improper installation is not covered under

the GEAppliance Warranty. Seewarranty information.

. Completion Time - 1 to 2;Hours. New installations require

more time than replacement installations.

READ CAREFULLY.

KEEP THESE INSTRUCTIONS.

IM PORTANT - The dishwasherMUST be installed

to allow for future removal from the enclosure if service is

required.

If you received a damaged dishwasher, you should

immediately contact your dealer or builder.

Optional Accessories - Seethe Owner's Manual for available

custom panel kits.

FOR YOUR SAFETY

Read and observe all CAUTIONSand WARNINGSshown

throughout these instructions. While performing

installations described in this booklet, gloves, safety glasses

or goggles should be worn.

31-30264 09/23/10 GE

Page 2

Installation Preparation

TOOLS YOU WILL NEED:

CI Phillips No.2 screwdriver

CI Flat blade screwdriver

CI Torx screwdriver sizeT 20 Ph

CI Adjustable wrench

CI Open-ended wrench (1/2" [!2 mm] or 5/8" [!6 mm])

CI Measuring tape

CI Safety glasses

CI Flashlight

CI Bucket to catch water when flushing the line Open-ended wrench

CI Gloves

CI Level

screwdriver

_ --__ Level

Flat blade _ Tar× screw-_%

screwdriver driver size T 20

Adjustable

Wrench _

Measuring Tape

Safety Glasses

For New Installations Only:

cI Tubing cutter

CI Drill and appropriate bits

CI Hole saw set

MATERIALS

CI Minimum 3/8" ODcopper tubing of sufficient length for your

installation

CI Shut-off valve and fittings for water supply line

Flashlight

%

Gloves

Hole Saw Set

Bucket

Page 3

Installation Preparation

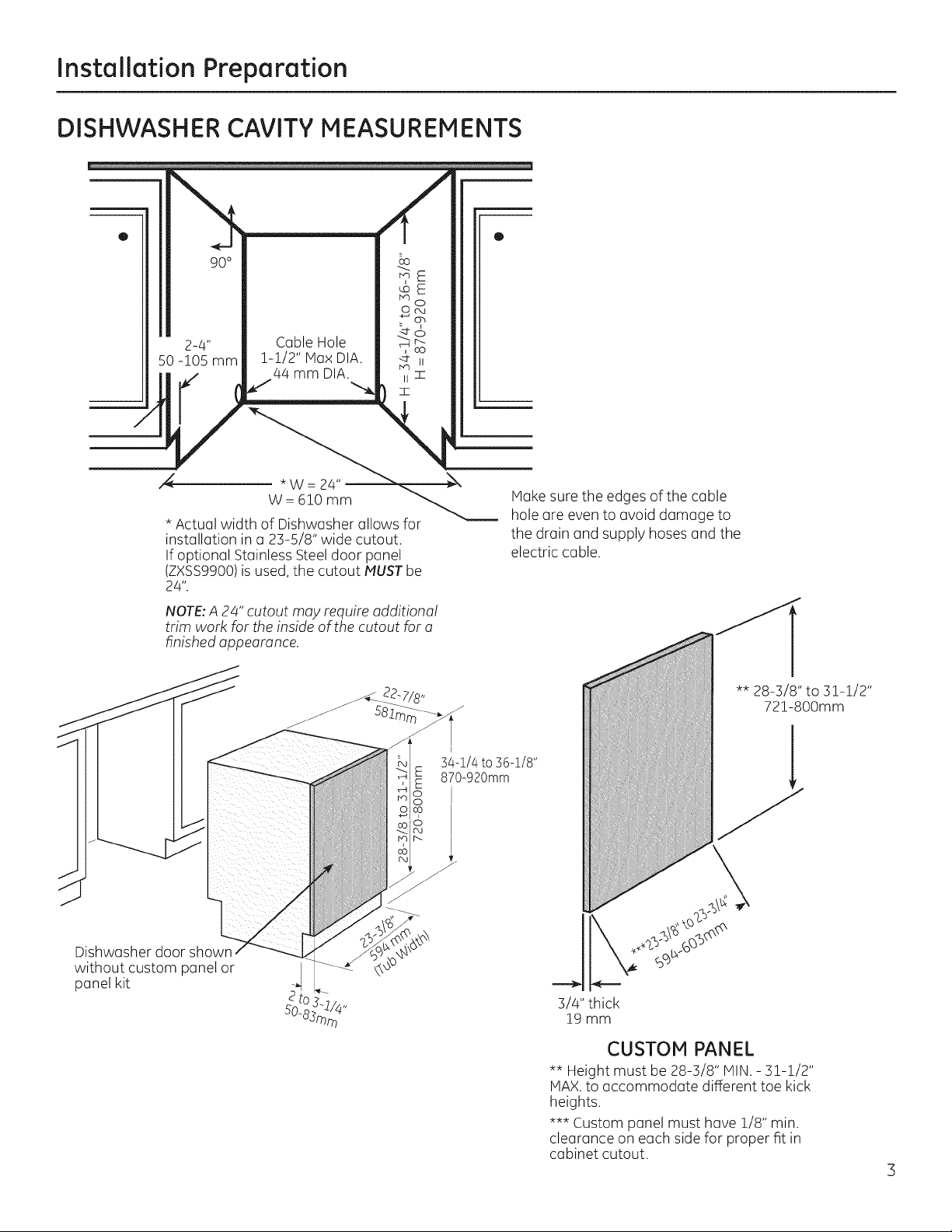

DISHWASHER CAVITY MEASUREMENTS

® O

90°

2 _/.j/,

50-i05mm

* Actual width of Dishwasher allows for

installation in a 23-5/8" wide cutout.

If optional Stainless Steel door panel

(ZXSS9900)is used, the cutout MUST be

24".

NOTE: A 24" cutout may require additional

trim work for the inside of the cutout for a

finished appearance.

Cable Hole

1-1/2" Max DIA.

QQmm DIA.

W : 610 mm

Make sure the edges of the cable

hole are even to avoid damage to

the drain and supply hoses and the

electric cable.

** 28-3/8" to 3!-!/2"

72!-800mm

I

34-1/4to 36-1/8"

_ 870-920mm

Dishwasher door shown

without custom panel or

panel kit

iO

J

3/4" thick

19 mm

CUSTOM PANEL

** Height must be 28-3/8" iVllN.- 31-1/2"

MAX.to accommodate different toe kick

heights.

*** Custom panel must have 1/8" min.

clearance on each side for proper fit in

cabinet cutout.

Page 4

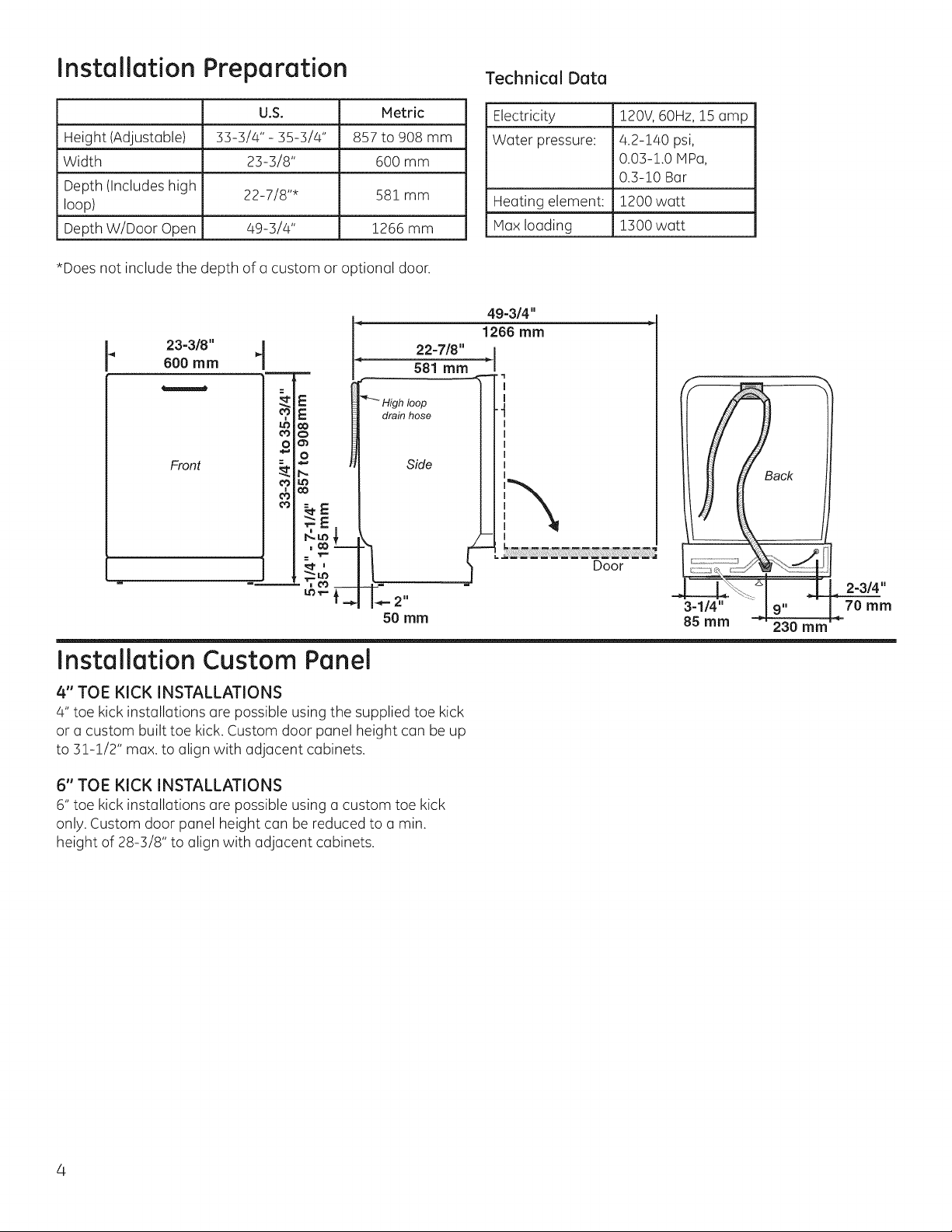

Installation Preparation Technical Data

U.S. Metric

Height (Adjustable) 33-3/4" - 35-3/4" 857 to 908 mm

Width 23-3/8" 600 mm

Depth (Includes high 22-7/8"* 581 mm

loop)

Depth W/Door Open 49-3/4" 1266 mm

*Does not include the depth of a custom or optional door.

23-3/8" ),_

600 mrn

_=,,=,=,=,=,=,=_

Front

m

=-

E

E

¢o

o

o_

o

o

Lo

|

¢o

22=7/8"

581 rnrn

E

Electricity 120V,60Hz, 15 amp

Water pressure: 4.2-140 psi,

0.03-!.0 HPa,

0.3-10 Bar

Heating element: 1200 watt

Max loading 1300 watt

49-3/4"

1266 rnrn

[12"

50 mm

Installation Custom Panel

4" TOE KICK INSTALLATIONS

4" toe kick installations are possible using the supplied toe kick

or a custom built toe kick. Custom door panel height can be up

to 31-1/2" max. to align with adjacent cabinets.

6" TOE KICK INSTALLATIONS

6" toe kick installations are possible using a custom toe kick

only. Custom door panel height can be reduced to a min.

height of 28-3/8" to align with adjacent cabinets.

'-'b

85 mm _ 238 mm _

2=3/4"

70 rnrn

Page 5

Installation Custom Panel

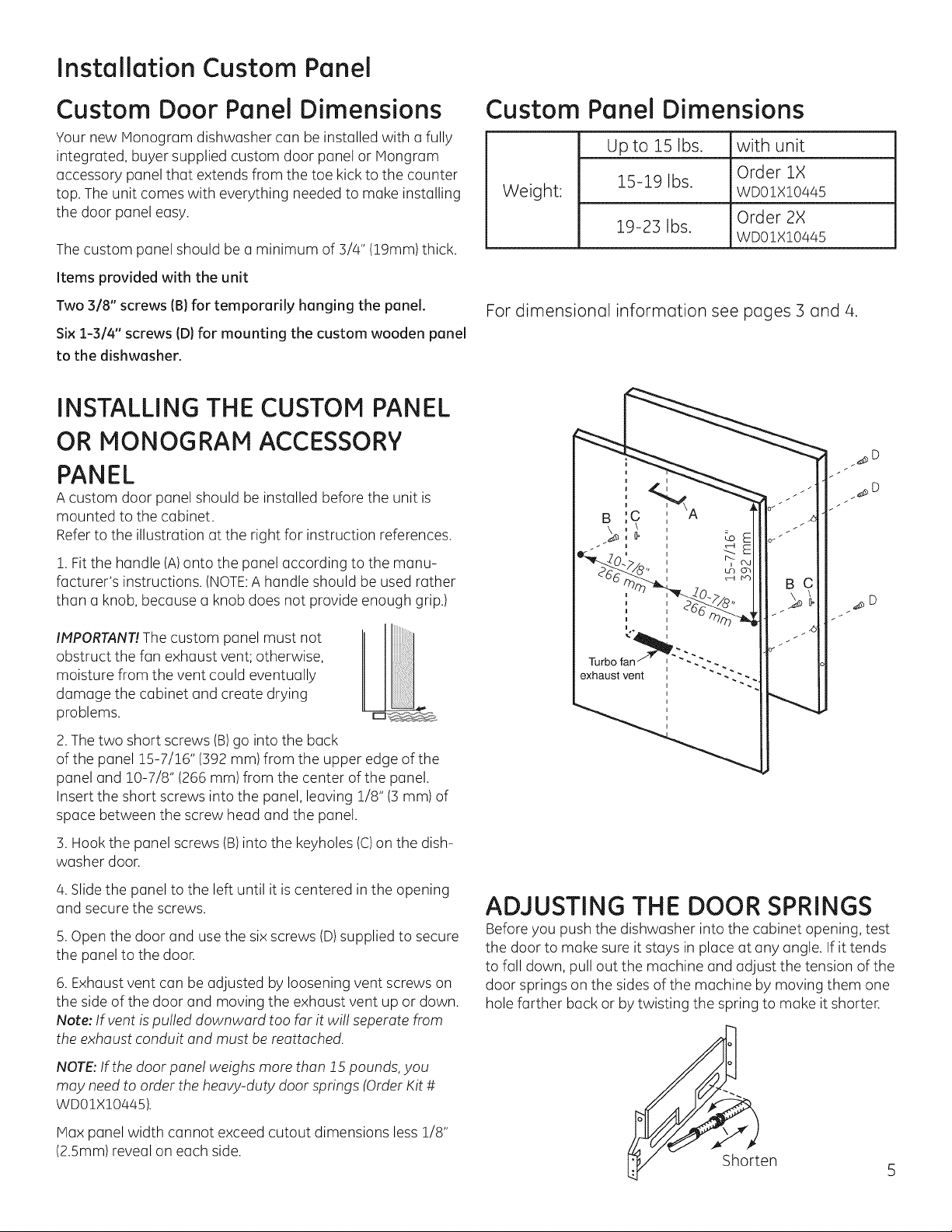

Custom Door Panel Dimensions

Your new Monogram dishwasher can be installed with afully

integrated, buyer supplied custom door panel or Hongram

accessory panel that extends from the toe kick to the counter

top. The unit comes with everything needed to make installing

the door panel easy.

The custom panel should be a minimum of 3/4" (!9mm) thick.

Items provided with the unit

Two 3/8" screws (B)for temporarily hanging the panel.

Six 1-3/4" screws (D)for mounting the custom wooden panel

to the dishwasher.

INSTALLING THE CUSTOM PANEL

OR MONOGRAM ACCESSORY

PANEL

A custom door panel should be installed before the unit is

mounted to the cabinet.

Refer to the illustration at the right for instruction references.

Custom Panel Dimensions

Up to 15 Ibs, with unit

wtnt'"eg": 15-19 Ibs. Order 1X

19-23 Ibs. Order 2X

For dimensional information see pages 3 and 4.

B

WD01X10445

WD01X10445

1. Fit the handle (A)onto the panel according to the manu-

facturer's instructions. (NOTE:A handle should be used rather

than a knob, because a knob does not provide enough grip.)

IMPORTANT!The custom panel must not IJ

obstruct the fan exhaust vent; otherwise,

moisture from the vent could eventually

damage the cabinet and create drying

problems. Ea

2.The two short screws (B)go into the back

of the panel 15-7/16" (392 mm) from the upper edge of the

panel and 10-7/8" (266 mm) from the center of the panel.

Insert the short screws into the panel, leaving 1/8" (3mm) of

space between the screw head and the panel.

3. Hook the panel screws (B)into the keyholes (C)on the dish-

washer door.

4. Slidethe panel to the left until it is centered inthe opening

and secure the screws.

5. Open the door and use the six screws (D)supplied to secure

the panel to the door.

6. Exhaust vent can be adjusted by loosening vent screws on

the side of the door and moving the exhaust vent up or down.

Note: If vent is pulled downward too far it will seperate from

the exhaust conduit and must be reattached.

L

ADJUSTING THE DOOR SPRINGS

Before you push the dishwasher into the cabinet opening, test

the door to make sure it stays in place at any angle. If it tends

to fall down, pull out the machine and adjust the tension of the

door springs on the sides of the machine by moving them one

hole farther back or by twisting the spring to make it shorter.

NOTE:If the door panel weighs more than !5 pounds, you

may need to order the heavy-duty door springs (Order Kit #

WD01X10445).

Max panel width cannot exceed cutout dimensions less 1/8"

(2.Smm)reveal on each side.

en

Page 6

PREPARING THE DISHWASHER FOR INSTALLATION

At this point the styrofoam, plastic wrap, and the wood pallet

(base)should be removed from the dishwasher. Now isan

excellent time to inspect for any shipping damage. Should you

find any damage, you should report it to your dealer or builder

immediately.

Be sure to remove the toe kick and toe kick insulation (only on

certain models) from the top of the dishwasher.

SLIDES FOR LEGS

The unit comes with white plastic slides for ........

the legs to protect the kitchen floor from being ........_._

damaged when you slide the unit into place. _The slides simply snap onto the bottom of the

legs.

Protective slides for legs simply snap onto the

bottom of the legs.

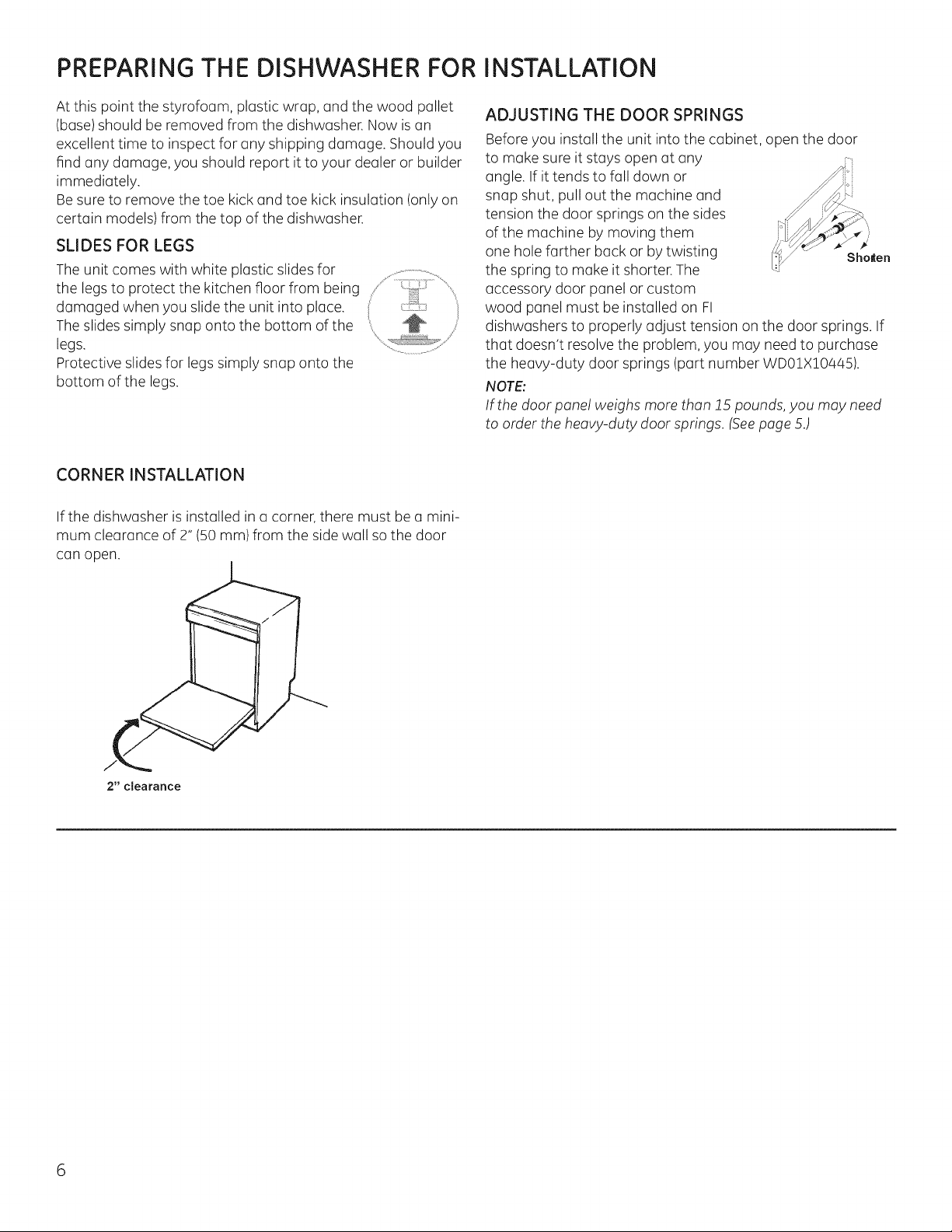

CORNER INSTALLATION

If the dishwasher is installed in a corner, there must be o mini-

mum clearance of 2" (50 mm) from the side wall so the door

can open.

ADJUSTING THE DOOR SPRINGS

Before you install the unit into the cabinet, open the door

to make sure it stays open at any .-

angle. If it tends to full down or

snap shut, pull out the machine and

tension the door springs on the sides

of the machine by moving them

one hole further back or by twisting

the spring to make it shorter. The

accessory door panel or custom

wood panel must be installed on FI

dishwashers to properly adjust tension on the door springs. If

that doesn't resolve the problem, you may need to purchase

the heavy-duty door springs (part number WD01X10/4/45).

NOTE:

If the door pond weighs more than !5 pounds, you may need

to order the heavy-duty door springs. (Seepage 5.)

2" clearance

Page 7

WATER SUPPLY

A WARNING:

Plumbing connections must comply with applicable sanitary, safety and plumbing codes in your area.

The machine can be connected to either a hot or cold water supply. If a cold water supply is used, the washing times will be

longer but the performance will not be affected.

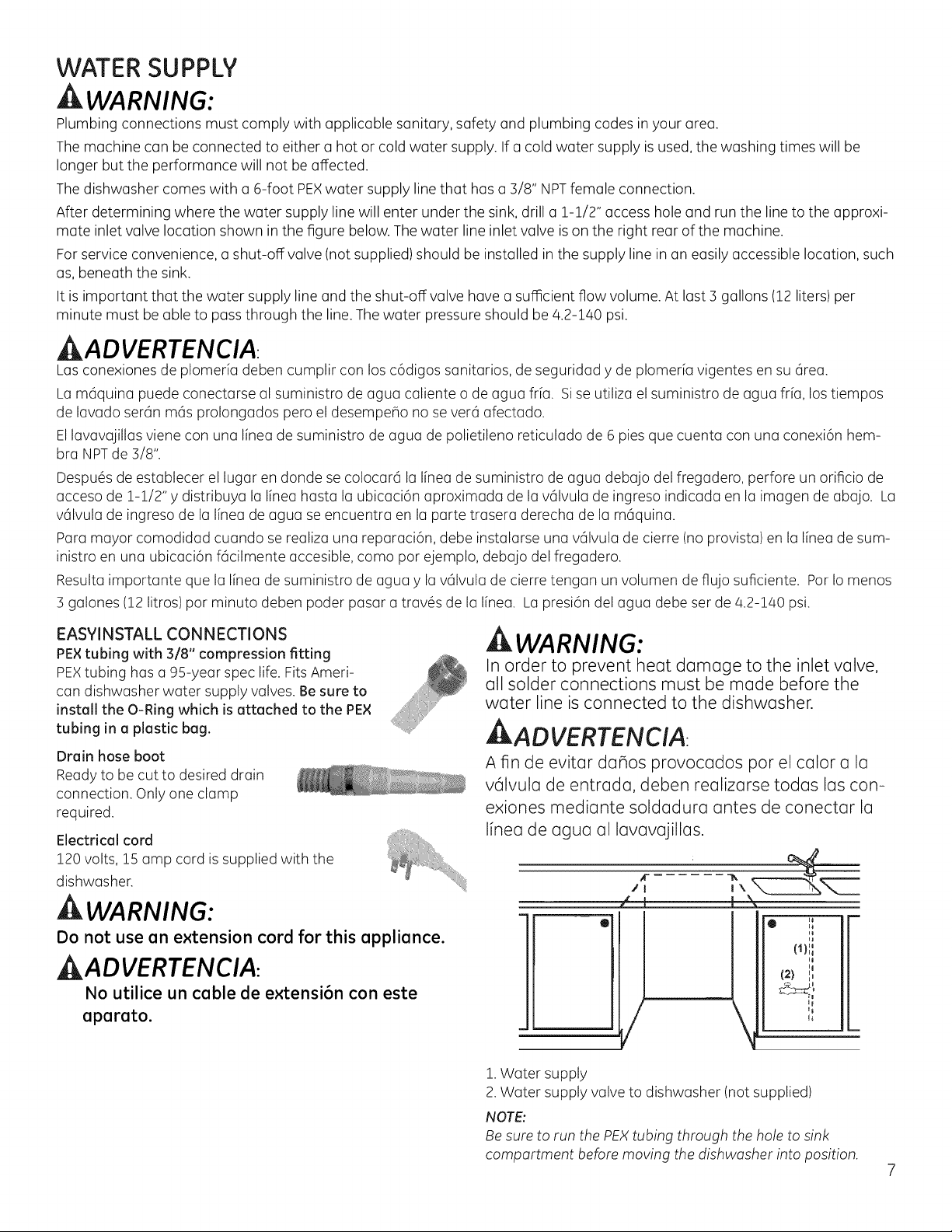

The dishwasher comes with a 6-foot PEXwater supply line that has a 3/8" NPTfemale connection.

After determining where the water supply line will enter under the sink, drill a 1-1/2" access hole and run the line to the approxi-

mate inlet valve location shown in the fgure below. Thewater line inlet valve ison the right rear of the machine.

For service convenience, a shut-off valve (not supplied) should be installed inthe supply line in an easily accessible location, such

as, beneath the sink.

It is important that the water supply line and the shut-off valve have a sumcient flow volume. At last 3 gallons (12 liters) per

minute must be able to pass through the line.The water pressure should be 4.2-140 psi.

ADVERTENCIA:

Las conexiones de plomer[a deben cumplir con los cbdigos sanitarios, de seguridad y de plomer[a vigentes en su _rea.

La m_quina puede conectarse al suministro de agua caliente o de agua frfa. Sise utiliza el suministro de agua if[a, los tlempos

de lavado ser_n m_s prolongados pero el desempe_o no sever_ afectado.

El lavavajillas viene con una I[nea de suministro de agua de polietileno reticulado de 6 pies que cuenta con una conexibn hem-

bra NPTde 3/8".

Despu_s de establecer el lugar en donde secolocar_ la I[nea de suministro de agua debajo del fregadero, perfore un orificio de

acceso de !-!/2" y distribuya la I[nea hasta la ubicacibn aproximada de la v_lvula de ingreso indicada en la imagen de abajo. La

vdlvula de ingreso de la I[nea de agua se encuentra en la parte trasera derecha de la m_quina.

Para mayor comodidad cuando se realiza una reparacibn, debe instalarse una v_lvula de cierre (no provista) en la I[nea de sum-

inistro en una ubicacibn f_cilmente accesible, coma par ejemplo, debajo del fregadero.

Resulta importante que la I[nea de suministro de agua y la v_lvula de cierre tengan un volumen de flujo suficiente. ParIo menos

3 galones (12 litros) par minuto deben poder pasar a travbs de la I[nea. La presibn del agua debe set de 4.2-!40 psi.

EASYINSTALL CONNECTIONS

PEXtubing with 3/8" compression fitting

PEXtubing has u 95-year spec life. Fits Ameri-

can dishwasher water supply valves. Be sure to

install the O-Ring which is attached to the PE×

tubing in a plastic bag.

Drain hose boot

Ready to be cut to desired drain

connection. Only one clamp

required.

Electrical cord

!20 volts, !5 amp cord is supplied with the

dishwasher.

A WARNING:

Do not use an extension cord for this appliance.

ADVERTENCIA:

No utilice un cable de extensi6n con este

aparato.

WARNING:

In order to prevent heat damage to the inlet valve,

all solder connections must be m(]de before the

water line is connected to the dishwasher.

DVERTEN CIA:

A fin de evitGr dGSos provocGdos par el cGIor e la

vblvulo de entradG, deben reGlizGrse todGs las con-

exiones mediGnte soldGdurG antes de conectGr IG

Ifnee de aguG al IGvavajillGs.

#r -1_ _-=_---='-==,_l _:'=====-=

t_

E_

(1)',:

Eg

Ig

I

(2) ,,

_ J

IF

h

1. Water supply

2. Water supply valve to dishwasher (not supplied)

NOTE:

Be sure to run the PEX tubing through the hole to sink

compartment before moving the dishwasher into position.

Page 8

DRAIN CONNECTIONS

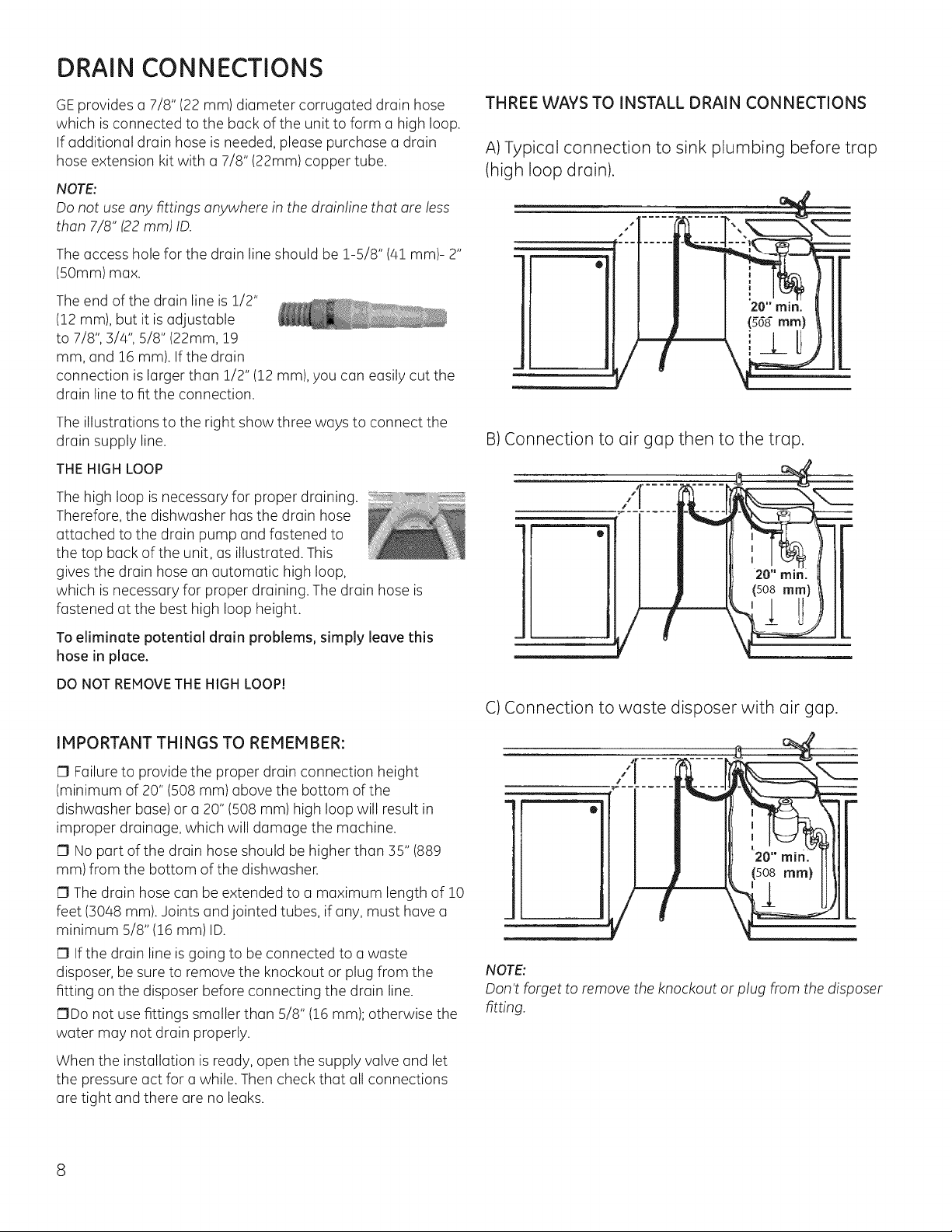

GEprovides a 7/8" (22 mm) diameter corrugated drain hose

which isconnected to the back of the unit to form a high loop.

If additional drain hose is needed, please purchase a drain

hose extension kit with a 7/8" (22mm) copper tube.

NOTE:

Do not use any fittings anywhere in the drainline that are less

than 7/8" (22mm) ID.

The access hole for the drain line should be 1-5/8" (41 mm)- 2"

(50mm) max.

The end of the drain line is 1/2"

(12 mm), but it is adjustable

to 7/8%3/4%5/8" (22mm, 19

mm, and 16 mm). If the drain

connection islarger than 1/2" (12 mm), you can easily cut the

drain line to fit the connection.

The illustrations to the right show three ways to connect the

drain supply line.

THE HiGH LOOP

The high loop is necessary for proper draining.

Therefore, the dishwasher has the drain hose

attached to the drain pump and fastened to

the top back of the unit, as illustrated. This

gives the drain hose an automatic high loop,

which isnecessary for proper draining. The drain hose is

fastened at the best high loop height.

THREE WAYS TO INSTALL DRAIN CONNECTIONS

A) Typical connection to sink plumbing before trap

(high loop drain).

,,'[11

B) Connection to air gap then to the trap.

To eliminate potential drain problems, simply leave this

hose in place.

DO NOT REMOVE THE HIGH LOOP!

IMPORTANT THINGS TO REMEMBER:

I_ Failure to provide the proper drain connection height

(minimum of 20" (508mm) above the bottom of the

dishwasher base) or a 20" (508 mm) high loop will result in

improper drainage, which will damage the machine.

I_ No part of the drain hose should be higher than 35" (889

mm) from the bottom of the dishwasher.

I_ The drain hose can be extended to a maximum length of 10

feet (3048 mm).Joints and jointed tubes, if any, must have a

minimum 5/8" (16 mm)ID.

I_ If the drain line is going to be connected to a waste

disposer, be sure to remove the knockout or plug from the

fitting on the disposer before connecting the drain line.

I_Do not use fittings smaller than 5/8" (16 mm); otherwise the

water may not drain properly.

When the installation is ready, open the supply valve and let

the pressure act for a while. Then check that all connections

are tight and there are no leaks.

C)Connection to waste disposer with air gap.

i'_Ji

.:,.- = --

/

NOTE:

Don't forget to remove the knockout or plug from the disposer

fitting.

Page 9

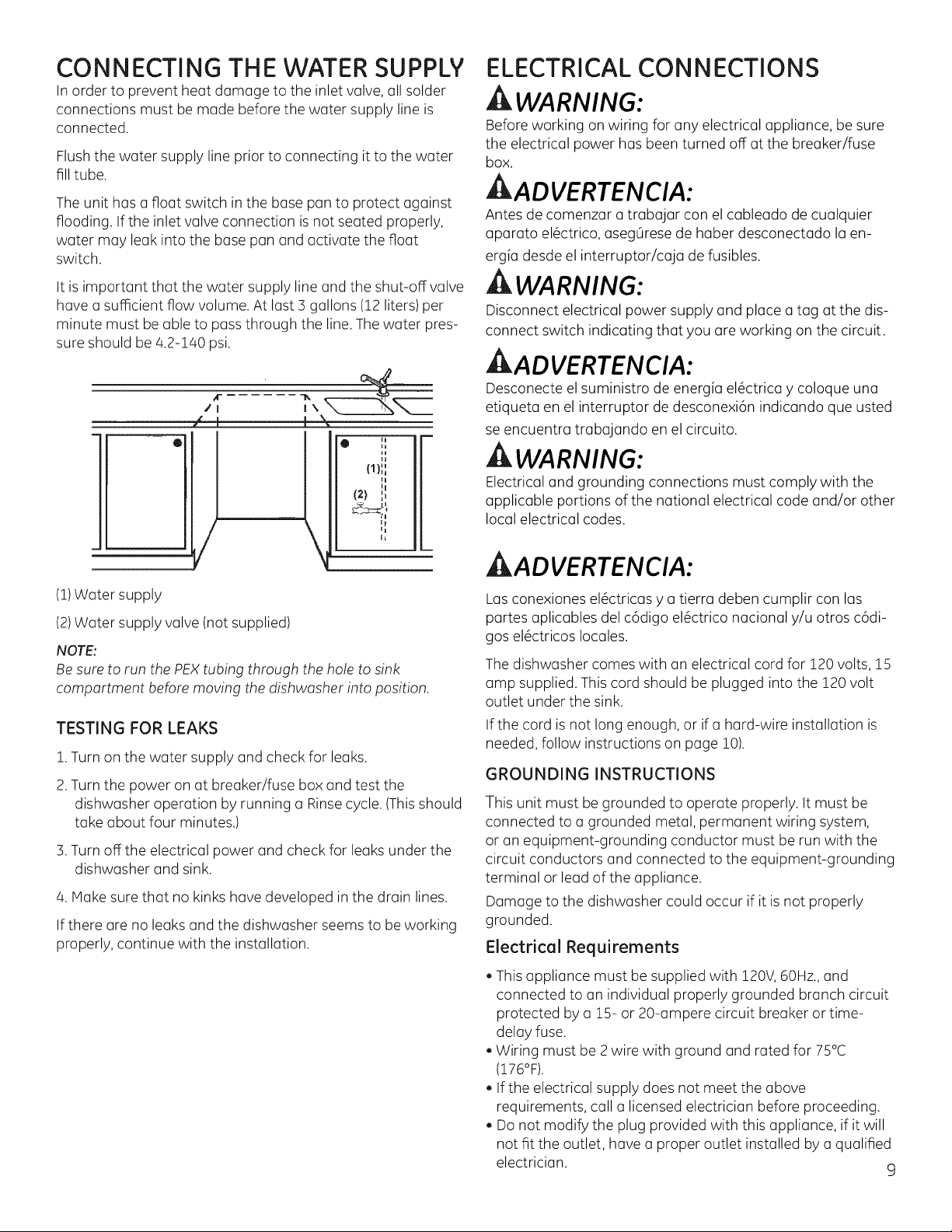

CONNECTING THE WATER SUPPLY

In order to prevent heat damage to the inlet valve, all solder

connections must be made before the water supply line is

connected.

Flush the water supply line prior to connecting it to the water

fill tube.

The unit has a float switch in the base pan to protect against

flooding. If the inlet valve connection is not seated properly,

water may leak into the base pan and activate the float

switch.

ELECTRICAL CONNECTIONS

WARNING:

Before working on wiring for any electrical appliance, be sure

the electrical power has been turned off at the breaker/fuse

box.

, ADVERTENCIA:

Antes de comenzar a trabajar con el cableado de cualquier

aparato el6ctrico, asegOresede haber desconectado la en-

erg[a desde el interruptor/caja de fusibles.

It is important that the water supply line and the shut-off valve

have a sumcient flow volume. At last 3 gallons (12 liters) per

minute must be able to pass through the line.The water pres-

sure should be 4.2-140 psi.

rl

t_

(1)I',

ii

h

(1)Water supply

(2)Water supply valve (not supplied)

NOTE'.

Be sure to run the PEXtubing through the hole to sink

compartment before moving the dishwasher into position.

TESTING FOR LEAKS

1.Turn on the water supply and check for leaks.

2.Turn the power on at breaker/fuse box and test the

dishwasher operation by running a Rinsecycle. (Thisshould

take about four minutes.)

3.Turn off the electrical power and check for leaks under the

dishwasher and sink.

4. Make sure that no kinks have developed in the drain lines.

If there are no leaks and the dishwasher seems to be working

properly, continue with the installation.

WARNING:

Disconnect electrical power supply and place a tag at the dis-

connect switch indicating that you are working on the circuit.

,tkADVERTENCIA:

Desconecte el suministro de energ[a el6ctrica y coloque una

etiqueta en el interruptor de desconexi6n indicando que usted

se encuentra trabajando en el circuito.

WARNING:

Electrical and grounding connections must comply with the

applicable portions of the national electrical code and/or other

local electrical codes.

, ADVERTENCIA:

Las conexiones el6ctricas y a tierra deben cumplir con las

partes aplicables del c6digo el6ctrico nacional y/u otros c6di-

gas el6ctricos locales.

The dishwasher comes with an electrical cord for 120 volts, 15

amp supplied. This cord should be plugged into the 120 volt

outlet under the sink.

If the cord is not long enough, or if a hard-wire installation is

needed, follow instructions on page 10).

GROUNDING INSTRUCTIONS

This unit must be grounded to operate properly. It must be

connected to a grounded metal, permanent wiring system,

or an equipment-grounding conductor must be run with the

circuit conductors and connected to the equipment-grounding

terminal or lead of the appliance.

Damage to the dishwasher could occur if it is not properly

grounded.

Electrical Requirements

. This appliance must be supplied with Z20V,60Hz.,and

connected to an individual properly grounded branch circuit

protected by a 15- or 20-ampere circuit breaker or time-

delay fuse.

. Wiring must be 2 wire with ground and rated for 75°C

(176°F).

. If the electrical supply does not meet the above

requirements, call a licensed electrician before proceeding.

. Do not modify the plug provided with this appliance, if it will

not fit the outlet, have a proper outlet installed by a qualified

electrician. 9

Page 10

ELECTRICAL CONNECTIONS (CANT)

Grounding Instructions-Power Cord Models

This appliance must be grounded. In the event of a

malfunction or breakdown, grounding will reduce

the risk of electric shock by providing a path of

least resistance for electric current. This appliance

is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The

plug must be plugged into an appropriate outlet

that is installed and grounded in accordance with all

local codes and ordinances.

,& WARNING:

Make sure the water supply line, drain line and

branch circuit wiring do not touch any exposed ter-

minals of dishwasher wiring.

AADVERTENCIA:

Verifique que la linea de suministro de agua, linea

de drenuje y cableudo del circuito derivudo no

toquen ningunu terminal expuestu del cubleudo del

luvuvujillus.

The improper connection of the equipment

grounding conductor can result in a risk

of electric shock. Check with a qualified

electrician or service representative if you

are in doubt that the appliance is properly

grounded.

La conexi6n incorrecta del conductor de

conexi6n a tierra del equipo puede resultar

en choque ei_ctrico. Consulte con un

electricista calificado o representante

de servicio si tiene dudas de la conexi6n

a tierra del aparato.

,& WARNING:

Do not use an extension cord for this appliance.

ADVERTENCIA:

No utilice un cable de extensi6n con este aparato.

a_

/I..

- i

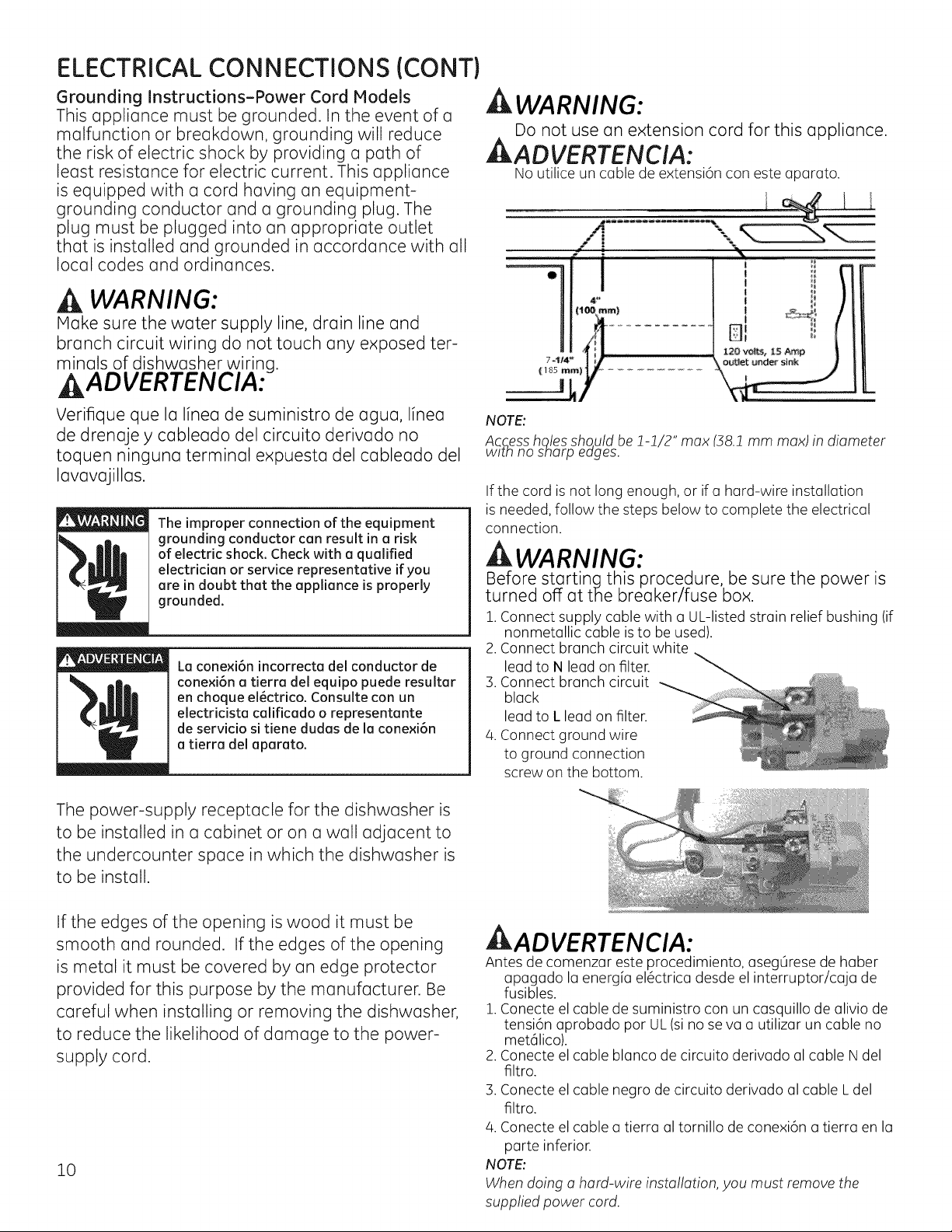

NOTE:

Access holes should be !-!/2" max (38.! mm max) in diameter

wlfl_ no sT_arpe_Iges.

If the cord is not long enough, or if a hard-wire installation

is needed, follow the steps below to complete the electrical

connection.

WARNING:

Before starting this procedure, be sure the power is

turned off at the breaker/fuse box.

1. Connect supply cable with a UL-listed strain relief bushing (if

nonmetallic cable is to be used).

2. Connect branch circuit white

lead to N lead on filter.

3. Connect branch circuit

black

lead to L lead on filter.

/4.Connect ground wire

to ground connection

screw on the bottom.

The power-supply receptacle for the dishwasher is

to be installed in a cabinet or on a wall adjacent to

the undercounter space in which the dishwasher is

to be install.

If the edges of the opening is wood it must be

smooth and rounded. If the edges of the opening

is metal it must be covered by an edge protector

provided for this purpose by the manufacturer. Be

careful when installing or removing the dishwasher,

to reduce the likelihood of damage to the power-

supply cord.

10

AADVERTENCIA:

Antes de comenzar este procedimiento, aseg0rese de haber

apagado la energ[a el6ctrica desde elinterruptor/caja de

fusibles.

1. Conecte el cable de suministro con un casquillo de alivio de

tensi6n aprobado par UL(sino seva a utilizar un cable no

met61ico).

2. Conecte el cable blanco de circuito derivado al cable Ndel

filtro.

3. Conecte el cable negro de circuito derivado al cable L del

filtro.

/4.Conecte el cable a tierra al tornillo de conexi6n a tierra en la

parte inferior.

NOTE:

When doing a hard-wire installation, you must remove the

supplied power cord.

Page 11

FASTENING THE DISHWASHER TO THE CABINET

NOTE:

If the door panel weighs more than !5 pounds, you may need

to order the heavy-duty door springs. (Seepage 5.)

It's necessary to fasten the dishwasher to the cabinet so

it won't tilt when the door isopened or if something heavy

is placed on the door. Use only the stainless steel screws

provided with the machine.

1. Use option A for mounting to underside

of counter-top. Useoption Bfor mount-

ing to cabinet side when counter-top isa

hard surface such as granite.

B

2. Cover the screw heads with the plastic plugs provided with

the machine.

3.When the machine is properly attached, check that the feet

are tight against the floor and that the machine is level.

NOTE:

Be sure to use white spacers to keep from over-tightening the

mounting screws.

MOVING THE MACHINE INTO PLACE

,tkWARNING:

Hake sure you put the protective slides on the legs

to prevent damaging the floor when you slide the

unit into place (see page 9).

1. Position the machine in front of the cabinet opening.

2. Hake the height adjustment while the dishwasher is in front

of the opening.

3. Pull out the drain hose to ensure there are no sharp bends.

4. Start to feed water and drain lines and electric cord (if nec-

essary) into the access hole in the cabinet.

5. Gently slide the unit into the dishwasher opening. As you do

this, feed the drain line and inlet hose into the access hole

in the side of the cabinet.

lit "1

Asyou slide the unit into place, feed the drain line and inlet

hose into the access hole in the side of the cabinet.

WARNING:

Be careful of sharp edges.

,tkADVERTENCIA:

Aseg0rese de colocar los deslizadores protectores en las

patas para evitar duflos ul piso cuundo deslice lu unidud en

su lugar (ver p6gina 9).

1. Coloque la m6quina frente u lu aberturu del gabinete.

2. Realice el ujuste de altura mientrus elluvuvajillus se en-

cuentra frente a la ubertura.

3.Tire de la manguera de drenaje para verificur que no haya

torceduras.

/4.Comience a colocar las lineas de agua y de drenaje y el

cable el6ctrico (sifuera necesario) dentro del orificio de ac-

ceso del gabinete.

5. Suavemente deslice la unidad dentro de la abertura del

lavavajillas. Hientras Io hace, coloque la linea de drenaje y

la manguera de entrada dentro del orificio de acceso en el

lado del gabinete.

DVERTEN CIA:

Tenga cuidado con los bordes afitados.

11

Page 12

LEVEL DISHWASHER

IMPORTANT Dishwasher must be levelfor proper

dish rack operation, wash performance and door operation.

The dishwasher must be leveled left to right and front to back.

This assures the dish racks will not roll in or out on their own,

circulation water will flow to the pump inlet, and the door will

close without hitting the side of the tub.

. Remove the lower dish rack and place a level on the door and

lower rack track.

. Adjust the level of the dishwasher by individually turning the

four legs on the bottom of the dishwasher.

. The dishwasher isproperly leveled when the level indicator is

centered left to right and front to back. Also, the dishwasher

door should close without hitting the side of the tub.

. Replace the lower rack.

1. Loosen the mounting screws on the dishwasher's

two front steel feet using a 5/8 inch (16mm) open-

ended wrench. Screw the mounting screws down

as close to the floor as possible.

Tip: Prevent unnecessary service charges. Verify dishwasher

is leveled.

Pull the dish racks half way out. They should stay put. Open

and close the door. The door should fit in the tub opening

without hitting the side of the tub. Ifthe racks roll on their own,

or the door hits the side of tub, re-level the dishwasher.

2. Adjust the height of the dishwasher by turning

the front steel feet with your hands. Leave enough

space to adjust them later.

12

.................... i f .....................

......... /:

rx

kJ'

©

Page 13

LEVEL DISHWASHER (CONT}

3. Screw in the back foot completely by turning the

adjustment screw at the front counterclockwise.

Use a flat-bladed or a 1/4 inch nut driver.

4. Push the plastic feet into place on all three steel

feet (included in document bag).

NOTE:

Do not attach the plastic feet if the installation space

is of minimum height.

5. Push the dishwasher into the cavity. At the same

time, pull the electric cable and drainage and supply

hoses through the cable hole.

13

Page 14

LEVEL DISHWASHER ICONT}

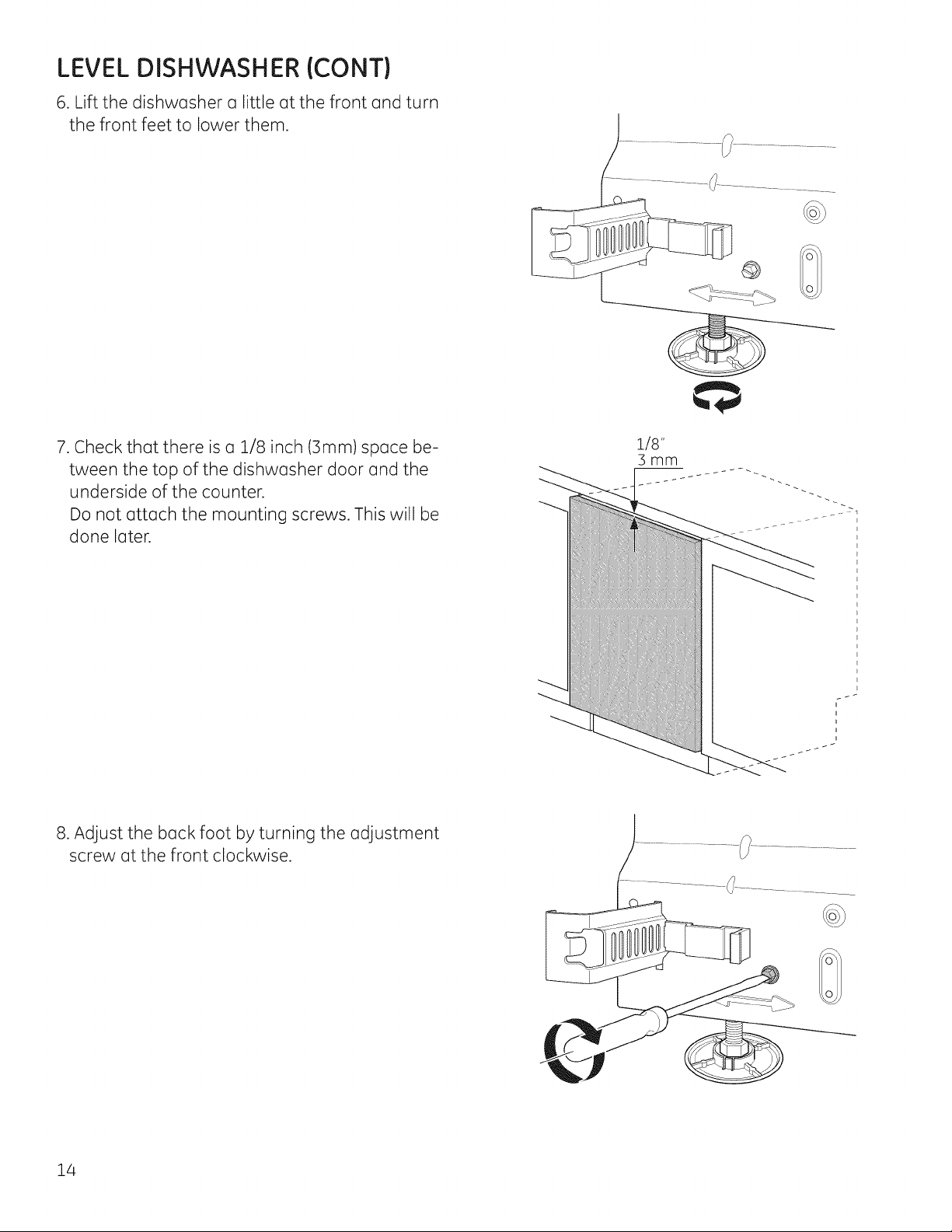

6. Lift the dishwasher (] little at the front and turn

the front feet to lower them.

7. Check that there is o 1/8 inch (3mm) space be-

tween the top of the dishwasher door and the

underside of the counter.

Do not ottoch the mounting screws. This will be

done later.

8. Adjust the back foot by turning the adjustment

screw at the front clockwise.

1/8"

3mm

i

i

i

i

i

14

Page 15

LEVEL DISHWASHER (CONT)

9. Place the spirit level on the dishwasher door to

check that the machine is level and adjust if nec-

essary. The door must be fully closed!

NOTE:

The dishwasher must be level!

An unlevel machine can affect the amount of water

taken in, the door can be difficult to close, and the

baskets difficult to place securely.

INSTALLING THE TOE KICK

SETTING THE TOE KICK DEPTH

I I

1. Pressthe grey catches towards each other to release the

toe kick brackets.

2. Pull out the toe kick brackets as far as the installation re-

quires to provide the proper toe kick depth.

3. Once the toe kick brackets are at the appropriate depth,

press the grey catches away from each other to lock the

toe kick brackets in place.

4.The back side of the toe kick has hooks that will hang the

toe kick on the toe kick brackets. Lift the toe kick up and let

the hooks slide onto the brackets as you lower the toe kick

to the floor.

15

Page 16

INSTALLATION CHECK LIST

Appliance Installation Checklist

• Remove packaging and check for cosmetic damages.

• Remove the information packets from inside the dishwasher.

• Attach any accessories as required by the installation. Fill strips, wooden door

panels, accessory door panels...

• Attach the drain line using the largest section of the disposer boot allowable.

Leave the high loop in place.

• Attach the PEX fill hose. Don't forget to use the O-ring.

• Plug the dishwasher into the wall.

• Turn on the water and check the fill line connections for leaks.

• Slide the unit into the cabinet and level the machine front to rear, and left to

right.

• Mount the unit to the cabinet.

• Turn the power to the unit on and start a cycle. Make sure there are no drain

leaks.

• Show the customer their warranty card, and help them locate the model and se-

rial number on the unit.

• Leave all user books for consumer.

36

Page 17

Instructions d'instailation

Lave-vaisse e encastr

Pourtoute question, appelez le 800.GE.CARES(800.432.2737) or consultez notre site internet" GEAp-

pliances.com.

AuCanada, appelez le 1.800.561.3344ou consultez le site internet www.geappliances.ca

AVANT DE COMMENCER

LISEZCESINSTRUCTIONSENTII_REMENTET

ATTENTIVEMENT.

M PORTANT - Respecteztouslescodeset

reglementsenvigueur.

. Remarque pour l'installateur- Assurez-vousderemettre

ces instructions a I'utilisateur et a I'inspecteur local.

Remarque pour I'Utilisateur- Conservez ces instructions

avec votre notice d'utilisation pour toute r6f@ence future.

Niveau de competence - L'installation de cet appareil

demande des connaissances de base en m6canique, en

61ectricit_ et en plomberie. L'installateur est responsable de

I'installation correcte de I'appareil. La panne de I'appareil

due (3une mauvaise installation n'est pas couverte par

la garantie GEElectrom_nagers. Veuillez consultez les

informations sur la garantie.

D_lai d'ex_cution - 1 a 3 heures. Lespremieres installations

demandent plus de temps que les installations de

remplacement.

LIRE ATTENTIVEMENT.

CONSERVEZ CES INSTRUCTIONS

IM PORTANT - Le lave-vaisselleDOIT@treinstall6

de mani@e a permettre le retrait ult@ieur de I'enceinte afin de

permettre toute intervention.

Sivous recevez un lave-vaisselle endommag@, contactez

imm6diatement votre vendeur ou votre installateur.

Accessoires en option - Consultez le Manuel d'Utilisation pour

les ensembles de panneaux sur mesure.

POURVOTRESECURITE

Lisez et respectez tous les AVERTISSEMENTSet MBES EN

GARDEdorm,s dans cette notice. IIest recommand_ de

porter des gants et des lunettes de s_curit_ ou des lunettes

_tanches lors de Pinstallation de cet appareil.

31-30264 09/23/10 GE

Page 18

Preparation pour I'installation

OUTILLAGE NI_CESSAIRE •

CI Tournevis cruciforme No. 2

CI Tournevis 6t_te plate

CI Tournevis Torx T 20

CI CI_6 molette

CI CI6anglaise (!/2po [12 mm] ou 5/8po [16 mm])

CI Ruban 6 mesurer

CI Lunettes de s6curit6

CI Torche

CI Seau pour collecter I'eau Iors de la vidange du tuyau

CI Gants

CI Niveau

Pour les premieres installations uniquement"

CI Coupe-tube

CI Perceuse et forets appropri6s

CI Sciecylindrique _-_

Gants

-___._ Nivea u

Tourne_e'_ Tournevis Tor-'_

plate taille T 20

CI6 6 molette

Ruban 6 mesurer

CI_ anglaise

Lunettes de s_curit_

Torche

Seau forets

MATERIAU×

C! Tube en cuivre de diam_tre externe minimum de 3/8 poet

d'une Iongueur suffisante pour votre installation

C! Robinet de sectionnement et accessoires pour le tube

d'alimentation d'eau

Page 19

Preparation pour I'installafion

MESURE DE L'ENCEINTE DU LAVE-VAISSELLE

®

90°

2-4po

50 -!05 mm

* La largeur r@elledu lave-vaisselle......... ......perme_-,__,, _ u t

I'installation dans une ouverture de 23-5/8

po. Si lepanneau en acier inox en option

(ZXSS9900)est utilis6, rouverture doit @tre

de 24 po.

REMARQUE : Une ouverture de 24 po de-

mande des travaux suppl_mentaires sur

I'int_rieur de I'ouverture pour un aspect

fini.

Ouverture pour le

cablel-1/2po DIA.

maxDIA 44 mm

• W_6}Omn_ ..

O

Assurez-vous que les bords de

I'ouverture pour le cable soient bien

lissespour 6viter tout dommage aux

tuyaux d'alimentation et d'6vacuation

ainsi qu'au cable d'alimentation.

La porte du lave-vaisselle

est montr6e sans panneau

sur mesure ou sans pan-

neau en kit.

34-!/4po 6 36-

E !/8po

::0

oo I70-920 mm

J

sApo

d'6paisseur19

mm

PANNEAU SUR MESURE

** La hauteur doit _tre de 28-3/8 po IVllN

- et de 31 V2po MAXpour s'adapter aux

diff@entes hauteurs de plinthe.

*** Lepanneau sur mesure doit avoir un

d@gagementde 1/8 po min de chaque

c6t6 pour une bonne installation dans

I'enceinte.

Page 20

Pr pa ration Donn_es techniques

pour I'installation

U.S. Metric

Hauteur (ragluble) 857 to 908 mm

33-3/4po - 35-

3/4po

Lurgeur 600 mm

Profondeur (Inclut le 581 mm

tuyuu suraleva)

Profondeur uvec 16 1266 mm

porte ouverte

23-3/8po

22-7/8po*

49-3/4"

Electricit6 120V,60Hz, 15 amp

Pression 4.2-140 psi,

d'ulimentution : 0.03-1.0 MPG,

0.3-10 Bar

El#ment chuuf- 1200 watt

runt :

L

Charge max 1300 watt

*N'inclut pus lu profondeur d'un porte sur mesure ou en option.

49-3/4po

1266 mm

23-3/8po _1600 mm

Avant o

O

O_

E

r_

E

i

t_

oo

r-r3

O

Oh

,ED

O_

Lr3

r_

OO

i

O

r_

C)_

22-7/8po

m 581 mm

sur#lev i

Cat#

_c_

.°T

-.1- L!h

Ln

]-i 2po -

50 mm

Installation d'un panneau sur mesure

INSTALLATIONS D'UNE PUNTHE DE 4 PO

Les installations de plinthe de 4po sont possibles en utilisant la plinthe

fournie ou une plinthe sur mesure. La hauteur des panneaux de porte sur

mesure peut allerjusqu'5:31-1/2 po max. pour _tre align# avec les meubles

de cuisine adjacents.

INSTALLATIONS D'UNE PLINTHE DE 6 PO

Les installations de plinthe de 6po sont possibles en utilisant uniquement

une plinthe sur mesure. La hauteur des panneaux de porte sur mesure peut

allerjusqu'a 28-3/8 po max. pour _tre align6 avec les meubles de cuisine

adjacents.

3-1/4p

85 mm

i

2-3/4po

70 mm

Page 21

Installation d'un panneau sur mesure

Dimensions d'un panneau de porte sur mesure

Votre nouveau lave-vaisselle Monogram peut _tre compl_te-

ment encastr6, install6 avec un panneau de porte sur mesure

ou un panneau Honogram qui va de la plinthe au comptoir.

Cet appareil est fourni avec tousles 616mentsn6cessaires 6

une installation de panneau de porte facile.

Le panneau sur mesure doit avoir une 6paisseur minimale de

sApo (19 mm).

I_l_ments fournis avec I'appareil

Deux vis de 3/8 po (B) pour suspendre temporairement le

panneau.

Sixvis de 1-3/4 po (D} pour fixer le panneau en bois sur

mesure au lave-vaisselle.

INSTALLATION DU PANNEAU SUR

MESURE OU DU PANNEAU ACCES-

SOIRE MONOGRAM

Un panneau de porte sur mesure doit _tre mis en place avant

que I'appareil ne soit install6 dans le meuble.

R6f@ez-vous aux illustrations donn6es 6 droite.

Dimensions d'un panneau sur mesure

Jusqu% 25 lb. avec I'appareil

Poids : WD01X10445

15-19 lb.

19-23 lb.

Commander 1X

Commender 2X

WD01X10445

Pour toute information sur les dimensions, voir

pages 3 et/4.

B

c

i. Installez lapoign6e (A)sur le panneau selon les instruc-

tions du fabricant. (REHARQUE:11est pr6f@able d'utiliser une

poign6e plut6t qu'un bouton, parce qu'un bouton ne donne

pas sulTisamment de prise.)

IMPORTANT!Le panneau sur mesure ne

doit pas obstruer I'_vent du conduit de

ventilation, I'humidit6 pourrait 6ventuelle-

ment endommager les meubles de cuisine

et poser des probl_mes de s6chage.

2. Lesdeux vis courtes (B)sont install_es (_I'arri@e du panneau

(_15-7/16 po (392 mm) du bord sup@ieur du panneau et (_10-

7/8po (266 mm) du centre du panneau. Ins@ezlesvis courtes

dans le panneau, en laissant 1/8po (3mm) entre la t_te devis

et le panneau.

3. Accrochez lesvis du panneau (B)dans les trous de serrure

(C)sur la porte du lave-vaisselle.

4. Faites glisser le panneau vers la gauchejusqu% ce qu'il soit

centr6 sur I'ouverture et fixez les vis.

5. Ouvrez la porte et utilisez les six vis (D)fournies pour fixer le

panneau (_la porte

6. Le conduit de ventilation peut _tre ajust6 en desserrant les

vis de la ventilation sur le c6t6 de la porte et en d6plaqant le

conduit de ventilation vers le haut ou vers le bas.

_D

Eve "

le ventilateur

double flux

...iii. i"

i

i

REGLAGE DES RESSORTSDE

PORTE

Avant de pousser le lave-vaisselle dans I'enceinte r6serv_e (3

cet effet, testez la porte pour s'assurer qu'elle reste en place

quelle que soit sa position. Si elle a tendance 6 tomber, sortez

le lave-vaisselle de I'enceinte et ajustez la tension sur les res-

sorts de la porte sur lesc6t6s de I'appareil en lesd@laqant

d'un trou ou en tournant le ressort pour qu'il soit plus court.

RENARQUE : Si vous d6placez trop 1'6vent vers le bas, il se

d@achera du conduit de ventilation et devra _tre fix6 (%nou-

veau.

RENARQUE:Si le panneau de la porte p_se plus de 15 livres,

vous aurez peut-_tre besoin de commander des ressorts de

porte plus r6sistants (Commander I'ensemble # WD01X10445).

La largeur maximale du panneau ne peut d_passer lesdimen-

sions de I'ouverture moins un espace de 1/8 po (2,5 mm) de

chaque c6t&

_!!accourcir

Page 22

PRI PARATION DU LAVE-VAISSELLE POUR L'INSTALLATION

Retirez la mousse de polystyr6ne, I'emballage plastique et la

palette en bois (base) du lave-vaisselle. Le moment est alors

id6al pour v6rifier que le lave-vaisselle n'a pas 6t6 endommag6

par I'exp6dition. En cas de dommages, il est important de le

signaler imm6diatement 6 votre revendeur ou installateur.

Assurez-vous d'avoir retir6 la plinthe et I'isolation de la plinthe

(uniquement sur certains mod61es)du haut du lave-vaisselle.

GLISSOIRS POUR LES PtEDS

L'appareil est livr6 avec des glissorrs en

plastique blancs (3placer sous les pieds du ;

lave-vaisselle, pour prot6ger le sol de la cuisine ._

Iorsque vous faites glisser le lave-vaisselle dans

I'enceinte. .........

Les glissoirs se fixent tout simplement (3la base

des pieds.

Les glissoirs de protection se fixent tout simplement (3la base

des pieds.

INSTALLATION DANS UN COIN

Pour une installation dans un coin, laissez un d6gagement

minimal de 2 po (50 mm) entre le lave-vaisselle et lemur adja-

cent pour que 16porte puisse d'ouvrir.

RE_GLAGE DES RESSORTS DE PORTE

Avant d'installer I'appareil dans son enceinte, ouvrez 16porte

et 6ssurez-vous qu'elle reste ouverte. .-

Si elle a tendance (3tomber ou (3se

refermer, sortez le lave-vaisselle de

I'enceinte et ajustez la tension sur les

ressorts de la porte sur les c6t6s de

I'appareil en lesd6plaqant d'un trou

ou en tournant le ressort pour qu'il courcir

soit plus court. Le panneau de porte

6ccessoire ou le panneau en bois sur

mesure doit 6tre install6 sur le lave-vaisselle pour permettre

de r6gler correctement la tension des ressorts de porte. Si

le probl6me n'est pas r6solu, il sera peut-6tre n6cessaire

d'acheter un ressort de porte plus r6sistant (num6ro de pi6ce

WD01X!0445).

REPIARQUE:

Si le panneau de la porte p_seplus de 15 livres, vous aurez

peut-_tre besoin de commander des ressorts de porte plus

rdsistants. (Voirpage 5).

D@gagement2po

Page 23

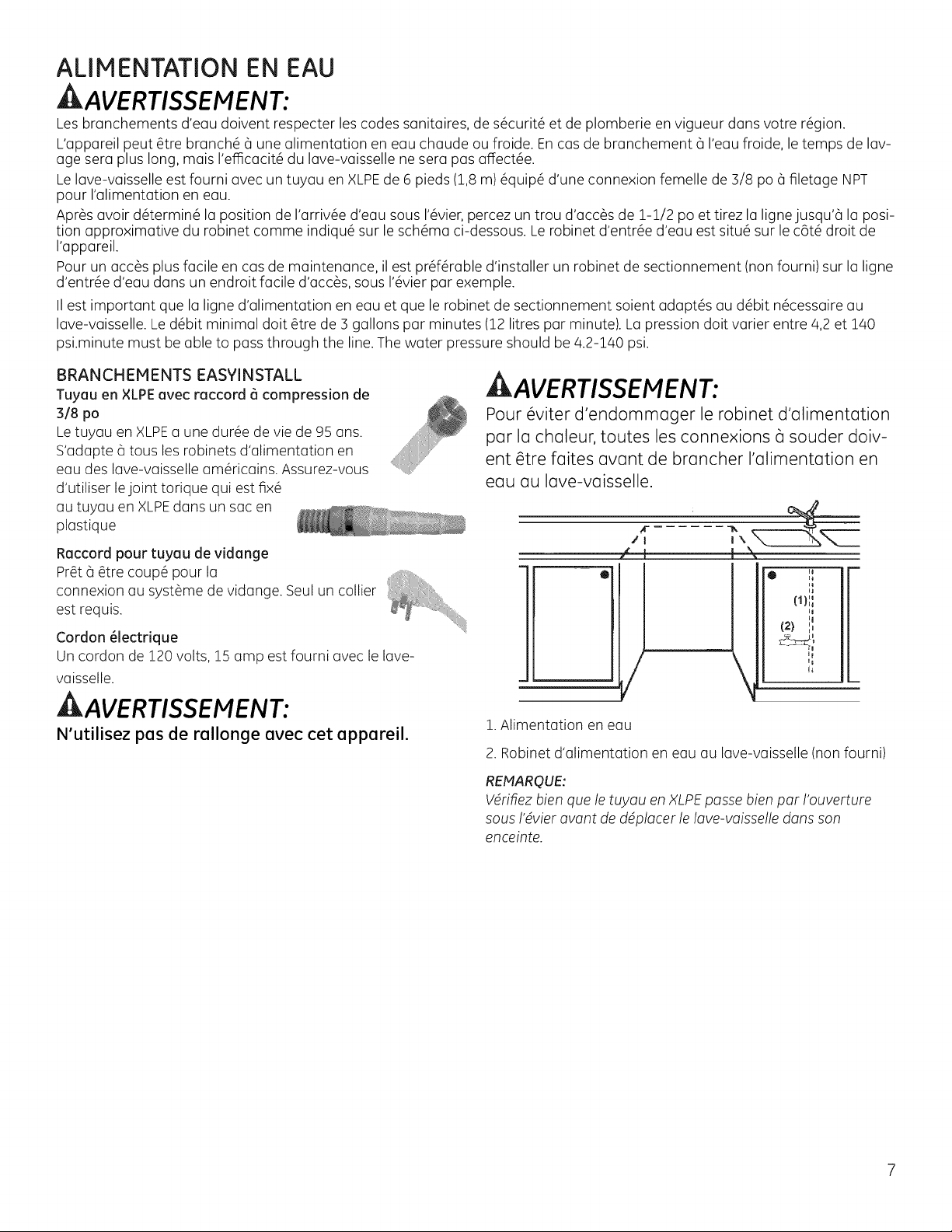

ALIMENTATION EN EAU

,AVERTISSEM ENT:

Les branchements d'eau doivent respecter les codes sanitaires, de s6curit6 et de plomberie en vigueur dans votre r6gion.

L'appareil peut _tre branch6 6 une alimentation en eau chaude ou froide. En cas de branchement (_I'eau froide, le temps de lay-

age sera plus long, mais I'el_cacit6 du lave-vaisselle ne sera pas affect6e.

Le lave-vaisselle est fourni avec un tuyau en XLPE de 6 pieds (1,8 m) 6quip6 d'une connexion femelle de 3/8 po (_filetage NPT

pour I'alimentation en eau.

Apr_s avoir d@ermin6 la position de I'arriv6e d'eau sous 1'6vier,percez un trou d'acc_s de i-i/2 poet tirez la ligne jusqu'(_ la posi-

tion approximative du robinet comme indiqu6 sur le sch6ma ci-dessous. Le robinet d'entr6e d'eau est situ6 sur le c5t6 droit de

I'appareil.

Pour un acc_s plus facile en cas de maintenance, il est pr6f@able d'installer un robinet de sectionnement (non fourni) sur la ligne

d'entr6e d'eau dans un endroit facile d'acc_s, sous 1'6vier par exemple.

II est important que la ligne d'alimentation en eau et que le robinet de sectionnement soient adapt6s au d6bit n6cessaire au

lave-vaisselle. Le d6bit minimal doit _tre de 3 gallons par minutes (12 litres par minute). La pression dolt varlet entre 4,2 et 140

psi.minute must be able to pass through the line. The water pressure should be 4.2-140 psi.

BRANCHEMENTS EASYINSTALL

Tuyau en ×LPE avec raccord 6 compression de

3/8 po

Le tuyau en XLPE a une dur6e de vie de 95 ans.

S'adapte 6 tousles robinets d'alimentation en

eau des lave-vaisselle am@icains. Assurez-vous

d'utiliser lejoint torique qui est fix6

au tuyau en XLPE dans un sac en

plastique

Raccord pour tuyau de vidange

Pr_t 6 _tre coup6 pour la

connexion au syst_me de vidange. Seul un collier

est requis.

Cordon _lectrique

Un cordon de 120 volts, 15 amp est fourni avec le lave-

vaisselle.

AVERTISSEMENT:

N'utilisez pes de rellonge evec cet eppereil.

AVERTISSEMENT:

Pour _viter d'endommuger le robinet d'utimentution

par lu chuleur, toutes les connexions 5 souder doiv-

ent _tre fuites uvunt de bruncher I'ulimentution en

euu uu luve-vuisselle.

t_

E_

(1)ll

ii

II

i

(2) ,,

_ J

IF

H

!. Alimentation en eau

2. Robinet d'alimentation en eau au lave-vaisselle (non fourni)

REMARQUE:

Vdrifiez bien que le tuyau en XLPEpasse bien par I'ouverture

sous I'dvier avant deddplacer le lave-vaisselle dans son

enceinte.

Page 24

BRANCHEMENTS AU SYSTI ME DE

VIDANGE

GEfournit un tuyau de vidange ondul6 de 7/8 po de diam_-

tre (22 mm) qui est brunch_ (_I'arri_re du lave-vuisselle pour

former une boucle sur61ev6e. Si un tuyuu de vidange sup-

pl6mentuire est n6cessaire, veuillez acheter une extension de

tuyau de vidange comprenant un tube en cuivre de 7/8 po (22

mm).

RENARQUE:

N'utilisez pas deraccord sur laligne de vidange qui a un

diam@treintdrieur infdrieur 8 7/8 po (22 ram).

Le trou d'acc_s pour le tuyau de

vidange doit _tre de 1-5/8 po (41

mm)jusqu'6 2 po (50 mm) max.

L'extr6mit_ du tuyuu de vidunge

est d'1/2 po (12 mm) muis est

r6glable 6 7/8 po, SApo,5/8 po (22 mm, !9 mm et !6 mm). Si

le ruccord de vidange est plus large que 1/2po (12 mm), vous

pouvez facilement d6couper la ligne de vidunge pour qu'elle

s'adapte 6 ce raccord.

Le schema de droite vous donne trois exemples de connexion

5 la ligne de vidange.

BOUCLESURELEVI_E

TROIS MI_THODES DE BRANCHEMENTS DES

TUYAU× DE VIDANGE

A)Connexion typique 6 lu tuyuuterie d'un 6vier event

le siphon (tuyuu de vidunge uvec boucle sur_lev_e)

B)Connexion uu dispositif unti-retour puis uu si-

phon.

La boucle sur61ev6eest n6cessaire pour

permettre une vidange efiqcace.Ainsi, le tuyau

de vidange du lave-vaisselle est branch6

6 la pompe de vidange et fix6 6 la partie

sup6rieure de I'appareil, comme indiqu6 sur le sch6ma. Ceci

cr6e automatiquement une boucle sur61ev6edans letuyau de

vidange, ce qui est n6cessaire (_un fonctionnement correct. Le

tuyau de vidange est fix6 6 la hauteur la plus appropri6e.

Pour _liminer tous les probl_mes potentiels eu niveeu de le

videnge, leissez simplement le tuyeu dens cette position.

NE RETIREZ PAS LA BOUCLE SURELEVEE

IMPORTANT:

El Si une hauteur ad6quate pour le branchement de la

vidange (hauteur minimale de 20 po / 508 mm)au dessus

de la base du lave-vaisselle) ou une boucle sur61ev6ede 20

po (508 mm) n'est pas utilis6e, le lave-vaisselle pourrait _tre

endommag&

IE!Aucune partie du tuyau de vidange ne doit _tre plus 61ev6e

que 35 po (889 mm) de la base du lave-vaisselle.

IEILetuyau devidange peut avoir une Iongueur maximale de

10 pieds (3048 mm). Lesjoints et lestubes articul6s doivent

avoir un diam_tre int6rieur de 5/8 po (16 mm).

Si le tuyau de vidange doit _tre connect_ 6un broyeur 6

d6chets, assurez-vous de retirer la d_bouchure ou lebouchon

du raccord sur le broyeur avant de connecter le tuyau de

vidange.

CIN'utilisez pas de raccord de diam_tre inf6rieur 6 5/8 po (16

mm), I'eau ne s'_vacuerait pas correctement.

Lorsque I'installation est termin6e, ouvrez le robinet

d'alimentation et laissez la pression s'6quilibrer quelques

instants. Puis v6rifiez que toutes les connexions sont bien

serr6es et sans fuite.

C)Connexion ou broyeur de d6chet ovec dispositif

untbretou r.

_'#'1"I

/

REPIARQUE:

N'oubliez pas deretirer la ddbouchure ou le bouchon du

raccord du broyeur.

Page 25

BRANCHEMENT

BRANCHEMENTS I LECTRIgUES

L'ALIMENTATION D'EAU

Pour 6viter d'endommager le robinet d'alimentation par la

chaleur, toutes les connexions 6 souder doivent _tre faites

avant de brancher I'alimentation en eau

Purgez le tuyau d'alimentation en eau avant de le brancher au

tuyau de remplissage.

L'appareil est 6quip6 d'un contacteur 6 flotteur dans la cuve

du fond pour 6viter tout d6bordement. Si le branchement du

robinet d'alimentation n'est pas correctement effectu6, I'eau

pourrait fuir dans la cuve et activer le contacteur 6 flotteur.

II est important que la ligne d'alimentation en eau et que le

robinet de sectionnement soient adapt6s au d6bit n6cessaire

r_

t_

(1)i',

ii

h

AVERTISSEMENT:

Avant de commencer I'installation _lectrique de

tout appareil, assurez-vous d'avoir d@connect_

I'alimentation _lectrique au niveau du disjoncteur /

boTte (_fusible

AVERTISSEMENT:

D_connectez I'alimentation _lectrique et placez un

panneau au niveau de I'interrupteur/disjoncteur

pour signaler que vous effectuez des travaux sur le

circuit @lectrique.

AVERTISSEMENT:

Les connexions @lectriques et les mises 6 la terre

doivent @re conformes aux sections applicables

du code @lectrique national et/ou (_tout autre code

@lectrique local en vigueur.

Le lave-vaisselle est livr_ avec un cordon d'alimentation de

!20 volts et de !5 amp. Cecordon doit _tre branch6 dans une

prise de 120 volts situ6e sous 1'6vier.Silecordon n'est pas as-

sez long ou si un c@blagefixe est requis, suivez les instructions

donn6es en page 10.

INSTRUCTIONS DE MISE A LATERRE

au lave-vaisselle. Le d6bit minimal doit _tre de 3 gallons par

minutes (!2 litres par minute). La pression de I'eau dolt varier

entre 4,2 et !40 psi.

(!) Alimentation en eau

(2)Robinet d'alimentation en eau au lave-vaisselle (non fourni)

REt_AROUE:

Vdrifiez que le tuyau en XLPE passe bien par I'ouverture sous

I'dvier avant de pousser le lave-vaisselle dans son enceinte.

VITRIFICATION DE L'ABSENCE DE FUITES

1. Ouvrez doucement I'alimentation d'eau et v@ifiez qu'il n'y a

pas de fuite.

2. Branchez I'alimentation 61ectrique au niveau du disjoncteur

/ boTte(3fusible et testez le fonctionnement du lave-

vaisselle en effectuant un cycle Rinse (Rinqage).(Cecidevrait

prendre 4 minutes).

3. D6branchez I'alimentation 61ectrique et v@ifiez I'absence de

fuite sous le lave-vaisselle et sous 1'6vier.

4.V@ifiezque lestuyaux de vidange ne sont pas tordus.

Sivous ne constatez aucune fuite et que le lave-vaisselle

semble fonctionner correctement, continuez I'installation.

Cet appareil doit _tre mis (_la terre pour fonctionner correcte-

ment. IIdoit _tre connect6 (_une pattie m@allique mise (_la

terre ou (_une borne de terre ou bien un fil de mise (_la terre

doit _tre install6 avec les fils d'alimentation et branch6 (_la

borne de terre de I'appareil ou (_un fil sur I'appareil.

Le lave-vaisselle pourrait _tre endommag6 s'il n'6tait pas cor-

rectement mis (_la terre.

Alimentation _lectrique

. Cet appareil doit _tre aliment_ par du !20V, 60Hz,et branch6

(_un circuit de d@ivation mis (_la terre et prot_g_ par un

disjoncteur de 15 ou 20 amp ou par un fusible (_action

diff@6e.

. Les cables 61ectriques doivent inclure deux fils et un fil de

terre et doivent _tre homologu_s pour une temp@ature de

75°C(176°F).

. Si I'alimentation _lectrique n'est pas conforme (_ces

exigences, appelez un _lectricien qualifi_ avant de

commencer.

. Ne modifiez pas la fche fournie avec I'appareil, si celle-ci

n'est pas adapt_e (_la prise existante, faites installer une

prise appropri_e par un _lectricien qualifi_.

Page 26

BRANCHEMENTS ELECTRIQUES (SUITE)

Instructions de mJse 6 la terre -ModUles avec un

cordon d'alimentation

Cet appareil dolt @tremis 6 la terre. Encas de mauvais

fonctionnement ou de panne, la mise a la terre r6duit le risque

de choc 61ectrique en fournissant au courant 61ectriqueun

chemin de moindre r6sistance. Cet appareil est 6quip6 d'un

cordon, muni d'un conducteur de raise a la terre de I'appareil

et d'une fiche de raise a la terre. Lafiche dolt @trebranch6e

dans une prise appropri6e, elle-m@me correctement install6e

et raccord6e @la terre, conform6ment 6 tousles codes et

r@glementations locales en vigueur.

AVERTISSEMENT:

Assurez-vous que le tuyau d'alimentation en eau,

le tuyau de vidange et le cablage _lectrique ne

touchent pas de bornes d_nud_es du cablage du

lave-vaisselle.

AVERTISSEM ENT:

N'utilisez pas de rallonge avec cet appareil.

REMARQUE:

Lestrous d'acc_sdoivent avoir un diam_tre max. de!-!/2 po

(58.! mm) sans bord acdrd.

Une connexion incorrecte de ce fil de terre

pourrait provoquer un risque de choc

_lectrique. V_rifiez aupr_s d'un _lectricien

qualifi_ ou d'un technicien de maintenance

si vous n'@tes pus sOr que votre appareil soit

correctement mis 6 la terre.

La prise d'alimentation du lave-vaisselle dolt 6tre situ6e dans

un des meubles de cuisine ou sur un mur adjacent a I'espace

sous le comptoir o0 le lave-vaisselle sera install&

Si les bords de I'ouverture sont en bois, ils doivent _tre lisses

et arrondis. Si les bords de I'ouverture sont m@alliques, ils

doivent _tre recouverts d'une protection fournie @cet effet

par le fabricant. Prenezgarde en installant ou en retirant le

lave-vaisselle, pour r6duire le risque d'endommager le cordon

d'alimentation.

Si le cordon n'est pas assez long ou si un cablage fixe

est requis, suivez les @apes ci-dessous pour terminer le

branchement 61ectrique.

AVERTISSEMENT:

Avant de commencer, assurez-vous d'avoir d&

branch_ I'alimentation _lectrique au niveau du

disjoncteur / 8 la boTte8 fusibles.

1. Branchez le cable d'alimentation avec un r6ducteur de ten-

sion homologu6 UL(si un cable non m@allique est utilis&

2. Connectez le cable blanc au cable Ndu filtre.

3. Connectez le cable noir au

cable L du filtre.

4. Connectez le fil de terre 5 la vis de mise 6 la terre 5 la base.

10

REMARQUE:

Lots d'un cablage fix< le cordon d'alimentation foumi dolt _tre

retird.

Page 27

FIXATION DU LAVE-VAISSELLE AUX MEUBLES DE CUISINE

REHARQUE:

Si le panneau de la porte p_seplus de 15 livms, vous aurez

peut-_tre besoin de commander des ressorts de porte plus

rdsistants. (Voirpage 5).

II est n6cessaire de fixer le lave-vaisselle au meuble de cuisine

de fa¢on @ce qu'il ne se renverse pas Iorsde I'ouverture de

la porte or si un objet Iourd est plac6 sur la porte. Utilisez

uniquement les vis en acier inoxydable fournies avec I'appareil.

1. Utilisez I'option A pour une fixation en

dessous du comptoir. Utilisez I'option B

pour une fixation sur les meubles de c6t6

Iorsque le comptoir est une surface dure

(en granite par exemple).

2. Couvrez les t_tes de vis avec les protections en plastique

fournies avec I'appareil.

3. Lorsque I'appareil est correctement fix6, v@ifiez que les

pieds sont bien pos6s au sol et que I'appareil est de niveau.

REMARQUE:

Assumz-vous d'utiliser les sdparateurs blancs pour dviter de

trop setter lesvis de montage.

lit "1

B

POSITIONNEMENT DE L'APPAREIL

AVERTISSEMENT:

Assurez-vous d'avoir plac@ les gtissoirs de protec-

tion sur les pieds pour @viter d'endommager le sol

Iorsque vous faites glisser I'appareil dans I'enceinte.

1. Placez I'appareil devant I'enceinte.

2. Faites les r6glages en hauteur pendant que le lave-vaisselle

est plac6 devant I'enceinte.

3.Tirez le tuyau de vidange pour v@ifier qu'il n'y a pas de pli

dans le tuyau.

4. Faites passer lestuyaux d'alimentation et de vidange ainsi

que le cordon 61ectrique (sin6cessaire) dans I'ouverture

dans le meuble.

5. Faites glisser I'appareil dans I'enceinte du lave-vaisselle.

Pendant cette @ape, faites passer les tuyaux d'alimentation

et de vidange dans I'ouverture dans le meuble de cuisine.

Pendant que vous faites glisser le lave-vaisselle dans

I'enceinte, faites passer lestuyaux d'alimentation et de vi-

dange dans I'ouverture dans le meuble de cuisine.

AVERTISSEMENT:

Attention aux bords ac6r6s.

11

Page 28

MISE #, NIVEAU DU LAVE-VAISSELLE

IMPORTANT- Letave-vaissettedolt tredeniveau

pour un bon fonctionnement de 1'6gouttoir,un lavage

performant et un bon fonctionnement de l° porte. Lelave-

vaisselle dolt _tre mis de niveau de gauche (3droite et de

I'avant vers I'arri_re. Ceci6rite que les 6gouttoirs n'entrent ou

ne sortent du lave-vaisselle, 6galement que I'eau coule vers l°

pompe et que l° porte seferme sans cogner le bord de l° cure.

. Retirez 1'6gouttoir inf6rieur et placez un niveau sur laporte et

sur le rail de 1'6gouttoir inf6rieur

. Mettez le lave-vaisselle en tournant individuellement les

quatre pieds (3l° base du lave-vaisselle.

. Le lave-vaisselle est de niveau Iorsque I'indicateur du niveau

est centr6 de gauche (3droite et d'avant en arri6re. L° porte

du lave-vaisselle doit fermer sans heurter lesc6t6s de la

cure.

. Replacez 1'6gouttoir inf6rieur.

1. Desserrez les vis de montage sur les deu× pieds

avant en acier du lave-vaisselle 6 I'aide d'une cl6

anglaise de 5/8 po (16 mm). Vissez les vis de mon-

tage aussi pr6s du sol que possible.

Conseil: Evitez des frais de services inutiles. V_rifiez que le

lave-vaisselle est de niveau

Sortez les 6gouttoirs de moiti6, lls devraient rester

stetionnaires. Ouvrez et fermez la porte. Ell° devrait tenir dans

I'ouverture de la cure sans heurter les c6t6s de la cure. Si les

6gouttoirs roulent par eux-m_mes ou si la porte heurte les

c6t6s de l° cure, refaites l° mise (3niveau.

2. Ajustez I(] hauteur du lave-v(aisselle en tourn(]nt

m(]nuellement les pieds en (Icier 6 I'(]v(]nt du

lave-vaisselle. Laissez suffisamment de place pour

effectuer des r_gl(]ges ult6rieurs.

12

.................... i / .....................

......... /:

Lj,

©

Page 29

MISE NIVEAU DU LAVE-VAISSELLE

3. Vissez le pied Grri_re compl_tement en tournGnt

IGvis de r6glGge _ I'GvGnt dGns le sens GntihorGire.

Utilisez un tournevis _ t6te plGte ou un tournevis

douille de 1Apo.

4. Inst(]llez les pieds en plGstique sur les trois pieds

en Gcier (fourni dGns IGpoche contenGnt les docu-

ments).

RENARQUE:

Ne fixez pas les pieds en plastique si la hauteur de

I'espace d'installation est minimale.

(SUITE)

5. Poussez le I(]ve-vGisselle d(]ns I'enceinte. Au m6me

moment, fGites pGsser les cables 61ectriques et

les tuyGux d'GlimentGtion et de vidGnge dGns

I'ouverture.

13

Page 30

MISE _, NIVEAU DU LAVE-VAISSELLE

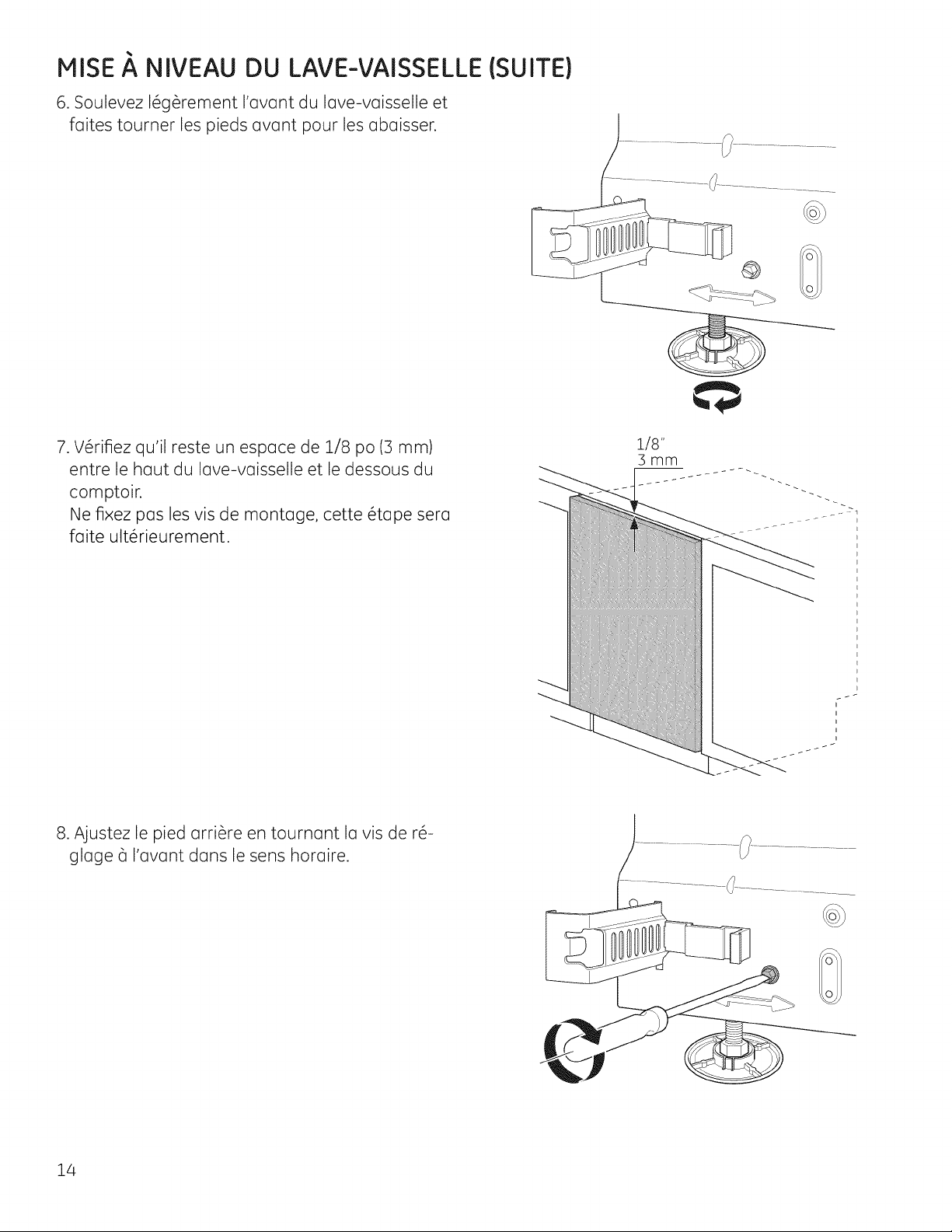

6. Soulevez 16g_rement I'avant du IGve-vaisselle et

faites tourner les pieds avant pour les abaisser.

(SUITE)

7. V6rifiez qu'il reste un espace de 1/8 po (3 mm)

entre le haut du lave-vaisselle et le dessous du

comptoir.

Ne fixez pas les vis de montage, cette #tape sera

faite utt#rieurement.

8. Ajustez le pied arri_re en tournant Io vis de r_-

gloge {_I'avant dans le sens horaire.

1/8"

3mm

i

i

i

i

i

14

Page 31

MISE _, NIVEAU DU LAVE-VAISSELLE (SUITE)

9. PIGcez le niveau 8 bulle sur la porte du lave-

vaisselle pour v_rifier que I'appareil est de niveau.

R_ajustez si n6cessGire. La porte dolt _tre com-

pl_tement ferm_e !

RENARQUE:

Le lave-vaisselle doit @trede niveau ! Si un appareil

n'est pas de niveau, ceci peut avoir un impact sur

la quantit@ d'eau utilis@e,la porte peut @tredifficile

fermer et les @gouttoirs peuvent @tredifficiles

mettre en place.

INSTALLATION DE LA PLINTHE

RE_GLAGE DE LA PROFONDEUR DE LA PLINTHE

I I

1. Poussezles fermetures grises I'une vers I'autre pour rel@cher

les supports de la plinthe.

2.Tirez lessupports de la plinthe aussi loin que le demande

I'installation pour r6gler la profondeur exacte de la plinthe.

3. Lorsque les supports de I(] plinthe sont a I(] profondeur req-

uise, 6cartez les supports gris de la plinthe pour verrouiller

les supports de I(] plinthe en place.

4. L'arri_re de la plinthe est 6quip6 de crochets qui permettront

de suspendre la plinthe au support. Soulevez la plinthe et

faites glisser les crochets sur les supports en (]b(]iss(]nt I(]

plinthe vers le sol.

15

Page 32

LISTE DE VITRIFICATION D'INSTALLATION

Liste de v_rification d'installation de l'appareil

• Retirez l'emballage et v_rifiez l'absence de dommages esth_tiques.

• Retirez les paquets contenant les manuels de l'int_rieur du lave-vaisselle.

,,Fixez tousles accessoires comme il l°est requis par l'installation. Bandes de rem-

plissage, panneaux de porte en bois, accessoires de panneaux de porte...

• Fixez le tuyau de vidange en utilisant la partie la plus large du broyeur il d_chets.

Conservez le tuyau sur_lev_.

• Fixez le tuyau de remplissage en XLPE. N'oubliez pas d'utiliser pas les joints

toriques.

• Branchez le lave-vaisselle dans la prise du mur.

• Ouvrez l'eau et v_rifiez que les connexions du tuyau de remplissage ne fuient

pas.

• Faites glisser l'appareil dans l'enceinte et mettez le lave-vaisselle de niveau de

l'avant vers l'arri_re et de la gauche vers la droite.

• Fixez l'appareil dans l'enceinte.

• Branchez l'appareil il l'alimentation _lectrique et lancez un cycle. Assurez-vous

qu'il n'y a pas de fuite au niveau du tuyau de vidange.

• Montrez la carte de garantie au client et aidez-le il localiser le num&o de modble

et le num&o de s_rie sur l'appareil.

• Laissez tous les manuels d'utilisation au client.

36

Loading...

Loading...