Page 1

GE Appliances

Technical Service Guide

September 2011

Top-Control Stainless

Steel Tub Dishwashers

GDWT668V

GDWT768V

PDWT180V

PDWT380V

PDWT560V

PDWT565V

CDWT280V

CDWT980V

ZBD6920V

ZBD7920V

ZBD8920V

31-9221

GE Appliances

General Electric Company

Louisville, Kentucky 40225

Page 2

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major ap pli ance may result in personal injury and property

damage. The man u fac tur er or seller cannot be responsible for the

in ter pre ta tion of this in for ma tion, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing

this prod uct . If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position and properly fastened.

GE Appliances

Copyright © 2011

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

– 2 –

Page 3

Table of Contents

Active Vent ...........................................................................................................................................................................26

Bottom Door Seal..............................................................................................................................................................27

Center Wash Arm .............................................................................................................................................................28

Coarse Filter ........................................................................................................................................................................30

Component Locator Views ...........................................................................................................................................13

Control Board ......................................................................................................................................................................22

Control Board Connector Locator View .................................................................................................................16

Control Features ................................................................................................................................................................ 7

Control Thermal Cutout (TCO)......................................................................................................................................22

Consumer Purge of the Bulk Dispenser Tank ......................................................................................................21

Cycle Chart ..........................................................................................................................................................................12

Cycles .....................................................................................................................................................................................11

Detergent/Rinse Module ................................................................................................................................................24

Dishwasher Components ..............................................................................................................................................17

Door Handle ........................................................................................................................................................................24

Door Switch Assembly ...................................................................................................................................................24

Drain Pump Assembly ....................................................................................................................................................35

Factory Test Mode ............................................................................................................................................................39

Fill Funnel ..............................................................................................................................................................................33

Fine Filter ..............................................................................................................................................................................29

Float Switch .........................................................................................................................................................................31

Heating Element ................................................................................................................................................................32

Inner Door Panel ...............................................................................................................................................................26

Introduction ......................................................................................................................................................................... 6

Lens .........................................................................................................................................................................................23

Lower Wash Arm ..............................................................................................................................................................28

Motor Pump Assembly ...................................................................................................................................................35

Nomenclature .................................................................................................................................................................... 5

Outer Door Panel ..............................................................................................................................................................17

Schematics and Wiring Diagrams ............................................................................................................................40

Service Mode ......................................................................................................................................................................37

– 3 –

(Continued next page)

Page 4

SmartDispenseTM ...............................................................................................................................................................18

Sump Filter ...........................................................................................................................................................................29

Tactile Switch ......................................................................................................................................................................23

Troubleshooting ...............................................................................................................................................................37

Tub Gasket ...........................................................................................................................................................................27

Tub Thermal Cutout (TCO) .............................................................................................................................................36

Turbidity Sensor ................................................................................................................................................................31

Upper Wash Arm ..............................................................................................................................................................28

Vent Fan ................................................................................................................................................................................25

Warranty ..............................................................................................................................................................................41

Water Hardness Test and Calibration .....................................................................................................................17

Water Inlet Valve ...............................................................................................................................................................33

– 4 –

Page 5

Model Number

Product Type

GDW = GE Long Door

PDW = Profi le

CDW = GE Café

Top Control

T = Top Control

Nomenclature

G D W T 6 6 8 V B B

Exterior Color

BB = Black

CC = Bisque

SS = Stainless Steel

WW = White

Feature Pack

Nomenclature

Access Panel

The nomenclature plate is lo cat ed on

the left side of the tub wall, inside the

door jamb.

The mini-manual is located behind

the access panel.

Door

8 = Stainless Door

Model Year Designator

Handle/Control Location

0 = Latch/Front Control

6 = Recessed/Top Control

8 = Towel Bar/Top Control

Serial Number

The fi rst two characters of the serial number

identify the month and year of manufacture.

Example: VV123456S = November, 2011

V - NOV

Z - DEC

A - JAN

B - FEB

F - MAR

G - APR

H - MAY

L - JUN

M - JUL

R - AUG

S - SEP

T - OCT

2011 - V

2010 - T

2009 - S

2008 - R

2007 - M

2006 - L

2005 - H

2004 - G

2003 - F

2002 - D

2001 - A

2000 - Z

The letter des ig nat ing

the year re peats every

12 years.

Example:

V - 2011

V - 1999

V - 1987

– 5 –

Page 6

Introduction

New Features and Benefi ts

• Five-stage fi ltration with Piranha™ hard food disposer

• Dedicated silverware jets

• Steam PreWash

• Fan assist dry with heated option and ActiveVent

• Fifty-two dBA sound level

• ENERGY STAR® qualifi ed and CEE Tier II rated

• SmartDispense™ (only on models GDWT7XX, PDWT3XX, PDWT5XX, CDWT980, and ZBD89XX)

Weights and Dimensions

Approximate Shipping Weight .........................................................................................................................................115 lb

Net Weight .................................................................................................................................................................................110 lb

Overall Height ..........................................................................................................................................................................34 in.

Height with Legs Extended ................................................................................................................................................35 in.

Overall Depth ...........................................................................................................................................................................24

Overall Width ............................................................................................................................................................................24 in.

3

/4 in.

– 6 –

Page 7

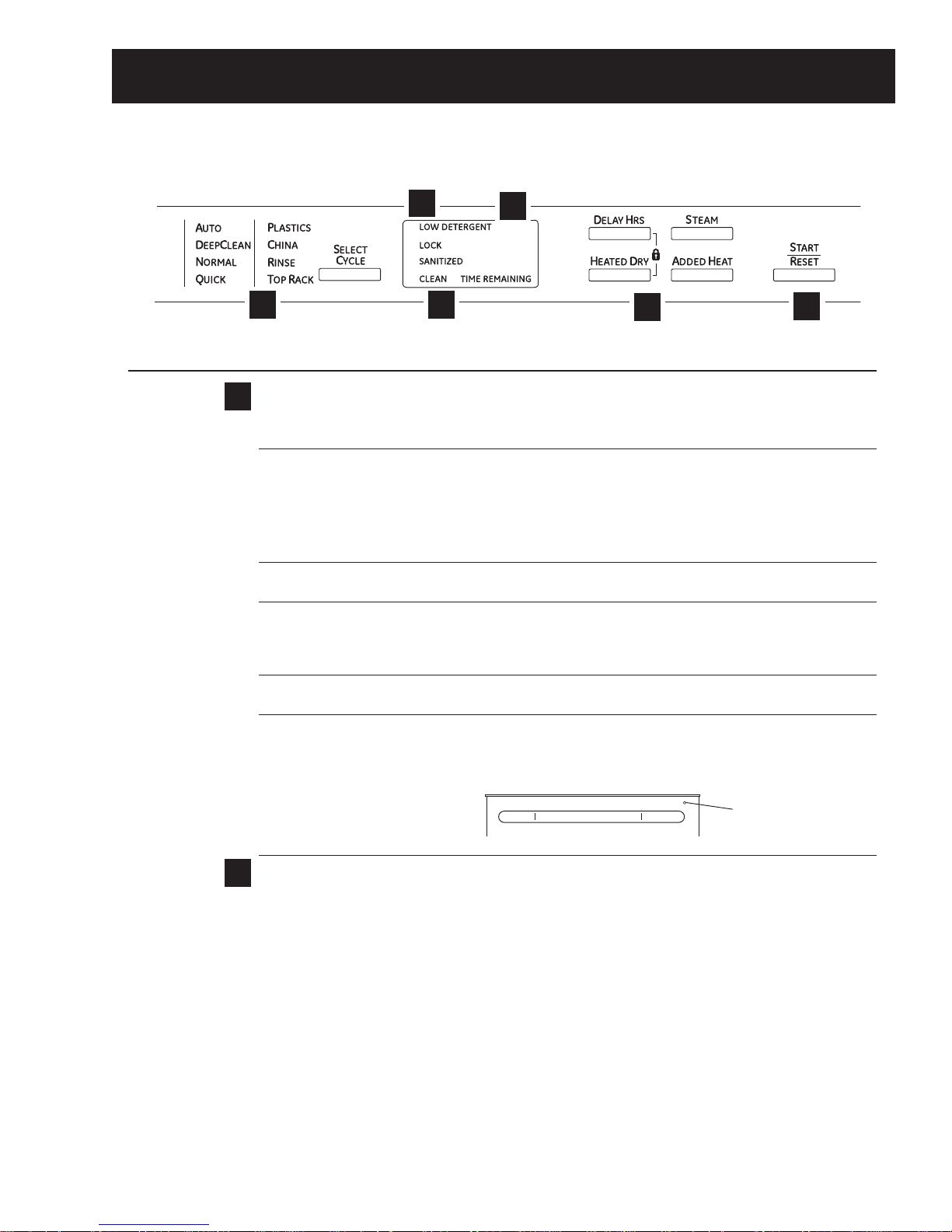

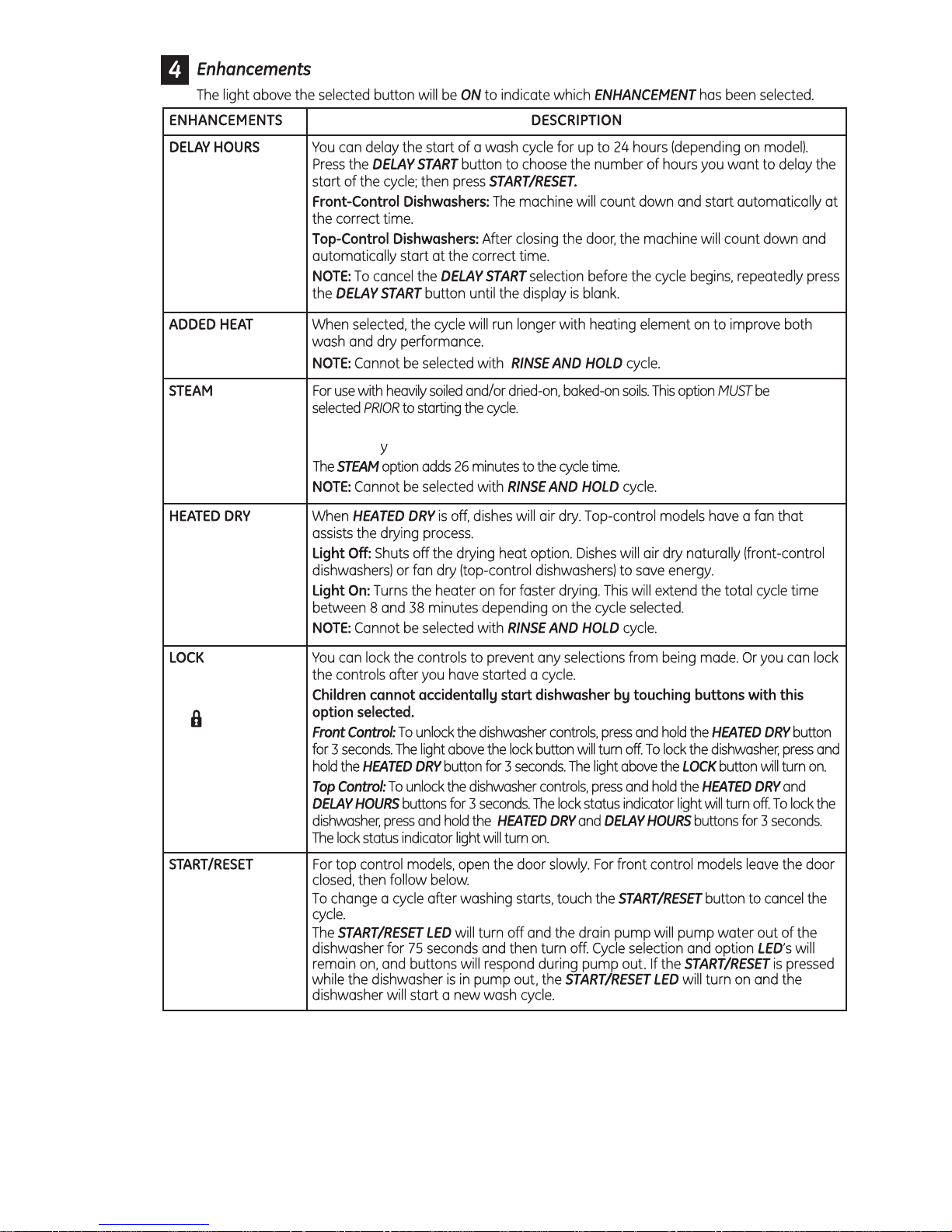

Control Features

Throughout this manual, features and appearance may vary from your model.

Top-Control Dishwashers

3

Control Settings

Status Indicator Lights (Indicators vary by models)

1

The Status display tells you what is happening while the dishwasher is in operation and may flash, indicating

a malfunction. The lights will come ON indicating the sequence of the dishwasher operation.

LOW DETERGENT Displayed when the SmartDispense

1

6

dishwasher detergent.

NOTE:If you are not using SmartDispense

LED light off, press the ADDED HEAT button 5 times within 3 seconds. You will hear 3

beeps; then the light will go off. You can turn the light back on by pressing the ADDED

HEAT button 5 times within 3 seconds.

SENSING Displayed while the Clean Sensor

of water. The dishwasher will adjust the selected cycle to achieve optimal performance.

SANITIZED Displayed at the end of the cycle when SANITIZE has been selected and the dishwasher

has met the requirements for sanitization. See SANITIZE, below, for complete cycle

description. Opening the door or pressing any key while the door is closed and latched

will turn off the light.

CLEAN Displayed when a wash cycle is complete. Refer to Item 6, page 9, for further

explanation of clean light operation

CYCLE ST ATUS The cycle status indicator light is located on the right side of the dishwasher, above the

INDICAT OR handle. This light comes on as amber while the selected cycle is running. The light turns

to green when the selected cycle is complete. The light stays ON as green as a reminder

that the dishes are clean until the door is opened or until another cycle is selected.

2

4

TM

needs to be refilled with liquid or gel automatic

TM

and you want to turn the LOW DETERGENT

TM

is measuring the amount of soil and temperature

5

Time Remaining Display (on some models)

2

During operation, the display shows the minutes remaining until the cycle is complete. The display may

adjust the remaining time while the Sensing light is on. The time displayed at the start of each cycle may

change from the factory setting as the unit customizes itself to home use. During a delay start, the display

will show hours of time remaining until the cycle starts.

NOTE: This dishwasher is equipped with CleanSensor

6

cycle length and time may vary depending on soil and water temperature conditions.

– 7 –

Cycle Status Indicator Light

TM

with automatic temperature control; therefore,

(Continued next page)

Page 8

– 8 –

(Continued next page)

Page 9

The STEAM option will use the heater to

increase the temperature of the water. The circulation pump will turn off

periodicall , allowing water to drip onto the hot calrod which will create steam.

– 9 –

(Continued next page)

Page 10

Start

5

– 10 –

Page 11

Cycles

Auto Hot Start:

Auto Hot Start is initiated by the control board when it senses water temperature is below 80°F. If the water

is below 80°F after prewash, the unit circulates for 1 to 5 minutes (depending on the cycle selected) and then

drains for 75 seconds. This procedure repeats up to 4 times or until the water reaches 80°F.

Added Heat:

The added heat option differs for the various cycles. Some cycles will not be modifi ed, some cycles will

increase the calrod time, and some cycles will get additional segments added (e.g., AUTO has 6 segments

without added heat and 9 segments with added heat).

Heated Dry:

During HEATED DRY, the heater cycles at a rate of 60 seconds on and 51 seconds off.

Cycle Explanations and Exceptions:

• Turbidity Response is used during the SANITIZED, NORMAL, and AUTO cycles only.

• Timed cycles can change depending on the water temperature. If the minimum temperature is not met,

an extended time is added until the temperature is met or the time expires.

• Partial Drain and Fill Algorithm is used during NORMAL and AUTO cycles only.

• Auto Hot Start may cause the fi rst prewash to repeat up to 4 times.

• Disabling STEAM will shorten the cycle time.

• If STEAM is selected during NORMAL or AUTO cycles, turbidity response is ignored, and cycle defaults to

the heavy soil algorithm.

• HEATED DRY takes 34 minutes for the NORMAL cycle while the other cycles vary to as long as 60

minutes for PLASTICS. There is no HEATED DRY for the RINSE cycle.

• Drain Overlap is a short period when both the wash and drain pumps run simultaneously as the

circulation cycle ends and draining begins.

• Drain Pause is a short period between the circulation cycle ending and the drain starting.

• Extend Times enables both the circulation pump and heater to operate simultaneously.

Turbidity Response

The turbidity response is measured in DC volts. Four to 5 VDC registers light soil and a shorter wash cycle,

while 0 to 2 VDC registers heavy soil and a longer wash cycle. SANITIZED wash measures the turbidity

response during the third prewash cycle and adjusts the time based on these measurements. NORMAL wash

measures the turbidity response during the fi rst prewash and the prewash before the main wash. If a clean

response is measured during the fi rst prewash, the cycle advances directly to the main wash with no drain or

fi ll. If a clean response is measured during the prewash before the main wash, the control shortens the active

heater time.

– 11 –

Page 12

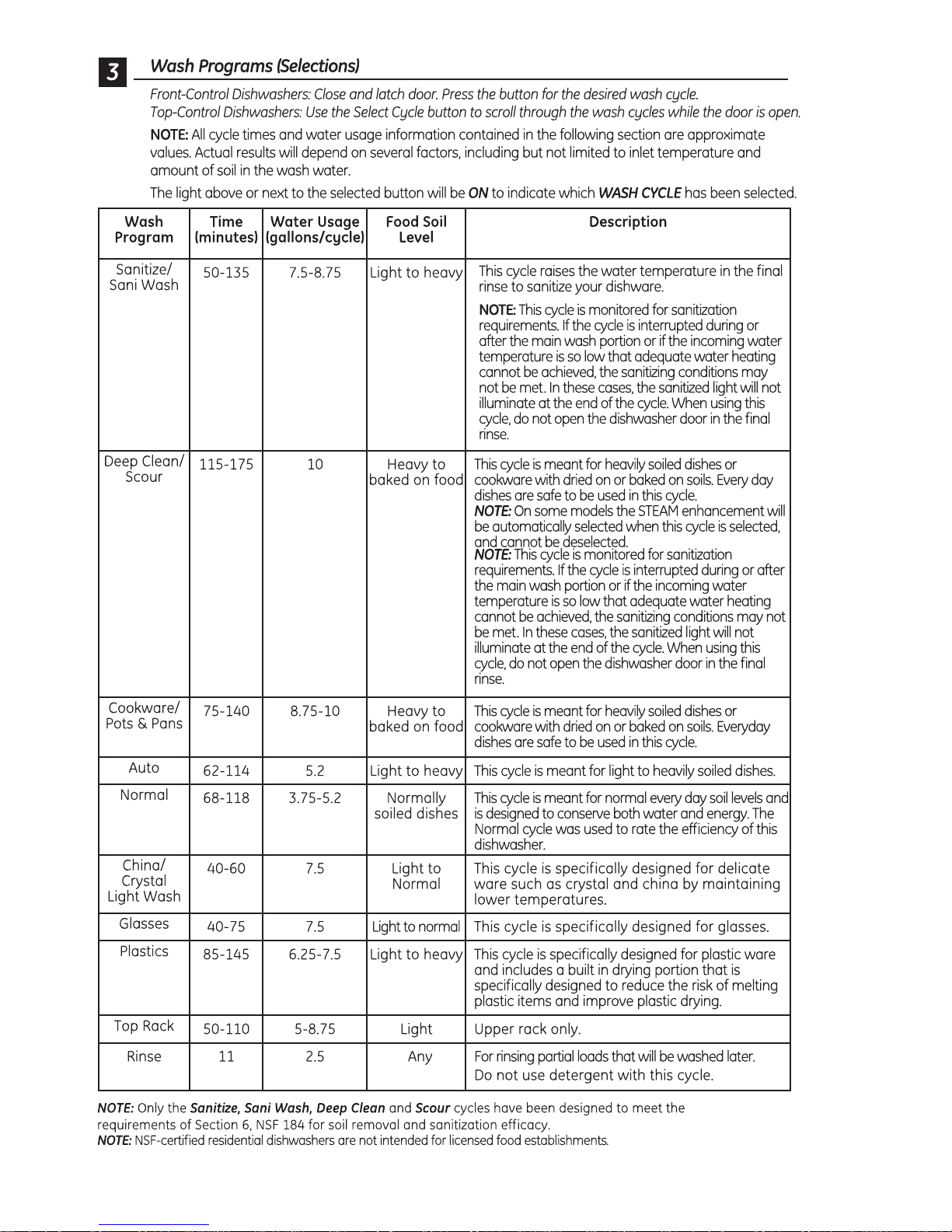

Normal Cycle PW1* PW2 PW3 PW4 PW5 MW** PR 1 PR2 FR Dry

Cool-

Down

Turb DOE [Vdc] 3.1 - 5.0 5.0 - -

Turb MIN [Vdc] 2.1 - 5.0 5.0 - -

Turb MED [Vdc] 2.1 - 5.0 5.0 - -

Turb MAX [Vdc] 1.0 - 0.1 0.1 - -

Time DOE [min] 5 - - 10 - -

Time MIN [min] 5 - - 10 - -

Time MED [min] 5 - - 10 - -

Time MAX [min] 1 - 3 10 - -

MW DOE Circulate Time [min] - - 30 -

MW DOE Heater Time [min] - - 28 -

MW MIN Circulat e Time [min] - - 30 -

MW MIN Heater Time [min] - - 27 -

MW MED Circulate Time [min] - - 30 -

MW MED Heater Time [min] - - 27 -

MW MAX Circulate Time [min] - - 30 -

MW MAX Heater Time [min] - - 30 -

Pre-Rinse 1 (PR 1) [min] - - 7 -

Pre-Rinse 2 (PR 2) [min] - - -

Final Rinse (FR) [min] - - - 6

Heater On Time [min] 0 - 0 10 - y** 0 - 5

Dry Time (Total Time) w/ HD [min] - - - 34

HD - Initial ON Time [min[ - - - 4

HD - Pulse OFF Time [sec] - - - 105

HD - Pulse ON Time [sec] - - - 75

Dry Time (Tot al Time) w/o HD [ min] - - - 0

Cool-Down Time [min] - - - 14

Fan Time w/ Heated Dry [min] - - - 48

W/ Out Heated Dry [min] - - - 14

Pause time (circ t o drain) [sec] 0 - 15 0 - 15 0 - 15

Fill Time (low flow water valve) [sec] 62 - 16 62 - 21 62 - 23

Fill Time (high flow water valve) [sec] 46 - 13 46 - 15 46 - 17

Drain Time [sec] 7 - 75 10 - 75 11 - 105

Max Temp Limit [F] - - - 158 - 158 - - 158

Min Temp Limit [F] ----- 120 - - 120

Extend Time [min] 0 - 0 0 - 5 0 - 5

Total Primiti ve [min] 6.15 - 4.52 11.20 - 31.25 8.22 - 8.13 34.00 14.00

31.60 13.13

Shortest Cycle [min] 67.63 36.60

Longest Cycle [min] 93.82

ART (Max) [min] 69.82

ART (Med) [min] 69.82

AH-MW [min] NA

HTD [min] 34.00

CD [min] 14.00

* IF on PW1 the turbidity is greater than the DOE response the cycle will skip the drain portion of PW1, completely skip PW3, PW4, and skip the fill into MW…effectively merging PW1 and MW circ

* IF on PW1 the turbidity is less than the DOE response but greater than the MI N response the cycle will skip PW3, PW4.

** Circulation and Heater ON times for Main Wash are determined by the turb valies in PW1

*** Detergent/Rinse Aid relay will be activated in FR

NOTE: ****PW2, PW5, PR2 intent ionally left blank due to separating the added heat functionality into its own cycle definition table. See Norm_Auto+AH cycle table.***

Cycle Chart

Fan

– 12 –

Page 13

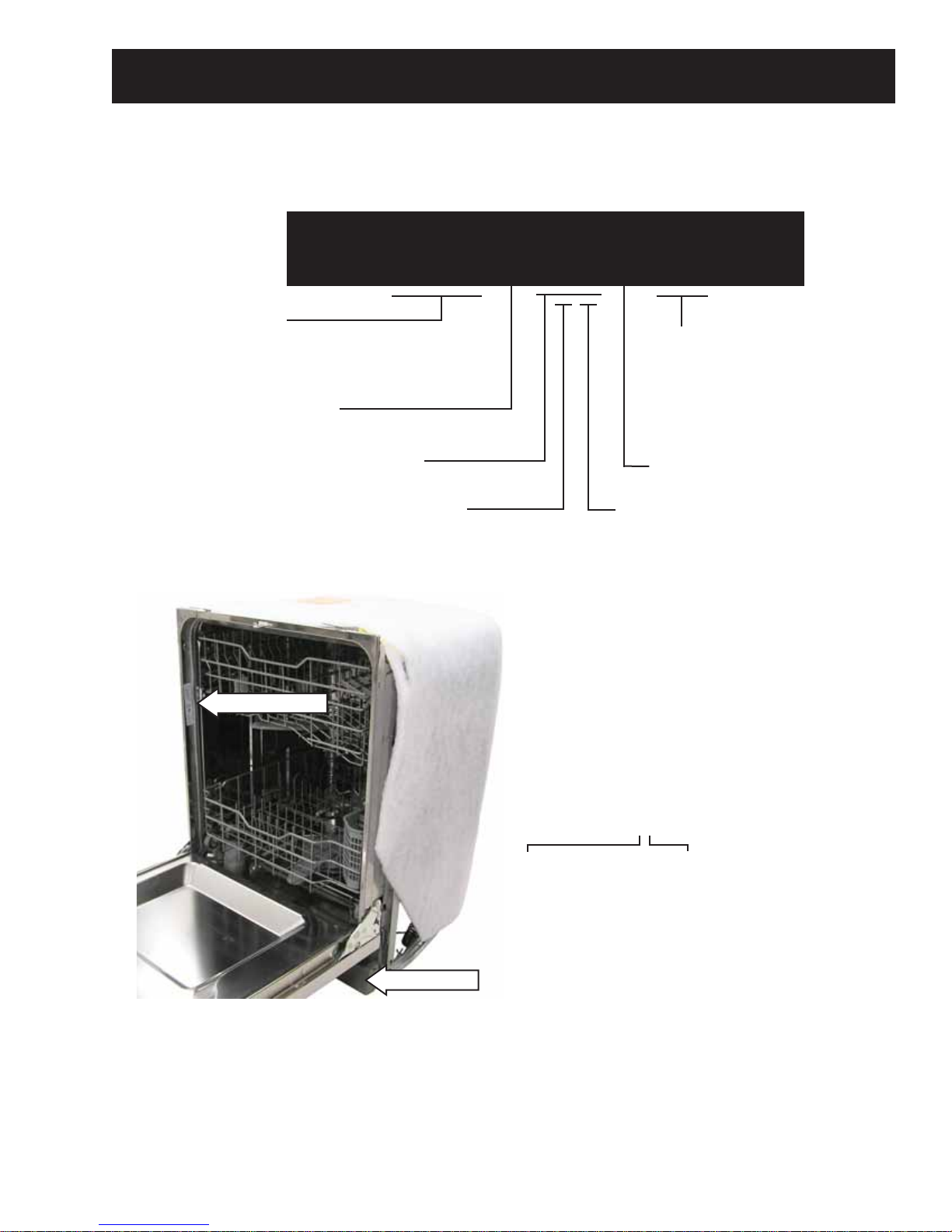

Front View

Door Panel

Component Locator Views

Control Panel

Insulation

Control Panel View

Access Panel

Door Latch

Control Assembly

(Continued next page)

– 13 –

Page 14

Interior View (Without Racks)

Detergent/Rinse Module Compartment View

Detergent Compartment

Detergent/Rinse Module

Vent

Rinse Agent Outlet

Indicator Window

Rinse Agent Cap

Compartment Lid

– 14 –

(Continued next page)

Page 15

Interior View of Basin (With Racks Removed) Left Side View (Insulation Removed)

Spray Arm

Coarse Filter

Float Dome

Heating Element

Fill Hose

Hub Nut

Fine Filter

Bottom View (Looking Up)

Front

Overfi ll Switch

Water Valve

Fill Funnel

Door Spring

Tub TCO

Drain Pump

Back

Motor Pump Assembly

Turbidity Sensor

Sump

Heater

– 15 –

Page 16

Control Board Connector Locator View

J2

J7

J5

J1 - Power Supply

J2 - Power Switching

J3 - Turbidity/Temperature Sensor

J3

J1

J5 - Active Vent

J7 - Keypad

– 16 –

Page 17

Dishwasher Components

Outer Door Panel

The outer door panel must be removed to access

the control board, detergent/rinse module, control

TCO, tactile switch, door switch, vent, and lens.

To remove the outer door panel:

1. Remove the two 1/4-in. hex-head screws from

the bottom of the front door panel (one on each

side).

3. Remove the single Phillips-head screw from the

control cover.

4. Disconnect the wire harness from the tactile

switch.

2. Remove the ten T-15 torx screws from the outer

door panel.

Caution: Carefully remove the outer door from the

inner door frame.

Disconnect

Water Hardness Test and Calibration

Test Water Hardness

The automatic liquid dishwasher detergent

dispenser (SmartDispenseTM) dispenses the optimum

amount of detergent to clean the dishes. The

amount of detergent introduced during each cycle

is based on the soil level of the dishes and the

hardness of the water. Therefore, the correct water

hardness setting is very important for both optimum

cleaning of dishes and detergent usage.

– 17 –

(Continued next page)

Page 18

Prior to its fi rst use, the dishwasher must be

calibrated for water hardness. This process requires

the use of a water hardness test strip (Part #

WD01X10295).

Test water hardness following the instructions on

the test strip package shown above.

1. Press the SELECT CYCLE and DELAY HRS

buttons simultaneously and hold for 3 seconds.

2. The current hardness setting is shown on the

TIME REMAINING display.

3. Enter the value from the test strip using the

STEAM button to increase the value or the

SELECT CYCLE button to decrease the value.

4. Press the START/RESET button to return the

dishwasher to normal operation. The last

displayed value is saved as the water hardness

value.

The 4 light green stripes on the test strip change

color depending on the water hardness. The harder

the water, the more stripes change from green to

red.

Note: If all stripes remain green after the test, the

outcome is "0 RED." The value to be entered into the

dishwasher is "1."

Convert the test reading according to the table

below.

Water Hardness Test Strip Indication

Red Stripes on Strip Value to Enter into Dishwasher

01

12

23

34

45

Note: 1 grain per gallon = 17.1 parts per million.

SmartDispense

TM

SmartDispense is a bulk liquid detergent dispenser

assembly consisting of the following components:

• Detergent Reservoir – Mounted within the inner

door panel.

• Detergent Level Sensor – Connected to a LOW

DETERGENT LED on the control panel.

• Positive Displacement Pump – Injects

the optimal amount of detergent into the

dishwasher during each cycle.

Detergent Reservoir

Note: The SmartDispense system can only be used

with liquid or gel automatic dishwasher detergent.

To access the reservoir, push down on the cap

covering the reservoir to engage the ratchet, then

turn it counterclockwise to open.

To enter water hardness value (on some models):

Note: Dishwasher must be in standby mode. Press

the SELECT CYCLE button to activate the tactile

switch and illuminate the lights on the control panel.

– 18 –

(Continued next page)

Page 19

Position the door at a 30- to 45-degree angle. Fill

LOW DETERGENT

SmartDispense

S

ENSING

W

ASHING

D

RYING

S

ANITIZED

C

LEAN

Light will

turn on

when time

to refill

the reservoir with a liquid automatic dishwasher

detergent until the detergent reaches the threads

of the reservoir access. The dispenser tank holds

approximately 45 ounces of liquid dishwasher

detergent (about 1 to 2 months' supply).

Place the cap on the reservoir access threads, push

down, and then turn clockwise until the cap is tight.

To remove the detergent reservoir:

Note: Removing the reservoir access collar causes

structural damage to the collar. It must be replaced

with a new part (Part # WD35X10059).

Remove the outer door panel. (See Outer Door

Panel.) Insert a small, fl at blade screwdriver into the

slot in the side of the retaining collar and push the

screwdriver handle counterclockwise while turning

the reservoir access collar counterclockwise a

quarter turn. Remove the retaining collar. Unplug the

tube from the reservoir outlet and disconnect the

sensor from the control module.

Detergent Level Sensor

The SmartDispense detergent level sensor consists

of a single-level detection continuity sensor and

includes the following components:

• A grommet seal

• A LOW DETERGENT LED indicator light

• A wire harness

When the detergent in the reservoir drops below

the continuity sensor, a signal is sent to the control

board, and the LOW DETERGENT LED indicator light

is turned on. The light indicates 3 to 7 wash cycles

are left before the detergent reservoir is completely

empty.

Note: The LOW DETERGENT LED may look like it

is illuminated when in fact it is not. An illuminated

indicator shines bright red.

Note: If the SmartDispense system is not being

used, the LOW DETERGENT light can be turned off

(or on) by pressing the ADDED HEAT button 5 times

within 3 seconds. There are 3 audible beeps when

the light goes off.

The sensor is similar to the type used in several

automotive applications, such as the windshield

wiper fl uid reservoir.

Note: The dispenser tank comes as an assembly.

It includes the sensor with wire harness, gasket,

and retaining collar. The complete assembly part

number is WD35X10058.

The control takes a reading of the detergent level at

power-up (when power is restored from an outage)

and each time the door is closed and latched.

The control outputs a pulsing 5-VDC analog signal

to the sensor and monitors the return voltage.

Changes in the quantity of detergent in the tank

change the amount of current drawn by the sensor.

(Continued next page)

– 19 –

Page 20

The routing of the DC wiring from the tank is very

123 4

133414957

2 35.4 43.4 51.4 59.4

3 37.8 45.8 53.8 61.8

4 40.2 48.2 56.2 64.2

5 42.6 50.6 58.6 66.6

Smart Dispense Bottle Duration

123 4

1 10.3 8.3 6.9 5.9

2 9.6 7.8 6.6 5.7

3 9.0 7.4 6.3 5.5

4 8.4 7.0 6.0 5.3

5 8.0 6.7 5.8 5.1

Dosage (ml)

Hardness

Soil Level

Hardness

Bottle Duration (wks)

Soil Level

important. The 3 tape points on the tank keep the

DC wiring perpendicular to the AC harness wiring

running down across the front of the tank.

The dispenser pump operates on 120 VAC. During

each prewash cycle, the pump is energized for 5

seconds, dispensing 4 ml of detergent.

The electronic control uses two inputs to determine

the total amount of detergent dispensed during the

main wash cycle:

Tape Point

Tape Point

Tank

Tape Point

Sensor and Gasket

Note: The dispenser tank, sensor with wire harness,

and gasket are only available as a complete

assembly (Part # WD35X10058). They are shipped

with a new dispenser tank retaining collar.

• Soil level determined by the turbidity sensor

• Water hardness as calibrated for the location

A water hardness selection mode permits the

calibration of the water hardness for the location

at installation. (See

Calibration.)

Water Hardness Test and

To determine the amount of detergent to dispense

during the main wash, the electronic control uses

the following formula:

4 ml x Number of Prewashes

+ 25 ml + Additional Quantity for Hardness

The additional quantity is a predefi ned quantity

of detergent based on the water hardness level

programmed into the control.

Approximate Detergent Use

SmartDispense Dosage Amount

Smart Dispense Dosage Amount

Detergent Level Sensor Strip Circuit

DETERGENT

BRN/YELLOW RED

J4-1

SENSOR

Positive Displacement Pump

The SmartDispense positive displacement pump

consists of a continuous fl exible tube running from

the detergent reservoir to the inner door detergent

outlet. The tube runs around the inside edge of the

pump housing. A 3-roller impeller fi ts tightly into

the center of the pump housing, with each of the

3 rollers squeezing the sidewall of the tube. As the

impeller is driven counterclockwise by the motor, it

squeezes out a predetermined amount of detergent

for each 1/3 revolution of the impeller.

Pump

Housing

Impeller

J4-3

SmartDispense Bottle Duration

From

Detergent

Reservoir

To Detergent

Outlet

(Continued next page)

– 20 –

Page 21

To remove the positive displacement pump:

1. Remove the outer door panel. (See

Panel.)

Outer Door

2. Remove 2 Phillips-head screws from the lower

right side of the door edge to release the pump

bracket.

A chemical reaction also takes place between the

chlorine detergent and the enzyme detergent,

which causes the two liquids to coagulate and

build up around the detergent level sensor. This

buildup may prohibit the sensor from sending the

low-detergent signal to the control board, and the

LOW DETERGENT light will not illuminate when the

dispenser tank is empty.

Consumer Purge Cycle

The consumer must enter service mode to activate

the purge cycle. (See

Service Mode.) The purge cycle

fi lls the dishwasher for 57 seconds, then energizes

the dispenser pump (instead of the main motor)

continuously to drain the dispenser tank.

The purge cycle deselects all other options and

runs for 65 minutes. The consumer should run the

purge cycle 3 times, fi lling the dispenser tank with

water for the second and third cycles. Total time is

approximately 3 hours.

3. Remove the grommet from the inner door panel

and unplug the tube from the reservoir outlet.

4. Disconnect the wires and remove the pump.

Positive Displacement Pump Strip Circuit

BULK DETERGENT

PUMP

M

875 Ω

J2-1

ORANGE

Consumer Purge of the Bulk Dispenser Tank

When to Purge the Bulk Dispenser Tank

Only liquid or gel automatic dishwasher detergent

can be used in the dispenser tank. The dispenser

tank must be purged if the consumer puts hand

dishwashing detergent or a rinse agent in the

dispenser tank. These products produce copious

amounts of suds, and water leaks result every time

the dishwasher is run, until the dispenser tank is

emptied.

The dispenser must also be purged if a liquid

dishwasher detergent containing chlorine (like

Cascade Pure Rinse Formula) and one containing

enzymes (like Cascade Complete) have been mixed

in the dispenser tank. When this happens, the

chlorine destroys the enzymes, resulting in poor

wash performance. You can tell if the detergent

contains chlorine or enzymes by reading the

content label on the container.

To purge the bulk dispenser tank (on some models):

1. Make sure STEAM, ADDED HEAT, and HEATED

DRY LEDs are off.

2. Press HEATED DRY button and SELECT CYCLE

button simultaneously for 3 seconds. If done

correctly, all the LEDs illuminate.

WHITE

3. Press SELECT CYCLE button and ADDED HEAT

button simultaneously for 3 seconds. If done

correctly, the AUTO and LOCK LEDs illuminate.

4. Press START/RESET button one time to exit

service mode.

5. Press START/RESET button to start an auto

cycle and make sure STEAM, ADDED HEAT, and

HEATED DRY LEDs are off.

6. Dishwasher runs a complete cycle with the

main motor instead of the dispenser tank. Cycle

is complete when the CLEAN light illuminates.

This should take approximately 60 minutes.

7. Open door and wipe up the excess detergent

from the door and tub.

8. Pour water on the door and tub where there is

detergent residue.

9. Remove SmartDispense cap and fi ll dispenser

tank with water. Replace the cap.

(Continued next page)

– 21 –

Page 22

10. Repeat steps 1 thru 9 one time.

11. Repeat steps 1 thru 6. When the CLEAN LED

illuminates, the system is purged and ready to

be refi lled with the correct detergent.

Control Thermal Cutout (TCO)

The control TCO is one shot with a trip temperature

of 250°F. If the control TCO trips, no voltage is

supplied to the control board or components.

Look for control or wire damage and replace as

necessary.

To remove the control TCO:

1. Remove the outer door panel. (See

Panel.)

2. Remove the T-15 torx screw from the control

TCO.

Outer Door

Control Board

The control board is attached to the right side of the

inner door panel.

Voltage from the control board to the turbidity

sensor can be tested by checking the voltage at J3

on the control board. (See Control Board Connector

Locator View.) A pulsed 2-VDC signal should be

measured across wires J3, pin 2 (dark blue wire), and

J3, pin 3 (gray wire).

Control Board Turbidity Sensor

YB

1

TURBIDITY/

TEMPERATURE

SENSOR

J3

NX

2

SX

3

OX

4

To remove the control board:

1. Remove the control TCO. (See

2. Disconnect the 4 wire harnesses from the

control board.

NTC

1

RECEIVER EMITTER

2

TRANSMITTER

3

CATHODE

4

Vcc

Control TCO.)

Control TCO

Note: When replacing the control TCO, splice a new

thermostat into the harness using connectors and

procedures approved for damp/wet conditions.

Silicone Grease

Disconnect

Disconnect

Disconnect

3. Remove the Phillips-head screw holding the

control board to the inner door panel.

– 22 –

(Continued next page)

Page 23

4. Disengage the control board tabs from the inner

door panel.

Lens

The lens is located behind the console and attached

to the front panel with double-back tope. A new lens

comes with the console as a kit.

Tab

Tab

Tactile Switch

The tactile switch includes a silicone pad to protect

the switch from moisture. The tactile switch buttons

and silicone pad come as an assembly.

To remove the tactile switch:

1. Remove the outer door panel. (See Outer Door

Panel.)

To remove the lens:

1. Remove the outer door panel. (See Outer Door

Panel.)

2. Remove the single Phillips-head screw from the

console.

3. Pull the console out of the door.

2. Remove the 2 Phillips-head screws and the

tactile switch from the console.

Note: When replacing the tactile switch, transfer the

model select plug to the new switch.

Model Select Plug

Note: The tactile switch buttons are keyed to fi t in

the proper place on the silicone pad.

Silicone Pad

Console

4. Pry the lens off the door panel with a fl at blade

screwdriver.

Lens

Tactile Switch Buttons

– 23 –

Page 24

Door Handle

The door handle is held in place by 2 screws that

can be accessed by removing the console.

To remove the door handle:

3. Disconnect the 2 wires from the door switch.

1. Remove the console. (See

Lens, steps 1-3.)

2. Remove the two 1/4-in. hex-head screws

holding the handle to the outer door (1 on each

side).

Disconnect

Disconnect

4. Remove the 3 Phillips-head screws from the

door switch.

Door Switch Assembly

The door switch assembly is activated by a springloaded plunger that connects or disconnects the line

(hot) side of 120 VAC.

When the door is in the closed position, the door

latch presses and holds down the switch plunger on

the door switch assembly. This action holds the door

fi rmly against the seal, with the contacts of the door

switch closed.

To remove the door switch assembly:

1. Disconnect the power supply to the dishwasher.

2. Remove the outer door panel. (See Outer Door

Panel.)

Detergent/Rinse Module

The inner door panel must be removed to access

the detergent/rinse module. (See Inner Door Panel.)

The detergent/rinse module is connected by 2 wires

and held in place by 6 Phillips-head screws and a

bracket.

The detergent/rinse module operates on 120 VAC

and has an approximate resistance value of 1.2 to

2.8 K

Bracket

– 24 –

(Continued next page)

Page 25

The detergent/rinse mod ule au to mat i cal ly

dis pens es both de ter gent and rinse agent at the

ap pro pri ate times. The module is activated twice

during a wash cycle. Detergent is dispensed at the

beginning of the main wash cycle and rinse agent at

the beginning of the fi nal rinse.

Operation of the detergent/rinse module can be

checked by using the service test mode. (See Service

Mode.)

The fi rst time the module is activated, the lever

slides up the right-hand path of the connecting rod

(1). This action releases the de ter gent cover.

1

Vent Fan

The vent fan runs at the end of the dry cycle,

whether HEATED DRY has been selected or not. It

will run for 1 to 15 minutes when not in HEATED

DRY and 30 to 50 minutes during some HEATED

DRY cycles. The vent is located on the upper-left

side of the inner door panel and has a resistance of

65 .

To remove the vent fan:

1. Remove the outer door panel. (See Outer Door

Panel.)

2. Disconnect the vent fan wire harness.

When the module is deactivated, the lever returns

down the left-hand path and comes to rest under

the notch (2) in the center of the connecting rod.

2

At the second activation of the module, the lever lifts

the con nect ing rod by the notch. This action lifts the

rinse dispenser plunger (3) and re leas es the rinse

agent. When the module is deactivated, the lever

returns to its original start ing position.

Disconnect

3. Remove the 4 Phillips-head screws from the

vent fan and lift it off the conduit exhaust.

3

Conduit

(Continued next page)

– 25 –

Page 26

4. Remove the 4 Phillips-head screws from the

back of the vent fan.

5. Remove the 2 Phillips-head screws from the

bottom of the vent fan.

3. Remove the single Phillips-head screw from the

vent switch housing.

Inner Door Panel

To remove the inner door panel:

Active Vent

The active vent is attached to the inner door panel

between the vent and door switch. It operates on 12

VDC and has a resistance of 103 The vent motor

turns the active vent switch clockwise to close the

vent and counterclockwise to open the vent.

To remove the active vent:

1. Remove the vent fan. (See Vent Fan, steps 1-3.)

2. Disconnect the active vent wire harness.

1. Remove the control TCO. (See Control TCO.)

2. Disconnect 3 wire harnesses from the control

board.

Disconnect

Disconnect

Disconnect

Disconnect

– 26 –

(Continued next page)

Page 27

3. Disconnect the 2 detergent/rinse module wires

and the vent fan wiring harness.

Bottom Door Seal

The bottom door seal is riveted to the inner door

panel. To remove the bottom door seal, replace the

inner door panel. (See Inner Door Panel.)

Disconnect

Disconnect

4. If the installation allows, pull the dishwasher out

to access the door hinges.

5. Insert 2 screwdrivers (1 on each side) thru the

door hinge bracket holes and secure them

under the dishwasher tub.

Tub Gasket

The dishwasher tub gasket prevents water leakage

and fi ts in a channel that lines the rim of the

dishwasher tub. The gasket uses a wire rod that

provides tension to the seal.

To remove the tub gasket:

1. Remove the outer door panel. (See Outer Door

Panel.)

2. Pull the wire rod out of the gasket.

Gasket

6. Remove the 4 Phillips-head screws holding the

inner door panel to the door hinges (2 on each

side).

7. Slide the inner door panel off the door hinges.

Wire Rod

3. Remove the dishwasher tub gasket by grasping

an end and peeling it away from the channel.

Channel

Tub Gasket

Caution: When installing the tub gasket, run your

fi nger over the gasket, assuring it is smooth and

even for a proper seal.

– 27 –

Page 28

Center Wash Arm

Lower Wash Arm

To remove the center wash arm:

1. Disengage the left upper rack slide by pressing

the lever down while pulling the rack out.

2. Disengage the right upper rack slide by pressing

the lever up while pulling the rack out.

The lower wash arm can be accessed by opening

the dishwasher door and removing the bottom rack.

Remove the lower wash arm by pulling it up while

turning it counterclockwise.

Upper Wash Arm

Remove the upper wash arm by removing the 1/4in. hex-head screw holding the arm to the conduit.

3. Remove the 1/4-in. hex-head screw from the

center wash arm.

– 28 –

Page 29

Fine Filter

To remove the fi ne fi lter:

4. Pull the 2 clip hinges (1 on each side) outward to

release the conduit tabs.

1. Remove the lower wash arm. (See

Arm.)

Lower Wash

2. Rotate the hub nut counterclockwise. Lift the

hub nut off the fi ne fi lter.

Hub Nut

3. Lift the fi ne fi lter off the wash arm hub.

Tab

Clip

5. Lift the tab on the wash arm hub while pulling

the conduit back to remove it.

Conduit

Tab

Wash Arm Hub

Fine Filter

Sump Filter

The sump fi lter prevents large particles from

entering the sump.

To remove the sump fi lter:

1. Remove the upper rack. (See Center Wash Arm,

steps 1-2.)

2. Remove the upper wash arm. (See

Arm.)

3. Remove the fi ne fi lter. (See Fine Filter.)

Upper Wash

6. Release the 4 tabs on the sump fi lter cover to

remove it.

Sump Filter Cover

– 29 –

(Continued next page)

Page 30

7. Release the 2 sump fi lter tabs with a fl at blade

screwdriver or putty knife.

Coarse Filter

To remove the coarse fi lter:

Tab

Sump Filter

1. Remove the sump fi lter. (See

Sump Filter.)

2. Turn the wash arm hub counterclockwise and

remove it from the tub.

3. Lift the coarse fi lter from the dishwasher.

Tab

8. Remove the sump fi lter by pulling it up and to

the right.

Coarse Filter

Note: Insure the wash arm bearing is in the proper

location before assembly.

Bearing

– 30 –

Page 31

Float Switch

Turbidity Sensor

The fl oat switch activates if water reaches the

fl oat stem inside the dishwasher. The switch only

terminates the voltage to the water valve.

To remove the fl oat swit ch:

1. Remove the two 1/4-in. hex-head screws and

the access panel.

2. Disconnect the fl oat switch wire harness.

3. Remove the 2 Phillips-head screws holding the

switch to the dishwasher.

The turbidity sensor measures the amount of

suspended particles in the wash water in the sump.

The sump water lays within the 1/4- to 3/8-in. gap

between the LED transmitter and the receptor

during the designated fi lls. Successive turbidity

measurements are supplied to the control module

and used to determine whether to add or skip any

prewash or rinse cycles and whether to adjust the

wash or heat times. By measuring the turbidity level,

the control module can conserve energy on lightly

soiled loads by skipping unnecessary cycles. If the

soil level is high, the control module adds one or

more rinse cycles and increases the wash and heat

times as necessary.

Note: If the turbidity sensor fails, the unit operates

for the maximum amount of time, using the

maximum number of wash and rinse fi lls for the

selected cycle.

The turbidity sensor can be tested by checking the

resistance across the wires on the control board at

J3, pin 1 (yellow/black wire), and J3, pin 4 (orange

wire). (See Control Board Connect Locator View.) The

thermistor's resistance has a negative temperature

coeffi cient.

Disconnect

4. Pull the fl oat switch out of the bracket.

• At 75°F, the resistance is approximately 9.9 K.

• At 140°F, the resistance is approximately 2.8 K

Control Board Turbidity Sensor

TURBIDITY/

TEMPERATURE

SENSOR

J3

1

2

3

4

YB

NX

SX

OX

NTC

1

RECEIVER EMITTER

2

TRANSMITTER

3

CATHODE

4

Vcc

– 31 –

(Continued next page)

Page 32

To remove the turbidity sensor:

To remove the heating element:

1. Remove the dishwasher from its installation.

2. Lay the dishwasher on its back.

3. Disconnect the wire harness from the turbidity

sensor.

4. Loosen the 5/16-in. hex-head screw from the

hose clamp and pull the turbidity sensor out of

the sump.

Note: When installing the turbidity sensor, align the

sensor tab in the cutout before tightening the hose

clamp.

Disconnect

1. Remove the dishwasher from its installation.

2. Lay the dishwasher on its back.

3. Disconnect the 2 wires from the heating element

terminals.

4. Remove the 2 nuts holding the heating element

to the dishwasher housing.

Disconnect

Disconnect

5. Remove the lower wash arm. (See Lower Wash

Arm.)

Tab

Heating Element

The heating element maintains water temperature

during some wash and rinse cycles.

The heating element has an approximate resistance

value of 16 . It is rated at 835 watts in wet

conditions and 665 watts in dry conditions.

Operation of the heating element can be checked

using the service test mode. (See Service Mode.) Allow

1 or 2 minutes before opening the dishwasher door

and note if heat is present.

6. Release the heating element from the 2

retainers and remove it from the tub.

Caution: To prevent water leakage, assure the

O-rings are placed between the heating element

and tub fl oor before installing the heating element

nuts.

O-ring

– 32 –

Page 33

Fill Funnel

The fi ll funnel is mounted on the left side of the tub.

Its purpose is to provide a method for supplying

water for the wash and rinse cycles. The air gap

prevents wash water that has been siphoned from

fl owing back into the water supply system should

the water pressure drop to less than atmospheric

pressure. The fi ll funnel also allows air into the tub to

permit airfl ow for drying dishware.

To remove the fi ll funnel:

1. Access the fi ll funnel by carefully pulling the

dishwasher out from its installation.

2. Remove the fi ll funnel cap by rotating it

counterclockwise.

Caution: To prevent water leakage, assure the

O-ring is in place before installing the fi ll funnel.

O-ring

3. Pull the hose off the fi ll funnel.

Fill Funnel Cap

Hose

Water Inlet Valve

The water inlet valve is electronically controlled and

solenoid-operated. The fl ow of water is controlled by

a rubber fl ow washer capable of maintaining a fl ow

rate of 1.1 to 1.3 gallons per minute with incoming

water pressure of 20 to 120 psi. The water inlet valve

is attached to a bracket located on the left side of

the front brace.

The water inlet valve is energized forapproximately

21 to 62 seconds during each fi ll. See the cycle chart

for specifi c times during cycles. (See Cycle Chart.)

The water inlet valve has an approximate resistance

value of 0.725 to 1.2 K

Operation of the water inlet valve can be checked

by using the service test mode. (See Service Mode.)

To remove the water inlet valve:

1. Remove the two 1/4-in. hex-head screws and

the access panel.

Fill Funnel

– 33 –

(Continued next page)

Page 34

2. Disconnect the overfi ll switch wiring harness.

Disconnect

3. Remove the two 5/16-in. hex-head screws from

the water inlet valve bracket.

6. Remove the clamp and outlet hose from the

valve.

Clamp

Hose

4. Slide the bracket down to disengage the tab

that holds the bracket to the dishwasher frame.

Tab

5. Disconnect the wiring harness from the water

inlet valve.

7. Remove the 4 Phillips-head screws from the

water inlet valve bracket.

Caution: To prevent water leakage, assure the

O-ring is retained in the valve before installing the

bracket.

Disconnect

O-Ring

– 34 –

Page 35

Drain Pump Assembly

Motor Pump Assembly

The drain pump assembly is located under the tub

and operates on 120 VAC. It is energized for the fi rst

60 seconds of a new cycle and for approximately

105 seconds after the wash pump shuts down to

remove any water in the dishwasher sump. The

drain pump forces water out of the drain line. A

check valve fl ap on the drain pump prevents the

discharged water from entering the sump.

The drain pump has an approximate resistance

value of 30 .

Operation of the drain pump assembly can be

checked by using the service test mode. (See Service

Mode.)

To remove the drain pump assembly:

1. Disconnect power.

2. Remove the dishwasher from its installation.

3. Lay the dishwasher on its back.

4. Disconnect the 2 wires from the drain pump.

The motor pump assembly is located under the

tub behind the sump. The motor utilizes a start

capacitor rated at 10 fd. The motor rotates

clockwise (as viewed from the terminal end) and

draws approximately 1 amp at 120 VAC.

The motor pump assembly has an approximate

resistance value of 10 .

Operation of the motor pump assembly can be

checked using the service test mode. (See Service

Mode.)

To remove the motor pump assembly:

1. Disconnect power.

2. Remove the dishwasher from its installation.

3. Lay the dishwasher on its back.

4. Disconnect the wire harness from the motor.

5. Loosen the 5/16-in. hex-head screw, then pull

the drain pump off the sump.

Disconnect

Disconnect

Disconnect

5. Loosen the two 5/16-in. hex-head screws from

the hose clamps.

– 35 –

(Continued next page)

Page 36

6. Disengage the motor hanger arm to remove the

motor pump assembly.

Tub Thermal Cutout (TCO)

4. Slide the tub TCO off the bracket.

Tub TCO

Note: When replacing the tub TCO, splice a new

thermostat into the harness using connectors and

procedures approved for damp/wet conditions.

Silicone Grease

The tub TCO trips at 165°F and it auto resets at

150°F.

The tub TCO is located under the tub behind the toe

kick panel.

To remove the tub TCO:

1. Disconnect power.

2. Remove the two 1/4-in. hex-head screws and

the access panel.

3. Remove the two 1/4-in. hex-head screws and

the shield.

Shield

– 36 –

Page 37

Troubleshooting

Service Mode

The dishwasher is programmed with a service mode to aid the technician in troubleshooting it. Each

component can be cycled to detect if it is functioning correctly. Components are cycled by pressing buttons

on the control panel.

To enter the service mode:

• Put the dishwasher in standby mode.

• Press the HEATED DRY and SELECT CYCLE buttons simultaneously.

If performed correctly, the control board responds with two beeps, and all LEDs illuminate for 4 seconds. To

exit the service mode, press the START/RESET button at any time. The dishwasher will automatically exit

service mode if the control panel is inactive for 5 minutes.

Service Mode Control Operation:

When a control is activated in the service mode, the output continues to remain active until the maximum

time has expired or another button is pressed. Once the water valve is activated, the microprocessor must

perform a drain cycle to pump out the water before exiting the service mode.

Control Replacement/Calibration:

The dishwasher enters into the test/00 calibration mode when the unit is fi rst powered on. The door must be

closed and latched. Wait approximately 6 minutes for the second fi ll before canceling the cycle by pressing

the START/RESET button. The dishwasher will be ready to operate after the water is pumped out.

– 37 –

(Continued next page)

Page 38

Top-Control

Activates/Deactivates fan

(Hold both buttons simultaneously for 3

seconds)

– 38 –

Page 39

Factory Test Mode

The factory test mode initiates automatically upon installation of a new main control board.

Factory test mode (approximately 5 minutes total):

• All LEDs light (10 seconds).

• Close door.

• Vent opens, fan activates for 5 seconds, and vent closes (15 seconds).

• Detergent rinse module and water inlet valve are energized (45-65 seconds, depending on model).

• Main pump is energized (55 seconds).

• Turbidity sensor is calibrated and other checks occur (90 seconds).

• Drain pump is energized (75 seconds).

• When second fi ll starts, exit test mode by pressing the START/RESET button.

In some cases, it may be necessary to unplug the unit to exit the test mode. If the unit is left in factory test

mode, the dishwasher could run as long as 75 minutes before exiting.

Turbidity Sensor Replacement/Calibration:

When the main control board is replaced, the dishwasher starts a factory test mode when powered on.

During this test, the turbidity sensor is calibrated. If the turbidity sensor is replaced without replacing the

control board, the sensor may be calibrated manually by pressing the START/RESET button 100 times.

If the turbidity sensor fails, the control board uses the maximum wash/rinse cycles.

– 39 –

Page 40

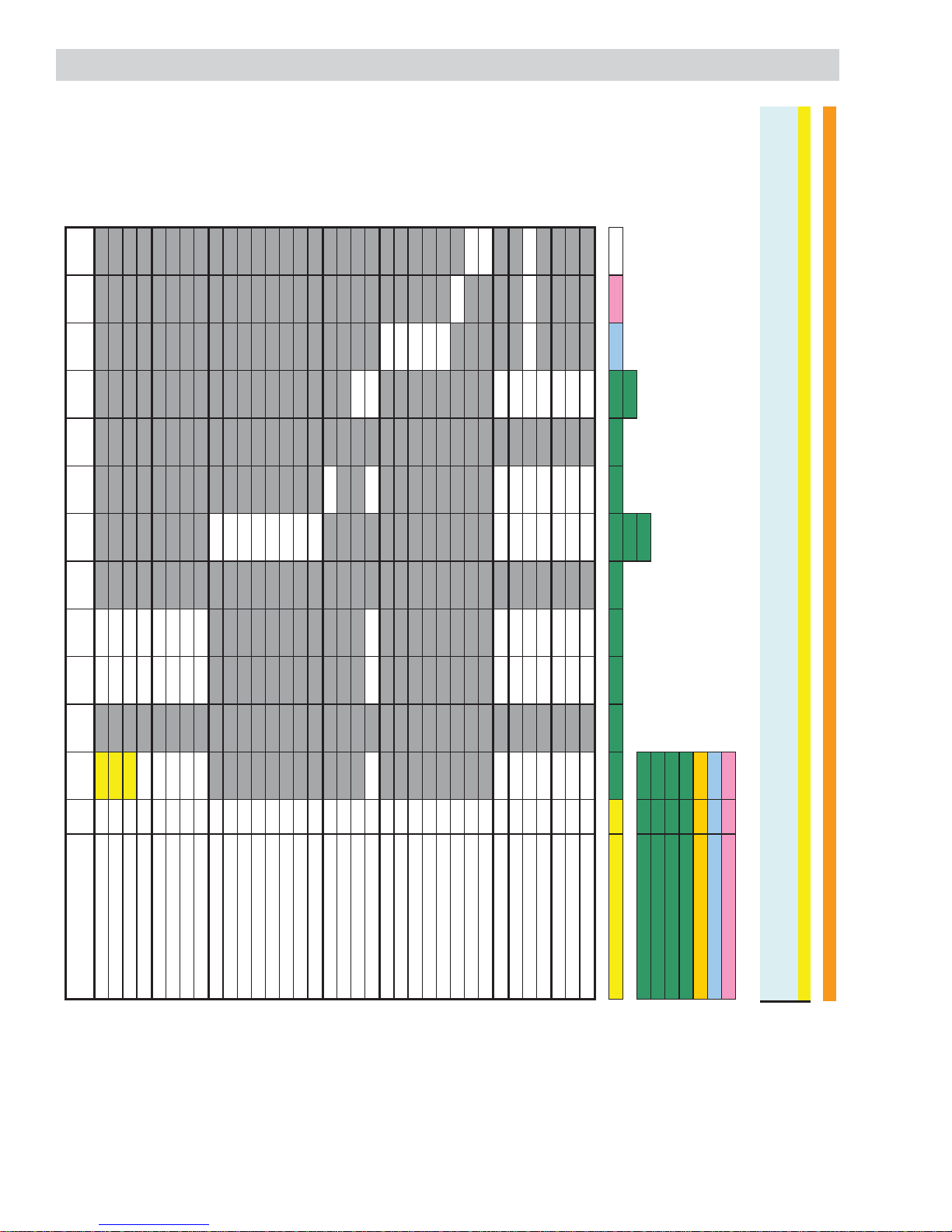

Schematics and Wiring Diagrams

WARNING: Disconnect electrical power before servicing.

Caution: Label all wires prior to disconnection. Wiring errors can cause improper and dangerous operation.

Verify operation after servicing.

NTC

3

2

4

1

YB

SX

OX

NX

TURBIDITY SENSOR

J5-1

WX

BXBW

WX

WX

BX

WX

WX

WX

WX

WX

RX

STRIP CIRCUITS

YB

725-1200

J2-11

THERMOSTAT

1

SUPPLY

89

71011

6

5

4

3

2

1

23

1

23

1

10

9

8

67

5

4

23

1

VENT

2

FLOOD

WATER VALVE

DOOR

YX

NO

SWITCH

C

PX

J2-5

BX

K

INTERLOC

BW

GY RX

DOOR

NO COM

INTERLOCK

BW

DOOR INTERLOCK

J2-10

Vcc

NTC

RECEIVER EMITTER

TRANSMITTER

CATHODE

3

2

4

1

NX

2

1

TURBIDITY/

SX

3

TEMPERATURE

OX

4

J3

SENSOR

DETERGENT

CNO

3

2

J1

POWER

J2

POWER SWITCHING

J4

SENSOR

J10

PQA

CONTROL CIRCUIT BOARD

J8

3-DIGIT DISPLAY

J7

J5

KEYPAD

ACTIVE

1

M

10

PUMP

CIRCULATION

NX

J2-4

PUMP MOTOR

NO COM

SENSOR

DETERGENT

HEATING ELEMENT

VX VX

J2-6

HEATING ELEMENT

WX

1200-2800

DETERGENT MODULE

RY

NO

C

THERMOSTAT

VX

J2-7

DRAIN PUMP

3-DIGIT DISPLAY

VENT MOTOR

WX

M

30

RX

M

RX

J5-2

DRAIN PUMP

WX

WX

HEATING ELEMENT

VX VX

M

30

DRAIN PUMP

RX

J2-8

NO

C

THERMOSTAT

LETTERS COLOR

COLOR CODE

LETTERS COLOR

2

1

BX

DETERGENT MODULE

RY

DETERGENT MODULE

FLOOD

SWITCH

RED

GRAY

RXSXTXVXWX

LT. BLUE

BLACK

AXBXCXNXOX

J1

3

4

J2-9

5

WX

PX YX

TAN

N

BROW

6

FAN

1200-2800

FAN

725-1200

CIRCULATION

CNO

PURPLE

WHITE

YELLOW

YX

DK. BLUE

ORANGE

GX GREEN

7

8

WX

NR

PUMP

PINK

PX

RX

M

65

J2-3

XB

XW

WX

NX

THE "X" INDICATES ONE SOLID COLOR -

NO TRACER. WIRES WITH TRACER SHOW

DR Module

1200-2800

(CIRCULATION PUMP)

SX

WAX MOTOR

J2-2

NL1

YG

G

WX

M

10

FAN

NR

BOTH COLORS. EXAMPLE -WR IS WHITE

WITH RED TRACER.

(optional)

M

M

BULK DETERGENT PUMP

OX

BULK DETERGENT PUMP

J2-1

65

WAX MOTOR

(CIRCULATION PUMP)

875

WX

SX

SENSOR

DETERGENT

DETERGENT SENSOR

1200-2800

BULK DETERGENT PUMP

GY

J4-1 J4-3

WX

M

875

OX

VENT

ACTIVE

MOTOR

E

Y

K

P

A

D

M

RX

BX

– 40 –

DOTTED LINE INDICATES

THE FEATURE IS NOT ON

ALL MODELS.

Page 41

GE Dishwasher Warranty.

Warranty

All warranty service provided by our Factory Service Centers,

or an authorized Customer Care

on-line, visit us at GEAppliances.com, or call 800.GE.CARES (800.432.2737) in

the United States. In Canada, call 1.800.561.3344. Please have serial number

and model number available when calling for service.

®

technician. To schedule service,

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

For The Period Of: GE Will Replace:

One Year Any part of the dishwasher which fails due to a defect in materials or workmanship. During

From the date of the this limited one-year warranty, GE will also provide, free of charge, all labor and in-home service

original purchase to replace the defective part.

Five Years The dishwasher racks and the electronic control module if they should fail due to a defect

(only for model numbers in materials or workmanship. During this five-year limited warranty, you will be responsible

beginning with PDW for any labor or in-home service costs.

or CDW) From the date

of the original purchase

Lifetime of Product The Stainlesstub or door liner, if it fails to contain water due to a defect in materials or

(only for model numbers workmanship. During this limited warranty, GE will also provide, free of charge, all labor and

beginning with PDW in-home service to replace the defective part.

or CDW)

What GE Will Not Cover (for customers in the United States):

■ Service trips to your home to teach you how to use

the product.

■ Improper installation, delivery or maintenance.

■ Failure of the product if it is abused, misused, or used for

other than the intended purpose or used commercially.

■ Replacement of house fuses or resetting of circuit breakers.

■ Product not accessible to provide required service.

■ Damage to the product caused by accident, fire, floods

or acts of God.

■ Incidental or consequential damage caused by possible

defects with this appliance.

■ Cleaning or servicing of the air gap device in the drain line.

■ Damage caused after delivery, including damage from

items dropped on the door.

EXCLUSION OF IMPLIED WARRANTIES—Your sole and exclusive remedy is product repair as provided in this Limited

Warranty. Any implied warranties, including the implied warranties of merchantability or fitness for a particular

purpose, are limited to one year or the shortest period allowed by law.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home use within the

USA. If the product is located in an area where service by a GE Authorized Servicer is not available, you may be responsible for a trip

charge or you may be required to bring the product to an Authorized GE Service location for service. Proof of original purchase date

is needed to obtain service under the warranty. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives you specific legal

rights, and you may also have other rights which vary from state to state. To know what your legal rights are, consult your local

or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

What Is Not Covered (for customers in Canada):

■ Service trips to your home to teach you how to use

the product.

■ Improper installation.

If you have an installation problem, contact your dealer

or installer. You

electrical, exhausting and other connecting facilities.

EXCLUSION OF IMPLIED WARRANTIES—Your sole and exclusive remedy is product repair as provided in this Limited

Warranty. Any implied warranties, including the implied warranties of merchantability or fitness for a particular

purpose, are limited to one year or the shortest period allowed by law.

This warranty is extended to the original purchaser and any succeeding owner for products purchased in Canada for home use

within Canada. In home warranty service will be provided in areas where it is available and deemed reasonable by Mabe to provide.

are responsible for providing adequate

■ Failure of the product if it is abused, misused, or used for

other than the intended purpose or used commercially.

■ Replacement of house fuses or resetting of circuit breakers.

■ Damage to the product caused by accident, fire, floods

or acts of God.

■ Damage caused after delivery.

WARRANTOR IS NOT RESPONSIBLE FOR CONSE QUEN TIAL DAMAGES.

Warrantor: MABE CANADA INC.

– 41 –

23

Loading...

Loading...