GE ZBD6900P00II, ZBD6900P10II, ZBD6900P30II, ZBD6910P00BB, ZBD6910P30BB Installation Guide

...Page 1

Installation

I struct" n

Built-In Dishwashers

*Custom front panel models include a kit that

contains a template, hardware and panel

installation instructions. Refer to the kit

instructions when installing the custom panel.

131-30246 I

10-08 JR

Page 2

Safetg Information

BEFORE YOU BEGIN

Read these instructions completelg and carefullg.

• IMPORTANT- Savetheseinstructionsfor

localinspector'suse.Observeallgoverningcodesand

ordinances.

• Note to Installer- Be sure to leave these

instructions with the Consumer.

• Note to Consumer- Keepthese instructions

with gour Owner's Manual for future reference.

• Skill Level- Installation of this dishwasher requires

basic mechanical and electrical skills. Proper

installationistheresponsibilitgoftheinstaller.

Productfailuredue toimproperinstallationisnot

coveredundertheGE ApplianceWarrantg.

• Completion Time - ito3 Hours.

New installations require more time than replacement

installations.

CONTENTS

Installation Preparation

Parts Supplied......................................................................................3

Materials You Will Need..................................................................3

Tools You Will Need ..........................................................................3

Advance Planning ..............................................................................4

Prepare Dishwasher Enclosure....................................................4

Prepare Drain Plumbing ..................................................................5

Prepare Electrical Wiring ................................................................6

Prepare Hot Water Line ..................................................................7

Installation Instructions

Step 1,Locate Installation Items ................................................7

Step 2, Install Trim Pieces ..............................................................7

Step 3, Check Door Balance ..........................................................8

Step 4, Remove Wood Base, Install Leveling Legs ............8

Step 5, Remove ToeKick..................................................................8

Step 6, Remove ToeKick Brace ....................................................8

Step 7,Install Power Cord..............................................................9

• IMPORTANT- The dishwasher MUST

be installedto allowforfutureremoval from

the enclosureifserviceisrequired.

Ifgou receiveda damaged dishwasher,gou should

immediatelg contact gour dealer or builder.

READ CAREFULLY.

KEEP THESE INSTRUCTIONS.

FOR YOUR SAFETY

Read and observe all CAUTION and WARNINGS shown

throughout these instructions.

While performing installations described in this booklet,

gloves, safetg glasses or goggles should be worn.

For Monogram local service in gout area, 1.800.444.1845.

For Monogram parts and accessories, call 1.800.626.2002.

For Monogram parts and accessories in Canada,

call1.800.561.3344.

Step 8, Install 90° Elbow..................................................................9

Step 9, Position Water Line and Housing Wiring ................9

Step 10, Install Drain Hose to Dishwasher Drain Port......9

Step 11, Insert Drain Hose Through Cabinet......................10

Step 12, Slide Dishwasher

Three-Fourths of the Wag Into Cabinet................................10

Step 13, Slide Dishwasher Into Final Position ............10, 11

Step 14, Level Dishwasher ..........................................................11

Step 15, Secure Dishwasher

to Countertop or Cabinet ............................................................12

Step 16, Connect Water Supplg ..............................................12

Step 17, Connect Drain Line ......................................................13

Step 18, Connect Power Supplg ..............................................14

Step 19, Pretest Checklist ............................................................14

Step 20, Dishwasher Wet Test ..................................................15

Step 21, Set Water Hardness ....................................................15

Step 22, Install Sound Upgrade Kit if Equipped ................15

Step 23, Install ToeKick ..............................................Back Cover

Step 2/4,Literature ........................................................Back Cover

Page 3

Installation Preparation

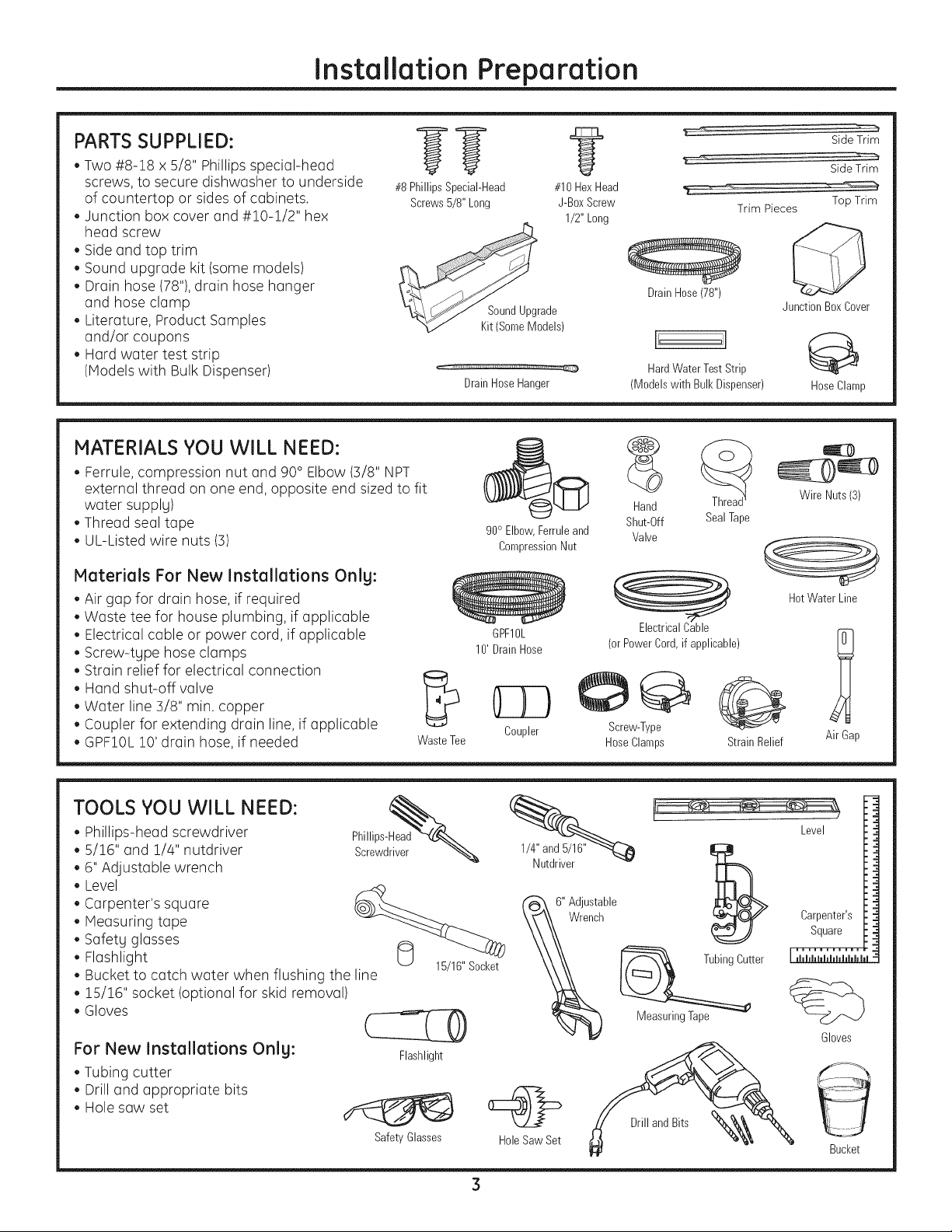

PARTS SUPPLIED:

• Two #8-18 x 5/8" Phillips special-head

screws, to secure dishwasher to underside

of countertop or sides of cabinets.

• Junction box cover and #10-!/2" hex

head screw

• Side and top trim

• Sound upgrade kit (some models)

• Drain hose (78"),drain hose hanger

and hose clamp

• Literature, Product Samples

and/or coupons

• Hard water test strip

(Models with Bulk Dispenser)

#8PhillipsSpecial-Head #10HexHead

MATERIALS YOU WILL NEED:

• Ferrule, compression nut and 90° Elbow (3/8" NPT

external thread on one end, opposite end sized to fit

water supply)

• Thread seal tape

• UL-Listed wire nuts (3)

Materials For New Installations Onlg:

• Air gap for drain hose, if required

• Waste tee for house plumbing, if applicable

• Electrical cable or power cord, if applicable

• Screw-type hose clamps

• Strain relief for electrical connection

• Hand shut-off valve

• Water line 3/8" min. copper

• Coupler for extending drain line, if applicable

• GPF!OL !0' drain hose, if needed

IjIj

Screws5/8" Long J-BoxScrew

1/2" Long

DrainHoseHanger

%0 Elbow,Ferruleand

CompressionNut

GPFIOL

10' DrainHose

Waste Tee

Coupler

Trim Pieces Top Trim

Q

DrainHose(78")

Hard Water Test Strip

(Modelswith BulkDispenser) HoseClamp

Hand

Shut-Off Seal Tape

Valve

ElectricalCable

(orPowerCord,if applicable)

Screw-Type

Hose Clamps

StrainRelief

JunctionBoxCover

Wire Nuts(3)

HotWater Line

Side Trim

SideTrim

4

Air Ga

TOOLS YOU WILL NEED:

• Phillips-head screwdriver

• 5/16" and !/4" nutdriver

• 6" Adjustable wrench

• Level

• Carpenter's square

• Measuring tape

• Safetu glasses

• Flashlight 8 15/16"Socket

• Bucket to catch water when flushing the line

• 15/16" socket (optional for skid removal)

• Gloves

For New Installations Onlg:

• Tubing cutter

• Drill and appropriate bits

• Hole saw set

PhlIrllpsi_

Flashlight

Safety Glasses

1/4"and5/16"

Nutdriver

HoleSaw Set

Wrench

6" djustable

Level

Carpenter's

Square

ter

Measuring Tape

Gloves

Drill and Bits

Bucket

Page 4

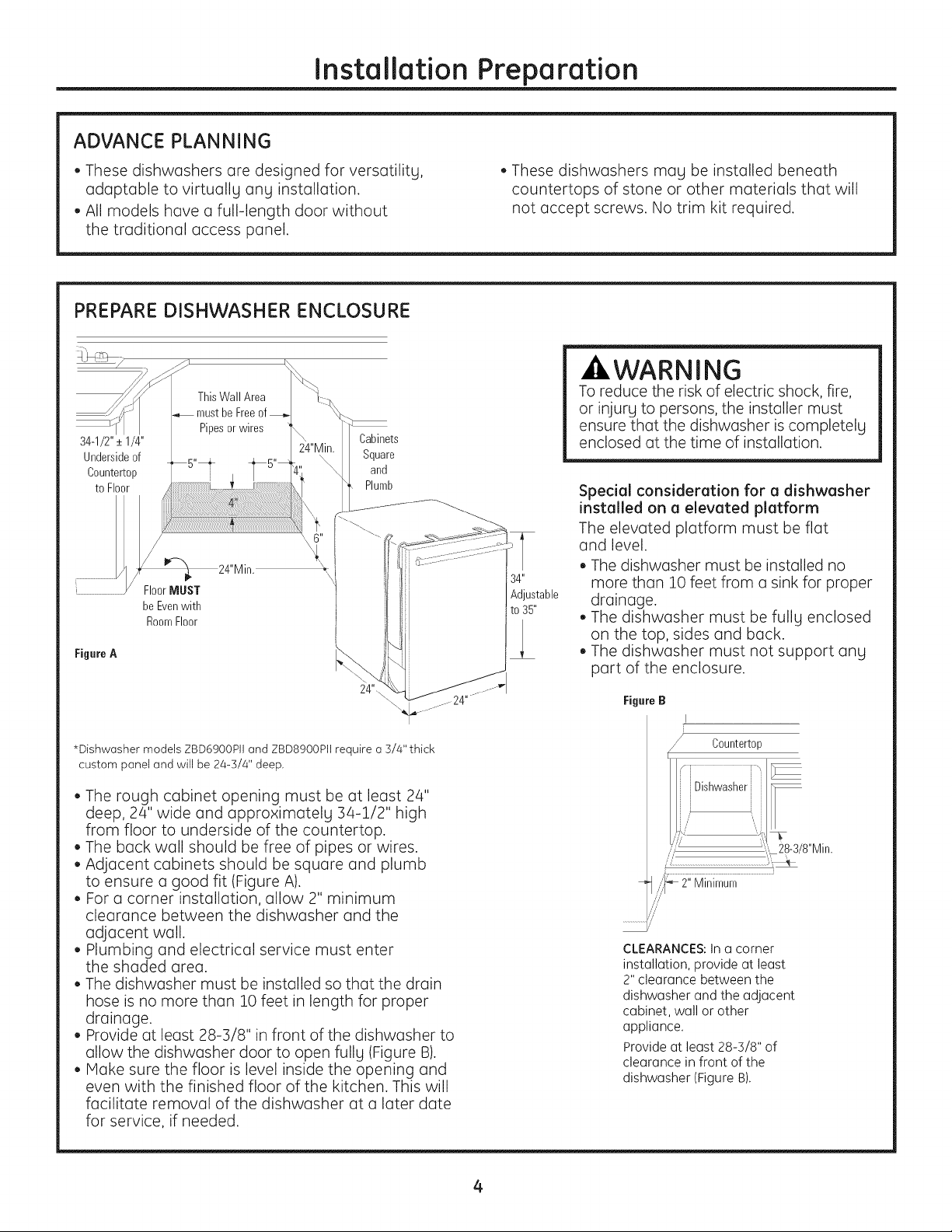

ADVANCE PLANNING

Installation Preparation

• These dishwashers are designed for versatilitg,

adaptable to virtuallg ang installation.

• All models have a full-length door without

the traditional access panel.

PREPARE DISHWASHER ENCLOSURE

ThisWallArea

mustbe

34-1/2"+ 1/4"

Pipesorwires

Undersideof

Countertop

to Floor

24"Min.

FloorMUST

beEvenwith

RoomFloor

Figure A

._ Cabinets

,n. Square

_ and

_k Plumb

\,

\\

• These dishwashers mag be installed beneath

countertops of stone or other materials that will

not accept screws. No trim kit required.

'kWARNING

To reduce the risk of electric shock, fire,

or injurg to persons, the installer must

ensure that the dishwasher is completelg

enclosed at the time of installation.

Special consideration for a dishwasher

installed on a elevated platform

The elevated platform must be flat

and level.

• The dishwasher must be installed no

Adjustable

to 35"

more than 10 feet from a sink for proper

drainage.

• The dishwasher must be fullg enclosed

on the top, sides and back.

The dishwasher must not support any

part of the enclosure.

*Dishwasher models ZBD6900PII and ZBD8900PlI require a 3/4" thick

custom panel and will be 24-3/4" deep.

• The rough cabinet opening must be at least 24"

deep, 24" wide and approximatelg 34-1/2" high

from floor to underside of the countertop.

• The back wall should be free of pipes or wires.

• Adjacent cabinets should be square and plumb

to ensure a good fit (Figure A).

• For a corner installation, allow 2" minimum

clearance between the dishwasher and the

adjacent wall.

• Plumbing and electrical service must enter

the shaded area.

• The dishwashermust be installedso thatthedrain

hose isno more than i0 feetinlengthforproper

drainage.

• Provideat least28-3/8"infrontofthe dishwasherto

allowthe dishwasherdoorto open fullg(FigureB).

• Make surethe floorislevelinsidethe opening and

even with the finished floor of the kitchen. This will

facilitate removal of the dishwasher at a later date

for service, if needed.

Figure B

I

Countertop

CLEARANCES:In a corner

installation, provide at least

2" clearance between the

dishwasher and the adjacent

cabinet, wall or other

appliance.

Provide at least 28-3/8" of

clearance in front of the

dishwasher (Figure B).

4

Page 5

Installation Preparation

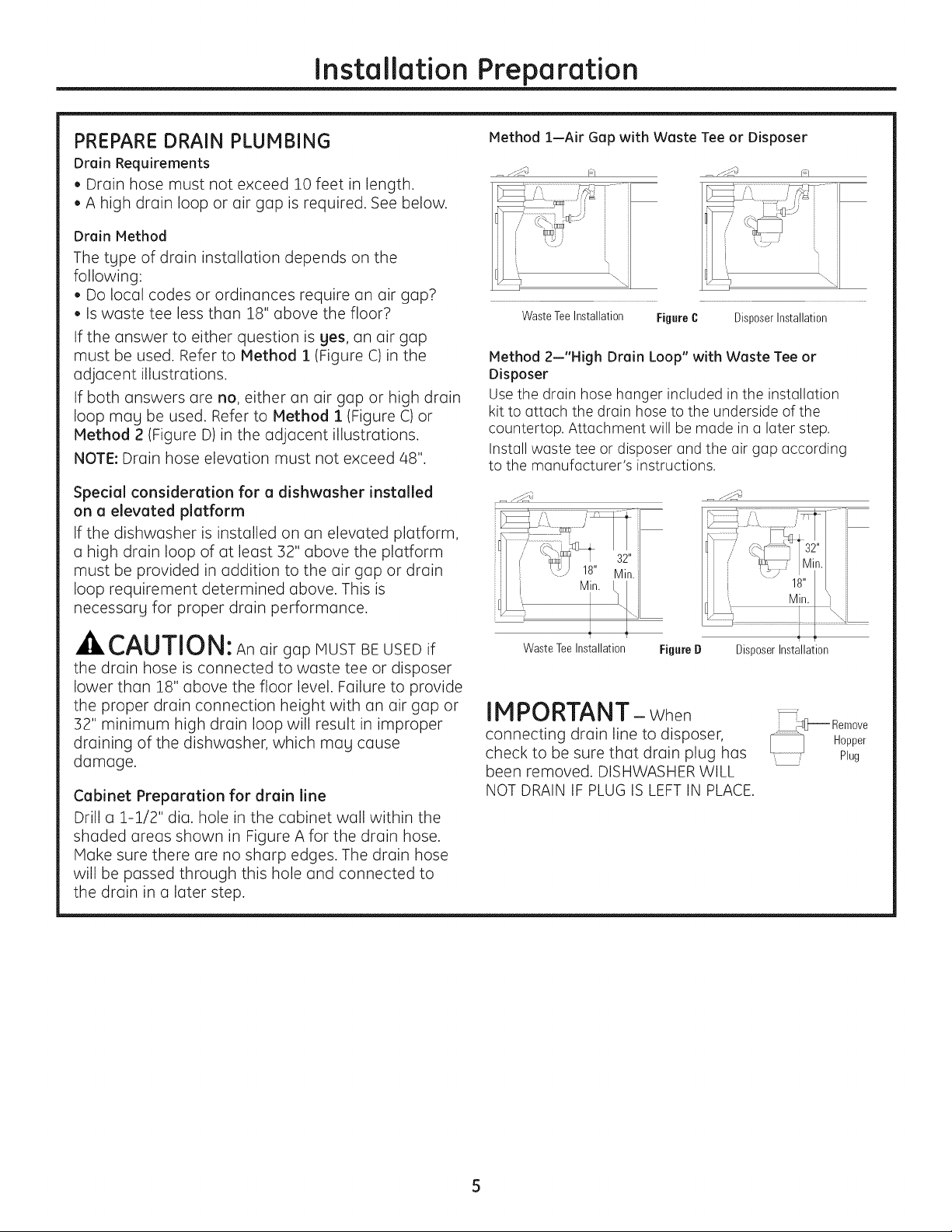

PREPARE DRAIN PLUMBING

Drain Requirements

• Drain hose must not exceed 10 feet in length.

• A high drain loop or air gap is required. See below.

Drain Method

The type of drain installation depends on the

following:

Do local codes or ordinances require an air gap?

Is waste tee less than 18" above the floor?

If the answer to either question is ges, an air gap

must be used. Refer to Method 1 (Figure C) in the

adjacent illustrations.

If both answers are no, either an air gap or high drain

loop may be used. Refer to Method 1 (Figure C) or

Method 2 (Figure D)in the adjacent illustrations.

NOTE: Drain hose elevation must not exceed 48".

Special consideration for a dishwasher installed

on a elevated platform

If the dishwasher is installed on an elevated platform,

a high drain loop of at least 32" above the platform

must be provided in addition to the air gap or drain

loop requirement determined above. This is

necessarg for proper drain performance.

Method 1--Air Gap with Waste Tee or Disposer

WasteTeeInstallation Figure C DisposerInstallation

Method 2--"High Drain Loop" with Waste Tee or

Disposer

Use the drain hose hanger included in the installation

kit to attach the drain hose to the underside of the

countertop. Attachment will be made in a later step.

Install waste tee or disposer and the air gap according

to the manufacturer's instructions.

CAUTION: An airgap MUST BE USED if

the drainhose isconnected to waste tee or disposer

lower than 18" above the floor level. Failure to provide

the proper drain connection height with on air gap or

32" minimum high drain loop will result in improper

draining of the dishwasher, which mag cause

damage.

Cabinet Preparation for drain line

Drill a 1-1/2" dia. hole in the cabinet wall within the

shaded areas shown in Figure A for the drain hose.

Make sure there are no sharp edges. The drain hose

will be passed through this hole and connected to

the drain in a later step.

Waste Tee Installation

Figure D DisposerInstallation

IMPORTANT- When

connectingdrainlineto disposer,

check to be surethatdrainplughas

been removed. DISHWASHER WILL

NOT DRAIN IFPLUG ISLEFT IN PLACE.

i N_----Rem0ve

Hopper

/ Plug

Page 6

Installation Preparation

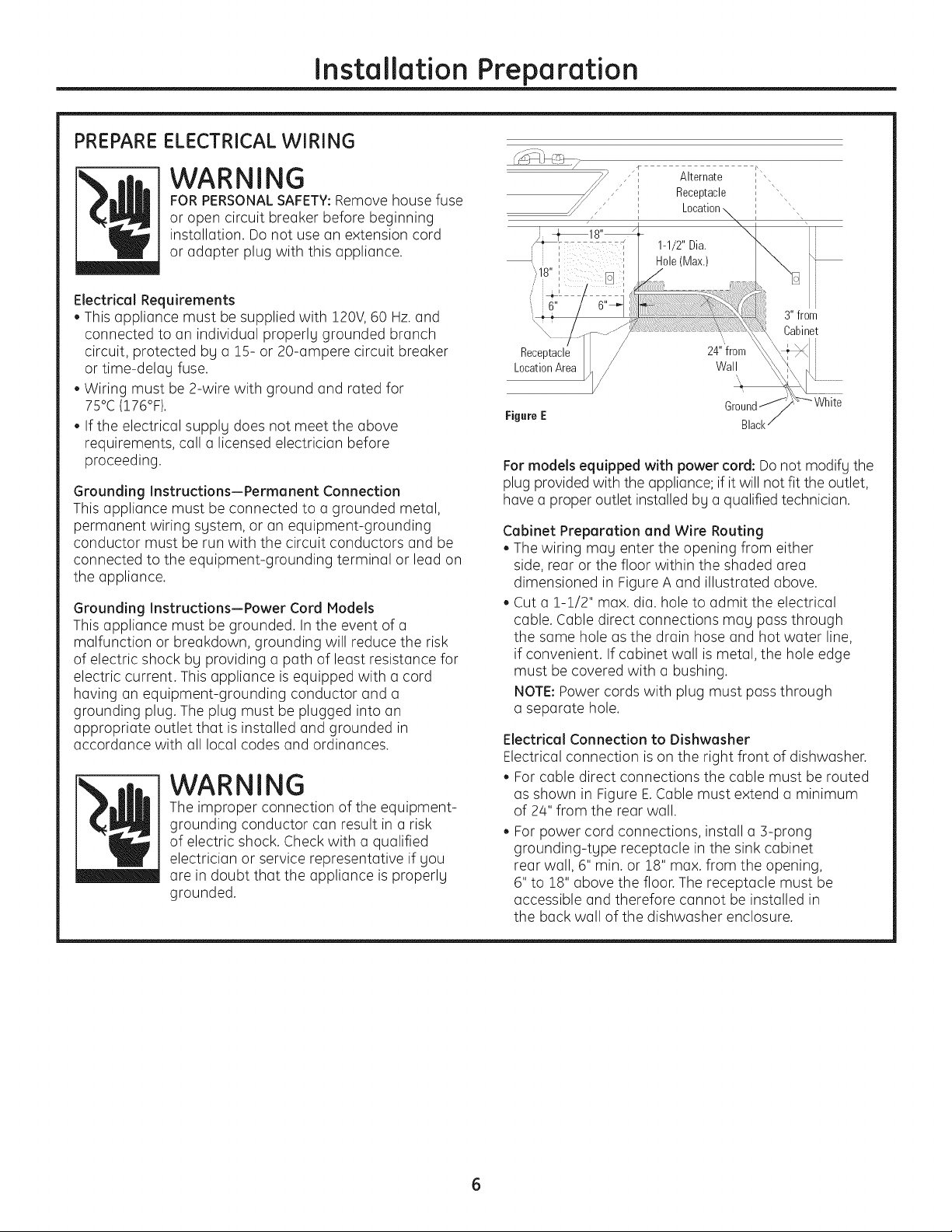

PREPARE ELECTRICAL WIRING

WARNING

FOR PERSONALSAFETY:Remove house fuse

or open circuit breaker before beginning

installation. Do not use an extension cord

or adapter plug with this appliance.

Electrical Requirements

• This appliance must be supplied with 120V,60 Hz. and

connected to an individual properlg grounded branch

circuit, protected bg a 15- or 20-ampere circuit breaker

or time-delag fuse.

• Wiring must be 2-wire with ground and rated for

75°C(176°F).

• If the electrical supplg does not meet the above

requirements, call a licensed electrician before

proceeding.

Grounding Instructions--Permanent Connection

This appliance must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and be

connected to the equipment-grounding terminal or lead on

the appliance.

Grounding Instructions--Power Cord Models

This appliance must be grounded. In the event of a

malfunction or breakdown, grounding will reduce the risk

of electric shock bg providing a path of least resistance for

electric current. This appliance isequipped with a cord

having an equipment-grounding conductor and a

grounding plug. The plug must be plugged into an

appropriate outlet that is installed and grounded in

accordance with all local codes and ordinances.

WARNING

The improper connection of the equipment-

grounding conductor can result in a risk

of electric shock. Check with a qualified

electrician or service representative if gou

are in doubt that the appliance is properlg

grounded.

Alternate _"

Receptacle :

FigureE

For models equipped with power cord: Do not modifg the

plug provided with the appliance; if it will not fit the outlet,

have a proper outlet installed bg a qualified technician.

Cabinet Preparation and Wire Routing

• The wiring mag enter the opening from either

side, rear or the floor within the shaded area

dimensioned in Figure A and illustrated above.

• Cut a 1-1/2" max. dia. hole to admit the electrical

cable. Cable direct connections mag pass through

the same hole as the drain hose and hot water line,

if convenient. If cabinet wall is metal, the hole edge

must be covered with a bushing.

NOTE:Power cords with plug must pass through

a separatehole.

Electrical Connection to Dishwasher

Electrical connection is on the right front of dishwasher.

• For cable direct connections the cable must be routed

as shown in Figure E.Cable must extend a minimum

of 24" from the rear wall.

For power cord connections, install a 3-prong

grounding-tgpe receptacle in the sink cabinet

rear wall, 6" min. or 18" max. from the opening,

6" to 18" above the floor. The receptacle must be

accessible and therefore cannot be installed in

the back wall of the dishwasher enclosure.

i

3" from

Cabinet

Page 7

Installation Instructions

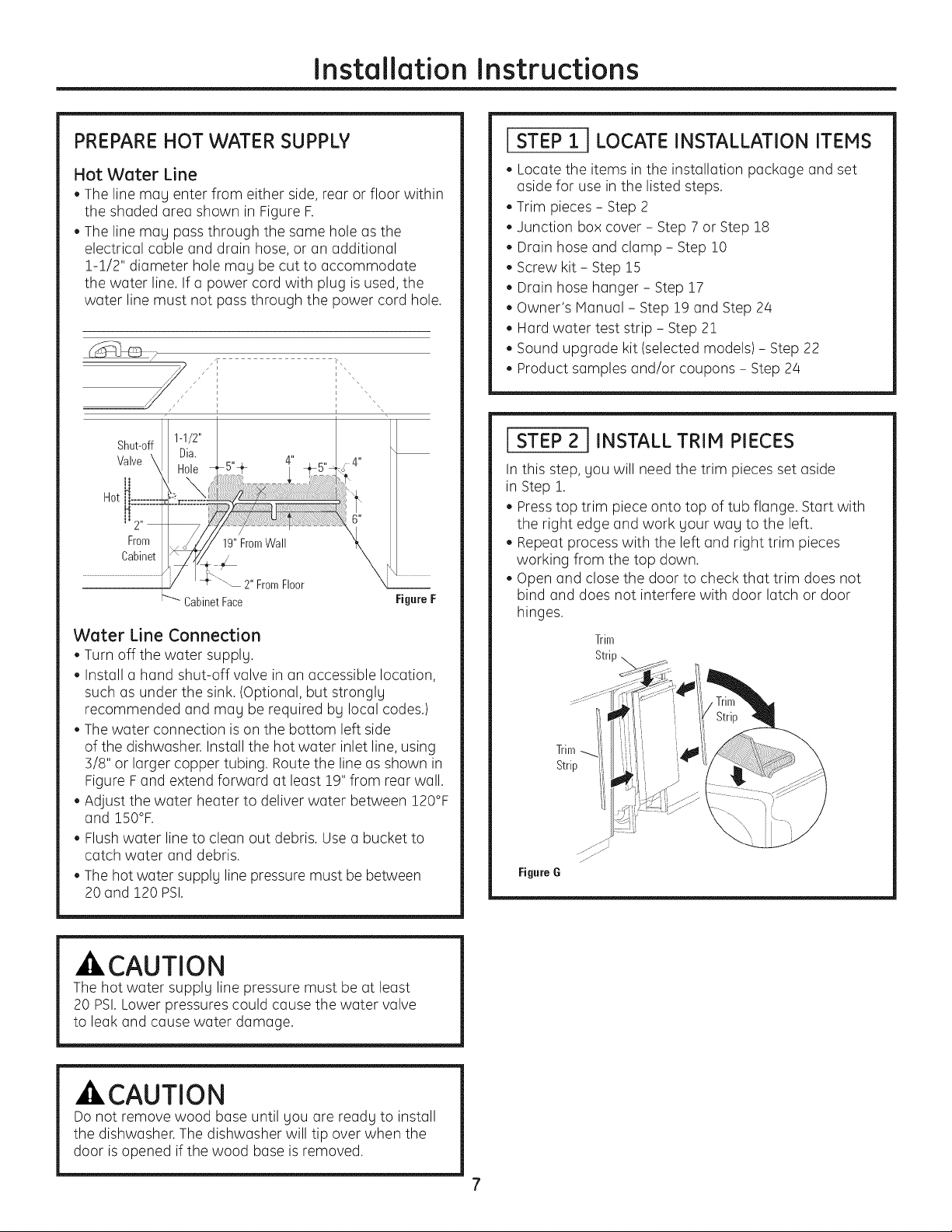

PREPARE HOT WATER SUPPLY

Hot Water Line

* The line mag enter from either side, rear or floor within

the shaded area shown in Figure F.

* The line mag pass through the same hole as the

electrical cable and drain hose, or an additional

1-!/2" diameter hole mag be cut to accommodate

the water line. If a power cord with plug is used, the

water line must not pass through the power cord hole.

i

i

i

i

i

FigureF

Water Line Connection

* Turn off the water supply.

* Install a hand shut-off valve in an accessible location,

such as under the sink. (Optional, but stronglg

recommended and mag be required bg local codes.)

* The water connection is on the bottom left side

of the dishwasher. Install the hot water inlet line, using

3/8" or larger copper tubing. Route the line as shown in

Figure Fand extend forward at least 19" from rear wall.

* Adjust the water heater to deliver water between 120°F

and !50°F.

* Flush water line to clean out debris. Use a bucket to

catch water and debris.

* The hot water supplg line pressure must be between

20 and 120 PSI.

STEP :I JLOCATE INSTALLATION ITEMS

* Locate the items in the installation package and set

aside for use in the listed steps.

* Trim pieces - Step 2

* Junction box cover- Step 7 or Step 18

* Drain hose and clamp- Step !0

* Screw kit - Step 15

* Drain hose hanger- Step 17

* Owner's Manual - Step 19 and Step 24

* Hard water test strip - Step 21

* Sound upgrade kit (selected models) - Step 22

* Product samples and/or coupons - Step 24

STEP 2 I INSTALL TRIM PIECES

In this step, gou will need the trim pieces set aside

in Step !.

* Presstop trim piece onto top of tub flange. Start with

the right edge and work gour wag to the left.

* Repeat process with the left and right trim pieces

working from the top down.

* Open and close the door to check that trim does not

bind and does not interfere with door latch or door

hinges.

Trim

Strip

Trim

Strip

FigureG

A' CAUTION

The hot water supplg line pressure must be at least

20 PSI.Lower pressures could cause the water valve

to leak and cause water damage.

,/kCAUTION

Donot remove wood base until gou are readg to install

the dishwasher. The dishwasher will tip over when the

door is opened if the wood base isremoved.

Page 8

Installation Instructions

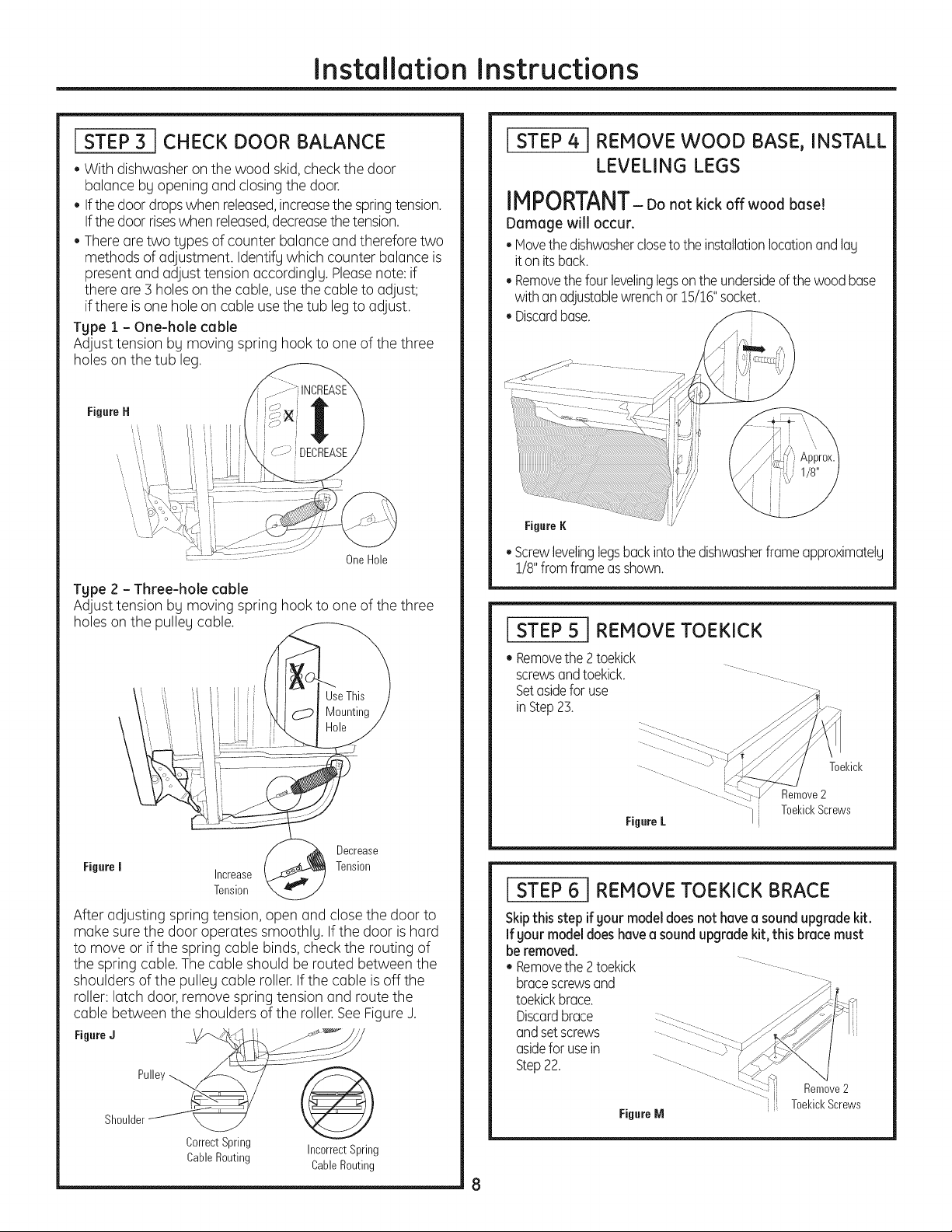

ISTEP 3 1CHECK DOOR BALANCE

• With dishwasher on the wood skid,check the door

balance bg opening and closing the door.

• Ifthedoor dropswhen released,increasethe spring tension.

Ifthedoor riseswhen released,decreasethetension.

Thereare two types of counter balanceand therefore two

methods of adjustment. Identify which counter balance is

present and adjust tension accordingly. Pleasenote: if

there are 5 holeson the cable, use the cable to adjust;

if there isone hole on cable usethe tub legto adjust.

Type 1 - One-hole cable

Adjust tension by moving spring hook to one of the three

holes on the tub leg.

One Hole

Type 2 - Three-hole cable

Adjust tension bUmoving spring hook to one of the three

holes on the pulley cable.

STEP 4 JREMOVE WOOD BASE, INSTALL

LEVELING LEGS

IMPORTANT-Donotkickoffwood base!

Damage will occur.

• Movethedishwasherdoseto the installationlocationandlag

iton itsback.

• Removethe fourlevelinglegsonthe undersideof thewoodbase

withan adjustablewrenchor 15/16"socket.

• Discardbase.

_%; .........

Figure K

• Screwlevelinglegsbackintothe dishwasherframeapproximately

1/8"fromframeas shown.

STEP 5 JREMOVE TOEKICK

• Removethe 2toekick

screwsandtoekick.

Setasideforuse

inStep23.

\

Decrease

Figure I Increase Tension

Tension

After adjusting spring tension, open and close the door to

make sure the door operates smoothly. Ifthe door is hard

to move or if the spring cable binds, check the routing of

the spring cable. The cable should be routed between the

shoulders of the pulley cable roller. If the cable isoff the

roller: latch door,remove spring tension and route the

cable between the shoulders of the roller.SeeFigureJ.

Figure J ___

Pulley

Shoulder ___

Correct Spring Incorrect Spring

Cable Routing Cable Routing

Toekick

Remove2

Figgre L

ToekickScrews

STEP 6 I REMOVE TOEKICK BRACE

Skipthisstep ifyour modeldoesnot havea soundupgradekit.

If your modeldoeshavea soundupgradekit,this bracemust

beremoved.

• Removethe 2toekick

bracescrewsand

toekickbrace.

Discardbrace

andsetscrews

asidefor usein

Step22.

Remove2

Figgre M

:: ToekickScrews

Page 9

Installation Instructions

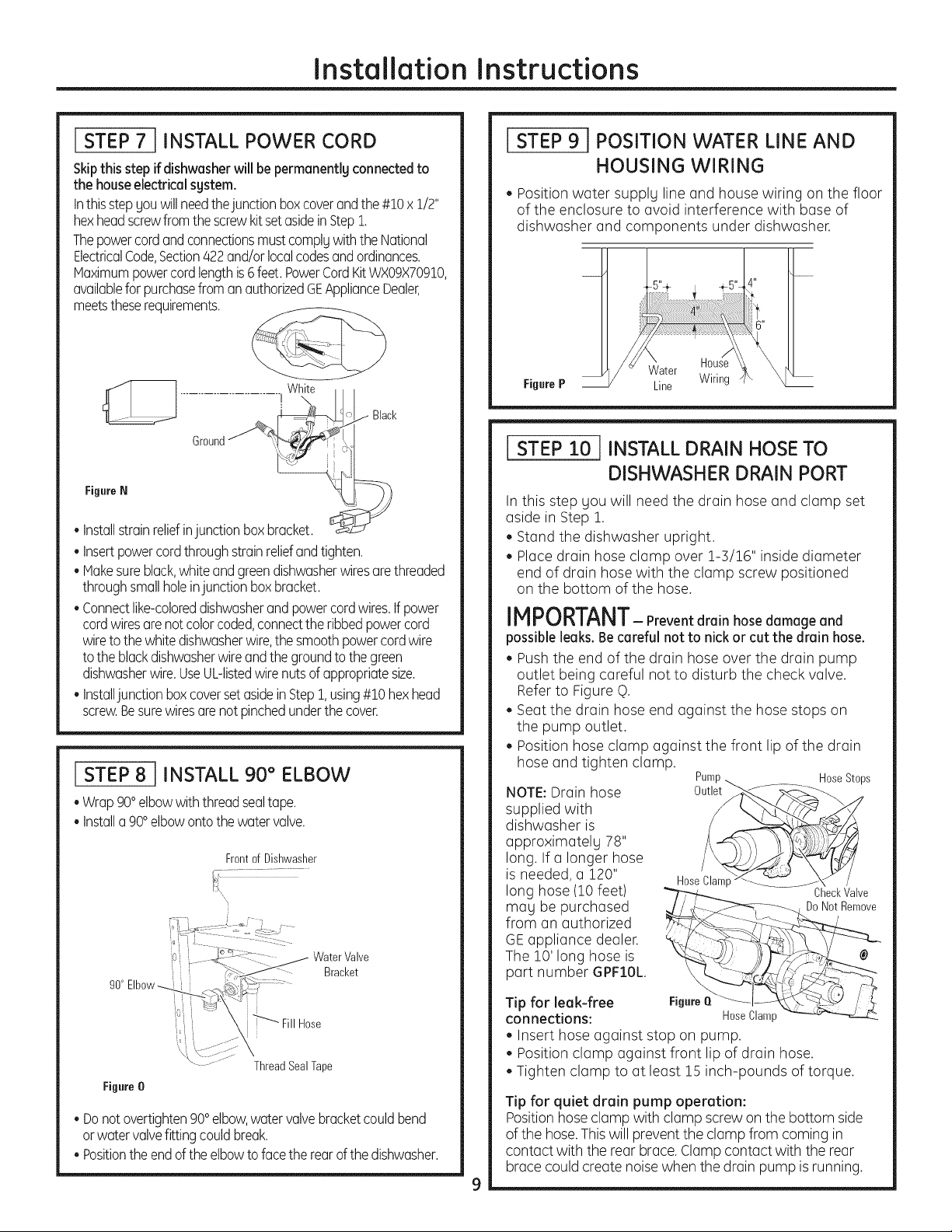

STEP 7 INSTALL POWER CORD

Skipthisstep ifdishwasherwillbepermanentlgconnectedto

thehouseelectricalsgstem.

Inthisstepyou willneedthejunctionboxcoverandthe#10x 1/2"

hexheadscrewfromthescrewkitsetasideinStep1.

ThepowercordandconnectionsmustcomplUwiththeNational

ElectricalCode,Section/422and/or localcodesandordinances.

Maximumpowercordlengthis6feet.PowerCordKitWXO9X70910,

availableforpurchasefromanauthorizedGEApplianceDealer,

meetstheserequirements.

..................... J \

White

i \

Figure N FZ_

• Installstrainreliefinjunctionboxb .

• Insertpowercordthroughstrainreliefandtighten.

• Makesureblack,whiteandgreendishwasherwiresarethreaded

throughsmallholeinjunctionboxbracket.

• Connectlike-coloreddishwasherandpowercordwires.Ifpower

cordwiresarenotcolorcodedconnecttheribbedpowercord

wireto thewhitedishwasherwire,thesmoothpowercordwire

tothe blackdishwasherwireandthegroundtothe green

dishwasherwire.UseUL-listedwire nutsofappropriatesize.

• InstalljunctionboxcoversetasideinStep1,using#10hexhead

screw.Besurewiresarenotpinchedunderthecover.

STEP 8 INSTALL 90 ° ELBOW

• Wrap%0elbowwiththreadsealtape.

• Installa90 elbowontothewatervalve.

• Donotovertighten900elbow,watervalvebracketcouldbend

orwatervalvefittingcouldbreak.

• Positiontheendofthe elbowto facetherearofthedishwasher.

o

90° Elbow-__

Figure0

Frontof Dishwasher

l

I

?_-" Fill Hose

ThreadSealTape

Bracket

STEP 9 JPOSITION WATER LINE AND

HOUSING WIRING

* Position water supplg line and house wiring on the floor

of the enclosure to avoid interference with base of

dishwasher and components under dishwasher.

Figure P

[ STEP 10 1INSTALL DRAIN HOSE TO

DISHWASHER DRAIN PORT

In this step gou will need the drain hose and clamp set

aside in Step !.

• Stand the dishwasher upright.

• Place drain hose clamp over !-3/!6" inside diameter

end of drain hose with the clamp screw positioned

on the bottom of the hose.

IMPORTANT-Preventdrain hose damage and

possible leaks.Becareful not to nick or cut the drain hose.

• Pushthe end of the drain hose over the drain pump

outlet being careful not to disturb the check valve.

Refer to Figure O.

• Seat the drain hose end against the hose stops on

the pump outlet.

• Position hose clamp against the front lip of the drain

hose and tighten clamp.

HoseStops

NOTE:Drain hose

supplied with

dishwasher is

approximately 78"

long. If a longer hose

is needed, a 120"

long hose (10 feet)

Hag be purchased

from an authorized

GEappliance dealer.

The 10' long hose is

part number GPFIOL.

Tip for leak-free

connections:

• Insert hose against stop on pump.

• Position clamp against front lip of drain hose.

• Tighten clamp to at least 15 inch-pounds of torque.

Tip for quiet drain pump operation:

Position hoseclamp with clamp screw on the bottom side

of the hose.Thiswill preventthe clamp from coming in

contact with the rear brace. Clamp contact with the rear

brace could create noise when the drain pump is running.

Page 10

Installation Instructions

STEP 11 INSERT DRAIN HOSE

THROUGH CABINET

• Position dishwasher in front of cabinet opening. Insert

drain hose into the hole in cabinet side. Ifa power cord is

used, guide the end through a separate hole.

Maximum

Insulation DrainHose

Blanket Length10'

Hose

HouseWiring

FigureR

..... PowerCord (If PowerCord

.......-. (If Used) is NOTUsed)

TIP: Position water line and house wiring on the floor

to avoid interference with base of dishwasher.

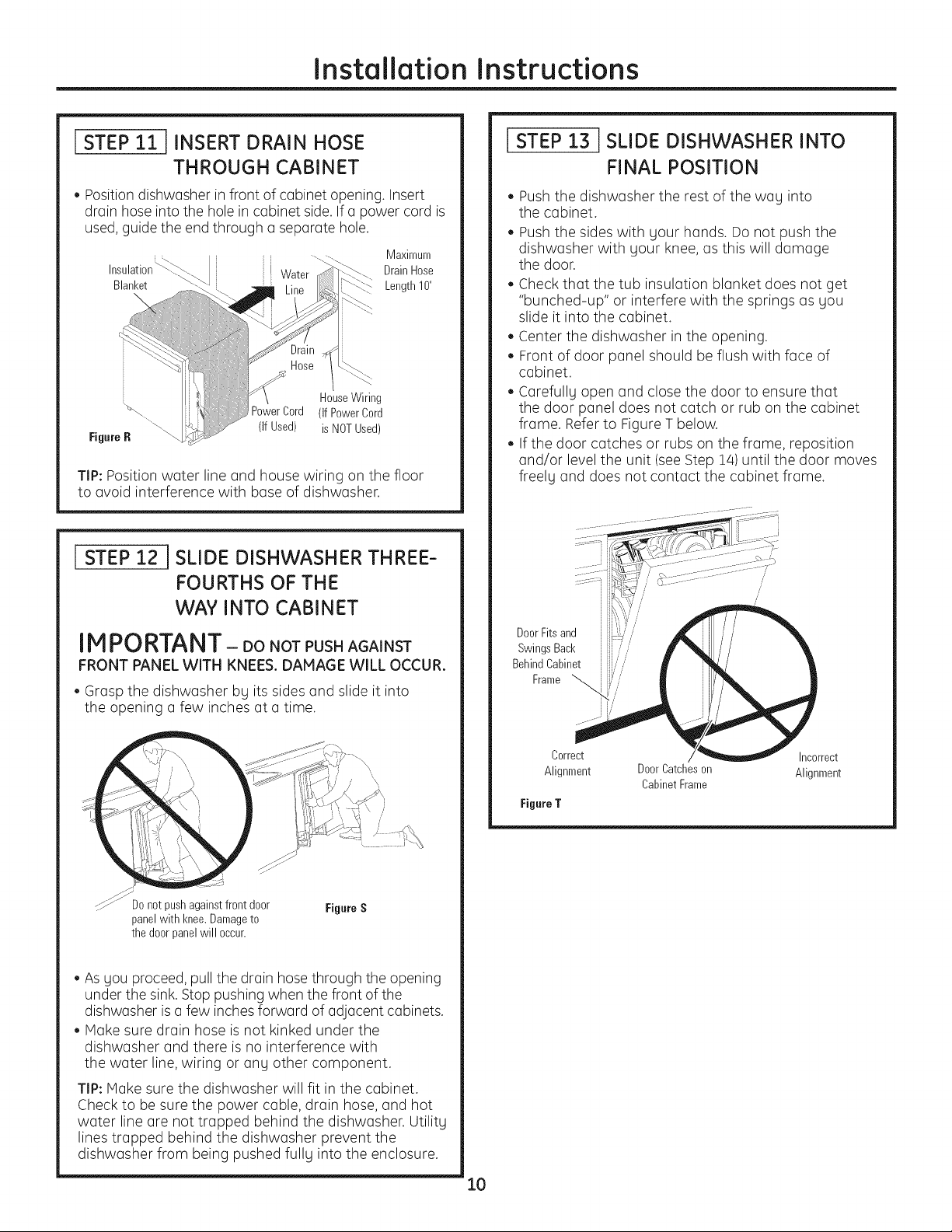

STEP 12 JSLIDE DISHWASHER THREE-

FOURTHS OF THE

WAY INTO CABINET

IMPORTANT- DONOTPUSHAGAINST

FRONT PANEL WITH KNEES. DAMAGE WILL OCCUR.

,,Grasp the dishwasher bU its sides and slide it into

the opening a few inches at a time.

STEP 13 SLIDE DISHWASHER INTO

FINAL POSITION

• Pushthe dishwasher the rest of the way into

the cabinet.

• Pushthe sides with your hands. Do not push the

dishwasher with your knee, as this will damage

the door.

• Check that the tub insulation blanket does not get

"bunched-up" or interfere with the springs as you

slide it into the cabinet.

• Center the dishwasher in the opening.

• Front of door panel should be flush with face of

cabinet.

• Carefully open and close the door to ensure that

the door panel does not catch or rub on the cabinet

frame. Referto Figure T below.

• If the door catches or rubs on the frame, reposition

and/or level the unit (seeStep 14) until the door moves

freely and does not contact the cabinet frame.

, ................,,,,,'

DoorFitsand

SwingsBack

BehindCabinet

Frame _

i

i

x

Donotpushagainstfront door

panelwith knee.Damageto

the door panelwill occur.

FigureS

• As you proceed, pull the drain hose through the opening

under the sink. Stop pushing when the front of the

dishwasher is a few inches forward of adjacent cabinets.

• Make sure drain hose is not kinked under the

dishwasher and there is no interference with

the water line,wiring or any other component.

TIP: Make sure the dishwasher will fit in the cabinet.

Check to be sure the power cable, drain hose, and hot

water line are not trapped behind the dishwasher. Utility

lines trapped behind the dishwasher prevent the

dishwasher from being pushed fully into the enclosure.

10

Alignment

FigureT

Correct

DoorCatcheson

CabinetFrame

Incorrect

Alignment

Page 11

Installation Instructions

STEP 13 SLIDE DISHWASHER INTO

FINAL POSITION {cont.)

Special Considerations for Positioning

The controls on these models are designed to be hidden

bg gour countertop. Align the dishwasher as shown in

Figure U. Leave a 1/2" minimum gap between the

underside of the countertop and the top of the

dishwasher door as shown in Figure V.

Use the leveling legsto increase or decrease the amount

of gap between the controls and the countertop.

IMPORTANT- Leaveai12"minimum

gap between the controls and the underside of the

countertop to prevent condensation and damage

to the control panel from screw heads.

Figure U

ControlsHiddenby

Countertop

STEP 14 LEVEL DISHWASHER

IN PORTANT- Dishwasher must be level for

proper dish rack operation and wash performance.

• Make sure 1/2" minimum gap is maintained.

to check that the

dishwasher is level C'

• Place level on door -!/ _'

side to side.

Remove lower '

rack, place

level on lower

rack track inside

tub to check that

the dishwasher is

level front to back.

Figure W

* If the dishwasher is not level, adjust the four leveling

legs as illustrated in Figure X.

* If adjustment to the right rear leveling leg is required,

access it bg loosening the junction box bracket screw

(through the access hole) and rotate bracket clockwise.

] i ! i J i i

1/2"

Min.

Figure V

AccessHo_._ JunctionBox

Countertop

/

-4

[

DishwasherDoor

F,glre×

* The dishwasher is properly leveled when the level

indicator is centered left to right and front to back.

The dishwasher door should close without hitting

the sides of the tub.

* Replace the lower rack when leveling is complete.

TiP:Avoid unnecessary service charges for poor wash

performance and rack operation.

Pullthe dish racks halfway out. They should remain

stationary. Open and close the door.The door should fit

in the tub opening without hitting the side of the tub. If

the racks roll on their own, or the door hits the side of

the tub, relevel the dishwasher.

IN PORTANT - After leveling, verify that

the dishwasher is centered in the enclosure and the

door does not hit adjacent cabinets.

11

Page 12

Installation Instructions

STEP 15 SECURE DISHWASHER TO

COUNTERTOP OR CABINET

In this step gou will need

the 2 Phillips special-

head screws set aside

in Step 1.

The dishwasher must be

secured to the Tub--_

countertop or the Frame

cabinet sides. When

countertops are made of FigureY

wood, use Method i. When countertops are granite

or other materials that will not accept screws, use

Method 2 to secure dishwasher at the sides.

SideMounting :::::_i_

IMPORTANT- Avoidunnecessargservice

charges. Drive screws straight and flush.

Protruding

screw heads Brackets Wood Countertop

will scratch the "/

top or sides of

the control

panel and can Screws

interfere with

door closing. Figurez

Method 1--Secure dishwasher to wood

countertop

• Fasten the dishwasher to the underside of the

countertop with 2 Phillips special-head screws

provided.

Method 2--Secure dishwasher with side-mounting

brackets

• Remove plug buttons (one on each side).

• Install screws through the dishwasher side mount

bracket and StoneCountertop SideMountingBrackets

into the

adjacent

cabinet on

each side.

Reinstall plug

buttons. FigureAA

Either Method--Make certain 112" gap minimum

is maintained.

• When step is complete, close dishwasher door

and verifg that gap between countertop and top

of dishwasher door is at least 1/2".

Screws

STEP 16 CONNECT WATER SUPPLY

Connect water supplg line to 90° elbow.

• Slide compression nut, then ferrule over end of

water line.

Insert water line into 90° elbow.

Slide ferrule against elbow and secure with

compression nut.

IMPORTANT-check to be surethat

door springdoes not rub orcontactthe fillhose

orwater supplg line.Testbg opening and closing

the door.Reroutethe linesifa rubbingnoiseor

interference occurs.

SupplyLine

FigureCC

go°Elbow

DoorSpring

Min.

1/2"

FigureBB

Countertop

/

/

DishwasherDoor

12

Page 13

Installation Instructions

STEP 17 CONNECT DRAIN LINE

The molded end of the drain hose will fit 5/8" through

1" diameter inlet ports on the air gap, waste tee or

disposer.

• Determine size of inlet port.

• Cut drain hose connector on the marked line,

if required, to fit the inlet port.

FigureDD

j CuttingLine

IMPORTANT:Do notcut corrugated

portionof hose

• If a longer drain hose is required, and you did not

purchase 10' long GPFIOL drain hose, add up to

3-1/2' of length for a total of 10' to the factory

installed hose. Use 5/8" or 7/8" inside diameter

hose and a coupler to connect the two hose ends.

Secure the connection with hose clamps.

DRAIN LINE INSTALLATION

• Connect drain line to air gap, waste tee or disposer

using the previouslg determined method.

• Secure the drain hose to the air gap, waste tee or

disposer with clamps.

Method 1--Air gap with waste tee or disposer

Insert the drain hose into the air gap as shown.

Waste Tee Installation

FigureFF

Method 2--High Drain Loop with the Waste Tee

or Disposer

Route the drain hose of the dishwasher to a

minimum height of 32" from the floor with the

supplied hanger as shown.

Fasten to underside Fasten to underside

of countertop of countertop

DisposerInstallation

Coupler

Hose Clamp

HoseClamp

NOTE: TOTAL DRAIN HOSE LENGTH MUST NOT EXCEED

!0' FOR PROPER DRAIN OPERATION.

Waste Tee Installation

Figure GG

DisposerInstallation

IMPORTANT-Oneof the above methods

must be used or dishwasher will not operate

properly.

IMPORTANT-when

connecting drain line to disposer,

check to be sure that drain plug

has been removed. DISHWASHER

WILL NOT DRAIN IF PLUG IS LEFT IN PLACE.

TIP: Avoid unnecessarg service call charges. Alwags

be sure disposer drain plug has been removed before

attaching dishwasher drain hose to the disposer.

i :E?-----Remove

Hopper

_ Plug

13

Page 14

Installation Instructions

STEP 18 CONNECT POWER SUPPLY

Skip this step if dishwasher is equipped with

power cord.

Verify that power is turned off at the source.

* Locate junction box cover set aside in Step 1.

* Secure house wiring to the back of the junction

box with a strain relief.

* Locate the three dishwasher wires, (white, black

and green) with stripped ends. Insert dishwasher

wires through the small hole in the junction box.

Connect like-colored dishwasher and power cable

wires using UL-listed wire nuts of appropiate size.

, Install the junction box cover. Check to be sure

that wires are not pinched under the cover.

STEP 19 PRETEST CHECK LIST

Review this list after installing gour dishwasher

to avoid charges for a service call that is not

covered bg gour warrantg.

o

Check to be sure power is OFF.

o

Open door and remove all foam and paper

packaging.

o

Locate the Owner's Manual set aside in Step 1.

o

Read the Owner's Manual for operating instructions.

o

Check door opening and closing. If door does not

open and close freely, check for proper routing of

spring cable over pulleg. If door drops or closes

when released, adjust spring tension. See Step 3,

Figure J.

Check to be sure that wiring is secure under the

dishwasher, not pinched or in contact with door

springs or other components. See Step 9.

Check door alignment with tub. If door hits tub,

level dishwasher. See Step 14.

Pull lower rack out about halfwag. Check to be

sure it does not roll back or forward on the door.

If the rack moves, adjust leveling legs. See Step 14.

WARNING

If house wiring is not 2-wire with

ground, a ground must be provided

by the installer. When house wiring

is aluminum, be sure to use UL-listed

anti-oxidant compound and

aluminum-to-copper connectors.

Check door alignment with cabinet. If door hits

cabinet, reposition or relevel dishwasher. See

Steps 13,14 and 15.

Check that door spring does not contact water line,

fill hose, wiring or other components. See Step 16.

Verifg water supplg and drain lines are not kinked

or in contact with other components. Contact with

motor or dishwasher frame could cause noise.

See Steps 9 and 11.

Turn on the sink hot water faucet and verifg water

temperature. Incoming water temperature must

be between 120°F and 150°F. A minimum of 120°F

temperature is required for best wash performance.

See "Prepare Hot Water Line/' page 7.

Add 2 quarts of water to the bottom of the

dishwasher to lubricate the pump seal.

Turn on water supplg. Check for leaks. Tighten

connections if needed.

Remove protective film if present from the control

panel and door.

Avoid service call charges bg ensuring there is

an air gap or drain hose routed through the

required 32" minimum height.

14

Page 15

Installation Instructions/Custom Panel Dimensions

STEP 20 DISHWASHER WET TEST

• Turnon power supply (or plug power cord into outlet,

ifequipped).

• Startthe unit to checkfor leaks.

- PushRINSEONLYpad.

- PushSTART/RESETpad one time.

- Closedoor.

• Checkto be sure that water enters the dishwasher.Ifwater

doesnot enter the dishwasher,check to be surethat water

and power are turned on.

• Checkfor leaksunderthe dishwasher.Ifa leakisfound,

turn power supply off,then tighten connections. Restore

power after leak iscorrected.

• Checkfor leaksaroundthe door.Aleakaroundthe door

could be caused by door rubbing or hitting against

adjacent cabinetry. Repositionthe dishwasher if

necessary.SeeStep 13,14 and 15.

• Thedishwasher willdrain and turn off about 5 minutes after

itwas started. Check drain lines.Ifleaksare found, turn off

power supply and correct plumbing as necessary.Restore

power after corrections are made. SeeStep 10 and 17.

• Opendishwasher door and make sure most of the water

hasdrained. If not, checkthat disposer plug has been

removed and/or air gap is clear.SeeStep17.Alsocheck

drain line to be sure it is not kinked.

• Runthe dishwasher through another "RinseOnly" cycle.

Checkfor leaks and correct if required.

STEP 22 INSTALL SOUND UPGRADE KIT

IF EQUIPPED

Skipthis step if gour model does not have the Sound

Upgrade Kit.

• Locate sound upgrade kit set aside in Step1 and the two

screwsset aside in Step6.

• Attach the plastic Sound Panelasshown in FigureII

usingthe two screws. Thelowerset of mounting holes

shouldbe used.

• Besurethe sound panel isseated inthe notches on frame

asshown in Figure II.

[ 1

Soundpanelis located

underdoorpanel,

STEP 22 SET WATER HARDNESS

Modelswith bulk dispenser only. Skipthis step if your

dishwasher does not havethe bulk dispense feature.

• Locatethe hard water test strip setaside in Step1.

• Removestrip from package.

• Turn on the hot water and hold the strip under the stream,

following the directions on the package.

• Usethe value on the test strip to calibrate your dishwasher

for water hardness.Referto the section titled "Water

HardnessCalibration" in your Owner's Hanual for

information on how to calibrate your dishwasher.

Besurethat the soundpanelisseated

in the notchinthe frame. (Bothsides)

15

Figure II

Page 16

STEP 23 INSTALL TOEKICK

• Locate toekick and screws set asidein step 5.

Toekick

Attachment

Figure JJ Screws

• Replacethe toekick and make sure it isagainstthe floor.

• Insert and tighten the 2 toekick attachment screws.The

toekick shouldstag in contact with the floor to ensure quiet

dishwasheroperation.

STEP 24 LITERATURE

• Besureto leavecomplete literature package,Installation

Instructions and product sampleswith the consumer.

NOTE: While performing installations described in this book,

safetg glasses or goggles should be worn.

For Monogram ®local service in gout area, call

2.800.444.1845.

NOTE: Product improvement is a continuing endeavor at

General Electric. Therefore, materials, appearance and

specifications are subject to change without notice.

[Pub.No.31-30246 I

IPartNo.206C155gP184

10-08JR

GE Consumer & Industrial

Appliances

General Electric Compang

Louisville, KY/40225

ge.com

Page 17

Instructions

d'installation

Lave-vaisselle encastr@

*Les mod@lesavec panneau frontal sur

commande viennent avec une trousse

comprenant un gabarit, la quincaillerie et les

instructions d'installation du panneau. Se

reporter aux instructions de la trousse pour

installer le panneau sur commande.

131-30246 I

10-08 JR

Page 18

Information de s@curit

AVANT DE COMMENCER

II faut lire soigneusement toutes ces instructions.

"IMPORTANT- Conservercesinstructionsafin

que I'inspecteur local s'en serve. II faut respecter tous

les codes et r_glements.

• Remarque pour I'installateur- Ne pas oublier

de remettre ces instructions au consommateur.

• Remarque pour le consommateur-II faut

garder ces instructions avec le manuel d'utilisation,

pour consultation ult@ieure.

• Niveau de competence - L'installation de ce

lave-vaisselle demande des talents m@caniqueset

_lectriques de base. L'installateur est responsable de

l'installation appropri_e. La garantie des appareils

m@nagers de GE ne couvre pas les d@faillances du

produit caus@espar une mauvaJse installation.

• Dur_e d'installation - 1 6 3 heures.

Lesinstallations initiales demandent plus de temps que

les installations de remplacement.

• IMPORTANT- Lelave-vaisselleDOIT@ire

instoll@de mani@re6 permettrelad@pose ult@rieure

de l'enceinteafinde permettretouteintervention.

Silelave-vaissellelivr_estendommag@, ilfaut

contacterimm@diatementleconcessionnaireou

l'entrepreneurde construction.

LIRE ATTENTIVEMENT.

IL FAUT GARDER CES INSTRUCTIONS.

J J

SECURITE

II faut lJreet observer tous les avertissements

(PRUDENCEet ATTENTION}montr@s dans ces

instructions.

Pendant l'JnstallatJon d@crJtedans ce lJvret, Jlfaut porter

des gants et des lunettes de s@curJt@.

Pour le service local Monogram dans votre r@gJon:

1.800.444.1845.

Pi_ceset accessoires Monogram, appeler le :

1.800.626.2002.

Pi_ces et accessoires Monogram au Canada,

appeler le : 1.800.561.3344.

CONTENU

Pr@paration pour HnstallatJon

Pi_cesfournies ....................................................................................3

Hat_riaux n_cessaires ....................................................................3

Outils n_cessaires ..............................................................................3

Planification pr_alable ..................................................................../4

Preparation de I'enceinte du lave-vaisselle ..........................4

Preparation de la plomberie de vidange ................................5

Preparation pour le branchement _lectrique ......................6

Preparation du tuyau d'eau chaude ........................................7

Instructions d'installation

Etape 1, Rep_rage des articles 6 installer ..............................7

Etape 2, Installation des pi_ces de finition ............................7

Etape 3,V@ification de I'_quilibre de la porte ......................8

Etape 4, Retrait de la base en bois,

installation des pattes de nivellement ....................................8

Etape 5, Retrait de la plinthe ........................................................8

Etape 6, Retrait du renfort de plinthe ......................................8

Etape 7, Installation du cordon

d'alimentation _lectrique ................................................................9

Etape 8, Installation du coude 6 angle droit ........................9

Etape 9, Mise en place du tugau

d'eau et des ills de la maison ......................................................9

Etape 10, Raccordement du tugau

de vidange 6 I'orifice de vidange du lave-vaisselle ..........9

Etape 11, Insertion du tugau

de vidange 6 travers I'armoire ..................................................10

Etape 12,Glissement du lave-vaisselle

au 3/4 de la distance dans I'armoire ....................................10

Etape 13,Glissement du lave-vaisselle

6 sa position finale ..................................................................10, 11

Etape 14, Mise 6 niveau du lave-vaisselle ..........................11

Etape 15, Fixation du lave-vaisselle

au plan de travail ou 6 I'armoire ..............................................12

Etape 16, Raccordement 6 I'alimentation d'eau ..............12

Etape 17, Raccordement du tugau de vidange ................13

Etape 18, Branchement 6 I'alimentation _lectrique ......14

Etape 19, Liste de v@ification

avant de faire les essais ..............................................................14

Etape 20, Essaidu lave-vaisselle avec de I'eau ................15

Etape 21, D_termination de la duret_ de I'eau ................15

Etape 22, Installation de la trousse d'am_lioration

de I'insonorisation (certains modules)....................................15

Etape 23, Installation de la plinthe ........Couverture arri_re

Etape 24, Documentation ..........................Couverture arri_re

Page 19

Preparation pour l'installation

PII_CES FOURNIES •

• Deux vis cruciformes sp6ciales #8-18 x 5/8 po

pour fixer le lave-vaisselle au dessous du plan

de travail ou aux c6t_s des armoires.

• Couvercle de boTtede jonction et vis

hexagonale #10-!/2 po

• Pi_ces de finition lat_rales et sup@laura

• Trousse d'am_lioration de I'insonorisation

(certains modules)

• Tuyau de vidange (78 po) avec support

et collier

• Documentation, _chantillons de produit

et/ou coupons

• Bande d'analyse de la duret_ de I'eau (ModUles

_quip_s d'un distributeur en vrac)

_.X_.... / de i'insonl_l_a°[_t_On

IFiF ?

Viscruciformessp_ciales Vis hexagonale#10

#8,Iongueurde5/8 po pourbottedejonction,

Supportdetuyaudevidange

MATERIAU× NECESSAIRES •

• Bague, 6crou de compression et coude 6 angle droit

(filetage externe de 3/8 po 6 une extr6mit6, I'autre

extr6mit6 correspondant 6 I'alimentation d'eau)

•Ruban d'6tanch6it6 de filetage

• Serre-fils sur la liste UL(3)

Mat_riaux pour une installation initiale seulement:

• Dispositif anti-siphon pour letuyau de vidange, sin_cessaire

• Raccord en t_ pour la plomberie d'_gout, si n_cessaire

• Cable _lectrique ou cordon d'alimentation, si n_cessaire

• Colliersde tuyau avis

• Dispositif de r_duction de tension pour les branchements

_lectriques

• Robinet de sectionnement

• Tuyau d'eau en cuivre de 3/8 po minimum

• Manchon pour allonger le tuyau de vidange, si n_cessaire

• Tuyau de vidange GPFIOLde 10 pi,si n_cessaire

Piece de finition lat@ale

Piece de finition lat@ale

Iongueurde1/2 po

(eertainsmodules)

Coude_ angle droit, hague

et _croudecompression

Tuyaudevidange

GPF10Lde10 pi

Tuyaudevidange(78po)

II, 4

Banded'analysede laduret6

deI'eau(Mod61es6quip@

d'un distrihuteurenvrac)

Robinetde

sectionnem d'_tanch_it6

ant defiletage

Cable61ectrique(oucordon

d'alimentation,si n_cessaire)

Piece de finition sup@ieure

Pi_ces des finition

Collierdetuyaude vidange

@@@

Colliersde Uispositif de

Raccordent_, @out tuyau_ vis r_ductiondetension

Q

Couverclede botte

dejonction

G

Serre-fils(3)

Tuyaud'eauchaude

Manchon

Dispositifanti-

siphon

OUTILS NI_CESSAIRES :

• Tournevis cruciforme

• Tournevis a douille de 5/!6 po et !/4 po

• CI6 a molette de !5 cm (6 po)

• Niveau

• Equerre de menuisier

•Ruban a mesurer

• Lunettes de s6curit6

• Lampe de poche

• Seau pour attraper I'eau lots de la purge

du tuyau

• Douille de !5/!6 po (optionnelle pour

la d_pose de la palette)

Pour les installations initiales seulement"

• Coupe-tube _-_• Perceuseetm_chesappropri_es _ _ r z_:_.-_

• Scie-cloche

Lunettesdes_curit_ Scie-cloche Seau

Lampe de poche

Page 20

Preparation pour l'installation

PLANIFICATION PRI_ALABLE

• Ces lave-vaisselle sont conqus afin d'#tre

polyvalents et de pouvoir s'adapter (_pour ainsi dire

n'importe quelle installation.

• Tousles mod61es ont une porte pleine Iongueur

sans le panneau d'acc_s traditionnel.

• Ces lave-vaisselle peuvent _tre install6s

au-dessous des plans de travail faits de pierre ou

d'autres mat6riaux dans lesquels on ne peut pas

placer de vis. II n'LI a pas besoin de trousse de

garniture.

PRI_PARATION DE L'ENCEINTE DU LAVE-VAISSELLE

Cetteportiondu

tournedolt pas

avoir detuyaux

ni deills

88cm

(34-1/2po)

min.dessous

duplande

travailau sol

Figure A

*Les Iove-voisselle modules ZBD6900PII et ZBD8900PII n6cessitent

un ponneou sur commonde de 1,9 cm (3/4 po) d'6poisseur et ouro

62,9 cm (24-3/4 po) de profondeun

12,7cm,

W_ 61cm

LesolDOIT

_treaum_me

niveauquele

solde la piece

(24po)min.

, L'ouverture de I'armoire doit avoir une profondeur d'au

moins 61 cm (24 po),une largeur d'au moins 61 cm

(24 po) et une hauteur d'environ 88 cm (34-1/2 po),

du sol au dessous du plan de travail.

, Lemur arri_re doit _tre exempt de tugaux et de ills.

, Les armoires adjacentes doivent _tre (_1'6querre et

d'aplomb pour un ajustement ad6quat (Figure A).

,Dans une installation de coin, laissez un d_gagement

minimal de 5,1 cm (2 po) entre le lave-vaisselle et

le mur adjacent.

, La plomberie et 1'61ectricit6doivent entrer dans la zone

ombr6e.

, Le lave-vaisselle doit _tre install6 de mani_re que le

tugau de vidange n'ait pas une Iongueur sup6rieure

6 3 m (10 pi) afin d'obtenir un bon 6coulement.

, Laissez au moins 72 cm (28-3/8 po) (_I'avant du lave-

vaisselle pour permettre I'ouverture complete de sa

porte (Figure B).

, Veillez (_ce que le plancher soit de niveau (_I'int6rieur

de I'ouverture et au m_me niveau que le plancher fini

de la cuisine. Cela facilitera le retrait du lave-vaisselle

dans 1'6ventualit6 d'une r6paration dans le futur.

Armoire

I'_querreet

d'aplomb

61,

(24po)

36,4cm

(34po)

ajustable

(35po)

cm

(24po)

88,9cm

A AVERTISSEMENT

Pour r6duire le risque de choc 61ectrique,

d'incendie ou de blessures, I'installateur

dolt s'assurer, au moment de I'installation,

que le lave-vaisselle est compl_tement

enclos.

Considerations sp_ciales dans le cas

d'un lave=vaisselle install6 sur une

plateforme sur6lev6e

La plateforme sur61ev6e doit _tre plane

et de niveau.

• Le lave-vaisselle doit _tre install6 6 moins

de 3 m_tres (10 pieds) d'un 6vier pour

obtenir une vidange correcte.

• Le lave-vaisselle doit _tre totalement

cloisonn6 dans le haut, les c6t6s et

6 I'arri_re.

• Le lave-vaisselle ne doit supporter

aucune partie de I'enceinte.

Figure B

I

Plandetravail

.....................................................

i',/" 2po ran.

ESPACES : En cos d'installation

dons un coin, Ioisser un espoce de

5cm (2 po) minimum entre le lave-

voisselle et I'ormoire, lemur ou un

autre apporeil adjacent.

IIdolt g ovoir un espoce d'au mois

72 cm (28-3/8 po) devont le Iove-

voisselle pour permettre

I'ouverture la porte (Figure B).

4

Page 21

Preparation pour l'installation

PRI_PARATION DE LA PLOHBERIE

DE VIDANGE

Exigences relatives au circuit de vidange

• Le tugau de vidange ne dolt pas d_passer 3 m

(10 pi) de Iongueur.

• Une boucle de vidange 61ev6e ou un dispositif

anti-siphon sont n#cessaires. Voir ci-dessous.

D_termination de la m_thode de vidange

Le tgpe d'installation de la vidange d6pend de la

r6ponse aux questions suivantes :

• Est-ce que les codes ou r_glements Iocaux exigent

un dispositif anti-siphon ?

• Est-ce que le raccord en t6 est 6 mains de 46 cm

(18 po) du sol ?

Si Io r6ponse est OUI 6 une de ces questions, il FAUT

utiliser un dispositif anti-siphon. Se reporter 6 la

m@thode n° 1 (Figure C)illustr6e ci-contre.

Si les r6ponses sont NON, il est possible d'utiliser soit

un dispositif anti-siphon, soit une boucle de vidange

61ev6e. Se reporter 6 la m_thode n° 1 (Figure C) ou 6

la m_thode n° 2 (Figure D)illustr6es ci-contre.

NOTE : L'61@ation du tugau de vidange ne dolt pas

d_passer 122 cm (48 po).

Considerations sp_ciales dans le cas d'un lave-

vaisselle install_ sur une plateforme sur_lev_e

Si le lave-vaisselle est install6 sur une plateforme

sur61ev6e, il faut placer une boucle de vidange 61ev6e

6 une distance minimale de 81,3 cm (32 po) au-

dessus de la plateforme, en plus du dispositif anti-

siphon ou de la boucle de vidange d6termin6s d'apr_s

les m@hodes ci-dessus. Cela est n_cessaire pour

assurer une vidange adequate.

kATTENTION :Un dispositif anti-siphon

DOlT ETRE UTILISE si le tugau de vidange est

connect6 au raccord en t_ ou au brogeur 6 d6chets

situ6 6 mains de 45,7 cm (18 po) au-dessus du niveau

du plancher. L'omission de procurer une hauteur

ad6quate au raccord de drain du dispositif anti-

siphon ou une hauteur minimale de 81,3 cm (32 po) 6

la boucle de vidange (_lev6e entraTnera un drainage

incorrect du lave-vaisselle et de possibles dommages.

M_thode 1--Dispositif anti-siphon avec raccord en t_

d'_gout ou brogeur (_d_chets

Installation avec raccord Figure C Installation avec broyeur

en t_ d'_gout _ d_chets

M_thode 2--<<Boucle de vidange _lev_e >>avec raccord

en t_ d'_gout ou brogeur 6 d_chets

Utilisez le tugau de vidange inclus dans le n_cessaire

d'installation pour le fixer en dessous du plan de travail.

La fixation sera effectu_e plus tard.

Installez le raccord en t_ d'_gout ou le brogeur 6 d_chets

et le dispositif anti-siphon selon les instructions du

fabricant.

s-s,

IJ / "_ (32po)min.

Installation avec raccord

en t_ d'_gout

IMPORTANT- Aumoment

de raccorder le tugau de vidange au _ lebouchon

brogeur 5 d6chets, assurez-vous que -_...../ devidange

le bouchon de vidange a 6t6 retir(_.

LE LAVE-VAISSELLE NE SE VIDANGERA

PAS SI LE BOUCHON EST LAISSE EN PLACE.

Figure D Installation avec broyeur

d6chets

i _ Retirer

Preparation de I'armoire pour le tugau de vidange

Percer un trou de 38 mm (1-1/2 po) de diam_tre dans

la paroi de I'armoire, 6 I'int@ieur des zones hachur6es

montr(_es 6 la figure A, pour le passage du tugau de

vidange. Le trou dolt _tre lisse, sans bards aigus. Le

tugau de vidange passera par ce trou et sera

raccord_ au drain Iors d'une 6tape ult@ieure.

Page 22

Preparation pour l'installation

PRI PARATION POUR LE BRANCHEMENT

I LECTRIQUE

AVERTISSEMENT

SI_CURITI_: Enlever le fusible du circuit ou

d_clencher le disjoncteur avant de

commencer I'installation. Avec cet appareil,

ne pas utiliser une rallonge ou un

adaptateur de prise.

Alimentation _lectrique

• Cet appareil doit avoir une alimentation en 120 V,60 Hz,

et _tre branch_ (_un circuit ind_pendant correctement

mis (_la terre, prot_g_ par un disjoncteur de 15 ou 20 A

ou un fusible temporis_.

• Le branchement doit _tre fait avec deux fils plus un fil

de terre, homologu_s pour une temp@ature de 80 °C

(176 OF).

• Si I'alimentation _lectrique n'est pas conforme _ ces

conditions, appeler un _lectricien agr_ avant de

continuer.

Mise _ la terre--Branchement direct

Cet appareil doit #tre branch# de faqon permanente _ un

circuit (_la terre avec un morceau de m#tal, ou il faut

installer un fil de mise (_laterre avec les fils d'alimentation.

¢e fil doit #tre branch# _ la borne de terre de I'#quipement

ou a un fil sur I'appareil.

Instructions de mise 6 la terre--Mod_les avec un cordon

d'alimentation

¢et appareil doit #tre mis a la terre. Encas de mauvais

fonctionnement ou de panne, la mise a la terre r#duit le

risque de choc #lectrique en fournissant un passage de

moindre r#sistance au courant #lectrique. Cet appareil est

#quip# d'un cordon d'alimentation avec un conducteur

de mise (_la terre et une fiche de terre. IIfaut brancher

la fiche dans une prise appropri#e, install#e et mise

la terre conform#ment aux codes et r_glements Iocaux.

AVERTISSEMENT

Le mauvais branchement du conducteur de

mise a la terre peut causer des risques de

choc #lectrique. Encas de doute sur la mise

la terre de I'appareil, consulter un

#lectricien agr#e ou un technicien de

r#paration.

4

," , Autre position , ,

"" l possiblede la :

," : prise de courant :

7,5 cm(3po)

de I'armoire

FigureE

ModUles_quip_s d'un cordon d'alimentation : Nepas

modifier la fiche fournie avec I'appareil.Sila fiche ne

correspond pas _ la prise,faire installer une prise

appropri_e par un _lectricien qualifi_.

Preparation de I'armoire et du passage des ills

• Lesfils doivent entrer dans la cavit_ d'un c6t_ ou de

I'autre, de I'arri_re ou du sol, dans la zone hachur_e.

• Couper un trou de 38 mm (1-!/2 po) de diam_tre

maximum pour permettre le passage des fils

d'alimentation _lectrique. Le cable de branchement

direct peut passer dans le m_me trou que le tugau de

vidange et le tugau d'eau chaude, si c'est plus pratique.

Si lemur de I'armoire est m_tallique, le bord du trou doit

_tre prot_g_ par un oeillet.

NOTE: Le cordon d'alimentation avec une fiche doit

passer dans un trou s_par_.

Branchement _lectrique du lave-vaisselle

Le branchement _lectrique se fait sur le c6t_ droit du

lave-vaisselle.

• Pour les branchements directs, le cable doit passer

comme illustr_ (_la Figure E.IIdoit g avoir une Iongueur

de cable d'au moins 61cm (24 po) d_passant du mur

arri_re.

Pour le branchement avec un cordon d'alimentation,

installer une prise (_la terre (_trois broches sur lemur

artiste de I'armoire d'_vier, de 15 cm (6 po) minimum

ou 46 cm (18 po) maximum de I'ouverture, de 15 cm

46 cm (6 (_18 po) au-dessus du sol. La prise doit _tre

accessible et ne peut donc pas _tre install_e sur le mur

arri_re dans I'enceinte du lave-vaisselle.

Page 23

Instructions d'installation

PREPARATION DU TUYAU D'EAU

CHAUDE

Tugau d'eau chaude

• Letugau peut entrer d'un c6t_ ou de I'autre, de I'arri_re

ou du sol, dans la zone hachur_e montr_e _ la Figure F.

• Letugau peut passer dans le m_me trou que le c6ble

_lectrique et le tugau de vidange. II est aussi possible

de couper un trou suppl_mentaire de 38 mm (1-1/2 po)

de diam_tre uniquement pour le tugau d'eau. En cas

d'utilisation d'un cordon d'alimentation avec fiche, le

tugau d'eau ne doit pas passer dans le trou du cordon.

i"

i

i

i

Robinet de 38mm (5 po) 10,2cm (5 po)

sectionnement (4 po)

Eau

chaude

5 cm

de I'armoire

12,7cm 12,7cm

,ATTENTION

II ne faut pas enlever la base de bois avant d'etre pr@t

installer le lave-vaisselle, q)uand la base de bois est

enlev_e et la porte ouverte, le lave-vaisselle bascule.

I TAPE 1 .REPERAGE DES ARTICLES

A INSTALLER

• Rep_rer les articles dans I'emballage d'installation et

les mettre de c6t_ en vue de leur utilisation dans les

_tapes _num_r_es.

Pi6ces de finition - Etape 2

Couvercle de boTtedejonction - Etape 7 ou _tape 18

Tugau de vidange et collier - Etape 10

Trousse de quincaillerie - Etape 15

Support de tugau de vidange- Etape 17

Manuel d'utilisation - Etape 19 et _tape 24

Bande d'analgse de la duret_ de I'eau - Etape 21

Trousse d'am_lioration de I'insonorisation (certains

modules)- Etape 22

Echantillons de produits et/ou coupons - Etape 2/4

5cm(2laO)dumur

Facede I'armoire Figure F

Branchement du tugau d'eau

• Couper I'alimentation d'eau.

• Installer un robinet de sectionnement dans un endroit

accessible, sous I'_vier par exemple (optionnel, mais

fortement recommand_ et peut _tre exig_ par les

codes Iocaux).

• Le branchement d'eau est sur la gauche inf_rieure du

lave-vaisselle. Installer le tuyau d'alimentation d'eau

chaude avec un tuyau en cuivre d'au moins 3/8 po de

diam_tre externe. Faire passer le tuyau comme montr_

la figure F et I'amener (_/48cm (19 po) du mur artiste.

• R_gler le chauffe-eau _ une temperature entre 49 °C et

65 °C (120 °F et 150 °F).

• Purger le tuyau d'eau pour _liminer tousles d_bris.

Utiliser un seau pour recueillir I'eau et les d_bris.

• Letuyau d'alimentation d'eau chaude doit avoir une

pression entre 1,4 et 8,3 bar (20 et 120 psi).

ATTENTION

La pression dans le tuyau d'eau chaude doit _tre d'un

minimum de 20 psi. Des pressions inf_rieures peuvent

causer des fuites _ la vanne d'eau et des dommages

connexes.

I TAPE 2 INSTALLATION DES PII CES

DE FINITION

Dans cette _tape, vous aurez besoin des pi_ces de

finition mise de c6t_ _ I'_tape 1.

• Enfoncer la piece de finition sup_rieure sur le rebord

de la cuve. Commencer par le bord droit et proc_der

vers la gauche.

• R_p_ter la manoeuvre avec les pi_ces de finition

gauche et droite, en proc_dant de haut en bas.

• Open and close the door to check that trim does not

bind and does not interfere with door latch or door

hinges.

Piecede

finition

Piecede

finition

FigureG

Page 24

Instructions d'installation

II_TAPE3_VITRIFICATIONDE L'I_QUILIBRE

DE LA PORTE

• Avec le Iove-voissellesur Iopalette de bois,ouvrir et farmer

Io porte pour v_rifier son _quilibre.

• SiIoporte tombe quand elleestrelach_e,augmenter la

tensiondu ressort.Silaportemonte quand elleestrelach_e,

diminuerla tensiondu ressort.

IIexiste deuxtgpes de contrepoids et donc deux m_thodes

de r_glage. Identifier lequelest present et r_gler la tension

en consequence. Prendrenote que: s'il g a 3 trous surle

c6ble, utiliser celui-ci pour le r_glage; siun seul trou est

present, utiliser Iopatte deIocure.

Tgpe 1 - C6ble(_un trou

R_glerIo tension en d6plaqant le crochet de ressort sur I'un

des trois trous de la patte de cuve.

AUGMENTER

Figure H

I DIMI!UER

Un trou

Tgpe 2 - Cable _ trois trous

R_glerIo tension en d_plaqant le crochet de ressort sur I'un

des trois trous du cable de poulie.

I_TAPE4 RETRAIT DE LA BASE EN BOIS,

INSTALLATION DES PATTES

DE NIVELLEHENT

IMPORTANT-,oefClut pasflapperI(:Ibase en

bois pour l'enlever ! Ceci endommage le l(_ve-vaisselle.

• Amenerlelave-vaissellec_proximit_deI'emplacementddinitif

etlebasculersur ledos.

• Avecunecl__ moletteouunedouillede15/16po,enleverles

quatrepattesdenivellementdu dessousdela baseenbois.

• Jeterlabase.

Env,3 mm

(1/8 po)

/

Figure K

• Visserlespattesde nivellementdanslecadredulave-vaisselle,

jusqu'@environ3mm(1/8po)ducadre,commamontr&

i!!

Utiliser cetrou

demontage

\

Figure I la tension la tension

Unefois r_gl_e la tension du ressort, ouvrir et fermer Io

porte pour s'assurer qu'elle fonctionne en douceur. Si Io

porte est difficile 5 bouger ou si le cable se prend, v_rifier le

passage du cable de ressort. Lecable doit passer entre les

_paules de lu roulette de poulie. Silecable est 5 I'ext_rieur

de la roulette :

verrouiller la porte,

relacher la tension Poulie

passer le cable

entre les_paules Epaule

du ressort et faire _

de la roulette.

Voir la Passage correct Passage incorrect

FigureJ. FigureJ duc_blede ressort duc_blede ressort

Augmente Diminue

#TAPE 5 RETRAIT DE LA PLINTHE

* Enleverlesdeuxvisde

laplintheetla plinthe.

Mettez-lesdec6t_

pourI'_tape23.

Figure L

I_TAPE6 RETRAIT DU RENFORT DE

PLINTHE

Suutercette _tupesivotre modulen'estpusdot_ d'unetrousse

d'um_liomtionde I'insonorisution.Sivotre moduleenestdot_,

cerenfortdolt @treretir&

* Enleverles2vis

du renfortdeplinthe

et lerenfort.Jeter

lerenfortetconserver

lesvispourI'@tape22.

FigureM renfortdeplinthe

JiEnleverdeuxvis du

Page 25

Instructions d'installation

I_TAPE7 INSTALLATION DU CORDON

D'ALIMENTATION I_LECTRIQUE

Sautercette _tapesile lave-vaisselleest raccord_directement

au r_seau_lectriquedelamaison.

Donscette@tape,vousaurezbesoinducouvercledeboTtede

jonctionetd'unevishexagonale#10x 1/2pode latroussede

quincailleriemisedec6t@a I'@tape1.

Lecordond'alimentationetlesconnexionsdoiventsatisfaireau

CodenationaldeI'@lectricit@Section/422etauxcodesetr@glements

Iocaux.LaIongueurmaximaledu cordonestde 1,8m@tre(6pieds).

Lotroussedecordond'alimentationNoWX09X70910,disponible

pourI'achatchezvotrerevendeurd'appareil@lectrom@nagersGE

autori@,r@ondaces exigences.

Blanc

Noir

Terre

Figure N

• Installerledispositifde r@ductiondetension

danslesupportde laboffedejonction.

• Ins@rerlecordond'alimentationatraversledispositifder@duction

detensionetserrer.

S'assurerquelesillsnoir,blancetvertdu lave-vaissellesont

pass@sparlepetittroudu supportdeboTtedejonction.

Raccorderlesillsdem@mecouleur,ceuxdulave-vaisselleetdu

cordond'alimentation.Silesillsducordonnesontpasidentifi@s

parlacouleur,raccorderlefilanervuresducordonaufilblancdu

lave-vaisselle,lefil lisseducordonaufil noirdu lave-vaisselle,et le

fildeterreau fil vertdulave-vaisselle.Utiliserdesserre-fils

homologu@sULducalibreappropri&

AI'aided'unevishexagonale#10,installerlecouvercledeboffede

jonctionmisdec6t@c_I'@tape1.S'assurerquelesillsnesontpas

coinc@ssouslecouvercle.

II_TAPE8_ INSTALLATION DU COUDE

_, ANGLE DROIT

• Mettreduruband'_tanch_it_defiletsurlecoudeaangledroit.

• Installerlecoudeaangledroitsurlavanne.

Avantdulave-vaisselle

Figure 0

Pattede la

Coude

angledroit

_k." ::: .... Ruband'_tanch_it_de filet

• Nepusserrerenexc@slecoudeaangledroit,cecipourraittordre

lapattedela vanneoubriserleraccorddelavanne.

Tournerlecoudepourqu'ilpointeversI'arri@redulave-vaisselle.

vanne

Tuyau de remplissage

I_TAPE9 MISE EN PLACE DU TUYAU D'EAU

ET DES FILS DE LA MAISON

* Mettre en place letugau d'eau et lesfils de la maisonsur

le solde I'ouverture,afind'@itertoute interf@enceavecla

basedu lave-vaisselleetdesdivers@l_mentssouscelui-ci.

(5po) (5po) I (4po)

iJ 12,7cm 12,7cm 10,2 cr_

Figure P Tuyau Filsdel/aa_

[ TAPElOl

-- d'eau maison

RACCORDEMENT DU TUYAU

DE VIDANGE A L'ORIFICE DE

VIDANGE DU LAVE-VAISSELLE

Donscette@tape,vous aurezbesoindutugaudevidangeet de

soncolliermisde c6t@_ I'@tape:1.

• Placerle lave-vaisselleenpositiondroite.

• Placerlecollierdutugau de vidangesurI'extr@mit_du tugau

dont le diam@treint_rieurfait 3 mm (1-3/16po),visde collier

du c6t_ inf_rieurdu tugau.

INPORTANT-Pr_venirlesdommages au tu£1aude

vidange et d'_ventuellesfuites.Veiller _ ne pas_br_cher ni

couper letugau.

• PousserI'extr6mit6dutugau sur I'orificede sortiede la pompe

de vidangeenfaisantattentionde ne pasnuireau clapetde

non-retour.Sereportera laFigureO.

• AppugerI'extr6mit6du tugau contre lesbut6esde tugau

situ_essur I'orificedesortie de lapompe.

• Placerlecollierde

Orificedesortie

tugau contre laI_vre de la pompe

frontale dutugau et

serrerlecollier.

NOTE: Letugau de

vidangefourni avecle

lave-vaissellemesure

environ2 m (78po)de

long.Sicela nesuffit

pas,on peut seprocurer

un tugau d'uneIongueur

de 3 m_tres(120po/

!0 pieds)aupr_s

d'un revendeur

d'_lectrom_nagers

GEautoris_,num_ro

de pieceGPFIOL

Conseilspour un raccordement exempt defuites :

• InsUrerletugau contrela butte sur la pompe.

• Placerlecolliercontrela I_vrefrontaledu tugau devidange.

• Serrerle colliera un coupled'au mainslS Ib-po.

Conseilspour unfonctionnement de pompesilencieux:

Installerlecollier detugau en plaqantla visde collierdu c6t_

inf_rieurdu tugau.Celaemp_cheralecollierd'entrer encontact

avec lerenfort arri_re.Lecontact entrelecollieretle renfort

arri_repeut@rebrugant Iorsquela pompe fonctionne.

But6es

detuyau

Page 26

Instructions d'installation

I_TAPE II INSERTION DU TUYAU DE

VIDANGE A TRAVERSUARMOIRE

• Placerlelave-vaisselle devant I'ouverture d'armoire.

InsUrerle tugau de vidange dans letrou sur le c6t_ de

I'armoire. Siun cordon d'alimentation est utilis_, en faire

passer I'extr_mit_ par un autre trou.

Couverture maximalede

isolante tuyau de 3 m

Cordon n'estPAS

d'alimentation utilis6)

FigureR

(s'il est utilis6)

Longueur

(10pi)

Filsde maison

(si le cordon

"_ d'alimentation

CONSEIL: Placerletuyau d'eauet lefilagedemaisonsur le

plancherpour@viterd'interf_reravecla basedu lave-vaisselle.

I_TAPE 12 GLISSEMENT DU LAVE=

VAISSELLE AU 3/4 DE LA

DISTANCE DANS L'ARMOIRE

| L J f'_ f% _'_"It'A k |"It"

I Ivll"Ull IRI_I/- NE PAS POUSSEZAVEC LES

GENOU× CONTRE LE PANNEAU FRONTAL. CELA

RISQUE DE L'ABI'MER.

• Agripper le lave-vaisselle par ses c6t_s et le glisser dans

I'ouverture une dizaine de centim_tres 6 la fois.

I_TAPE 13 GLISSEMENT DU LAVE=

VAISSELLE _, SA POSITION

FINALE

• Pousser le lave-vaisselle dans I'armoire.

• Pousser sur les bords, avec les mains. Ne pas utiliser

un genou contre la porte, car ceci endommage la

porte.

• Pendant la mise en place dans I'armoire, v6rifier que

la couverture isolante sur la cure ne <<retrousse >>

pas et qu'elle n'interf6re pas avec les ressorts.

• Centrer le lave-vaisselle dans I'ouverture.

• Le devant du panneau frontal doit 6tre au m6me

niveau que la face avant de I'armoire.

• Ouvrir et fermer la porte avec pr6caution pour v6rifier

que le panneau de la porte n'accroche pas ou ne

frotte pas sur le cadre de I'armoire. Se reporter a la

Figure Tci-dessous.

• Si la porte accroche ou frotte sur le cadre, changer

a position ou mettre I'appareil de niveau (Etape !/4)

jusqu'a ce que la porte se d6place librement et n'est

pas en contact avec le cadre de I'armoire.

La porte rentre i

bien et se i

referme derri6re i

le cadrede i

I'armoire_ '

\

Nepaspoussezlepanneau

frontal aveclesgenoux.Cela

risquede I'abtmer.

FigureS

• Tout en progressant, tirer sur le tuyau de vidange a

travers I'ouverture, du c6t6 de 1'6vier.Cesserde pousser

le lave-vaisselle Iorsque celui-ci ne d6passe I'avant des

armoires adjacentes que d'une dizaine de centim6tres.

• S'assurer que letuyau de vidange n'est pas coinc6

sous le lave-vaisselle et qu'il n'y a pas d'interf6rence

avec le tuyau d'eau, le filage ou d'autres composants.

CONSEIL: S'assurer que le lave-vaisselle se placera

correctement dans I'armoire. Veiller a que le cordon

d'alimentation, le tuyau de vidange et le tuyau d'eau

chaude ne soient pas coinc6s derri6re le lave-vaisselle.

Le coincement de ces conduites emp6chera de pousser

compl6tement le lave-vaisselle au fond de I'enceinte.

10

Alignement

FigureT

correct

Laportes'accroche

surle cadrede

I'armoire

Alignement

incorrect

Page 27

Instructions d'installation

I_TAPE 13 GLISSEMENT DU LAVE-

VAISSELLE #, SA POSITION

FINALE (suite)

Considerations sp@ciales concernant la raise

en place

Les commondes sur ces modules sont conques pour _tre

dissimul_s sous le plan de travail. Aligner le lave-vaisselle

comme illustr_ (_la Figure U. Luisser un espace minimum

de 1,3 cm (1/2 po) entre le dessous du plan de travail et

le dessus de la porte du lave-vaisselle comme illustr_

Io Figure V.

Utiliser les pattes de nivellement pour augmenter ou

diminuer I'espace entre les commandes et le plan de

travail.

IMPORTANT- Lcdsser un espclce minimum de

1,3 cm (i/2 po) entre les commandes et le dessous du

plan de travail pour pr_venir la condensation et les

dommages au panneau de commande par les t_tes

de vis.

Figure U

Commandesdissirnul_es

sousle plandetravail

I_TAPE 14 MISE #, NIVEAU DU

LAVE-VAISSELLE

IMPORTANT- Le love-voisselledolt@trede

niveoupourossurerlebonfonctionnementde l'@gouttoir

etun lovogeperformont.

*S'ossurerqu'unespoceminimum de 1,3cm (I/2po)est

mointenu.

Plocer un niveou

sur Io porte pour

v@rifiersi le Iove-

voisselle est de

niveou d'un c6t@

I'outre. Retirer Wrf I_'i i

I'@gouttoir inf@rieur: er e / _.......

nivellement _i_' _/ Verifier le

plocer le niveou d,avanten_i?,ii_, '+,\l nivellement

sur Io glissi@rede arri_re 1,?_ _', d'unc6t@_

I'_gouttoir inf_rieur _,,'_................. 'autre

cuvea ,'int@rieurde,Opourv@rifiersi 1_' _ .......... '' O' _: _i' "''_1 _" ' ',

le Iove-voisselle est . Lczj_ '_:_,

de niveou d'ovont

en orri@re.

• Si le Iove-voisselle n'est pos de niveou r@glerles quotre

pottes de nivellement comme illustr@_ Io Figure X.

Si le r@glogede Io potte de nivellement orri@redroite est

n@cessoire,g acceder en d@vissontIo vis du support de

boTtede jonction (5 trovers le trou d'occ@s)puis tourner

le support dons le sens des oiguilles d'une montre.

Figure X Troud'acc_s i

; \

(o, :.....................=......

Figure W

1,3cm z

(1/2 po)rain.

Figure V

........................................................_ Bottede jonction

Plandetravail

/

/

i

Portedu lave-vaisselle

Tourner les pattes _

poura_

Le Iove-voisselle est de niveou Iorsque I'indicoteur du

niveou est centr@de gouche 5 droite et d'ovont en

orri@re.Lo porte du Iove-voisselle doit fermer sons

heurter les c6t@sde Io cure.

* Replocer I'@gouttoirinf@rieurune fois le nivellement

termin_.

CONSEIL : Un bon nivellement _viter_ des frais de service

superflus en raison d'un lavage non performant ou du

mauwis fonctionnement d'un _gouttoir.

Sortir les @gouttoirs de moiti@.IIs devroient rester

stotionnoires. Ouvrir et fermer Io porte. Lo porte devroit

tenir dons I'ouverture de Io cuve sons heurter les c6t@s

de Iocuve. Si les @gouttoirs roulent por eux-m@mes ou si

Io porte heurte les c6t_s de Io cuve, refoire le nivellement.

IM PORTANT- Apr_s le nivellement, s'clssurer

que le lave-vaisselle est centr_ dans l'enceinte et que

la porte ne heurte pas les armoires adjacentes.

11

Page 28

Instructions d'installation

I_TAPE 15 FIXATION DU LAVE-VAISSELLE

AU AU PLAN DE TRAVAIL OU

#, L'ARMOIRE

Dans cette _tape, vous Supports de

aurez besoin de 2 vis 6 montagelat6raux

t6te cruciforme sp@dale

mises de c6t_ 6 I'_tape 1. __

Le lave-vaisselledolt _tre :;/

fix_ au plan de travail ou Cadre ('.....

aux c6t_s de I'armoire. dela_ _'_

Sileplan detmvailesten cuve ]

bob, utiliser la M_thode 1. it.

Supports 'de

montage

surplande

travail

S'ilest fait de granite ou FigureY

d'un outre mot6riou qui n'occeptem pos de vis,utiliser

la M6thode 2 pour fixer le lave-vaisselleaux c6t6s.

IMPORTANT- Pour @iter les frois de service

superflus, visser les vis en ligne droite, t_te rentr_e au

niveou de Io surface. Les t_tes de vis qui d_possent

vont _gratigner le FigureZ Supports Plandetravail en bois

dessus ou les c6t6s __ /

du ponneou de

commande et

peuvent g6ner

la fermeture

de la porte. Vis

M_thode 1--Fixation du lave-vaisselle au plan