GE ZBD4800XBB, ZBD4800XWW, ZBD4700XBB, ZBD4700XWW, ZBD4600XBB Installation Instructions Manual

...Page 1

GE Monogram

Installation

Instructions

®

Built-In Dishwashers

Models

ZBD4600XWW

ZBD4600XBB

ZBD4700XWW

ZBD4700XBB

ZBD4800XWW

ZBD4800XBB

Page 2

WARNING

CAUTION

Before you begin—Read these instructions completely and carefully.

IMPORTANT: Save these instructions for local inspector’s use.

IMPORTANT: OBSERVE ALL GOVERNING CODES AND ORDINANCES.

NOTE TO INSTALLER: Be sure to leave these instructions with the Con-

sumer.

NOTE TO CONSUMER: Keep these instructions with your Use and Care

Book for future reference.

This appliance must be properly grounded. See “Electrical Supply”, page 6.

If the dishwasher is a new installation most of work must be done before the

dishwasher is moved into place. If the dishwasher is replacing another

dishwasher the connections for the dishwasher being replaced must be

checked for compatibility with this dishwasher and replaced as necessary.

Contents

If you have a question concerning the installation of this product, call the GE Answer

Center® Consumer Information Service at

800.626.2000, 24 hours a day, 7 days a week.

Consumer must supply custom panels.

Before you begin: Make sure that custom

panels are available. Custom panels must be

installed onto the dishwasher before final

installation. If they are not, the dishwasher

will have to be removed from under the

counter to install these panels.

Models ZBD4600X and ZBD4700X have a

finished front door and access panel. 1/4"

thick custom panels may be installed onto

these models.

Design Information

Installation Notes .......................................................... 3

Standard Installation in 24" or 25" Deep Cabinets.... 3

Double Dishwashers...................................................... 4

Divider Panel Installation............................................. 4

Double Dishwashers Water Supply.............................. 4

Double Dishwashers Drain Hose, Air Gaps ................ 4

Preparation

Choosing the location .................................................. 5

Dimensions & Specifications ....................................... 5

Electrical Supply ........................................................... 6

Hot Water Supply.......................................................... 7

Prepare Drain Plumbing .............................................. 8

Step 1: Check Installation Hardware .......................... 9

Tools Required............................................... 10

Materials Required ........................................ 10

Step 2: Remove Packaging ......................................... 10

Models ZBD4600X and ZBD4700X ONLY

Step 3: Prepare 1/4" Custom Panels......................... 11

Install Custom Access Panel .......................... 11

Insert Custom Door Panel............................. 11

If you received a damaged

dishwasher, you should

immediately contact your

dealer or builder.

Models ZBD4800X does not have a finished

door or access panel. A custom 3/4" thick

door and access panel must be supplied by

the consumer.

Installation instructions for both 1/4" and

3/4" thick custom panels are included in

this booklet.

Models ZBD4800X ONLY

Step 3A: 3/4" Door and Access Panels...................... 12

Remove Access Panel Assembly.................. 12

Install Custom Access Panel to Assembly .. 13

Remove Plastic Chassis Cover..................... 13

Secure Custom Panel to Dishwasher ... 14, 15

Installation – All Models

Step 4: Adjust The Door Balance ............................ 16

Step 5: Install Leveling Legs .................................... 16

Step 6: Install Water Inlet Fittings ........................... 17

Step 7: Protect the Countertop ............................... 17

Step 8: Connect Electrical (For Power Cord

Installation Only)......................................... 17

Step 9: Level the Dishwasher ................................... 18

Step 10: Install Side Filler Strips................................ 18

Step 11: Connect Drain Hose .................................... 18

Step 12: Slide Dishwasher Into Opening .................. 18

Step 13: Connect Water Line..................................... 19

Step 14: Install Drain Line ......................................... 19

Step 15: Connect Electrical (For direct Connection

to House Wiring) ......................................... 20

Step 16: Secure Dishwasher to Countertop.............. 20

Step 17: Reinstall Chassis Cover ................................ 20

Step 18: Install Toekick and Access Panel ................ 21

Install Optional Custom Toekick................ 21

Finalize Installation ..................................... 21

Questions & Answers .................................................. 23

2

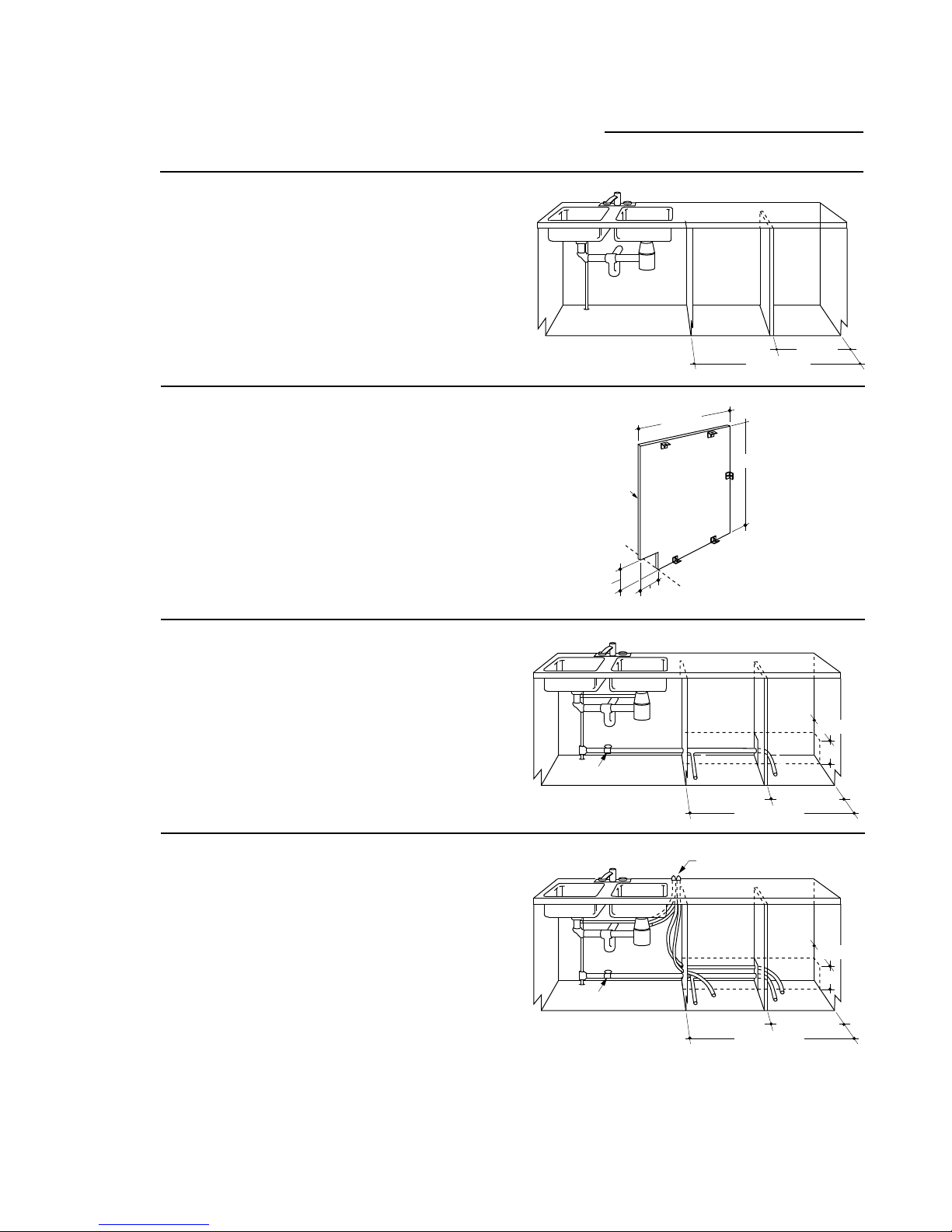

Page 3

Design Information

Stainless Steel Interior Dishwashers

Installation

Notes

Standard

Installation

in 24" or 25"

deep cabinets

Models ZBD4600X and ZBD4700X

dishwashers are supplied as either a black or

white model. Door and access panels may be

replaced with custom decorative panels of

wood or other materials to match surrounding cabinetry.

•Standard door and access panel trim will

accommodate custom panels up to 1/4"

thick.

Models ZBD4600X and ZBD4700X as supplied:

•The dishwasher door will be flush with the

front face of the cabinetry.

•The dishwasher control panel will extend

1/4" beyond the front face of cabinetry.

The addition of a 1/4" thick custom door and

access panel will make the door and control

panel nearly flush.

Models ZBD4800X:

•With the 3/4" thick custom panel in place,

the exterior is trimless and fits flush with

adjacent cabinetry.

Model ZBD4800X dishwashers are supplied as

either a black or white model. These models

do not have a finished door or access panel. A

custom 3/4" thick door and access panel must

be custom made to suit the installation.

•All dishwasher models may be installed

beneath any type of countertop.

•A matching toekick is supplied with all

models and may be customized to match

surrounding cabinetry.

•Side trim is not required. All models come

equipped with vinyl strips to fill a 24" wide

opening.

Cabinet

Depth

24"

Cabinet Resting

Against Wall

3

Page 4

Design Information

Stainless Steel Interior Dishwashers

Double

Dishwashers

Divider Panel

Installation

Double

Dishwashers

When installing double dishwashers side-by-side:

•Make cabinet opening 47-3/8" wide.

•Depth and height are same as for single unit.

•Must be supplied by installer at time of

installation. Locate divider panel in center of

47-3/8" opening provided for two dishwashers.

•Suggest attachment to floor, countertop and

rear wall.

When installing two dishwashers side-by-side,

run a branch water supply line as shown.

1/8" Thick

Masonite

5"

47-3/8" Min.

23-5/8"

24-1/4"

34-1/4"-35"

2"

W ater Supply

Double

Dishwashers

Drain Hose,

Air Gaps

When installing two dishwashers side-by-side,

place drain hoses and air gaps as shown.

Note: Each dishwasher

must have a separate

drain hose as shown.

1-3/4"

6"

Shut-Off Valve Optional

23-5/8" Min.

47-3/8" Min.

Air Gap

1-3/4"

6"

Shut-Off Valve Optional

23-5/8" Min.

47-3/8" Min.

4

Page 5

Choosing

the Location

Select a location as

close to the sink as

possible for easy

access to water and

drain lines.

Installation Preparation

34" to 35"

Underside of

Countertop

to Floor

Stainless Steel Interior Dishwashers

This Wall Area

must be Free of

Pipes or wires

1-3/4"

Plumbing and Electric Service

Must Enter Inside This Area

23-5/8" Min.

24" Max.

24"

Min.

6"

Dimensions

& Clearances

•The dishwasher must be located within reach

of the drain hose. The maximum drain hose

length is 10 feet. Consideration for the

installation of a high drain loop or air gap

must be included when determining the

installation location. See “Prepare Drain

Plumbing”, page 8 and “Install Drain Plumbing”, page 19.

•The rough opening should be 23-5/8" min.

to 24" max. wide, 24" deep and 34" to 35"

high.

If the dishwasher is installed in a corner, allow

2" min. clearance between dishwasher and

adjacent cabinet, wall or other appliances.

•Adjacent cabinets should be square and

plumb to ensure a good fit.

•The floor inside the opening must be level

and even with the kitchen floor.

•The dishwasher must be fully enclosed on

the top, sides and back.

•Filler strips are provided to cover gaps on the

sides of dishwasher.

23-3/8"

34" Min.

35" Max.

22-5/8"

25-1/4"

From Inside

Front Frame

5

Page 6

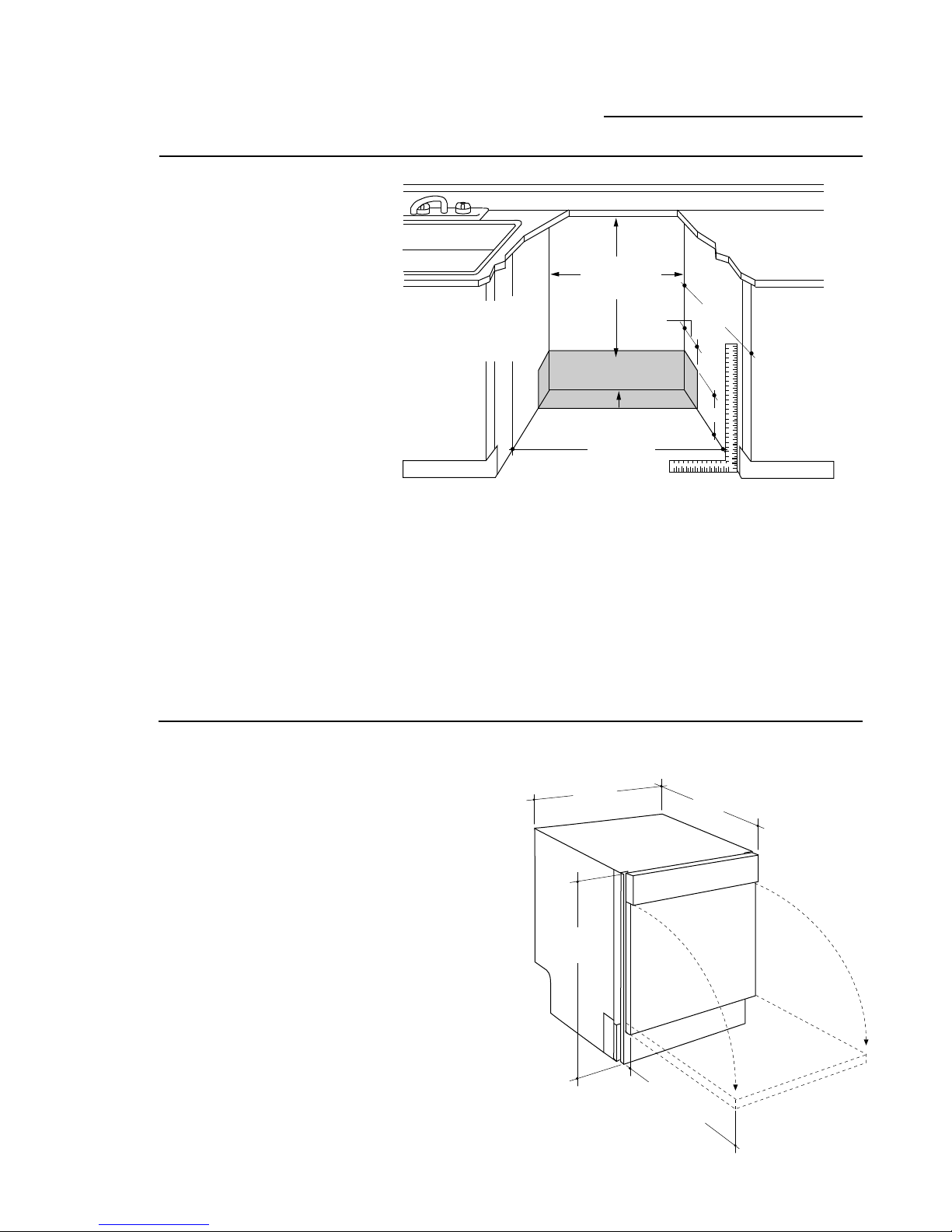

Electrical

Supply

CAUTION

WARNING

Warning, for

Personal Safety:

Remove house

fuse or open

circuit breaker

before beginning installation.

Do not use an extension

cord or adapter plug with

this appliance. Follow

National electrical codes

or prevailing local codes

and ordinances.

18"

Installation Preparation

Stainless Steel Interior Dishwashers

18"

1-1/2" Dia. Hole (Max.)

6"

Receptacle

Location

Area

6"

24"

from Wall

Ground

Black (Live)

Alternate

Receptacle

Location

1-3/4"

6"

Cabinet

White (Neutral)

3"

from

Electrical Requirements

•This appliance must be supplied with 120V,

60 Hz., and connected to an individual,

properly grounded branch circuit, protected

by a 15 or 20 ampere circuit breaker or time

delay fuse.

•Wiring must be 2 wire with ground.

•If the electrical supply provided does not

meet the above requirements, call a licensed

electrician before proceeding.

•A side-by-side dual installation requires two

separate circuits.

Grounding Instruction

This appliance must be connected to a

ground metal, permanent wiring system, or an

equipment-grounding terminal or lead on the

appliance.

WARNING

CAUTION

Warning: The improper connection of the equipment-grounding

conductor can result in a risk of

electric shock. Check with a

qualified electrician or service

representative if you are in doubt whether

the appliance is properly grounded.

Cabinet Preparation & Wire Routing

•Wiring may enter from either side of the

opening, from the rear, or from the floor

within the shaded area shown.

•Cut hole 1-1/2" max. dia. within the shaded

area to admit the electrical cable or power

cord. The hole must be free of sharp edges. If

the cabinet wall partition is metal, the edge

of the hole must be covered with a rubber

cord protector.

Electrical Connections to Dishwasher

•For cable direct connections the cable must

be routed as shown in the diagram. Cable

must extend a minimum of 24" from the rear

wall.

•For power cord connections, install a 3-prong

grounding type receptacle in the rear wall of

sink cabinet next to the dishwasher. The

receptacle should be installed at least

6", but not more than 18", from the cabinet

opening for dishwasher. Power cord must be

no longer than 6 feet from the junction box

to the plug.

6

Page 7

Hot Water

Supply

Installation Preparation

Stainless Steel Interior Dishwashers

1-1/2" Dia.

Shut-off

Valve

Hot

The hot water supply

line may enter from

either side, the rear

or from the floor

within the shaded

area.

Cabinet Face

•Turn off the water supply.

•Cut a hole approximately 1-1/2" dia. within

the shaded area to admit the water line.

Access holes must be round and smooth.

•Install a hand shut-off valve in the hot water

supply line in an accessible location, such as

under the sink. (The shut-off valve is optional, but recommended and may be

required in some local codes.)

1-3/4"

Hole

6"

Right Side Entry

Approx. 40" from Wall

Left

Side Entry

Approx. 30"

from Wall

2" from Floor

•Install the hot water inlet line, using no less

than 3/8" O.D. copper tubing or 1/2" O.D.

plastic tubing.

•The water line must be long enough to form

a smooth natural loop with no sharp bends

or kinks between the cutout entr y and fill

valve location. For a left side entry, allow

approximately 30" length. For a right side

entry, allow approximately 40" length.

•Extend the water line forward to approximate fill valve location.

•Adjust the water heater to deliver 120 °F min.

water temperature.

•The water pressure of the hot water supply

line must be 20 to 120 psi.

7

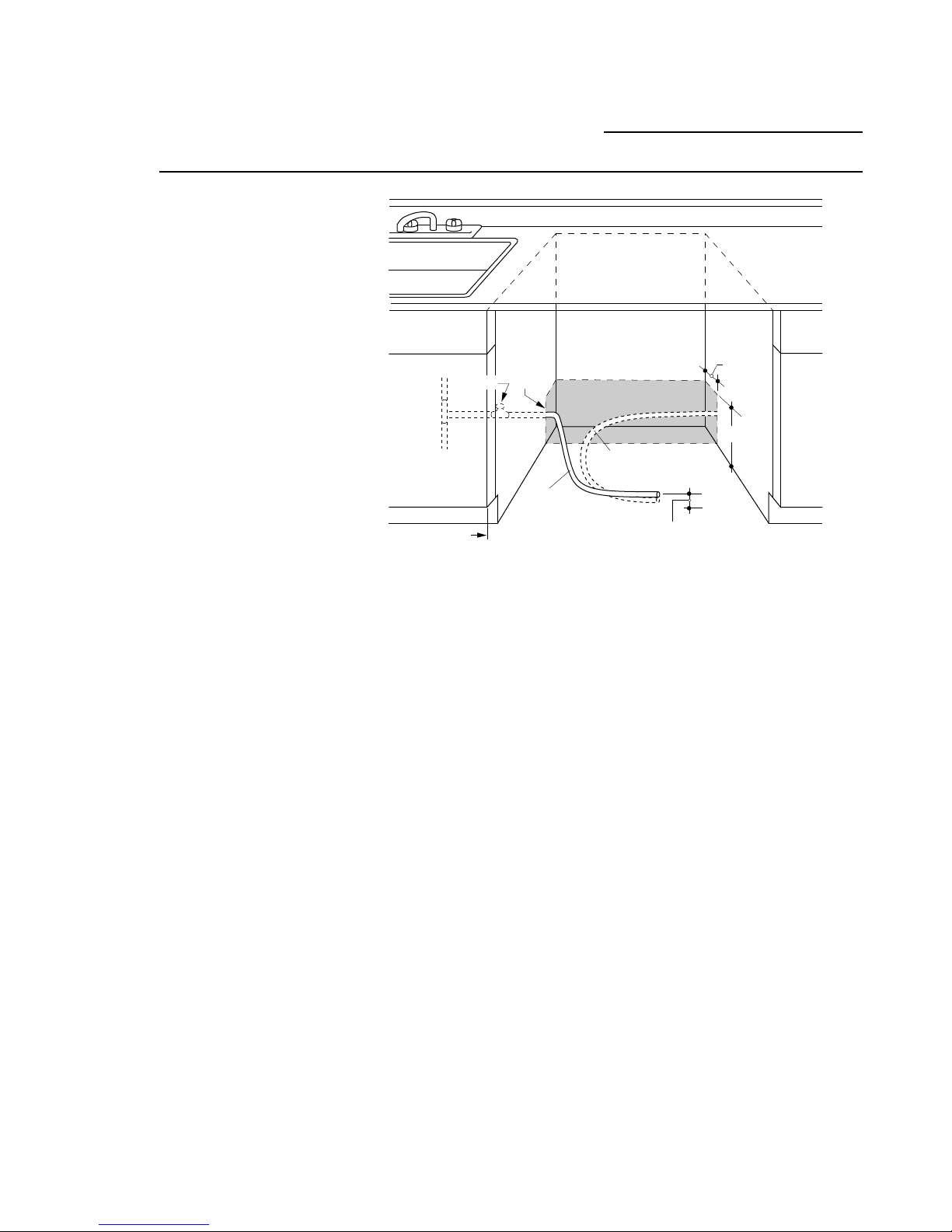

Page 8

Installation Preparation

Stainless Steel Interior Dishwashers

Prepare

Drain

Plumbing

DRAIN REQUIREMENTS

•Follow local codes and ordinances.

•Dishwasher drain hose must not exceed 10

feet in length for proper drainage.

•Dishwasher must be connected to waste line

with an air gap (not supplied) or 32" minimum high drain loop depending on local

codes and ordinances to prevent back flow

into the dishwasher.

•Air gap must be used if waste tee or disposer

connection is less than 18 inches above floor

to prevent shopping.

CAUTION

An air gap MUST BE

USED if the drain

hose is connected to

waste tee or disposer

lower than 18" above

the floor level.

Failure to provide the

proper drain connection height with air

gap or 32" minimum

height drain loop will

result in improper

draining of the dishwasher which may

cause damage.

METHOD 1–High Drain Loop with Waste Tee or Disposer

Drain hose to be fastened

to underside of countertop

in a later step.

METHOD 2–Air Gap with Waste Tee or Disposer

DRAIN PREPARATION

The type of drain installation depends on

answers to the following questions:

l Do local codes or ordinances require an

air gap?

l Will waste tee or disposer connection be

less than 18" above floor?

l Will installation have a drain loop less than

32" above floor?

If the answer to ANY of the 3 questions above

is YES, Method 2 MUST be used. Otherwise

either Method 1 or Method 2 may be used.

Drain hose to be fastened

to underside of countertop

in a later step.

32"

18"

Min.

32"

Min.

Min.

18"

Min.

Install air gap, waste tee or disposer according to

manufacturer’s instructions. Provide a method to support

drain hose at least 32" above floor to prevent back flow

into dishwasher.

8

Page 9

Installation Preparation

Stainless Steel Interior Dishwashers

Step

1

Check

Installation

Hardware

Remove the hardware accessory bag and other

parts from inside or taped to the outside of

the dishwasher. Check contents against

drawings to assure that all parts are present.

All Models

4 Lock Washers

4 Leveling Legs

2 Screws to

Secure

Dishwasher

to Countertop

4 Nuts

Side

Filler

Strips

Clear Plastic

Self-Adhesive

Countertop Shield

2 Slides

1/2" Water Inlet

Extension

Fitting, 3/8" NPT

both top and bottom

Corrugated

Drain Hose

Color Matched

Toekick

(taped to the outside of dishwasher)

Screw Type

Hose Clamp

Model ZBD4800X Only

2 Access Panel

Mounting Brackets

Screws A

4 Flathead Phillips

Screws for Access

Panel Brackets

Door Panel Template

Access Panel Template

Template for

Custom Door

and

Access

Panel

Taped to

the Outside

of the Dishwasher

Screws B

2 Plastic Door Panel

Mounting Brackets

16 Round Head

Phillips Screws

for Door Panel

Brackets

Actual Size

Screw A Screw B

2 Metal Door

Panel Mounting

Brackets

Screws C

Screw C

2 Screws to

Secure Custom Panel

to Dishwasher Door

9

Page 10

Installation Preparation

Stainless Steel Interior Dishwashers

Tools

Required

(not supplied)

If you have a question concerning the installation of this product, call the GE Answer

Center® Consumer Information Service at

800.626.2000, 24 hours a day, 7 days a week.

If you received a damaged

dishwasher, you should

immediately contact your

dealer or builder.

Installation of this dishwasher requires basic

electrical and mechanical skills. Proper

installation is the responsibility of the installer.

Product failure due to improper installation is

not covered under the GE Appliance Warranty. See the back cover of the Use & Care

Guide for warranty information.

•Tape measure

•Spirit level

•Flat blade

screwdriver

•Phillips

screwdriver

•Awl

•Carpenters square

The dishwasher MUST be installed in such a

manner to allow for future removal from the

enclosure if ser vice is required.

Before starting make sure that the custom

panel is available. If not, the dishwasher will

have to be removed from under the counter

to install the panels.

•Wire cutter

•Adjustable wrench

•Wire stripper

•Electric drill

•1-1/2" drill bit

or hole saw

•Pliers

Materials

Required

(not supplied)

Step

2

Remove

Packaging

•Minimum 3/8" OD

copper tubing of

sufficient length for

your installation

•Shut-of f valve

•Compression nut

•Compression sleeve

Cut the shipping carton and use it as a pad

under the dishwasher. This will protect the

finished flooring of the room.

•Remove the toekick taped to the top of the

dishwasher.

•Remove the template taped to the side (on

Model ZBD4800X only).

•Lay the dishwasher on its back close to the

opening.

•Place a 2x4 block or two cor ner posts from

packaging beneath the dishwasher. This

will prevent the dishwasher from falling

when the shipping bolts are removed.

•Remove 4 shipping bolts with an

adjustable wrench and discard.

•90° compression

elbow (3/8" NPT

one end)

•Two 1-1/4" adjustable hose clamps (to

accommodate drain

line)

•120 Volt 60 Hz. 15

Amp or 20 Amp, 2

wire with ground

Properly grounded

branch circuit

Block

•1/2" strain relief

bushing for electrical supply cable.

•3 wire nuts

10

Page 11

1/4" Custom Panels

Custom Panel

Step

3

Prepare

1/4" Custom

Panels

For Model

ZBD4600X and

ZBD4700X ONLY

Install Custom

Skip this step if you are

not using custom panels.

Models ZBD4600X and ZBD4700X will

accept 1/4" thick custom door and

access panels.

•Cut 1/4" thick door panel: 23-1/4"

wide, 22-11/16" high.

•Cut 1/4" thick access panel: 23-1/4"

wide, 1-1/2" high.

Cut edges of the panels will be concealed by the trim.

Cut a notch in the top corners of the

door panel, 1/8" wide and 3/16" deep.

This will allow the panel to slide under

the escutcheon. The bottom corners of

the door panel trim and all 4 corners

of the access panel trim are rounded.

Therefore, for a good fit, a 5/16"

radius cut is required.

Notch 1/8"

3/16"

5/16"

Radius

Cut

Models ZBD4600X and ZBD4700X

1/4" Thick

Door Panel

1/4" Thick Access Panel

23-1/4"

22-11/16"

1-1/2"

Access Panel

Insert Custom

Door Panel

Remove 2 Screws

•Remove the two screws below the access

panel assembly and lift off.

•Remove the 4 Phillips head color matched

screws on the bottom side of the assembly

and 2 screws on the top.

•Lift off the trim piece.

•Remove 2 Phillips head color matched

screws on each side of the door trim.

•Remove 2 screws on the bottom of the door

trim.

•Slide the door trim down and remove.

•Slide the 1/4" thick custom panel under the

escutcheon lip. Making sure the panel is

centered left to right.

•Re-install the door trim using the screws

previously removed.

Remove

4 Screws

•Place the custom panel on top of the assembly and reinstall the trim with the same color

matched screws.

•Set the assembled access panel aside. Do not

reinstall this piece until final installation is

complete.

Important: Do not overtighten screws. Handtighten with a Phillips head screwdriver.

11

Page 12

3/4" Custom Panels

Step

3A

3/4" Door

and

Access Panels

For Model

ZBD4800X

ONLY

Skip This Step

If You Are

Installing Other

Models

Models ZBD4800X do not have a finished door or

access panel. 3/4" thick custom panels are required.

Door and access panels should be constructed

in the same manner as surrounding cabinetry.

Cut edges will show and must be finished for

optimum appearance. Provide these dimensions to the cabinet manufacturer to ensure

that the panels are constructed accurately.

This dishwasher has an adjustable spacer bar

below the control panel. The spacer bar allows

you to match the height of adjacent drawers.

When adjacent drawers are shorter height

than the control panel, align the bottom of

the control panel by pushing the spacer bar

upwards and tightening two screws. Maximum

spacer bar adjustment is 3/4".

5-1/2"

4-3/4"

Spacer Bar

Models ZBD4800X Dishwashers

3/4" Thick

Door Panel

3/4" Thick Access Panel

23-3/8"

22-1/2" Min.

23-1/4" Max.

See Example

1-5/8"

3/8"

Gap

Remove

Access Panel

Assembly

Adjustment

Screws

Any adjustment to the spacer bar will affect

the height of the custom panel.

EXAMPLE: Minimum panel height is 22-1/2"

Add adjusted dimension 1/4"

TOTAL PANEL HEIGHT22-3/4"

OR

Measure the adjusted height of the control

panel. Subtract that dimension from 28". The

panel height will be 22-1/2" Min. to 23-1/4"

Max.

28"

4-3/4" Min.

5-1/2" Max.

Panel

Height

Remove 2 Screws

•Remove the two screws below the access

panel assembly.

•Lift the assembly off and set aside.

12

Page 13

Step

3A

(continued)

Install

Custom

Access Panel

to Assembly

Locate the access panel template provided.

•Place the template on the back side of custom

access panel with top edges and sides aligned.

•Use an awl or punch to mark 4 screw hole

locations.

•Remove the template and drill four 3/32"

pilot holes 3/8" deep in the marked locations.

•Place the mounting brackets on the access

panel, aligning screw holes.

•Secure the brackets to the panel with four

screws (A) provided.

•Drop the access panel with mounting

brackets into the slots on the assembly and

push down.

•Set the access panel assembly and custom

panel aside. Do not reinstall until final

installation is completed.

3/4" Custom Panels

Models ZBD4800X Dishwashers

Custom

Panel

Access Panel Template

Screw A

Remove

Plastic

Chassis

Cover

Remove 2 Screws

Remove the two screws with spacers on each

side of the plastic chassis cover.

•Lift and rotate upwards until the chassis

cover snaps out of position. Remove and set

aside. Do not re-install until final installation

is completed.

13

Page 14

3/4" Custom Panels

Models ZBD4800X Dishwashers

Step

3A

(continued)

Secure

Custom

Panel to

Dishwasher

Use the template supplied to find the location

of the support brackets which hold the custom

panel to the front of the dishwasher door.

•Check to be sure the spacer bar below the

control panel is set to the desired location.

•Measure the total height of the control

panel. See illustration on page 12.

•Find and mark that location on the graded

rule on both top corners of the template.

•Lay the custom panel on a flat surface with

the appearance side down. Locate the

vertical center of the panel at the top. Use a

carpenters square to draw a center line from

top to bottom on the panel.

•Place the template on the panel with the

large “V” notch at the top and small “V”

notch at bottom. Align the template center

line to the center line drawn on the panel.

Align the top of the template with dimensions previously marked on the graded rules.

The windows on both sides of the template

will help you align the template to the panel

accurately.

MM INCHES CONTROL PANEL HEIGHT

115

125

135

145

155

4-3/4

5

5-1/4

5-1/2

•Tape the template in place and use an awl to

mark screw hole locations indicated.

•Remove the template and drill pilot holes

3/32" deep in the marked locations.

•Secure all brackets to the custom panel using

Screws (B) provided.

Screw B

14

Page 15

Step

3A

(continued)

3/4" Custom Panels

Models ZBD4800X Dishwashers

•Fit the panel to the door by inserting the top

and bottom mounting brackets into the

matching slots.

•The top plastic brackets will fit into keyhole

slots and the bottom metal brackets will fit

into the side slots.

•Press the panel against the door and push

upwards until the side bracket screw hole

aligns with the inner door screw hole on

both sides.

•Install one screw (C) on both

sides to secure the panel to the

door.

Screw C

15

Page 16

Installation

Remove 3 Screws

Stainless Steel Interior Dishwashers

Step

4

Adjust

The Door

Balance

•Carefully upright the dishwasher.

Important: The weight of the door panel may

cause the door to fall heavily. The correct

spring tension will prevent the door from

falling too heavily or raising by itself from a

fully open position.

•Hold the door and open fully. If the door

falls too heavily, or if the door starts to close

by itself, the spring tension will need to be

adjusted.

If adjustment is required:

•To locate the spring adjustment slots,

carefully lay the dishwasher on its back.

•Remove the 3 screws holding the base plate

to the bottom of the dishwasher.

•Locate the spring tension slots on the sides.

•With a pair of pliers, pull the spring clip out

and down to the next slot for more tension,

or up to the next slot for less tension.

•Upright the dishwasher and test door

balance. Continue this procedure until the

door is balanced.

•Reinstall the base plate with screws.

Spring

Clip

Step

5

Install

Leveling Legs

Locate the 4 leveling legs, 4 nuts and 4

locking washers.

•Install a nut followed by a lock washer onto

each leveling leg.

•Insert the leveling leg into the bottom of the

dishwasher. Screw the leg in until the total

dishwasher height nearly matches cutout

height.

•Screw the nut up against the bottom of the

dishwasher, do not tighten until final

installation is completed.

If the plastic chassis cover has not been

removed, do so at this time. See page 13,

“Remove plastic chassis cover.”

Lock

Washer

Nut

Leveling

Leg

Install

and

Adjust

4 Legs

16

Page 17

Step

6

Install

W ater Inlet

Fittings

Step

7

Protect the

Countertop

Installation

Stainless Steel Interior Dishwashers

•Install the water inlet extension fitting and

90° elbow (not supplied) onto the dishwasher. Use thread sealing tape or pipe

thread compound.

•The 90° elbow should face the left side of

the dishwasher.

Note: 90° elbow

should face the left

side.

•To protect the countertop from moisture,

apply the self-adhesive plastic strip provided

to the underside of the countertop.

Step

8

Connect

Electrical

(For Power Cord

Installation Only)

•Remove the screw holding the junction box

to the dishwasher frame. Remove the

junction box.

•Install a strain relief onto the junction box.

•Tighten the strain relief against the incoming wires.

•Strip 1/2" insulation from end of wires.

•Connect incoming wires to dishwasher wires

using wire nuts of appropriate size. Connect

white to white, black to black and incoming

ground to green wire.

•Push all wires into the junction box and

place on dishwasher frame. Secure with

screw.

Note: The power

cord and connection

must comply with the

National Electrical

Code, Section 422

and/or local codes

and ordinances.

IMPORTANT: Power cord must be no longer

than 6 feet from the junction box to the plug.

Do not plug in power cord at this time.

Screw

17

Page 18

Step

9

Level The

Dishwasher

Step

10

Install

Side Filler

Strips

•Carefully upright the dishwasher, so as not to

bend the leveling legs.

•Tilt the dishwasher slightly and slip leg slides

under the leveling legs.

•Check to be sure the dishwasher is level and

at the proper cutout height.

•Tighten the bolts on each leveling leg against

the bottom of the dishwasher.

Side filler strips are packed with the product.

If the cabinet cutout is wider than the dishwasher, install the filler strips on both sides of

the dishwasher to cover gaps.

•Open the door fully.

•Remove the two screws on the inside front

frame of the dishwasher.

•Remove the plastic covering the adhesive

strip on the back side of the filler strip.

•Carefully, align the screw holes on the filler

strip with screw holes on the dishwasher.

Press firmly into place.

•Secure filler strips with original screws.

Installation

Stainless Steel Interior Dishwashers

Level

Top

And

Sides

Leg Slides

Step

11

Connect

Drain Hose

Step

12

Slide

Dishwasher

Into Opening

Locate the drain hose packed with the

dishwasher.

•Fit the drain hose onto the drain hose

adapter on the back of the dishwasher.

•Press together firmly and secure with a screw

type clamp supplied.

•Insert the drain hose into the cabinet wall.

•Slide the dishwasher into the opening a few

inches at a time.

•As you proceed, pull the drain hose through

the cabinet wall under the sink.

•If a power cord has been installed, insert the

cord through a separate hole in the cabinet

wall and pull along with drain hose.

•Check to be sure there is no interference

with waterline or house wiring.

Leg Slides

18

Page 19

Step

13

Connect

W ater Line

The water supply line should be flushed to

clear any foreign material before connecting

to the dishwasher.

•Make sure there are no sharp bends or kinks

which could restrict the water flow.

•Connect the water supply line to the 90°

elbow.

•Turn on the water supply and check for

leaks.

Installation

Stainless Steel Interior Dishwashers

Hot Water

Supply

90° Elbow

Step

14

Install

Drain

Line

Follow all local codes and

ordinances.

Drain Line Preparation

•The dishwasher is supplied with a

78" long corrugated drain hose.

The molded end is designed to fit

5/8", 3/4" or 1" diameter connections to the air gap, waste tee or

disposer. Cut on premarked line as

required for your installation.

Note: Do not cut corrugated portion

of hose.

Cutting Lines

3/4"

1"

•If the location requires a longer

drain hose, add up to 42" length to

the supplied hose. Use 5/8" inside

diameter hose and thin wall copper

coupler to join the hose ends.

5/8"

Do not cut corrugated

portion of hose

Method 1–High drain loop with waste tee or disposer

Fasten to underside

of countertop

32"

Min.

18"

Min.

Waste tee installation Disposer Installation

Note: Be sure to remove drain plug from disposer before

attaching drain line. Dishwasher will not drain if plug is

left in place.

Method 2–Air gap with waste tee or disposer

Fasten to underside

of countertop

32"

18"

Min.

Min.

Note: Total drain hose length must

not exceed 10 feet for proper drain

operation.

Drain Line Installation

•Connect drain line to air gap, waste

tee or disposer using either

Method 1 or Method 2 as previously determined.

•Secure connection using appropriate clamps (not supplied).

•Make sure drain hose is not

kinked.

Waste tee installation Disposer Installation

19

Page 20

Installation

Stainless Steel Interior Dishwashers

Step

15

Connect

Electrical

(For direct

connection to

house wiring)

Verify that power is turned off at source.

CAUTION

WARNING

•Remove the screw holding the junction

box to the dishwasher frame. Remove the

junction box.

•Install a strain relief onto the junction box.

•Tighten the strain relief against the incoming

wires.

•Strip 1/2" insulation from end of wires.

•Connect incoming wires to dishwasher wires

using wire nuts of appropriate size. Connect

white to white, black to black and incoming

ground to green wire.

•Push all wires into the junction box and place

on dishwasher frame. Secure with screw.

If house wiring is not 2-wire with a

ground wire, a ground must be

provided by the installer.

When house wiring is aluminum,

be sure to use U.L. approved antioxidant compound and aluminum-to-copper connectors.

Screw

Step

16

Secure

Dishwasher

to Countertop

Step

17

Reinstall

Chassis Cover

To maintain dishwasher position and alignment, drill pilot holes through the mounting

flange and into the underside of the

countertop. Install 2 screws provided.

Note: Open and close dishwasher door to

insure proper clearance between tub and

door. If there is any binding or rubbing,

readjust leveling legs.

•To reinstall the plastic chassis cover, tilt and

rotate the cover under the door. Press the

bottom of the cover against the metal frame

of the dishwasher until it fits into position.

•Secure the cover to the dishwasher using the

the two screws with attached spacers.

NOTE: The small

ring of the spacer

goes against the

chassis cover.

20

Page 21

Step

18

Install

Toekick

and

Access Panel

•Place the toekick against the chassis cover,

aligning screw holes.

• Hang the access panel assembly on the screw

with the spacer ring. The lip of the assembly

will slip into the notch on the ring.

•Secure the assembly with the original Phillips

head color matched screws.

Installation

Stainless Steel Interior Dishwashers

Chassis Cover

Toekick

Access Panel

Optional

Custom

Toekick

Finalize

Installation

The supplied toekick may be covered with a

custom toekick to match surrounding

cabinetry.

BEFORE YOU BEGIN:

1. Install the supplied toekick as described

above.

2. Compare the toekick depth of the dishwasher to the toekick depth of the

cabinetry. Cabinet toekick depth will vary

among manufacturers.

3. The difference will determine the thickness

of the custom material to be used.

4. Cut the custom toekick to fit the width of

the dishwasher opening.

A continuous toekick, bridging the dishwasher

cutout can be used if cabinet toekick depth is

not less than the dishwasher depth. Secure the

continuous toekick in such a manner that it

could be removed if service is requir ed.

•Turn on the hot water shut-off valve and

electrical supply.

•Operate dishwasher through one cycle and

check for plumbing leaks.

•Leave Installation Instructions and Use &

Care literature with the owner.

•Discard any unused parts.

21

Page 22

Notes

Stainless Steel Interior Dishwashers

22

Page 23

Questions & Answers

Stainless Steel Interior Dishwashers

Q. Can I use a custom toekick with the stainless steel interior dishwasher

models?

A. Yes, a matching toekick is supplied with these models and can be

covered with a custom toekick to match surrounding cabinetr y.

Q. Can I use custom panels on the stainless steel interior dishwasher

models?

A. Yes, Models ZBD4600X and ZBD4700X will accept 1/4" thick custom

panels. The custom panels are secured to the dishwasher with the

factor y installed trim and does not require a trim kit.

Models ZBD4800X do not have a finished door or access panel.

These models require a 3/4" thick custom door and access panel.

Mounting brackets for the panels are provided with the product. The

installation of custom panels on all models must be completed before

the product is installed.

23

Page 24

®

Monogram.

General Electric Company

Louisville, KY 40225

Note: While performing installations described in this book,

safety glasses or goggles should be worn.

To obtain specific information concerning any

Monogram product or service, call GE Answer Center

®

consumer information service at 800.626.2000—any

time, day or night.

For Monogram local service in your area, call

1-800-444-1845.

NOTE: Product improvement is a continuing endeavor at General Electric.

Therefore, materials, appearance and specifications are subject to change

without notice.

Pub. No. 49-5774

Dwg. No. 165D4700P122

1996 GE Appliances

(N.D. 466) 9/96

Loading...

Loading...