Page 1

Installation Sheet No. 1337ZE R3.0

Z630-3 Conventional Optical Smoke Detector

2435-01

Brief description

The Conventional Optical Smoke Detector provides an

early response to a wide range of slow burning to

smouldering fires, and provides reliable sensing for

most conventional fire alarm applications. The detectors

aesthetic design and proven stability in air movements

associated with air conditioning systems, have made it

an ideal selection for modern building interiors.

Specifications

General information

Designation Optical Smoke Detector

Specification EN54 Part 7

Sensitivity 0.1 dB/m

Model number Z630-3

Part number 1337

Compatibility Compatible 24 V conventional

systems

Mounting Plugs into surface or semi

recessed base

Area coverage 80 m², subject to local codes

Wiring 2-wire zonal

Monitoring

Base Open and short circuit by end of

line resistor

Diode base Open and short circuit, and head

out continuity with suitable end

of line (EOL) component.

Indication Alarm LED (red)

Detection principle Photo electric light scatter

Environmental

Application Indoor use

Environmental rating IP32

Temperature range -20 to +70ºC

Humidity range 20 to 95% RH (non condensing)

Primary supply

Operating voltage 12 to 30 VDC

Current (quiescent) <60 µA @ 24 VDC

Current (alarm) Maximum 50 mA (limited by panel)

Mechanical details

Material Moulded ABS

Colour White

Dimensions (D x H) 106 x 52 mm – excluding base

Height (from ceiling

with base) surface base – 60mm

recessed base – 38mm

Weight 100 g (excluding base)

Manufacturer traceability

A barcode label is affixed to each product (see example

below). This label reflects, amongst other things, the date of

manufacture of the product in the form YYDDD.

These numbers are interpreted as follows:

YY = year of manufacture

DDD = day of manufacture

For example the numbers 07134 would indicate that the

product was manufactured on the 134th day of the year 2007,

that is 14

th

May 2007.

Page 1 501-1337ZE-1

www.gesecurity.eu • Copyright © 2007 GE Security B.V. All rights reserved 12 November 2007

Page 2

Installation Sheet No. 1337ZE R3.0

Z630-3 Conventional Optical Smoke Detector

Page 2 501-1337ZE-1

www.gesecurity.eu • Copyright © 2007 GE Security B.V. All rights reserved 12 November 2007

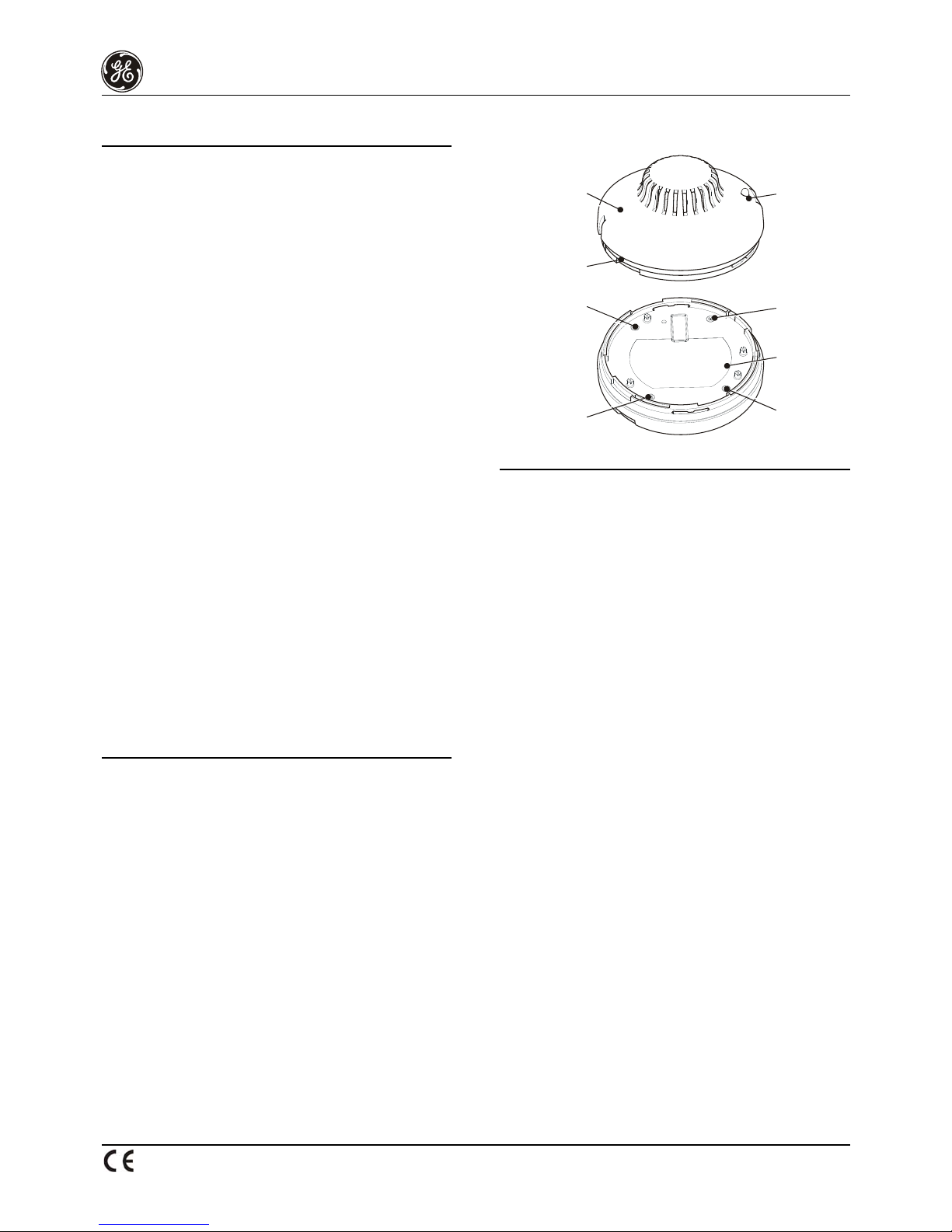

Figure 1: Mounting the detector

Detector Housing

Component

Cover Plate

Component

Cover Plate

Housing Assy

Screw

Housing Assy

Screw

Housing Assy

Screw

Housing Assy

Screw

2437-01

Top View

Bottom View

Indent Zone Labelling

Installation instructions

Note: No wiring is required during detector installation.

Refer to base datasheet for line wiring installation. All

installation should be in accordance with the

requirements of the authority having jurisdiction.

Refer to Figure 1. The detector attaches to compatible

bases with a plug-and-twist action as follows:

1. Align the detector with the base and turn it slowly

until the location lugs and grooves mate, allowing

the detector to slide completely into the base.

2. Rotate the detector clockwise until it locks. To

remove the unit from the base, perform these steps

in reverse order.

Note: To prevent unauthorized removal, a plastic breakout

tab is provided in the detector housing. Once the

breakout tab is removed the detector can only be

released by use of a special tool.

Functional test

3. Prior to initial testing remove the yellow plastic dust

cover from the detector and notify the proper

authorities that the fire alarm system is undergoing

maintenance and will be temporarily out of service.

Refer to local codes prior to testing.

Perform a functional test using an aerosol detector

tester.

4. An indent is provided on the detector exterior for

application of Zone number labelling to allow easy

zone identification.

Warnings: This device detects smoke from slow burning

to smouldering fires, and should only be used

as part of a broad-based life safety system.

For further information consult your local fire

protection specialist.

5. For head out continuity, a diode base must be used

and zone wiring must be terminated with a suitable

end of line (EOL) component. The choice of EOL is

dependant on the control panel used (refer to

Control Panel datasheet). For Control panels

without a head out facility, an active end of line unit

may be used.

Maintenance should be planned in

accordance with the requirements of the

authority having jurisdiction.

Cleaning

Refer to Figure 1.

1. Refer to local codes prior to cleaning.

2. Remove housing screws and the exterior. Remove

the optic chamber by releasing the catch on the

edge of the chamber and twisting the chamber out.

Care should be taken not to damage the insect

mesh window during this operation.

3. Clean the inside of the chamber using compressed

air.

4. Clean the optics and insect mesh windows using

alcohol and cotton buds.

5. Reassemble optic chamber and detector.

6. Check device is functioning correctly.

7. If the device is not functioning correctly, return to

your supplier.

Loading...

Loading...