GE WNCJ2050D0WC, WNCK2050D0WC, WNCK2050D1WC, WNRD2050D1WC, WNRD2050DCWC Installation Guide

...Page 1

i i =ll = i i =• L •

BEFORE YOU BEGIN

Read these instructions completely and

carefully.

IMPORTANT - ObserveaH

governing codes and ordinances.

. Note to Installer- Be sure to leave these instructions

for the consumer's and local inspector's use.

, Skill revel - Installation of this commercial washer

requires basic mechanical and electrical skilrs. Proper

installation is the responsibility of the installer.

Product failure due to improperinstallation is not

covered underthe GEAppliance Warranty.

i i ii

IMPORTANT -I you,eceiveda

damaged commercial washer, you should immediately

contact your dealer or builder.

FOR YOUR SAFETY

Read and observe all CAUTIONS and WARNINGS

shown throughout these instructions.

Hit i= i ==n = i

READ CAREFULLY.

KEEP THESE INSTRUCTIONS.

IPub,No,31-t5558

[Dwg,No,143BB310P032

ND 658-04 (7/03)

Page 2

Installation Preparation

i i i ] i

i i i i

TOOLS YOU WILL NEED:

Socketset

Slip]oint pliers

i i i i

INSTALLATION REQUIREMENTS:

LOCATION

Washer must be installed on firm flooring to minimize

vibration during spin cycles. Concrete flooring is

best, but wood base [ssufficient providedthat floor

support meets FHA standards. Washer should not be

installed on rugs or carpet, be exposed to weather or

temperatures below freezing.

ELECTRICAL AND PLUMBING

REQUIREMENTS

• FORPERSONAL SAFETYDO NOTUSE

AN EXTENSION CORDORADAPTER

PLUGWiTH THIS APPLIANCE.

WARNING

• DONOT,UNDERANY CIRCUM-

STANCE, CUTORREMOVETHETHIRD

GROUNDING PRONG FROMTHEPOWERCORD,

• FOLLOWNATIONAL ELECTRICCODEANSIINFPA

70 ORLOCALCODESAND ORDINANCES.

i i i i ii i

i.iq

i

PLUMBING

•Water Pressure-Must be 10 psi minimum to 150psi

maximum dynamJc pressLire measured at faucet.

•Water Temperature-Water heater should be set to

deliver water at 120°F to 150% (50°Cto 66°C)IN

THEWASHER when HOTwash is selected.

• Shutoff Valves-Both hot and cold shutoff valves

(faucets) should be supplied.

• Drain-Water may be drained into a standpipe or set

tub. The discharge height MUST NOT BE LESS

THAN 30INCHES nor more than 8feet above the

base of the washer. The standpipe must be 1-1/2

inches minimum inside diameter and must be open

to the atmosphere.

i i i

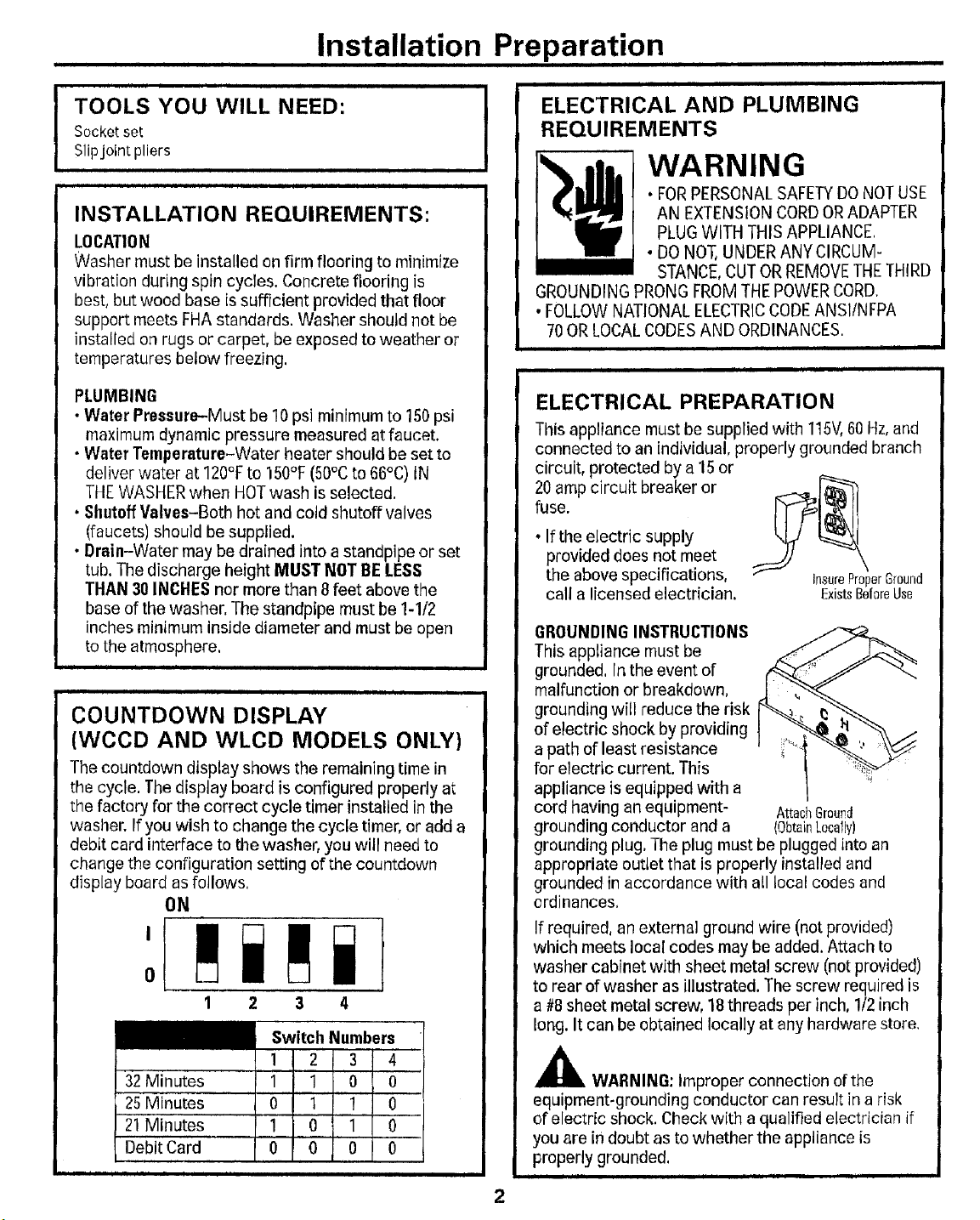

COUNTDOWN DISPLAY

(WCCD AND WLCD MODELS ONLY)

The countdown display shows the remaining time in

the cycle. The display board isconfigured properly at

the factory for the correct cycle timer installed in the

washer. If you wish to change the cycle timer, or add a

debit card interface to the washer, you will need to

change the configuration setting of the countdown

display board as follows.

ON

1 2 3 4

Switch Numbers---]

ELECTRICAL PREPARATION

This appliance must be supplied with 115V,60Hz,and

connected to an individual, properly grounded branch

circuit, protected by a 15or

20 amp circuit breaker or

fuse.

• If the electric supply

provided does not meet

the above specifications,

call a licensed electrician.

GROUNDING INSTRUCTIONS

This appliance must be

grounded. In the event of

malfunction or breakdown,

grounding will reduce the risk

of electric shock by providing

a path of least resistance

for electric current. This

appliance is equipped with a

cord having an equipment- AttachGroun_l

grounding conductor and a (ObtainLocally)

grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

If required, an external ground wire (not provided)

which meets local codes may be added. Attach to

washer cabinet with sheet metal screw (not provided)

to rear of washer as illustrated. The screw required is

a #8 sheet metal screw, 18 threads per inch, 1/2 inch

long. It can be obtained locally at any hardware store,

InsureProperGround

ExistsBefareUse

32 Minutes

25 Minutes

21 Minutes

Debit Card

i i

1 1 0 0 '

0 1

1 0 10 _

o 0

i

,_ WARNING: improper connection of the

equipment-grounding conductor can result in a risk

of electric shock. Check with a qualified electrician if

you are in doubt as to whether the appliance is

properly grounded.

iii

ii ii i

Page 3

i i i

Installation Instructions

ii i i

rSTEP11 PREPARE WASHER ISTEP 3t ATTACH DRAIN HOSE

FOR INSTALLATION TO WASHER

•Grasp shipping rod on MoveWasherClose • Make certain all installation items have been

lower right side (it has a toFinalPosition removed from the washer basket.

tag or strap), and pull Shipping •IMPORTANT'.Remove red plug , Grommet

discard, NOTE',Some water may be

present, this is normal, Plug

rod straight out and Roe from drain hose port. _i_ t /iI,__

Remove inner pack _ Inner secure hose adapter to drain

• hose, Push plastic hose clamp over hose adapter into

and installation _ Pack grooved slot.

under lid, Drain hose is _[ _. _ Water positive click when forced into port. A positive click

in washer basket, __ Hoses(2) will ensure that the proper amount of force has been

[!,:_/1_ \ Drain Hose Drain

• Move washer to | Drain

t

_gor . Locate plastic drain hose

adapter, Place hose clamp over

drain hose on& Insert drain

hose adapter into bent end of

drain hose, Position clamp to

NOTE:This requires some force to install, and has aaccessories from Partsand

applied,

Screws Port

installation location for _ Hose

remaining hose and

Ti Hose Adapter Hose

electrical preparation.

i i i ii iii i ]

ii] i i

ISTEP21ATTACH FILL HOSES

• Push plastic conical end of drain hose adapter into

TO WASHER washer drain hose port. Insert two screws found in

insert rubber washers into both ends of each fill installation pack, and drive screws to mount drain

hose. Attach fill hose marked HOTto hot washer inlet hose to washer,

valve. Attach fill hose marked COLDto cold washer AntisiphanCip

inlet valve. Couplings should be hand

tightened plus 112turn with pliers, _,_!Cab!e tie

ColdWater_ Less

l-lose\ __ Hose _/ _aa..._ _

Water Washers ElectricalCord hose through supplied antisiphon clip and mount to

Hose

...... inserting top clip into top mounting hole and snap

HandTightenPlus 3C)"_'_ : , ]

1/2TurnwithPliers Iti_r_ /

Hose

Cabl_ Drain

NOTE:tf drain hose facility does not meet the 30"

minimum standpipe height requirement, thread drain

cabinet back as shown. Mount antisiphon clip by

second clip into position.

, ii

Page 4

]1 , lu

Installation Instructions

i ii i i i

iiii

ii

i

ii

ISTEP 41 ADJUST LEVELING LEGS

•Ptace level on front top edge of washer,

, Adjust front leveling legs until washer is level from

side-to-side. Remove level,

•Tilt washer forward (pivot on front legs) 4 to 6

inches, This action will set rear leg adjustments to

correspond to front setting.

•Gently set washer back down,

m

TiltWasherForward

4to6 Inchesto Set

ide

ont

LevelingLegs

RearLegAdjustment.

ISTEP 5J INSTALL FILL HOSES

• Be sure water supply lines have been thoroughly

flushed,

•Move washer to final location, DO NOT let fill or

drain hoses drag and get under washer.

!STEP 61 INSTALL DRAIN HOSE

• Insert one end of aluminum drain nozzle into

standpipe,

• Slip or cut wire wrap back approximately 2" below

top of standpipe,

• Cut drain hosejust below standpipe, Place silver

hose clamp over black drain hose end,

• Insert drain nozzle into end of drain hose, and

position clamp to secure drain nozzle to drain hose,

•Install drain hose in drain facility and secure with

cable tie strap provided as illustrated.

Secureto

Hose

CAUTION - BESUREFILL

HOSESAREFIRMLY SECUREDTO FAUCETS.

• Determine which is the HOT water line before

attaching fill hoses to faucets. Traditionally, HOT

faucet is on the left. Be sure rubber washers are in

both ends of washer flit hoses, Connect hose from

inlet valve on washer (marked HOT)to hot faucet

and connect hose from COLDinlet valve to cold

faucet. Couplings should be hand tightened plus

t/2 turn with pliers.

HandTightenPius

1/2TurnwithPliers

,o

t _ scr=_ _. Cold

Water.. L=IRubber"Water

Hose "-_ wa_ Hose

CableTie Hose

Drain

NOTE:Drain hose nozzle may be shortened if original

length prevents full insertion into drain facility.

CAUTION - BESURE

DRAIN HOSEIS TAPEDORSECUREDTO STANDPIPE

OROTHERDRAIN FACILITY.

NOTE:Water may be drained into astandpipe, The

discharge height must not be less than 30 inches, nor

more than 8 feet above base or washer. Standpipe

must be 1-1/2" minimum inside diameter and must be

open to atmosphere.

4

Page 5

i

i

Installation Instructions

= = = = i

ISTEP 71 ECONOMY WATER USAGE

The pressure sw tch sset nthe factory for the high

water level and usage,

Tochange setting from high water level to medium or

low:

WARNING - MA*E

SUREWASHER IS UNPLUGGED FROM ELECTRICAL

OUTLET.

• Remove 4 torx screws from back of control panel

and lay control panel front on cover.

Remove

. Fromthe front, move white plastic cam on pressure

switch inthe clockwise position with your finger

until it clicks over into the medium or low water

position, (See illustration below,)

RotaLe

kwise

[STEP 9] SPECIAL INSTRUCTIONS

COVERSECURITYLOCK INSTALLATION

Washer cover is designed to accept stud type lock

as shown below,

518"

5/16"-t8 Thread

I_- i-1/16"-"-I %arVbw

CamLockAvailable.__

FromGreenwald

Part#8-I222

To install lock:

• Remove plastic insert infront of cover,

•Install the lock washer on the lock shaft and locate

so that the lock can be engaged in a counterclock-

wise direction.

• Insert lock mechanism into cover opening and

tighten until snug. (Overtightening may damage

painted surfaces.)

• Install cam and tighten until snug,

ACCESSDOORLOCKINSTALLATION

Toremove the access door retainer before installing

a lock, place the door over a wood block with a t/2"

hole drilled in it and tap end of screw lightly with a

hammer.

!-*-L_f

11mF

i iJ i

i ii i i i i

ISTEP 81 ELECTRICAL CONNECTION

CAUTION -BEFORE

PLUGGING IN APPLIANCE, READ ELECTRICALAND

PLUMBING REQUIREMENTSAND CHECKLIST,

Plug electrical power cord into a properly grounded

wall outlet.

_-Wood

Bock

_) -SpringWasher

Nut_,,._l,._am

Nut

LockWasher

Page 6

Installation Instructions

ii i

i i i i i i

[STEP 1OI CHECK LIST

Review this list after installing the washer to avoid a

charge for a service call not covered by the warranty,

i

i i

i ii i i.i i ii

ii ii i ii ii

WARNING

Foryoursafety,the informationin these instructions mustbe

followed to minimizethe risk of fire or explosion, electric shock,or to

prevent property damage,personal Injury,orlossof life.

AFTER INSTALLATI0 N CH ECK TtIE FOLLOWI NG:

[] Drain hose must be pulled tight and secured to

drain facility to prevent lifting out of drain facility

during discharge, Nozzle clamp must be securely

tightened to prevent leaks. MAKE SURE DRAIN

HOSE IS NOT RUBBING AGAINST CONCRETE OR

BLOCK WALL. RUBBING MAY WEAR HOLES IN

HOSE.

[] Hose Washers-Rubber washers in both ends offitl

hoses.

El Hose Connections-Hot side (left valve) connected

to hot water supply, cold side (right valve) to cold

water supply. All connections should be hand

tightened plus 1/2 turn with pliers.

[] Grounding-Must be properly grounded to conform

to !ocal codes and ordinances.

[] Leveling-Adjust front leveling legs as necessary

(preleveled from the factory at 1"). Check side to

side and front to back. Tilt forward approximately

4" to adjust rear self-leveling legs.

[] 0peration-Turn on faucets and run washer com-

pletely through cycle by hand. Check for leaks,

noise, vibration, correct water temperatures and

proper operation in wash and spin. While washer

is in spin, raise lid and check Lid switch and brake

operation,

i

i i

ISTEP 11t LITERATURE

• Be sure to leave complete literature package and

installationinstructions with consumer.

IL i

i i iji ii ii i i

TYPICAL HOSE INSTALLATIONS:

WATER HEATER SAFETY

• Undercertain conditions hydrogengas maybe produced ina

water heater that has not been usedfor two wealdsormore.

Hydrogengas can be explosive under these circumstances.

• tf the hot water has not beenused for twoweeks or more,prevent

the possibility ofdamageor injury byturning onall hotwater

faucets andallowing them to run for several minutes.Dothis

before using any electrical appliancewhich isconnected tothe

hot water system.This simple procedure will allow anybuilt-in

hydrogengas to escape, Sincethe gas is flammable,do not smoke

or usean openflame or appliance duringthis process.

YOUR LAUNDRY AREA

•Keep the areaunderneath and aroundyourappliances freeof

• combustible materials such as lint,paper,rags,chemicals,etc.

Closesupervisionis necessary if this appliance is usedbyor near

children. Donot allow children te play on.with, or insidethisor

any other appliance.

WHEN USING THE WASHER

•Never reach intowasher while itis moving.Wait until the machine

has completely stopped before opening the _id.

•Do not mix chlorine bleachwith ammonia or acidssuch asvinegar

and/or rust remover. Mixing different chemicals can produce a

• toxic gaswhich maycause death,

Do not washor dryarticles that have beencleaned in, washed in,

soakedin, or spottedwith combustible or explosivesubstances

(suchaswax, oil, paint, gasoline, degreaaers,dry-cleaning

solvents,kerosene,etc.). Thesesubstancesgive offvaporsthat

may ign_taor explode.Do not add these substancesto thewash

water. Donot use or place these substances aroundyourwasher

or dryer during operation.

. Thelaundry process can reduce the flame retardancyoffabrics. To

avoidsuch a result,carefully follow the garmentmanufacturers

wash and care instructions.

• Tominimizethepossibility of electric shock, unplug this appliance

fromthe power supply or disconnect thewasher at the household

distribution panel by removing the fuse or switching off thecircuit

breaker beforeattempting anymaintenanceor cleaning.NOTE:

Turningthe Cycle Selector knobto anoff positiondoesNOT

disconnect the appliance from the power supply.

, Never attemptto o.j3eratethis appliance if it isdamaged,malfunc-

tioning,partially disassembled,or has missingor brokenparts,

including a damagedcord or plug.

WHEN NOT IN USE

• Turnoffwater faucets to relieve pressure onhosesand valvesand

tominimize leakageif a break or rupture should occur.Checkthe

condition ofthefill hoses;theyshouldbe replaced every5years.

• Before discardinga washer,or removingit from service, remove

the washer lid to prevent children fromhidlng inside.

• Donot attempt torepair or replaceany partof this appliance

unless specifically recommendedin these instructions or in

published user-repair instructions that youunderstandandhave

the skills tocarry out.

• Donot tamper with controls.

U

TypicalCompletedWasherAssembly

II J III

SPE01FICATIONSSUBJECTTOCHANGEWITHOUTNOTIOE

READ AND FOLLOW THIS SAFETY

INFORMATION CAREFULLY.

SAVE THESE INSTRUCTIONS

Loading...

Loading...