Page 1

Technical Bulletin

GE Appliances

SmartCard System

WNCJ2050AWC

WNCK2050AWC

Commercial SmartCard Washer

TO REDUCE THE RISK OF

WARNING

• The power must be disconnected before servicing by unplugging the

machine or disconnecting the circuit breaker.

• The machine must be electrically grounded through the grounding

lead in the three-prong power cord. The cord must be plugged into a

properly installed and grounded appliance outlet. If local codes

require an additional ground connection, use a 16-gauge or larger

wire to connect the washer cabinet to an established ground. In all

cases the grounding method must comply with all local codes and

ordinances.

IMPORTANT - RECONNECT ALL GROUNDED DEVICES

IF GROUNDING WIRES, SCREWS, STRAPS, CLIPS, NUTS OR WASHERS USED

TO COMPLETE A PATH TO GROUND ARE REMOVED FOR SERVICE, THEY

MUST BE RETURNED TO THEIR ORIGINAL POSITION AND PROPERLY

FASTENED.

IMPORTANT SAFETY NOTICE

THIS INFORMATION IS INTENDED FOR USE BY INDIVIDUALS POSSESSING

ADEQUATE BACK-GROUNDS OF ELECTRICAL, ELECTRONIC AND

MECHANICAL EXPERIENCE. ANY ATTEMPT TO REPAIR A MAJOR APPLIANCE

MAY RESULT IN PERSONAL INJURY AND PROPERTY DAMAGE. THE MANUFACTURER OR SELLER CANNOT BE RESPONSIBLE FOR THE INTERPRETATION

OF THIS INFORMATION, NOR CAN IT ASSUME ANY LIABILITY IN CONNECTION WITH ITS USE.

This document provides the following technical information for GE SmartCard washer models WNCJ2050 and

WNCK2050:

• Introduction

• Features

• Accessing Components

• Troubleshooting and Service Information

• Wiring Diagram

ELECTRICAL SHOCK:

Introduction

The GE models WNCJ2050 and WNCK2050 introduce

SmartCard technology to the GE commercial laundry

line. SmartCard technology allows commercial laundry

establishments and customers to conduct commercial

transactions without hard currency. This technology

uses a memory chip based card that can store all the

necessary transaction information and provides the

consumer great convenience and flexibility. The

SmartCard system also provides owners of commercial

establishments improved security and added managerial

features as well as greater flexibility.

To use the card, the user would insert the card into a

special central vending station along with a money

deposit that will credit the SmartCard. The machine

encodes credit for the amount of money deposited onto

the card. The user then takes the card to the washer,

inserts the card and selects the wash cycle. Based on

the cost of the cycle, the card reader in the washer

deducts that amount from the card. When the total

amount on the card has been used, the card is inserted

back into the vending station where additional credit

may be added to the card for the amount of money

deposited.

GE Washer WNCJ2050 and WNCK2050 contain a

SmartCard reader located to the right of electronic

Control Panel. WNCJ2050 uses the BridgePoint SmartCard control reader. WNCK2050 uses the ESD SmartCard

control reader. A keypad electronic washer control has

been added to the model line to improve ease of use

and serviceability. The main wash functions are still

accomplished through a two-speed motor, hot and

cold water valves and a pump. The components are

controlled by the electronic control, the dual pressure

switch, and the keypad selector switches. The L3D

electronic control consists of a printed circuit board,

transformer and housing.

As detailed in the product warranty, the SmartCard

control reader is serviced by the reader’s original

equipment manufacturer. In cases where the field

service diagnostics indicates the error code EO (serial

communication – external), the user should contact the

reader original equipment manufacturer for service at

the following numbers:

Model WNCJ2050 BridgePoint: 1-800-562-5875

Model WNCK2050 ESD: 1-770-425-6298

Features

• Super Plus 2.7 cu. ft. Capacity

• 3 Wash/Spin Speed Combinations

• 3 Wash/Rinse Temperatures

• Automatic Water Levels

• Digital Cycle Countdown with LED indicators

• 5 Wash Cycles: Cottons - White, Colored; Bright Colors;

Permanent Press; Delicates

• BridgePoint SmartCard Reader with Alphanumeric

Display and Control Card (WNCJ2050)

• ESD SmartCard Reader with Alphanumeric Display and

Control Card (WNCK2050)

• Lid Instructions

Page 2

Accessing Components

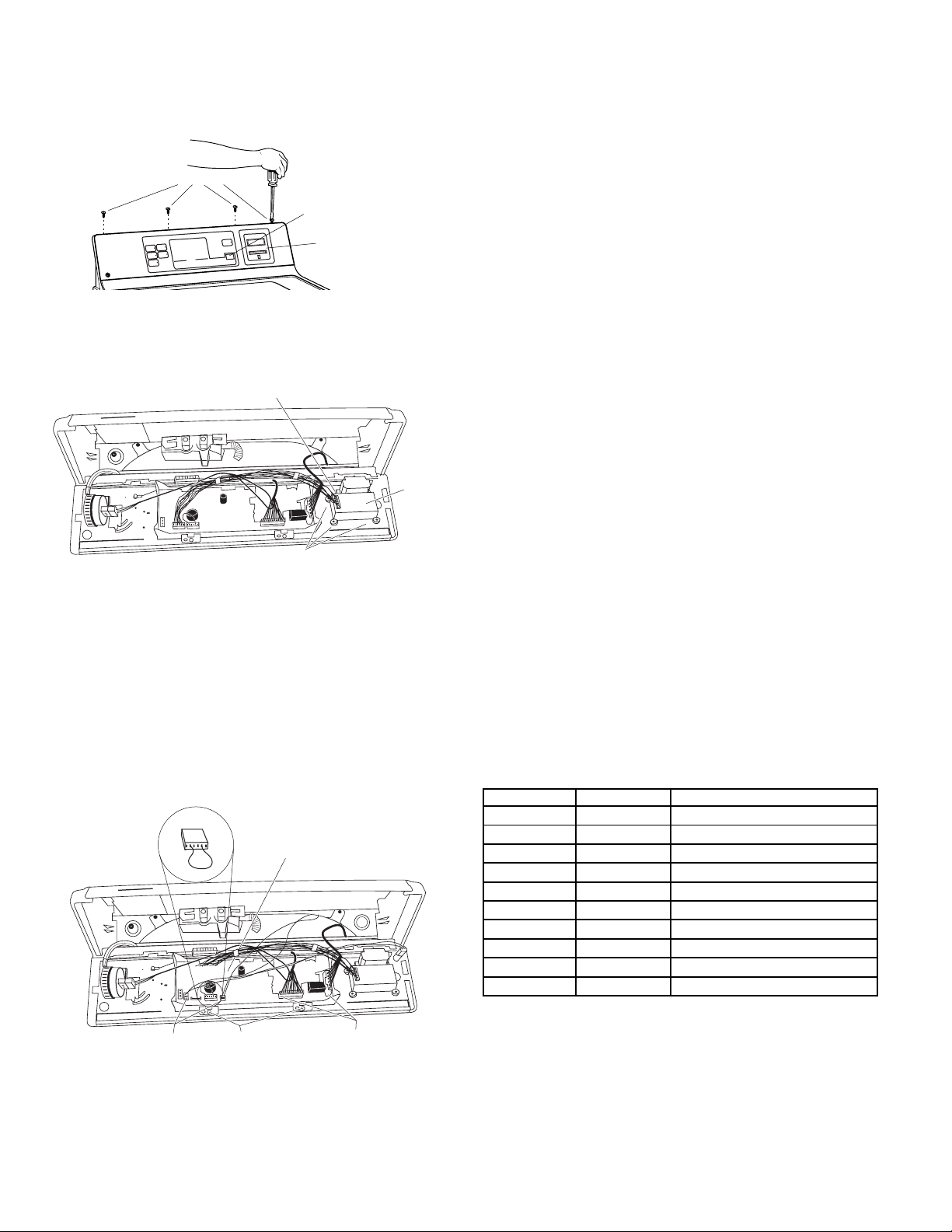

SmartCard Reader – Removal and Replacement

1. Remove four screws from top panel and pull forward.

Remove 4 Screws

/RINSE SPEED

ASH

W

TEMPERATURE

CLOTHES CARE SELECTION

RMAL/SLOW

NO

PERM

SH

A

HOT W

E

HIT

S

W

RES

P

NS

TTO

CO

ENTLE/SLOW

G

ASH

M W

AR

W

S

TE

ST

A

ELIC

D

AL/FA

RED

LO

ORM

CO

N

ASH

COLD W

NS

OTTO

C

STATUS

BRIGHT

LORS

CO

AL SP

FIN

SE

RIN

ASH

W

FILL

D

S

E

y

b

E

D

I

L

S

d

r

a

C

START

E

M

I

T

T

S

E

G

N

I

N

I

A

M

E

R

ISHED

FIN

IN

Dual Seven

Segment Display (DSSD)

SmartCard

Reader

2. Remove the four corner screws from the SmartCard

Reader.

3. Remove connector cable from reader.

4. Reverse the above procedure to reinstall.

Connector Cable

SmartCard

Reader

Remove 4 Screws

Electronic Control Board – Removal and Replacement

1. Follow step 1 above.

2. Remove 4 harness connections. Remove and retain the

model selector harness plug for reassembly.

3. Remove 2 screws (1/4-in) from the control board.

CAUTION: To prevent electrostatic discharge, ground

yourself to the washer cabinet or use an ESD wristband.

4. Remove the electronic control board.

Note: When reassembling, align the LEDs with the

appropriate control panel indicators.

5. Reverse the above procedure to reinstall.

Model Selector/

Service Selector

Harness

Remove Harness

Connections (2)

Electronic

Control Board

Screws

(2)

Remove Harness

Connections (2)

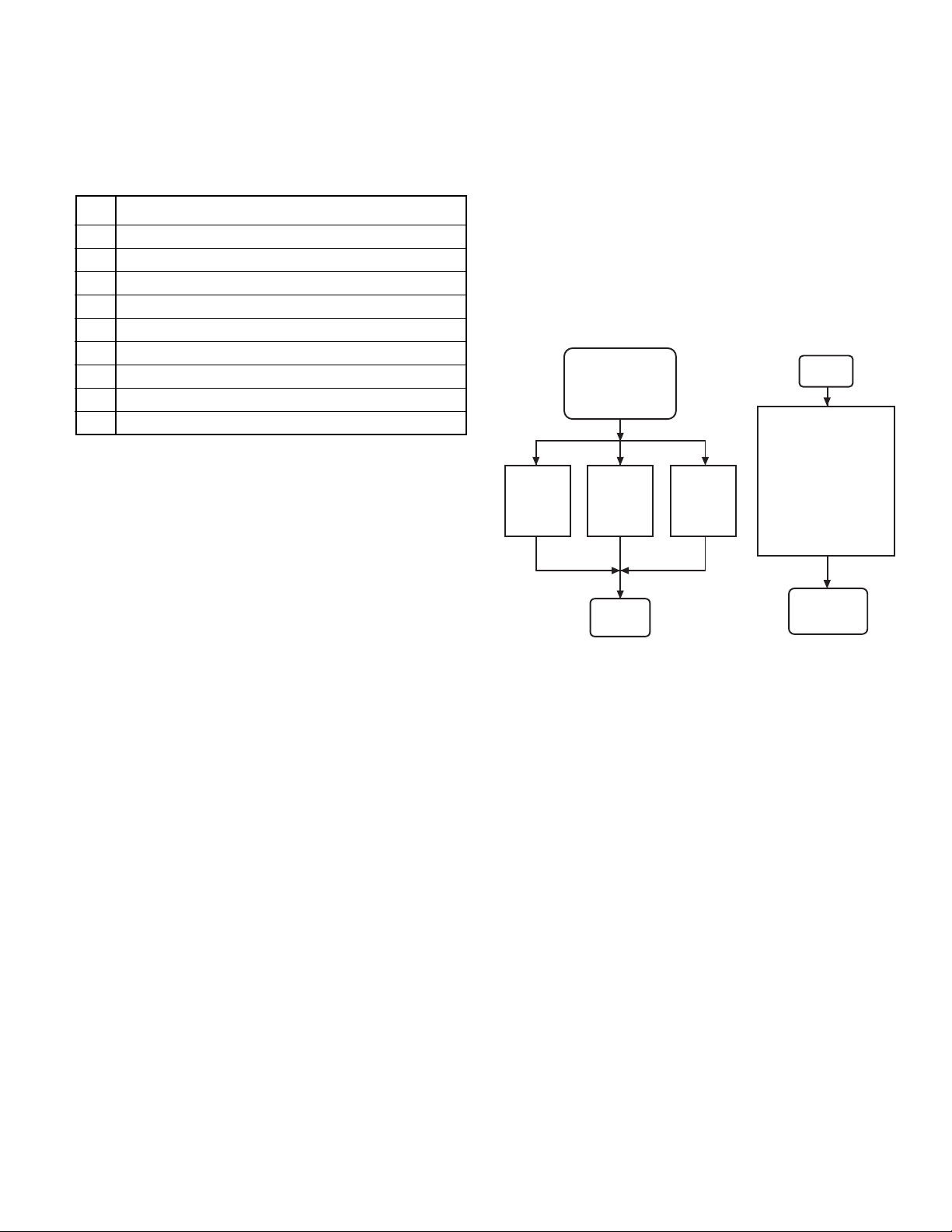

Field Service Mode

T

he Field Service Mode for L3D controls allows the field

service technician to test the inputs and outputs of the

control. It also allows the technician to step through the

test cycle and operate components on the washer.

The Field Service Mode can be entered manually or by

inserting a special Service Mode card (available to commercial laundry owners) into the SmartCard reader.

Manual entry into the Field Service mode requires the Model

Selector harness WD21X10026, to be installed into the L3D

control. This is the Service Selector harness. To install the

Service Selector harness, disconnect power to the machine

and remove the currently installed Model Selector harness.

Save the removed Model Selector harness for reinstallation

after service. Install the Service Selector harness into the

control board and reconnect power to the machine. Note:

When the service operation is completed, remove the

Service Selector harness and reinstall the previous Model

Selector harness.

After reconnecting power, the L3D control test cycle is

entered by pressing and holding the White Cotton and the

Start button simultaneously for 3 seconds. As soon as the

test cycle is entered, the control will power the Dual Seven

Segment Display (DSSD) to output the letters Fd (Field

Service Diagnostics).

Manual entrance into Field Service mode will be restricted to

the time period of 15 seconds after Power-On-Reset of the

L3D electronic control. Following this time, the key sequence

method of entry into the service mode will be disabled.

The service mode may also be entered by receiving the

appropriate command via the serial communication port

using the Service Mode Card. Entry into the Field service

mode will be allowed at any time the machine is powered

and in the idle state.

When any of the above buttons are pressed or when the

pressure switch is pushed or contacted, the control will beep

for 0.5 seconds.

The initial step after entering service mode for the L3D

electronic control will be defined as Step 0. This will

signal the DSSD to output Fd and the control will light all

LEDs. The following table gives required functions for

subsequent steps. To proceed to the next step, press the

Color Cottons pushbutton. To return to the previous position,

press the White Cottons.

DSSD

Position Output Function

0-Initial Fd LED Check

1 ** Model Code

2 E# Error Codes

3 H Hot Water Valve Active

4 C Cold Water Valve Active

5 AL Slow Agitate (Dry)

6 AH Fast Agitate (Dry)

7 P Pump

8 SP Spin

* ➔ Indicates model number

# ➔ Indicates number of error code if there is more than

one error, each error will display for 2 seconds, followed

by the next error)

This feature holds true for all tests with exception of the

serial communication test. The serial communication test

can be run only once due to the limited time required to

run the test. Once the serial communication test has

been run, the operator must exit and reenter the mode to

repeat the test.

2

Page 3

The lid switch will affect the LEDs by deactivating any

active LED in the service mode for L3D control when the

lid is raised. This allows the technician to determine if

the switch is working.

Service Mode Error Codes

E1 EEPROM Error

E2 Thermistor Error

E3 Flood Condition Detected Error

E4 Slow Pump Error

E5 Never Fills Error

E6 Pump Detection Circuit Error

E7 Pushbutton Error (shorted pushbutton)

E8 Pressure Switch Error

E9 Serial Communication – L3D Internal

E0 Serial Communication – External

If you are in the Error Codes Function Display and you

press the Start pushbutton, then the control will clear all

errors.

If you are in the Model Code Function Display and you

press the Start/Pause pushbutton, the control will

display the EEPROM Revision contained in the EEPROM

only while the button is depressed.

If you are in the Hot Water Valve Active Display and you

press the Start/Pause pushbutton, the control will

display the ROM Revision of the software only while the

button is depressed.

The service mode will allow the technician to operate

the washer in dry agitate. However, if the washer is

placed in either agitate function during the diagnostics

and the Start pushbutton is pressed for 2 seconds the

dry agitate will become wet agitate. This wet agitate

stops the motor, and energize the cold water valve until

the pressure switch is made. To determine if the pressure switch is working correctly, the control turns on

wash temperature LEDs in sequential order from the

smallest load size LED to the largest load size LED. For

example, the Cold Wash size LED will represent a small

load and the Hot Wash size LED represent a full basket

of water. After the tub has reached the full basket, then

the washer resumes agitation.

When advancing through the service mode functions,

energizing LEDs and the accompanying beeps will occur

immediately. However, a 0.5-second delay will occur

before initiating the new function. The sequence of

events are: the previous function will stop; the LED for

the previous function will deactivate; the LED for the

new function will activate and the beeper will beep; one

(1) second will pass and the new function will begin. This

will allow the technician to hear one function stop and

another start.

Termination of the Service Mode can be Accomplished

in Three Ways:

1. The user may remove power by unplugging the unit.

2. The control will exit the S1 – Field Service Mode 30

minutes after the beginning of the Mode.

3. Removal of the Service Mode Card

By removing the Service Mode Card, the DCR will

recognize that the service mode is terminated. The DCR

will transmit a Stop command to the L3D control to

return the L3D to the idle state.

L3D Field Service Mode

Entrance/Exit

Field

Service Mode

Removal

of

Service

Card

30 min

time-out

from

start of

mode

Idle

Loss of

Power to

Control

Diagnostics

The control provides diagnostics to inform the operator

of the current status of the washer. The LEDs displayed

to indicated the fault will flash at a rate of 1 hertz.

Serial Communication Diagnostic Test

To perform the serial communication diagnostic test, the

L3D control will issue a request to the DCR for its software version number. Verification of the transmitted

packet data will confirm the serial communication

hardware on the L3D is functional. Alternatively, reception of a machine status request command from the DCR

will also be considered sufficient to demonstrate functional serial communication hardware. If no status

request is received and there is either no response to

the DCR version number request or the response is

invalid, then an external communication error will be

assumed, generating a E0 error code on the DSSD.

If the external communication test fails, the L3D control

will perform a loop-back test by verifying the transmitted

packet data is also seen upon the RxD pin on the microprocessor. A failure in the loop-back test indicates a

potential failure on the L3D hardware or a short circuit

on the Data Comm I/O line, yielding an E9 fault.

3

Idle

Initiate field Service

Mode by using the

Service Mode card

or simultaneously

pressing and holding

the Start and

the White Cotton

pushbuttons with the

Service Selector

Harness inserted

Field

Service

Mode

Page 4

Troubleshooting Flowcharts

Component Operation Troubleshooting

Initiate field Service Mode by using

the Service Mode card

or simultaneously pressing and

holding the Start and the

White Cotton pushbuttons with

the Service Selector

Harness inserted

DSSD output displays Fd

Press Colored Cotton button

3 times

DSSD output displays H

Hot water valve is activated

Press Colored Cotton button

DSSD output displays C

Cold water valve is activated

Press Colored Cotton button

DSSD output displays AL

Slow agitate (dry) is activated

Press Colored Cotton button

Press Start button

for 2 seconds

Slow agitate

(wet)

Press Colord Cotton

button to

return to Fd

DSSD output displays AH

Fast agitate (dry) is activated

Press Colored Cotton button

DSSD output displays P

Pump is activated

Press Colored Cotton button

DSSD output displays SP

Spin is activated

4

Press Start button

for 2 seconds

Press Stop button

Fast agitate

(wet)

Exit field

service mode

Page 5

Error Code Troubleshooting

Washer

Proper voltage to

Washer

Yes

Initiate field Service

Mode by using

the Service Mode card

or simultaneously

pressing and holding

the Start and the

White Cotton

pushbuttons with

the Service

Selector Harness

inserted

No

Test

Mode

House fuse,

breaker, or wall

outlet problem

DSSD output

displays Fd

Lift lid, Cycle

Status, LEDs will go

OFF (confirms lid

switch operation)

Yes

Press Colored

Cotton button - DSSD

output indicates

model code

Check error codes

Press Colored

Cotton button - DSSD

ouput displays

error codes for

existing errors

No

NOTE: If control is operating, it is

likely that the control is not faulty.

Record all the error codes and

recheck error message at the

component level. Record errors on

the call sheet.

Check lid switch and contact

Replace if faulty

EEPROM faulty - Replace PC board

E1

Thermistor faulty or disconnected (if

present) - Check resistance (50k

E2

E3

E4

ohms) - Replace if faulty

Flood - Check water valves, pressure

switch - Replace if faulty

Slow pump - Check pump, standpipe

height and drain - Look for pump

obstructions - Replace pump if faulty

Press Stop to exit

field service mode

Press Colored

Cotton button to

proceed to Component

Operation

Troubleshooting

*If high level pressure switch is opened before low, or if

high pressure closes before low, the E8 error code is

displayed. If during the 20 second pump out, the high

pressure switch does not reset (opened to normally

closed), E8 is generated.

No fill - Check water is on, check

water valves, pressure switch-

E5

E6

Stuck Pushbutton - Replace PC board

E7

E8*

E9

Check SmartCard to PC board

connector harness and SmartCard

control reader - if faulty change

harness or SmartCard control reader

E0

by contacting reader manufacturer at:

BridgePoint: 1-800-562-5875

ESD: 1-770-425-6298

Replace if faulty

No pump - Check for pump

obstructions, operation - Replace

pump if faulty

Pressure switch faulty or

dicconnected-

Replace if faulty

Check serial port in PC board-

If faulty, replace PC board

5

Page 6

Wiring Diagram

Selector harness plug options:

09 for short wash cycles

01 for long wash cycles

14 Service Selector Harness

1

2

3

4

OX

5

6

7

DEBIT CARD

READER

VW

YX

RX

WX

NX

RW

0121110 9 8 7 6 5 4 3 2 1 0

NX

OX

TX

VX

BX

WR

WX

YR

321

RX

1234567

SELECTOR

HARNESS

PLUG

START

WX

NX

YX

CONTROL CIRCUIT BOARD

LID

COM

SWITCH

11

M2

M3

START

M7

M1

MOTOR

HIGH

LOW

M6

M5

16

HI

LOW

12

WATER

LEVEL

SWITCH

WATER LEVEL SWITCH

BEFORE DISCONNECTING HOSE FROM

WATER LEVEL SWITCH. BE SURE

WATER LEVEL IN MACHINE IS

BELOW BOTTOM OF WASH BASKET.

AFTER RECONNECTING HOSE, PUT

MACHINE IN SPIN FOR AT LEAST

ONE MINUTE BEFORE CHECKING

WR

N

PUMP

RR

RS

M

LI

OPERATION OF SWITCH.

COLOR CODE

LETTERS COLOR

AX

LT. BLUE

BX

BLACK

CX

BROWN

NX

DK. BLUE

OX

ORANGE

PX

PINK

LETTERS COLOR

RX

RED

SX

GRAY

TX

TAN

VX

PURPLE

WX

WHITE

YX

YELLOW

THE "X" INDICATES ONE SOLID COLORNO TRACER. WIRES WITH TRACER SHOW

BOTH COLORS. EXAMPLE -WR IS WHITE

WITH RED TRACER.

6

Page 7

Notes: _____________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

7

Page 8

GE Commercial Washer Warranty.

Coin-Operated and Smart Card-Operated Models

Parts and service are available from your General Electric

Commercial Laundry distributor.

For The Period Of: We Will Replace:

Three Years Any part of the washer which fails due to a defect in materials or workmanship. During this

From the date of the limited three-year warranty, you will be responsible for any labor and related service costs.

original purchase

Five Years The outer tub and inner basket, if either of these parts should fail due to a defect in materials or

From the date of the workmanship, and the cabinet side panels, base and cover, if they should fail due to rust-through.

original purchase During this limited additional two-year warranty, you will be responsible for any labor and related

service costs.

What Is Not Covered:

■ Coin drop meter, coin slide mechanism, coin vault and

locks, smart card modules and cards, smart card system

accessories.

■ Service trips to your place of business to teach you how

to use the product.

■ Improper installation.

■ Failure of the product if it is abused, misused, or used for

other than the intended purpose.

■ Any and all implied warranties of merchantability and

fitness for a particular purpose.

■ Replacement of fuses or resetting of circuit breakers at

place of business.

■ Damage to the product caused by accident, fire, floods

or acts of God.

■ Incidental or consequential damage caused by possible

defects with this appliance.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for commercial

use within the USA. In Alaska, the warranty excludes the cost of shipping to your place of business.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives you

specific legal rights, and you may also have other rights which vary from state to state. To know what your legal rights

are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

Pub. No. 49-90149

Dwg. No. 175D1807P412

N.D. 368-11

8

Loading...

Loading...