GE WCCB1030H1WC, WCCB1030H2WC, WCCB1030H3WC, WCCB1030H4WC, WCCB1030H5WC Installation Guide

...Page 1

,_, _/ _ / _ _ ' / _'_ _ _ _

Appliances

Installation Instructions

Commercial ClothesWasher

If you have questions, call 800.GE.CARES(800A32.2737) or visit our website at: www.ge.com

BEFORE YOU BEGIN

Readthese instructions completely and

carefully.

I!I PORTANT Observe all governing codes and

ordinances.

, Note to Installer - Be sure to leave these instructions for the

consumer's and local inspector's use.

, Note to Consumer - Keep these instructions with your

Owner's Manual for future reference.

, Skill Level - Installation of this dishwasher requires

basic mechanical, electrical and plumbing skills. Proper

installation is the responsibilitg of the installer. Product

failure due to improper installation is not covered under

the GEAppliance Warrantg. Seewarrantg information.

, Completion Time - 1to 3 Hours. New installations require

more time than replacement installations.

READ CAREFULLY.

KEEP THESE INSTRUCTIONS.

I11PORTANT- The washer MUSTbe installed to allow

for future removal from the enclosure if service is required.

If you received a damaged dishwasher, you should

immediately contact your dealer or builder.

Optional Accessories - Seethe Owner's Manual for available

custom panel kits.

FOR YOUR SAFETY

Readand observe all CAUTIONSand WARNINGS

shown throughout these instructions. While performing

installations described in this booklet, gloves, safetg glasses

or goggles should be worn.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

GE Consumer & Industrial

General Electric Compan 9

Louisville, Kentucky 40225

ge.com

© 2006 GeneralElectric Company

143B9310P035

Pub. No. 31-16545

ND 07D-2178 (4/07)

Page 2

Installation Preparation

TOOLS YOU WILL NEED

o Socket set

Slipjoint pliers

INSTALLATION REQUIREMENTS:

LOCATION

Washer must be installed on firm flooring to minimize vibration

during spin cgcles. Concrete flooring is best, but wood base

issufficient provided that floor support meets FHAstandards.

Washer should not be installed on rugs or carpet, be exposed

to weather or temperatures below freezing.

PLUMBING

, Water Pressure-Must be 20 psi minimum to 150 psi

maximum dynamic pressure measured at faucet.

Water Temperature-Water heater should be set to deliver

water at 120°F to 150°F (50°C to 66°C)IN THE WASHER when

HOT wash is selected.

, Shutoff Valves-Both hot and cold shutoff valves (faucets)

should be supplied.

, Drain-Water mag be drained into a standpipe or set tub.

The discharge height MUST NOT BE LESSTHAN 30 INCHES

nor more than 6 feet above the base of the washer. The

standpipe must be 1-1/2 inches minimum inside diameter

and must be open to the atmosphere.

PREPARE ELECTRICAL WIRING

FORPERSONALSAFETY:

• FORPERSONALSAFETYDO NOT USE

AN EXTENSIONCORDORADAPTOR

PLUGWITH THISAPPLIANCE.

• DO NOT, UNDERANY CIRCUMSTANCE,

CUTOR REMOVETHETHIRD GROUNDING

PRONGFROMTHE POWERCORD.

• FOLLOW NATIONALELECTRICCODE

ANSI/NFPA 70 ORLOCALCODESAND

ORDINANCES.

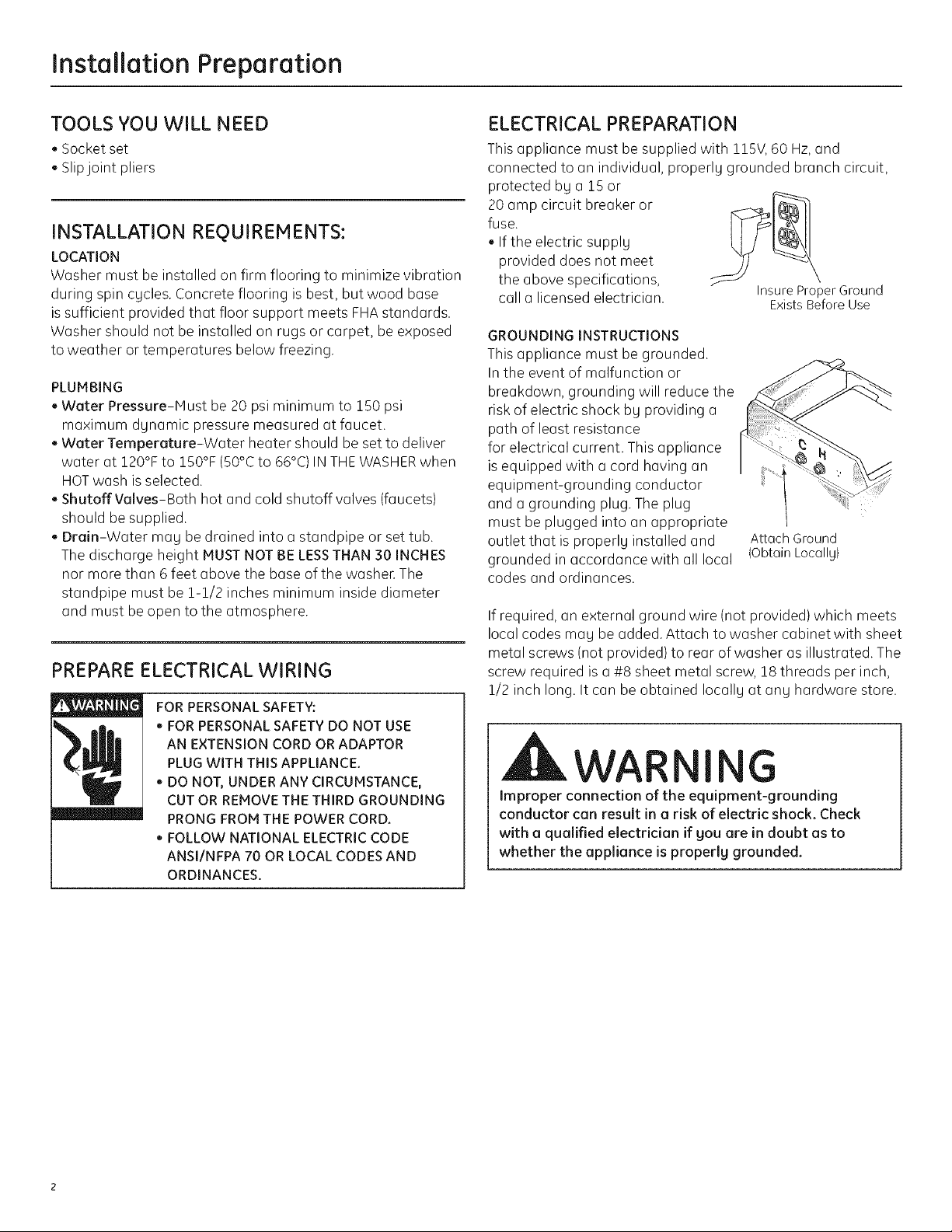

ELECTRICAL PREPARATION

This appliance must besupplied with 115V,60 Hz,and

connected to an individual, properlu grounded branch circuit,

protected bUa 15or

20 amp circuit breaker or

fuse.

. If the electric supplu

provided does not meet

the above specifications,

call a licensed electrician.

GROUNDING INSTRUCTIONS

This appliance must begrounded.

Inthe event of malfunction or

breakdown, grounding will reduce the

risk of electric shock bUproviding a

path of least resistance

for electrical current. This appliance

is equipped with a cord having an

equipment-grounding conductor

and a grounding plug. The plug

must be plugged into an appropriate

outlet that isproperlg installed and

grounded inaccordance with all local

codes and ordinances.

If required, an external ground wire (not provided) which meets

local codes mag beadded. Attach to washer cabinet with sheet

metal screws (not provided) to rear of washer as illustrated. The

screw required is a#8 sheet metal screw, 18 threads per inch,

1/2 inch long. It can be obtained locally at any hardware store.

Insure Proper Ground

Exists Before Use

Attach Ground

(Obtain Locallg)

WAR I G

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check

with a qualified electrician if gou are in doubt as to

whether the appliance is properlg grounded.

Page 3

Installation Instructions

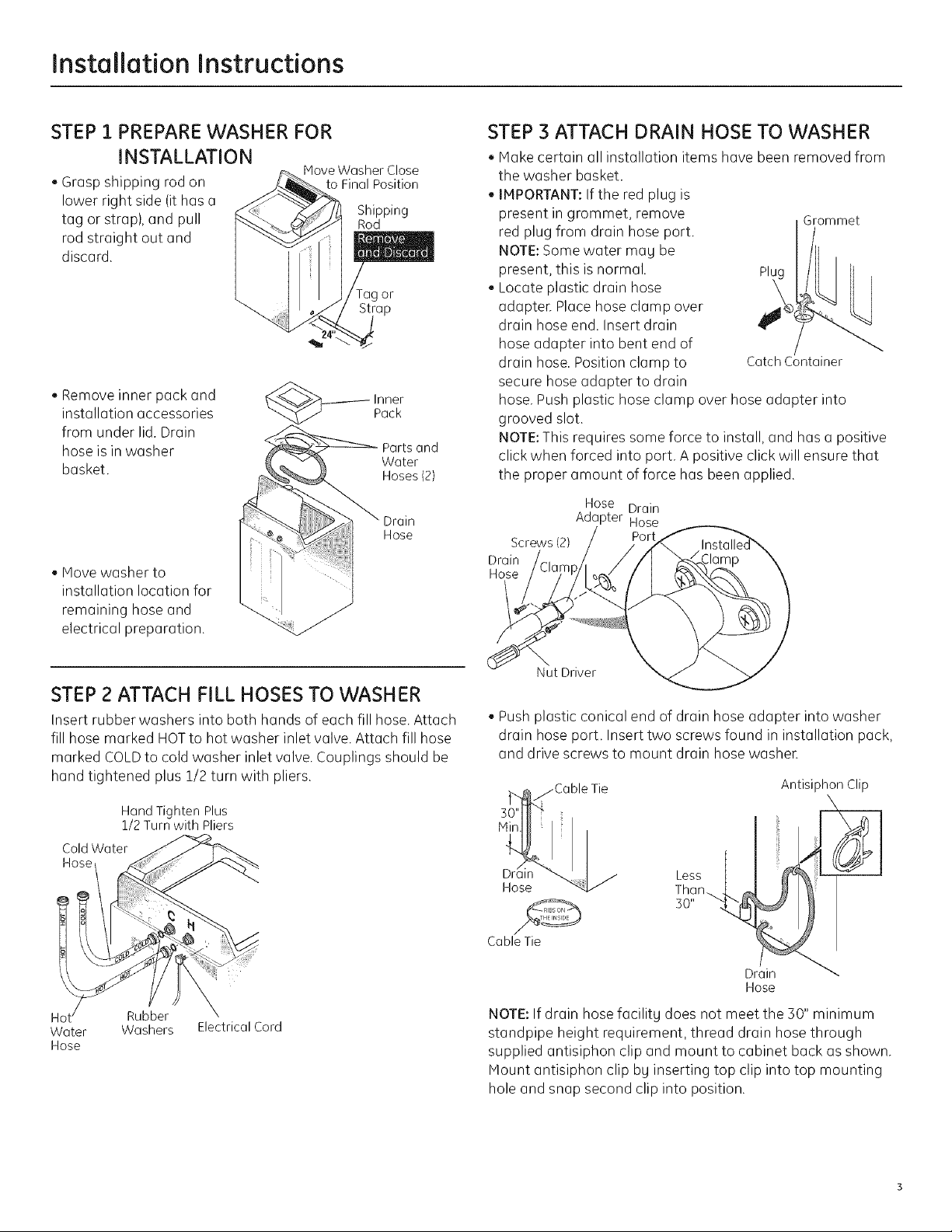

STEP 1 PREPARE WASHER FOR

INSTALLATION

" Grasp shipping rod on __ FinalPosition

lower right side (it has a d'__/l Shipping

tag or strap), and pull I_'_. (:_7// Rod

rod straight out and .....

discard. IV _TTs_rgOr

Hove Washer Close

o P

d

o Remove inner pack and

installation accessories

from under lid. Drain

hose is inwasher

basket.

Move washer to

installation location for

remaining hose and

electrical preparation.

i

STEP 3 ATTACH DRAIN HOSE TO WASHER

, Hake certain all installation items have been removed from

the washer basket.

IMPORTANT:If the red plug is

present in grommet, remove

red plug from drain hose port.

NOTE:Some water may be

present, this is normal.

Locate plastic drain hose

adapter. Place hose clamp over

drain hose end. Insert drain

hose adapter into bent end of

drain hose.Position clamp to

secure hose adapter to drain

hose. Push plastic hose clamp over hose adapter into

grooved slot.

NOTE:This requires some force to install, and has a positive

click when forced into port. A positive click will ensure that

the proper amount of force has been applied.

Hose Drain

Adapter Hose

Screws (2) Port

Drain

Hose

CatchContainer

Grommet

STEP 2 ATTACH FILL HOSES TO WASHER

Insert rubber washers into both hands of each fill hose. Attach

fill hose marked HOTto hot washer inlet valve. Attach fill hose

marked COLDto cold washer inlet valve. Couplings should be

hand tightened plus 1/2 turn with pliers.

Hand Tighten Plus

1/2 Turn with Pliers

Cold Water

Hose

Hot

Water

Hose

Rubber

Washers Electrical Cord

Nut Driver

Pushplastic conical end of drain hose adapter into washer

drain hose port. Insert two screws found in installation pack,

and drive screws to mount drain hose washer.

AntisiphonClip

3_/Cable Tie

rca'n

Cable Tie

Drain

Hose

NOTE:If drain hose facilitg does not meet the 30" minimum

standpipe height requirement, thread drain hose through

supplied antisiphon clip and mount to cabinet back as shown.

Mount antisiphon clip bg inserting top clip into top mounting

hole and snap second clip into position.

Page 4

Installation Instructions

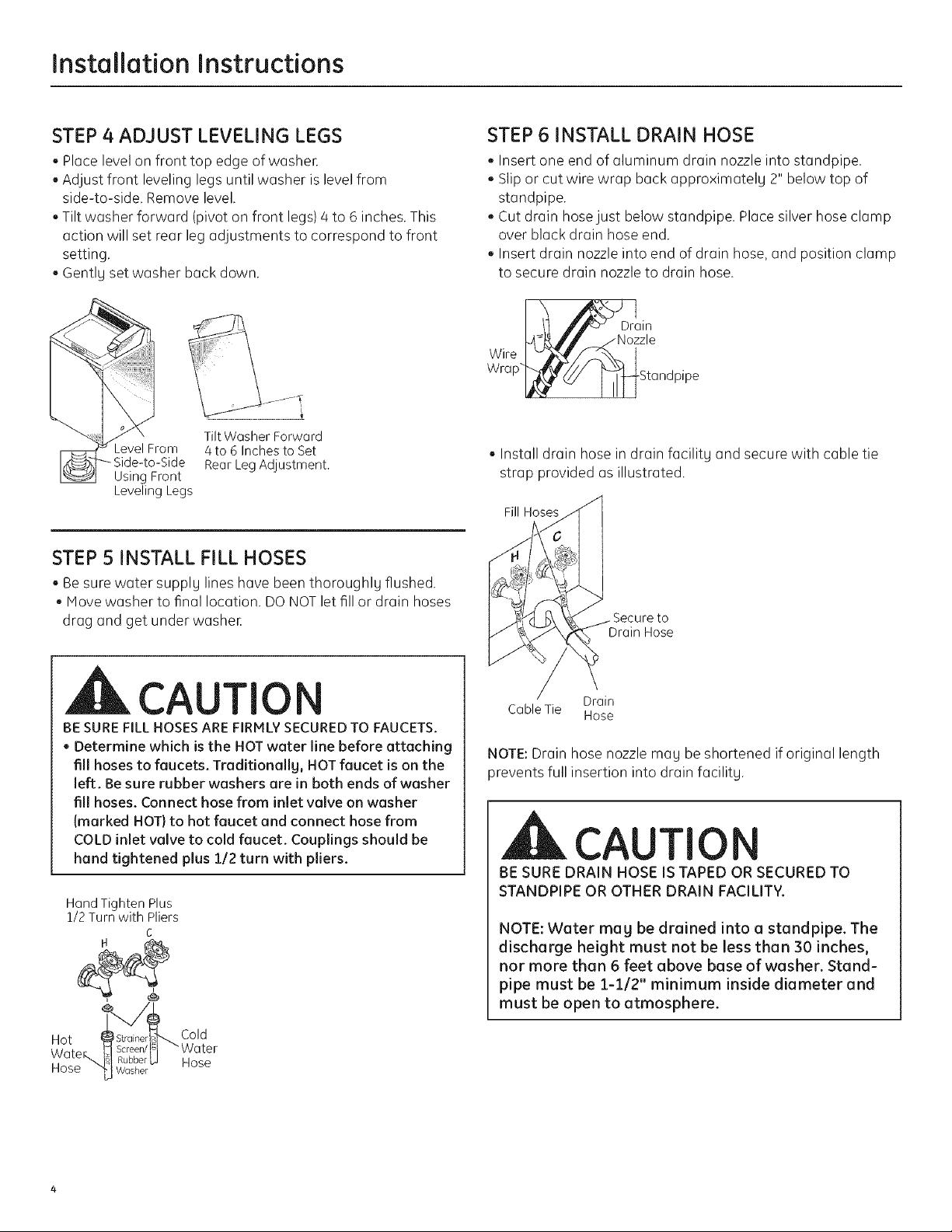

STEP 4 ADJUST LEVELING LEGS

, Place level on front top edge of washer.

Adjust front leveling legs until washer is level from

side-to-side. Remove level.

Tilt washer forward (pivot on front legs)4to 6 inches. This

action will set rear leg adjustments to correspond to front

setting.

Gentlg set washer back down.

.evel From

Using Front

Leveling Legs

Tilt Washer Forward

4 to 6 Inches to Set

Rear Leg Adjustment.

STEP 5 INSTALL FILL HOSES

, Be sure water supplg lines have been thoroughlg flushed.

, Move washer to final location. DO NOTlet fill or drain hoses

drag and get under washeE

STEP 6 INSTALL DRAIN HOSE

Insert one end of aluminum drain nozzle into standpipe.

Slip or cut wire wrap back approximatelg 2" below top of

standpipe.

Cut drain hosejust below standpipe. Place silver hose clamp

over black drain hose end.

, Insert drain nozzle into end of drain hose, and position clamp

to secure drain nozzle to drain hose.

Dro,n

Wrapwu [i'll-Standpipe

Install drain hose in drain facilitg and secure with cable tie

strap provided as illustrated.

Fill Hoses

Drain Hose

CAUTIO

BE SUREFILLHOSESAREFIRMLYSECUREDTO FAUCETS.

• Determine which is the HOTwater line before attaching

fill hoses to faucets. Traditionallg, HOTfaucet is on the

left. Be sure rubber washers are in both ends of washer

fill hoses. Connect hose from inlet valve on washer

{marked HOT)to hot faucet and connect hose from

COLD inlet valve to cold faucet. Couplings should be

hand tightened plus 112turn with pliers.

Hand Tighten Plus

1/2 Turn with Pliers

g

Hot _ StrainertsP'_

,W,ateF',..HRubber'U "Hose

Hose _j Washer

Screen/ Water

Cable Tie Hose

Drain

NOTE:Drain hose nozzle mag be shortened if original length

prevents full insertion into drain facilitg.

CAUTIO

BE SURE DRAIN HOSE IS TAPED OR SECURED TO

STANDPIPE OR OTHER DRAIN FACILITY.

NOTE: Water mag be drained into a standpipe. The

discharge height must not be less than 30 inches,

nor more than 6 feet above base of washer. Stand-

pipe must be 1-1/2" minimum inside diameter and

must be open to atmosphere.

Page 5

Installation Instructions

STEP 7 COIN BOX MODELS ONLY

ECONOMY WATER USAGE

The pressure switch is set in the foctoru for the high water level

and usage.

To change setting from high water level to medium or low:

WAR ! G

MAKESUREWASHERISUNPLUGGEDFROMELECTRICAL

OUTLET.

o Remove 4 torx screws from back of control panel and lay

control panel front on cover.

! Remove

_Screws

STEP 9 SPECIAL INSTRUCTIONS ON MODELS

WITH SECURITY LOCK CAPABILITY

COVERSECURITYLOCKINSTALLATION

Washer cover is designed to accept stud tgpe lock as shown

below.

Width

Cam Lock Available

From Greenwald

Part #8-1222

To install lock:

, Remove plastic insert in front of coveE

, Install the lock washer on the lock shaft and locate so that

the lock can be engaged in a counterclockwise direction.

, Insert lock mechanism into cover opening and tighten until

snug. (Overtightening mag damage painted surfaces.)

, Install cam and tighten until snug.

o From the front, move white plastic cam on pressure switch in

the clockwise position with gour finger until it clicks over into

the medium or low water position. (See illustration below).

_ Rotate

kwise

STEP 8 ELECTRICAL CONNECTION

CAUTIO

BEFOREPLUGGINGIN APPLIANCE,READELECTRICALAND

PLUMBING REQUIREMENTSAND CHECKLIST.

Plug electrical power cord into a properlg grounded wall

outlet.

ACCESS DOOR LOCK INSTALLATION

To remove the access door retainer before installing a lock,

place the door over a wood block with a 1/2" hole drilled in it

and tap end of screw lightl U with a hammer.

_Lock Washer

_Nut

ill -Spring Washer

_od Nut_"_q[ 'L_Cam

Block

Page 6

Installation Instructions

STEP 10 CHECK LIST

Reviewthis list after installing the washer to avoid a charge for

a service call not covered bg the warrantg.

AFTER INSTALLATION CHECK THE FOLLOWING:

[] Drain hose must be pulled tight and secured to drain facilitg

to prevent lifting out of drain facilit U during discharge.

Nozzle clamp must be securel Utightened to prevent

leaks. MAKE SURE DRAIN HOSE IS NOT RUBBING AGAINST

CONCRETE OR BLOCK WALL. RUBBING MAYWEAR HOLES

IN HOSE.

[] Hose Washers-Rubber washers in both ends of fill hoses.

[] Hose Connections-Hot side (left valve) connected to hot

water suppl U,cold side (right valve) to cold water suppl U.

All connections should be hand tightened plus 1/2 turn

with pliers.

[] Grounding-Must be properl U grounded to conform to local

code and ordinances.

[] Leveling-Adjust front leveling legs as necessar U (preleveled

from the factorg at 1"). Check side to side and front to back.

Tilt forward approximatel U4" to adjust rear self-leveling

legs.

[] Operation-Turn on faucets and run washer completelg

through cycle bg hand. Check for leaks, noise, vibration,

correct water temperatures and proper operation in wash

and spin. While washer is in spin, raise lid and check lid

switch and brake operation.

STEP 11 LITERATURE

, Be sure to leave complete literature package and installation

instructions with consumer.

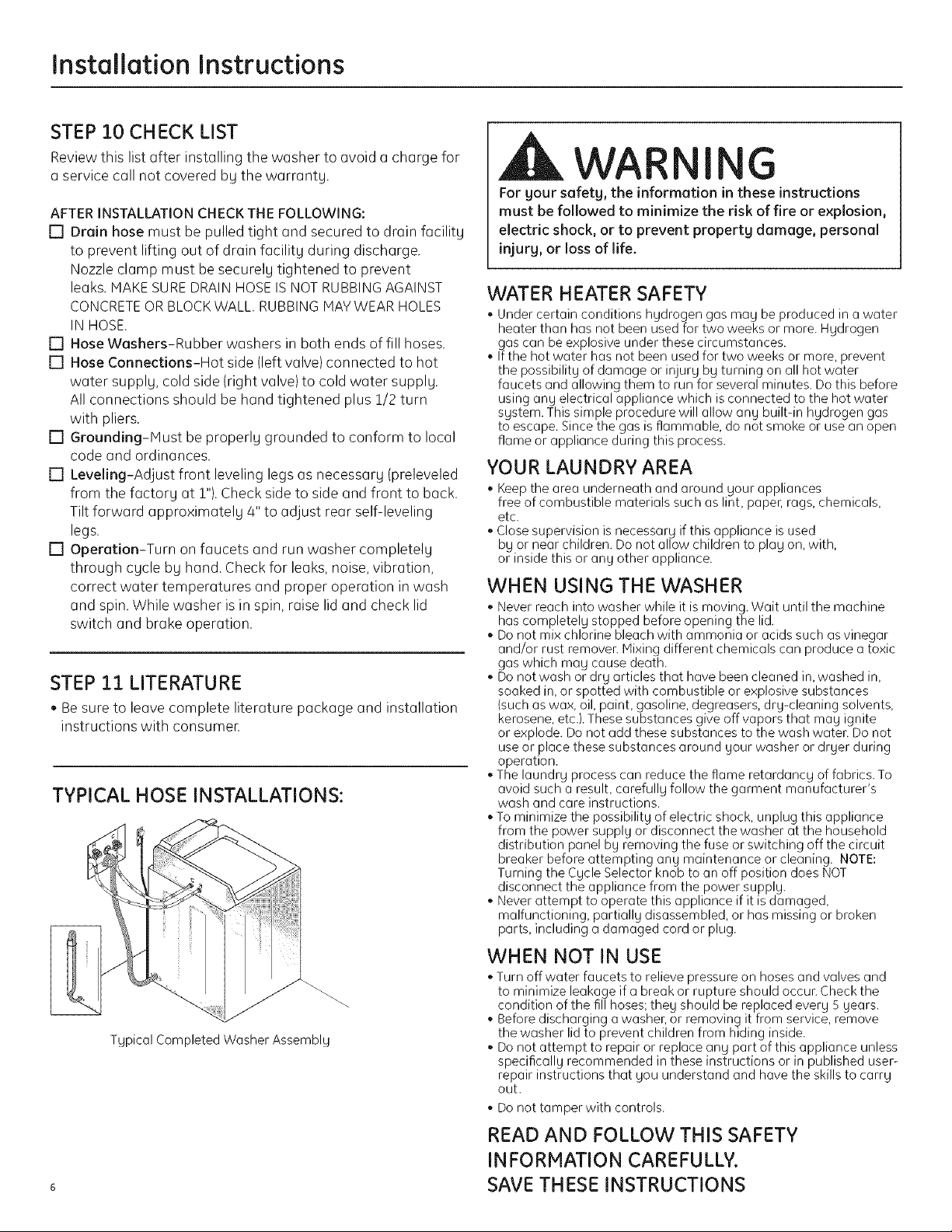

TYPICAL HOSE INSTALLATIONS:

Tgpical Completed Washer Assemblg

WA ING

For gout safetg, the information in these instructions

must be followed to minimize the risk of fire or explosion,

electric shock, or to prevent propertg damage, personal

injurg, or loss of life.

WATER HEATER SAFETY

, Under certain conditions hgdrogen gas mag be produced in a water

heater than has not been used for two weeks or more. Hgdrogen

gas can be explosive under these circumstances.

, If the hot water has not been used for two weeks or more, prevent

the possibilitg of damage or injurg bg turning on all hot water

faucets and allowing them to run for several minutes. Do this before

using ang electrical appliance which is connected to the hot water

sgstem. This simple procedure will allow ang built-in hgdrogen gas

to escape. Since the gas is flammable, do not smoke or use an open

flume or appliance during this process.

YOUR LAUNDRY AREA

, Keep the area underneath and around gour appliances

free of combustible materials such as lint, paper, rags, chemicals,

etc.

, Close supervision is necessarg if this appliance is used

bg or near children. Do not allow children to plag on, with,

or inside this or ang other appliance.

WHEN USING THE WASHER

, Never reach into washer while it is moving. Wait until the machine

has completelg stopped before opening the lid.

Do not mix chlorine bleach with ammonia or acids such us vinegar

and/or rust removen Mixing different chemicals can produce a toxic

gas which mag cause death.

Do not wash or drg articles that hove been cleaned in, washed in,

soaked in, or spotted with combustible or explosive substances

/such as wax, oil, point, gasoline, degreasers, @g-cleaning solvents,

kerosene, etc.). These substances give off vapors that mag ignite

or explode. Do not add these substances to the wash waten Do not

use or place these substances around gour washer or drger during

operation.

The laundrg process con reduce the flame retardancg of fabrics. To

ovoid such a result, carefullg follow the garment manufacturer's

wash and core instructions.

To minimize the possibilitg of electric shock, unplug this appliance

from the power supplg or disconnect the washer at the household

distribution panel bg removing the fuse or switching off the circuit

breaker before attempting ang maintenance or cleaning. NOTE:

Turning the Cgcle Selector knob to an off position does NOT

disconnect the appliance from the power supplg.

Never attempt to operate this appliance if it is damaged,

malfunctioning, purtiallg disassembled, or has missing or broken

parts, including a damaged cord or plug.

WHEN NOT IN USE

, Turn off water faucets to relieve pressure on hoses and valves and

to minimize leakage if a break or rupture should occun Check the

condition of the fill hoses; theg should be replaced everg 5 gears.

, Before discharging a washer, or removing it from service, remove

the washer lid to prevent children from hiding inside.

, Do not attempt to repair or replace ang part of this appliance unless

specificallg recommended in these instructions or in published user-

repair instructions that gou understand and have the skills to carrg

out.

Do not tamper with controls.

READ AND FOLLOW THIS SAFETY

INFORMATION CAREFULLY.

SAVE THESE INSTRUCTIONS

Page 7

Appliances

Instructions d'installation

IVlachine@laver commerciale

Si vous avez des questions, appelez 800-GECARES ou visitez notre site Web"

www.GEAppliances.com

AVANT DE COMMENCER

Lire ces consignes avec grande attention.

IMPORTANT-II faut respecter tous les codes

et ordonnances en vigueur.

• Remarque 6 I'installateur - Veillez (_laisser cette notice sur

le lieu d'installation pour que le consommateur et

I'inspecteur local puissent s'u r@f@er.

• Niveau de competence requis - IIfaut poss@der des

capacit@s m@caniques et @lectriquxes @l@mentaires pour

installer cette machine (_laver commerciale. L'installateur

est responsable de I'installation correcte de la machine. La

garantie des appareils GE ne couvre pas une d_faillance

qui r_sulte d'une installation incorrecte.

LISEZ SOIGNEUSEMENT.

SAUVEGARDEZ CES DIRECTIVES.

I M PO RTA N T - Prenezimm_diatementcon-

tactavec le distributeur ou le fabricant si vous avez requ

une machine (_laver endommag@e.

CONSIGNES DE

SECURITE

IIfaut life et respecter toutes les ATTENTIONS (mises en garde)

et AVERTISSEMENTS contenus dans cette notice.

CES SPECIFICATIONS PEUVENT ETRE MODIFIEES SANS PREAVIS.

GE Consumer & Industrial

General Electric Compan U

Louisville, Kentuck U 40225

ge.com

© 2006 GeneralElectric Compang

143Bg310P035

Pub. No. 31-16545

ND 07D-2178 (_071

7

Page 8

Preparation pour I'installation

OUTILS REOUIS •

Jeu de douilles

Pince _jointure glissante

CONDITIONS D'INSTALLATION •

EMPLACEMENT

La machine 6 laver doit _tre install_e sur un sol r_sistant pour

minimiser les vibrations au cours des cycles d'essorage. Un

plancher en b_ton est ce qu'il g a de mieux, mais une base

de bois convient _galement, 6 condition que lesupport se

conforme au× normes de I'administration FHA.Ne pas installer

la machine 6 laver surun tapis ou de la moquette, ne pas la

laisser 6 I'ext@ieur ou I'exposer 6 des temp@atures de gel.

PLOMBERIE

, Pression d'euu - la pression dgnamique dolt setrouver dans

une plage de minimum 20 psi (_maximum 150 psi, mesur_e

au robinet.

, Temp(_rature d'eau - r_gler lechauffe-eau de la maison de

sorte que I'eau coule DANSLAMACHINE_ une

temp@ature entre 120(_ 150 °F(50 a 66 °C)Iors d'un lavage

a CHAUD.

, Robinets d'arr_t - les robinets d'arr_t d'eau chaude et d'eau

froide doivent _tre fournis.

, Vidange - I'eau peat s'_couler dans un tugau ascendant

ou un bac a laver. La hauteur d'_vacuation NEPEUTPAS

[_TREMAINS DE30 po 176cm} ou plus de 6 pieds (1,8 m)au-

dessus de la base de la machine a laveELetugau ascendant

dolt avoir undiam_tre interne d'au mains 1-1/2 po (3,8cm)et

_tre expos_ a I'air.

SPI CIFICATIONS POUR

L'INSTALLATION DU SYSTI ME

I LECTRIQUE ET DE LA PLOMBERIE

ALIMENTATION 15LECTRIQUE

Cette machine dolt _tre aliment_e par un courant de 115

volts, 60 Hz et dolt _tre raccord_e (_un circuit de d@ivation

individuel, misa terre

correctement et prot_g& par

un disjoncteur ou un fusible

temporis_ de 15 (_20 amperes.

, Si I'alimentation &lectrique

ne r_pond pas aces

specifications, consulter

un _lectricien qualifi_.

INSTRUCTIONSDE MISEA LATERRE

Cet appareil doit _tre mis 6 la terre. Encos de mauvais

fonctionnement ou de panne, la mise 6 la terre r_duit le risque

de choc _lectrique enfournissant un passage de moindre

r&sistance au courant &lectrique. L'appareil est _quip_ d'un

cordon d'alimentation 6 conducteur

de mise 6 laterre d'_quipement

et fiche de mise 6 la terre. IIfaut

brancher la fiche sur une prise

appropri_e, correctement

install_e et mise 6 la terre

conform&ment aux codes

et ordonnances Iocaux.

Si n_cessaire, on peut ajouter

un fil de mise a terre externe

(non fourni) qui r_pond aux

codes Iocaux. Leraccorder a I'arri_re de I'armoire de la

machine a laver avec des visa t61e(nonfournies), tel illustr_.

II faut une visa t61eno8, 18 filets par pouce et Iongue de

1-1/2 po. Ellepeut _tre obtenue dans n'importe quelle

quincaillerie.

Verifierque la machine

est c0rrectementmise

la terreavantI'utiliser

Brancherlefil

demisea laterre

(obtenirIocalement)

, POUR DES RAISONS DE

PERSONNELLE, NE PAS UTILISER UNE

RALLONGE OU UN ADAPTATEUR DE PRISE

AVEC CET APPAREIL.

• NE JAMAIS COUPER OU ENLEVER LA

TROISII_ME BROCHE DE MISE A LA TERRE

DU CORDON D'ALIMENTATION.

• RESPECTER LE CODE I_LECTRIQUE

ANSl/NFPA 70 OU LES CODES ET

ORDONNANCES LOCAU×.

SI_CURITI_

AVERTISSM T

il peut g avoir un risque de choc _lectrique si le

conducteur de mise 6 la terre de lu machine est mal

reccord6. S'il existe un doute que lu machine a 6t_

correctement mise 6 la terre, consultez un technicien

qualifi_.

Page 9

Preparationpour l'installation

I_TAPEI PRI_PARATION #, L'INSTALLATION

DE LA MACHINE A LAVER

o Tirer la tige d'exp@dition

situ6e au c6t@ inf@ieur

droit (elle porte une

@tiquette ou une

lani@re) vers le

dehors et s'en

d_barrasser.]

_ Tiged'expedition

Rapprocher

lamachine

nemplacementfinal

uette

oulani_re

.d

Enlever le carton

int@ieur et les

accessoires

d'installation situ@s

sous le couvercle. Le

tuyau de vidange se

trouve dans la cuve

de lavage.

, D@placerla machine

6 laver vers le lieu

d'installation pour

mettre en place les

tuyau× et pr@parerle

syst@me@lectrique.

f

-- Carton

mt@neur

I_TAPE3 RACCORDEMENT DU TUYAU DE

VIDANGE A LA MACHINE

V@ifier que toutes les pi@ces de

montage ont 6t@enlev6es du panier

de la machine a laven

IMPORTANT : Si le bouchon

rouge est pr@sent dans I'anneau:

enlever le bouchon rouge

de I'orifice du tuyau de vidange.

REMARQUE:II peut y avoir un peu

d'eau. C'est normal.

Trouver le adaptateur du tuyau de

vidange. Placer la bride d'attache

sur I'extr@mit@du tuyau de vidange. Introduire I'adaptateur

dans I'extr@mit@courb@edu tuyau de vidange. Placer le

collier de serrage defagon a raccorder I'adaptateur de tuyau

au tuqau de vidange. Pousser la bride d'attache par-dessus

I'adaptateur dans la rainure.

REHARQUE:11faut pousser @nergiquementjusqu'a ce qu'on

entende un d@clicIorsque la bride rentre dans I'orifice. Le

d@clicassure qu'assez de force a @t@utilis@e.

Troud'entr@

Adaptateur du tuyau

dutuyau devidange

Vis(2)

Tuyau

devidange

Bouc_n1![._ l[

R_cipientcollecteur

Bridei_stallee

_illet

I_TAPE2 RACCORDEMENT DES TUYAUX DE

REHPLISSAGE A LA MACHINE

Introduire les rondelles de caoutchouc dans les deu×

extr_mit_s de chaque tuyau de remplissage. Raccorder le

tuyau marqu_ HOT(chaud) au robinet de remplissage d'eau

chaude de la machine 4]laver. Raccorder le tuyau marqu_

COLD(froid) au robinet de remplissage d'eau froide e la

machine a lave. Serrer les raccords (_la main, puis donner un

demi-tour avec des pinces.

Serrer _ la main,

plusundemi-tour

avecdespinces

Tuyau

d'eaufroide

Tuvau Rondelles Cordond'alimentation

d'eauchaude decaoutchouc 61ectrique

Serre-ecrou

o Introduire lebout conique de I'adaptateur du tuyau de

vidange dans I'orifice du tuyau de vidange de la machine.

Visser lesdeux vis qui se trouvent dans le paquet

d'installation pour attacher le tuyau de vidange a la

machine (_laveE Agrafeanti-siphon

_,.jAttache de c_ble

76 c'm[_" /

min.

Tuyau -_ I /

devidange "_'q-_"

Attachedec_ble devidange

REMARQUE:Si le tuyau de r@servoirn'atteint pas la

hauteur minimale requise de 30 po (76 cm), fake passer le

tuyau a travers I'agrafe anti-siphon foumie et I'attacher au

dos de la machine, tel illustr& Installer I'agrafe anti-siphon en

glissant I'agrafe sup@ieure dans le trou de montage sup@ieur

et en enclenchant la deuxi_me agrafe en place.

I Mo,ns

de 76 cm

_NERVURES VERSL'INTERIEdR Tuyau

9

Page 10

Preparationpour I'installation

I_TAPE4 AJUSTEMENT DES PATTES

DE MISE A NIVEAU

, Placerle niveou surla portia event du hout de la machine 6

IoveE

, Ajuster los pattes avant de raise a niveaujusqu'a ce que la

machine soit a niveau d'un c6t@a I'autre. Enlever le niveau.

Basculer la machine vers I'avant de 4 a 6 po (!0 a !5 cm).

Cette manoeuvre r@glelos pattes arri@e de raise a niveau de

faqon a correspondre au niveau des pattes avant.

Remettre doucement la machine en place sur le sol.

Basculer la machine

laver vers I'avant de

Mettre a niveau 10 _ 15 cmpour r_gler

en los pattes arri_re

utilisant los pattes

de mise 8 niveau event

I_TAPE5 INSTALLATION DES TUYAUX

DE REMPLISSAGE

, S'ossurer que les conduites d'alimentation d'eau ont _t_

compl@tement vidang@es.

, D@placerla machine 6 laver vers son emplacement final. NE

PASPERMETTREaux tugaux de remplissage et de vidange de

traTner par terre ou de secoincer sous la machine.

I_TAPE6 INSTALLATION DU TU?AU

DE VIDANGE

, Introduire un bout du coude de vidonge en oluminium dons le

tuyau ascendant.

Repousser ou cooper lagarniture du fil m@talliquejusqu'a

environ 2 po (5 cm) en dessous du haut du tugau ascendant.

Cooper le tuyau de vidangejuste en dessous du tuyau

ascendant. Placer I'attache de c6ble argent@eau-dessus de

I'extr@mit@du tuyau devidange noin

Introduire lecoude de vidange clans I'extr@mit@du tuyau de

vidange et placer I'attache de c6ble defaqon a raccorder le

coude au tuyau.

Ga_ni_r_'_e_°_l_g_

m@allique I'_// IVI_-Tuv au

I_ _ I Ill Iascendant

, Placer letuyaudevidange dons le syst@mede vidange et

attacher avec I'attache de c6ble fournie ou avec du ruban

adh@sif,tel illustr&

Tuyaux

deremplissag_

Attacherau

tuyaudevindage

ATTE TIO

VERIFIERQUELETAYUA×DE REMPLISSAGESONT

FERMEMENTRACCORDESAU× ROBINETS.

* Identifier la sortie d'eeu CHAUDE(HOT)event de

reccorder les tugeux de remplissege eux robinets. Le

robinet d'eeu CHAUDE{HOT)setrouve hebituellement 6

gauche. S'essurer qua des rondelles en caoutchouc ont

_t_ plec_es 6 cheque extr_mit_ des deux tugeux de

remplissage. Reccorder le

tuyeu du robJnet d'entr_e avecdespinces

de lamachine 6 laver (marqu_

HOT- chaud) au robinet d'eu

chaude et raccorder letagau

robinet d'entr_e marqu_ COLD

ffroid) au robinet d'eeu froide.

Serrer los raccords 6 la

main, puis donner un Tuyayd'eau

demi-tour evec des pinces.

i0

Serrer_ lamain,plusundotal-tour

C

_tamis/

Rondo%

@caoutchouc

froide

Attache Tuyaude

dec_ble vindage

REMARQUE :On peut raccourcir le coude du tuyau de

vidange si la Iongueur originelle ne permet pas de I'introduire

compl_tement clans le sgst@me de vidange.

ATTE TIO

VERIFIERQUELETUYAUDEVlDANGE EST81ENCOLLEOU

AUTREMENTATTACHf_AU TUYAUASCENDANTOU/_ UN

AUTRESYSTI_MEDE VlDANGE.

REMARQUE - Ueau peut 6tre vidang6e dens un tugeu

ascendant. La hauteur d'_vacuation ne peut pus 6tre

moins de 30 po (76 cm) ou plus de 6 pieds (1,8 m) eu-

dessus de le base de le machine 6 laver. Le tugau

ascendant doit avoir un diam_tre interne d'au moins

1-1/2 po {3,8 cm) et _tre expos(_ 6 l'eJr.

Page 11

Preparationpour l'installation

ETAPE

7 IUTILISATION I'=CONOMIQUE D'EAU

UNIQUEMENT SUR LES MACHINES

PAYANTES

Le manostat est r_gl_ 6 I'usine pour un niveau et un usage

d'eau 61ev6s.

Pour changer le r6glage du niveau 6lev6 6 un niveau mogen

ou has

AV RTISSE T

VI_RIFIERQUE LA MACHINE/_ LAVERN'EST PASBRANCHIAE

SURUNE PRISEDECOURANT°

, Retirer les quatre vis torx de I'arri@redu panneau de

commande et coucher I'avant du panneau sur le couvercle.

Retirer

leavia

T

, De I'avant. pousser du doigt la came blanche en

plastique du manostat vers la droitejusqu'@ ce qu'elle

s'enclenche en position niveau d'eau mogen ou bas.

(Voir I'illustration ci-dessous.)

T0urner

I_TAPE9 DIRECTIVES PARTICULII_RES POUR

LES MODELES EQUIPES D'UNE

SERRURE DE SECURITE

INSTALLATIOND'UNE SERRUREDE SECURITESURLE

COUVERCLE

Le couvercle de la machine 6 laver peut _tre _quip_ d'une

serrure de contact, comme illustr@ci-apr@s.

16mm

Filetde7,94mm-18 I_1

19m3n[_'__ 7mm

_ delarge

I-.q_--27mm---_H Vuearri_re

Verrouacameoffert

parGreenwald

piecen°8-1222

Installotion de Io serrure :

, Enlever la pi@ceen plastique de I'avant du couvercle.

, Placer la rondelle de serrure sur I'arbre de verrouillage de

sorte que le verrou puisse s'enclencher vers la gauche.

, Introduire le m@canismede verrouillage clans I'ouverture

du couvercle et serrerjusqu'6 ce qu'il soit bien ajust& (Un

serrage excessif peut endommager les surfaces peintes.)

, Installer la came et serrerjusqu'6 ce qu'elle soit bien ajust@e.

INSTALLATIONDELA SERRUREDELA PORTED'ACCES

Pour enlever le dispositif de fixation de la porte d'acc@savant

I'installation d'une serrure, placer la porte sur un bloc en

bois clans lequel on a for@un trou de 1/2 po(12 mm) ettaper

I@g@rementsur le bout de I'@crouavec un marteau.

adroite

I_TAPE8 RACCORDEMENT I_LECTRIOUE

ATTENTIO

CONSULTERLESSPI_CIFICATIONSDEL'ALIMENTATION

ELECTRIgUEET DELA PLOMBERIEETVERIFIERLA LISTE

DECONTROLEAVANT DEBRANCHERL'APPAREIL

Brancher le cordon d'alimentation sur une prise murole

correctement mise 6 la terre.

E0roa U came

__ Blocenbois

_.,.J_ Rondelledeblocage

/ Ecrou

II -Rondelleelastique

i

11

Page 12

Pr6paration pour l'installation

I]TAPE 10 LISTE DE CONTROLE

Etudier cette liste apr_s avoir install6 la machine 6 laver ;

ceci peut pr@enir les frais d'un appel de service non

couvert sous la garantie.

APRILSL'INSTALLATION,VERIFIERLESUIVANT:

[] Letugau de vidange dolt _tre bien tendu et solidement

raccord6 au sgst_me devidange pour emp_cher qu'il ne

sorte du sgst_me de vidange pendant I'@acuation

d'eau. LQbride d'attache du coude doit _tre bien serr6e

pour 6viter des fuites d'eau. VERIFIEROUE LETUYAUDE

VIDANGENETOUCHENILESOL,NILE HUR. LAFRICTION

PEUTPROVOQUERDESTROUSDANSLETUYAU.

[] Rondelles des tugaux - Des rondelles de caoutchouc

doivent 6tre en place dans chaque extr6mit6 des tugaux de

remplissage.

[] Raccordement des tugau× - Lec6t6 chaud (robinet de

gauche) dolt 6tre raccord6 6 I'eau chaude, le c6t6 froid

(robinet de droite) 6 I'eau froide. Tousles raccords doivent

6tre serr6s 6 la main, plus un demi-tour avec

des pinces.

[] Mise 6 la terre - La mise 6 la terre doit se conformer aux

codes et ordonnances Iocaux.

[] Mise 6 niveau - Ajuster les pieds avant selon le besoin (ils

ont 6t6 pr66just6s 6 1 po (25mm) 6 I'usine).V6rifier d'un

c6t6 6 I'autre et de I'avant 6 I'arr_re. Pencher I'appareil vers

I'avant d'environ 4 po (10 cm )pour ajuster lamise 6 niveau

automatique des pieds arri_res.

[] Fonctionnement - Ouvrir les robinets et faire passer la

machine par un cycle complet 6 la main. V@ifier qu'il n'g a

pas de fuites, de bruits et de vibrations, que la temp@ature

de I'eau est correcte et que la machine 6 laver fonctionne

correctement au cours des cgcles de lavage et d'essorage.

Pendant le cgcle d'essorage, lever le couvercle et v6rifier le

fonctionnement du commutateur de couvercle et du frein.

I]TAPE 11 DOCUMENTATION

, N'oublier pas de remettre au consommateur I'ensemble

complet de la documentation et des instructions d'installation.

RACCORDEMENT TYPE DES TUYAUX •

Assemblage type de la machine _ laver

Page 13

Preparation pour I'installation

AV RTISSE

Pour des raisons de s_curit_, suivre les pr(_sentes

consignes efin de minimiser le risque d'incendie,

d'explosion et de choc _lectrique et pour pr_venir les

dommeges materiels, les blessures ou le mort,

SECURIT#: DU CHAUFFE-EAU

,Dans certoines conditions, de I'hydrog_ne peut se d_velopper

dans un chauffe-eau qui n'o pos _t_ utilis_ pendant plus de

deux semaines. Dons de telles circonstances, le gaz peat _tre

explosif.

, Si le chauffe-eau n'o pas _t_ utilis_ pendant plus de deux

semaines, pr_venir le risque de dommoges ou de blessures

en ouvrant tousles robinets d'eau chaude et en Ioissant

couler I'eau chaude pendant plusieurs minutes. IIfaut

effectuer cette manoeuvre ovant d'utiliser tout appareil

_lectrique raccord_ au chouffe-eau. Cette procedure simple

permet 6 I'hudrog_ne accumul_ de s'_chappen Le gaz _tant

inflammable, ne pas fumer ou utiliser une flomme ouverte ou

un appareil _lectrique pendant ce processus.

LA BUANDERIE

• Enlevertoutes moti_res combustibles, telles que les peluches,

le poplar, les chiffons ou les produits chimiques, des surfaces

en dessous ou autour de la machine.

, Unesupervision stricte est de rigueur si cat appareil est utilis&

par ou 8 proximit_ des enfonts. Ne pas permettre aux enfonts

dejouer sur,avec ou 8 I'int@ieur de cette machine ou detout

autre apporeil _ctrom_noger.

T

, Le lavage peat r@duireles qualit@signifuges d'un tissu. Pour

@viterque ceci se produise, il faut toujours scrupuleusement

suivre les directives de nettouage et d'entretien du fabricant

du v@tement.

, Pour minimiser le risque de choc @lectrique,d@brancher la

machine 6 laver de la source d'alimentation ou d@connecter-

la au tableau de distribution en enlevant lefusible ou en

fermant le disjoncteur avant de tenter d'entretenir ou de

nettouer Iomachine. REMARQUE:Le fait de placer le bouton

s@lecteurde cucle sur <<OFF>>(arr@t)ne d@onnecte PASla

machine de lasource d'alimentation.

, Nejomais tenter defaire marcher cette machine Iorsqu'elle

fonctionne mal, est endommag@e ou partiellement d@mont@e

ou si des pi@cesmanquent ou sont endommag@es, Ucompris

le cable d'alimentation ou la fiche.

LORSQUE LA MACHINE EST HORS

USAGE

,Fermer les robinets d'eou pour oll_ger la pression sur les

tuuaux et lesvannes et minimiser les fuites en cas de cassure

ou de rupture. V@ifier I'@tatdes tuuaux de remplissage. Ceux-

ci doivent @treremplac@stousles 5 ans.

Avant de se d@barrasserd'une machine ou de I'enlever de

son emplacement pour le service, enlever le couvercle de

la machine pour amp@charqu'un enfant ne se dissimule 6

I'int@ieur.

Ne pas tenter de r@parerou de remplacer une pi@cede cette

machine sauf Iorsque sp@cifiquement recommand@ dans

ces directives ou dans une publication contenont

des directives de r@paration par I'utilisateur qui sont

compr_hensibles et adapt_es aux capacit_s de I'utilisateuc

Ne pas modifier lescommandes.

PENDANT L'UTILISATION DE LA MACHINE

LAVER

, Nejomais mettre le bras dans la machine Iorsqu'elle

fonctionne. Attendre qu'elle s'est compl@tement arr@t@eavant

d'ouvrir lecouvercle.

, Nepas m@langerde I'eau dejavel 8 de I'ammoniaque ou

8 des acides tels le vinaigre et/ou un produit antirouille. Le

m@langede diff@ents produits chimiques peat produire un

gaz toxique pouvant @tremortel.

, Nepas laver ou s@cherun article qui a @t@nettou@ou lay@

dans une substance combustible ou explosive ou qui en a

@t@imbib@ou tach@(par example, de la cire, de la graisse,

de la peinture, de I'essence, du d@graissant,du solvant de

nettouage 6 sac ou du k_ros_ne). Cessubstances _mettent

des vapeurs pouvant causer un incendie ou une explosion. Ne

pas ajouter detelles substances @I'eau de lavage. Ne pas les

utiliser ou les placer @proximit@dela machine @laver ou le

s@che-lingeIorsqu'une des machines fonctionne.

SOIGNEUSEMENT LIRE ET SUIVRE CETTE

INFORMATION SUR LA SECURITE.

SAUVEGARDER CES DIRECTIVES

13

Page 14

f"_ _> _'_ /'_ '_ C _ _ _ _ /

....... ' iq i_ (_

Appliances

Instrucciones de instalaci6n

Lavadoracomercial

Si tiene preguntas, Ilame a 800-GECARES o visite nuestro sitio web:

www.GEAppliances.com

ANTES DE COMENZAR

Leo cuidodosomente todos estos instrucciones.

IMPORTANTE-Debe cumplir con todos los c6digos

g ordenanzas locales vigentes.

, Aviso para el instalador - Deje estas instrucciones Dora usa

del consumidor Uel inspector local.

Nivel de capacitaci6n - Se requieren conocimientos

mec6nicos Uel@ctricosb6sicos para instalar esto lavadora

comercial. El instalador es responsable por ia instalaci6n

correcta. La garantia de productos electrodom_sticos

de GEno cubre fallas de productos debido a instalaci6n

incorrecta.

LEA CUIDADOSAMENTE.

CONSERVE ESTAS INSTRUCCIONES.

IM PORTANTE- si ha recibido una lavadora

comercial da_ada, comuniquese inmediatamente con su

distribuidor o constructon

PARA SU SEGURIDAD

Lea y observe todas las PRECAUCIONES y

ADVERTENCIAS que contiene estas instrucciones.

LAS ESPECIFICACIONES ESTAN SUJETAS A CAMBIO SIN AVISO PREVIO.

GEConsumer & Industrial

General Electric Compan U

Louisville, Kentuck U40225

ge.com

14

© 2006 General Electric Compang

Illust. ]43Bg3]0P032

Pub. N0m. 31-15556

ND 07D-2178 (4/07)

Page 15

Preparaci6n pare la instalaci6n

HERRAMIENTAS NECESARIAS:

Juego de casquillos

Alicate ajustable

REQUERIMIENTOS DE INSTALACION:

UBICACI6N

La lavadoro se debe instalar sabre un piso firme a fin de

minimizer las vibraciones durante los ciclos de

centrifugado. Un piso de concreto esideal, pero una base de

madera bastar6, cuando dicha base cumpla con las normas

FHA.La lavadora no se debe instalar sabre alfombra ni

exponer ala intemperie o a temperaturas inferiores al punto

de congelaci6n.

PLOMERJA

, Presi6n del ague-Presi6n din6mica minima de 20 ps, g

m6xima de 150 psi medida en elgrifo.

, Temperature del ague-El calentador de agua de la casa se

debe ajustar para proveer agua a una temperatura de 120 a

150° F(50a 66° C)ENLA LAVADORAcuando se selecciona el

ciclo de lavado HOT(caliente).

, V61vulas de cierre-Se debe proveer v61vulasde cierre (grifos)

de agua fria g agua caliente.

Desegiie-EI agua se puede drenar a un tuba vertical o a una

cubeta fija. Laaltura de descarga NO DEBEQUEDAR

A MENOSDE30 PULGADAS(76 cm) ni a m6s de 6 pies

(1,8 m)por encima de Io base de la lavadora. Eltubo vertical

debe tener un di6metro interior minimo de 1-1/2 pulgadas

(3,8cm) g ventilar al medio ambiente.

REQUISITOS ELI CTRICOS Y DE PLOMER/A

o

PARA SU SEGURIDAD, NO UTILICE UN

CABLE DE EXTENSI6N NI UN ENCHUFE

ADAPTADOR CON ESTEARTEFACTO

ELECTRODONESTICO.

POR NINGUNA RAZ6N SE DEBE CORTAR

O ELININAR LA TERCERA CLAVIJA

DE PUESTA A TIERRA DEL CABLE DE

ALINENTACI6N ELECTRICA.

OBSERVE LAS DISPOSlCIONES DEL

C6DIGO NACIONAL DE ELECTRICIDAD

ANSI / NFPA 70 O LOS C6DIGOS Y

ORDENANZAS LOCALES VlGENTES.

INSTALACI6N ELECTRICA

Este artefacto electrodom@stico

debe tener un suministro de

!!BY, 60 Hz,g se debe conectar

a un circuito derivado indi-

vidual con un sistema de

puesta a tierra adecuado

protegido con un disguntor o

fusible de !5 6 20 amperios.

Si la alimentaci6n el@ctricano

AsegOresedequehave

sistemadepuesta a tierra

adecuadoantesdeusarlo

cumple con los requisitos

mencionados arriba, consulte un

t@cnicoelectricista profesional.

INSTRUCCIONES PARA PUESTA A TIERRA

Esta unidad debe tener una conexi6n para puesta a tierra

adecuada, ga que si se avefia o no funciona correctamente,

la puesta a tierra reducir6 el riesgo de electrocuci6n al

proveer una ruta de menor resistencia para la corriente

el@ctrica. La unidad est6 equipada con un

cable que posee tanto un conductor

como un enchufe para puesta a

tierra. El enchufe se debe

enchufar en un tomacorriente

apropiado que est@correc-

tamente instalado g conectado

a tierra seg0n Io estipulado en

los c6digos g reglamentos

locales. /

Si se requiere, un conductor

externo de puesta a tierra (no (obtenerIocalmente)

incluido) que cumpla con los

c6digos locales se puede

instalar en la parte posterior de la lavadora con un tornillo para

chapa met61ica (no incluido), segQn se indica la ilustraci6n. Se

debe usar un tornillo para chapa met61ica n. 8 de 18 vueltas

par pulgada g !/2 pulgada (!,3 cm) de largo, el cual se puede

obtener en cualquier ferreteria local.

Instalela conexi6natierra

ADVERTE ClA

Le conexi6n incorrecte del conductor de pueste e tierre

podria resultar en riesgo de electrocuci6n. Consulte con

un electricista calificedo si tiene dudes sobre le puesta a

tierre correcte de su artefecto.

Page 16

Instrucciones para la instalaci6n

PASO I PREPARE LA LAVADORA

PARA LA INSTALACI6N

o Tire Io borra pora transporte

que est6 en Io porte inferior

derecho (tiene una corea o

etiqueta) y des_chela.

Saque el paquete

interior y los

accesorios de

instalaci6n que

est6n debajo de la

tapa. La manguera

de desagOe se

encuentra dentro

del cesto de la

lavadora.

Coloque la lavadora

en elsitio donde

se instalar6 para

conectar las

mangueras y el

sistema el@ctrico.

[_ Barra para

24

(61 cm)

_ Paquete interior

Pongalalavadora

cercadesuposiciOn

final

3orte

Corea

o etiqueta

PASO 3 INSTALE LA MANGUERA

DE DESAGOE

Aseg0rese de sacar todos los

componentes de instalaci6n del

cesto de la lavadora.

, IMPORTANTE- Siel tap6n rojo se

encuentra en el anillo protector, quite

el tap6n rojo de la conexi6n de la

Enchufe_®_Ik _

manguera de desag0e.

AVlSO:Puede haber agua presente,

esto es normal.

Envasederecolecci6n

, Localice el adaptador de pl6stico dela manguera de

desag0e. Coloque la abrazadera de la manguera en el

extremo de la misma. Inserte el adaptador de la manguera

en el extremo acodado y asegurarla con laabrazadera.

Posicione la abrazadera de la manguera de pl6stico sobre el

adaptador g presione hasta que entre en la ranura

acanalada.

AVISO:Esta instalaci6n requiere un poco de fuerza y se

escucha un clic cuando la abrazadera se encaja en la

lumbrera. Adaptador de la

manguera

Tornillos (2) de la manguera

Lumbrera

Abrazadera

Manguera

de @sac

Arandela

\

PASO 2 CONECTE LAS MANGUERAS

DE LLENADO

Instale las arandelas de caucho en ambos extremos de las

mangueras de Ilenado. Conecte la manguera de Ilenado

denominada HOT(caliente) ala v61vula de entrada para agua

caliente dela lavadora. Conecte la manguera denominada

COLD(fria)ala v61vulade entrada para agua fria de la

lavadora. Los acoplamientos de deben apretar primero a mano

y despu@sse les debe dar medio giro adicional con alicate.

Apriete amano y d_le 1/2 giro

adicional con alicate

Manguera

de ague fria

Manguera Arandelas

de agua el6ctrica

caiiente

de caucho Cable de alimentaci6n

Llave para tuercas

Inserte el extremo c6nico de pl6stico del adaptador en la

lumbrera de la manguera de desagCiede la lavadora. Fije

la manguera de desag_e ala lavadora con dos tornillos

del paquete de instalaci6n. Abrazaderaantisif6n

Amarre

30 pulg. Menos

(76 cm)_ de

mfn.

Manguera (76 c_.._

de desagQe

Amarre Estriasadentro

30 pulg.

Manguera

de desagBe

AVlSO:Si la instalaci6n pare la manguera de desag0e

no cumple con el requerimiento de altura minima de 30

pulgadas (76 cm) para el tubo vertical, pase la manguera pot

la abrazadera antisif6n que se proporciona y col6quela en la

porte trasera de la unidad, como se muestra en la ilustraci6n.

Pare instalar la abrazadera antisif6n, inserte su parte de

arriba en el orificio superior y la parte de abajo en el orificio

inferior.

Page 17

Instrucciones pare la instalaci6n

PASO 4 AJUSTE LAS PATAS NIVELADORAS

, Ponga un nivel sabre el borde superior delantero de la

lavadora.

Ajuste los patas niveladoras delanteras hasta nivelar

lateralmente la lavadora. Retire el nivel.

Incline la lavadora hacia delante (pivotar sabre las patas

delanteras) de 4 a 6 pulgadas(10 a 16cm) del piso. Esta

acci6n ajustar6 las patas traseras de igual forma que las

delanteras.

Baje con cuidado la lavadora.

Inclinerlalavadorahacia

4ivelardelado

in los

patesniveladoras

delanteras

delantede10a 15cm

pareajustar los pates traseras

PASO 5 INSTALE LAS MANGUERAS DE

LLENADO

, Verifique que haga drenado todo el agua en los lineas.

Coloque la lavadora en su sitio definitivo. Los mangueras de

Ilenado g desagOe NOSEDEBENarrastrar ni deben quedar

debajo de la lavadora.

PASO 6 INSTALE LA MANGUERA

DE DESAGUE

, Inserte un extremo de la boquilla de desag0e de aluminio en

el tuba vertical.

, Deslice o recorte el forro de alambre unas 2 pulgadas (5cm)

par debajo del extremo superior del tuba vertical.

, Carte la manguera de desagi]ejusto debajo del tuba vertical

g coloque el amarre plateado en el extremo de la manguera

de desag0e negro.

Inserte la boquilla de desag0e en el extremo de la manguera

de desag0e g fije la boquilla a la manguera con el amarre.

, Conecte lamanguera de desag0e al sistema de drenaje

g fijela con el amarre incluido, como se muestra en la

ilustraci6n.

Mangueras

deIlenado

Fijeala

manguera

dedesagOe

PRECAUCI6

VERIFIQUEQUE LASMANGUERASDELLENADO ESTEN

FIRMEMENTECONECTADASA LOSGRIFOS.

, Define cu6l es la linea de ague caliente (HOT)antes de

conectar los man gueras de llenado a los grifos. Par Io

general, el grifo de ague caliente se encuentra del lado

izquierdo. Verifique que los arandelas de caucho est@n

cola ca des en los extremos de ambas mangueras de

llenado. Conecte la manguera de la

v61vula de entrada de la lavadora

(denominada HOT)al grifo de Aprieteamonayd_le

ague caliente y la manguera 1/2giroadicionalconalicate

de la v61vula de entrada fria c

(COLD)al grifo de ague fria. _/_

Losacopla mi entos de

deben apretar primero

a mano g despu@sse les

debe dar media giro

adicional con alicate.

,v,anguera HArandelatSl _de agua fria

deagua _t_t de b;

caliente LJ caucho

T m,z, Man0uera

Amarre dedesag0e

Manguera

AVISO: La boquillade lamanguera de desagOe se puede

acortarsisu longitudoriginalno perrniteque se inserte

completamente en elsisternade drenaje.

ECAUCI6

LA MANGUERADEDESAGUESEDEBEFUARCONaNTA O

POROTROSMEDOOSALTUBO VERTICALO ELSlSTEMADE

DESAGOE.

AVISO:Elagua puededrenar a un tubo vertical. Laaltura de

descarga nodebequedar a menos de 30 pulgadas (76cm) ni

a m6s de6 pies (1,8m)por encima de la basede la lavadora.

El tubo vertical debe tener un di6metro interior minimo de

1-i/2 pulgadas (3,8cm) g ventilar al medio ambiente.

17

Page 18

Instruccionespara la instalaci6n

PASO 7 AHORRO DE AGUA SOLAMENTE EN

MODELOS CON MONEDERO

El interruptor de presi6n se configura en la f6brica paro Io

posici6n de usa y nivel alto de agua.

Para cambiar la configuraci6n de nivel alto de agua a mediano

o bajo:

ADVERTE ClA

DESENCHUFE PRIMERO LA LAVADORA DEL

TOMACORRIENTE.

, Quite los 4 tornillos de torsi6n de la porte trasera del panel de

control g recoste el panel de control sobre la lavadora.

Quite

_ los tornillos

1

1

o Desde el frente, gire con el dedo la leva de pl6stico en el

interruptor de presi6n en sentido de los agujas del reloj hasta

que encaje en la posici6n media o baja del agua. (Vea la

ilustraci6n de abajo).

Giraren

e_sentido

delas

agujas.

reloj

PASO 9 INSTRUCCIONES ESPECIALES PARA

MODELOS CON CAPACIDAD PARA

USAR CERRADURA DE SEGURiDAD

INSTALACI6N DE LA TRABA DE SEGURIDAD EN LA TAPA

La tapa de la lavadora se disefl6 para permitir la instaloci6n

de una cerradura con pasador como la que se muestra en la

ilustraci6n.

18vueltas- 5/16depub 15,88mm

(7,94ram) I_L_I

19,05 _' _ ancho

rnr_-_r_] 7,14mm

t-,_- 27mm -_1 Vista posterior

Bloqueadorde leva

disponibleatrav_s

deGreenwald

N°-8-1222

Para instalar la cerradura:

o Quite la guarnici6n de pl6stico que est6 en la porte delantera

de latapa.

Coloque la arandela en el eje de la cerradura e inst61ela

de forma que se pueda accionar en sentido contrario a los

agujas del reloj.

, Instale el mecanismo de la cerradura en el orificio de la tapa

g apri_telo bien. (Sise aprieta demasiado los superficies

pintadas podrian da_arse).

, Instale laleva g apriete bien.

INSTALAClON DE LA TRABA EN LA PUERTA DE ACCESO

Para retirar el sujetador de la puerto de acceso a fin de instalar

una cerradura, coloque la puerto sobre un bloque de madera

que tenga un orificio de !/2 pulg. (!,2 cm) g golpee ligeramente

el extremo del tornillo con un martillo.

PASO 8 CONE×IONES ELI_CTRICAS

PRECAUCI6

ANTES DE ENCHUFAR LA UNIDAD, DEBE LEER

CUIDADOSAMENTE LOS REQUISITOS V LA LISTADE

VERIFICACI6N DE COMPONENTES ELECTRICOS V DE

PLOMERiA.

Enchufe el cable de alimentaci6n en un tomacorriente de

pared qua tenga un sistema de puesta a tierra adecuado.

/Tuerca

_._-------Arandela de seguridad

]_l -Arandela de res0rte

_e

demadera

Tuerc_.,r_[ ,L_Leva

Page 19

Instrucciones para la instalaci6n

PASO 10 LISTA DE VERIFICACI6N

Reviseesta Iista despu_s de instalar la lavadora para evitar

que se le cobre una Ilamada de servicio que no est@cubierta

par esta garantia.

VERIFICARLO SIGUIENTEAL CONCLUIRLA INSTALACI6N:

[] Manguera de desag_ie - Deber6 estar estirada y fijada

a la instalaci6n de desagQe para evitar que se salga del

sistema de drenaje durante la descarga deagua. Elamarre

de la boquilla debe quedar apretada para evitar fugas.

LA MANGUERADEDESAGUENO DEBEROZARCONTRA

LA PAREDDEBLOQUEOCONCRETO.DICHORaCE PUEDE

DESGASTARY ROMPERLA MANGUERA.

[] Arandelas en mangueras - Arandelas de caucho en ambos

extremos de los mangueros de Ilenado.

[] Cone×iones de las mangueras - Lado deagua coliente

(v61vulaizquierda) conectodo al suministro de agua caliente;

lado de agua fria (v61vuloderecha) conectado al suministro

de aguo fria.Todas las conexiones se deben apretar primero

omano U despu@sse les debe dor media giro odicional con

alicate.

[] Puesta a tierra - Elartefacto debe contar con un sistema

de puesta a tierra adecuado a fin de cumplir con todos los

c6digos y ordenanzas locales vigentes.

[] Nivelado - Ajuste las patas niveladoras delanteras

(niveladas en f6brica a ! pulgada (2,5cm) segOnsea

necesario. Verifique elnivelado lateral Uentre el frente U

la parte posterion Incline la unidad hacia delante unas 4

pulgadas (!0 cm) para ajustar las patas de autonivelado

traseras.

[] Operaci6n - Abra los grifos Ucorra manualmente un ciclo

de lavado completo. Reviseque no existan fugas, ruidos ni

vibraciones y revise que las temperaturas de agua sean las

correctas y que la unidad funcione correctamente durante

los ciclos de lavado Ucentrifugado. Cuando la lavadora est@

en elciclo de centrifugado, levante la tapa para verificar el

interruptor de la tapa Ula operaci6n defrenado.

PASO 11 MATERIAL IMPRESO

,,Todo el material impreso Ulos instrucciones de instalaci6n

se deben entregar al consumidon

INSTALACI6N TIPICA DE MANGUERAS:

Conexionestfpicas

19

Page 20

Instrucciones para la instalaci6n

ADVERTENCIA

Para su seguridad debe observar estas instrucciones

a fin de minimizar el riesgo de incendio, explosi6n

o electrocuci6n g pare evitar daSos a la propiedad,

lesiones personales g p_rdida de vida.

LA SEGURIDAD Y EL CALENTADOR DE AGUA

. Bajo ciertas circunstancias se puede crear gas de hidr6geno

dentro de un calentador de agua que nose ha utilizado

durante dos semanas o m6s. Elgas de hidr6geno puede set

explosivo bajo estas circunstancias.

. Si no se ha utilizado agua caliente darante dos semanas o

m6s, se debe abrir todos los grifos de agua caliente g permitir

que el agua corra darante ratios minutos para prevenir la

posibilidad de daBos o lesiones. Haga esto antes de utilizar

caalquier artefacto electrodom@stico que est@conectado

al sistema de agaa caliente. Este sencillo procedimiento

permitir6 que escape cualquier cantidad de gas de hidr6geno

acumulado. No se debe fumar ni utilizar llamas ni artefactos

durante este proceso debido a que el gas es inflamable.

SU ,REA DE LAVADO

. Mantenga el 6tea que est6 deba]o galrededor de sus

artefactos libre de materiales combustibles como hilaza,

papeL trapos, sustancias quimicas, etc.

Se debe realizar una supervisi6n cuidadosa sieste artefacto

seva a usar cerca de ni_os ova a set usado pot niBos. No se

debe permitir que ni_osjueguen sobr< con nidentro de @ste

o cualquier otto artefacto.

AL USAR LA LAVADORA

gam6s introduzca las manos dentro de la lavadora cuando

est@en uso. Espere a que la unidad se haga detenido

completamente antes de abrir la tapa.

No mezcle lejia con amoniaco ni sustancias 6cidas como

vinagre g removedor de 6xido. La mezcla de diferentes

sustancias quimicas puede producir gases t6xicos que

podrian causar la muerte.

No lave niseque articulos que ban sido desmanchados,

lavados o remojados en, ni limpiados con, sustancias

combustibles o explosivas (como cera, aceit< pintura,

gasolina, desengrasadores, solventes para lavado en seco,

keros@n,etc.).Estas sustancias despiden vapores que se

pueden incendiar o explotan No a_ada estas sustancias al

agua de lavado. No use ni coloque estas sustancias alrededor

de la lavadora o la secadora durante su uso.

El proceso de lavado g secado puede reducir la retardancia

de las telas alas llamas. Para evitar este tipo de resultado,

se debe observar cuidadosamente las instrucciones de

lavado g cuidado del fabricante de laprenda devestin

Para minimizar la posibilidad de electrocuci6n, se debe

desenchufar este artefacto de sufuente de alimentaci6n

el@ctricao desconectar la lavadora en el panel de distri-

buci6n dom@stico retirando el fusible o desactivando el

disguntor el@ctricoantes de realizar labores de manteni-

miento o limpieza. NOTA:Girar la perilla de selecci6n de ciclos

a la posici6n apagada NO desconecta el artefacto de su

fuente de alimentaci6n el@ctrica.

Nunca se debe operar este artefacto si no funciona correc-

tamente, est6 averiado, parcialmente desarmado o tiene

componentes extraviados o rotos, inclugendo un enchufe o

cable de alimentaci6n el_ctrica da_ado.

CUANDO NO SE ESTI UTILIZANDO

Cierre los grifos de agua para aliviar la presi6n en las

mangueras gv61vulasg minimizar fugas en caso de ocurrir

una ruptura. Verifique la condici6n de las mangueras de

Ilenado g reempl6celas cada 5 aflos.

Antes de desechar o sacar de servicio una lavadora, se debe

retirar su tapa para evitar que se ocalten ni_os en su interion

No reemplace ni repare ninguna parte de este artefacto a

menos que se recomiende hacerlo en estas instrucciones o

en un instructivo sobre reparaci6n para usuarios que haga

sido publicado, el cual se entienda g se est@en capacidad

de realizar las labores necesarias.

. No modifique los controles.

LEER Y OBSERVAR CUIDADOSA- MENTE

LA PRESENTE INFORMACI6N

SOBRE SEGURIDAD.

CONSERVAR ESTAS INSTRUCCIONES

Loading...

Loading...