GE WCCB1030D1KC, WCCB1030D1WC, WCCB1030F2WC, WCCD2050D1KC, WCCD2050D1WC Installation Guide

...Page 1

INSTALLATION REQUIREMENTS

LOCATION

Washer must be installed on firm

flooring to minhnize vibration during

spin cycles, Concrete flooring is best,

but wood base is sufllcient providing

floor support meets FHA standards.

Washer should not be installed on rugs

or exposed to the weather.

PLUMBING

• WATER PRESSURE - Must be 10 psi

minimum to 150 psi maximum

dynamic pressure measured at faucet.

• WATER TEMPERATURE - House-

hold water heater should be set to

deliver water at i20 ° to 150°F (50 ° to

66_'C) IN THE WASHER when HOT

wash is selcctcd.

• SHUT-OFF VALVES - Both hot and

cold shut-off valves (faucets) should be

supplied.

. DRAIN - Water may be drained into

a standpipe or set tub The discharge

height MUST NOT BE LESS THAN 30

INCHES nor more than g t:eet above

the base of the washer, The standpipe

must be 1-1/2 inches minimum inside

diameter and must be open to the

atmosphere,

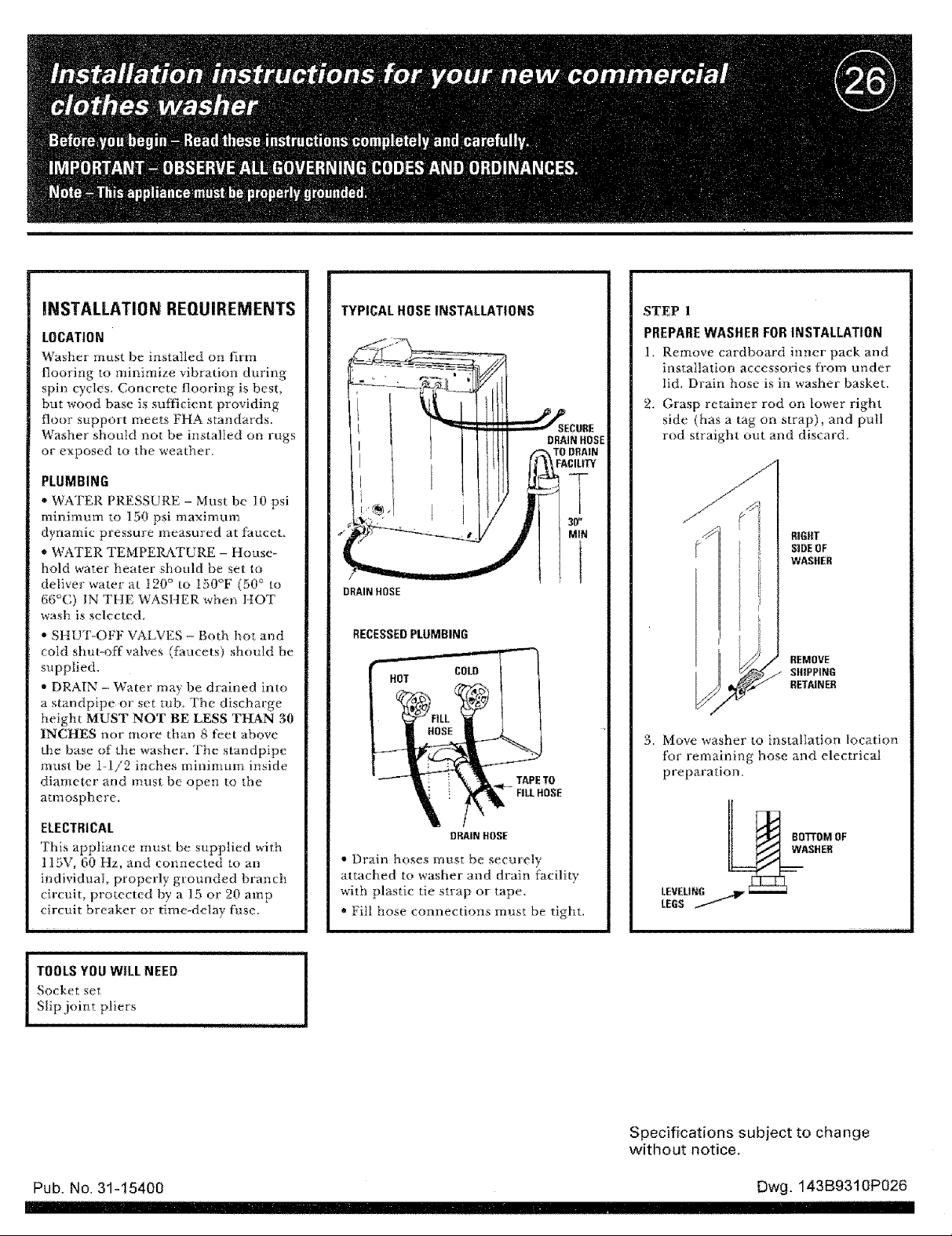

TYPICAL HOSEINSTALLATIONS

i

I I 1 I Itlitl D NHOSEC"RE

DRAIN HOSE

RECESSEDPLUMBING

TAPETO

FILLHOSE

STEP 1

PREPAREWASHER FORINSTALLATION

1. Remove cardboard inner pack and

installation accessolics from under

Iid, Drain hose is in washer basket.

2. Grasp retainer rod on lower right

side (has a tag on strap), and pull

rod straight out and discard.

RIGHT

SiDE OF

WASHER

REMOVE

S]{IPPIN6

RETAINER

3. Move washer to instaItation location

for remaining hose and electrical

preparation.

ELECTRICAL

This appliance must be supplied with

i 15V, 60 Hz, and connected to an

individual, properly grounded branch

circuit, protected by a 15 or 20 amp

circuit breaker or thne-delay fuse,

TOOLS YOU W|LL NEED

Socket set

Slip,joint pliers

DRAIN HOSE

• Drain hoses must be securely

attached to washer and drain facility

with plastic tie strap or tape,

• Fil! hose connections must be tight.

LEVELI SHER

LEGS /

BOTI'OM OF

Specifications subiect to change

without notice.

Pub. No. 31-15400 Dwg. 143B9310P026

Page 2

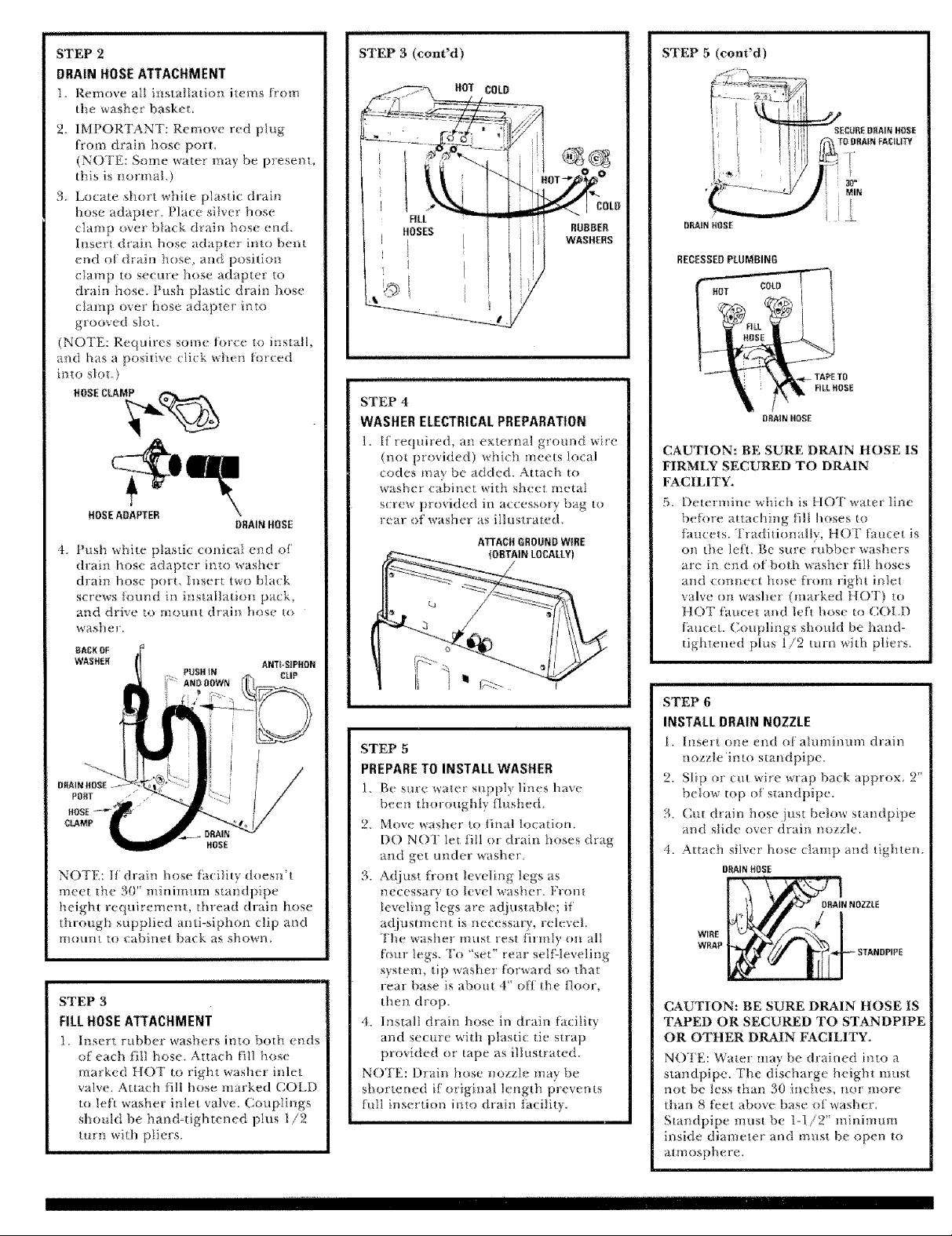

STEP 2

DRAIN HOSEATTACHMENT

1. Remove atl installatio_ items from

the washe_ basket,

2. IMPORTANT: Remove red plug

flora draio hose porL

(NOTE: Some water may be presem,

this is normal.)

3, Locate short white plastic drain

hose adapter, Place sliver hose

clamp over black drain hose end.

Insert drain hose adapter into bent

end ol drain hose, and position

clamp to secure hose adapter to

drain hose. Push plastic d_ai_ hose

damp over hose adapter into

gtooved slou

(NOTE: Requires some I_n'ce m install,

and has a positive click when tinred

into slot,)

HOSEADAPTER

4 Push wtite plastic conicaI end of'

(hair_ bose adapter i*_to washer

drain hose port, Insert two hla_k

screws fom{d m installation pack,

and drive to mount drain hose to

w _sher,

DRAINHOSE

ANTbSIPffON

CLIP

NOTE: If drain hose {acility doesn't

meet the 30" minimum standpipe

height requirement, thread thaii_ hose

through supplied anti-siphon clip and

mount to cabinet back as showm

STEP 3

FILLHOSEATTACHMENT

1. lnse*t rubber washers i_to both tmds

of each fie hose Attach fill hose

marked }lOT to right washer inlet

valve, Attach fill hose marked CO[[)

to left washer inlet valve. Coupliogs

shoukt be hand-tightened plus 1/2

turn with pliers.

STEP 3 (cont'd)

HOT COLD

FILL

HOSES

U

RUBBER

WASHERS

I

STEP 4

WASHER ELECTRICALPREPARATION

1. if requited, an external grotmd wire

(not provided) which meets local

codes may be added. Attach to

washer cabinet with sheet metal

s(rew proxided in accessory bag to

rear of washer as illustrated.

ATTACHGROUNO WIRE

STEP 5

PREPARETO INSTALL WASHER

I. Be sine water suppl) lines hav{

been thoroughly flushed.

2 Mov( washer to lina! location

DO NOT iet fi[I or drain hoses d,ag

aud get under washer,

:< A@_st front levelirlg legs as

_ecessary to level wash_ r, Flont

leveling legs are adjustable; it

adjustment is necessary, relevel

The washer must rest tirmty on all

Inur legs. I'D *'set" rear selgleveliiig

system, tip _asher forward so that

rear base is about 4" off the floor,

theo drop

4. Instalt drain hose in chain facility

and secure wid_ plastic tic strap

provided or tape as illustrated,

NOTI'h l)rain hose nozzle may be

shorte_*ed if original l_ngtb prevents

full insertion into drain iacility.

= H

STEP 5 (eont'd)

DRAIN HOSE

RECESSEDPLUMBING

V

O_IAIN HOSE

CAUTION: BE SURE DRAIN HOSE IS

FIRMLY SECURED TO DRAIN

FACILITY.

5. Determine which is HOT wate_ line

befi)re Utaching till hoses _o

faucets. Traditionally, HOT t:mcet is

on the/eh. Be st{re rubber washers

are in end of both washer fill hoses

md connect hose fi-om right inlet

valve on washe_ (marked }lOT) to

}lOT faucet a_d left ho_e to COI,D

faucet. Couplings should be hand-

tightened pins 1/2 turn with pliers,

STEP 6

INSTALL DRAIN NOZZLE

I. Itlsert ntm end of a}umintnn drain

nozzle into standpipe

2. Slip o_ cm wu'e wrap back approx. 2"

beIow top o_ standpipe.

3 Cut drain hose just below standpipe

and slide over drain nozzle,

4. Attach silver hose clamp a_{d tighten.

ORAI_ _OSE

W_RE

WRAP

CAUTION: BE SURE DKAIN HOSE IS

TAPED OR SECURED TO STANDPIPE

OR OTHER DRAIN FACILITY°

NOIE: Water may be drained into a

standpipe. The discharge height must

not be less than 30 inches, Ho_ more

than 8 feet above base of washer,

S[a_ dpipe must be I-1/2" minimum

inside diamete_ a_td mnst be {)pen to

almosphere,

I Hill

Page 3

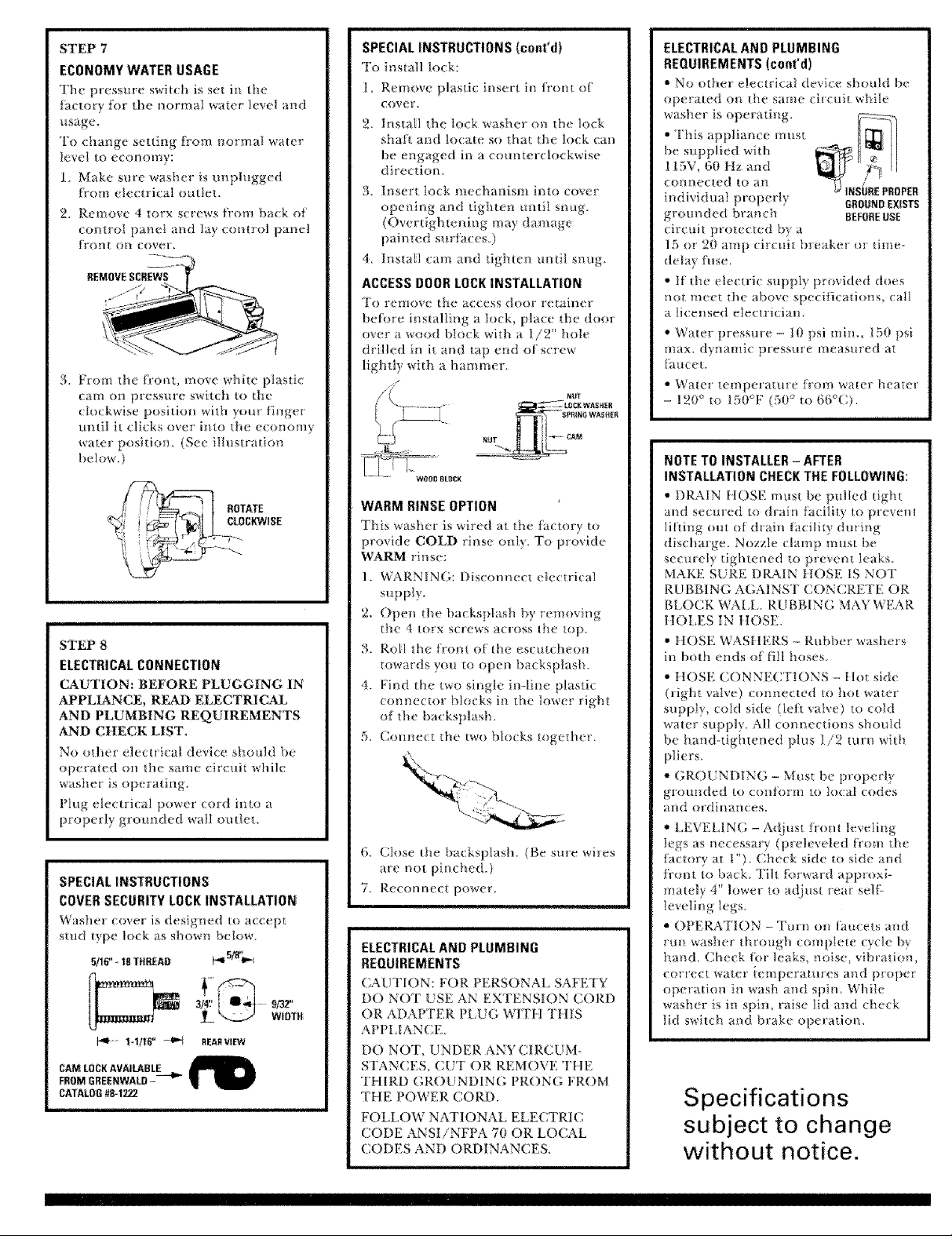

STEP 7

ECONOMYWATER USAGE

The pressu_e switch is set in the

iactory for the oormal water kwcl and

Hsage.

To change setting from _?ormal water

leve! to economy:

1. Make sure washer is unplugged

from electrical outlet.

2. Remove 4 torx screws fl'om back of

control panel and lay control panel

_:roilt O1| cover.

3. F_om the front, move white plastic

cam on pressure switch to the

clockwise position with your fiuger

m_til it dicks over imo the eco_omy

water positio,_. (See illnstr _tion

below.)

STEP 8

ELECTRICALCONNECTION

CAUTION: BEFORE PLUGGING IN

APPLIANCE, READ ELECTRICAL

AND PLUMBING REQUIREMENTS

AND CHECK LIST,

No od_el electrkal device should be

operated on file same circuit while

washer is operating.

Plug electrical power cord into a

properly grotmded wall outlet.

SPECIALINSTRUCTIONS

COVERSECURITYLOCKINSTALLATION

'Washer {over is designed to accept

stud type lock as shown below.

5/16"-18THREAD p,_5,_.,,._

l+l/lg _ -4_ REARViEW

CAM LOCKAVAILABLE

FROM OREENWALD---q_

CATALOG#8+t_

SPECIALINSTRUCTIONS (toni+d)

Fo install 1o k:

1. Remove plastic insert in frontof

cover.

2. Install the lock washer on the k_ck

shaft and locale so that d?e lock can

be engaged in a counterclockwise

d rectiom

3. Iusert lock mechanism into cover

opening ai}d tighten until snug.

(Overtigbtening may damage

painted surLaces.)

4_ Iustall cam and tighten until snug.

ACCESSDOOR LOCRINSTALLATION

To remove the access door retainer

before i_lstalli_g a !ock, place the door

over a _ood block with a I/2" hole

drilled in it and mp end of screw

lightly with a hammer_

.I _ _+SPFI+P+ _ WASP+ER

WODE_ ElL(_gK

WARM RINSE OPTION

This wasl+er is wired a_ the factory to

provide COLD ri_*se only, To provide

WAA_-M rinse:

1, WARNING: Disconnect (lectrical

supply.

2. Open the backsp_ _sh by removing

the 4 form screws across the _op.

3. Roll the front of the escutcheon

towards yo/i to open backsplash+

4. Find the two single in-line plas+ic

connector blocks in tbe lower right

of the backsptash+

5+ (onnect the two blocks together.

g_0_

6. Close the backsptash. (Be sme wi*es

are not pinched.)

7+ Reconnect power.

ELECTRICALAND PLUMBING

REQUIREMENTS

CAL!TION: FOR PERSONAI SAFETY

DO NOT USE AN EXTENSION CORD

OR ADAPTER PI U(', WITtl THIS

APPLIANCE.

DO NOT, LINDER ANYCIR(IM-

STANCES.(I I'ORREMOVETIIE

THIRD (;ROUNI)IN(; PRONG FROM

THE POWER CORD.

FOLLOW NATIONAL ELECTRIC

CODE ANSI/NFPA 70 OR LO<YL'_L

CODES AND ORDINANCES.

ELECTRICALAND PLUMBING

REQUIREMENTS(toni'd)

• No o_her electrical device should be

operated on Ihe same eirctlit wililt +

washer is operating.

• This appliance must

be supplied wlth

tlSV, 60 Hz and

connected to an

individual properly

grounded b_ancb

INSUREPROPER

GROONDEXIST5;

BEFOREUSE

circuit p_oteeted by a

15 or 20 amp circui_ breaker or time-

detay fuse.

• If the electric supply provided does

not mtet die above spe(ifieati{ms, call

a licensed electrician.

+ Water pressure - i0 psi n]iH., !50 psi

max. dynamic pressme llleastned at

t_uce t+

• Water temperature from water heater

+ 1_0 _ to 150+F (50 _ to 66+C}.

NOTETOINSTALLER+ AFTER

INSTALLATION CHECKTHE FOLLOWING:

• DRAIN IIOSE must be pulled tight

az_d seemed to drain ia{ility to I}tevenl

lifting om o} drain t+acili_y during

discharge. Nozzle clamp muse be

secure y _ightened to p,e_em leaks.

MAKE SI RE DRAIN IIOSE IS NOT

RUBBING AGA1NSI CONCRETE OR

BI,OCK WAId,. RIIBBING MAYWEAR

tIOLES tN tlOSE.

• IIOSE WASIIERS + Rubber washers

in both ends {if 1111hoses.

• ttOSE CONNECTIONS ,+ Itot side

(right valve) connected to hot water

supply, cotd side (Iett ,,alve) to cold

water supply. All conBections should

1)e hand+tightened plus l/2 turn with

pliers.

° GROt NDING _ Must be properly

grounded to conlorm to k}cal <+:{}des

alld olalinalices.

•' LEVELING - Adius_ irc, nt leveling

legs as necessary (preleveled tiom the

f:_ctory at t")+ {beck side to side and

from to back+ Tilt forward approxi-

mat{ly 4" lower to adjust _eat selt 2

tevelh_g legs.

• OPERATION - Turn o_* fat*eeLs and

run washer through compIele cycle h)

hand_ Cheek fm leaks, noise, vibration,

cnrrect water temperatures and proi)eF

operation in wash and spin While

washer is in spin, raise lid a+*d check

lid switch and brake operation

subject to change

without notice.

Page 4

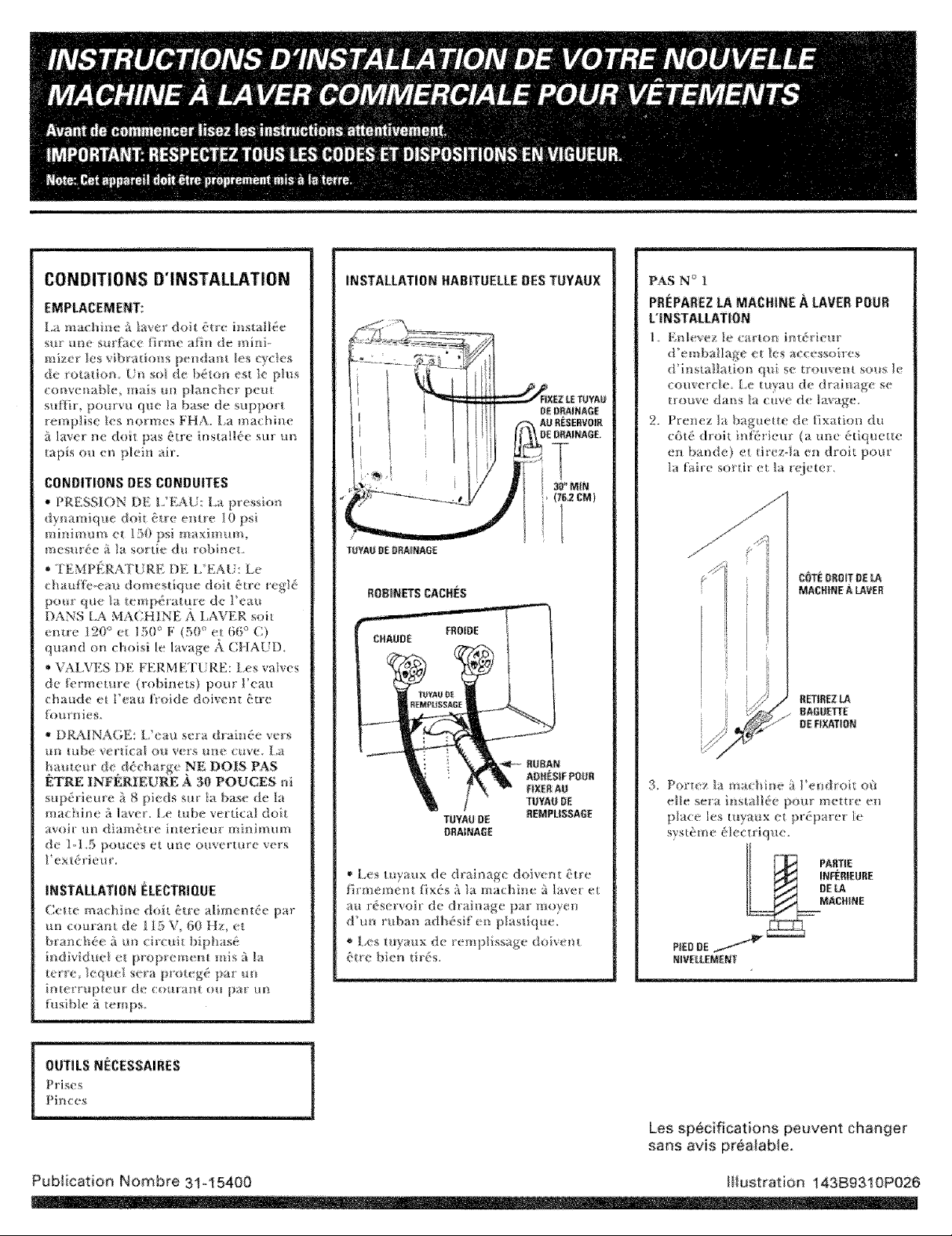

CONDITIONS D'INSTALLATION

EMPLACEMENT:

La maehne _'_laver (Ioi_ _*_+_in taJi_e

sur _me su_{ce fi_me afi+l de rob*i+

mize_/es vibration, s pro*dam les eyc_es

de Ro_afiom t2u so/de b_t<m est }e ph*s

co_we*_aMe_ mars u+_pla_cher peut

su[fi_, pomvu que l_ base de suppoN

remplise les normes FHA La machine

_ilaver ne dolt pas &ue installde sur m_

tapis ou en plein ah.

CONDITIONS DES CONDUITES

* PRESSION DE L+EA[ : La pressio+_

d}namique doit &+e em+e i0 psi

mh+immr_ et !50 pi maximum,

mesmg-e _ita so*tie d_ _obh_( u

*TEMPI_IRATUREDEi EAt+:Le

chauft_>e m d m+estiqu{ dolt {ire regId

pore' qlie _1 temp&a_t[re de Feau

DANS LA MACHINE A I,AVER soi!

enue 120_'et 1:>{! F (50 _'et 6{F C)

qualm on choisi Iv b_vage 2\_CIIAUD+

+ VALVI',S I)E t I'RME[( RE: Les valves

de fi:tm_:lm_ (robi_e_s) pour Feau

chaud{ et Feau hoide doiven{ &Ire

Iota'hies,

* DRAINAGE; I/eau sera drabtde _ers

un robe ve_+dcM o_i _ers une cm'e+ Ia

ha_aem' de ddch _rg_ .NE DOIS PAS

ETRE INF_RIEURE A 311POUCES ni

sup_'irieme 2_8 ph:ds sur la base de la

machi_+_ Ah_++Ia mbever_.icddoi{

l%*,t}il'/ttl dial[l{ lie iu[< iieur mhfimum

d_ 1_I+5 pouccs _t tree ou%e+mre _e+s

Fextdrieur.

INSTALLATION ELECTRIOUE

Cctt,, ma_:hine doh _'t_e alhrlc_de par

un couram de 1I5 V, 60 Hz, et

branch£'e it m_ circtfi_ bipha,_;i *

ir_dividt+el e_ t>roprem_ m mis i_ ta

te_re, lequeI se+a p+otegi _ pa_ _t*+

interr +pte/_ de em_ram on par tm

INSTALLATION ItAB|TUELLE DESTUYAUX

+ Les myaux de drai_age doiv( nt btre

fh meme,_t lixds :;ila machine ii laver el

au r_servoir de drainage par moyen

d'tm ruban adh¢°sif en plasfique.

* les t_._yaux de remplissage doivem

i'{re bie_ tirds.

PAS N ° 1

PFtEPAREZ LA MACHINE A LAVER POUR

L+INSTALLATION

d'emba/I_e et _es aeeessoi_s

d'ins_aliafio_ qu_ _ trouvem sot+s +e

eouverelie+ Le _t_yau de drainage se

t_ott_e darts Ia _lve (/_ lavage

2+ Prenez la baguette de fixation du

c6t(' droit itd'(,_+i< ur (a ut*e dtiqtmtte

en ba.de) et tirez+la en droit pour

la fahe sortir et la rt_ieter.

MACff|NEALAVEff

RETi8EZLA

BA6_ETTE

3, Por_ez Ix maehb_e fi Fe_droi_ of_

eife sera h*staIhSe pour mettre _n

place/es myaux et prdparer le

syst_me dlecu ique+

PA_+TJE

IDIF.EL2_|EUIIE

ACHINE

PIE0 DE

NIVEfllENEN_

i-u

OUTILSNECESSAIRES

J I'r+ e+

Pit/t?es

,,m, ............ i

Les sp6cifications peuvent changer

sans avis preaiabie.

Publication Nombre 31+15400 IHustration 143B9310P026

Page 5

PAS N_ 2

FIXATION DU TUYAU DE DRAINAGE

1 Enlevez ou le dispositi_

d installation de k_ t-m,e de lavage

2. [MPOR'IANT: E_devez |e bo_chon

rouge du myau de drai_age

(NOTE: H peut y avoir un peu

d_eau. C'est normal)

3. Fmuvez le petit adaptateur blanc du

tuya*_ de drab_age, hls{rez |a bride

d'attache de da_s te tuyau argeut(,e

bout d_ myau de drainage noir,

Embo_tez Fadapta_.eur dans le bout

eourb? _du mya-a et plaeez la b'ide

pow/ixer Fadapta_eur au myau de

dr _]nage Pot,ssez la bride d'a_tache

sm l'adap a_emZit sqtF5 ce qu eiie

rent_e _ans h_ _ainm'e.

(NOTE: [/km_ pousser eaergiquemew;

la bride d'altaehe lera un bruit

particulier quand elle aura _entv_ dans

la rai_m_ e.)

BRmDElYATrACRE _._,%

DOTOYAO

PAS N ° 3

FIXATION DESTUYAUX DEREMPLISSAGE

L lns_rez les rondelles en p/a_th_ue au

_empHssage, A_co_ p ez h_ tu_au de

rempliss _ge marqu{ avec ]e mo_

CItAUD a la vahe d_{ ire de

tempiissage de ]a machine a laver,

et le myau FROID fl ]a vahe gauche.

i_e serrage se_a fail a ]a main, plus

un demi _ot_r avee des pinees.

PAS N _ 5 (CONTtNUATTION)

oHt ajustables R_ites le

ni_eliement n/'cessaire. La machine

fi laver dolt s_ap myer lirmemen_

s_r hs q_a_re pieds_ Pour

"d_clencher" le svst_me posWrh m"

d'amomiveilement, pe_d ez _a

machine {_ avam,jusqu'k ce que ]a

pattie postdriem_e de la base soil fi

4' environ du sol et ]ficbezda

4_ Aecouphz le tuyau de draim_ge au

rdse_voir de drainage et fixez le

avec le _uban adb_sK inclu, eomme

iIh_s_r/' dans Ia figure.

NOTE: Lc coade du myau de

d_ainage peu_ 0ire _accourcie s la

[ongue_ origi_ale r_e permet pas de

I'i*_trod _h'e compl_temer_ darts _e

r4sm _oir de drainage.

NOTE: Si le tabe vertical pour le tuyau

de drainage n at_eim pas les 30"

minimum de hamem-, _ntrod,aisez/e

myau de d_ainage _ Uavers Fagrafe

am.i--sbipo*_ inch_e dans le sac

d aee_ssoires et accrochezole darts la

parvie post rieme de la machh_e,

comm_ illustr4 dans Ia figure.

PAS N c 4

PREPARATIONELECTRIQUEDELA

MACHINE A LAVER

1. Si] le taut, on peut _]outc_ m_ cSb]e

de raise fi la terre (pas indus), qui

remplisse Ies _ o_mes locales.

Fixez-le a la pattie posl:driem'e de la

machine avee/a vis e_ plaqt_e de

mdtat incIue dans te sac

d'aec_ssoires_

_:IXEZ_ ga_L__E_S A

PAS N o 5

PREPARAT|ONPOURINSTALLERLA

MACHINE A LAVER

1. V&'ifiez que les co*Muite_

d'alimemation d'eau soiem

completemem vid/-es

2. Amenez Ja machine i_laver fl son

emp_acemm_t d{fhfiti£ Faites

attention que les myau× de

TRAINENI'P\S{t _erestentpas

coblcds au dcssous de h_ machin< fi

laver.

S'H le t_m_, r{'gk z les pieds de

niveJiement du Iront de la machine.

Les pieds de ni*_ ]h me_ dt_ front

_JYA_ DEDRAINAG[

R0_INETS CACHES

. BUBANAEIHESJF

POURFIXERAU

TUYAU0E

AEMPUSSA_E

TUYAUDE

ORA_NARE

KUFENTION: VER1FIEZ QUE LE

TUYAU DE DRAINAGE SOIT

FIRMEMENT FIXI); AU RESERVOIR DE

DRAINAGE,

5, lde_tiiiez quelle est la sortie d'eau

( ttAUDE avant d'accoupler _es

tuya*_x de remp/issage aux robinets

Er_ g4_g'ral, le robinet d'eau

CHAUDE se trouve i_gauche.

Vdrifiez que les rondeiles en

plast_q_e soient at_ bota des deux

tuyaax de _emplissage et aeeo_,_plez

e myat_ de la valve droite d emr/'e

de Is machhle fl laver (marquee

CHAUDE) au robinet &eat*

CIIAUDE, et Ie myau de gauche au

robir_el deau FRO1DE, Le serrag_:

sera tail fl ]a main, plus tm dcmi

tom avec des piuces

I'lll'llll¸ II II!!!!

PAS N <_6

INSTALLATION DU C01t/DEDE DRAINAGE

] lt_tro(h_isez mI de t}o_._{gdu eoude

de dra Base en alumiuium duns *e

tube vertical

2, Poussez en arri&re ou coupez le B1

miq:aiIique de garniture environ 2

er>dessous de ]a parfie supdrieur du

tube vertieai.

3, Co_lpez le tuyat de drai_age juste

el* dessot_s de tube ver_icale, Ptae{ z

la bride du tuyau arger, ff.e sur le

bou_ Imire du tuyatL

4, tnJ, rez Ie eonde tie drainage daus Ie

bov, t de myau de drainage et ptacez

la bride pore _ixe_ ]e eoude de

drainage at_ tuya/_ de drain*age.

TUYAU DEDRAINAGE

NFFENTION: VERIFIEZ _UE LETUYAU

DE DRAINAGE SOIT FtXE PAR MOYEN

D'UN RUBAN ADHESIF OU AUTREMENT

AU TUBE VERTIC_4LO/5 AU RESERVOIR

DE DRAINAGE QuI SOFF UTII.ISfL

NO_IE:I ea_setadrai_deversm/ tube

vertical La hauteur d'dvacuation _e

dolt pas #:Ire inIi?rieure a 30" ni

supd*ieure a 8 pieds su Ia base de la

macbiu< _'tlaver, [e tube vertical dolt

avolr tin diam/:t_e h_tiT_iem mb_irrmm

de I I.5 p<mces e_ doi_ avoir nne

omertu_e vers Fext<;riel_r.

PAS N ° 7

USAGEAVEC ECO{'_0MISAT|ONO'EAU

I/imelr_pteur de pressim, a 4t& fixd 5.

la _abriq_m pour le l@,,e m e_ usage

nor mallx d'eau

Pm_r changer du lfi_eau t*orlllal d'ea!l

aH I_livea/t d'('co_lol_ttie;

1. _,_rifiez qv)e }a machb)e a laver n<:

soit pas b) inch&: i_It p_ise,

3, Dans ]a partie hontale, tournez a_ee

h: doigts la came en plastique blame

sur I'iuteHv*pteur de presion da_s le

se_ls des aigtfilles de l'ho_/oge

jusqu*5 ee qu'eIle arrive g la

pos lion d'dco_omie d'eau et _hse

tm dick. (Voil Ia rlgure ea has,)

PAS N o 8

CONNEXION ELECTRIQUE

ATTENTION: AVANT DE BP.ANCHER

L'APPAREIL, LISEZ LES CONDITIONS

ELECTRIQUES El" DES CONDUITES

ET VERIFIEZ-EN LA LISTE.

Aucun apparel! dolt f,tre branch¢, au

m6me circle t pendant que la machine

laver soil en op_ratiom

Le eSbIe <!'lectrique doit _*'e branch(- _

role prise qui soil p_op_eme_t mine it Ia

tel're.

lnstalJatiol* de ]a serrur{

1 Fnhvez l'eneart el_ plastique du

froll{ flit <'o/lverc!_

20 h_s(_Hrz_a rol_delle de !_ ser>_re

dale Parb_e de la ser_/re ([ plaeez4a

de telle sorte que la se_rure puisse

tourl/er dans le sells des aiguilles de

I'horloge.

3. P/acez le m&a_fism< de la serrure

dai_s |e couverck, en Fouvrant et |e

ser_amjusqu'a ce q_il soil aiust&

(t sm rage e×e{ssi[ peut abimer/es

surfaces pebbles )

4. lnstaIlez la came et serrez-la ]usqu'fi

ee qi/elle soit.juste.

INSTALLATION DE LA SERRUREDE LA

PORTED_ACCES

Pout eulever I'_idmem_ de fix'ation de

la porte d'aeebs avant d'ir_staller la

selrme, ptaeez la polte sur un bloc e!l

buis dora on aura per_brd un trou de

05", et tapez y doueeme_t avee tm

marteatL

ER _O_S

22Z22--Z2_/ 222 21 2 ,U_2P2X222

INSTRUCTIONS Spt=CIALES

{CONTINUA_t0N)

OPTION DERIN_AGE ,'_C_AUD

Cette ma_ hiuc ii laver a (:t_' preparee a

Ia f_/briq_e pour iafre seulement du

5 FRO1D Pore obterH_ m_

rincage fi CHAUD:

1. ATIEN2ION: Ddb_anehez

5. Bra_;c}lez les deux e_d:}es.

6, l;erm_z It pamieau. (%{_rifiez que te

cRbles _le soietu pas pine&0

7. Bial_ct/_ z ]a machine _ la prise.

CONDITIONS POUR L'INSTALLMION

ELECTRI_UE ET DES CONDUITES

ATTENTION: POUP. VtYFRE

$142CURITt!; PERSONH,LE:

CET APPARE1L NE DOFF PAS 12_FP.E

UTILISI_2 AVEC D'EX'I ENSIGN

[_it EC_I RIQL E NI D'ADAPI'ATEL R D|

PRISE

POUR AU(UN MOTIF NE CO[_PEZ NI

ENLEVEZ LE TROISI]_?,ME DEN2' DE

MISE .,_ LA TEP.RE DE! (_,BI E

RESPECTEZ I.E CODE |_;LE{:TRIQt E

NATIONAi, ANSi!NFPA 70 O[LES

CODES ET ORDONNAN( ES

LOCAUX.

• Auetm appareil ne dolt ;.:,{)ebranchd

au mi*me <ireuit pendar)t que la

maehi_le _ilave_ soil eu op/,ratioll.

• (eitl _lla(}iiile doE{ 7_-_-_7

dire alime_t/Se par un

comant d{ i 15 V, 60 l/z, '_,

et brant:hi,{ fi un circa*it _ i:i'-'_

biphasd indi_iduel et

i

AVANT B'_TILIgE_

UAPPA_EI[ VI_tFIEZ

pH teg_ p_r tm.

interr/_pteur de eom'a_t ou par un

f'usible a temps

• Si votre h_stallation dlectrique ne

remplit pas ces eoi_d[dons, eousultez

un 61ectriciea quali_i&

• Presskm de l'eatt: I.a pressiim

dynamique dolt d-_re entIe i0 psi

l)til]i]rr_[llll et t50 psi maximum,

mestlr(:e £_ta sortie du robinet,

, Tempi_ramre de Peau: A_la sortie

du ehau_fe eau: /20 '_et/50 ° F (50 ° et

66 :_()

'1¸ I

Page 7

NOTE POUR UtNSTALLATEUR,

APRESL'INSTALLATION VERIF|EZ LE

SUIVANT:

" I_e myau de d_ainage dolt _tre bien

tir_ el firmeme_ fixf_ au _4servoir de

d,'ainage pour (:viter que !e rdservoir se

dg_tache pendant la d6charge. [a bride

d'attache du coude dolt Etre bien

serri, e pore" {'viter des fuites d'eau.

VERIFIEZ @'IL N'YAIT PAS DE

FRICTION ENTRE I,E TUYAU DE

DRA1NA(;E ET I.E M[R. |A

l R1C[TION PEUF PROVOQUER

1F(){VEgI'{ RE DE FROUES DANS

I,E TU_L,'x[ .

• RONDELI.ES DES 'FU_%UX: Les

rondelles en plastique doivent fitre an

bout des tuyaux de reinpHssage.

* CONNEC'I !ONS DES TUYAI_X: La

valve d'eau chaude (droite) accoupld.e

a la sortie d'eau chaude; la valve d'eau

fro/de (gauche) accoupl4e a ]a so_tie

d'eau froide. Tousles serrages doivent

{_t_'efairs :'_la main, plus un demi tour

avec des pinces.

, MISE A LA TERRE: La machine dolt

_ue proprement raise h la terre pour

respecter les codes et ordonnances

locales.

* NIVELLEMENT: tes pieds de

niveIlement sont fixg,s ;t la fabrh]ue _'_

1"; s'i! le faut, rb.glez-tes. V&'ifie:, le

niveIleme,_t _-ontale el lati'rale.

Pe_ehez la machi_ie en avant environ

4" pour d{.clel?cbe_ le syst_me

prostdrieur d'automivetlemeJat.

• FONGTIONNEMENT: Onvrez les

robinets et taites tHle rotation

comph'-te fi la maim V_rifiez qu'il n'y

air pas de fifits d*cau, du bruit ou des

vib, ations; r_gIez les temp_ratures de

Feau et ve*ifiez que k: lavage et les

rot.atkms soie_/t corrects. Pendant que

Ia machine est en op6ration, ouvrez le

cottvercle et verifiez ie _[(tllel;iol/-

heine*it de l'interrupteur de main et

automatique.

Les specifications peuvent

changer sans avis prealable.

Page 8

REQUER|MIENTOS DE

INSTALACION

UB|CACR_N

E1 lavarropas se debe_fi instala_ sobre

un piso filme con el objeto de

minimiza* las vibrado_ms durame los

ciclos de cemrilhgado. 1.o meiov es un

piso de concreto, per(} una base de

madera bastar_i, siempre y cuando

dicba base {st4 de confl}rmidad con ]as

normas de la FHA. E1 lavalropas no se

deber_ instalar sobre alfombras ni

tampoco deber;_ estar expuesto a ta

intempcrie.

PLOMERiA

* PRESION DEI, AGUA _Deber_ ser de

tm _:_i_fimo de t0 psi, y de un m_xinm

de 150 psi, de presidn dinfmfica

medida en eI grifo.

* '1EMPERJ_ I'UI_L/'_DEL AGUA - La

caldera de la casa se deber_ _justar

para proporcionar agua a una

temperamra de 120 ° a 15W F (50 ° a

6{5° C)EN EL LAVARROPAS para las

ocasiones en las que se selecciona el

cido de lavado CAMENTE.

* V_,{LVULAS DE CERRE - Sera

necesario proporcionar las v_Ivulas de

cierre (g*itbs) tango de agt*a frfa como

de agua caliente.

',, 1)t, A( [t_- El agua se puede

desaguar tanto al desagfie como a tma

cubeta f_a. la ahura de descarga NO

DEBERA ESTAR POR DEBAJO DE LAS

30 PULGADAS, y tampoco a mils de 8

pies pot eneima de la base de la

lavadora. El tubo vertical deber,4 comar

col* tm difimetro interior ndnimo de

1-1/2 p_figadas y deber_ esta_ abierto al

medfo ambiente,

INSTALACR}N ELI:CTRICA

Estc aparato electrodomdsfico deberfi

tene* un suministro de 115V, 60 Hz y

debe_fi esta* t onectado a un circuito

derivado individual con un sist( ma de

ti<r_a adecuado, p*otegido con un

disyuntor de 15 6 20 amperios o a tma

espoieta de tlempo.

HERRAMIENTAS NECESARIAS

Jnego de casquillos

Pinza _justabie

INSTALAC|OFtES TiPiCAS DE MANGUEI1A

MANGt/ERA DE DESAGI)E

PLOMERJAEMPOTRADA

FI3E ALA

LLENADO

MANGUERA DE

DESAR{}E

* Las mangueras de desagiie se deberfin

fijar firmemente al hvarropas y a la

instalaci6n de desagfie con una

liga(h_ra de plfistieo o cox, cinta.

,, Las conexi(mes de la mang/m_a de

llenado deberffn estar ap_etadas.

Las especificaciones estan sujetas a

cambio sin notificaci6n previa,

Pub. N6m, 31-15400 Itust, I43B9310P026

Page 9

PASO 1

PREPAREELLAVARROPASPARAEA

INSTALAC|6R

1. Qui_e el empaque imm'ior de cart6_

y saq_e los accesorios de insialaci6_

que se encnentrarl por deb_0o de la

tapa [a manguera de desag_e se

e_]c,,_e_tra dentro deI ces{o de_

iavarropas

2. St{iete la barra de retencidn que se

encuentra del Iado derecho int[k'rior

(_iene una etique_a er, la correa)_ y

tire y saque la barra y des@chela.

tAD0 0ERECH0 DEL

LAVARROPAS

QUITELA ttAJgRADE

R_CI6N PAPA

EMSARQUE

3_ Ileve el lavarropas a! sitio de la

ir_s[alaci6n para seguir adela_te co*_

la preparaci6n de mangueras y de_

sistema el@ctrico.

t _ PAlaTE|NFERi0R

I_VARROPA$

..2-

PATA_

NJVElaetDORAS

__ rmT

PASO 2

COLOCACIONDELA MANGUERA DE

DESAGOE

I_ Saque todos los artN_dos de

il_sialaci6n de] cesto del lavarropas_

2. 1MPORTANTE - Q_ite e/tap6n rRjo

de1 puerto de _a mangaera de

PASO 2 (CONTINUACi6N)

3. Encum:t_e e_ adaptador (:otto de

pISstico btanco para la mangtmra

( oloque Ia abrazadera de [esorte

plateada eJ_ el extremo de la

ma_lguera aegra de desagiie, lr_serte

el adaptador de ia mang*_era de

desagfie aI extremo acodado de _a

ma_g_era de desag_m y co_oqne Ia

abrazadera para f0ar el adaptador

de ia mangt_era a la ma_g_era de

desagfie, Empnie ta abrazadera de la

mangtm_a de desagiie de pl_stico

por e_cima de adaptador de ]a

ma_g_mra basra que erme en la

ramara aca_alada

(NOTA: Esta _}staIacidr_ req_iiere de

urt poco de fuerza y se esct_cha un

son|do posi{ivo cuando e_ma a ia

ran_ra.)

AS_E_ tie I/t _

MARGLtE_

ADAPTAD_3R_E

LAMANGgE_A MAR_UEF:A

4.

lnserge el extremo c6niCO de pl_stico

OE _}ESAGUE

blanco det adaptador para ]a

mat_guera de desag_e ea e_ puerto

papa la manguera de desagiie de1

lavarropas Inserte _oa do_ {o_n [_os

*_egros q_e _ e_cuemran en ei

paqtie_c de insta_aci6_ y a_o:n_lle:os

para montar [a manguera de desag_e

e_ el lavarropas.

PASO 3

COLOCACI{}RDELA MANRUERA OE

LLEI'{ADO

1. [nstale las arandelas de caucho en

ambos ex_remos de cada tma de las

mang_mras de llenado, h_stale la

ma_gue_a de _le_ado de_omi_ada

HOT (CALIENTE) en _a v_lvula de

en_rada e_ el costado derecI_o del

lavarropas. I_s_ale la mapguera

denominada COLD (FRIA) en la

vkIvMa de entrada en eI costado

izquierdo del tavarropas. Los

acoplamiemos se debergn apretar a

maao y co_ 1/2 giro adidona!

mi|izm_do p _zas

PASO 4

PREPARAC|{IN[}ELA|r'/STALACI_N

ELECTR|CADEL_VARROPAS

1, En caso de se_ necesario, se pt*ede

agregar ur_ cable de tierra exte_no

(no inclu]do) q_e cm_p[a co_ los

cddigos k)cales_ Fijelo a| gabirlete

trasero de1 lavarropas con e_

tornilIo de ¢}_apa metSlica que se

proporcio_a ea la bolsa de

accesorios, CofIto se mucstra 01_la

ilustrac}dm

|NSTALE El. gA_ DET|_R_A

_OI_TENfiALOE_ SU

(NOTA: Es posib]e qtm encucntre u_

poco de agna, esto es _lormaL)

NOTA: Si ta ir_stalacidn para la

mange*era de desag_;,e no c_mple con

_os requerimie_tos de aimra minima

de 3&' papa el t_bo vertica!, pase I;i

mm_guera de desagiie pot ia

abrazadera m_tisif6n que se

proporciona y m&_tela er_ la parte

trasera del gabinete, Como se m_estra

en Ia ih_s_raci6n.

Page 10

PASO 5

PREPARELA |NSTALAC_ONDEL

LAVARROPA$

I Verifiqm" qu< haya corrido agua pot

los ducvos de sumi_s_ro de agua

para q_e est&_ totalmen e Iimpios,

2. Co_oque el Iava_*_pas en su

ubicaci6_ definitiva. NO permita

que las ma_g,,eras de lIenado o de

desagik se arrastren y que queden

p{_ d< baio del lavarropas.

3. _i_ste las patas r_iveladoras

deiameras co_?iorm< sea necesario

para _ive/ar el lavarropas. Ias patas

niveIadoras dela_teras son

air stables; si es necesario m'_ *_}tste,

w_elva a nivela_las. El lavarropas

deber:i desca_asar firmeme_{e sobre

_a_ c _atro pata Para "@as_ar" e}

sistema de nivetado {rasero

au/omvitico inclb e e! Iavarropas

hacia adela_te de taI manera que la

base est" a ima distancia aproximada

de 4" de] piso y despu0s d(_}eto caet

ha{ia su h_ga_,

4. hs{ak ia mang_mra de desagiie e_

la b_smiaeidn de desag/ie y ffiela co_

Ia abrazadera de phis_ c< hac/_ida o

CO_I {_glta, C01110 se _le ira el? la

ih, s ra_ idn

NOTA: I,a boq_i la de la manguera de

desagfic se puede acortar si el largo

original no permite _ma instalaci6_?

compteia e_ la ins_alacidn de desagfie.

PASO 5 (CONTINUACION)

5 EstaMezca emil e_ e/grifo de agaa

CAL1ENTE a_es de _!}a_ las

_ ang_m_asdeHe_adoalo gri_s_

Po_ to ge _eral, e g_ifi> de agua

CA1 IENFE se encuentra det tado

izquierdo. Verifiq_*e qx_e Ias

ara *delas de cmcho es_{:_ colocadas

en los extremos de ambas

ma_gueras de llenado y conecte la

manguera de la vfilrtlia de erm ada

del lado derecho del lavar_opas

(de_mminada HOF (CALIENTE) al

g_ifo de agua CAL[ENTE y }a

manguera _!el lado izq_ierdo al g_Ko

de agua FRIA. Los acopla _ emos se

debergn apreta amanoy

posterio-_mente {on //2 gi_o

PASO 6

INSTALACI0N DE LA BOQUILLADE

DESAGOE

t, h serte tm _:xtrcrrm de Ia boq_illa

de desagg_e de ahm_inio en e1 mbo

vertica.

2. Destiee o recorte la abrazadera (e

metal apmximadame ,{e _'* po_

deb_{}o de la par{e s_perior del tub<

verdcaI

3. Corte la manguera dc desagfie

aproximadamente 2 ptflgadas ius{o

pot deba:jo del ttd)_ verticat y

col6quel la ab, azadera ptateada por

e_*cima de! extremo neg*o de }a

mangnera de desagfie.

4. tr_serte la bogui la de desag{ie en el

extremo de ia ma_ gwera de desagih

y cologue la ab_azadera para ti)a_ la

boq_511a de desagfie a la mang_mra

de desagfie.

PASO 7

AHORR0 DEAGUA

El ir_err*_p_or de prcsi(m cs_g ;_i_slad

en la fiibrica para propo -_ionar _m

hive! y <_sonormal de ag_*a

Si desea cambiar el _}us e de t_so

norm_ I de ag*t_ a aho'_o de agna:

1, Verffique que e1 _avanopas este

desco_lectado del tomacorrien_e.

2. Quite los 4 {Oln_Ilos de torsidn de la

parle _rasera del panel de control y

coloq_e el panel de c<mtlol e_cima

de la tapa det lavarropas.

3. Desde el f'rente de la unidad, gire,

atiliz _ndo st_ dedo, la leva d(

pt_s_ico banco q_m se e_ct_erara

e_ et inter_p_o_ de presidn, _n ia

di_e_cidn _e ias ma_eeiiias deI

r{h_i _as_a q_*e entre a la posicidn

de ahorro de ag_*a. (Consul{e la

ih_straeidn que se prese_ta a

con tin_aci(h*.)

MANGLIE_ADE0E_;AG_E

PLOMERiA EMPOTBADA

FJJEA LA

LLENA00

MAN_3E_ADE

ADVER'I EN( IA: VER1FIQUE QUE I,A

MANGUERA DE DESAGUE ESTE

F!JADA FIR_HSIMENTE A [.._}

INSTALACION DE DESAGUE

Illll I!lIll

INSTRUCCtONES ESPECIALES

INSTALACION DE LA TRABA DE

SEGURIDAD EN LA TAPA

[.a _apa d_I h:varropas se dlsefi6 para

inchfir nna traba lipo p_ 111o, ¢*)111o se

muestra en ht ih/straci6n,

ROSCADE5/16"* tB _ s_l_

ANCHOOE

9_2"

t-1/t6" *_ VISTA TRAS_;RA

0PCIONALTRABA

DE_VA COBTE

GR_ENWALD# [!E

CATALOGO8.1222 TRABADELEVA

Para instalar ht l.raba:

1 Quite la guar_ficidn de pl_stico que

se etlcue*_tra en la parte dela_Uer _

de Ia tapa.

2. Instale ]a arandela de seguridad en

el 1_: de ]a Iraba y coldqueia de ml

malle_a que }a traba se pueda

acciolml en ta di*ecci61_ comraria

a Ia de las ma,_edllas de1 reloi.

3. lnstale el Inecax:ismo de la traba en

la abertura de la tapa y apridtelo

basra que quede f!jo_ (Si Io aprieta

cn exceso puedc calzsarle danos a

Ias superficies pintadas.)

4. lnstale la leTa y apridtela basra que

quede [_ja.

INSTALACION DE LA TRABA EN LA

PUERTA DE ACCESO

Para quitar Ia rete,_ci6n de la puerta

de acceso antes de instalar tma traba,

coloque Ia pucrta { ncim _ de un

bioqut de madera con m! hovo de

1/2" ml el mismo y goipee

Iigerameme el extremo de! tor_illo

(OPi /li/ mariillo.

IUERCA

TU{RgA i_gA

INSTRUCCIONESESPECIALES

(CONTINUACION)

3. Ruede la parte de/antera del

escud{ te de cerradura hacia Usted

para abrir el tablero de soportc de

los disposiiivos de conlroi.

4. l,o(:alice ]os dos bloql_es de

empah]le para l_I_e ft.|ca de

entrada de pl_s_Jco que se

encuenttTa_l en et costado derecho

inferior de] tablero.

5, Conecte lm bloque aI otto.

6 CieM'e e! tablcro dc so|)oltc dc los

disposhivos de {:ontrol, (Rtvise que

los cables {]o cstdn p_c_:sados.)

7. Vuelva a co_cctar el suminist_o,

REQLIERIMIENTOS ELECTRICOS Y DE

TUSERIA

ADVERTEN(2IA: PAR_ SE(;URIDAD

DEI. PERSONAIo, NO UTII ICE UN

(ABI_I( DE EXTENSI£)N NI UNA

(:[.AVIJA DE ADAH ADOR (:ON ESTE

APARA'IO ELECTP.OI) O M I_2STI{20.

NO DEBEILk, POR NiNGUNA

RAZ(}N CORTAR {3 EIJMINAR EL

"IERCER POSTE DI TIERRADE |A

( LAVIJA DEL CABLE DE

SUMINISTRO.

C[JMPI A CON IAS DISPOSICIONES

DEI (161)IGO DE EI,ECFRICIDAD

ANSI!NI,'PA 70 6 CON LOS

C()I)[(;OS Y ORI)ENANZAS

MUNICEPALES EN VIGOR,

NOTA PARA LA PERSONA flUE INSTALE

LA UNIDAD - VEFUFIQUE LOS SIGUIENTES

PUNTOS DESPUES DE CONCLUIR LA

INSTALACI()N

• LA MANGLIEIL'k DE I)ESAGt_'E

debe (_esta_ estirada y fijada a la

i_]stalaci6n de desag(ie para prevenir

que se levante y se salga de la

insmiacidn de desagfie durante la

desca_ga de agua. La abrazadera tte la

boquitia deberS, estar apretada para

evitar fugas. REVISE QUE LA

MANGUEI_k DE DESAGUE NO ROCE

CONTRA CONCRETO O

CUAI,@JIFR TIPO I)E MURO,

DICHO ROCE P/EDE DESGASTAR

LA MANGUERA IIASTA CREAR IJN

A(;_[IERO,

• ARANDELAS 1)E I,AS MAN(;UERAS -

Arandelas de caucho en ambos

extrelnOS de las ma_igtleras de lie_ado.

• CONEXIONES DE LAS

MANGUERAS - Lado de agm_ caliente

(v_ilvula derecha) concctado aI

sumi_istro de agua caliente, lad() de

agua fr{a (v_dw_Ia izquierda) {'onectado

al suministro de agua fffa, Todas las

cot_exiones se deber_].il ap_eta_ a mare)

> posteriorme++[e {+>t] I/2 gh+o

utiliza_do ph)]as+

" TII';RRA - El apara/o (teber5 coil*at

{'O12 t1II sis|cilia d( {iCFi+a ;I{[eCI1;It_[O COI1

el o_)}etu dc ( umplir con todos los

c6digos y tas ordemmzas muni{ipales

en vigor.

• NIVEI ADO - _}uste ]as paras

nivelad(nas delanteras, niveladas en ia

ff_b] |ca a t 2 {:o_ll{_I Ille sea rlecesario,

Ver_[ique et nivelado lateral, y del

fr(llte y el {rase*o, /ncli_*e eI aparato

hacia adela_te aproximadamemc 4"

para _jusmr Ias paras traseras de

nivelado auroral*rico,

• OPERACI(')N - Abra los grilos y {:orra

un (i{lo fetal {t1"1hw;n ropas a mano.

[_,{'%ise qtl(* 1io ¢.+XiS{_tIi {'tightS, VIIi(tON lii

vibracioncs, y ,evis{. quc ]as

IeIllpl'ratllraS tic ag/ta s{!all las

correctas y {ILte la unidad {LiIl{ iollc

correctamente dmante los ciclos de

lavado y cemrifugado, Cuando el

lavarropas es_e cn el (:iclo de

cemFifugado, levani_ la tapa y Fevise el

inleHupto+ de la [apa y ta operacidn

de flemido+

OPCION DE LAVAD0 CON AGUA TIBIA

Este lavarropas ticnc circuitos

inslalados en la f_brica flnicament_

para proj)c,/Tional ml eqjt_ague __o_i

agua FRIA Si des{-a cnjuagar c{m

agua TIBIA:

1. AI)VERTENCIA: Desconecte et

aparato del tomacorriente.

2. Abra el tableio de soporte de los

dispositivos de control quita_,do

los 4 tor_il_os de torsi6n que se

eJ?cue*uran en ta parte superior

deI tablero.

CAMBIO SIN NOTIF[CA( |ON PREVL.\

TESPECIIqCi'_CION ES SLiJ E'IAS A

Page 12

SPECIFICATIONS SUBJECT TO CHANGE W_THOUT NOTICE

IIII

Loading...

Loading...