Page 1

GE

OUT

INT

OFF

LOOP

PWR

READ

EXT

UPS - II

mA

%

*

VALVE

LIN

FLO

W

%

M

A

STEPS

FIXED

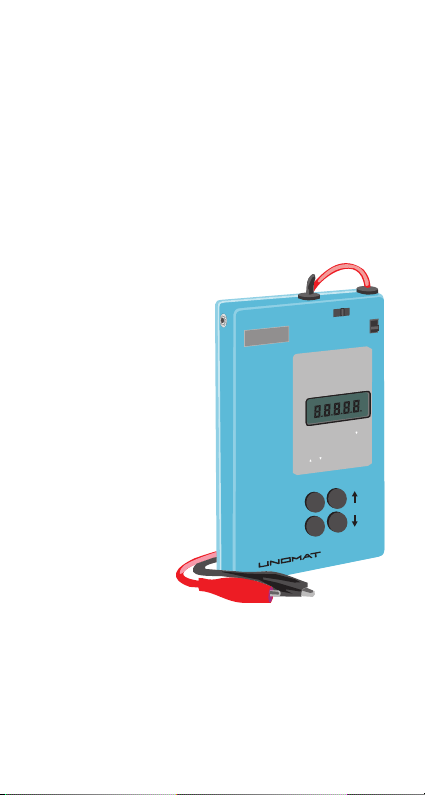

loop calibrator

RANGES:

OUTPUT& REA

D0 - 22.2 mA

PRES

S* 2 SEC.

TODISPLAY MENU

SCROLLFUNCTIONS WITH KEY

PRESS* TO ENTER FUNCTION

PRESS* TO SELECT FIXED STEPS

USE OR TOADJUST OUTPUT

a

Druck

a

ADruckCompany

Sensing & Inspection Technologies

Druck UPS-II

Loop Calibrator

User manual - K0434

Page 2

Approved Service Agents

For the list of service centres visit our web site:

www.gesensinginspection.com

Symbols

This equipment meets the requirements of all

relevant European safety directives. The

equipment carries the CE mark.

Do not dispose of this product as household

waste. Use an approved organisation that

collects and/or recycles waste electrical and

electronic equipment. For more information:

Contact us at www.gesensinginspection.com

This instrument is fitted with four size AA batteries either

rechargeable (nickel cadmium) or non-rechargeable

(alkaline).

Before storing this instrument remove the batteries.

When fitting batteries make sure the electrical contacts are

clean and observe the correct polarity.

The battery compartment should be inspected for corrosion

caused by leaking batteries. Corrosion must be removed

using approved methods*.

When storing and transporting batteries make sure that they

cannot be short circuited. A short-circuited battery can

become very hot and can, in certain circumstances, explode.

It is recommended that a suitable container is used for

storing and transporting batteries.

Dispose of old batteries using a safe, approved method.*

*Refer to the manufacturer for this information:

© General Electric Company. All rights reserved.

Battery Safety

Page 3

Introduction

The Druck UPS-II Loop Calibrator can supply power (source

mode) and produce readings (measure mode) to perform

field calibrations on 2-wire devices.

Operation

For different applications place switches in position as

indicated below:

MODE OUT READ EXT. INT.

Milliamp. source • •

Transmitter sim. • •

Milliamp measure • •

Transmitter cal. • •

(transmitters are 4-20mA 2 wire)

The UPS-II has special functions for fixed steps and readings

in %. To open menu press

contents with key and make your choice. Press

confirm your choice.

MENU CHOICE SWITCH DISPLAY READING IN:

4-20mA lin # out 0 to 22mA or % span

0-20mA lin out 0 to 22mA or % span

4-20mA flow out 0 to 22mA or % span

0-20mA flow out 0 to 22mA or % span

4-20mA valve out 0 to 22mA

4-20mA lin # read 0 to 22mA or % span

0-20mA lin read 0 to 22mA or % span

4-20mA flow read 0 to 22mA or % span

0-20mA flow read 0 to 22mA or % span

Note: Functions marked with # are directly available after

selection. Flow = SQ.RT in %.

Press mA/% key to read in mA or %. Press * to select

"continuous" or "fixed steps" in output mode.

Fixed Steps

To output fixed calibration currents in series as indicated

below: choose range from the menu and select "fixed steps".

Press or to advance one step

4-20mA lin# 4 - 8 - 12 - 16 - 20mA

0-20mA lin 0 - 5 - 10 - 15 - 20mA

4-20mA flow 4 - 5 - 8 - 13 - 20mA

0-20mA flow 0 - 1,25 - 5 - 11,25 - 20mA

4-20mA valve 3,8-4-4,2 - 12 - 19 - 20 - 21mA

* for 2 seconds. Scroll menu

* again to

out

or

read

1 K0434 Issue No. 2

Page 4

To output these currents automatically select "fixed steps"

and press keys simultaneously. Time between steps is

10 seconds. Stepping starts at the low end of span.

To return to manual press or .

Valve mode

In the valve mode, stepping will be 3,8 - 4 - 4,2 or 19 - 20 - 21

mA. Select appropriate current to start auto-stepping.

Ramp mode

To output a continuous up/down ramp cycle press keys

simultaneously. Ramp travel time between range limits is 60

seconds cycle starts at displayed value. Press or first

to select start direction. To return to manual press or .

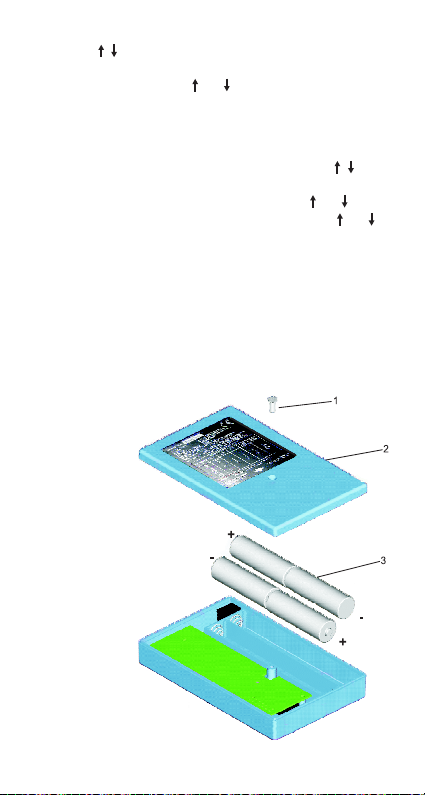

Batteries

Use alkaline or rechargeable NiCad batteries only. The

display shows LO BAT when battery capacity goes low.

CAUTION

DO NOT LEAVE DISCHARGED BATTERIES IN THE INSTRUMENT .

O

LD BATTERIES CAN LEAK AND CAUSE CORROSION.

W

HEN FITTING THE BATTERIES MAKE SURE THE ELECTRICAL CONTACTS

ARE CLEAN AND OBSERVE THE CORRECT POLARITY

1Centre screw.

2Battery

compartment

cover.

3Batteries size AA

x4.

Replacement

Unscrew the

centre screw (1).

Remove the

cover (2).

Make sure the

polarity of the

new batteries (3)

is correct.

Page 5

UPS-II Loop Calibrator Technical Notes

Current reading

Switch positions

Function

Loop power

Read

Ext.

Transmitter Calibration

Switch positions

Function

Loop power

Read

Int.

3 K0434 Issue No. 2

Page 6

Transmitter Simulation

Switch positions

Function

Loop power

Out

Ext.

Valve Stroking

Switch positions

Function

Loop power

Out

Int.

Page 7

Calibration Instructions

General

A calibration period of 12 months is recommended. The

actual calibration interval depends on instrument usage and

the total measurement uncertainty acceptable for the

specified application.

UPS-II

is a precise measuring instrument and the test

The

equipment and conditions of test must be suitable for the

type of work. The calibration check and calibration

adjustment should be carried out in a controlled

environment by a calibration technician*.

The manufacturer offers a comprehensive and, if required,

UKAS accredited calibration service.

*

A calibration technician must have the necessary technical knowledge,

documentation, special test equipment and tools to carry out the

calibration work on this equipment.

Calibration Equipment

The following tables give the accuracy requirements for the

calibration equipment and the UPS-II.

Calibration requires a stable temperature of 21° ±1°C (70° ±2°F).

UPS-II measure mode

Applied mAPermitted UPS-II

0 0.007 0

4 0.007 0.00014

12 0.007 0.00030

20 0.007 0.00046

UPS-II source mode

Applied mAPermitted UPS-II

00.01 0

4 0.01 0.00012

12 0.01 0.00011

20 0.01 0.00015

Table 1

error (mA)

Table 2

error (mA)

Calibrator error

(mA)

Calibrator error

(mA)

5 K0434 Issue No. 2

Page 8

Calibration Check

Calibration Procedure mA Input

2 seconds

Apply zero - open circuit test leads

Connect test leads to mA source

apply full-scale

Adjust mA source to any

value within range - check reading

example

serial number

READ

and

+

Enter

*

Enter

*

Enter

*

VALVE

LIN

FLOW

MA

VALVE

LIN

FLOW

MA

and

+

-

*

adjust each

digit

adjust each digit

adjust each digit

Enter

*

Input calibration complete new offset values stored

continue with output calibration.

VALVE

LIN

FLOW

MA

1. Check the instrument for accuracy in measure and

source modes, if there is an error greater than the

permitted error, the instrument requires a calibration

adjustment.

Calibration Adjustment

Note:

For complete accuracy, the measure mode and source mode adjustment

must be carried together and in the following order.

Measure mode

1. Connect the UPS-II to the electrical calibrator. Switch on

the electrical calibrator and allow it to thermally

stabilise.

2. Switch on the UPS-II and allow the instrument to

thermally stabilise.

3. Select EXT on the LOOP PWR slide switch. Use the

display menu to select the calibration values:

Page 9

Source mode

Calibration Procedure mA Output

2 seconds

Connect test leads to mA-meter

compare values.

serial number

OUT

and

+

Enter

*

Enter

*

Enter

*

Enter

*

Enter

*

and

+

-

*

adjust each

digit

adjust each digit

adjust each digit

Calibration complete new output values stored

Compare values.

Check reading.

Check reading.

VALVE

LIN

FLOW

MA

VALVE

LIN

FLOW

MA

VALVE

LIN

FLOW

MA

VALVE

LIN

FLOW

MA

1. Connect the UPS-II to the electrical calibrator. Switch on

the electrical calibrator and allow it to thermally

stabilise.

2. Switch on the UPS-II and allow the instrument to

thermally stabilise.

3. Select INT on the LOOP PWR slide switch. Use the

display menu to select the calibration values:

Completion

1. Switch off and disconnect the calibration equipment.

2. Update the calibration records for the instrument.

7 K0434 Issue No. 2

Page 10

Range........................................................................................ 0 to 22.2 mA

Specifications

Accuracy........................................................................ 0,05% of range

Resolution...................................................................... 10 microamps

Temperature effect.............................. 0,003%/°C - 0,0015%/°F

Internal loop power...................................................24 VDC stabilized

External loop power............................................................48 VDC max.

Measurement input................................................... 12 ohms fused

Drive capability..................................................................... 900 ohms

Operating temperature............ -10°C to 50°C - 14°F to 122°F

Storage temperature .............. -20°C to 60°C - -4°F to 140°F

Battery......................... 4 x 1.5V alkaline or rechargeable size AA

Battery life (alkaline)............................. source 12mA; 18 hours

................................................................................. measure 900 hours

Loop mismatch........................................................... flashes "LOOP"

Low battery................................................................... flashes "LOBAT"

Over-range.................................................................... flashes "EEEE"

Reversed polarity....................................................... flashes "POL"

Adaptor line/6VDC

230V/50Hz............................ part numbers - UNO-13600-1 (UK)

...................................................................... - UNO-13600-2 (Europe)

110V/60Hz............................ part number - UNO-13600-3 (USA)

Housing.......................................................................... high impact ABS

Size................................................................................... 3" x 5" x 0,83"

................................................................................. 77 x 124 x 21 mm

Weight ............. ..................... ..................... ........... 212 grams - 7.5 oz

................................................................................. (including batteries)

Page 11

Traceability and quality

UPS-II

Serial No: ...........................................................................................

Month: ...........................................................................................

Year: ...........................................................................................

This notification serves to certify that the unit described

above has been inspected and tested in accordance with the

specifications.

The unit calibration is traceable to international standards.

Loading...

Loading...