Page 1

GE Healthcare

Getting Started with

ÄKTAavant and UNIC ORN 6

™ ™

Page 2

Page 3

Table of Contents

Table of Contents

51 About this guide ...................................................................................................

61.1 Get started ...............................................................................................................................................

101.2 Regulatory information ......................................................................................................................

122 Safety instructions ...............................................................................................

132.1 Safety precautions ...............................................................................................................................

202.2 Labels .........................................................................................................................................................

232.3 Emergency procedures ......................................................................................................................

263 Start up .................................................................................................................

273.1 Start the system and log on to UNICORN ..................................................................................

314 The instrument and the software .....................................................................

324.1 ÄKTAavant instrument overview ...................................................................................................

364.2 UNICORN software overview ..........................................................................................................

394.3 UNICORN software modules ...........................................................................................................

404.3.1 Method Editor module ......................................................................................................................

434.3.2 System Control module ...................................................................................................................

454.3.3 Evaluation module .............................................................................................................................

475 Files and folders in UNICORN .............................................................................

485.1 Navigator overview .............................................................................................................................

515.2 Handling files and folders .................................................................................................................

556 Create a method ..................................................................................................

566.1 Guide to method creation .................................................................................................................

576.1.1 Create and edit methods ................................................................................................................

656.1.2 Predefined methods ..........................................................................................................................

676.1.3 Predefined phases .............................................................................................................................

686.2 Print a method .......................................................................................................................................

707 Prepare the system for a run .............................................................................

717.1 Before you prepare the system ......................................................................................................

727.2 Prepare the flow path .........................................................................................................................

787.3 Prime buffer inlets and purge System pumps .........................................................................

837.4 Connect a column ................................................................................................................................

887.5 Calibrate the pH monitor ..................................................................................................................

907.6 Prepare the Fraction collector ........................................................................................................

958 Run a method ........................................................................................................

968.1 Before you start .....................................................................................................................................

988.2 Applying the sample ............................................................................................................................

1018.3 Start a method run ..............................................................................................................................

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 3

Page 4

Table of Contents

1068.4 Monitor the run ......................................................................................................................................

1118.5 After run procedures ...........................................................................................................................

1159 Evaluate and print the results ...........................................................................

1169.1 View the results .....................................................................................................................................

1209.2 Peak integration ....................................................................................................................................

1259.3 Print the results ......................................................................................................................................

13010 Maintenance .........................................................................................................

13110.1 Maintenance program .......................................................................................................................

4 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 5

1 About this guide

Introduction

This chapter describes the purpose of the guide and provides regulatory information

relevant for ÄKTAavant system.

Contents

This chapter contains the following sections:

1 About this guide

See pageSection

61.1 Get started

101.2 Regulatory information

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 5

Page 6

1 About this guide

1.1 Get started

1.1 Get started

Introduction

Read this section for an understanding of the purpose and conventions of this guide, as

well as the requirements that you must fulfill before using the ÄKTAavant system.

Purpose of Getting Started

The purpose of this guide is to present a quick and easy guide to the system for a user

with limited or no experience of UNICORN software and ÄKTAavant instrument. The work

flow is presented as practical instructions on how to operate the software and the

instrument. The instructions form a basic framework that you can expand on by reading

selected parts in the other manuals. This Getting Started guide includes the following

topics:

•

Basic features of ÄKTAavant and UNICORN

•

Create methods

•

Prepare the system for runs

•

Perform runs

•

Make simple evaluations

•

Print reports

For best results, follow the guide from page to page in front of the system.

Prerequisites

In order to follow this guide and use the system in the manner it is intended, it isimportant

that:

•

you have a general understanding of how the computer and Windows™ work.

•

you understand the concepts of liquid chromatography.

•

you have read and understood the Safety instructions chapter in the user

documentation.

•

the instrument and software are installed, configured and calibrated according to

ÄKTAavant and UNICORN 6 Installation Guide.

•

a user account has been created according to UNICORN 6 Administration and

Technical Manual.

6 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 7

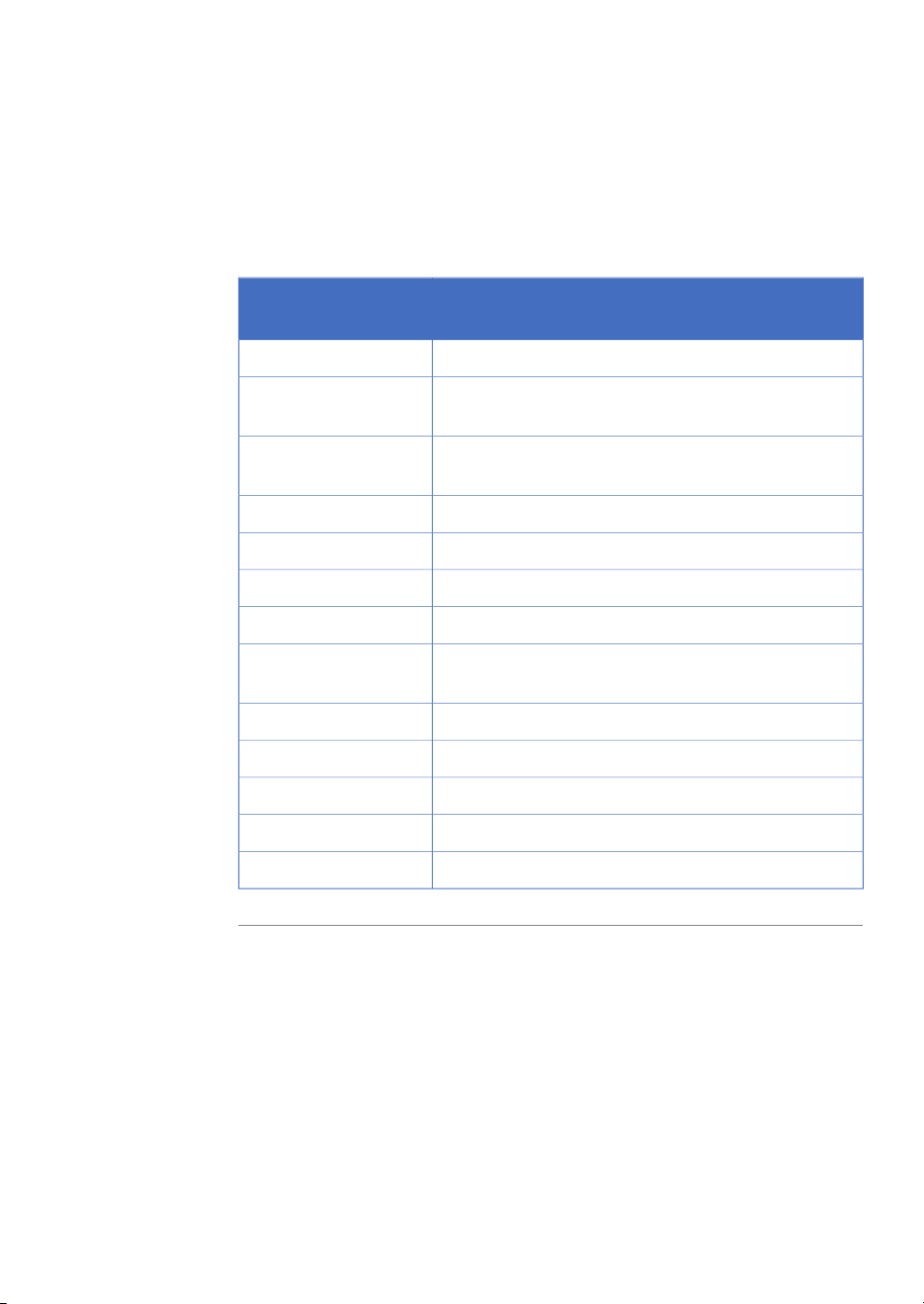

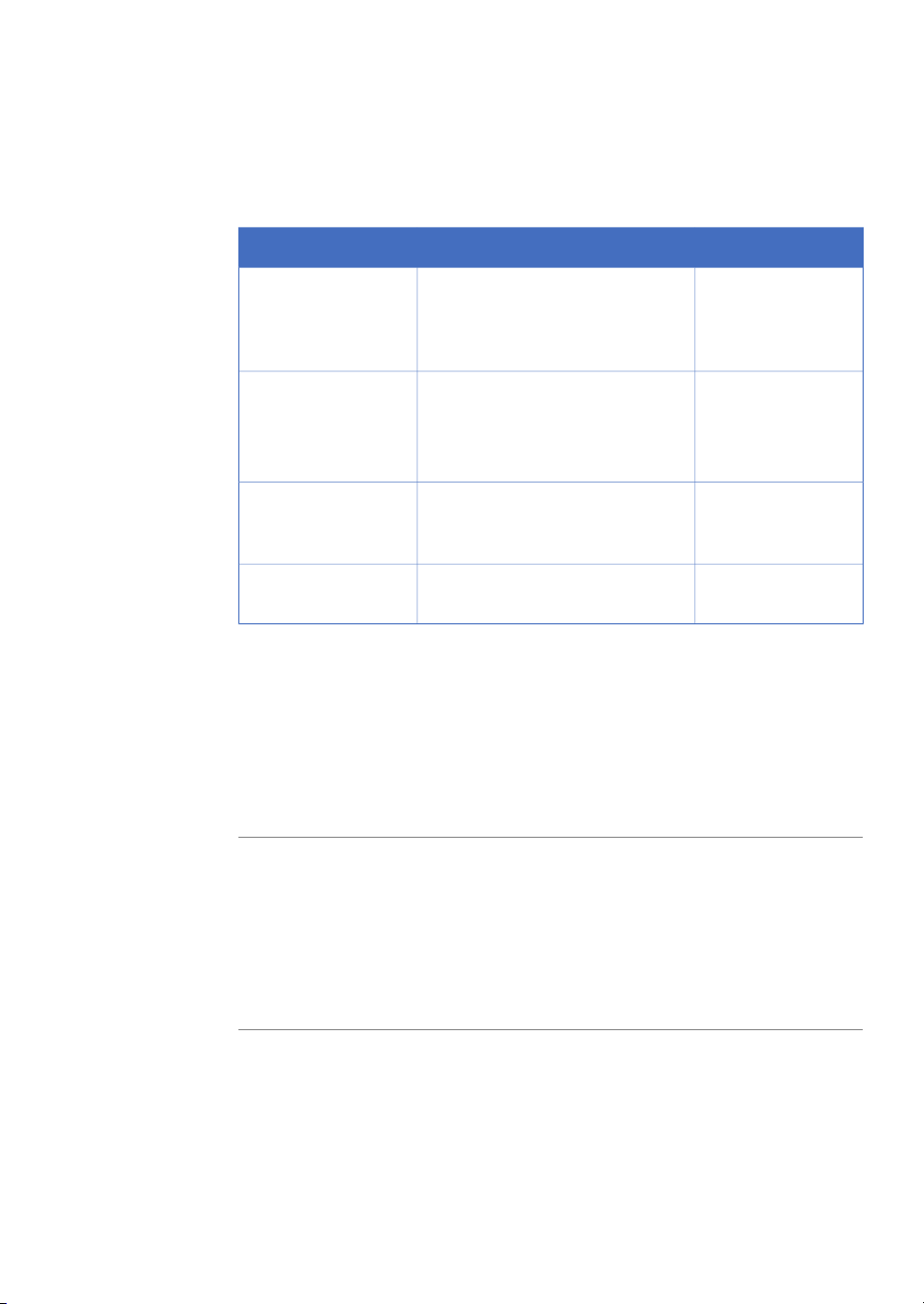

Pushing the limits beyond

Getting Started

Users who are familiar with the instrument and software and want to learn more about

the system’s advanced features should refer to the list below.

about...

databases

functions

1 About this guide

1.1 Get started

please read..To find out more

ÄKTAavant and UNICORN 6 Installation Guideinstallation

UNICORN 6 Administration and Technical Manualadministration of

ÄKTAavant and UNICORN 6 User Manualinstrument modulesand

ÄKTAavant and UNICORN 6 User Manualcalibration

UNICORN 6 Method Manualpredefined methods

UNICORN 6 Method Manualcolumn handling

UNICORN 6 Method Manualmanual method editing

buffer preparation

UNICORN 6 Method ManualBufferPro–automatic

UNICORN 6 Method Manualscouting

UNICORN 6 Method ManualDesign of Experiment

UNICORN 6 Evaluation Manualevaluation

UNICORN 6 Evaluation Manualpeak integration

UNICORN 6 Evaluation Manualcustomized printformat

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 7

Page 8

1 About this guide

1.1 Get started

Intended use

ÄKTAavant is a liquid chromatography system intended for method development. The

system can be used to screen for optimal choice of columns, media and running

parameters to purify selected proteins.

The ÄKTAavant system is intended for research use only, and shall not be used in any

clinical procedures, or for diagnostic purposes.

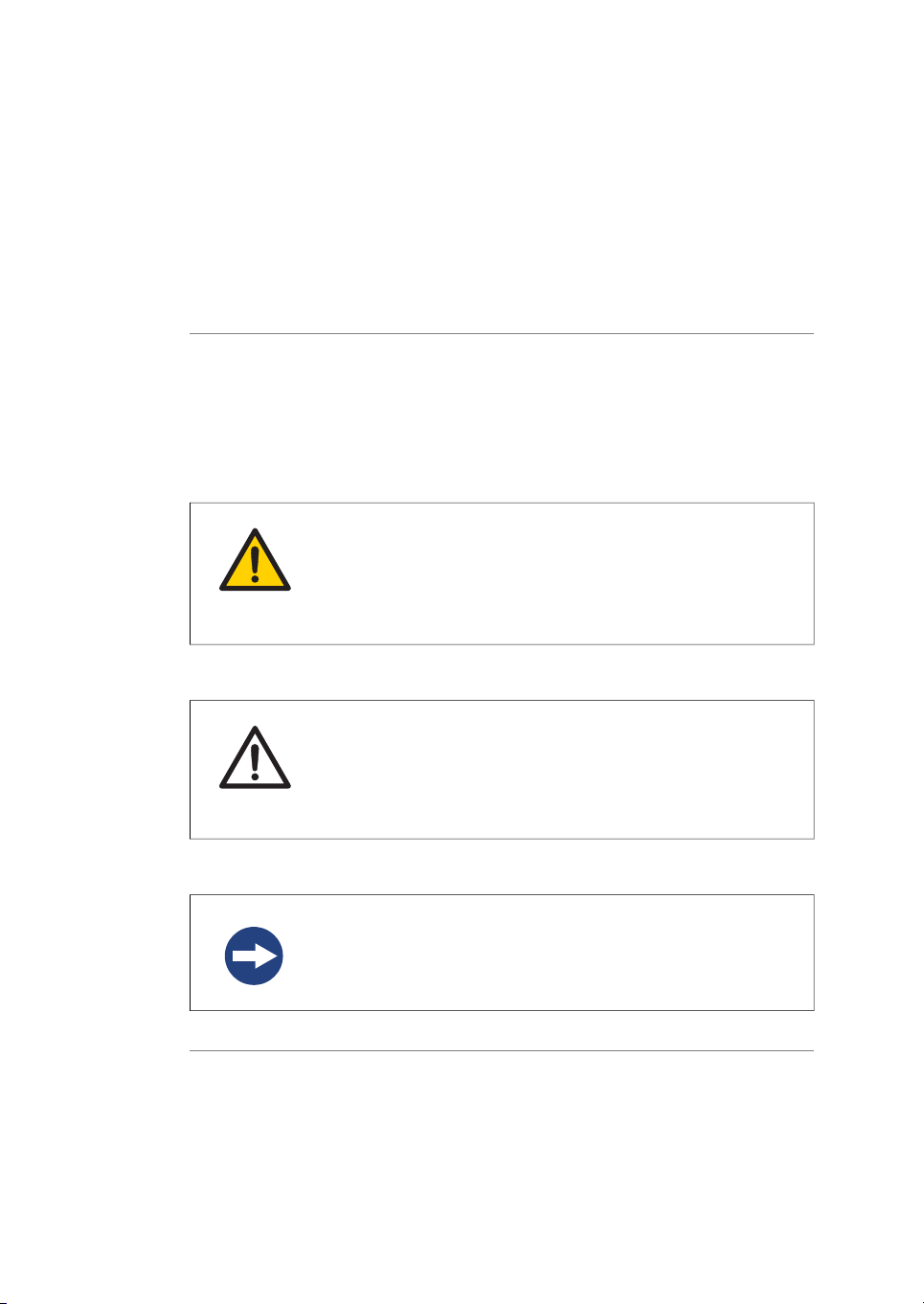

Safety notices

This user documentation contains WARNINGS, CAUTIONS and NOTICES concerning the

safe use of the product. See definitions below.

Warnings

WARNING

WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury. It is important not to proceed

until all stated conditions are met and clearly understood.

Cautions

Notices

CAUTION

CAUTION indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury. It is important not to

proceed until all stated conditions are met and clearly understood.

NOTICE

NOTICE indicates instructions that must be followed to avoid

damage to the product or other equipment.

8 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 9

Typographical conventions

Software items are identified in the text by bold italic text. A colon separates menu levels,

thus File:Open refers to the Open command in the File menu.

Hardware items are identified in the text by bold text (e.g., Power switch).

Text entries that UNICORN generates or that the user must type are represented by a

monotype typeface (e.g., \Program Files\GE

Healthcare\UNICORN\bin\UNICORN Instrument Server.exe.config).

1 About this guide

1.1 Get started

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 9

Page 10

1 About this guide

1.2 Regulatory information

1.2 Regulatory information

Introduction

This section describes the directives and standards that are fulfilled by the ÄKTAavant

system.

CE conformity

This product complies with the European directives listed in the table below, by fulfilling

the corresponding harmonized standards. A copy of the Declaration of Conformity is

available on request.

TitleDirective

Machinery Directive2006/42/EC

Low Voltage Directive2006/95/EC

ElectroMagnetic Compatibility (EMC) Directive2004/108/EC

CE marking

1999/5/EC

The CE marking and the corresponding declaration of conformity, is valid for the

instrument when it is:

•

used as a stand-alone unit, or

•

connected to other CE marked GE Healthcare instruments, or

•

connected toother products recommended or describedin the user documentation,

and

•

used in the same state as it was delivered from GE Healthcare, except for alterations

described in the user documentation.

Radio Equipment and Telecommunications Terminal

Equipment Directive

10 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 11

International standards

This product fulfills the requirements of the following standards:

1 About this guide

1.2 Regulatory information

NotesDescriptionStandard

EN 61010-1, IEC

61010-1, UL 61010-1,

CAN/CSA-C22.2

No.61010-1

EN 61326-1

EN-ISO 12100-1,

12100-2

EN ISO 14121-1,

14121-2

Software declaration of

conformity

UNICORN 6 is technically compatible with all relevant sections of FDA 21 CFR Part 11.

A part 11-system assessment checklist is available on request through the local GEHC

representative.

Safety requirements for electrical

equipment for measurement,

control, and laboratory use

EMC emissions and immunity

requirements for electrical

equipment for measurement,

control and laboratory use.

Safety of machinery — Basic

concepts, general principles for

design

Safety of machinery — Principles of

risk assessment

Harmonized with

2004/108/EC

CISPR 11 Group 1,

Class B

Harmonized with

2006/42/EC

Harmonized with

2006/42/EC

Regulatory compliance of

connected equipment

Any equipment connected to the ÄKTAavant system should meet the safety requirements

of EN 61010-1/IEC 61010-1, or other relevant harmonized standards. Within EU,

connected equipment must be CE marked.

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 11

Page 12

2 Safety instructions

2 Safety instructions

Introduction

This chapter contains instructions of how to handle the ÄKTAavant instrument in a safe

way.

Contents

This chapter contains the following sections:

See pageSection

132.1 Safety precautions

202.2 Labels

232.3 Emergency procedures

12 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 13

2.1 Safety precautions

Introduction

The ÄKTAavant instrument is poweredby mains voltage and handles pressurized liquids

that may be hazardous. Beforeinstalling, operating or maintaining the system, youmust

be aware of the hazards described in this manual. Follow the instructions provided to

avoid personal injuries or damage to the equipment.

The safety precautions in this section are grouped into the following categories:

•

General precautions

•

Personal protection

•

Installing and moving the instrument

•

System operation

•

Maintenance

2 Safety instructions

2.1 Safety precautions

General precautions

•

Do not operate the ÄKTAavant instrument in any other way than described in the

ÄKTAavant and UNICORN manuals.

•

Operation and user maintenance of the ÄKTAavant instrument should be performed

by properly trained personnel only.

•

Before connecting a column to the ÄKTAavant instrument, read the instructions for

use of the column. To avoid exposing the column to excessive pressure, make sure

that the pressure limit is set to the specified maximum pressure of the column.

•

Do not use any accessories not supplied or recommended by GE Healthcare.

•

Do not use the ÄKTAavant instrument if it is not working properly, or if it has suffered

any damage, for example:

-

damage to the power cord or its plug

-

damage caused by dropping the equipment

-

damage caused by splashing liquid onto it

WARNING

Always followthese General precautions toavoid injury when using

the ÄKTAavant instrument.

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 13

Page 14

2 Safety instructions

2.1 Safety precautions

Using flammable liquids

•

Fire Hazard. Before starting the system, make sure that there are no unintentional

leakage in the instrument or tubing.

•

Explosion hazard. To avoid building up an explosive atmosphere when using

flammable liquids, make sure that the room ventilation meets the requirements

specified in ÄKTAavant and UNICORN 6 Installation Guide.

•

Fraction collector. Do not fractionate flammable liquids. When running RPC methods,

or other procedures using solvent based buffers, collect fractions through the outlet

valve.

NOTICE

Avoid condensationby letting the instrument equilibrate to ambient

temperature.

WARNING

When using flammable liquids with the ÄKTAavant instrument,

follow these precautions to avoid any risk of fire or explosion.

Personal protection

Warnings

WARNING

To avoid hazardous situations when working with the ÄKTAavant

system, take the following measures for personal protection.

•

Always use appropriate personal protective equipment during operation and

maintenance of ÄKTAavant system.

•

Hazardous substances. When using hazardous chemical and biological agents,

take all suitable protective measures, suchas wearing protective glassesand gloves

resistant to the substances used. Follow local and/or national regulations for safe

operation and maintenance of the system.

14 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 15

2 Safety instructions

2.1 Safety precautions

•

Spread of biological agents. The operator has to take all necessary actions to avoid

spreading hazardous biological agents in the vicinity of the instrument . The facility

should comply with the national code of practice for biosafety.

•

High pressure. The ÄKTAavant instrument operates under high pressure. Wear

protective glasses at all times.

Cautions

CAUTION

To avoid hazardous situations when working with the ÄKTAavant

system, take the following measures for personal protection.

•

Close doors. To minimize the risk of exposure to hazardous chemicals and pressurized

liquids, always close the Foldable door and the Pump cover before starting a run.

•

Cut injuries. The tubing cutter is very sharp and must be handled with care to avoid

injuries.

Installing and moving the

instrument

Warnings

•

Heavy object. The ÄKTAavant instrument weighs about 100 kg. Use proper lifting

equipment, or use four or more persons when moving the instrument. All lifting and

moving must be performed in accordance with local regulations.

•

Moving theinstrument horizontally. Three persons arerecommended when moving

the instrument horizontally.

•

Supply voltage. Make sure that the supply voltage at the wall outlet corresponds to

the marking on the instrument, before connecting the power cord.

•

Protective ground. The ÄKTAavant instrument must always be connected to a

grounded power outlet.

•

Power cord. Only use power cords delivered or approved by GE Healthcare.

WARNING

To avoid personal injury when installing or moving the ÄKTAavant

instrument, follow the instructions below.

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 15

Page 16

2 Safety instructions

2.1 Safety precautions

•

•

Notices

•

•

•

Access to power switch and power cord. Do not block the rear and side panel of

the instrument. The Power switch must always be easy to access. The power cord

must always be easy to disconnect.

Installing the computer. The computer should be installed and used according to

the instructions provided by the manufacturer of the computer.

NOTICE

To avoid damage to ÄKTAavant or otherequipment when installing

or moving the instrument, follow the instructions below.

Vents on the ÄKTAavant instrument. To ensure adequate ventilation, keep papers

and other objects away from the vents of the instrument.

Disconnect power. To prevent equipment damage, always switch off power to the

ÄKTAavant instrument before an instrument module is removed or installed, or a

cable is connected or disconnected.

Misuse of UniNet-9 connectors. The UniNet-9 connectors at the rear panel should

not be mistaken for Firewire connectors. Do not connect any external equipment to

the UniNet-9 connectors. Do not disconnect or move the UniNet-9 bus cable.

System operation

Warnings

WARNING

To avoid personal injury when operating the ÄKTAavant system,

follow the instructions below.

•

Rotating theinstrument. Make surethat there is always at least 20 cm offree space

around the ÄKTAavant instrumentto allow rotation on theswivel foot. When rotating

the system, take care not to stretch or squeeze tubing or cables. A disconnected

cable may cause power interruption or network interruption. Stretched tubes may

cause bottles to fall, resulting in liquid spillage and shattered glass. Squeezed tubing

may cause increase in pressure, or block liquid flow. To avoid the risk of turning over

bottles, always place bottles on the buffer tray, and close the doors before rotating

the instrument.

16 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 17

2 Safety instructions

2.1 Safety precautions

•

Fasten sample bottles. Always fasten bottles and cassettes to the rails at the sample

tray. Use appropriate holders for bottles. Shattered glass from falling bottles may

cause injury. Spilled liquid may cause fire hazard and personal injury.

•

Electrical shock hazard after spillage. If there is a risk that large volumes of spilled

liquid may penetrate the casing of the ÄKTAavant instrument, immediately switch

off the instrument , disconnect the power cord, and contact an authorized service

engineer.

•

Moving parts in Fractioncollector. Do not open the Fraction collector drawer when

the Fraction collector is active. If you need to access the Fraction collector, press

Pause, and make sure that the movement has stopped before opening the drawer.

•

Using a Superloop. After loading a Superloop, always plug the Syr port on the

Injection valve with a Stop plug. With a Superloop connected to the valve, an

over-pressure may be created during injection.

•

Hazardous chemicals during run. When using hazardous chemicals, run System

CIP and Column CIP to flush the entire system tubing with distilled water, before

service and maintenance.

•

Hazardous biological agents during run. When using hazardous biological agents,

run System CIP andColumn CIP to flush theentire system tubing withbacteriostatic

solution (e.g., NaOH) followed by a neutral buffer and finally distilled water, before

service and maintenance.

•

RPC runs with 100% acetonitrile. Always replace the green PEEK tubing between

the used system pump and the pressure monitor with orange PEEK tubing, i.d. 0.5

mm, before running RPC with 100% acetonitrile. Set the System pressure alarm to

10 MPa.

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 17

Page 18

2 Safety instructions

2.1 Safety precautions

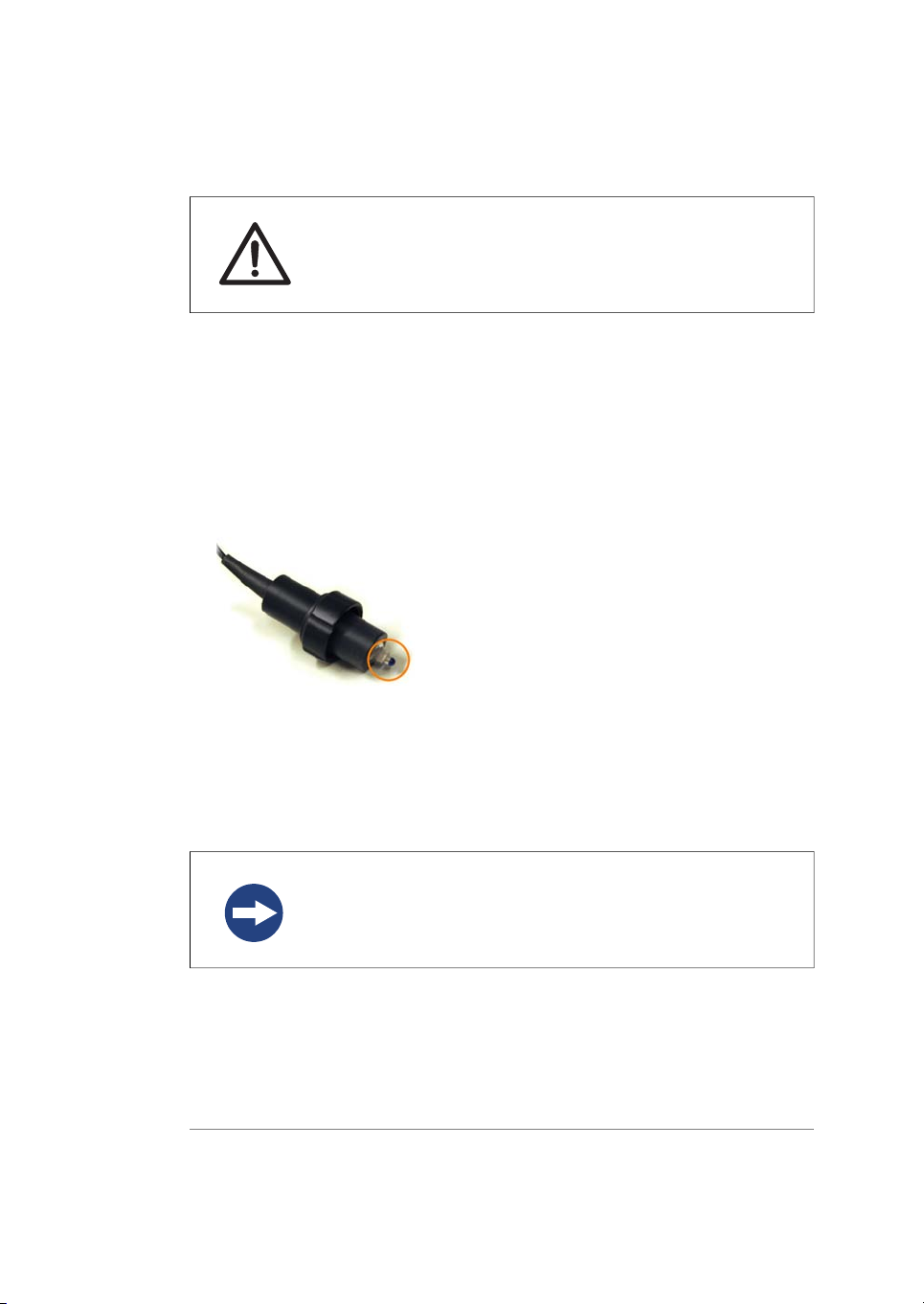

Cautions

•

•

•

CAUTION

To avoid hazardous situations when operating the ÄKTAavant

system, follow the instructions below.

Risk of breaking test vials. Do not use excessive force to press vials with incorrect

dimensions into the Fraction collector cassettes. Glass vials may break and cause

injuries.

Hazardous chemicalsor biological agents inUV flow cell. Make sure that the entire

flow cell has been flushed thoroughly with bacteriostatic solution (e.g., NaOH) and

distilled water, before service and maintenance.

pH-electrode. Handle the pH-electrode with care.The glass tip may break and cause

injury.

•

Max. weight on top tray. Do not place containers with a volume of more than 10

liters on the top tray. The total allowed weight on the top tray is 40 kg.

•

Max. size of bottles on front panel. Do not fasten bottles with a volume of more

than 1 liter in the front panel rails.

Notices

NOTICE

To avoid damage to ÄKTAavant or other equipment when operating

the instrument, follow the instructions below.

•

Keep UV flow cell clean. Do not allow solutions containing dissolved salts, proteins

or other solid solutes to dry out in the flow cell. Do not allow particles to enter the

flow cell, as damage to the flow cell may occur.

•

Waste container height. The maximum level of the waste container content must

be lower than 30 cm above the lab bench, for trouble-free use.

18 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 19

Maintenance

2 Safety instructions

2.1 Safety precautions

Warnings

WARNING

To avoid personal injury when performing maintenance on the

ÄKTAavant instrument, follow the instructions below.

•

Electrical shock hazard. All repairs should be done by service personnel authorized

by GE Healthcare. Do not open any covers or replace parts unless specifically stated

in the user documentation.

•

Disconnect power. Always switch off power to the instrument before replacing any

component on the instrument, unless stated otherwise in the user documentation.

•

Hazardous chemicals during maintenance. When using hazardous chemicals for

system or column cleaning, wash the system or columns with a neutral solution in

the last phase or step.

NOTICE

Cleaning. Keep the instrument dry and clean. Wipe regularly with

a soft damp tissue and, if necessary, a mild cleaning agent. Let the

instrument dry completely before use.

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 19

Page 20

2 Safety instructions

2.2 Labels

2.2 Labels

Introduction

This section describes the safety labels and labels concerning hazardous substances

that are attached to the ÄKTAavant instrument. For information about marking of the

computer equipment, refer to the manufacturer’s instructions.

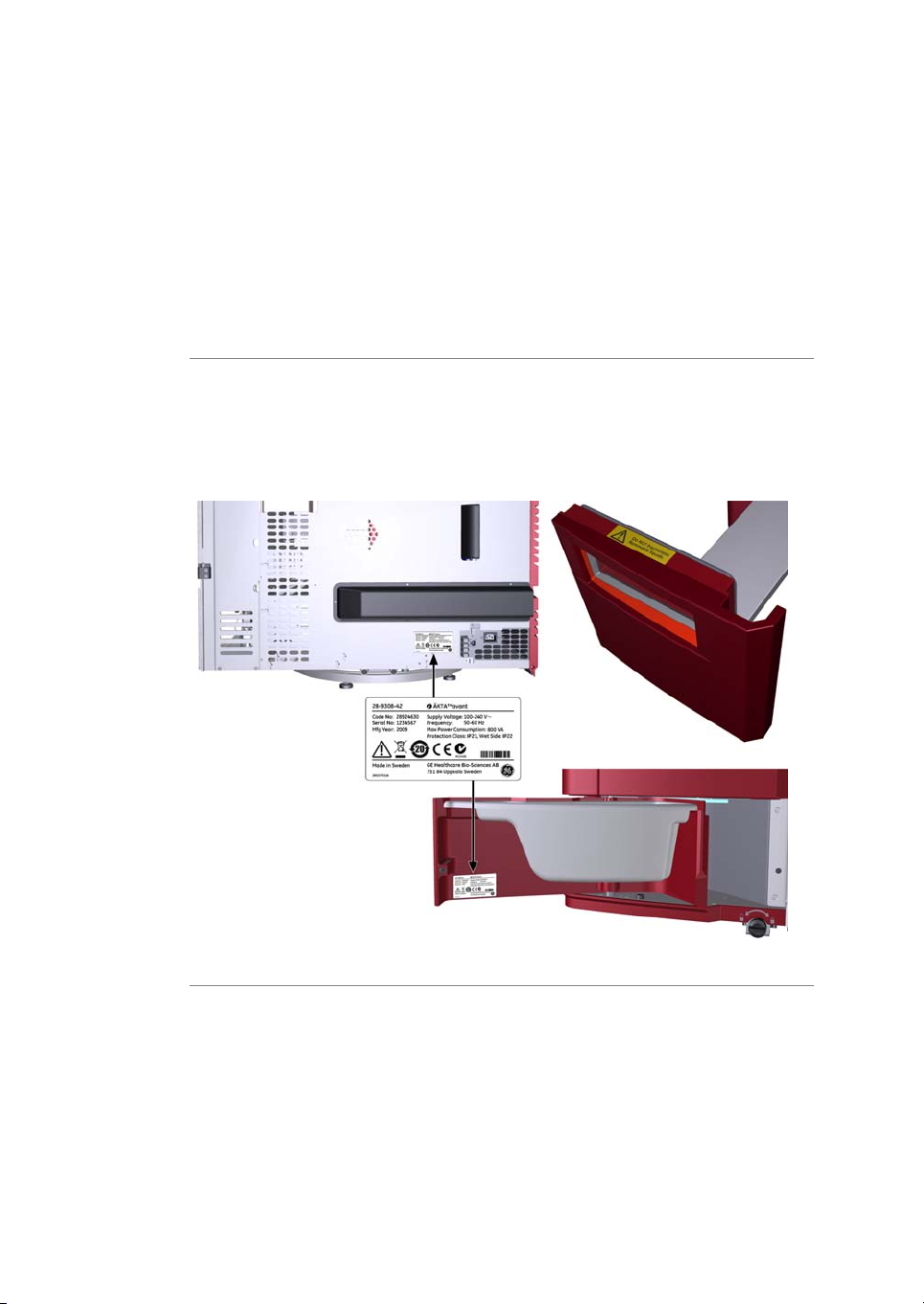

Labels on the ÄKTAavant

instrument

The illustrations below show the labels that are attached to the ÄKTAavant instrument.

20 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 21

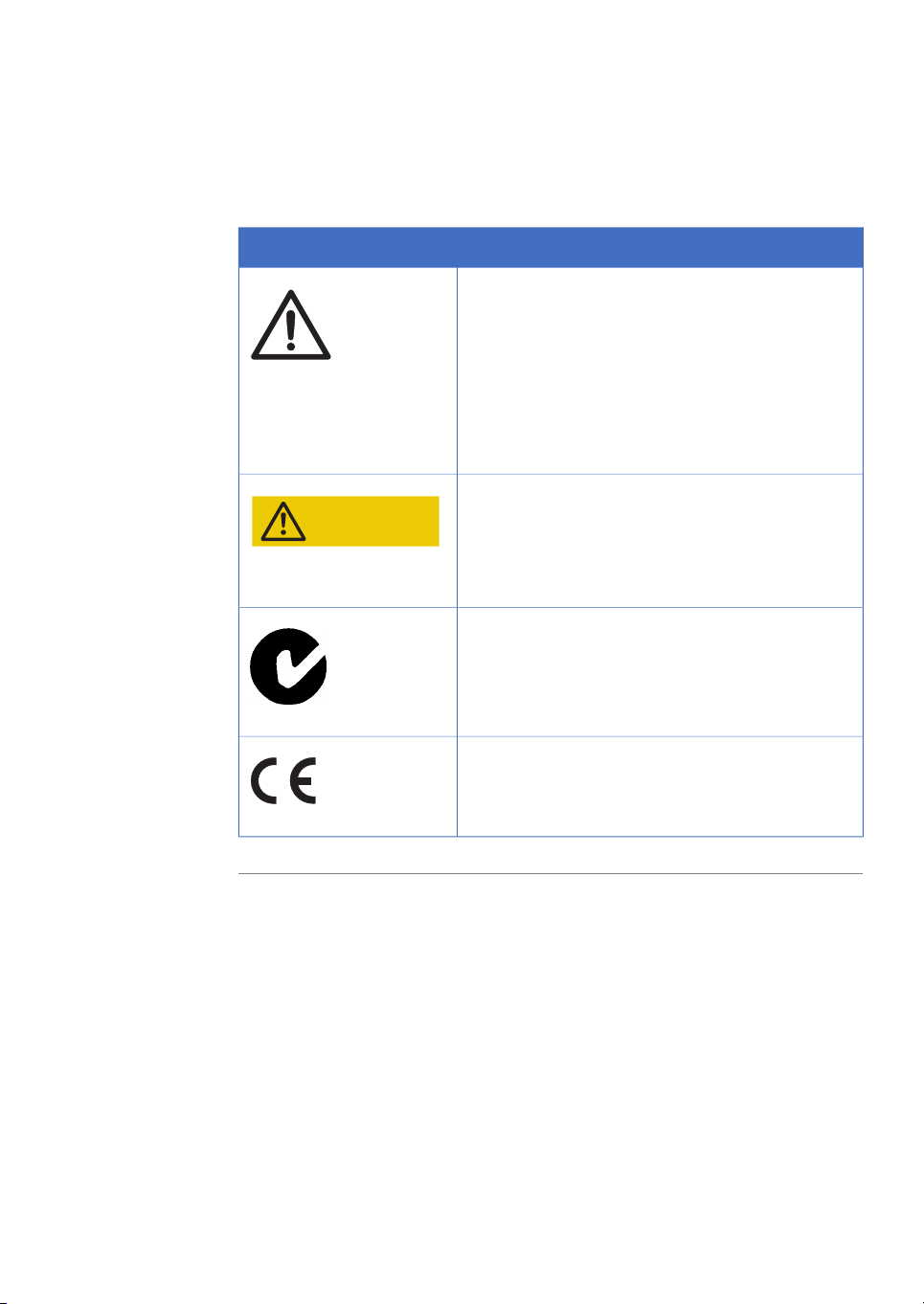

Safety symbols

Do NOT fractionate

flammable liquids.

The following safety symbols are used in the labels:

2 Safety instructions

2.2 Labels

MeaningLabel

Warning!

Electrical shock hazard. All repairs should be done by

service personnel authorizedby GE Healthcare. Do not

open any covers or replace parts unless specifically

stated in the user documentation.

Supply voltage. Make sure that the supply voltage at

the wall outlet corresponds to the marking on the

instrument, before connecting the power cord.

Warning!

Fraction collector. Do not fractionate flammable

liquids. When running RPC methods, or other

procedures using solvent based buffers, collect

fractions through the outlet valve.

The system complies with the requirements for

electromagnetic compliance (EMC) in Australia and

New Zealand.

The system complies with applicable European

directives.

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 21

Page 22

2 Safety instructions

2.2 Labels

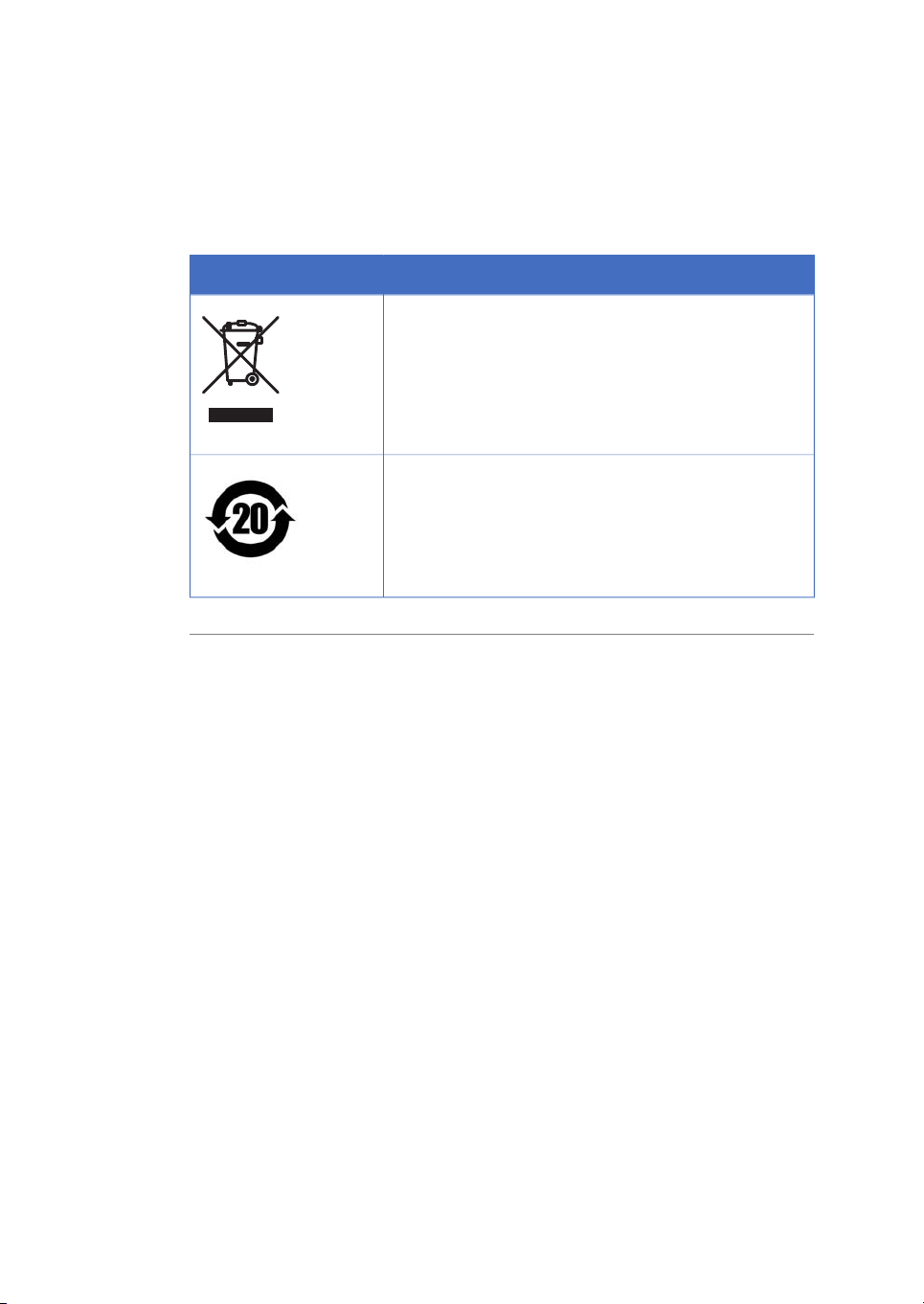

Labels concerning hazardous

substances

The following symbols on the labels concern hazardous substances:

MeaningLabel

This symbol indicates that electrical and electronic

equipment mustnot be disposed of as unsorted municipal

waste and must be collected separately. Please contact

an authorized representative of the manufacturer for

information concerning the decommissioning of

equipment.

This symbol indicates that the productcontains hazardous

materials in excess of the limits establishedby the Chinese

standard SJ/T11363-2006 Requirements for Concentration

Limits for Certain Hazardous Substances in Electronic

Information Product.

22 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 23

2.3 Emergency procedures

Introduction

This section describes how to do an emergency shutdown of the ÄKTAavant system.

The section also describes the result in theevent of power failure or network interruption.

Emergency shutdown

In an emergency situation, follow the steps below to stop the run:

ActionStep

2 Safety instructions

2.3 Emergency procedures

1

Press the Pause button on the instrument display. This will stop all pumps

in the instrument .

To pause the run from UNICORN, click the Pause icon:

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 23

Page 24

2 Safety instructions

2.3 Emergency procedures

ActionStep

Power failure

2

The result of a power failure depends on which unit is affected.

ÄKTAavant instrument

If required, switch off power to the instrument by pressing the Power switch

to the O position. The run is interrupted immediately.

will result in...Power failure to...

The run is interrupted immediately

•

The data collected up to the time of the power

•

failure is available in UNICORN.

24 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 25

2 Safety instructions

2.3 Emergency procedures

will result in...Power failure to...

Computer

Uninterruptible power supply

(UPS)

A UPS can eliminate data loss after a power failure, and allow time for a controlled

shut-down of the ÄKTAavant system.

The UNICORN computer shuts down

•

The instrument display shows status Not

•

connected

The run is interrupted immediately

•

Data generated up to 10 seconds before the

•

power failure can be recovered

Note:

The UNICORN client may

close down during a

temporary overload of the

processor. This may appear

as a computer failure. The

run continues and you can

restart the UNICORN client to

regain control.

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 25

Page 26

3 Start up

3 Start up

Introduction

This chapter describes how to start the system, both the software and the instrument,

and also how to log off and exit UNICORN.

It is assumed that your user profile is already created. For information about how to set

up and define users, user groups and access rights, please refer to UNICORN 6

Administration and Technical Manual.

Contents

This chapter contains the following sections:

See pageSection

273.1 Start the system and log on to UNICORN

26 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 27

3.1 Start the system and log on to UNICORN

3.1 Start the system and log on to UNICORN

Introduction

This section describes how to start UNICORN and the instrument, and how to connect

to the system.

Start UNICORN and log on

Follow the instruction below to start and log on to UNICORN.

ActionStep

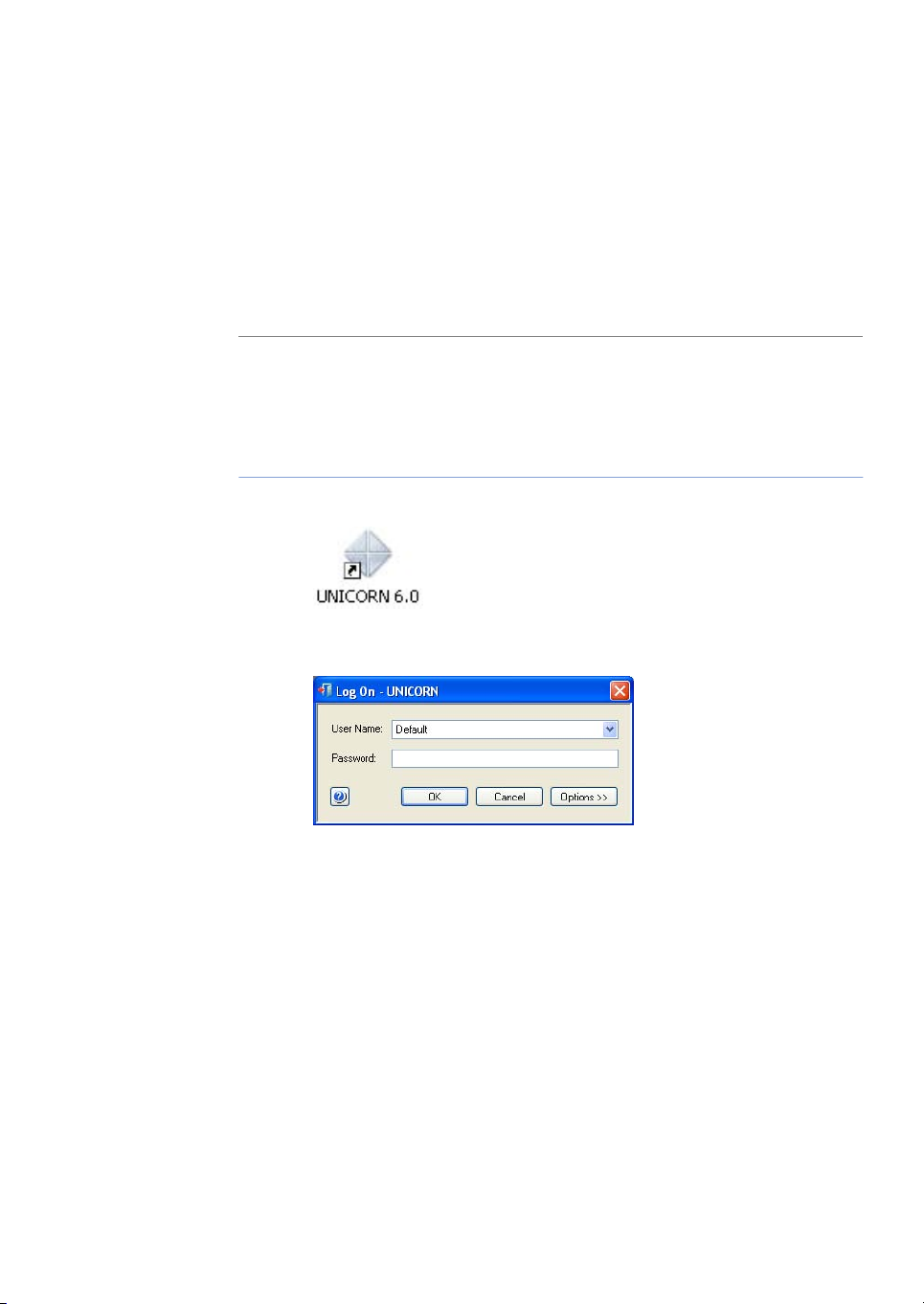

To start the program, double-click the UNICORN icon on the desktop.1

3 Start up

Result: The Log On dialog opens.

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 27

Page 28

3 Start up

3.1 Start the system and log on to UNICORN

ActionStep

In the Log On dialog:2

Select your User Name from the drop-down list.

•

Enter your Password.

•

Click the Options button.

•

Result: Checkboxes for each of the UNICORN modules are displayed in

the Log On dialog.

In the Log On dialog:3

Select which UNICORN modules to start by clicking the corresponding

•

checkboxes.

Click OK.

•

Result: The selected UNICORN modules open.

28 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 29

Start the instrument and connect

to the system

Follow the instruction below to start the instrument and connect to the UNICORN

software.

ActionStep

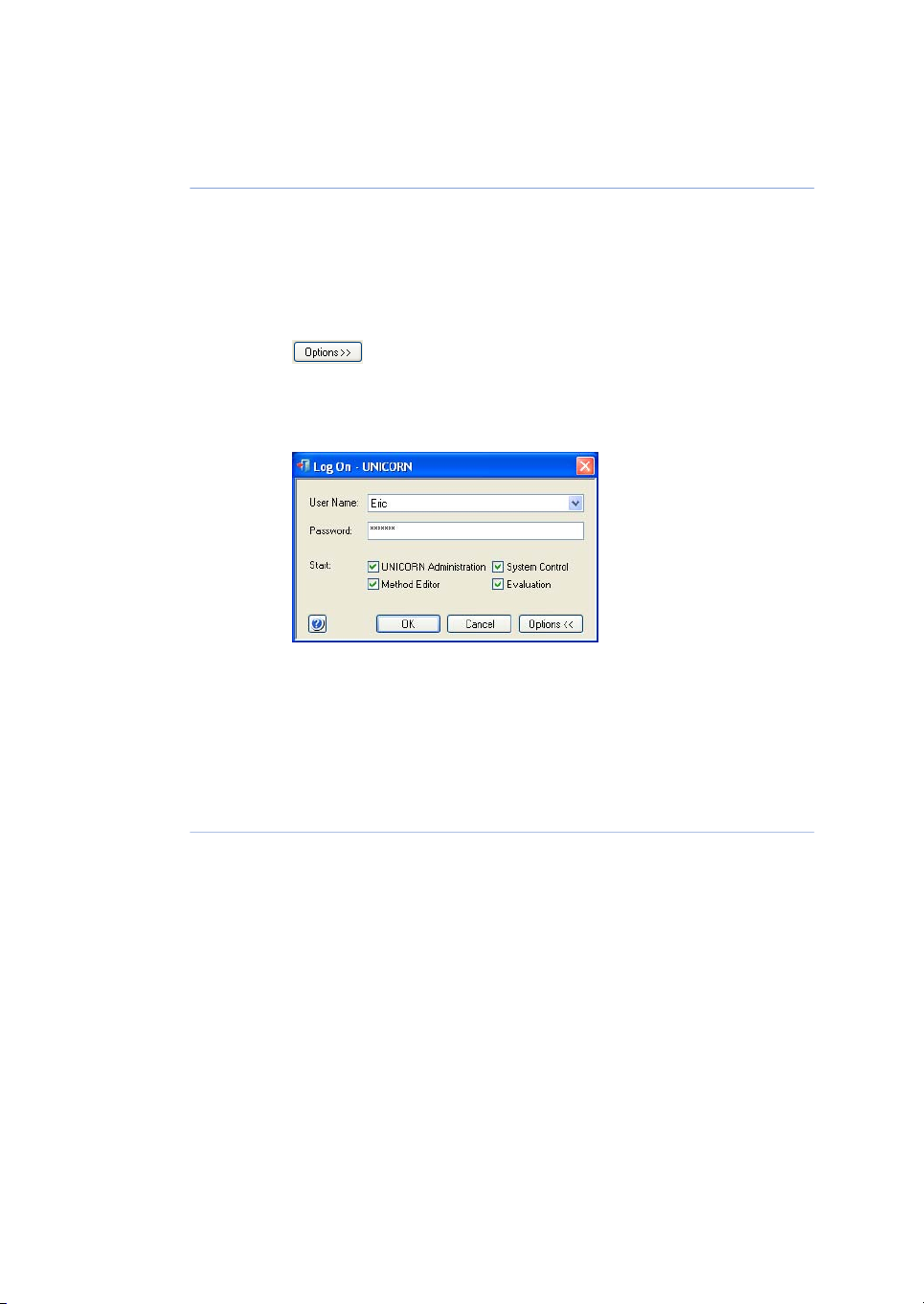

Switch on the instrument by pressing the Power switch to the I position.1

3 Start up

3.1 Start the system and log on to UNICORN

2

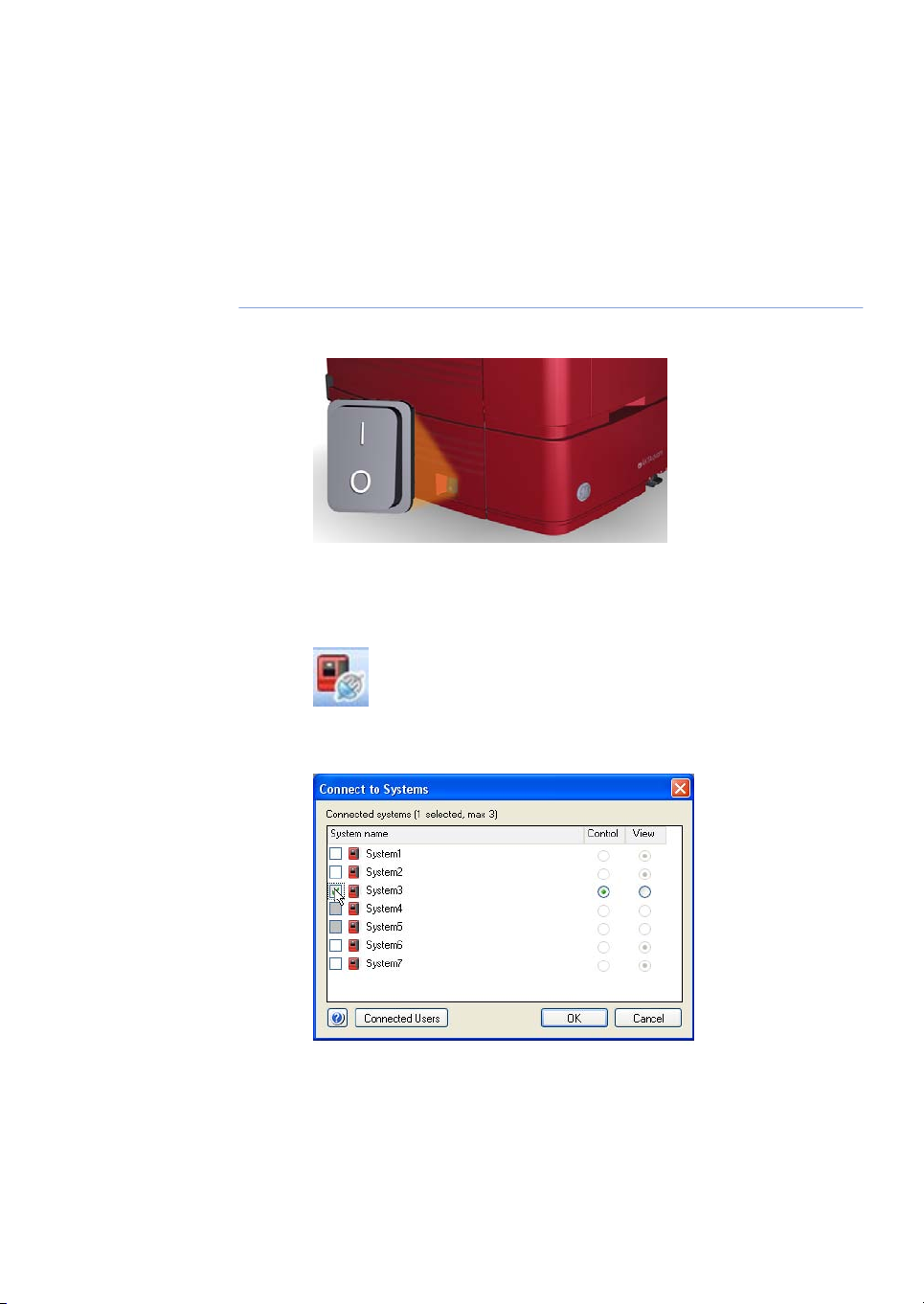

Open the the System Control module in UNICORN and click the Connect to

Systems icon.

Result: The Connect to Systems dialog opens.

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 29

Page 30

3 Start up

3.1 Start the system and log on to UNICORN

ActionStep

In the Connect to Systems dialog:3

Select the instrument .

•

Select Control mode.

•

Click OK.

•

Result: The selected instrument can now be controlled by the software.

30 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 31

4 The instrument and the software

4 The instrument and the software

Introduction

This chapter gives an overview of the ÄKTAavant system: instrument, software and

accessories.

Illustration of the system

The illustration below shows the ÄKTAavant instrument with UNICORN software installed

on a computer.

Contents

This chapter contains the following sections:

See pageSection

324.1 ÄKTAavant instrument overview

364.2 UNICORN software overview

394.3 UNICORN software modules

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 31

Page 32

4 The instrument and the software

4.1 ÄKTAavant instrument overview

4.1 ÄKTAavant instrument overview

Introduction

This section provides an overview of the ÄKTAavant instrument. Technical details about

the instrument and the individual modules are found in ÄKTAavant and UNICORN 6 User

Manual.

Exterior design

ÄKTAavant has a modular design, with all the liquid handling modules placed on the

exterior of the instrument. Buffer vessels are placed on the Buffer tray on top of the

instrument. An Instrument display is placed on the front. From this side the built-in

Fraction collector is handled, as well as the sample. The rest of the modules are placed

on the right-hand side of the instrument. This side can be covered by a foldable door

and a pump cover. By rotating the instrument using the swivel foot any side is easily

accessed.

Operating ranges

The table below shows some of the instrument’s operational limits.

LimitsParameter

Up to 25 ml/minFlow rate

20 MPaMax. operating pressure

190 - 700 nmWavelength

32 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 33

Illustration of the main parts of

the instrument

The illustration below shows the location of the main parts of the instrument.

4 The instrument and the software

4.1 ÄKTAavant instrument overview

DescriptionPart

Fraction collector1

Buffer tray2

Instrument display3

Wet side4

Foldable door5

Pump cover6

Holder rails7

Swivel foot Lock/Unlock knob8

Swivel foot9

Swing out toolbox10

Power switch11

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 33

Page 34

4 The instrument and the software

4.1 ÄKTAavant instrument overview

Illustration of the wet side

modules of the instrument

The illustration below shows the modules of the wet side of the instrument.

DescriptionPart

Injection valve1

Column valve2

Flow restrictor3

pH valve4

UV monitor5

Conductivity monitor6

Inlet valve B7

Quaternary valve8

System pump B9

Pressure monitor of System pumps10

Inlet valve A11

34 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 35

4 The instrument and the software

4.1 ÄKTAavant instrument overview

DescriptionPart

System pump A12

Mixer13

Pressure monitor of Sample pump14

Sample pump15

Pump piston rinsing system tubes16

Sample inlet valve17

Outlet valve18

Holder rails19

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 35

Page 36

4 The instrument and the software

4.2 UNICORN software overview

4.2 UNICORN software overview

Introduction

This section gives a brief overview of the UNICORN software—a complete package for

control, supervision and evaluation of chromatography instruments and purification

runs. It also describes how to access the help utility that is included in UNICORN.

UNICORN modules overview

UNICORN consists of four modules: Administration, Method Editor, System Control and

Evaluation. The main functions of each module are described in the table below.

Main functionsModule

Administration

Enter a UNICORN module

To enter a module:

•

click the Taskbar button of the module of interest,

or

•

choose the module of interest in the Tools menu inany of the other software modules.

The illustration below shows the Tools menu of the Evaluation module.

Perform userand system setup, system log and database

administration.

Create and edit methods.Method Editor

Start, view and control runs.System Control

Open results, evaluate runs and create reports.Evaluation

36 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 37

Access the help utility

A comprehensive help utility is included in the UNICORN software. The table below

describes how to access the different parts of the help utility.

a UNICORN module

4 The instrument and the software

4.2 UNICORN software overview

then...If you want to...

select Help:Help for... in the UNICORN module of interestfind information about

find information about

the item currently

selected and in focus

(e.g., a pane, a dialog, or

a method phase)

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 37

press the F1 key with the item of interest selected and

•

in focus

Note:

or

click the Help icon in the open dialog

•

To find information about a phase,

make sure that the Phase

Properties tab is selected before

pressing the F1 key.

Page 38

4 The instrument and the software

4.2 UNICORN software overview

then...If you want to...

navigate the online help

search for a specific

term in the online help

access any of the

manuals in PDF format

select Help:Help for... in any of the UNICORN modules

•

(see illustration above)

in the TOC pane, expand the headings of interest to

•

navigate the content structure

click the heading of interest to open a section

•

select Help:Help for... in any of the UNICORN modules

•

(see illustration above)

in the Search pane, enter the term of interest in the

•

input field

click the Search button

•

select Help:Help for... in any of the UNICORN modules

•

(see illustration above)

in the TOC pane, expand theheading UNICORN online

•

documentation portal and select Online

documentation overview

in the PDF manuals section, click one of the text links

•

click the illustration or the text link of the manual of

•

interest

In the Method Editor module:find information about

a method instruction

open a method

•

select the instruction of interest in the Instruction box

•

in the Text instruction pane

press the F1 key

•

In the System Control module:

select Manual:Execute Manual Instructions

•

expand a heading and select the instruction of interest

•

click the Help icon in the dialog

•

38 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 39

4.3 UNICORN software modules

Introduction

Three ofthe four UNICORN modules are used in this Getting Started guide and described

in this section: Method Editor, System Control and Evaluation. The Administration

module and its icons are described in UNICORN 6 Administration and Technical Manual.

Contents

This section contains the following subsections:

4 The instrument and the software

4.3 UNICORN software modules

See pageSection

404.3.1 Method Editor module

434.3.2 System Control module

454.3.3 Evaluation module

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 39

Page 40

4 The instrument and the software

4.3 UNICORN software modules

4.3.1 Method Editor module

4.3.1 Method Editor module

Introduction

In UNICORN software, the instructions to control a chromatography run are defined in

a method. The Method Editor module is used to create or edit such methods. The

graphical user interface combines default settings with the ability to change settings.

This simplifies method creation and replaces the method wizard in earlier versions of

UNICORN.

Predefined methods and phases

A method is built up by a number of phases. Each phase represents a major process

step in the method, for example, equilibrationor elution. Predefined methods,that include

all the phases necessary to run the system, are available for different chromatography

techniques and also for system cleaning.

40 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 41

Method Editor panes

1

32

4

As illustrated below, four panes show in the Method Editor by default . Available phases

are found in the Phase Library (1), and an overview of the phases included in the active

method is displayed in a Method Outline (2). Detailed information about the method is

presented in the upper right-hand pane (3), containing the two tabs Phase Properties

and Text Instructions. The gradient used in the method is displayed in a Gradient

illustration (4).

4 The instrument and the software

4.3 UNICORN software modules

4.3.1 Method Editor module

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 41

Page 42

4 The instrument and the software

4.3 UNICORN software modules

4.3.1 Method Editor module

Method Editor toolbar icons

The table below shows the Method Editor toolbar icons that are referredto in this Getting

Started guide.

FunctionIconFunctionIcon

New Method: Opens the

New Method dialog where

methods can be created.

Save: Saves the active

method.

Copy: Copies the selected

method or folder.

Undo: Restores the method

to the state it was in before

the last change.

Open Method Navigator:

Opens the Method

Navigator where available

methods are listed.

Print: Opens the Print

dialog from where a

method can be printed.

Paste: Pastes a copied

method or folder to a new

location.

Redo: Restores the method

to the state it was in before

the Undo command was

used.

42 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 43

4.3.2 System Control module

1

2

3 4

Introduction

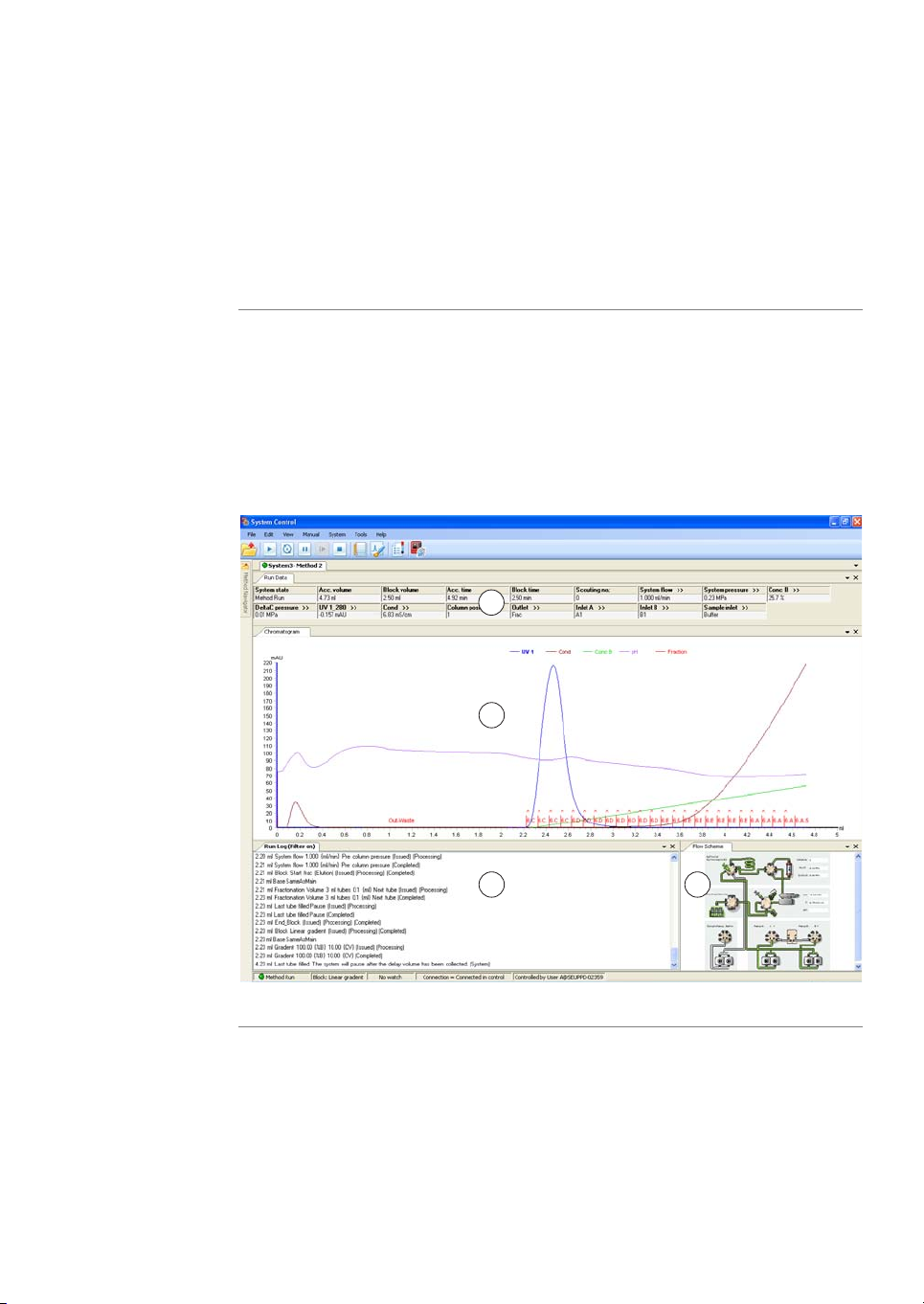

The System Control module is used to start , view, and control a method run.

System Control panes

As illustrated below, four panes show in the System Control by default. The Run Data

pane (1) presents current data in numerical values, while the Chromatogram pane (2)

illustrates data as curves during the entire method run. Information about the method

progression is presented in the Run Log (3) and the current flow path is illustrated in the

Flow Scheme (4).

4 The instrument and the software

4.3 UNICORN software modules

4.3.2 System Control module

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 43

Page 44

4 The instrument and the software

4.3 UNICORN software modules

4.3.2 System Control module

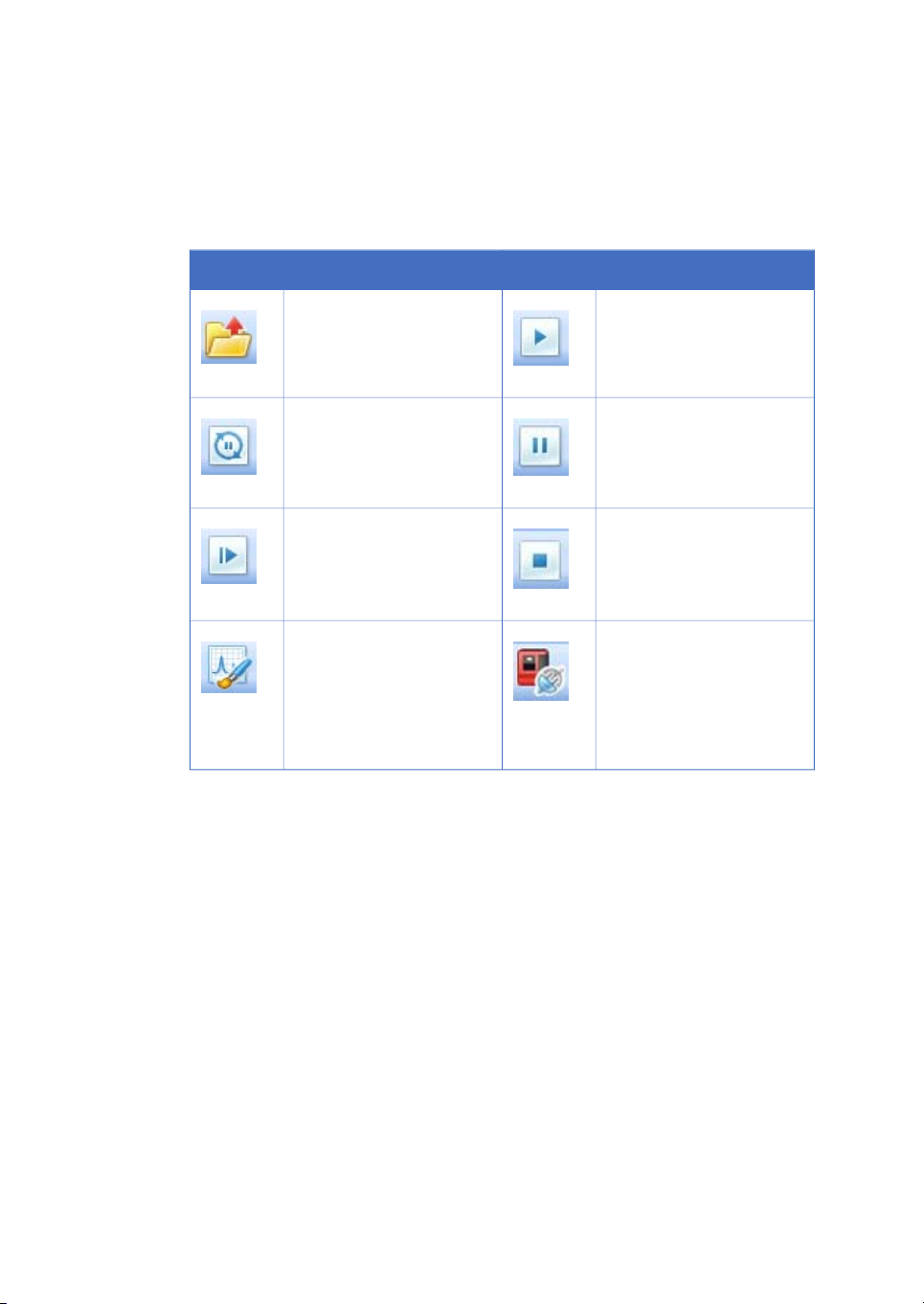

System Control toolbar icons

The table below shows the System Control toolbar icons that are referred to in this

Getting Started guide.

Opens the Method

Navigator where available

methods are listed.

FunctionIconFunctionIcon

Run: Starts a method run.Open Method Navigator:

Hold: Suspends the method

run, while current flow rate

and valve positions are

sustained.

Continue: Resumes for

example a held or paused

method run.

Customize: Opens the

Customize dialog where

curve settings, run data

groups and run log

contents can be set.

Pause: Suspends the

method run and stops all

pumps.

End: Permanently ends the

method run.

Connect to Systems: Opens

the Connect to Systems

dialog where systems can

be connected,and currently

connected users are

displayed.

44 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 45

4.3.3 Evaluation module

1

2

3

Introduction

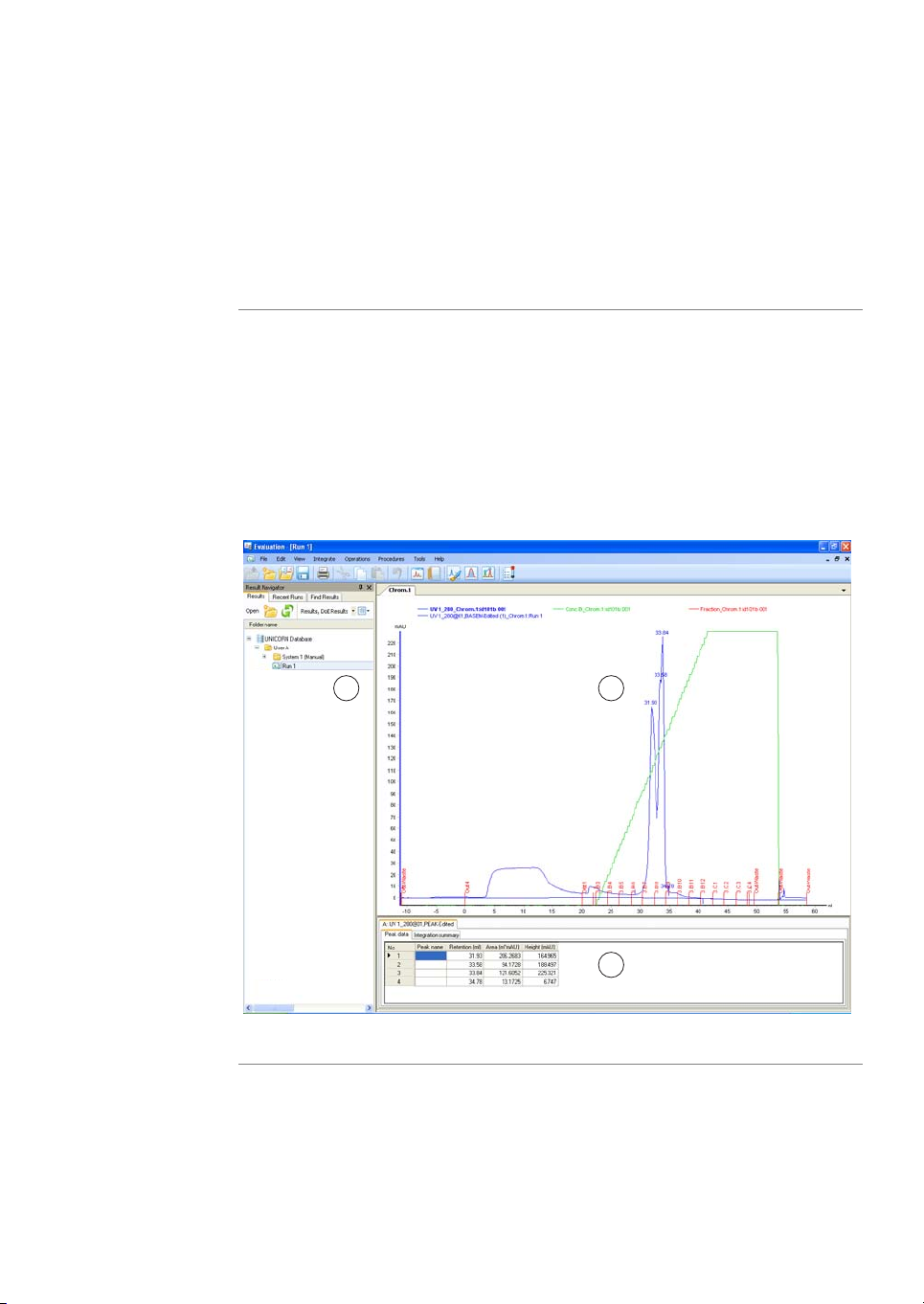

The Evaluation module is used to evaluate the results from chromatography runs.

Evaluation panes

As illustrated below, the Evaluation module contains three panes. When a result is

opened from the Result Navigator (1) the Chromatogram pane (2) is displayed. After a

peak integration has been performed, details about the peaks are shown in the lower

right-hand pane (3), in the tabs Peak data and Integration summary. In the Evaluation

module it is also possible to view the complete documentation about the results, and to

generate reports.

4 The instrument and the software

4.3 UNICORN software modules

4.3.3 Evaluation module

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 45

Page 46

4 The instrument and the software

4.3 UNICORN software modules

4.3.3 Evaluation module

Evaluation toolbar icons

The table below shows the Evaluation toolbar icons that are referred to in this Getting

Started guide.

FunctionIconFunctionIcon

Open Result Navigator:

Opens theResult Navigator

where available results are

listed.

Print: Opens the Print

chromatograms dialog

from where a

chromatogram can be

printed.

Paste: Pastes a copied

result or folder to the

selected folder.

Report: Opens the Create

report dialog where a

report of the result can be

created.

Customize: Opens the

Customize dialog where

curve settings, peak table

content andheader content

can be set .

Save: Saves the changes

made to the current result.

Copy: Copies the selected

result or folder.

Undo: Restores the method

to the state it was in before

the last change.

View Documentation:

Opens the Documentation

dialog that contains the

complete documentation

for a method run.

Peak Integrate: Opens the

Peak Integrate dialog from

where curves can be

integrated.

46 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 47

5 Files and folders in UNICORN

5 Files and folders in UNICORN

Introduction

In the UNICORNuser interface, method and result data are represented by files. All users

have a designated home folder where all methods and result files created by the user

will automatically be located. The files and folders are displayed in Navigator panes.

This chapter briefly describes the Navigator panes available in the different modules. It

also describes how to handle the files and folders.

Contents

This chapter contains the following sections:

See pageSection

485.1 Navigator overview

515.2 Handling files and folders

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 47

Page 48

5 Files and folders in UNICORN

5.1 Navigator overview

5.1 Navigator overview

Introduction

This section describes the navigator panes that are available in all UNICORN modules,

with exception for the Administration module. The navigator panes can be used to

locate and open methods and results, and to handle files and folders.

In the modules Method Editor and System Control, the navigator panes are called

Method Navigator and are used primarily to access methods.

In the Evaluation module, the navigator pane is called Result Navigator. In this navigator

pane three different panes can be used to access the results–Results, Recent Runs and

Find Results.

Show the navigator pane

To openand display the navigator pane in any of the UNICORN modules, click the Open...

toolbar icon.

The navigator panes may either be displayed statically in the position where they open,

or the Auto Hide function can be selected by clicking the pin symbol in the top right-hand

corner of the pane (illustrated below). If Auto Hide is selected, the panes open

automatically whenthe mouse pointeris placed overthe corresponding tab, and remain

open as long as the mouse pointer remains over the pane. The pane closes automatically

when the pointer is moved outside.

48 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 49

Navigator toolbar icons

The table below shows the common navigator toolbar icons.

FunctionIcon

Open: Opens the selected file.

New folder: Creates a new folder in the folder that is currently selected.

Refresh: Updates all items in the navigator pane to the current status.

Opens the View Details droplist (see illustration below) where the following

optional information may be selected for display in the navigator pane:

5 Files and folders in UNICORN

5.1 Navigator overview

System

•

Created by (user name of the person who created the original file)

•

Last modified (date and time when then file or folder was lastmodified)

•

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 49

Page 50

5 Files and folders in UNICORN

5.1 Navigator overview

Filter settings

By default, the Method Navigator shows only methods, and the Result Navigator only

results. This is the Default Filter setting for the items that are displayed. However, each

navigator may also show items that primarily are used in another UNICORN module.

The options are:

•

Default Filter: only items belonging to the active module show

-

In Method Editor and System Control: "Methods, Method Queues"

-

In Evaluation: "Results, DoE Results"

•

All: all items show, regardless of the active module

•

All except Archived: only items that are not archived show

The illustration below shows the filter settings available in the Method Navigator.

Close the navigator pane

Click the smallcross in the top right-handcorner of the pane to close the navigator pane.

50 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 51

5.2 Handling files and folders

Introduction

The handling of files and folders in UNICORN is similar to thegeneral Windows functions.

This section describes how to create new folders and how to copy, move, delete and

rename both files and folders. It also describes the general search function that helps

you find the files and folders that you are looking for.

Create a folder

To arrange your files for better overview, you can create sub-folders in any folder that

you have access to. Follow the instruction below to create a new folder in the Method

Navigator or in the Result Navigator.

ActionStep

Select the folder in which you want to create the new sub-folder.1

Click the New Folder icon.2

5 Files and folders in UNICORN

5.2 Handling files and folders

Result: A sub-folder named "New Folder" is created in the selected folder.

Note:

Type a name for the new folder.3

Result: The new folder is renamed.

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 51

The new folder is placed after all other sub-folders, but

before any files directly in the selected folder.

Page 52

5 Files and folders in UNICORN

5.2 Handling files and folders

Copy and paste files and folders

Follow the instructionbelow to copy and paste files and folders in the Method Navigator

or in the Result Navigator. If you copy a folder you will also copy all the files and folders

that it contains.

ActionStep

Select one or several files and/or folders.1

Click the Copy toolbar icon.2

Result: The selected items are copied.

Select a target folder.3

Click the Paste toolbar icon.4

TIP:

Move files and folders

Files and folders may be moved by drag-and-drop within the folder structure that you

have access to. The destination must always be a folder and the contents will normally

be re-sorted automatically so that:

•

folders are placed first, in alphabetical order, and

•

individual files are placed in alphabetical order, after the folders.

Note:

Result: The copied items are pasted into the selected folder.

You can select a range of items by pressing the keyboard Shift key or

several individual items by pressing the keyboard Ctrl key

The sorting order may be changed by clicking the header of each

column. You can also move folders and files by using Cut and Paste in

the same manner as Copy and Paste.

52 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 53

Delete files and folders

Follow the instruction below to delete files and folders in the Method Navigator or in

the Result Navigator.

Note:

ActionStep

Select the item(s) that you want to delete.1

Choose Edit:Delete.2

Result: A dialog for confirmation of the delete action opens.

Press Yes to confirm the delete action in the confirmation dialog.3

Result: The selected items are deleted.

5 Files and folders in UNICORN

5.2 Handling files and folders

Top levelfolders, for example homefolders, cannot be deleted thisway.

Refer to UNICORN 6 Administration and Technical Manual for more

information about home folders.

Note:

Rename files and folders

Follow the instruction below to rename files and folders in the Method Navigator or in

the Result Navigator.

ActionStep

Select the item that you want to rename.1

Choose Edit:Rename.2

Result: The current name is selected.

If you have chosen to delete a folder that is not empty, a special

confirmation dialog opens. This dialog displays all the items that will

be deleted as a consequence, both items in the active UNICORN module

and items in other UNICORN modules (see illustration below).

Type a new name.3

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 53

Page 54

5 Files and folders in UNICORN

5.2 Handling files and folders

ActionStep

Press Enter.4

Result: The selected item is renamed.

Find files and folders

Follow the instruction below to use the Find dialog to search for files or folders in the

Method Navigator or in the Result Navigator.

ActionStep

1

2

Select the file or folder in the navigator pane from where you want to

•

perform the search.

Choose Edit:Find.

•

Result: The Find dialog opens.

Type a name or a partial name in the Find what field.

•

Select none, one, or both of the the matching levels described below.

•

Match whole word only: Matches only whole words and disregards

-

partial matches.

Match case: Matches the case of the Find what field entry.

-

Select a Direction for the search.

•

Up: The search proceeds upwards in the folder structure from the

-

selected level.

Down: The search proceeds downwardsin the folder structure from

-

the selected level.

Click Find Next.3

Result: The first located match is selected in the navigator pane. The search

can be continued step by step until the whole folder structure has been

searched.

54 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 55

6 Create a method

Introduction

A method is created in the Method Editor module. Thischapter describes method creation

based on predefined methods, and also how to print a method.

Contents

This chapter contains the following sections:

6 Create a method

See pageSection

566.1 Guide to method creation

686.2 Print a method

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 55

Page 56

6 Create a method

6.1 Guide to method creation

6.1 Guide to method creation

Introduction

This section describes how to create a new method based on a predefined method, and

how to edit a method. The section also provides an overview of the predefined methods

and phasesthat are available.You can createboth purification methodsand maintenance

methods. You can also add a maintenance phase at the end of a purification method.

For further information about method creation, see UNICORN 6 Method Manual.

Contents

This sections contains the following subsections:

See pageSection

576.1.1 Create and edit methods

656.1.2 Predefined methods

676.1.3 Predefined phases

56 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 57

6.1.1 Create and edit methods

1

32

4

Introduction

Method creation in UNICORN 6 is performed in the Method Editor module. Predefined

methods areavailable for a number of different chromatographytechniques, for example

affinity chromatographyand gel filtration. There are also predefined methodsfor column

preparation and system cleaning. A method is comprised of a number of phases. Each

phase represents a major process step in the method, for example, equilibration or

elution. If desired, a predefined method can be edited by adding, deleting and/or

rearranging phases, and also by editing the settings of each phase included in the

method.

Illustration of the Method Editor

user interface

The illustration and table below shows the Method Editor module and its panes.

6 Create a method

6.1 Guide to method creation

6.1.1 Create and edit methods

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 57

Page 58

6 Create a method

6.1 Guide to method creation

6.1.1 Create and edit methods

DescriptionPart

Phase Library: Displays all available phases.1

2

Create a method

Follow the instruction below to create and edit a chromatographic method based on a

predefined method.

Method Outline: Presentsan overview of the phases included in the active

method.

Phase Properties: Presents detailed settings for the selected phase.3

Gradient: Illustrates the gradient used in the active method.4

ActionStep

Open the Method Editor module and click the New Method icon.1

Result: The New Method dialog opens.

Select System and Predefined Method in the dialog. Click OK.2

Result: The phases included in the chosen method show in the Method

Outline pane, and the default settings for each of the phases show in the

Phase Properties pane.

58 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 59

6 Create a method

6.1 Guide to method creation

6.1.1 Create and edit methods

ActionStep

3

In the Phase Properties pane of the Method Settings phase, edit general

settings like Column type and Method Base Unit. UNICORN automatically

calculates correct settings for volume, flow rate, and pressure limits based

on the selected column type.

The illustration below shows the Method Outline pane and the Phase

Properties pane of the Method Settings phase.

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 59

Page 60

6 Create a method

6.1 Guide to method creation

6.1.1 Create and edit methods

ActionStep

4

In the Phase Properties pane of the Method Settings phase, click the Result

Name & Location button to specify the name and location of the results

from the method runs.

Result: The Result Name & Location dialog opens.

In the Result Name & Location dialog:

Set Result location by clicking the Browse button and select a folder in

•

which to save the results. By default, the results will be saved in your

home folder.

Select Result name. With the default selection Method name the results

•

will be named with the method name together with a serial number.

Click OK to confirm and close the dialog.

•

60 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 61

6 Create a method

6.1 Guide to method creation

6.1.1 Create and edit methods

ActionStep

5

In the Phase Properties pane of the Method Settings phase, click the Start

Protocol button if you wish to include a start protocol.

Result: The Start Protocol dialog opens.

In the Start Protocol dialog:

Select items to display at method start. Result Name and Location is

•

selected by default .

Click OK to confirm and close the dialog.

•

6

Select the next phase in the Method Outline pane by clicking it, and choose

appropriate parameter values in the Phase Properties pane.

Repeat step 6 until all phases are edited.7

TIP:

If the instrument will not be used for a couple of days or

longer, add one or several System CIP phases to the end

of the method as described below.

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 61

Page 62

6 Create a method

6.1 Guide to method creation

6.1.1 Create and edit methods

ActionStep

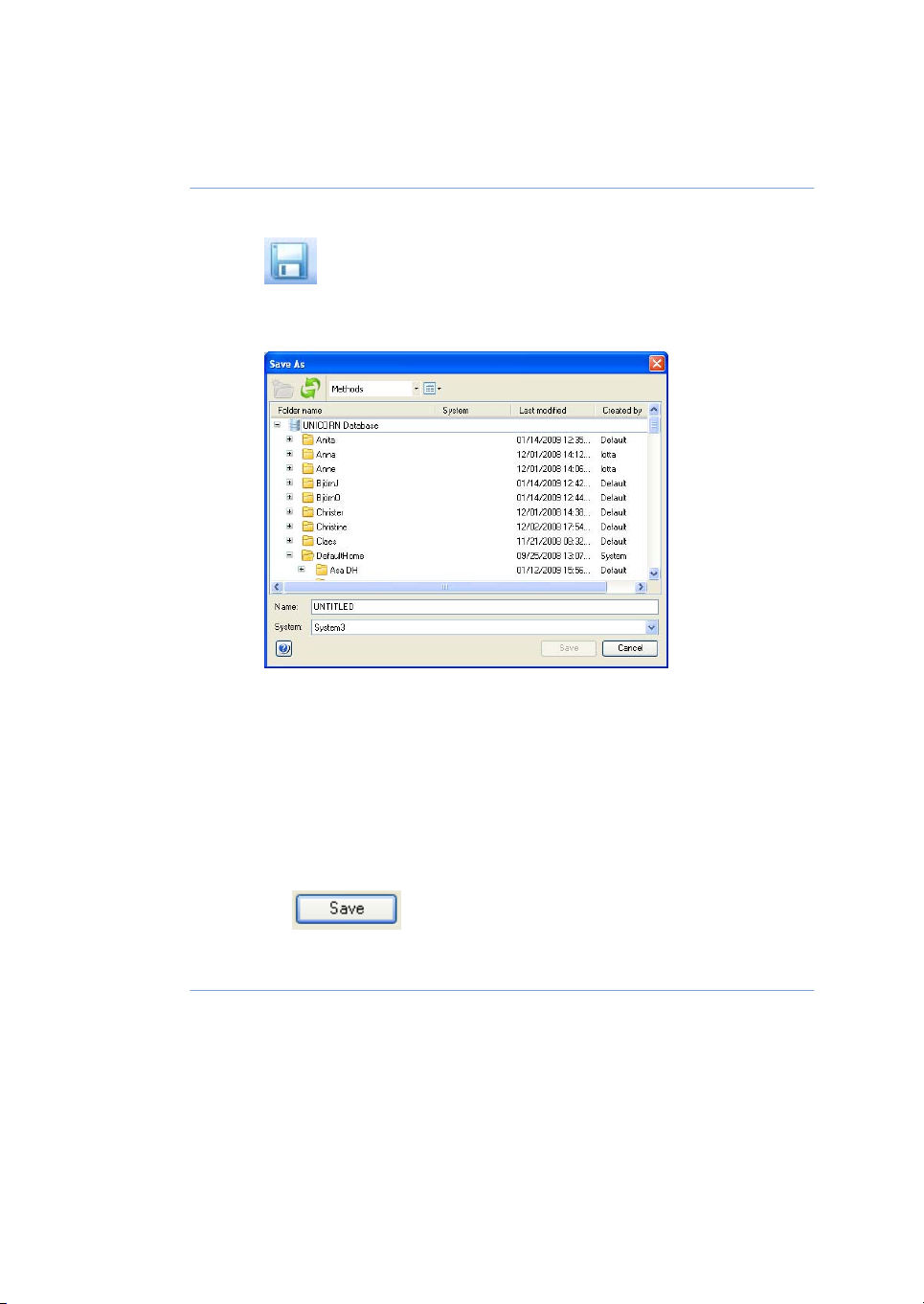

Click the Save the method icon.8

Result: The Save As dialog opens.

In the Save As dialog:9

Select a target folder to enable the Save button.

•

Type a Name for the method.

•

Select a System from the list.

•

Click the Save button.

•

Result: The created method is saved in the selected folder.

62 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 63

Add phases to a method

Follow the instruction below to add phases to a method.

ActionStep

Select the desired phase in the Phase Library pane.1

6 Create a method

6.1 Guide to method creation

6.1.1 Create and edit methods

2

Drag-and-drop thephase to requested position in the Method Outline pane.

The phase can be placed at any postion below the Method Settings phase.

Result: The phase is included in the method at the the requested position.

Delete phases from a method

Follow the instruction below to delete phases from a method.

ActionStep

Select the phase to delete in the Method Outline pane.1

Note:

Click the Delete button located below the Method Outline pane.2

Result: The selected phase is excluded from the method.

Rearrange phases within a

method

Follow the instruction below to rearrange phases within a method.

The Method Settings phase cannot be deleted.

ActionStep

Select the phase to move in the Method Outline pane.1

Note:

Drag-and-drop thephase to requested position in the Method Outline pane.2

Result: The selected phase is moved to the requested position.

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 63

The Method Settings phase cannot be moved.

Page 64

6 Create a method

6.1 Guide to method creation

6.1.1 Create and edit methods

Choose a maintenance method

A number of predefined methods for preparation and cleaning are available. Use these

maintenance methods to prepare and clean the system and columns, and to fill the

system and columns with storage solution. The table below gives suggestions for what

methods and solutions to choose for the different purposes.

before a run

SolutionPhase/MethodIf you wish to...

suitable buffersSystem PreparationPrepare tubing and instrument modules

suitable buffersColumn PreparationPrepare column before a run

0.5-1 M NaOHSystem CIPClean tubing and modules

0.5-1 M NaOHColumn CIPClean column

20% EthanolSystem CIPLeave system in storage solution

20% EthanolColumn CIPLeave column in storage solution

TIP:

TIP:

Note:

CIP (Cleaning-In-Place) and preparation of columns and system may

be run either as separate predefined methods or as phases included

in chromatographic methods.

The System CIP and System Preparation phases are designed to use

one cleaning solution each. The System Preparation method includes

two System Preparationphases and the System CIP method includes

three System CIP phases. To use additional solutions sequentially, add

phases to the method.

Usually 0.5-1 M NaOH is used for cleaning of the system and column.

However, before choosing cleaning agent always consider the media

and buffers used, and also the chemical resistance of the column.

64 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 65

6.1.2 Predefined methods

The predefined methods that are available are described in the table below.

6 Create a method

6.1 Guide to method creation

6.1.2 Predefined methods

DescriptionMethod

Affinity

chromatography

(AC)

Anion Exchange

Chromatography

(AIEX)

Cation Exchange

Chromatography

(CIEX)

Chromatofocusing

(CF)

Column CIP

After equilibration and sample application, the protein of

interest is adsorbed to the column ligand. After a wash to

remove unboundsample, elution is performed either by using

a buffer containing a competitor to displace the protein of

interest, or by changing the pH or ionic strength. Finally, the

column is re-equilibrated with start buffer.

After equilibration and sample application, negativelycharged

proteins are adsorbed to the column ligand. After a wash, to

remove unbound sample, elution isperformed using a gradient

of increasing salt concentration (of e.g., NaCl). Finally, the

column is washed and re-equilibrated with start buffer.

After equilibration and sample application, positively charged

proteins are adsorbed to the column ligand. After a wash, to

remove unbound sample, elution isperformed using a gradient

of increasing salt concentration (of e.g., NaCl). Finally, the

column is washed and re-equilibrated with start buffer.

After equilibrationand sample application, elution is performed

using a pH gradient. The proteinsseparate and elute according

to their isoelectricpoints. Finally, the column is re-equilibrated.

The column is filled with a cleaning solution. Select inlet

positions. Enter the solution identity, volume, flow rate and

incubation time. By adding steps, several cleaning solutions

can be used. Suggestions for cleaning steps are available for

a number of column types.

Column

Performance Test

Column

Preparation

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 65

After equilibration of the column, sample is injected via a

capillary loop and eluted isocratically. A non-adsorbing sample

like acetone or salt should be used. After the run, calculate

column performance in the Evaluation module. The efficiency

of the column is determined in terms of height equivalent to

a theoreticalplate (HETP), and the peak asymmetry factor (As).

The result is logged in the column logbook.

The column is filled with buffer solution. Select inlet positions.

Enter the solution identity, volume, flow rate and incubation

time. By adding steps, several preparation solutions can be

used.

Page 66

6 Create a method

6.1 Guide to method creation

6.1.2 Predefined methods

DescriptionMethod

Desalting (DS)

Gel filtration (GF)

Hydrophobic

Interaction

Chromatography

(HIC)

Reversed Phase

Chromatography

(RPC)

System CIP

After equilibration and sample application, the proteins are

eluted isocratically.This technique is commonly used for buffer

exchange.

After equilibration and sample application, proteins separate

and elute according to their size (largest first).

After equilibration and sample application (use a buffer

containing a high salt concentration, for example 2 M

Ammonium Sulphate) hydrophobic proteins are adsorbed to

the column ligand. After a wash to remove unbound sample,

elution is performed using a gradient of decreasing salt

concentration. Finally, the column is washed and

re-equilibrated with start buffer.

After equilibration and sample application, hydrophobic

proteins adsorb to the column ligand. After a wash to remove

unbound sample,elution is performed by generating a gradient

of a non-polar, organic solvent such as Acetonitrile. Finally,

the column is washed and re-equilibrated.

The system is filled with cleaning solution. Select for example

inlets, outlets and column positions to be cleaned. Three

System CIP phases are included in the method to facilitate

the use of three different cleaningsolution. Additional System

CIP phases can be added from the Phase Library if desired.

System

Preparation

The system is filled with preparation solution. Select for

example inlets, outlets and column positions to be prepared.

Two System Preparation phases are included in the method.

Additional System Preparation phases can be added from

the Phase Library if desired.

66 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 67

6.1.3 Predefined phases

The predefined phases that are available in the predefined methods and in the Phase

Library are described in the table below.

6 Create a method

6.1 Guide to method creation

6.1.3 Predefined phases

DescriptionPhase

Method Settings

Equilibration

Sample Application

Column Wash

Elution

Column

Preparation

Column CIP

System

Preparation

The first, and mandatory, phase in any method. Defines

common parameters used in the subsequent phases.

Equilibrates the column before purification, or re-equilibrates

the column after purification.

Applies sample to the column. Defines the sample application

technique, the sample volume, and the handling of

flowthrough.

Washes out unbound sample after sample application or

removes strongly bound proteins after elution.

Elutes the sample from the column. Defines parameters for

the elution and fractionation settings.

Prepares the column before use by removing the storage

solution and equilibrating the column. By adding steps, several

preparation solutions can be used sequentially.

Cleans the column after purification runs by rinsing the column

with a cleaning solution to remove unspecifically bound

proteins. By adding steps, several cleaning solutions can be

used sequentially.

Prepares the system before arun by removing storage solution

and filling the system and inlets with buffer solution. One

preparation solution is used per phase.

System CIP

Column

Performance Test

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 67

Cleans the system after purification runs by rinsing the system

with a cleaning solution. One cleaning solution is used per

phase.

Tests the efficiency of a packed column in terms of height

equivalent to a theoretical plate (HETP), and the peak

asymmetry factor (As).

Page 68

6 Create a method

6.2 Print a method

6.2 Print a method

Introduction

This section describes how to print the text instructions and variables of a method.

UNICORN uses the printers and printer settings that are installed on your computer.

How to print a method

Follow the instruction below to print a method.

ActionStep

1

2

Open the Method Editor module and click the Open Method Navigator icon

in the toolbar.

Result: The Method Navigator pane opens.

Select themethod to print and click the Open a Method iconin the navigator

toolbar.

Result: The selected method opens.

68 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 69

ActionStep

Click the Print icon.3

Result: The Print dialog opens.

In the Print dialog:4

select Printer

•

6 Create a method

6.2 Print a method

click OK

•

Result: The method is printed.

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 69

Page 70

7 Prepare the system for a run

7 Prepare the system for a run

Introduction

Follow this chapter to perform the necessary preparations of the system before starting

a run.

WARNING

Always use appropriate personal protective equipment during

operation and maintenance of ÄKTAavant system.

Contents

This chapter contains the following sections:

See pageSection

717.1 Before you prepare the system

727.2 Prepare the flow path

787.3 Prime buffer inlets and purge System pumps

837.4 Connect a column

887.5 Calibrate the pH monitor

907.6 Prepare the Fraction collector

70 Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB

Page 71

7.1 Before you prepare the system

Introduction

It is important to prepare the system in accordance with the settings in the method to

be run. Before preparing the system, check the settings in the Method Editor and make

sure that all accessories to be used are available.

Checklist

Make sure to prepare the system in accordance with the settings in the method to be

run. Remember to check:

•

which valve ports to use for inlets and outlets

•

which cassettes with corresponding deep well plates and/or tubes to use in the

Fraction collector, if applicable

•

which column type to use

•

which column position to use

•

which sample application technique to use

•

that the pH electrode is connected, if applicable

•

if it is a reversed phase chromatography (RPC) run

7 Prepare the system for a run

7.1 Before you prepare the system

WARNING

RPC runs with 100% acetonitrile. Always replace the green

PEEK tubing between the used system pump and the pressure

monitor with orange PEEK tubing, i.d. 0.5 mm, before running

RPC with 100% acetonitrile. Set the System pressure alarm to

10 MPa.

WARNING

Fraction collector. Do not fractionate flammable liquids. When

running RPC methods, or other procedures usingsolvent based

buffers, collect fractions through the outlet valve.

Getting Started with ÄKTAavant and UNICORN 6 28-9440-69 AB 71

Page 72