Page 1

VAT2000 AC Drive Series

U2KV23PI0

Parallel Inter f ac e

INSTRUCTION MANUAL

GE Power Controls

NOTICE

1. Read both this manual and VAT2000 Instruction

Manual (PCST-3251) before using the

U2KV23PI0, and store in a safe place for

reference.

2. Observe the warnings, cautions and other matters

described in this manual.

3. Make sure that this manual is delivered to the final

user.

GE Power Controls

PCST-3303E-R0

Page 2

Contents

1. Specifications and Co nfiguration....................................................................... 1

2. Installation Into Inverter ...................................................................................... 2

3. Parallel Data Input................................................................................................ 4

3-1. Connection and setting procedure.................................................................. 4

3-2. Data input mode selection and signal specifications....................................... 5

3-3. Signal logic and circuit format selection.......................................................... 7

4. Usage of PSO Termin al Function........................................................................8

Appendix Table 1 CN1 pin layout ............................................................................... 9

Appendix Table 2 TB1 terminal functions.................................................................. 9

Appendix Table 3 Hardware Option Function Setting ............................................ 10

Page 3

1. Specifications and Configuration

1. Specifications and Configuration

Table 1-1 U2KV23PI0 specifications

Item Specification s

Parallel input section

Frequency setting/Speed setting

resolution

Data format

Synchronization method

Data width Select from 16-bit non-multiplexed or 8-bit m ultiplexed

Circuit voltage/ c ur r ent 24VDC/5mA (toler able leakage current 0.5mA)

Interface power

Open collector outpu t section

No. of points 2 points (PSO4, 5)

Max. voltage/current 30VDC/50mA

Min. 0.01Hz (0.1rpm)

Select from a total of elev en types i nc luding

binary/BCD, 8/ 16 bits

Select from synchronous method with strobe signal or

asynchronous method with sample

24V±10%, 0.2A or higher capacit y to be provided by

the user.

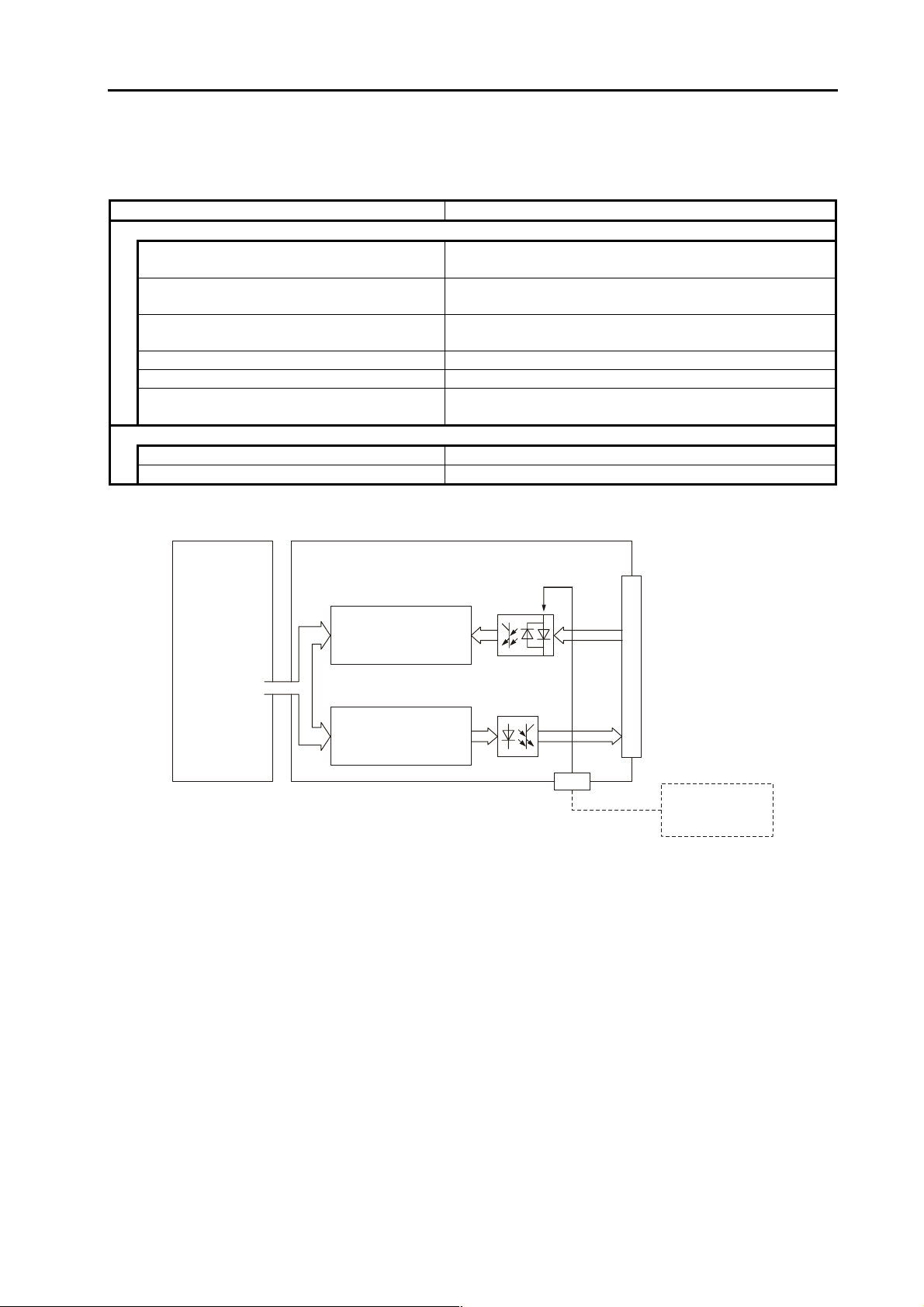

Control PCB

V23-P I0 Option PCB

Parallel data

input section

Open collector

output section

Fig. 1-1 Configuration

TB1

1

N

C

External power

supply fo r p a rallel

input

- 1 -

Page 4

2. Installation Into Inverter

2. Installation Into Inverter

The installation procedure and points of cauti on ar e as descri bed below.

(1) Remove the inverter unit' s fr ont cov er.

CAUTION

1. Wait at least 20 mi nutes after turning the power OFF bef or e star ting work. Make sure that the

displays on the operation panel have gone out before r em ovi ng the cov er.

2. After removing the cov er, confirm that the “CHARGE” LED on the unit has gone out.

Also check that the v oltage bet ween term inals L+1 or L+2 and L- is 15V or less before start ing

the inspecti ons.

(Check with the “CHA RGE” LED if t he unit is not provided with the L- terminal .)

(2) If the other option PCB is installed onto the position for option II on the control PCB cover,

install this PCB onto the position for option III.

Refer to Fig. 2-1.

2

(3) When wiring to TB1 use AWG26 to 16 (0.14 to 1.5mm

Wires should be termi nated correctly, with suitable crimp terminals or ferrules.

Pass the wires through the cable connection hole on the inver ter unit and then connect.

CAUTION

1. Observe the cauti ons li sted in Fig. 3-1 and Section 2-4 in the VAT2000 Instruction Manual

(PCST-3251) when wiring.

) for the wires.

- 2 -

Page 5

2. Installation Into Inverter

The m ou nting position

of V23-PI0

Option

Option

II

III

Option cover

Fig. 2-1 Installation of optional PCB

Control PCB cover

Option

I

NPSF - ST19 -

01

TB1

1

MEIDEN

25

26

2

N62P 30449 1 /5A MA D E IN JA PAN

SINK

CP1

1

W1

2

SOURCE

1

2

CN1

Fig. 2-2 Optional PCB

- 3 -

Page 6

3. Parallel Data Input

3. Parallel Data Input

3-1. Connection and setting procedure

(1) Connection

The parallel data input connection is shown in Fig. 3- 1.

The parallel data is i nput f r om CN1. CN1 is a DDK FRC2-C26L11-0L.

The flat cable (FRC2-A A 26- 10S ) must be provided by the user.

1. The cable length must be 30m or less.

2. The external power can be supplied from the flat cable; but if the cable length is 2m or more,

supply the power from TB 1.

The wires that can be used for TB1 are AWG26 to 16 (0.14 to 1.5mm2).

If the flat cable cannot be passed through the inv erter unit's cabl e connection hole, r emove t he

plate of the cable connec tion hole.

In this case, the protec tive structure will be IP00.

CAUTION

Parallel data

input short pin

TB1

1

2

24V power

supply

The 24V power supply is to be provided by the user

Note)

EX0

EX24

1

W1

2

CN125 1

26 2

26-core

flat cable

Sequ encer or digital sw itch

Max. 30m

Fig. 3-1 Connection of parallel data input section

(2) Se tting proced ure

1) Decide the cir c uit f ormat and data format.

2) Decide the cir c uit f ormat (open collector/open emi tt er ) with W1. (Fig. 3-5).

3) Turn ON the power, Set the parameter C02-0 to 2 (parall el fixed). (Refer t o Fig. 5-9 in the

VAT2000 Instruction M anual ( P CST- 3251) .)

4) Set the data input mode, circuit format, and parall el data format in C32-0 to C32-2.

Set the A05-2 setting v alue to 1 to cancel the hardware opti on display skip when setti ng

Note)

the C32-0 to C32-2 parameters.

(The default value is di spl ay skip.)

- 4 -

Page 7

3. Parallel Data Input

3-2. Data input mode selection and signal specifications

The following t hr ee methods can be used for the parallel input dat a input method.

1) 16-bit with strobe

2) 8-bit multi plex ed with strobe

3) 16-bit sample

These methods are select ed with parameter No. C32-0.

(1) 16-bit with strobe (C32-0 = 1)

The 16-bit data (D0 to 15) is l oaded with the rising edge of the strobe (STB).

tcy

ts th

D0~D15

OFF

STB

Inte r na l d a ta

ON

Data 0 Data 1 D ata 2

tw

Data 0 Data 1

tds

Fig. 3-2 16-bit with strobe time chart

(2) 8-bit multiplexed with strob e (C32-0 = 2)

The 16-bit data is divided into the low-order 8-bi t and high-order 8-bit wit h the LSB signal, and

each is loaded with the rising edge of the strobe (STB).

tcy

ts th

D0~D7

LSB

Data 0 (high-order) Data 1 (low-orde r) Data 2 (high-order)

OFF

ON

OFF

STB

Inte r na l d a ta

ON

tw

Data 0 Data 1

tds

Fig. 3-3 8-bit multiplexed with strobe time chart

- 5 -

Page 8

3. Parallel Data Input

(3) 16-bit sample (C32-0 = 3)

The 16-bit data is sampled every 10mS, and is loaded when the data for f our samples match.

Data 0 Data 1 Data 2 Data 3

tsp

123412

Fig. 3-4 Sample mode time chart

(4) Timing specifications

Table 3-1

Symbol Name Specifications

t cy Cycle time • 25mS

t w STB pulse width • 3mS

t s Dat a setup time • 2mS

t h Data hold time • 2mS

t ds Strobe delay 15 ~ 25mS

t da Sample mode delay 50 ~ 60mS

t sp Internal sample time 10 ± 2mS

3

412121

Data 0 Data 1

tda

Data 2 and 3 are not loaded

Note)

in this cas e.

- 6 -

Page 9

3. Parallel Data Input

3-3. Signal logic and circuit format selection

(1) Signal logic selection (D0 ~ D15)

Dn = 1 when the contact connect ed to D0 t o D15 i s ON (closed ci rcuit), or Dn = 1 when the

contact is OFF (open ci rcuit ) c an be select ed with parameter No. C32-1. (Appendix Table 3)

(2)Signal common selection (W1)

Setting of all signal c ommons to EX0 or EX24 can be selected with the W1 setting.

The sequence output m ethod open collector and open emitter can bot h be corresponded to with

this.

V23-PI0

W1

EX0

1

2

EX24

TB1-2

TB1-1

+

External

24V po wer supp ly

-

D0~D15

5 K

STB, LSB

5 K

Open collector output

Controller such as sequencer

Fig. 3-5 Short pin W1 setting

Open emitter output

- 7 -

Page 10

4. Usage of PSO Terminal Function

4. Usage of PSO Terminal Function

When using the U2KV23PI0 PSO4, 5 termi nals, set parameter C33-0, 1 sequence output signal.

(Appendix Table 3)

Refer to Table 5-4 in the VAT2000 Instruction Manual (PCST-3251) for details on the sequence

output signal functions.

Table 4-1 PSO terminal settings

Sequence output signal

Terminal Parameter No.

setting data output signal

PSO4A-PSO4B-PSO4C C33-0 5 LCL

PSO5A-PSO5B-PSO5C C33-1 6 REV

The sequence output (PSO4, 5) terminals are laid out in CN1. (Appendix Table 1)

V23-PI0

default values

PSO4

PSO5

CN1-21

CN1 -22, 23

CN1-24

CN1-25,26

Load

max. 50mA

Fig. 4-1 PSO terminal connection

max. 30V

- 8 -

Page 11

Appendix Table

Appendi x Table 1 CN1 pin la you t

Terminal No.

Symbol

CN1 - 1 D0

< Low significant bit >

Function

- 2 D1

- 3 D2

- 4 D3

- 5 D4

- 6 D5

- 7 D6

- 8 D7

- 9 D8

- 10 D9

Parallel data

CN1 - 11 D10

- 12 D11

- 13 D12

- 14 D13

- 15 D14

- 16 D15

- 17 LSB

- 18 ST B

- 19 EX24

- 20 EX0

< Most significant bit >

Indicates l ow-order 8- bit when ON. (Use for 8-bit time

multiplexed mode)

Loaded at the strobe ON to OFF edge. ( Use f or strobe

mode)

External 24V power supply i nput for the parallel dat a

input

External 24V power supply i nput common for the

parallel dat a input

CN1 - 21 PSO4 PSO4 output termi nal ( open c ollector)

- 22 COM1

- 23 COM1

PSO output terminal common

- 24 PSO5 PSO5 out put t erminal (open collector)

- 25 COM1

- 26 COM1

PSO output terminal common

25

26 2

CN1

1

View from connector insertion side

1

Appendix Table 2 TB1 ter m i na l fun c t io ns

Terminal No.

TB1 - 1 EX24

- 2 EX0

Symbol

External 24V power supply i nput for the parallel dat a

input

External 24V power supply i nput common for the

parallel dat a input

Function

- 9 -

Page 12

Appendix Table

Appendix Table 3 Hardware Option Function Setting

Block-C parameters (Basic function constants) list

No. Parameter Unit Default Min. Max. Function

C02 – Various setting input selection

=1: Analog fixed

Speed setting input

0

points selection

Traverse center

1

frequency input

points selection

T orque setting

2

input points

selection

Torque ratio 1

3

setting input points

selection

Torque bias 1

4

setting input points

selection

Torque ratio 2

5

setting input points

selection

Drive/regenerative

6

torque limit input

points selection

ASR response

7

input points

selection

Machine time

8

const ant in pu t

points selection

4. 1. 4.

2. 1. 3.

3. 1. 4.

2. 1. 3.

3. 1. 4.

2. 1. 3.

3. 1. 3.

2. 1. 3.

2. 1. 3.

=2: Serial/parallel fixed

=3: Panel fixe d

=4: Sequence

=1: Analog fixed

=2: Panel fixe d

=3: Sequence

=1: Analog fixed

=2: Serial fixed

=3: Panel fixe d

=4: Sequence

=1: Serial fixed

=2: Panel fixe d

=3: Sequence

=1: Analog fixed

=2: Serial fixed

=3: Panel fixe d

=4: Sequence

=1: Serial fixed

=2: Panel fixe d

=3: Sequence

=1: Analog fixed

=2: Serial fixed

=3: Sequence

=1: Serial fixed

=2: Panel fixe d

=3: Sequence

=1: Serial fixed

=2: Panel fixe d

=3: Sequence

Application

ST V/f VEC PM

O

O

OO

OO

OO

OO

OO

OO

OO

Block-C parameters (H/W option function constants) list

No. Parameter Unit Default Min. Max. Function

C32 – PC (parallel) Interface

Input mode

0

(strobe)

Input mode (input

1

logic)

2 Data format 1. 0. 10.

Setting data Format Setting resolution Setting range

0

1

2

3

4

5

6

7

8

9

10

Hz = Frequency setting [ For V/f control (Constant torque, reduced torque) (C30-0 = 1, 2) ]

rpm: Speed setting

Set this when th e P ar all el in terfac e opti on (U 2K V 2 3PL 0) h as b een mou nt ed .

16-bit binary

16-bit binary

16-bit binary

16-bit binary

16-bit BCD

16-bit BCD

16-bit BCD

16-bit BCD

8-bit binary

12-bit binary

16-bit binary

1. 1. 3.

1. 1. 2.

0.01Hz/LSB (0.1rpm/LSB)

0.1Hz/LSB ( 1rpm/LSB)

0.01%LSB

0.1%LSB

0.01Hz/LSB (0.1rpm/LSB)

0.1Hz/LSB ( 1rpm/LSB)

0.01%LSB

0.1%LSB

1/255%

1/4095%

1/65535%

For IM speed sensorless vector control (C30-0 = 3)

For IM speed vector control (C30-0 = 4)

For PM motor c ontrol (C30- 0 = 5)

=1: 16 -bit strobe

=2: 8 -bit time multiplexed strobe

=3: 16 -bit sample

=1: 1 at closed circuit

=2: 1 at opened circ u it

Set accord in g to th e f oll owi ng

table.

0 to 440.00Hz (0.0 to 6553.5rpm or Nmax)

440.0Hz (0 to Nmax rpm)

100.00%

100.0%

99.99Hz (0.0 to 999.9rpm)

100.0Hz (0 to Nmax rpm)

99.99%

100.0%

100.0%

100.0%

100.0%

Application

ST V/f VEC PM

O

O

O

- 10 -

Page 13

Appendix Table

Block-C parameters (H/W option function constants) list

No. Parameter Unit Default Min. Max. Function

C33 – Sequence output terminal function (Option)

PSO4 Output

0

parameters

PSO5 Output

1

parameters

5. 0. 24. O

6. 0. 24.

Set this when th e r el ay in t erface

option (U2KV23RY0) and Parallel

interface option (U2KV23PI0) are

mounted.

Refer to Instruction Manual

(PCST-3301) for other details.

Application

ST V/f VEC PM

O

Value Output

signal

0 RUN 8 ATN 16 ACC 24 ULMT

1 FLT 9 SPD1 17 DCC

2 MC 10 SPD2 18 AUXDV

3 RDY1 11 COP 19 ALM

4RDY2 12EC0 20FAN

5 LCL 13 EC1 21 ASW

6 REV 14 EC2 22 ZSP

7 IDET 15 EC3 23 LLMT

Value Output

signal

Value Output

signal

Value Output

signal

- 11 -

Loading...

Loading...