Page 1

GE Oil & Gas

Turboexpander-generators

Page 2

Turboexpandergenerators

A turboexpander expands process fluid

from the inlet pressure to the discharge

pressure in two steps: first through variable

inlet guide vanes and then through the

radial wheel. As the accelerated process

fluid moves from the inlet guide vanes

to the expander wheel, kinetic energy is

converted into useful mechanical energy

– extracting energy from the process

fluid and cooling it down. The mechanical

energy is available to drive other process

equipment – in this case, a generator.

Our turboexpander-generator designs

respond to specific industry needs for

increased capacity, reduced costs and

maximized reliability in a wide range of

applications, including:

Continually expanding capabilities

After more than 50 years of turboexpander design, GE now

has about 1,200 units operating worldwide (over 150 coupled

with generators) – and a proven record of delivering higher

power levels, performing at extreme operating temperatures

and achieving greater pressure ratios.

This success across the natural gas and hydrocarbon

industries is a result of our continuous improvement in areas

such as rotor and bearing design, efficiency optimization and

control systems.

• Oil & Gas processing Natural Gas Liquids

(NGL) plants, Liquefied Petroleum Gas

(LPG) recovery; tail gas treatment; GasTo-liquids (GTL); Integrated Gasification

Combined Cycle (IGCC)

• Liquefaction and purification of gases on

air treatment plants

• Petrochemicals: hydrogen, nitrogen

and ammonia purification; ethylene

production

• Pressure Let Down (PLD) on pipeline

• Geothermal power generation

(e.g. Organic Rankine Cycle, Kalina and

direct steam)

• Waste-heat recovery (WHR) and

Combined Heat and Power (CHP)

• Ocean Thermal Energy Recovery (OTEC)

Page 3

Excellence in design and testing

Construction Modifications and Uprates

The GE Turboexpander Center of Excellence brings together

GE specialists in design, manufacturing and testing to ensure

continuous innovation of application-specific solutions.

We work in close cooperation with customer engineering and

plant operation teams – and are therefore highly attuned to the

challenges they face every day. In-depth performance data

and myriad operating insights are continually fed back into our

engineering processes so that our designs are always on the

leading edge.

Our advanced testing facilities are completely

equipped with real-time data acquisition systems

and integrated analysis tools to provide a complete

map of equipment performance. Our capabilities

include tests and inclusion of feed gas preparation

systems – for tests with virtually any gas mixture

of interest to a customer. We also have the

ability to perform full-load string tests with up- or

downstream compressors.

GE turboexpander-generators are normally tested

with low-pressure air in an open loop setup in

accordance with ASME PTC10, Type 2.

Our Global Services teams provide a comprehensive range of

specialized solutions designed to maximize plant productivity and

return on investment.

We develop customized solutions for every installation and

application. Whether your goal is to economically modify

your process or to inject the latest technologies for increased

productivity with minimal downtime, our approach typically

minimizes impact on the turboexpander installation and piping.

From engineering design to on-site installation, all work is

performed to the highest standards by GE-trained specialists,

with full support for the entire process provided by our network of

facilities and resources.

Technologies

for extreme challenges

Page 4

GE Oil & Gas

Turboexpander-generators

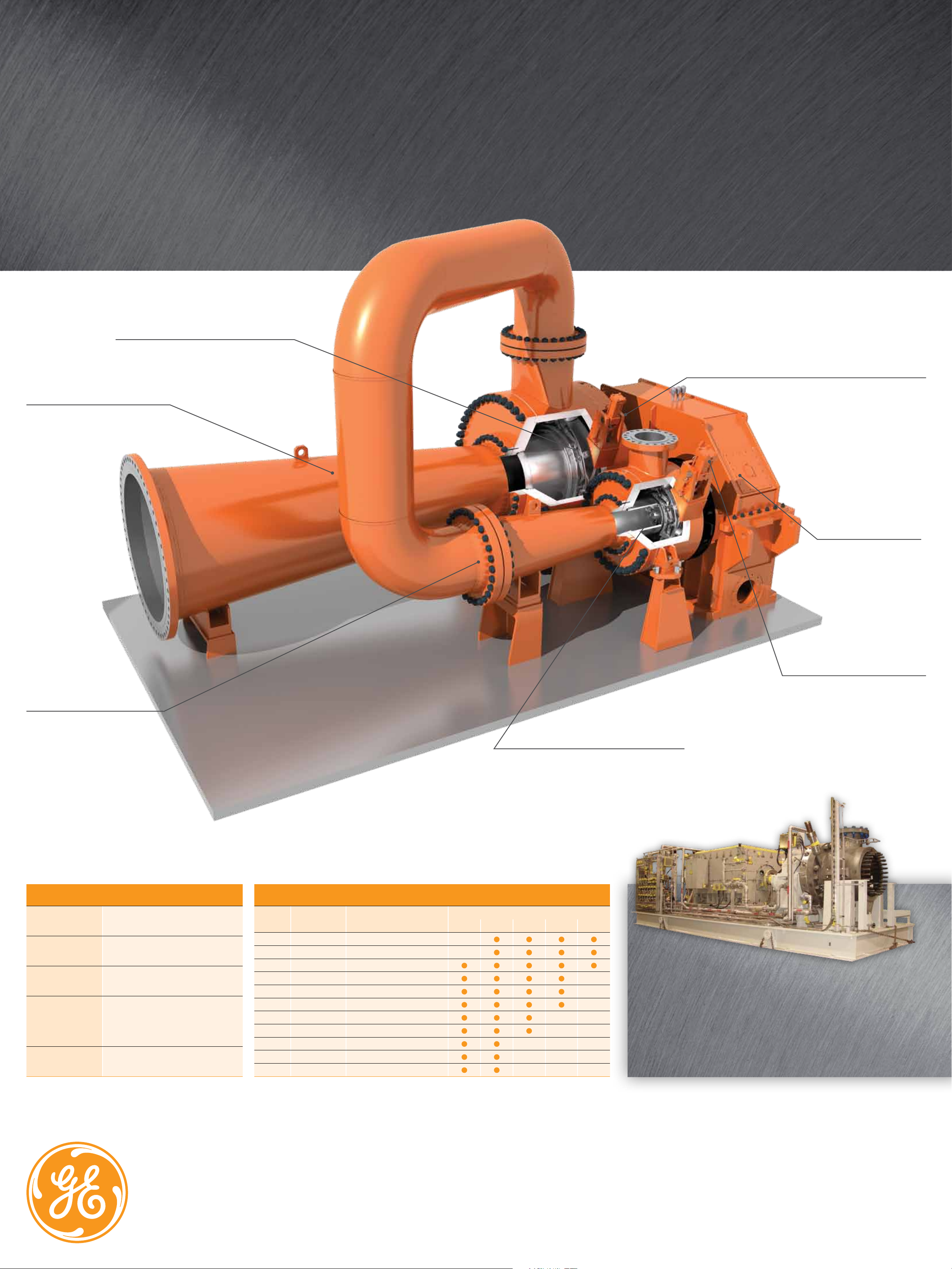

With design features to increase performance and reduce

maintenance downtime in extreme natural gas applications

Patented multi-link Inlet Guide Vanes (IGVs)

for precise control and smooth adjustment.

High-efficiency aerodynamics

customized to customer specifications.

Dynamic dry gas seals can be applied in single, double or

tandem configurations to minimize buffer gas leakage.

High pressure ratios or high

flow rates require multistage

arrangement. GE expanders can

accommodate up to four stages

on a common integral gearbox.

The expander wheels are

mounted directly on the

high-speed pinions, and

the generator is coupled

to the low-speed gear.

Hydraulic, pneumatic or electric

actuators control the IGVs and

provide precise control from 0 to

130% of design flow.

If the monitored pressures of two opposed

thrust bearings are imbalanced, the controller

automatically adjusts pressure behind the

expander wheel to keep the rotor centered

at all times.

GE’s Turboexpander-generator capabilities

Pressure

Temperature

Expansion ratio

Process fluid

Liquid

* Movable IGVs available up to 300ºC

up to 3,000 psia (200 BarA)

-450ºF to 925ºF (-270ºC to 500ºC*)

up to 14 per stage

All pure or mixed fluids including

natural gas, petrochemical products,

hydrogen, air, steam, etc.

up to 30% of weight at discharge

Expander-Generator Frame Size Distribution

Shaft power Expander outlet flow max. Available casing ratings

Frame

(kW) (m

20 1,600 4,000

25 2,000 5,500

30 4,800 9,000

40 6,500 16,000

50 10,000 25,000

60 15,000 36,000

80 20,000 45,000

100 25,000 70,000

130 30,000 100,000

160 40,000 150,000

180 45,000 200,000

3

/h) 150 300 600 900 1500

Drive and speed options

GE also offers turboexpanders with direct drive or external

gearboxes as required, with a common oil supply system for the

complete package. The installed fleet ranges from 50 to 15,000

kW. When feasible, the direct-drive option eliminates the need for

speed reduction, gearboxes and associated equipment.

GE imagination at work

ge.com/oilandgas

Page 5

GE Oil & Gas

ge.com/oilandgas

Global Headquarters

Via Felice Matteucci, 2

50127 Florence, Italy

T +39 055 423 211

F +39 055 423 2800

customer.service.center@ge.com

Nuovo Pignone S.p.A.

Nuovo Pignone S.r.l.

Americas Regional Headquarters

4424 West Sam Houston Parkway North

Houston, Texas 77041

P.O. Box 2291

Houston, Texas 77252-2291

T +1 713 683 2400

F +1 713 683 2421

For complete contact information,

please refer to our website.

The information contained herein is general in nature

and is not intended for specific construction, installation

or application purposes. GE reserves the right to make

changes in specifications or add improvements at any

time without notice or obligation.

GE, the GE Monogram, and imagination at work are

registered trademarks of the General Electric Company.

©2012 General Electric Company

All Rights Reserved

GE imagination at work

GEOG_TurboXGen_Brochure _012412

Loading...

Loading...