Page 1

GE Oil & Gas

Benefits

Get more from your

What it is

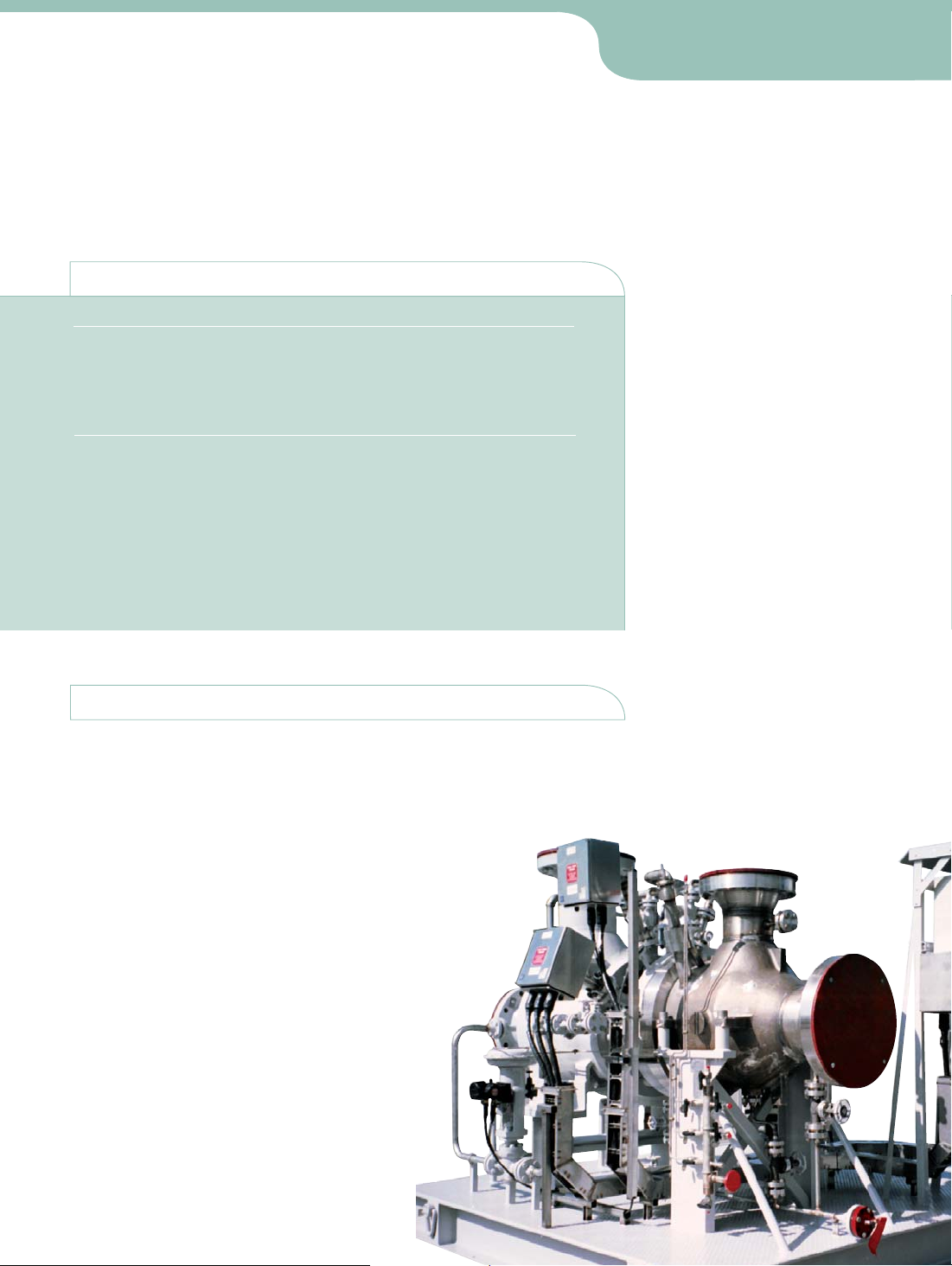

Turboexpanders

Performance Improvement and Uprate

g g g

Increased production

g g c

Higher efficiency

g c c

Compliance with environmental regulations

g g c

Availability and Reliability

g g c

Life extension

Possible performance improvements by turboexpander uprate include:

• Increased production up to 50%

• Maximized refrigeration capability to increase overall plant performance

• Automation of controls including Remote Monitoring and Diagnostics

• Elimination of oil system with improved reliability and availability

GE Oil & Gas and its legacy Rotoflow

business is a pioneer in turboexpander

technology and solving industry

challenges. As GE Oil & Gas we are

focused on removing barriers to allow

our customers to maximize their plant

production and return on investment.

Although we can provide standard

solutions, our expertise and flexibility

allow us to develop custom solutions

for every customer and application.

We are able to deliver, whether the

goal is to modify your process with

minimal investment, or to use stateof-the-art upgrade to minimize

production downtime. Either approach

typically have no impact on the

turboexpander installation or piping,

and GE’s worldwide field and service

shop network can support the entire

process.

g

Page 2

What it is

How it works

Every upgrade project begins with a

deep analysis of customer’s needs

and plant characteristics. After this

critical step, desired process

conditions are reviewed to develop

the optimal solution. Depending on

the application, upgrades provide

high return on investment through

optimized efficiency, even with minor

changes in the gas dynamics.

We will evaluate the existing

turboexpander performance on the

current and/or proposed process

conditions. If operation is possible,

this will be compared to an upgraded

design with estimated costs.

If project economics are feasible, our

sales and engineering teams will

perform a complete study of the

system and develop a complete

upgrade solution.

In addition to the performance

upgrade, optional value packages can

be implemented to improve

performance, availability and

reliability:

• Upgrade to active magnetic

bearing system

• Upgrade controls and auxiliary

systems to current standards

including remote control,

monitoring and diagnostics

• Upgrade turboexpander controls

including inlet guide vanes, thrust

balance system and condition

monitoring

• Upgrade process seal to dry

gas seal

• Upgrade driven equipment

(compressor, generator,

dynamometer) to match upgraded

expander

• Operation and maintenance

training for customer’s personnel

• Contractual Service Agreements

g

GE Oil & Gas

Global Headquarters

Via Felice Matteucci, 2

50127 Florence, Italy

T +39 055 423 211

F +39 055 423 2800

GE imagination at work

Nuovo Pignone S.p.A.

Nuovo Pignone S.r.l.

E customer.service.center@ge.com

www.ge.com/oilandgas

GE, the GE Monogram,

and imagination at work

are registered trademarks of

the General Electric Company.

COMK/MARK 839/II - Designed by: Studio Tre Fasi

Printed by: Sagraf - 12-2011

©2011 General Electric Company

All Rights Reserved

Loading...

Loading...