Page 1

GE Energy

TRANSPORT X

Portable Dissolved Gas Analysis

Users Guide

40-0157-04

2011 Kelman Ltd. All Rights Reserved

Page 2

TRANSPORT X Users Guide

TRANSPORT X

Users Guide

Contents ........................................................................................................................ 2

(EN) Safety Warnings .................................................................................................. 3

(FR) Consignes de sécurité ......................................................................................... 4

1. Introduction ........................................................................................................ 5

2. Technical Specifications................................................................................... 5

3. System Description ........................................................................................... 5

3.1 TRANSPORT X ................................................................................................................................... 5

3.2 Sample Bottle and Connectors ................................................................................................. 6

3.3 Accessories Kit .................................................................................................................................. 8

3.4 Thermal Printer ................................................................................................................................. 8

4. Operation ............................................................................................................ 9

4.1 Turning On/Off ................................................................................................................................ 10

4.2 Preventing Contamination ........................................................................................................ 11

4.3 TRANSPORT X Operation ........................................................................................................... 11

5. Taking an Oil Sample ..................................................................................... 42

6. Cleaning the Apparatus ................................................................................ 44

6.1 Cleaning the Syringe, Valves and Lid Assembly .............................................................. 44

6.2 Cleaning the Syringe .................................................................................................................... 44

6.3 Cleaning the Bottle and Lid Assembly ................................................................................. 45

7. Sampling and Analyzing Gases from Gas-Collecting (Buchholz) Relays45

7.1 Gas Sampling .................................................................................................................................. 45

7.2 Gas Sample Injection and Analysis ....................................................................................... 47

8. System Check .................................................................................................. 49

8.1 System Gas Check Procedure ................................................................................................. 49

8.2 Hydrogen .......................................................................................................................................... 55

9. Troubleshooting ............................................................................................. 55

10. Logfile Extraction ........................................................................................... 62

10.1 System Requirements ................................................................................................................. 62

10.2 Installation Instructions .............................................................................................................. 62

10.3 Logfile Retrieval .............................................................................................................................. 62

10.4 File Structure ................................................................................................................................... 62

11. Exchanging a Bottle Lid Assembly .............................................................. 62

Appendix 1: Operating Environment for DGA Equipment ................................ 65

Appendix 2: Installing the TRANSPORT X Driver in Windows 7 or Vista ......... 66

Appendix 3: Importing TRANSPORT X Results Into PERCEPTION ..................... 73

Appendix 4: Glossary ............................................................................................... 76

All rights Reserved. Kelman Ltd.

This release of this document is accurate at the time of this writing. Kelman Ltd. reserves the

right to change the TRANSPORT X and this document without notice.

Kelman Ltd, Lissue Industrial Estate East

Lissue Road, Lisburn, BT28 2RE, United Kingdom

Tel: +44 28 9262 2915; Fax: +44 28 9262 2202

e-mail: transportx@ge.com

Page 3

TRANSPORT X Users Guide

Web: www.gedigitalenergy.com

(EN) Safety Warnings

MODE OF OPERATION OF TRANSPORT X

If the TRANSPORT X is used in a manner not specified by the manufacturer, the protection provided

by the TRANSPORT X may be impaired.

DISCONNECTION FROM POWER SUPPLY

Disconnection from the supply is achieved through the power inlet connector. To disconnect from

the supply, turn off the device using the touch screen, then power off using the ON/OFF switch, then

disconnect the supply cord.

EXHAUSTED GASES

Gases exhausted by the TRANSPORT X are at concentrations that are non-flammable and non-toxic.

All exhausted gases are quickly diluted into the surrounding atmosphere.

BATTERY REPLACEMENT AND DISPOSAL

The TRANSPORT X uses a lithium coin cell battery. The lithium coin cell battery is a long-life

battery and may never need to be replaced. If battery replacement is necessary it should be

performed by an authorized service technician.

CAUTION: There is a danger of a new battery exploding if it is incorrectly installed. Replace

the battery only with the same or equivalent type recommended by the manufacturer. Do

not dispose of the battery in a fire or with household waste. Contact your local waste

disposal agency for the address of the nearest battery deposit site.

WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT WEEE DIRECTIVE

In the European Union, this label indicates that this product should not be disposed of with

household waste. It should be deposited at an appropriate facility to enable recovery and

recycling. GE recommends that you follow local WEEE requirements or alternatively contact

ge4service@ge.com for further information on returning your product.

This product has been tested to the requirements of CAN/CSA-C22.2 No. 61010-1, second

edition, including amendment 1, or a later version of the same standard incorporating the

same level of testing requirements.

Warnings:

There are no serviceable parts inside the TRANSPORT X.

For continued fire protection, use only an approved and recommended fuse.

Do not use the TRANSPORT X if the power cord is visibly damaged or worn out or missing, or

if the PE pin is damaged.

Use only a safety-approved power cord.

Do not operate the TRANSPORT X (top cover open) in rain conditions.

The TRANSPORT X should be stored with the lid closed when not in use to avoid accidental

damage during transit.

The TRANSPORT X should not be left operating unsupervised.

Page 4

TRANSPORT X Users Guide

(FR) Consignes de sécurité

MODE DE FONCTIONNEMENT DU TRANSPORT X

La garantie commerciale pourra être annulée si la défectuosité est causée par une utilisation non

conforme, une négligence ou une modification non autorisée du TRANSPORT X.

MISE HORS TENSION

La mise hors tension est réalisée par le connecteur d’admission de puissance. Pour déconnecter le

TRANSPORT X, arrêter le dispositif en utilisant l’écran tactile, puis mettre hors tension en utilisant le

commutateur « MARCHE/ARRÊT », ensuite débrancher le cordon d’alimentation de la prise secteur.

GAZ D’ÉCHAPPEMENT

Les gaz produits par le TRANSPORT X sont à des concentrations qui sont non inflammables et non

toxiques. Tous les gaz d’échappement sont rapidement dilués dans l’atmosphère environnante.

REMPLACEMENT ET RECYCLAGE DE LA BATTERIE

Le TRANSPORT X utilise une batterie bouton au lithium, qui est une batterie de longue vie et

peut ne jamais devoir être remplacée. Si le remplacement de la batterie est nécessaire, il

devra être exécuté par un technicien autorisé.

ATTENTION: Il y a un risque d’explosion si la nouvelle batterie n’est pas installée correctement.

Remplacez la batterie uniquement par le modèle recommandé par le fabricant. Ne pas

éliminer cette batterie dans un feu ou avec des déchets municipaux. Contactez votre agence

locale de recyclage pour connaître l’emplacement le plus proche.

DIRECTIVE SUR LA COLLECTE DES DÉCHETS DES ÉQUIPEMENTS ÉLECTRIQUES ET ÉLECTRONIQUES

A l’intérieur de la Communauté Européenne, cette étiquette indique que ce produit ne doit

pas être jeté avec les ordures ménagères. Il doit être déposé dans un centre de traitement

qui permet le recyclage.GE vous conseille d’utiliser les méthodes et directives WEEE locales

ou sinon de contacter ge4service@ge.com pour plus d’information sur comment renvoyer

votre produit

Ce produit a été testé aux exigences de la CAN/CSAC22.2 No 610101, deuxième édition, y

compris l’amendement 1, ou une version ultérieure de la même norme comportant le même

niveau d’exigences relatives aux essais.

Consignes de sécurité:

Aucune pièce à l’intérieur du TRANSPORT X n’est réparable par l’utilisateur.

Utiliser uniquement le modèle de fusible approuvé et recommandé.

Ne pas utiliser le TRANSPORT X si le cordon d’alimentation de secteur est endommagé, usé ou

manquant.

Utiliser uniquement un cordon d’alimentation sécuritaire et approuvé.

Ne pas utiliser le TRANSPORT X (couvercle supérieur ouvert) par temps de pluie.

Le TRANSPORT X doit être entreposé avec le couvercle fermé afin d’éviter tout dommage

accidentel durant le transport.

Le TRANSPORT X ne doit pas être laissé sans surveillance durant son fonctionnement.

TRANSPORT X Users Guide Page 4 Ver. 40-0157-04 03/07/2013

Page 5

TRANSPORT X Users Guide

FAULT GAS

CALIBRATED RANGE (ppm)

Hydrogen (H2)

5 – 5,000

Carbon dioxide (CO2)

2 – 50,000

Carbon monoxide (CO)

1 – 50,000

Methane (CH4)

1 – 50,000

Ethane (C2H6)

1 – 50,000

Ethylene (C2H4)

1 – 50,000

Acetylene (C2H2)

0.5 – 50,000

Water (H2O)

0 – 100 % relative saturation

PARAMETER

VALUE/MEETS

Accuracy

Gas: ± 5 % or ± 2 ppm (whichever is greater) *

Water: ± 3 ppm

Power supply

115/230 Vac, 50/60 Hz, 40 W

Fuse

F6.3 AH, 250 V, 5 x 20 mm

Battery

Maxell CR2032 lithium coin cell, 3 V

Digital output

USB

Hardcopy output

2-inch thermal printer

Operating temperature

0 – 50 °C (32 – 122 °F)

Operating altitude

Maximum 2,000 m

Operating pressure

760 – 1040 millibar

Weight

11 kg (24 lbs), excluding accessories case

Dimensions

440 x 340 x 220 mm

IP Rating

IP20 (operating)

1. INTRODUCTION

Accurate knowledge of the condition of oil-filled equipment is of paramount importance to electrical

utilities. Dissolved Gas Analysis (DGA) has been essential in this area for many years, allowing faults

to be detected in their early stages, costly outages to be avoided and assets to be optimized.

The TRANSPORT X represents a new generation of test equipment for DGA in equipment oil, allowing

accurate, rapid, reliable results in the field. To ensure optimum performance of the TRANSPORT X it is

important to read this manual fully before using the equipment.

2. TECHNICAL SPECIFICATIONS

Table 1. Technical Specifications

* Accuracy is defined as accuracy of the gas analysis system and does not purport to define

gas-in-oil measurement accuracy which is affected by sampling and/or oil type.

3. SYSTEM DESCRIPTION

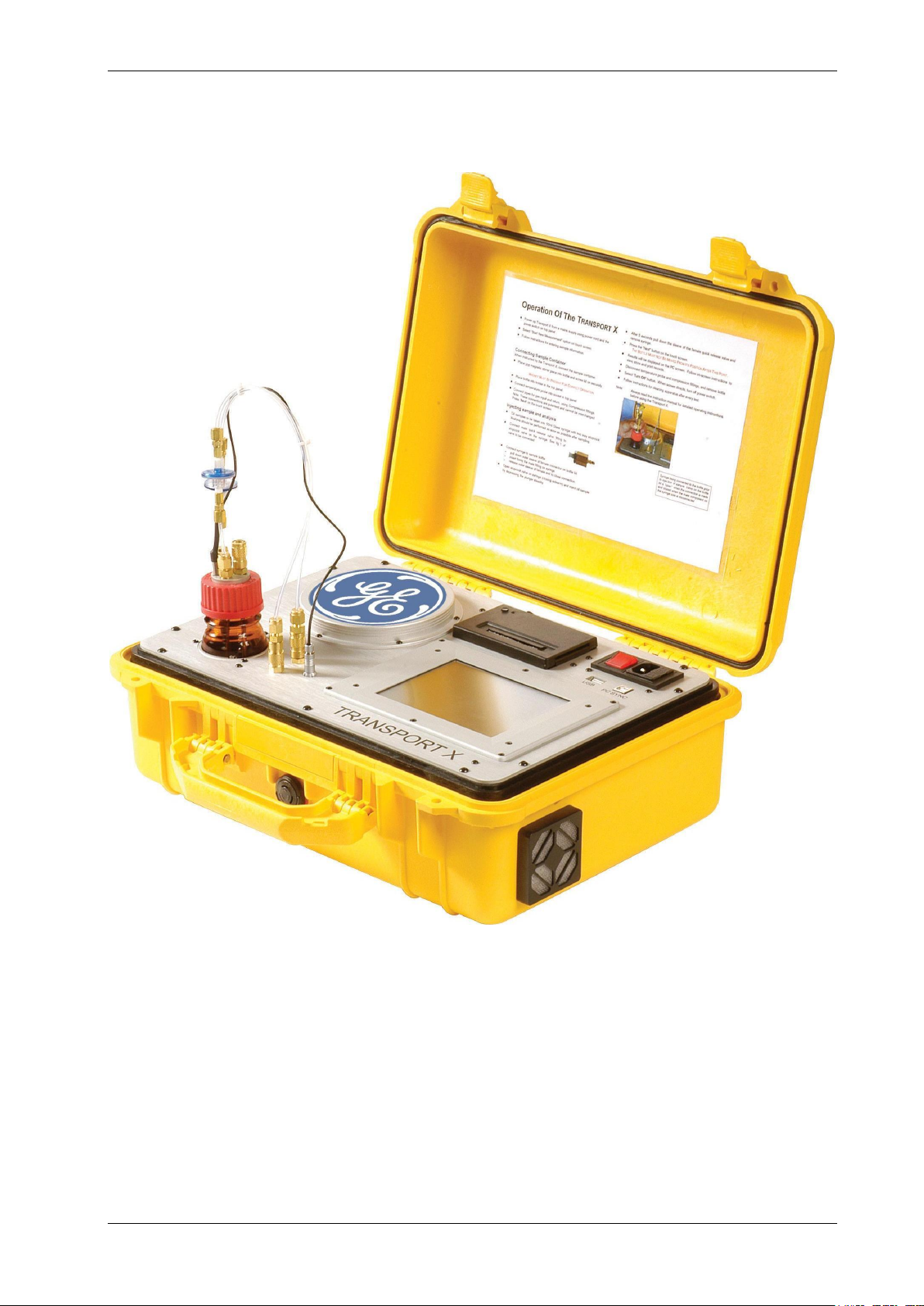

3.1 TRANSPORT X

The TRANSPORT X (see Figure 1) utilizes photo-acoustic spectroscopy (PAS) to perform extremely

high quality DGA analyses, giving measurements of all the fault gases plus moisture.

The gases extracted from the oil sample using a highly stable headspace equilibrium extraction

method are then measured using infrared photo-acoustic spectroscopy (a semiconductor sensor for

hydrogen). The TRANSPORT X can also test gas samples taken from a Buchholz relay (although with

reduced accuracy due to a very large dilution factor). The wide dynamic range of measurement of

the TRANSPORT X means it is also very suitable for testing tap-changer and circuit breaker oil.

The TRANSPORT X is contained within a rugged, impact-resistant, carrying case. Accessories for DGA

tests of oil are contained within a separate lightweight case. These include a sample bottle with

connections and pipes, and a syringe for extracting a 50-mL oil sample from the equipment and

injecting it directly into the bottle (see Section 3.2).

The TRANSPORT X contains an embedded PC and touch screen. The incorporated software contains

instructions to guide the user through the operation of the system and algorithms to assist the

TRANSPORT X Users Guide Page 5 Ver. 40-0157-04 03/07/2013

Page 6

TRANSPORT X Users Guide

diagnosis of the electrical equipment. The PC has an internal database that can store over

16,000 records. Communication with external PC’s is possible via USB connections, allowing

databases to be downloaded to a laptop or desktop PC and then shared as required.

Figure 1. TRANSPORT X

A 2-inch thermal printer is provided, enabling the user to maintain hard copy records of all samples

tested on the instrument.

The power supply requirements are 115/230 Vac, 50/60 Hz.

A System Check Kit is available to allow the user to check the calibration accuracy of the

TRANSPORT X (see Section 8).

Optional extras are available for sampling of direct gas samples (see Section 7), and also for the

forced cooling of oil samples.

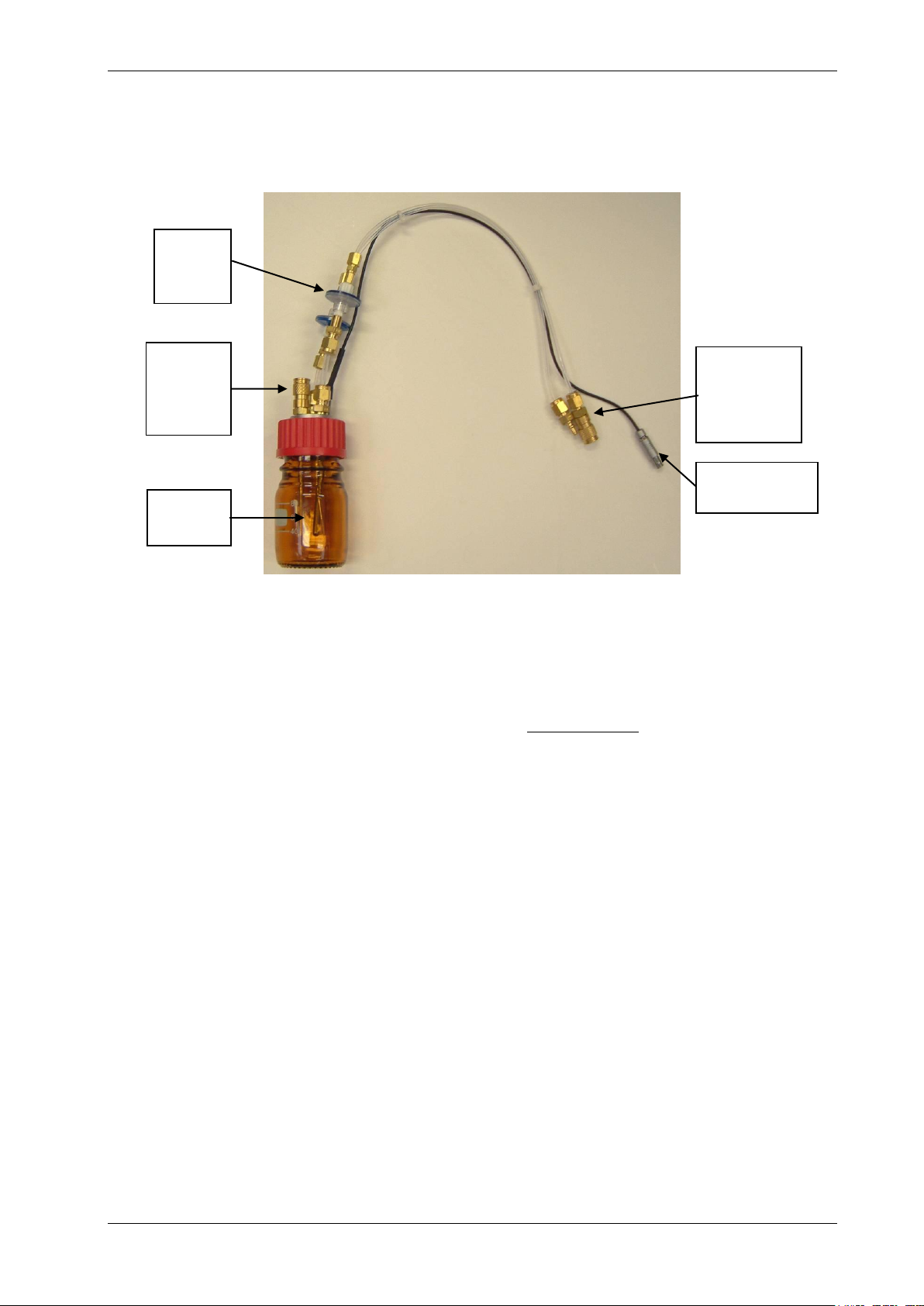

3.2 SAMPLE BOTTLE AND CONNECTORS

The sample bottle provided includes a “lid assembly” (see Figure 2) that incorporates airtight

compression fittings and a temperature probe incorporating a capacitance moisture sensor, all of

TRANSPORT X Users Guide Page 6 Ver. 40-0157-04 03/07/2013

Page 7

TRANSPORT X Users Guide

Sample

Bottle

Airtight

gas inlet

and outlet

fittings

Airtight

sample

injection

valve

Temperature

probe

In-line

Teflon

filters

which are to be connected to the top panel of the TRANSPORT X. These gas connectors are of the

simple “snap-in” type but they are “polarized” so that only one order of connection of the input and

return is possible. Users must ensure that these connections are fully made when using the

TRANSPORT X.

Figure 2. Sample Bottle and Lid Assembly

It is recommended to analyze the sample as soon as possible after extraction, so that minimal

degradation of the oil sample occurs. However, GE Energy provides a ground glass syringe with the

TRANSPORT X that can be used for reliable sample storage for several days, provided it is kept out of

direct sunlight and extremes of temperature.

It is essential that the sample bottle be kept upright and not be inverted or placed in storage on its

side while containing oil to avoid ingress of oil into the pipe work. Dispose of the oil as soon as the

sample has been tested to minimize the risk of accidental pipe contamination (see Section 6).

Clean the bottle thoroughly after each test with a clean dry cloth or tissue (see Section 6).

It is important to ensure there is no residue of oil left in the oil injection port of the lid assembly or the

connections valve of the syringe, as this could cause contamination of the next sample to be tested.

Expel any oil trapped in these locations using a syringe filled with normal ambient air. This will ensure

that no unwanted residue of oil remains from a previous sample.

Care should also be taken to prevent any contamination from the syringe and thorough cleaning

should be performed after each analysis (see Sections 5 and 6).

Two Teflon-coated magnetic stirrers are provided; place one in the bottle before the lid is screwed on

during assembly of the pipe work. This magnet is rotated within the bottle during the analysis cycle,

and its presence is essential for the accurate operation of the TRANSPORT X. The magnetic stir bar

should also be wiped clean after each test. The stir bar can be removed from the oil in the bottle

using the retriever stick provided.

An in-line Teflon filter is fitted in both the return and inlet gas pipes. Luer lock fittings are used to

connect these filters. These fittings allow for quick replacement of the filters at regular intervals or if

oil should get into the pipe work by accident, thus blocking the filters. These filters are impervious to

oil at operating pressure and function to protect the instrument from oil aerosol, accidental spills and

airborne dust. Both these filters must be present at all times; if a spill occurs and oil makes its way

into the gas analysis chamber of the photo-acoustic module, the instrument will require a new

spectrometer.

It is recommended that the Teflon filters be changed after every 20 samples and the user will be

reminded to do this by the TRANSPORT X. If any oil residue is present in the pipes, or the filters

TRANSPORT X Users Guide Page 7 Ver. 40-0157-04 03/07/2013

Page 8

TRANSPORT X Users Guide

50-mL

syringe

Sample

Bottles

Bottle lid

assembly

Teflon

filters

115/230 V

power

cable

Quick

connection

valve

Magnet

retriever

Tefloncoated

magnets

3-way

plastic

stopcock

appear discolored, then the filters should be replaced before testing the next sample. Clean the pipes

by a compressed air blowout if oil is present in the pipes.

3.3 ACCESSORIES KIT

The TRANSPORT X comes complete with a full range of accessories and some replacement spare

parts. These include:

1 x 50-mL ground glass syringe

1 x three-way plastic stopcock (for use with syringe)

1 x bottle lid assembly

1 x magnet retriever

1 x quick connection valve (for oil injection from the syringe)

2 x Teflon coated stir bars

12 x replacement Teflon filters

1 x 115/230 V power cable

3 x sample bottles

All of the accessories are supplied in a light carry case (see Figure 3), with protective foam inserts.

Figure 3. Accessories Kit

3.4 THERMAL PRINTER

The TRANSPORT X is equipped with an in-built 2-inch thermal printer that can provide hard copies of

results on-site. Changing the paper roll is very simple. Release the paper holder cover by depressing

the black catch on the left hand side of the holder (see Figure 4). To gain access to the paper roll

holder, lift the holder cover by its left hand edge, and swivel it on its right hand edge.

Place the new roll of paper over the roll holder and then lock back the paper holder cover in its

original position. The button on the top left corner allows the user to feed the paper through the

printer when fitting a new roll of paper, and also to check the function of the printer. Care must be

taken to ensure the thermo-sensitive side of the paper is orientated correctly during installation.

TRANSPORT X Users Guide Page 8 Ver. 40-0157-04 03/07/2013

Page 9

TRANSPORT X Users Guide

PC sync

port

Note: If the printouts from the thermal printer begin to show a red tint, it is an indication that a new roll of paper will be

needed soon.

Figure 4. Thermal Printer With Release Catch on the Left Hand Side

4. OPERATION

The TRANSPORT X has been designed to provide the user with a reliable device that is easy to use in

the field. The embedded PC and touch-screen display step-by-step user instructions, and there is also

an Instruction Card inserted in the lid of the case. A syringe and valves are supplied for oil sampling

and injection.

Note: Please read carefully and observe the following instructions.

Read and follow the on-screen instructions carefully.

Always use 50-mL samples of oil.

Always use a clean syringe, lid assembly and bottle (see Sections 4.2 and 6).

DO NOT use solvents to clean any of the apparatus or accessories.

Place one magnetic stirrer piece in the bottle for the sample to be analyzed correctly.

Following oil injection the sample bottle must not be moved until the analysis is complete. If the

bottle is moved the results will be adversely affected.

When containing oil the sample bottle must be kept upright to avoid ingress of oil into the pipe

work of the lid assembly.

Always ensure the pipes’ quick connect fittings are connected correctly and securely, as per

instructions.

When removed, the bottle lid assembly should be held upright then cleaned carefully with a cloth

or tissue after use and before storage to avoid any ingress of oil into the pipe work (see

Section 6).

Always empty the sample bottle waste oil after a test is completed. Also, clean the apparatus

after every test (see Section 6).

The Purge time can be increased (maximum 10 minutes) to help prevent carry-over from a

heavily gassed sample to the next sample. 10 minutes should be used where available time

permits.

Once the TRANSPORT X is unpacked from new, or after storage, the user should run a System

Flush operation to help clear the gas paths from potential contamination from any packing

material/gas effluents (see Section 4.2).

TRANSPORT X Users Guide Page 9 Ver. 40-0157-04 03/07/2013

Page 10

TRANSPORT X Users Guide

4.1 TURNING ON/OFF

Where possible the instrument should be powered up 20 minutes prior to the first sample injection to

allow it to heat up. Oil sampling can be performed in this time if desired. The instrument can also

undergo a system flush during this period if desired.

The TRANSPORT X is powered by mains-supplied electricity or a suitable AC supply from a DC

inverter. To connect the unit to the mains supply, use the IEC cable supplied with the unit. With the

unit connected to the mains, switch the power On using the red power switch at the top right of the

front panel. The touch screen will then show the launch of the TRANSPORT X software (there will be

up to 20 seconds during which the software will boot) and the Main Menu screen (see Figure 5) will

be displayed.

Figure 5. Main Menu Screen

To turn the unit Off, press the Turn Off button found at the bottom left of the Main Menu (see

Figure 5). The system will then advise when it is ready to be switched off (see Figure 6). Use the red

power switch to switch off the mains supply.

Figure 6. “Safe to Switch off Power Supply” Screen

Similar to a PC, it is not recommended to turn off the unit directly from the power switch without

following the above shutdown procedure.

TRANSPORT X Users Guide Page 10 Ver. 40-0157-04 03/07/2013

Page 11

TRANSPORT X Users Guide

4.2 PREVENTING CONTAMINATION

The TRANSPORT X is designed to prevent contamination between samples using only simple

cleaning techniques for the syringe, jar and lid assembly (see Section 6).

For best results:

Clean the syringe thoroughly between each sample with a cloth or tissue (see Section 6).

Clean the bottle and stirrer with a cloth or tissue.

Clean the lid assembly pipes and probes with a cloth or tissue.

It is recommended that after first unpacking the unit and whenever time permits, the user should

implement a System Flush. This process flushes ambient air through the TRANSPORT X for

20 minutes, and will help clear any potential contamination from packing material/prior samples.

This function can also be used to clear the TRANSPORT X of gas after a concentrated gas-in-oil

sample e.g. LTC. Details regarding the use of this function are given at Section 4.3.5.2.

4.3 TRANSPORT X OPERATION

The instructions displayed on the touch screen are used to control the operation of the

TRANSPORT X. Upon powering-up the screen shows the Main Menu display (see Figure 5).

There are five options:

Start New Measurement: see Section 4.3.1.

View Previous Results: see Section 4.3.4.

Turn Off: see Section 4.1.

PC Sync: communicating with PC software – see manual.

Settings: see Section 4.3.5.

4.3.1 Performing a New Measurement

4.3.1.1 Entering Measurement Details Into the Database

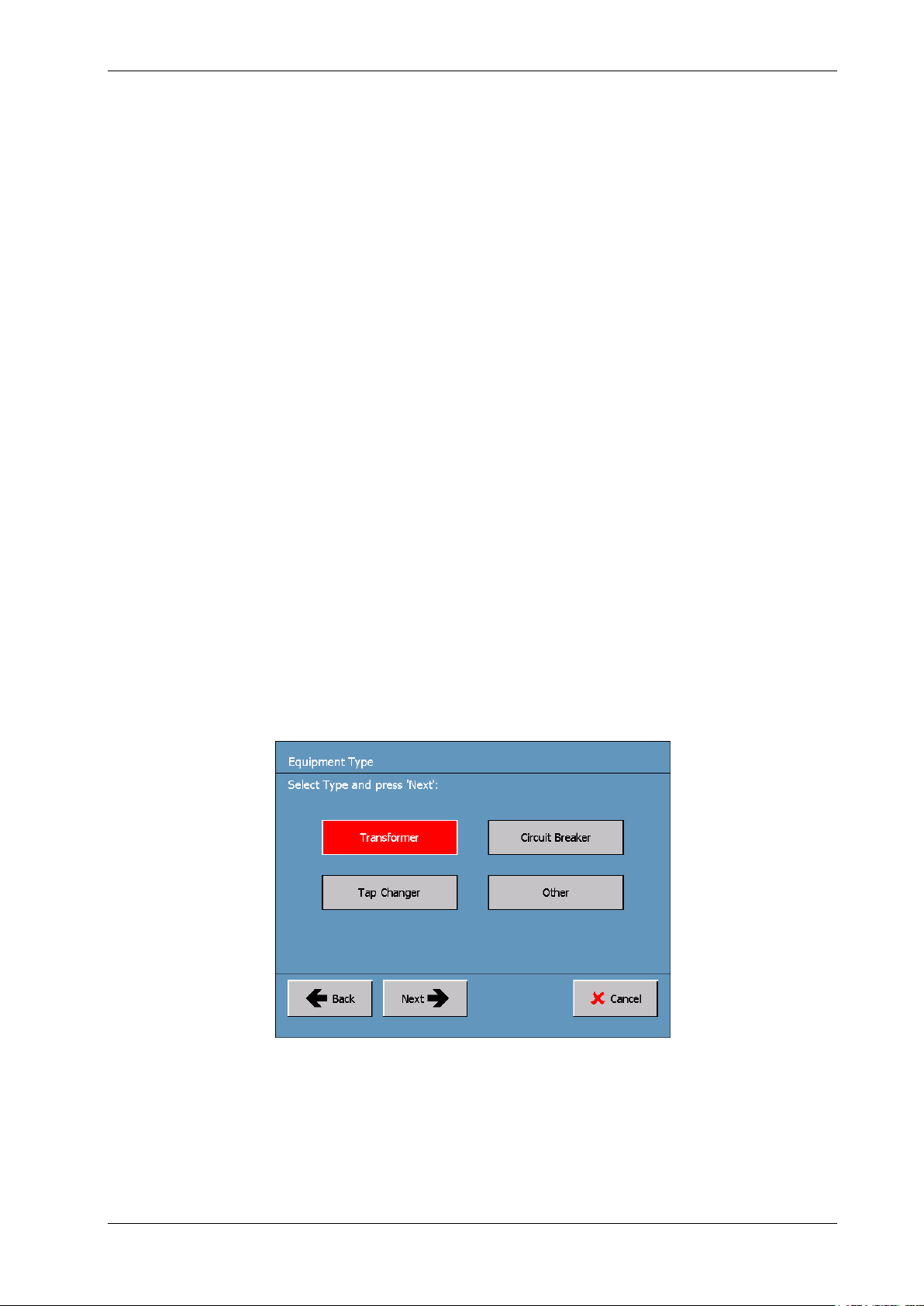

After selecting Start New Measurement in the Main Menu screen (Figure 5), the user must select the

Equipment Type to be analyzed from the options available (see Figure 7). This selection is important

for the database and the diagnosis options for the sample.

Figure 7. Equipment Type Screen

Highlight the desired option and then press the Next button (the default selection is displayed in red).

The TRANSPORT X now requests that the information for the database relating to the Equipment

Location and the Equipment Identification (ID) is entered into the unit’s memory. The information

required by these two screens is vital as it forms the store and search criteria for all records. If the

information is new (i.e. not already stored in the Transport X memory), the unit will use the new

information and store it as a new set of records with the appropriate date stamp.

TRANSPORT X Users Guide Page 11 Ver. 40-0157-04 03/07/2013

Page 12

TRANSPORT X Users Guide

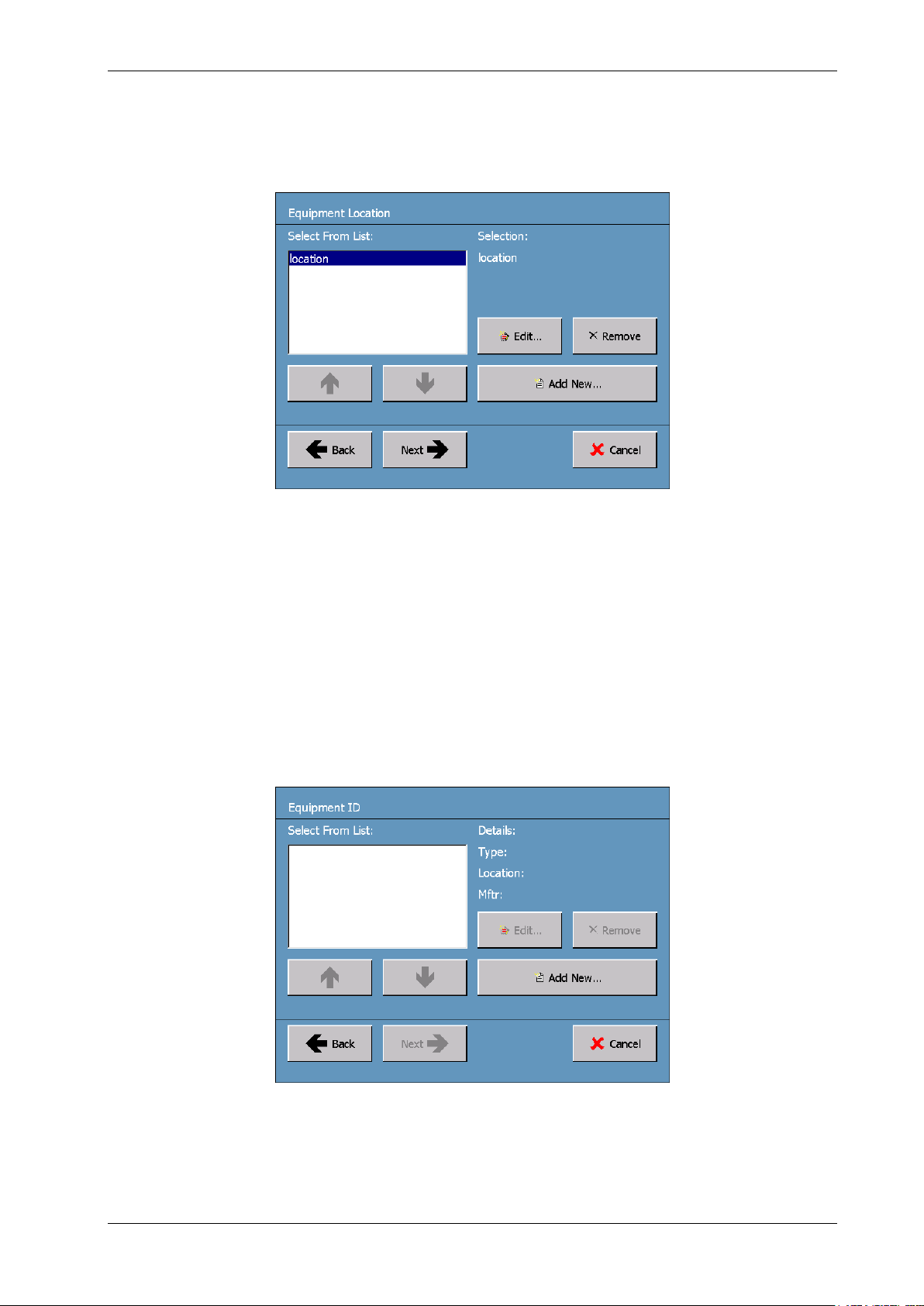

First, the Equipment Location screen is displayed (see Figure 8). If the equipment location already

exists in the database from a previous test, then the user can select this from the existing database

list displayed on the screen using the Up and Down arrows. Once the correct location is highlighted

in the left hand window, press the Next button to move to the Equipment ID screen, which is the next

screen in the information/data input process.

Figure 8. Equipment Location Screen

If the correct location information does not already exist in the database, then the user has to enter

it. To do this the user must first press the Add New… button found in the Equipment Location screen

(Figure 8). This action causes the display of the keypad on the touch screen (similar to Figure 10).

Enter the Equipment Location details using the keypad.

The information stored in the database relating to Equipment Location can also be edited using the

Edit… button located in the middle of the screen – highlight the record to be edited using the Up and

Down arrows, then press the Edit… button and again the Keypad screen is displayed (similar to

Figure 10) to enable the user to edit an existing database record.

Once the Equipment Location details are correctly entered into the database, press the OK button

(which is now active) at the bottom of the Keypad screen. The Equipment ID screen is then displayed

(see Figure 9).

Figure 9. Equipment ID Screen

Select from the displayed list the appropriate Equipment Identification details of the equipment that

is to be used for the analysis then press the Next button. As in the case for the Equipment Location

screen, existing details of a record of the Equipment ID screen can be edited by pressing the Edit…

TRANSPORT X Users Guide Page 12 Ver. 40-0157-04 03/07/2013

Page 13

TRANSPORT X Users Guide

button. However, if the database contains no information concerning the equipment about to be

tested, it will be necessary to add this information to the database for the first time.

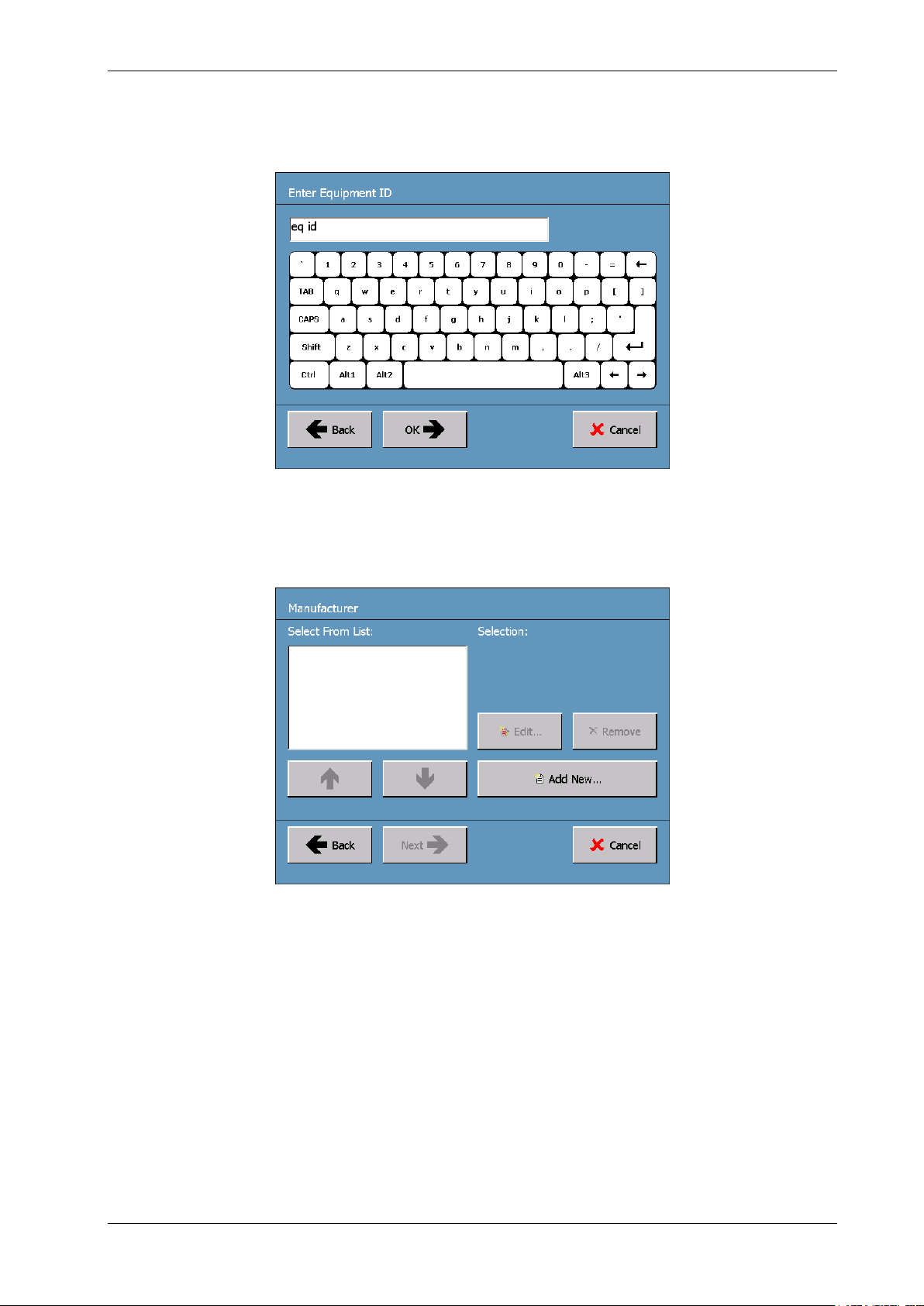

To add new Equipment Identification information, press the Add New… button. The keypad for

entering Equipment Identification details is then displayed on the screen (see Figure 10).

Figure 10. Keypad for Entering Equipment ID Details

Add the new Equipment ID details and then press the now active OK button. The Manufacturer

screen is then displayed (see Figure 11).

Figure 11. Manufacturer Screen

Using the Up and Down arrows, select the appropriate Equipment Manufacturer from the entries in

the displayed list, then press the Next button. Alternatively, to add a new manufacturer to the list,

press the Add New… button; the keypad is displayed (similar to Figure 10). Enter the new

Manufacturer details into the database, press the OK button at the bottom of the keypad and the

Manufacturer Model screen is displayed (see Figure 12).

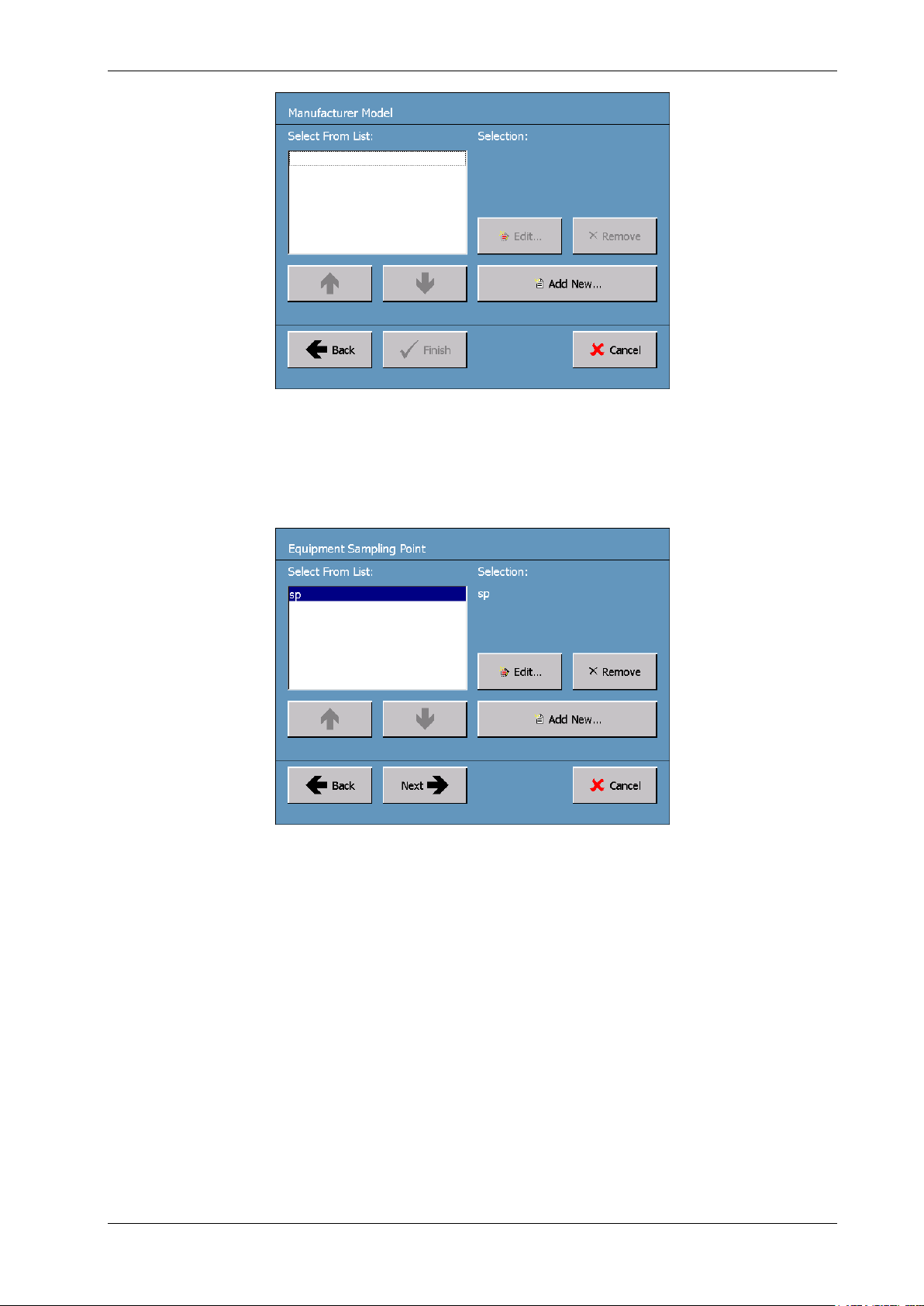

As for the Manufacturer screen, choose from the displayed list the appropriate model of the

equipment about to be analyzed, or press the Add New… button to add a new model to the

database. When the correct model details are either selected or entered into the database, press the

Finish button at the bottom of the Manufacturer Model screen or the OK button at the bottom of the

Keypad screen. The Equipment ID screen (Figure 9) is again displayed to allow for confirmation of all

the details entered up to this point.

TRANSPORT X Users Guide Page 13 Ver. 40-0157-04 03/07/2013

Page 14

TRANSPORT X Users Guide

Figure 12. Manufacturer Model Screen

When the Equipment ID details have been correctly entered into the database, press the OK button

at the bottom of the keypad screen. This causes the display of the Equipment Sampling Point screen

(see Figure 13).

Figure 13. Equipment Sampling Point Screen

The Equipment Sampling Point details are entered into the software following the same procedure as

discussed above for Equipment Location and Equipment ID. Typical sampling points may be Top,

Bottom, Cooling loop, etc. Once the Equipment Sampling Point details have been correctly entered in

the database, the user is required to provide details of the source of the sample that is about to be

used for a new measurement. To enter the Sample Source details, select the source from the two

options displayed on the Sample Source screen (see Figure 14).

The default is Oil Sample, but if the sample is gas from the Buchholz relay, then select Gas Sample.

Details regarding the sampling and analysis of gases from gas-collecting (Buchholz) relays are

described in Section 7. Press the Next button once the correct option has been selected.

TRANSPORT X Users Guide Page 14 Ver. 40-0157-04 03/07/2013

Page 15

TRANSPORT X Users Guide

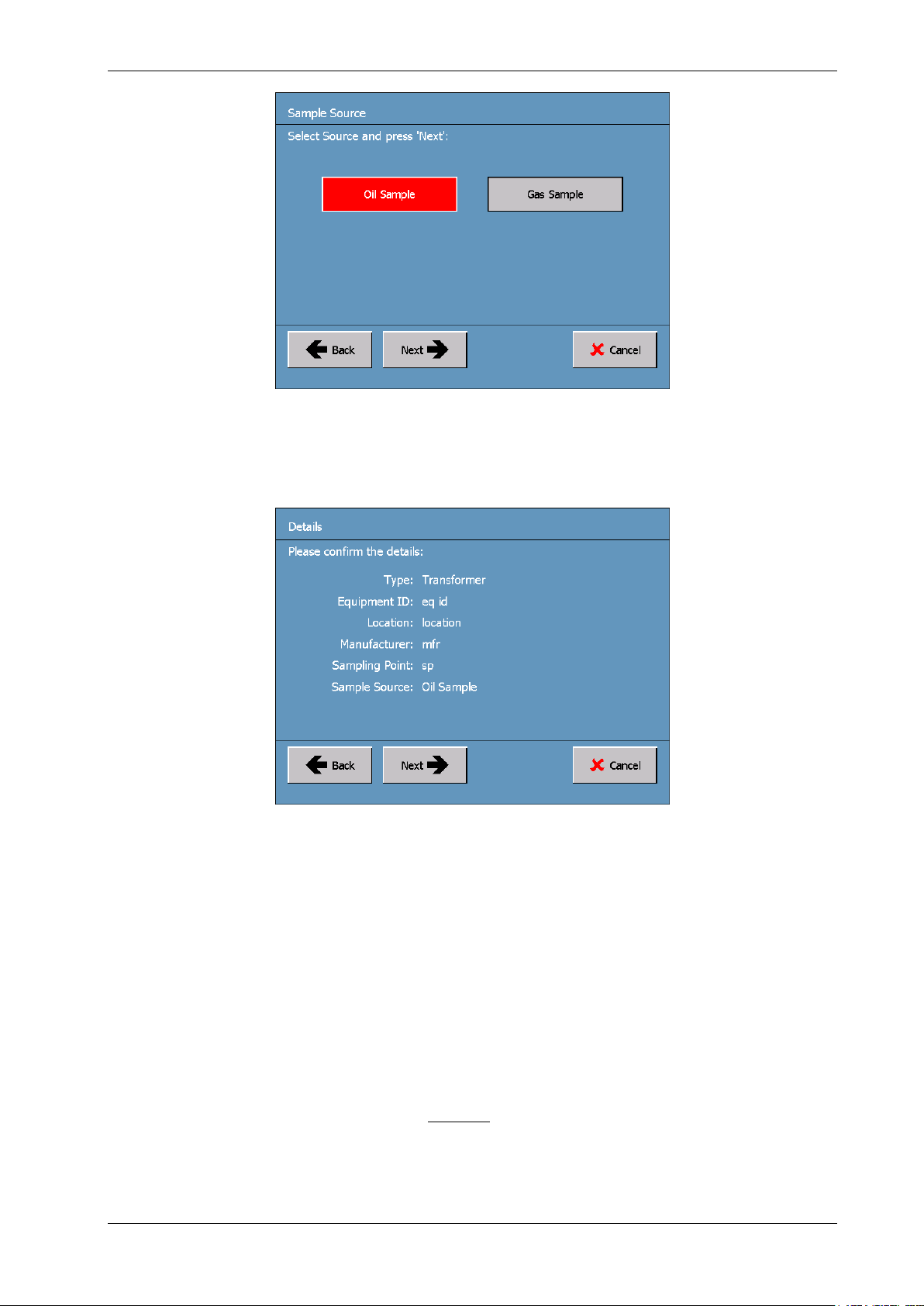

Figure 14. Sample Source Screen

At this point, when all the necessary information has been entered into the database, a summary of

the New Measurement details is displayed in the Details screen (see Figure 15).

Figure 15. Details Screen

The user is required to check and confirm all the information that has been entered into the

database before continuing. If any errors are noted in the information displayed on the Details

screen, use the Back button to reverse back to the screen in the sequence of screens described

above where the incorrect entry has been made. Then correct the information entered into the

database at that point.

Pressing the Next button on the Details screen causes the display of the Optional Details screen

(see Figure 16). This screen provides the user with the option of adding comments to a Comment:

field for the sample data. This can be used to record additional information for a particular sample or

equipment. If this option is required, press the Set button found at the left of the Comment: field to

display the keyboard (similar to Figure 10) for entering comments. Press the OK button at the bottom

of the keyboard after typing in any comments.

The user also has the option of adding the Oil Sampling Temperature (in degrees Celsius), i.e. the

temperature of the oil at the time it was sampled as displayed by the transformer temperature

gauge or another temperature measurement option. This is used to calculate the % Relative

Saturation (%RS) of the sample. If the temperature is not added then the results will not include a

%RS figure. To enter the oil temperature, press the Set button found at the left of the Extraction

Temperature: field to display the keyboard (similar to Figure 10) for making the temperature entry.

Press the OK button at the bottom of the keyboard when the oil temperature has been entered.

TRANSPORT X Users Guide Page 15 Ver. 40-0157-04 03/07/2013

Page 16

TRANSPORT X Users Guide

Figure 16. Optional Details Screen

After all the sample information has been selected or entered, the software guides the user through

the testing process. Press the Next button to begin the testing process.

4.3.1.2 Readying the TRANSPORT X for Making a Test

While the user is entering the new Measurement Details into the database (Section 4.3.1.1), in the

background the TRANSPORT X is undertaking a process of system venting in preparation for taking a

new measurement.

Note: Venting occurs only upon the initial start-up of the TRANSPORT X.

Progress in performing the system venting is shown in the Venting System Progress screen (see

Figure 17), which will be observed if the first set of new Measurement Details are all entered before

the venting process has completed.

Figure 17. Venting System Progress Screen

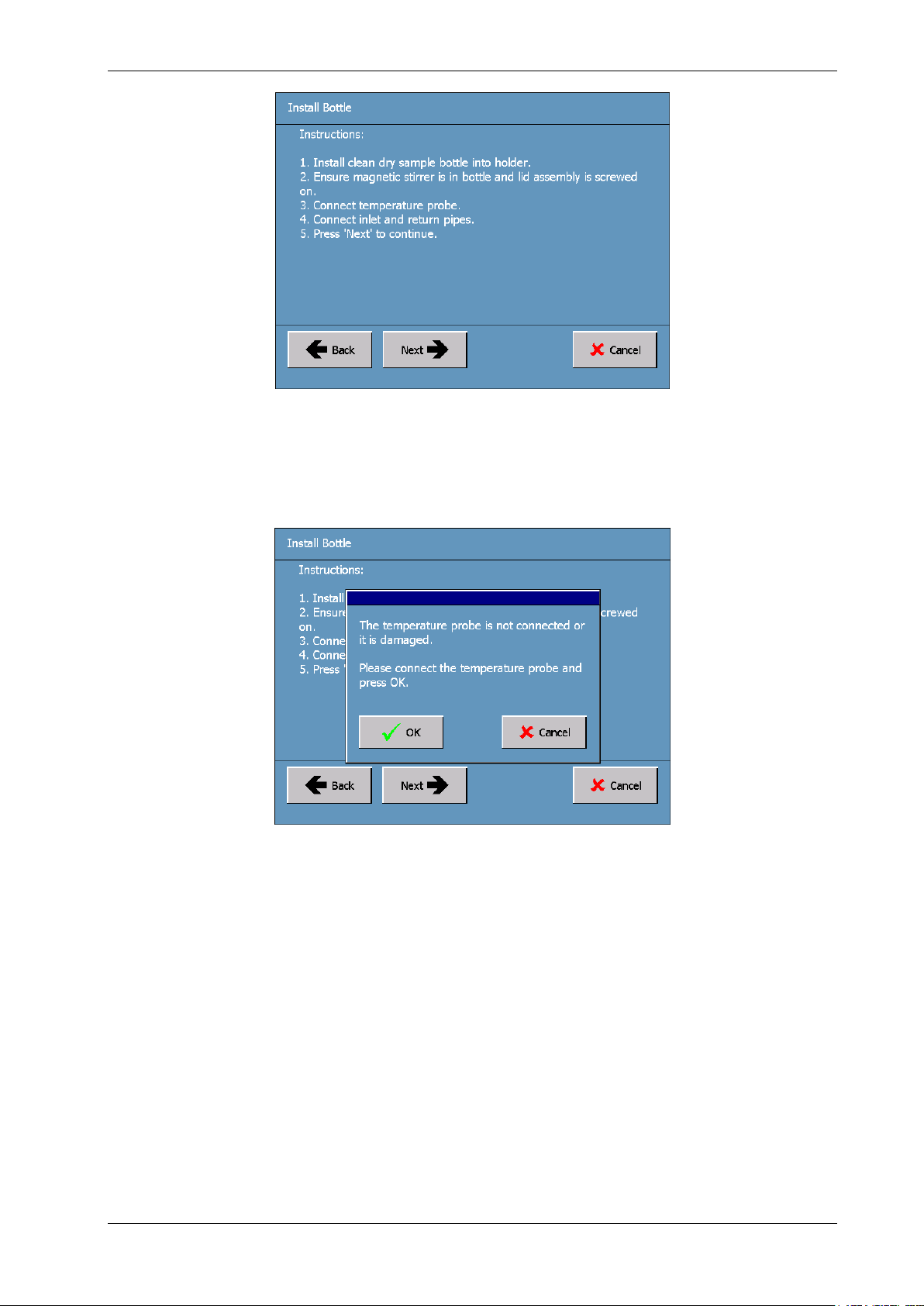

It is a requirement that a clean dry bottle be used for each test. Figure 18 shows the initial instruction

screen for the testing process – the Install Bottle Instructions screen. Follow the on-screen

instructions and connect the sample bottle to the TRANSPORT X. Press the Next button to proceed

with the testing process.

TRANSPORT X Users Guide Page 16 Ver. 40-0157-04 03/07/2013

Page 17

TRANSPORT X Users Guide

Figure 18. Install Bottle Instructions Screen

If the temperature probe is not properly connected, the warning window shown in Figure 19 is

displayed. If this occurs, confirm correct connection of the temperature probe, then press the OK

button to proceed with the testing.

Figure 19. Bottle Installation Error Message

If the bottle temperature connection is in order, the Purging Time window (see Figure 20) is

displayed. The unit prepares for the oil sample by first “purging” with ambient air, and then by

automatically taking a zero reference measurement. The user selects the required Purging Time,

typically between 5 and 10 minutes. The default is 5 minutes, but longer purges can help eliminate

contamination from previous samples which were heavily gassed, for example from Tap Changer oil

samples.

TRANSPORT X Users Guide Page 17 Ver. 40-0157-04 03/07/2013

Page 18

TRANSPORT X Users Guide

Figure 20. Purging Time Window

Progress in purging the unit is shown in the Purging Progress screen (see Figure 21).

Note: If 5 minutes is selected, the actual time is approximately 5 minutes and 40 seconds as this is a default minimum.

If 6 minutes is selected, the actual time 6 minutes.

Figure 21. Purging Progress Screen

When the purging is completed, the unit automatically calculates the gas concentrations in the air of

the TRANSPORT X / dry sample bottle combination in order to provide a zero reference for sample

measurements using the selected sample bottle. The Progress screen is shown in Figure 22.

TRANSPORT X Users Guide Page 18 Ver. 40-0157-04 03/07/2013

Page 19

TRANSPORT X Users Guide

Figure 22. “Calculating the Gas Concentrations in Air” Progress Screen

Once the zero references have been calculated, the TRANSPORT X is ready for the oil sample to be

injected into the unit’s sample bottle.

4.3.1.3 Injecting Oil Samples Into the TRANSPORT X

Having obtained a representative oil sample (see Section 4), it is important that the sample be

handled correctly in order to ensure reliable results. Problems with sampling, storing or injecting the

oil sample can all affect eventual results.

Note: If a sample is not tested immediately after being taken, it is recommended to store it in a dark, cool place.

Follow the following procedural steps to inject the sampled oil into the TRANSPORT X sample bottle.

If the oil was hot when the sample was taken, shake the oil sample with a slight positive pressure on

the syringe plunger before submitting it to the TRANSPORT X for analysis. The reason for this advice

is that if the oil was hot when the sample was taken, it is possible for gas from the sample to come

out of solution and form a bubble as the oil cools. By shaking the sample with a slight positive

pressure on the syringe, the gas should be dissolved back into the oil and the sample should then be

ready for analysis.

Once the sample is confirmed to be correct, follow the on-screen instructions in the Gas Analysis

Instructions screen (see Figure 23) to inject the oil sample. These instructions are described in more

detail in the rest of this Section 4.3.1.3.

Figure 23. Gas Analysis Instructions Screen

TRANSPORT X Users Guide Page 19 Ver. 40-0157-04 03/07/2013

Page 20

TRANSPORT X Users Guide

Only 90 seconds are available to complete the injection process. The Gas Analysis Instructions

screen displays a progress bar representing the run-down of these 90 seconds and the Time

remaining for sample injection is displayed on the screen. The TRANSPORT X also emits a beep

sound at 5-second intervals during the injection period.

If the sample injection is not completed in the 90-second injection period that is available, the

Sample Injection Timeout screen is displayed (see Figure 24). The user is then required to press the

OK button and return to the start of the injection process.

Figure 24. Sample Injection Timeout Screen

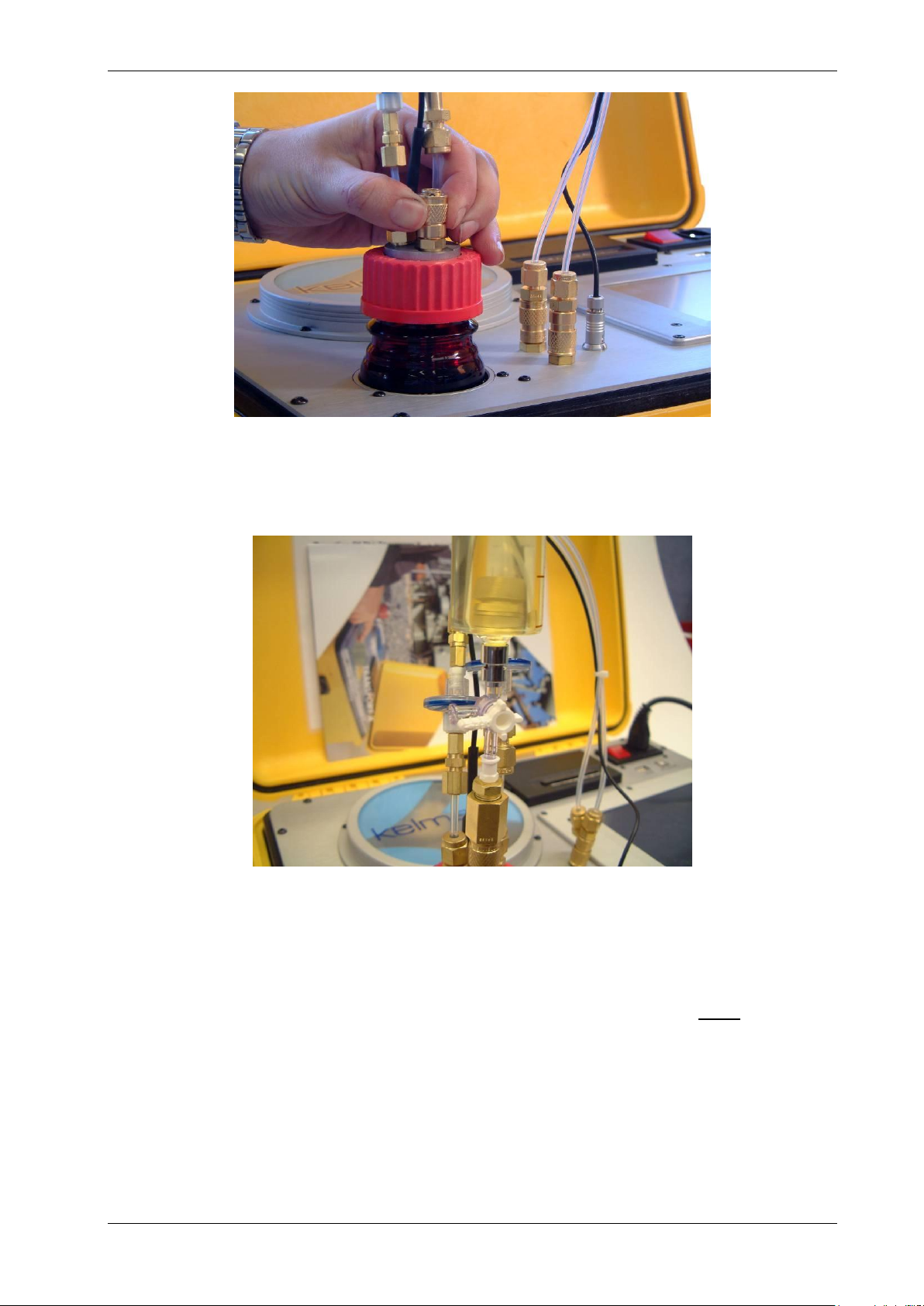

Prior to sample injection, the male quick-connect fitting should be attached to the syringe’s

three-way stopcock (see Figure 25).

Figure 25. Male Section of the Quick-Release Valve Connected to the Syringe

Connect the syringe to the sample bottle. The outer sleeve of the female fitting on the lid assembly

should be held between the thumb and the forefinger and pressed downwards as far as it will go (see

Figure 26). Insert the male quick-connect fitting that is attached to the syringe firmly into the female

connector. A slight click is heard when the connection is fully made. Release the outer sleeve of the

female connector to secure the connection.

TRANSPORT X Users Guide Page 20 Ver. 40-0157-04 03/07/2013

Page 21

TRANSPORT X Users Guide

Figure 26. Outer Sleeve of the Female Connector

Turn the three-way valve 90 degrees to open the arm from the syringe to the bottle, thus closing the

side arm of the valve (see Figure 27).

Figure 27. Stopcock (Three-Way Valve) With Side Arm Closed

Note: If the side arm of the valve is not closed, the oil will escape.

Slowly depress the plunger of the syringe fully. When the syringe is fully depressed, maintain gentle

downward pressure on the plunger, wait 3-4 seconds and disconnect the syringe at the quickrelease valve. To do this, press down the sleeve of the female section and lift the syringe, three-way

valve and male quick-connect assembly away from the female section. Take care not to separate the

male quick-release section from the valve/syringe until the syringe is disconnected from the bottle at

the quick-release valve as that would provide an open channel for the gases to escape to

atmosphere.

Press the Next button on the Gas Analysis Instructions screen (Figure 23) to proceed with the

sample analysis.

4.3.1.4 Sample Analysis

Once the sample has been injected into the bottle, the temperature of the oil is measured. This is to

avoid condensation in the internal pipe-work of the system. Therefore it is recommended that “hot”

TRANSPORT X Users Guide Page 21 Ver. 40-0157-04 03/07/2013

Page 22

TRANSPORT X Users Guide

oil not be tested, and that it has time to cool. The important criterion is that the analysis cell is

warmer than the oil so it may be necessary to allow the unit to warm up if it has been stored in a cold

location prior to use. The temperature measurement takes 90 seconds.

If the oil temperature is higher than the internal cell temperature, then the sample analysis will not

continue. The screen will display this temperature difference and its countdown (see Figure 28). Do

not remove the bottle from the bottle holder cavity during this period. When the temperature

difference figure reaches 0.0 °C, the unit will automatically start the analysis, possibly with a delay

while the unit resets. Ensure the bottle is in place in the holder when the unit commences the

analysis.

Note: If the bottle is not in place at this time, the magnetic stirrer will not operate and therefore the results will not be

correct.

Figure 28. Temperature Countdown Screen

After the oil temperature measurement has been taken, the unit begins the process of measuring the

dissolved gases in the oil sample. Progress in making the measurements is shown by the display, in

succession, of the Direct Moisture Measurement Progress screen (see Figure 29) and the

Measuring Dissolved Gas Concentrations Progress screen (see Figure 30). The measurements take

approximately 22 minutes to complete.

Note: Do not touch or remove the bottle from the holder during the measurement process.

Figure 29. Direct Moisture Measurement Progress Screen

TRANSPORT X Users Guide Page 22 Ver. 40-0157-04 03/07/2013

Page 23

TRANSPORT X Users Guide

Figure 30. Measuring Dissolved Gas Concentrations Progress Screen

When the measurement procedure is complete, the results of the measurement are shown on the

Results screen (see Figure 31). It shows the concentration levels of the various dissolved gases and

the Total Dissolved Combustible Gas (TDCG) level that have been measured in the sample oil. The %

Relative Saturation (% RS) of the sample is also displayed if the Sample Oil Extraction Temperature

was entered into the TRANSPORT X’s diagnostic software (Figure 16).

Figure 31. Results Screen (Oil Sampling Point)

Pressing the Next button displays the Results Options screen shown in Figure 32.

TRANSPORT X Users Guide Page 23 Ver. 40-0157-04 03/07/2013

Page 24

TRANSPORT X Users Guide

Figure 32. Results Options Screen

The Results Options screen makes available to the user a number of options for the next step:

Print Results: to activate the TRANSPORT X’s built-in thermal printer and produce a hardcopy

printout of the dissolved gas measurement results. When this button is pressed, the Printing

screen (see Figure 33) appears whilst the printing is in progress. An example of the type of

printout that is available is shown in Figure 34.

Figure 33. Printing Screen

Advanced…: to continue analysis of the measurement results using the TRANSPORT X’s

embedded DGA diagnostic tools (see Section 4.3.2).

Finish: to store the measurement results in the TRANSPORT X’s database.

Cancel: to abort the measurement results and delete it from the TRANSPORT X’s memory.

4.3.2 Analysis Tools

Note: The analysis tools incorporated into the TRANSPORT X do not represent the opinion of GE Energy; rather they are

based upon widely recognized standards and algorithms, with the various caution and warning alarm thresholds set

by the user.

By selecting Advanced… in the Results Options screen (Figure 32), the operator can use the

incorporated software tools to aid in the analysis of DGA results. This option is only available for

Transformer oil samples. If the user has entered Tap Changer, Circuit Breaker or Other in the

Equipment Type screen (Figure 7), then the analysis tools do not apply.

TRANSPORT X Users Guide Page 24 Ver. 40-0157-04 03/07/2013

Page 25

TRANSPORT X Users Guide

Figure 34. Results Printed by the TRANSPORT X’s Built-in Thermal Printer

4.3.2.1 DGA Analysis Using Caution and Warning Thresholds

The first diagnostic tool made available to the user after pressing the Advanced… button found in the

Results Options screen (Figure 32) is that which compares measured dissolved gas concentration

levels with the preset Caution and Warning levels for each gas that were previously entered into the

TRANSPORT X diagnostic software.

Note: Default gas concentration threshold levels have been pre-programmed into the TRANSPORT X diagnostic

software, but the thresholds are settable by the user, as described in this Section 4.3.2.1.

If the measured concentration value for any gas is above one of the threshold levels for that gas, an

appropriate warning is advised to the user. For example, if the DGA measurement for a particular gas

is above either the Caution or Warning threshold levels, that situation is highlighted in yellow (if above

the Caution level) or red (if above the Warning level) on the Analysis screen (see Figure 35). An overall

Transformer Condition of Normal, Caution or Warning can be provided based upon these alarm

levels.

TRANSPORT X Users Guide Page 25 Ver. 40-0157-04 03/07/2013

Page 26

TRANSPORT X Users Guide

Figure 35. Analysis Screen Showing Caution and Warning Levels

The operator can examine the current gas concentration threshold settings, or limits, by pressing the

View Limits… button shown on the Analysis screen above. The limits are then displayed in the Gas

Concentration Limits screen (see Figure 36).

Figure 36. Gas Concentration Limits Screen

To change the Caution and/or Warning threshold levels, return to the Main Menu screen (Figure 5)

and press the Settings button followed by the Gas Limits button. The Gas Concentration Limits

Reset screen is displayed (see Figure 37). By highlighting in turn each gas displayed on this screen

using the Up and Down arrows, their Caution Limit and Warning Limit levels can be reset as desired

using the appropriate Up and Down arrows.

TRANSPORT X Users Guide Page 26 Ver. 40-0157-04 03/07/2013

Page 27

TRANSPORT X Users Guide

Figure 37. Gas Concentration Limits Reset Screen

The Default button on the Gas Concentration Limits Reset screen resets the gas concentration

thresholds to the default Caution and Warning levels. If this button is pressed, the Default Reset

Warning window is displayed (see Figure 38). Click the Yes button to continue resetting the

thresholds to the default levels.

Figure 38. Default Reset Warning Window

When the desired thresholds have been set in the Gas Concentration Limits Reset screen

(Figure 37), press the OK button to return to the Settings screen.

4.3.2.2 DGA Analysis Using Diagnostic Algorithms

The operator can select the Diagnosis… option shown in the Analysis screen (Figure 35) to give

access to four analysis diagnostic tools: Key Gas (see Figure 39), Rogers’ Ratios, Duval’s Triangle and

Japan ETRA (see Figure 40). Access to these analysis options is obtained by pressing the tab of the

desired option found at the top of the screen.

TRANSPORT X Users Guide Page 27 Ver. 40-0157-04 03/07/2013

Page 28

TRANSPORT X Users Guide

Figure 39. Analysis Screen – Key Gas Tab

Figure 40. Analysis Screen – Japan ETRA Tab

These analysis tools are based on empirical data derived from the study of transformer degradation

and failures. They are not designed for the detection of transformer faults – rather they are intended

to provide warning of potential failures or aid in the diagnosis of transformer faults. If the gas levels

are very low and the transformer does not appear to have a fault, then these algorithms can give

misleading results and should not be applied. The user-settable thresholds discussed in

Section 4.3.2.1 are very useful for this purpose. These issues are explained fully in the standards and

references that are cited on the tabs that relate to the individual analysis tools found in the Analysis

screen (Figures 39 and 40).

To use a particular diagnostic method, press the button for the appropriate tab located along the top

of the Analysis screen (Figures 39 and 40). This action will cause re-configuration of the Analysis

screen to reflect the chosen diagnostic option. Then press the button bearing the name of the

selected diagnostic method (found in the central Diagnosis Information panel of each Analysis

screen) to enter the selected diagnostic algorithm.

Note: for the Japan ETRA case shown in Figure 40, there are two Diagnostic buttons in the central Diagnosis

Information panel, entitled Gas Pattern and Diagnostic Diagram.

1) Key Gas Method – IEEE C57.104-1991

This technique allows visual comparison of the measurement result with 4 “typical” fault results. The

user should determine which typical result, if any, matches most closely the TRANSPORT X result. The

user can scroll through the 4 “typical” failure options using the arrow keys. These failure options

appear on the touch screen as pink columns alongside the TRANSPORT X result, which is shown by

TRANSPORT X Users Guide Page 28 Ver. 40-0157-04 03/07/2013

Page 29

TRANSPORT X Users Guide

the blue columns (see Figure 41). The user should choose the failure option that most resembles their

own result from the diagnosis by pressing the Select button on the appropriate option screen. If

there is no applicable comparison, the user should not make a diagnosis selection and press the

Cancel button, which equates to selecting the None diagnosis. Pressing either the Select or Cancel

button returns the display to the Analysis screen (Figures 39 and 40).

Figure 41. Key Gas Method (Showing Overheated Oil as the “Typical” Failure Comparison)

2) Rogers’ Ratios – IEEE C57.104-1991

This method uses established ratios between various dissolved gases to determine the type of fault

(see Figure 42). However, if the gas concentration levels are low, the Roger’s Ratios screen will show a

warning that gas levels may be too low for this algorithm to produce a reliable result. The fault code

and diagnosis may still be displayed, but caution should be used when applying this result. Press the

OK button to return to the Analysis screen (Figures 39 and 40).

Figure 42. Rogers’ Ratios Screen

3) Duval’s Triangle – TechCon 2004 – Michel Duval

Duval’s method uses a triangle to plot the intersecting point of certain gas concentration values (see

Figure 43). Where this point is located within this triangle indicates the type of fault the transformer

may have. The diagnosis is indicated at the bottom right of the Duval Triangle screen. Press the OK

button to return to the Analysis screen (Figures 39 and 40).

TRANSPORT X Users Guide Page 29 Ver. 40-0157-04 03/07/2013

Page 30

TRANSPORT X Users Guide

Figure 43. Duval’s Triangle Screen (Showing Low Energy Discharges)

4) Japan ETRA – Volume 54, No. 5

The Japanese Electric Technology Research Association (ETRA) has reviewed many DGA diagnoses in

Japan and elsewhere and has reached certain conclusions regarding the detection of faults in

transformers. From these studies a series of patterns have been produced that depict the relative

concentration levels of certain dissolved gases (H2, CH4, C2H6, C2H2 and C2H4) present in the oil of

failing transformers at the time internal faults appear and these patterns have been associated with

specific types of failure. They have also developed two diagnostic charts or diagrams that are based

on the ratios of concentrations of certain dissolved gases that have been correlated with particular

types of transformer failure. These two forms of failure diagnosis have been incorporated into the

TRANSPORT X’s failure analysis suite.

a) Gas Pattern Analysis Method

Press the Gas Pattern button located in the central Diagnosis Information panel under the Japan

ETRA tab of the Analysis screen (Figure 40). A series of dissolved gas patterns (see Figure 44) are then

made available using the forward or backward arrows, each pattern being derived from the Japan

ETRA analysis of transformer failures. Also included for comparison purposes is the pattern, produced

in an identical manner to the ETRA failure patterns, that is based on the TRANSPORT X

measurements.

Note: All these patterns have been produced by a normalization process using the concentration level of the dissolved

gas with the highest concentration discovered in the oil of a failing transformer.

Figure 44. Gas Pattern Based on TRANSPORT X Measurements

TRANSPORT X Users Guide Page 30 Ver. 40-0157-04 03/07/2013

Page 31

TRANSPORT X Users Guide

In Figure 44, the most recent set of dissolved gas concentration measurements made by the

TRANSPORT X are displayed. It can be seen that the measured concentration of C2H

to normalize the concentration levels of the other measured dissolved gas constituents. Thus the

measured concentration of C2H

is approximately 37 % of the concentration of C

6

In Figure 45 we find the ETRA pattern for a type C2H4-A failure displayed in the right-hand chart with

the measured gas pattern previously depicted in Figure 44 shown in the left-hand chart. The

TRANSPORT X makes available a number of such ETRA gas patterns, each pattern representing a

different type of failure. The user is required to decide which of the available patterns is closest to

their measured pattern and then by using the Select button choose that pattern (or none) as the

failure pattern.

has been used

4

.

2H4

Figure 45. C2H4-A Type Failure Pattern Compared With Gas Pattern Based on TRANSPORT X

Measurements

b) Diagnostic Chart Method

Press the Diagnostic Diagram button located in the central Diagnosis Information panel under the

Japan ETRA tab of the Analysis screen (Figure 40). On the first diagram (Diagram A) shown in

Figure 46, the white spot is the result derived from the most recent set of dissolved gas concentration

measurements made by the TRANSPORT X for the particular gas ratios used in this chart. It can be

seen that in this instance the diagram suggests that the transformer failure is because of Discharges.

Figure 46. Japan ETRA Diagnostic Diagram A

TRANSPORT X Users Guide Page 31 Ver. 40-0157-04 03/07/2013

Page 32

TRANSPORT X Users Guide

Press the button to display the Diagnostic Diagram B (Figure 47). As previously with

Diagnostic Diagram A, plotted on this diagram (as the white spot) is the result derived from the most

recent set of dissolved gas concentration measurements made by the TRANSPORT X using the gas

ratios of Diagnostic Diagram B. It can be seen that in this instance the diagram suggests that the

transformer failure is because of Partial Discharge (Low Energy). Press the OK button to return to the

Analysis screen (Figures 39 and 40).

Figure 47. Japan ETRA Diagnostic Diagram B

4.3.2.3 Concluding the Analysis Process

Press the OK button on the Analysis screen (Figures 39 and 40), and then press the OK button on the

DGA Analysis screen (Figure 35). These actions cause the Analysis Conclusion screen (see Figure 48)

to be displayed.

Figure 48. Analysis Conclusion Screen

This screen presents the user with the following options:

Print Results: to print the results (both Measurement Results and Diagnostic Analysis Results).

The Print process is as described previously in relation to the Results Options screen (Figure 32).

Advanced…: to re-enter the Analysis process. The user is returned to the beginning of

Section 4.3.2, i.e. to the analysis of the measurement result using the TRANSPORT X’s embedded

DGA diagnostic tools.

TRANSPORT X Users Guide Page 32 Ver. 40-0157-04 03/07/2013

Page 33

TRANSPORT X Users Guide

Finish: to finish the measurement and analysis process. The measurement and analysis results

are saved in the TRANSPORT X database and the database is then closed (see Figure 49).

Figure 49. Saving and Closing the Database

Once the database is closed, the Clean Up screen (see Figure 50) is displayed. This screen contains

instructions to the user to disconnect the sample bottle and shut down the TRANSPORT X following

the DGA measurement and diagnosis.

Figure 50. Clean Up Screen

Press the Next button to return to the Main Menu screen (Figure 5) for shutdown of the unit.

4.3.3 Internal Error Checking

The TRANSPORT X includes a function for monitoring the internal operation of the system and

checking the validity of oil samples. If an anomaly is detected, then this will be reported to the user at

the end of the sample measurement process. In addition, any result invoking an error code is

highlighted in yellow in the database Records screen (see Figure 51) – see also Section 4.3.4 for

further information about the database Records screen.

TRANSPORT X Users Guide Page 33 Ver. 40-0157-04 03/07/2013

Page 34

TRANSPORT X Users Guide

Figure 51. Records Screen (Database List Showing 2 Results With Errors)

The user can navigate to a stored result in the Records screen by using the Up and Down arrows.

The result highlighted in grey/blue is the current or active result. When the user navigates to a result

which is subject to an error, the Caution button is displayed advising the user that the highlighted

result contains some sort of error. This feature is illustrated in Figure 51, where the database list

contains two results containing errors, one of which is the active result causing the Caution button to

be displayed. Pressing the Caution button causes the ErrorCheck Results screen (see Figure 52) to

be displayed.

Figure 52. ErrorCheck Results Screen

Error codes for each fault detected by the TRANSPORT X unit are displayed in the Code column of the

ErrorCheck Results screen. Error codes are divided into two main types – hardware or instrument,

and gas or environmental errors. The ErrorCheck Results screen gives an example of a hardware

error. The hardware type of error relates to an issue with the TRANSPORT X unit, whereas the gas

type describes issues with the sample being measured or the local environment:

Hardware error classified as a Warning (highlighted in red): the user should contact the GE

Energy Customer Support immediately as a malfunction with the TRANSPORT X unit has been

detected.

Hardware error classified as a Caution (highlighted in yellow): the user should take certain action,

such as change the in-line filters. If this code persists, the user should contact the GE Energy

Customer Support.

TRANSPORT X Users Guide Page 34 Ver. 40-0157-04 03/07/2013

Page 35

TRANSPORT X Users Guide

Gas error classified as a Warning (highlighted in orange): the TRANSPORT X had detected a

serious problem with the sample. This would mainly be caused by interference of the sample

from a solvent and the results from such a sample could not be relied upon.

Gas error classified as a Caution (highlighted in white): an issue has arisen with the sample, but

the results are still valid, albeit they may have a larger than normal margin for error. Such a

situation may be caused by high target gas levels being detected in the ambient air. In such a

situation, the user could potentially take the TRANSPORT X unit to another location for further

sample testing or increase the purge time for future tests.

If the instrument detects any error codes, the user is given the option of resolving the problem using

the Resolve button that is found at the bottom of the ErrorCheck Results screen (Figure 52). By

pressing the Resolve button, the user is presented with the ErrorCheck Response screen (see

Figure 53), where the two best options for preventing a reoccurrence of the error are displayed.

Figure 53. ErrorCheck Response Screen

The user should follow the instructions in the First response and, if this fails to fix the issue, proceed

to the Second response. If the Resolve function is not used, the user may consult the

Troubleshooting Guide (Section 9) and follow the suggestions for action to resolve the error. If the

error cannot be resolved, contact GE Energy. If the user chooses to continue a measurement having

failed to resolve the issues highlighted, results may be affected. A warning to this effect will be given

in the Potential Error Warning window (see Figure 54).

Figure 54. Potential Error Warning Window

TRANSPORT X Users Guide Page 35 Ver. 40-0157-04 03/07/2013

Page 36

TRANSPORT X Users Guide

4.3.4 Viewing Previous Results

The TRANSPORT X offers users the option of examining results stored in its database. To do this,

press the View Previous Results button on the Main Menu screen (Figure 5). The options for

searching the database are then displayed on the Display Results screen (see Figure 55).

Figure 55. Display Results Screen

The Show All Results button is highlighted (in red) as the default option when this screen is first

displayed. Pressing the Next button when the Show All Results button is highlighted causes the

database Records screen (Figure 51) to be displayed. The Records screen displays all the database

records without any application of a search category.

The organization of the database is based upon information categories entered by the user when

doing the DGA tests and this information is searchable using the Display Results screen. To display a

particular result (as compared to displaying all the database records in the Records screen), the user

should first select the desired search category button on the Display Results screen and then press

the Next button – all the data entered in the database under the selected category is then displayed.

As an example of the database search process, to conduct a search based on the location category,

first press the Location button on the Display Results screen. All the location records entered in the

database are then listed in the Equipment Location screen (Figure 8). Using the scroll buttons on the

Equipment Location screen, highlight the location that is of interest. Then by pressing the Next

button at the bottom of the Equipment Location screen, all the records for this one location will be

displayed in a list on the database Records screen (Figure 51). To display the results for a particular

record, highlight the record of interest using the Up and Down arrows, then press the View Result

button. The results can then be printed and/or analyzed as previously described in relation to the

Results Options screen (Figure 32).

All searches for a particular record stored in the database are conducted in a manner similar to that

described above for a location-based search, although there is a minor variation for the Date of

Sample search.

In the case of a Date of Sample search, the user is required to commence the process by setting

start and end dates for the query. Therefore, Start Date and End Date screens of the form shown in

Figure 56 are displayed successively at the beginning of the process for setting the date range of the

search of the database records. The user should first enter the start date of the search on the Start

Date screen. Then by pressing the Next button on the Start Date screen, the End Date screen is

displayed; the end date for the search should then be entered on the End Date screen.

Dates are entered on both the Start Date and End Date screens in the same manner. The forward

and back calendar arrows on the Date screens are used first to select the required year/month

combinations and then the days are indicated by highlighting the required days on the displayed

monthly calendars.

TRANSPORT X Users Guide Page 36 Ver. 40-0157-04 03/07/2013

Page 37

TRANSPORT X Users Guide

Figure 56. End Date Screen

4.3.5 Settings

Pressing the Settings button on the Main Menu screen (Figure 5) causes the Settings screen shown

in Figure 57 to be displayed.

Figure 57. Settings Screen

The various buttons on this screen enable the user to perform the following functions:

Date & Time…: to set the Date, Time and Time Zone – see Section 4.3.5.1.

Touchscreen…: to adjust the sensitivity of the touch screen. It is not recommended to change the

default settings for the touch screen.

Language…: to select the desired language from the available list.

Gas Limits…: to set the gas thresholds for the diagnostic tools – see Section 4.3.2.1

System…: to perform vital system housekeeping, checking and maintenance functions on the

unit – see Section 4.3.5.2.

Normalization…: to normalize to a specific temperature the DGA concentration results measured

in ppmv. Select the temperature of normalization using the Normalization Temperature screen

(see Figure 58); the default temperature is 20 °C.

TRANSPORT X Users Guide Page 37 Ver. 40-0157-04 03/07/2013

Page 38

TRANSPORT X Users Guide

Figure 58. Normalization Temperature Screen

4.3.5.1 Setting the Date/Time

By pressing the Date & Time… button on the Settings screen (Figure 57), the Date/Time Picker

screen (see Figure 59) is displayed. Use the Up and Down arrows on this screen to set the Date, Time

and Time Zone as required.

Note: The database is pre-populated with a number of Time Zones relative to GMT. The user should select the zone

closest to their time zone.

Figure 59. Date/Time Picker Screen

After making the required Date, Time and Time Zone settings, a warning message is displayed

asking whether the user wishes to proceed with implementation of the changes. Press the Yes button

on this warning screen if the changes are in order. A second screen is then displayed indicating that

the Date and Time have been updated; press the OK button on the second screen to return to the

display of the Settings screen.

4.3.5.2 Performing System Housekeeping, Checking and Maintenance Functions

By pressing the System… button on the Settings screen (Figure 57), the System screen (see Figure 60)

is displayed. On this screen are found details of the last times when a System Check was performed.

TRANSPORT X Users Guide Page 38 Ver. 40-0157-04 03/07/2013

Page 39

TRANSPORT X Users Guide

Figure 60. System Screen

From this screen, four option functions can be accessed:

Start System Check: see Section 8.

Advanced…: this option is password-protected and is only for the GE Service staff.

Start System Flush: see also Section 4.2. Pressing the Start System Flush button on the System

screen initiates a flushing process whereby ambient air is circulated through the TRANSPORT X

for 20 minutes in order to help clear any potential contamination from packing material or prior

samples from the system. Pressing the Start System Flush button causes a caution window to be

displayed (see Figure 61).

Figure 61. System Flushing Caution Window

Click the Yes button to continue. The System Flush Instructions screen is then displayed (see

Figure 62).

TRANSPORT X Users Guide Page 39 Ver. 40-0157-04 03/07/2013

Page 40

TRANSPORT X Users Guide

Figure 62. System Flush Instructions Screen

Follow the on-screen instructions by connecting a clean, dry sample bottle to the unit as detailed.

Press the Next button to initiate the system flushing. The Flushing Progress screen (see

Figure 63) is then displayed. The process takes approximately 20 minutes to complete. The

Cancel button on this screen can be used for early termination of the flushing process.

Figure 63. Flushing Progress Screen

When the flushing is completed successfully, the System Flush Completed screen is displayed

(see Figure 64). Press the Next button to return to the Main Menu screen (Figure 5).

TRANSPORT X Users Guide Page 40 Ver. 40-0157-04 03/07/2013

Page 41

TRANSPORT X Users Guide

Figure 64. System Flush Completed Screen

Start Pressure Test: the Pressure Test follows an identical process to the System Flush process

(above). The unit is checked for its ability to maintain pressure in the working gas system. If

pressure can be maintained, the Pressure Test Passed screen is displayed (see Figure 65).

Figure 65. Pressure Test Passed Screen

If pressure cannot be maintained (i.e. a leak is detected) in the working gas system, the Pressure

Test Failed screen is displayed (see Figure 66). In this case, follow the on-screen instructions and

re-run the Pressure Test.

TRANSPORT X Users Guide Page 41 Ver. 40-0157-04 03/07/2013

Page 42

TRANSPORT X Users Guide

Figure 66. Pressure Test Failed Screen

5. TAKING AN OIL SAMPLE

The sampling procedure provided below has been adapted from the international standard IEC 567

for the sampling of oil from oil-filled electrical equipment for the analysis of dissolved gas. Correct

sampling of the insulating oil is essential to ensure that a representative sample is obtained which

will give an accurate snapshot of the overall condition of the oil within the equipment.

The method recommended here for sampling ensures that a secure sample is obtained and is ready

for injection into the TRANSPORT X without risk of contamination, post or pre sampling. The method

is described with the aid of reference to diagrams (Figures 67 to 70).

The technique assumes that there is an available fitting on the equipment to be sampled that will

allow connection of a two-way Luer lock valve directly to the equipment, either in-line in a sampling

pipe, or as a fitting that can be connected directly to the sampling point. Many different

configurations are possible but the requirement is the same for all.

The sample container consists of a 50-mL ground glass syringe to which is connected a two-way

plastic stopcock. Although this stopcock is removable from the syringe, for the purpose of this

sampling description, it should be considered as part of the syringe/sample container assembly.

Proceed as follows:

1. Connect the syringe via a Luer lock 3-way valve to the equipment sampling line.

2. Turn the valve in the equipment sampling line and the valve on the syringe to allow equipment oil

to flow out to waste from the syringe valve (see Figure 67). Allow at least 1 liter of oil to flow to a

waste container.

Figure 67. Allow Equipment Oil to Flow out to Waste

3. Turn the syringe valve to the position where oil can be drawn into the syringe (see Figure 68).

4. Gently draw oil fully into the syringe. At this stage bubbles of air from the dead volume in the

neck of the syringe are drawn into the syringe and some of the gas present is dissolved into the

oil. Also some of the gas in the oil escapes into the air bubbles. This oil and gas must be rejected

as unrepresentative of the oil in the transformer.

TRANSPORT X Users Guide Page 42 Ver. 40-0157-04 03/07/2013

Page 43

TRANSPORT X Users Guide

Figure 68. Draw Oil Into the Syringe

5. Turn the Luer lock valve fitted to the equipment sampling line to allow oil to flow out from the

syringe to a waste container. At the same time, holding the syringe upright, expel all of the

bubbles and almost all of the oil from the syringe (see Figure 69).

Figure 69. Expel Oil and Air From the Syringe

TRANSPORT X Users Guide Page 43 Ver. 40-0157-04 03/07/2013

Page 44

TRANSPORT X Users Guide

6. Close the syringe valve when most of the oil has been expelled, leaving approximately 2 mL of oil

remaining in the syringe.

7. Turn the syringe valve to permit the gentle drawing of 50 mL of oil into the syringe (see Figure 70).

Note: The head pressure from the transformer main tank may actually push the oil into the syringe so care must be

taken not to allow the plunder to come out the end of the syringe body at this point.

Figure 70. Draw Oil Into the Syringe

8. Flush this oil out of the syringe into the waste container.

9. Repeat the steps 7 and 8 at least 2 times.

10. Draw exactly 50 mL of oil into the syringe.

11. Turn the equipment valve to prevent any further oil escaping from the transformer.

12. Turn the syringe valve to the fully closed position.

13. Disconnect the syringe from the equipment sampling line.

A representative sample of oil from the equipment is now ready for injection into the TRANSPORT X.

6. CLEANING THE APPARATUS

After performing a test, it is important to use the correct clean-out procedure to avoid any

contamination from one sample to the next. A small amount of residual oil left in the sample

container or injection pipe-work may have an impact on the results and diagnosis obtained from the

TRANSPORT X for the next sample.

Note: DO NOT use any solvents to clean any part of the TRANSPORT X or its accessories as this can affect results.

6.1 CLEANING THE SYRINGE, VALVES AND LID ASSEMBLY

The sample bottle, the syringe with its 3-way valve, the male quick-connect valve that is connected

to the syringe, and the oil injection tube in the lid assembly should be cleaned out after every sample

analysis.

The sample bottle, the syringe inner surfaces (barrel and plunger) and the lid assembly are cleaned

using clean absorbent cloth or tissue. The syringe with its 3-way valve, the male quick-connect valve

and the oil injection tube are cleaned by air pumped from the syringe.

By following these best practices, the TRANSPORT X can easily clear the effects of heavily gassed

samples for the next test.

6.2 CLEANING THE SYRINGE

It is imperative that the syringe is kept clean in order to prevent cross-contamination of results. The

syringe cleaning steps are as follows.

1. Wipe all surfaces with an absorbent cloth or tissue.

2. Ensure the male quick-release valve (Figure 25) is connected to the syringe.

3. Turn the 3-way valve on the syringe to permit air to be drawn into the syringe through the side

arm of the valve.

4. Draw in air to the syringe through the side arm of the valve.

5. Hold the syringe with the quick-release valve pointing vertically down.

6. Turn the 3-way valve to open the in-line arm and close the side arm.

7. Push air through the syringe and valves, flushing out any oil residue.

8. Repeat 4 or 5 times the steps 3 to 7.

TRANSPORT X Users Guide Page 44 Ver. 40-0157-04 03/07/2013

Page 45

TRANSPORT X Users Guide

This process will flush oil out of the syringe, the 3-way valve fitted to the syringe and the male quickconnect valve.

Note: When performing the above cleaning process, use a cloth or waste container to expel excess oil into.

Note: It is recommended that the user thoroughly cleans the syringe after each sample and before storage / reuse. To

do so, remove the plunger from the syringe barrel. The plunger and barrel are both then cleaned with a cloth or tissue.

Note: Ensure no oil residue remains in the quick release valve or syringe 3-way valve. Use the technique of vigorously

flushing air through these valves using the syringe as a pump, as described above.

6.3 CLEANING THE BOTTLE AND LID ASSEMBLY

After the TRANSPORT X has completed its analysis, the oil sample should be disposed of properly and

the bottle and lid assembly cleaned as described below.

Note: The same oil sample cannot be re-tested as most of the gas will have escaped during analysis.

The sample bottle and lid cleaning steps are as follows.

1. Unscrew the lid assembly from the sample bottle, holding the lid assembly upright to avoid any