Page 1

GE

Oil & Gas Flow

TransPort® PT900

Portable Ultrasonic Flow Meter for Liquids

User’s Manual

910-315 Rev. C

Page 2

Page 3

Transport® PT900

Portable Ultrasonic Flow Meter for Liquids

User’s Manual

910-315 Rev. C

September 2019

www.gemeasurement.com

©2017 General Electric Company. All rights reserved.

Technical content subject to change without notice.

Page 4

[no content intended for this page]

ii TransPort® PT900 User’s Manual

Page 5

Contents

Typographical Conventions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vii

Safety Issues - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

Auxiliary Equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ix

Product Registration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - x

Services- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - x

Terms and Conditions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - x

Regulatory Compliance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - xi

Chapter 1. Introduction

1.1 Product Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Chapter 2. Installation

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.2 Unpacking the PT900 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.3 Installing a Battery Pack in the Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.4 Mounting the PT900 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.5 Installing the Clamp-On Fixture and Transducers . . . . . . . . . . . . . . . . . . . . . . .7

2.5.1 A Sample Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.5.2 Transducer Spacing Calculation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.5.3 Mounting the PT9 Clamp-On Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.5.4 Checking the Transducer Holders . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5.5 Installing the Transducers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.5.6 Even and Odd-Traverse Installations . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.6 Making the Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.6.1 Connecting the Line Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.6.2 Connecting the Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.6.3 Connecting the Digital Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.6.4 Connecting the Analog Inputs and Output . . . . . . . . . . . . . . . . . . . . 37

2.6.5 Connecting the Energy Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.6.6 Using the USB Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.6.7 Using the Bluetooth Wireless Interface . . . . . . . . . . . . . . . . . . . . . . . 38

2.7 Caring for the PT900 Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.7.1 Charging and Storing the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.7.2 Replacing the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.7.3 Disposing of the Batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.8 Powering On and Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

TransPort® PT900 User’s Manual iii

Page 6

Contents

2.9 PT900 LED Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.9.1 Power LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.9.2 Bluetooth LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.9.3 Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.9.4 Battery LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Chapter 3. Initial Setup

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.2 Charging the PT900 Transmitter and Tablet . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.3 Installing or Updating the PT900 APP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.3.1 Checking the APP Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.3.2 Installing or Updating the PT900 Android and iOS APP . . . . . . . . . 46

3.3.3 Installing the Tablet APP from the SD Card (Applicable only to

Android APP)47

3.4 Pairing the Tablet and the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.4.1 Removing paired devices from PT900 APP . . . . . . . . . . . . . . . . . . . . 58

3.4.2 Removing paired devices from iPhone/Tablet . . . . . . . . . . . . . . . . . 59

3.5 Using the APP Main Menu and the Slide Menu . . . . . . . . . . . . . . . . . . . . . . . . 61

3.5.1 The Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3.5.2 The Slide Menu (Applicable only to Android) . . . . . . . . . . . . . . . . . . . 62

Chapter 4. Programming

4.1 Configuring the Units of Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.2 Configuring a Channel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.3 Programming the PIPE Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.3.1 Pipe Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.3.2 Pipe Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.3.3 Pipe Lining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.4 Programming the FLUID Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.5 Programming the TRANSDUCERS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.5.1 Programming the Transducer Parameters . . . . . . . . . . . . . . . . . . . . 74

4.5.2 Setting the Reynolds Correction Factor . . . . . . . . . . . . . . . . . . . . . . . 76

4.5.3 Programming the Meter Factor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4.6 Programming the PLACEMENT Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.6.1 Viewing the Traverse Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.6.2 Viewing the Transducer Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.7 Configuring the Program Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

iv TransPort® PT900 User’s Manual

Page 7

Contents

4.7.1 Programming the ENERGY Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

4.7.2 Programming the INPUTS Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4.7.3 Programming the OUTPUTS Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

4.7.4 Programming the USER FUNCTIONS Tab. . . . . . . . . . . . . . . . . . . . . . 93

Chapter 5. Measurements

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

5.2 Setting Up the Measurements for Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

5.3 Viewing Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

5.3.1 Displaying Multiple Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . 101

5.3.2 Displaying a Single Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

5.3.3 Displaying the Totalizer Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

5.3.4 Displaying the Diagnostics Parameters . . . . . . . . . . . . . . . . . . . . . . 106

Chapter 6. Logging Data

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6.2 Adding a Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6.3 Deleting, Stopping or Editing a Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

6.3.1 Deleting a Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

6.3.2 Editing a Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

6.3.3 Viewing a Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Chapter 7. Configuring the Transmitter

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7.2 Updating the PT900 Transmitter Software. . . . . . . . . . . . . . . . . . . . . . . . . . . 118

7.3 Programming the Transmitter SERVICE Menu. . . . . . . . . . . . . . . . . . . . . . . . 121

7.3.1 Programming the CALIBRATION Menu . . . . . . . . . . . . . . . . . . . . . . . 121

7.3.2 Programming the METER SETUP Menu. . . . . . . . . . . . . . . . . . . . . . . 124

7.3.3 Programming the TESTING Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

7.3.4 Programming the ERROR LIMITS Menu. . . . . . . . . . . . . . . . . . . . . . . 130

Chapter 8. Error Codes and Troubleshooting

8.1 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

8.1.1 Error Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

8.1.2 Flow Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

8.2 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

8.2.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

8.2.2 Fluid and Pipe Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

TransPort® PT900 User’s Manual v

Page 8

Contents

8.3 Diagnostic Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

8.4 Getting Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

8.4.1 The About Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

8.4.2 The Diagnostics Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

8.4.3 The Service Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

8.4.4 The Spare Parts Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

8.5 Help Topics List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

8.6 The Quick-Start Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Chapter 9. Communication

9.1 Modbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

9.2 Modbus Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

9.3 Bluetooth Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Appendix A. Specifications

A.1 Operation and Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

A.2 PT900 Flow Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

A.3 User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

A.4 Software Application (PT900 APP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

A.5 Clamp-On Transducers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

A.6 Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

A.7 Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

A.8 Customer Cable Requirements for AIO/DIO Connections . . . . . . . . . . . . . 161

Appendix B. Data Records

B.1 Service Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

B.2 Initial Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

B.3 Initial Diagnostic Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

vi TransPort® PT900 User’s Manual

Page 9

Preface

Typographical Conventions

Note: “Note” paragraphs provide additional information about the topic which is

helpful but is not essential to proper completion of the task.

Important : “Important” paragraphs provide emphasis to instructions that are

essential to proper setup of the equipment. Failure to follow these

instructions carefully may cause unreliable performance.

CAUTION! “Caution” paragraphs indicate a potentially

hazardous situation which can result in minor or moderate injury

to personnel or damage to the equipment.

WARNING! “Warning” paragraphs indicate a potentially

hazardous situation which can result in serious personal injury or

death.

Paragraphes d'informations

Remarque : Ces paragraphes fournissent des informations à même de faciliter

la compréhension de la situation, mais n'est pas indispensable à la

bonne utilisation des instructions.

Important : Ces paragraphes fournissent des informations qui mettent l'accent

sur les instructions qui sont essentielles à une configuration correcte

de l'équipement. Le non-respect de ces instructions peut entraîner

une dégradation des performances.

MISE EN GARDE! Ce symbole indique un risque potentiel

mineur de blessure aux personnes et / ou de sérieux dommages

à l'équipement, à moins que ces instructions soient

rigoureusement suivies.

AVERTISSEMENT! Ce symbole indique un risque potentiel

grave de blessures aux personnes, à moins que ces instructions

sont soient rigoureusement.

TransPort® PT900 User’s Manual vii

Page 10

Preface

Safety Issues

WARNING! It is the responsibility of the user to make sure all

local, county, state and national codes, regulations, rules and

laws related to safety and safe operating conditions are met for

each installation.

WARNING! If the clamp-on fixture and transducers are installed

on a pipeline above a work area or walkway, safe work site

practices for protection from falling objects must be followed.

WARNING! It is the responsibility of the user to make sure the

PWR, Hart, Modbus and IO cables meet the cable specifications

listed in Appendix A.

Questions de sécurité

AVERTISSEMENT! Il est de la responsabilité de l'utilisateur de

s'assurer que tous les règlements, codes et lois locaux, nationaux

et européens relatifs à la sécurité et aux conditions d'exploitation

en toute sécurité soient respectés pour chaque installation. La

sécurité de tout système intégrant l'équipement est de la

responsabilité de celui qui l'assemble.

AVERTISSEMENT! If the clamp-on fixture and transducers are

installed on a pipeline above a work area or walkway, safe work

site practices for protection from falling objects must be

followed.

AVERTISSEMENT! Il est de la responsabilité de l'utilisateur de

s'assurer que les câbles d'alimentation, Hart, Modbus et

Entrées / Sorties répondent à la spécification décrite à l'annexe A.

viii TransPort® PT900 User’s Manual

Page 11

Preface

Auxiliary Equipment

Local Safety Standards

The user must make sure that he operates all auxiliary equipment in accordance

with local codes, standards, regulations, or laws applicable to safety.

Working Area

WARNING! Auxiliary equipment may have both manual and

automatic modes of operation. As equipment can move suddenly

and without warning, do not enter the work cell of this equipment

during automatic operation, and do not enter the work envelope

of this equipment during manual operation. If you do, serious

injury can result.

WARNING! Make sure that power to the auxiliary equipment is

turned OFF and locked out before you perform maintenance

procedures on the equipment.

Matériel auxiliaire

Standards de sécurité locaux

L'utilisateur doit s'assurer que les équipements auxiliaires utilisés sont en tout point

conforme aux codes, standards et réglementations relatifs à la sécurité.

Zone de travail

AVERTISSEMENT! Les équipements auxiliaires peuvent avoir à

la fois des modes de fonctionnement manuel et automatique.

Comme l'équipement peut bouger brusquement et sans signe

préalable, ne pas entrer dans la zone de travail de ce dernier

pendant le fonctionnement automatique, et ne pas s'en

approcher de trop près pendant le fonctionnement manuel. Si

vous le faites, cela peut entraîner de graves blessures.

AVERTISSEMENT! Assurez-vous que l'alimentation de

l'équipement auxiliaire est éteinte et verrouillée avant d'effectuer

toute opération de maintenance ou d'entretien de l'équipement.

TransPort® PT900 User’s Manual ix

Page 12

Preface

Qualification of Personnel

Make sure that all personnel have manufacturer-approved training applicable to the

auxiliary equipment.

Personal Safety Equipment

Make sure that operators and maintenance personnel have all the safety equipment

applicable to the auxiliary equipment. Examples include safety glasses, protective

headgear, safety shoes, etc.

Unauthorized Operation

Make sure that unauthorized personnel cannot gain access to the operation of the

equipment.

Product Registration

Thank you for purchasing a model TransPort® PT900 from GE. Please register

your product at

such as the latest software/firmware upgrades, product information and special

promotions.

www.gemeasurement.com/productregistration for product support

Services

GE provides customers with an experienced staff of customer support personnel

ready to respond to technical inquiries, as well as other remote and on-site support

needs. To complement our broad portfolio of industry-leading solutions, we offer

several types of flexible and scalable support services including: Training, Product

Repairs, Service Agreements and more. Please visit

www.gemeasurement.com/services for more details.

Terms and Conditions

GE’s sales Terms and Conditions for your recent purchase of a GE product,

including the applicable product Warranty, can be found on our website at the

following link:

x TransPort® PT900 User’s Manual

www.gemeasurement.com/sales-terms-and-conditions

Page 13

Preface

Regulatory Compliance

Waste Electrical and Electronic Equipment (WEEE) Directive

GE is an active participant in Europe’s Waste Electrical and Electronic Equipment

(WEEE) take-back initiative (Directive 2012/19/EU).

The equipment that you bought has required the extraction and use of natural

resources for its production. It may contain hazardous substances that could impact

health and the environment.

In order to avoid the dissemination of those substances in our environment and to

diminish the pressure on the natural resources, we encourage you to use the

appropriate take-back systems. Those systems will reuse or recycle most of the

materials of your end life equipment in a sound way. The crossed-out wheeled bin

symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please

contact your local or regional waste administration. Visit

http://www.gemeasurement.com/environmental-health-safety-ehs

back instructions and more information about this initiative.

for take-

RoHS

The TransPort® PT900 fully complies with RoHS regulations

(Directive 2011/65/EU).

TransPort® PT900 User’s Manual xi

Page 14

Preface

FCC Rules/Industry Canada License

CAUTION! This device complies with Part 15 of the FCC Rules /

Industry Canada licence-exempt RSS standard(s). Operation is

subject to the following two conditions: (1) this device may not

cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation.

MISE EN GARDE! Le présent appareil est conforme aux CNR

d'Industrie Canada applicables aux appareils radio exempts de

licence. L'exploitation est autorisée aux deux conditions

suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2)

l'utilisateur de l'appareil doit accepter tout brouillage

radioélectrique subi, même si le brouillage est susceptible d'en

compromettre le fonctionnement.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

xii TransPort® PT900 User’s Manual

Page 15

Preface

FCC Rules/Industry Canada License (cont.)

Under Industry Canada regulations, this radio transmitter may only operate using

an antenna of a type and maximum (or lesser) gain approved for the transmitter by

Industry Canada. To reduce potential radio interference to other users, the antenna

type and its gain should be so chosen that the equivalent isotropically radiated

power (e.i.r.p.) is not more than that necessary for successful communication.

Conformément à la réglementation d'Industrie Canada, le présent émetteur radio

peut fonctionner avec une antenne d'un type et d'un gain maximal (ou inférieur)

approuvé pour l'émetteur par Industrie Canada. Dans le but de réduire les risques de

brouillage radioélectrique à l'intention des autres utilisateurs, il faut choisir le type

d'antenne et son gain de sorte que la puissance isotrope rayonnée équivalente

(p.i.r.e.) ne dépasse pas l'intensité nécessaire à l'établissement d'une communication

satisfaisante.

This device complies with Industry Canada's licence-exempt RSSs. Operation is

subject to the following two conditions:

1. This device may not cause interference; and

2. This device must accept any interference, including interference that may

cause undesired operation of the device.

MPE Reminding

To satisfy FCC/IC RF exposure requirements, a separation distance of 20 cm or

more should be maintained between the antenna of this device and persons during

device operation. To ensure compliance, operations at closer than this distance is

not recommended.

Les antennes installées doivent être situées de facon à ce que la population ne

puisse y être exposée à une distance de moin de 20 cm. Installer les antennes de

facon à ce que le personnel ne puisse approcher à 20 cm ou moins de la position

centrale de l' antenne. La FCC des éltats-unis stipule que cet appareil doit être en

tout temps éloigné d'au moins 20 cm des personnes pendant son functionnement.

TransPort® PT900 User’s Manual xiii

Page 16

Preface

Taiwan Warning Letter

վ࣏⦷䴫⌒䕫ሴᙗ䴫㇑⨶䗖⌅

ㅜҼọ㏃රᔿ䂽䅹Ṭѻվ࣏⦷ሴ乫䴫ˈ䶎㏃䁡ˈޜǃ୶

㲏ᡆ֯⭘㘵൷нᗇ㠚䆺ᴤ乫⦷ǃ࣐བྷ࣏⦷ᡆ䆺ᴤ䁝䀸ѻ⢩ᙗ৺࣏

㜭DŽ

ㅜഋọվ࣏⦷ሴ乫䴫ѻ֯⭘нᗇᖡ丯伋㡚ᆹޘ৺ᒢᬮ⌅䙊ؑ

˗㏃Ⲭ⨮ᴹᒢᬮ⨮䊑ᱲˈ៹・ণڌ⭘ˈі᭩ழ㠣❑ᒢᬮᱲᯩᗇ㒬㒼֯

⭘DŽ

Korean KCC Warning

1. EMC (B Type) Warning

ࣗ طی ࡈ ߇ ΰ ח

B

( ɼࢽࡈ ࢽؿݦ )

2. RF Warning

зଢ ב۱۳ٵВ ࢴર୍ݣ ɹЙۺࢄ ࢎࡰԸ ࢆֵ߄ࢴ˒

˔ԭѶۭٵݘВଜܶߴࡵ

ࢇ Е ɼࢽࡈ (B ) ࢷળࢶଢ

Ի۰ ࣯

Ի ɼࢽ߾۰ یࡈଜЕ ʨࡶ ּࢶࡳԻ ଜֲ

, ֻҘࠇ߾۰ یࡈଟ ܹ ݡТЬ.

xiv TransPort® PT900 User’s Manual

Page 17

Chapter 1. Introduction

Chapter 1. Introduction

1.1 Product Registration

Thank you for purchasing a TransPort® PT900 from GE. Please register your

product at www.gemeasurement.com/productregistration

such as the latest software/firmware upgrades, product information and special

promotions.

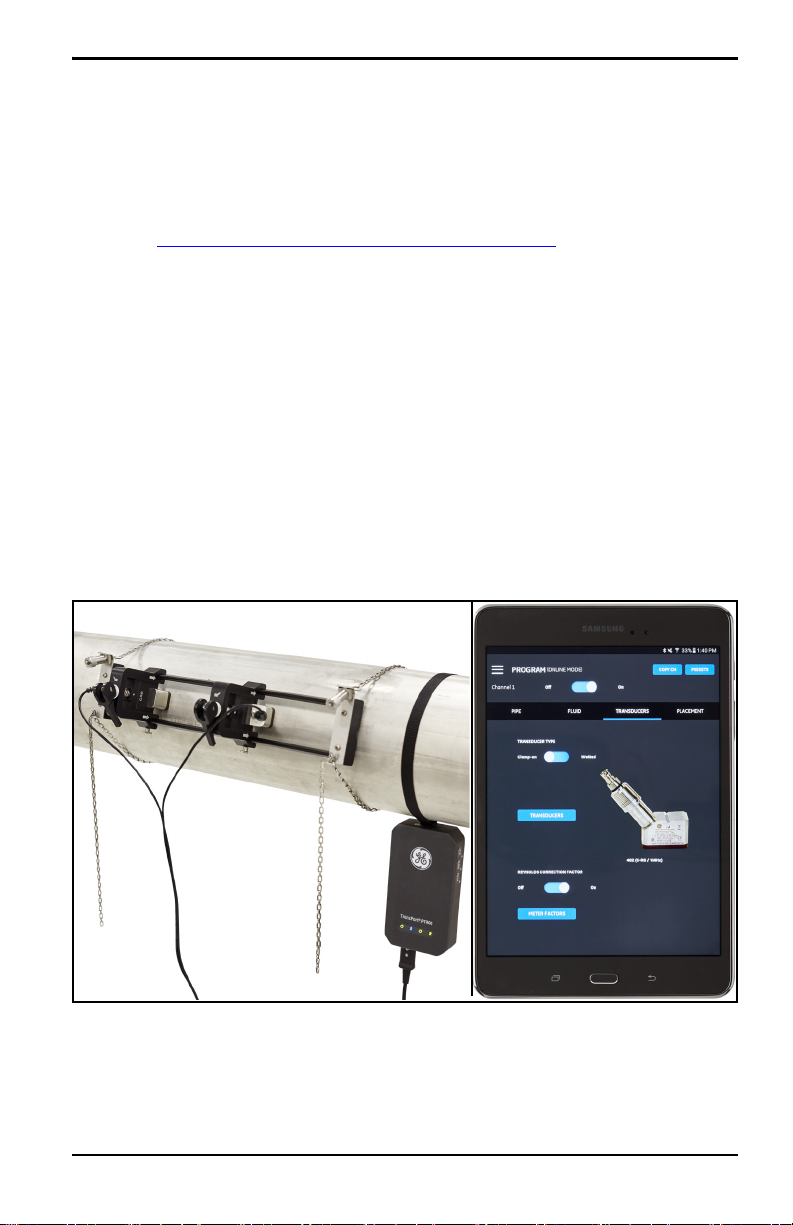

1.2 System Description

The PT900 is a portable flow transmitter for the measurement of liquid products. It

utilizes a new electronics platform and a simplified industrial design to make it

extremely easy to install and use. The system includes: a transmitter, a pair of

transducers, a new clamp-on fixture and a transducer cable (see Figure 1 below).

Optional accessories for the PT900 include: a tablet with the Android

operating system (see Figure 1 below), a thickness gauge, clamp-on temperature

transmitters and a clamp-on mounting fixture for pipes up to 48” in diameter. The

PT900 communicates with its remote display tablet via Bluetooth

for product support

®

or iOS

®

.

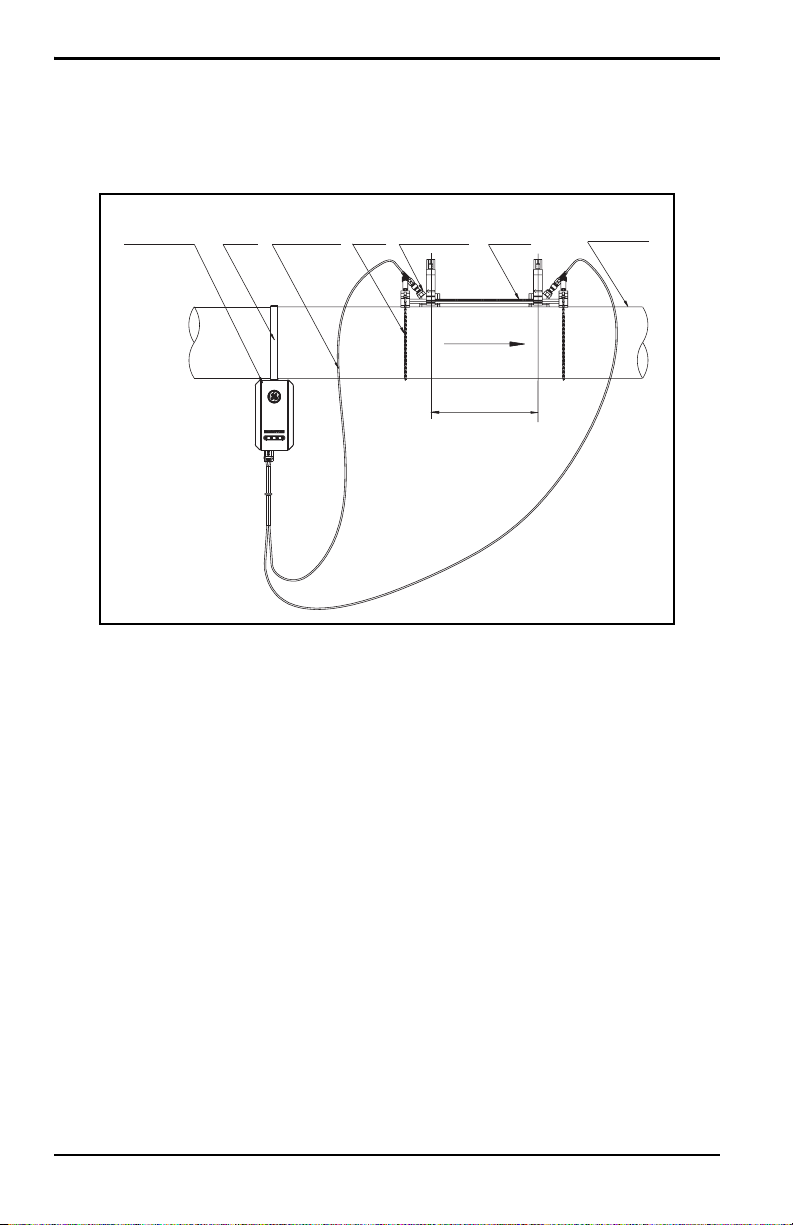

Figure 1: A PT900 Mounted on a Pipe and a Tablet (sold separately)

TransPort® PT900 User’s Manual 1

Page 18

Chapter 1. Introduction

[no content intended for this page]

2 TransPort® PT900 User’s Manual

Page 19

Chapter 2. Installation

Chapter 2. Installation

2.1 Introduction

To ensure safe and reliable operation of the PT900, the system must be installed in

accordance with established GE guidelines. Those guidelines are explained in

detail in this chapter and include the following topics:

• Unpacking the PT900 (see page 4)

• Mounting the PT900 Transmitter (see page 7)

• Installing the Clamp-On Fixture and Transducers (see page 7)

• Making the Electrical Connections (see page 33)

WARNING! The PT900 flow transmitter can measure the flow

rate of many fluids, some of which are potentially hazardous.

The importance of proper safety practices cannot be

overemphasized.

WARNING! Be sure to follow all applicable local safety codes

and regulations for installing electrical equipment and working

with hazardous fluids or flow conditions. Consult company safety

personnel or local safety authorities to verify the safety of any

procedure or practice.

ATTENTION EUROPEAN CUSTOMERS! To meet CE Mark and UL

Mark requirements, all cables must meet the specifications in

“Customer Cable Requirements for AIO/DIO Connections” on

page 161.

TransPort® PT900 User’s Manual 3

Page 20

Chapter 2. Installation

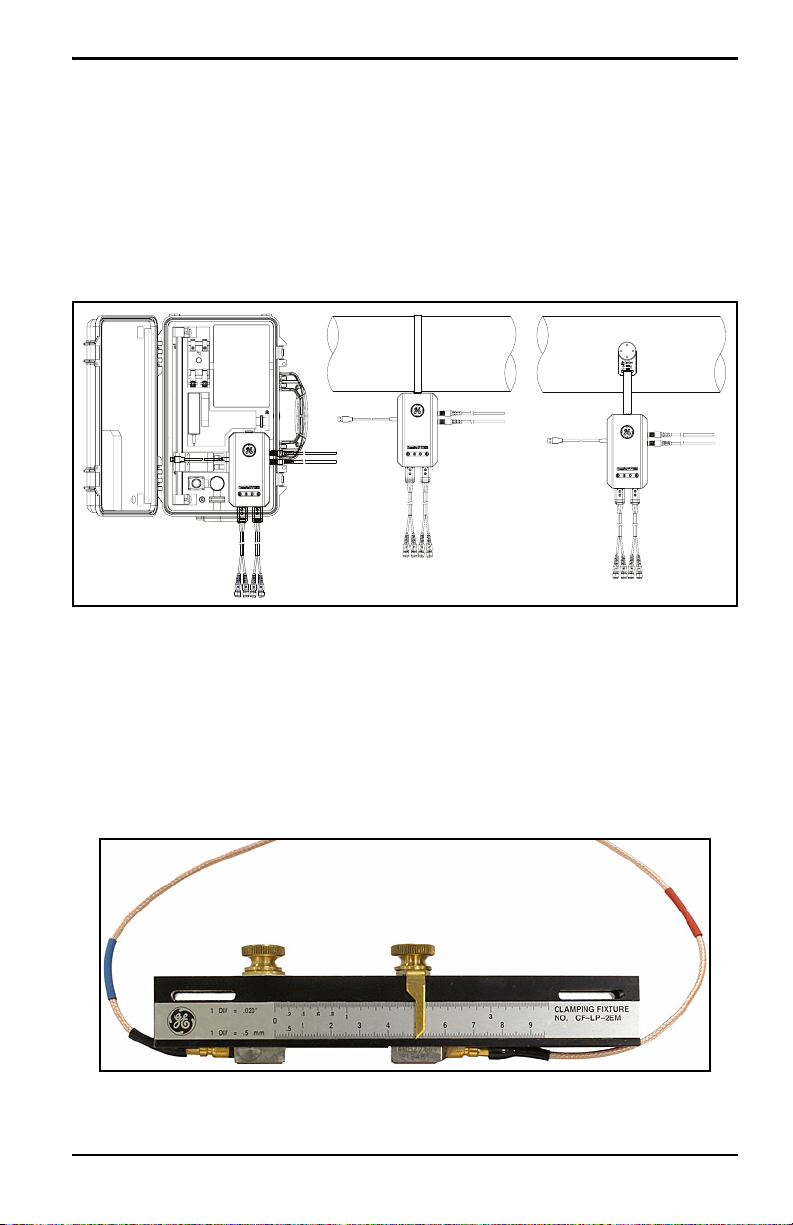

2.2 Unpacking the PT900

Before removing the PT900 from its carrying case (see the optional hard shell

carrying case in Figure 2 on page 5), inspect the contents of the case carefully.

Before discarding any of the packing materials, account for all components and

documentation listed on the packing slip. If anything is missing or damaged,

contact GE Customer Care immediately for assistance.

Because the PT900 may be ordered in many different configurations, the following

packing list is shown only as a typical example:

1. Transducers (2) 7. Case

2. Clamping Fixture 8. PT900 Power Supply

3. Transducer Cables 9. OD Tape

4. Transmitter 10. Couplant

5. Tablet Power Cord 11. PT900 Mounting Strap w/Magnet

6. SD Card

In addition to the standard components, the following optional components are

available for use with the PT900:

12. Tablet with protective case

13. Energy kit with an RTD module and an RTD cable for connection to the

PT900 transmitter

14. AIO cable with cabling box

• DIO cable with cabling box

• Battery charger

• Transducer extension cable up to 100 ft long

• 48" chain for the clamp-on fixture

4 TransPort® PT900 User’s Manual

Page 21

2.2 Unpacking the PT900 (cont.)

1

2

4

13

9

6

7

10

11

3

5

8

12

14

Chapter 2. Installation

Figure 2: PT900 in Hard Carrier Case

TransPort® PT900 User’s Manual 5

Page 22

Chapter 2. Installation

Cover

Battery Pack

Screws

2.3 Installing a Battery Pack in the Transmitter

To install a new battery pack in the transmitter (see Figure 3 below):

1. Using a slotted screwdriver, rotate the two quick-screws on the battery

cover 90° to open the transmitter.

2. Remove the existing battery pack.

3. Install the new battery pack in the battery compartment and replace the

battery cover. Secure the cover by tightening the two quick-screws.

Figure 3: Installing the Battery Pack in the Transmitter

6 TransPort® PT900 User’s Manual

Page 23

Chapter 2. Installation

Hard Carrier Case

Soft Strap

Magnetic Clamp

2.4 Mounting the PT900 Transmitter

The PT900 portable transmitter is housed in a durable rubberized enclosure suitable

for indoor or outdoor use. It can be placed in the hard carrier case or mounted on

the pipe with the either the soft strap or the magnetic clamp (see Figure 4 below).

Note: The pipe temperature must be between -20°C and about +40°C to safely

use the soft strap or magnetic clamp for mounting the transmitter.

Figure 4: PT900 Transmitter Mounting Options

2.5 Installing the Clamp-On Fixture and Transducers

This section describes in detail how to mount the standard PT9 clamp-on transducer

fixture on the pipe.

Note: Consult GE for instructions on installing the optional CF-LP clamping

fixture (shown in Figure 5 below).

Figure 5: CF-LP Clamping Fixture

TransPort® PT900 User’s Manual 7

Page 24

Chapter 2. Installation

Spacing

Flow Direction

PT900

Transmitter

Soft

Strap

Transducer

Cable

Chain

(x2)

Pipe (Not

Provided)

PT900

Fixture

Pair of CRR

Transducers

Important: Transducers shown

on top of pipe for clarity only.

Always mount on side of pipe!

2.5.1 A Sample Installation

For reference, a typical completed PT900 installation is shown in Figure 6 below.

Figure 6: Typical PT900 Installation

8 TransPort® PT900 User’s Manual

Page 25

Chapter 2. Installation

2.5.2 Transducer Spacing Calculation

ATTENTION! The required transducer spacing is calculated by the

APP after you program the PIPE, FLUID, TRANSDUCER and

PLACEMENT menus. Before proceeding with this installation, you

must complete the programming starting in Chapter 4.

Programming on page 63 up to “Viewing the Transducer Spacing”

on page 79. Use that calculated transducer spacing in the

following sections.

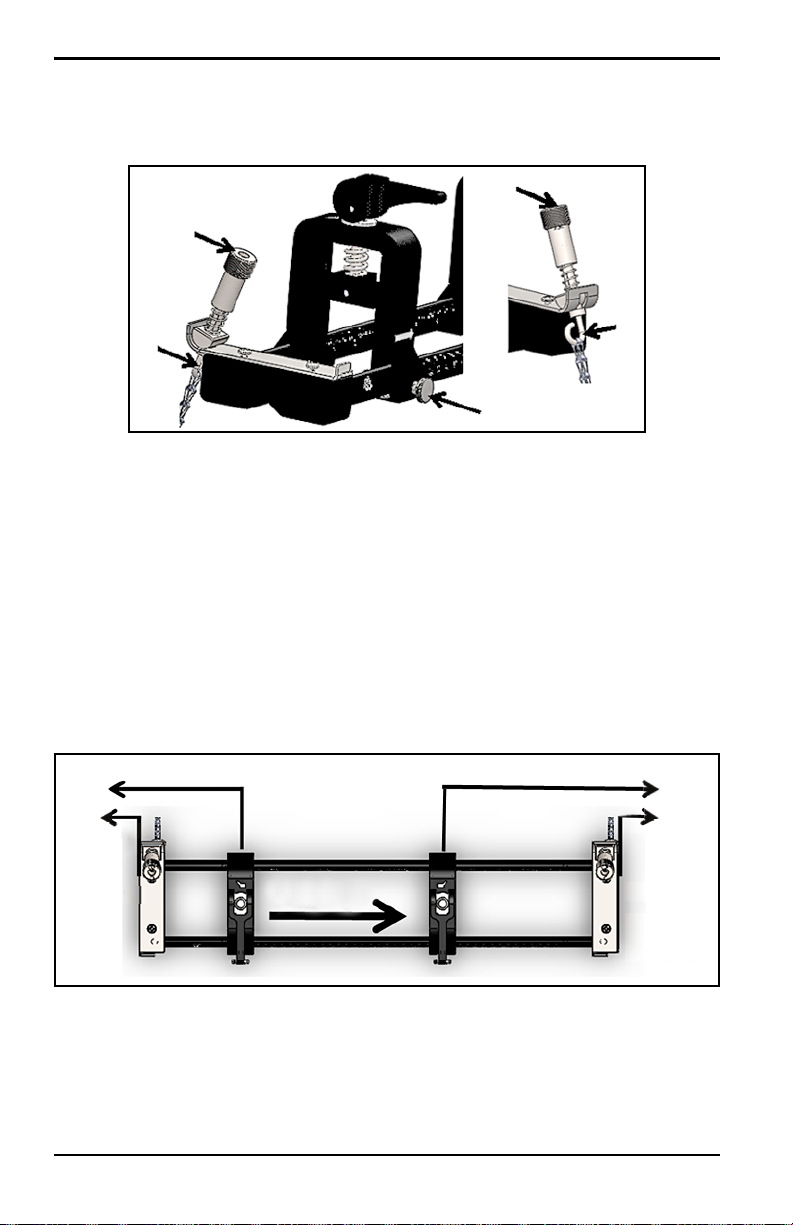

2.5.3 Mounting the PT9 Clamp-On Fixture

To mount the PT9 clamp-on fixture (see Figure 7 below) on the pipe, complete the

following steps:

Figure 7: PT9 Clamp-On Fixture with CRR Transducers

1. Before mounting the clamp-on fixture, refer to Figure 8 on page 10 and

proceed as follows:

• Ensure that the chain mechanism screws (A) that are attached to the

end piece flats are fully loosened.

• Ensure that the last link on the chain is secured within the chain

mechanism screw slot (

B) on both sides of the end piece.

• Ensure that the thumb screw (C) is tightened on the movable clamp so

that no motion is allowed during the mounting process.

TransPort® PT900 User’s Manual 9

Page 26

Chapter 2. Installation

A

B

C

A

B

2.5.3 Mounting the Clamp-On Fixture (cont.)

Figure 8: Bracket Preliminary Setup

2. Select a clamp-on fixture mounting location on the pipeline which meets

the following requirements (see Figure 9 below):

• A straight pipe run of at least 10 nominal pipe diameters (with no

fittings or bends) before the upstream transducer

• A straight pipe run of at least 5 nominal pipe diameters (with no

fittings or bends) after the downstream transducer

• A clearance of at least 6” (150 mm) from the outer edge of each end

piece to the nearest joint, welding or flange in the pipeline

>10 Diameters >5 Diameters

Fitting

Joint

>6”/150 mm

Upstream Downstream

Flow Direction

Figure 9: Selecting the Pipe Location

10 TransPort® PT900 User’s Manual

Fitting

Joint

>6”/150 mm

Page 27

Chapter 2. Installation

>6”/150 mm

2.5.3 Mounting the Clamp-On Fixture (cont.)

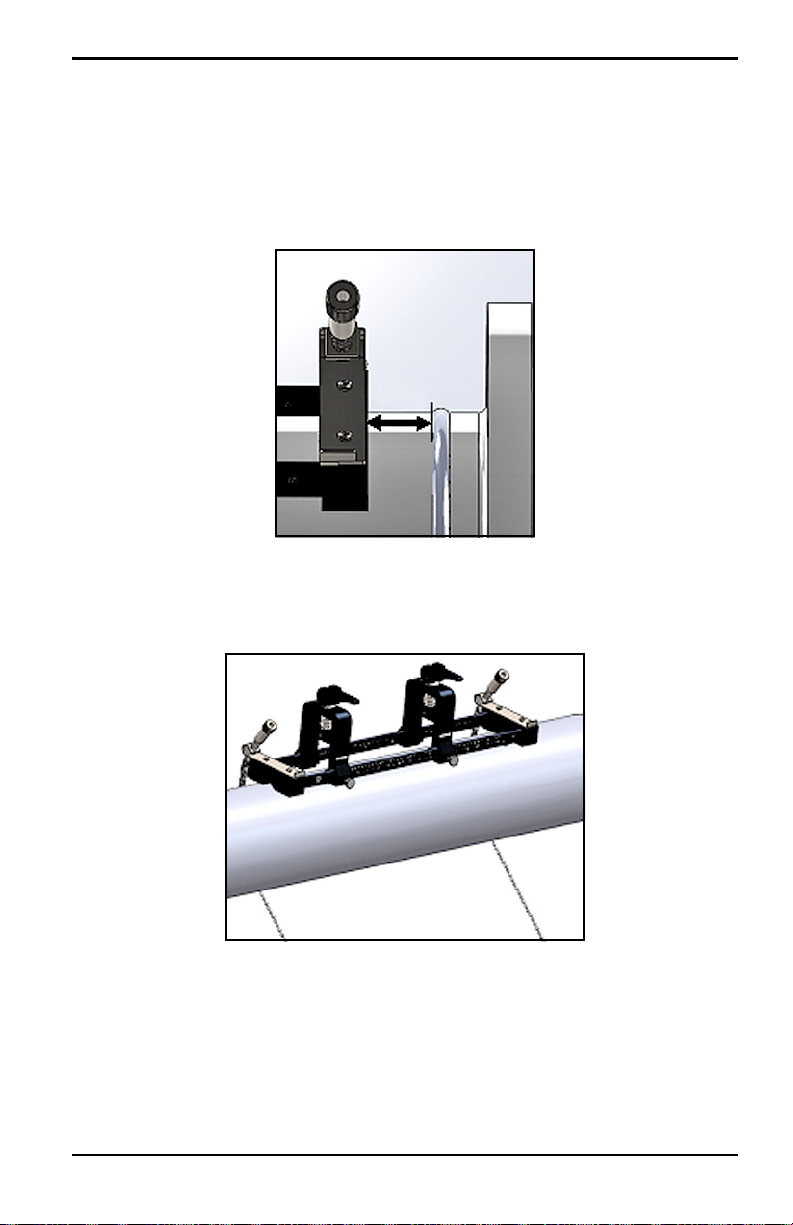

3. Adjust the clamp-on fixture position so that the outer edge of the closest

end piece is located at the chosen distance from the nearest inlet, outlet,

joint or fitting in the pipeline (see Figure 10 below).

Figure 10: Adjusting the Fixture Position

4. Place the clamp-on fixture on top of the pipe so that minimal effort is

required to maintain its position during installation (see Figure 11 below).

Figure 11: Fixture Placed on Top of Pipe

TransPort® PT900 User’s Manual 11

Page 28

Chapter 2. Installation

Slot

2.5.3 Mounting the Clamp-On Fixture (cont.)

5. Verify that the pipe rests in the small cutout slot on the bottom of the end

pieces (see Figure 12 below). Also, be sure that the scale markings on the

rail rod of the clamp-on fixture can be easily read after the installation has

been completed.

Figure 12: Cutout Slot

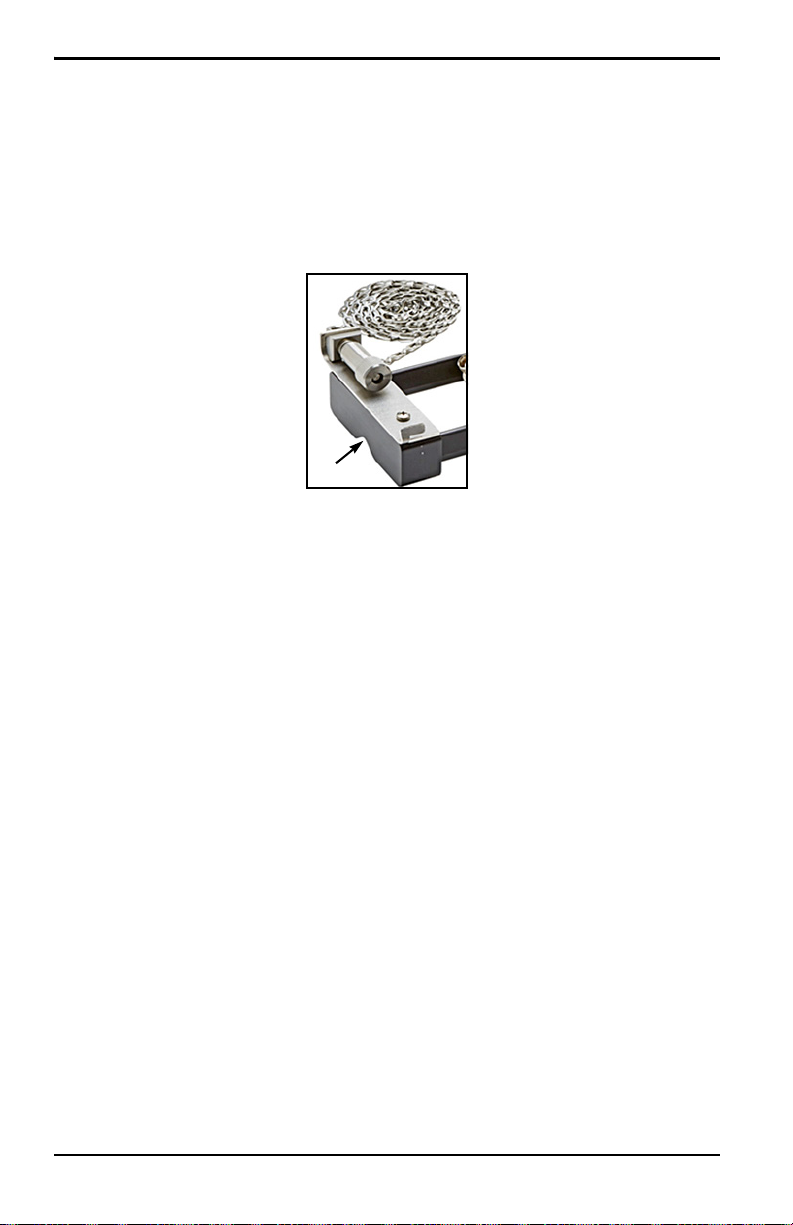

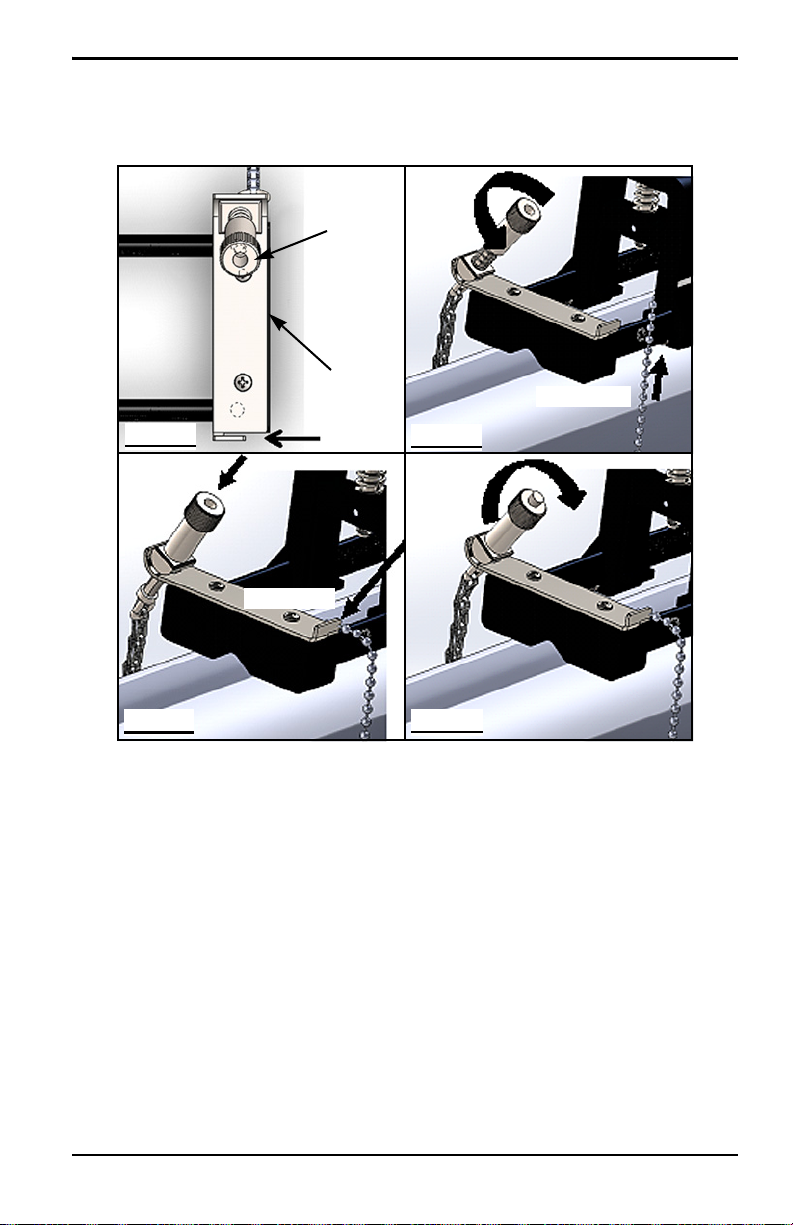

6. To install a chain around the pipe, refer to Figure 13 on page 13 and

complete the following steps:

a. Identify the chain screw mechanism, the end flat and the chain slot on

the clamping fixture end piece closest to the reference pipe fitting.

b. Unscrew the chain screw mechanism, then wrap the metal chain all

the way around the pipe.

c. Push down on the top of the chain screw mechanism and hold it

down. Then, pull the chain so that it is snug around the pipe and slide

the chain into the small slot located at the opposite side of the end

piece from the chain screw mechanism.

d. Release the chain screw mechanism and tighten it just enough to

remove any slack in the chain.

12 TransPort® PT900 User’s Manual

Page 29

2.5.3 Mounting the Clamp-On Fixture (cont.)

Chain Slot

End Flat

Chain Screw

Mechanism

Step 6a

Step 6b

Step 6c

Step 6d

Unscrew

Press Down

Insert Chain

Tighten

End of Chain

Chapter 2. Installation

TransPort® PT900 User’s Manual 13

Figure 13: Installing a Chain

Page 30

Chapter 2. Installation

2.5.3 Mounting the Clamp-On Fixture (cont.)

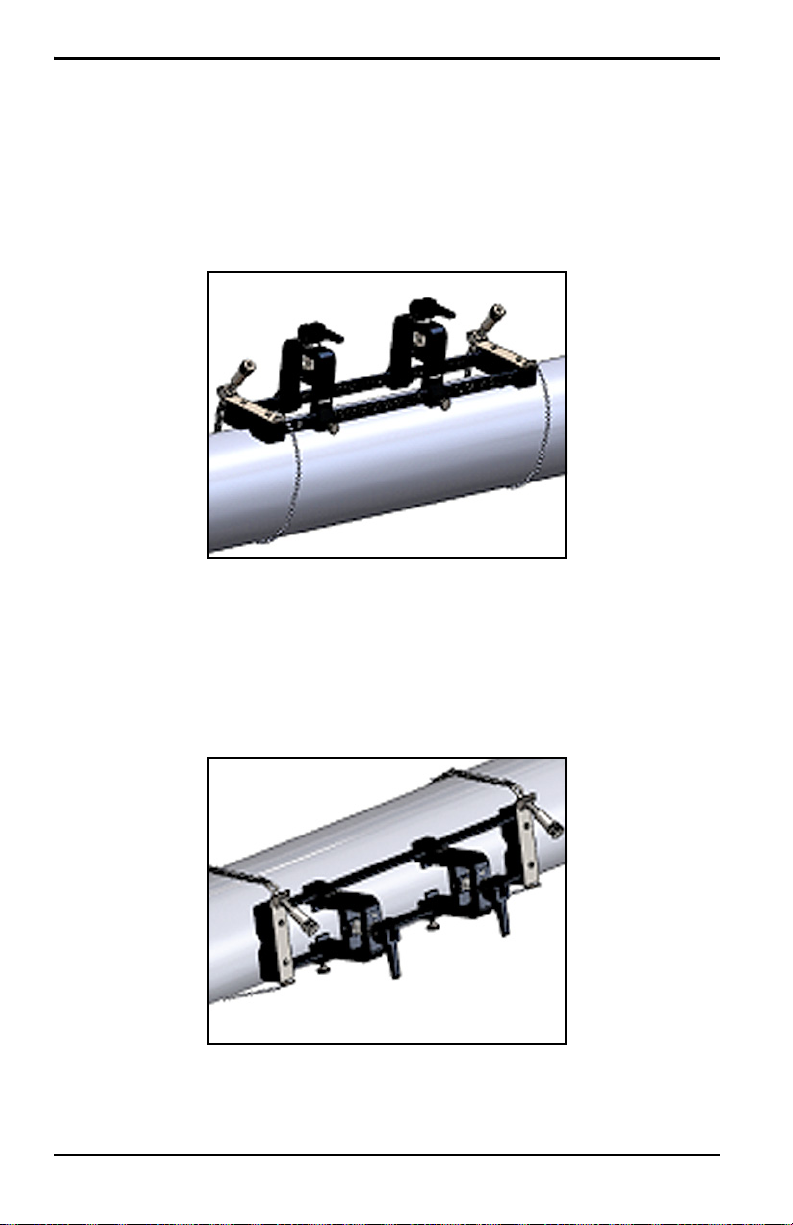

7. Repeat the previous steps to install the chain at the opposite end of the

clamp-on fixture (see Figure 14 below). The clamp-on fixture should be

firmly mounted to the pipe, but it should still be loose enough to allow

final alignment.

Figure 14: Fixture With Chains Installed

8. Rotate the fixture to the 3 o’clock or 9 o’clock position on the pipe (see

Figure 15 below). Installation on the top or bottom of the pipe is not

recommended. Make sure the pipe still rests in the cutout slot on the

bottom of both end pieces, to ensure that the fixture is parallel to the pipe

centerline.

Figure 15: Fixture Rotated to Horizontal Position

14 TransPort® PT900 User’s Manual

Page 31

Chapter 2. Installation

2.5.3 Mounting the Clamp-On Fixture (cont.)

9. After final alignment is complete, fully tighten both chains by turning the

nut on top of both chain screw mechanisms (see Figure 16 below) until the

chain is tight enough to resist any fixture movement.

Figure 16: Secure the Fixture to the Pipe

Note: As the last two steps affect each other, repeat them until the fixture is both

properly aligned and securely fastened to the pipe.

TransPort® PT900 User’s Manual 15

Page 32

Chapter 2. Installation

Clamp

Transducer

Hex Socket

Set Screw

Holder

Transducer Holder

Hex Socket Set Screw

2.5.4 Checking the Transducer Holders

Before installing the transducers into the clamp-on fixture, a transducer holder must

be attached to the each transducer. A transducer holder is installed on each

transducer by GE prior to shipment. Verify that your transducers have their holders

already installed and that they are secure. If so, you may skip this section.

A complete transducer assembly includes the following components:

• Clamp Holder: Permanently attached to the fixture clamp

• Transducer Holder: Semi-permanently attached to the transducer

• Transducer: Prior to mounting, the transducer is installed into the

transducer holder and secured with set screws. During mounting, the

transducer holder slides into the clamp holder and attaches with a plunger

If for some reason a transducer’s holder was not installed or has been removed,

refer to Figure 17 below and reinstall the holder as follows:

1. Slide the holder onto the top of the transducer so that the circle slots near

the top of the transducer sides are closely aligned with the filled holes on

the side of the transducer holder.

2. Screw the hex socket set screws from the transducer holder into the holes

of the transducer. These screws will lock the holder into place.

Figure 17: Transducer Assembly

16 TransPort® PT900 User’s Manual

Page 33

Chapter 2. Installation

Fixed Clamp

(at zero)

Movable Clamp

(at transducer spacing)

2.5.5 Installing the Transducers

To install the transducers into the mounting bracket, complete the following steps:

1. If necessary, loosen the thumb screw on the movable transducer clamp to

permit axial positioning.

2. Note that the fixed transducer clamp is set at the zero mark on the scale.

Position the movable transducer clamp so that it aligns with the mark on

the bracket’s graduated scale that matches the calculated transducer

spacing. Measurement markings should be read on the side of the

transducer clamp indicated by the arrows. Typically, set the holder on the

left to the zero position and the other holder to the desired spacing.

Figure 18: Secure the Fixture to the Pipe

Note: The required spacing between the transducers varies based on many

factors. The tablet APP automatically calculates your transducer spacing.

(see “Viewing the Transducer Spacing” on page 79).

3. Tighten the thumb screw to lock the movable transducer clamp into place,

being cautious not to disturb the established axial positioning.

TransPort® PT900 User’s Manual 17

Page 34

Chapter 2. Installation

2.5.5 Installing the Transducers (cont.)

4. Move both cams to the loaded position, so that the clamp holders rest in

their furthest radial position from the pipe (see Figure 19 below).

Figure 19: Loaded Cams

5. Apply the supplied couplant to both transducer faces (see Figure 20

below). The couplant displaces any air gaps between the transducer and

the pipe to ensure a uniform acoustic signal path. For pipes up to 14” OD,

do not apply couplant in the red areas shown; for pipes >14” OD, cover

the entire surface with couplant.

Note: Using a water-based lubricant as a couplant is not recommended for

heated or long-term installations.

Figure 20: Transducer Face with Couplant

18 TransPort® PT900 User’s Manual

Page 35

Chapter 2. Installation

2.5.5 Installing the Transducers (cont.)

6. Slide a transducer, which is already locked into its transducer holder, into

one of the clamp-on fixture’s clamp holders until the plunger from the top

of the transducer holder snaps into its position on the bottom of the clamp

holder (see Figure 21 below).

Important: The cable connectors on the mounted transducers must point away

from each other and toward opposite ends of the clamp-on fixture. To

assist in this requirement, the arrows on the end pieces help to

indicate the cable connector direction.

Figure 21: Inserting the Transducer

TransPort® PT900 User’s Manual 19

Page 36

Chapter 2. Installation

2.5.5 Installing the Transducers (cont.)

7. Release the cams on both transducer clamps so that the transducers are

pushed towards the pipe to ensure that the couplant completely fills the

gaps between the transducer faces and the pipe surface (see Figure 22

below).

CAUTION! When releasing the cams, the cam springs may

cause the cam to make hard contact with the clamp face. Any

objects or body parts between the contact faces could suffer

damage or minor injury.

Figure 22: Released Cams

Important: You must determine the required transducer spacing before

proceeding (see “Viewing the Transducer Spacing” on page 79).

20 TransPort® PT900 User’s Manual

Page 37

Chapter 2. Installation

2.5.6 Even and Odd-Traverse Installations

The transducers for a PT900 system may be installed in either of the following

configurations:

• Even-Traverse - The signal from one of the transducers traverses the fluid

flow an even number of times before being received by the other

transducer (two traverses is recommended for most applications).

• Odd-Traverse - The signal from one of the transducers traverses the fluid

flow once or an odd number of times before being received by the other

transducer.

2.5.6a Even-Traverse Installations (Spacing <305 mm/12 in.)

The standard PT900 clamp-on fixture is designed for an even-traverse installation,

as illustrated in Figure 23 below. After mounting the clamp-on fixture on the pipe,

refer to “Viewing the Transducer Spacing” on page 79 to adjust the spacing of the

transducer clamps to the required axial distance.

Figure 23: An Even-Traverse Installation (Top View)

Important: The installation above assumes a transducer spacing of

<305 mm/12 in. For even-traverse installations with transducer

spacings >305 mm/12 in., see “Even-Traverse Installations

(Spacing>305 mm/12 in.)” on page 28 for instructions.

TransPort® PT900 User’s Manual 21

Page 38

Chapter 2. Installation

Yoke

Screw

Loosened

Loosened

Completely

25 mm/1 in.

minimum

2.5.6b Odd-Traverse Installations

For an odd-traverse installation, the separate yoke included with the clamp-on

fixture is required (see Figure 24 below).

Figure 24: Yoke for Odd-Traverse Installations

Important: The clamping fixture must be installed before the yoke (see

“Mounting the PT9 Clamp-On Fixture” on page 9). You must

determine the required transducer spacing before proceeding (see

“Viewing the Transducer Spacing” on page 79).

To install the yoke, complete the following steps:

1. Loosen the yoke screw at least 25 mm/1 in. (all the way for pipes

<50 mm/2 in.) and loosen the J-Hooks all the way (see Figure 25 below).

Figure 25: Loosened Yoke Screw and J-Hooks

22 TransPort® PT900 User’s Manual

Page 39

Chapter 2. Installation

[Spacing

[Spacing

>305 mm/12 in.]

<305 mm/12 in.]

2.5.6b Odd-Traverse Installations (cont.)

2. Place the yoke on the top of the pipe (see Figure 26 below). If the required

transducer spacing is <305 mm/12 in., the yoke chain must be placed

within the clamping fixture as shown.

Figure 26: Yoke Placement On Top of Pipe

3. Wrap the yoke chains around the pipe and secure them to the yoke bracket,

TransPort® PT900 User’s Manual 23

as shown in Figure 27 below.

Figure 27: Yoke Chains Secured

Page 40

Chapter 2. Installation

[Spacing >305 mm/12 in.]

[Spacing <305 mm/12 in.]

Bracket Surfaces

Bracket Surfaces

2.5.6b Odd-Traverse Installations (cont.)

4. Rotate the yoke until it is located in a horizontal position on the opposite

side of the pipe from the previously installed clamping fixture, as shown

in Figure 28 below.

Figure 28: Yoke Rotated into Horizontal Position

5. Ensure that the top surfaces of the yoke bracket and the clamping fixture

brackets lie precisely in the same horizontal plane (see Figure 28 above).

Place the fixed clamp in the clamping fixture at zero on the scale.

Note: If the required axial spacing is 305-375 mm/12 in.-14.8 in., place the fixed

clamp at 100/4 in. on the scale instead of zero.

24 TransPort® PT900 User’s Manual

Page 41

2.5.6b Odd-Traverse Installations (cont.)

Fixed Clamp at Zero

Marking on Yoke

17.13 in. (435 mm)

Fixed Clamp

Marking

4.72 in.

on Yoke

at Zero

(120 mm)

6. Set the yoke axial position as follows:

• Spacing >305 mm/12 in. (435 mm/17.13 in. is used as an example):

Measure the required 435 mm/17.13 in. distance from the edge of the

fixed clamp to the marked line on the yoke (see Figure 29 below).

Figure 29: Yoke Set at 435 mm/17.13 in.

Chapter 2. Installation

• Spacing <305 mm (120 mm/4.72 in. is used as an example): Measure

the required 120 mm/4.72 in. distance from the edge of the fixed

clamp to the marked line on the yoke (see Figure 30 below).

TransPort® PT900 User’s Manual 25

Figure 30: Yoke Set at 120 mm/4.72 in.

Page 42

Chapter 2. Installation

2.5.6b Odd-Traverse Installations (cont.)

7. Tighten the nuts to secure the yoke to the pipe (see Figure 31 below).

Figure 31: Secure the Yoke

8. Loosen the yoke screw. Then, apply couplant to the transducer face and

insert the transducer into the yoke, as shown in Figure 32 below.

Figure 32: Insert Transducer into Yoke

26 TransPort® PT900 User’s Manual

Page 43

Chapter 2. Installation

[Spacing

[Spacing

<305 mm/12 in.]

>305 mm/12 in.]

2.5.6b Odd-Traverse Installations (cont.)

9. Tighten the yoke screw until the transducer firmly contacts the pipe. Your

completed odd-traverse installation should look like Figure 33 below.

TransPort® PT900 User’s Manual 27

Figure 33: Completed Odd-Traverse Installation (Top View)

Page 44

Chapter 2. Installation

Yoke

Screw

Loosened

Loosened

Completely

25 mm/1 in.

minimum

2.5.6c Even-Traverse Installations (Spacing>305 mm/12 in.)

For an even-traverse installation with a transducer spacing >305 mm/12 in., the

separate yoke included with the clamp-on fixture is required (see Figure 34 below).

Figure 34: Yoke for Even-Traverse With S>305 mm/12 in.

Important: The clamping fixture must be installed before the yoke (see

“Mounting the PT9 Clamp-On Fixture” on page 9). You must

determine the required transducer spacing before proceeding (see

“Viewing the Transducer Spacing” on page 79).

To install the yoke, complete the following steps:

1. Loosen the yoke screw at least 25 mm/1 in. (all the way for pipes

<50 mm/2 in.) and loosen the J-Hooks all the way (see Figure 25 below).

Figure 35: Loosened Yoke Screw and J-Hooks

28 TransPort® PT900 User’s Manual

Page 45

Chapter 2. Installation

2.5.6c Even-Traverse Installations (Spacing>305 mm/12 in.)

(cont.)

2. Place the yoke on the top of the pipe (see Figure 36 below). If the required

transducer spacing is <305 mm/12 in., the yoke chain must be placed

within the clamping fixture as shown.

Figure 36: Yoke Placement On Top of Pipe

3. Wrap the yoke chains around the pipe and secure them to the yoke bracket,

as shown in Figure 37 below.

Figure 37: Yoke Chains Secured

TransPort® PT900 User’s Manual 29

Page 46

Chapter 2. Installation

2.5.6c Even-Traverse Installations (Spacing>305 mm/12 in.)

(cont.)

4. Rotate the yoke until it is located in a horizontal position on the same side

of the pipe as the previously installed clamping fixture, as shown in

Figure 38 below.

Figure 38: Yoke Rotated into Horizontal Position

5. Ensure that the top surfaces of the yoke bracket and the fixed clamping

fixture bracket lie precisely in the same horizontal plane (see Figure 38

above).

30 TransPort® PT900 User’s Manual

Page 47

Chapter 2. Installation

Fixed Clamp

Yoke

435 mm/17.13 in.

at Zero

Marking

Line

2.5.6c Even-Traverse Installations (Spacing>305 mm/12 in.)

(cont.)

6. Place the fixed clamp in the clamping fixture at zero on the scale. As an

example, if the required transducer spacing is 435 mm/17.13 in., measure

the required 435 mm/17.13 in. distance from the edge of the fixed clamp

to the marked line on the yoke (see Figure 39 below).

Figure 39: Yoke Set at 435 mm/17.13 in.

7. Tighten the nuts to secure the yoke to the pipe (see Figure 40 below).

Figure 40: Secure the Yoke

TransPort® PT900 User’s Manual 31

Page 48

Chapter 2. Installation

2.5.6c Even-Traverse Installations (Spacing>305 mm/12 in.)

(cont.)

8. Loosen the yoke screw. Then, apply couplant to the transducer face and

insert the transducer into the yoke, as shown in Figure 41 below.

Figure 41: Insert Transducer into Yoke

9. Tighten the yoke screw until the transducer firmly contacts the pipe. Your

completed odd-traverse installation should look like Figure 42 below.

Figure 42: Completed Installation (Top View)

32 TransPort® PT900 User’s Manual

Page 49

Chapter 2. Installation

2.6 Making the Electrical Connections

Before taking measurements with the PT900, you must make all the necessary

cable connections to the transmitter. To wire your transmitter, complete the

following sections:

• Connecting the Line Power (see page 33)

• Connecting the Transducers (see page 35)

• Connecting the Digital Output (see page 36)

• Connecting the Analog Inputs and Output (see page 37)

• Using the USB Port (see page 38)

• Using the Bluetooth Wireless Interface (see page 38)

Note: For basic operation, you only need to connect the Transducer cables. The

I/O connections are required only if you intend to use those features.

After the PT900 is completely wired, proceed to Chapter 3, Initial Setup, to

configure the meter for operation.

2.6.1 Connecting the Line Power

An example of the PT900 transmitter product label is shown in Figure 43 below.

Be sure to power the transmitter only with the voltage specified on the label.

Figure 43: PT900 Transmitter Label

TransPort® PT900 User’s Manual 33

Page 50

Chapter 2. Installation

2.6.1 Connecting the Line Power (cont.)

WARNING! To ensure the safe operation, you must install and

operate the PT900 as described in this manual. Also, be sure to

follow all applicable safety codes and regulations for installing

electrical equipment in your area. The PT900 and its transducers

are designed for use only in general-purpose locations.

The PT900 is powered by either a 100-240 VAC wall mount plug-in module or by a

Lithium Ion high-energy rechargeable smart battery pack. In either case, you must

connect the power cord to the Power connector (see Figure 44 below).

In normal operation mode, the PT900 can be operated with a battery pack in the

transmitter. When you receive the PT900, the battery pack is not fully charged. To

charge the battery pack, you must use an external power adapter with an input

rating of 100-240VAC and output rating of 12VDC. When the AC power adapter is

connected to the transmitter, the battery LED will start flashing, which indicates

that the battery is charging. When the battery LED is continuously

that the battery is at full charge. When the external power adapter is removed, the

battery LED will be

Off.

On, it indicates

Figure 44: Transmitter Power Connection (Right Side)

WARNING! To ensure safe operation, do not turn the PT900 On

while the battery pack is being charged by an external power

adapter connected to a mains voltage of greater than 150VAC. If

the PT900 is turned

On in such a situation, make sure that you do

not touch the transducer connectors.

34 TransPort® PT900 User’s Manual

Page 51

Chapter 2. Installation

2.6.2 Connecting the Transducers

To connect the transducers, see Figure 45 below and proceed as follows:

1. Connect the cables from each of the transducers to the transmitter:

a. Connect the transducer cable with the

to the transmitter connector labeled

b. Connect the transducer cable with the

to the transmitter connector labeled

UP label on the cable connector

UP.

DN label on the cable connector

DN.

2. If your transmitter is configured for two channels, connect the second

transducer pair by repeating the above step.

3. Properly configure the transmitter to work properly with your specific

transducer type. See “Programming the Transducer Parameters” on

page 74 for instructions.

Important: Be sure to insert the cable connectors straight into the transmitter

connectors to avoid damaging the connectors.

Figure 45: Transducer Connections (Bottom)

TransPort® PT900 User’s Manual 35

Page 52

Chapter 2. Installation

2.6.3 Connecting the Digital Output

The PT900 provides one RS485/Modbus digital output and also supports a digital

frequency/pulse output and a totalizer/control gate input. Connect the digital output

as shown in Figure 46 below (see the cable to the right). The pin numbers for the

connector and the color code for the standard input/output cable are shown in

Ta bl e 1 below.

Table 1: DIO Cable Wiring Diagram

Connection Pin # Color Description

RS484- 1 Black RS485/Modbus Negative

RS485+ 2 Red RS485/Modbus Positive

RS485 COM 3 Green RS485/Modbus Common

DIO 4 White Digital IO Positive

DRTN 5 Yellow Digital IO Return

SHD 6 Silver Cable Shield

Figure 46: Transmitter I/O Connections (Right Side)

36 TransPort® PT900 User’s Manual

Page 53

Chapter 2. Installation

2.6.4 Connecting the Analog Inputs and Output

The PT900 provides one 0/4-20 mA analog current output and two 4-20 mA analog

inputs, with a switchable 16 V supply for loop-powered temperature transmitters.

Connect the analog inputs and output as shown in Figure 46 on page 36 (see the

cable to the left). The pin numbers for the connector and the color code for the

standard input/output cable are shown in Ta bl e 2 below.

Table 2: AIO Cable Wiring Diagram

Connection Pin # Color Description

Aout+ 1 Red 4-20mA OUTPUT

Aout- 2 Black 4-20mA RETURN

16VDC 3 Blue +16VDC OUTPUT

ARTN 4 Yellow ANALOG INPUTS RETURN

AIN1 5 Orange ANALOG INPUT 1

AIN2 6 Green ANALOG INPUT 2

SHD 7 Silver Cable Shield

Important: The Analog Output is an active mode type. Do not supply a 24V

supply to this circuit, as the circuit is powered by the transmitter.

2.6.5 Connecting the Energy Cables

The AIO port is commonly used for connecting a pair of energy cables to permit

energy measurements (see Figure 47 below).

Figure 47: Energy Cable Connection (Right Side)

TransPort® PT900 User’s Manual 37

Page 54

Chapter 2. Installation

2.6.6 Using the USB Port

The PT900 provides one USB2.0 full-speed interface. The receptacle is a

micro-USB Type B connector, as shown in Figure 48 below. Data logs and other

information from the transmitter’s embedded storage can be uploaded to a PC via

the USB port. In addition, the transmitter’s configuration files can be changed

directly via the USB port.

Figure 48: Transmitter USB Connector (Left Side)

2.6.7 Using the Bluetooth Wireless Interface

The PT900 comes equipped with an internal Bluetooth transceiver that enables

wireless communication between the transmitter and Bluetooth-enabled tablets.

The transmitter can then be configured by the PT900

tablet connected via the wireless Bluetooth interface. For more information on the

APP, see Chapter 3, Initial Setup.

APP software installed on a

2.7 Caring for the PT900 Batteries

The PT900 comes with a self-contained, built-in, rechargeable battery pack to

support portable operation. For optimum performance, these batteries require a

minimum of maintenance.

CAUTION! Use only GE-approved batteries and desktop

chargers, which are designed to maximize battery life. Using

other batteries or chargers voids your warranty and may cause

damage to the equipment.

CAUTION! For CE compliance, the PT900 is classified as a

battery-powered device, and it is not to be operated with the AC

power adapter connected.

38 TransPort® PT900 User’s Manual

Page 55

Chapter 2. Installation

2.7.1 Charging and Storing the Batteries

When you receive the PT900, you will need to initially charge the batteries. Also,

the batteries may need to be recharged if they have not been used for a long period

of time. The batteries must be charged for up to 3 hours to go from 0% (totally

depleted) to 100% (fully charged). When fully charged, the batteries provide

18-20 hours of continuous operation. An internal battery gauge indicates the

remaining power in the battery.

To charge the battery, simply plug the AC power adapter cord into the power jack

(see Figure 44 on page 34) and be sure the battery pack is installed in the

transmitter (see “Installing a Battery Pack in the Transmitter” on page 6). Whether

the PT900 is

internal transmitter battery charger automatically charges the battery. The battery

LEDs (see Figure 49 below) indicate the battery charging status.

On or Off, when the AC power adapter is plugged into line voltage the

Figure 49: Battery Charging Status LEDs

For optimal run time, charge the batteries only in temperatures from 32°F to 113°F

(0°C to 45°C). Otherwise, the batteries will not be properly charged and will have

significantly reduced run time. Store the batteries at temperatures ranging from

-4°F to 122°F (-20°C to 50°C). The recommended storage temperature range is

-4°F to 77°F (-20°C to 25°C). Extended storage at temperatures above 104°F

(40°C) could degrade battery performance and service life.

TransPort® PT900 User’s Manual 39

Page 56

Chapter 2. Installation

[Battery Panel]

2.7.2 Replacing the Batteries

CAUTION! Replace the PT900 batteries only with the specified

rechargeable batteries. The battery charges even when the unit

is

Off. Do not attempt to recharge non-rechargeable batteries.

To replace the battery pack:

1. Remove the rubber boot from the transmitter.

2. Open the panel on the back of the transmitter (see Figure 50 below).

3. Disconnect and remove the old battery pack.

4. Install the new battery pack.

5. Reinstall the panel and the rubber boot on the transmitter.

Figure 50: Battery Panel Location

40 TransPort® PT900 User’s Manual

Page 57

Chapter 2. Installation

2.7.3 Disposing of the Batteries

CAUTION! Never dispose of the batteries by incineration. Do

not attempt to disassemble or short-circuit the batteries. For

safety, do not handle a damaged or leaking battery.

CAUTION! Be sure to dispose of your batteries properly. In

some areas, battery disposal in business or household trash may

be prohibited. For safe disposal options, contact your nearest GE

authorized service center.

2.8 Powering On and Off

To operate the PT900, the power cord must be plugged into line voltage or the

battery pack must be charged as described in the previous sections.

CAUTION! For CE compliance, the PT900 is classified as a

battery-powered device, and it is not to be operated with the AC

power adapter connected. To comply with CE certification,

unplug the AC power adapter before operating the PT900.

WARNING! If the PT900 fails the backup battery test, you must

send the unit back to the factory for a battery replacement. Make

sure you keep the battery charged until you are ready to ship the

unit back to the factory. Before shipping, print out all of the log

and site data, or transfer it to your PC. Never dispose of the

battery by incineration. Do not attempt to disassemble or

short-circuit the battery pack. For safety, do not handle a

damaged or leaking battery.

TransPort® PT900 User’s Manual 41

Page 58

Chapter 2. Installation

Power

Bluetooth

Battery

Status

2.8 Powering On and Off (cont.)

To turn the PT900 On, press the Power On/Off button on the top of the transmitter

(see Figure 51 below) for about 3 seconds. Initially, only the Green Power LED

shows solid

show solid

On. However, after the system powers up completely, all the LEDs

On.

To turn the PT900

(see Figure 51 below) for about 3 seconds. All of the LEDs will turn

Off, press the Power On/Off button on the top of the transmitter

Off.

Figure 51: Transmitter Power Button (Top)

2.9 PT900 LED Indicators

The four colored LEDs on the front of the PT900 transmitter (see Figure 52 below)

provide real time information on the meter status. See the next page for details.

Figure 52: Transmitter LEDs (Front)

42 TransPort® PT900 User’s Manual

Page 59

2.9.1 Power LED

• Solid Green light when the meter is powered On

• No light when the meter is Off

• Blinking Green light when the meter is in power save mode

2.9.2 Bluetooth LED

Chapter 2. Installation

• Solid Blue light when Bluetooth

• Blinking Blue light when Bluetooth

pairing process

• Solid Red light when the meter is on and Bluetooth

to a transmitter

• No light when Bluetooth

®

is linked to a transmitter

®

is in the click-button to confirm

®

is in configuration mode

®

is idle or is not linked

2.9.3 Status LED

• Solid Green light when the meter is in measure mode without any errors

• Red light when an error occurs while the meter is in measure mode

• No light when the meter is in configure mode

2.9.4 Battery LED

• Solid Green light when the battery is fully charged (>99%), but the AC

adapter is connected

• Solid Green light when the battery level is high (>20%), but the AC

adapter is not connected

• Blinking Green light when the battery is not fully charged, but it is

charging with the AC adapter connected

• Red light when the battery level is low (20%) and the battery needs to be

charged immediately

• Blinking Red light when the battery level is low (10%) and the meter will

be out of power soon

• Light off when the meter is On, but the battery is completely discharged

and the AC adapter is connected

TransPort® PT900 User’s Manual 43

Page 60

Chapter 2. Installation

[no content intended for this page]

44 TransPort® PT900 User’s Manual

Page 61

Chapter 3. Initial Setup

Chapter 3. Initial Setup

3.1 Introduction

This chapter provides instructions for programming the PT900 flow meter via the

tablet APP prior to initial operation.

3.2 Charging the PT900 Transmitter and Tablet

Before proceeding, make sure that both the PT900 Transmitter and the Tab l et are

fully charged. The AC power adapters are shipped in the carry case. If either the

transmitter or the tablet cannot be powered On after charging, contact your GE

representative or visit www.gemeasurement.com

contact the tablet manufacturer for tablet assistance.

3.3 Installing or Updating the PT900 APP

The instructions in the following sections explain the procedures for downloading

the current version of the PT900 APP and installing it on your tablet.

3.3.1 Checking the APP Version

To check the APP version currently on your tablet, click on the About option in the

Help menu to open a screen similar to Figure 53 below. This screen displays

general information about the PT900. This information includes: model name,

instrument type, software version, and the copyright year of the APP.

for transmitter assistance or

Figure 53: The About Screen

TransPort® PT900 User’s Manual 45

Page 62

Chapter 3. Initial Setup

3.3.2 Installing or Updating the PT900 Android and iOS APP

Update your existing PT900 APP from one of the below options:

Android App

• Google Play Store: To obtain a newer version of the APP from Google

Play Store, search for “Transport PT900” and install it. Google Play Store

is the preferred method of installation because updates will automatically

be loaded to your tablet with the latest version of the application.

• QR Code or GE Website: To obtain a newer version of the APP, scan the

QR Code in Figure 54 below.

Figure 54: QR Code

Alternatively, download the latest version of the APP from the GE

website, go to the below URL and search for “TransPort PT900”

https://www.industrial.ai/download-center

• SD Card: To obtain a newer version of the APP from an SD card, plug the

SD card directly into the Tablet. Then, select the APK file from the SD

folder.

iOS App

• Minimum iOS Device Requirements: Device should have

- BLE 4.0 and above

- iOS version 11.0 and above

- Capacity: 16GB and above

• Apple App Store: To obtain a newer version of the APP from Apple App

Store, search for “Transport PT900” and install it. Apple App Store is the

only method to install the iOS application and updates will automatically

be loaded to your tablet with the latest version of the application.

46 TransPort® PT900 User’s Manual

Page 63

Chapter 3. Initial Setup

3.3.3 Installing the Tablet APP from the SD Card (Applicable only to Android APP)

To install the APP, complete the following steps:

1. Open the “My Files” folder on the tablet screen and select the APP from

the SD folder (see Figure 55 below).

Figure 55: The “My Files” Folder

2. In the tablet settings, enable the security option to allow the installation of

software from “Unknown sources” for this installation only (see Figure 56

below).

Figure 56: Security Settings

TransPort® PT900 User’s Manual 47

Page 64

Chapter 3. Initial Setup

3.3.3 Installing the Tablet APP from the SD Card (cont.)

3. Click on the APK file, and the Android operating system will verify the

checksum and signature for the file. Depending on whether this is an

initial installation or an update installation, you will see one of the screens

shown in Figure 57 below. Click

Note: If the file signature is not verified, the APP will be treated by the Android

operating system as an unrecognized APP.

INSTALL to begin the installation.

Figure 57: Initial (Left) and Update (Right) Installation Screens

48 TransPort® PT900 User’s Manual

Page 65

Chapter 3. Initial Setup

3.4 Pairing the Tablet and the Transmitter

To set up the APP and pair with the PT900 transmitter, complete the following

steps:

1. After the APP has been downloaded to your tablet, find the icon shown in

Figure 58 below on the tablet

Figure 58: PT900 APP Icon

2. While the APP is loading, you should see the initialization screen shown

in Figure 59 below.

APPS and click on it to launch the APP.

Figure 59: APP Loading Screen

TransPort® PT900 User’s Manual 49

Page 66

Chapter 3. Initial Setup

3.4 Setting Up the PT900 APP (cont.)

3. At the screen shown in Figure 60 below, select the desired language for

the APP and click

OK.

Figure 60: PT900 APP Language Options

4. At the License Agreement screen (see Figure 61 below), read the

agreement and then click

click

CANCEL to stop the APP installation.

AGREE to continue with the APP installation or

Figure 61: PT900 APP License Agreement

50 TransPort® PT900 User’s Manual

Page 67

Chapter 3. Initial Setup

3.4 Setting Up the PT900 APP (cont.)

5. At the Registration screen (see Figure 62 below), click OK to register your

PT900 or click

Note: If you skip the registration, the screen will popup as a reminder the first

five times you launch the APP and then it will never appear again.

6. After the APP finishes loading, the default Transmitter list is displayed.

During initial installation, this list is empty (see Figure 63 below).

CANCEL to skip the registration.

Figure 62: PT900 Registration

Figure 63: Initial Transmitter List

TransPort® PT900 User’s Manual 51

Page 68

Chapter 3. Initial Setup

3.4 Setting Up the PT900 APP (cont.)

7. To connect to a new PT900 transmitter, click SCAN. Pairing steps are

different for Android and iOS application. For Android, follow the below

steps (8 & 9) and for iOS, follow the steps 10 & 11.

Figure 64: Scanning Transmitter

Note: Your PT900 transmitter is identified by the serial number on its label (see

Figure 65 below).

Figure 65: Transmitter Serial Number

52 TransPort® PT900 User’s Manual

Page 69

Chapter 3. Initial Setup

Click Here

8. In Android, APP will search for all available transmitters via Bluetooth.

After the scan has been completed, any new transmitters which were

found are listed in the

AVAILABLE DEVICES section of the tablet screen (see

red arrow in Figure 66 below). Click on your transmitter to pair it with the

tablet via Bluetooth.

Important: Although Bluetooth is installed in many devices, the PT900 APP is

designed to filter out all devices except those with names of the form

PT900-Mxxxxxxxx.

Figure 66: Available Devices List

9. During the pairing process, PT900 security features require the user to

confirm the pairing (see Figure 67 below). When the Bluetooth pairing

request appears on the tablet (ignore the random passkey), click

OK to

continue. Then, confirm that the blue LED on the transmitter is flashing

and click the transmitter power button.

Important: The pairing is completed only after it is confirmed at both the tablet

and the transmitter. Otherwise, the pairing will fail.

TransPort® PT900 User’s Manual 53

Page 70

Chapter 3. Initial Setup

1. Click Here 2. See Blue LED

3. Click Button

Figure 67: Confirm the Pairing

For iOS:

10. In iOS, APP will search for all available transmitters via Bluetooth. After

the scan has been completed, any new transmitters which were found are

listed in the AVAILABLE DEVICES section of the tablet screen. Click on

your transmitter to pair it with the tablet via Bluetooth.

Figure 68: Available Devices List

Note: In Android, if Bluetooth is turned off then app can turn on the Bluetooth

programmatically but in iOS, there is no control over the Bluetooth to turn

on from application side.

Note: If you try to pair iPhone with firmware below 1.2.1, then you may see a

connection error popup. In such case after upgrading the firmware to

1.2.1 or above (supports iOS and android), turn the bluetooth off/on on

your device settings to start the connection again.

54 TransPort® PT900 User’s Manual

Page 71

Chapter 3. Initial Setup

1. Enter the Passkey - 843278 3. See Blue LED

4. Press the Power Button2. Click Pair

1

2

3

4

11. During the pairing process, PT900 security features require the user to

confirm the pairing (see Figure 69 below). When the Bluetooth pairing

request appears on the tablet, enter the passkey and click Pair. Then,

confirm that the blue LED on the transmitter is flashing and click the

transmitter power button within 10s. Passkey for this device is 843278.

Figure 69: Confirm the Pairing

TransPort® PT900 User’s Manual 55

Page 72

Chapter 3. Initial Setup

12. Click the BACK button on the tablet to return to the PT900 APP main

menu. Then, select your PT900 transmitter in the

list and click

PT900-M09160025 transmitter is selected from the list in Figure 70 below.

NEXT to open the Main Menu. For example, the

TRANSMITTERS PAIRED

Figure 70: Paired Transmitters List

Note: If desired, you may simulate the APP operation without connecting to the

transmitter. To do so, click the

Note: The transmitter can hold only a maximum of four paired devices at a time.

WORK OFFLINE option in Figure 70 above.

When you try to pair more than four devices, then the first paired device

will be automatically removed from the transmitter to allow the new

device for pairing.

56 TransPort® PT900 User’s Manual

Page 73

Chapter 3. Initial Setup

13. In iOS, if the power button is not pressed within 10s, then the pairing

process will fail at the transmitter end. Though it is not paired, this

unpaired device will also be displayed in the transmitter paired list. But

when you try to connect, below error pop-up will appear.

Figure 71: Connection Error

Important: To pair this transmitter again, user needs to remove the device

manually from PT900 APP and iPhone. To remove the device, refer to

“Removing paired devices from PT900 APP” on page 58 and

“Removing paired devices from iPhone/Tablet” on page 59.

TransPort® PT900 User’s Manual 57

Page 74

Chapter 3. Initial Setup

3.4.1 Removing paired devices from PT900 APP

1. Select the transmitter from the list that you want to remove and click Edit

button in the top right of the below screen.

Figure 72: Paired Transmitter Screen

2. Below screen appears. Click

Delete icon next to the transmitter name.