GE

H

FLOW

L

Filter must be

attached to the

“H” side of the

pitot tube

Sensing

Telaire Ventostat® 8000 Series CO2 Sensors

User Instructions

Introduction

The GE Telaire Ventostat® 8001/

8002 carbon dioxide (CO

controllers are designed for Demand

Controlled Ventilation (DCV) in

buildings. This approach, using CO2 as

an indicator of occupancy, allows

ventilation based on actual occupancy

while still maintaining ASHARE

recommended per-person ventilation

rates. Over ventilation of buildings can

be reduced, energy can be saved, and

quality can be optimized.

The optional black case (PN 8001B and

PN 8002B) is UL94-V5 rated, making

these models suitable for mounting

directly inside the ductwork. Typical

applications for Ventostat

conference rooms, schools, retail stores, restaurants, gymnasiums, and

movie theatres.

) sensors and

2

®

8001/8002 series include office buildings,

Installing the Sensor

NOTICE!

Use of cellular telephones or radio transceivers within two (2) feet of the

sensor during calibration process could cause sensor interference,

calibration errors and affect sensor accuracy. Please refrain from using

these devices during sensor calibration.

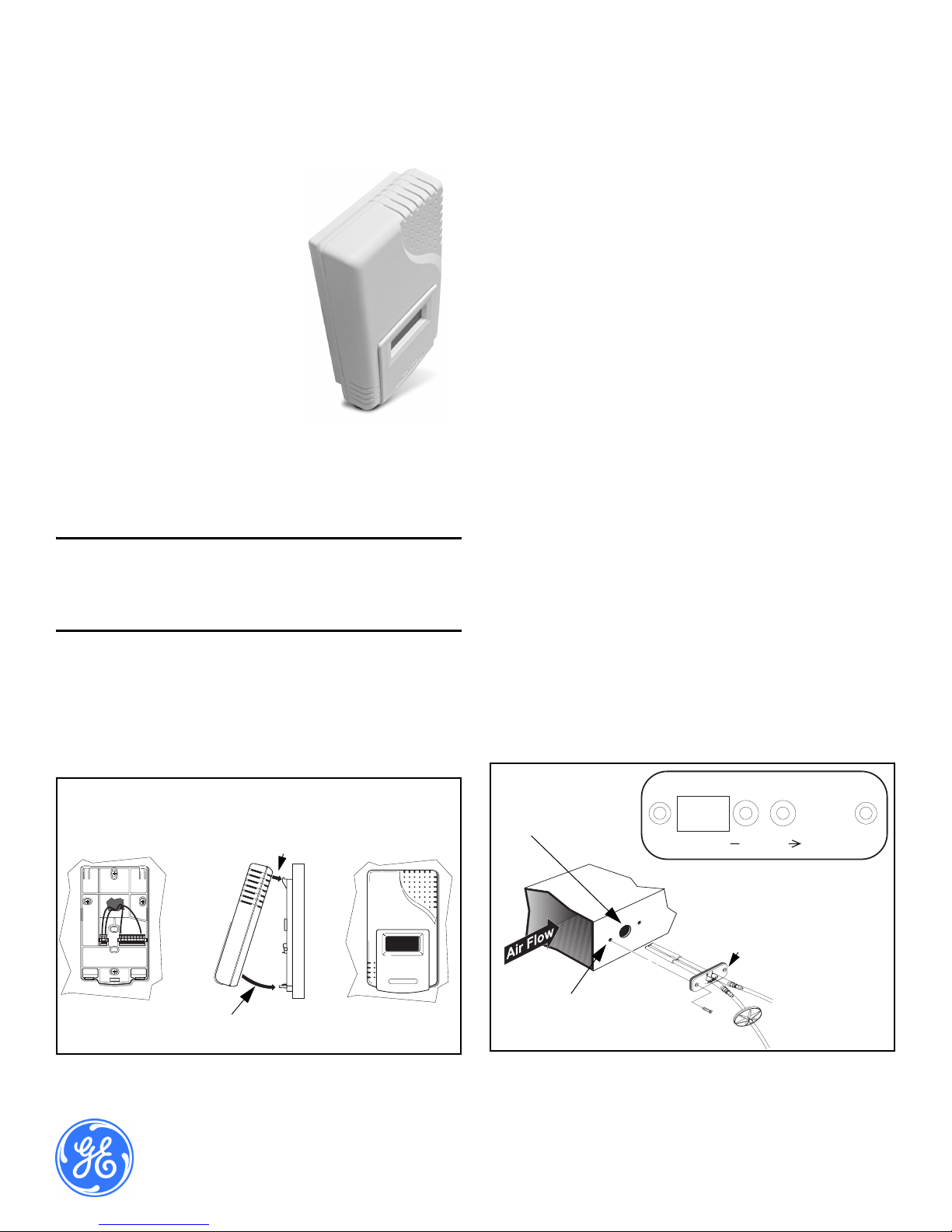

Install the mounting plate and sensor as follows:

1. Prepare for installation by using the mounting holes configured for

US or European junction boxes.

2. Use the mounting plate as a template to mark the mounting holes.

See Figure 1, View A below.

3. Secure the mounting plate to the wall or junction box and make

necessary wire connections.

4. Mount the controller on the base by aligning the top clips and then

securing to the bottom clips, as shown in Figure 1, View B above. A

“snap” sound will indicate that the sensor is secure. The sensor will

now have power. A 2 minute warm-up will take place. After 2

minutes, the sensor will stabilize and display the “Normal Mode”

(current CO

5. At this point one of nine preset programs or one custom channel can

be selected for operation. See the section “Configuring the Sensor”

on page 3.

6. Finish installation by sliding the cover over the menu keys and

secure with the supplied screw.

readings).

2

Mounting the Sensor into the Duct

The 8001B and 8002B have the UL94-V5 rated black case and are

specifically designed for mounting inside the return air ductwork. When

mounting these products inside the ductwork, seal the hole around the

wires and leave the duct insulation in place to prevent condensation

which may damage the sensor.

Pitot Tube Installation for the

8001 and 8002

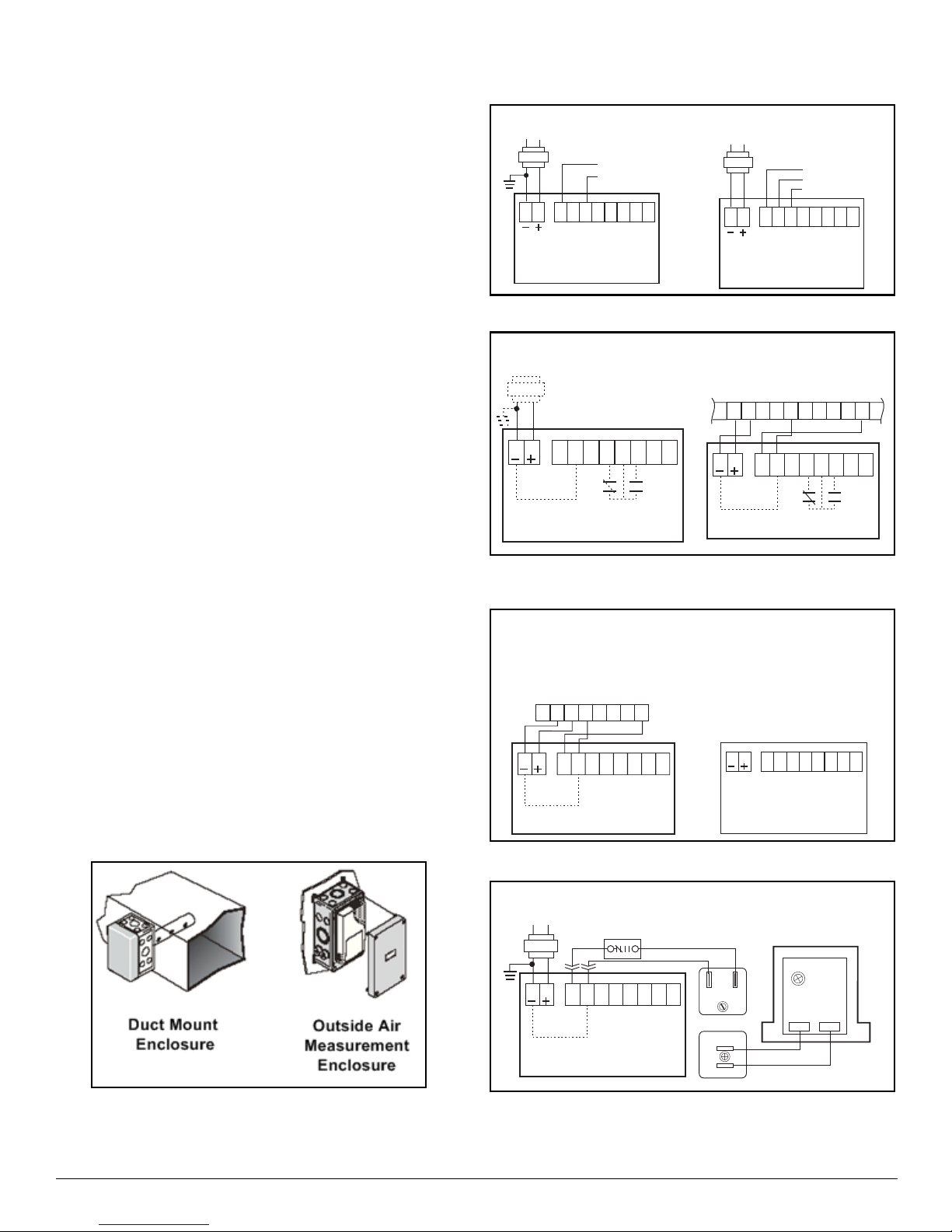

Install the mounting bracket, then install the pitot tube assembly as

follows:

Note: The length of the Tygon

maintain optimum accuracy, the tubing should not be

lengthened. If the sensor is mounted closer than three

feet, the excess tubing should be shortened to avoid

interference with mechanical or moving devices.

1. To mount the pitot tube, drill one 7/8” hole through the duct as

shown in Figure 2 below.

®

tubing is three feet. In order to

Mounting

Plate

Bottom Clips

View A View B View C

Ventostat

CO

Controller

Top Clips

2

Figure 1: Ventostat® CO2 Controller - Mounting

Sensor/

Drill One Hole

7/8” in Diameter

View in Direction of A

Mounting

Flange

clear

mode

enter

Drill Two Machine

Screw Holes

Figure 2: Pitot Tube - Installation

T62659-007

October 2006

Page 1 of 7

2. Insert the pitot tube and mark the two remaining holes for the

mounting screws.

3. Punch or drill the two marked holes.

4. Note the direction of airflow in the duct (see View in Direction of A)

above.

5. Note the marking on the pitot tube flange and insert the tube so that

it is properly aligned with the airflow.

6. To ensure an airtight seal, make sure the mounting surface of the

duct is clear of dirt or obstructions. Then, attach the pitot tube to the

duct with sheet metal screws or rivets.

7. On top of the sensor, unscrew the protective caps from the tube

connectors.

8. Check the length of the tubing before attaching to the sensor. The

tubing should connect without stretching or pulling. If the length is

long enough to create a loop or bind in the tubing, it should be

shortened.

9. To shorten the tubing, remove the connectors that attach to the

sensor and cut the tubing to the required length.

10. Replace the tubing connectors by using a twisting or screwing

motion.Verify the connection is secure.

Note: If the tubing length has been shortened, be sure the in-

line filter is replaced on the pitot tube connector marked

with an “H” as shown in Figure 2, View in Direction of

A (on the previous page).

11. Complete the installation by screwing the tube connectors to the

input ports on the sensor. The tubing connectors can be attached to

either input port. It will not affect the performance of the sensor.

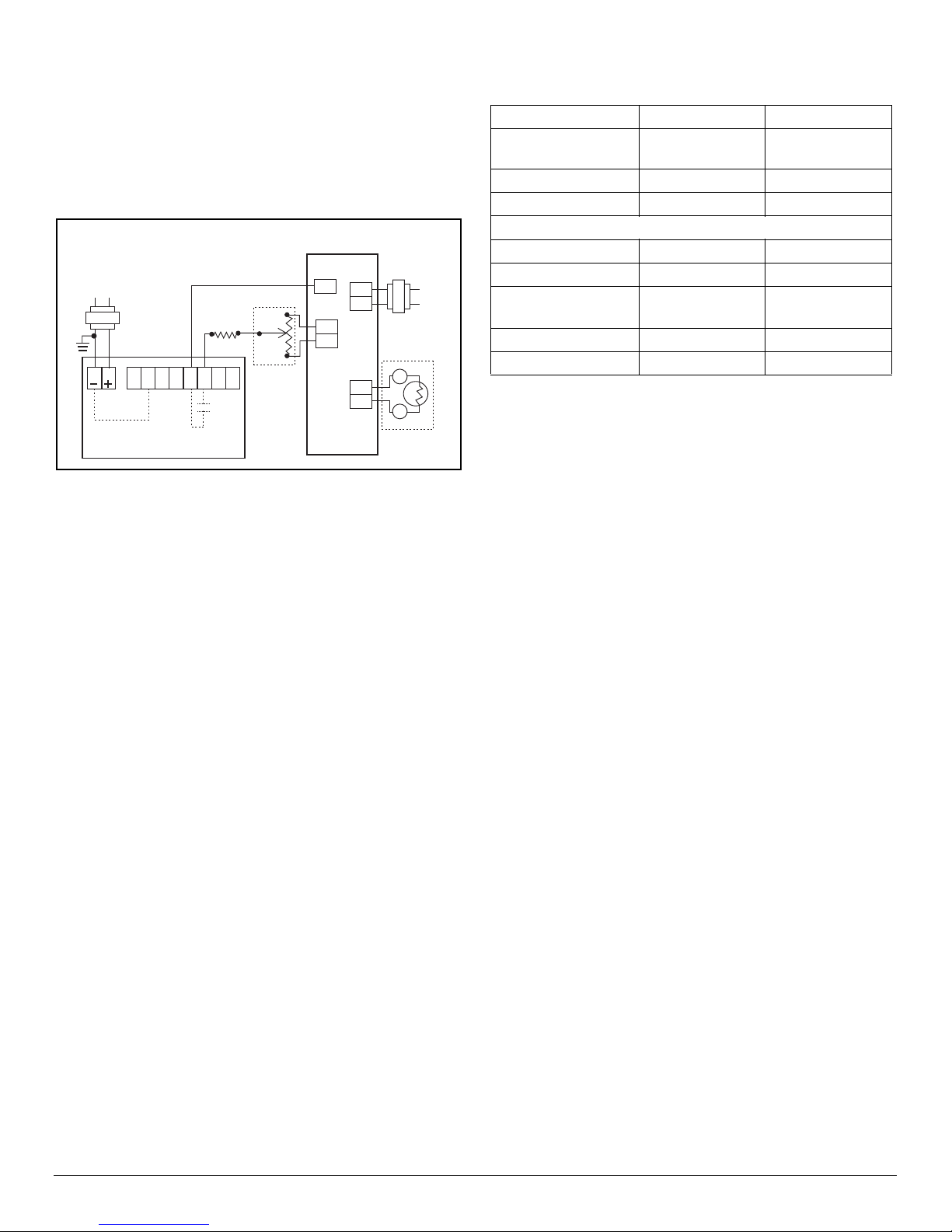

Accessory Enclosures

Three kinds of accessory enclosures are listed below, and two are shown

in Figure 3 below.

• Model 1508 Duct Mount Enclosure (Aspiration Box) - Any 8000

product can be installed inside this enclosure.

• Model 1551 Outside Air Measurement Enclosure - This NEMA-

3R enclosure is weatherproof for measuring outside air CO2 con-

centrations. It also includes heat stabilizers.

• Model 1505 Harsh Environment Enclosure - For extreme envi-

ronments where the sensor might be subjected to condensation or

water spray such as those found in greenhouses or breweriesNEMA-3R rated.

The typical wiring diagrams appear in Figure 4 through Figure 8

below.

AC Power 3-Wire System

L1

L2

18-30 VAC RMS

Use Either Output

0-10Vout

4-20mAout

1

2

Input

MountingBracket

78

6

Ventostat

5

®

Isolated AC Power 4-Wire System

L1

L2

18-30 VAC RMS

1234

1

2

Input

Ventostat

MountingBracket

5

78

6

0-10Vout

SignalGround

4-20mAout

®

1234

Figure 4: AC Power 3/4 Wires System - Diagrams

Using the Relay Contacts

18-30 VAC RMS

L1

L2

5

7

6

8

1

2

Input

Common

Ventostat

Mounting Bracket

3

4

NC NO

COM

®

Lennox L-Series

TB1

12

2

Ventostat MountingBracket

+

24VAC

6

7

1

Input

Common

24VAC

GND

8

8

AC In

Common

24V

9

10

11 121314

7

6

NC NO

5

4

COM

+10VDCIn

16

15

3

12

Figure 5: Relay Contacts and Lennox L-Series

Diagrams

Lennox L-Series w/Johnson Controls

Metasys UNT or Facilitator FA-UNT

+

AC

24V

GND

24VAC

AI-CM

5

4

6

8

7

7

8

1

2

Input

Common

6

Ventostat MountingBracket

AI-3

3

2

TB1

1

5

3

12

4

8-Pin and 2-Pin Terminal

Block Pin Designations on

the Ventostat Mounting Bracket

AC- / GND

AC+ / DC+

0-10V Output

Signal Ground

4-20mA Output

Relay Norm Closed

Relay Common

Relay Norm Open

Not Used

Not Used

5

78

1

2

Input

Ventostat

Mounting Bracket

6

1234

®

Figure 6: Lennox L-Series/Mounting Bracket Diagrams

Figure 3: Accessory Enclosures

Typical Wiring Diagrams

Page 2 Telaire Ventostat™ 8000 Series

Honeywell M7415 Damper Actuator with W7459 Logic Module

(+)

Honeywell Damper

Actuator M7415 and

W7459 Logic Module

PP1

18-30 VAC RMS

L1

L2

1

2

Input

Common

OptionalHigh

and/or Low

Temp Swtich

5

78

6

Ventostat MountingBracket

Honeywell

Q769C 0-10 Vdc

Adaptor

Black

White

3

1

4

2

(-)

Front View

(P1)

(P)

Rear View

Figure 7: Damper Actuator and W7459 Logic Module

Diagrams

Set minimum position potentiometer to twice the design load. For

example, if the space is designed for 30 people at 15 cfm/person, adjust

the minimum position potentiometer at the economizer logic to 900 cfm.

This will allow the economizer to introduce 450 cfm (1000 ppm CO

level) at the design load. The CO

sensor should use “STDSET#1.”

2

2

Note: For 24V, do not use a HVAC unit transformer. Provide

24 V by using a non-grounding transformer.

Johnson Controls M100E Economizer Actuator with R81EAA-2

Interface Board

L1

L2

1

2

Input

Common

Ventostat MountingBracket

Y45AA-9 Remote Minimum

Position Potentiometer

(1,000-10,000 ohm)

5

78

6

3

4

Common

M100E

8

T2

Open

Close

12

T1

9

10

S2

S1

L1

L2

A91Mixed Air

Thermistor

B

T

R

Figure 8: Economizer Actuator and Interface Board -

Diagrams

Table 1: 8000 Series Adjustment Parameters and

Factory Settings

Adjustment Range Factory Setting

Altitude Above Sea

Level

ABC Logic™ ON/OFF ON

Select Standard Setting 1 to 9 1

Customize Setting:

PPM Range 0 - 10,000 0-2,000

Output Range 4-20 mA/ 0 - 10 V 4 - 20 mA/ 0-10 V

Proportional/

Exponential Output

Relay Setpoint 0 - 10,000 PPM 1000 PPM

Relay Hysteresis 0 - 10,000 PPM 50 PPM

All GE Telaire 8000 series products are calibrated at sea level. As

altitude increases, the accuracy of this sensor, as of all gas sensors,

introduces an error of approximately -3% of the reading per 1,000 ft of

elevation. Users that are in elevations significantly higher than sea level,

such as Denver, Colorado, should consider adjusting the altitude to have

the most accurate reading. The altitude setting can be adjusted on the

unit in 500 ft increments.

0 - 10,000 ft. 0 ft.

Select One Proportional

Configuring the Sensor

The sensor has two different settings:

• User Adjustable Sensor Settings

• Factory Settings

User Adjustable Sensor Settings

The GE Telaire 8000 series includes features which are user adjustable.

These adjustments can be made using the keypad on display units, or by

the PC based UIP program that communicates to the sensor via a custom

RS232 interface cable.

Factory Settings

The default settings are the typical settings used by a building control

system.

If the installation requires changes to the sensor, the user can customize

certain characteristics of the sensor. For example, non-factory settings

may be applicable when the sensor is being connected to equipment that

has a fixed input range (e.g., actuators used with economizer systems).

Sensor Programming Features

Outlined below in Table 1 are the adjustable parameters of the sensor

and the factory setting. In addition to offering these adjustable features,

the programming interface allows for a fast and simple adjustment of

sensor calibration.

ABC Logic™ Self Calibration System

All GE Telaire 8000 series sensors are factory set with the ABC Logic

(Automatic Background Calibration) self calibration feature ON. This

feature allows the sensor to continually re-calibrate itself when the

indoor concentrations drop to outside levels while the building is

unoccupied. Generally a building must be regularly unoccupied for 4

hours or more for this self-calibration system to operate properly. Under

these conditions, the ABC Logic feature should maintain sensor

calibration over the lifetime of the sensor. The ABC Logic feature should

be turned OFF where a building is continuously occupied 24 hours per

day, or where there could be significant sources of non-occupant related

CO

such as greenhouses, breweries and other industrial and food

2

processing applications.

Pre-Programmed Settings

In addition to the factory setting for the 8000 series sensors, nine

standard settings can easily be selected using the keypad (display units

only) or the PC based UIP Program. Table 2 on the next page describes

each of the settings. The definitions for some of the terms used in the

table are described in more detail as part of the custom settings outline in

the “Custom Settings” section on the next page.

Settings 1, 2 and 3 are applicable for automated or computerized

building control systems.

Settings 4 to 7 are specifically designed for operation with economizer

controls and actuators where a 0-10 VDC signal will provide 0-100%

outside air modulation. These control settings provide different

modulation ranges, depending on the target cfm-per-person ventilation

rate desired. As described below, the exponential setting is best used in

applications that have large volumes of air and people, such as

auditoriums, gyms and large conference areas.

Telaire Ventostat™ 8000 Series Page 3

Setting 8 is for use in occupational health and safety applications where

users want to measure concentrations in relation to the 5000 ppm, 8 hour

exposure levels established by OSHA (Occupation Safety and Health

Administration).

Loading...

Loading...