GE TBQ440ANDR, TBQ470ANDR, TBR427ANDR, TBG470ANDR, TBR463ANDR Technician Service Manual

...

g GE Appliances Service Training

____________________________

TECHNICIAN

SERVICE MANUAL

Refrigerator

MODELS:

TBG440ANDR TBQ440ANDR TBR427ANDR

TBG470ANDR TBQ470ANDR TBR463ANDR

TBG530ANDR TBQ530ANDR TBR527ANDR

TBG570ANDR TBQ570ANDR TBR565ANDR

TMG432ANDR

TMQ432ANDR

TMR432ANDR

PUB NO. : SPWR1020E

November 2001 - Revised (3)

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic and mechanical experience. Any attempt to repair

a major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible

for the interpretation of this information, nor can it assume any

liability in connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing

this product. If electrical power is required for diagnosis or

test purposes, disconnect the power immediately after performing the necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used

to complete a path to ground are removed for service, they

must be returned to their original position and properly fastened.

Page 2

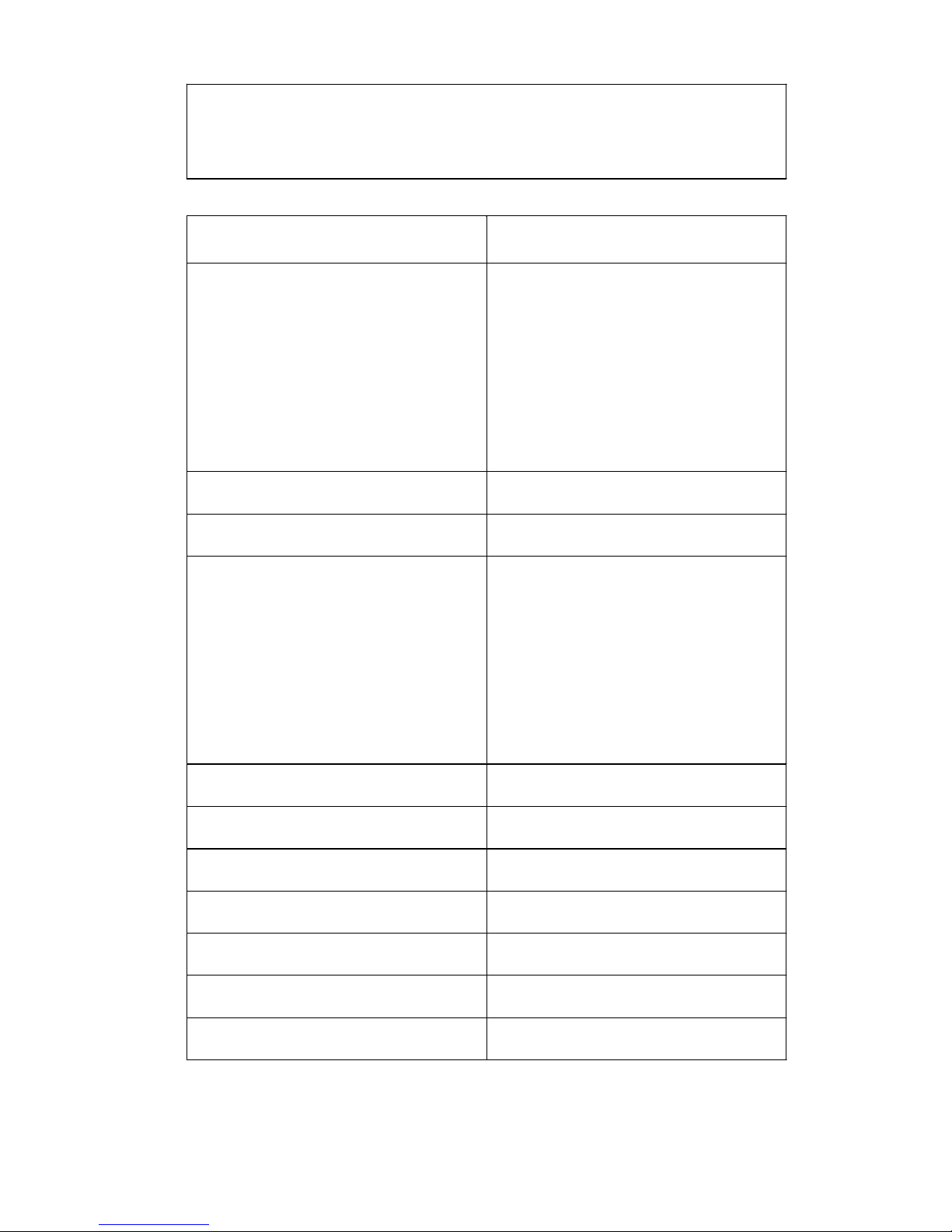

THE MANUAL COVERS THE

FOLLOWING MODELS

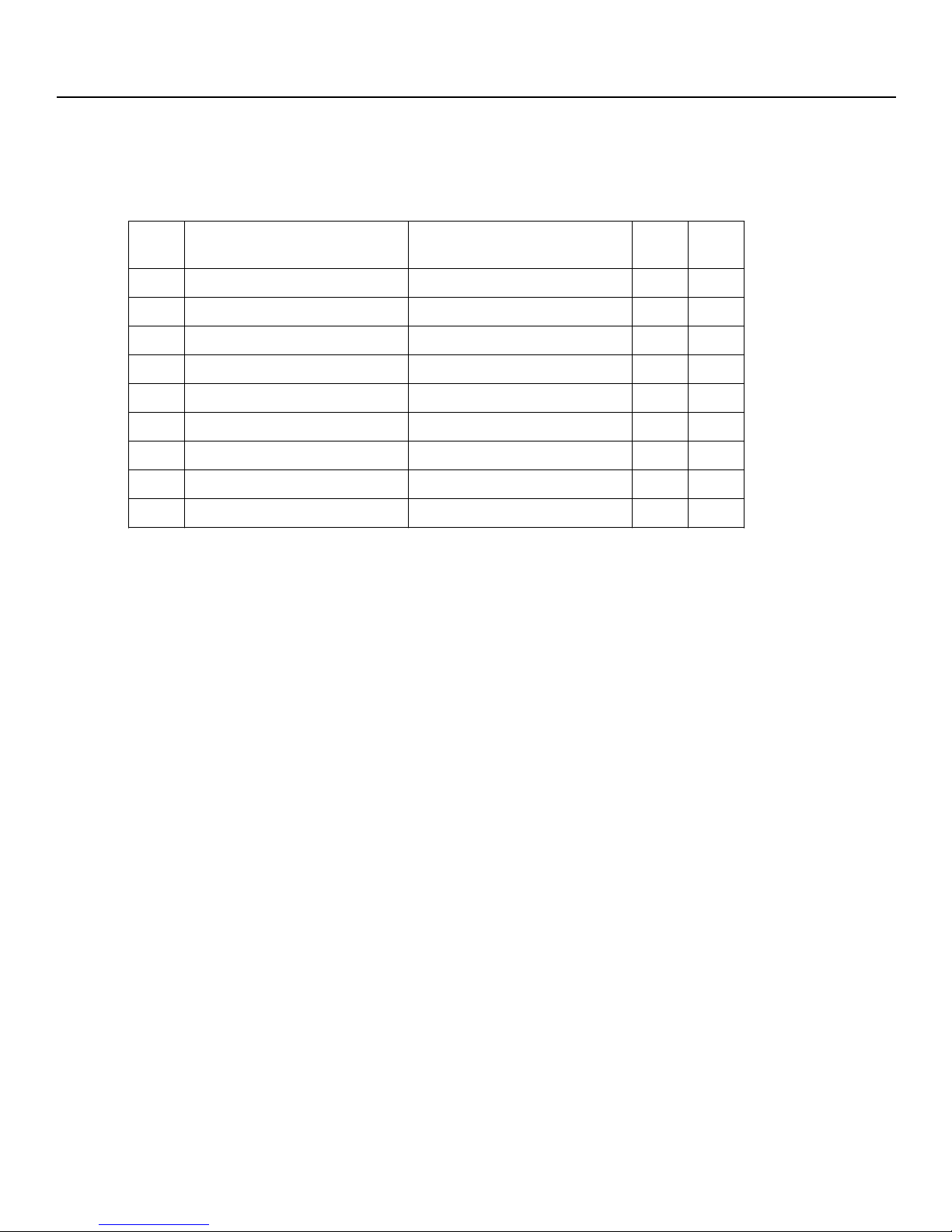

MODEL # COUNTRY

TBR427ANDR

TBR463ANDR

TBR527ANDR

TBR565ANDR

TMR432ANDR

N/A BANGLADESH

N/A CHINA

TBQ440ANDR

TBQ470ANDR

TBQ530ANDR

TBQ570ANDR

AUSTRALIA

HONG KONG

TMQ432ANDR

N/A INDIA

TMG432ANDR INDONESIA

N/A JAPAN

N/A KOREA

N/A MALAYSIA

N/A PAKISTAN

N/A PHILIPPINES

Page 3

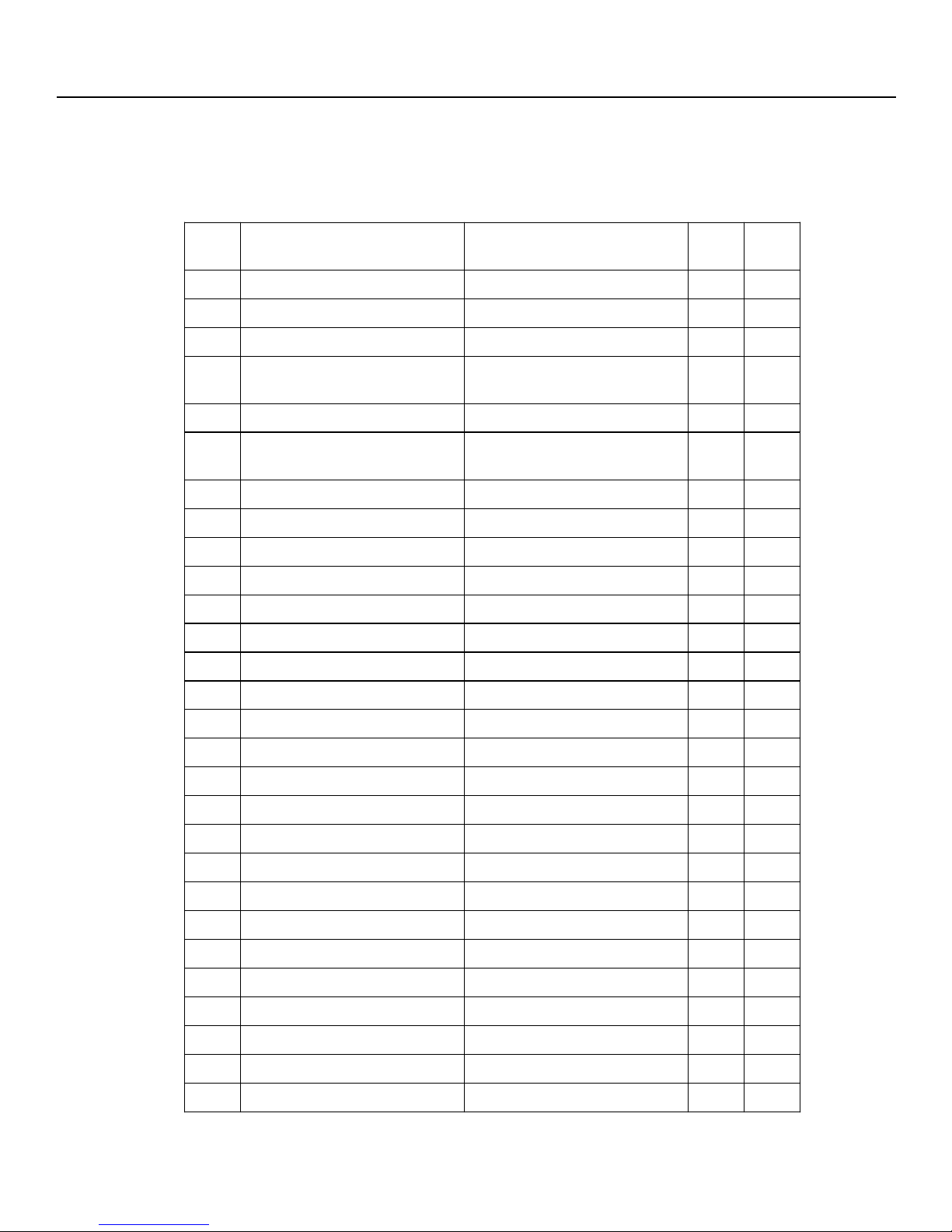

THE MANUAL COVERS THE

FOLLOWING MODELS

MODEL # COUNTRY

TBQ440ANDR

TBQ470ANDR

TBQ530ANDR

TBQ570ANDR

TMQ432ANDR

N/A TAIHITI

N/A TAIWAN

TBG440ANDR

TBG470ANDR

TBG530ANDR

TBG570ANDR

SINGAPORE

THAILAND

TMG432ANDR

TMG432ANDR VIETNAM

Page 4

I. SAFETY PRECAUTIONS

PLEASE READ THE FOLLOWINGS BEFORE SERVICING YOUR REGRIGERATOR.

1. Check if an electric leakage occurs in the set.

2. To prevent electric shock, unplug prior to servicing.

3. In case of testing with power on, wear rubber gloves to prevent electric shock.

4. If you use any appliances, check regular current, voltage and capacity.

5. Dont touch metal products in cold freezer with wet hand. It may cause frostbite.

6. Prevent water flowing to electric elements in mechanical parts.

7. When you stand up during observing the lower part with the upper door open, move with care to prevent head would

which may happen by hitting the upper door.

8. When sloping the set, remove any materials on the set, especially thin plate type. (ex.: glass shelf or books.)

9. When servicing evaporator part, wear cotton gloves without fail. It is to prevent wound by sharp fin of evaporator.

10. Leave a breakage of refrigerating cycle to a heavy service center. The gas in cycle inside may soil ambient air.

Page 5

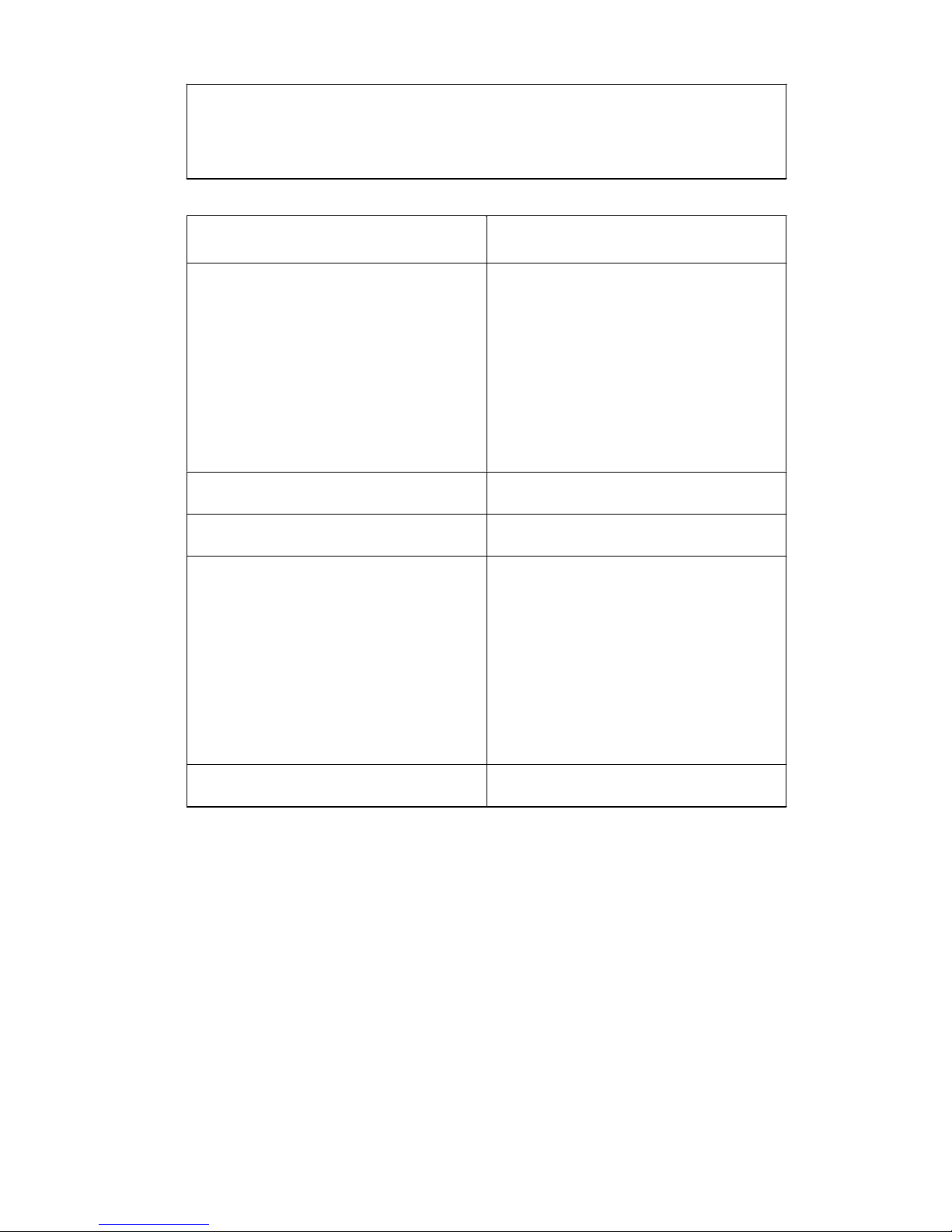

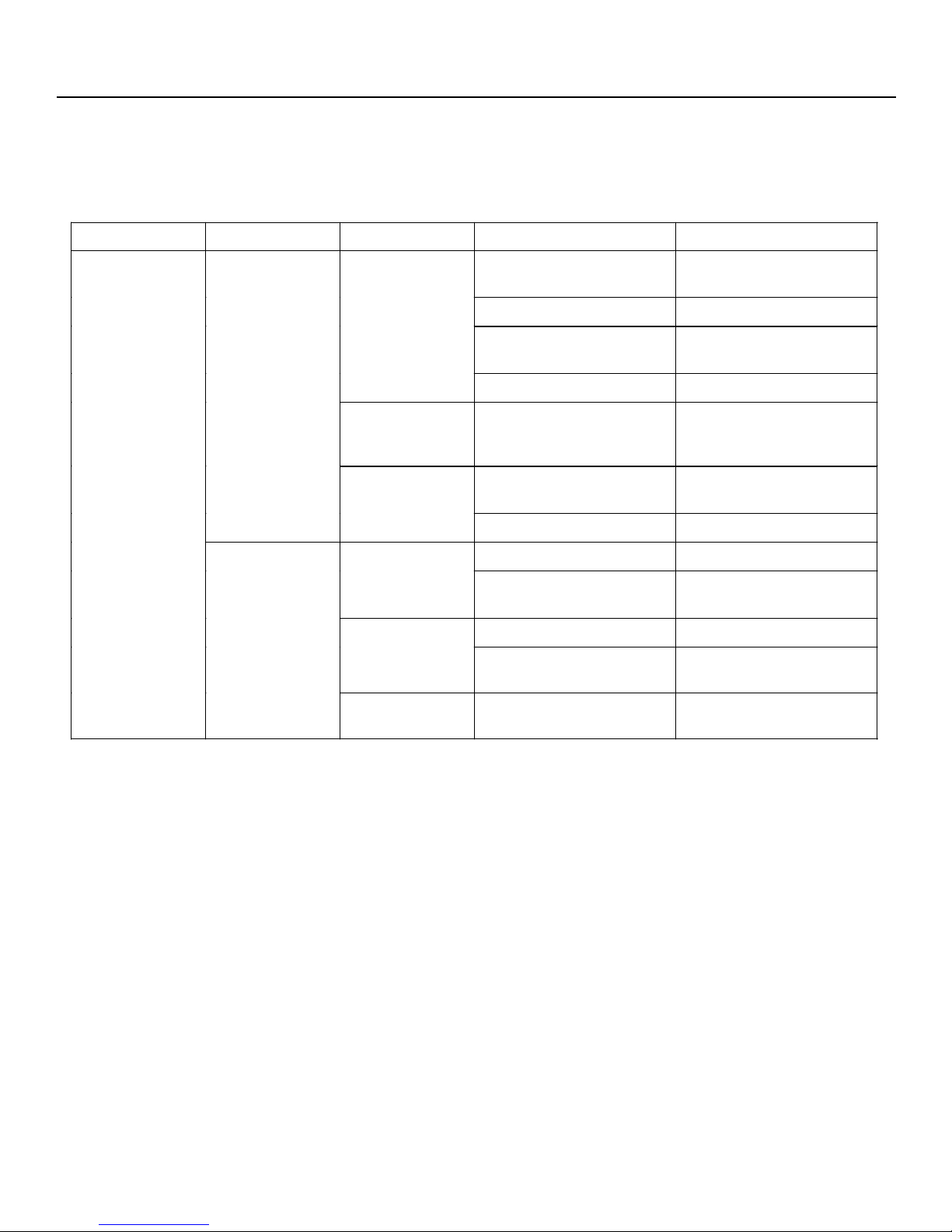

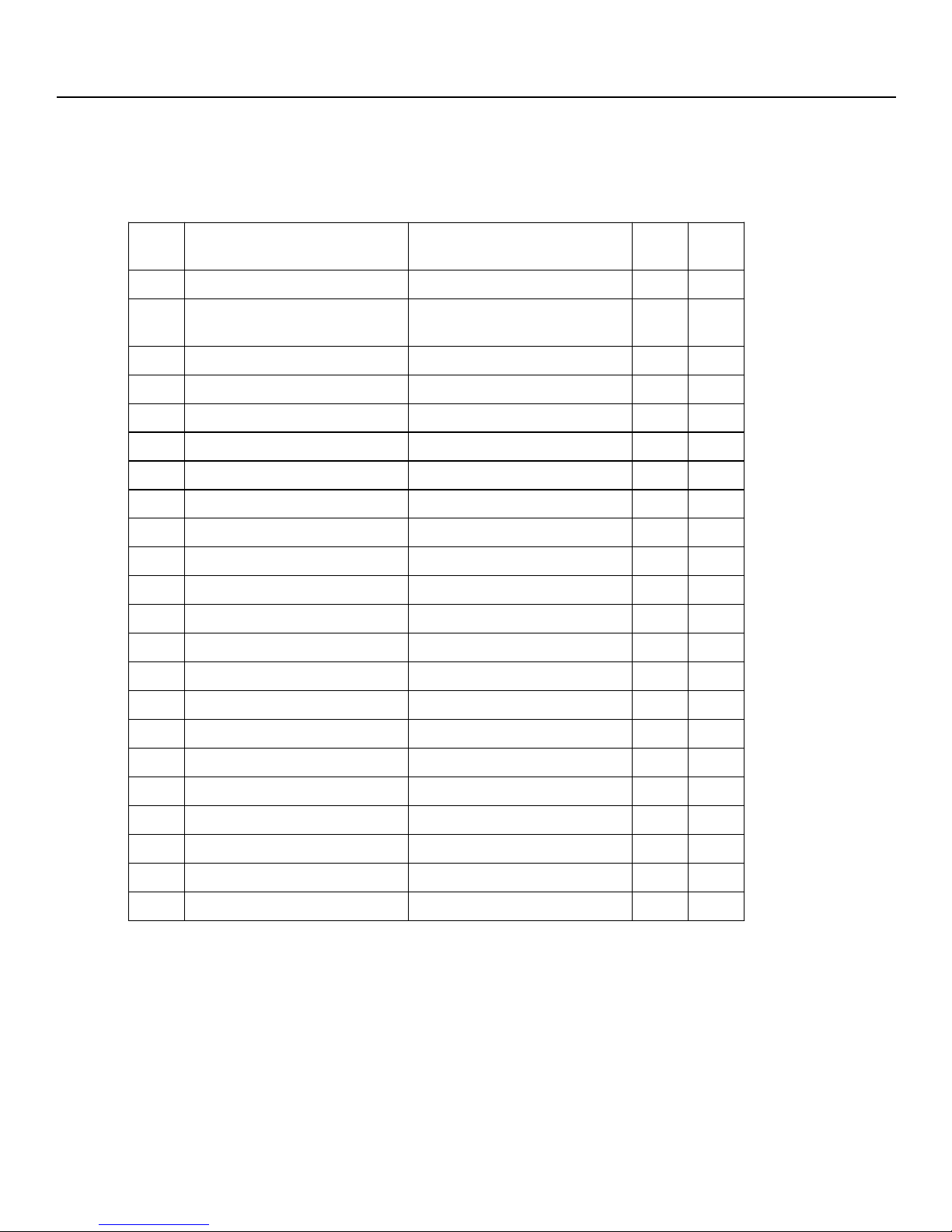

TBR / TBQ / TBG 570 ANDR

TBR / TBQ / TBG 530 ANDR

TBR / TBQ / TBG 470 ANDR

TBR / TBQ / TBG 440 ANDR

TMG / TMR / TMQ432 ANDR

Refrigerant R-134a R-134a R-134a R-134a

Capacities (Liter) 560 500 450 410

Capacities (Cu. Feet) 19.8 17.7 15.9 14.5

Fan cooling ****

Exterior

New Round Face & Arc Design ****

Recessed Handle ****

Automatic Defrosting System ****

Interior Lamp

II. SPECIFICATIONS

565 / 570

ANDR

527 / 530

ANDR

463 / 470

ANDR

427 / 440

/ 432

ANDR

Transparent Plastic Shelf ****

Freezer

Twisted Ice Tray ****

Transparent Door Racks ****

Deodorizing Device ****

Multi Air Flow ****

Temperature Controlled Meat Keeper ****

Transparent Shelf with Steel Frame ****

Large Interior Lamp ****

Vegetable Crisper with Moisture Control * *

Refrigerator

Traditional Vegetable Crisper * *

Transparent Door Racks ****

Large Bottle / Beer Storage Rack ****

Egg Storage Bucket ****

Silver Gray ****

Navy Blue * *

Color

Wine Red ****

Net Dimension (mm)

W 754 754 674 674

Packing Dimension (mm)

H 1803 1701 1776 1676

D 690 690 660 660

W 824 824 744 744

H 1881 1779 1844 1744

D 780 780 780 780

Page 6

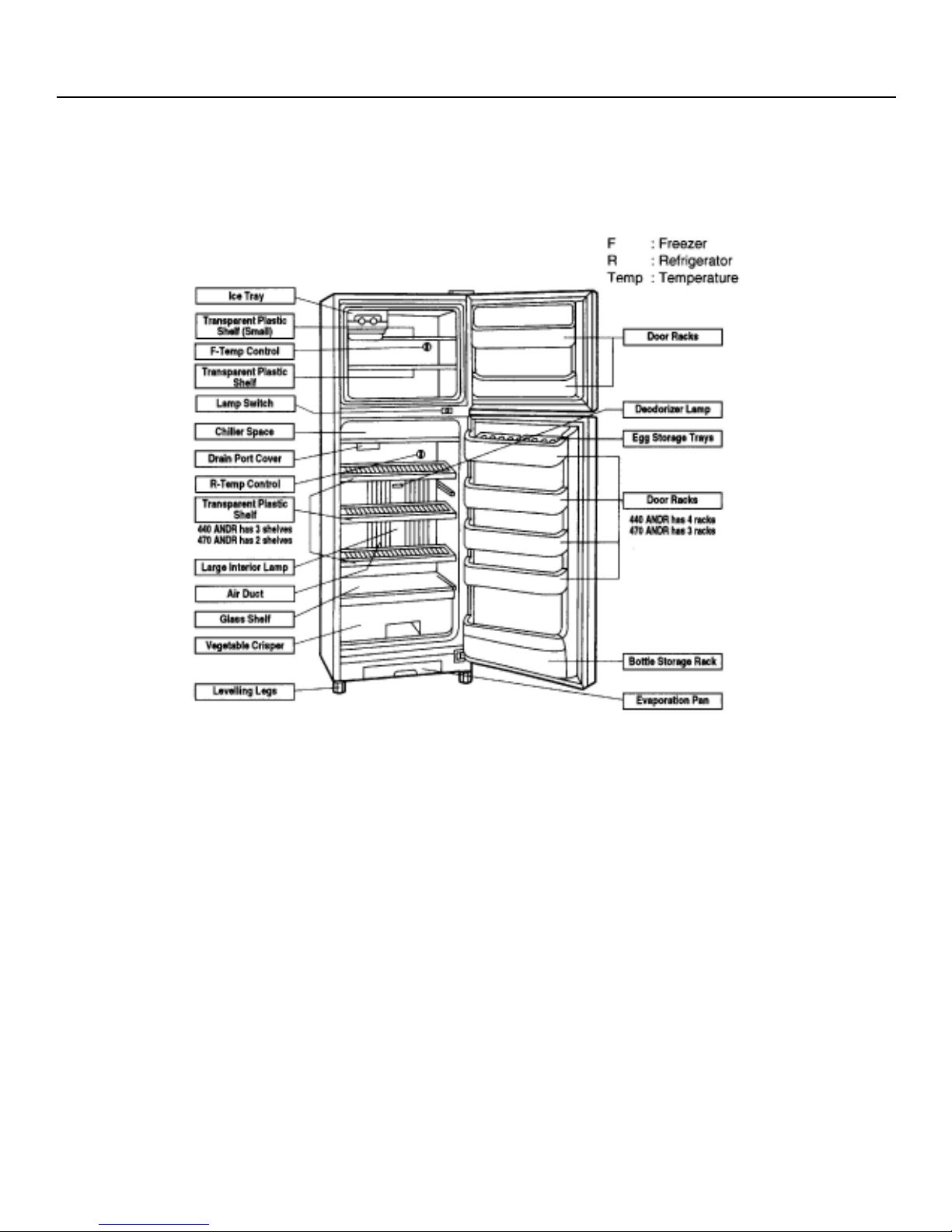

TBG440ANDR / TBG470ANDR

TBQ440ANDR / TBQ470ANDR

TBR427ANDR / TBR463ANDR

III. PARTS IDENTIFICATION

Note : Because of ice expansion, containers with water may deform in the freezer.

3.1 FEATURES

Ice Tray : Can make and store 1 kg of ice cube.

Temp Controlled Meat Keeper : The fish and meats which will be cooked within 2 days can store here, no

Evaporation Pan : Water discharged from the refrigerator is evaporated here.

Door Racks (F) : Short-term storage of frozen food.

Egg Storage Basket : Can store 16 eggs

Door Racks (R) : Short-term storage of refrigerated food.

Bottle Storage Rack : Can store 5 bottles of beer or soda.

Regulator : For regulation of the refrigerator.

thawing is required.

Page 7

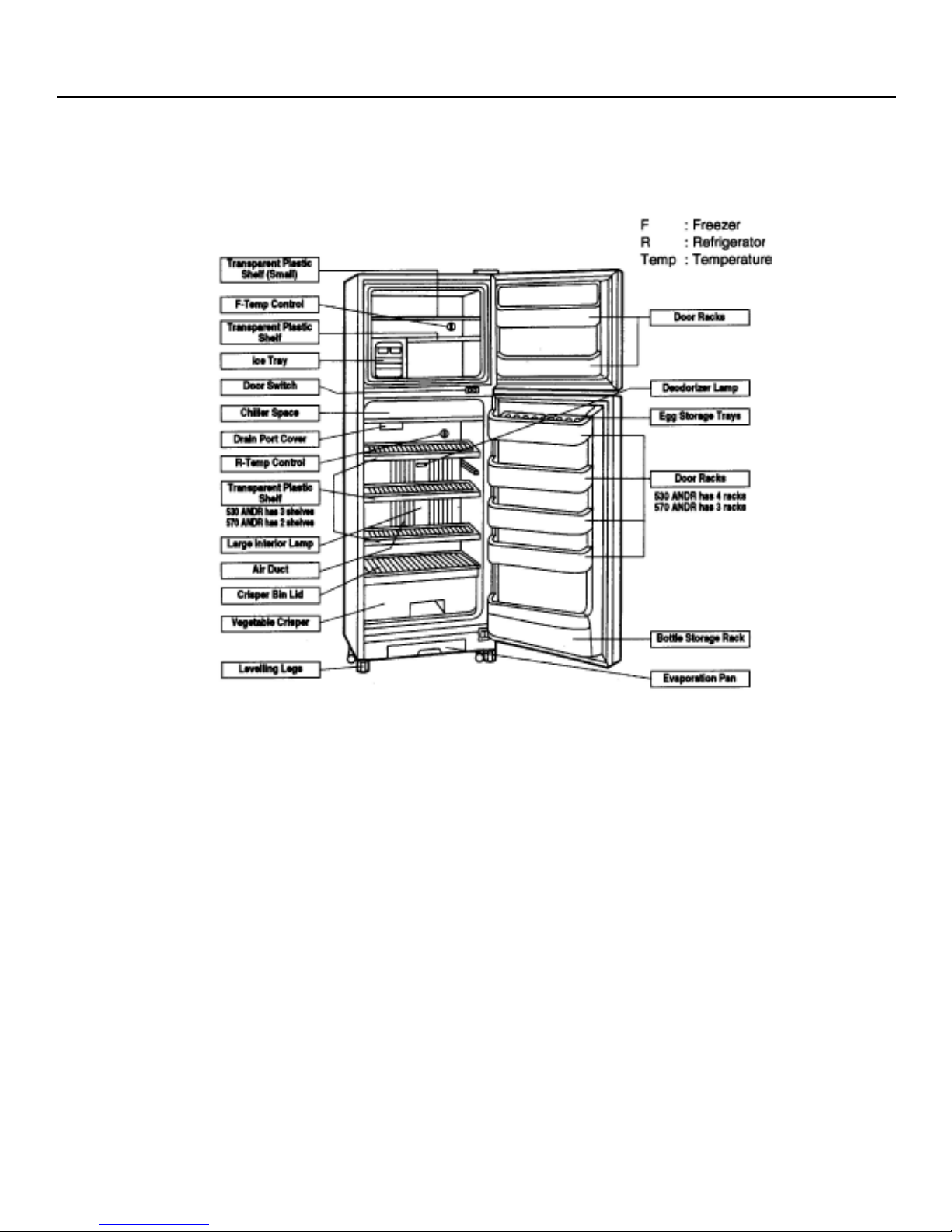

TBG530ANDR / TBG570ANDR

TBQ530ANDR / TBQ570ANDR

TBR527ANDR / TBR565ANDR

III. PARTS IDENTIFICATION

Note : Because of ice expansion, containers with water may deform in the freezer.

3.2 FEATURES

Ice Tray : Can make and store 1 kg of ice cube.

Temp Controlled Meat Keeper : The fish and meats which will be cooked within 2 days can store here, no

Evaporation Pan : Water discharged from the refrigerator is evaporated here.

Door Racks (F) : Short-term storage of frozen food.

Egg Storage Basket : Can store 20 eggs

Door Racks (R) : Short-term storage of refrigerated food.

Bottle Storage Rack : Can store 5 bottles of beer or soda.

Regulator : For regulation of the refrigerator.

thawing is required.

Page 8

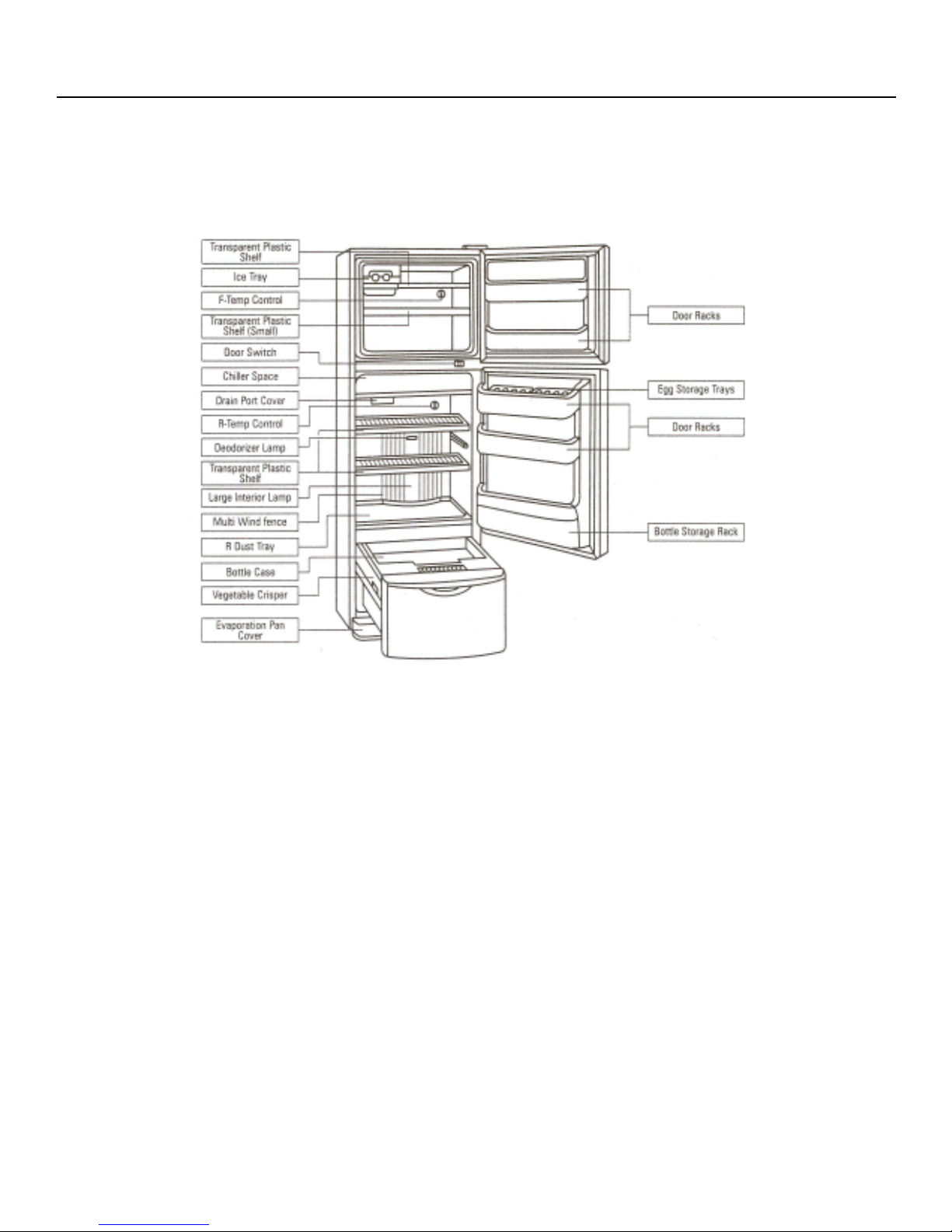

TMQ / TMR / TMQ432ANDR

III. PARTS IDENTIFICATION

Note : Because of ice expansion, containers with water may deform in the freezer.

3.3 FEATURES

Ice Tray : Can make and store 1 kg of ice cube.

Temp Controlled Meat Keeper : The fish and meats which will be cooked within 2 days can store here, no

Evaporation Pan : Water discharged from the refrigerator is evaporated here.

Door Racks (F) : Short-term storage of frozen food.

Egg Storage Basket : Can store 20 eggs

Door Racks (R) : Short-term storage of refrigerated food.

Bottle Storage Rack : Can store 5 bottles of beer or soda.

Regulator : For regulation of the refrigerator.

thawing is required.

Page 9

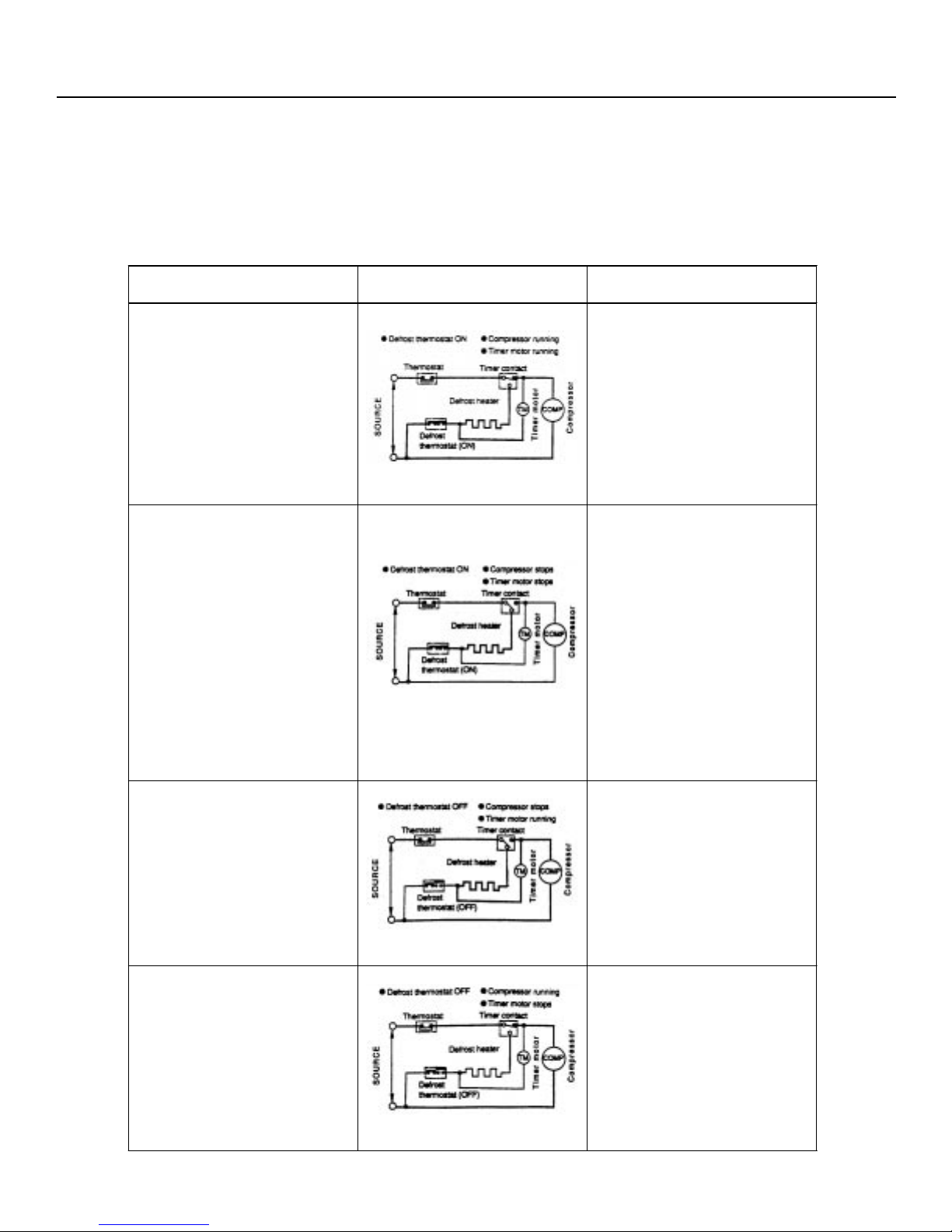

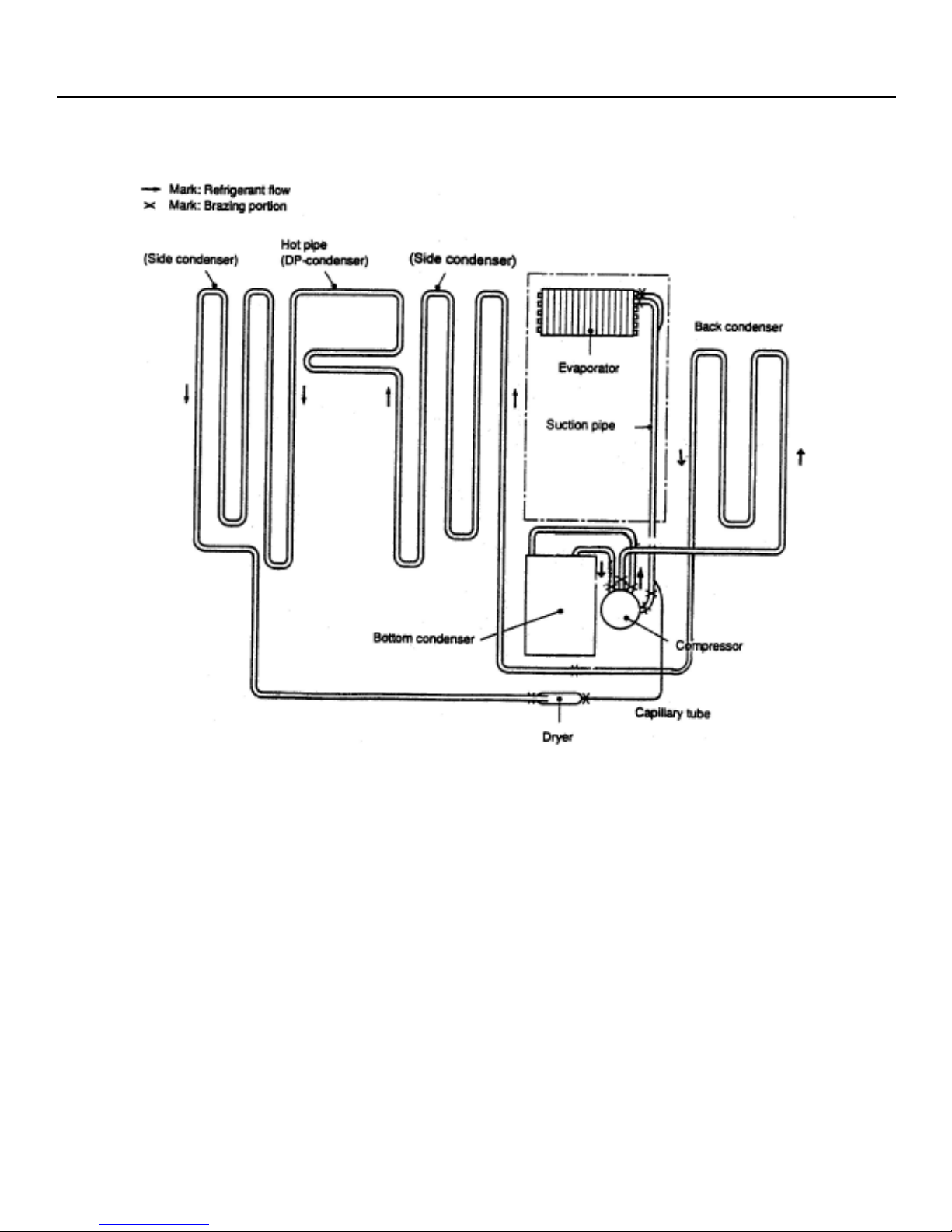

4.1 DEFROSTING

4.1.1 No defrosting operation is

necessary

No defrosting operation is necessary.

As this machine is so designed that a

built-in evaporator cools air and a fan

circulates cooled air, neither the

freezer nor the refrigerator is frosted,

though the evaporator is frosted.

The frosted evaporator is defrosted

automatically due to the function of

defrosting timer and heater, requiring

no defrosting operation.

4.1.2 Where is melted ice brought

IV. FUNCTIONS

i. Melted ice is brought into the

evaporating pan at the bottom of

the set and is evaporated here

by the heat of sub condenser.

ii. Be sure to use the evaporating

pan as inserted so as to be level

with the outer case.

Page 10

IV. FUNCTIONS

4.1.3 The following circuit diagrams in the table show automatic defrosting function of the refrigerator with time

and defrost thermostat.

Operation Electric Diagram Description

Cooling (Normal)

Defrosting

(Time 20 to 30 min.)

Fig 1

Fig 2

The integration timer

integrates running time of the

compressor. When it reaches

8 hours 50 min. at 50Hz, the

timer contact is changed to

start defrosting.

The timer contact is

·

changed to start

defrosting, the timer motor

stops, and power is

supplied to the defrost

heater.

It takes about 20 to 30

·

min. to defrost. When little

frosted the defrosting

takes little time. When

much frosted, the

defrosting takes much

time.

Drain (Time approx. 3 min.)

Cooling (Start)

(Time approx. 5 min.)

Fig 3

Fig 4

Page 11

When the defrost thermostat

becomes OFF, the timer motor

at rest starts running. During

the operation time (2 MIN, 48

SEC / 50 Hz) defrosted water

is drained outside the

refrigerator.

Timer contact is changed

·

to cooling operation and

the compressor starts

running and the timer

motor stops.

Defrost thermostat contact

·

becomes ON when its

cooled. (Figure F-1)

IV. FUNCTIONS

4.1.4 As a reference to determine the causes of

trouble, malfunction and phenomena are

described below. Refer to the following

when repairing.

i. Disconnection of defrost heater

As off-cycle defrosting is performed, the

defrosting time is extremely prolonged.

Each time defrosting is started, the

freezer temperature rises and a portion

of ice and stored foods are melted.

ii. Melted thermo fuse or opened-circuit

due to the defect of defrost thermostat.

When the above mentioned trouble

occurs in cooling operation, the timer

motor does not run, defrosting will not

take place, and consequently freezing is

caused. In the above mentioned

condition, when the time shaft is turned

by hand to defrost, the timer motor runs

during the operation time. However, the

motor stops from the time wien the

contact is changed, and freezing

causes.

4.2 DEW PREVENTION

The hot pipe, namely D P condenser, is arranged

around the flange part of cabinet and the C-partition

plate, preventing dew from being generated on the

cabinet.

Note :

i. D P Condenser pipe may be felt hot if touched

by hand while the compressor is in operation.

ii. If you are asked about this, please explain that

the hot pipe serve to prevent the dew

generation.

Note :

As the thermo fuse assembly is

intended to prevent dangers, do not use

it under shorted condition even for a

short period.

Page 12

IV. FUNCTIONS

4.3 INSPECTION OF INITIAL STARTING

4.3.1 Inspection of Cooling Unit

i. Set the temperature control knob to

MAX and check that the

compressor starts to operate.

ii. Check that cool air is blown out of

the cold air outlet of the freezer and

the refrigerator.

iii. when the compressor does not

work, check that the timer is not set

to defrost position.

iv. It takes about an hour and a half or

two hours to put food in the

refrigerator after starting operation.

Note :

- After return the temperature

control knob to MED position.

- When the refrigerator is

operated initially after installed,

the compressor may vibrate

excessively for 1 to 2 min.

However, vibration becomes

normal if it is continuously

operated.

4.3.2 Inspection of defrost device

Operate the refrigerator for 20 to 30

min. and then check the defrost device

in the following procedures. Allow 5

min. to restart the compressor since

immediate starting after stopping will

cause unsmooth operation.

i. Turn the timer shaft clockwise with

a screw driver. At this time, make

certains the timer clinks and the

compressor stops.

ii. After more than 5 min., turn the

shaft further to operate. Make

certain cooling operation is started

again.

Note :

- Its not necessary to switch the timer

by changing of source frequency

(50Hz 60Hz)

Page 13

IV. FUNCTIONS

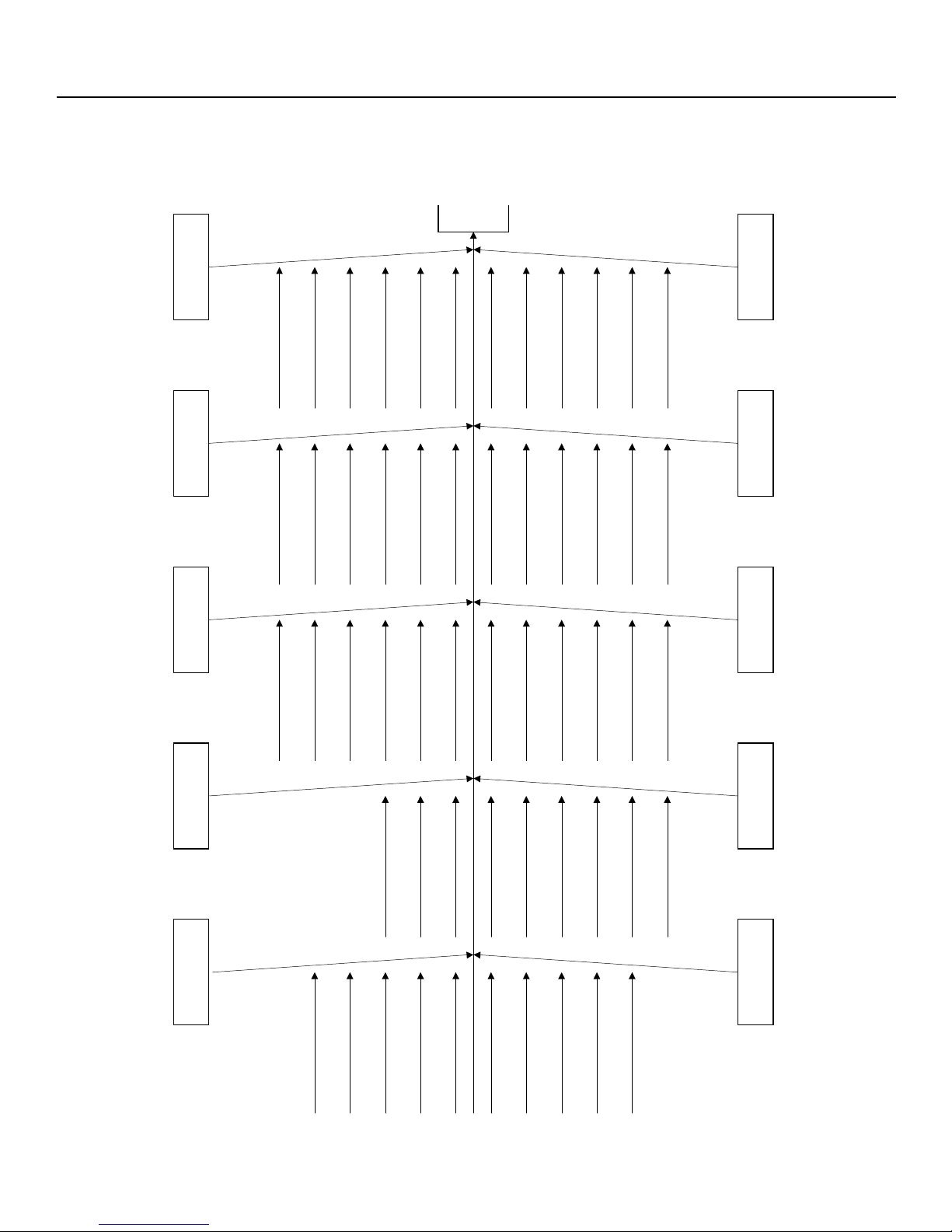

Figure 1 - Cooling Unit

Page 14

V. ADJUSTMENT

5.1 COMPRESSOR

5.1.1 Role

The Compressor inhales low temp.

and low pressure gas evaporated

from Evaporator of the refrigerator,

and condenses this gas to high temp.

and high pressure gas, and then

plays delivering role to Condenser.

5.1.2 Composition

The compressor is composed of

Compressor Apparatus compressing

gas. Compressor Motor moving

Compressor Apparatus and Case

protecting Compressor Apparatus

and Motor.

There are PTC-Starter, and Over

Load Protector in the Compressor

outside.

v. Be careful that dust, humidity, and flux

due to welding dont inflow in

Compressor inside in replacing

Compressor. Dust, humidity, and flux

due to welding which inflows to

Cylinder may cause lock and noise.

On the other hand, because the

Compressor consists of 1/1000mm

processing precision components

and is sealed after producing without

dust or humidity, deal and repair with

care.

5.1.3 Note to Use

i. Be careful not to allow over

voltage and over current.

ii. No Strike

If applying forcible power or strike

(dropping or careless dealing),

poor operation and noise may

occur.

iii. Use proper electric components

appropriate to the compressor.

iv. Note to keep Compressor

If Compressor gets wet in the rain

and dust in the pin of Hermetic

Terminal, poor operation and poor

contact may cause.

Page 15

V. ADJUSTMENT

5.2 PTC-STARTER

5.2.1 Composition of PTC-Starter

i. PTC (Positive Temperature

Coefficient) is no-contact

semiconductor starting device which

uses ceramic material and the

material consists of BaTiO3.

ii. The higher the temperature is, the

higher resistance value becomes.

These features are used as starting

device of motor.

5.2.2 Role of PTC-Starter

i. PTC is attached to hermetic

Compressor used for refrigerator,

show case and starts motor.

ii. Compressor for household

refrigerator applies single-phase

induction motor. For normal

operation of single-phase induction

motor, in the starting operation flows

in both main coil and sub coil. After

the starting is over, the current is cut

off in sub coil. The proper features

of PTC play the above all roles. So,

PTC is used as a starting device of

motor.

5.2.4 Relation of PTC Starter and OLP

i. If power off during operation of

Compressor and power on before

PTC is cooled, (instant shut-off within

2 min. or reconnect a power plug due

to misconnecting), PTC isnt cooled

and a resistance value grows. As a

result, current cant flow to the subcoil and motor cant operate and OLP

operates by flowing over current in

only main-coil.

ii. While the OLP repeats on and off

operation about 3-5 times, PTC is

cooled and Compressor Motor

performs normal operation.

If OLP doesnt operate when PTC is

not cooled, compressor motor is

worn away and cuases circuit-short

and fire. Therefore, use a proper

fixed OLP without fail.

5.2.5 Note to Use PTC-Starter

i. Be careful to over voltage and over

current.

ii. No Strike.

Dont apply a forcible power or strike.

5.2.3 Motor Restarting and PTC Cooling

i. For restarting after power off during

normal Compressor Motor operation,

plug the power cord after 5 min. for

pressure balance of refrigerating

cycle and PTC cooling.

ii. During normal operation of

Compressor Motor, PTC elements

generate heat continuously.

Therefore, if PTC isnt cooled for a

while after power off, Motor cant

operate again.

iii. Keep apart from any liquid

If liquid such as oil or water inflows

into PTC, PTC materials may break

due to insulation breakdown of

material itself.

iv. Dont change PTC at your

convenience.

Dont disassemble PTC and mold.

If damaging to outside of PTCStarter, resistance value alters and

poor starting of Compressor motor

may cause.

v. Use a properly fixed PTC.

Page 16

V. ADJUSTMENT

5.3 OLP (OVER LOAD PROTECTOR)

5.3.1 Definition of OLP

i. OLP (Over Load Protector) is

attached to hermetic Compressor

and protects motor by cutting off

current in Compressor motor by

Bimetal in the OLP in case of overrising temperature.

ii. When oven voltage flows to

Compressor motor, Bimetal works by

heating the heater inside OLP, and

OLP protects motor by cutting off

current which flows to compressor

motor.

5.3.2 Role of OLP

i. OLP is attached to hermetic

Compressor used to refrigerator and

show case and prevents motor coil

form being started in the

Compressor.

ii. Do not turn the Adjust Screw of OLP

in any way from normal operation of

OLP.

Page 17

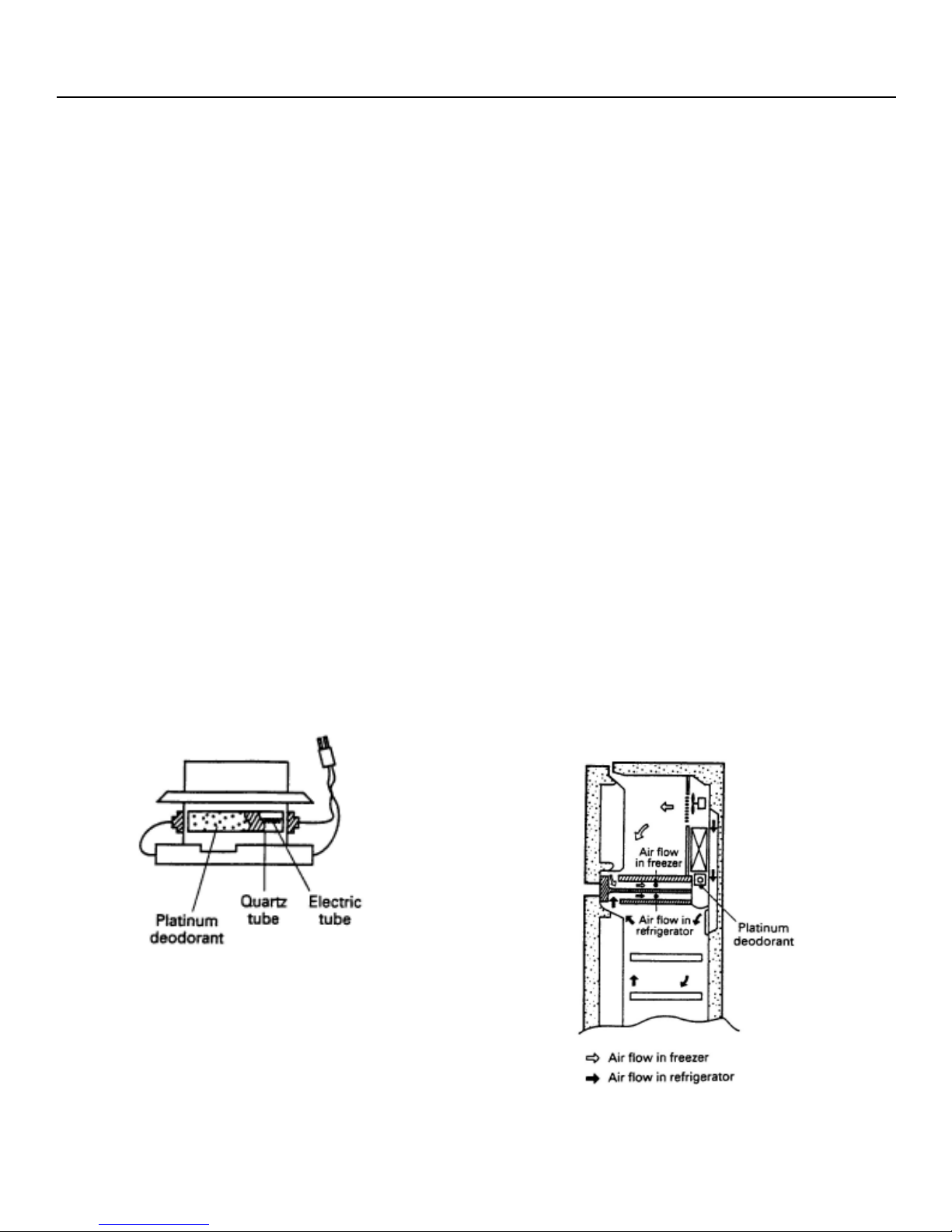

VI. DEODORIZATION WITH PLATINUM

6.1 DEDORIZATION WITH PLATIMUM

6.1.1 This material is used for

Deodorization and defrosting

because of its high temperature

acidification to get rid of odors in the

refrigerator.

6.1.2 This is a platinum-based catalyst

deodorant evenly coated on the

quartz tube. It is a highly active and

adhesive metal.

6.1.3 In the refrigerator, the odor passes

by the deodorant catalyst and is

attracted by the deodorant coated on

the quartz tube.

6.1.4 When defrosting, the 250°C heat

produced in the quartz tube dissolves

the acidified odor and purifies the

cold air in the refrigerator.

6.1.5 After defrosting, the clean and odorfree cold air refrigerates the food. At

the next defrosting, it carries out

Deodorization and this process is

repeated.

6.2 APPLICATION OF PLATINUM AS

DEODORANT

6.2.1 A fan is used in the frost-free refrigerator

for refrigeration.

6.2.2 The Platinum deodorizer is installed

beneath the cooler at the cold air outlet

that cools the freezer compartment.

Because the refrigerator is a sealed

cabinet, the rotating cool air is forced to

rotate by the fan and cause odor to pass

through the deodorizer.

6.2.3 When not defrosting, the deodorant is

highly activated and odor is absorbed.

6.2.4 After running for a while and during the

defrosting stage, the heat produced by the

defrosting heater that goes through the

quartz tube to the deodorant on the

surface at over 250°C, causes odor to

attach to the deodorizer where it is

acidified into pure gas, free of odor.

6.2.5 At the end of defrosting, the fan resumes

work and the high temperature does not

go down. The acidified gas causes the

deodorant to continue to absorb odor.

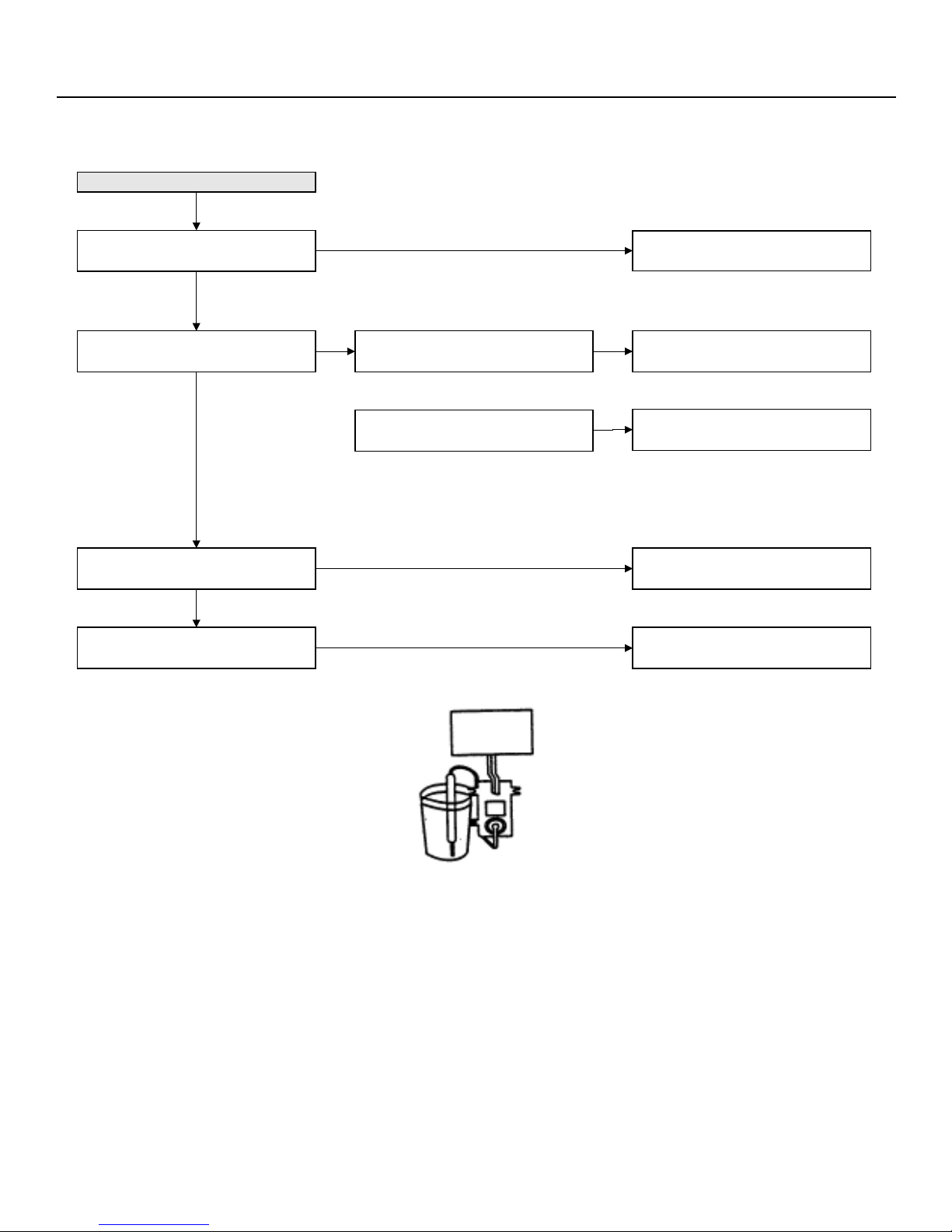

Diagram of Defrosting Heater

Page 18

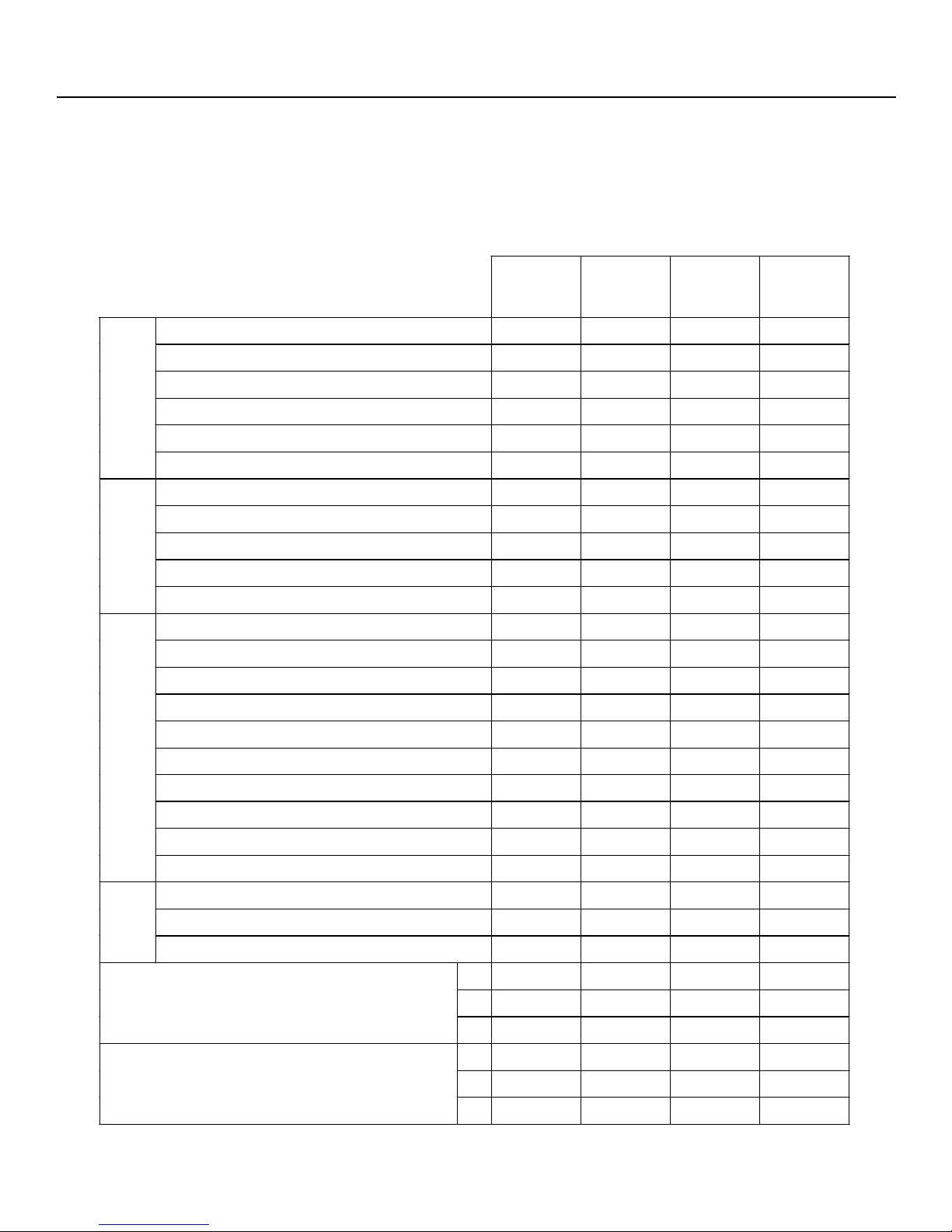

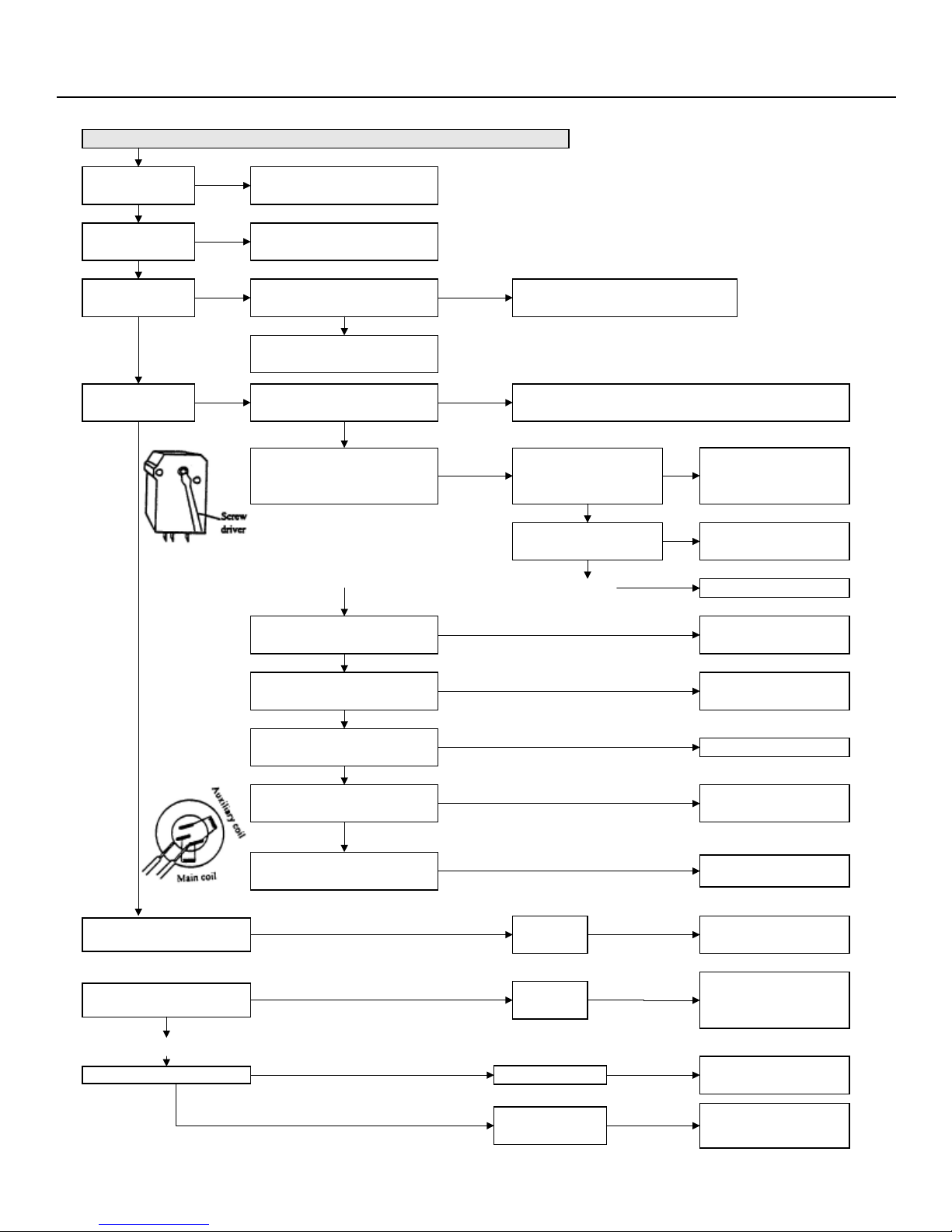

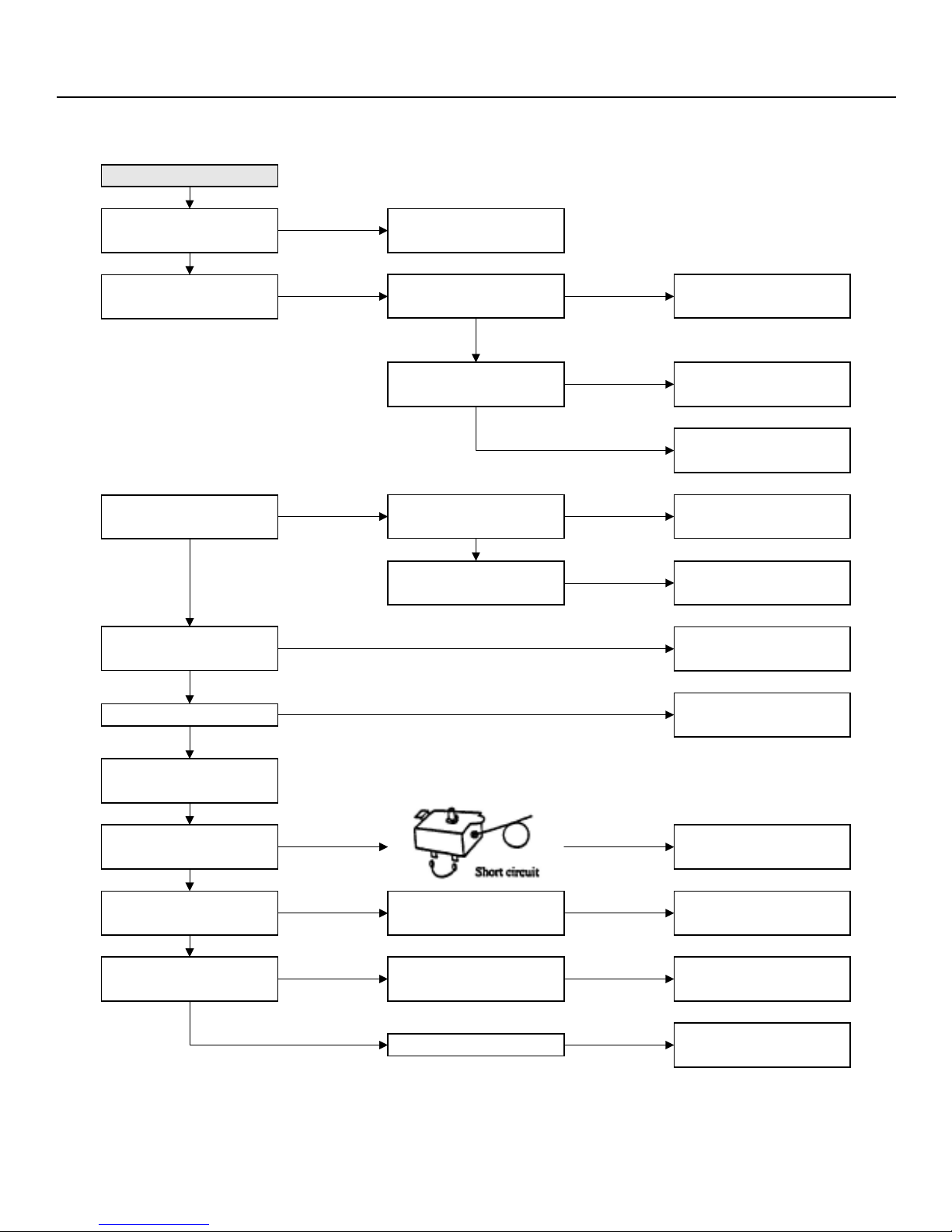

VII. FAILURE DIAGNOSIS

1. Not cold at all (freezing storage and cooling chamber are not cold)

Is the plug being

inserted?

Yes

Is the plug being

inserted?

Yes

Is the voltage over

99V?

Yes

Is the compressor

operating?

No

No

No

No

Insert the power plug.

Any shutdown? Check the abnormal

power cord or switch

Is a special socket used by the

refrigerator?

Is the geographical environment being

using a special one?

Short the F thermostat and see if the

compressor is operating.

When regulat e D meter to cooling

operation side, is the compressor

operation?

Non-operating

No

Yes

Operating

Not operated

Operating

* Turn D time to right side

till heating two noises

Is a socket affected by other electrical wiring?

Change F-THM, then check is it due to the freon leakage of thermo

Is the temperature fuse

Is temperature switch

sensor or by poor contacting point?

No

melted?

Engaged

No

engaged?

Replace the temperature fuse

Replace the temperature

switch

Replace D meter.Engaged

Short the overload protector and see if

the compressor is operation.

Yes

Is the relay of PTC starter normal?

Is the capacitor normal at starting or

The contacting point being poor? Repair the contacting point.

Is the circuit of compressor coil

Ice beads or serious frost formed

Inspection of the frosted cooler

Non defrost

Inspection of freon leakage Freon leakage

No freon leakage

Defective freon circuit Clogged by impurities

The lower pressure tube of

compressor fails to such the air.

in the cooler chamer

Check the leakage

location

operating?

Freon circuit

clogged

Non-operating

Yes

Yes

No

normal?

Operating

Abnormal

Abnormal

Yes

Abnormal

Poorly

defrosted

Poor compression of

the compressor

Replace the overload

protector.

Replace the relay of PTC

starter.

*Impedance short (0Ω) and poor circuit (0∞)

Replace the capacitor.

*In case of the normal item, the needle of the

panel will become (∞Ω) after one vibration.

* Remove the pin from the connecting point and

check if it has turned into black.

Replace the compressor and

drying filter.

* Check the circuit of mail coil, auxiliary coil

and resistance value.

Refer to the mothod of non-

defrost

Poor location be repaired.

Replace the compressorm

drying filter. Clean the freon

circuits.

* When the inner side of compressor is too dirty,

it must be replaced.

Replace the clogged parts.

Replace the drying filter.

Clean the freon circuit

Replace the compressor,

drying filter. Clean the freon

circuit.

Page 19

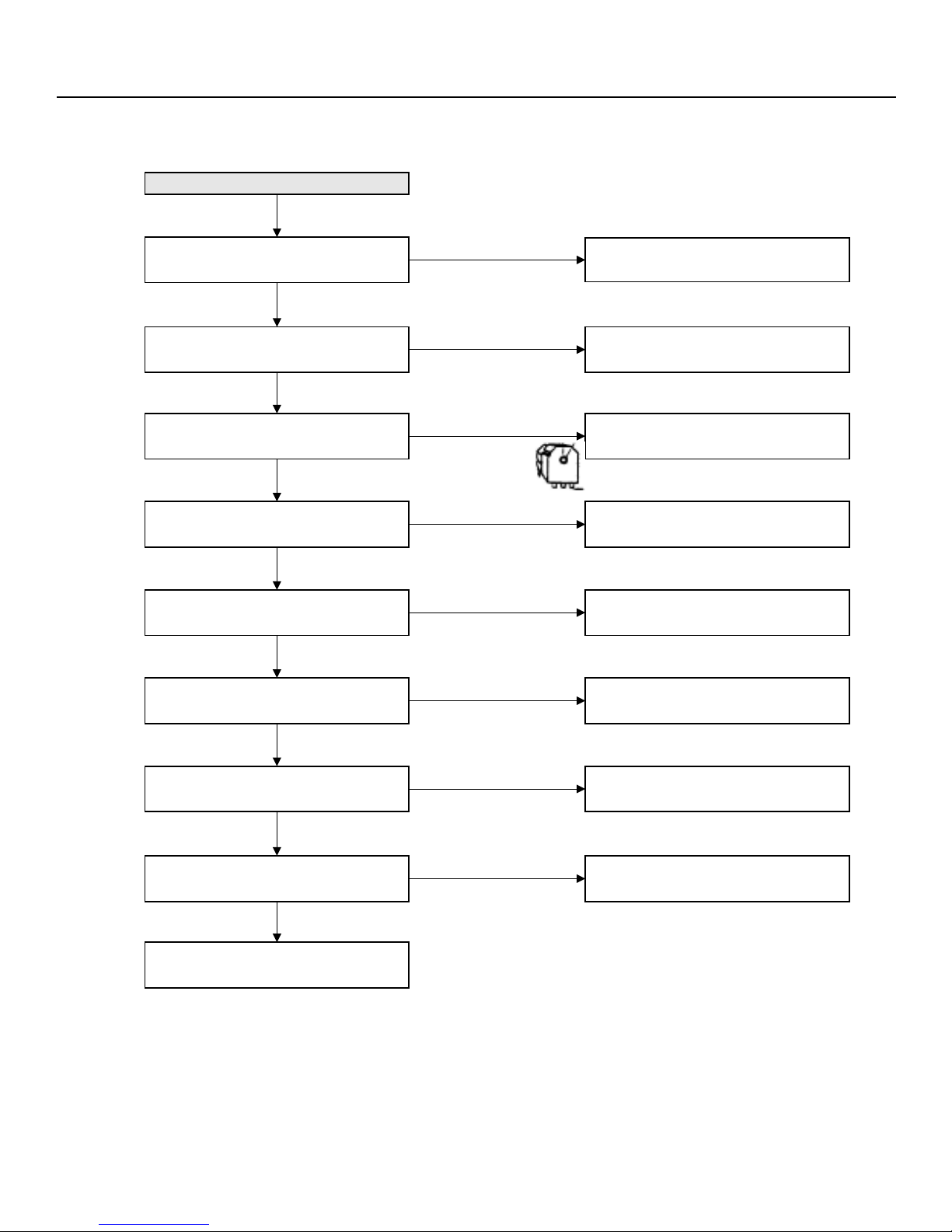

2. Not cold enough

VII. FAILURE DIAGNOSIS

Is the turn button set at "MAX"

position?

No

Setting the temperature of

each chamber in the storage.

High temperature

Set the turn button to

"Medium" and confirm

High temperature

in the freezing storing

and the cooling

chamber

Is the storage environment

appropriate?

Yes

Is the storing method of the

food inside the storage room

appropriate?

Yes

Only freezing

room (including

0°C room)

No Yes

Is the turn button set at "MAX"

position?

Confirm the bumper cohesion

of bumper thermostat

Opened

Any clearance at the door

knob?

No

The ambient space of the

refrigerator being too small

No

The ambient temperature of

the refrigerator being too high.

No

Fully closed

Yes

Yes

Replace bumper thermostat

(Freon leakage at the thermo

sensor of bumper thermostat)

Adjust door and replace the

door knob

Frequent opening of door.

Insufficient convection of cold

air due to over loaded food.

Adjust the storing place of

refrigerator

Avoid direct sun beam or

move the gas stove away from

the refrigerator.

Note if the food stored inside

the storage room being too

much.

Yes

The clearance of door knob

No

Mist and frost formed at the

top of freezing chamber and

quick freezing chamber.

No

Will F thermostat become cold

after the short circuit?

No

Is the fan in the storage room

operated normally?

Yes

Confirm the frosting of the

cooler.

Frozen or frosted in

the cooler chamber

Yes

No

Yes

Is the motor of fan operated

normally?

Inspect the freon leakage

location

Poorly defrosted

Adjust door and replace door

Replace the motor of fan

YesMinor frost

Defect repairs and replace the

Refer to the method of non-

knob

Replace F thermostat

drying filter

defrost

Page 20

3. Fail to Defrost

VII. FAILURE DIAGNOSIS

Confirm the frosting of the cooler

more

frost

Is the coil circuit of D meter working? Replace D meter (broken coil)

Yes

Turn the pin of D meter to defrost side. Is the

circuit of defrost heater working?

No

Is the circuit at the defrost side of D meter

working?

Yes

Short circuit at the temperature switch, is the

circuit of defrost heater working?

No

Is the circuit of defrost heater working? Replace the defrost heater.

Lesser frost

No

Green & black circuit of D

meter

Defrost

Yes

No

Green & black circuit of D

meter

Yes

No

Clearance of door knob and forget to close the

Agent

Replace D meter (poor operation of D meter)

Replace D meter, (poor contacting point)

freezing chamber door.

Replace the temperature switch.

Yes

Is the circuit of temperature fuse working? Replace temperature fuse.

Yes

Is the circuit of water dripping tray working? Inspect the heater of water dripping tray.

Yes

Clean the water and impurities in the water

dripping tray.

No

No

Page 21

4. Too cold

VII. FAILURE DIAGNOSIS

Is the turn button set at "Strong Position"? Turn the button at "Weak" Position.

No

Temperature set of each chamber in the

storage room.

Turn all the buttons to

"Medium" for

confirmation.

Low temperature

Confirm the cohesion of bumper thermostat Replace the bumper thermostat

Closed

Mist and frost formed at the top of freezing

chamber and quick freezing chamber.

* If setting the button of the freezing chamber at

"Strong" while the cooling chamber is at "Medium",

then the cooling chamber and fressness-keep

chamber will become too cold.

Is the ambient temperature below 5°C?

Only for the freezing of food near the suction

outlet of bumper thermostat.

* When the food containing more moist (bean curd,

vegetable, fruit, etc) is placed at the inner side of

shelve or the freshness-keep chamber, then the food

would be easily frozen. So, it is necessary to change

* Use ice to cool the thermo sensing part for confirmation.

* Freezing phenomenon formed at the bumping part of the

Yes

the storage method.

Opened

Yes

bumper thermostat.

YesNormal

Yes

Turn the button to "Weak" position.

Change the storing method of the food.

Forget to close the freezing chamber door.

Repair the contact of food and door rail.

* When the bumper thermostat is replaced

due to poor cooling, be sure not to install the

cooling chamber bumper correctly and it must

be secured on the original leverage.

* Put iced water in to the cup or placed it into

the freezing chamber to cool it down, so as to

confirm the action of the bumper.

Page 22

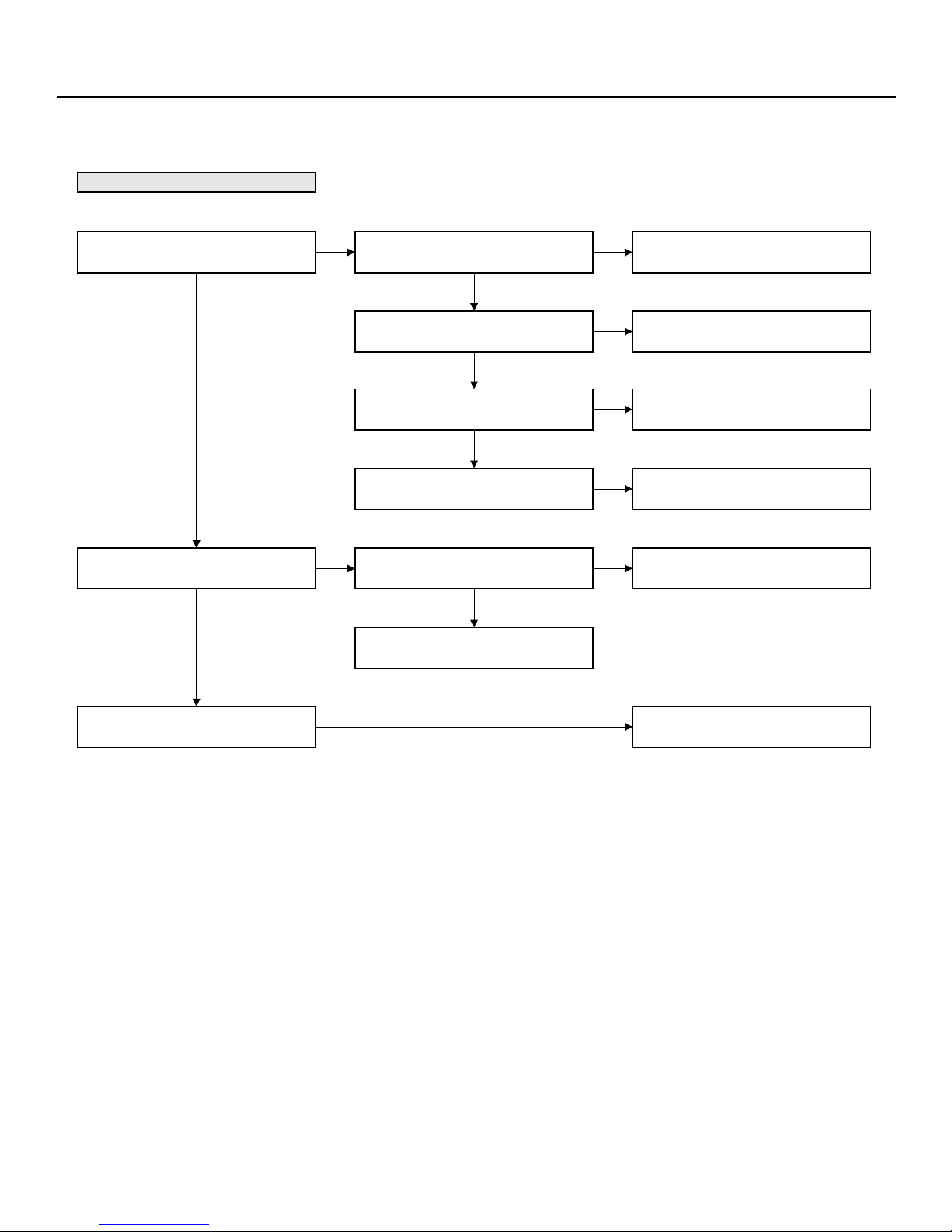

5. Unusual Noise

VII. FAILURE DIAGNOSIS

Unusual noise during the compressor running

in the mechanical room.

If any unusual noise of the fan (upon opening

the door)?

No

unusual

noise

Yes

Yes Yes

Is the ground horizontally flat?

Yes

If the mechanical piping being slanted or

contacted.

No

If all the piping in the mechanical room are

resonant.

No

Inspect the vibration of compressor and adjust

the rubber pad to reduce vibration.

Check if the fan is contacting EV cover or the

grate.

No

Inspect the assembly of fan and grate and

adjust it to create air tightness with the inner

case.

No

Yes

Yes

Yes

Adjust by the adjusting foot.

Be properly adjusted.

Adjust the location of counter-weight

Change the storage method of the food.

Press down the fan to the end to confirm that

the fan will not contact the grate.

Unusual noise in D meter

Open the electrical case and replace new D

meter.

Page 23

VII. FAILURE DIAGNOSIS

g

o

r

in

sto

High

refri

C. Slight air leakage A. Too much freon.

Discharge tube temp. being

(suction tube)

E. Clogged by dusts

Slight raise of heatdissipater

tube.

High suction pressure.

not too high.

temperature

Frosted or fogged suction

Low suction pressure Fair heat dissipater temp. High current & power

over -18°C

and heat dissipater

Inadequate coldness

High temp. at discharge tube

Evaporator temperature being

Low current & power

Frosting being clogged

Almost no frosting

Inadequate coldness

Inadequate coldness

Without flowing sound

Almost no frosting

Poor freezing effect

Low current & power

Cycle frost & mist

Change of current & power

Change of suction pressure

Inadequate coldness

High current & power

Frosting being clogged

Low suction pressure

Low heat dissipater temp.

Low discharge tube temp.

Intermittent raise of

dissipater temperature

Intermittent raise of heat

Intermittent flowing sound

Low suction pressure

compressor temperature

clogged by dust

Unusual noise at the

High compressor temp.

discharge section due to

D. Water clogging B. Insufficient Freon

exhaust

F. Dusts clog the

cannot be

condensated.

G. Containing air that

I. Air leakage

dissipator not raised

Temperature at the heat

High current & power

High suction pressure

low

low.

Without flowing sound Low current & power Low suction pressure

Current & power being too

Temp. discharged being too

Inadequate temperature

Being not cold

Inadequate coldness

Normal frosting

Page 24

Low current & power

High suction pressure

High current & power

Low heat dissipater temp

Sound of oil flow

Normal suction pressure

suction tube

cannot be frosted

No temperature difference

between discharge tube and

No flowing sound and almost

J. Over filled oil H. Poor compressing

VII. FAILURE DIAGNOSIS

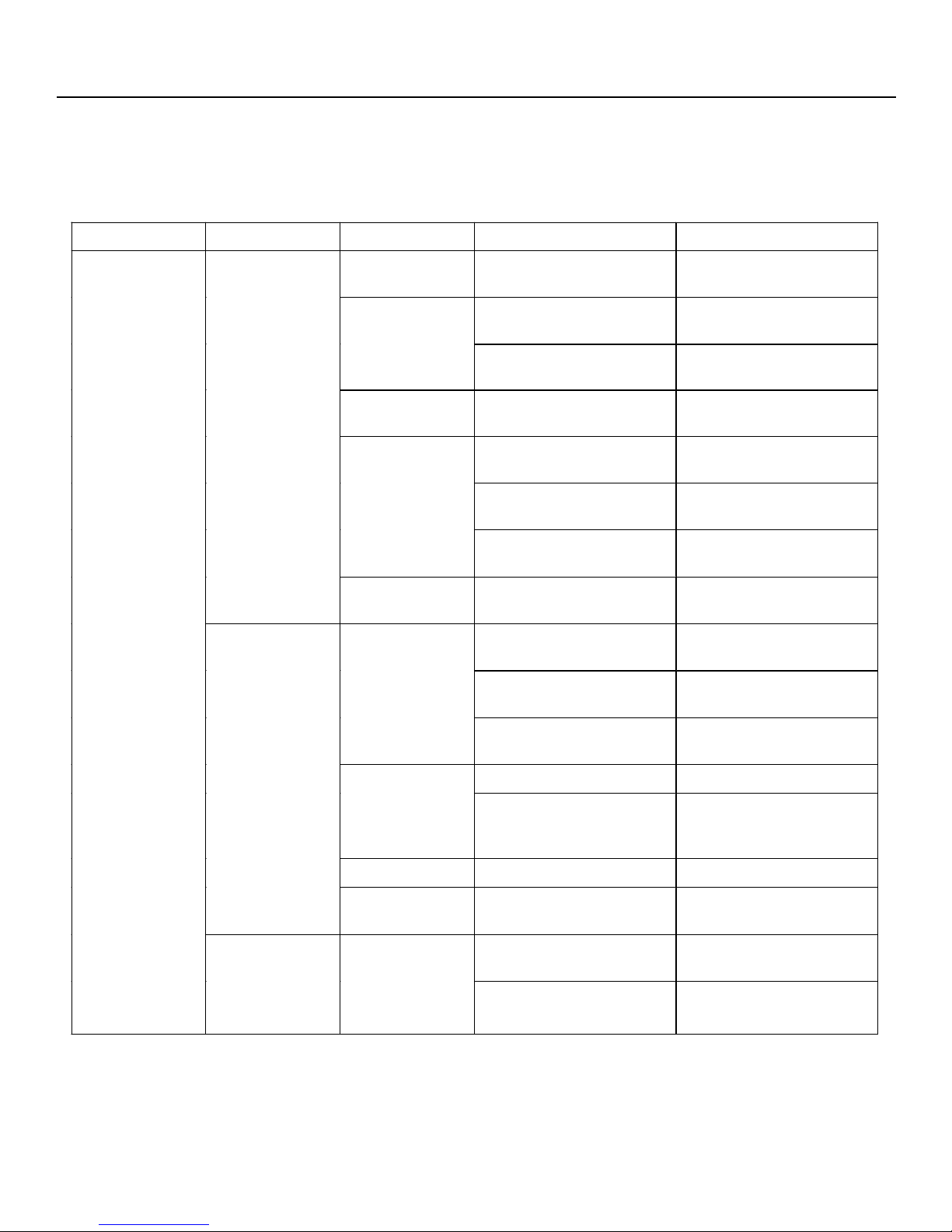

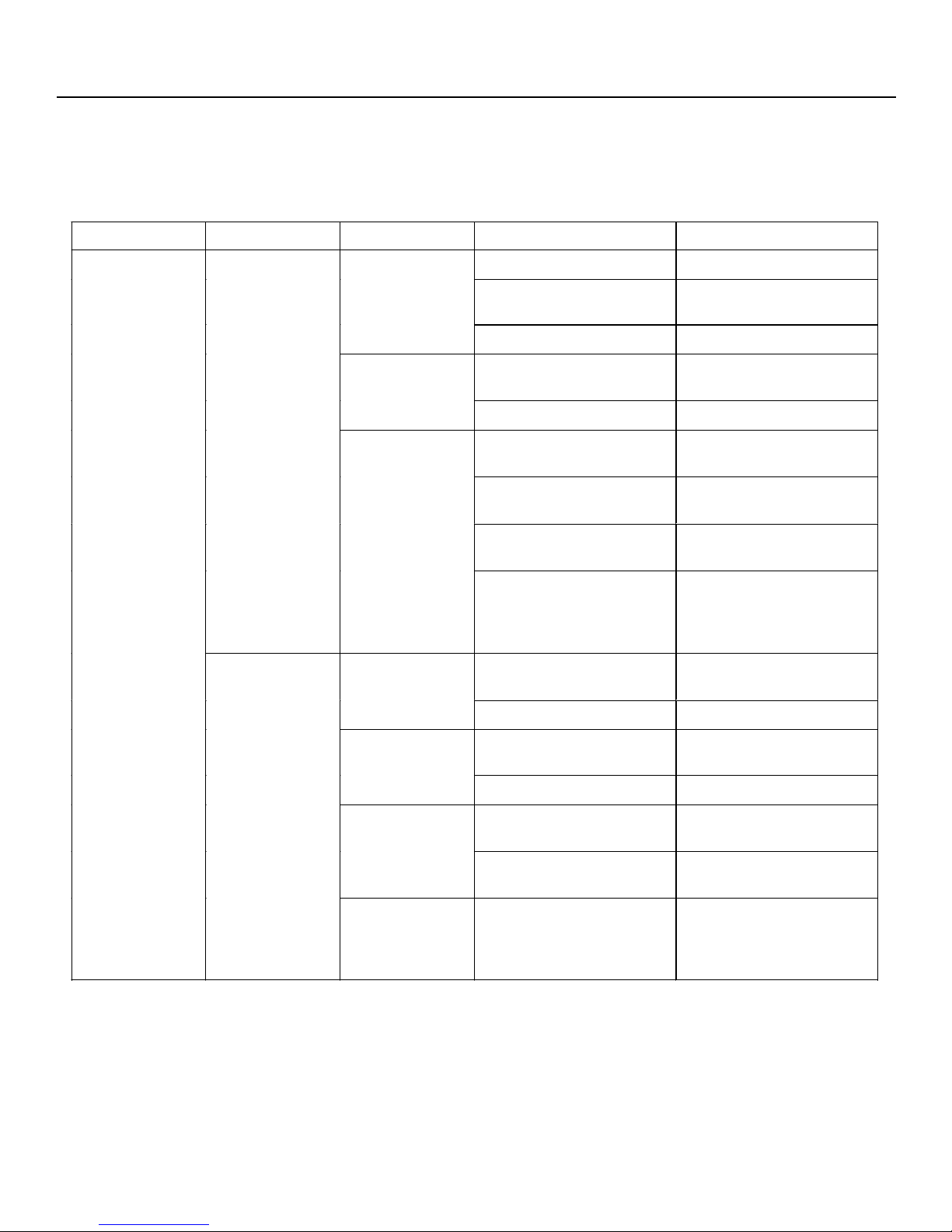

CAUSES & TREATMENT OF REFRIGERATOR FAILURES

Phenomenon Failure Condition Inspection Part Causes Treatment Actions

Refrigerator fails

to operate

Electric current

meter remains

still

Instant power

stop of major

motor

Electric power 1. Power cord not being

engaged

Compressor

Relay Broken electrical heating

Control Switch

Defrost Switch 1. Poor practice

Compressor

1. Broken main coil of the

motor.

2. Broken wiring of the

refrigerator.

wire

1. Button set at OFF

position.

2. Poor practice

3. Air leakage (freon).

1. Choking

2. Short circuit between

motor

Any power shut off or

·

melted fuse?

Replace the

·

compressor

Check & repairs

·

Replace the relay

·

Replace the control

·

switch

Replace the control

·

switch

Replace the control

·

switch

Replace the defrost

·

switch

Replace the

·

compressor

Replace the

·

compressor

Defrost switch

fails to recover

or longer time

needed for

recovery

3. Broken auxiliary coil of

the motor.

Starter

Capacitor 1. Burnt out

Power 1. Abnormal voltage

Defrost switch

1. Poor practice

2. Poor contacting point

1. Poor practice

2. Low room temperature

Page 25

Replace the

·

compressor

Replace the starter

·

Contacting point be

·

polished or replaced

with a new one.

Replace the capacitor

·

Explanation for the

·

customer.

Replace the defrost

·

switch

Explanation for the

·

customer.

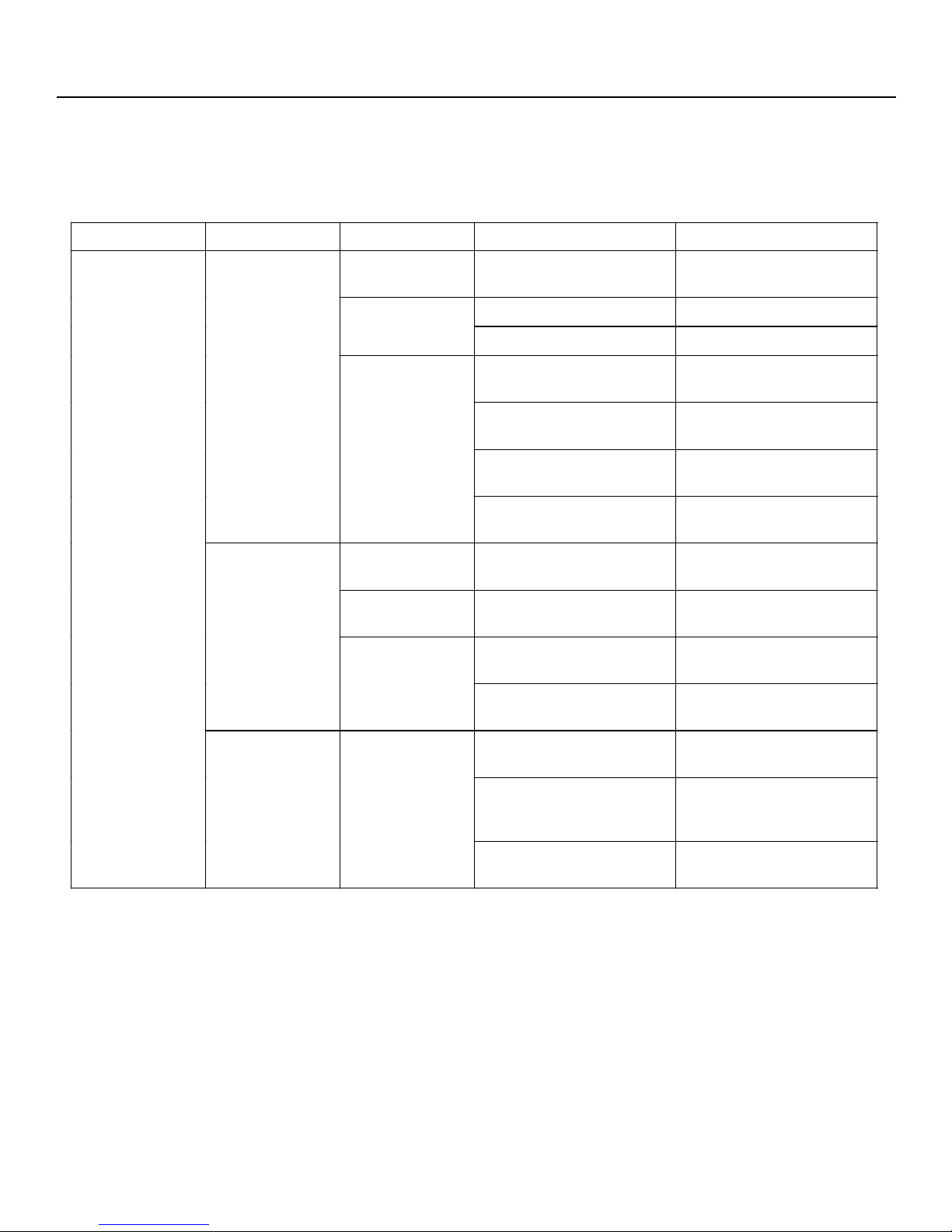

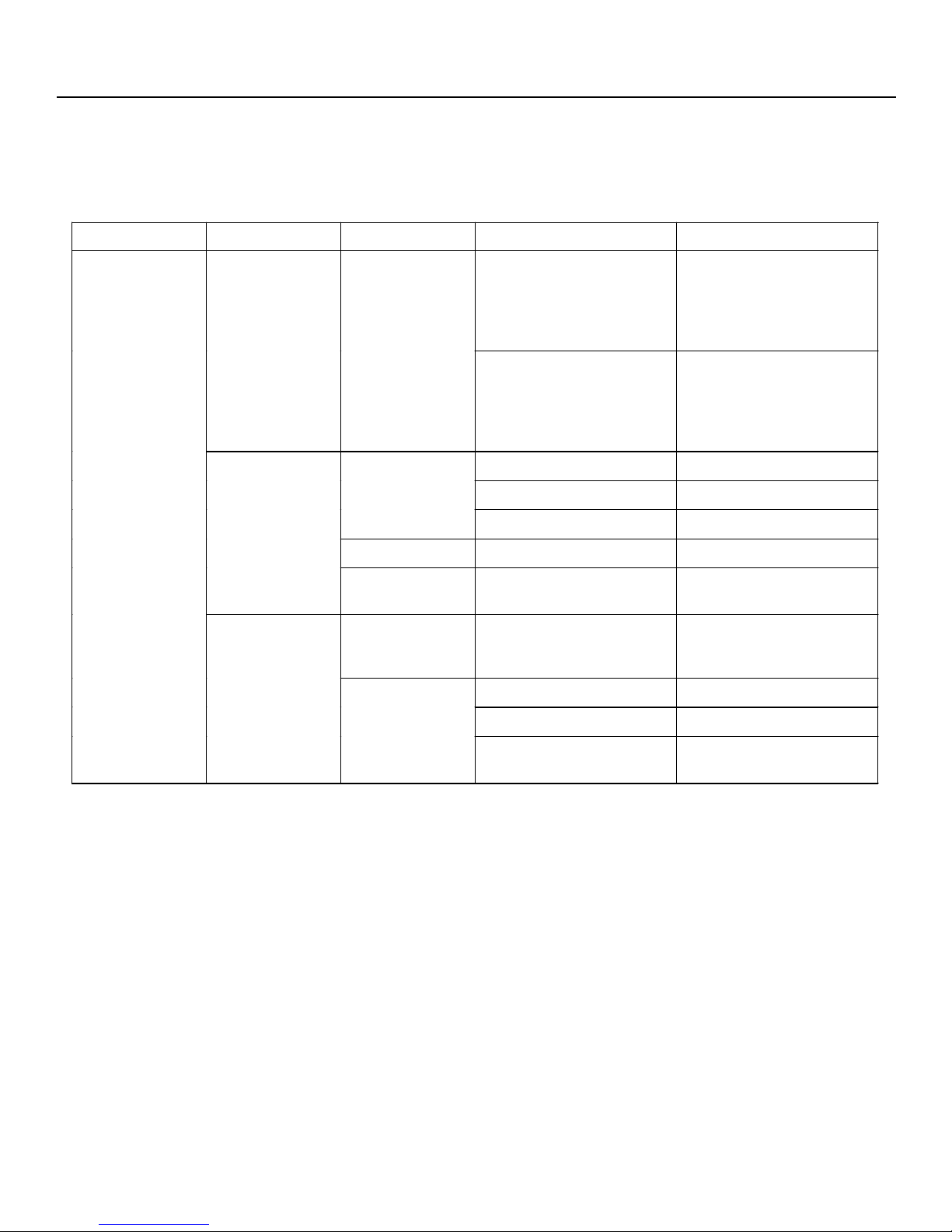

VII. FAILURE DIAGNOSIS

CAUSES & TREATMENT OF REFRIGERATOR FAILURES

Phenomenon Failure Condition Inspection Part Causes Treatment Actions

Operation time

being too long

Compressor fails

to control the

stop

Bigger power

consumption

Control Switch 1. Poor practice

Door Knob

Others

Control Switch 1. Inappropriate position

Electric power 1. Voltage being too high.

Others

1. Poor knob

2. Poor door clearance

1. Too much food being

stored.

2. The food stored being

too warm.

3. Door opening being too

frequent.

4. Improper storage

location.

of turn button.

1. Too much food being

stored.

2. Improper storage

location.

Replace the control

·

switch

Replace the door knob

·

Be adjusted.

·

Explanation for the

·

customer.

Explanation for the

·

customer.

Explanation for the

·

customer.

Explanation for the

·

customer.

Explanation for the

·

customer.

Explanation for the

·

customer.

Explanation for the

·

customer.

Explanation for the

·

customer.

Temperature

being too low

Control Switch

1. Inappropriate position

of turn button.

2. Poor contact between

thermo-sensing tube

and evaporator.

3. Poor practice.

Page 26

Explanation for the

·

customer.

Be adjusted.

·

Replace the control

·

switch.

VII. FAILURE DIAGNOSIS

CAUSES & TREATMENT OF REFRIGERATOR FAILURES

Phenomenon Failure Condition Inspection Part Causes Treatment Actions

The refrigerator

being operated

but not cold.

Not cold at all Freezing System

Not cold even

after longer time

of operation

Freezing system

Door knob

Evaporator 1. Too thick of frost

Control Switch 1. Inappropriate position

1. Freon leakage.

2. Clogged by dusts and

moisture.

3. Defective pressure

exhaustion.

1. Insufficient freon

2. Clogged by dusts and

oil

3. Poor discharge

1. Poor clearance of door

knob

2. Defective door knob

of the turn button.

Replace / Repair the

·

freezing system

Replace / Repair the

·

freezing system

Replace / Repair the

·

freezing system

Replace / repair the

·

freezing system

Replace / repair the

·

freezing system

Replace / repair the

·

freezing system

Be adjusted.

·

Replace the door

·

knob.

Explanation for the

·

customer.

Explanation for the

·

customer.

Motor of the fan 1. Fails to turn.

Condenser 1. Being dirty or poorly

ventilated.

Others

1. Too much food being

stored.

2. Door opening being too

frequent.

3. Improper storage

location.

Page 27

Defrost switch, door

·

opening and wiring be

Inspected.

Explanation for the

·

customer.

Explanation for the

·

customer.

Explanation for the

·

customer.

Explanation for the

·

customer.

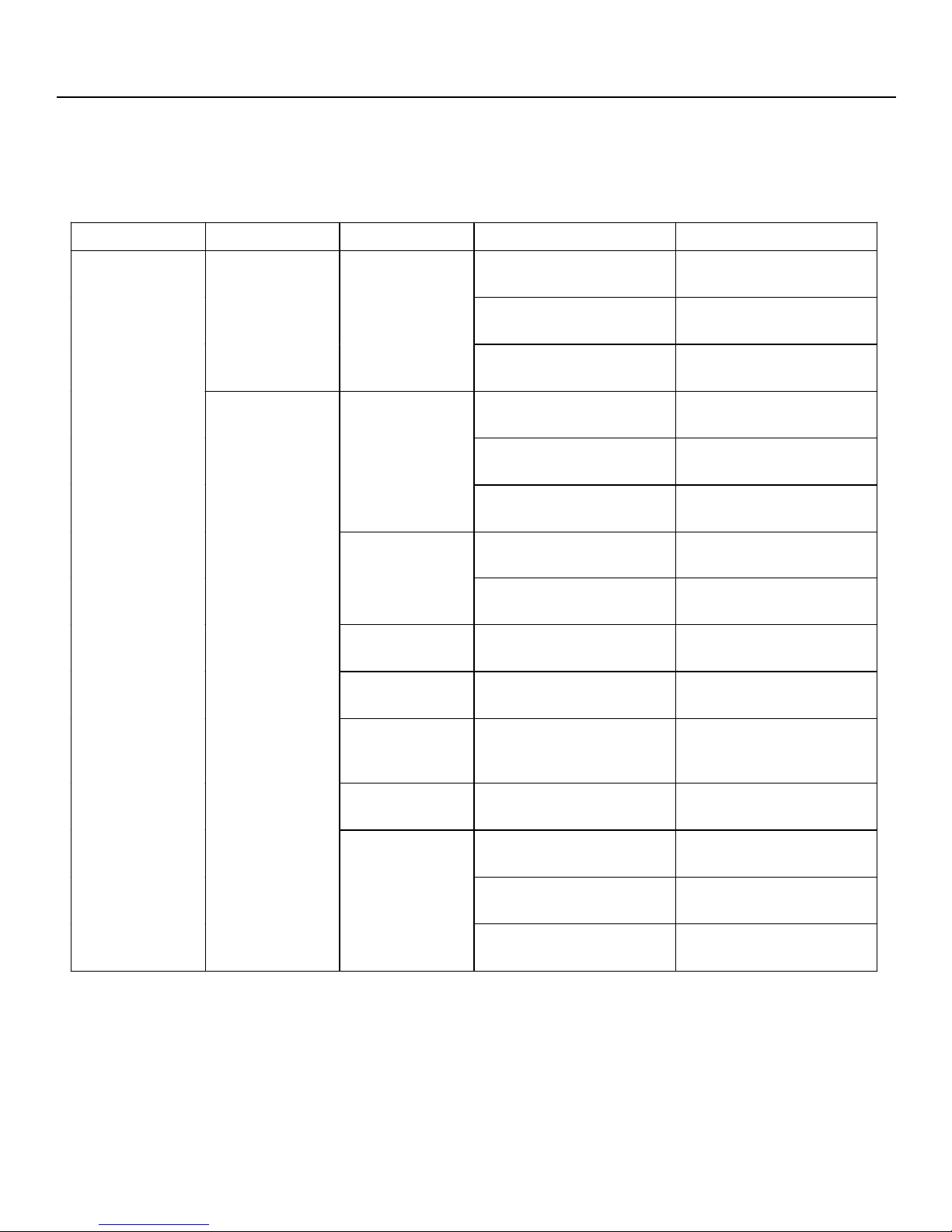

VII. FAILURE DIAGNOSIS

CAUSES & TREATMENT OF REFRIGERATOR FAILURES

Phenomenon Failure Condition Inspection Part Causes Treatment Actions

Noise

Louder noise

during the

operation and at

start, stop

Vibration during

start, stop and

operation (noise

heard from the

stored food and

from the articles

on the board)

Compressor

Contacting

vibration of each

part.

Noise from the

evaporating tray

Installation

Tubing

Compressor 1. Screw locking being

1. Being unusual inside.

2. Poor installation.

3. Voltage being too low

(below 90V).

4. Contacting noise

1. Poor installation and

fixed contact.

1. Inappropriate position

of the evaporating tray.

2. Poor flatness of base.

1. Poor leg regulating.

2. The floor being to

weak.

1. Tubing contact.

2. Poor shock absorption

of the tubing.

too tight.

Replace the

·

compressor.

Be adjusted.

·

Explanation for the

·

customer.

Be adjusted.

·

Be adjusted.

·

Explanation for the

·

customer.

Be adjusted.

·

Be adjusted.

·

Explanation for the

·

customer.

Be adjusted.

·

Be adjusted.

·

Be adjusted.

·

Page 28

VII. FAILURE DIAGNOSIS

CAUSES & TREATMENT OF REFRIGERATOR FAILURES

Phenomenon Failure Condition Inspection Part Causes Treatment Actions

Sweating

Sweating at the

outer surface

Overflow or

leakage or

internal sweating

Insulator

Anti-mist electric

heater.

Others

Door

Drainage device

being clogged

1. Poor mounting method.

2. Poor heat-insulating of

the tubing.

3. Wet insulator.

1. Broken wires.

2. Poor wiring.

1. Humidity being very

high.

2. Being stored highly

humidified place.

3. Incorrect using method

4. Poor generator being

installed

1. Poor clearance of door

sealing gasket.

2. Loosen door opening

1. Poorly sealed drainage

valve.

Accurate installation.

·

Add more insulator.

·

Replace the insulator.

·

Replace the anti-mist

·

electric heater.

Inspection & repairs.

·

Explanation for the

·

customer.

Explanation for the

·

customer.

Explanation for the

·

customer.

Improve the

·

installation and

replenish the

insulation.

Replace the door

·

sealing gasket.

Be adjusted.

·

Be adjusted.

·

Poor method

being used

Dripping tray

being unable to

sustain the

frosted water.

2. Clogged drainage tube.

1. Moisturized food being

unwrapped.

2. Frequent opening

during summer time.

1. Inappropriate storing

location.

Page 29

Clear for draining.

·

Explanation for the

·

customer.

Explanation for the

·

customer.

Explanation for the

·

customer.

VII. FAILURE DIAGNOSIS

CAUSES & TREATMENT OF REFRIGERATOR FAILURES

Phenomenon Failure Condition Inspection Part Causes Treatment Actions

Other

Electricity

leakage

Door opening

being not

smooth

Door opening

lamp not shown

Wiring & other

electrical

appliances

Door hinges and

stop lever.

Door knob 1. Defective clearance

Internal 1. Slanted door.

Lamp switch

inside the

refrigerator.

Lamp inside the

refrigerator

1. Insulation defect.

2. Static capacity

1. Loosening fixed part

2. Poor practice

3. Wearing

1. Defective contact

1. Broken wires

2. Poor lamp holder

3. Defective wiring

Repair the defective

·

part, and provide

explanation for the

customer, or use

earthing termina.

Repair the defective

·

part, and provide

explanation for the

customer, or use

earthing termina.

Be adjusted.

·

Be adjusted.

·

Be replaced.

·

Door be adjusted.

·

Be adjusted or

·

replaced.

Be adjusted.

·

Be adjusted.

·

Be adjusted.

·

Be inspected or

·

repaired.

Page 30

VIII. MAINTENANCE OF ENVIRONMENTAL PROTECTION REFRIGERATOR

8.1 SYNOPSIS

Freon is a usable scientific substance being used

in the freezing system and heat-insulating material

of refrigerator, which is inflammable completely

without direct harm to human body. Despite its

contribution to modern civilization, however the part

being used in the cleanser, aerosol spray, and

refrigerator will destroy the ozone layer. Till the

end of 1995, the production of such kind of freon

was suspended and then it was replaced by the

one which brings lesser influence to the ozone

layer.

8.2 FEATURES AND CAUTIONS OF HFC134A SYSTEM

8.2.1 Cautions for Changing Freon (CFC-12

→→

→

HFC-134a)

→→

i. It is absolutely banned to use the

freon containing flurochloromethane

(freon), including the use of cleaning.

ii. HFC-134a cannot be used together

with the dryer using CFC-12.

Instead, it must be exclusively used

(by changing to smaller freon parties,

the drying agent will be different).

iii. If cannot be used together with the

existing leakage detector (CFC-12,

CFC-22) (because the original

leakage detector was operated by

using flurochloromethane (freon) to

detect, but not the case with HFC134a).

iv. Repairing tools exclusively for HFC-

134a must be used.

In the existing tools, rubber material

(sealing material) tends to expand with

the result of weaker tension. Please use

the special tool based on the instructions

(changes existed with the rubber sealing

material).

Page 31

VIII. MAINTENANCE OF ENVIRONMENTAL PROTECTION REFRIGERATOR

8.2.2 The Change of Compressor Oil

The original Naphten type of mineral oil

and Olefines type of syntheic oil have

now been changed to Ester oil.

i. Vacuum treatment must be

conducted within 15 minutes after

opening the sealing plastic

membrane of compressor,dryer and

capillary tube to avoid the invasion

of water.

The Ester type of oil has a stronger

water absorption power capable of

absorbing 200 ppm of saturated

moist, which is 40 times more than

the original oil.

The acid reaction will be producted

for water from the Ester oil and this

type of acid will display metallic

chloride reaction for the metal, which

tends to clog the capillary tube.

Thus, special care should be drawn

to the time duration after opening the

sealed compressor and dryer

(treatment must be conducted within

15 minutes).

ii. The tool used for HFC-134a freon

system must be exclusive and the

new parts material must be firstly

cleaned before use. The Ester used

for HFC-134a contains 10ppm 20ppm of sobubility which is lower

than the original product (the CFC12 for compressor oil, joint, pressure

gauge, anti-rust oil). When mixing

with the original oil system, the

residues will be separated from the

capillary tube that has formed the

cause of ,ist clogging. Therefore, it

is prohibited to use the current tools

(for R-12, R-22, R502); instead,

thenew and special tools for HFC134a are used together with HFC134a Ester oil as well. (For the freon

container, freon filling tank, coupling,

pressure gauge, valve, tubes,

compound pressure gauge, vacuum

pump, tube cutter, fast coupling, etc.

the mixing of the original system oil

should be avoided). In addition, the

tools for the new product must be

cleaned by Alcohol. It should be

noted that even the mixture of few

grams of oil will deteriorate the

function of the freezing system.

Page 32

iii. The use of flux is prohibited for

welding:

Water may seep into the system

when the water soluble flux is used

for welding, so it is prohibited to use.

Basically, the cooper tube and iron

tube welding will be avoided as much

as possible and if necessary, fresh

water will be used to dissolve it. To

prevent the fluochlorine of tap water

from getting into the freezing system,

the cleaning flux should be prevented

from seeping into the freezing

system.

VIII. MAINTENANCE OF ENVIRONMENTAL PROTECTION REFRIGERATOR

8.2.3 Nitrogen being used in tube welding

During the welding of tubes, the

oxidized dirt in the tubes will cause the

clogging of capillary tube. So nitrogen

must be used to blow (nitrogen welding)

the tubes during the welding.

8.2.4 Vacuum degree (enhance the

accuracy of vacuum degree)

i. Operational sequency of below

should be based for the vacuum

extraction and freon-filling.

The air in the freezing system

expecially in the case of oxygen, will

make ester become an oil-base

substance. Chemical reaction will be

developed by the oxidized oil and

metal in producing fluoride metal

which is one of the reasons of

capillary tube clogging. For this

reason, higher degree of vacuum is

required.

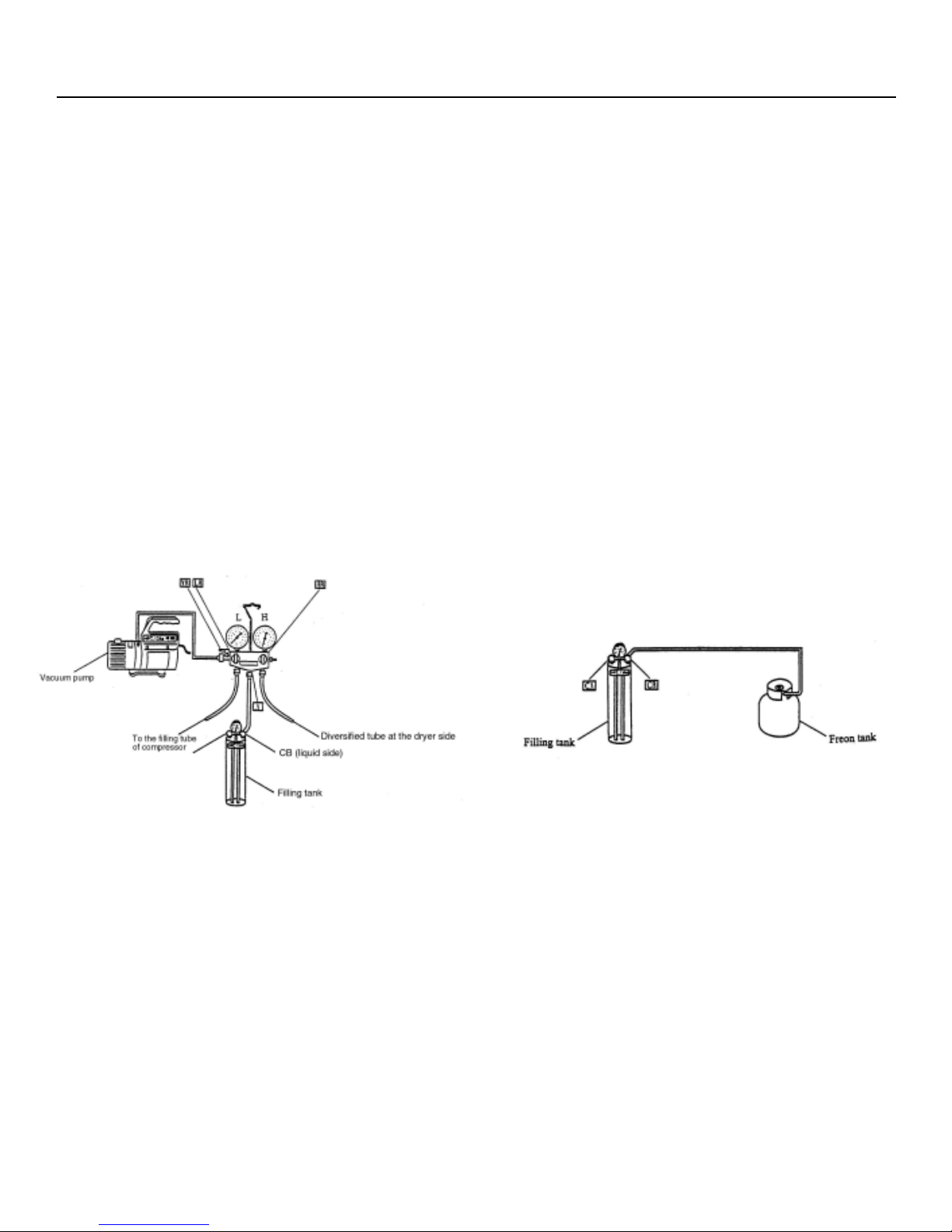

8.3 MAINTENANCE SEQUENCY FOR HFC134A FREEZING SYSTEM

8.3.1 Reactions for CRC-12

Upon repairing the freezing system,

connect the compound pressure gauge,

vacuum pump and filling tank as

indicated in the following figure. When

the repairs of HFC-134a system is

required, it is necessary to enhance the

vacuum degree and so, different the

connections will be applied (as per

figure of below).

Page 33

VIII. MAINTENANCE OF ENVIRONMENTAL PROTECTION REFRIGERATOR

8.3.2 Reactions for HRC-134a

i. Upon welding the tube, blow with

nitrogen to avoid the capillary tube

clogging by the oxidized membrane.

ii. Aiming at the improvement of

vacuum degree for the vacuum

pump of pressure gauge, install

additional valves for the equipment

using bolt to keep non-condense air

from getting in.

iii. shorten the service time as indicated

in the figure.

Operate by the tubing type as shown

on the right side figure:

1st time vacuum extracting (5 min.)

↓

Fill the freon in (50 gr)

↓

2nd time vacuum extracting (20 min.)

↓

Fill the freon in (reqd amount)

iv. The tool cannot be used together

with the existing CFC-12. So the tool

must be re-ordered to avoid incorrect

use. Eact connectng part will be

changed from 1/4 inch to 3/8 inch.

Note :

The tool used for HFC-134a

System must be exclusive,

such as the fast coupling,

vacuum pump, guide tube of

pressure gauge, valve, etc.

Use alcohol to clean the new

parts and the use of oil is

prohibited.

Compressor

The dryer must be specially

used for HFC-134a and the

process from unpacking to

welding and vacuum

extracting must be completed

within 15 minutes.

Cautions in case of freon

leakage of the freezing

system:

a. In case of freon leakage,

the entire set of

compressor and dryer

must be replaced.

b. The lower pressure side

and the higher pressure

side at the freon leakage

must be completed

exchanged.

Page 34

VIII. MAINTENANCE OF ENVIRONMENTAL PROTECTION REFRIGERATOR

c. Sequence of nitrogen

welding

- Remove the

compressor and dryer.

- Secure the compressor

on the base board.

- Connect all other tubing

in addition to the

connection part of dryer

and capillary tube.

- Connect the nitrogen

tank to the filling tank of

compressor at the

pressure of 80 x 104pa

(approx. 8KG / cm2)

and fill in the nitrogen

for 3-5 seconds (as

indicated in the figure).

- Weld all other tubing in

addition to the

connection part of dryer

and capillary tube.

d. In case of leakage, wipe

out the soap water being

applied on the leakage and

reduce the nitrogen

pressure to prevent water

from getting into the piping.

Note :

If the concurrent

welding of all the tubing

is impossible, then fill

the nitrogen in the lower

and higher pressure

sides respectively. For

the flowing direction,

please refer to Fig. 2 &

3.

The cleansing flux

cannot be used for the

welding to avoid water

getting into the freezing

ystem and causing

defective result.

- Weld the tubing

connected to the dryer

and capillary tube.

- Engage the filling tank

of compressor with the

nitrogen tank at the

pressure of 100 x 104pa

(approx. 10KG / cm2)

and then use soap

water to test any

leakage.

(Note) Various shapes of tubes guided from the

compressor

Page 35

VIII. MAINTENANCE OF ENVIRONMENTAL PROTECTION REFRIGERATOR

* Nitrogen circulation at the high pressure side

Circulation of bottom side and internal heat dissipaters.

* Nitrogen circulation at the lower pressure side

Circulation of bottom side and internal heat dissipaters.

Fig. 2

Blow nitrogen at the suction tube and dryer.

- Blow nitrogen from the suction tube

Blow nitrogen at the compressor and filler tube.

- Blow nitrogen from the filling tube of compressor

- Blow nitrogen from the cooling tube of compressor

Fig. 3

Page 36

VIII. MAINTENANCE OF ENVIRONMENTAL PROTECTION REFRIGERATOR

8.4 SEQUENCE OF EXTRACTING VACUUM

AND FILLING NITROGEN

8.4.1 Vacuum Extraction

¬ Vacuum extraction (5 min.) Õ freon

filling (50 g) Õ ® Vacuum extraction (20

min) Õ ¯ freon filling (presumed

amount). No reverse flow of the

vacuum pump oil. The power of

vacuum pump cannot be switched off

until the operation of the aforesaid ¬ - ®

is completed (continuous vacuum

extraction without pause).

Please operate by the following

sequence

(Compound Pressure Gauge Specially

Used For HFC-134a)

Each valve means the operational

sequence

l Means the closed condition of valve

m Means the opened condition of valve

G Preparations

i. Fill the freon in the freon filling tank

(Note) The air in the freon filling

tank and the connecting tube must

be discharged.

(The required filling amount + 50g +

α)

ii. By the connection method shown on

the right side figure, close all the

valves.

iii. Connect the compressor to the

starter and the overload protector,

making it operable.

Sequence of Valve Operation

Page 37

VIII. MAINTENANCE OF ENVIRONMENTAL PROTECTION REFRIGERATOR

8.4.2 Operational Sequence

i. Vacuum pump starts to operate (to

be stopped until finishing the vacuum

extraction till to Point 13).

ii. Open VB valve first and then open

LB, HB valves.

iii. Vacuum extraction (5 minutes)

iv. After extracting vacuum for 5

minutes, close HB, VB valves and

leave LB valve open.

vi. Close both CB and LB valves

vii. Loosen the nut of connection point

A to discharge the air. Confirm the

balance of high, low pressures.

v. Open CB valve and let 50g of freon

enter the freezing system from LB

side, the low pressure gauge be kept

at 3~4 kgf/cm2 of pressure at this

time.

viii. Open HB valve to discharge the air

until the high pressure gauge

reaches 1.0 kgf/cm2G, then close HB

valve at this time.

Page 38

VIII. MAINTENANCE OF ENVIRONMENTAL PROTECTION REFRIGERATOR

ix. Open LB valve to discharge the air

until the high pressure gauge

reaches 1.0 kgf / cm2G.

- In operating (viii) & (ix), be

sure to discharge the freon

from the system and at this

time, do not allow the air get

into the system. The pressure

must not be lower than 1.0

kgf/cm2G.

Close the valve at pressure 1.0 kgf/cm2G

x. Lock the nut of connection point A

indicated in (vii).

xi. Open VB valve of the vacuum pump

and then open LB and HB valves

slowly to extract vacuum in the

system (easing the load of vacuum

pump).

xii. Vacuum extraction for 20 minutes till

the valve becomes the condition of

Fig. (xi).

xiii After the vacuum extraction, close all

the valves.

- Open CB valve slightly to

discharge the freon, then

close the purge in the tube.

xiv. Identify the graduation of the filling

tube.

xv. Open LB valve and seal the required

amount of freon through BC valve.

- Seal the required amount of

freon through CB valve and

then adjust by the graduation

of the filling tube.

Page 39

VIII. MAINTENANCE OF ENVIRONMENTAL PROTECTION REFRIGERATOR

xvi. The condition of valve after sealing

the freon (only LV valve is left open)

xvii. The high pressure gauge should be

over 1.0 kgf/cm2G and then use the

sealing wrench to seal the filling tube

from this end. Then remove the

compound pressure gauge and seal

the front end of the filling tube.

- When sealing the filling tube

at pressure below 1.0 kgf/

cm2G, the air may be sucked

in.

xxi. Seal the filling tube at the low

pressure side and remove the

compound pressure gauge, then

seal the filling tube.

- Confirm the pressure be over

1.0 kgf/cm2G

xx. After running the compressor,

confirm the coldness.

- Confirm the temperature raise

of discharge tube and back

side heat dissipater).

xviii. Run the refrigerator compressor and

push the freon of the filling tube and

compound pressure gauge into the

system.

- When the low pressure gauge

is pointing at 1.0 kgf/cm2G,

close LB valve to stop the

compressor.

Note :

HFC-134a of the aforesaid operation

aims to reach high degree of vacuum

and prevent the reverse flow of

vacuum pump oil into the system.

The repairing tools used for the

service of aforesaid HFC-134a must

be exclusive, and it is prohibited to

substitute with the repairing tools

used for the original CFC-12 service.

Page 40

IX. WIRING DIAGRAM

TBG440ANDR / TBQ440ANDR / TBR427ANDR / TMQ432ANDR

Page 41

IX. WIRING DIAGRAM

TBG470ANDR / TBQ470ANDR / TBR463ANDR

Page 42

IX. WIRING DIAGRAM

TBG530ANDR / TBQ530ANDR / TBR527ANDR

Page 43

IX. WIRING DIAGRAM

TBG570ANDR / TBQ570ANDR / TBR565ANDR

Page 44

TBG440ANDR / TBQ440ANDR

X. PARTS LIST AND EXPLODED VIEW

Page 45

TBG440ANDR / TBQ440ANDR

X. PARTS LIST AND EXPLODED VIEW

Page 46

TBG440ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

1 13LHLD-0227K2FS-- DRAIN CONNECTOR E 1

1 13LHLD-0227K2FS-- DRAIN CONNECTOR Q 1

3 * 41FEVA-0324K2K0-2 EVA ASS'Y 1

4 87LHLD-0235K2P0-1 DEFROST HEATER SUPPORT 1

5 77LHLD-0445K2P0-- DEFROST HEATER COVER 1

6 * 20RHET-0183K2E0-- DEODER DEFROST HEATER 1

7 84DCAB-0589K2KQ-- CABINET ASS'Y E 1

7 20DCAB-0589K2KY-- CABINET ASS'Y Q 1

8 * 78DDOR-0585K2KQ-- R DOOR PU ASS'Y E 1

8 * 14DDOR-0585K2KY-- R DOOR PU ASSY Q 1

9 * 25DDOR-0583K2KQ-- F DOOR PU ASSY E 1

9 * 50DDOR-0583K2KY-- F DOOR PU ASSY Q 1

10 39FHNG-0017K2M0-- BOTTOM HINGE ASS'Y 1

11 89GCOVH0056K2FS-- R CONTROL BOX E 1

QTY

11 89GCOVH0056K2FS-- R CONTROL BOX Q 1

12 02MSPR-0119K2E0-- KNOB SPRING 2

13 * 25NSTNP0052K2KQ-- BADGE E 1

13 * 25NSTNP0052K2KQ-- BADGE Q 1

14 24JKNB-0082K2FS-- F KNOB E 2

14 24JKNB-0082K2FS-- F KNOB Q 2

15 33LHLD-0204K2FS-- MEAT CASE HOLDER E 3

15 33LHLD-0204K2FS-- MEAT CASE HOLDER Q 3

16 73LPIN-0053K2FS-- STOPPER PIN E 2

16 73LPIN-0053K2FS-- STOPPER PIN Q 2

17 78LPLTM0811K2F0-- DRYER CLAMPER 1

18 49LPLTP0176K2FS-- DRAIN HOLE COVER E 1

18 49LPLTP0176K2FS-- DRAIN HOLE COVER Q 1

19 51LX-XZ0064K2E0-- FIX SCREW 5

20 84MHNG-0002K2M0-- TOP HINGE 1

Page 47

TBG440ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

21 16MHNG-0055K2M0-- CENTER HINGE 1

22 * 11PAJS-0002K2FD-- ADJ. LEG E 2

22 * 11PAJS-0002K2FD-- ADJ. LEG Q 2

23 14PCOV-0002K2FQ-1 TOP HINGE COVER E 1

23 39PCOV-0002K2FY-1 TOP HINGE COVER Q 1

24 01PCOV-0118K2FA-- LAMP COVER E 1

24 01PCOV-0118K2FA-- LAMP COVER Q 1

25 15PCOV-0155K2FS-- EV SCREW COVER E 2

25 15PCOV-0155K2FS-- EV SCREW COVER Q 2

26 04PCOV-0580K2FS-- F LOUVER E 1

26 04PCOV-0580K2FS-- F LOUVER Q 1

27 * 73PDRY-0046K2E0-2 DRYER 1

28 50PPIPC0003K2E0-1 CHARGE PIPE 1

29 46PSPAP0006K2E0-1 TOP HINGE SPACER 1

32 25PSPAP0026K2E0-- BOTTOM HINGE SPACER 2

QTY

33 86PSPAP0030K2E0-1 CENTER HINGE SPACER 2

34 16QACC-1121K2E0-- POWER CORD 1

35 * 37QSW-P0105K2E0-- DOOR SWITCH 1

36 53PCOV-0220K2F0-- WRING COVER 1

37 11PCOV-0106K2F0-- ELECTRIC BOX 1

32 82QW-VZ0855K2E0-- DOOR SWITCH WIRING 1

38 * 19FCAG-0191K2F0-- DOOR RACKS 5

39 * 01FCAG-0192K2FS-- BOTTLE STORAGE RACKS E 1

39 * 01FCAG-0192K2FS-- BOTTLE STORAGE RACKS Q 1

40 * 67FPAN-0052K2ES-- ICE CUBE ASS'Y E 1

40 * 67FPAN-0052K2ES-- ICE CUBE ASS'Y Q 1

Page 48

TBG440ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

41 22LFRM-0087K2FS-1 ICE SLIDER E 1

41 22LFRM-0087K2FS-1 ICE SLIDER Q 1

43 * 32UCOVP0077K2F0-1 CHILL ROOM COVER 1

44 * 35UPAN-0071K2F0-- F TRANSPARENT SHELF 1

45 * 88UPAN-0073K2F0-- CHILL ROOM 1

46 * 70UPAN-0074K2F0-- F TRANSPARENT SHELF SM 1

47 * 10UPAN-0079K2K0-- R TRANSPARENT SHELF 2

48 * 39URCV-0075K2F0-- ICE STORAGE BOX 1

49 * 43URCV-0112K2F0-- VEGETABLE CRISPER 1

50 15USRA-0014K2FQ-2 EVAPORATION PAN E 1

50 40USRA-0014K2FY-2 EVAPORATION PAN Q 1

51 06UTNA-0018K2FA-- EGG STORAGE BUCKET E 2

51 06UTNA-0018K2FA-- EGG STORAGE BUCKET Q 2

52 45HDECQ0463K21S-- GLASS TRIM E 1

52 45HDECQ0463K21S-- GLASS TRIM Q 1

QTY

53 * 35UTNA-0170K210-- GLASS PANEL 1

54 37HGRL-0014K2F0-- COMPRESSOR COVER 1

61TINSC1967K2R0-1 USER MANUAL 1

73SPAKC3693K2R0-- BOX CARTON 1

58 66FCONS0102K2S0-- SUB CONDENSER ASS'Y 1

59 41LFRM-0114K2P0-1 CHASSIS 1

Page 49

TBG440ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

61 * 22PCMPL0145K2K0-1 COMPRESSOR ASS'Y 1

62 50PPIPC0003K2E0-1 CHARGE PIPE 1

63 56LHLD-0261K2P0-- MOTOR FIXED LARGE 1

64 20LHLD-0263K2P0-- MOTOR FIXED SMALL 1

65 20MSPR-0118K2E0-- FAN SPRING 1

66 14NFANP0066K2F0-- FAN 1

67 * 30FMOTR0070K2E0-- FAN MOTOR 1

68 87LHLD-0232K2F0-- MOTOR FIXING RUBBER 2

69 32HPNL-0463K2RS-- DECORATION PANEL E 1

69 32HPNL-0463K2RS-- DECORATION PANEL Q 1

70 79PCOV-0147K2FS-3 MULTI AIR LOUVER E 1

70 79PCOV-0147K2FS-3 MULTI AIR LOUVER Q 1

71 45PGID-0054K2F0-- MULTI AIR GUIDE 1

72 * 45RLMP-0034K2E0-- LAMP 1

73 46QW-VZ0857K2E0-- LAMP HOLDER WIRING 1

QTY

74 * 01QSOC-0065K2E0-- LAMP HOLDER 1

75 51LHLD-0203K2FS-- B-THM SUPPORT E 1

75 51LHLD-0203K2FS-- B-THM SUPPORT Q 1

76 60PGID-0049K2F0-- R AIR GUIDE TOP 1

77 31PGID-0050K2F0-- R AIR GUIDE B 1

78 76PSEL-0221K2E0-- R KNOB SEALER 1

79 20PSEL-0397K2E0-- SEALER 1

80 62PSEL-0746K2E0-- R AIR GUIDE SEALER 1

Page 50

TBG440ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

81 65RTHM-0171K2E0-- DAMPER THERMISTOR 1

82 87LSTP-0019K2FB-1 F DOOR STOPPER Q 1

82 45LSTP-0019K2FQ-1 F DOOR STOPPER E 1

83 35PPACG0336K2EB-- F DOOR PACKING Q 1

83 82PPACG0336K2EQ-- F DOOR PACKING E 1

84 29GLIN-0356K2P0-- R DOOR LINER 1

85 01LPLTM0716K2P0-- R DOOR STOPPER PLATE 1

86 53LSTP-0011K2FB-1 R DOOR STOPPER Q 1

86 11LSTP-0011K2FQ-1 R DOOR STOPPER E 1

87 88PPACG0338K2EB-- R DOOR PACKING Q 1

87 46PPACG0338K2EQ-- R DOOR PACKING E 1

88 48LBND-0012K2E0-- D BAND 3

89 87LHLD-0232K2F0-- MOTOR FIXING RUBBER 2

90 04LHLD-0250K2P0-- MOTOR HOLDER 1

91 23PCOV-0199K2FS-1 EVAPORATOR COVER E 1

QTY

91 23PCOV-0199K2FS-1 EVAPORATOR COVER Q 1

93 43PSEL-0702K2E0-- EV COVER SEALER 1

94 58PSEL-0728K2E0-- EV COVER HOLE SEALER 1

95 41QW-VZ0733K2E0-1 F-THM WIRING 1

96 47QW-VZ0779K2E0-1 MOTOR WIRING 1

97 * 10RTHM-0179K2E0-- F-THM 1

98 * 70RTHM-0180K2E0-- D-THM ASS'Y 2

100 14QW-VZ0877K2E0-- COMP.WIRING 1

Page 51

TBG440ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

101 * 87RSTT-0058K2E0-- STARTING RELAY 1

102 * 78QSWTD0066K2E0-- DEFROST TIMER 1

103 50QW-VZ0754K2E0-2 DEFROST TIMER WIRING 1

104 * 21RGAD-0151K2E0-- OVERLOAD RELAY 1

105 * 09FMOTR0071K2E0-- FAN MOTOR 1

106 20MSPR-0118K2E0-- FAN SPRING 1

107 03NFANP0028K2FE-- FAN E 1

107 03NFANP0028K2FE-- FAN Q 1

108 44GLIN-0413K2P0-- F DOOR LINER 1

QTY

Remarks :

i. MOD COL (Model Color) : E (Black) / Q (Silver)

ii. * Recommended Spare Parts Inventory

Page 52

TBQ440ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

1 13LHLD-0227K2FS-- DRAIN CONNECTOR E 1

1 13LHLD-0227K2FS-- DRAIN CONNECTOR Q 1

3 * 41FEVA-0324K2K0-2 EVA ASS'Y 1

4 87LHLD-0235K2P0-1 DEFROST HEATER

SUPPORT

5 77LHLD-0445K2P0-- DEFROST HEATER COVER 1

6 * 20RHET-0183K2E0-- DEODER DEFROST

HEATER

7 84DCAB-0589K2KQ-- CABINET ASS'Y E 1

7 20DCAB-0589K2KY-- CABINET ASS'Y Q 1

8 * 78DDOR-0585K2KQ-- R DOOR PU ASSY E 1

8 * 14DDOR-0585K2KY-- R DOOR PU ASSY Q 1

9 * 25DDOR-0583K2KQ-- F DOOR PU ASS'Y E 1

9 * 50DDOR-0583K2KY-- F DOOR PU ASS'Y Q 1

10 39FHNG-0017K2M0-- BOTTOM HINGE ASS'Y 1

QTY

1

1

11 89GCOVH0056K2FS-- R CONTROL BOX E 1

11 89GCOVH0056K2FS-- R CONTROL BOX Q 1

12 02MSPR-0119K2E0-- KNOB SPRING 2

13 * 25NSTNP0052K2KQ-- BADGE E 1

13 * 25NSTNP0052K2KQ-- BADGE Q 1

14 24JKNB-0082K2FS-- F KNOB E 2

14 24JKNB-0082K2FS-- F KNOB Q 2

15 33LHLD-0204K2FS-- MEAT CASE HOLDER E 3

15 33LHLD-0204K2FS-- MEAT CASE HOLDER Q 3

16 73LPIN-0053K2FS-- STOPPER PIN E 2

16 73LPIN-0053K2FS-- STOPPER PIN Q 2

17 78LPLTM0811K2F0-- DRYER CLAMPER 1

18 49LPLTP0176K2FS-- DRAIN HOLE COVER E 1

18 49LPLTP0176K2FS-- DRAIN HOLE COVER Q 1

19 * 51LX-XZ0064K2E0-- FIX SCREW 5

20 84MHNG-0002K2M0-- TOP HINGE 1

Page 53

TBQ440ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

QTY

COL

21 16MHNG-0055K2M0-- CENTER HINGE 1

22 * 11PAJS-0002K2FD-- ADJ. LEG E 2

22 * 11PAJS-0002K2FD-- ADJ. LEG Q 2

23 14PCOV-0002K2FQ-1 TOP HINGE COVER E 1

23 39PCOV-0002K2FY-1 TOP HINGE COVER Q 1

24 01PCOV-0118K2FA-- LAMP COVER E 1

24 01PCOV-0118K2FA-- LAMP COVER Q 1

25 15PCOV-0155K2FS-- EV SCREW COVER E 2

25 15PCOV-0155K2FS-- EV SCREW COVER Q 2

26 04PCOV-0580K2FS-- F LOUVER E 1

26 04PCOV-0580K2FS-- F LOUVER Q 1

27 * 73PDRY-0046K2E0-2 DRYER 1

28 50PPIPC0003K2E0-1 CHARGE PIPE 1

29 46PSPAP0006K2E0-1 TOP HINGE SPACER 1

32 25PSPAP0026K2E0-- BOTTOM HINGE SPACER 2

33 86PSPAP0030K2E0-1 CENTER HINGE SPACER 2

34 34QACC-1139K2E0-- POWER PLUG 1

35 * 37QSW-P0105K2E0-- DOOR SWITCH 1

36 53PCOV-0220K2F0-- WRING COVER 1

37 11PCOV-0106K2F0-- ELECTRIC BOX 1

38 * 19FCAG-0191K2F0-- DOOR RACKS 5

39 * 01FCAG-0192K2FS-- BOTTLE STORAGE RACKS E 1

39 * 01FCAG-0192K2FS-- BOTTLE STORAGE RACKS Q 1

40 * 67FPAN-0052K2ES-- ICE CUBE ASS'Y E 1

40 * 67FPAN-0052K2ES-- ICE CUBE ASS'Y Q 1

Page 54

TBQ440ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

41 22LFRM-0087K2FS-1 ICE SLIDER E 1

41 22LFRM-0087K2FS-1 ICE SLIDER Q 1

43 * 32UCOVP0077K2F0-1 CHILL ROOM COVER 1

44 * 35UPAN-0071K2F0-- F TRANSPARENT SHELF 1

45 * 88UPAN-0073K2F0-- CHILL ROOM 1

46 * 70UPAN-0074K2F0-- F TRANSPARENT SHELF

SM

47 * 10UPAN-0079K2K0-- R TRANSPARENT SHELF 2

48 * 39URCV-0075K2F0-- ICE STORAGE BOX 1

49 * 43URCV-0112K2F0-- VEGETABLE CRISPER 1

50 15USRA-0014K2FQ-2 EVAPORATION PAN E 1

50 40USRA-0014K2FY-2 EVAPORATION PAN Q 1

51 06UTNA-0018K2FA-- EGG STORAGE BUCKET E 2

51 06UTNA-0018K2FA-- EGG STORAGE BUCKET Q 2

52 45HDECQ0463K21S-- GLASS TRIM E 1

QTY

1

52 45HDECQ0463K21S-- GLASS TRIM Q 1

53 * 35UTNA-0170K210-- GLASS PANEL 1

54 37HGRL-0014K2F0-- COMPRESSOR COVER 1

61TINSC1967K2R0-1 USER MANUAL 1

73SPAKC3693K2R0-- BOX CARTON 1

58 66FCONS0102K2S0-- SUB CONDENSER ASS'Y 1

59 41LFRM-0114K2P0-1 CHASSIS 1

Page 55

TBQ440ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

61 * 22PCMPL0145K2K0-1 COMPRESSOR ASSY 1

62 50PPIPC0003K2E0-1 CHARGE PIPE 1

63 56LHLD-0261K2P0-- MOTOR FIXED LARGE 1

64 20LHLD-0263K2P0-- MOTOR FIXED SMALL 1

65 20MSPR-0118K2E0-- FAN SPRING 1

66 14NFANP0066K2F0-- FAN 1

67 * 30FMOTR0070K2E0-- FAN MOTOR 1

68 87LHLD-0232K2F0-- MOTOR FIXING RUBBER 2

69 32HPNL-0463K2RS-- DECORATION PANEL E 1

69 32HPNL-0463K2RS-- DECORATION PANEL Q 1

70 79PCOV-0147K2FS-3 MULTI AIR LOUVER E 1

70 79PCOV-0147K2FS-3 MULTI AIR LOUVER Q 1

71 45PGID-0054K2F0-- MULTI AIR GUIDE 1

72 * 45RLMP-0034K2E0-- LAMP 1

73 46QW-VZ0857K2E0-- LAMP HOLDER WIRING 1

QTY

74 * 01QSOC-0065K2E0-- LAMP HOLDER 1

75 51LHLD-0203K2FS-- B-THM SUPPORT E 1

75 51LHLD-0203K2FS-- B-THM SUPPORT Q 1

76 60PGID-0049K2F0-- R AIR GUIDE TOP 1

77 31PGID-0050K2F0-- R AIR GUIDE B 1

78 76PSEL-0221K2E0-- R KNOB SEALER 1

79 20PSEL-0397K2E0-- SEALER 1

80 62PSEL-0746K2E0-- R AIR GUIDE SEALER 1

Page 56

TBQ440ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

81 65RTHM-0171K2E0-- DAMPER THERMISTOR 1

82 87LSTP-0019K2FB-1 F DOOR STOPPER Q 1

82 45LSTP-0019K2FQ-1 F DOOR STOPPER E 1

83 35PPACG0336K2EB-- F DOOR PACKING Q 1

83 82PPACG0336K2EQ-- F DOOR PACKING E 1

84 29GLIN-0356K2P0-- R DOOR LINER 1

85 01LPLTM0716K2P0-- R DOOR STOPPER PLATE 1

86 53LSTP-0011K2FB-1 R DOOR STOPPER Q 1

86 11LSTP-0011K2FQ-1 R DOOR STOPPER E 1

87 88PPACG0338K2EB-- R DOOR PACKING Q 1

87 46PPACG0338K2EQ-- R DOOR PACKING E 1

88 48LBND-0012K2E0-- D BAND 3

89 87LHLD-0232K2F0-- MOTOR FIXING RUBBER 2

90 04LHLD-0250K2P0-- MOTOR HOLDER 1

91 23PCOV-0199K2FS-1 EVAPORATOR COVER E 1

QTY

91 23PCOV-0199K2FS-1 EVAPORATOR COVER Q 1

93 43PSEL-0702K2E0-- EV COVER SEALER 1

94 58PSEL-0728K2E0-- EV COVER HOLE SEALER 1

95 41QW-VZ0733K2E0-1 F-THM WIRING 1

96 47QW-VZ0779K2E0-1 MOTOR WIRING 1

97 * 10RTHM-0179K2E0-- F-THM 1

98 * 70RTHM-0180K2E0-- D-THM ASSY 2

100 14QW-VZ0877K2E0-- COMP WIRING

Page 57

TBQ440ANDR

p

y

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

101 * 87RSTT-0058K2E0-- STARTING RELAY 1

102 * 78QSWTD0066K2E0-- DEFROST TIMER 1

103 * 50QW-VZ0754K2E0-2 DEFROST TIMER WIRING 1

104 * 21RGAD-0151K2E0-- OVERLOAD REAY 1

105 09FMOTR0071K2E0-- FAN MOTOR 1

106 20MSPR-0118K2E0-- FAN SPRING 1

107 03NFANP0028K2FE-- FAN E 1

107 03NFANP0028K2FE-- FAN Q 1

108 44GLIN-0413K2P0-- F DOOR LINER 1

Remarks :

i. MOD COL (Model Color) : E (Black) / Q (Silver)

ii. * Recommended S

are Parts Inventor

QTY

Page 58

TBG470ANDR

X. PARTS LIST AND EXPLODED VIEW

Page 59

TBG470ANDR

X. PARTS LIST AND EXPLODED VIEW

Page 60

TBG470ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

1 13LHLD-0227K2FS-- DRAIN CONNECTOR E 1

1 13LHLD-0227K2FS-- DRAIN CONNECTOR Q 1

2 14NBRGP0003K2F0-1 HINGE BOSS 1

3 * 41FEVA-0324K2K0-2 EVA ASS'Y 1

4 87LHLD-0235K2P0-1 DEFROST HEATER

SUPPORT

5 77LHLD-0445K2P0-- DEFROST HEATER COVER 1

6 * 20RHET-0183K2E0-- DEODER DEFROST

HEATER

7 13DCAB-0588K2KQ-- CABINET ASS'Y 1

7 38DCAB-0588K2KY-- CABINET ASS'Y 1

8 * 42DDOR-0587K2KQ-- R DOOR PU ASS'Y E 1

8 * 67DDOR-0587K2KY-- R DOOR PU ASSY Q 1

9 * 25DDOR-0583K2KQ-- F DOOR PU ASS'Y E 1

9 * 50DDOR-0583K2KY-- F DOOR PU ASSY Q 1

QTY

1

1

10 39FHNG-0017K2M0-- BOTTOM HINGE ASS'Y 1

11 89GCOVH0056K2FS-- R CONTROL BOX E 1

11 89GCOVH0056K2FS-- R CONTROL BOX Q 1

12 02MSPR-0119K2E0-- KNOB SPRING 2

13 * 60NSTNP0052K2KQ-- BADGE E 1

13 * 60NSTNP0052K2KQ-- BADGE Q 1

14 24JKNB-0082K2FS-- F KNOB E 2

14 24JKNB-0082K2FS-- F KNOB Q 2

15 33LHLD-0204K2FS-- MEAT CASE HOLDER E 3

15 33LHLD-0204K2FS-- MEAT CASE HOLDER Q 3

16 73LPIN-0053K2FS-- STOPPER PIN E 2

16 73LPIN-0053K2FS-- STOPPER PIN Q 2

17 78LPLTM0811K2F0-- DRYER CLAMPER 1

18 49LPLTP0176K2FS-- DRAIN HOLE COVER E 1

18 49LPLTP0176K2FS-- DRAIN HOLE COVER Q 1

Page 61

TBG470ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

19 * 51LX-XZ0064K2E0-- FIX SCREW 5

20 84MHNG-0002K2M0-- TOP HINGE 1

21 16MHNG-0055K2M0-- CENTER HINGE 1

22 * 11PAJS-0002K2FD-- ADJ. LEG E 2

22 * 11PAJS-0002K2FD-- ADJ. LEG Q 2

23 14PCOV-0002K2FQ-1 TOP HINGE COVER E 1

23 39PCOV-0002K2FY-1 TOP HINGE COVER Q 1

24 01PCOV-0118K2FA-- LAMP COVER E 1

24 01PCOV-0118K2FA-- LAMP COVER Q 1

25 15PCOV-0155K2FS-- EV SCREW COVER E 2

25 15PCOV-0155K2FS-- EV SCREW COVER Q 2

26 04PCOV-0580K2FS-- F LOUVER E 1

26 04PCOV-0580K2FS-- F LOUVER Q 1

27 * 73PDRY-0046K2E0-2 DRYER 1

28 * 50PPIPC0003K2E0-1 CHARGE PIPE 1

QTY

29 46PSPAP0006K2E0-1 TOP HINGE SPACER 1

31 25PSPAP0026K2E0-- BOTTOM HINGE SPACER

1T

33 86PSPAP0030K2E0-1 CENTER HINGE SPACER 1T 2

34 16QACC-1121K2E0-- POWER CORD 1

35 * 37QSW-P0105K2E0-- DOOR SWITCH 1

36 53PCOV-0220K2F0-- WRING COVER 1

37 11PCOV-0106K2F0-- ELECTRIC BOX 1

38 * 19FCAG-0191K2F0-- DOOR RACKS 6

39 * 01FCAG-0192K2FS-- BOTTLE STORAGE RACKS E 1

39 * 01FCAG-0192K2FS-- BOTTLE STORAGE RACKS Q 1

40 * 67FPAN-0052K2ES-- ICE CUBE ASS'Y E 1

40 * 67FPAN-0052K2ES-- ICE CUBE ASS'Y Q 1

2

Page 62

TBG470ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

41 22LFRM-0087K2FS-1 ICE SLIDER E 1

41 22LFRM-0087K2FS-1 ICE SLIDER Q 1

43 * 32UCOVP0077K2F0-1 CHILL ROOM COVER 1

44 * 35UPAN-0071K2F0-- F TRANSPARENT SHELF 1

45 * 88UPAN-0073K2F0-- CHILL ROOM 1

46 * 70UPAN-0074K2F0-- F TRANSPARENT SHELF

SM

47 * 10UPAN-0079K2K0-- R TRANSPARENT SHELF 3

48 * 39URCV-0075K2F0-- ICE STORAGE BOX 1

49 * 43URCV-0112K2F0-- VEGETABLE CRISPER 1

50 15USRA-0014K2FQ-2 EVAPORATION PAN E 1

50 40USRA-0014K2FY-2 EVAPORATION PAN Q 1

51 06UTNA-0018K2FA-- EGG STORAGE BUCKET E 2

51 06UTNA-0018K2FA-- EGG STORAGE BUCKET Q 2

52 * 45HDECQ0463K21S-- GLASS TRIM E 1

QTY

1

52 45HDECQ0463K21S-- GLASS TRIM Q 1

53 * 35UTNA-0170K210-- GLASS PANEL 1

54 37HGRL-0014K2F0-- COMPRESSOR COVER 1

61TINSC1967K2R0-1 USER MANUAL 1

55SPAKC3694K2R0-- BOX CARTON 1

58 66FCONS0102K2S0-- SUB CONDENSER ASS'Y 1

59 41LFRM-0114K2P0-1 CHASSIS 1

Page 63

TBG470ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

61 * 22PCMPL0145K2K0-1 COMPRESSOR ASS'Y 1

62 * 50PPIPC0003K2E0-1 CHARGE PIPE 1

63 56LHLD-0261K2P0-- MOTOR FIXED LARGE 1

64 20LHLD-0263K2P0-- MOTOR FIXED SMALL 1

65 20MSPR-0118K2E0-- FAN SPRING 1

66 14NFANP0066K2F0-- FAN 1

67 * 30FMOTR0070K2E0-- FAN MOTOR 1

68 87LHLD-0232K2F0-- MOTOR FIXING RUBBER 2

69 32HPNL-0463K2RS-- DECORATION PANEL E 1

69 32HPNL-0463K2RS-- DECORATION PANEL Q 1

70 79PCOV-0147K2FS-3 MULTI AIR LOUVER E 1

70 79PCOV-0147K2FS-3 MULTI AIR LOUVER Q 1

71 45PGID-0054K2F0-- MULTI AIR GUIDE 1

72 * 45RLMP-0034K2E0-- LAMP 1

73 46QW-VZ0857K2E0-- LAMP HOLDER WIRING 1

QTY

74 * 01QSOC-0065K2E0-- LAMP HOLDER 1

75 51LHLD-0203K2FS-- B-THM SUPPORT E 1

75 51LHLD-0203K2FS-- B-THM SUPPORT Q 1

76 60PGID-0049K2F0-- R AIR GUIDE TOP 1

77 31PGID-0050K2F0-- R AIR GUIDE B 1

78 76PSEL-0221K2E0-- R KNOB SEALER 1

79 20PSEL-0397K2E0-- SEALER 1

80 62PSEL-0746K2E0-- R AIR GUIDE SEALER 1

Page 64

TBG470ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

81 * 36RTHM-0113K2E0-- DAMPER THERMISTOR 1

82 * 87LSTP-0019K2FB-1 F DOOR STOPPER Q 1

82 * 45LSTP-0019K2FQ-1 F DOOR STOPPER E 1

83 35PPACG0336K2EB-- F DOOR PACKING Q 1

83 82PPACG0336K2EQ-- F DOOR PACKING E 1

84 80GLIN-0349K2P0-- R DOOR LINER 1

85 01LPLTM0716K2P0-- R DOOR STOPPER PLATE 1

86 * 53LSTP-0011K2FB-1 R DOOR STOPPER Q 1

86 * 11LSTP-0011K2FQ-1 R DOOR STOPPER E 1

87 17PPACG0337K2EB-- R DOOR PACKING Q 1

87 64PPACG0337K2EQ-- R DOOR PACKING E 1

88 48LBND-0012K2E0-- D BAND 3

89 87LHLD-0232K2F0-- MOTOR FIXING RUBBER 2

90 04LHLD-0250K2P0-- MOTOR HOLDER 1

91 23PCOV-0199K2FS-1 EVAPORATOR COVER E 1

QTY

91 23PCOV-0199K2FS-1 EVAPORATOR COVER Q 1

93 43PSEL-0702K2E0-- EV COVER SEALER 1

94 58PSEL-0728K2E0-- EV COVER HOLE SEALER 1

95 41QW-VZ0733K2E0-1 F-THM WIRING 1

96 47QW-VZ0779K2E0-1 MOTOR WIRING 1

97 * 10RTHM-0179K2E0-- F-THM 1

98 * 70RTHM-0180K2E0-- D-THM ASS'Y 2

100 14QW-VZ0877K2E0-- COMP WIRING 1

Page 65

TBG470ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

101* 87RSTT-0058K2E0-- STARTING RELAY 1

102* 78QSWTD0066K2E0-- DEFROST TIMER 1

103 50QW-VZ0754K2E0-2 DEFROST TIMER WIRING 1

104* 21RGAD-0151K2E0-- OVERLOAD RELAY 1

105* 09FMOTR0071K2E0-- FAN MOTOR 1

106 20MSPR-0118K2E0-- FAN SPRING 1

107 03NFANP0028K2FE-- FAN E 1

107 03NFANP0028K2FE-- FAN Q 1

108 44GLIN-0413K2P0-- F DOOR LINER 1

Remarks :

i. MOD COL (Model Color) : E (Black) / Q (Silver)

ii. * Recommended Spare Parts Inventory

QTY

Page 66

TBG530ANDR

X. PARTS LIST AND EXPLODED VIEW

Page 67

TBG530ANDR

X. PARTS LIST AND EXPLODED VIEW

Page 68

TBG530ANDR

X. PARTS LIST AND EXPLODED VIEW

NO. PARTS CODE DESCRIPTION MOD

COL

1 13LHLD-0227K2FS-- DRAIN CONNECTOR E 1

1 13LHLD-0227K2FS-- DRAIN CONNECTOR Q 1

2 * 14FEVA-0295K2K0-2 EVAPORATOR 1

3 49LHLD-0208K2P0-- DEFROST HEATER

SUPPORT

4 * 68LHLD-0233K2P0-- DEFROST HEATER COVER 1

5 02RHET-0184K2E0-- DEODER DEFROST

HEATER

6 31DCAB-0587K2KQ-- CABINET ASS'Y E 1

6 56DCAB-0587K2KY-- CABINET ASS'Y Q 1

7 * 60DDOR-0586K2KQ-- R DOOR PU ASS'Y E 1

7 * 85DDOR-0586K2KY-- R DOOR PU ASSY Q 1

8 * 07DDOR-0584K2KQ-- FDOOR PU ASSY E 1

8 * 32DDOR-0584K2KY-- FDOOR PU ASSY Q 1

9 60FCOVH0018K2KS-- R CONTROL BOX ASSY E 1

QTY

1

1

9 60FCOVH0018K2KS-- R CONTROL BOX ASSY Q 1

10 21FHNG-0018K2M0-- BOTTOM HINGE ASS'Y 1

11 53PCOV-0220K2F0-- WRING COVER 1

12 * 25NSTNP0052K2KQ-- BADGE E 1