Page 1

g

Title Page

GE Industrial Systems

T35 Transformer Management Relay

UR Series Instruction Manual

T35 Revision: 4.6x

Manual P/N: 1601-0114-K1 (GEK-113015)

Copyright © 2005 GE Multilin

GE Multilin

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 201-2098

Internet: http://www.GEindustrial.com/multilin

828742A1.CDR

T

E

S

I

R

E

G

D

E

R

ISO9001:2000

G

E

GE Multilin's Quality Management

System is registered to

ISO9001:2000

QMI # 005094

UL # A3775

N

I

M

L

I

U

T

L

Page 2

Page 3

g

Addendum

GE Industrial Systems

ADDENDUM

This Addendum contains information that relates to the T35 Transformer Management Relay relay, version 4.6x. This

addendum lists a number of information items that appear in the instruction manual GEK-113015 (revision K1) but are

not included in the current T35 operations.

The following functions/items are not yet available with the current version of the T35 relay:

•N/A

Version 4.0x and higher releases of the T35 relay includes new hardware (CPU and CT/VT modules).

• The new CPU modules are specified with the following order codes: 9E, 9G, and 9H.

• The new CT/VT modules are specified with the following order codes: 8F, 8G, 8H, 8J.

The following table maps the relationship between the old CPU and CT/VT modules to the newer versions:

MODULE OLD NEW DESCRIPTION

CPU 9A 9E RS485 and RS485 (Modbus RTU, DNP)

9C 9G RS485 and 10Base-F (Ethernet, Modbus TCP/IP, DNP)

9D 9H RS485 and Redundant 10Base-F (Ethernet, Modbus TCP/IP, DNP)

CT/VT 8A 8F Standard 4CT/4VT

8B 8G Sensitive Ground 4CT/4VT

8C 8H Standard 8CT

8D 8J Sensitive Ground 8CT/8VT

The new CT/VT modules can only be used with the new CPUs (9E, 9G, 9H), and the old CT/VT modules can only be

used with the old CPU modules (9A, 9C, 9D). To prevent any hardware mismatches, the new CPU and CT/VT modules

have blue labels and a warning sticker stating “Attn.: Ensure CPU and DSP module label colors are the same!”. In

the event that there is a mismatch between the CPU and CT/VT module, the relay will not function and a

HARDWARE MISMATCH error will be displayed.

All other input/output modules are compatible with the new hardware.

With respect to the firmware, firmware versions 4.0x and higher are only compatible with the new CPU and CT/VT modules. Previous versions of the firmware (3.4x and earlier) are only compatible with the older CPU and CT/VT modules.

DSP ERROR or

Page 4

Page 5

Table of Contents

TABLE OF CONTENTS

1. GETTING STARTED 1.1 IMPORTANT PROCEDURES

1.1.1 CAUTIONS AND WARNINGS ........................................................................... 1-1

1.1.2 INSPECTION CHECKLIST ................................................................................ 1-1

1.2 UR OVERVIEW

1.2.1 INTRODUCTION TO THE UR ........................................................................... 1-2

1.2.2 HARDWARE ARCHITECTURE......................................................................... 1-3

1.2.3 SOFTWARE ARCHITECTURE.......................................................................... 1-4

1.2.4 IMPORTANT CONCEPTS ................................................................................. 1-4

1.3 ENERVISTA UR SETUP SOFTWARE

1.3.1 PC REQUIREMENTS ........................................................................................ 1-5

1.3.2 INSTALLATION.................................................................................................. 1-5

1.3.3 CONNECTING ENERVISTA UR SETUP WITH THE T35................................. 1-7

1.4 UR HARDWARE

1.4.1 MOUNTING AND WIRING............................................................................... 1-10

1.4.2 COMMUNICATIONS........................................................................................ 1-10

1.4.3 FACEPLATE DISPLAY.................................................................................... 1-10

1.5 USING THE RELAY

1.5.1 FACEPLATE KEYPAD..................................................................................... 1-11

1.5.2 MENU NAVIGATION ....................................................................................... 1-11

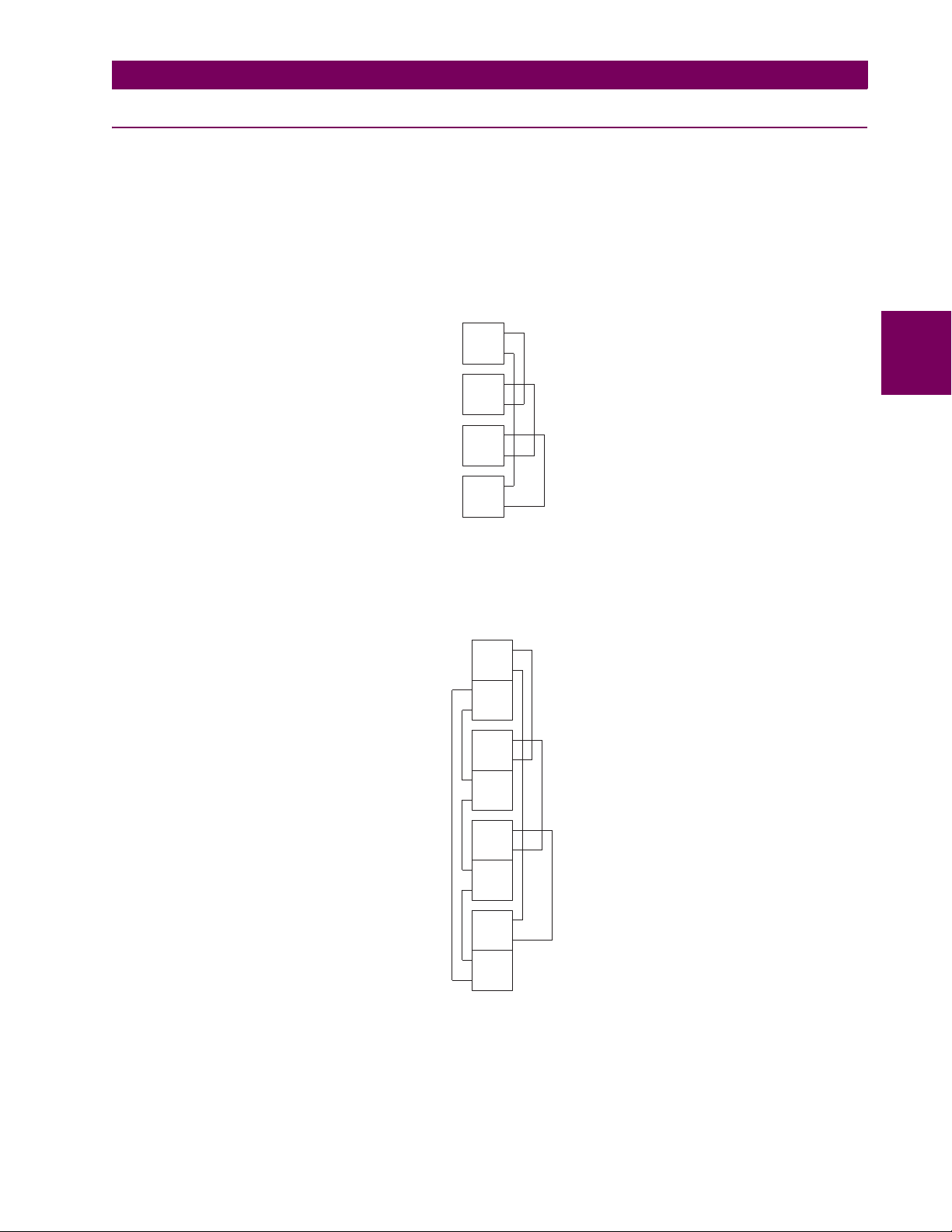

1.5.3 MENU HIERARCHY ........................................................................................ 1-11

1.5.4 RELAY ACTIVATION....................................................................................... 1-12

1.5.5 RELAY PASSWORDS..................................................................................... 1-12

1.5.6 FLEXLOGIC™ CUSTOMIZATION................................................................... 1-12

1.5.7 COMMISSIONING ........................................................................................... 1-13

2. PRODUCT DESCRIPTION 2.1 INTRODUCTION

2.1.1 OVERVIEW........................................................................................................ 2-1

2.1.2 ORDERING........................................................................................................ 2-2

2.2 SPECIFICATIONS

2.2.1 PROTECTION ELEMENTS ............................................................................... 2-5

2.2.2 USER-PROGRAMMABLE ELEMENTS............................................................. 2-6

2.2.3 MONITORING.................................................................................................... 2-7

2.2.4 METERING ........................................................................................................ 2-7

2.2.5 INPUTS ..............................................................................................................2-8

2.2.6 POWER SUPPLY .............................................................................................. 2-8

2.2.7 OUTPUTS .......................................................................................................... 2-9

2.2.8 COMMUNICATIONS........................................................................................ 2-10

2.2.9 INTER-RELAY COMMUNICATIONS............................................................... 2-10

2.2.10 ENVIRONMENTAL .......................................................................................... 2-11

2.2.11 TYPE TESTS ................................................................................................... 2-11

2.2.12 PRODUCTION TESTS .................................................................................... 2-11

2.2.13 APPROVALS ................................................................................................... 2-11

2.2.14 MAINTENANCE ............................................................................................... 2-11

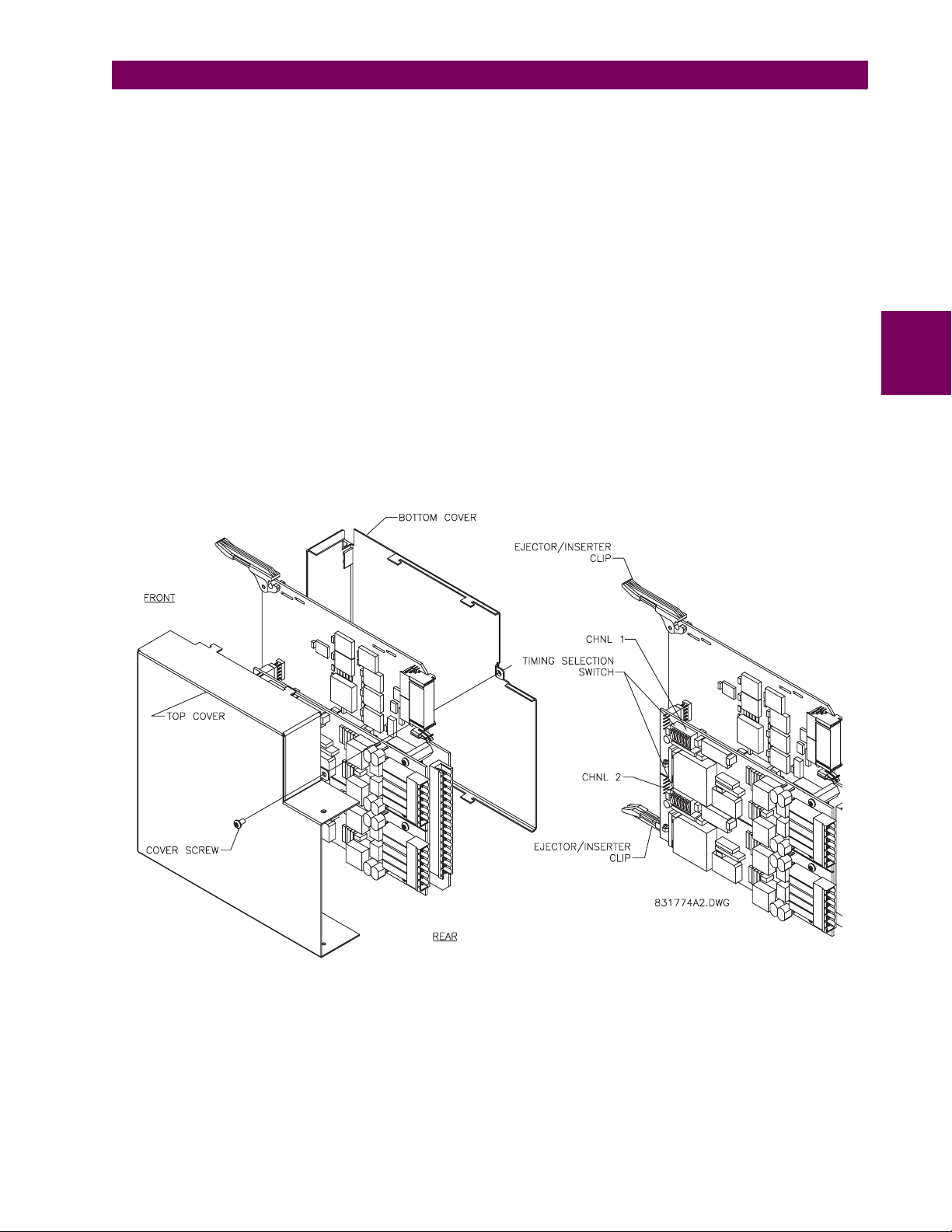

3. HARDWARE 3.1 DESCRIPTION

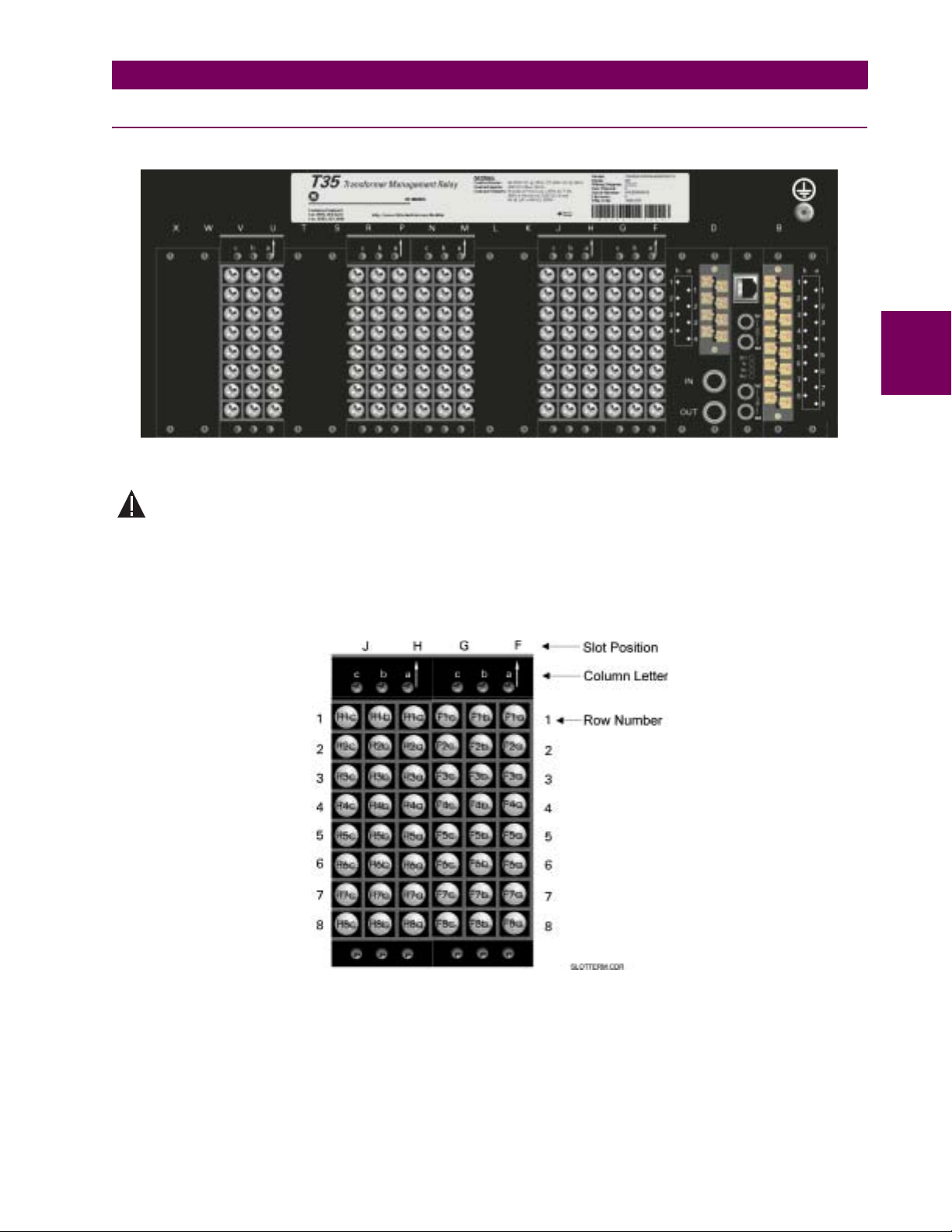

3.1.1 PANEL CUTOUT ............................................................................................... 3-1

3.1.2 MODULE WITHDRAWAL AND INSERTION ..................................................... 3-2

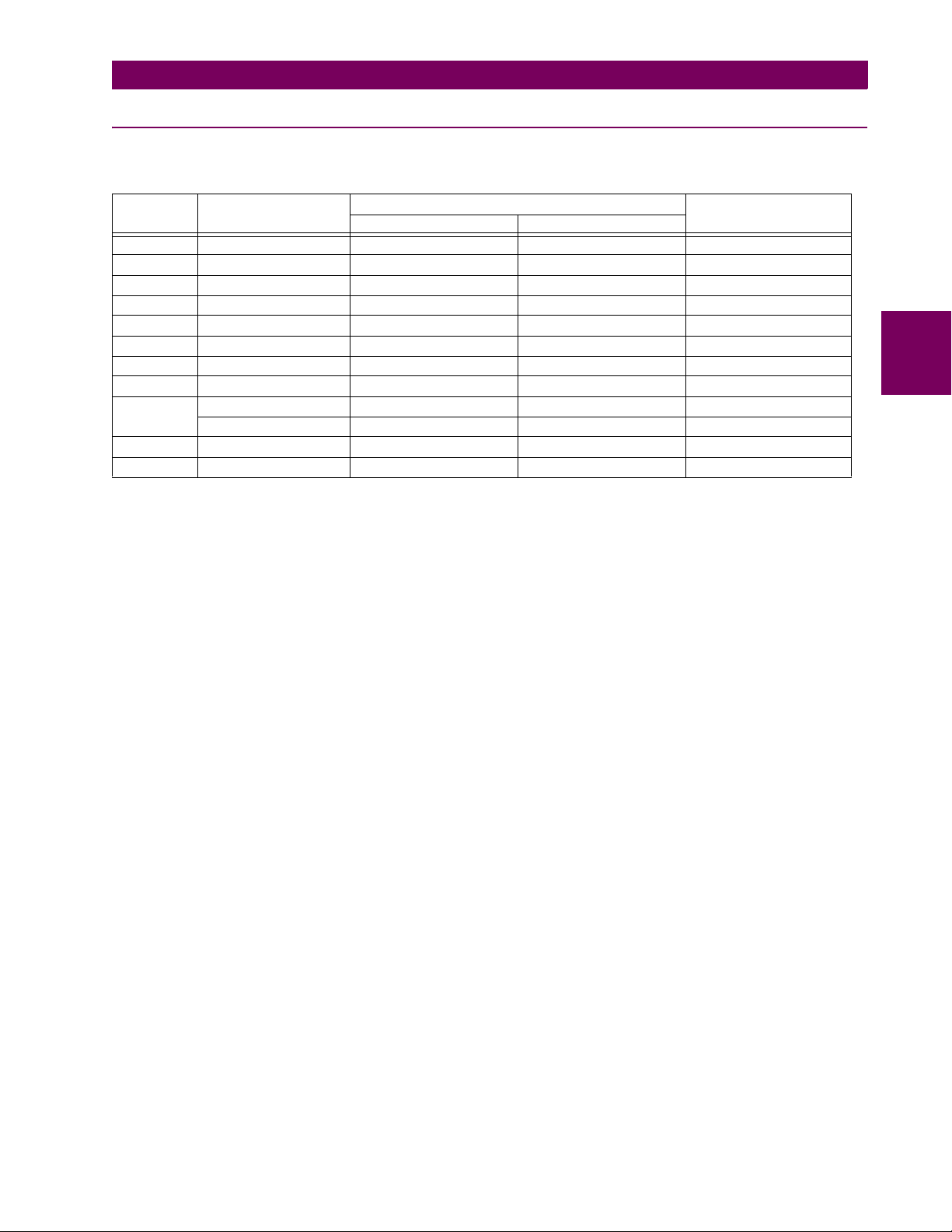

3.1.3 REAR TERMINAL LAYOUT............................................................................... 3-3

3.2 WIRING

3.2.1 TYPICAL WIRING.............................................................................................. 3-4

3.2.2 DIELECTRIC STRENGTH ................................................................................. 3-5

3.2.3 CONTROL POWER ........................................................................................... 3-6

3.2.4 CT/VT MODULES .............................................................................................. 3-6

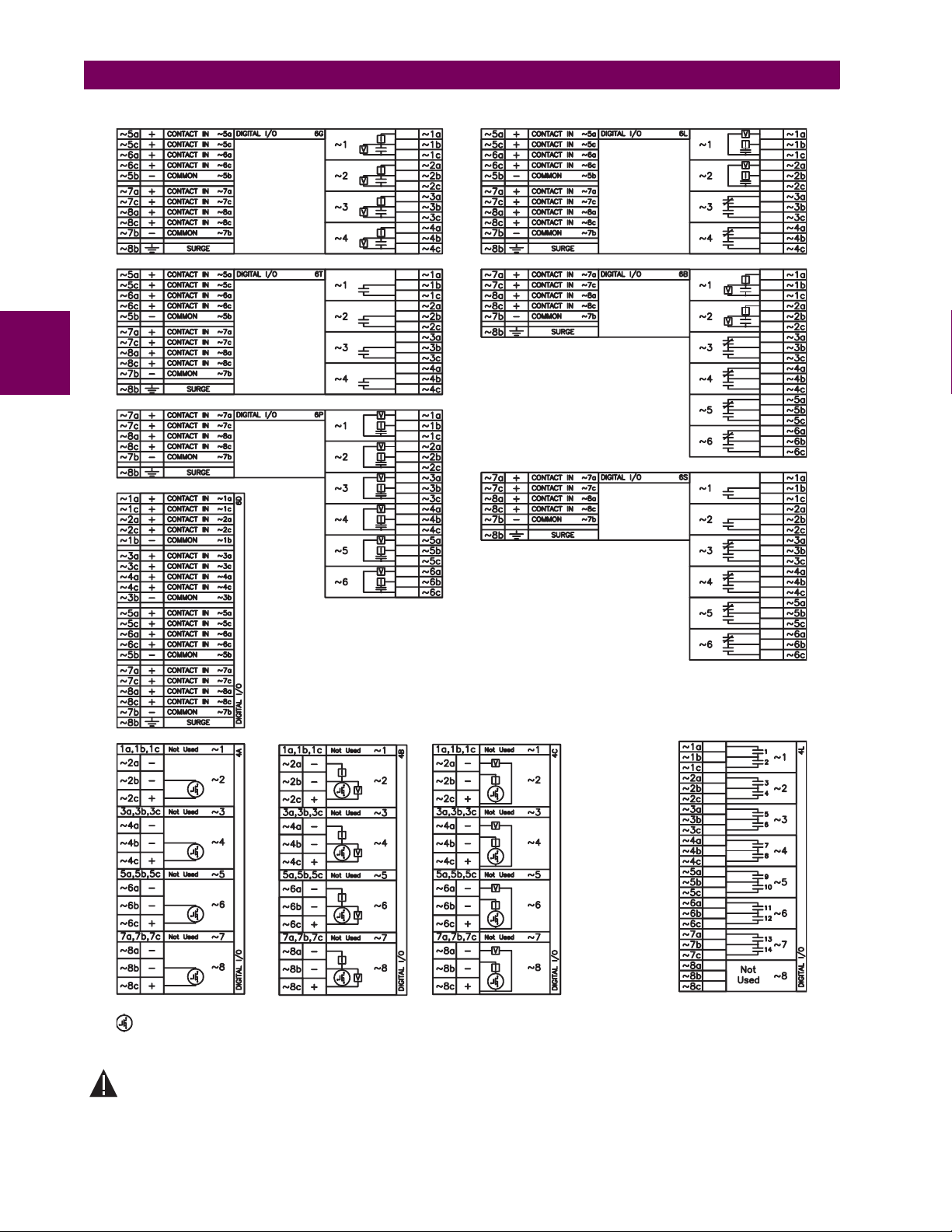

3.2.5 CONTACT INPUTS/OUTPUTS ......................................................................... 3-8

3.2.6 TRANSDUCER INPUTS/OUTPUTS................................................................3-14

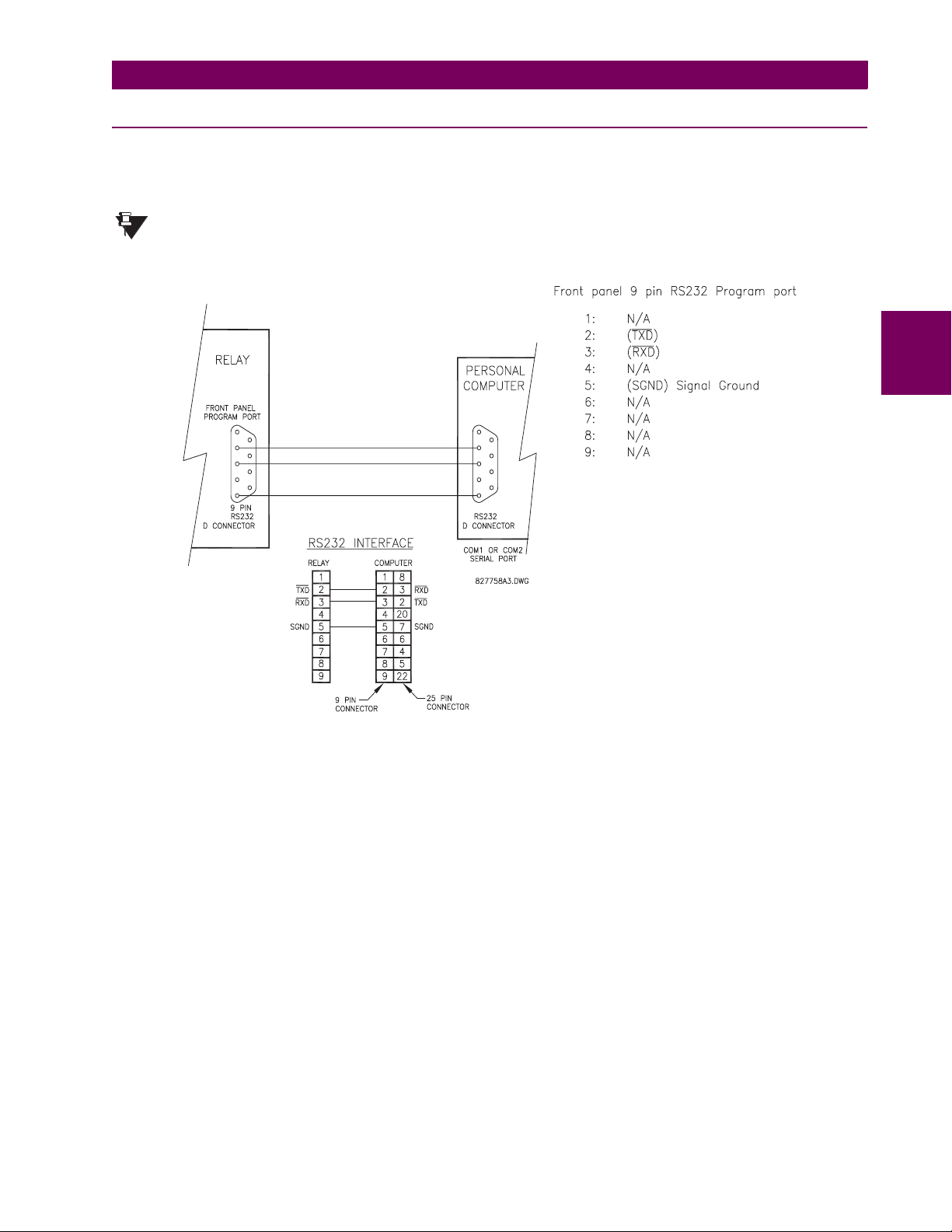

3.2.7 RS232 FACEPLATE PORT ............................................................................. 3-15

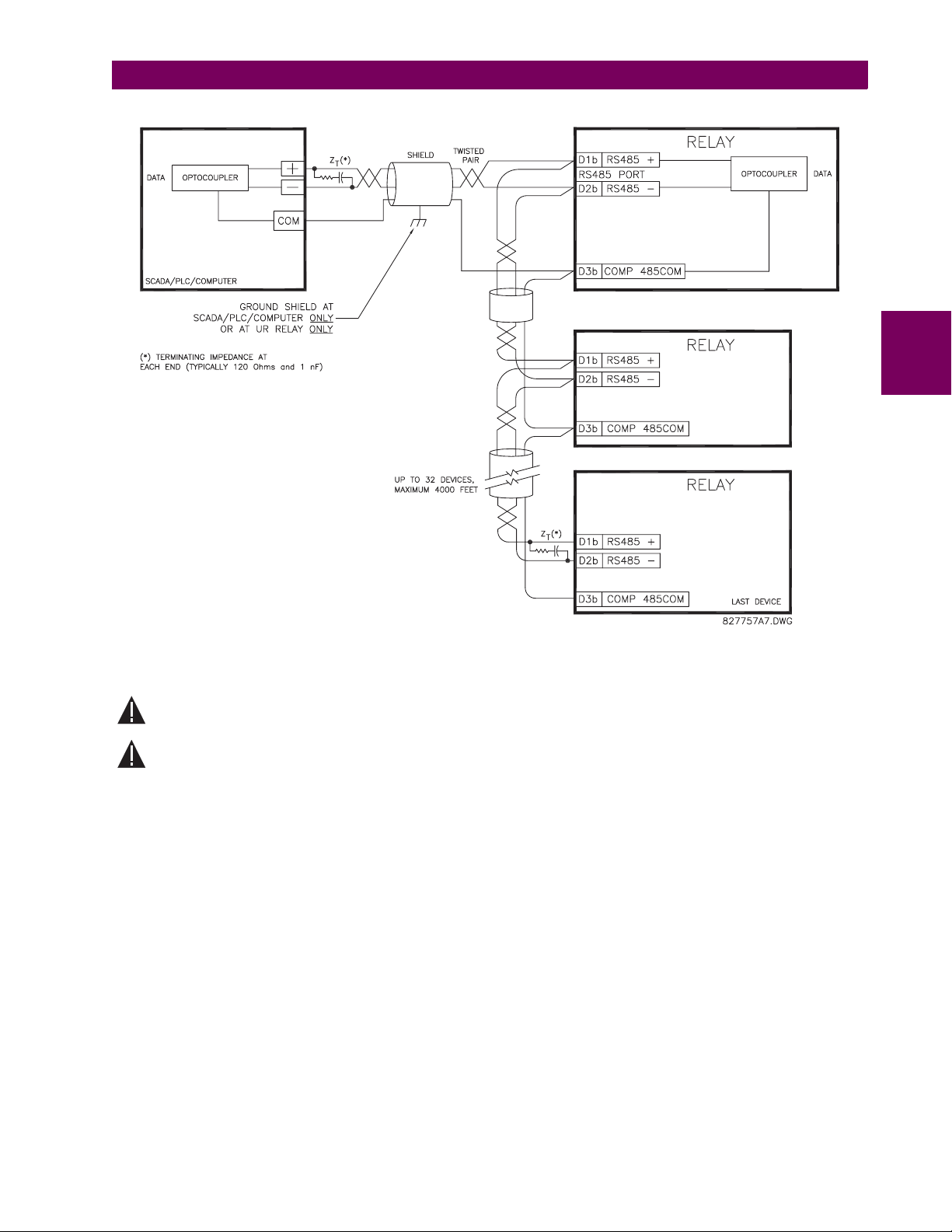

3.2.8 CPU COMMUNICATIONS PORTS.................................................................. 3-16

3.2.9 IRIG-B .............................................................................................................. 3-18

GE Multilin T35 Transformer Management Relay v

Page 6

TABLE OF CONTENTS

3.3 DIRECT I/O COMMUNICATIONS

3.3.1 DESCRIPTION .................................................................................................3-19

3.3.2 FIBER: LED AND ELED TRANSMITTERS ......................................................3-21

3.3.3 FIBER-LASER TRANSMITTERS .....................................................................3-21

3.3.4 G.703 INTERFACE...........................................................................................3-22

3.3.5 RS422 INTERFACE .........................................................................................3-24

3.3.6 RS422 AND FIBER INTERFACE .....................................................................3-27

3.3.7 G.703 AND FIBER INTERFACE ......................................................................3-27

3.3.8 IEEE C37.94 INTERFACE................................................................................3-28

4. HUMAN INTERFACES 4.1 ENERVISTA UR SETUP SOFTWARE INTERFACE

4.1.1 INTRODUCTION ................................................................................................4-1

4.1.2 CREATING A SITE LIST ....................................................................................4-1

4.1.3 ENERVISTA UR SETUP OVERVIEW................................................................4-1

4.1.4 ENERVISTA UR SETUP MAIN WINDOW..........................................................4-3

4.2 FACEPLATE INTERFACE

4.2.1 FACEPLATE.......................................................................................................4-4

4.2.2 LED INDICATORS..............................................................................................4-4

4.2.3 DISPLAY.............................................................................................................4-7

4.2.4 KEYPAD .............................................................................................................4-7

4.2.5 MENUS...............................................................................................................4-7

4.2.6 CHANGING SETTINGS .....................................................................................4-9

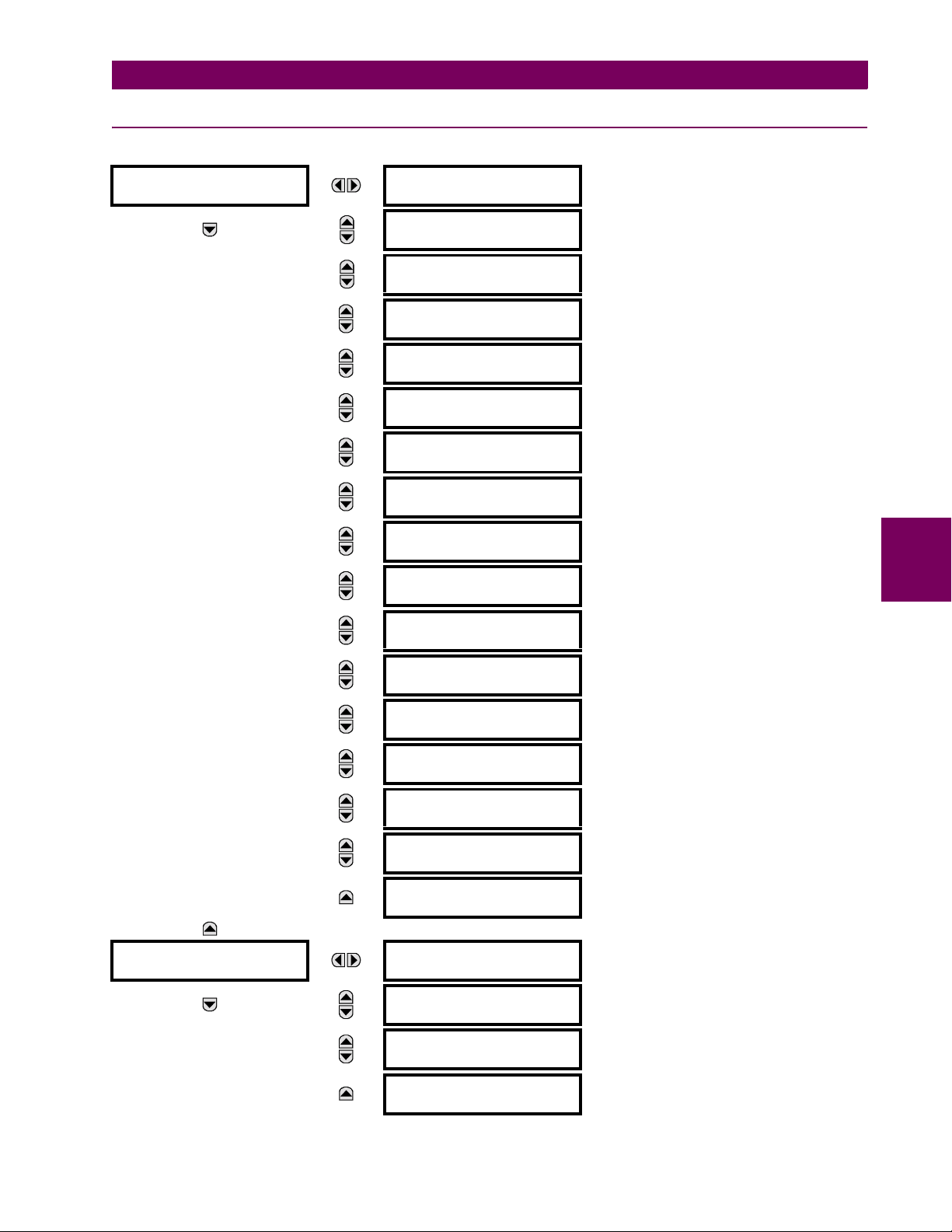

5. SETTINGS 5.1 OVERVIEW

5.1.1 SETTINGS MAIN MENU ....................................................................................5-1

5.1.2 INTRODUCTION TO ELEMENTS......................................................................5-3

5.1.3 INTRODUCTION TO AC SOURCES..................................................................5-4

5.2 PRODUCT SETUP

5.2.1 PASSWORD SECURITY....................................................................................5-7

5.2.2 DISPLAY PROPERTIES ....................................................................................5-8

5.2.3 CLEAR RELAY RECORDS ..............................................................................5-10

5.2.4 COMMUNICATIONS ........................................................................................5-11

5.2.5 MODBUS USER MAP ......................................................................................5-21

5.2.6 REAL TIME CLOCK .........................................................................................5-21

5.2.7 USER-PROGRAMMABLE FAULT REPORT....................................................5-22

5.2.8 OSCILLOGRAPHY ...........................................................................................5-23

5.2.9 DATA LOGGER................................................................................................5-24

5.2.10 USER-PROGRAMMABLE LEDS .....................................................................5-25

5.2.11 USER-PROGRAMMABLE SELF TESTS .........................................................5-28

5.2.12 CONTROL PUSHBUTTONS ............................................................................5-29

5.2.13 USER-PROGRAMMABLE PUSHBUTTONS....................................................5-30

5.2.14 FLEX STATE PARAMETERS ..........................................................................5-31

5.2.15 USER-DEFINABLE DISPLAYS ........................................................................5-32

5.2.16 DIRECT INPUTS/OUTPUTS ............................................................................5-34

5.2.17 INSTALLATION ................................................................................................5-39

5.3 SYSTEM SETUP

5.3.1 AC INPUTS.......................................................................................................5-40

5.3.2 POWER SYSTEM ............................................................................................5-42

5.3.3 SIGNAL SOURCES..........................................................................................5-43

5.3.4 TRANSFORMER ..............................................................................................5-45

5.3.5 FLEXCURVES™ ..............................................................................................5-56

5.4 FLEXLOGIC™

5.4.1 INTRODUCTION TO FLEXLOGIC™................................................................5-63

5.4.2 FLEXLOGIC™ RULES .....................................................................................5-68

5.4.3 FLEXLOGIC™ EVALUATION ..........................................................................5-68

5.4.4 FLEXLOGIC™ EXAMPLE ................................................................................5-69

5.4.5 FLEXLOGIC™ EQUATION EDITOR................................................................5-73

5.4.6 FLEXLOGIC™ TIMERS ...................................................................................5-73

5.4.7 FLEXELEMENTS™..........................................................................................5-74

5.4.8 NON-VOLATILE LATCHES..............................................................................5-78

vi T35 Transformer Management Relay GE Multilin

Page 7

TABLE OF CONTENTS

5.5 GROUPED ELEMENTS

5.5.1 OVERVIEW...................................................................................................... 5-79

5.5.2 SETTING GROUP ...........................................................................................5-79

5.5.3 TRANSFORMER ELEMENTS......................................................................... 5-79

5.5.4 PHASE CURRENT .......................................................................................... 5-85

5.5.5 GROUND CURRENT....................................................................................... 5-92

5.6 CONTROL ELEMENTS

5.6.1 OVERVIEW...................................................................................................... 5-93

5.6.2 SETTING GROUPS ......................................................................................... 5-93

5.6.3 SELECTOR SWITCH....................................................................................... 5-94

5.6.4 DIGITAL COUNTERS ...................................................................................... 5-99

5.6.5 MONITORING ELEMENTS ........................................................................... 5-101

5.7 INPUTS/OUTPUTS

5.7.1 CONTACT INPUTS........................................................................................ 5-103

5.7.2 VIRTUAL INPUTS.......................................................................................... 5-105

5.7.3 CONTACT OUTPUTS.................................................................................... 5-106

5.7.4 VIRTUAL OUTPUTS...................................................................................... 5-108

5.7.5 REMOTE DEVICES....................................................................................... 5-109

5.7.6 REMOTE INPUTS.......................................................................................... 5-110

5.7.7 REMOTE OUTPUTS...................................................................................... 5-111

5.7.8 RESETTING................................................................................................... 5-111

5.7.9 DIRECT INPUTS/OUTPUTS ......................................................................... 5-112

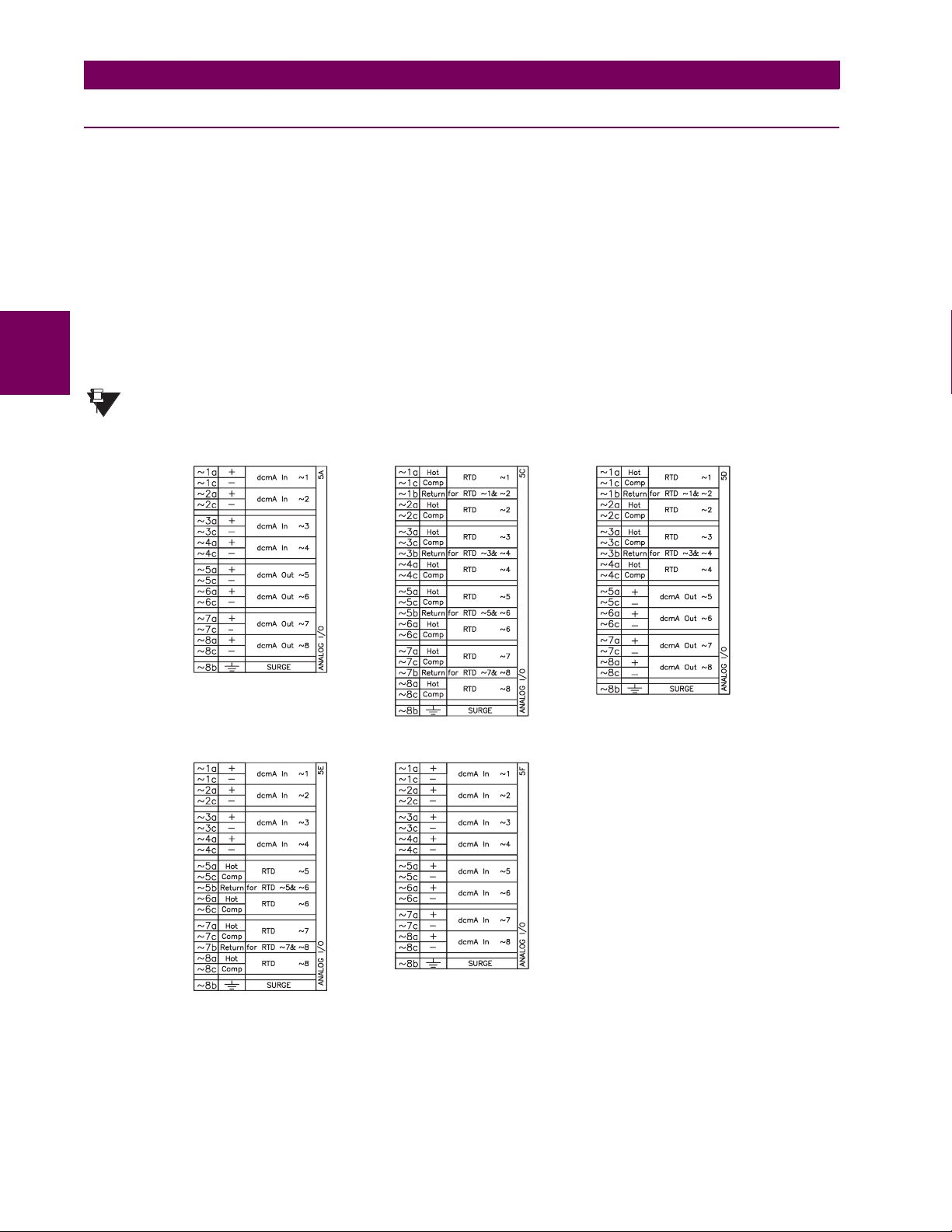

5.8 TRANSDUCER I/O

5.8.1 DCMA INPUTS ..............................................................................................5-116

5.8.2 RTD INPUTS.................................................................................................. 5-117

5.8.3 DCMA OUTPUTS ..........................................................................................5-117

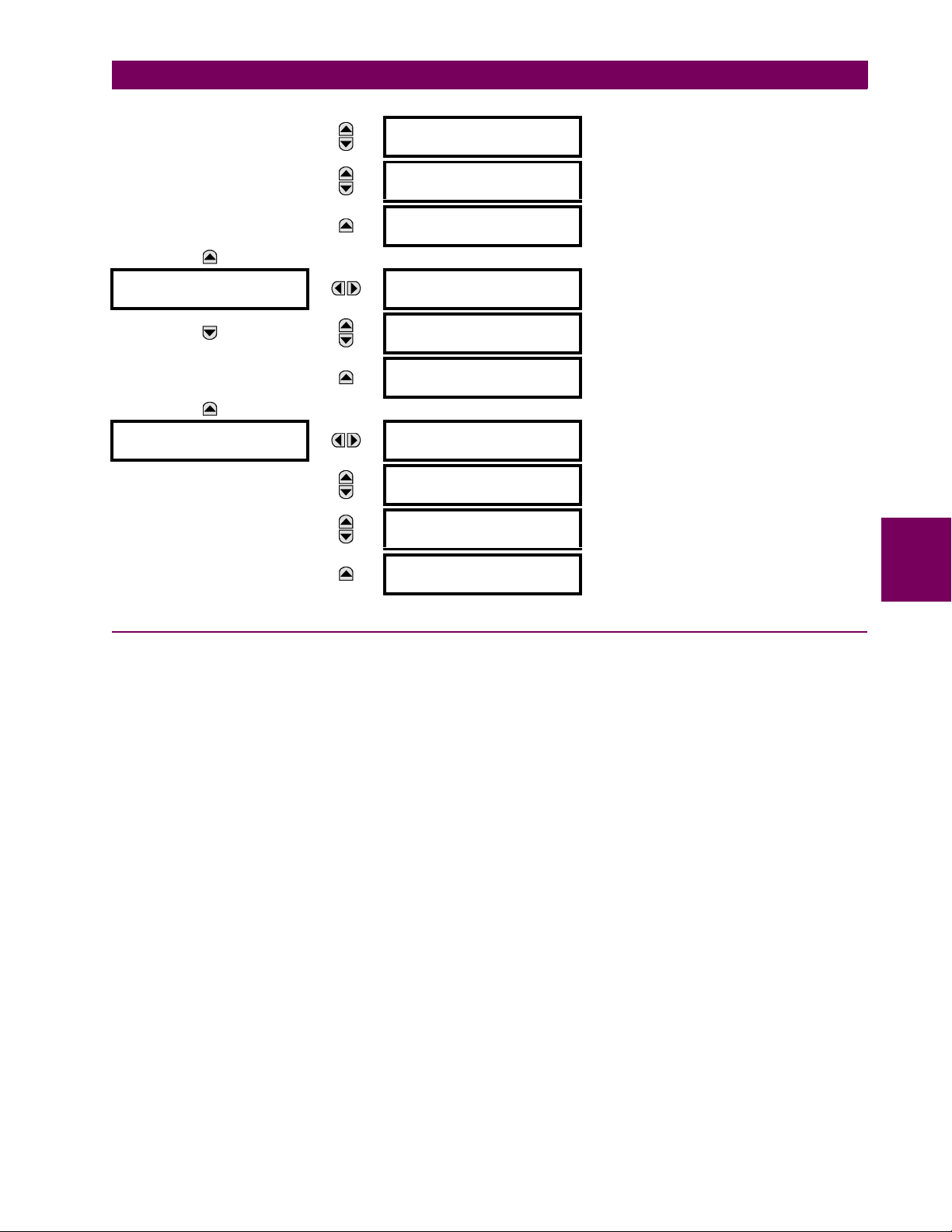

5.9 TESTING

5.9.1 TEST MODE .................................................................................................. 5-121

5.9.2 FORCE CONTACT INPUTS .......................................................................... 5-121

5.9.3 FORCE CONTACT OUTPUTS ...................................................................... 5-122

6. ACTUAL VALUES 6.1 OVERVIEW

6.1.1 ACTUAL VALUES MAIN MENU ........................................................................ 6-1

6.2 STATUS

6.2.1 CONTACT INPUTS............................................................................................ 6-3

6.2.2 VIRTUAL INPUTS.............................................................................................. 6-3

6.2.3 REMOTE INPUTS.............................................................................................. 6-3

6.2.4 CONTACT OUTPUTS........................................................................................ 6-4

6.2.5 VIRTUAL OUTPUTS.......................................................................................... 6-4

6.2.6 REMOTE DEVICES........................................................................................... 6-4

6.2.7 DIGITAL COUNTERS ........................................................................................ 6-5

6.2.8 SELECTOR SWITCHES.................................................................................... 6-5

6.2.9 FLEX STATES ................................................................................................... 6-5

6.2.10 ETHERNET ........................................................................................................ 6-6

6.2.11 DIRECT INPUTS................................................................................................ 6-6

6.2.12 DIRECT DEVICES STATUS .............................................................................. 6-7

6.2.13 EGD PROTOCOL STATUS ............................................................................... 6-7

6.3 METERING

6.3.1 METERING CONVENTIONS............................................................................. 6-8

6.3.2 TRANSFORMER ............................................................................................. 6-11

6.3.3 SOURCES ....................................................................................................... 6-12

6.3.4 TRACKING FREQUENCY ............................................................................... 6-14

6.3.5 FLEXELEMENTS™ ......................................................................................... 6-15

6.3.6 TRANSDUCER INPUTS/OUTPUTS................................................................6-15

6.4 RECORDS

6.4.1 USER-PROGRAMMABLE FAULT REPORTS ................................................ 6-16

6.4.2 EVENT RECORDS .......................................................................................... 6-16

6.4.3 OSCILLOGRAPHY .......................................................................................... 6-16

6.4.4 DATA LOGGER ............................................................................................... 6-17

6.4.5 BREAKER MAINTENANCE............................................................................. 6-17

GE Multilin T35 Transformer Management Relay vii

Page 8

TABLE OF CONTENTS

6.5 PRODUCT INFORMATION

6.5.1 MODEL INFORMATION...................................................................................6-18

6.5.2 FIRMWARE REVISIONS..................................................................................6-18

7. COMMANDS AND

TARGETS

7.1 COMMANDS

7.1.1 COMMANDS MENU...........................................................................................7-1

7.1.2 VIRTUAL INPUTS ..............................................................................................7-1

7.1.3 CLEAR RECORDS.............................................................................................7-1

7.1.4 SET DATE AND TIME ........................................................................................7-2

7.1.5 RELAY MAINTENANCE.....................................................................................7-2

7.2 TARGETS

7.2.1 TARGETS MENU ...............................................................................................7-3

7.2.2 TARGET MESSAGES ........................................................................................7-3

7.2.3 RELAY SELF-TESTS .........................................................................................7-3

8. COMMISSIONING 8.1 DIFFERENTIAL CHARACTERISTIC TEST

8.1.1 DESCRIPTION ...................................................................................................8-1

8.2 DIFFERENTIAL CHARACTERISTIC TEST EXAMPLES

8.2.1 INTRODUCTION ................................................................................................8-3

8.2.2 TEST EXAMPLE 1..............................................................................................8-4

8.2.3 TEST EXAMPLE 2..............................................................................................8-9

8.2.4 TEST EXAMPLE 3............................................................................................8-10

8.2.5 TEST EXAMPLE 4............................................................................................8-11

8.3 INRUSH INHIBIT TEST

8.3.1 INRUSH INHIBIT TEST PROCEDURE ............................................................8-12

8.4 OVEREXCITATION INHIBIT TEST

8.4.1 OVEREXCITATION INHIBIT TEST PROCEDURE ..........................................8-13

8.5 COMMISSIONING TEST TABLES

8.5.1 DIFFERENTIAL RESTRAINT TESTS ..............................................................8-14

8.5.2 INRUSH INHIBIT TESTS..................................................................................8-14

8.5.3 OVEREXCITATION INHIBIT TESTS................................................................8-15

A. FLEXANALOG

A.1 FLEXANALOG LIST

PARAMETERS

B. MODBUS

COMMUNICATIONS

viii T35 Transformer Management Relay GE Multilin

B.1 MODBUS RTU PROTOCOL

B.1.1 INTRODUCTION ............................................................................................... B-1

B.1.2 PHYSICAL LAYER ............................................................................................ B-1

B.1.3 DATA LINK LAYER ........................................................................................... B-1

B.1.4 CRC-16 ALGORITHM ....................................................................................... B-2

B.2 MODBUS FUNCTION CODES

B.2.1 SUPPORTED FUNCTION CODES ................................................................... B-3

B.2.2 READ ACTUAL VALUES OR SETTINGS (FUNCTION CODE 03/04H) ...........B-3

B.2.3 EXECUTE OPERATION (FUNCTION CODE 05H)........................................... B-4

B.2.4 STORE SINGLE SETTING (FUNCTION CODE 06H)....................................... B-4

B.2.5 STORE MULTIPLE SETTINGS (FUNCTION CODE 10H)................................ B-5

B.2.6 EXCEPTION RESPONSES............................................................................... B-5

B.3 FILE TRANSFERS

B.3.1 OBTAINING UR FILES VIA MODBUS ..............................................................B-6

B.3.2 MODBUS PASSWORD OPERATION............................................................... B-7

B.4 MEMORY MAPPING

B.4.1 MODBUS MEMORY MAP ................................................................................. B-8

Page 9

TABLE OF CONTENTS

B.4.2 DATA FORMATS .............................................................................................B-40

C. IEC 61850

COMMUNICATIONS

C.1 INTRODUCTION

C.1.1 OVERVIEW........................................................................................................C-1

C.1.2 COMMUNICATION PROFILES .........................................................................C-1

C.1.3 MMS PROTOCOL..............................................................................................C-1

C.1.4 PEER-TO-PEER COMMUNICATION................................................................C-1

C.1.5 FILE SERVICES ................................................................................................C-1

C.1.6 COMMUNICATION SOFTWARE UTILITIES .....................................................C-2

C.1.7 NON-IEC 61850 DATA ......................................................................................C-2

C.1.8 TCP CONNECTION TIMING .............................................................................C-2

C.1.9 LOGICAL NODE MMXU DATA MAPPING ........................................................C-2

C.1.10 LOGICAL NODE GGIO DATA MAPPING..........................................................C-2

C.1.11 OTHER LOGICAL NODE MAPPING .................................................................C-2

C.2 ASCI CONFORMANCE

C.2.1 ASCI BASIC CONFORMANCE STATEMENT...................................................C-3

C.2.2 ASCI MODELS CONFORMANCE STATEMENT ..............................................C-3

C.2.3 ASCI SERVICES CONFORMANCE STATEMENT ...........................................C-4

C.3 LOGICAL NODES

C.3.1 LOGICAL NODES TABLE .................................................................................C-7

D. IEC 60870-5-104

COMMUNICATIONS

D.1 IEC 60870-5-104 PROTOCOL

D.1.1 INTEROPERABILITY.........................................................................................D-1

D.1.2 POINT LIST......................................................................................................D-10

E. DNP COMMUNICATIONS E.1 DNP PROTOCOL

E.1.1 DEVICE PROFILE DOCUMENT........................................................................E-1

E.1.2 IMPLEMENTATION TABLE............................................................................... E-4

E.2 DNP POINT LISTS

E.2.1 BINARY INPUTS................................................................................................E-8

E.2.2 BINARY AND CONTROL RELAY OUTPUTS..................................................E-13

E.2.3 COUNTERS .....................................................................................................E-14

E.2.4 ANALOG INPUTS ............................................................................................E-15

F. MISCELLANEOUS F.1 CHANGE NOTES

F.1.1 REVISION HISTORY ......................................................................................... F-1

F.1.2 CHANGES TO THE T35 MANUAL ....................................................................F-1

F.2 ABBREVIATIONS

F.2.1 STANDARD ABBREVIATIONS ......................................................................... F-4

F.3 WARRANTY

F.3.1 GE MULTILIN WARRANTY ............................................................................... F-6

GE Multilin T35 Transformer Management Relay ix

Page 10

TABLE OF CONTENTS

x T35 Transformer Management Relay GE Multilin

Page 11

1 GETTING STARTED 1.1 IMPORTANT PROCEDURES

®

®

Technical Support:

Tel: (905) 294-6222

Fax: (905) 201-2098

http://www.GEindustrial.com/multilin

Model:

Mods:

Wiring Diagram:

Inst. Manual:

Serial Number:

Firmware:

Mfg. Date:

T35H00HCHF8FH6AM6BP8GX7A

000

828747

D

MAZB98000029

D

1998/01/05

Control Power:

Contact Inputs:

Contact Outputs:

88-300V DC @ 35W / 77-265V AC @ 35VA

300V DC Max 10mA

Standard Pilot Duty / 250V AC 7.5A

360V A Resistive / 125V DC Break

4A @ L/R = 40mS / 300W

RATINGS:

T35

Transformer Management Relay

GE Multilin

Made in

Canada

- M A A B 9 7 0 0 0 0 9 9 -

1 GETTING STARTED 1.1IMPORTANT PROCEDURES

Please read this chapter to help guide you through the initial setup of your new relay.

1.1.1 CAUTIONS AND WARNINGS

Before attempting to install or use the relay, it is imperative that all WARNINGS and CAUTIONS in this manual are reviewed to help prevent personal injury, equipment damage, and/

WARNING CAUTION

or downtime.

1.1.2 INSPECTION CHECKLIST

• Open the relay packaging and inspect the unit for physical damage.

• View the rear nameplate and verify that the correct model has been ordered.

Figure 1–1: REAR NAMEPLATE (EXAMPLE)

• Ensure that the following items are included:

• Instruction Manual

• GE enerVista CD (includes the EnerVista UR Setup software and manuals in PDF format)

• mounting screws

• registration card (attached as the last page of the manual)

• Fill out the registration form and return to GE Multilin (include the serial number located on the rear nameplate).

• For product information, instruction manual updates, and the latest software updates, please visit the GE Multilin web-

site at http://www.GEindustrial.com/multilin

.

If there is any noticeable physical damage, or any of the contents listed are missing, please contact GE

Multilin immediately.

NOTE

1

GE MULTILIN CONTACT INFORMATION AND CALL CENTER FOR PRODUCT SUPPORT:

GE Multilin

215 Anderson Avenue

Markham, Ontario

Canada L6E 1B3

TELEPHONE: (905) 294-6222, 1-800-547-8629 (North America only)

FAX: (905) 201-2098

E-MAIL: gemultilin@indsys.ge.com

HOME PAGE: http://www.GEindustrial.com/multilin

GE Multilin T35 Transformer Management Relay 1-1

Page 12

1.2 UR OVERVIEW 1 GETTING STARTED

1.2UR OVERVIEW 1.2.1 INTRODUCTION TO THE UR

1

Historically, substation protection, control, and metering functions were performed with electromechanical equipment. This

first generation of equipment was gradually replaced by analog electronic equipment, most of which emulated the singlefunction approach of their electromechanical precursors. Both of these technologies required expensive cabling and auxiliary equipment to produce functioning systems.

Recently, digital electronic equipment has begun to provide protection, control, and metering functions. Initially, this equipment was either single function or had very limited multi-function capability, and did not significantly reduce the cabling and

auxiliary equipment required. However, recent digital relays have become quite multi-functional, reducing cabling and auxiliaries significantly. These devices also transfer data to central control facilities and Human Machine Interfaces using electronic communications. The functions performed by these products have become so broad that many users now prefer the

term IED (Intelligent Electronic Device).

It is obvious to station designers that the amount of cabling and auxiliary equipment installed in stations can be even further

reduced, to 20% to 70% of the levels common in 1990, to achieve large cost reductions. This requires placing even more

functions within the IEDs.

Users of power equipment are also interested in reducing cost by improving power quality and personnel productivity, and

as always, in increasing system reliability and efficiency. These objectives are realized through software which is used to

perform functions at both the station and supervisory levels. The use of these systems is growing rapidly.

High speed communications are required to meet the data transfer rates required by modern automatic control and monitoring systems. In the near future, very high speed communications will be required to perform protection signaling with a

performance target response time for a command signal between two IEDs, from transmission to reception, of less than 3

milliseconds. This has been established by the IEC 61850 standard.

IEDs with the capabilities outlined above will also provide significantly more power system data than is presently available,

enhance operations and maintenance, and permit the use of adaptive system configuration for protection and control systems. This new generation of equipment must also be easily incorporated into automation systems, at both the station and

enterprise levels. The GE Multilin Universal Relay (UR) has been developed to meet these goals.

1-2 T35 Transformer Management Relay GE Multilin

Page 13

1 GETTING STARTED 1.2 UR OVERVIEW

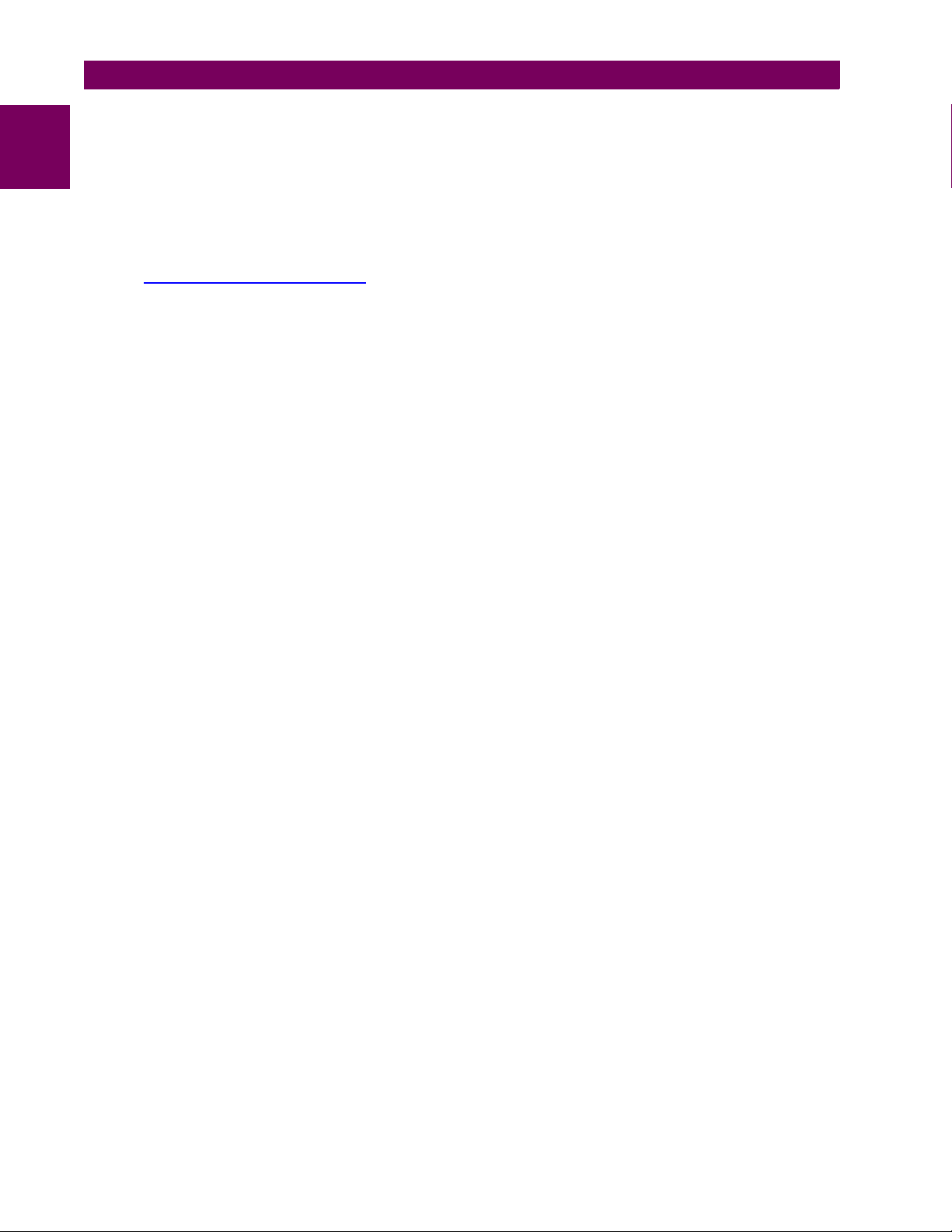

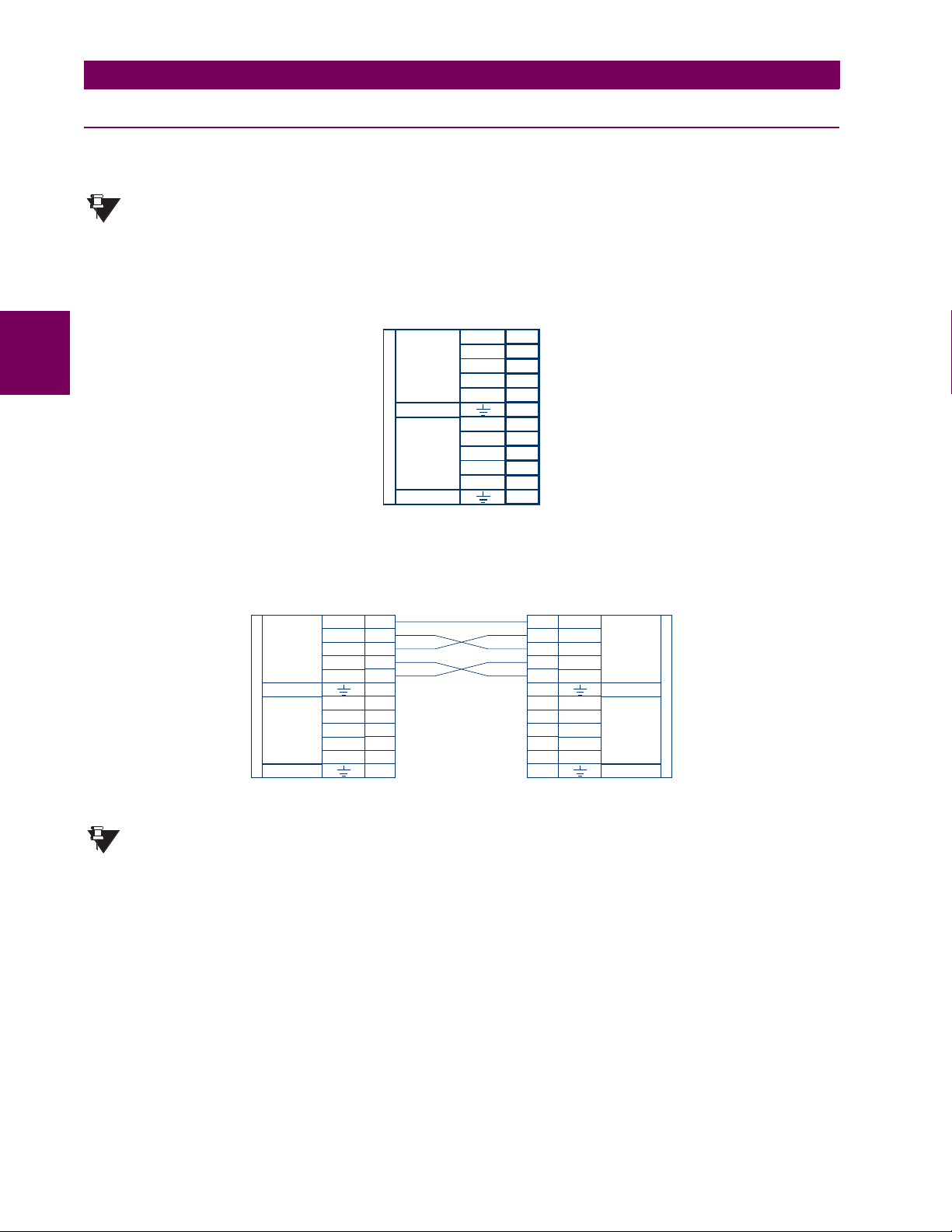

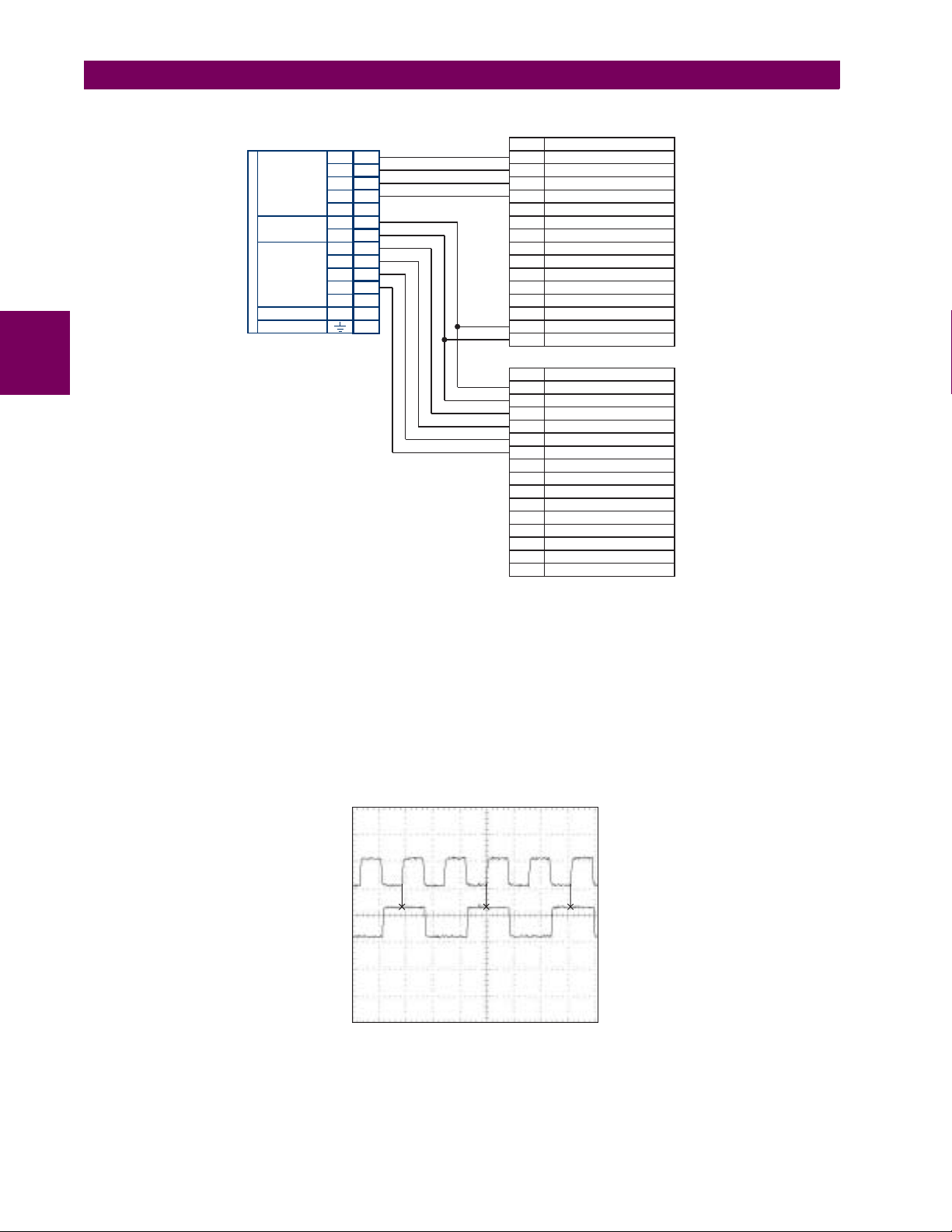

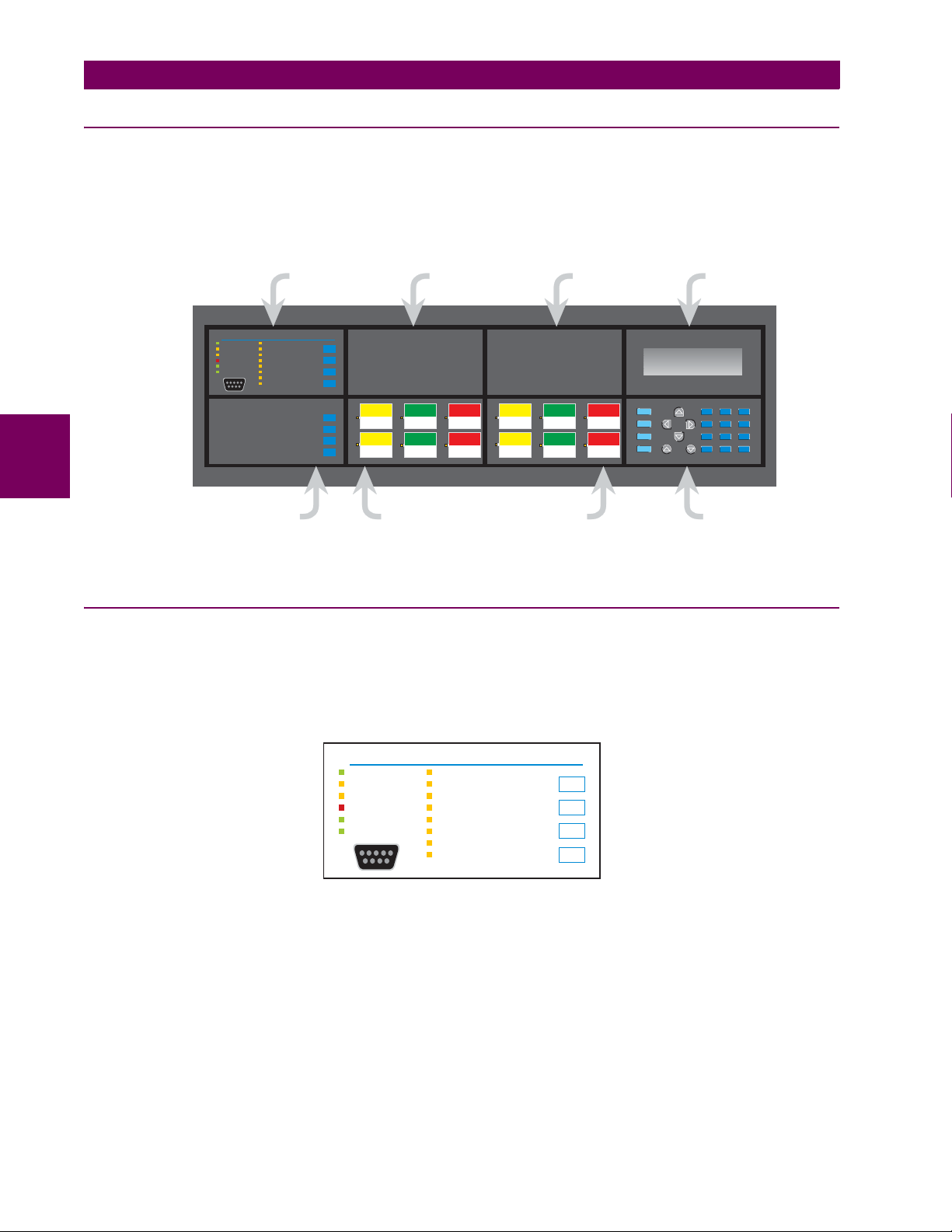

1.2.2 HARDWARE ARCHITECTURE

a) UR BASIC DESIGN

The UR is a digital-based device containing a central processing unit (CPU) that handles multiple types of input and output

signals. The UR can communicate over a local area network (LAN) with an operator interface, a programming device, or

another UR device.

Input Elements

Contact Inputs Contact Outputs

Virtual Inputs

Analog Inputs

CT Inputs

VT Inputs

Remote Inputs

Direct Inputs

Input

Status

Table

CPU Module Output Elements

Protective Elements

Logic Gates

Pickup

Dropout

Operate

Output

Status

Table

Virtual Outputs

Analog Outputs

Remote Outputs

-DNA

-USER

Direct Outputs

LAN

Programming

Device

Figure 1–2: UR CONCEPT BLOCK DIAGRAM

The CPU module contains firmware that provides protection elements in the form of logic algorithms, as well as programmable logic gates, timers, and latches for control features.

Input elements accept a variety of analog or digital signals from the field. The UR isolates and converts these signals into

logic signals used by the relay.

Output elements convert and isolate the logic signals generated by the relay into digital or analog signals that can be used

to control field devices.

Operator

Interface

827822A2.CDR

1

b) UR SIGNAL TYPES

The contact inputs and outputs are digital signals associated with connections to hard-wired contacts. Both ‘wet’ and ‘dry’

contacts are supported.

The virtual inputs and outputs are digital signals associated with UR-series internal logic signals. Virtual inputs include

signals generated by the local user interface. The virtual outputs are outputs of FlexLogic™ equations used to customize

the device. Virtual outputs can also serve as virtual inputs to FlexLogic™ equations.

The analog inputs and outputs are signals that are associated with transducers, such as Resistance Temperature Detec-

tors (RTDs).

The CT and VT inputs refer to analog current transformer and voltage transformer signals used to monitor AC power lines.

The UR-series relays support 1 A and 5 A CTs.

The remote inputs and outputs provide a means of sharing digital point state information between remote UR-series

devices. The remote outputs interface to the remote inputs of other UR-series devices. Remote outputs are FlexLogic™

operands inserted into IEC 61850 GSSE and GOOSE messages.

The direct inputs and outputs provide a means of sharing digital point states between a number of UR-series IEDs over a

dedicated fiber (single or multimode), RS422, or G.703 interface. No switching equipment is required as the IEDs are connected directly in a ring or redundant (dual) ring configuration. This feature is optimized for speed and intended for pilotaided schemes, distributed logic applications, or the extension of the input/output capabilities of a single relay chassis.

GE Multilin T35 Transformer Management Relay 1-3

Page 14

1.2 UR OVERVIEW 1 GETTING STARTED

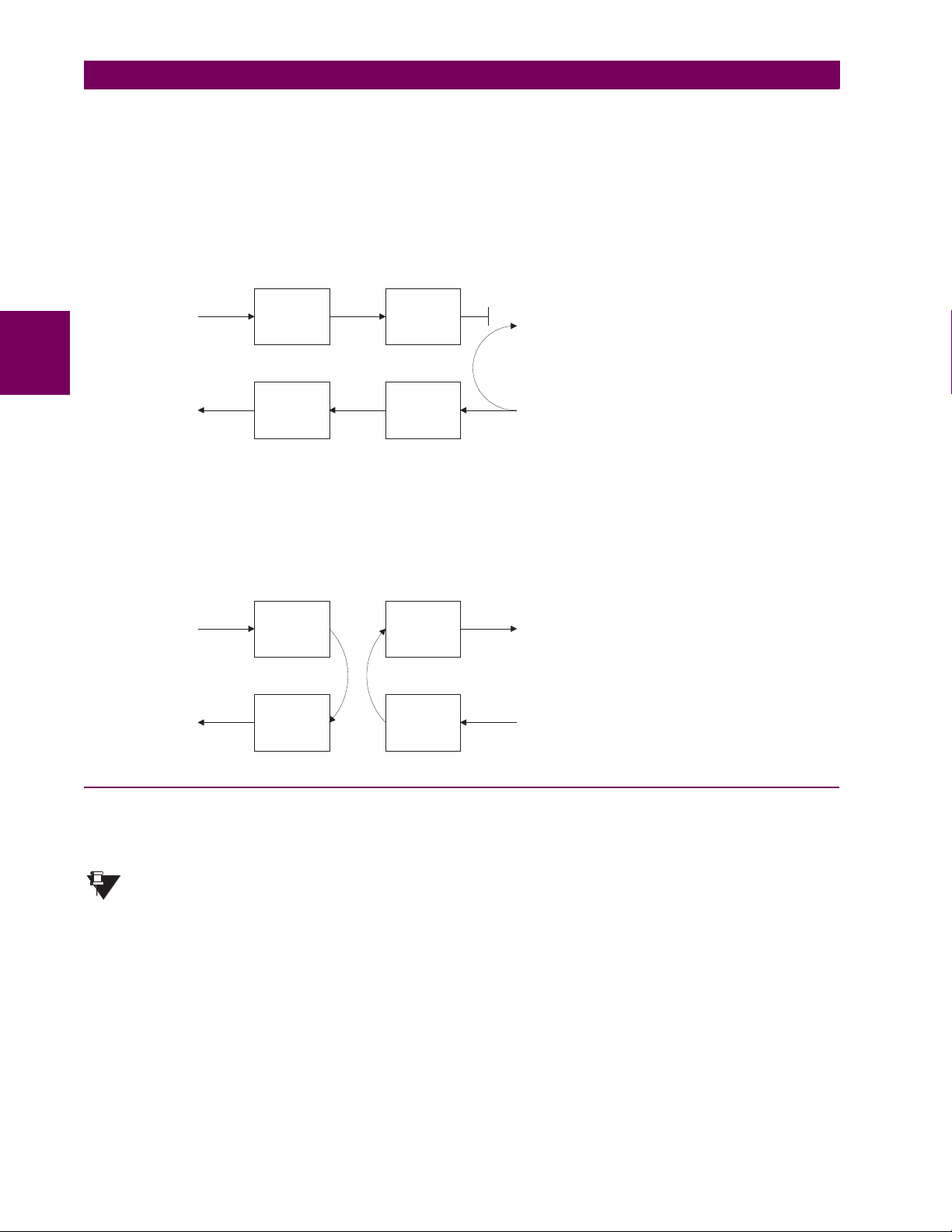

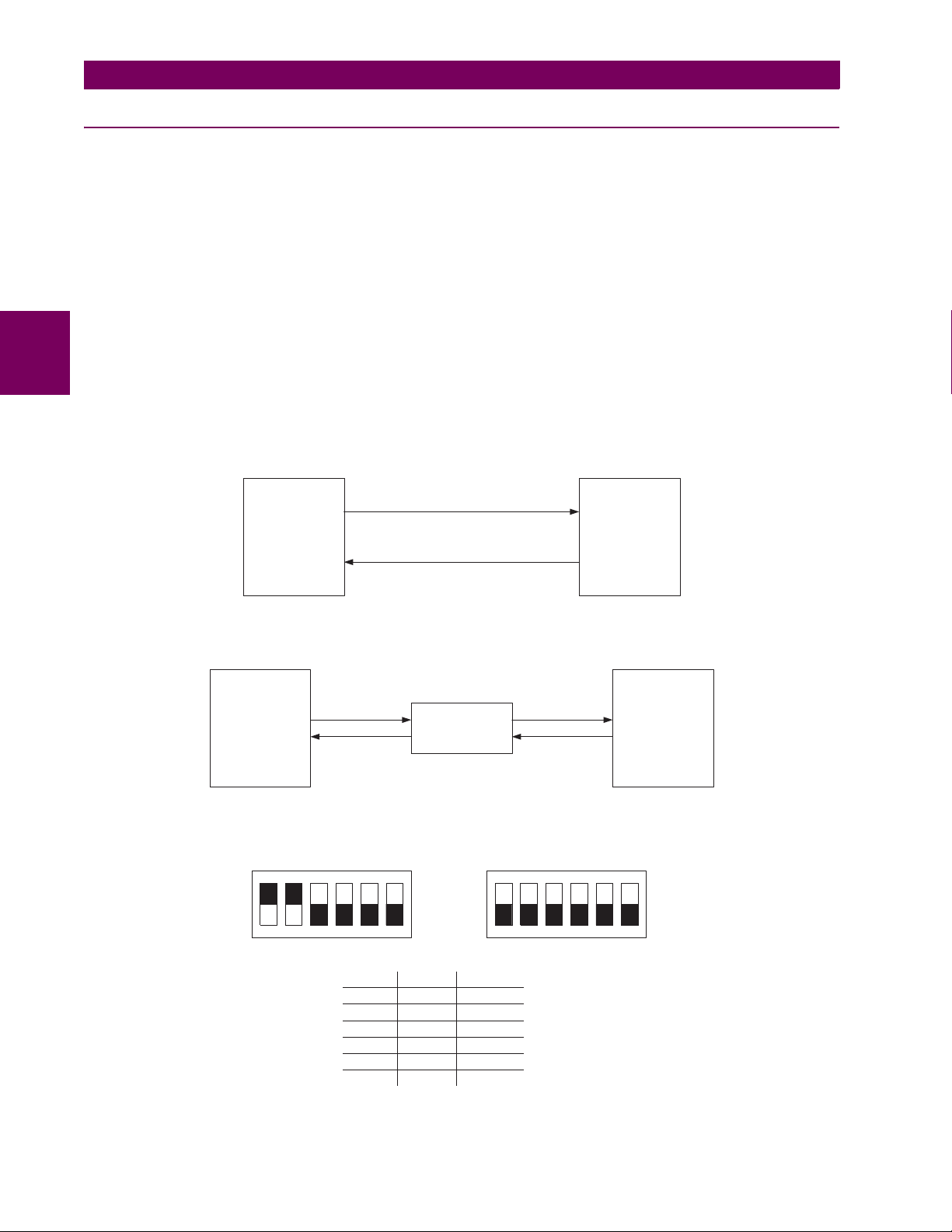

c) UR SCAN OPERATION

The UR-series devices operate in a cyclic scan fashion. The device reads the inputs into an input status table, solves the

1

logic program (FlexLogic™ equation), and then sets each output to the appropriate state in an output status table. Any

resulting task execution is priority interrupt-driven.

Read Inputs

Protection elements

serviced by sub-scan

Protective Elements

Solve Logic

PKP

DPO

OP

Set Outputs

827823A1.CDR

Figure 1–3: UR-SERIES SCAN OPERATION

1.2.3 SOFTWARE ARCHITECTURE

The firmware (software embedded in the relay) is designed in functional modules which can be installed in any relay as

required. This is achieved with Object-Oriented Design and Programming (OOD/OOP) techniques.

Object-Oriented techniques involve the use of ‘objects’ and ‘classes’. An ‘object’ is defined as “a logical entity that contains

both data and code that manipulates that data”. A ‘class’ is the generalized form of similar objects. By using this concept,

one can create a Protection Class with the Protection Elements as objects of the class such as Time Overcurrent, Instantaneous Overcurrent, Current Differential, Undervoltage, Overvoltage, Underfrequency, and Distance. These objects represent completely self-contained software modules. The same object-class concept can be used for Metering, Input/Output

Control, HMI, Communications, or any functional entity in the system.

Employing OOD/OOP in the software architecture of the Universal Relay achieves the same features as the hardware

architecture: modularity, scalability, and flexibility. The application software for any Universal Relay (e.g. Feeder Protection,

Transformer Protection, Distance Protection) is constructed by combining objects from the various functionality classes.

This results in a ’common look and feel’ across the entire family of UR-series platform-based applications.

1.2.4 IMPORTANT CONCEPTS

As described above, the architecture of the UR-series relays differ from previous devices. To achieve a general understanding of this device, some sections of Chapter 5 are quite helpful. The most important functions of the relay are contained in

“elements”. A description of the UR-series elements can be found in the Introduction to Elements section in Chapter 5. An

example of a simple element, and some of the organization of this manual, can be found in the Digital Elements section. An

explanation of the use of inputs from CTs and VTs is in the Introduction to AC Sources section in Chapter 5. A description of

how digital signals are used and routed within the relay is contained in the Introduction to FlexLogic™ section in Chapter 5.

1-4 T35 Transformer Management Relay GE Multilin

Page 15

1 GETTING STARTED 1.3 ENERVISTA UR SETUP SOFTWARE

1.3ENERVISTA UR SETUP SOFTWARE 1.3.1 PC REQUIREMENTS

The faceplate keypad and display or the EnerVista UR Setup software interface can be used to communicate with the relay.

The EnerVista UR Setup software interface is the preferred method to edit settings and view actual values because the PC

monitor can display more information in a simple comprehensible format.

The following minimum requirements must be met for the EnerVista UR Setup software to properly operate on a PC.

• Pentium class or higher processor (Pentium II 300 MHz or higher recommended)

• Windows 95, 98, 98SE, ME, NT 4.0 (Service Pack 4 or higher), 2000, XP

• Internet Explorer 4.0 or higher

• 128 MB of RAM (256 MB recommended)

• 200 MB of available space on system drive and 200 MB of available space on installation drive

• Video capable of displaying 800 x 600 or higher in high-color mode (16-bit color)

• RS232 and/or Ethernet port for communications to the relay

The following qualified modems have been tested to be compliant with the T35 and the EnerVista UR Setup software.

• US Robotics external 56K FaxModem 5686

• US Robotics external Sportster 56K X2

• PCTEL 2304WT V.92 MDC internal modem

1.3.2 INSTALLATION

After ensuring the minimum requirements for using EnerVista UR Setup are met (see previous section), use the following

procedure to install the EnerVista UR Setup from the enclosed GE enerVista CD.

1. Insert the GE enerVista CD into your CD-ROM drive.

2. Click the Install Now button and follow the installation instructions to install the no-charge enerVista software.

3. When installation is complete, start the enerVista Launchpad application.

4. Click the IED Setup section of the Launch Pad window.

1

5. In the enerVista Launch Pad window, click the Install Software button and select the “T35 Transformer Management

Relay” from the Install Software window as shown below. Select the “Web” option to ensure the most recent software

GE Multilin T35 Transformer Management Relay 1-5

Page 16

1.3 ENERVISTA UR SETUP SOFTWARE 1 GETTING STARTED

release, or select “CD” if you do not have a web connection, then click the Check Now button to list software items for

the T35.

1

6. Select the T35 software program and release notes (if desired) from the list and click the Download Now button to

obtain the installation program.

7. enerVista Launchpad will obtain the installation program from the Web or CD. Once the download is complete, doubleclick the installation program to install the EnerVista UR Setup software.

8. Select the complete path, including the new directory name, where the EnerVista UR Setup will be installed.

9. Click on Next to begin the installation. The files will be installed in the directory indicated and the installation program

will automatically create icons and add EnerVista UR Setup to the Windows start menu.

1-6 T35 Transformer Management Relay GE Multilin

Page 17

1 GETTING STARTED 1.3 ENERVISTA UR SETUP SOFTWARE

10. Click Finish to end the installation. The T35 device will be added to the list of installed IEDs in the enerVista Launch-

pad window, as shown below.

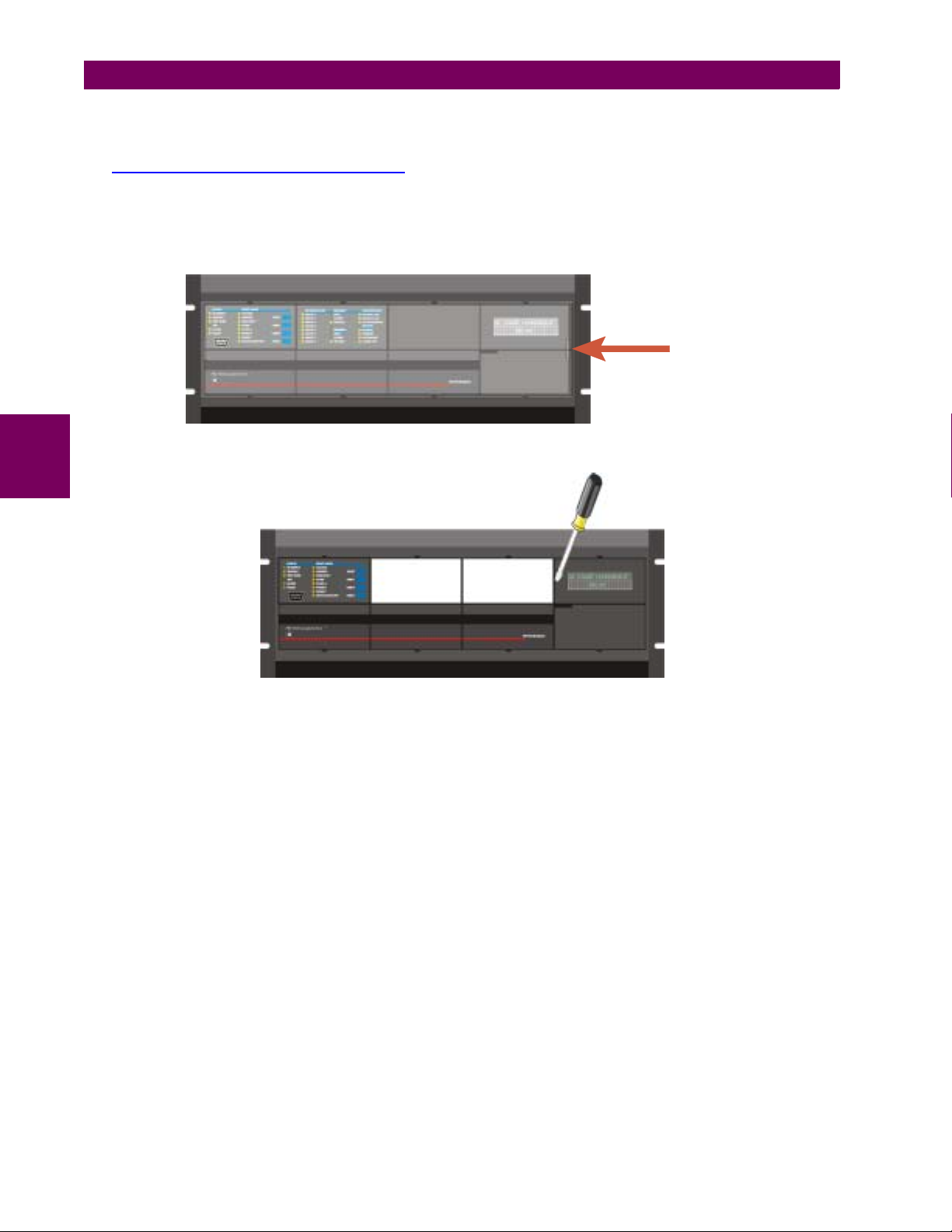

1.3.3 CONNECTING ENERVISTA UR SETUP WITH THE T35

1

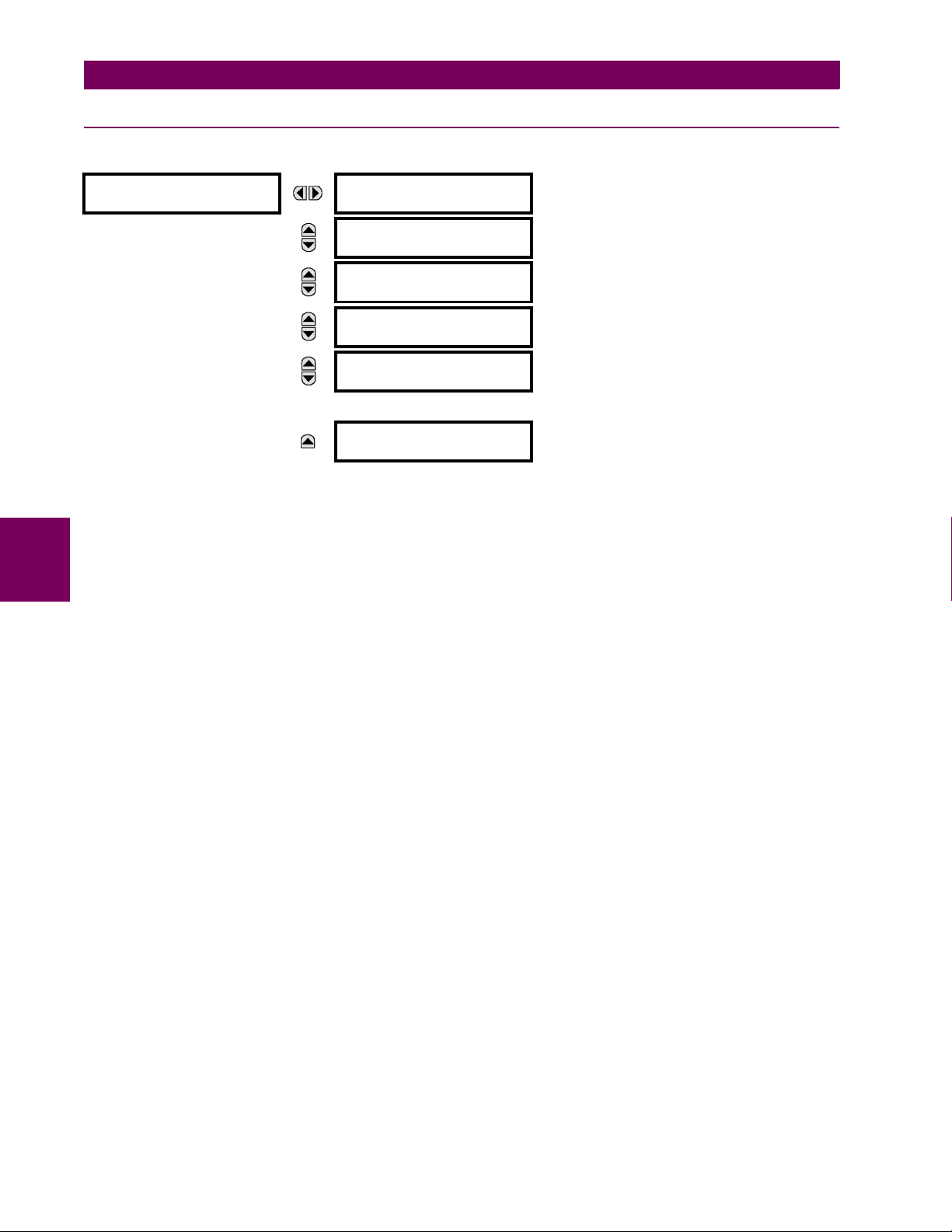

This section is intended as a quick start guide to using the EnerVista UR Setup software. Please refer to the EnerVista UR

Setup Help File and Chapter 4 of this manual for more information.

a) CONFIGURING AN ETHERNET CONNECTION

Before starting, verify that the Ethernet network cable is properly connected to the Ethernet port on the back of the relay. To

setup the relay for Ethernet communications, it will be necessary to define a Site, then add the relay as a Device at that site.

1. Install and start the latest version of the EnerVista UR Setup software (available from the GE enerVista CD or online

from http://www.GEindustrial.com/multilin

2. Select the “UR” device from the enerVista Launchpad to start EnerVista UR Setup.

3. Click the Device Setup button to open the Device Setup window, then click the Add Site button to define a new site.

4. Enter the desired site name in the “Site Name” field. If desired, a short description of site can also be entered along

with the display order of devices defined for the site. Click the OK button when complete.

5. The new site will appear in the upper-left list in the EnerVista UR Setup window. Click on the new site name and then

click the Device Setup button to re-open the Device Setup window.

6. Click the Add Device button to define the new device.

7. Enter the desired name in the “Device Name” field and a description (optional) of the site.

8. Select “Ethernet” from the Interface drop-down list. This will display a number of interface parameters that must be

entered for proper Ethernet functionality.

• Enter the relay IP address (from

in the “IP Address” field.

• Enter the relay Modbus address (from the PRODUCT SETUP !" COMMUNICATIONS !" MODBUS PROTOCOL ! MOD-

BUS SLAVE ADDRESS

• Enter the Modbus port address (from the PRODUCT SETUP !" COMMUNICATIONS !" MODBUS PROTOCOL !"

MODBUS TCP PORT NUMBER setting) in the “Modbus Port” field.

9. Click the Read Order Code button to connect to the T35 device and upload the order code. If an communications error

occurs, ensure that the three EnerVista UR Setup values entered in the previous step correspond to the relay setting

values.

setting) in the “Slave Address” field.

(see previous section for installation instructions).

SETTINGS ! PRODUCT SETUP !" COMMUNICATIONS !" NETWORK ! IP ADDRESS)

GE Multilin T35 Transformer Management Relay 1-7

Page 18

1.3 ENERVISTA UR SETUP SOFTWARE 1 GETTING STARTED

10. Click OK when the relay order code has been received. The new device will be added to the Site List window (or

1

Online window) located in the top left corner of the main EnerVista UR Setup window.

The Site Device has now been configured for Ethernet communications. Proceed to Section c) below to begin communications.

b) CONFIGURING AN RS232 CONNECTION

Before starting, verify that the RS232 serial cable is properly connected to the RS232 port on the front panel of the relay.

1. Install and start the latest version of the EnerVista UR Setup software (available from the GE enerVista CD or online

from http://www.GEindustrial.com/multilin

2. Select the Device Setup button to open the Device Setup window and click the Add Site button to define a new site.

3. Enter the desired site name in the “Site Name” field. If desired, a short description of site can also be entered along

with the display order of devices defined for the site. Click the OK button when complete.

4. The new site will appear in the upper-left list in the EnerVista UR Setup window. Click on the new site name and then

click the Device Setup button to re-open the Device Setup window.

5. Click the Add Device button to define the new device.

6. Enter the desired name in the “Device Name” field and a description (optional) of the site.

7. Select “Serial” from the Interface drop-down list. This will display a number of interface parameters that must be

entered for proper serial communications.

• Enter the relay slave address and COM port values (from the

!" SERIAL PORTS menu) in the “Slave Address” and “COM Port” fields.

• Enter the physical communications parameters (baud rate and parity settings) in their respective fields.

8. Click the Read Order Code button to connect to the T35 device and upload the order code. If an communications error

occurs, ensure that the EnerVista UR Setup serial communications values entered in the previous step correspond to

the relay setting values.

9. Click “OK” when the relay order code has been received. The new device will be added to the Site List window (or

Online window) located in the top left corner of the main EnerVista UR Setup window.

The Site Device has now been configured for RS232 communications. Proceed to Section c) Connecting to the Relay

below to begin communications.

.

SETTINGS ! PRODUCT SETUP !" COMMUNICATIONS

c) CONNECTING TO THE RELAY

1. Open the Display Properties window through the Site List tree as shown below:

1-8 T35 Transformer Management Relay GE Multilin

Page 19

1 GETTING STARTED 1.3 ENERVISTA UR SETUP SOFTWARE

Expand the Site List by double-clicking

or by selecting the [+] box

1

Communications Status Indicator

Green LED = OK, Red LED = No Communications

UR icon = report open

842743A1.CDR

2. The Display Properties window will open with a status indicator on the lower left of the EnerVista UR Setup window.

3. If the status indicator is red, verify that the Ethernet network cable is properly connected to the Ethernet port on the

back of the relay and that the relay has been properly setup for communications (steps A and B earlier).

If a relay icon appears in place of the status indicator, than a report (such as an oscillography or event record) is open.

Close the report to re-display the green status indicator.

4. The Display Properties settings can now be edited, printed, or changed according to user specifications.

Refer to Chapter 4 in this manual and the EnerVista UR Setup Help File for more information about the

using the EnerVista UR Setup software interface.

NOTE

GE Multilin T35 Transformer Management Relay 1-9

Page 20

1.4 UR HARDWARE 1 GETTING STARTED

1.4UR HARDWARE 1.4.1 MOUNTING AND WIRING

1

Please refer to Chapter 3: Hardware for detailed mounting and wiring instructions. Review all WARNINGS and CAUTIONS

carefully.

1.4.2 COMMUNICATIONS

The EnerVista UR Setup software communicates to the relay via the faceplate RS232 port or the rear panel RS485 / Ethernet ports. To communicate via the faceplate RS232 port, a standard “straight-through” serial cable is used. The DB-9 male

end is connected to the relay and the DB-9 or DB-25 female end is connected to the PC COM1 or COM2 port as described

in the CPU Communications Ports section of Chapter 3.

Figure 1–4: RELAY COMMUNICATIONS OPTIONS

To communicate through the T35 rear RS485 port from a PC RS232 port, the GE Multilin RS232/RS485 converter box is

required. This device (catalog number F485) connects to the computer using a “straight-through” serial cable. A shielded

twisted-pair (20, 22, or 24 AWG) connects the F485 converter to the T35 rear communications port. The converter terminals (+, –, GND) are connected to the T35 communication module (+, –, COM) terminals. Refer to the CPU Communica-

tions Ports section in Chapter 3 for option details. The line should be terminated with an R-C network (i.e. 120 Ω, 1 nF) as

described in the Chapter 3.

1.4.3 FACEPLATE DISPLAY

All messages are displayed on a 2 × 20 character vacuum fluorescent display to make them visible under poor lighting conditions. An optional liquid crystal display (LCD) is also available. Messages are displayed in English and do not require the

aid of an instruction manual for deciphering. While the keypad and display are not actively being used, the display will

default to defined messages. Any high priority event driven message will automatically override the default message and

appear on the display.

1-10 T35 Transformer Management Relay GE Multilin

Page 21

1 GETTING STARTED 1.5 USING THE RELAY

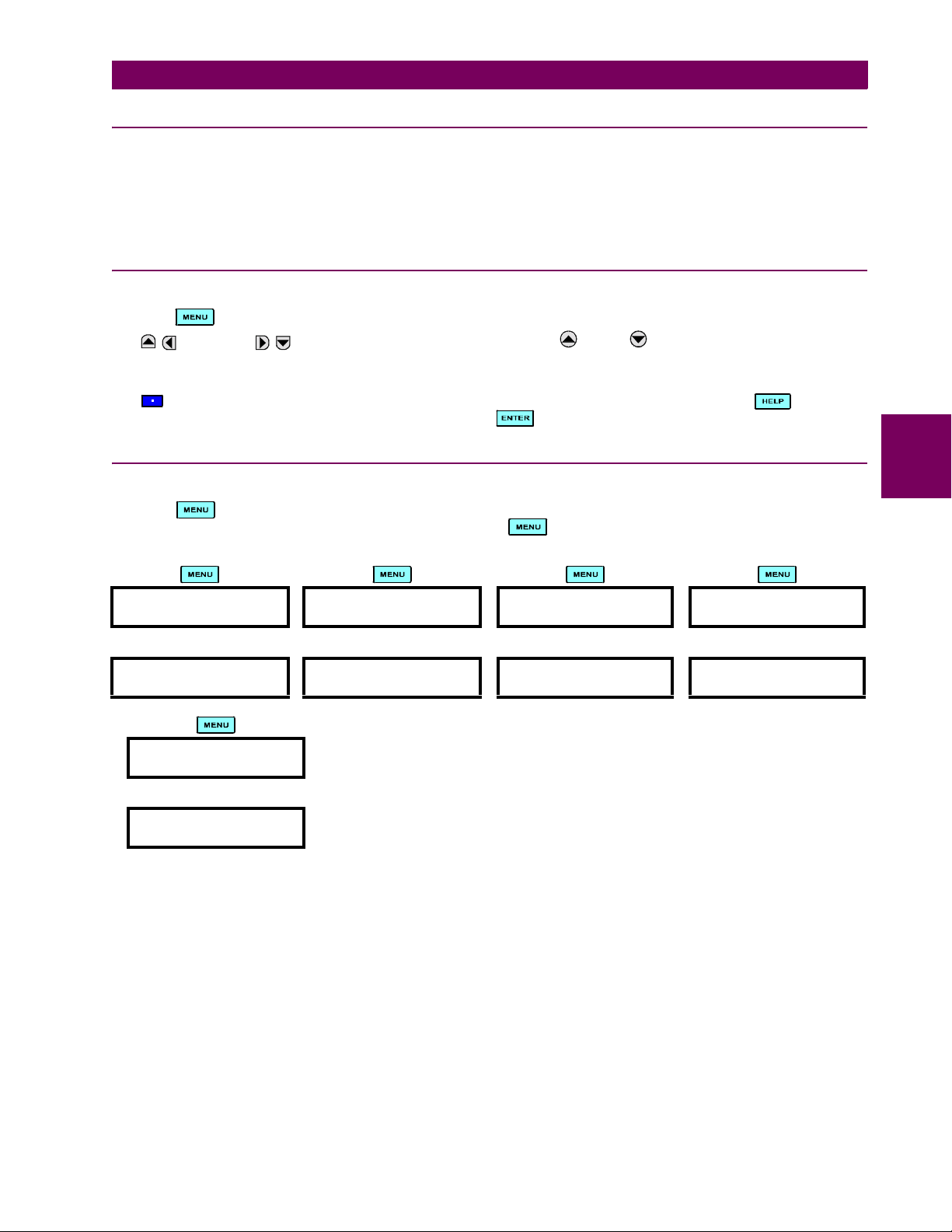

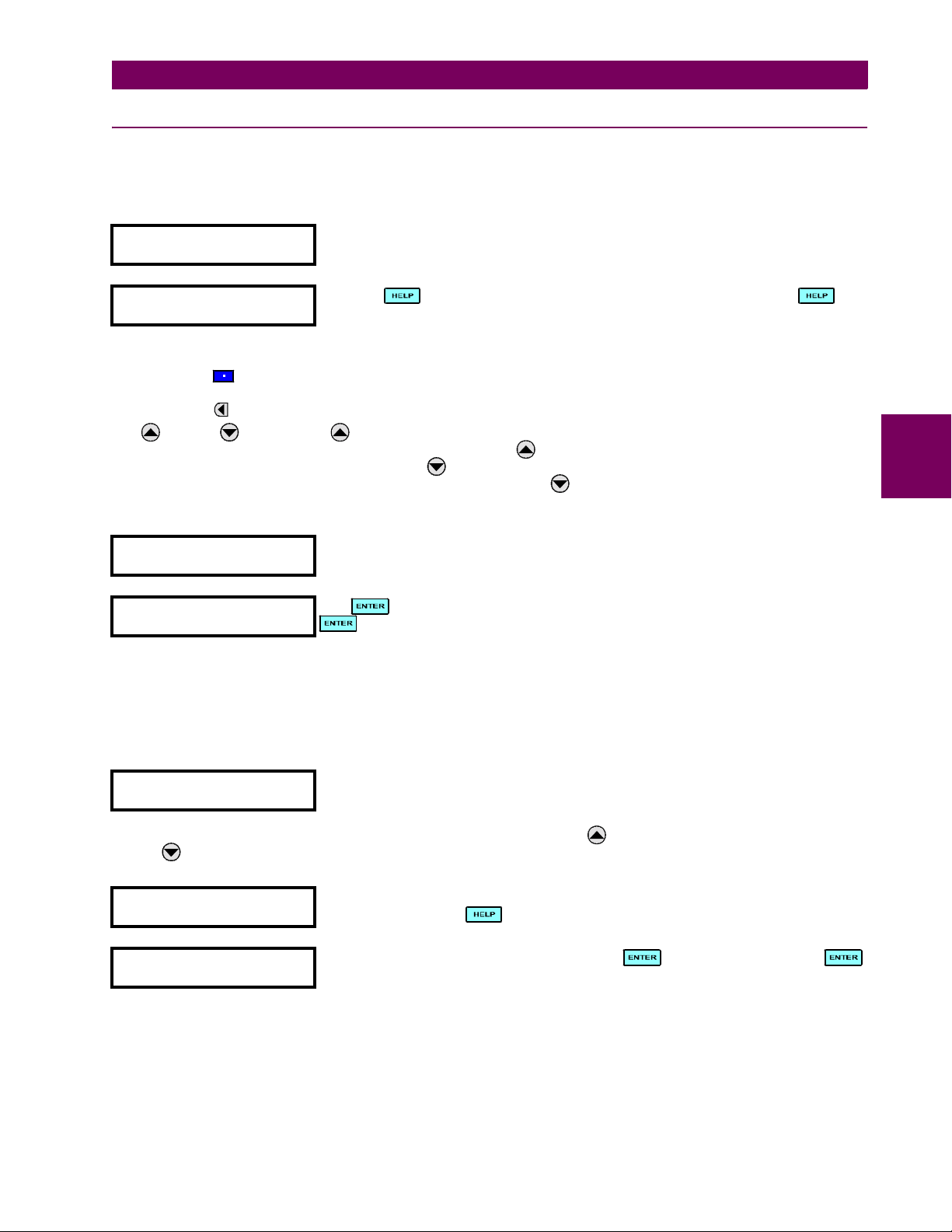

1.5USING THE RELAY 1.5.1 FACEPLATE KEYPAD

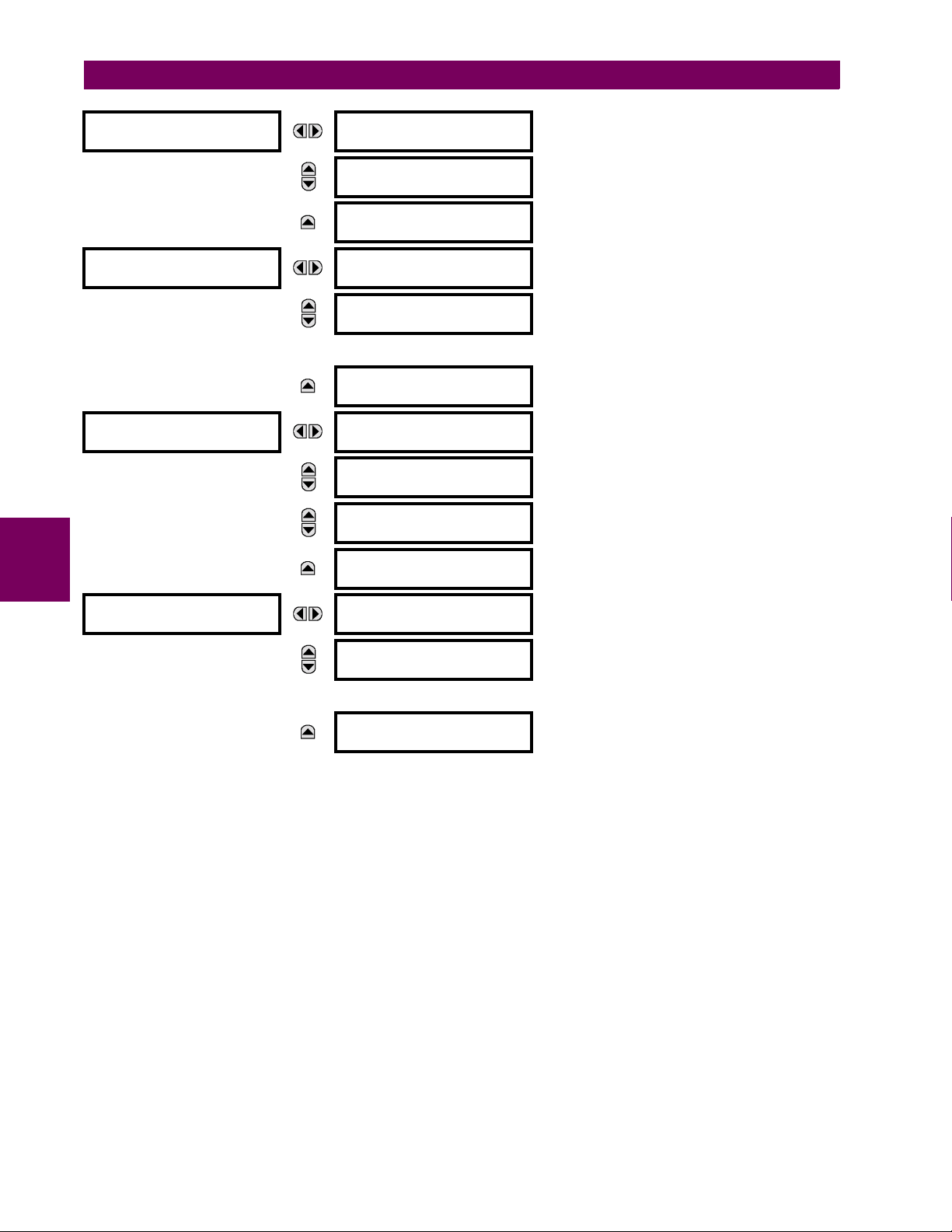

Display messages are organized into ‘pages’ under the following headings: Actual Values, Settings, Commands, and Targets. The key navigates through these pages. Each heading page is broken down further into logical subgroups.

The MESSAGE keys navigate through the subgroups. The VALUE keys scroll increment or decrement

numerical setting values when in programming mode. These keys also scroll through alphanumeric values in the text edit

mode. Alternatively, values may also be entered with the numeric keypad.

The key initiates and advance to the next character in text edit mode or enters a decimal point. The key may be

pressed at any time for context sensitive help messages. The key stores altered setting values.

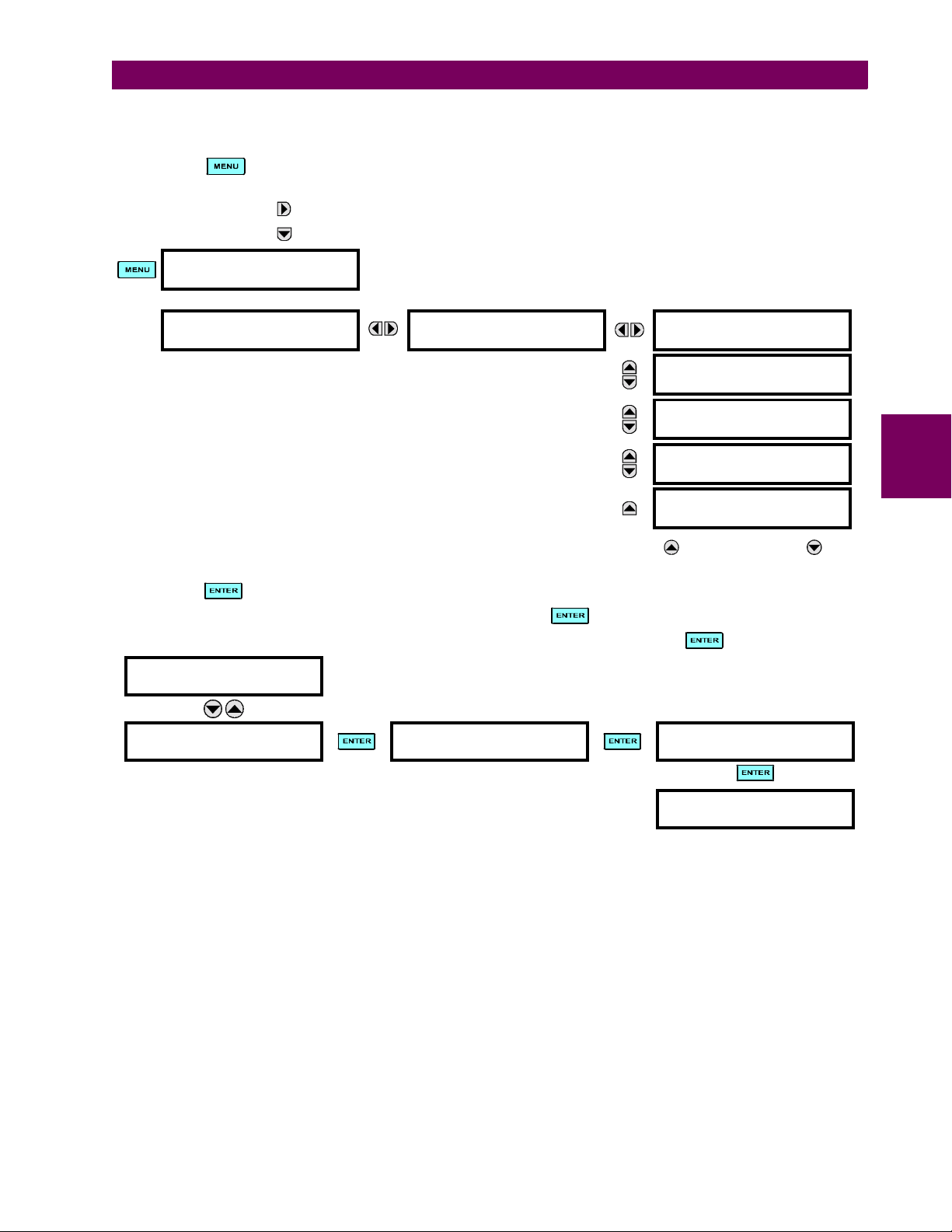

1.5.2 MENU NAVIGATION

Press the key to select the desired header display page (top-level menu). The header title appears momentarily followed by a header display page menu item. Each press of the key advances through the main heading pages as

illustrated below.

!!!

ACTUAL VALUES SETTINGS COMMANDS TARGETS

""""

## ACTUAL VALUES

## STATUS

## SETTINGS

## PRODUCT SETUP

## COMMANDS

## VIRTUAL INPUTS

No Active

Targets

!

USER DISPLAYS

(when in use)

"

1

User Display 1

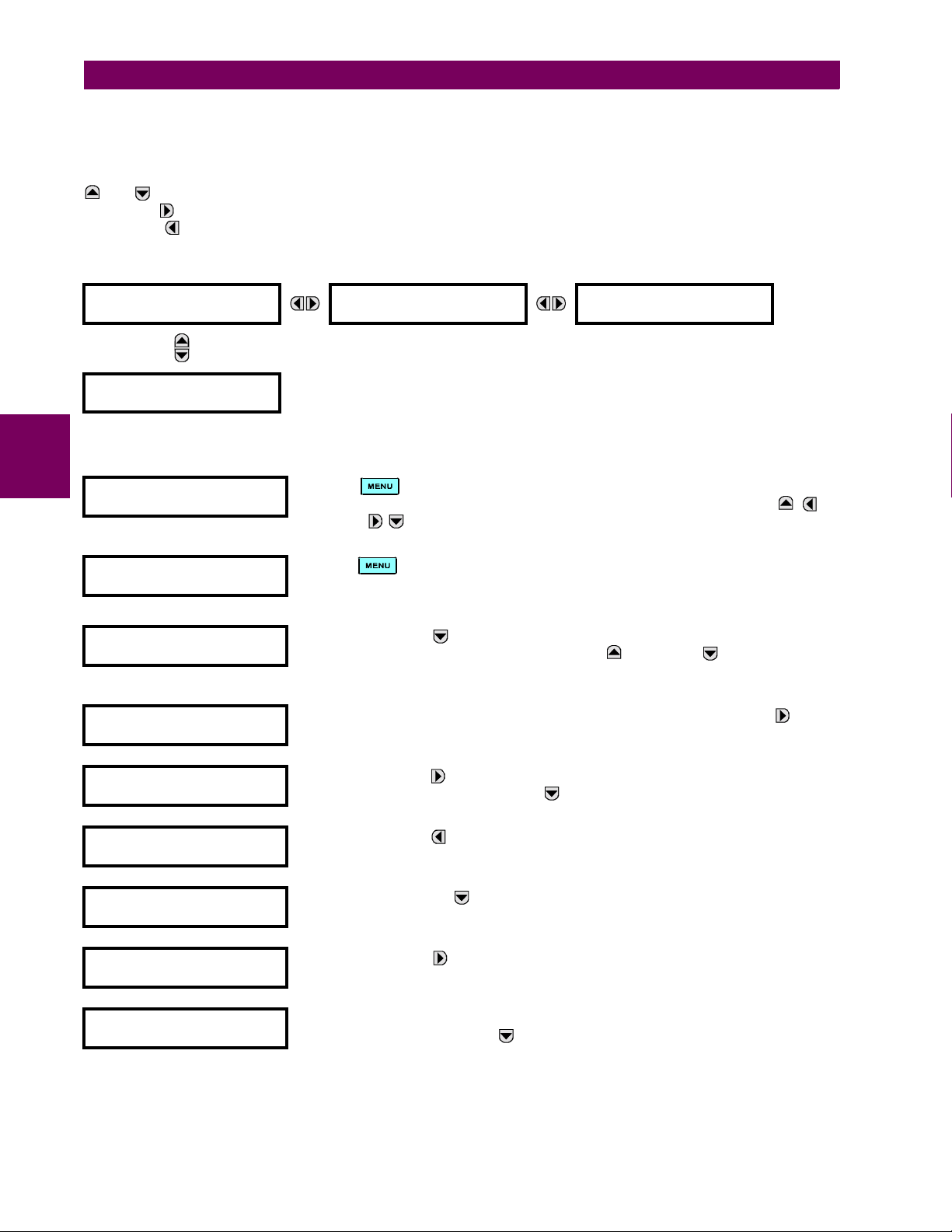

1.5.3 MENU HIERARCHY

The setting and actual value messages are arranged hierarchically. The header display pages are indicated by double

scroll bar characters (##), while sub-header pages are indicated by single scroll bar characters (#). The header display

pages represent the highest level of the hierarchy and the sub-header display pages fall below this level. The MESSAGE

and keys move within a group of headers, sub-headers, setting values, or actual values. Continually pressing the

MESSAGE key from a header display displays specific information for the header category. Conversely, continually

pressing the MESSAGE key from a setting value or actual value display returns to the header display.

HIGHEST LEVEL LOWEST LEVEL (SETTING VALUE)

## SETTINGS

## PRODUCT SETUP

## SETTINGS

## SYSTEM SETUP

# PASSWORD

# SECURITY

ACCESS LEVEL:

Restricted

GE Multilin T35 Transformer Management Relay 1-11

Page 22

1.5 USING THE RELAY 1 GETTING STARTED

1.5.4 RELAY ACTIVATION

1

The relay is defaulted to the “Not Programmed” state when it leaves the factory. This safeguards against the installation of

a relay whose settings have not been entered. When powered up successfully, the Trouble LED will be on and the In Service LED off. The relay in the “Not Programmed” state will block signaling of any output relay. These conditions will remain

until the relay is explicitly put in the “Programmed” state.

Select the menu message

RELAY SETTINGS:

Not Programmed

To put the relay in the “Programmed” state, press either of the VALUE keys once and then press . The faceplate Trouble LED will turn off and the In Service LED will turn on. The settings for the relay can be programmed manually

(refer to Chapter 5) via the faceplate keypad or remotely (refer to the EnerVista UR Setup Help file) via the EnerVista UR

Setup software interface.

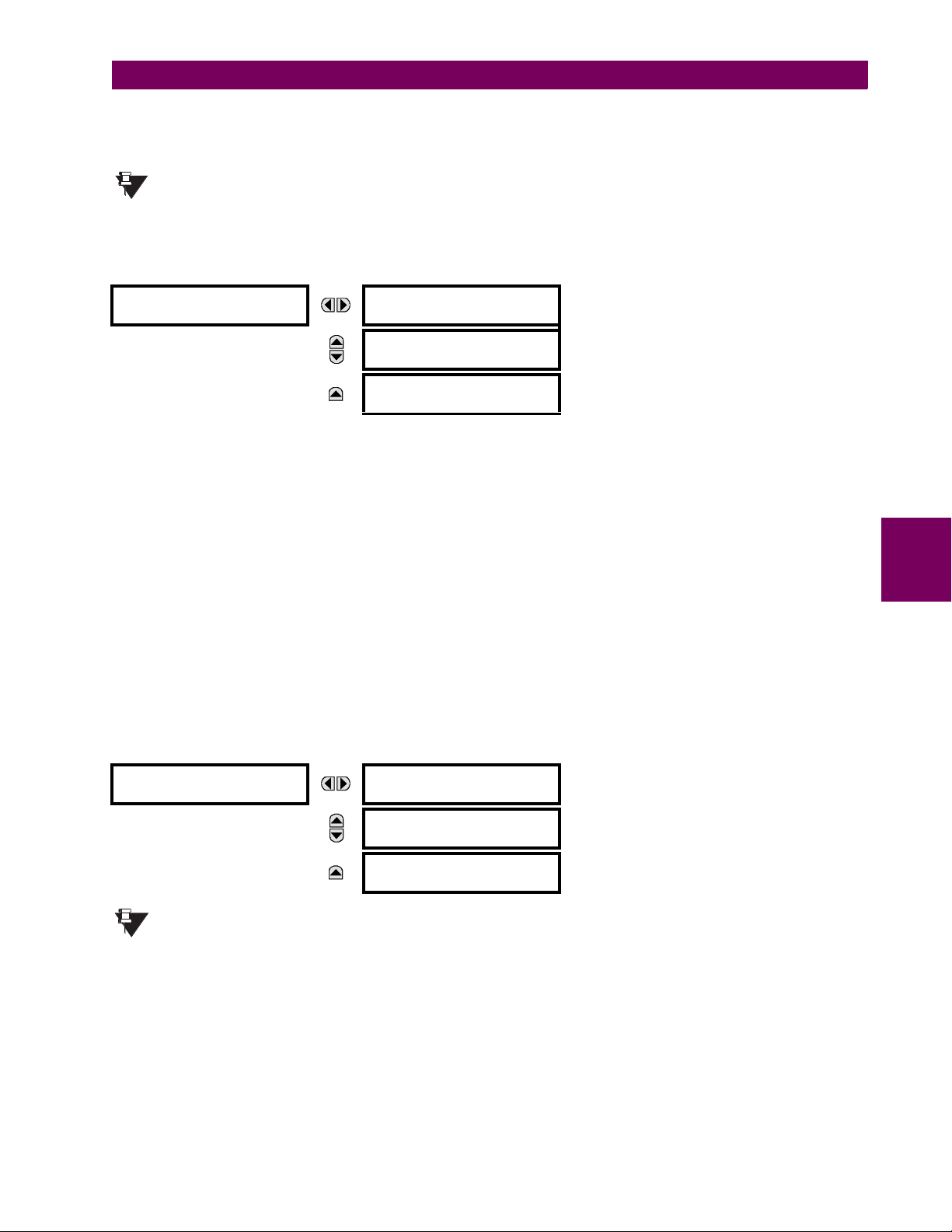

It is recommended that passwords be set up for each security level and assigned to specific personnel. There are two user

password security access levels, COMMAND and SETTING:

1. COMMAND

The COMMAND access level restricts the user from making any settings changes, but allows the user to perform the following operations:

• change state of virtual inputs

• clear event records

• clear oscillography records

• operate user-programmable pushbuttons

2. SETTING

The SETTING access level allows the user to make any changes to any of the setting values.

Refer to the Changing Settings section in Chapter 4 for complete instructions on setting up security level

passwords.

NOTE

SETTINGS ! PRODUCT SETUP !" INSTALLATION ! RELAY SETTINGS

1.5.5 RELAY PASSWORDS

1.5.6 FLEXLOGIC™ CUSTOMIZATION

FlexLogic™ equation editing is required for setting up user-defined logic for customizing the relay operations. See the FlexLogic™ section in Chapter 5 for additional details.

1-12 T35 Transformer Management Relay GE Multilin

Page 23

1 GETTING STARTED 1.5 USING THE RELAY

1.5.7 COMMISSIONING

Templated tables for charting all the required settings before entering them via the keypad are available from the GE Multilin website at http://www.GEindustrial.com/multilin

The T35 requires a minimum amount of maintenance when it is commissioned into service. The T35 is a microprocessorbased relay and its characteristics do not change over time. As such no further functional tests are required.

Furthermore the T35 performs a number of ongoing self-tests and takes the necessary action in case of any major errors

(see the Relay Self-Test section in Chapter 7 for details). However, it is recommended that maintenance on the T35 be

scheduled with other system maintenance. This maintenance may involve the following.

In-service maintenance:

1. Visual verification of the analog values integrity such as voltage and current (in comparison to other devices on the cor-

responding system).

2. Visual verification of active alarms, relay display messages, and LED indications.

3. LED test.

4. Visual inspection for any damage, corrosion, dust, or loose wires.

5. Event recorder file download with further events analysis.

Out-of-service maintenance:

1. Check wiring connections for firmness.

2. Analog values (currents, voltages, RTDs, analog inputs) injection test and metering accuracy verification. Calibrated

test equipment is required.

3. Protection elements setpoints verification (analog values injection or visual verification of setting file entries against

relay settings schedule).

4. Contact inputs and outputs verification. This test can be conducted by direct change of state forcing or as part of the

system functional testing.

5. Visual inspection for any damage, corrosion, or dust.

6. Event recorder file download with further events analysis.

7. LED Test and pushbutton continuity check.

Unscheduled maintenance such as during a disturbance causing system interruption:

1. View the event recorder and oscillography or fault report for correct operation of inputs, outputs, and elements.

If it is concluded that the relay or one of its modules is of concern, contact GE Multilin or one of its representatives for

prompt service.

.

1

GE Multilin T35 Transformer Management Relay 1-13

Page 24

1

1.5 USING THE RELAY 1 GETTING STARTED

1-14 T35 Transformer Management Relay GE Multilin

Page 25

2 PRODUCT DESCRIPTION 2.1 INTRODUCTION

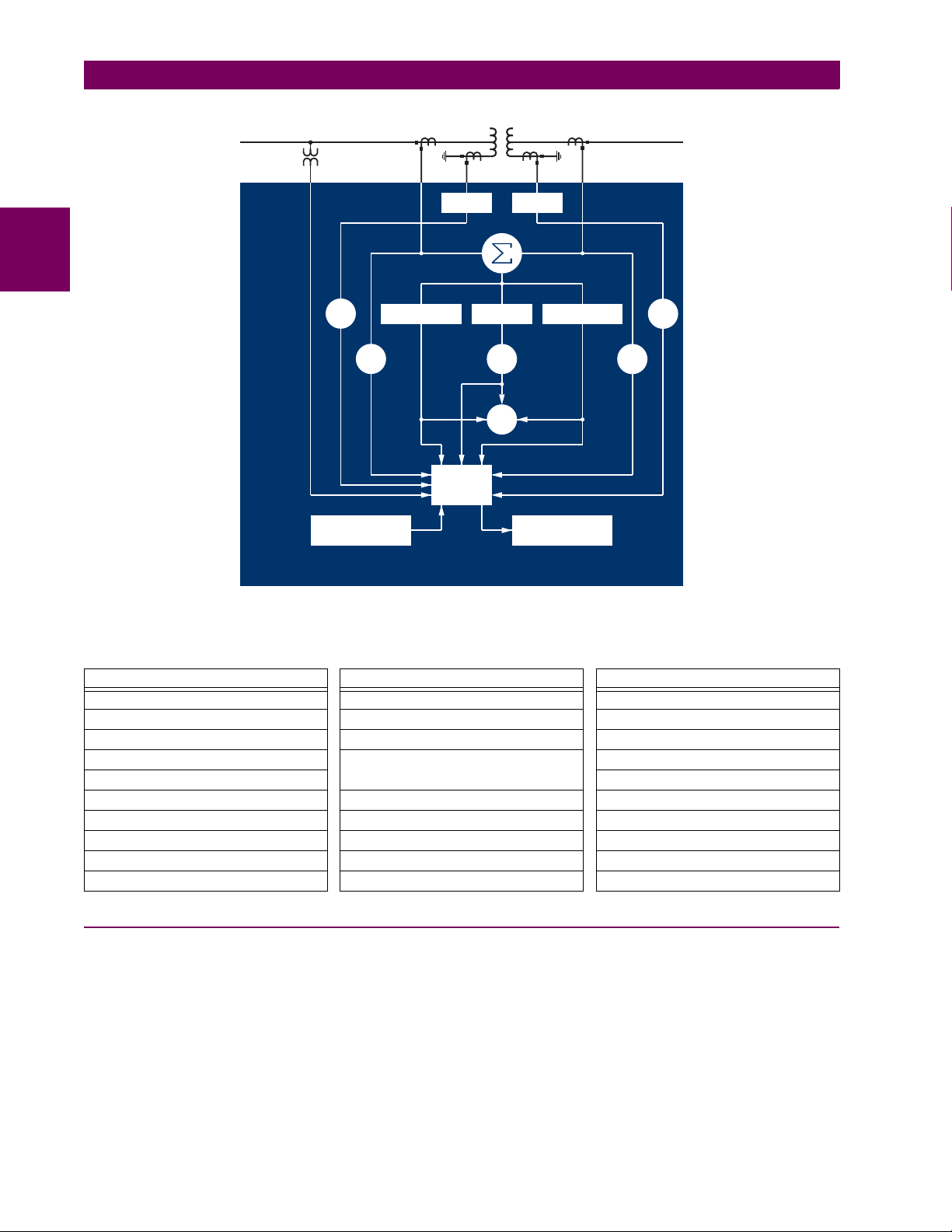

2 PRODUCT DESCRIPTION 2.1INTRODUCTION 2.1.1 OVERVIEW

The T35 Transformer Management Relay is a microprocessor-based relay intended for protecting small, medium, and large

three-phase power transformers involved in complicated power system configurations. The relay is available with two to six

banks of three-phase inputs: either CTs or CTs and VTs. Typical T35 applications include:

• Transformers with windings connected between two or more breakers,

• Transformers with windings without associated breakers, where the only available ones are those on buses, lines, or

feeders.

The percent and instantaneous differential elements are the primary protection elements. The backup protection elements,

such as instantaneous overcurrent, can be expressed in fully configurable FlexElements™. The relay can also be configured to protect transformers with any phase shift between the windings and handle up to 32 times the ratio mismatch (see

the Phase and Magnitude Compensation descriptions).

Voltage, current, and power metering is built into the relay as a standard feature. Current parameters are available as total

waveform RMS magnitude, or as fundamental frequency only RMS magnitude and angle (phasor).

The internal clock used for time-tagging can be synchronized with an IRIG-B signal or via the SNTP protocol over the

Ethernet port. This precise time stamping allows the sequence of events to be determined throughout the system. Events

can also be programmed (via FlexLogic™ equations) to trigger oscillography data capture which may be set to record the

measured parameters before and after the event for viewing on a personal computer (PC). These tools significantly reduce

troubleshooting time and simplify report generation in the event of a system fault.

A faceplate RS232 port may be used to connect to a PC for the programming of settings and the monitoring of actual values. A variety of communications modules are available. Two rear RS485 ports allow independent access by operating and

engineering staff. All serial ports use the Modbus

®

RTU protocol. The RS485 ports may be connected to system computers

with baud rates up to 115.2 kbps. The RS232 port has a fixed baud rate of 19.2 kbps. Optional communications modules

include a 10BaseF Ethernet interface which can be used to provide fast, reliable communications in noisy environments.

Another option provides two 10BaseF fiber optic ports for redundancy. The Ethernet port supports IEC 61850, Modbus

TCP, and TFTP protocols, and allows access to the relay via any standard web browser (T35 web pages). The IEC 608705-104 protocol is supported on the Ethernet port. DNP 3.0 and IEC 60870-5-104 cannot be enabled at the same time.

The T35 IEDs use flash memory technology which allows field upgrading as new features are added. The following Single

Line Diagram illustrates the relay functionality using ANSI (American National Standards Institute) device numbers.

2

®

/

Table 2–1: DEVICE NUMBERS AND FUNCTIONS

DEVICE

NUMBER

50/87 Instantaneous Differential Overcurrent

51G Ground Time Overcurrent

51P Phase Time Overcurrent

87T Transformer Differential

FUNCTION

GE Multilin T35 Transformer Management Relay 2-1

Page 26

2.1 INTRODUCTION 2 PRODUCT DESCRIPTION

2

Measure

3I_0

51P-1

Calculate

Restraint Amps

Metering

51G

Transducer Input

T35 Transformer Management Relay

Figure 2–1: SINGLE LINE DIAGRAM

Calculate

Operate Amps

50/87

87T

Measure

3I_0

Calculate

2nd, 5th harmonics

FlexElement

51G

51P-2

TM

828725A3.CDR

Table 2–2: OTHER DEVICE FUNCTIONS

FUNCTION FUNCTION FUNCTION

Breaker Arcing Current I

Contact Inputs (up to 96) FlexLogic™ Equations Time Synchronization over SNTP

Contact Outputs (up to 64) IEC 61850 Communications Transducer Inputs/Outputs

Control Pushbuttons Metering: Current, Voltage, Power,

Data Logger User-Programmable Fault Reports

Digital Counters Modbus Communications User Programmable LEDs

Direct Inputs/Outputs (32) Modbus User Map User Programmable Pushbuttons

DNP 3.0 or IEC 60870-5-104 Protocol Non-Volatile Latches User Programmable Self-Tests

Ethernet Global Data (EGD) Protocol Non-Volatile Selector Switch Virtual Inputs (32)

Event Recorder Oscillography Virtual Outputs (64)

2

t FlexElements™ Setting Groups (6)

Power Factor, Frequency

User Definable Displays

2.1.2 ORDERING

The relay is available as a 19-inch rack horizontal mount unit and consists of the following modules: power supply, CPU,

CT/VT, digital input/output, transducer input/output. Each of these modules can be supplied in a number of configurations

specified at the time of ordering. The information required to completely specify the relay is provided in the following table

(see Chapter 3 for full details of relay modules).

2-2 T35 Transformer Management Relay GE Multilin

Page 27

2 PRODUCT DESCRIPTION 2.1 INTRODUCTION

Table 2–3: T35 ORDER CODES

T35 - * 00 - H * * - F ** - H ** - M ** - P ** - U ** - W **

BASE UNIT

CPU

SOFTWARE

MOUNTING

FACEPLATE/ DISPLAY

(applicable only to

horizontal mount units)

POWER SUPPLY

(redundant supply only

available in horizontal units; must

be same type as main supply)

CT/VT MODULES

DIGITAL INPUTS/OUTPUTS

TRANSDUCER

INPUTS/OUTPUTS

(select a maximum of 3 per unit)

INTER-RELAY

COMMUNICATIONS

(select a maximum of 1 per unit)

NOTE

T35 - * 00 - V F * - F ** - H ** - M ** -#**

T35 | | ||| | | | | | |

E

| | | | | | | | | |

G

| | | | | | | | | |

H

| | | | | | | | | |

00

||| | | | | | |

01 ||| | | | | | |

03 ||| | | | | | |

04 ||| | | | | | |

H|| | | | | | |

V F

| | | | | | |

C || | | | | |

P || | | | | |

A || | | | | |

B || | | | | |

D || | | | | |

G || | | | | |

R || | | | | |

S || | | | | |

H | | | | | |

H | | | | | RH

L | | | | | |

L | | | | | RL

8F | 8F | 8F |

8G | 8G | 8G |

8H | 8H | 8H |

8J | 8J | 8J |

For vertical mounting units, # = slot P for digital and transducer

input/output modules; # = slot R for inter-relay communications

modules

XX XX XX XX XX

4A 4A 4A 4A 4A

4B 4B 4B 4B 4B

4C 4C 4C 4C 4C

4L 4L 4L 4L 4L

67 67 67 67 67

6A 6A 6A 6A 6A

6B 6B 6B 6B 6B

6C 6C 6C 6C 6C

6D 6D 6D 6D 6D

6E 6E 6E 6E 6E

6F 6F 6F 6F 6F

6G 6G 6G 6G 6G

6H 6H 6H 6H 6H

6K 6K 6K 6K 6K

6L 6L 6L 6L 6L

6M 6M 6M 6M 6M

6N 6N 6N 6N 6N

6P 6P 6P 6P 6P

6R 6R 6R 6R 6R

6S 6S 6S 6S 6S

6T 6T 6T 6T 6T

6U 6U 6U 6U 6U

5A 5A 5A 5A 5A

5C 5C 5C 5C 5C

5D 5D 5D 5D 5D

5E 5E 5E 5E 5E

5F 5F 5F 5F 5F

For Full Size Horizontal Mount

Reduced Size Vertical Mount (see note below for value of slot #)

Base Unit

RS485 + RS485 (ModBus RTU, DNP)

RS485 + 10BaseF (Ethernet, Modbus TCP/IP, DNP)

RS485 + Redundant 10BaseF (Ethernet, Modbus TCP/IP, DNP)

No Software Options

Ethernet Global Data (EGD); only available with Type G and H CPUs

IEC 61850

Ethernet Global Data and IEC 61850; only available with Type G and H CPUs

Horizontal (19” rack)

Vertical (3/4 rack) with English display

English display

English display with 4 small and 12 large programmable pushbuttons

Chinese display

Chinese display with 4 small and 12 large programmable pushbuttons

French display

French display with 4 small and 12 large programmable pushbuttons

Russian display

Russian display with 4 small and 12 large programmable pushbuttons

125 / 250 V AC/DC power supply

125 / 250 V AC/DC with redundant 125 / 250 V AC/DC power supply

24 to 48 V (DC only) power supply

24 to 48 V (DC only) with redundant 24 to 48 V DC power supply

Standard 4CT/4VT

Sensitive Ground 4CT/4VT

Standard 8CT

Sensitive Ground 8CT

No Module

4 Solid-State (No Monitoring) MOSFET Outputs

4 Solid-State (Voltage w/ opt Current) MOSFET Outputs

4 Solid-State (Current w/ opt Voltage) MOSFET Outputs

14 Form-A (No Monitoring) Latching Outputs

8 Form-A (No Monitoring) Outputs

2 Form-A (Volt w/ opt Curr) & 2 Form-C outputs, 8 Digital Inputs

2 Form-A (Volt w/ opt Curr) & 4 Form-C Outputs, 4 Digital Inputs

8 Form-C Outputs

16 Digital Inputs

4 Form-C Outputs, 8 Digital Inputs

8 Fast Form-C Outputs

4 Form-A (Voltage w/ opt Current) Outputs, 8 Digital Inputs

6 Form-A (Voltage w/ opt Current) Outputs, 4 Digital Inputs

4 Form-C & 4 Fast Form-C Outputs

2 Form-A (Curr w/ opt Volt) & 2 Form-C Outputs, 8 Digital Inputs

2 Form-A (Curr w/ opt Volt) & 4 Form-C Outputs, 4 Digital Inputs

4 Form-A (Current w/ opt Voltage) Outputs, 8 Digital Inputs

6 Form-A (Current w/ opt Voltage) Outputs, 4 Digital Inputs

2 Form-A (No Monitoring) & 2 Form-C Outputs, 8 Digital Inputs

2 Form-A (No Monitoring) & 4 Form-C Outputs, 4 Digital Inputs

4 Form-A (No Monitoring) Outputs, 8 Digital Inputs

6 Form-A (No Monitoring) Outputs, 4 Digital Inputs

4 dcmA Inputs, 4 dcmA Outputs (only one 5A module is allowed)

8 RTD Inputs

4 RTD Inputs, 4 dcmA Outputs (only one 5D module is allowed)

4 RTD Inputs, 4 dcmA Inputs

8 dcmA Inputs

C37.94SM, 1300nm single-mode, ELED, 1 channel single-mode

2A

C37.94SM, 1300nm single-mode, ELED, 2 channel single-mode

2B

Bi-phase, single channel

2E

Bi-phase, dual channel

2F

1550 nm, single-mode, LASER, 1 Channel

72

1550 nm, single-mode, LASER, 2 Channel

73

Channel 1 - RS422; Channel 2 - 1550 nm, single-mode, LASER

74

Channel 1 - G.703; Channel 2 - 1550 nm, Single-mode LASER

75

IEEE C37.94, 820 nm, multimode, LED, 1 Channel

76

IEEE C37.94, 820 nm, multimode, LED, 2 Channels

77

820 nm, multi-mode, LED, 1 Channel

7A

1300 nm, multi-mode, LED, 1 Channel

7B

1300 nm, single-mode, ELED, 1 Ch annel

7C

1300 nm, single-mode, LASER, 1 Channel

7D

Channel 1 - G.703; Channel 2 - 820 nm, multi-mode

7E

Channel 1 - G.703; Channel 2 - 1300 nm, multi-mode

7F

Channel 1 - G.703; Channel 2 - 1300 nm, single-mode ELED

7G

820 nm, multi-mode, LED, 2 Channels

7H

1300 nm, multi-mode, LED, 2 Channels

7I

1300 nm, single-mode, ELED, 2 Channels

7J

1300 nm, single-mode, LASER, 2 Channels

7K

Channel 1 - RS422; Channel 2 - 820 nm, multi-mode, LED

7L

Channel 1 - RS422; Channel 2 - 1300 nm, multi-mode, LED

7M

Channel 1 - RS422; Channel 2 - 1300 nm, single-mode, ELED

7N

Channel 1 - RS422; Channel 2 - 1300 nm, single-mode, LASER

7P

Channel 1 - G.703; Channel 2 - 1300 nm, single-mode LASER

7Q

G.703, 1 Channel

7R

G.703, 2 Channels

7S

RS422, 1 Channel

7T

RS422, 2 Channels

7W

2

GE Multilin T35 Transformer Management Relay 2-3

Page 28

2.1 INTRODUCTION 2 PRODUCT DESCRIPTION

The order codes for replacement modules to be ordered separately are shown in the following table. When ordering a

replacement CPU module or faceplate, please provide the serial number of your existing unit.

Table 2–4: ORDER CODES FOR REPLACEMENT MODULES

POWER SUPPLY

(redundant supply only

available in horizontal units; must

be same type as main supply)

CPU | 9E | RS485 and RS485 (ModBus RTU, DNP 3.0)

2

FACEPLATE/DISPLAY | 3C | Horizontal faceplate with keypad and English display

DIGITAL

INPUTS/OUTPUTS

CT/VT

MODULES

(NOT AVAILABLE FOR THE C30)

UR INTER-RELAY COMMUNICATIONS

TRANSDUCER

INPUTS/OUTPUTS

UR - ** -

| 1H | 125 / 250 V AC/DC

| 1L | 24 to 48 V (DC only)

| RH | redundant 125 / 250 V AC/DC

| RH | redundant 24 to 48 V (DC only)

| 9G | RS485 and 10Base-F (Ethernet, Modbus TCP/IP, DNP 3.0)

| 9H | RS485 and Redundant 10Base-F (Ethernet, ModBus TCP/IP, DNP 3.0)

| 3F | Vertical faceplate with display and keypad

| 3P | Horizontal faceplate with keypad, user-programmable pushbuttons, and English display

| 3R | Horizontal faceplate with keypad and Russian display

| 3S | Horizontal faceplate with keypad, user-programmable pushbuttons, and Russian display

| 4A | 4 Solid-State (no monitoring) MOSFET Outputs

| 4B | 4 Solid-State (voltage with optional current) MOSFET Outputs

| 4C | 4 Solid-State (current with optional voltage) MOSFET Outputs

| 4L | 14 Form-A (no monitoring) Latching Outputs

| 67 | 8 Form-A (no monitoring) Outputs

| 6A | 2 Form-A (voltage with optional current) and 2 Form-C Outputs, 8 Digital Inputs

| 6B | 2 Form-A (voltage with optional current) and 4 Form-C Outputs, 4 Digital Inputs

| 6C | 8 Form-C Outputs

| 6D | 16 Digital Inputs

| 6E | 4 Form-C Outputs, 8 Digital Inputs

| 6F | 8 Fast Form-C Outputs

| 6G | 4 Form-A (voltage with optional current) Outputs, 8 Digital Inputs

| 6H | 6 Form-A (voltage with optional current) Outputs, 4 Digital Inputs

| 6K | 4 Form-C & 4 Fast Form-C Outputs

| 6L | 2 Form-A (current with optional voltage) and 2 Form-C Outputs, 8 Digital Inputs

| 6M | 2 Form-A (current with optional voltage) and 4 Form-C Outputs, 4 Digital Inputs

| 6N | 4 Form-A (current with optional voltage) Outputs, 8 Digital Inputs

| 6P | 6 Form-A (current with optional voltage) Outputs, 4 Digital Inputs

| 6R | 2 Form-A (no monitoring) and 2 Form-C Outputs, 8 Digital Inputs

| 6S | 2 Form-A (no monitoring) and 4 Form-C Outputs, 4 Digital Inputs

| 6T | 4 Form-A (no monitorin g) Outputs, 8 Digital Inputs

| 6U | 6 Form-A (no monitoring) Outputs, 4 Digital Inputs

| 8F | Standard 4CT/4VT

| 8G | Sensitive Ground 4CT/4VT

| 8H | Standard 8CT

| 8J | Sensitive Ground 8CT

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 5A | 4 dcmA Inputs, 4 dcmA Outputs (only one 5A module is allowed)

| 5C | 8 RTD Inputs

| 5D | 4 RTD Inputs, 4 dcmA Outputs (only one 5D module is allowed)

| 5E | 4 dcmA Inputs, 4 RTD Inputs

| 5F | 8 dcmA Inputs

| C37.94SM, 1300nm single-mode, ELED, 1 channel single-mode

2A

| C37.94SM, 1300nm single-mode, ELED, 2 channel single-mode

2B

| 1550 nm, single-mode, LASER, 1 Channel

72

| 1550 nm, single-mode, LASER, 2 Channel

73

| Channel 1 - RS422; Channel 2 - 1550 nm, single-mode, LASER

74

| Channel 1 - G.703; Channel 2 - 1550 nm, Single-mode LASER

75

| IEEE C37.94, 820 nm, multimode, LED, 1 Channel

76

| IEEE C37.94, 820 nm, multimode, LED, 2 Channels

77

| 820 nm, multi-mode, LED, 1 Channel

7A

| 1300 nm, multi-mode, LED, 1 Channel

7B

| 1300 nm, single-mode, ELED, 1 Channel

7C

| 1300 nm, single-mode, LASER, 1 Channel

7D

| Channel 1 - G.703; Channel 2 - 820 nm, multi-mode

7E

| Channel 1 - G.703; Channel 2 - 1300 nm, multi-mode

7F

| Channel 1 - G.703; Channel 2 - 1300 nm, single-mode ELED

7G

| 820 nm, multi-mode, LED, 2 Channels

7H

| 1300 nm, multi-mode, LED, 2 Channels

7I

| 1300 nm, single-mode, ELED, 2 Channels

7J

| 1300 nm, single-mode, LASER, 2 Channels

7K

| Channel 1 - RS422; Channe l 2 - 820 nm, multi-mode, LED

7L

| Channel 1 - RS422; Channel 2 - 1300 nm, multi-mode, LED

7M

| Channel 1 - RS422; Channel 2 - 1300 nm, single-mode, ELED

7N

| Channel 1 - RS422; Channel 2 - 1300 nm, single-mode, LASER

7P

| Channel 1 - G.703; Channel 2 - 1300 nm, single-mode LASER

7Q

| G.703, 1 Channel

7R

| G.703, 2 Channels

7S

7T

7W

RS422, 1 Channel

RS422, 2 Channels

2-4 T35 Transformer Management Relay GE Multilin

Page 29

2 PRODUCT DESCRIPTION 2.2 SPECIFICATIONS

2.2SPECIFICATIONSSPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE

2.2.1 PROTECTION ELEMENTS

The operating times below include the activation time of a trip rated Form-A output contact unless otherwise indicated. FlexLogic™ operands of a given element are 4 ms faster. This should be taken into account when using

NOTE

FlexLogic™ to interconnect with other protection or control elements of the relay, building FlexLogic™ equations, or

interfacing with other IEDs or power system devices via communications or different output contacts.

PERCENT DIFFERENTIAL

Characteristic: Differential Restraint pre-set

Number of zones: 2

Minimum pickup: 0.05 to 1.00 pu in steps of 0.001

Slope 1 range: 15 to 100% in steps of 1%

Slope 2 range: 50 to 100% in steps of 1%

Kneepoint 1: 1.0 to 2.0 pu in steps of 0.0001

Kneepoint 2: 2.0 to 30.0 pu in steps of 0.0001

nd

harmonic inhibit level: 1.0 to 40.0% in steps of 0.1

2

nd

harmonic inhibit function: Adaptive, Traditional, Disabled

2

nd

harmonic inhibit mode: Per-phase, 2-out-of-3, Average

2

th

harmonic inhibit range: 1.0 to 40.0% in steps of 0.1

5

Operate times:

Harmonic inhibits selected: 20 to 30 ms

No harmonic inhibits selected: 5 to 20 ms

Dropout level: 97 to 98% of pickup

Level accuracy: ±0.5% of reading or ±1% of rated

(whichever is greater)

INSTANTANEOUS DIFFERENTIAL

Pickup level: 2.00 to 30.00 pu in steps of 0.01

Dropout level: 97 to 98% of pickup

Level accuracy: ±0.5% of reading or ±1% of rated

(whichever is greater)

Operate time: < 20 ms at 3 × pickup at 60 Hz

PHASE/GROUND TOC

Current: Phasor or RMS

Pickup level: 0.000 to 30.000 pu in steps of 0.001

Dropout level: 97% to 98% of Pickup

Level accuracy:

for 0.1 to 2.0 × CT: ±0.5% of reading or ±1% of rated

(whichever is greater)

for > 2.0 × CT: ±1.5% of reading > 2.0 × CT rating

Curve shapes: IEEE Moderately/Very/Extremely