Page 1

INSTALLATION AND OPERATION

SX TRANSISTOR CONTROL Page 1

SEPARATELY EXCITED (SX) TRANSISTORIZED TRACTION MOTOR CONTROL

AND SERIES PUMP MOTOR CONTROL

INSTALLATION AND OPERATION MANUAL

(GE Models IC3645SR5W606F1 [software rev. BL3C and higher] and IC3645SP5U600F1)

Note: The information contained herein is intended to assist OEM's, Dealers and Users of electric vehicles

in the application, installation and service of GE solid-state controllers. This manual does not purport to

cover all variations in OEM vehicle types. Nor does it provide for every possible contingency to be met

involving vehicle installation, operation or maintenance. For additional information and/or problem

resolution, please refer the matter to the OEM vehicle manufacturer through his normal field service

channels. Do not contact GE directly for this assistance.

Table of Contents

General Electric Company May 2003

Section 1.0 INTRODUCTION .........................................................................................................................................................4

1.1 Motor Characteristics...............................................................................................................4

1.2 Solid-State Reversing................................................................................................................5

1.3 Flexible System Application..................................................................................................... 5

1.4 More Features with Fewer Components.................................................................................5

Section 2.0 FEATURES OF SX FAMILY OF MOTOR CONTROLLERS .....................................................................................6

2.1 Performance .............................................................................................................................. 6

2.1.1 Oscillator Card Features...................................................................................................6

2.1.1.a Standard Operation...................................................................................................6

2.1.1.b Creep Speed...............................................................................................................6

2.1.1.c Controlled Acceleration ...........................................................................................6

2.1.2 Current Limit.......................................................................................................................6

2.1.3 Braking................................................................................................................................6

2.1.3.a Regenerative Braking to Zero Speed.......................................................................6

2.1.3.b Pedal Position Plug Braking..................................................................................... 6

2.1.3.c Auto Braking .............................................................................................................. 6

2.1.4 Auxiliary Speed Control ....................................................................................................6

Revised May 2003

Page 2

INSTALLATION AND OPERATION

SX TRANSISTOR CONTROL Page 2

Table of Contents ( Continued )

2.1.4.a Field Weakening ................................................................................................................6

2.1.4.b Speed Limits ...................................................................................................................... 7

2.1.5 Ramp Operation.................................................................................................................7

2.1.5.a Ramp Start..................................................................................................................7

2.1.5.b Anti-Rollback..............................................................................................................7

2.1.6 On-Board Coil Drivers and Internal Coil Suppression .................................................7

2.2 System Protective Override......................................................................................................7

2.2.1 Static Return to Off (SRO) ................................................................................................7

2.2.2 Accelerator Volts Hold Off ...............................................................................................7

2.2.3 Pulse Monitor Trip (PMT)................................................................................................. 7

2.2.4 Thermal Protector (TP)................................... ..................................................................7

2.2.5 Low Voltage .......................................................................................................................7

2.3 Diagnostics................................................ ................................................................................8

2.3.1 Systems Diagnostics......................................................................................................... 8

2.3.2 Status Codes......................................................................................................................8

2.3.2.a Standard Status Codes........................................ ..................................................... 8

2.3.2.b Stored Status Codes .................................................................................................8

2.3.3 Hourmeter Readings .........................................................................................................8

2.3.3.a Maintenance Alert and Speed Limit ....................................................................... 8

2.3.4 Battery Discharge Indication (BDI)................................................................................. 8

2.3.4.a Internal Resistance Compensation ..................... ...........................................................8

2.3.5 Handset ..............................................................................................................................8

2.3.6 RS-232 Communication Port ............................... ............................................................8

2.3.6.a Interactive Dash Display Modes ................... ................................................................8

2.3.7 Circuit Board Coil Driver Modules...................................................................................9

2.3.8 Truck Management Module (TMM)................................................................................ 9

2.4 Hydraulic Pump Control............................................................................................................9

Section 3.0 ORDERING INFORMATION, ELEMENTARY AND OUTLINE DRAWINGS ......................................................10

3.1 Ordering Information for Separately Excited Controls .................................................................10

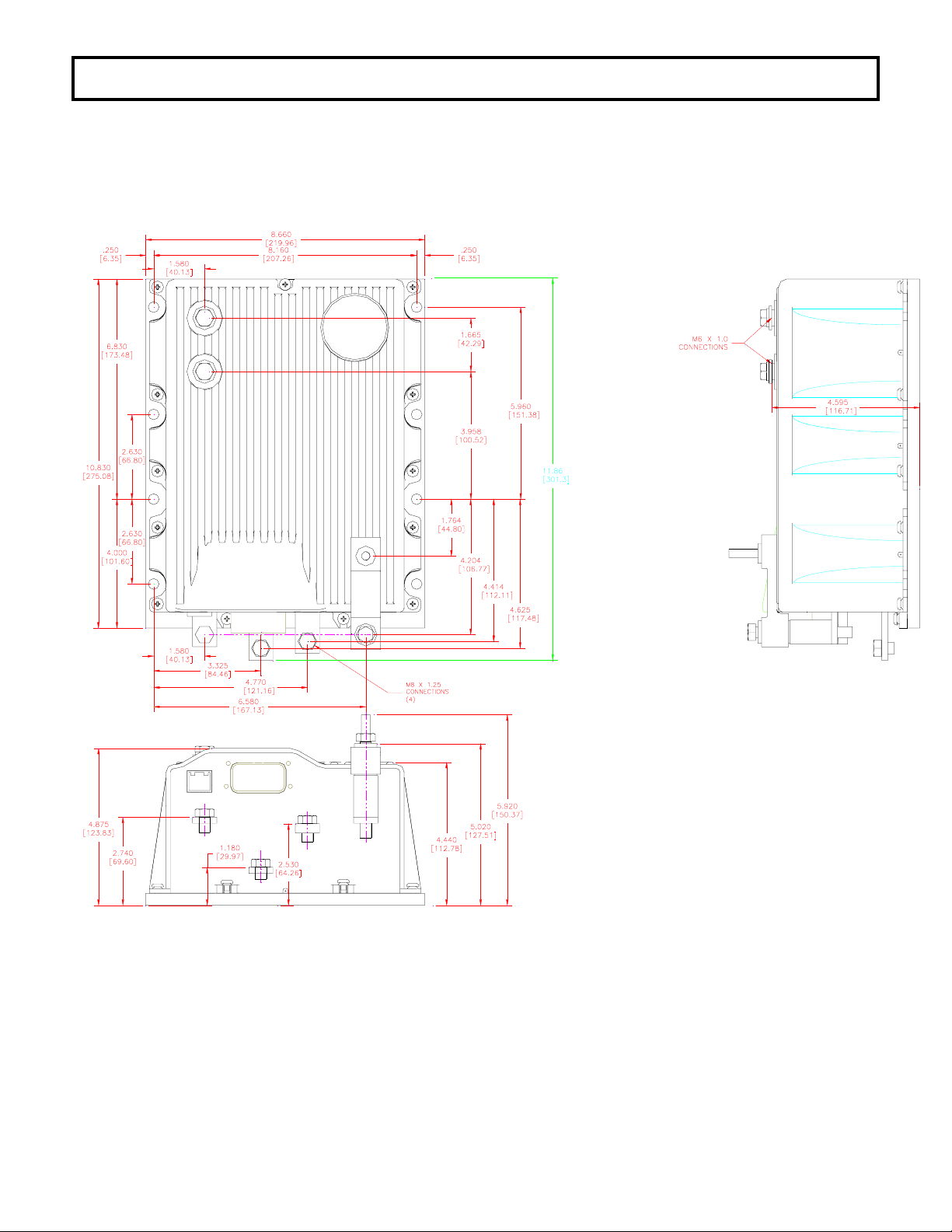

3.2 Outline: SX-4 and SR-4 Package Size............................................................................................. 11

3.3 Outline: SX-3 and SR-3 Package Size............................................................................................. 12

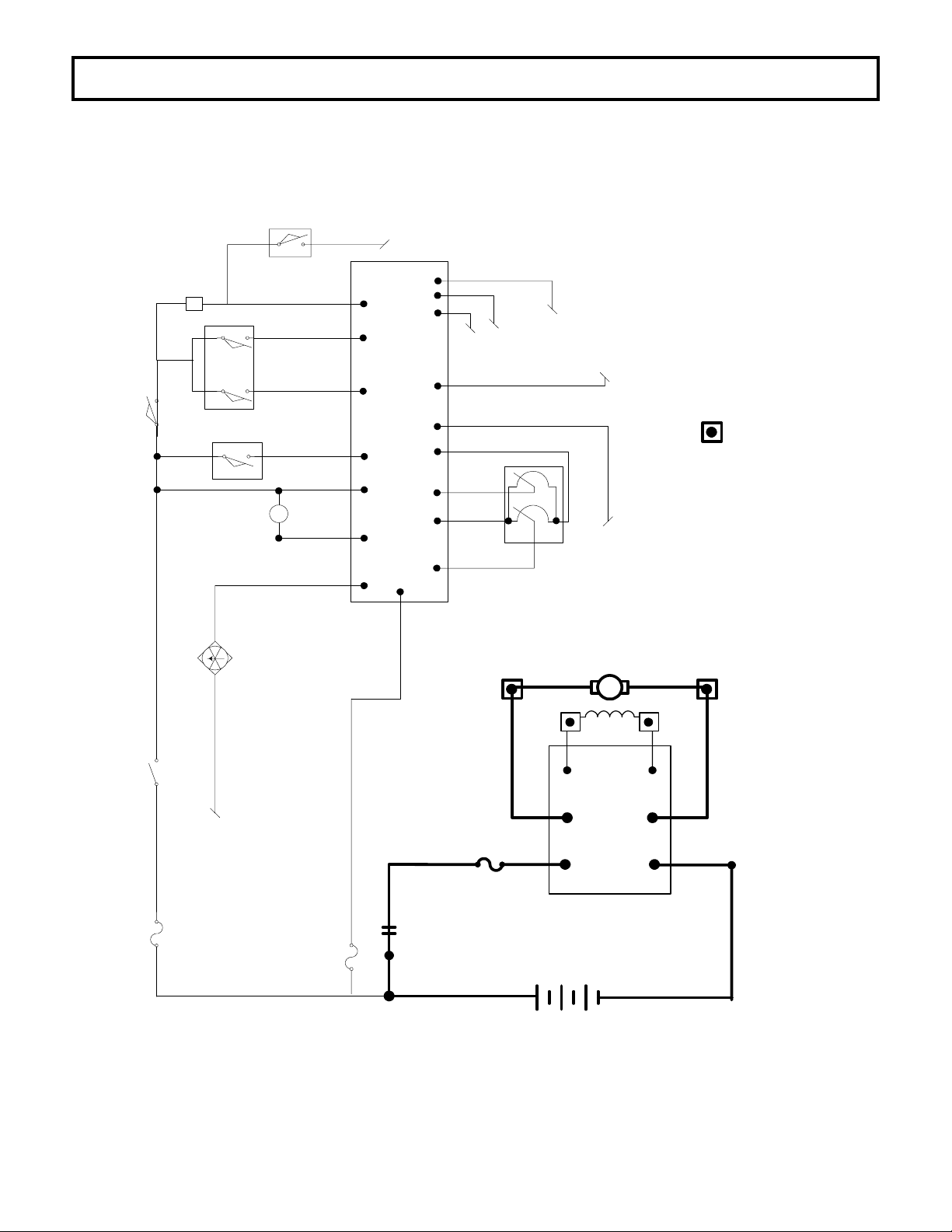

3.4 Traction Elementary.......................................................................................................................... 13

3.5 Pump Elementary...............................................................................................................................14

3.6 Traction and Pump Control Input / Output List.............................................................................. 15

Section 4.0 TROUBLESHOOTING AND DIAGNOSTIC STATUS CODES ..............................................................................16

4.1 General Maintenance Instructions .................................................................................................16

4.2 Cable Routing and Separation ................................................................................................ 16

4.2.1 Application Responsibility................................................................................................ 16

4.2.2 Signal/Power Level Definitions................................................................................................ 16

4.2.2.a Low Level Signals (Level L)...............................................................................................16

4.2.2.b High Level Signals (Level H)............................................................................................. 17

4.2.2.c Medium-Power Signals (Level MP)................................................................................. 17

4.2.2.d High-Power Signals (Level HP)........................................................................................17

4.2.3 Cable Spacing Guidelines.........................................................................................................17

4.2.3.a General Cable Spacing ..................................................................................................... 17

4.2.4 Cabling for Vehicle Retrofits ....................................................................................................17

4.2.5 RF Interference .......................................................................................................................... 17

4.2.6 Suppression............................................................................................................................... 17

Revised May 2003

Page 3

INSTALLATION AND OPERATION

SX TRANSISTOR CONTROL Page 3

Table of Contents ( Continued )

4.3 Recommended Lubrication of Pins and Sockets Prior to Installation........................................18

4.4 Controller Mounting Guidelines.......................................................................................................19

4.4.1 Necessary Tools........................................................................................................................ 19

4.4.2 The GE Control Mounting Surface ..........................................................................................19

4.4.3 Vehicle Mounting Surface........................................................................................................19

4.4.4 Application of Thermal Compound..........................................................................................19

4.4.5 Mounting the GE Control..........................................................................................................20

4.4.6 Maintenance.............................................................................................................................. 20

4.5 General Troubleshooting Instructions............................................................................................ 20

4.6 Traction Controller Status Codes.................................................................................................... 22-39

4.7 TMM Module Status Codes .............................................................................................................39-41

4.8 Pump Control Status Codes .............................................................................................................42-52

Section 5.0 SX FAMILY - GE HANDSET INSTRUCTIONS.......................................................................................................53

5.1 General Features .............................................................................................................................. 53

5.2 Purpose/Setup Functions ...............................................................................................................53

5.3 Setup Function Procedures .............................................................................................................54

5.3.1 Setup Mode ............................................................................................................................... 54

5.3.2 Status Code Scrolling.................................. .............................................................................54

5.3.3 SX Handset Plug Connections & Outline Drawing................................................................54

5.4 Setup Functions for Traction Controller ........................................................................................55-60

5.5 Summary of Current Limit Adjustments..........................................................................................61

5.6 Setup Functions for Hydraulic Pump Controller............................................................................62-64

Section 6.0 AUTO CALIBRATION OF ACCELERATOR POTENTIOMETERS................................................. ........................65

Section 7.0 TRACTION MEMORY MAP......................................................................................................................................66-68

Revised May 2003

Page 4

BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 4

Section 1. INTRODUCTION

Section 1.1 Motor Characteristics

The level of sophistication in the controllability of traction

motors has changed greatly over the past several years.

Vehicle manufacturers and users are continuing to expect

more value and flexibility in electric vehicle motor and

control systems as they are applied today. In order to

respond to these market demands, traction system

designers have been forced to develop new approaches to

reduce cost and improve functions and features of the

overall system. Development is being done in a multi-

current to increase, providing the greater torque needed to

drive the increased mechanical load. If the mechanical

load is decreased, the process reverses. The motor speed

and the back EMF increase, while the armature current and

the torque developed decrease. Thus, whenever the load

changes, the speed changes also, until the motor is again

in electrical balance.

In a shunt motor, the variation of speed from no load to

normal full load on level ground is less than 10%. For this

reason, shunt motors are considered to be constant speed

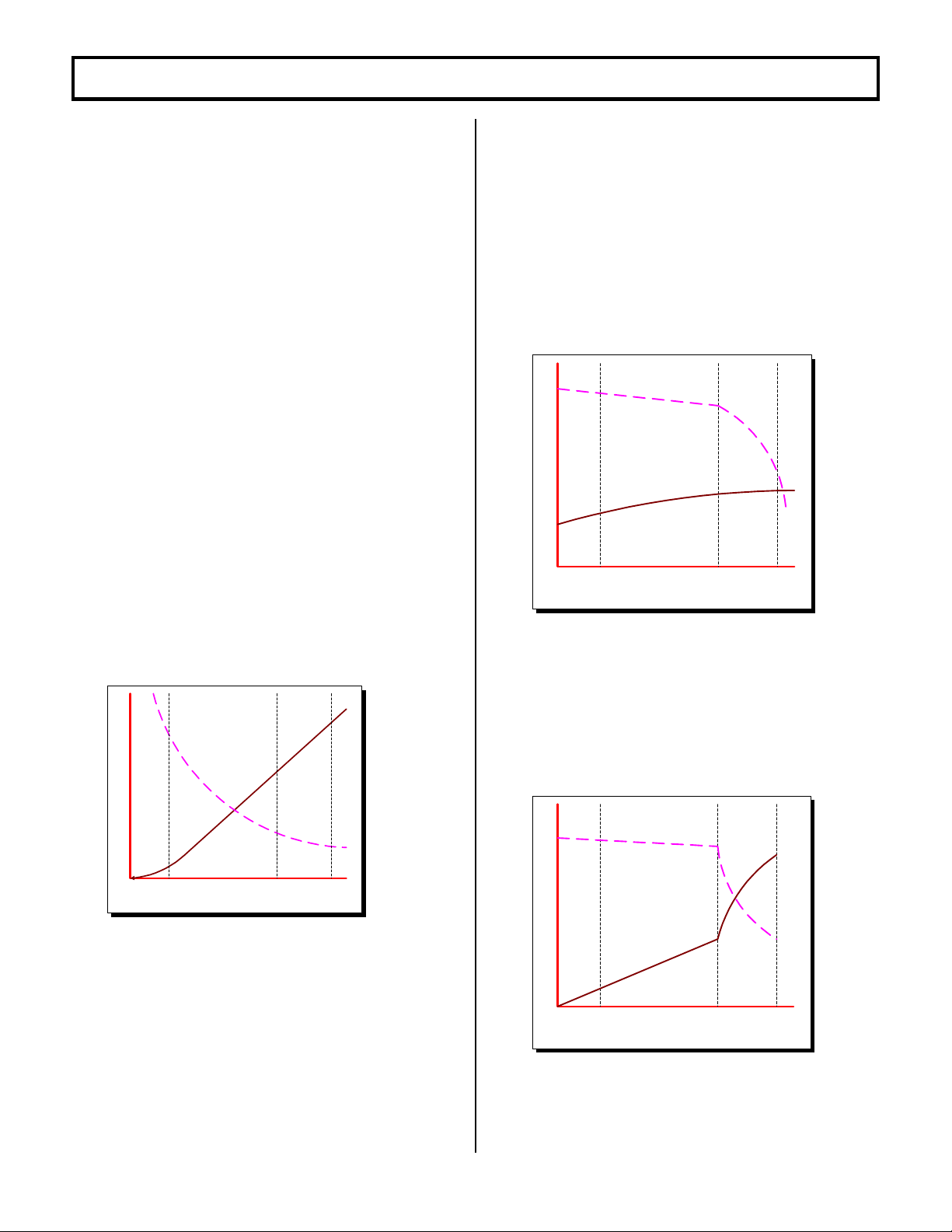

motors (Figure 2).

generational format that allows the market to take

advantage of today’s technology, while looking forward to

SPEED

new advances on the horizon. GE has introduced a second

generation system using separately excited DC shunt

wound motors. The separately excited DC motor system

offers many of the features that are generally found on the

advanced AC systems. Historically, most electric vehicles

have relied have on series motor designs because of their

ability to produce very high levels of torque at low speeds.

NO LOAD CURRENT

TORQUE

FULL

LOAD CURRENT

STARTING

CURRENT

But, as the demand for high efficiency systems increases,

i.e., systems that are more closely applied to customers’

specific torque requirements, shunt motors are now often

being considered over series motors. In most applications,

by independently controlling the field and armature

currents in the separately excited motor, the best attributes

of both the series and the shunt wound motors can be

combined.

In the separately excited motor, the motor is operated as a

fixed field shunt motor in the normal running range.

However, when additional torque is required, for example,

ARMATURE CURRENT

Figure 2

to climb non-level terrain, such as ramps and the like, the

field current is increased to provide the higher level of

torque. In most cases, the armature to field ampere turn

SPEED

ratio can be very similar to that of a comparable size series

motor (Figure 3.)

FULL

NO LOAD CURR ENT

TORQUE

STARTING

LOAD CURRENT

CURRENT

SPEED

ARMATURE CURRENT

Figure 1

As shown in from the typical performance curves of Figure

1, the high torque at low speed characteristic of the series

motor is evident.

In a shunt motor, the field is connected directly across the

voltage source and is therefore independent of variations in

load and armature current. If field strength is held

constant, the torque developed will vary directly with the

armature current. If the mechanical load on the motor

increases, the motor slows down, reducing the back EMF

(which depends on the speed, as well as the constant field

strength). The reduced back EMF allows the armature

FULL

LOAD CURRENT

NO LOAD CURRENT

TORQUE

ARMATURE CURRENT

Figure 3

STARTING

CURRENT

Aside from the constant horsepower characteristics

described above, there are many other features that

provide increased performance and lower cost. The

RevisedMay 2003

Page 5

BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 5

following description provides a brief introduction to

examples of some of these features.

Section 1. 2 Solid-State Reversing

The direction of armature rotation on a shunt motor is

determined by the direction in which current flows through

the field windings. Because of the of the shunt motor field

only typically requires about 10% of the armature current at

full torque, it is normally cost effective to replace the

double-pole, double-throw reversing contactor with a low

power transistor H-Bridge circuit (Figure 4).

armature, the motor performance curve can be maximized

through proper control application.

Section 1. 4 More Features with Fewer Components

Field weakening with a series wound motor is

accomplished by placing a resistor in parallel with the field

winding of the motor. Bypassing some of the current

flowing in the field into the resistor causes the field current

to be less, or weakened. With the field weakened, the motor

speed will increase, giving the effect of “overdrive”. To

change the “overdrive speed”, it is necessary to change

the resistor value. In a separately excited motor,

independent control of the field current provides for

LINE

FUSE

CAP

POS

A1 +

Q2

ARM

A2 -

Q1

Q3

Q4

Q5

F2F1

Q6

infinite adjustments of “overdrive” levels, between

motor base speed and maximum weak field. The

desirability of this feature is enhanced by the

elimination of the contactor and resistor required for

field weakening with a series motor.

With a separately excited motor, overhauling speed

limit, or downhill speed, will also be more constant. By

its nature, the shunt motor will try to maintain a

constant speed downhill. This characteristic can be

enhanced by increasing the field strength with the

control. Overhauling load control works in just the

NEG

Figure 4

By energizing the transistors in pairs, current can be made

to flow in either direction in the field. The armature control

circuit typically operates at 12KHZ to 15KHZ, a frequency

range normally above human hearing. This high frequency

coupled with the elimination of directional contactors,

provides very quiet vehicle operation. The field control

circuits typically operate at 2 KHZ.

The line contactor is normally the only contactor required

for the shunt motor traction circuit. This contactor is used

for both pre-charge of the line capacitors and for

emergency shut down of the motor circuit, in case of

problems that would cause a full motor torque condition.

The line can be energized and de-energized by the various

logic combinations of the vehicle, i.e. activate on key, seat

or start switch closure, and de-energize on time out of idle

vehicle. Again, these options add to the quiet operation of

the vehicle.

Section 1. 3 Flexible System Application

Because the shunt motor controller has the ability to

control both the armature and field circuits independently,

the system can normally be adjusted for maximum system

efficiencies at certain operating parameters. Generally

speaking, with the ability of independent field and

opposite way of field weakening, armature rotation

slows with the increase of current in the field.

Regenerative braking (braking energy returned to the

battery) may be accomplished completely with solid-state

technology. The main advantage of regenerative braking is

increased motor life. Motor current is reduced by 50% or

more during braking while maintaining the same braking

torque as electrical braking with a diode clamp around the

armature. The lower current translates into longer brush

life and reduced motor heating. Solid state regenerative

braking also eliminates a power diode, current sensor and

contactor from the circuit.

For GE, the future is now as we make available a new

generation of electric traction motor systems for electric

vehicles having separately excited DC shunt motors and

controls. Features that were once thought to be only

available on future AC or brushless DC technology vehicles

systems are now achievable and affordable.

RevisedMay 2003

Page 6

BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 6

Section 2. FEATURES OF SX FAMILY OF TRANSISTOR

MOTOR CONTROLLERS

Section 2.1 Performance

Section 2.1.1 Oscillator Card Features

Section 2.1.1.a Standard Operation

With the accelerator at maximum ohms or volts, the creep

speed can be adjusted by Function 2 of the Handset or a

trimpot. The field control section allows the adjustment of

the field weakening level in order to set the top speed of the

motor. This top speed function (Minimum Field Current) is

enabled when the armature current is less than the value

set by Function 24 and the accelerator input voltage is less

than 1 volt. Top Speed can be adjusted by Function 7 of the

Handset or a trimpot.

The percent on-time has a range of approximately 0 to 100

percent. The SX controllers operate at a constant

frequency and the percent on-time is controlled by the

pulse width of the voltage / current applied to the motor

circuits.

Section 2.1.1.b Creep Speed

With the accelerator at maximum ohms or volts

(approximately 3.7 to 3.5 VDC), the creep speed can be

adjusted by Function 2 of the Handset. At creep speed, the

ON time can decrease to approximately 5%, with the OFF

time at approximately 95%. At full transistor operation, this

condition will be reversed (short OFF time, long ON time).

This variation of ON and OFF time of the oscillator varies

the voltage applied to the motor, thereby varying the speed

of the motor for a given load.

Section 2.1.1.c Control Acceleration

This feature allows for adjustment of the rate of time it

takes for the control to accelerate to 100% applied battery

voltage to the motor on hard acceleration. Armature C/A is

adjusted by Function 3 from 0.1 to 22 seconds.

Section 2.1.2 Current Limit

This circuit monitors motor current by utilizing sensors in

series with the armature and field windings. The

information detected by the sensor is fed back to the card

so that current may be limited to a pre-set value. If heavy

load currents are detected, this circuit overrides the

oscillator and limits the average current to a value set by

Function 4 and Function 8 of the Handset. The C/L setting is

based on the maximum thermal rating of the control.

Because of the flyback current through 3REC, the motor

current is usually greater than battery current, except at

100% ON time.

Section 2.1.3 Braking

Section 2.1.3.a Regenerative Braking to Zero Speed

Slow down is accomplished when

reversing direction by providing a

small amount of retarding torque for

Q2

deceleration. If the vehicle is

moving, and the directional lever is

ARM

moved from one direction to the

other, the regen signal is initiated.

Q1

Figure 5

Once the regen signal has been

initiated, the field current is

increased (armature circuit shown in

Figure 5). Armature current is

regulated to the regen current limit as set by Function 9. As

the vehicle slows down, the field current continues to

increase, and transistor Q2 begins to chop. The field

current will increase until it reaches a preset value set by

Function 10, and transistor Q2 on-time will increase until it

reaches 100% on-time. Once both of the above conditions

have been met, and regen current limit can no longer be

maintained, the braking function is canceled. The fields

will then reverse, and the control reverts back to motoring.

Part of the energy produced by the motor during regen is

returned to the battery, and part is dumped in the motor as

heat.

Section 2.1.3.b Pedal Position Regenerative Braking

This feature allows control of the plugging distance based

on pedal position when there has been a “directional

switch" change. Pedal position will reduce the regenerative

current to the "value set by this function" as the accelerator

is returned to the creep speed position. Maximum regen

current is obtained with the accelerator in the top speed

position.

Section 2.1.3.c Auto Braking

This feature is enabled by initiating a "neutral position"

using either the directional switch or the accelerator

switch. Once activated, Auto Braking operates similar to

Pedal Position Plug Braking and is adjusted by using

Function 21 of the Handset.

Section 2.1.4 Auxiliary Speed Control

Section 2.1.4.a Field Weakening

This function allows the adjustment of the field weakening

level in order to set the top speed of the motor. The function

is enabled when the armature current is less than the value

set by Function 24 and the accelerator input voltage is set

for max speed. It is important to note that this function is

used to optimize motor and control performance, and this

setting will be determined by GE and OEM engineers at the

RevisedMay 2003

Page 7

BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 7

time of vehicle development. This setting must not be

changed by field personnel, without the permission of the

OEM.

Section 2.1.4.b Speed Limits

This feature provides a means to control speed by limiting

motor volts utilizing three "adjustable speed limits. This

motor volt limit regulates top speed of the transistor

controller, but actual truck speed will vary at any set point

depending on the loading of the vehicle. Each speed limit

can be adjustable with the Handset using Functions 11, 12,

and 13.

Section 2.1.5 Ramp Operation

Section 2.1.5a Ramp Start

This feature provides maximum control torque to restart a

vehicle on an incline. The memory for this function is the

directional switch. When stopping on an incline, the

directional switch must be left in its original or neutral

position to allow the control to initiate full power when

restarted. The accelerator potentiometer input will

modulate ramp start current.

Section 2.1.5b Anti-Rollback

This feature provides retarding torque to limit rollback

speed in the non-travel direction when the ACC pedal is

released when stopping on a grade, or when the brake

pedal is released when starting on a grade. This feature

forces the vehicle to roll very slowly down the grade when

accelerator or brake is released. Because the vehicle can

gain significant speed during roll-back, the torque needed

to re-start on the ramp is lower than an unrestricted rollback speed.

Section 2.1.6 On-Board Coil Drivers & Internal Coil

Suppression

Coil drivers for the LINE contactor and fan motor are onboard the control card. This contactor must have a coil

rated for the vehicle battery volts, and the fan should also

be rated for battery volts.

Section 2.2 System Protective Override

Section 2.2.1 Static Return to Off (SRO)

This inherent feature of the control is designed to require

the driver to return the directional lever to the neutral

position anytime he leaves the vehicle and returns.

Additionally, if the seat switch or key switch is opened, the

control shuts off and cannot be restarted until the

directional lever is returned to neutral. A time delay of

approximately 2 seconds is built into the seat switch input

to allow momentary opening of the seat switch, if a bump is

encountered.

Section 2.2.2 Accelerator Volts Hold Off

This feature checks the voltage level at the accelerator

input whenever the key switch or seat switch is activated.

If, at start up, the voltage is less than 1.8 volts, the control

will not operate. This feature assures that the control is

calling for low speed operation at start up.

Section 2.2.3 Pulse Monitor Trip (PMT)

The PMT design contains three features which shut down,

or lock out, control operation if a fault conditions occurs

that would cause a disruption of normal vehicle operation:

· Look ahead

· Look again

· Automatic look again and reset

The PMT circuit will not allow the control to start under the

following conditions:

· The control monitors both armature and field FET's at

start-up and during running.

· The control will not allow the line contactor to close at

start-up, or will drop it out during running, if either the

armature or field FET's are defective, so as to cause

uncontrolled truck movement.

Section 2.2.4 Thermal Protector (TP)

This temperature sensitive device is internal to the power

transistor (Q1) module. If the transistor's temperature

begins to exceed the design limits, the thermal protector

will lower the maximum current limit, and maintain the

transistors within their temperature limits. Even at a

reduced current limit, the vehicle will normally be able to

reach sufficient speed. As the control cools, the thermal

protector will automatically reset, returning the control to

full power.

Section 2.2.5 Low Voltage

Batteries under load, particularly if undersized or more

than 80 percent discharged, will produce low voltages at

the control terminals. The SX control is designed for use

down to 50 percent of a nominal battery voltage of 36-84

volts, and 75 percent of a nominal battery voltage of 24

volts. Lower battery voltage may cause the control to

operate improperly, however, the resulting PMT should

open the Line contactor, in the event of a failure.

RevisedMay 2003

Page 8

BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 8

Section 2.3 Diagnostics

Section 2.3.1 Systems Diagnostics

The control detects the system's present operating status

and can be displayed to either the Dash Display or the

Handset. There are currently over 70 status codes that are

available with SX systems using Traction and Pump

controls and Truck Management Module (TMM). Along

with the status code display from the TMM, the SX control

is capable of reducing the current to the motor, alerting the

operator of a critical fault condition.

Section 2.3.2 Status Codes

Section 2.3.2a Standard Status Codes

The SX traction control has over 30 Status Codes that

assist the service technician and operator in trouble

shooting the vehicle. If mis-operation of the vehicle occurs,

a status code will be displayed on the Dash Display for

vehicles so equipped, or be available by plugging the

Handset into the “y” plug of the logic card.

With the status code number, follow the procedures

outlined in DIAGNOSTIC STATUS CODES to determine the

problem and a solution.

Note: The Status Code Instruction Sheets do not claim to

cover all possible causes of a display of a "status code ".

They do provide instructions for checking the most direct

inputs that can cause status codes to appear.

Section 2.3.2.b Stored Status Codes

This feature records the last 16 "Stored Status Codes" that

have caused a PMT controller shut down and/or disrupted

normal vehicle operation. (PMT type faults are reset by

cycling the key switch). These status codes, along with the

corresponding BDI and hourmeter readings, can be

accessed with the Handset, or by using the RS 232

communications port and dumping the information to a

Personal Computer terminal.

Section 2.3.3 Hourmeter Readings

This feature will display the recorded hours of use of the

traction and pump control to the Dash Display each time

the key switch is turned off.

Section 2.3.3.a Maintenance Alert & Speed Limit

This feature is used to display Status Code 99 and/or

activate a speed limit when the vehicle operating hours

match the hours set into the maintenance alert register.

This feature is set with the Handset using Functions 19 and

20. The operator is alerted that maintenance on the vehicle

is required.

Section 2.3.4 Battery Discharge Indication (BDI)

The latest in microprocessor technology is used to provide

accurate battery state of charge information and to supply

passive and active warning signals to the vehicle operator.

Features and functions:

· Displays 100 to 0 percent charge.

· Display blinks with 20% charge. Disables pump circuit

with 10% charge. Auto ranging for 36/48 volt operation.

Adjustable for use on 24 to 48 volts.

Section 2.3.4.a Internal Resistance Compensation

This feature is used when the Battery Discharge Indicator

is present. Adjustment of this function will improve the

accuracy of the BDI.

Section 2.3.5 Handset

This is a multi-functional tool used with the LX, ZX, and SX

Series GE solid state controls. The Handset consists of a

Light Emitting Diode (LED) display and a keyboard for data

entry. Note, for ordering purposes, a separate Handset part

is required for SX controls.

Features and functions:

· Monitor existing system status codes for both traction

and pump controls. Monitor intermittent random status

codes.

· Monitor battery state of charge, if available.

· Monitor hourmeter reading on traction and pump

controls. Monitor or adjust the control functions.

Section 2.3.6 RS 232 Communication Port

This serial communication port can be used with

Interactive Custom Dash Displays to allow changes to

vehicle operating parameters by the operator. Or, it can be

used by service personnel to dump control operating

information and settings into a personal computer program.

Section 2.3.6.a Interactive Dash Display

Modes

The Interactive Custom Dash Display allows the operator to

select the best vehicle performance for changing factory

(task) conditions. There are four (4) "operator interaction

modes" that can be selected by depressing a push button

on the dash display.

From the Dash Display, the operator may select any of four

pre-set interactive modes consisting of (4) Min Field levels,

(4) Field Weakening levels, (4) Ratio levels, and (4) Regen

Current Limit levels.

These interactive modes are "pre-set" using the Handset

(Functions 48-63) or a personal computer (Functions 97-

RevisedMay 2003

Page 9

BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 9

112). This feature allows the operator to select the best

vehicle performance for changing factory (task) conditions.

Section 2.3.7 Circuit Board Coil Driver Modules

The Coil drivers are internal to the control card, and are the

power devices that operate the Line contactor coil. On

command from the control card, these drivers initiate

opening and closing the contactor coils. All driver modules

are equipped with reverse battery protection, such that, if

the battery is connected incorrectly, the contactors can not

be closed electrically.

Section 2.3.8 Truck Management Module (TMM)

The Truck Management Module is a multifunction

accessory card, or an integral function of the GE Pump

controls when used with the SX Traction control. The

Module provides the OEM the ability to initiate status codes

or operator warning codes to be displayed on the Dash

Display, whenever a normally open switch or sensor wire

provides a signal to the Module.

The TMM Module can be used to display a separate status

code indicating over-temperature of traction motors,

hydraulic motors, or any other device or system that can

activate a switch that closes.

The TMM Module can also be used as a Brush Wear

Indicator (BWI). The Brush Wear Indicator is designed to

detect a "worn out brush" and display a fault code on the

Dash Display to warn maintenance personnel that the

motor brushes need to be replaced before they wear to the

point of causing destructive damage to the motor

commutator surface.

Section 2.4 Hydraulic Pump Control

This hydraulic motor controller consists of the following

features:

· Four speeds, adjustable from O to 100% on.

· Fixed speeds actuated by switch closure to negative.

· Current limit and controlled acceleration adjustable.

· Battery Discharge Indicator interrupt compatible.

· 0 – 100% on, controlled by accelerator voltage (P7).

Operation of voltage regulator card: This card provides the

basic functions required for controlling the pump control,

optional contactors, and PMT functions. Battery positive is

applied through a main control fuse to the key switch,

energizing the control card power supply input to P1.

When a pump contactor is used, PMT operation is the

same as outlined for the traction controllers.

The four speed reference points P12, P19, P20 and P21 are

selected by connecting these points independently to

battery negative.

The first speed is obtained by closing Speed Limit I (P12) to

control negative. SLl is adjustable by Function 11 using the

Handset to adjust percent on from O to 100%. The specified

motor volts will be regulated, however, the magnitude of

motor current will vary depending on the loading of the

vehicle.

The second speed is obtained by closing SL2 (P19) to

control negative. SL2 is adjusted using the Handset and

Function 12 similar to SL1.

The third speed is obtained by closing SL3 (P20) to control

negative. SL3 is adjusted using the Handset and Function

13 similar to SL1.

The fourth speed is obtained by closing SL4 (P21) to control

negative. SL4 is adjusted using the Handset and Function

14 similar to SL1.

If more than one Speed Limit is activated, the selected

speed with the highest motor volts will override the low

motor volt speed. The current limit circuit is adjustable and

operates the same as the traction current limit.

The controlled acceleration circuit is adjustable and

operates the same as the traction circuit. Adjustment range

is from 0.1 to 5.5 seconds.

The Battery Discharge Indicator (BDI) interrupt will disable

the hydraulic controller if the connection at P10 loses the

12 volt signal from the traction control. BDI interrupt can be

disabled by Function 17 using the Handset. Select card type

with or without BDI function.

RevisedMay 2003

Page 10

OUTLINE DRAWINGS, ELEMENTARY DRAWINGS AND INPUTS/OUTPUTS

SX TRANSISTOR CONTROL Page 10

Section 3.0 ORDERING INFORMATION, ELEMENTARY AND OUTLINE DRAWINGS

Section 3.1 Ordering Information for Separately Excited Controls

Example:

Part Number: IC3645 SE 4 D 33 2 C3

Argument Number: 01 02 03 04 05 06 07

Argument 01: Basic Electric Vehicle Control Number

Argument 02: Control Type:

SP = Series Control (Pump)

SH = Separately Excited Control ( Plugging )

SR = Separately Excited Control ( Regen to Zero )

Argument 03: Operating Voltage:

1 = 120 volts 4 = 48 volts

2 = 24 volts 5 = 36/48 volts

3 = 36 volts 6 = 24/36 volts

7 = 72/80 volts

Argument 04: Package Size:

D = 6.86” X 6.67”

R = 6.86” X 8.15”

U = 8.66” X 8.13”

W = 8.66” X 10.83”

Argument 05: Armature Current

( 2 characters )

22 = 220 Amps

33 = 330 Amps

40 = 400 Amps

etc.

Argument 06: Field Current

( 1 character )

2 = 20 Amps

3 = 30 Amps

4 = 40 Amps

etc.

Argument 07: Customer / Revision

A1 = Customer A / Revision 1

B1 = Customer B / Revision 1

etc.

Revised May 2003

Page 11

OUTLINE DRAWINGS, ELEMENTARY DRAWINGS AND INPUTS/OUTPUTS

SX TRANSISTOR CONTROL Page 11

Section 3.2 Outline: SX-4 and SR-4 Package Size

Revised May 2003

Page 12

OUTLINE DRAWINGS, ELEMENTARY DRAWINGS AND INPUTS/OUTPUTS

SX TRANSISTOR CONTROL Page 12

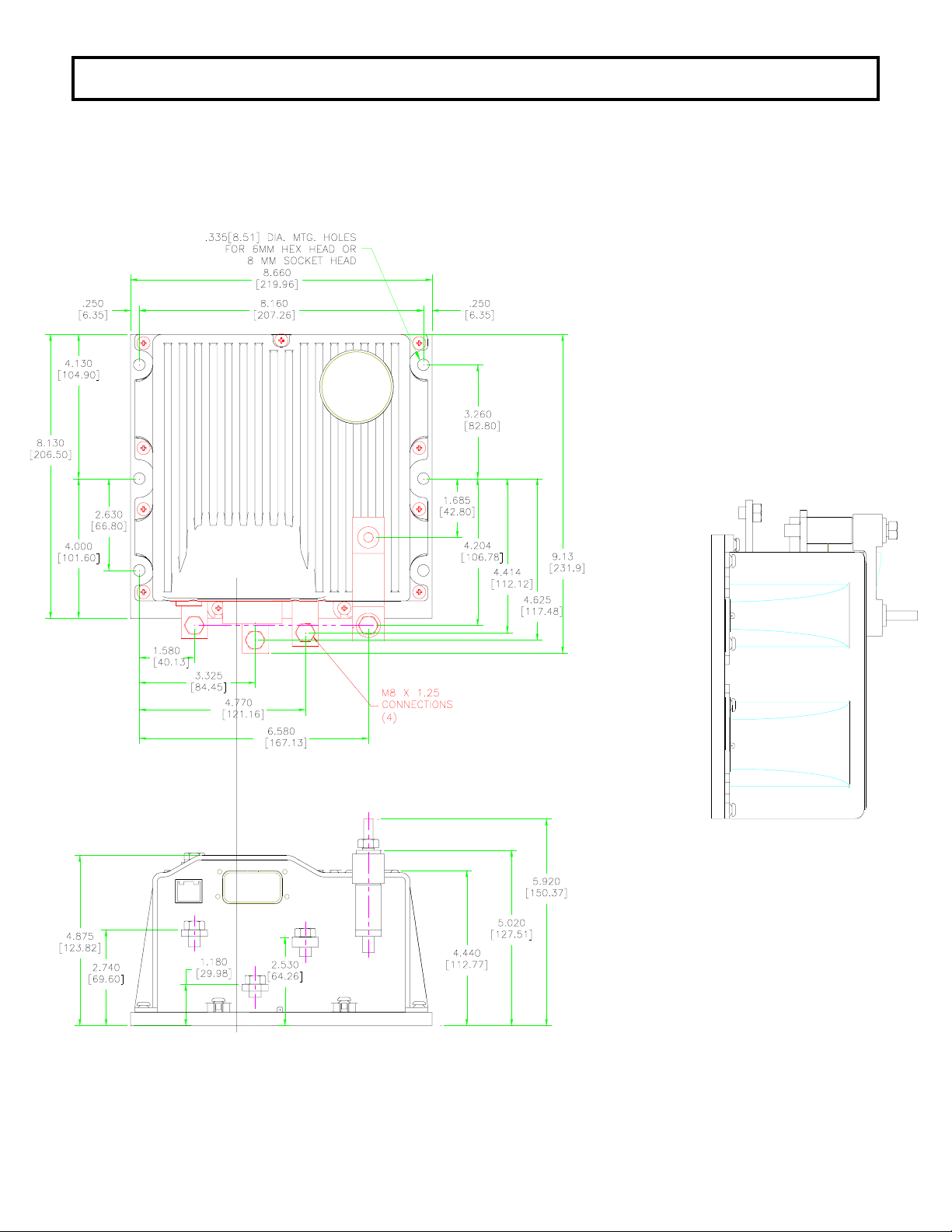

Section 3.3 Outline: SX-3 and SR-3 Package Size

Revised May 2003

Page 13

OUTLINE DRAWINGS, ELEMENTARY DRAWINGS AND INPUTS/OUTPUTS

SX TRANSISTOR CONTROL Page 13

Section 3.4 Traction Elementary

P21

P4 P5

P6

P17 P2

P18

NEG

P14

P23P22

MOTOR

TACH SIGNAL

SENSOR INPUT

+12V TACH

P20

P10

P8

P13

TRACTION CONTROL PLUG PL-2

P9

TEMPERATURE

FROM TRACTION

*

P7

P1

OPEN INPUT OR

SIGNAL DISABLED

VOLTAGE > 3V = BDI

TEMPERATURE INPUT

FROM PUMP CONTROL;

CUSTOMER SUPPLIED

MOTOR CONNECTIONS

*

CONTROLLER

BDI INTERRUPT TO JOY STICK

ACCEL SWITCH

*

ARMATURE

*

2W

2.2K

*

REV

FWD

*

BRAKE SWITCH

DIRECT

SEAT SWITCH

*

*

SWITCH

PARK BRAKE

SWITCH

L

*

FAN

A1

24V

*

KEY SWITCH

FAN ENABLE

FU1

F1

*

FIELD

F2

*

CONNECTION

CONTROL POWER

POS A1 F1

NEG A2 F2

*

A2

*

FU3

LINE

*

FU5

+

-

*

Revised May 2003

Page 14

OUTLINE DRAWINGS, ELEMENTARY DRAWINGS AND INPUTS/OUTPUTS

SX TRANSISTOR CONTROL Page 14

Section 3.5 Pump Elementary

SPEED 1

SPEED 2

PUMP CONTROL TEMP

ACCEL POT INPUT

P7

P18

*

L

P2

FU4

P12

P17

P3

P1

STATUS CODE 93 INPUT

*

P

P4

P5P6P8

STATUS CODE 93 INPUT

STATUS CODE 94 INPUT

P19

STATUS CODE 94 INPUT

STATUS CODE 95 INPUT

P9

STATUS CODE 95 INPUT

P15

STATUS CODE 92 INPUT

P21

P20

STATUS CODE 90 INPUT

PUMP CONTROL PLUG PL-2

P13

P16

P14

P11

OVER TEMP OUTPUT

BRUSH WEAR OUTPUT

STATUS CODE 91 INPUT

A1

SPEED 3

SPEED 4

*

A1

A1

P

*

FU2

*

*

*

*

SUPPLIED BY CUSTOMER

POWER CONNECTION

*

*

A2

ARMATURE

PUMP CONTROL

POWER CONNECTION

FIELD

A2

A2N

N

LINE

*

CONTACTOR

KEY SW.

BATT (+)

BATT (-)

Revised May 2003

Page 15

OUTLINE DRAWINGS, ELEMENTARY DRAWINGS AND INPUTS/OUTPUTS

SX TRANSISTOR CONTROL Page 15

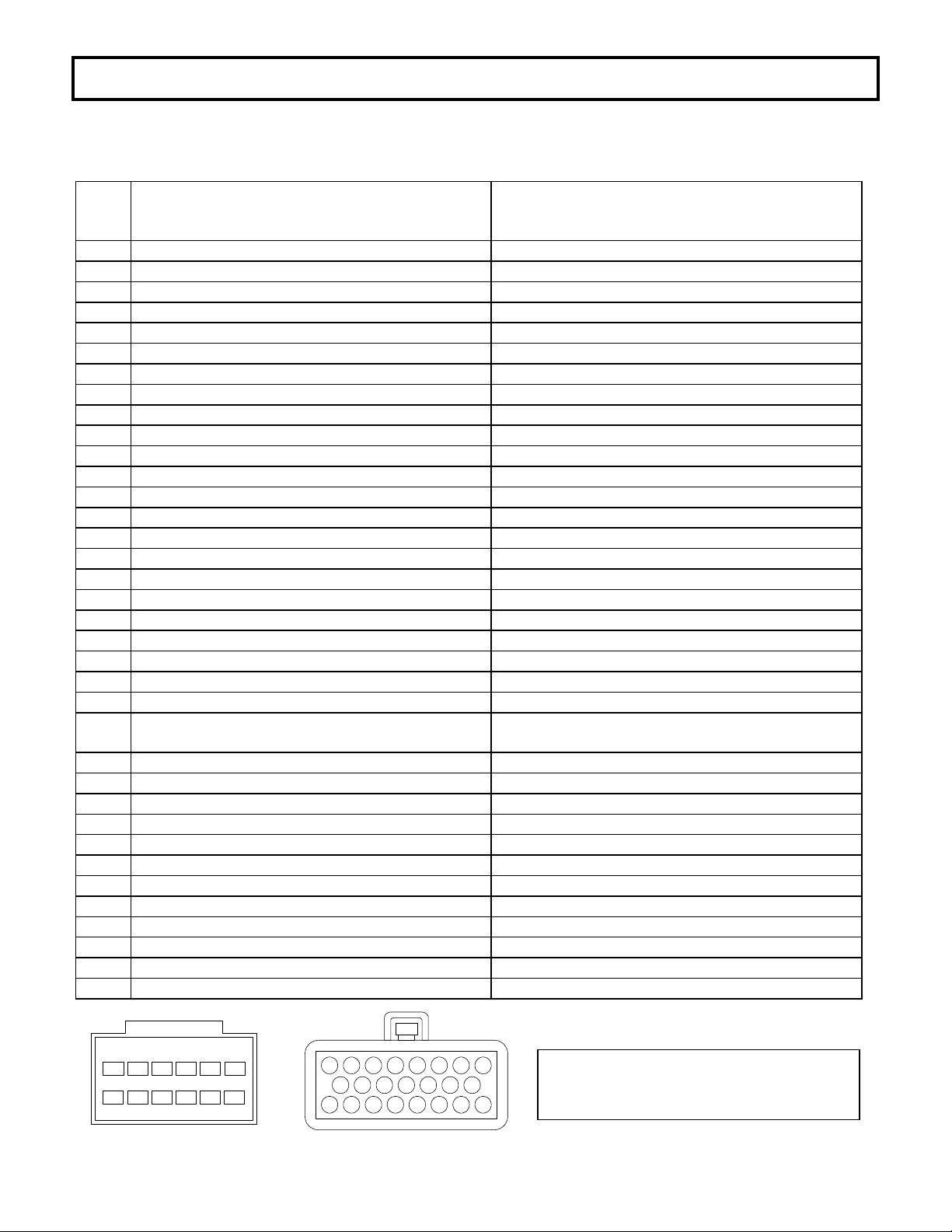

Section 3.6 Traction and Pump Control Input and Output List

CONNECTIONS TO MAIN PLUG (23 PIN) AND "Y" PLUG (12 PIN)

TRACTION PUMP

PIN INPUT/OUTPUT DESCRIPTION INPUT/OUTPUT DESCRIPTION

1 BATTERY VOLTS FROM BATTERY BATTERY VOLTS FROM BATTERY

2 BATTERY VOLTS FROM KEY BATTERY VOLTS FROM KEY

3 BATTERY VOLTS FROM START SWITCH -OPTIONAL STATUS CODE 93 INPUT

4 BATTERY VOLTS FROM FORWARD SWITCH -OPTIONAL STATUS CODE 93 INPUT

5 BATTERY VOLTS FROM REVERSE SWITCH -OPTIONAL STATUS CODE 94 INPUT

6 BATTERY VOLTS FROM SEAT SWITCH STATUS CODE 94 INPUT

7 ACCELERATOR INPUT VOLTAGE SIGNAL POTENTIOMETER INPUT VOLTAGE SIGNAL

8 ACCELERATOR NEGATIVE STATUS CODE 95 INPUT

9 ACCELERATOR POT +5 VOLTS SUPPLY STATUS CODE 95 INPUT

10 BDI INTERRUPT PUMP ENABLE SIGNAL 12VDC

11 PLUG/RGN OUTPUT SIGNAL +12V 1=PLUG STATUS CODE 91 INPUT

12 NOT USED SPEED LIMIT #1 INPUT

13 AUX ACCELERATOR INPUT TMM1 BRUSHWEAR INDICATER OUTPUT

14 LINEAR TRACTION MOTOR TEMPERATURE TMM1 OVER TEMPERATURE OUTPUT

15 NOT USED STATUS CODE 92 INPUT

16 NOT USED STATUS CODE 90 INPUT

17 LINE CONTACTOR DRIVER AND SUPPRESSION LINE CONTACTOR DRIVER

18 FAN PUMP CONTROL TEMPERATURE 0 = COLD

19 NOT USED SPEED LIMIT #2 INPUT

20 TEMPERATURE FROM PUMP CONTROL SPEED LIMIT #3 INPUT

21 PARK BRAKE (NEG=SL1) SPEED LIMIT #4 INPUT

22 TACH +12V SERIAL RECEIVE

23 TACH INPUT SERIAL TRANSMIT

MOTOR PROPORTIONING "Y" PLUG PUMP "Y" PLUG

PIN INPUT/OUTPUT DESCRIPTION INPUT/OUTPUT DESCRIPTION

1 CLOCK (OUT) CLOCK (OUT)

2 DATA (OUT) DATA (OUT)

3 ENABLE (OUT) ENABLE (OUT)

4 NEGATIVE NEGATIVE

5 +5V SUPPLY +5V SUPPLY

6 CONT/STORE (IN) (HANDSET) CONT/STORE (IN) (HANDSET)

7 NOT USED NOT USED

8 BWI INPUT/VALUE VALUE

9 OVER TEMP INPUT/FUNCTION FUNCTION

10 NOT USED NOT USED

11 SERIAL RECEIVE / CONNECT TO P22 SERIAL RECEIVE / CONNECT TO P22

12 SERIAL TRANSMIT / CONNECT TO P23 SERIAL TRANSMIT / CONNECT TO P23

1 2 3 4 5 6

7 8 9 10 11 12

WIRE END VIEW "Y" PLUG

1 2 3 4 5 6 6 8

9 10 11 12 13 14 15

16 17 18 19 20 21 22 23

WIRE END VIEW - MAIN PLUG

* Pins 3, 4 and 5

These input functions are provided by the

accelerator pot input value.

Revised May 2003

Page 16

DIAGNOSTIC STATUS CODES

SX TRANSISTOR CONTROL Page 16

Section 4.0 TROUBLESHOOTING AND DIAGNOSTIC STATUS CODES

Section 4.1 General Maintenance Instructions

The transistor control, like all electrical apparatus, does

have some thermal losses. The semiconductor junctions

have finite temperature limits, above which these devices

may be damaged. For these reasons, normal maintenance

should guard against any action which will expose the

components to excessive heat and/or those conditions

which will reduce the heat dissipating ability of the control,

such as restricting air flow.

The following Do’s and Don’t’s should be observed:

Any controls that will be applied in ambient temperatures

over 100° F (40° C) should be brought to the attention of the

vehicle manufacturer.

All external components having inductive coils must be

filtered. Refer to vehicle manufacturer for specifications.

The wiring should not be directly steam cleaned.

areas, blow low-pressure air over the control to remove

dust. In oily or greasy areas, a mild solution of detergent or

denatured alcohol can be used to wash the control, and

then low-pressure air should be used to completely dry the

control.

For the control to be most effective, it must be mounted

against the frame of the vehicle. The metal vehicle frame,

acting as an additional heat sink, will give improved vehicle

performance by keeping the control package cooler. Apply

a thin layer of heat-transfer grease (such as Dow Corning

340) between the control heat sink and the vehicle frame.

Control wire plugs and other exposed transistor control

parts should be kept free of dirt and paint that might

change the effective resistance between points.

CAUTION: The vehicle should not be plugged when the

vehicle is jacked up and the drive wheels are in a free

wheeling position. The higher motor speeds can create

excessive voltages that can be harmful to the control.

Do not hipot (or megger) the control. Refer to control

manufacturer before hipotting.

Use a lead-acid battery with the voltage and ampere hour

rating specified for the vehicle. Follow normal battery

maintenance procedures, recharging before 80 percent

discharged with periodic equalizing charges.

Visual inspection of GE contactors contained in the traction

and pump systems is recommended to occur during every

160 hours of vehicle operation. Inspection is recommended

In dusty

to verify that the contactors are not binding and that the

tips are intact and free of contaminants.

GE does not recommend that any type of welding be

performed on the vehicle after the installation of the

control(s) in the vehicle. GE will not honor control failures

during the warranty period when such failures are

attributed to welding while the control is installed in the

vehicle.

Section 4.2 Cable Routing and Separation

Electrical noise from cabling of various voltage levels can

interfere with a microprocessor-based control system. To

reduce this interference, GE recommends specific cable

separation and routing practices, consistent with industry

standards.

Section 4.2.1 Application Responsibility

The customer and customer’s representative are

responsible for the mechanical and environmental

locations of cables. They are also responsible for applying

the level rules and cabling practices defined in this section.

To help ensure a lower cost, noise-free installation, GE

recommends early planning of cable routing that complies

with these level separation rules.

On new installations, sufficient space should be allowed to

efficiently arrange mechanical and electrical equipment.

On vehicle retrofits, level rules should be considered during

the planning stages to help ensure correct application and

a more trouble-free installation.

Section 4.2.2. Signal/Power Level Definitions

The signal/power carrying cables are categorized into four

defining levels: low, high, medium power, and high power.

Within those levels, signals can be further divided into

classes.

Sections 4.2.2.a through 4.2.2.d define these levels and

classes, with specific examples of each. Section 4.2.3

contains recommendations for separating the levels.

4.2.2.a Low-Level Signals (Level L)

Low-level signals are designated as level L. These consist

of:

· Analog signals 0 through ±15 V

· Digital signals whose logic levels are less than 15 V DC

· 4 – 20 mA current loops

· DC busses less than 15 V and 250 mA

The following are specific examples of level L signals used

in drive equipment cabling:

Revised May 2003

Page 17

DIAGNOSTIC STATUS CODES

SX TRANSISTOR CONTROL Page 17

· Control common tie

· DC buses feeding sensitive analog or digital hardware

· All wiring connected to components associated with

sensitive analog hardware with less than 5V signals (for

example, potentiometers and tachometers)

· Digital tachometers and resolvers

· Dash display cabling

· RS-232 cabling

Note: Signal inputs to analog and digital blocks should be

run as shielded twisted-pair (for example, inputs from

tachometers, potentiometers, and dash displays).

4.2.2.b High-Level Signals (Level H)

High-level signals are designated as level H. These signals

consist of:

· Analog and digital signals greater than 15 V DC and

less than 250 mA

For example, switch inputs connected to battery volts are

examples of level H signals used in drive equipment

cabling.

4.2.2.c Medium-Power Signals (Level MP)

Medium power signals are designated as level MP. These

signals consist of:

· DC switching signals greater than 15 V

· Signals with currents greater than 250 mA and less than

10A

The following are specific examples of level MP signals

used in drive equipment cabling:

· DC busses less than 10 A

· Contactor coils less than 10 A

· Machine fields less than 10 A

4.2.2.d. High Power Signals (Level HP)

Power wiring is designated as level HP. This consists of DC

buses and motor wiring with currents greater than 10 A.

The following are specific examples of level HP signals

used in drive equipment cabling:

· Motor armature loops

· DC outputs 10 A and above

· Motor field loops 10 A and above

4.2.3. Cable Spacing Guidelines

Recommended spacing (or clearance) between cables (or

wires) is dependent on the level of the wiring inside them.

For correct level separation when installing cable, the

customer must apply the general guidelines (section

4.2.3.a), outlined below.

4.2.3.a General Cable Spacing

The following general practices should be used for all

levels of cabling:

· All cables and wires of like signal levels and power

levels must be grouped together.

· In general, different levels must run in separate wire

bundles, as defined in the different classes, identified

above. Intermixing cannot be allowed, unless noted by

exception.

· Interconnecting wire runs should carry a level

designation.

· If wires are the same level and same type signal, group

those wires from one location to any other location

together in multiconductor cables or bind them

together with twine or zip-ties.

· When unlike signals must cross, cross them in 90°

angles at a maximum spacing. Where it is not possible

to maintain spacing, place a grounded steel barrier

between unlike levels at the crossover point.

4.2.4 Cabling for Vehicle Retrofits

Reducing electrical noise on vehicle retrofits requires

careful planning. Lower and higher levels should never

encircle each other or run parallel for long distances.

It is practical to use existing wire runs or trays as long as

the level spacing (see section 4.2.2) can be maintained for

the full length of the run.

Existing cables are generally of high voltage potential and

noise producing. Therefore, route levels L and H in a path

separate from existing cables, whenever possible.

For level L wiring, use barriers in existing wire runs to

minimize noise potential.

Do not loop level L signal wires around level H, level MP, or

HP wires.

4.2.5 RF Interference

To prevent radio frequency (RF) interference, care should

be taken in routing power cables in the vicinity of radiocontrolled devices.

Section 4.2.6 Suppression

Unless specifically noted otherwise, suppression (for

example, a snubber) is required on all inductive devices

controlled by an output. This suppression minimizes noise

and prevents damage caused by electrical surges.

Revised May 2003

Page 18

DIAGNOSTIC STATUS CODES

SX TRANSISTOR CONTROL Page 18

Section 4.3 Recommended Lubrication of Pins and

Sockets Prior to Installation

Beginning in January of 1999, GE will implement the

addition of a lubricant to all connections using pins and

sockets on EV100/EV200 and Gen II products. Any

connection made by GE to the A, B, X, Y, or Z plugs will

have the lubricant NYE 760G added to prevent fretting of

these connections during vehicle operation.

Fretting occurs during microscopic movement at

the contact points of the connection. This movement

exposes the base metal of the connector pin which, when

oxygen is present, allows oxidation to occur. Sufficient

build up of the oxidation can cause intermittent contact

and intermittent vehicle operation. This can occur at any

similar type of connection, whether at the control or in any

associated vehicle wiring, and the resultant intermittent

contact can provide the same fault indication as actual

component failure.

The addition of the NYE 760G lubricant will prevent

the oxidation process by eliminating the access of oxygen

to the contact point. GE recommends the addition of this

lubricant to the 12 pin and 23 pin plugs of all new Gen II

controls at the time of their installation into a vehicle

When servicing existing vehicles exhibiting

symptoms of intermittent mis-operation or shutdown by the

GE control, GE recommends the addition of this lubricant to

all 12 and 23 pin plugs, after proper cleaning of the

connectors, as a preventative measure to insure fretting is

not an issue before GE control replacement. Also, for long

term reliable control operation, the plug terminals must be

maintained per these instructions with the recommended

contact cleaner and lubricant which provides a high

degree of environmental and fretting protection.

New and re-manufactured control plugs are cleaned and

lubricated prior to shipment from the factory. However, in

applications where severe vibration or high temperature

cycling and excessive humidity ( such as freezers ) are

present, it is recommended that the plug terminals be

cleaned and lubricated every year, per this instructions. In

normal applications, plug maintenance should be

performed every two years, unless intermittent problems

arise with the plugs, requiring more immediate attention.

Warning: Do not use any other cleaners or lubricants

other than the ones specified.

WARNING: Before conducting maintenance on the

vehicle, jack up the drive wheels, disconnect the battery

and discharge the capacitors. Consult the Operation and

Service Manual for your particular vehicle for details on

discharging the capacitors; this procedure differs

between SCR and Transistor controls.

1. Disconnect plug from controller or mating plug.

2. Locate the plug that contains the socket (female)

terminals. Maintenance needs only to be performed on

the plug containing the socket (female) type terminals.

Reconnecting the plugs will lubricate the pin (male)

terminals.

3. Clean each terminal using Chemtronics

â contact

cleaner “Pow-R-WasH CZ “ as shown in Figure 1.

s

c

i

n

o

r

t

m

e

h

C

r

e

n

a

e

l

c

t

c

a

t

n

o

c

Z

C

H

R

-

s

a

w

o

W

P

e

n

a

z

o

r

i

c

Figure 1

4. Lubricate each terminal using Nye

â 760G lubricant as

shown in figure 2. Apply enough lubricant to each

terminal opening to completely fill each opening to a

depth of .125” minimum.

Nye

LU

B

RICA

N

TS

Figure 2

5. Reconnect plugs.

Reference

Cleaner Chemtronics

â Pow-R-WasH CZ Contact

Cleaner

Lubricant Nye

â Lubricants NYOGELâ 760G

GE Plug Lub Kit Contains both above products:

328A1777G1

Revised May 2003

Page 19

DIAGNOSTIC STATUS CODES

SX TRANSISTOR CONTROL Page 19

Section 4.4 Controller Mounting Guidelines

In the design of the GE family of motor controls,

performance assumptions were made based on heat

transfer between the control and the ambient environment.

The vehicle mounting surface acts as a heat sink, which

increases the effective surface area for heat dissipation. If

this assumed heat transfer is not achieved during control

installation and operation, GE controllers will fall short of

their anticipated performance. It should be noted that the

condition of the mounting surface, and the quality of the

resulting interface between the control and the vehicle, can

significantly hinder heat transfer from the control. The

presence of contaminants, or of air voids created by

surface inconsistencies in either the vehicle or the control,

degrade the control’s capacity for heat transfer. The

control’s performance is de-rated proportionally as its own

thermal sensors reduce its operation to protect it from

damage due to excessive heating.

Contained within the software of the GE controls are

several diagnostic status codes related to controller

thermal performance. Failure to follow these mounting

recommendations increases the likelihood of encountering

these status codes, through no fault of the control itself,

thus voiding controller warranty for units returned solely

due to the presence of these status codes.

Careful surface preparation, including adequate

application of thermal compound, as detailed in the

following paragraphs, must be completed during the

installation of GE controls. There are many techniques for

applying thermal compound, and we have outlined one

approach below that has shown to apply a consistent

thickness of material.

Section 4.4.1 Necessary Tools

GE recommends the use of the following components, or

equivalent substitutions, during the control installation

process:

a) Thermal compound, (Dow Corning #340),

maintained per the manufacturer’s

recommendations and free of contaminants

b) 3/32” notched trowel, such as a Krusin

adhesive spreader, model 00031

c) Calibrated torque wrench (0 – 15 ft-lbs)

Section 4.4.2 The GE Control Mounting Surface

During the manufacture of the GE control, the surface

flatness is maintained at 0.005” per linear inch (not to

exceed 0.025” per 10.0 inches). The surface finish of the GE

control has an R

(average roughness) of 64 (microinches),

a

or better. This finish is consistent with cold rolled or

extruded aluminum.

Care should always be taken in the handling and storage of

controllers. The base of the control should be free from

nicks, bumps, protrusions or any other foreign object that

would prevent the control from sitting flush with the vehicle

mounting surface. Examine the base of the control to verify

that it is in good condition and free from damage or

contamination.

Section 4.4.3 Vehicle Mounting Surface

The quality of the vehicle mounting surface is critical for

the optimum heat transfer between the control and the

ambient environment. Conduction through the base of the

control is the control’s only means of heat rejection. While

GE controls are highly efficient, a few percent of the

electrical energy will be converted into heat. As previously

mentioned, if this energy is not dissipated through the base

of the control, a thermal protector will reduce the

performance of the control until the temperature stabilizes.

For optimal heat transfer from control to vehicle, the

flatness of the vehicle mounting surface should be

equivalent to the flatness of the control surface (0.005” per

linear inch). Use a straight edge or dial indicator to verify

the mounting surface.

The biggest hindrance to heat transfer is the presence of

rust, scale, weld splatter or paint on the vehicle mounting

surface. If any of these items are noted, prepare the

surface per the following guidelines:

a) Clean the mounting surface with a rotary wire

brush until the metal surface is exposed.

b) Using 80-100 grit emery paper, sand the

surface until the metal shines.

c) Flush the surface clean with an appropriate

liquid de-greaser or parts cleaner.

Section 4.4.4 Application of Thermal Compound

Due to the minute differences in the control mounting

surface and the vehicle mounting surface, small pockets of

air will be created. These air pockets will add to the overall

thermal resistance of the interface.

To avoid these air pockets and improve thermal

conductivity, thermal compound must be applied between

the GE control base plate and the vehicle mounting surface.

The function of this compound is to conform to surface

discrepancies, filling gaps and optimizing the metal-tometal contact of the control and the vehicle.

a) Prepare the two mounting surfaces (control

and vehicle) as indicated above.

b) Using a triangular notched trowel of 3/32”

(.09” +/- .01), apply the grease to the vehicle

mounting surface.

c) Use straight, non-crossing strokes of the

trowel to apply the compound.

d) Make multiple vertical passes until a uniform

consistency is achieved.

Revised May 2003

Page 20

DIAGNOSTIC STATUS CODES

SX TRANSISTOR CONTROL Page 20

1 4

1 3

Krusin adhesive spreader model 00031

Vehicle surface after proper grease application

Section 4.4.5 Mounting the GE Control

a) Place the control unit with desired orientation on

mounting plate with mounting holes aligned.

b) Move the control slightly in all directions to eliminate

voids and enhance the distribution of the thermal

compound.

c) Insert the all of the mounting hardware (4, 6 or 8 bolts,

M6 or M8, necessary for the mounting of the

respective family of controls).

d) Tighten these bolts (as per sequence shown in

diagrams below) to half of the nominal torque value

(7.5lb-ft).

e) Lastly, tighten the bolts to the nominal torque value (15

lb-ft), following the same sequence.

Calibrated torque wrench for hardware installation

2

4

2

6

5

1

3

3 2

8

2

4

6

Proper sequence for use in tightening hardware during

control mounting

Section 4.4.6 Maintenance

If it is necessary to remove the control for service, careful

consideration must be given to removing the old thermal

compound from the control and mounting surface, prior to

replacement of the unit. Never re-use thermal compound.

Use a putty knife or similar straight edge to carefully

remove all thermal compound residue without damaging

either mounting surface. Flush the surfaces with a liquid

de-greaser or parts cleaner and allow them to dry, before

re-applying the thermal compound and mounting the

control. Take care not to contaminate the surfaces with

hydraulic fluid or battery acid.

Section 4.5 General Troubleshooting Instructions

Trouble-shooting the SX family of controls should be quick

and easy when following the instructions outlined in the

following status code instruction sheets.

If mis-operation of the vehicle occurs, a status code will be

displayed on the Dash Display (for vehicles equipped with a

Dash Display) or made available by plugging a Handset into

the plug "Y" location, and then reading the status code.

Note: Status code numbers from 00 to 99 are traction

control status codes. Status codes with the prefix 1 (101 to

199) are pump control status codes.

5

3

1

7

Revised May 2003

Page 21

DIAGNOSTIC STATUS CODES

SX TRANSISTOR CONTROL Page 21

With the status code number, follow the procedures

outlined in the status code instruction sheets to determine

the problem.

Important Note: Due to the interaction of the logic card

with all vehicle functions, almost any status code or

control fault could be caused by the logic card. After all

other status code procedures have been followed and no

problem is found, the controller should then be replaced as

the last option to correct the problem.

The same device designations have been maintained on

different controls but the wire numbers may vary. Refer to

the elementary and wiring diagrams for your specific

control. The wire numbers shown on the elementary

diagram will have identical numbers on the corresponding

wiring diagrams for a specific vehicle, but these numbers

may be different from the numbers referenced in this

publication.

WARNING: Before trouble-shooting, jack up the drive

wheels, disconnect the battery and discharge the

capacitors. Reconnect the battery as needed for specific

checks. Capacitors should be discharged by connecting a

200 ohm 2 watt resistor between the positive and negative

terminals on the control panel.

Check resistance on R x 1000 scale from frame to power

and control terminals. A resistance of less than 20,000

ohms can cause misleading symptoms. Resistance less

than 1000 ohms should be corrected first.

Before proceeding, visually check for loose wiring,

mis-aligned linkage to the accelerator switch, signs of

overheating of components, etc.

Tools and test equipment required are: clip leads, volt-ohm

meter (20,000 ohms per volt) and basic hand tools.

Revised May 2003

Page 22

DIAGNOSTIC STATUS CODES

PARK BRAKE SWITCH

SX TRANSISTOR CONTROL Page 22

Section 4.6 Traction Control Codes

TRACTION

STATUS CODE

NONE

MEMORY RECALL

NO

Circuits valid

for

Traction

Controller

DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION

Segments do not illuminate on the

Dash Display and/or the Handset.

No input voltage to the control card or the display unit.

CORRECTIVE ACTIONS TROUBLE-SHOOTING DIAGRAM

SYMPTOM

Display screen on Dash Display and/or

Handset is blank.

POSSIBLE CAUSE

Positive or negative control voltage is not

present.

· Insure that the key switch is closed and

voltage is present between P1 & battery

negative (Power Terminal “NEG”). Also

check for voltage between P2 and control

negative.

Open circuit between control card AND the

Dash Display or Handset.

· Check for an open circuit or loose

connection going from the control and

the Dash Display or Handset.

Defective Dash Display or Handset.

· Replace Dash Display or Handset.

FU3

FU5

+

-

NEG

KEY

SWITCH

P1

P2

TRACTION

STATUS CODE

-01

MEMORY RECALL

NO

Circuits valid

for

Traction

Controller

DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION

No brake switch or deadman switch

input (no voltage to P6).

This status code will be displayed when P6 is less

than 50% battery volts.

CORRECTIVE ACTIONS TROUBLE-SHOOTING DIAGRAM

SYMPTOM

Control will not operate.

POSSIBLE CAUSE

Mis-adjusted or defective brake or

deadman switch.

· Check to see that the brake switch

closes properly.

Open circuit between battery positive and

P6.

· Check for loose connections or broken

wires:

- Between the brake switch and P6

- Between the key switch and the

battery positive side of the brake

switch.

- Between the brake switch and P2.

· On vehicles without a brake/deadman

switch, check for a loose connection or

broken wire from P2 and/or P6.

*

KEY SWITCH

*

24V

FAN

FAN

ENABLE

P1

P7

ACCEL

SWITCH

BDI INTERRUPT TO JOY

STICK CONTROLLER

P18

TRACTION CONTROL PLUG PL-2

P9

P13

*

BRAKE SWITCH

*

L

P17 P2

P8

P6

P10

P20

+12V TACH

TACH SIGNAL

TEMPERATURE SENSOR

INPUT FROM TRACTION

TEMPERATURE INPUT FROM

PUMP CONTROL; OPEN INPUT

OR VOLTAGE > 3V = BDI

SIGNAL DISABLED

*

SEAT SWITCH

*

FWD

DIRECT

SWITCH

P4 P5

MOTOR

2.2K

2W

REV

*

NEG

P21

P14

P23P22

Revised May 2003

*

Page 23

DIAGNOSTIC STATUS CODES

SX TRANSISTOR CONTROL Page 23

TRACTION

STATUS CODE

-02

DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION

Standard truck configuration where the

direction is set by accelerator volts –

This status code will be displayed when voltage

at P7 is less than 1.9V.

forward direction selected on power up.

MEMORY RECALL

CORRECTIVE ACTIONS TROUBLE-SHOOTING DIAGRAM

NO

Circuits valid

for

Traction

Controller

TRACTION

STATUS CODE

SYMPTOM

Control will not operate because of Static Return

to Off (SRO) lock out.

POSSIBLE CAUSE

Accelerator calibration is incorrect and it must

be recalibrated for a new accelerator pot

installation.

24V

FAN

ENABLE

*

KEY SWITCH

*

FAN

BRAKE SWITCH

*

L

*

SEAT SWITCH

*

· Repeat the accelerator pot calibration routine

outlined in this operating manual

The voltage at P9 is less than 4.2V.

· Measure the accelerator pot to verify that it

reads above 3K ohms. If not, replace the

accelerator pot.

Defective control.

· Replace the controller unit.

P1

P7

ACCEL

SWITCH

BDI INTERRUPT TO JOY

STICK CONTROLLER

P18

TRACTION CONTROL PLUG PL-2

P9

P13

*

P17 P2

P8

P6

P10

P20

+12V TACH

TACH SIGNAL

TEMPERATURE SENSOR

INPUT FROM TRACTION

TEMPERATURE INPUT FROM

PUMP CONTROL; OPEN INPUT

OR VOLTAGE > 3V = BDI

SIGNAL DISABLED

DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION

FWD

REV

DIRECT

SWITCH

P4 P5

MOTOR

2.2K

2W

*

NEG

P21

P14

P23P22

*

PARK BRAKE SWITCH

-02

MEMORY RECALL

NO

Circuits valid

for

Traction

Controller

Optional truck configuration with directional

switch input - forward directional switch is

closed on initial power up.

This status code will be displayed when P4 is

greater than 60% of battery voltage at initial key

switch on.

CORRECTIVE ACTIONS TROUBLE-SHOOTING DIAGRAM

SYMPTOM

Control will not operate because of Static Return

to Off (SRO) lock out.

POSSIBLE CAUSE

Forward directional switch is closed on initial

start up (i.e. closure of battery, key switch or

brake switch).

· Return directional switch lever to neutral and

then return lever to forward position.

Forward directional switch is welded closed or

mis-adjusted to be held closed.

· Replace or adjust directional switch to insure

that it opens when the directional switch is

returned to neutral.

Short circuit between B+ and P4.

· Disconnect the wire from P4 and check for

positive voltage. Correct source of voltage.

Defective control. Replace the controller unit.

*

KEY SWITCH

*

24V

FAN

FAN

ENABLE

P1

P7

ACCEL

SWITCH

BDI INTERRUPT TO JOY

STICK CONTROLLER

P18

TRACTION CONTROL PLUG PL-2

P9

P13

*

BRAKE SWITCH

*

L

P17 P2

P8

P6

P10

P20

+12V TACH

TACH SIGNAL

TEMPERATURE SENSOR

INPUT FROM TRACTION

TEMPERATURE INPUT FROM

PUMP CONTROL; OPEN INPUT

OR VOLTAGE > 3V = BDI

SIGNAL DISABLED

*

SEAT SWITCH

*

FWD

REV

DIRECT

SWITCH

P4 P5

MOTOR

2.2K

2W

*

P23P22

P21

P14

NEG

*

PARK BRAKE SWITCH

Revised May 2003

Page 24

DIAGNOSTIC STATUS CODES

SX TRANSISTOR CONTROL Page 24

TRACTION

STATUS CODE

DESCRIPTION OF STATUS CAUSE OF STATUS INDICATION

-03

MEMORY RECALL