GE STS-400-25-4, STS-400-40-3, STS-400-25-3, STS-400-40-4, STS-400-63-4 Installation And Operating Manual

...Page 1

g

GE Consumer & Industrial

Digital Energy™

INSTALLATION and

OPERATING MANUAL

Digital Energy™ STS-400-25/40/63/100-3/4

Static Transfer Switch

400V-25/40/63/100A-3/4-pole

GE Digital Energy™

General Electric Company Telephone +41 (0)91 / 850 51 51

CH - 6595 Riazzino (Locarno) Fax +41 (0)91 / 850 51 44

Switzerland Website www.gedigitalenergy.com

STS

GE imagination at work

Ver 1.1 - GB

Page 2

Digital Energy™ Static Transfer Switch

g

INSTALLATION AND OPERATING MANUAL

Digital Energy STS-400-25/40/60/100 Static Transfer Switch

LX-DOC File: OPM_STS_400_25A_100_1GB_V011

Manual version 1.1 June 2004

INSTALLATION and

OPERATING MANUAL

Digital Energy™ STS-400-25/40/63/100-3/4

Static Transfer Switch

400V-25/40/63/100A-3/4-pole

Preface

We thank you for selecting a General Electric Digital Energy™ STS Series Static Transfer Switch and

recommend that you read these instructions carefully before installation and start-up of the device.

The instructions in this manual are for:

the 3-phase 3-pole models STS-400-25-3, STS-400-40-3, STS-400-63-3 and STS-400-100-3;

the 3-phase 4-pole models STS-400-25-4, STS-400-40-4 and STS-400-63-4.

Please keep this manual in a safe place for future reference and carefully read the important safety instructions

in chapter 1 before installation of this device.

© 2004 by GE Consumer & Industrial

All rights reserved.

The information contained in this publication is intended solely for the purposes indicated.

The present publication and any other documentation supplied with the Static Transfer Switch system is not to be reproduced, either in part

or in its entirety, without the prior written consent of GE.

The illustrations and plans describing the equipment are intended as general reference only and are not necessarily complete in every

detail.

The content of this publication may be subject to modification without prior notice.

OPM_STS_400_25A_100_1GB_V011

1

GE DE STS: installation and operating manual 1.1 (GB)

Page 3

Digital Energy™ Static Transfer Switch

g

CONTENTS

1 IMPORTANT SAFETY INSTRUCTIONS ..................................................................3

1.1 Save these instructions

1.2 Safety warnings and symbols

1.3 General

1.4 Intended use

1.5 Transport, storage, unpacking

1.6 Installation

1.7 Electrical connection

1.8 Operation

1.9 Fire regulations

1.10 Standards applied and conformity

2 INTRODUCTION .......................................................................................................8

2.1 Warranty

2.2 Description

2.3 Application

2.4 Fuses and TVSS circuits

3 INSTALLATION ........................................................................................................16

3.1 Transport

3.2 Unpacking

3.3 Location

3.4 Installation

3.5 Connection

3.6 Starting up

4 OPERATION ............................................................................................................21

4.1 Operation mode settings

4.1.1 Preferred source selection

4.1.2 Automatic retransferring

4.1.3 Manual operation

4.1.4 Reset button

4.2 Manual bypass operation

4.2.1 Bypassing load to primary source

4.2.2 Return from primary bypass mode to STS operation

4.2.3 Bypassing load to secondary source

4.2.4 Return from secondary bypass mode to STS operation

4.3 Service

4.3.1 STS operation test

4.3.2 Main fuse exchange procedure

4.3.3 TVSS fuse exchange procedure

4.3.4 Trouble shooting

4.4 Parameter settings (dip switches)

4.5 Default dip switch settings

4.6 Terminals

4.6.1 Relay communication terminal block

4.6.2 Communication Interface Module CI-M1

4.6.3 High current terminal

4.7 Fuse selection

5 SPECIFICATIONS ...................................................................................................43

5.1 Technical data

5.2 Dimensions

OPM_STS_400_25A_100_1GB_V011

2

GE DE STS: installation and operating manual 1.1 (GB)

Page 4

Digital Energy™ Static Transfer Switch

g

1 - Important Safety Instructions

1.1 Save these instructions

This manual contains important instructions that should be followed during erection, installation, use

and maintenance of the Static Transfer Switch. Before attempting to erect, install and use of the

device, carefully read this manual. Keep this manual next to the device for future references

Full understanding of and compliance with the safety instructions and warnings

contained in this manual are

THE ONLY CONDITION

to avoid any dangerous situation during erection, installation, operation and

maintenance work, and to preserve the maximum reliability of the system.

In the event of equipment failures or special problems it is not permitted to take unauthorised remedial

action. In such cases the responsible GE technical service department must be contacted and the

GE refuses any responsibility in case of non-observance, unauthorized alterations or improper use of

While every care has been taken to ensure the completeness and accuracy of this manual, GE accepts

This document shall not be copied nor reproduced without the permission of GE.

Due to technical improvements, some of the information contained in this manual may be changed

1.2 Safety warnings and symbols

Safety warnings

The text of this manual contains warnings to avoid risk to persons and to avoid damages to the UPS

The non-observance of the warnings reminding hazardous situations could result in human injury and

required information obtained.

the delivered device.

no responsibility or liability for any loss or damage resulting from the use of the information contained in

this document

without notice

system and the supplied critical loads. Do not proceed beyond these warnings if you do not fully

understand and/or are not able to meet the mentioned conditions.

equipment damage. Please pay attention to the meaning of the following warnings and symbols.

WARNING !

Refers to procedures or operations which, when not correctly performed,

could cause personal injury or serious damage to the system

NOTE

Warns the user about important operations or procedures described in this

manual

Safety Symbols

CAUTION

The product may be in danger: when procedures or operations are not

correctly performed, damage to the product may be the result.

DANGER OF PARTS ELECTRICALLY LIVE

Related to all situations with potentially hazardous voltage

OPM_STS_400_25A_100_1GB_V011

3

GE DE STS: installation and operating manual 1.1 (GB)

Page 5

Digital Energy™ Static Transfer Switch

g

1.3 General

DANGER!

RISK OF ELECTRIC SHOCK.

When the STS operates, some of its parts are necessarily under a hazardous

voltage.

Do not remove the cover; there are no user serviceable parts inside.

There may be danger, loss of life or personal injury if warnings are not strictly

observed.

CAUTION

There may be damage to the equipment if procedures and practices are not

strictly observed and followed.

NOTE

Do not attempt to service the STS unless you have had proper training. Refer

all maintenance and servicing to properly qualified, skilled and competent

service personnel.

Properly qualified, skilled and competent service personnel are persons who:

• Are familiar with the erection, installation and operation of the equipment and the system that is

being installed.

• Are capable of performing switching operations according to safety technology standards and

entitled and authorized to switch the equipment on and off and to isolate from the voltage.

• Are instructed according to the standards of safety technology in the care and use of safety

equipment.

• Are trained to immediate rescue measures (first aid).

• Have completed instructions with appropriate confirmation of GE.

1.4 Intended use

• A Static Transfer Switch (STS) is designed to transfer power supply between independent AC power

sources, thus protecting the connected load from power supply interruptions. It protects automatic

systems for power industry, power supply systems for petrochemical industry, computer and

telecommunication centers, automatic and security systems of ‘intelligent’ buildings as well as other

equipment that is highly sensitive for power supply interruptions.

• The STS is intended to be operated by technically qualified personnel.

Technically qualified personnel are persons who (because of their training, experience, and position

as well as their knowledge of appropriate standards, regulations, health and safety requirements and

working conditions) are authorised to be responsible for the safety of the equipment, at all times whilst

carrying out their normal duties and are therefore aware of, and can report, possible hazards (observe

IEC 364, DIN VDE 0105 and national wiring regulations and accident prevention rules).

• The technical data as well as information concerning connecting requirements can be found on the

rating label and in this document and shall be strictly observed.

OPM_STS_400_25A_100_1GB_V011

4

GE DE STS: installation and operating manual 1.1 (GB)

Page 6

Digital Energy™ Static Transfer Switch

g

1.5 Transport, storage, unpacking

• The STS should be transported in a container truck with shock protection against moves during

transport. The STS should be belted to the wall of the container.

• Any special treatment during storage of the STS is not needed.

• Move the STS in its original package to the final destination room.

• Check for sufficient floor and elevator loading capacity.

• Immediately after unpacking carefully check the integrity of the equipment. In case you note

recognizable damage, do not connect any voltage to the STS, do not put the STS into operation, but

contact the nearest Service Centre.

1.6 Installation

The following instructions are provided for the personal safety of operators and also for the protection

of the described product and connected equipment.

• Observe the prescribed accident prevention and safety rules for the specific application.

• When installing the STS strictly observe all information on technical data and operating conditions.

Comply with all warnings, and strictly follow the procedures and practices as described in this manual.

• This STS is intended to be used in a controlled indoor environment and free of conductive

contaminants and protected against animal intrusion.

• Check for sufficient floor loading capacity.

• Avoid placing the unit in direct sunlight or near heat sources.

• It is important that the unit has adequate ventilation. Maintain air movement around and through the

unit. Do not block the air vents.

• The unit must be placed in a sufficiently ventilated area; the ambient temperature should not exceed

40°C (104°F).

• Do not install the STS in an excessively humid environment or near water, relative humidity should not

exceed 90% at 20°C (68°F).

• Avoid spilling liquids or dropping any foreign object into the STS.

• Emergency stop devices must be provided for all applications. An emergency stop must inhibit any

further uncontrolled operation.

• The electric connections must be covered.

• Earth connection must be checked for safe function after assembly.

• Countermeasures should be taken to avoid accidental turning on of previously switched off systems

through either a control vault or a third party (e.g. key switches).

• Do not touch electronic components. They may be electrostatic sensitive and are for that reason easily

damaged due to improper handling.

• To avoid potential health risks, electrical components should not be mechanically damaged or

destroyed.

• Isolate from mains and battery before installation or dismantling work, as well as for fuse changes or

post installation modifications.

OPM_STS_400_25A_100_1GB_V011

5

GE DE STS: installation and operating manual 1.1 (GB)

Page 7

Digital Energy™ Static Transfer Switch

g

1.7 Electrical connection

• All electrical connections are to be realized by properly qualified, skilled and competent service

personnel only.

• When working on live STS, be sure to comply with the applicable national accident prevention rules.

• Before putting into operation make sure that the rated voltage for the unit corresponds to the local

supply voltage.

1.8 Operation

• These instructions cover normal operation in the automatic as well as in manual modes. Special

operating conditions, such as short circuit tests, input supplies, etc., are not covered in this document.

These operating modes require comprehensive knowledge of the overall system and should be carried

out by properly qualified, skilled and competent service personnel only. Refer to section 1.3 for further

details.

• Operators shall make sure that the system is ready for operation and that all cabinet doors are properly

closed before switching it on.

• Warning signs are placed on all cabinet doors to warn of excessive voltage (over 50 V) in the control

cabinets, but also of voltages in the power section and enormous short circuit currents. These signs

supply a warning not to open the doors during operation.

DANGER ! High Voltage!

Only qualified personnel may carry out work or manipulation of the device.

• Operators are prohibited from performing any work inside the control cabinets.

• Service and maintenance will not be covered in this document.

1.9 Fire regulations

WARNING

Should a fire break out inside the system, a fire extinguisher with CO2 or

halogen must be used. Do not inhale vapors.

OPM_STS_400_25A_100_1GB_V011

6

GE DE STS: installation and operating manual 1.1 (GB)

Page 8

Digital Energy™ Static Transfer Switch

g

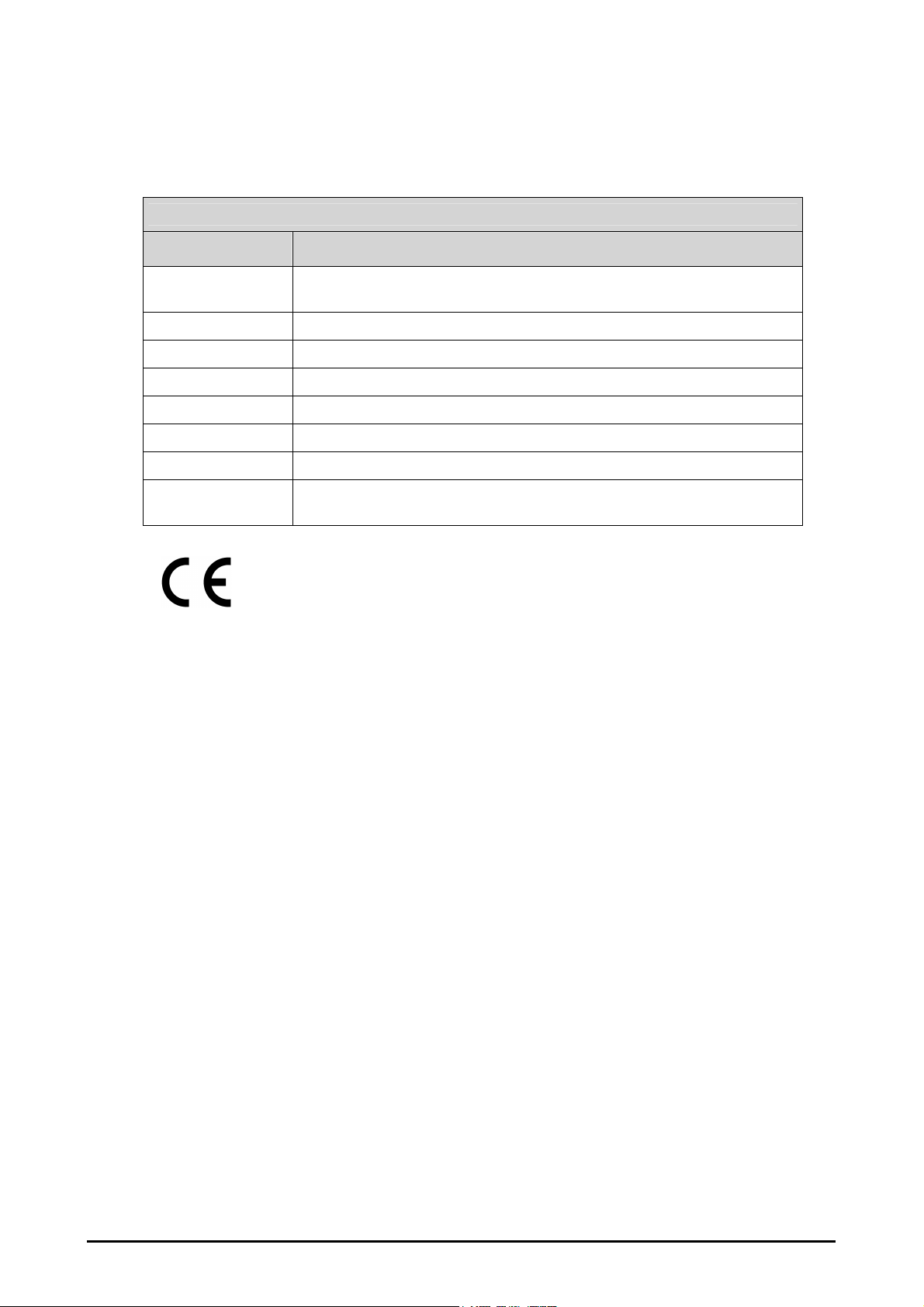

1.10 Standards applied and conformity

European Standards

Standard

EN 60950

EN 50178 (project)

IEC 600076

IEC 60146-1-2

IEC 60529

IEC 60617

EN 50082-2

DIN 41773 Part 1

Safety of information technology equipment, including electrical

business equipment

Equipment of Power Plants with electronic resources

Power transformers

General requirements and line commutated converters

Degrees of protection provided by enclosures (IP codes)

Graphical symbols and diagrams

EMC Requirements

Static power converters, semiconductor rectifiers equipment with IU

characteristics for charging of Lead Acid batteries - guideline

The standards mentioned above fulfil the

Description

requirements for CE marking.

The product mentioned in this manual conforms to the relevant requirements to the appropriate EU

Directive, i.e. that this product meets all relevant EU Directives and that it can be sold inside the

European Union without national commercial hindrances.

Relevant EU Directives for GE are called EMC- and Low Voltage Directives:

• EU Directive on Electromagnetic Compatibility 89/336/EU, in version 92/31/EU, 93/68/EU

• EU Directive on Electrical Equipment designed for use within certain Voltage Limits (Low

Voltage Directive) 73/23/EU, in version 93/68/EU

The directives themselves define only on a modest scale what's to do and refer to the harmonised

Standards. One of the EU harmonised product standards is applicable for rectifier systems. According

to this standard GE fulfils the basic requirements.

OPM_STS_400_25A_100_1GB_V011

7

GE DE STS: installation and operating manual 1.1 (GB)

Page 9

Digital Energy™ Static Transfer Switch

g

2 - Introduction

2.1 Warranty

GE Digital Energy, operating through its authorized agents, warrants that the standard products will be free of

defects in materials and workmanship for a period of 24 months after the date of invoice, or such other period

as may be specified.

NOTE

This warranty does not cover failures of the product which result from incorrect

installation, misuse, alterations by persons other than authorized agents, or abnormal

operating conditions

2.2 Description

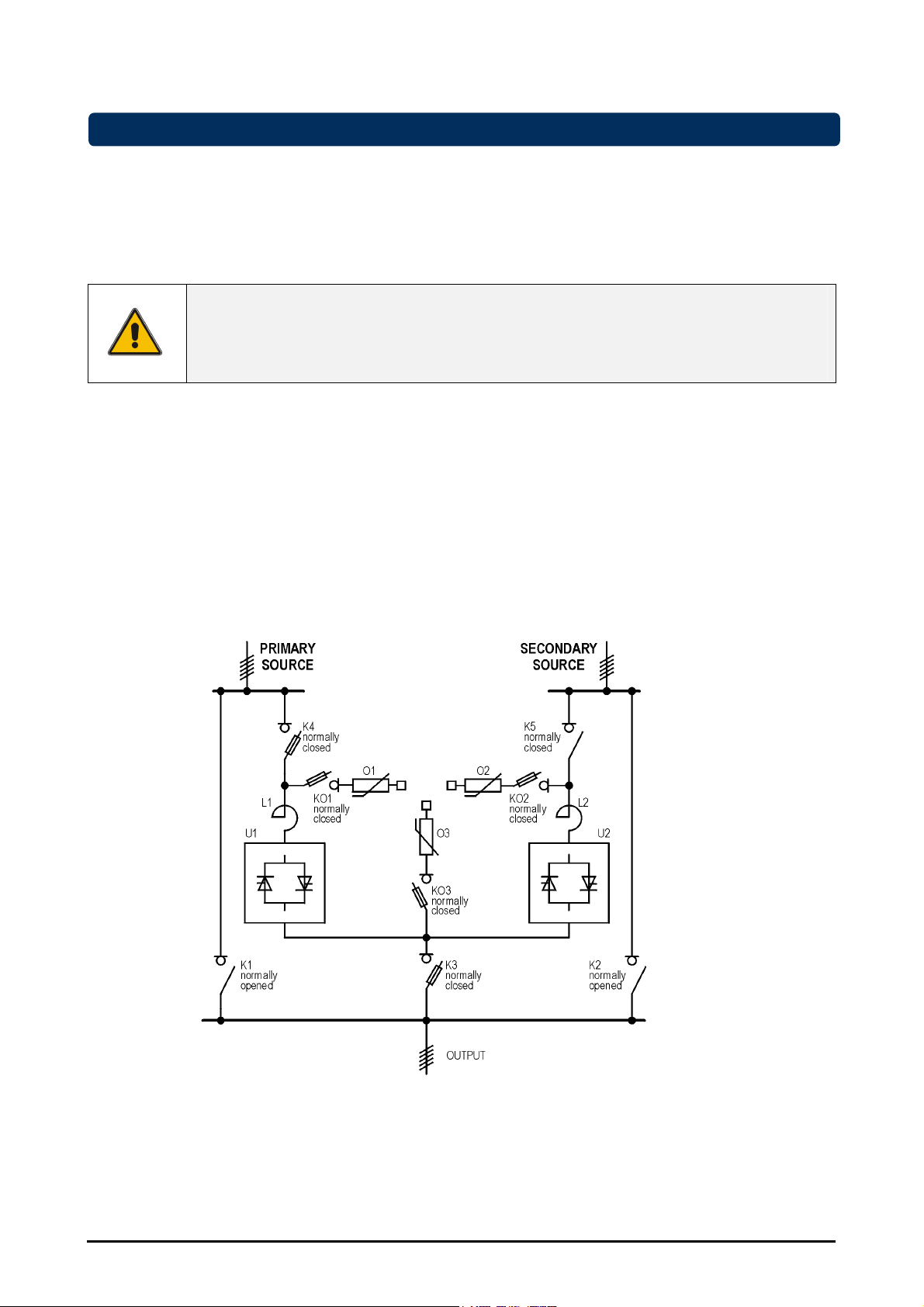

Static Transfer Switches type STS-400-XX-3/4 (four 3-pole models STS-400-25/40/63/100-3 and three 4-pole

models STS-400-25/40/63-4) are designed for switching between two alternative electrical power sources

without interruption of the power supplied to the load. The neutral wires in the 3-pole STS type are connected

together, whereas the neutral wires in the 4-pole type are being switched the same way as the phase wires.

The static transfer switch (STS) is connected to two sources of electrical power with terminals called X01

PRIMARY SOURCE and X02 SECONDARY SOURCE. The rated voltage of both sources is 400V AC phaseto-phase and the frequency is 50Hz. Depending on the current settings and the state of the system, one of the

two sources (either the PRIMARY SOURCE or the SECONDARY SOURCE) is “connected” to the output

terminal called X03 STS OUTPUT. Possible methods for transferring the load from one source to other are

explained in chapter 4.

Figure 1. Electrical diagram of Static Transfer Switch (STS) with manual bypasses

Each single line on the diagram represents three wires inside the 3-pole STS and four wires inside the 4-pole

STS.

PRIMARY SOURCE, SECONDARY SOURCE and STS OUTPUT connections consist of five wires each

including Protective Earth (PE).

OPM_STS_400_25A_100_1GB_V011

8

GE DE STS: installation and operating manual 1.1 (GB)

Page 10

Digital Energy™ Static Transfer Switch

g

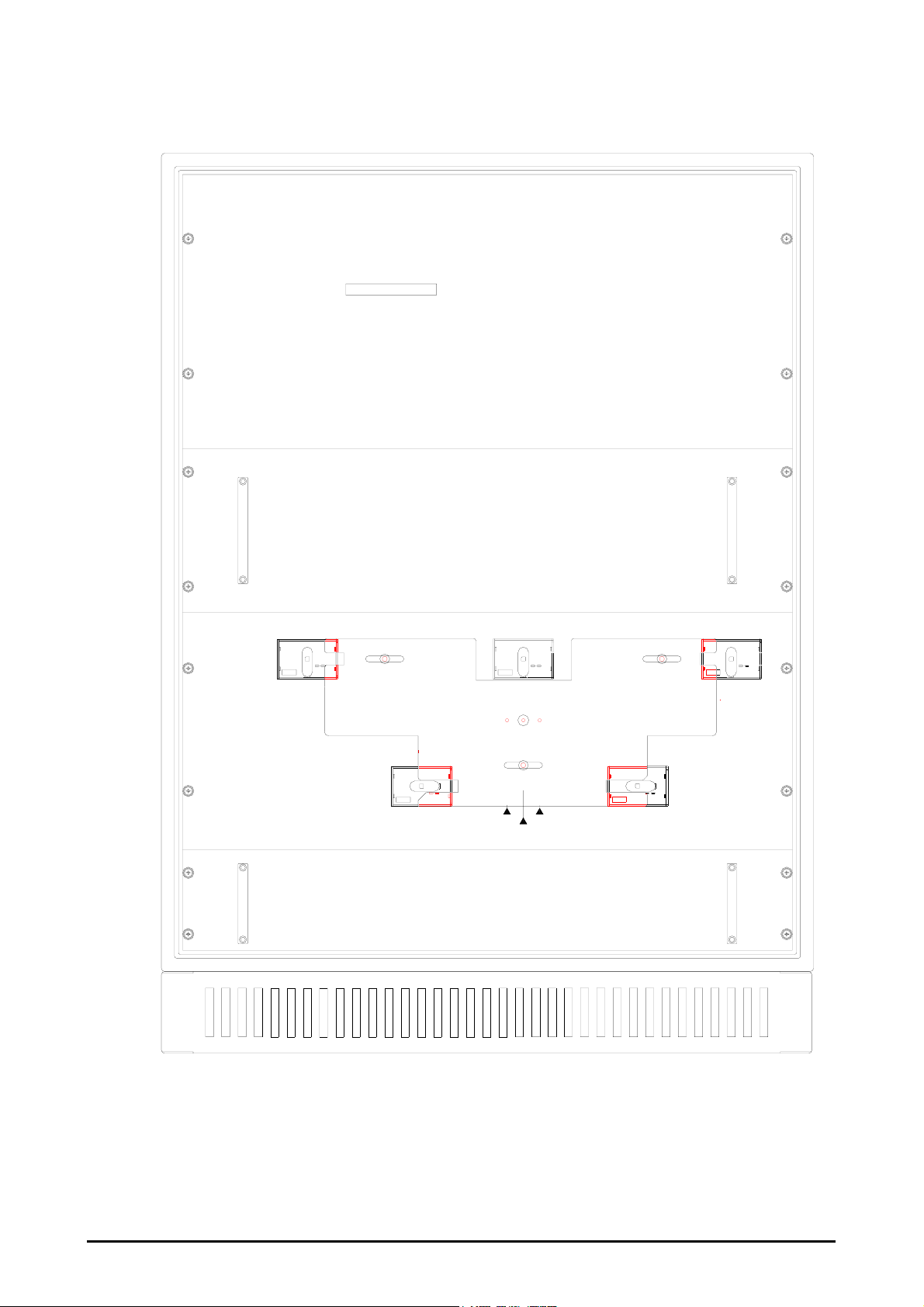

Five switches (figure 3) are set from the front panel without need for taking out the panel. These switches are

equipped with a mechanical interlock that prevents against short circuit between both supplying sources. Each

of them may be set manually into one of two positions: either “ON” or “OFF”. The device operates in STS mode

if the switches are set as in table 1.

Table 1

K1 STS

PRIMARY BYPASS

OFF

K2 STS

SECONDARY BYPASS

K3 STS

OUTPUT

K4 STS

PRIMARY SOURCE

K5 STS

SECONDARY SOURCE

OFF

ON

ON

ON

In normal mode of operation, the process of transferring the supply from one input to the other one is performed

automatically. The start up procedure is described in chapter 3, operation is explained in chapter 4.

The device is equipped with a mechanical interlock plate that prevents against unintentional short circuit during

manipulation with high current switches. The interlock plate is being moved aside during manipulation and may

be set in three positions: SECONDARY BYPASS, NORMAL MODE and PRIMARY BYPASS. The interlock

plate is equipped with a knurled nut that is screwed after a change of plate position. In that way the interlock

plate positions are locked with the knurled nut to prevent unintentional move of the plate.

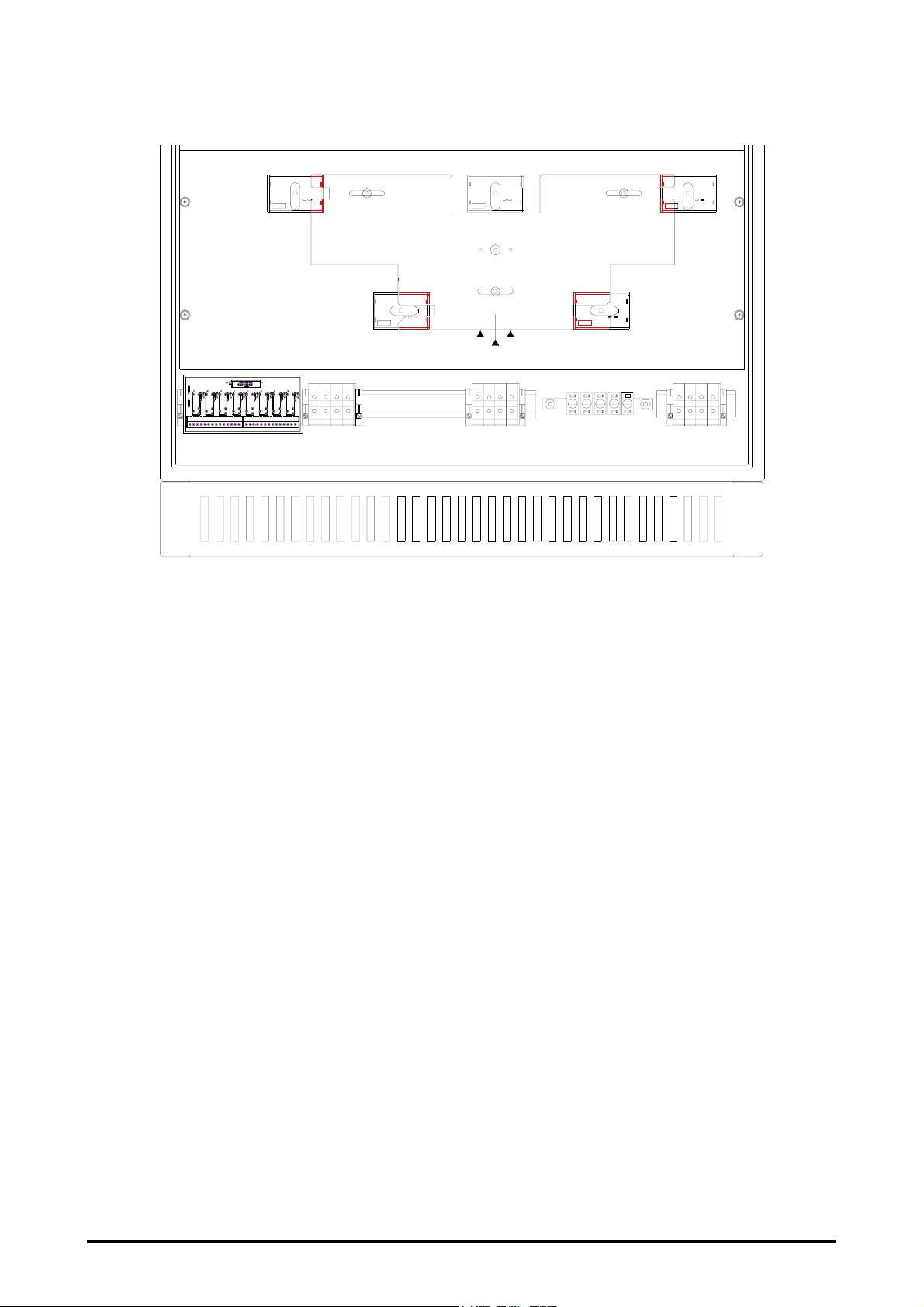

Figure 2. STS front

OPM_STS_400_25A_100_1GB_V011

9

GE DE STS: installation and operating manual 1.1 (GB)

Page 11

Digital Energy™ Static Transfer Switch

g

OFF

ON

MAIN AND AUXILARY FUSES

K4 STS

PRIMARY SOURCE

RELAY COMMUNICA TION

TERMINAL BLOCK

Figure 3. STS with opened door

SW1SW2SW3SW4SW5SW6SW8SW7

K1 STS

PRIMARY

BYPASS

XO1

PRIMARY SOURCE

K3 STS

OUTPUT

NORMAL

MODE

XO3

OUTPUT

K5 STS

SECONDARY SOURCE

PRIMARYSECONDARY

BYPASSBYPASS

K2 STS

SECONDARY

BYPASS

XO2

SECONDARY SOURCE

OPM_STS_400_25A_100_1GB_V011

10

GE DE STS: installation and operating manual 1.1 (GB)

Page 12

Digital Energy™ Static Transfer Switch

g

K4 STS

PRIMARY SOURCE

K1 STS

PRIMARY

BYPASS

N

1

X10 X11

1

14

14

L1 L2 L3

X01

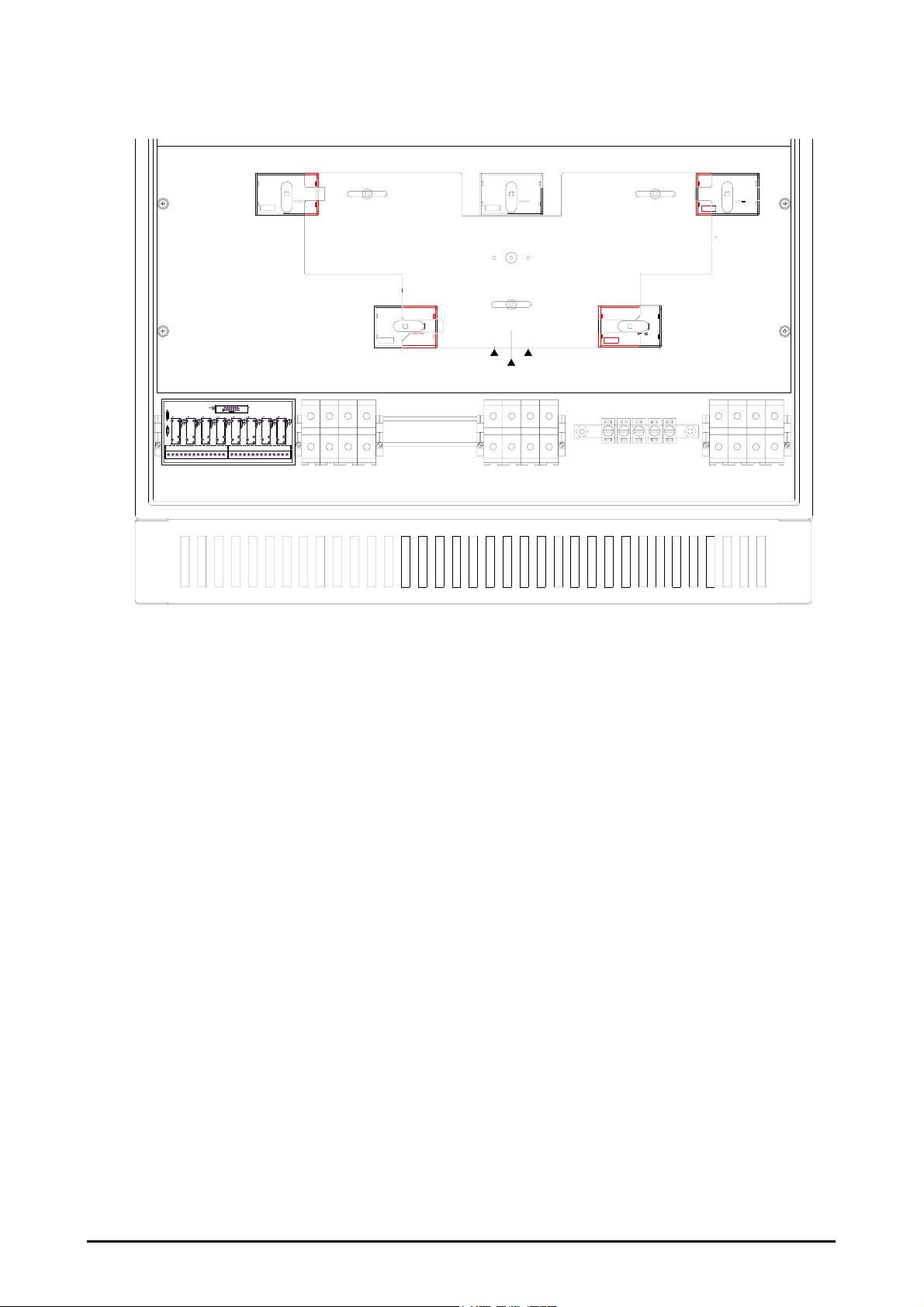

Figure 4.a. High current terminals location for all types excluding STS-400-100-3

K3 STS

OUTPUT

PRIMARYSECONDARY

BYPASSBYPASS

NORMAL

MODE

L1 L2 L3

X03

(cover removed)

K5 STS

SECONDARY SOURCE

K2 STS

SECONDARY

BYPASS

PE PE PE

PE

N

PE

L1 L2 L3

X02

N

OPM_STS_400_25A_100_1GB_V011

11

GE DE STS: installation and operating manual 1.1 (GB)

Page 13

Digital Energy™ Static Transfer Switch

g

K4 STS

PRIMARY SOURCE

K1 STS

PRIMARY

BYPASS

1

1

14

X10 X11

14

L1 L2

X01

N

L3

Figure 4 b. High current terminals location for STS-400-100-3

K3 STS

OUTPUT

NORMAL

MODE

L1 L2

(cover removed)

X03

K5 STS

SECONDARY SOURCE

PRIMARYSECONDARY

BYPASSBYPASS

N

L3

K2 STS

SECONDARY

BYPASS

PE PE PE

PE

PE

L1 L2

X02

N

L3

OPM_STS_400_25A_100_1GB_V011

12

GE DE STS: installation and operating manual 1.1 (GB)

Page 14

Digital Energy™ Static Transfer Switch

g

O1

Primary Source

Fuses

KO1 KO2

K4 STS

PRIMARY SOURCE

Figure 5 a. Fuses and TVSS location (without STS-400-100-3)

Fuse burn

indication for

primary source

fuses

KO3

O3

K3 STS

OUTPUT

Output

Fuses

Fuse burn

indication for

output fuses

K5 STS

SECONDARY SOURCE

O2

OPM_STS_400_25A_100_1GB_V011

13

GE DE STS: installation and operating manual 1.1 (GB)

Page 15

Digital Energy™ Static Transfer Switch

g

O1

Primary Source Fuses

KO1

K4 STS

PRIMARY SOURCE

Figure 5b. Fuses and TVSS location for STS-400-100-3

Fuse burn

indication for

primary source

fuses

KO3

O3

K3 STS

OUTPUT

Output

Fuses

Fuse burn

indication for

output fuses

KO2

K5 STS

SECONDARY SOURCE

O2

OPM_STS_400_25A_100_1GB_V011

14

GE DE STS: installation and operating manual 1.1 (GB)

Page 16

Digital Energy™ Static Transfer Switch

g

2.3 Application

The STS-400-XX is designed to operate with two electrically separated electrical power sources connected to

terminals X01 PRIMARY SOURCE and X02 SECONDARY SOURCE. The sources are connected to the STS

with a five-wire cable each (three wires for the phases, one for neutral and one for PE). Electrical parameters of

the input sources (PRIMARY SOURCE and SECONDARY SOURCE) and output external circuit (STS

OUTPUT) should meet the specifications for the STS. Three cables coming into the STS, two from the sources

and one from the load, create three outgoing lines on the diagram showed in figure 1. Lines going from the

sources are called input lines and consequently the line going to the load is called output line. Input line voltage

and output line current values should not exceed acceptable ranges.

2.4 Fuses and TVSS circuits

Fuses and TVSS units (TVSS – Transient Voltage Surge Suppressor) are placed behind the plate with MAIN

AND AUXILARY FUSES label (figure 4). Exchange of fuses and TVSS units is possible after removing that

plate (figure 6).

Fuses are placed in the primary input line and in the output line (figure 1). Each fuse is equipped with a

signalling circuit which indicates a burnt fuse. The signalling circuit is based on an auxiliary overcurrent circuit

breaker which is connected in parallel to the main fuse. When the main fuse is burnt the auxiliary circuit breaker

is energized too. In this way the state of the auxiliary circuit breaker indicates which fuse was burnt. In case of

exchanging the burnt fuse, the auxiliary circuit breaker should be set into position “on”.

Each line (two input lines and output line) is protected by TVSS units against voltage transients. In case of short

circuit inside the TVSS unit caused by a voltage transient, each TVSS is equipped with an overcurrent circuit

breaker that cuts off the circuit with a burnt TVSS. TVSS burning is indicated by a LED diode placed on the

control panel (figure 7). In case of a TVSS alarm, each TVSS unit should be checked. Each burnt TVSS unit

should be replaced as well as its fuse.

OPM_STS_400_25A_100_1GB_V011

15

GE DE STS: installation and operating manual 1.1 (GB)

Page 17

Digital Energy™ Static Transfer Switch

g

3 - Installation

3.1 Transport

The STS should be transported in a container truck with shock protection against moves during transport. The

STS should be belted to the wall of the container. Because of limitation of height for air transport up to 1.6

meter, the STS is placed horizontally on a palette.

Move the STS in its original package to the final destination room using a pallet truck or forklift.

For storage and transport the cabinet of the Static Transfer Switch (STS) is covered with cardboard sheet

belted with steel wrapping bands to europalettes or other suitable for forklift transport.

The package box supplies the following information:

• Name or logo of manufacturer

• Quality control sign

CAUTION

During transport, pay attention to:

• Warnings according to PN-67/O-79252 Standard

Figure 6. View of crate package

In case of installing a STS on upper levels, four lifting eyes are available on top of the cabinet allowing transport

with a crane or others.

The STS should be stored in closed rooms free of chemically aggressive vapours, temperature 0°C to +40°C

(32°F to 104°F) and humidity lower than 90% at 20°C (68°F).

OPM_STS_400_25A_100_1GB_V011

16

GE DE STS: installation and operating manual 1.1 (GB)

Page 18

Digital Energy™ Static Transfer Switch

g

3.2 Unpacking

1. Cut the wrapping bands, and remove the shipping box.

2. Immediately after unpacking carefully check the integrity of the equipment. In case you note

recognizable damage,

• notify the carrier and place of purchase

• contact the nearest Service Center.

WARNING! In case of recognizable damage:

DO NOT connect any voltage to the unit

DO NOT put the unit into operation

3. Turn the unit into vertical position and place it on a frame. Screw the pedestal of the STS to the

frame.

4. Recycle the packing material in compliance with all applicable regulations.

3.3 Location

• This STS is intended to be used in a controlled indoor environment and free of conductive

contaminants and protected against animal intrusion.

• Check for sufficient floor loading capacity.

• Avoid placing the unit in direct sunlight or near heat sources.

• It is important that the unit has adequate ventilation. Maintain air movement around and through the

unit. Do not block the air vents.

• The unit must be placed in a sufficiently ventilated area; the ambient temperature should not exceed

40°C (104°F).

• Do not install the STS in an excessively humid environment or near water, relative humidity should not

exceed 90% at 20°C (68°F).

• Avoid spilling liquids or dropping any foreign object into the STS.

OPM_STS_400_25A_100_1GB_V011

17

GE DE STS: installation and operating manual 1.1 (GB)

Page 19

Digital Energy™ Static Transfer Switch

g

3.4 Installation

External cable connections are being made during the installation procedure.

• When installing the STS strictly observe all information on technical data and operating conditions.

Comply with all warnings, and strictly follow the procedures and practices as described in this manual.

• Do not touch electronic components. They may be electrostatic sensitive and are for that reason easily

damaged due to improper handling.

• To avoid potential health risks, electrical components should not be mechanically damaged or

destroyed.

NOTE

The STS may only be installed by properly qualified, skilled and competent

service personnel.

Refer to section 1.3 for further details.

CAUTION

Make sure that condensation does not occur as a result of a relatively low

temperature of the unit. Especially if transport took place at sub-zero

temperatures, allow the unit to warm up before installation and starting up.

NOTE

Before making any connection and switching on the STS, check the following

conditions.

• Make sure that the rated voltage and frequency for the unit corresponds with the local supply voltage

and frequency.

NOTE

Rated voltage of both sources is 400V AC phase to phase and the frequency

is 50Hz.

• Make sure that the total power requirement of the equipment connected to the STS does not exceed

the rated output power of the STS.

CAUTION

Wrong connection of the external sources to the STS may cause a fault inside

the STS and unpredicted operation of external devices connected to the STS.

OPM_STS_400_25A_100_1GB_V011

18

GE DE STS: installation and operating manual 1.1 (GB)

Page 20

Digital Energy™ Static Transfer Switch

g

3.5 Connection

1. Switch off the supply in both supplying lines outside the STS. Switches for both sources may be

placed in some distance to the STS depending on the topology of the rest of the power system.

2. Check the absence of the voltage in the two input lines with a proper voltmeter.

3. Open the door of the STS.

4. Set the switches into positions as in table 2.

5. Unscrew 4 screws (figure 3) from the lowest panel and take the panel out.

6. Firmly connect five wires coming from the first supplying device (PRIMARY SOURCE) into the

X01 PRIMARY SOURCE terminal (figure 4).

7. Firmly connect five wires coming from the second supplying device (SECONDARY SOURCE) into

the X02 SECONDARY SOURCE terminal (figure 4).

8. Firmly connect the five wires going to the load (STS OUTPUT) into the X03 STS OUTPUT

terminal (figure 4).

9. Check the connection of three external lines. Especially the output line going to the load should be

connected to the right terminal in the STS.

10. Check if L1, L2 and L3 of each source are connected to right terminal.

11. Put the front panel of the lower board back in place and fasten it with screws.

12. Switch on the supply for the two input sources. The STS is ready to start up.

K1 STS

PRIMARY BYPASS

Table 2

OFF

K2 STS

SECONDARY BYPASS

K3 STS

OUTPUT

K4 STS

PRIMARY SOURCE

K5 STS

SECONDARY SOURCE

OFF

OFF

OFF

OFF

OPM_STS_400_25A_100_1GB_V011

19

GE DE STS: installation and operating manual 1.1 (GB)

Page 21

Digital Energy™ Static Transfer Switch

g

3.6 Starting up

Make sure that all necessary connections described in chapter 3.5 have been made.

Make sure that the internal switches are in the positions as described in table 2, and that the bypass

interlock plate is in position “NORMAL MODE”.

Start up procedure for connecting the PRIMARY SOURCE to the STS OUTPUT should proceed as

follows:

1. Choose the primary source as preferred with the button “PREFERRED SOURCE” on the control

panel (button is released if primary source is preferred).

2. Choose manual operation mode with the button “OPERATION” (button is released if manual

mode is on). Remote control is blocked when manual mode is on.

3. Set switch K4 STS PRIMARY SOURCE into “ON” position.

4. Check if the LEDs on the control panel indicate that the primary source is preferred, healthy, and

on.

5. Set switch K5 STS SECONDARY SOURCE into “ON” position.

6. Check if the LEDs on the control panel indicate the secondary source as healthy and proper

synchronization of both sources.

7. Set switch K3 STS OUTPUT into “ON” position.

8. Choose automatic operation mode with the button “OPERATION” on the control panel. In case of

automatic operation the button is pressed.

9. Close the door of the STS.

After the start up procedure the states of the switches should be as in table 3.

K1 STS

PRIMARY BYPASS

Table 3

OFF

K2 STS

SECONDARY BYPASS

K3 STS

OUTPUT

K4 STS

PRIMARY SOURCE

K5 STS

SECONDARY SOURCE

OFF

ON

ON

ON

OPM_STS_400_25A_100_1GB_V011

20

GE DE STS: installation and operating manual 1.1 (GB)

Page 22

Digital Energy™ Static Transfer Switch

g

The STS operates in one of the following three modes:

Preferred source mode – the selected preferred source supplies the load.

The load is transferred to the other source if the voltage of the preferred source is outside acceptable range.

Automatic retransferring mode – After a transfer triggered by disturbances in the preferred source, the

load is transferred again to the preferred source with a minimum delay of 6 seconds if the preferred source is

healthy again.

Manual mode – connections are set manually (not automatically).

4 - Operation

4.1 Operation mode settings

Three buttons on the control panel determine the current operation mode: OPERATION, RETRANSFER and

PREFERRED SOURCE.

Figure 7. Control panel

4.1.1 Preferred source selection

Button designation Position Operation

PRIMARY SOURCE or REMOTE CONTROL

selected.

*NOTE

SECONDARY SOURCE selected. SECONDARY

BUTTON LED is on.

PREFERRED SOURCE

*NOTE

PRIMARY –

button is released

SECONDARY –

button is pushed

If remote control signal is connected, its selection is valid. Preferred source may be

selected by remote signal when switch PREFERRED SOURCE is set into

“PRIMARY” position. If MANUAL mode is on, remote control is not active.

OPM_STS_400_25A_100_1GB_V011

21

GE DE STS: installation and operating manual 1.1 (GB)

Page 23

Digital Energy™ Static Transfer Switch

g

4.1.2 Automatic retransferring

Button designation Position Operation

RETRANSFER

4.1.3 Manual operation

ON – button

is pushed

OFF – button

is released

Retransfer operates

Retransfer does not operate. RETRANSFER

OFF LED is on.

Button designation Position designation Operation

Manual operation is active. OPERATION

MANUAL is on. MANUAL LED is on.

*NOTE

Automatic operation is active

OPERATION

MANUAL – button

is released

AUTOMATIC – button

is pushed

*NOTE

Remote control is blocked when manual mode is on. If MANUAL mode of operation

is selected, the active source may be changed even if the second one is not

operational.

4.1.4 Reset button

The reset button allows states of the alarms and LEDs which are memorized to be reset to default states.

OPM_STS_400_25A_100_1GB_V011

22

GE DE STS: installation and operating manual 1.1 (GB)

Page 24

Digital Energy™ Static Transfer Switch

g

4.2 Manual bypass operation

4.2.1 Bypassing load to primary source

Initial states of the switches are described in table 3 (figure 8). The Interlock Plate is set in “NORMAL MODE”

position. Bypassing the load to the primary source is achieved by the following steps:

1. Set button “PREFERRED SOURCE” into “PRIMARY” position (button is released if primary

2. Check if LEDs on the control panel indicate that the primary source is preferred, healthy and

3. Open the door of the STS.

4. Unscrew the knurled nut that locks the Interlock Plate.

5. Set switch K5 STS SECONDARY SOURCE into “OFF” position.

6. Move the Bypass Interlock Plate into PRIMARY BYPASS position.

7. Set switch K1 STS PRIMARY BYPASS into “ON” position.

8. Set switch K3 STS OUTPUT into “OFF” position.

9. Set switch K4 STS PRIMARY SOURCE into “OFF” position.

10. Screw the knurled nut that locks the Interlock Plate.

NOTE

In case of STS failure, switch to bypass of active source

source is preferred)

currently supplying the load.

After described above procedure, the states of the switches should be as in table 4 (figure 9).

Table 4

K1 STS

PRIMARY BYPASS

K2 STS

SECONDARY BYPASS

K3 STS

OUTPUT

K4 STS

PRIMARY SOURCE

K5 STS

SECONDARY SOURCE

ON

OFF

OFF

OFF

OFF

OPM_STS_400_25A_100_1GB_V011

23

GE DE STS: installation and operating manual 1.1 (GB)

Page 25

Digital Energy™ Static Transfer Switch

g

K4 STS

PRIMARY SOURCE

K1 STS

PRIMARY

BYPASS

RELAY COMMUNICATION

TERMINAL BLOCK

PRIMARY SOURCE

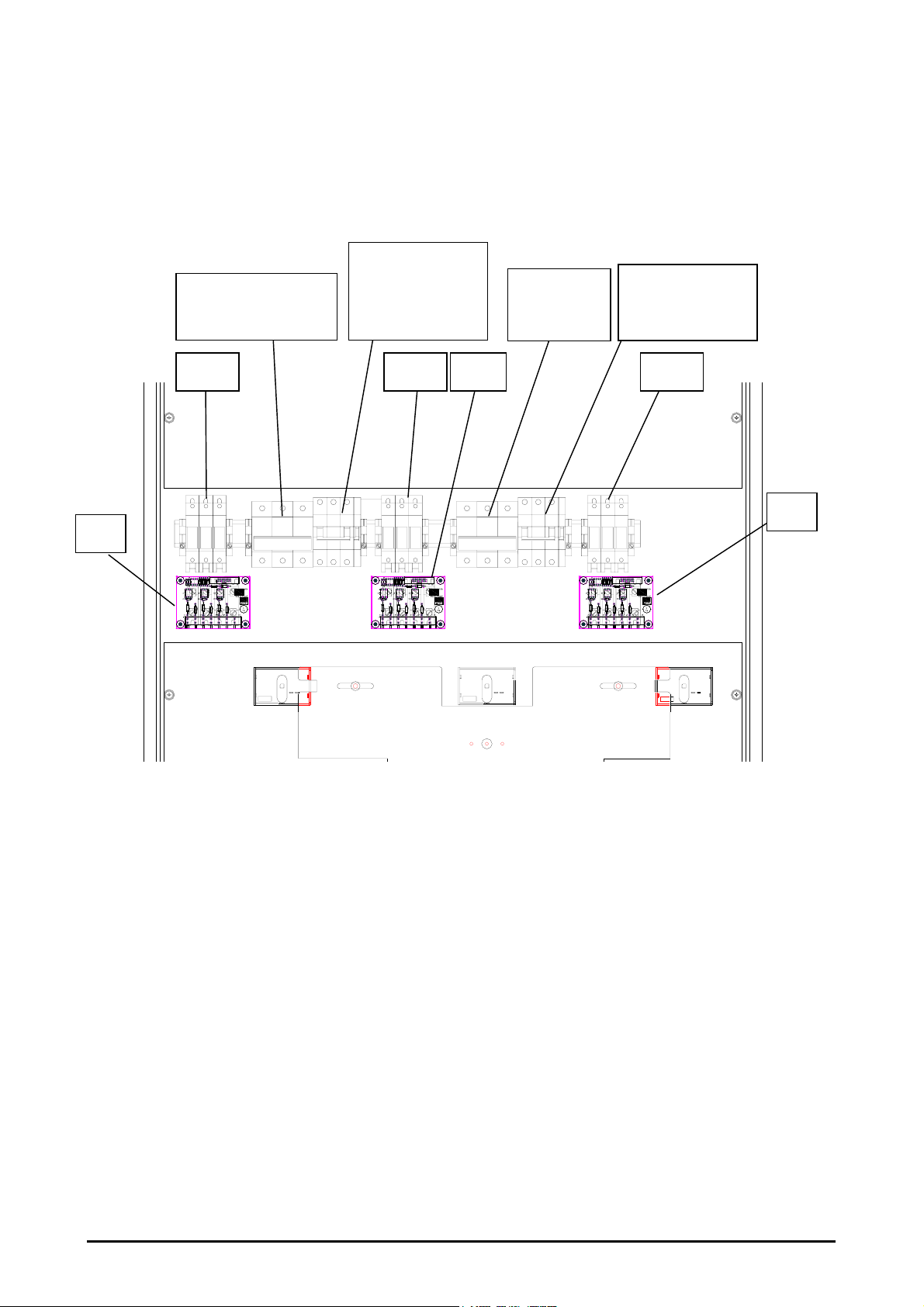

Figure 8. Switches set for normal STS mode of operation

MAIN AND AUXILARY FUSES

K4 STS

PRIMARY SOURCE

K1 STS

PRIMARY

BYPASS

RELAY COMMUNICATION

TERMINAL BLOCK

Figure 9. Switches set for primary bypass mode of operation

XO1

PRIMARY SOURCE

XO1

OUTPUT

K3 STS

NORMAL

MODE

XO3

OUTPUT

K3 STS

OUTPUT

NORMAL

MODE

XO3

OUTPUT

PRIMARYSECONDARY

BYPASSBYPASS

K5 STS

SECONDARY SOURCE

PRIMARYSECONDARY

BYPASSBYPASS

K2 STS

SECONDARY

BYPASS

SECONDARY SOURCE

K2 STS

SECONDARY

BYPASS

XO2

SECONDARY SOURCE

XO2

K5 STS

SECONDARY SOURCE

OPM_STS_400_25A_100_1GB_V011

24

GE DE STS: installation and operating manual 1.1 (GB)

Page 26

Digital Energy™ Static Transfer Switch

g

4.2.2 Return from primary bypass mode to STS operation

Initial states of the switches are described in table 4 (figure 9). The Interlock Plate is set in PRIMARY

BYPASS position. Return from bypassing to STS primary source operation is achieved by the following

steps:

1. Set button “PREFERRED SOURCE” into “PRIMARY” position (button is released if primary

source is preferred).

2. Set button “OPERATION” into “AUTOMATIC” position (button is pushed in case of automatic

operation).

3. Open the door of the STS.

4. Unscrew the knurled nut that locks the Interlock Plate.

5. Set switch K4 STS PRIMARY SOURCE into “ON” position.

6. Check if LEDs on the control panel indicate that the primary source is preferred, healthy and

currently supplying the load.

7. Set switch K3 STS OUTPUT into “ON” position.

8. Set switch K1 STS PRIMARY BYPASS into “OFF” position.

9. Move the Bypass Interlock Plate into “NORMAL MODE” position.

10. Set switch K5 STS SECONDARY SOURCE into “ON” position.

11. Screw the knurled nut that locks the Interlock Plate.

After the procedure described above, the states of the switches should be as in table 5 (figure 8).

Table 5

K1 STS

PRIMARY BYPASS

K2 STS

SECONDARY BYPASS

K3 STS

OUTPUT

K4 STS

PRIMARY SOURCE

K5 STS

SECONDARY SOURCE

OFF

OFF

ON

ON

ON

OPM_STS_400_25A_100_1GB_V011

25

GE DE STS: installation and operating manual 1.1 (GB)

Page 27

Digital Energy™ Static Transfer Switch

g

4.2.3 Bypassing load to secondary source

NOTE

In case of STS failure, switch to bypass of active source

Initial states of the switches are described in table 5 (figure 8). The Interlock Plate is set in NORMAL MODE

position. Bypassing the load to the secondary source is achieved by the following steps:

1. Set button “PREFERRED SOURCE” into “SECONDARY” position (button is pushed if secondary

source is preferred).

2. Check if LEDs on the control panel indicate that the secondary source is preferred, healthy and

currently supplying the load.

3. Open the door of the STS.

4. Unscrew the knurled nut that locks the Interlock Plate.

5. Set switch K4 STS PRIMARY SOURCE into “OFF” position.

6. Move the Bypass Interlock Plate into “SECONDARY BYPASS” position.

7. Set switch K2 STS SECONDARY BYPASS into “ON” position.

8. Set switch K3 STS OUTPUT into “OFF” position.

9. Set switch K5 STS SECONDARY SOURCE into “OFF” position.

10. Screw the knurled nut that locks the Interlock Plate.

After the procedure described above, the states of the switches should be as in table 6 (figure 10).

Table 6

K1 STS

PRIMARY BYPASS

K2 STS

SECONDARY BYPASS

K3 STS

OUTPUT

K4 STS

PRIMARY SOURCE

K5 STS

SECONDARY SOURCE

OFF

ON

OFF

OFF

OFF

OPM_STS_400_25A_100_1GB_V011

26

GE DE STS: installation and operating manual 1.1 (GB)

Page 28

Digital Energy™ Static Transfer Switch

g

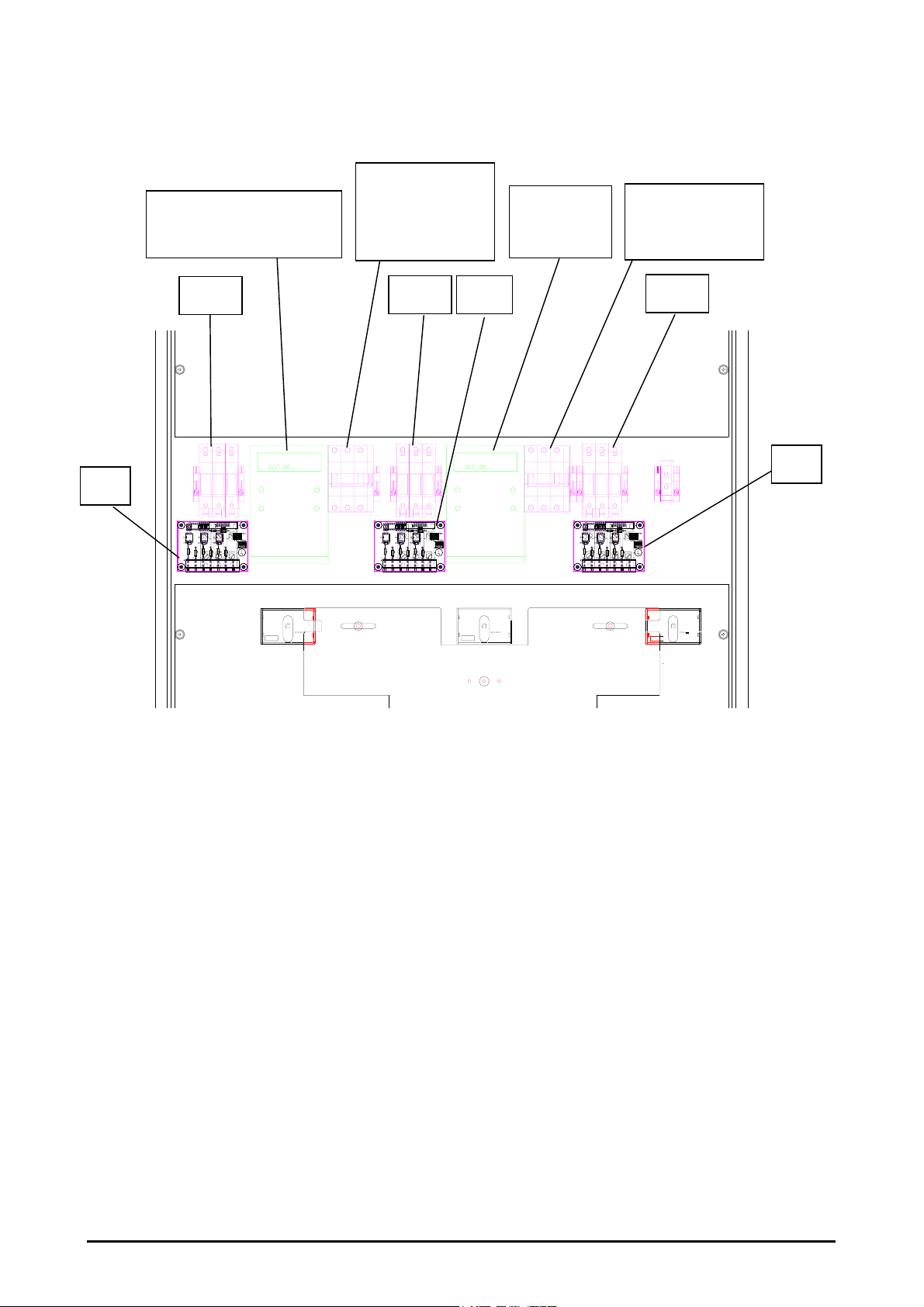

MAIN AND AUXILARY FUSES

K4 STS

PRIMARY SOURCE

K1 STS

PRIMARY

BYPASS

RELAY COMMUNICATION

TERMINAL BLOCK

PRIMARY SOURCE

Figure 10. Switches set for secondary bypass mode of operation

XO1

K3 STS

OUTPUT

NORMAL

MODE

XO3

OUTPUT

K5 STS

SECONDARY SOURCE

PRIMARYSECO NDARY

BYPASSBYPASS

K2 STS

SECONDARY

BYPASS

XO2

SECONDARY SOURCE

OPM_STS_400_25A_100_1GB_V011

27

GE DE STS: installation and operating manual 1.1 (GB)

Page 29

Digital Energy™ Static Transfer Switch

g

4.2.4 Return from secondary bypass mode to STS operation

Initial states of the switches are described in table 6 (figure 10). The Interlock Plate is set in SECONDARY

BYPASS position. Return from bypassing load to secondary source to STS operation is achieved by the

following steps:

1. Set button “PREFERRED SOURCE” into “SECONDARY” position (button is pushed if secondary

source is preferred).

2. Set button “OPERATION” into “AUTOMATIC” position (button is pushed in case of automatic

operation).

3. Open the door of the STS.

4. Unscrew the knurled nut that locks the Interlock Plate.

5. Set switch K5 STS SECONDARY SOURCE into “ON” position

6. Check if LEDs on the control panel indicate that the secondary source is preferred, healthy and

currently supplying the load.

7. Set switch K3 STS OUTPUT into “ON” position.

8. Set switch K2 STS SECONDARY BYPASS into “OFF” position.

9. Move the Bypass Interlock Plate into “NORMAL MODE” position.

10. Set switch K4 STS PRIMARY SOURCE into “ON” position.

11. Screw the knurled nut that locks the Interlock Plate.

After the procedure described above, the states of the switches should be as in table 7 (figure 8).

Table 7

K1 STS

PRIMARY BYPASS

K2 STS

SECONDARY BYPASS

K3 STS

OUTPUT

K4 STS

PRIMARY SOURCE

K5 STS

SECONDARY SOURCE

OFF

OFF

ON

ON

ON

OPM_STS_400_25A_100_1GB_V011

28

GE DE STS: installation and operating manual 1.1 (GB)

Page 30

Digital Energy™ Static Transfer Switch

g

4.3 Service

4.3.1 STS operation test

1. Check if both sources are healthy (their LEDs are on) and if both sources are synchronized.

2. Set secondary source as preferred, using the PREFERRED button.

3. The STS transfers the load to the secondary source within 30 seconds; the transfer time depends

on the dipswitch settings.

4. Set primary source as preferred using the PREFERRED button.

5. The STS transfers the load to primary source within 30 seconds; the transfer time depends on the

dipswitch settings.

NOTE

The next step can cause loss of output voltage if the SECONDARY SOURCE

or the STS is out of order.

6. Switch off K4 PRIMARY SOURCE.

7. STS immediately transfers the load to the secondary source. You can check the output transfer

time locking output voltage waveform during transfer by oscilloscope.

8. Switch on K4 PRIMARY SOURCE.

9. STS transfers the load to the preferred primary source within 30 seconds; the transfer time

depends on the dipswitch settings.

10. Set the secondary source as preferred one using PREFERRED button.

NOTE

The next step can cause loss of output voltage if the PRIMARY SOURCE or

the STS is out of order.

11. Switch off K5 SECONDARY SOURCE.

12. The STS immediately transfers the load to the primary source. You can check the output transfer

time locking output voltage waveform during transfer by oscilloscope.

13. Switch on K5 SECONDARY SOURCE.

14. The STS transfers load to the preferred secondary source within 30 seconds. The transfer time

depends on the dipswitch settings.

OPM_STS_400_25A_100_1GB_V011

29

GE DE STS: installation and operating manual 1.1 (GB)

Page 31

Digital Energy™ Static Transfer Switch

g

4.3.2 Main fuse exchange procedure

4.3.3 TVSS fuse exchange procedure

1. Open the door of the STS.

2. Bypass the load to either the primary or secondary source according to one of the two procedures

described in chapters 4.2.1 and 4.2.3. After that procedure switches K3 STS OUTPUT, K4 STS

PRIMARY SOURCE and K5 STS SECONDARY SOURCE should be in “OFF” position.

3. Remove the panel marked with label “MAIN AND AUXILARY FUSES”.

4. Check the state of the circuit breakers used for fuse burn indication. If neither is switched off,

probably there is no need to exchange fuses at all. If any fuse should be exchanged, its circuit

breaker should be in off position.

5. Remove burnt fuses and close the cover properly.

6. Switch on the circuit breaker(s) used for fuse burn indication.

7. Reinstall the panel marked with label “MAIN AND AUXILARY FUSES”.

8. Return from bypass to STS operation according to one of two procedures described in chapters

4.2.2 and 4.2.4. After that procedure switches K3 STS OUTPUT, K4 STS PRIMARY SOURCE

and K5 STS SECONDARY SOURCE should be in “ON” position. Switches K1 STS PRIMARY

BYPASS and K2 STS SECONDARY BYPASS should be in “OFF” position.

9. Close the door of the STS.

1. Open the door of the STS.

2. Bypass the load to either the primary or secondary source according to one of the two procedures

described in chapters 4.2.1 and 4.2.3. After that procedure switches K3 STS OUTPUT, K4 STS

PRIMARY SOURCE and K5 STS SECONDARY SOURCE should be in “OFF” position.

3. Remove the panel marked with label “MAIN AND AUXILARY FUSES”.

4. Check fuses KO1, KO2 and KO3 (9 fuses in three fuse holders) and the TVSS units with an

ohmmeter. Burnt TVSS may be located with an ohmmeter or just by visual inspection, without any

tools.

5. Exchange the damaged TVSS units as well as their fuses.

6. Reinstall the panel marked with label “MAIN AND AUXILARY FUSES”.

7. Return from bypass to STS operation according to one of two procedures described in chapters

4.2.2 and 4.2.4. After that procedure switches K3 STS OUTPUT, K4 STS PRIMARY SOURCE

and K5 STS SECONDARY SOURCE should be in “ON” position. Switches K1 STS PRIMARY

BYPASS and K2 STS SECONDARY BYPASS should be in “OFF” position.

8. Close the door of the STS.

OPM_STS_400_25A_100_1GB_V011

30

GE DE STS: installation and operating manual 1.1 (GB)

Page 32

Digital Energy™ Static Transfer Switch

g

4.3.4 Trouble shooting

A. Check if OVERCURRENT LED is off

B. Check if OVERTEMP LED is off

FAILURE LED is ON

DISTURBANCE LED is ON

OVERCURRENT LED is ON

OVERTEMP LED is ON

C. Press RESET button to remove memorized alarm

D. Check PRIMARY FUSES and their indication switches

E. Check STS OUTPUT FUSES and their indication switches

A. Check if PRIMARY SOURCE HEALTHY LED is ON

B. Check if SECONDARY SOURCE HEALTHY LED is ON

C. Check if SYNCHRONIZATION LEDs are ON

D. Check if TVSS ALARM LED is OFF

E. Check if RETRANSFER OFF LED is OFF

F. Check if MANUAL LED is OFF

A. Check with clamp meter if the output current of STS in all phases

is correct (notice crest factor of output current)

B. Switch off some load

A. Check if air ventilation in the cabinet is sufficient

B. Check if each fan in STS is working

C. Check with clamp meter if the output current of STS in all phases

is correct (notice crest factor of output current). After restoring right

condition (nominal load), heatsink temperature drops down below

sensor deactivation level (hysteresis). It takes about 1 hour time.

During that time OVERTEMP LED is on.

TVSS ALARM LED is ON

RETRANSFER OFF LED is ON

MANUAL LED is ON

SYNCHRONIZATION LEDs are

OFF

Check if any of transient voltage surge suppressors fuses are burnt

and replace them with new ones

Check position of RETRANSFER button – turn it into ON position

(button is pushed)

Check position of OPERATION button – turn it into AUTOMATIC

position (button is pushed)

A. Check phase order in both inputs X01 and X02

B. Check phase delay in right phases between voltages in both

supplying sources

OPM_STS_400_25A_100_1GB_V011

31

GE DE STS: installation and operating manual 1.1 (GB)

Page 33

Digital Energy™ Static Transfer Switch

g

4.4 Parameters settings (dipswitches)

WARNING !

DIP switch manipulation is allowed with STS set in manual bypass mode of

operation and with switches K3, K4 and K5 in OFF position.

OFF

ON

SW1SW2SW3SW4SW5SW6SW8SW7

DIP switches

OFF

ON

MAIN AND AUXILARY FUSES

Figure 11. Access to DIP switches

12

ON

3

4

3

4

12

ON

3

4

12

ON

3

4

12

ON

3

4

12

ON

3

4

12

ON

3

4

12

ON

3

12

4

ON

SW1SW2SW3SW4SW5SW6SW8 SW7

Figure 12. DIP switches (zoom)

NOTE

DIP switches numbering order is from left to right side !

Each single DIP switch is in upside down position.

OPM_STS_400_25A_100_1GB_V011

32

GE DE STS: installation and operating manual 1.1 (GB)

Page 34

Digital Energy™ Static Transfer Switch

g

NOTE

DIP switches numbering order is from left to right side as in figure 11 !

Designation

on the

enclosure

SW1

SW2

SW3

SW4

SW5

X – either OFF or ON freely (it is not important for this function)

Function

Undervoltage

level for

PRIMARY

SOURCE

Overvoltage

level for

PRIMARY

SOURCE

Undervoltage

level for

SECONDARY

SOURCE

Overvoltage

level for

SECONDARY

SOURCE

Level of delay

angle between

two

synchronized

input line

voltages

1 2 3 4

OFF OFF OFF X forbidden

ON OFF OFF X -8%

ON ON OFF X -12%

OFF ON OFF X -16%

OFF ON ON X

OFF OFF ON X

OFF OFF OFF X

ON OFF OFF X

ON ON OFF X

OFF ON OFF X

OFF ON ON X

OFF OFF ON X

OFF OFF OFF X forbidden

ON OFF OFF X -8%

ON ON OFF X -12%

OFF ON OFF X -16%

OFF ON ON X

OFF OFF ON X

OFF OFF OFF X

ON OFF OFF X +6%

ON ON OFF X +9%

OFF ON OFF X +13%

OFF ON ON X +16%

OFF OFF ON X

OFF OFF OFF X forbidden

ON OFF OFF X

ON ON OFF X

OFF ON OFF X

OFF ON ON X

OFF OFF ON X

3

4

Designation

12

ON

Value

-20%

-24%

forbidden

+6%

+9%

+13%

+16%

+20%

-20%

-24%

forbidden

+20%

8°

12°

16°

20°

24°

If delay angle is

larger than set

level, transfer is

performed with

additional delay.

OPM_STS_400_25A_100_1GB_V011

33

GE DE STS: installation and operating manual 1.1 (GB)

Page 35

Digital Energy™ Static Transfer Switch

g

NOTE

DIP switches numbering order is from left to right side as in figure 11 !

Designation

on the

enclosure

SW6

SW7

Function

Overcurrent

level

Retransferring

delay

Switching delay

with

unsynchronized

sources

OFF OFF OFF X

ON OFF OFF X

ON ON OFF X

OFF ON OFF X

OFF ON ON X

OFF OFF ON X

OFF OFF X X 25 s

OFF ON X X 1 s

ON OFF X X 8 s

ON ON X X 0.8 s

X X OFF OFF

X X OFF ON

X X ON OFF 25 ms

X X ON ON

4

1 2 3 4

3

Designation

12

ON

3I

4.5I

6I

7.5I

9I

50 ms

17 ms

13 ms

Value

- Transfer without

n

n

n

n

n

If instantaneous

current is larger

than set level,

transfer is not

Delay between

switching off and

overcurrent

control

performed.

switching on

OFF X X X

Sequence of

SW8

X – either OFF or ON freely (it is not important for this function)

OPM_STS_400_25A_100_1GB_V011

the thyristors

firing

ON X X X

34

GE DE STS: installation and operating manual 1.1 (GB)

Only possible setting for

STS-400-XX-4. Other setting

may cause wrong operation of

the device.

Only possible setting for

STS-400-XX-3. Other setting

may cause wrong operation of

the device.

Page 36

Digital Energy™ Static Transfer Switch

g

4.5 Default DIP switch settings

Designation Function

SW1

SW2

SW3

SW4

SW5

SW6 Overcurrent level ON OFF OFF OFF 3In

SW7

SW8

NOTE

DIP switches numbering order is from left to right side as in figure 11 !

4

3

12

ON

Default value

1 2 3 4

Undervoltage level

for PRIMARY

SOURCE

Overvoltage level

for PRIMARY

SOURCE

Undervoltage level

for SECONDARY

SOURCE

Overvoltage level

for SECONDARY

SOURCE

Level of delay

angle between two

synchronized input

line voltages

Retransferring

delay

Switching delay

with

unsynchronized

sources

Sequence of the

thyristors firing

ON OFF OFF OFF -8%

ON OFF OFF OFF +6%

ON OFF OFF OFF -8%

ON OFF OFF OFF +6%

ON OFF OFF OFF

ON ON ON ON

OFF OFF OFF OFF for STS-400-XX-4

ON ON ON ON for STS-400-XX-3

Meaning

8°

0.8s

13ms

OPM_STS_400_25A_100_1GB_V011

35

GE DE STS: installation and operating manual 1.1 (GB)

Page 37

Digital Energy™ Static Transfer Switch

g

4.6 Terminals

4.6.1 Relay communication terminal block

Inputs to and outputs from device for controlling or monitoring functions are accessed through the RELAY

COMMUNICATION TERMINAL BLOCK.

Terminal

designation

1 1 NC

2 2 NO

3 3 COMM

4 4 NC

5 5 NO

6 6 COMM

7 7 NC

X10

8 8 NO

9 9 COMM

10 10 NC

11 11 NO

12 12 COMM

13 13 NC

14

15 1 COMM

16 2 NC

17 3 NO

18 4 COMM

19 5 NC

20 6 NO

21 7 COMM

22 8 NC

23 9 NO

24 10 COMM

25 11 Not used

26 12 Not used

27 13

X11

28 14

X11

Meaning

SECONDARY SOURCE OK.

Output

Output

Output

Output

14 NO

Output

Output

Output

Output

Input

Secondary source operates if there is electrical

connection between “common” and “NC” terminal.

PRIMARY SOURCE OK.

Primary source operates if there is electrical connection

between “common” and “NC” terminal.

DISTURBANCE ALARM *1)

Alarm is set if there is electrical connection between

“common” and “NO” terminal.

FAILURE ALARM *2)

Alarm is set if there is electrical connection between

“common” and “NO” terminal.

SECONDARY SOURCE ON

Secondary source was selected if there is electrical

connection between “common” and “NC” terminal.

PRIMARY SOURCE ON

Primary source was selected if there is electrical

connection between “common” and “NC” terminal.

RETRANSFER OFF

Retransfer function was blocked if there is electrical

connection between “common” and “NO” terminal.

MANUAL ON *3)

Manual mode of operation was chosen if there is

electrical connection between “common” and “NO”

terminal.

REMOTE CONTROL

If closed secondary source is selected. Otherwise

primary source is selected. This selection is valid if

PREFERRED SOURCE switch is set in “PRIMARY or

remote control” position.

OPM_STS_400_25A_100_1GB_V011

36

GE DE STS: installation and operating manual 1.1 (GB)

Page 38

Digital Energy™ Static Transfer Switch

g

*1) DISTURBANCE ALARM appears if at least one of the following events takes place:

• Overvoltage in at least one of input sources

• Undervoltage in at least one of input sources

• Input sources not synchronized

• Transient voltage surge protection device was burnt

• Retransfer was blocked

• Internal supply failure

• Manual mode of operation was chosen

*2) FAILURE ALARM appears if at least one of the following events takes place:

• Fuse was burnt

• Overcurrent

• Overtemperature

• Internal STS failure

*3) If MANUAL mode of operation is selected, active source may be changed even if second one is not

operational.

4.6.2 Communication Interface Module CI-M1

The Communication Interface Module CI-M1 is delivered as an option and it is used to communicate

between devices and an external overall system with MODBUS communication protocol. This module allows

the device to be monitored by user control systems.

Data transmission is performed through a serial port that works in RS485 standard. The serial

communication channel is optically isolated from the other part of the module and in consequence it is

isolated from the connected device. The task of the Communication Interface Module CI-M1 is to pass

information about states of signalizing contactors to the overall system.

Transmission parameter:

• asynchronous serial transmission

• preset transmission speed

• 1 stop bit

• 8 data bits

• without parity bit

OPM_STS_400_25A_100_1GB_V011

37

GE DE STS: installation and operating manual 1.1 (GB)

Page 39

Digital Energy™ Static Transfer Switch

g

The transmission speed is selected by setting a switch on the PCB (printed board). The switch is marked as

PR TRANS and it has 16 positions. Table 8 below shows the settings and corresponding transmission

speed.

Table 8

PR TRANS setting Transmission speed in bauds

0 600

1 1200

2 2400

3 4800

4 9600

5 19200

6 38400

7 57600

8 115200

X2

Figure 13. PCB of Communication Interface Module CI-M1

The X2 user connector is a socket type RJ10 with outlets as in figure 14.

A485

B485

ISO GND

1

2

3

4

X2

V+

A485

B485

GND

RJ10

Figure 14. RS485 connector

OPM_STS_400_25A_100_1GB_V011

38

GE DE STS: installation and operating manual 1.1 (GB)

Page 40

Digital Energy™ Static Transfer Switch

g

Logical address setting

The switches ADR HIGH and ADR LOW are used to give each device its own unique -within the systemdevice number (logical address). The device number may be set within the range from 0 to 255. The number

is set in hexadecimal code. ADR HIGH setting refers to higher number tetrad and ADR LOW to lower

number tetrad.

Table 10 presents the logical address numbers based on ADR HIGH (ADRH) and ADR LOW (ADRL) switch

settings.

Transmitted data description

Data transmission from the device to the overall system is performed in accordance with the MODBUS RTU

protocol, where the transmission module is in Slave mode of operation. Register value and its meaning is

presented in table 9 below.

Table 9. Objects map for MODBUS protocol

Word Byte Bit Parameter Format

0 0 0 MANUAL_ON Logic 1=active

1 RETRANSFER_OFF Logic 1=active

2 PRIMARY_SOURCE_ON Logic 0=active

3 SECONDARY_SOURCE_ON Logic 0=active

4 FAILURE_ALARM Logic 1=active

5 DISTURBANCE_ALARM Logic 1=active

6 PRIMARY_SOURCE_OK Logic 0=active

7 SECONDARY_SOURCE_OK Logic 0=active

1 8..15 Reserved

Device compatibility with MODBUS standard

The device transmits and receives frames in binary variety of MODBUS standard. Frames are protected by

double byte control sum CRC (first the lower byte is transmitted, then the higher one)

The Module executes the following commands of the protocol:

03 - reading of word block,

01 - reading of bit sequence

OPM_STS_400_25A_100_1GB_V011

39

GE DE STS: installation and operating manual 1.1 (GB)

Page 41

Digital Energy™ Static Transfer Switch

g

Table 10. Switches settings: ADR HIGH (higher tetrad) and ADR LOW (lower tetrad).

No ADR

HIGH

0 0 0 53 3 5 106 6 A 159 9 F 212 D 4

1 0 1 54 3 6 107 6 B 160 A 0 213 D 5

2 0 2 55 3 7 108 6 C 161 A 1 214 D 6

3 0 3 56 3 8 109 6 D 162 A 2 215 D 7

4 0 4 57 3 9 110 6 E 163 A 3 216 D 8

5 0 5 58 3 A 111 6 F 164 A 4 217 D 9

6 0 6 59 3 B 112 7 0 165 A 5 218 D A

7 0 7 60 3 C 113 7 1 166 A 6 219 D B

8 0 8 61 3 D 114 7 2 167 A 7 220 D C

9 0 9 62 3 E 115 7 3 168 A 8 221 D D

10 0 A 63 3 F 116 7 4 169 A 9 222 D E

11 0 B 64 4 0 117 7 5 170 A A 223 D F

12 0 C 65 4 1 118 7 6 171 A B 224 E 0

13 0 D 66 4 2 119 7 7 172 A C 225 E 1

14 0 E 67 4 3 120 7 8 173 A D 226 E 2

15 0 F 68 4 4 121 7 9 174 A E 227 E 3

16 1 0 69 4 5 122 7 A 175 A F 228 E 4

17 1 1 70 4 6 123 7 B 176 B 0 229 E 5

18 1 2 71 4 7 124 7 C 177 B 1 230 E 6

18 1 3 72 4 8 125 7 D 178 B 2 231 E 7

20 1 4 73 4 9 126 7 E 179 B 3 232 E 8

21 1 5 74 4 A 127 7 F 180 B 4 233 E 9

22 1 6 75 4 B 128 8 0 181 B 5 234 E A

23 1 7 76 4 C 129 8 1 182 B 6 235 E B

24 1 8 77 4 D 130 8 2 183 B 7 236 E C

25 1 9 78 4 E 131 8 3 184 B 8 237 E D

26 1 A 79 4 F 132 8 4 185 B 9 238 E E

27 1 B 80 5 0 133 8 5 186 B A 239 E F

28 1 C 81 5 1 134 8 6 187 B B 240 F 0

29 1 D 82 5 2 135 8 7 188 B C 241 F 1

30 1 E 83 5 3 136 8 8 189 B D 242 F 2

31 1 F 84 5 4 137 8 9 190 B E 243 F 3

32 2 0 85 5 5 138 8 A 191 B F 244 F 4

33 2 1 86 5 6 139 8 B 192 C 0 245 F 5

34 2 2 87 5 7 140 8 C 193 C 1 246 F 6

35 2 3 88 5 8 141 8 D 194 C 2 247 F 7

36 2 4 89 5 9 142 8 E 195 C 3 248 F 8

37 2 5 90 5 A 143 8 F 196 C 4 249 F 9

38 2 6 91 5 B 144 9 0 197 C 5 250 F A

39 2 7 92 5 C 145 9 1 198 C 6 251 F B

40 2 8 93 5 D 146 9 2 199 C 7 252 F C

41 2 9 94 5 E 147 9 3 200 C 8 253 F D

42 2 A 95 5 F 148 9 4 201 C 9 254 F E

43 2 B 96 6 0 149 9 5 202 C A 255 F F

44 2 C 97 6 1 150 9 6 203 C B

45 2 D 98 6 2 151 9 7 204 C C

46 2 E 99 6 3 152 9 8 205 C D

47 2 F 100 6 4 153 9 9 206 C E

48 3 0 101 6 5 154 9 A 207 C F

49 3 1 102 6 6 155 9 B 208 D 0

50 3 2 103 6 7 156 9 C 209 D 1

51 3 3 104 6 8 157 9 D 210 D 2

52 3 4 105 6 9 158 9 E 211 D 3

ADR

LOW

No ADR

HIGH

ADR

LOW

No ADR

HIGH

ADR

LOW

No ADR

HIGH

ADR

LOW

No ADR

HIGH

ADR

LOW

OPM_STS_400_25A_100_1GB_V011

40

GE DE STS: installation and operating manual 1.1 (GB)

Page 42

Digital Energy™ Static Transfer Switch

g

4.6.3 High current terminal

Terminal designation Designation

PE 70 mm2 35 mm2

L1 70 mm2 35 mm2

Cross section for the wire (maximum)

STS-400-100-3 Others

X01, X02, X03

4.7 Fuse selection

L2 70 mm2 35 mm2

L3 70 mm2 35 mm2

2

N 70 mm

35 mm2

Figure 15. Overcurrent protection for supply and load lines of the STS

(Figure shows values for the STS-400-63-4)

OPM_STS_400_25A_100_1GB_V011

41

GE DE STS: installation and operating manual 1.1 (GB)

Page 43

Digital Energy™ Static Transfer Switch

g

For selective fuse operation, fuse sizes should be selected as in the tables below

STS-400-100-3

Fuses of line A and B

(minimum value)

160A gG 100A gG 63A gG

125A gG 80A gG 50A gG

100A gG 63A gG 40A gG

STS-400-63-3/4

Fuses of line A and B

(minimum value)

100A gG 63A gG 40A gG

80A gG 50A gG 32A gG

63A gG 40A gG 25A gG

STS-400-40-3/4

Fuses of line A and B

(minimum value)

63A gG 40A gG 25A gG

50A gG 32A gG 20A gG

40A gG 25A gG 16A gG

STS fuses Fuses of load lines

(maximum value)

STS fuses Fuses of load lines

(maximum value)

STS fuses Fuses of load lines

(maximum value)

STS-400-25-3/4

Fuses of line A and B

(minimum value)

40A gG 25A gG 16A gG

32A gG 20A gG 10A gG

STS fuses Fuses of load lines

(maximum value)

OPM_STS_400_25A_100_1GB_V011

42

GE DE STS: installation and operating manual 1.1 (GB)

Page 44

Digital Energy™ Static Transfer Switch

g

5 - Specifications

5.1 Technical data

Input line parameters (supply)

Rated input voltage 3 x 400 V RMS phase to phase TN-C, TN-S

Acceptable changes of input

voltages

Frequency 50 Hz

Acceptable changes of

frequency

Voltage surge withstand

Voltage insulation AC 2kV 60s

Efficiency >99%

Output line parameters

STS-400-63-4

STS-400-40-4

STS-400-25-4

Rated output current

Maximum crest factor 3,5

Power factor cos(φ)

Voltage surge withstand

Acceptable overload

Short circuit withstand for

thyristors (130°C)

I2t value for thyristors (130°C)

Breaking ability for fuses 50kA

STS-400-100-3

STS-400-63-3

STS-400-40-3

STS-400-25-3

<1,5kV Iimp 15kA 8/20us

<1,0kV Iimp 5kA 8/20us

0,5-1 lag, lead

<1,5kV Iimp 15kA 8/20us

<1,0kV Iimp 5kA 8/20us

125%

400%

800%

1000%

1500%

8000 A/20ms for STS-400-100-3

320000 A

-25% ÷ +20%

-9% ÷ +6%

3 x 63 A RMS

+ 125 A RMS (neutral)

3 x 40 A RMS

+ 80 A RMS (neutral)

3 x 25 A RMS

+ 50 A RMS (neutral)

3 x 100 A RMS

+ 200 A RMS (neutral)

3 x 63 A RMS

+ 125 A RMS (neutral)

3 x 40 A RMS

+ 80 A RMS (neutral)

3 x 25 A RMS

+ 50 A RMS (neutral)

3200 A/20ms

51200A

2

s for STS-400-100-3

2

s

cos(φ) > 0,8

t=1h

t=5s

t=0,4s

t=0,2s

t=20ms

OPM_STS_400_25A_100_1GB_V011

43

GE DE STS: installation and operating manual 1.1 (GB)

Page 45

Digital Energy™ Static Transfer Switch

g

Operational parameter

PRIMARY SOURCE

Preferred source selection

SECONDARY SOURCE

Remote preferred source

selection

Overvoltage level setting

Undervoltage level setting

Phase delay limit for

synchronized sources

Transfer blocked after output

current limit exceeding

PRIMARY SOURCE

SECONDARY SOURCE

or

or

+6%

+9%

+13%

+16%

+20%

-8%

-12%

-16%

-16%

-24%

±8°

±12°

±16°

±20°

±24°

3 In

4.5 In

6 In

7.5 In

9 In

With retransfer or without

retransfer after disturbance

disappearing

Remote relay selection for

preferred source

Transfer is performed when

voltage value crosses the level.

Programmed by DIP switch

selection

Transfer is performed when

voltage value crosses the level.

Programmed by DIP switch

selection

Programmed by DIP switch

selection

Programmed by DIP switch

selection

Transfer without overcurrent blockade

Transfer delay after manual

triggering with both sources

synchronized

Transfer delay in automatic

mode with both sources

synchronized

Transfer delay in manual or

automatic mode without

synchronization

Retransfer to preferred source

delay with both sources

operational

<0,1ms

<6ms

13ms

17ms

25ms

50ms

0.8 s

1s

8s

25s

Programmed by DIP switch

selection

Programmed by DIP switch

selection

OPM_STS_400_25A_100_1GB_V011

44

GE DE STS: installation and operating manual 1.1 (GB)

Page 46

Digital Energy™ Static Transfer Switch

g

Alarm signals

FAILURE ALARM appears if at least one of the following

events takes place:

Failure alarm relay

Disturbance alarm relay

MANUAL ON relay

RETRANSFER OFF relay Retransfer to preferred source is not performed

PRIMARY

SOURCE OK.

SECONDARY

SOURCE OK.

PRIMARY

SOURCE ON

SECONDARY

SOURCE ON

relay Indicating if primary source is healthy

relay Indicating if secondary source is healthy

relay Indicating if primary source is active

relay Indicating if secondary source is active

• Fuse was burnt

• Overcurrent

• Overtemperature

• Internal STS failure

DISTURBANCE ALARM appears if at least one of the following

events takes place:

• Overvoltage in at least one of input sources

• Undervoltage in at least one of input sources

• Input sources not synchronized

• Voltage surge protection device was burnt

• Retransfer was blocked

• Internal supply failure

• Manual mode of operation was chosen

If MANUAL mode of operation is selected, active source may

be changed even if second one is not healthy

Alarm connectors parameters

Maximum operational voltage 300V= or 250V~

Maximum current

Operation conditions

Ambient temperature 0÷40°C

Storage temperature 0÷40°C

Humidity max 95% Without condensation

Maximum altitude. 1000m

Cooling Forced with redundancy Forced cooling is applied only to increase

Acoustic noise level Below 55dBA

Interference’s level Level B EN55022, EN60555-2,-3

Enclosure

Protection IP20

4A for 220V~

0,3A for 220V=

MTBF factor

OPM_STS_400_25A_100_1GB_V011

45

GE DE STS: installation and operating manual 1.1 (GB)

Page 47

Digital Energy™ Static Transfer Switch

g

5.2 Dimensions

Figure 16. Front view

OPM_STS_400_25A_100_1GB_V011

46

GE DE STS: installation and operating manual 1.1 (GB)

Page 48

Digital Energy™ Static Transfer Switch

g

Figure 17. Side view of STS

OPM_STS_400_25A_100_1GB_V011

47

GE DE STS: installation and operating manual 1.1 (GB)

Page 49

Digital Energy™ Static Transfer Switch

g

Assembly holes:

Figure 18. Top view of STS

OPM_STS_400_25A_100_1GB_V011

48

GE DE STS: installation and operating manual 1.1 (GB)

Loading...

Loading...