Page 1

BEFORE YOU BEGIN

Read these instructions completely and

carefully.

•

IMPORTANT – Save these

instructions for local electrical

inspector’s use.

•

IMPORTANT – Observe all

governing codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with the Consumer.

• Note to Consumer – Keep these instructions

for future reference.

• Installation and service must be performed

by a qualified installer.

• Proper installation is the responsibility of

the installer.

Installation Stack Stand Kit

Instructions

Questions? Call 800.GE.CARES (800.432.2737) or visit our Web site at: www.GEAppliances.com

FOR YOUR SAFETY:

WARNING

• Electric Shock Hazard. Disconnect power

before servicing. Failure to do so could

result in serious injury or death.

• Potential Personal Injury. More than one

person is recommended to lift the dryer

into position because of its weight and

size. Failure to do so could result in

personal injury or death.

• Avoid Tipping and Rupture of Utility

Services. Stand must be securely

assembled and dryer fastened to stand,

per installation instructions. Stand must be

securely fastened to wall, per installaiton

instructions. Failure to do so could result in

personal injury/death or property damage.

FOR USE WITH RECOMMENDED

COMPACT-TYPE ELECTRIC DRYERS

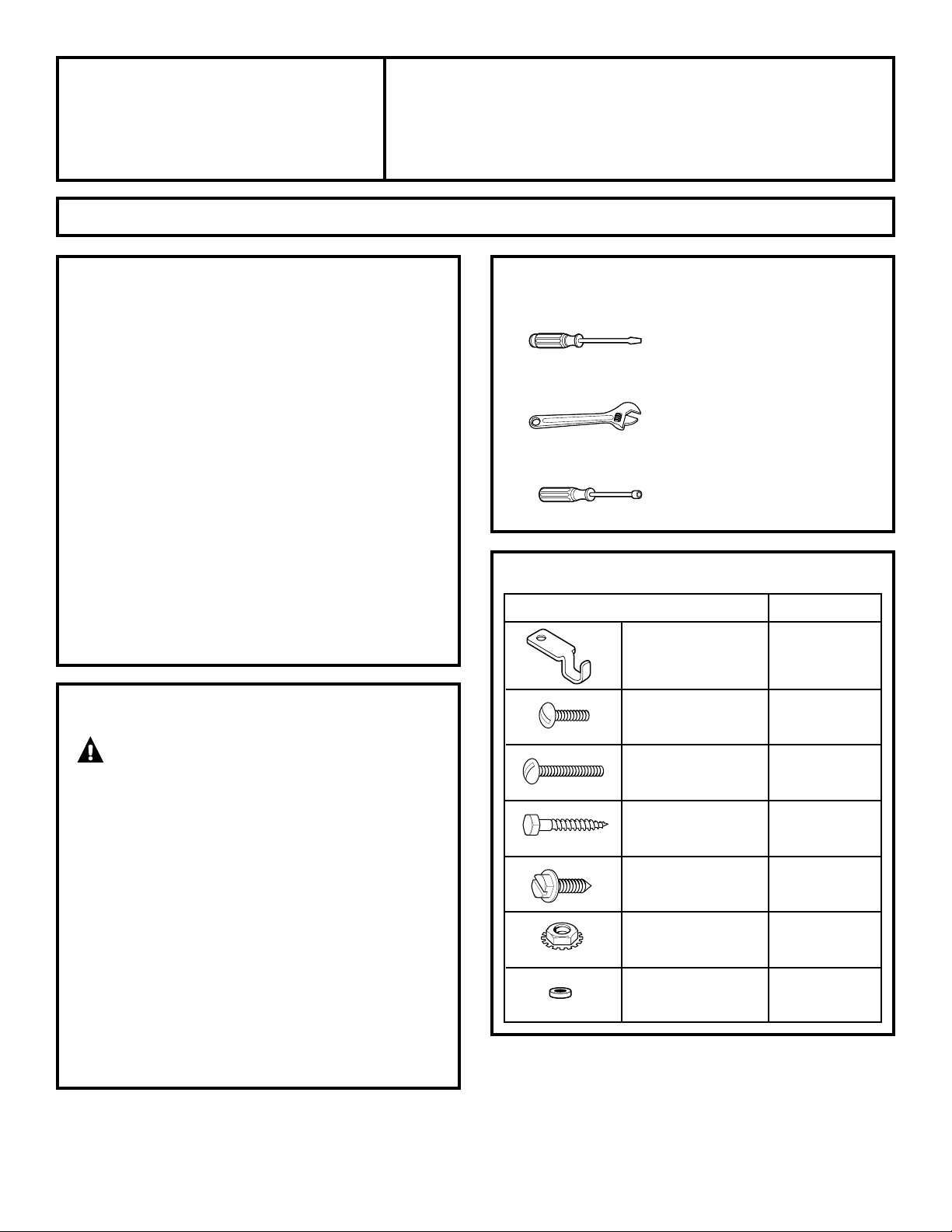

TOOLS YOU WILL NEED

• Flat-head screwdriver

• Adjustable wrench

• Nut driver

PARTS INCLUDED

PART QUANTITY

Lid Latch 1

Type A Screw 2

1/4–20 x 3/4

Type B Screw 6

1/4–20 x 1

1

⁄2

Type C Screw 2

1/4–10 x 1

3

⁄4

Type D Screw 7

10–16 x 5/8

Lock Nut 8

1/4–20

Spacer Ring 1

175D1807P423

49-90159

03-03 JR

Page 2

Installation Instructions

2

PARTS INCLUDED (cont.)

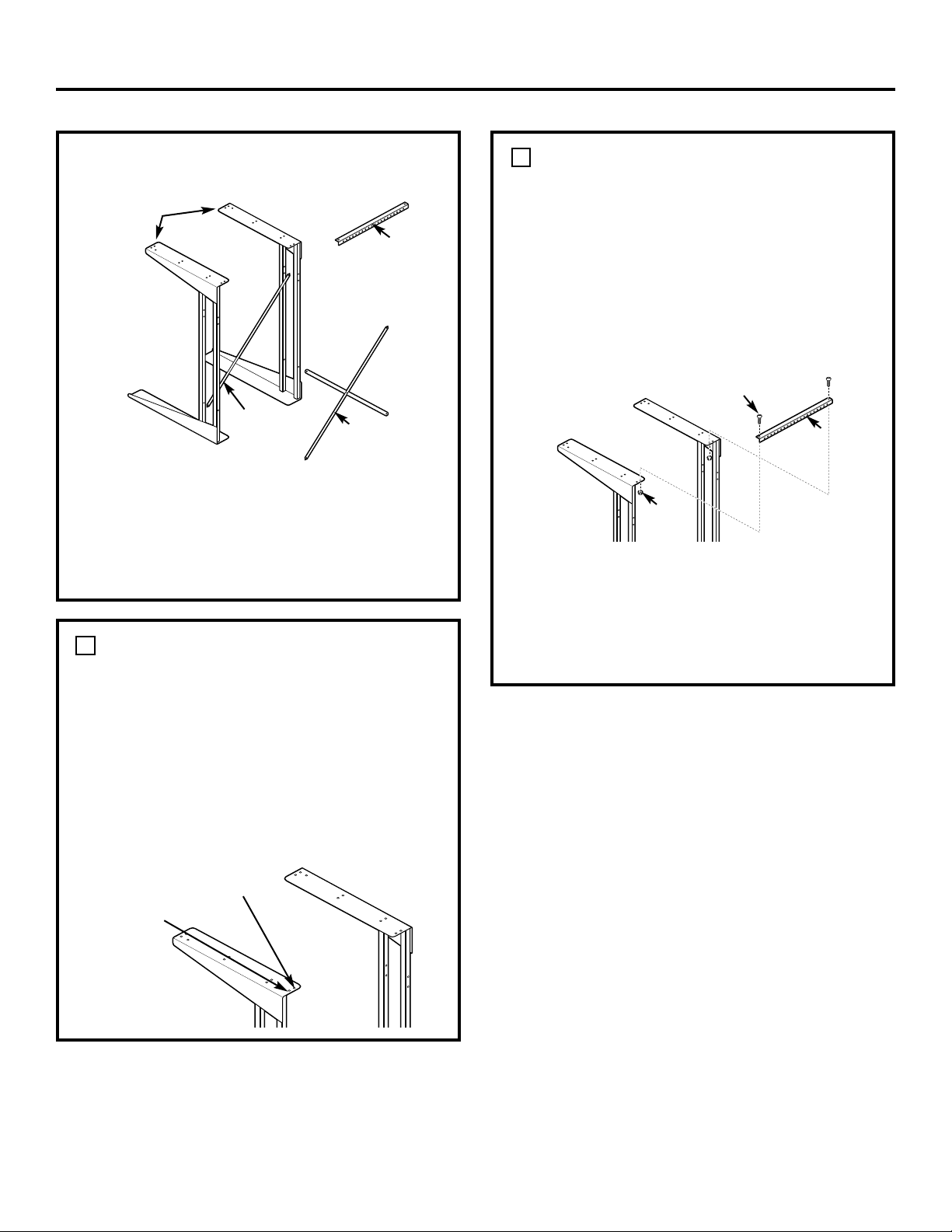

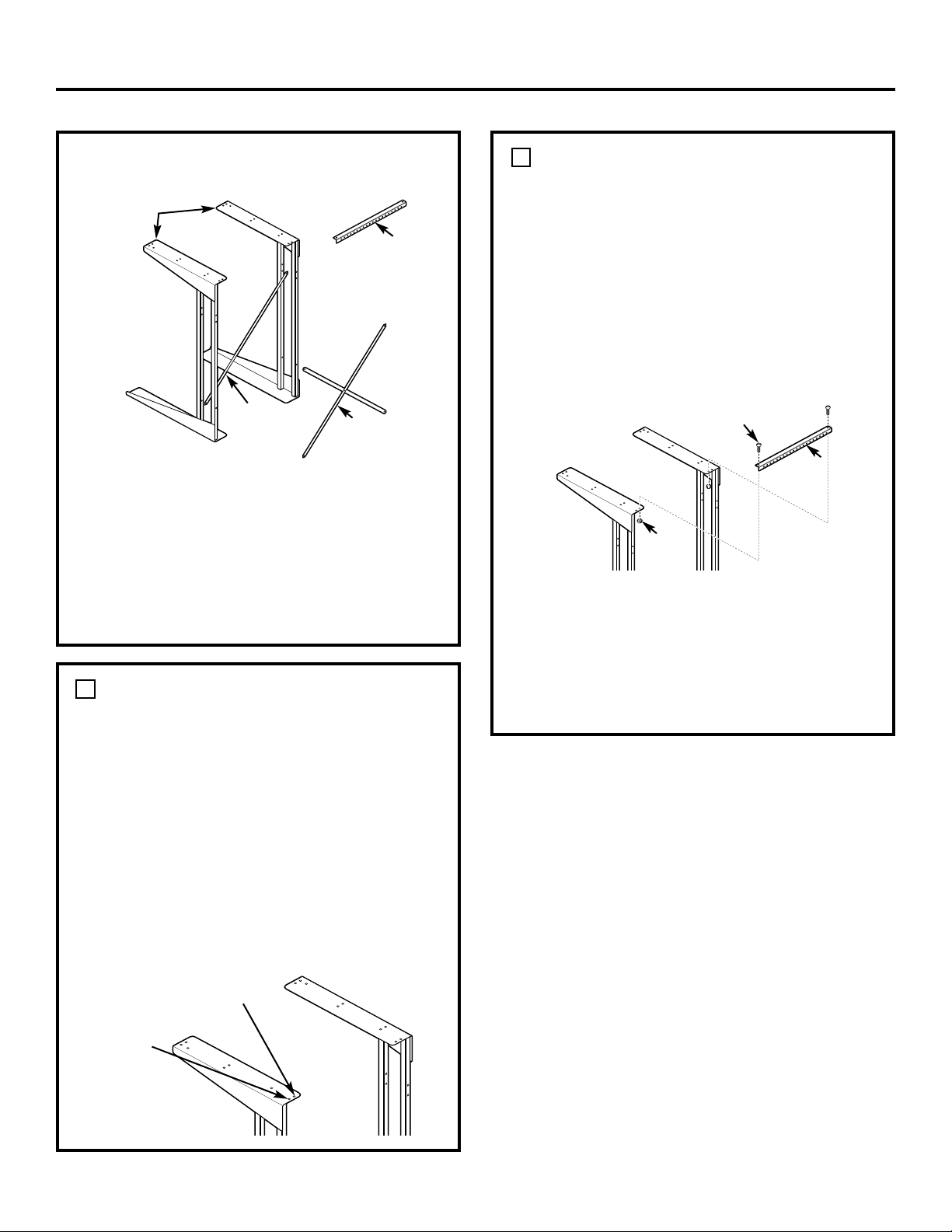

The stand base has an angle bracket at each

end. One end of the angle bracket is 22

1

⁄2″

long and has mounting holes in it. This end

goes up. The other end of the angle bracket

is 28″ long and has no holes. This longer end

(without holes) goes down.

DETERMINE STAND WIDTH

Your new stand can be assembled to two

different widths:

• 22″ for smaller, compact washers

• 24″ for larger washers

Check your washer width to determine the

stand width you need. The compact dryer

will assemble to either width.

1

ATTACH WALL MOUNTING BRACKET

Attach one end of the wall mounting

bracket to one of the upper rear holes on

one of the stand bases using a Type A

screw and a lock nut. Make sure screws are

inserted from the top and the lock nuts are

on the bottom. Use the inside hole on the

stand base for 24″ width. Use the outside

hole for 22″ width.

2

Attach the other end of the bracket to the

upper rear hole of the other stand base the

same way. Use the inside hole on the stand

base for 24″ width or the outside hole for

22″ width. Hand-tighten the screws and

nuts.

Bracket

Type A Screw

Lock

Nut

Use outside

holes for

22″ models

Use inside

holes for

24″ models

Wall

Mounting

Bracket

Cross

Brace

Diagonal

Brace

Stand Bases

Page 3

Installation Instructions

3

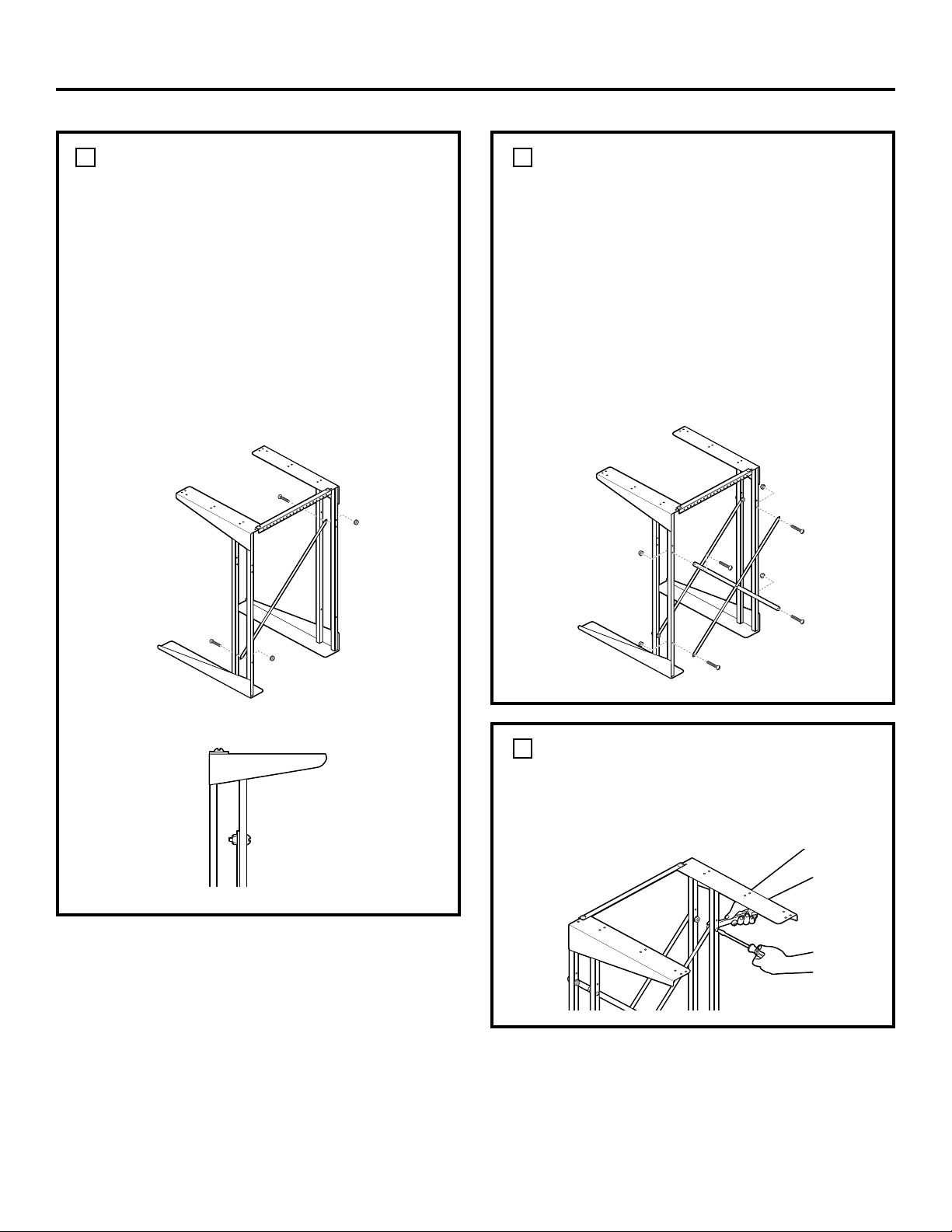

ATTACH DIAGONAL BRACE

Attach the diagonal brace to the back of the

front uprights on the stand bases. The brace

must run from the lower left to the upper

right when viewed from the rear of the stand.

Insert a Type B screw from the front of the

stand into the lower hole on the left upright

and secure with a lock nut. The lock nut will

be on the inside of the upright.

Insert another Type B screw into the hole on

the right upright. The top hole is used for 22″

width, and the lower hole is used for 24″

width. Hand-tighten the screws and lock nuts.

3

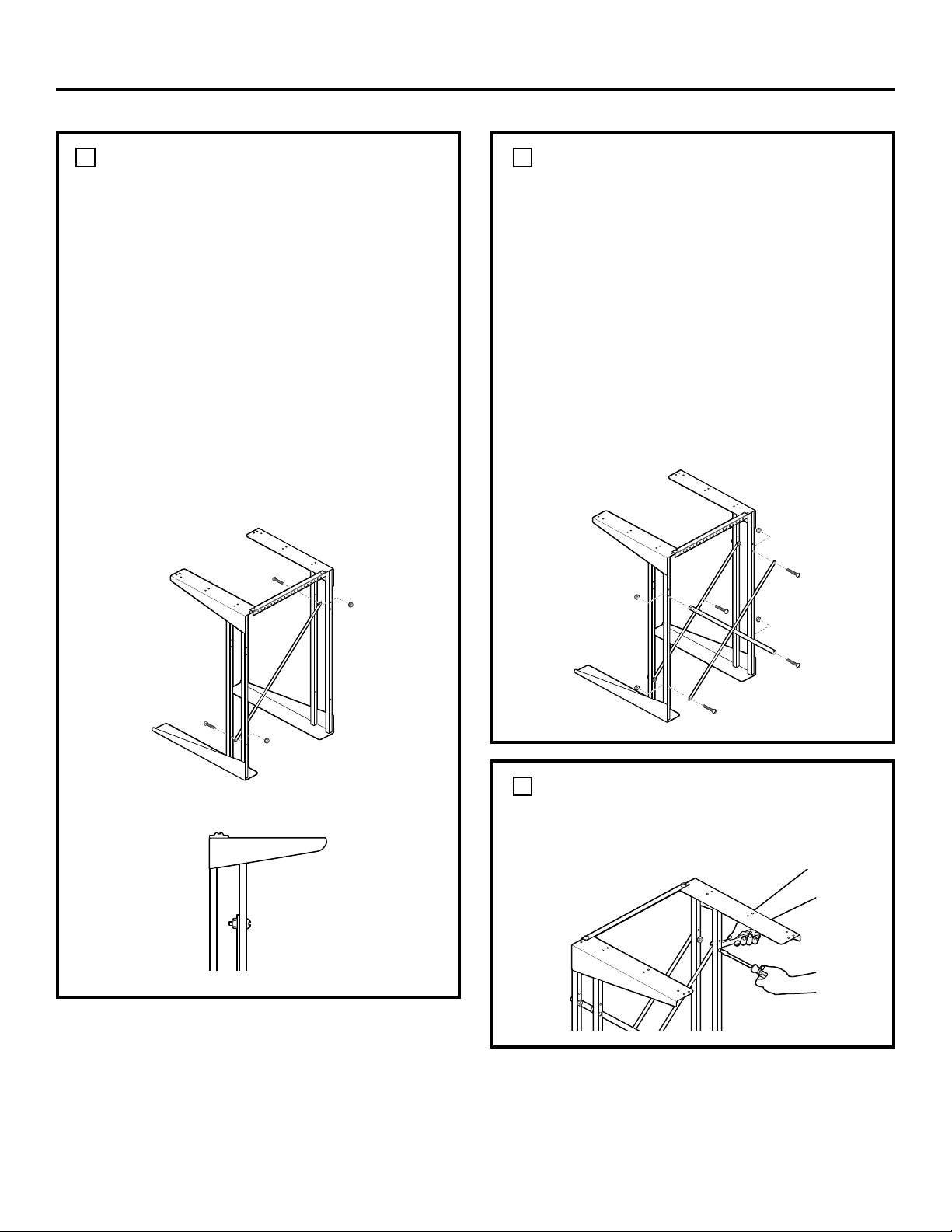

ATTACH CROSS BRACE

Attach the cross brace to the rear uprights

on the stand bases.

Insert two Type B screws from the rear

of the stand into the lower holes on the

uprights and secure with lock nuts. The lock

nuts will be on the insides of the uprights.

Insert two Type B screws into the upper

holes on the uprights. The top holes are

used for 22″ width, and the lower holes are

used for 24″ width. Hand-tighten the screws

and lock nuts.

4

TIGHTEN LOCK NUTS

Securely tighten all lock nuts using a

screwdriver and an adjustable wrench

or nut driver.

5

Page 4

Installation Instructions

4

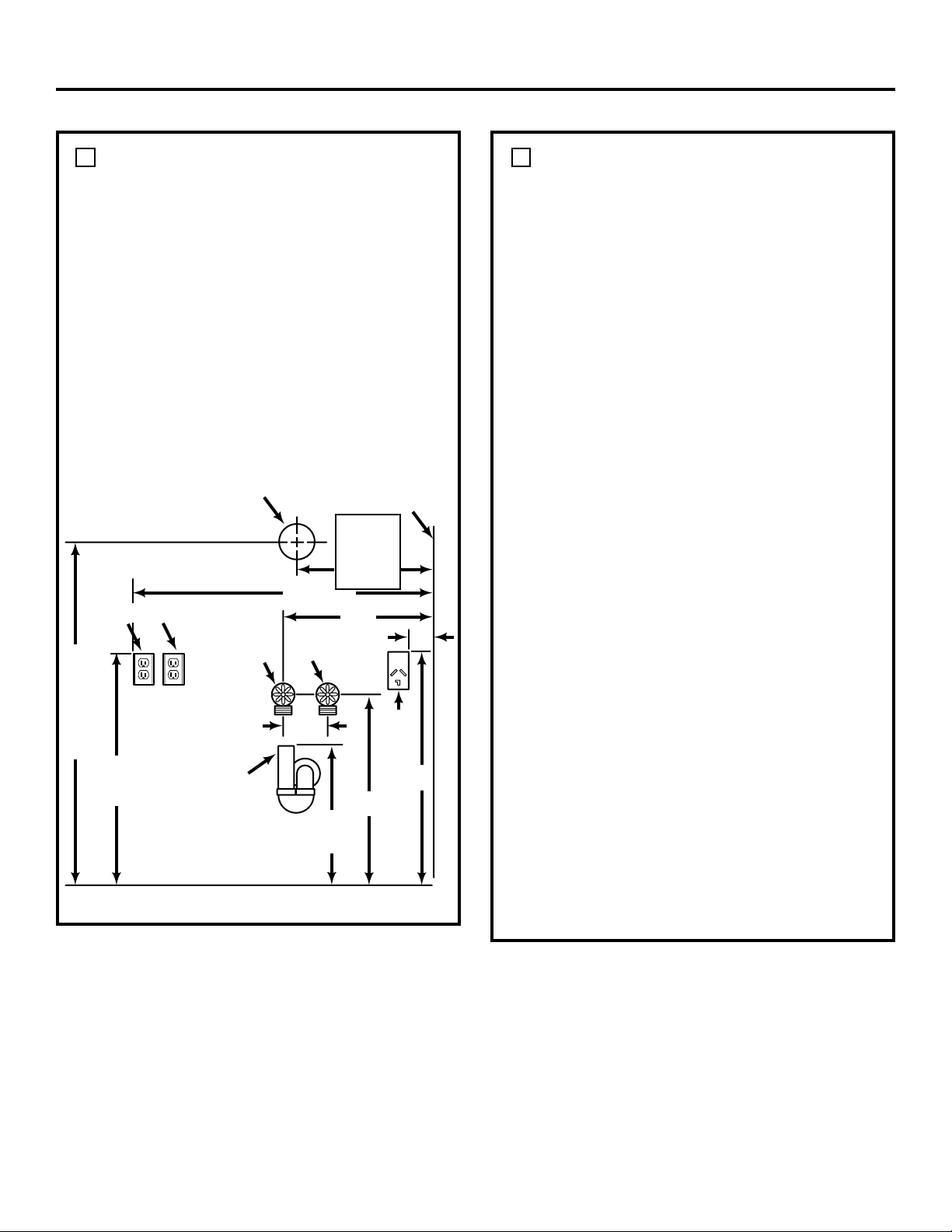

DETERMINE LOCATION

Locate the stand in an appropriate level

area. This location should be suitable for the

size, function, and protection of the stack

stand and appliances. Use the stack stand

only for the purpose for which it was

designed. To prevent restriction of airflow,

do not use top of dryer for storage.

The proper location of all utility

connections is shown in the Utilities and

Grounding illustration. These are not all

needed in each installation, but those

used should be located according to these

dimensions so that utilities can be reached

after installation.

6

DETERMINE LOCATION (cont.)

Dryers

Dryer models may require different utilities;

refer to the Installation Instructions included

with your new dryer for details on required

utilities.

Refer to the Utilities and Grounding

illustration and the Dryer Installation

Instructions for details on final utility

connections and grounding information.

NOTE: All fittings and outlets must be

located so that they clear cross members

of stack stand.

Automatic Washers

All automatic washers require a hot and

cold water supply, a proper drain and a

120-volt electrical supply. Refer to the

Installation Instructions included with

your new automatic washer for detailed

installation requirements.

If the automatic washer is to be operated

in a different location (portable) and only

stored in the stack stand, those utilities

marked with an asterisk (*) in the Utilities

and Grounding illustration would not be

required at this location. They would be

required at the location where the automatic

washer is to be operated, with the exception

of the drain pipe, since the machine can be

drained into a sink or laundry tub.

NOTE: If both the automatic washer and

dryer require a 120-volt electrical supply,

TWO separate 15-ampere circuits must be

used (one for each appliance). DO NOT,

under any circumstances, connect both

appliances to the same circuit as blown

fuses will result.

6

Utilities and Grounding

240

Vol t

Outlet

221⁄2″

15″

161⁄4″

(22″ Width)

17

1

⁄4″

(24″ Width)

Right Side of

Dryer Stand

Installed

4″ Diameter

Exhaust Location

120 Volt Outlets*

Cold Water

Faucet*

4″

381⁄4″

36″

32″

Minimum

From Floor

2″

Diameter

Pipe*

Minimum

383⁄4″

From

Floor

831⁄2″

(Top

Exhaust)

731⁄2″

(Rear

Exhaust)

From

Floor

Hot

Water

Faucet*

6″

Page 5

Installation Instructions

5

LOCATE MOUNTING HOLES

Push the dryer and stand against the wall

in the selected location and locate two wall

studs.

Start 2 Type C screws through holes in the

mounting bracket that line up with studs. DO

NOT SCREW IN ALL THE WAY. Multiple holes

in the bracket allow for variation in location

of wall studs.

7

INSTALL DRYER TO STAND

Carefully follow section entitled Preparing

Your Dryer for Installation in the Installation

Instructions for your new dryer. The dryer

weighs approximately 100 pounds.

WARNING

Potential Personal Injury. More than one

person is recommended to lift the dryer

into position because of its weight and size.

Failure to do so could result in personal

injury or death.

Use 6 Type D screws to secure the dryer to

the stand. Tighten the screws using an

adjustable wrench or nut driver. The dryer

will sit approximately 1

1

⁄4″ forward of the

end of the top angle.

8

NOTE: The outside holes are used for 22″

width, and the inside holes are used for 24″

width.

Once the holes are started, remove the screws

from the mounting bracket and move the

stand away from the wall.

For installations requiring clearance from

the wall:

If the stand cannot be pushed all the way

against the wall, secure a piece of wood to

the wall studs to line up with the holes on the

mounting bracket. The wood must be the

same thickness as the clearance. Follow the

steps above, starting the screws in the piece

of wood.

Page 6

Installation Instructions

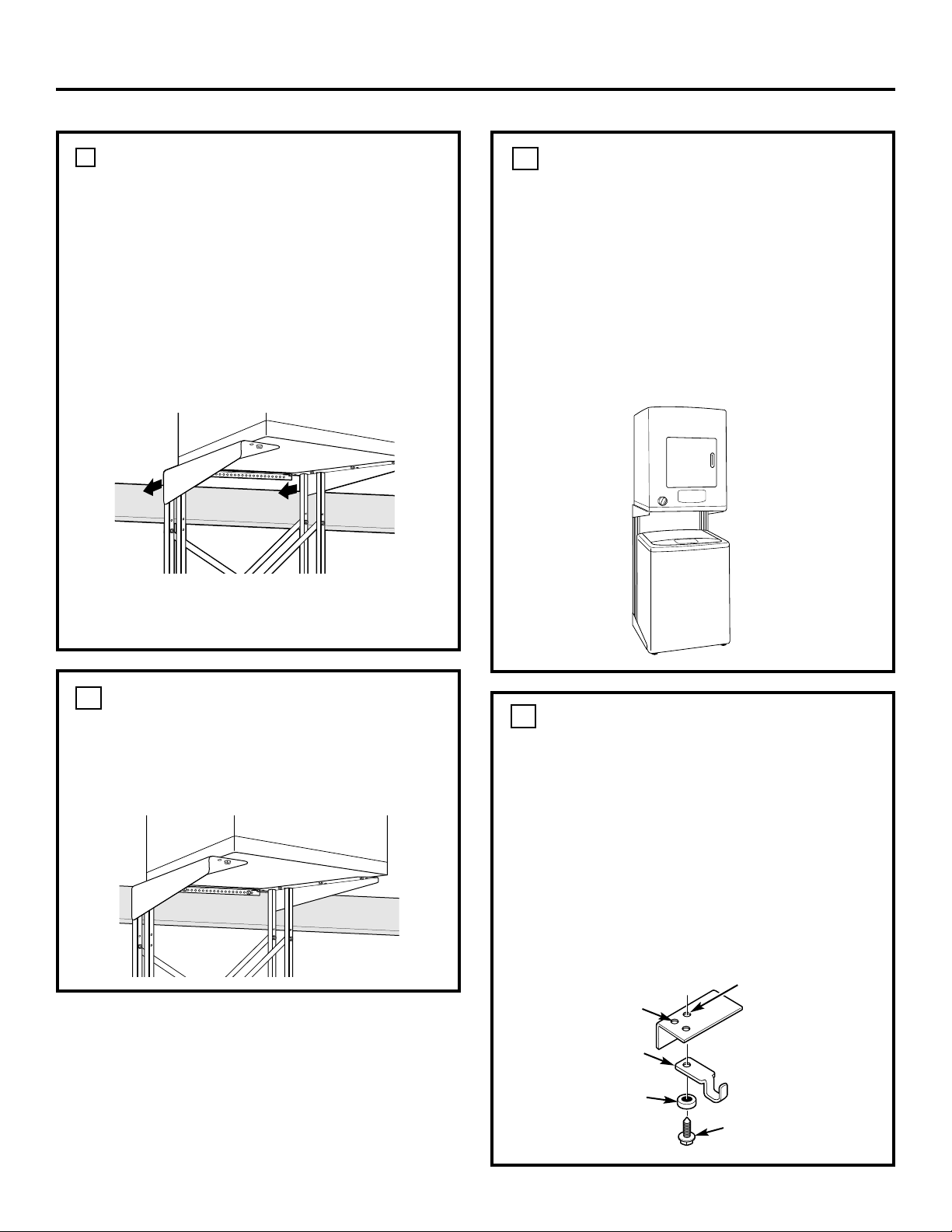

MOVE DRYER AND STAND INTO FINAL POSITION AND INSTALL DRYER EXHAUST

Push the dryer and stand against the wall in

the selected location.

If the hole for the exhaust has been

located as shown in the Utilities and

Grounding illustration, it will align with the

dryer exhaust when the stack stand and

dryer are placed in the selected operating

position.

9

INSTALL WASHER

Follow the Installation Instructions

included with your washer to make washer

connections.

After washer connections are made,

move the washer into its operating position

between the stand side sections and push it

completely toward the rear. Use care not to

kink or pinch the water inlet hose, and be

sure the drain hose is placed in the drain

pipe with no kinks or twists.

Follow the Installation Instructions

included with your dryer to make exhaust

connections.

SECURE STAND TO WALL

After the exhaust is connected and the dryer

and stack stand are in the selected operating

position, secure the stand to the wall using 2

Type C screws in the holes started earlier.

10

INSTALL LID LATCH

If a washer with a lift lid is to be installed and

used under the stand, install the washer lid

latch as shown using a Type D screw in the

hole behind one of the front mounting holes.

The lid latch may be installed on either side.

NOTE: The screw for the lid latch will thread

into bottom of the dryer. Tighten securely

using a nut driver.

11

12

Dryer Mounting

Holes

Lid Latch

Mounting Hole

Lid Latch

Type D Screw

Spacer Ring

6

Page 7

AVANT DE COMMENCER

Veuillez lire les instructions complètement et

attentivement.

•

IMPORTANT

– Conservez ces instructions

pour l’inspecteur local en électricité.

•

IMPORTANT – Respectez tous les codes

et décrets pertinents.

• Note à l’installateur – N’oubliez pas de remettre

ces instructions au consommateur.

• Note au consommateur – Conservez ces

instructions pour consultation future.

• L’installation et l’entretien doivent être effectués

par un installateur qualifié.

• L’installateur assume la responsabilité d’une

bonne installation.

Instructions

Nécessaire de

d’installation

support d’empilage

Questions ? Appelez le 800.GE.CARES (800.432.2737) ou visitez notre site Web à : www.GEAppliances.com

POUR VOTRE SÉCURITÉ:

AVERTISSEMENT

• Risque de choc électrique. Débranchez l’appareil

avant de l’entretenir. Sinon, vous risquez de

vous blesser gravement ou mortellement.

• Risque de blessures corporelles. Il est

recommandé de se mettre à deux personnes

pour soulever la sécheuse afin de la mettre en

place en raison de son poids et de sa taille.

Sinon, vous risquez de vous blesser gravement

ou mortellement.

• Évitez d’incliner l’appareil et de couper l’eau

ou l’électricité. Le support doit être assemblé

avec soin et la sécheuse fixée sur son support

selon les instructions d’installation. Le support

doit être solidement fixé au mur, selon les

instructions d’installation. Sinon, vous risquez

de vous blesser gravement/mortellement ou

d’endommager des biens.

POUR EMPLOI AVEC LES SÉCHEUSES

ÉLECTRIQUES RECOMMANDÉES DE TYPE

COMPACT

LES OUTILS DONT VOUS AUREZ

BESOIN

• Tournevis à lame plate

• Clé à molette

• Monte-démonte écrou

PIÈCES INCLUSES

PIÈCE QUANTITÉ

Loquet de 1

couvercle

Vis de type A 2

de 1/4–20 x 3/4

Vis de type B 6

de1/4–20 x 1

1

⁄2

Vis de type C 2

de 1/4–10 x 1

3

⁄4

Vis de type D 7

de 10–16 x 5/8

Contre-écrou 8

1/4–20

Cale en 1

rondelle

175D1807P423

49-90159

03-03 JR

Page 8

Instructions d’installation

2

La base du support comporte une cornière

d’angle à chaque extrémité. Une extrémité

de la cornière d’angle mesure 22

1

⁄

2 po. de

longueur et est percée de trous de montage.

Cette extrémité est horizontale. L’autre

extrémité de la cornière d’angle mesure

28 po. de longueur et n’a pas de trou.

L’extrémité la plus longue (sans trou)

est verticale.

DÉTERMINEZ LA LARGEUR DU SUPPORT

Votre nouveau support peut être monté selon

deux largeurs différentes :

• 22 po. pour les petites laveuses

compactes

• 24 po. pour les grosses laveuses

Vérifiez la largeur de votre laveuse afin

de déterminer la largeur du support

nécessaire. La sécheuse compacte

se monte sur l’une ou l’autre des largeurs.

1

FIXEZ L’APPLIQUE DE

MONTAGE MURALE

Fixez une extrémité de l’applique

de montage murale sur l’un des trous

arrière supérieurs de l’une des bases du

support à l’aide d’une vis de type A et d’un

contre-écrou. Assurez-vous d’insérer les vis

par le haut et de poser les contre-écrous par

le bas. Utilisez le trou intérieur de la base

du support pour une largeur de 24 po.

Utilisez le trou extérieur pour une largeur

de 22 po.

2

Fixez l’autre extrémité de l’applique sur

le trou arrière supérieur de l’autre base

du support en procédant de la même façon.

Utilisez le trou intérieur de la base du

support pour une largeur de 24 po. ou le

trou extérieur pour une largeur de 22 po.

Serrez à la main les vis et les contre-écrous.

Applique

Vis de type A

Contreécrou

Utilisez

les trous

extérieurs

pour les

modèles

de 22 po.

Utilisez les trous

intérieurs pour les

modèles de 24 po.

PIÈCES INCLUSES (suite)

Applique de

montage

murale

Entretoise

transversale

Entretoise

diagonale

Bases du

support

Page 9

Instructions d’installation

3

FIXEZ L’ENTRETOISE

DIAGONALE

Fixez l’entretoise diagonale à l’arrière

des montants avant des bases du support.

L’entretoise doit aller du coin inférieur

gauche jusqu’au coin supérieur droit

lorsqu’on regarde le support par l’arrière.

Insérez une vis de type B par l’avant du

support dans le trou inférieur sur le montant

de gauche et fixez-la avec un contre-écrou.

Le contre-écrou doit se trouver à l’intérieur

du montant.

Insérez une autre vis de type B dans le trou

du montant de droite. Utilisez le trou du haut

pour une largeur de 22 po. ou le trou du bas

pour une largeur de 24 po. Serrez à la main

les vis et les contre-écrous.

3

FIXEZ L’ENTRETOISE

TRANSVERSALE

Fixez l’entretoise transversale aux montants

arrière des bases du support.

Insérez deux vis de type B par l’arrière

du support dans les trous inférieurs des

montants et les fixer avec les contre-écrous.

Les contre-écrous doivent se trouver à

l’intérieur des montants.

Insérez deux vis de type B dans les trous

supérieurs des montants. Utilisez les trous

du haut pour une largeur de 22 po. ou les

trous du bas pour une largeur de 24 po.

Serrez à la main les vis et les contre-écrous.

4

SERREZ LES CONTRE-ÉCROUS

Serrez à fond tous les contre-écrous à l’aide

d’un tournevis et d’une clé à molette ou

d’un monte-démonte écrou.

5

Page 10

Instructions d’installation

4

DÉTERMINEZ L’EMPLACEMENT

Placez le support sur une surface de niveau

appropriée. L’endroit doit être convenable

aux dimensions, à la fonction et à la

protection du support d’empilage et des

appareils. N’utilisez le support d’empilage

qu’aux fins pour lesquelles il a été conçu.

Afin d’éviter de bloquer le débit d’air, ne pas

utiliser le dessus de la sécheuse comme

surface de rangement.

L’illustration ci-dessous montre les

endroits appropriés pour le branchement

de l’eau, de l’électricité et de la prise de terre.

Tous ces services d’utilité publique ne sont

pas nécessaires pour chaque installation,

mais ceux utilisés devraient être situés

conformément à ces dimensions afin de

pouvoir être atteint après l’installation.

6

DÉTERMINEZ L’EMPLACEMENT

(suite)

Sécheuses

Divers modèles de sécheuses peuvent

nécessiter différents services d’utilité

publique; consultez les instructions

d’installation incluses avec votre nouvelle

sécheuse pour des détails sur les services

requis.

Consultez l’illustration des services d’utilité

publique et de mise à la terre ainsi que les

instructions d’installation de votre sécheuse

pour des détails sur les branchements

définitifs et des renseignements sur la

mise à la terre.

NOTE : Tous les raccords et les prises

doivent être placés de façon à être dégagés

de toute partie du support d’empilage.

Laveuses automatiques

Toutes les laveuses automatiques ont

besoin d’une arrivée d’eau chaude et d’eau

froide, d’un drain approprié et d’une prise

de courant de 120 volts. Consultez les

instructions d’installation incluses avec

votre nouvelle laveuse automatique pour

des détails sur les exigences de l’installation.

Si la laveuse automatique doit fonctionner

dans un endroit différent (modèle portatif)

et uniquement rangée dans le support

d’empilage, il n’y a pas besoin d’y avoir

ici les services marqués d’un astérisque (*)

dans l’illustration des services d’utilité

publique et de mise à la terre. Par contre,

ils seront nécessaires à l’endroit où la

laveuse automatique doit fonctionner, à

l’exception du tuyau de drain, étant donné

que la machine peut être vidée dans un

évier ou une cuve de lavage.

NOTE : Si la laveuse automatique et la

sécheuse exigent toutes deux un courant

de 120 volts, utilisez deux circuits distincts

de 15 ampères chacun (un pour chaque

appareil). En aucun cas, NE branchez PAS

les deux appareils sur le même circuit, car

les fusibles sauteront.

6

Services d’utilité publique et mise à la terre

Prise

de 240

volts

221⁄

2

po.

15

po.

161⁄4 po.

(22 po. de larg.)

171⁄4 po.

(24 po. de larg.)

Côté droit de

la sécheuse

installée

Sortie d’air de 4

po. de diamètre

Prises de 120 volts*

Robinet

d’eau froide*

4 po.

381⁄4

po.

36 po.

32 po. au minimum

du plancher

Tuyau* de

2 po. de

diam. au

minimum

38

3

⁄4

po. à

partir du

sol

831⁄2 po.

(Sortie

du haut)

731⁄2 po.

(Sortie

arr.)

À partir

du sol

Robinet

d’eau

chaude*

6″

Page 11

Suivez attentivement la section intitulée

Préparez votre sécheuse pour l’installation,

dans les instructions d’installation de

votre nouvelle sécheuse. La sécheuse

pèse environ 100 livres.

AVERTISSEMENT

Risque de blessures corporelles.

Il est recommandé de se mettre à deux

personnes pour soulever la sécheuse en

position en raison de son poids et de sa

taille. Sinon, vous risquez de vous blesser

sérieusement ou même mortellement.

Utilisez des vis de type D pour fixer

la sécheuse sur le support. Serrez les

vis à l’aide d’une clé à molette ou un

monte-démonte écrou. La sécheuse

reposera environ à 1

1

⁄

4 po en avant de

l’extrémité de l’angle supérieur.

Instructions d’installation

5

REPÉREZ LES TROUS

DE MONTAGE

Poussez la sécheuse et le support contre

le mur à l’endroit que vous avez choisi et

repérez deux colombages dans le mur.

Insérez deux vis de type C dans les

trous de l’applique de montage en face de

colombages. NE VISSEZ PAS À FOND. Il y a

plusieurs trous dans l’applique afin de

s’aligner facilement avec les colombages.

7

INSTALLEZ LA SÉCHEUSE SUR LE SUPPORT

8

NOTE : Utilisez les trous extérieurs pour

une largeur de 22 po. ou les trous intérieurs

pour une largeur de 24 po.

Une fois que les trous sont commencés,

enlevez les vis de l’applique de montage et

retirez le support complètement du mur.

Pour les installations qui exigent un

espace libre entre le mur :

Si le support ne peut pas être complètement

adossé au mur, glissez un morceau de bois

contre les colombages dans le mur en face

des trous de l’applique de montage. Le

morceau de bois doit avoir la même épaisseur

que l’espace libre nécessaire. Suivez les

étapes ci-dessus, en commençant à engager

les vis dans le morceau de bois.

Page 12

Instructions d’installation

6

PLACEZ LA SÉCHEUSE ET LE

SUPPORT À LEUR POSITION

DÉFINITIVE ET INSTALLEZ LA

SORTIE D’AIR DE LA SÉCHEUSE

Poussez la sécheuse et le support contre le

mur à l’endroit voulu.

Si le trou de la sortie d’air a été placé comme

il est montré dans l’illustration des services

d’utilité publique et de mise à la terre, il

s’alignera avec la sortie de la sécheuse

lorsque le support d’empilage et la sécheuse

seront placés à l’endroit choisi.

9

INSTALLEZ LA LAVEUSE

Suivez les instructions d’installation

fournies avec votre laveuse pour effectuer

les raccordements.

Une fois que les raccordements de la

laveuse sont effectués, placez la laveuse

à sa position de fonctionnement entre les

sections latérales du support et poussez-la

complètement vers l’arrière. En veillant à ne

pas plier ni coincer le boyau d’arrivée d’eau,

et assurez-vous que le tuyau de drain est

inséré dans le drain sans pli ni torsion.

Suivez les instructions d’installation

fournies avec votre sécheuse pour effectuer

les raccordements de sortie d’air.

FIXEZ LE SUPPORT AU MUR

Une fois que la sortie d’air est branchée et

que la sécheuse et le support se trouvent à

l’endroit choisi, fixez le support au mur à

l’aide de deux vis de type C dans les trous

qui ont été commencés auparavant.

10

INSTALLEZ LE LOQUET DU COUVERCLE

Si une laveuse avec un couvercle soulevable doit

être installé et utilisé sous le support, installez le

loquet du couvercle comme illustré à l’aide d’une

vis de type D dans le trou derrière l’un des trous

de montage avant.

Le loquet du couvercle peut s’installer d’un côté

ou de l’autre.

REMARQUE : La vis du loquet du couvercle se fixe

dans le bas de la sécheuse. La serrer à fond avec

un monte-démonte écrou.

11

12

Trous de montage

de la sécheuse

Trou de montage du

loquet de couvercle

Loquet du

couvercle

Vis de type D

Cale en rondelle

Loading...

Loading...