Page 1

GE Transportation

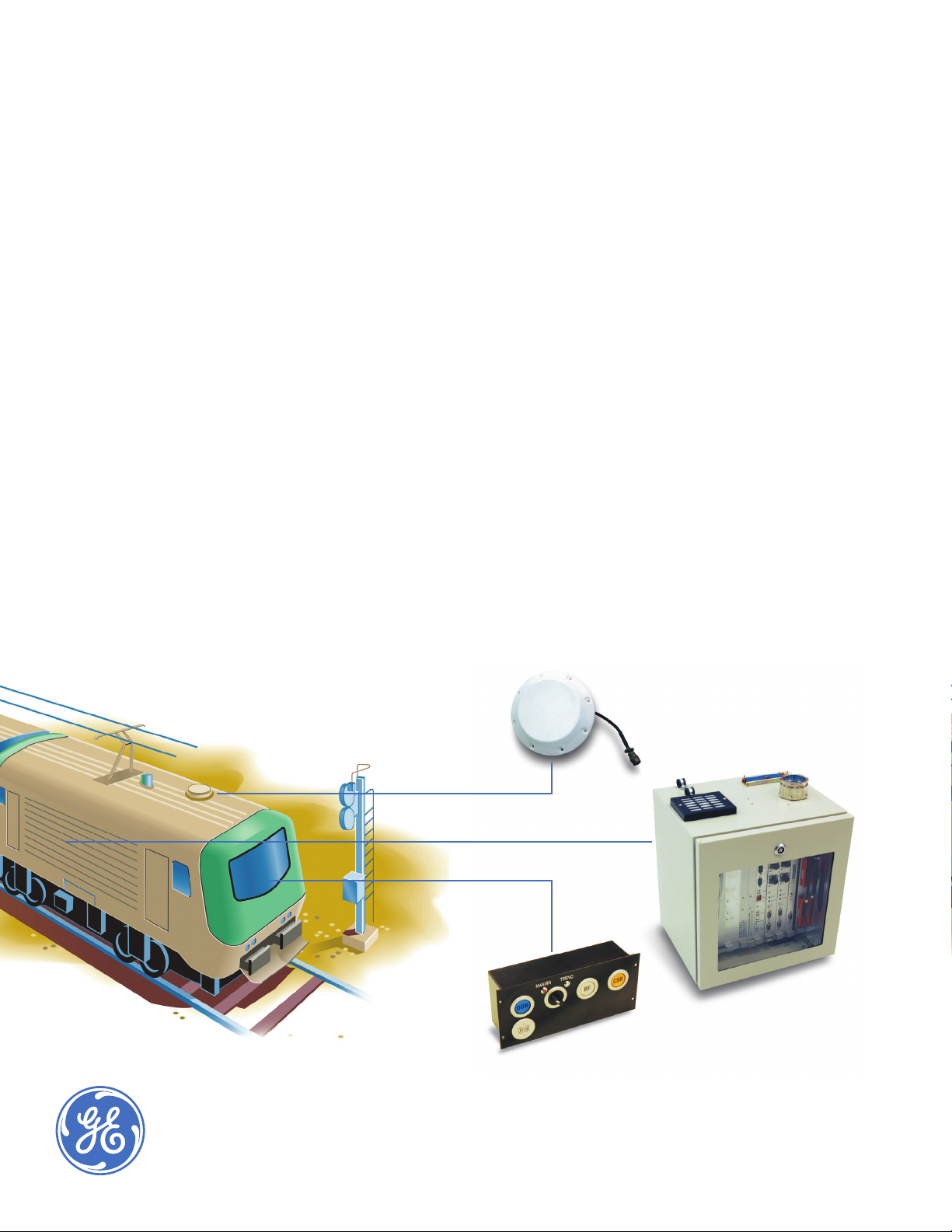

SSC

Automatic Train Protection

GE Transportation’s SSC Automatic Train Protection

delivers safe, cost-eective operation and easy installation,

without changing driving rules. This advanced train

protection system oers an innovative and unique design

on track-to-train data transmission for train control.

Unlike other solutions, deploying GE Transportation’s SSC

Automatic Train Protection does not require devices or

cables mounted in the track area. Its wayside components

are mounted line side, deriving their power from the

existing signals, eliminating the need for new power cables.

Consequently, installation on an existing infrastructure

is simple and quick, with minimal trac disruption.

SSC Automatic Train Protection is an overlay spot train

protection system that uses microwave technology to

transmit signal and track information to the train. By

enforcing them, SSC Automatic Train Protection can

maintain the existing operating rules without requiring

a massive re-training of railway sta.

Its modular design also allows optimizing the line’s

performance while improving safety.

GE imagination at work

Page 2

SSC Automatic Train Protection

Components

This system has two main components:

wayside and on-board units.

The wayside subsystem is overlaid

on the existing infrastructure and is

designed to minimize installation costs

and deployment time. Safe track-to-

train transmission occurs at signal

locations via a low-power microwave

channel.

The SSC Automatic Train Protection’s

on-board unit equipment is a fail-

safe supervision system with minimal

impact on the driver’s operations.

Wayside equipment

Wayside components are installed at

the side of the line, typically one unit

for each signal of the infrastructure.

The wayside consists of one encoder

and one transponder antenna, both

with very low power consumption,

allowing them to safely be powered by

the signal lamps.

The wayside equipment including the

transmission device (i.e. transponder)

can be installed entirely on the signal

pole, reducing costs for installation,

eliminating the need to stop trac for

both installation and maintenance, and

increasing vandal resistance.

The wayside transmits the signaling

status to the on-board unit through

microwave track-to-train link. At each

point of information, SSC Automatic

Train Protection provides the applicable

speed level for the line stretch after the

signal.

On-board equipment

SSC Automatic Train Protection’s on-

board equipment continuously ensures

the movement authority is enforced

with respect to the signaling status and

speed information received from the

wayside. Otherwise, the driver receives

a warning, and ultimately, braking

is enforced if the train driver fails to

obey the warning. Train braking is also

enforced when a signal at danger is

passed (SPAD protection).

The on-board also checks if any track-

to-train transmission is missed due to a

distance-based linking function.

SSC Automatic Train Protection’s on-

board unit is fast and easy to install

and maintain, with no device mounted

under the rolling stock.

Radio inll

The system’s innovative radio inll

function augments the performances

of the discontinuous automatic train

protection.

It guarantees:

• Required running capacity

• Maximum speed limits applied

even in those stretches of lines with

impaired visibility (e.g. excessively

short visibility distances)

• Prompt reaction to signal aspect

change

The radio inll function can be limited

to those signals that require continuous

information to the train in advance so

there is no need for full radio coverage

of the line.

Standards compliance

GE Transportation’s SSC Automatic

Train Protection complies with the

most recent and demanding European

standards: CENELEC 50126, 50128,

50129 and 50159. SSC is CENELEC

SIL-4.

Environment: CENELEC 50125, 50155

(trackside part designed to -40°C to

+85°C range).

GE imagination at work

To learn more,

visit www.getransportation.com.

GE, the GE Monogram, imagination at work, ecomagination and all

other trademarks, and service marks, unless otherwise noted, are

owned or licensed by General Electric Company or its subsidiaries.

All other brand names, product names or trademarks belong to their

respective holders.

Copyright © 2012. General Electric Company. All rights reserved.

Recycled Paper

20199-A

Loading...

Loading...