Page 1

OSMONICS

TONKAFLOPUMPS

SS SERIES

INSTALLATION, OPERATION, AND

MAINTENANCE MANUAL

For SS500, SS1000, and

SS1800 Series

Tonkaflo Centrifugal

Pumps with X, XB, and XC

Motor Adapters

Without Bearing Frames

GE Infrastructure

Water & Process Technologies

Page 2

Page 3

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

FOR SS500, SS1000 AND SS1800 SERIES

TONKAFLOCENTRIFUGAL PUMPS

WITH X-, XB-

OR XC-FRAMES

MOTOR ADAPTERS WITHOUT

BEARING FRAME

T

ABLE OF C

ONTENTS

Page

1.0 INTRODUCTION 1

2.0 TONKAFLO SPECIFICATIONS 2

2.1 Capacities 2

2.2 Maximum Developed Boost Pressure 3

2.3 Maximum Recommended Operating Temperature 3

2.4 Standard Materials of Construction 3

2.5 Special Materials of Construction 3

2.6 Pump Nomenclature 4

2.7 Special Liquids 4

3.0 PUMP INSTALLATION 5

3.1 Inspection 5

3.2 Pump Mounting and Location 5

3.3 Inlet and Discharge Piping and Connections 5

3.3.1 Inlet Piping 5

3.3.2 Discharge Piping 6

3.3.3 Pump Piping Connections 7

3.3.4 Inlet Line Screen/Filter 7

3.3.5 Discharge Screen (Strainer) 7

3.4 Pump Priming 8

3.5 Protection Against Running Dry 8

3.6 Motor Wiring 9

3.6.1 Single-Phase Motors 9

3.6.2 Three-Phase Motors 9

3.6.3 Three-Phase Power Imbalance 10

Page 4

Page

4.0 GENERAL TROUBLESHOOTING FOR ALL PUMPS 12

4.1 Troubleshooting Chart 12

4.2 Mechanical Seal Leakage 13

4.3 Mechanical Seal Replacement: SS500, SS1000 and

SS1800 Series Pumps 13

4.4 High-Pressure Mechanical Seal Replacement: SS500, SS1000

and SS1800 Series 16

5.0 TONKAFLO PUMP FIELD MAINTENANCE 17

5.1 Motor Bearing Lubrication 17

5.2 Motor Removal: XB and XC Motor Adapter Pump 17

5.3 Motor Installation: XB and XC Motor Adapter Pump 18

5.4 Motor Removal: X Motor Adapter Pump 18

5.5 Motor Installation: X Motor Adapter Pump 19

6.0 LIQUID END, TONKAFLO SERVICE POLICY 21

7.0 TONKAFLO PUMP RETURNED GOODS AUTHORIZATION

(RGA) PROCEDURE 22

7.1 Motor Warranty 22

7.2 In-of-Warranty Pump Failure 22

7.3 Out-of-Warranty Pump Failure 22

8.0 DIMENSIONAL DRAWINGS 23

8.1 500X Motor Adapter Pump 23

8.2 500XB Motor Adapter Pump 24

8.3 1000X and 1800X Motor Adapter Pump 25

8.4 1800XB Motor Adapter Pump 26

8.5 1800XC Motor Adapter Pump 27

9.0 CUTAWAY DRAWINGS 28

9.1 X Motor Adapter Pump 28

9.2 XB and XC Motor Adapter Pump 29

Page 5

Page

10.0 STANDARD MODEL PARTS LIST 30

10.1 Spare Parts List 30

10.2 Accessories 31

10.3 Mechanical Seal Replacement Kit 32

11.0 ORDERING PARTS 33

12.0 TONKAFLO PUMP WARRANTY 34

LIST OF FIGURES

Figure Title

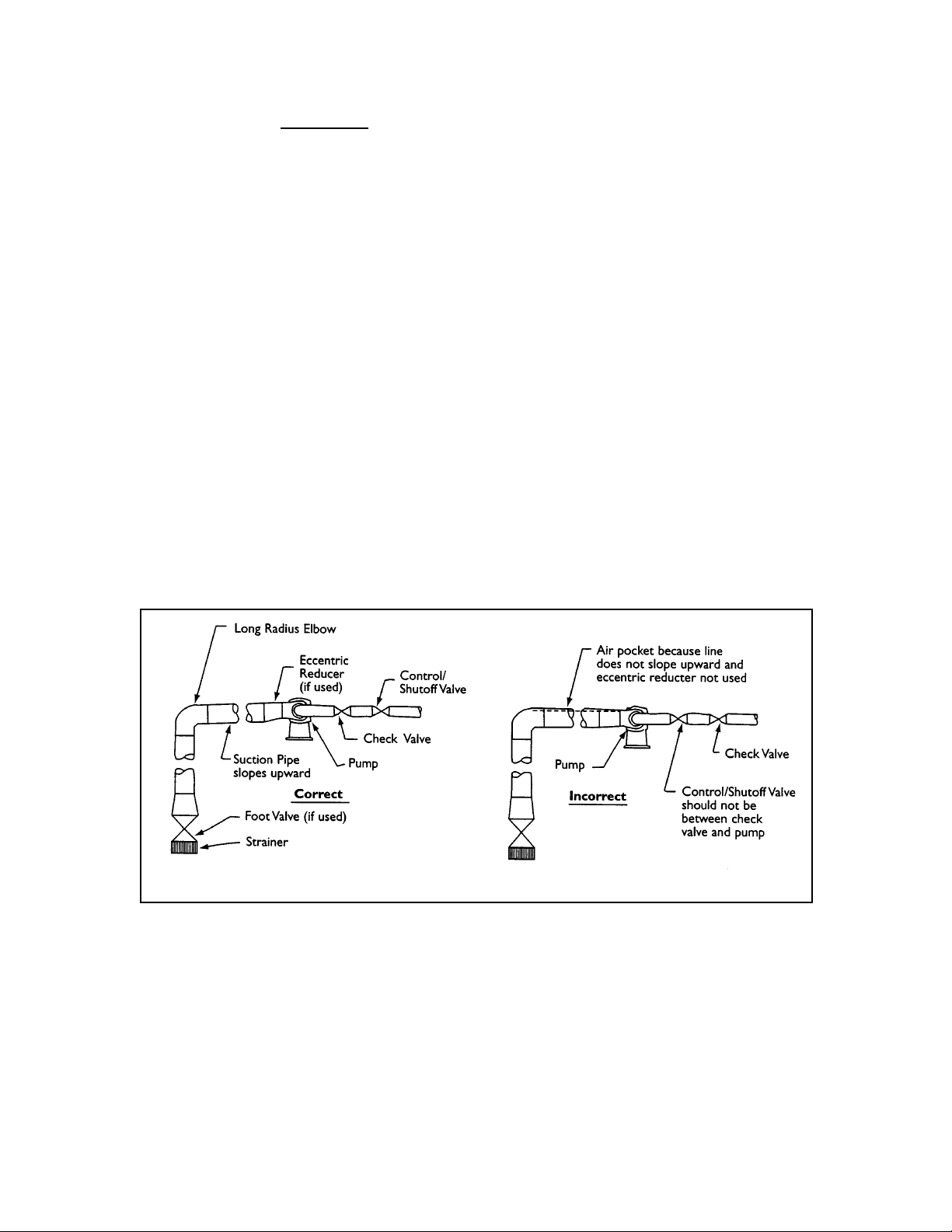

3.1 Inlet Piping 6

3.2 Installation of Discharge Screen 8

3.3 Changing Motor Rotation 10

3.4 Rolling the Leads to Balance Current Draw 11

4.5 Removal of Pump Liquid-End from Motor Adapter 14

4.6 Removal of Mechanical Seal Holder from

Motor Adapter 14

4.7 Removal of Mechanical Seal from Pump Shaft

and Cavity of Mechanical Seal Holder 15

8.8 500X Motor Adapter Pump 23

8.9 500XB Motor Adapter Pump 24

8.10 1000X and 1800X Motor Adapter Pump 25

8.11 1800XB Motor Adapter Pump 26

8.12 1800XC Motor Adapter Pump 27

9.13 X Motor Adapter Pump 28

9.14 XB and XC Motor Adapter Pumps 29

LIST OF T

ABLES

T

able Title

2.1 Capacities 2

2.2 Maximum Developed Boost Pressure 3

Page 6

Page 7

1.0 INTRODUCTION

This manual contains information important to the installation, operation, and maintenance

of your Tonkaflomulti-stage centrifugal pump. Your Tonkaflo pump has been designed for

reliable service in many types of pumping applications. Proper installation and normal maintenance will help ensure extended pump life and prevent costly downtime.

Before installing and operating your Tonkaflo pump, read these instructions carefully and

keep this manual handy for future reference. This manual is intended for general maintenance only.

Further information may be obtained by contacting your nearest Tonkaflo distributor or

GE Infrastructure at:

GE Infrastructure

Water & Process Technologies

5951 Clearwater Drive

Minnetonka, MN 55343-8995 USA

Phone: (952) 933 - 2277

Toll Free: (800) 848 - 1750

Fax: (952) 988 - 6060

This manual is not int

ended for repair or overhaul of the Tonkaflo pump liquid ends.

Only the factory and those certified by the Factory Service School are authorized to repair,

service, or overhaul of Tonkaflo pump liquid ends.

Your new Tonkaflo multi-stage centrifugal pump is designed for quiet, smooth-running, and

highly efficient operation. The materials of construction make Tonkaflo pumps suitable for

many chemical and pure water applications.

Tonkaflo pumps' unique modular design allows the user to choose the number of stages

which most closely match the desired performance and, thereby, achieve the highest pumping efficiency. Unlike many other pump manufacturers, Tonkaflo will produce pumps to fit

your particular applications should a standard model pump not suit your requirements.

NO

TE: This manual, along with all GE Infrastructure manuals, is available at

www.ge.water.com.

1

Page 8

2.0 TONKAFLO SPECIFICATIONS

The Tonkaflo pumps covered in this instruction manual are the lower capacity SS500, SS1000,

and SS1800 Series pumps. These pumps cover a flow range of 1.5 - 18 gpm (0.34 - 4.1 m3/h)

with single unit pressure up to 700 psig (48.3 barg). The capacity and discharge pressure can

be increased by operating pumps in parallel or series, respectively. There is no maximum limit

on capacity when operating Tonkaflo pumps in parallel. When operating pumps in series, the

maximum rated discharge is 750 psig (51.7 barg) with standard pumps, and 1000 psig

(69 barg) with optional high-pressure construction on the downstream pump. With inlet pressures greater than 200 psig (13.8 barg), optional high-pressure mechanical seals should be

used.

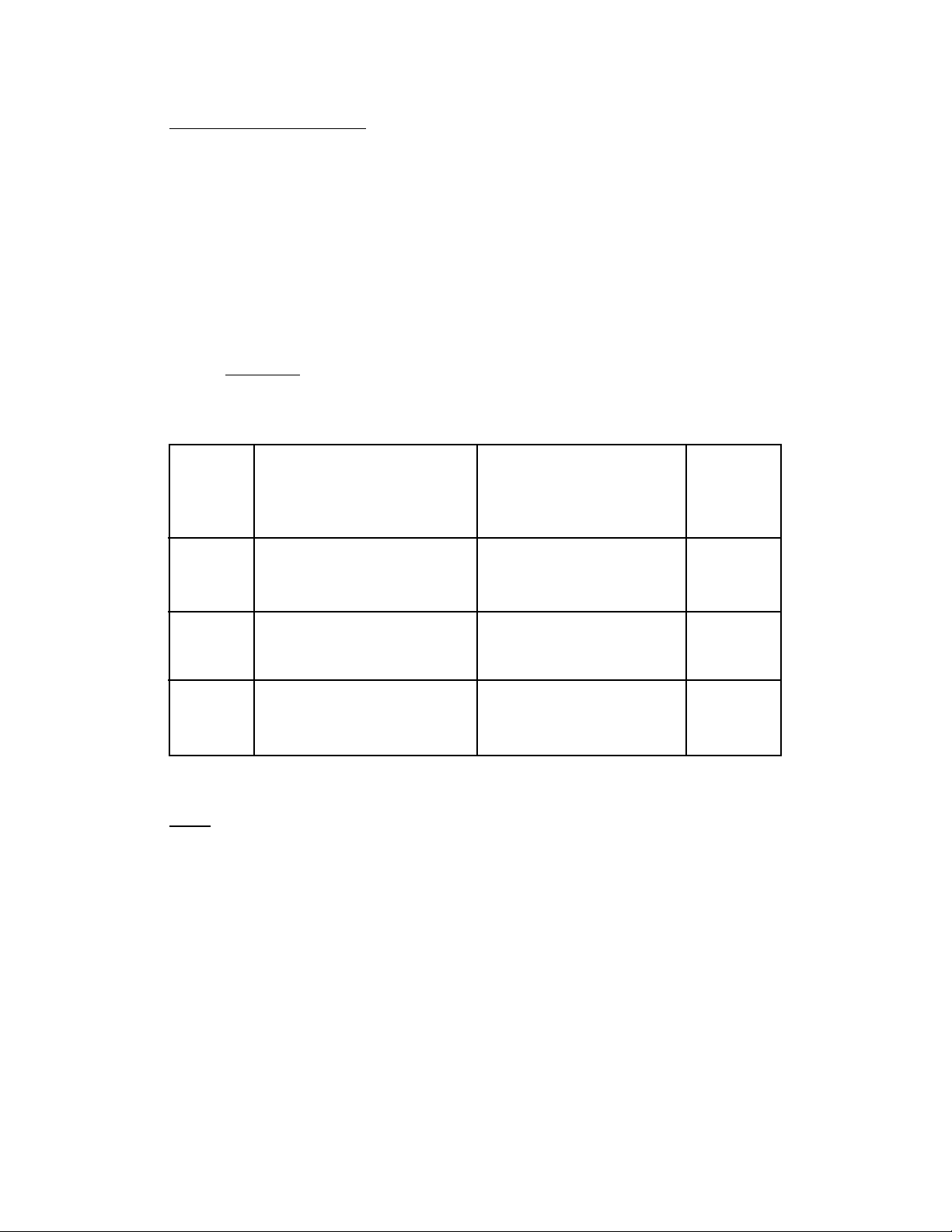

2.1 Capacities

Table 2.1

Capacities

NO

TE: There must be adequate flow at all times through the pump to prevent excessive

heat build-up.

2

SS

Series

500

1000

1800

2900 rpm

50 Hertz

Minimum - Maximum

1 - 6 gpm

(0.23 - 1.4 m3/h)

3.3 - 11 gpm

(0.75 - 2.5 m

3

/h)

4 - 17.5 gpm

(0.91 - 4.0 m

3

/h)

3500 rpm

60 Hertz

Minimum - Maximum

1.5 - 7 gpm

(0.34 - 1.6 m3/h)

4 - 13 gpm

(0.91 - 30. m

3

/h)

5 - 21 gpm

(1.14 - 4.8 m

3

/h)

Maximum

Efficiency

40%

49%

57%

Page 9

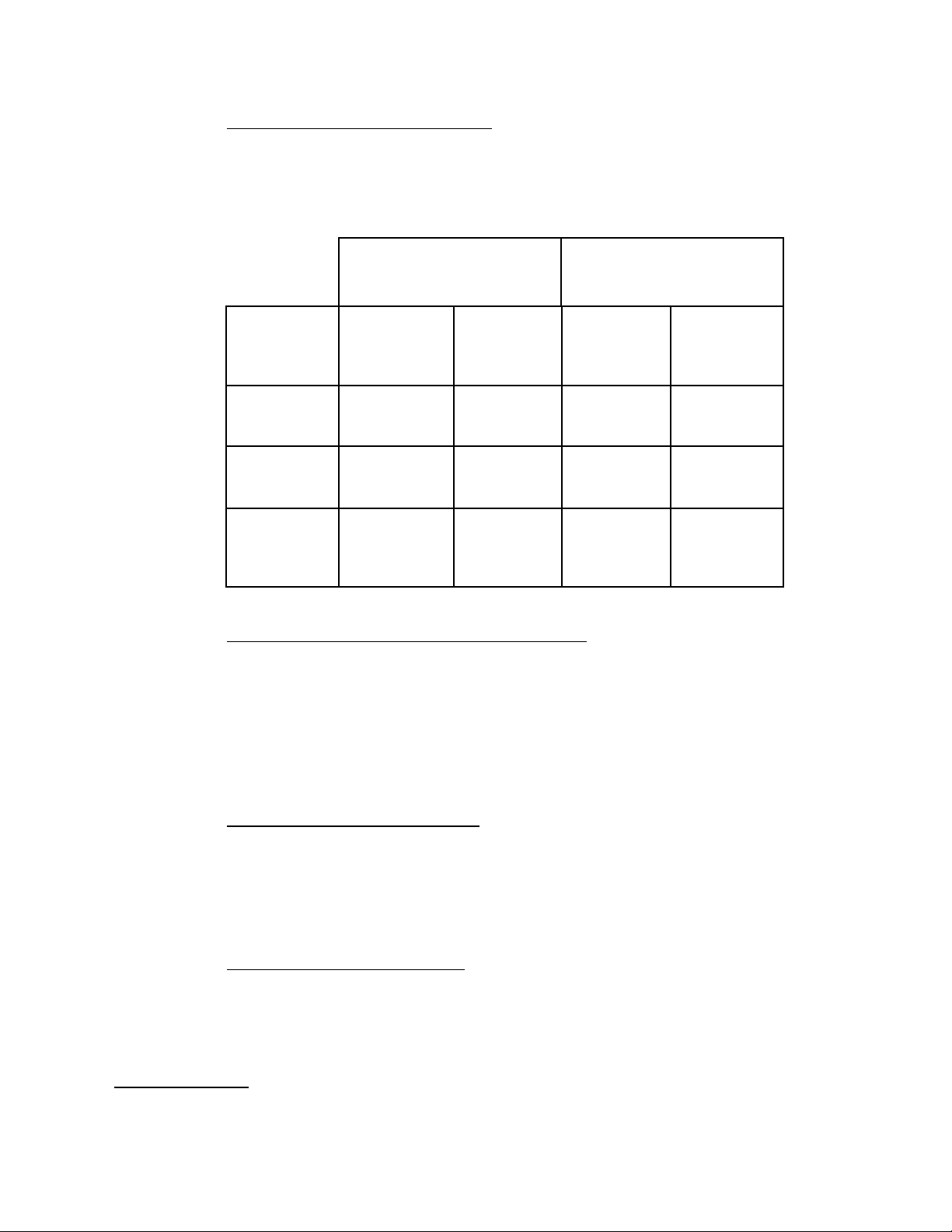

2.2 Maximum Developed Boost Pressure

Table 2.2

Maximum Developed

Boost Pressure

2.3 Maximum Recommended Operating Temperature

The maximum recommended operating temperature range is 125°F (52°C). The maximum operating temperature is dependent upon the operating pressure. For high

temperature applications, consult the factory for special materials of construction.

The maximum recommended temperature is stated on the pump case. The temperature stated is for the design flow and pressure.

2.4 S

tandard Materials of Construction

SS: Wetted castings and pump shaft are 316 stainless steel (SS). The pump casing

is 316SS. Impellers and diffusers are Noryl. The mechanical seal has a carbon

rotating face and a ceramic stationary face. The secondary sealing element of

the mechanical seal is Buna-N. The O-rings and diffuser bearings are Buna-N.

2.5 Special Materials of Construction

Optional ethylene propylene (EPDM), Viton*, and Teflon* elastomers are available.

Contact the factory.

3

* Viton and Teflon are trademarks of E.I. DuPont de Nemours and Company, Inc.

SS

Series

500

1000

1800

60 Hertz

700 (48.3)

340 (23.4)

680 (46.9)

50 Hertz

630 (43.4)

300 (20.7)

570 (39.3)

60 Hertz

58

28

48

50 Hertz

76

N/A

56

Maximum Developed

Pressure

psig (barg)

Number of Centrifugal

Stages

Page 10

2.6 Pump Nomenclature

Example:

2.7 Special

Liquids

For liquids other than water, aqueous solutions, or corrosive solutes, consult the

factory for compatibility.

4

Model SS505X

SS = Materials of Construction

5 = Series 500

05 = Number of Stages

X = Motor Adapter,

No Bearing Frame,

56J Motor

Model SS1848XB-50

SS = Materials of Construction

18 = Series 1800

48 = Number of Stages

XB = Motor Adapter,

No Bearing Frame,

182/184TC Motor

50 = 50 Hertz Operation

Page 11

3.0 PUMP INSTALLATION

3.1 Inspection

Your pump was inspected and tested at the factory prior to shipment to ensure it

meets the requirements of your order. It is suggested the pump be checked upon

receipt for possible damage due to shipping. Any damage should be immediately

reported to the carrier.

3.2 Pump Mounting and Location

The pump is supported by the motor base, and on longer pumps, a support at the discharge end. The X, XB, and XC motor adapter pumps may be mounted and operated

in either a horizontal or vertical position. The vertical position requires the motor to

be up.

The inlet casting may be rotated to any of four positions by removing the four (4) bolts

on the inlet casting, turning the inlet casting to the desired position and replacing the

4 bolts.

When mounting the pump, be sure the pump casing support and motor base are in

line and on the same plane so that no stress results in the pump after fastening down.

CA

UTION: The inlet and discharge piping should be independently supported.

3.3 Inlet and Discharge Piping and Connections

3.3.1 Inlet Piping

THE INLET PIPING AND PUMP MUST BE FILLED WITH LIQUID

(i.e., PRIMED) BEFORE START-UP. A pressure/vacuum gauge installed in the

inlet piping to measure positive or negative pressure is recommended. Be

sure the pump is not mounted above the liquid source and the inlet (suction)

plumbing not restricted so adequate suction pressure is available.

The inlet piping should be at least as large as the pump inlet port. The discharge piping should be sized to properly handle the maximum flow and pressure developed by the pump.

The recommended pipe size for most applications should result in frictional

line loss of 5 psig/100 feet (0.34 barg/100 meters) or less for suction lines and

10 psig/100 feet (0.7 barg/100 meters) or less for discharge lines. A larger pipe

size will reduce the frictional line loss.

The pump inlet piping should be designed to avoid areas where air may be

trapped and accumulate. Keep the inlet pipe free of high points, which could

trap air and could disrupt pump priming and start-up. Pump inlet pipe size

changes just ahead of the pump should be tapered. Reducers should be

eccentric to avoid air pockets.

5

Page 12

IMPORTANT: Should your application require pump operation with a neg-

ative gauge pressure at the inlet, consult the factory or your

local Tonkaflo pump distributor.

When the pump operates with a suction lift, the suction pipe should slope

upward to the pump from the source of supply. Provision must be made for

priming the pump. To maintain pump prime, a foot valve can be used with an

opening at least as large as the inlet piping.

When pumping liquid from a tank, the suction line must be submerged

enough so air is not drawn into the suction line from a vortex. Increasing the

size of the inlet pipe to reduce the velocity will help to prevent the vortex from

forming.

Hot liquids within the temperature range of the pump must have sufficient

positive head to prevent vaporization at the impeller inlet. The Net Positive

Suction Head (NPSH) required data are included on the pump performance

curves provided with this instruction manual.

The pump must never be throttled on the suction side.

After installation, test the suction line with water with a range of 20 - 100 psig

(1.4 - 6.9 bar) pressure to detect any leaks.

Figure 3.1

Inlet Piping

3.3.2 Discharge Piping

The discharge piping should be sized to properly handle the maximum flow

and pressure developed by the pump.

6

Page 13

Size selected should result in frictional line loss of 5 psi/100 ft (1.1 kPa/M) or

less for suction lines and 10 psi/100 ft (2.3 kPa/M) or less for discharge lines.

A larger pipe size will reduce the frictional line loss.

W

ARNING: THE PUMP MUST NOT RUN WITH A CLOSED DISCHARGE OR

IRREVERSIBLE DAMAGE TO THE WETTED INTERNAL PARTS

OF THE PUMP WILL RESULT!

3.3.3 Pump Piping Connections

The standard inlet and discharge connections for a Series 500 pump is a

3/4-inch NPT female pipe thread, and for Series 1000 and 1800 pumps is

1-1/4-inch Victaulic couplings/clamped unions with gasket. Victaulic couplings are available worldwide. Contact the factory or your local industrial

piping wholesaler.

3.3.4 Inlet Line Screen/Filter

This is a precision multi-stage pump with close tolerances to provide maximum efficiency. It is good practice to install a large area 30-mesh or finer

screen, or a cartridge filter in the pump inlet line to collect any foreign objects

or large particles. Size the screen or filter so as to induce a minimal pressure

drop.

W

ARNING: THE PUMP MUST NOT BE OPERATED WITH RESTRICTED SUC-

TION LINE (INLET) FLOW.

Positive gauge pressure must be maintained at the pump inlet (downstream

from the screen or filter). A clogged screen or filter will result in a greater

pressure drop than a clean screen or filter. To prevent possible pump damage from low inlet pressure, a low-pressure alarm or shut-off switch should be

located between the screen or filter and the pump. A low-flow shut-off switch

should also be located in the same area.

3.3.5 Discharge Screen (Strainer)

A 30-mesh screen (available as an accessory for 500, 1000 and 1800 Series

pumps) located in the discharge piping will protect your process fluid should

the pump be damaged. The installation of the screen is shown in

Figure 3.2 (Installation of Discharge Screen).

7

Page 14

Figure 3.2

Installation of

Discharge Screen

3.4 Pump Priming

IMPORTANT: THE INLET PIPING AND PUMP MUST BE FILLED WITH LIQUID (i.e.,

PRIMED) BEFORE START-UP.

If the pump is abov

e the liquid source, fill the pump and supply line with liquid from

an ext

ernal source.

W

ARNING: THE PUMP MUST BE SHUTOFF IMMEDIATELY IF PRIME IS LOST TO

AVOID POSSIBLE DAMAGE TO THE INTERNALS OF THE LIQUID END.

W

ARNING: NEVER RUN PUMP DRY.

The liquid end of your Tonkaflo pump is lubricated by the process fluid. The pump

must never be run dry to avoid damage to the liquid end.

3.5 Prot

ection Against Running Dry

It is suggested that controls to protect the pump from running dry be used. These

controls include: pressure switches, flow switches, and temperature switches.

8

Page 15

3.6 Motor Wiring

3.6.1 Single-Phase Motors

When initially connecting to the power source, be certain that the motor voltage connections and available line voltage are the same. Connect electrical

wires as shown on the motor wiring diagram located on the motor nameplate, electrical junction box, junction box cover, or wiring tag. Be sure your

pump is electrically grounded at the junction box on the motor.

3.6.2 Three-Phase Motors

The wiring diagram located on the motor nameplate, electrical junction box,

junction box cover, or wiring tag should be used to correctly wire the motor

according to the line voltage available. Be sure your pump is electrically

grounded at the junction box on the motor.

CA

UTION: The 500X, 1000X and 1800X motor adapter pumps have a

threaded motor shaft. Reverse operation can damage the

motor shaft, pump shaft, or centrifugal stages.

Before S

tarting Three-Phase Motors:

STEPS

1. Prime pump before applying power to avoid damage to the pump.

2. Apply power for ONE SECOND MAXIMUM to check the direction of

motor shaft rotation. The motor shaft should turn in a clockwise direction as viewed from the motor end. The direction of rotation for threephase motors may be reversed by interchanging any two (2) leads

(Figure 3.3, Changing Motor Rotation).

Three-phase motors can run in either direction, depending on how

they are connected to the power supply. When the three cable leads

are first connected to the power supply, there is a 50% chance that

the motor will run in the proper direction. To make sure the motor is

running in the proper direction, carefully follow the procedure below.

STEPS

A. Start the pump and note the pressure and flow rate developed

at the pump discharge.

B. Stop the pump and interchange any of the two leads.

C. Start the pump again and recheck the flow rate and pressure.

9

Page 16

D. Compare the results observed. The wire connection that yield-

ed the highest pressure and flow rate is the proper connection.

Interchange the two leads only if necessary

(Figure 3.3, Changing Motor Rotation).

Figure 3.3

Changing Motor

Rotation

3.6.3 Three-Phase Power Imbalance

Current imbalance should not exceed 5% of the average three-phase current.

The current imbalance can be calculated as follows:

STEPS

1. Measure the current through each of the three legs.

2. Average the three current measurements together.

3. Determine the difference between the current in each leg and the

average of all three legs.

4. Take the difference with the largest value, and divide it by the average

current. Multiply by 100 to obtain the current imbalance percentage.

5. If the current imbalance is greater than 5%, “roll” the leads and retest

(Figure 3.4, Rolling the Leads to Balance Current Rotation). If “rolling”

the leads does not correct the problem, the source of imbalance must

be located and corrected. For more information on current imbalance, refer to the motor operation manual.

10

Page 17

Figure 3.4

“Rolling” the Leads

to Balance Current

Draw

11

Page 18

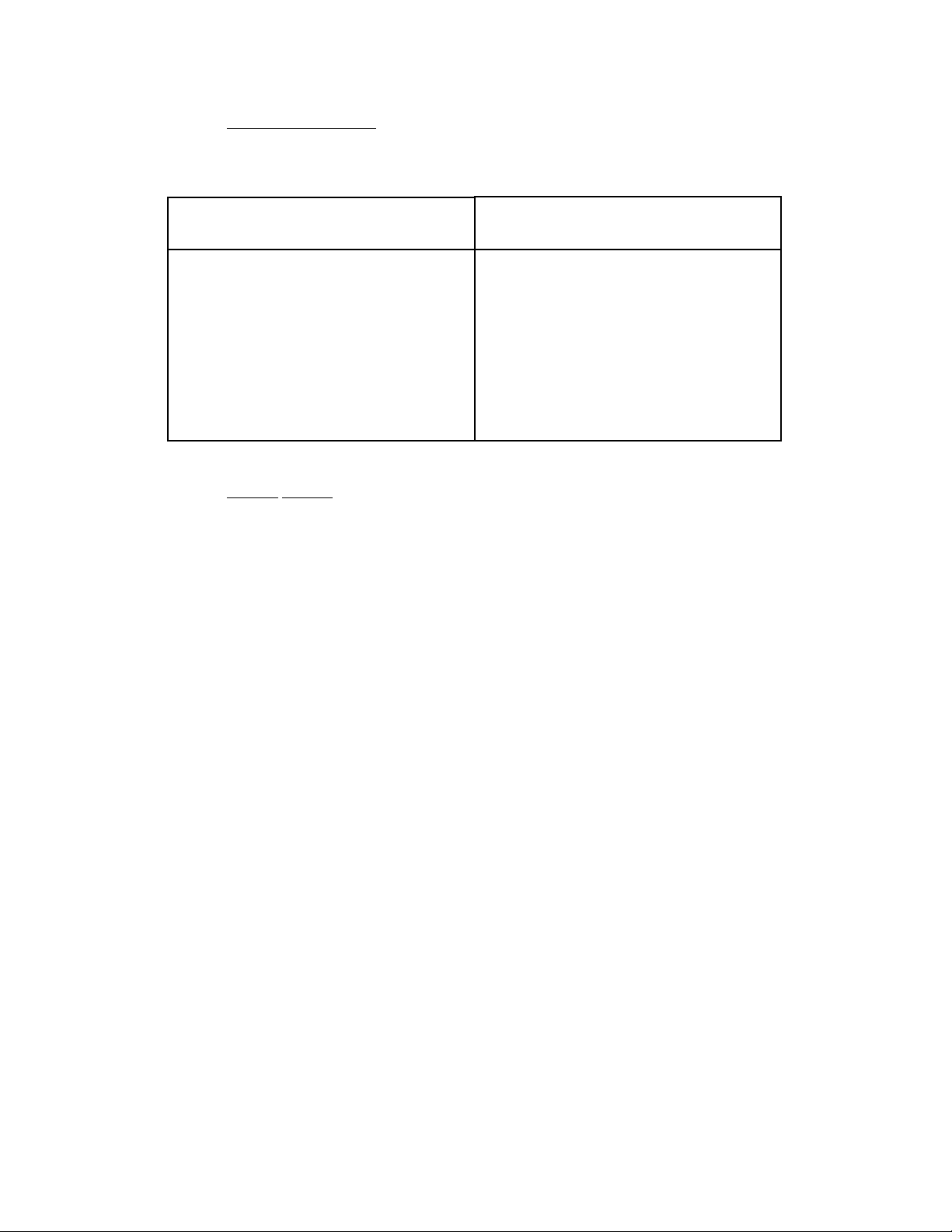

4.0 GENERAL TROUBLESHOOTING FOR ALL PUMPS

4.1 Troubleshooting Chart

12

MOTOR RUNS HOT OR STOPS

1. Motor surface temperature up to

104°F (40°C) over ambient can

occur. The motor will feel hot to the

touch.

2. Bad connection

3. Motor exceeded rated amp draw

4. Excessive ambient temperature

5. Heater size to small in motor heater

6. Binding rotation in the pump shaft

7. Bearings not adequately lubricated

8. Specific gravity or viscosity of liquid

higher than design conditions

9. Motor wired improperly

LOW PRESSURE

1. Pump not adequately primed

2. Air leak in inlet piping

3. Excessive flow

4. Clogged suction line filter or screen

5. Reverse rotation of pump shaft

6. Foot valve operating improperly

7. Wrong ratio for belt drive

PUMP LEAKING

1. Mechanical seal needs replacing

2. O-rings in pump casing damaged

3. Oil seals need replacing

4. Piping not sealed properly

LOW FLOW

1. Restrictions in inlet or discharge

2. Foot valve operating improperly

3. Air leak in inlet piping

4. Air leak in mechanical seal

5. Wrong installation of belt drive

6. Suction lift too high

7. Reverse rotation of pump shaft

8. Pump not primed adequately

9. Inlet strainer/filter plugged.

10. Pump throttling valve on discharge

closed (pump deadheaded)

MOTOR DOES NOT RUN

1. Blown fuse or tripped circuit breaker or

overload heater

2. Motor to hot - allow to cool

3. Motor voltage connection and line

voltage different

4. Bad connection

5. Motor wired improperly

6. Wrong ratio for belt drive

PUMP VIBRATION

1. Misalignment of flexible coupling

2. Bent pump shaft

3. Improper mounting

4. Starved suction

5. Worn bearings

6. Motor out of balance

7. Operating beyond specified capacity

range of the pump

Page 19

4.2 Mechanical Seal Leakage

W

ARNING: POWER MUST BE DISCONNECTED BEFORE MAINTENANCE!

If liquid is leaking from the hole on the bottom or on either side of the motor adapter,

the mechanical seal may need to be replaced. With new pumps, pumps with new

mechanical seals, or pumps which have been dormant for long periods, the seal faces

may not be completely seated and a slight leakage will occur. If this leakage continues for more than 60 seconds, the first remedy is to remove the discharge piping and

tap the pump shaft using a wooden dowel to seat the seal.

W

ARNING: BE CAREFUL NOT TO DAMAGE THE SHAFT.

If this does not stop the leak, then the liquid end assembly needs to be partially

removed to gain access to the mechanical seal as shown in Figure 4.5 (Removal of

Pump Liquid-End from Motor Adapter) or Figure 4.6 (Removal of Mechanical Seal from

Motor Adapter).

The ceramic seal seat also needs to be wiped clean and then coated very lightly with

oil or Vaseline. Also, the carbon wear ring needs to be wiped clean and coated lightly with petroleum grease. Then, reassemble the pump.

4.3 Mechanical Seal Replacement: SS500, SS1000 and SS1800 Series Pumps

NOTE: On Tonkaflo X frame pumps, the mechanical seal must be replaced by

removal of the complete liquid end assembly from the pump shaft. On

Tonkaflo XB and XC frame pumps, you can service the mechanical seal by

either removing the complete liquid end assembly from the pump shaft, or

by loosening the cone-point set screw which secures the pump shaft to the

shaft coupler, and removing the pump shaft with the liquid end assembly.

STEPS

1. Remove the four (4) 5/16-inch bolts and lock washers from the inlet casting

and firmly grasp the liquid end (Figure 4.5, Removal of Pump Liquid-End from

Motor Adapter). Pull the liquid end straight off the pump shaft being careful

not to bend the pump shaft. Two (2) flat-blade screwdrivers may be needed

to remove the seal holder from the liquid end assembly.

W

ARNING: EXTREME CARE MUST BE TAKEN NOT TO BEND PUMP SHAFT!

2. Remove the stainless steel retaining ring (size 5160-62H) from the pump shaft

using the proper size retaining ring pliers (Truarc L1520 or equivalent). These

pliers are available from the factory or can be purchased from a local source.

13

Page 20

Figure 4.5

Removal of Pump

Liquid-End from

Figure 4.6

Removal of Mechanical

Seal Holder from

Motor Adapter

14

Page 21

Figure 4.7

Removal of Mechanical Seal

from Pump Shaft and Cavity

of Mechanical Seal Holder

3. Remove the rotary portion (spring, washer, and face assembly) of the seal

assembly from the pump shaft by rotating and pulling the rotary portion until

it slides off the pump shaft (Figure 4.6, Removal of Mechanical Seal Holder

from Motor Adapter).

4. Remove the mechanical seal holder from the motor adapter by sliding the

holder off the pump shaft. Two (2) flat-blade screwdrivers may be needed to

remove seal holder from the motor adapter (Figure 4.6).

5. Remove the stationary seat of the mechanical seal from the cavity of the

mechanical seal holder (Figure 4.7, Removal of Mechanical Seal from Pump

Shaft and Cavity of Mechanical Seal Holder).

6. Install the new stationary seat into the seal holder cavity. Lubricate the rubber boot on the outside of the stationary seal with petroleum or silicone

grease before replacement. Make sure the stationary seat is fully seated.

Lightly lubricate the ground surface of the stationary seat with grease.

15

Page 22

7. Examine the rubber O-ring on the mechanical seal holder and, if the O-ring is

damaged, replace it with a new one. A new O-ring is included with the factory-supplied Mechanical Seal Replacement Kit (Section 10.3). Be sure to lubricate with grease before installing.

8. Place the mechanical seal holder containing the new stationary seat onto the

pump shaft and slide it down the shaft until fully engaged with the motor

adapter. Care must be taken not to damage seal seat when sliding over the

pump shaft.

9. Lubricate the round surface of the pump shaft with grease. After lubrication,

replace the rotary portion of the mechanical seal by placing onto the pump

shaft and carefully rotating and pushing it down the pump shaft until it is fully

seated against the stationary portion of the mechanical seal.

W

ARNING: USE CARE WHEN SLIDING THE ROTARY PORTION OF THE

MECHANICAL SEAL OVER THE RETAINING RING GROOVE IN

THE PUMP SHAFT. THE RUBBER ON THE MECHANICAL SEAL

CAN BE DAMAGED IF NOT LUBRICATED WITH GREASE.

10. Place the stainless steel retaining ring back onto the shaft to hold the rotary

portion of the mechanical seal in place with the square edges of the retaining

ring away from the seal spring. A retaining ring is included in the factory supplied mechanical seal replacement kit. Use of retaining rings that are not

stainless steel or equivalent may cause the seal to fail in operation.

11. Be sure the retaining ring is properly seated in the groove on the pump shaft.

12. Firmly grasp the liquid end and insert the splined pump shaft into the liquid

end by carefully rotating the liquid end clockwise and then counterclockwise

while applying light pressure toward the motor adapter. Be sure the splined

shaft and splined bore of each impeller meshes properly until the inlet casting

mates with the mechanical seal holder. It may be necessary to lift the assembly up slightly when rotating it, then place it onto the splined shaft .

W

ARNING: CARE MUST BE TAKEN NOT TO BEND THE PUMP SHAFT OR TO

FORCE THE SHAFT INTO THE IMPELLER BORE.

13. Install the four (4) 5/16-inch bolts and lock washers and tighten.

4.4 High-Pressure Mechanical Seal Replacement: SS500, SS1000 and SS1800 Series

Pumps

High pressure mechanical seals have the same basic design as standard mechanical

seals. Replace them using the same procedure as denoted in Section 4.3 (Mechanical

Seal Replacement SS500, SS1000 and SS1800 Series Pumps), Figure 4.6 (Removal of

Mechanical Seal Holder from Motor Adapter), and Figure 4.7 (Removal of Mechanical

Seal from Pump Shaft and Cavity of Mechanical Seal Holder).

16

Page 23

5.0 TONKAFLO PUMP FIELD MAINTENANCE

5.1 Mot

or Bearing Lubrication

Motors up to 3 Hp typically have sealed bearings. Motors of 5, 7.5, and 10 Hp may or

may not have sealed bearings. For these larger motors, lubrication intervals vary

between manufacturers but generally lubrication every 2000 hours is required.

Consult Your Local Motor Distributor For Lubrication Advice, or the motor information

supplied with your pump.

5.2 Mot

or Removal: XB and XC Motor Adapter Pumps

STEPS

1. Disconnect the motor electrical power.

2. Remove the wiring to the motor.

3. Remove the piping from the pump.

4. Remove the pump mounting bolts, and place the pump on a work bench.

5. Remove the cone-point set screw from the shaft coupler, which is located

through either side port in the motor adapter adjacent to the inlet housing. Do

not remove the two knurled cup-point set screws securing the shaft coupler

to the motor shaft at this time.

6. Remove the four (4) 5/16-18NC bolts that hold the pump liquid end to the

motor adapter.

7. Slide the liquid end assembly away from the motor adapter 1/4- to 1/2-inch

(6 - 13 mm).

8. Use two (2) flat-blade screwdrivers or small pry bars to remove the seal holder from the motor adapter along with the pump shaft (Figure 4.5, Removal of

Pump Liquid-End from Motor Adapter). Remove the liquid-end assembly

including the pump shaft as a unit.

9. Remove the four (4) 1/2-12NC bolts that hold the motor adapter to the motor

and remove the motor adapter.

10. Loosen the two set screws that hold the shaft coupler to the motor shaft, and

remove the shaft coupler. The motor may now be serviced by a qualified vendor or replaced (Figure 4.6, Removal of Mechanical Seal Holder from Motor

Adapter).

17

Page 24

5.3 Motor Installation: XB and XC Motor Adapter Pumps

STEPS

1. On a used motor, file the motor shaft smooth where the set screws were

seated.

2. Coat the motor shaft with an anti-seize compound.

3. Slide the shaft coupler onto the motor shaft until fully seated, and tighten the

two set screws.

4. Place the motor adapter onto the motor, such that the one drain hole is locat-

ed down and the four side access ports are horizontal when the pump is reinstalled.

5. Coat the round end of the pump shaft and shaft key with an anti-seize com-

pound.

6. Place the pump liquid-end assembly with pump shaft and shaft key into the

motor adapter, with the key aligned with the coupler key way.

7. Install the four (4) 5/16-18NC bolts and tighten.

8. Using a wood dowel, place it against the pump shaft end located in the discharge port. Tap on the end of the wood dowel until the pump shaft is fully

seated in the shaft coupler, and then tighten the cone-point set screw

(Figure 4.6, Removal of Mechanical Seal Holder from Motor Adapter).

9. Reinstall the pump and pump piping connections.

10. Reinstall the motor wiring.

11. For pump start-up see Section 3.0 (Pump Installation).

5.4 Mot

or Removal: X Motor Adapter Pumps

STEPS

1. Disconnect the motor electrical power.

2. Remove the wiring to the motor.

3. Remove the piping from the pump.

4. Remove the pump mounting bolts, and place the pump on a work bench.

5. Remove the four (4) 5/16-18NC bolts that hold the pump liquid end to the

motor adapter.

18

Page 25

6. Slide the liquid end assembly off of the pump shaft, taking care not to bend

the pump shaft.

7. Remove the retaining ring and remove. The rotary head of the mechanical

seal.

8. Remove the seal holder along with the stationary seal seat.

9. Remove the four (4) 3/8-16NC bolts that hold the motor adapter to the motor,

and remove the motor adapter.

10. Remove the pump shaft assembly where it is screwed to the threaded motor

shaft by first heating the joint area to loosen the thread-locking compound.

Secure the motor shaft using a vise grip, and loosen the pump shaft assembly. An impeller may be used to grip the shaft, taking proper care not to damage the impeller. Or, use a vise grip and fabric rug to grip the splined shaft,

taking care not to damage the splines.

11. The motor can now be serviced by a qualified service center, or replaced.

5.5 Mot

or Installation: X Motor Adapter Pumps

STEPS

1. To re-use a repaired motor, clean the threads on the shaft of any threadsealant residue.

2. Reinstall the pump shaft onto the threaded motor shaft until fully seated.

Rotate the pump shaft to make sure it runs true. Run-out should be less than

0.03 inch (0.76 mm) for every 10 inches of pump shaft length.

3. Loosen the pump shaft from the motor shaft, apply thread sealant to the

threads, and tighten the shaft again until fully seated. Use standard strength

thread sealant on single-phase motors, and a high-strength thread sealant on

three-phase motors.

4. Install the motor adapter onto the motor and install and tighten the four bolts

into the motor.

5. Position the seal holder into the motor adapter, using Vaseline or grease on

the O-ring as a lubricant. Replace the O-ring if damaged.

6. Install a new mechanical seal stationary seat, using Vaseline, grease, or water

as a lubricant on the rubber portion.

7. Install the rotary portion of the mechanical seal using a small amount of

Vaseline lubricant on the round body of the shaft, and also on the face of the

ceramic seat face where the carbon wear ring contacts it.

19

Page 26

8. Install the retaining ring into the shaft groove with the sharp edges away from

the motor.

9. Install the liquid end assembly onto the pump shaft. Do not force it in. Rotate

and place the liquid end onto the mechanical seal holder until seated against

motor adapter.

10. Install the four (4) 5/16-inch lock washers and bolts to hold the liquid end onto

the motor adapter and tighten.

11. Reinstall the pump (Section 3.0, Pump Installation).

20

Page 27

6.0 LIQUID END - TONKAFLO SERVICE POLICY

Sections 4.0 (General Troubleshooting for All Pumps) and 5.0 (Tonkaflo Pump Field

Maintenance) in the Tonkaflo Installation, Operation, and Maintenance Manual were written

to assist our customers in performing minor maintenance in the field of Tonkaflo pumps.

Proper maintenance will ensure longer pump life and minimize downtime. Tonkaflo pumps

are manufactured to make field repairs on the mechanical seal a quick and easy process. If

a repair at the factory is desired, call the factory for a Return Goods Authorization (RGA)

number (Section 7.0) and follow the directions provided by a GE representative. For motor

problems, such as worn-out motor bearings, it is recommended that maintenance be done at

a local motor repair shop.

W

ARNING: FIELD SERVICE OF THE LIQUID END, WITH THE EXCEPTION OF MECHANICAL

SEAL REPLACEMENT, IS NOT RECOMMENDED.

If a liquid end is damaged by running the pump dry, inadequate flow, deadheading, cavitation, or other reasons, return it with the motor to the factory for repair.

21

Page 28

7.0 TONKAFLO PUMP RETURN GOODS AUTHORIZATION (RGA) PROCEDURE

If you wish to return goods for repair, warranty evaluation and/or credit, please have your

original sales order or invoice available when you call GE. Call (800) 848-1750 and ask to

speak with Customer Service. A GE Customer Service representative will provide instructions

and a return authorization number which needs to be clearly written on the outside of the box

used to ship your materials. All equipment must be shipped to GE with the freight prepaid by

the customer. Call our Customer Service Center with any questions or issues concerning

freight claims and a representative will discuss your situation.

All mat

erials to be returned must be rendered into a non-hazardous condition prior to ship-

ping.

There are two ways to handle a return: (1) send in the pump for repair and return or (2) purchase a new pump and when desired, send the defective pump to the factory for repair and

return.

7.1 Mot

or Warranty

Mot

ors must be sent to the nearest authorized motor service station cent

er for repair,

replacement, and warranty disposition.

7.2 In-W

arranty Pump Failure

STEPS

1. Return the defective pump to the factory for repair, on an RGA, within 15 days.

from RGA issue date. GE absorbs the cost of repair. The repaired pump will

be returned and is under warranty for the remainder of the original warranty

period or three months, whichever is longer.

2. GE will not restock or issue return credit against a new, customer-built, pump

purchase regardless of the warranty status of the failed pump. The warranty

(Section 12.0, Tonkaflo Pump Warranty) is 12 months from installation or 15

months from receipt, whichever occurs first.

7.3 Out

-of-Warranty Pump Failure

Return the pump on an RGA for repair. The pump will be repaired and repair charges

invoiced to the customer. The warranty for repairs is three months.

22

Page 29

8.0 DIMENSIONAL DRAWINGS

8.1 500X Mot

or Adapter Pumps

Figure 8.8

500X Motor

Adapter Pump

23

Page 30

8.2 500 XB Motor Adapter Pumps

Figure 8.9

500 XB Motor

Adapter Pump

24

Page 31

8.3 1000X and 1800X Motor Adapter Pumps

Figure 8.10

1000X and 1800X

Motor Adapter Pump

25

Page 32

8.4 1800XB Motor Adapter Pumps

Figure 8.11

1800XB Motor

Adapter Pump

26

Page 33

8.5 1800XC Motor Adapter Pumps

Figure 8.12

1800XC Motor

Adapter Pump

27

Page 34

9.0 CUTAWAY DRAWINGS

9.1 X Mot

or Adapter Pump

Figure 9.13

X Motor Adapter

Pump

28

Page 35

9.2 XB and XC Motor Adapter Pump

Figure 9.14

XB and XC

Motor Adapter

Pump

29

Page 36

10.0 STANDARD MODEL PARTS LIST

10.1 Spare P

arts List

30

Item

1

2

4

5

6

7

8

9

10

11

12

13a

13b

13c

14

15

16

Description

Liquid End Assembly

Motor Adapter

Shaft Coupler

Set Screw, Shaft Coupler

Set Screw, Cone-Point

Pump Shaft Key, 3/16 x 3/16 x 1-inch

Pump Shaft Extension & Sleeve

Spiral Pin

Pump Shaft

Seal Holder, SS

O-ring, Buna-N

Mechanical Seal, Standard Kit

Mechanical Seal, 300 psig (barg), Kit

Mechanical Seal, 400 psig (barg), Kit

(a) Retaining Ring

Discharge Bracket

Clamp, Discharge

Series

500XB

1800XB

Specify

Model

1125921

1125795

1125137

1113769

1120062

1123244

1120500

Specify

Model

1122719

1122786

1121174

1120312

1120477

1120054

1120075

1112951

Series

500X

1000X

1800X

Specify

Model

1123229

N/A

N/A

1113769

1120062

N/A

N/A

Specify

Model

1122719

1122786

1121174

1120312

1120477

1120054

1120659

1112951

Series

1800XC

Specify

Model

1125921

1125758

1125137

1113769

1120062

1123244

1120500

Specify

Model

1122719

1122786

1121174

1120312

1120477

1120054

1125914

1112951

Part Number

Page 37

10.2 Accessories

31

Item

17a

18

19a

19b

20a

20b

Description

Bolt, 5/16-18NC x 1

Lock washer, 5/16

Bolt, 3/8-16NC x 1.25 Long

Bolt, 1/2-13NC x 1.25 Long

Lock washer, 3/8

Lock washer, 1/2

Series

500XB

1800XB

1113102

1112256

N/A

1113973

N/A

1113104

Series

500X

1000X

1800X

1113102

1112256

1110984

N/A

1110012

N/A

Series

1800XC

1113102

1112256

N/A

1113973

N/A

1113104

Part Number

Description

Installation, Operation, and Maintenance

Manual

Retaining Ring Pliers

Loctite 242 Standard Strength, 0.5 cc tube

Loctite 271 High Strength, 50 cc bottle

Anti-Seize, Thread Compound

Series

500XB

1800XB

1125857

1120108

N/A

N/A

1120110

Series

500X

1000X

1800X

1125857

1120108

1120109

1113690

1120110

Series

1800XC

1125857

1120108

N/A

N/A

1120110

Part Number

Page 38

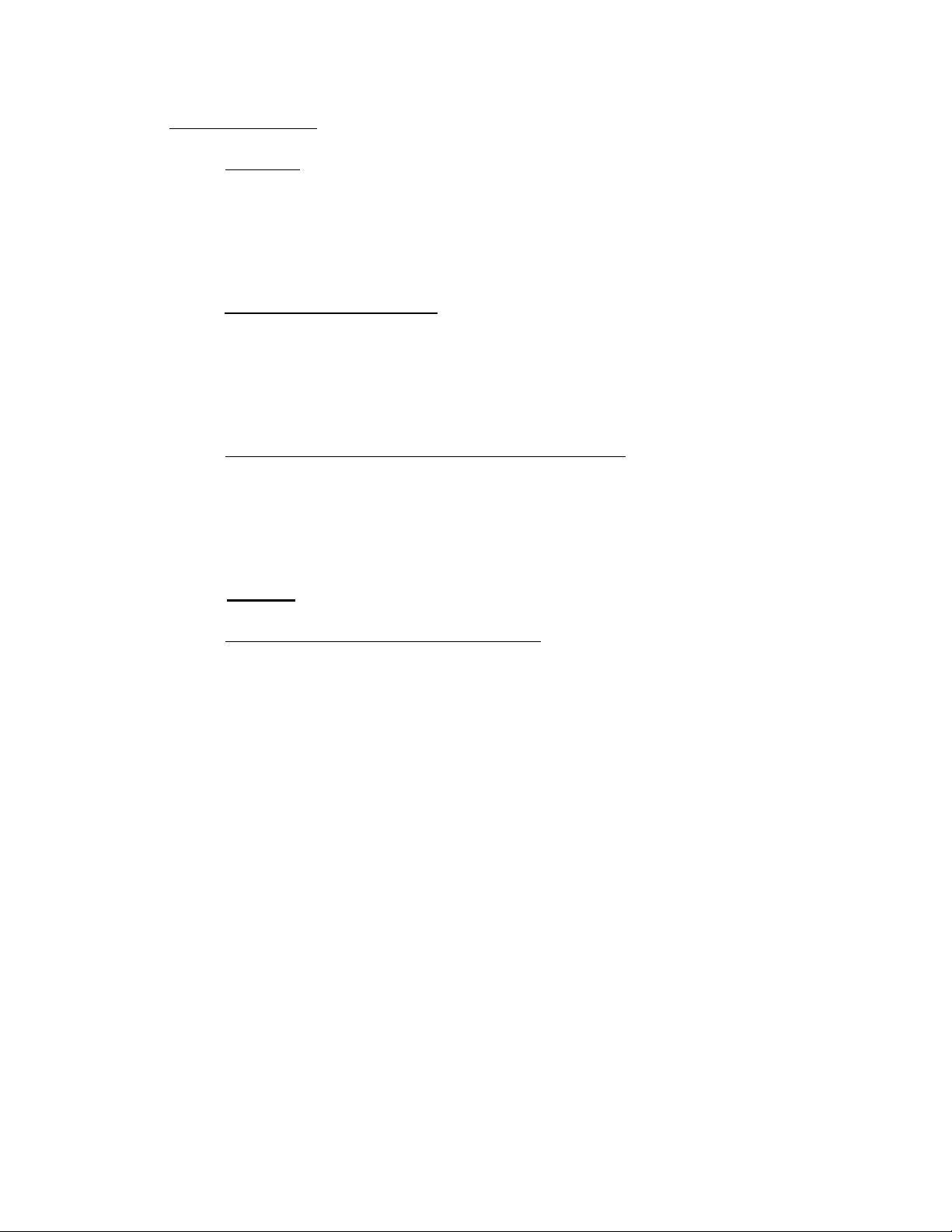

10.3 Mechanical Seal Replacement Kit

32

Description

Standard, 200 psig (13.8 barg)

High-Pressure, 300 psig (20.7 barg)

High-Pressure, 400 psig (27.8 barg)

Allen Wrench, 3/16-inch

Victaulic Adapters, 1.25 x 1.25, M-NPT, 316SS

Victaulic Adapters, 1.25 x 1, F-NPT, 316SS

Victaulic Adapters, 1.25 x 0.75, F-NPT, 316SS

Victaulic Coupling, 1.25, 1000 psig (69 barg)

Pump Discharge Screen, 1.25

Series

500XB

1800XB

1121174

1120312

1120477

1113770

1113653

1120797

1120229

1110597

1120264

Series

500X

1000X

1800X

1121174

1120312

1120477

N/A

1113653

1120797

1120229

1110597

1120264

Series

1800XC

1121174

1120312

1120477

1113770

1113653

1120797

N/A

1110597

1120264

Part Number

Page 39

11.0 ORDERING PARTS

Order parts through your local distributor or directly from:

GE Infrastructure

Water & Process Technologies

5951 Clearwater Drive

Minnetonka, MN 55343-8995 USA

Phone (952) 933-2277

Fax: (952) 933-0141

Toll Free (800) 848-1750

To order parts, the following information is necessary:

1. Pump model number

2. Pump serial number (from nameplate)

3. Other nameplate information such as operating temperature or material code, and

type of mechanical seal

4. Motor horsepower, motor frame size and enclosure specifications

5. Part name

6. Part number

7. Quantity desired

8. Special materials of construction, if any.

33

Page 40

12.0 WARRANTY

T

ONKAFLO PUMP WARRANTY

GE warrants its pumps to be free from defects in design, material, or workmanship for a period of 15 months from receipt or 12 months from installation of the product, whichever occurs

first , when said products are operated in accordance with written instructions and are

installed properly. If Tonkaflo pumps are altered or repaired without prior approval of GE, all

warranties are void. If any defects or malperformance occur during the warranty period, GE’s

sole obligation shall be limited to alteration, repair or replacement at GE's expense, freight on

board (F.O.B.) factory, of parts or equipment which, upon return to GE and upon GE’s examination, prove to be defective. Equipment and accessories not manufactured by GE are warranted only to the extent of and by the original manufacturer's warranty. GE shall not be

liable for damage or wear to equipment caused by abnormal conditions, excessive temperatures, vibration, failure to properly prime or to operate equipment without flow, or caused

by corrosives, abrasives or foreign objects. The foregoing warranty is exclusive and in lieu of

all other warranties, whether expressed or implied including any warranty of merchantability or fitness for any particular purpose. In no event shall GE be liable for consequential or

incidental damages.

34

Pump Model Number:

Pump Serial Number:

P/N 1125857 Rev B

Page 41

Page 42

For more information call 952-933-2277 or 800-848-1750 in the U.S., or visit www.gewater.com.

© 2004, General Electric Company. All rights reserved.

P/N 1125857 Rev. B

North American Sales Euro/Africa Sales Asia/Pacific Sales

5951 Clearwater Drive 230 rue Robert Schurman 1044/8 SOI 44/2

Minnetonka, MN ZA des Uselles Sukhumvit Road Parkanog

55343-8995 77350 Le Mée sur Seine Bangkok 10110

USA FRANCE THAILAND

(952) 933-2277 Phone +33 1 64 10 2000 Phone + 66 2 38 14213 Phone

(952) 933-0141 Fax +33 1 64 10 3747 Fax + 66 2 39 18183 Fax

GE Infrastructure

Water & Process Technologies

Loading...

Loading...