GE SPS Pumps Brochure

GE Oil & Gas

Surface Pumping Systems

Product line

GE imagination at work

We know that the life cycle of industrial pumps

are often at the center of your decision making

process. That is why GE is your partner for the long

run. We carefully consider the life-cycle operating

eciencies, power consumption, environmental

impact and reliability of our pumps to ensure they

will meet your needs now and in the future.

Improved surface pumping solutions

The drive for long-lasting, highly-reliable, environmentally-friendly pumping solutions has led many customers to appreciate our SPS™ Surface Pumping Systems.

GE’s SPS pumping systems provide versatile, low-maintenance alternatives to many high-speed integral geardriven centrifugal (OH6), positive displacement (PD) and

vertical-turbine pump (VTP) models.

Trouble-free service

The SPS pump is designed for years of trouble-free

operation. There are no V-belts or packing to service.

Routine maintenance consists of a quarterly lubricant

change and component check. SPS units generate little

to no vibration-related wear or stress on piping components and they are available with a variety of mechanical seal options (including API 682 seals).

Pre-packaged units

Our SPS pumps are available in gas, electric or dieselpowered models and can handle up to 2,500 gpm

(85,000 BFPD) and discharge pressures up to 6000 psi.

SPS systems are delivered to the job site pre-assem-

bled—only requiring suction ange, discharge ange

and power hookups. The Easily Modied SPS Frame

(EMF™) is pre-wired with instrumentation and cabling

terminated in a central junction box. This proprietary

frame, paired with the versatile design of our pumps,

allows for easy on-site installation and maintenance

with minimal site preparation.

The modular design makes SPS units suitable for a wide

variety of applications, from routine water injection to

mine dewatering and leaching operations. The GE SPS

pump is very reliable, highly-ecient and easily modied in the eld, saving you maintenance time.

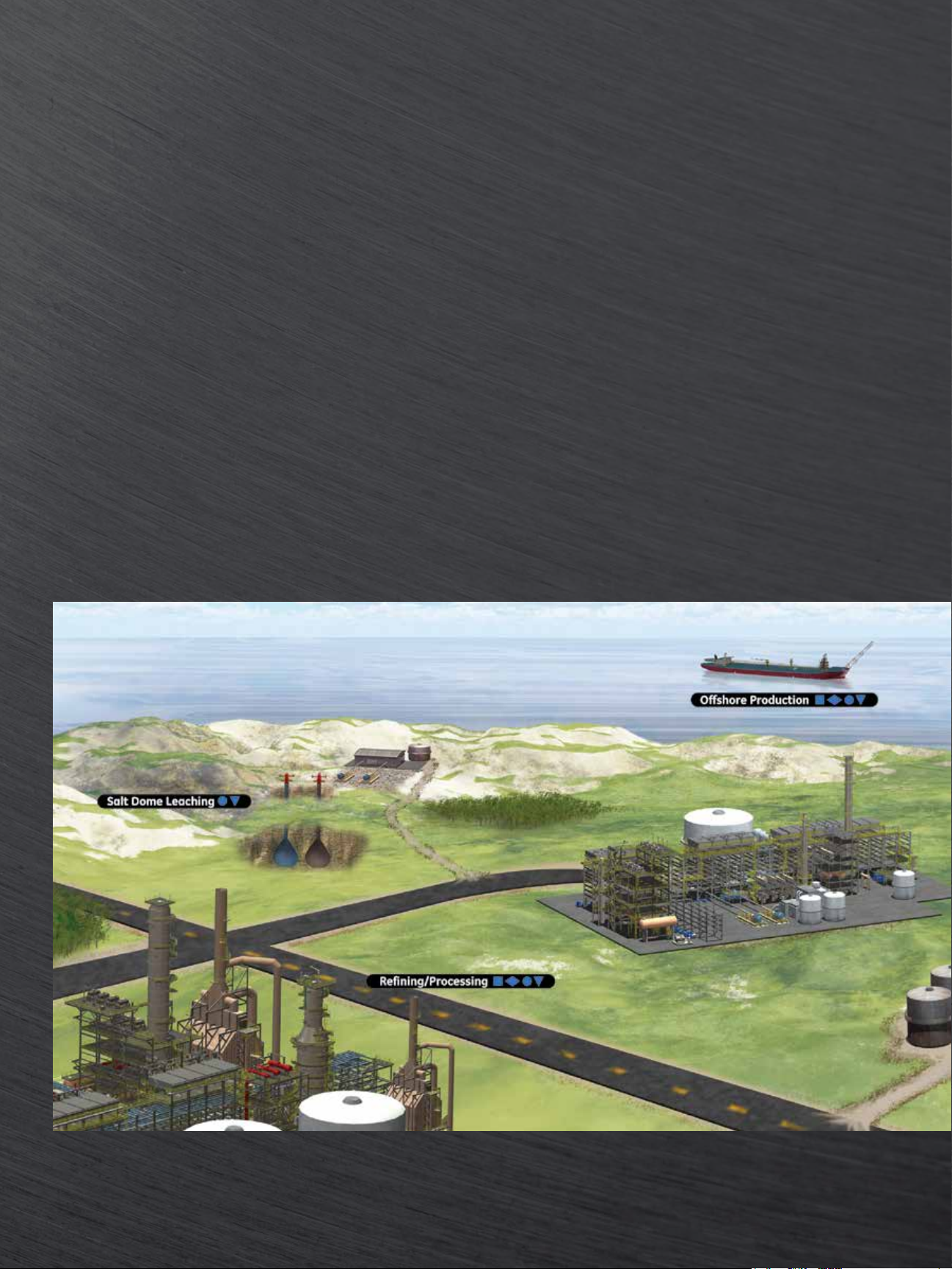

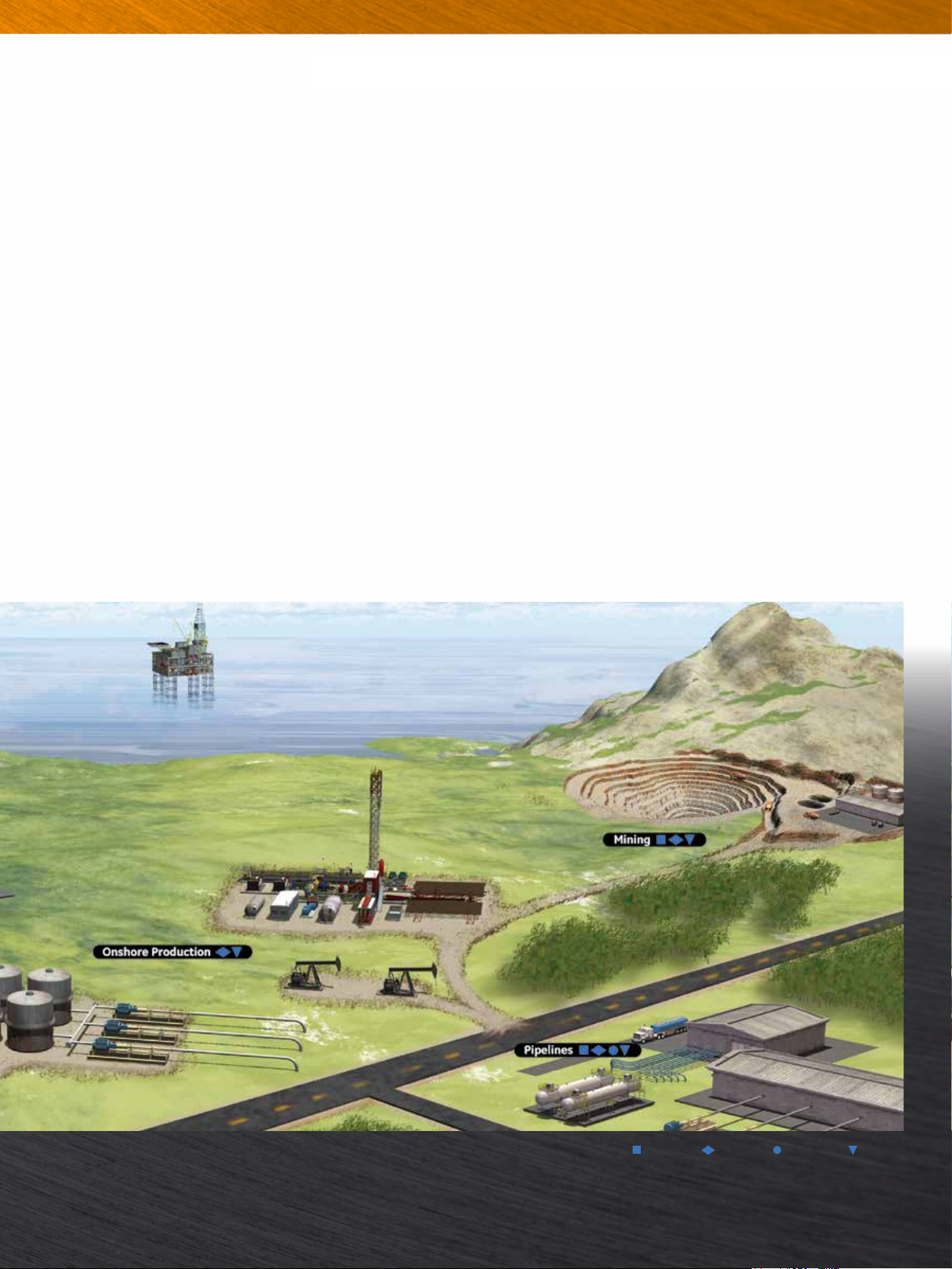

SPS APPLICATIONS: BOOSTER TRANSFER CIRCULATION INJECTION

GE’s Surface Pumping Systems (SPS)

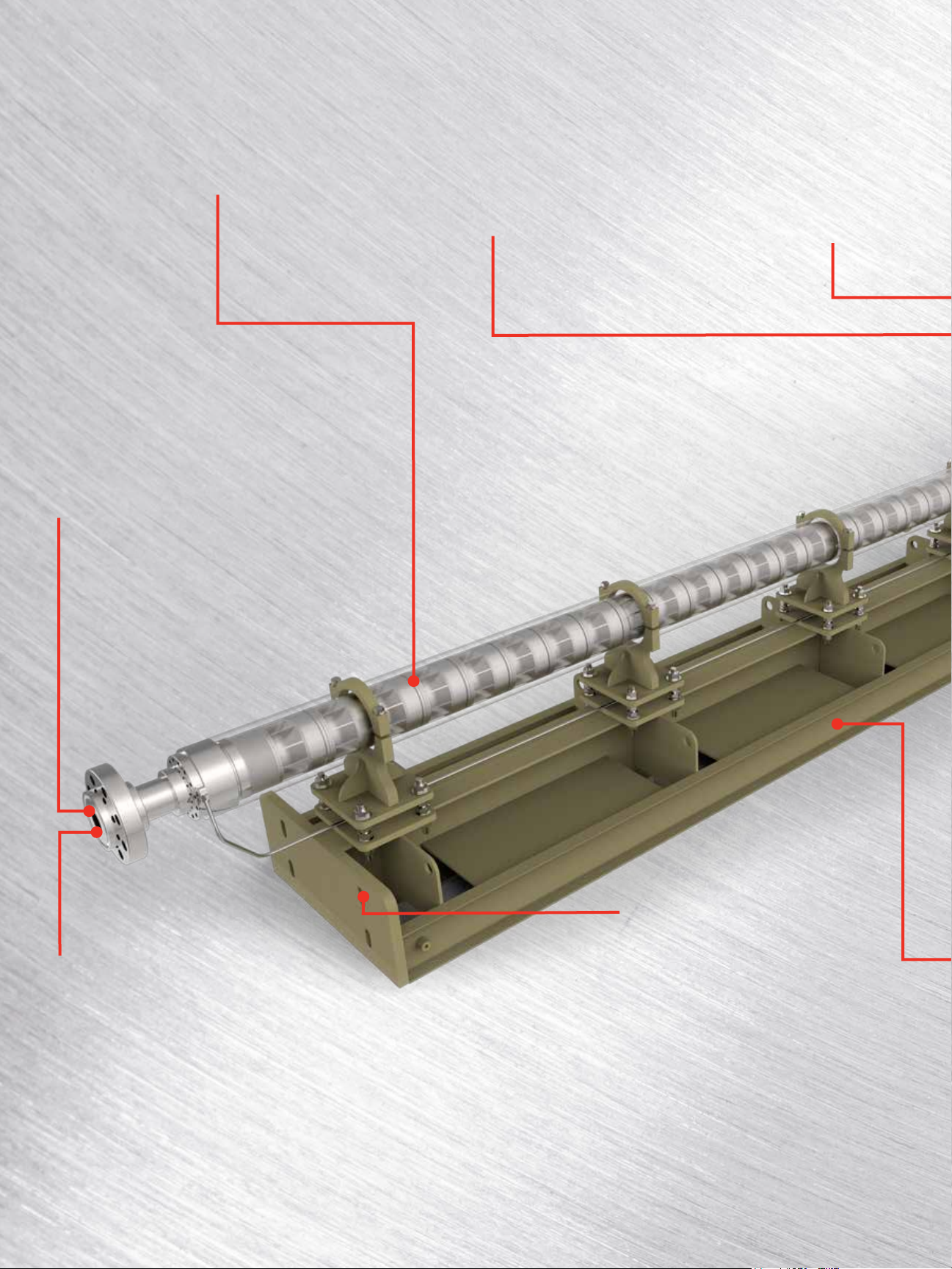

Pump

Multi-stage centrifugal pump with industry-leading,

high-eciency designs. The pump is supplied as an

easily replaceable module. Additional pump elements

can be added or “re-staged,” if required for changing

duty conditions. Most pumps are “mixed ow” design

for enhanced abrasion resistance, improved gas han-

dling and higher eciency.

Pipe-work Height

The xed pipe-work height minimizes pipe-work changes in the event of possible system recongurations.

Should the pump or motor require changing for any

reason; the pump, bearing frame, suction, discharge

and motor shaft are maintained at the same level.

Mechanical Seal

All units feature an optimized mechanical seal and stub

shaft with silicon carbide faces that operates at suction

pressure. Seals are available up to 3000 PSI. Options

include API-682 cartridge type, as well as API ush and

quench plans. The patented Front Pull-Out™ design

allows for rapid change-out of the seal and/or stub

shaft without disturbing the bearing frame and exible motor coupling, thus avoiding realignment or the

spacer coupling requirement.

Thrust Chamber

The bearing-frame thrust chamber is an easilyinterchangeable module that is compatible with other

SPS units regardless of the pump size. It features a

low number of rotating parts for long, trouble-free life,

requires minimal maintenance, optimizes oil dispersion

and reduces operating temperatures using an oil-ring

lubrication system, and includes a thermocouple to

provide temperature monitoring and shut-down protection. Labyrinth shaft seals protect the internals from

the environment without wearing the shaft surface.

Discharge Head

Standard anges are ANSI-B16.5 class 300 through

2,500, lap joint type to allow for alignment with

pipe work. Other connections/ ange standards

are available.

4

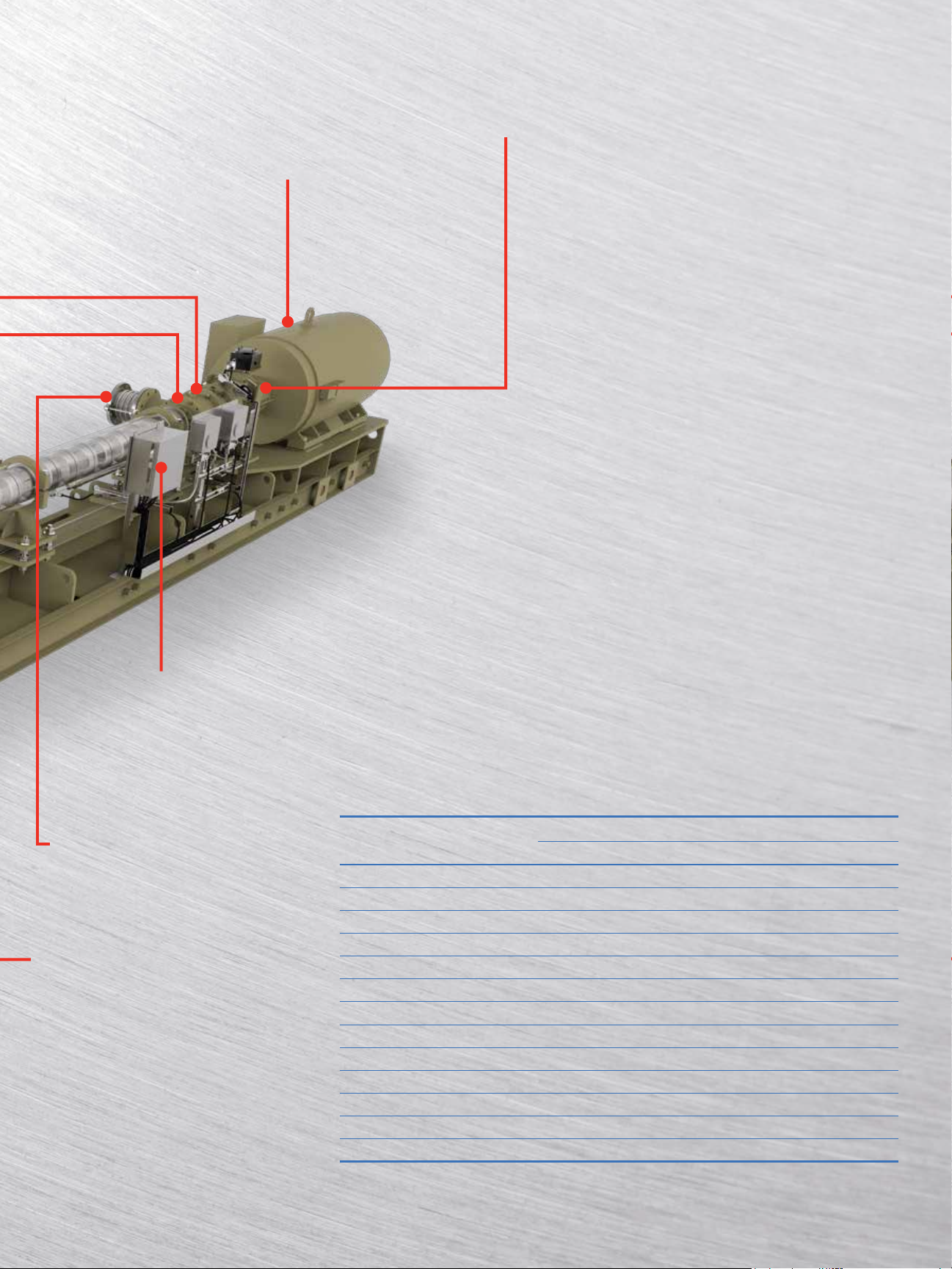

Frame Extensions

The EMF Frame can easily accommodate changing

duty conditions or the re-deployment of an existing

SPS unit for an entirely dierent application. Additionally, where limited site access (i.e., underground mines)

exists, multiple component skids can be provided to

facilitate portability and assembly.

Motor/Prime Mover

An industry standard 2-pole NEMA and IEC footmounted electric motor is used in congurations to

suit local requirements for enclosure type, voltage,

frequency, insulation class, hazardous area, etc.

Other drive options include gas or diesel engine via a

speed increaser.

Instrumentation/Control

Package

The standard SPS instrumentation package includes

suction and discharge pressure gauges and control

switches, a vibration switch and bearing frame thermocouple. Other instrumentation and control options

are available.

Flexible Coupling

A standard grid-style coupling provides for long life and

minimizes maintenance requirements. Other coupling

types are available on request.

Pump Comparison

Benets

• Lower initial and whole-life cost

• Short construction lead-times

• Increased reliability and runtime

• Low noise and vibration levels

• Easy installation

• Remote monitoring and

diagnostic capability

• Worldwide support

Applications

• Borehole mining

• CO2 injection/booster

• CO2 sequestration

• Condensate transfer

• Crude oil boosting/transfer

• Dust suppression

• Geothermal

• Hydraulic power uid boosting

• Jet pumping

• Lean amine circulation

• Mine dewatering

• NGL boosting/transfer

• Oshore facilities uid handling

• Pipeline boosting

• Process uids transfer

• Produced water disposal/injection

• Salt dome leaching

• Seawater disposal/waterooding

• Wash water circulation

• Water transfer

Suction Chamber

This chamber can be rotated in 45° increments. Stan-

dard anges are ANSI-B16.5 class 150 through 2500.

Other connections/ange standards are available.

EMF™ Frame*

The patented Easily Modied Frame™ features a rigid

base frame for low vibration and ease of installation.

It incorporates integral lifting lugs throughout and or

machined motor adapter plate (shown in green), which

together with the frame motor plate are predrilled for

virtually all available motor options.

*A model FM1000 EMF frame is shown. Other models

include FM75, FM150, FM1500 and FM3000.

Issue

SPS PD OH6

Pump Type

Capital cost Low Low Moderate

Whole-life cost Low High High

Up time High % Low % Moderate %

Down time Low % High % High %

Daily/weekly maintenance No Yes No

Downtime per repair Low Moderate Moderate

Cost of repair Low Moderate High

Noise level Low High High

Vibration Low High Low

Pulsation Nil High Nil

Seal (qty) Mechanical (1) Packing (3 or 5) Mechanical (1)

Environmental leakage Virtually Nil High Virtually Nil

Flow/pressure exibility High Moderate Low

PD = positive displacement reciprocating pump

OH6 = API 610 type OH6 High-speed integral gear-driven vertical single-stage overhung pump

5

Crude Oil Transfer (North America)

Waterood (North America)CO2 injection (North America) Water injection

6

Loading...

Loading...