Page 1

g

t

GE Power Managemen

SPM

SYNCHRONOUS MOTOR PROTECTION

AND CONTROL

Instruction Manual

Software Revision: 210.000

Manual P/N: 1601-0072-A6

Copyright © 2001 GE Power Management

GE Power Management

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 294-8512

Internet: http://www.GEindustrial.com/pm

Manufactured under an

ISO9001 Registered system.

Page 2

Page 3

These instructions do not purpor t to cover all detai ls or varia tions in equipment nor provide fo r every p ossibl

e

e

e

t

contingency to be met in connection with installation, operation, or maintenance. Should further information b

desired or should pa rticula r pro blems arise whi ch are no t cove red su ffici ently for the p urchas er’s purpose, th

matter should be referred to the General Electric Company.

To the extent required the products des cribed herein meet applic able ANSI, IEE E, and NEMA s tandards; bu

no such assurance is given with respect to local codes and ordinances because they vary greatly.

Page 4

Page 5

TABLE OF CONTENTS

1. INTRODUCTION

2. INSTALLATION

1.1 OVERVIEW

1.1.1 GENERAL DESCRIPTION........................................................................1-1

1.1.2 FUNCTIONAL OVERVIEW........................................................................1-1

1.2 ORDERING

1.2.1 ORDER CODES........................................................................................1-3

1.2.2 ACCESSORIES.........................................................................................1-3

1.3 SPECIFICATIONS

1.3.1 SPM SPECIFICATIONS............................................................................ 1-4

2.1 OVERVIEW

2.1.1 DESCRIPTION..........................................................................................2-1

2.1.2 ELEMENTS OF A SYNCHRONOUS MOTOR CONTROLLER................. 2-1

2.2 MECHANICAL INSTALLATION

2.2.1 UNPACKING THE SPM.............................................................................2-2

2.2.2 REMOVING THE DRAWOUT RELAY....................................................... 2-2

2.2.3 INSERTING THE DRAWOUT RELAY....................................................... 2-2

2.2.4 MOUNTING THE SPM.............................................................................. 2-2

2.2.5 SPM MOUNTING ACCESSORIES............................................................2-2

2.3 ELECTRICAL INSTALLATION

2.3.1 DESCRIPTION..........................................................................................2-4

2.3.2 GROUNDING.............................................................................................2-6

2.3.3 FIELD AND EXCITER VOLTAGE INPUTS ...............................................2-6

2.3.4 RELAY OUTPUTS ..................................................................................... 2-6

2.3.5 CURRENT TRANSFORMER INPUT.................................... .....................2-6

2.3.6 POWER FACTOR OUTPUT......................................................................2-6

2.3.7 DC FIELD CURRENT INPUT....................................................................2-6

2.3.8 EXCITER VOLTAGE OUTPUT MONITOR................................................ 2-6

2.3.9 POWER FACTOR REGULATION OUTPUT ............................................. 2-7

2.3.10 CONTROL VOLTAGE.............. ..................... ..................... ....................... 2-7

2.3.11 EXTERNAL VOLTAGE PF REFERENCE............... ..................................2-7

2.3.12 RS485 COMMUNICATIONS PORT ..........................................................2-8

3. SYNCHRONOUS MOTOR

APPLICATIONS

3.1 OVERVIEW

3.1.1 GENERAL..................................................................................................3-1

3.2 COLLECTOR-RING MOTORS

3.2.1 STARTING AND SYNCHRONIZING......................................................... 3-5

3.2.2 RELUCTANCE TORQUE SYNCHRONIZING........................................... 3-6

3.2.3 STARTING PROTECTION...................................... ..................... .............3-7

3.2.4 REDUCED VOLTAGE STARTING............................................................3-8

3.2.5 POWER FACTOR (PULL-OUT) PROTECTION...................................... 3-10

3.2.6 POWER FACTOR OPERATION.............................................................3-11

3.2.7 CONTROLLER ACTION DURING PULL-OUT........................................3-12

a RESYNC MODE......................................... ..................... ........................3-12

b RIDE-THRU MODE .................................................................................3-12

3.2.8 EFFECT OF VOLTAGE DIPS ON MOTOR POWER FACTOR .............. 3-13

3.2.9 POWER FACTOR DETECTION & INDICATION – OVERHAULING LOAD 3-

15

3.2.10 POWER FACTOR REGULATION........................................................... 3-16

3.3 BRUSHLESS CONTROLLER

3.3.1 DESCRIPTION........................................................................................3-17

GE Power Management SPM Synchronous Motor Protection & Control

i

Page 6

TABLE OF CONTENTS

3.3.2 BRUSHLESS MOTOR REVIEW..............................................................3-17

3.3.3 STARTING THE BRUSHLESS MOTOR............... ..................... .............3-18

3.3.4 STALL PROTECTION ............................................................................. 3-19

3.3.5 POWER FACTOR (PULL-OUT) PROTECTION...................................... 3-19

3.3.6 POWER FACTOR REGULATION...........................................................3-19

4. USER INTERFACE

5. SETPOINTS

4.1 SPMPC SOFTWARE

4.1.1 DESCRIPTION ..........................................................................................4-1

4.1.2 SPMPC INSTALLATION........ .................................................................... 4-2

4.1.3 CONFIGURATION.................................................................................. ... 4-3

4.1.4 CREATING A NEW SETPOINT FILE ........................................................ 4-4

4.1.5 EDITING A SETPOINT FILE .....................................................................4-5

4.1.6 LOADING SETPOINTS FROM A FILE.................. ..................... ...............4-6

4.1.7 UPGRADING SETPOINT FILES TO A NEW REVISION.......................... 4-7

4.1.8 PRINTING SETPOINTS & ACTUAL VALUES........................................... 4-8

4.1.9 TRENDING................................................................................................ 4-9

4.2 KEYPAD INTERFACE

4.2.1 DESCRIPTION ........................................................................................4-10

4.2.2 CHANGING SETPOINTS ........................................................................ 4-11

4.2.3 CHANGING CALIBRATION VALUES............ .........................................4-12

4.2.4 CHANGING CONFIGURATIONS............................................................4-13

4.2.5 VIEWING & CHANGING STATUS MODE PARAMETERS.....................4-14

4.2.6 ALTERNATE MENU OPERATION ..........................................................4-14

5.1 OVERVIEW

5.1.1 DESCRIPTION ..........................................................................................5-1

5.2 SETPOINTS MENU

5.2.1 POWER FACTOR TRIP............................................................................ 5-2

5.2.2 POWER FACTOR DELAY......................................................................... 5-2

5.2.3 POWER FACTOR SUPRESSION.............................................................5-2

5.2.4 POWER FACTOR MODE..........................................................................5-3

5.2.5 FIELD APPLICATION RELAY DELAY ............... .......................................5-3

5.2.6 FIELD CONTACTOR AUXILIARY RELAY DELAY.................................... 5-3

5.2.7 AC CT PRIMARY RATING........................................................................5-4

5.2.8 MOTOR FULL LOAD AMPS......................................................................5-4

5.2.9 MOTOR LOCKED ROTOR AMPS.............................................................5-4

5.2.10 SYNCHRONOUS SLIP.............. ................................................................5-5

5.2.11 STALL TIME .................. ..................... .......................................................5-5

5.2.12 RUN TIME..................................................................................................5-5

5.2.13 DIRECT CURRENT CT PRIMARY RATING .............................................5-6

5.2.14 FIELD OVERTEMPERATURE (HIGH FIELD OHMS) PROTECTION.......5-7

5.2.15 FIELD UNDERCURRENT ....................................... .................................. 5-8

5.2.16 FIELD UNDERCURRENT DELAY................................................ .............5-8

5.2.17 FIELD UNDERVOLTAGE .......................................................................... 5-8

5.2.18 FIELD UNDERVOLTAGE DELAY................ ........................................ ..... 5-9

5.2.19 INCOMPLETE SEQUENCE DELAY..........................................................5-9

5.3 OPTIONAL POWER FACTOR REGULATION SETPOINTS

5.3.1 DESCRIPTION ........................................................................................5-10

5.3.2 POWER FACTOR REGULATOR............................................................5-10

5.3.3 REGULATOR GAIN................................................................................. 5-10

5.3.4 STABILITY............................................................................................... 5-10

5.3.5 REGULATOR OUTPUT LIMIT.................................................................5-11

ii

SPM Synchronous Motor Protection & Control

GE Power Management

Page 7

TABLE OF CONTENTS

5.3.6 FLOOR VOLTS........................................................................................ 5-11

5.4 CONFIGURATIONS MENU

5.4.1 MOTOR TYPE.......................................... ............................................... 5-12

5.4.2 LINE FREQUENCY .................................... .............................................5-12

5.4.3 POWER FACTOR REFERENCE............................................................ 5-12

5.4.4 RTU ADDRESS.................................... ............................................ ....... 5-12

5.4.5 BAUD RATE ................ ..................... ..................... ..................... ............. 5-12

5.4.6 PARITY........... ..................... .................................................................... 5-12

5.4.7 TURNAROUND ........................ ...............................................................5-13

5.4.8 STATUS MODE....................................................... ..................... ........... 5-13

5.4.9 PASSWORD......................................................................................... ...5-13

5.5 CALIBRATION MENU

5.5.1 FULL-SCALE EXCITER DC VOLTAGE ..................................................5-14

5.5.2 FULL-SCALE EXCITER DC AMPS .........................................................5-14

5.5.3 FULL-SCALE MOTOR AC AMPS............................................................5-14

6. ACTUAL VALUES

7. TESTING AND

TROUBLESHOOTING

6.1 DISPLAY SCROLLING

6.1.1 DESCRIPTION..........................................................................................6-1

6.2 STATUS

6.2.1 MOTOR RUNNING HOURS...................................................................... 6-2

6.2.2 INCOMPLETE SEQUENCE TRIP COUNTER .......................................... 6-2

6.2.3 FIELD LOSS TRIP COUNTER .................................................................. 6-2

6.2.4 PULL-OUT TRIP COUNTER..................................................................... 6-2

6.2.5 RESYNCRONIZATION ATTEMPTS TRIP COUNTER.............................. 6-2

6.2.6 MISSING EXTERNAL PF VOLTAGE REFERENCE COUNTER.............. 6-2

6.2.7 CHECK EXCITER TRIP COUNTER.......................................................... 6-3

6.2.8 POWER FACTOR TRIP COUNTER.......................................................... 6-3

6.2.9 SQUIRREL CAGE TRIP COUNTER......................................................... 6-3

6.2.10 FIELD OVERVOLTAGE TRIP COUNTER................................................. 6-3

7.1 START-UP PROCEDURE

7.1.1 INSPECTION.............................................................................................7-1

7.1.2 SPM TEST CHECKS...... ............. .............. .. ............. ............. .. .............. .... 7- 1

a STANDBY MODE ...................................................................................... 7-1

b TEST MODE..............................................................................................7-1

7.1.3 START-UP DESCRIPTION....................................................................... 7-2

7.2 DISPLAY AND MESSAGES

7.2.1 DISPLAY.................................................................................................... 7-3

7.2.2 SPM MESSAGES...................................................................................... 7-3

7.3 REGULATOR TUNE-UP

7.3.1 INSTRUCTIONS........................................................................................ 7-5

7.4 TROUBLESHOOTING

7.4.1 TROUBLESHOOTING GUIDE....................................................... ........... 7-6

7.5 PROGRAMMING

7.5.1 PROGRAMMING EXAMPLE..................................................................... 7-8

7.6 DOs AND DON’Ts

7.6.1 DOs.......................................................................................................... 7-12

7.6.2 DON'Ts.................................................................................................... 7-12

GE Power Management SPM Synchronous Motor Protection & Control

iii

Page 8

TABLE OF CONTENTS

7.7 FREQUENTLY ASKED QUESTIONS

7.7.1 SPM FAQ.................................................................................................7-13

7.8 REVISION HISTORY

7.8.1 FIRMWARE .............................................................................................7-15

7.8.2 SUMMARY...............................................................................................7-16

8. ACCESSORIES

9. MODBUS

COMMUNICATIONS

10. FUNCTIONAL TESTS

8.1 VOLTAGE DIVIDER NETWORK

8.1.1 GE POWER MANAGEMENT VDN............................................................ 8-1

8.1.2 GE MEBANE VDN.....................................................................................8-2

8.2 FIELD CURRENT CALIBRATION MODULE

8.2.1 GE POWER MANAGEMENT MODULE....................................................8-3

8.3 DC CURRENT TRANSFORMER

8.3.1 DESCRIPTION ..........................................................................................8-5

9.1 IMPLEMENTATION

9.1.1 MODBUS PROTOCOL.............................................................................. 9-1

9.1.2 PERFORMANCE REQUIREMENTS......................................................... 9-1

9.1.3 SETPOINTS............................................................................................... 9-1

9.1.4 EXECUTE OPERATION COMMAND CODES (COIL NUMBERS) ...........9-1

9.2 MEMORY MAPPING

9.2.1 MODBUS MEMORY MAP ......................................................................... 9-2

9.2.2 FORMAT CODES......................................................................................9-7

10.1 INTRODUCTION

10.1.1 DESCRIPTION ........................................................................................10-1

10.2 COLLECTOR-RING MOTOR FIELD APPLICATION TEST

10.2.1 SETUP..................................................................................................... 10-2

10.2.2 RELAY PROGRAMMING........................................................................10-2

a CONFIGURATIONS ................................................................................ 10-2

b SETPOINTS............................................................................................. 10-2

10.2.3 TEST ........................................................................................................ 10-2

10.3 COLLECTOR-RING MOTOR POWER FACTOR TEST

10.3.1 SETUP..................................................................................................... 10-3

10.3.2 RELAY PROGRAMMING........................................................................10-3

a CONFIGURATIONS ................................................................................ 10-3

b SETPOINTS............................................................................................. 10-3

10.3.3 TEST ........................................................................................................ 10-3

10.4 COLLECTOR-RING MOTOR POWER FACTOR TRIP TEST

10.4.1 SETUP..................................................................................................... 10-4

10.4.2 RELAY PROGRAMMING........................................................................10-4

a CONFIGURATIONS ................................................................................ 10-4

b SETPOINTS............................................................................................. 10-4

10.4.3 TEST ........................................................................................................ 10-4

10.5 BRUSHLESS MOTOR FIELD APPLICATION TEST

10.5.1 SETUP..................................................................................................... 10-5

10.5.2 RELAY PROGRAMMING........................................................................10-5

a CONFIGURATIONS ................................................................................ 10-5

b SETPOINTS............................................................................................. 10-5

iv

SPM Synchronous Motor Protection & Control

GE Power Management

Page 9

TABLE OF CONTENTS

10.5.3 TEST........................................................................................................ 10-5

10.6 BRUSHLESS MOTOR POWER FACTOR TEST

10.6.1 SETUP..................................................................................................... 10-6

10.6.2 RELAY PROGRAMMING........................................................................10-6

a CONFIGURATIONS ................................................................................ 10-6

b SETPOINTS............................................................................................. 10-6

10.6.3 TEST........................................................................................................ 10-6

10.7 BRUSHLESS MOTOR POWER FACTOR TRIP TEST

10.7.1 SETUP..................................................................................................... 10-7

10.7.2 RELAY PROGRAMMING........................................................................10-7

a CONFIGURATIONS ................................................................................ 10-7

b SETPOINTS............................................................................................. 10-7

10.7.3 TEST........................................................................................................ 10-7

10.8 AC CURRENT METERING AND PULL-OUT TEST

10.8.1 SETUP..................................................................................................... 10-8

10.8.2 RELAY PROGRAMMING........................................................................10-8

a CONFIGURATIONS ................................................................................ 10-8

b SETPOINTS............................................................................................. 10-8

10.8.3 TEST........................................................................................................ 10-8

10.9 EXCITER / FIELD VOLTAGE METERING TEST

10.9.1 SETUP..................................................................................................... 10-9

10.9.2 RELAY PROGRAMMING........................................................................10-9

a CONFIGURATIONS ................................................................................ 10-9

b SETPOINTS............................................................................................. 10-9

10.9.3 TEST........................................................................................................ 10-9

10.10 EXCITER / FIELD CURRENT METERING TEST

10.10.1 SETUP................................................................................................... 10-10

10.10.2 RELAY PROGRAMMING...................................................................... 10-10

a CONFIGURATIONS .............................................................................. 10-10

b SETPOINTS........................................................................................... 10-10

10.10.3 TEST...................................................................................................... 10-10

A. COMMISSIONING

B. FIGURES AND TABLES

C. WARRANTY

A.1 COMMISSIONING

A.1.1 COLLECTOR-RING SETTINGS..................................................... ...........A-1

A.1.2 BRUSHLESS SETTINGS..........................................................................A-2

B.1 FIGURES AND TABLES

B.1.1 LIST OF FIGURES................................. ..................... ..............................B-1

B.1.2 LIST OF TABLES.......................................................................................B-2

C.1 WARRANTY

C.1.1 WARRANTY..............................................................................................C-1

GE Power Management SPM Synchronous Motor Protection & Control

v

Page 10

TABLE OF CONTENTS

vi

SPM Synchronous Motor Protection & Control

GE Power Management

Page 11

1 INTRODUCTION 1.1 OVERVIEW

1 INTRODUCTION 1.1 OVERVIEW 1.1.1 GENERAL DESCRIPTION

The SPM controls starting, synchronizing, and protection of collector-ring and brushless type synchronous

motors.

The SPM control funct ion s for s tar tin g sy nc hronous motors include ac cu ra te se ns in g of mot or spe ed an d ro tor

angle, allowing the unit to apply excitation at optimum speed and angle. This per mits closer matching of the

motor to the load. Optim um application of excitation al so reduces power system dist urbance, which occurs

when the motor goes through a comple te slip cycle with the field energized. In addition, the SPM can take

advantage of the extended stall time of a r educe d volta ge star t. It also res ponds with the proper applica tio n of

excitation in the event that the motor synchronizes on reluctance torque.

The SPM provides the functions necessary to protect the motor durin g startup and in the event of async hronous operation. D uring startup and r estarting, the S PM prevents over heating of the c age winding. To protect

against asynchronous operation, the motor power factor is monitored. Two modes of pull-out protection can trip

the motor if resynchroniz ation does no t occur a fter a programm ed time del ay. Motor run time and the number

and type of trips are recorded.

The SPM has an optional power factor regulator containing five adjustable setpoints that can be changed while

the motor is running for convenient regulator tune-up.

A backlit LCD dis play and keys allow user conf igurable setting ranges to meet many applications. The unit

comes in a compact S1 drawout case.

The SPM can be ap plied as part of a co mplete synchronous motor co ntroller. This consists of four parts. A

main device switche s the motor on and off the power system. Multifunction digital relays (such as the GE

Power Management 46 9 Motor Manageme nt Relay) provide stator protec tion. DC field p rotection and c ontrol

are provided by the SPM. The field contactor and field discharge resistor completes the control assembly.

1

1.1.2 FUNCTIONAL OVERVIEW

The DC portion of the s ync hronous motor (rotor assembl y) is prote cted and c ontro lled u sing a d rawout micr oprocessor based mul tifunction re lay. The relay is adaptable to either col lector-ring or b rushless ty pe synchronous motors. Protection features inc l ude all of the followi ng :

• Cage winding and stall protection during start

• Lockout feature to protect a hot rotor after an incomplete start

• Incomplete sequence trip due to failed acceleration

• Automatic acceleration time adjustment for reduced voltage starting

• Power factor (pull-out) trip with auto resynchronizing feature

• Loss of DC field current trip

• Loss of DC field voltage trip

• Field winding overtemperature trip

After a successful sta rt, the relay automatically applies the DC field to the rotor at a prescribed slip an d slip

angle to minimize mec hanical stresses to the shaft as well as minimiz es possible electrical t ransients to the

power system. This is achieved by a dedicated output to close the DC field contactor. The relay is also capable

of reluctance torque synchronizing (collector-ring machines only).

A dedicated output is prov ide d in the relay to enab le th e loa din g of the motor followi ng the DC fiel d app li ca tio n

and unloading of the motor following a trip and/or loss of synchronization (pole slipping).

Control of an SCR type exc itation syste m by me ans of a n analog output to maintain po wer fact or (PF re gulation) is available as an option.

GE Power Management SPM Synchronous Motor Protection & Control 1-

1

Page 12

1.1 OVERVIEW 1 INTRODUCTION

The man-machine in terface (MMI) cons ists of a backlit alpha numeric displa y and a keypad to ac commodate

relay programming as well as viewing actual motor parameters which comprise:

1

• AC stator current

• Power fa ctor

• DC field current

• DC field voltage

• DC field resistance

• Running time meter (RTM)

Statistical data includes number and type of trips.

The SPM performs a complete system check prior to starting the motor.

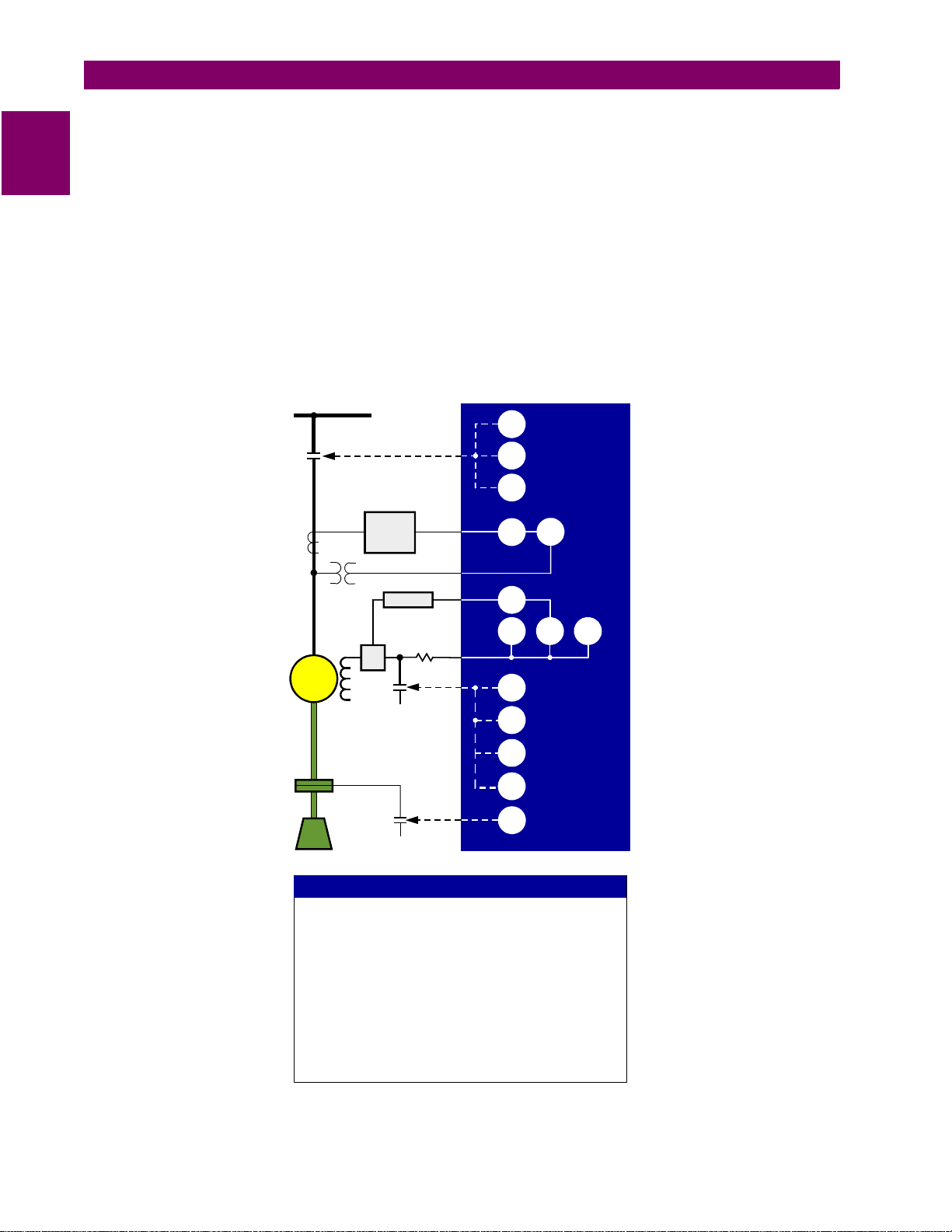

AC BUS

48

SPM

86

94

MOTOR

LOAD

CLUTCH

COUPLING

Stator

Protection

(469)

Calibrator

DC

CT

DC SUPPLY

I

AC

V

AC

I

DC

V

DC

ANSI DEVICE NUMBERS

Field overtemperature

26F

Undervoltage

27

Undercurrent or underpower

37

Incomplete sequence

48

Instantaneous overcurrent

50

Power factor

55

Field application

56

Lock out

86

Tripping

94

Reluctance torque sync. / resync.

95

Autoloading relay

96

55

50

37

27 26F 95

48

94

95

56

96

701767A9.CDR

1-

Figure 1–1: SINGLE LINE DIAGRAM

2

SPM Synchronous Motor Protection & Control GE Power Management

Page 13

1 INTRODUCTION 1.2 ORDERING

1.2 ORDERING 1.2.1 ORDER CODES

The SPM has all features built into the standard relay and programmable by the user to fit the specific application. The only option in the order code is for Power Facto r Regulation. Som e of the standard featu res require

an optional external hard ware package that must be ordered in addition to the relay it self. These separate

packages are explained in the foll owi ng se cti on.

Base Unit

Configuration

SPM

SPM |

Standard starting and protection relay with VDN board

Power Factor regulation option. Used on motors with SCR exciter

PF

(not recommended for brushless applications)

1.2.2 ACCESSORIES

PG2SPM

: External hardware package for overtemperature and current loss protection up to 200 A

(includes 1-DCCT200 & 1-CM)

PG4SPM

: External hardware package for overtemperature and current loss protection up to 400 A

(includes 1-DCCT400 or DCCT500 and 1-CM)

MPSPM

: Mounting panel to retrofit existing µSPM cutouts for SPM

1

GE Power Management SPM Synchronous Motor Protection & Control 1-

3

Page 14

1.3 SPECIFICATIONS 1 INTRODUCTION

1.3 SPECIFICATIONS 1.3.1 SPM SPECIFICATIONS

1

PHASE CURRENT INPUTS

CT Primary: 5 to 2000 A

CT Secondary: 5 A

Conversion Range: 0.05 to 6 × CT

Frequency: 50 / 60 Hz

Accuracy: at < 2 × CT: ±0.5% of 2 × CT true RMS

≥ 2 ×

at

CT: ±1% of 6 × CT true RMS

FIELD CURRENT INPUTS

CT Primary: 5 to 1000 A

Conversion Range: 0.05 to 1 × CT

Accuracy: ±2%

EXCITER VOLTAGE INPUTS

Conversion: 0 to 350 V DC (prior to VDN)

Accuracy: ±1%

POWER FACTOR

Range: 0.01 to 1 to –0.01

Time Delay: 0.1 to 10 seconds

Accuracy: ±5%

SWITCH INPUTS (MX & NX)

Type : Dr y c ont a c t

Internal Interrogation Voltage: 85 to 265 V AC (control voltage)

PF ANALOG OUTPUT

Ty pe : Ac ti ve

Output: 0 to 10 V DC max. at R

Accuracy: ±10% (0.1 V)

Isolation: 36 V pk

≥ 1 KΩ (min. load)

L

CONTROL VOLTAGE

Input: 85 to 265 V AC at 48 to 60 Hz

Power: 10 VA nominal

Holdup: 100 ms typical at 120 V AC

RELAY CONTACT

Type : FA R , T RP Form A

FCX Form C

Rated Load: 10 A AC continuous NEMA A300

1 A DC continuous NEMA R300

Break: 10 A at 250 V AC or 30 V DC

Max. Operating Voltage: 250 V AC

ENVIRONMENT

Humidity: 0 to 95% non-condensing

Operating Temp.: –20°C to +70°C

Storage Temp.: –40°C to +85°C

TYPE TESTS

Dielectric Strength: Per IEC 255-5 and ANSI/IEEE C37.90

2.0 kV for 1 min. from relays, CTs, VTs

power supply to Safety Ground

Insulation

Resistance: IEC255-5 500 VDC, from relays, CTs, VTs

power supply to Safety Ground

Transients: ANSI C37.90.1 Oscillography (2.5kV/1MHz)

ANSI C37.90.1 Fast Rise (5kV/10ns)

Ontario Hydro A-28M-82

IEC255-4 Impulse/High Frequency Disturbance,

Class III Level

Impulse Test: IEC 255-5 0.5J 5kV

EMI: C37.90.2 Electromagnetic Interference at

150 MHz and 450 MHz, 10V/m

Static: IEC801-2 Static Discharge

Vibration: Sinusoidal Vibration 8.0g for 72 hrs.

CERTIFICATION

UL: UL listed

CSA: CSA approved

PHYSICAL

Shipping Box: 12.50" × 10.50" × 9.75" (L × H × D)

318 mm × 267 mm × 248 mm (L × H × D)

Ship Weight: 14.25 lb. / 6.45 kg

1-

Specifications subject to change without notice

4

SPM Synchronous Motor Protection & Control GE Power Management

Page 15

2 INSTALLATION 2.1 OVERVIEW

2 INSTALLATION 2.1 OVERVIEW 2.1.1 DESCRIPTION

The SPM can be incorporate d in synch ronous mot or control equ ipment as a co mplete cont roller (incl uding an

AC power-switching devi ce for the motor starter) or as a field pane l (AC power switching supplied by ot her

device).

2.1.2 ELEMENTS OF A SYNCHRONOUS MOTOR CONTROLLER

A complete synchronou s-m otor contr oller has the ability to s witch the motor on to and off of the power system

and protect the motor from damage that can occur if the motor is running in an abnormal condition such as outof-synchronization.

A complete synchronou s-motor cont roller consist s of a motor starter and swi tching devic e (typically a contactor) which controls the ma in power to the motor. In addition, protectiv e relaying is pro vided for both the sta tor

and the rotor (such as a 469 /SPM com binati on). Con trols for starti ng and st opping the motor (start-s top pushbuttons) are also included. Indicating and metering de vic es such as li ne am met e rs are s upp li ed if no t in cl ude d

in the relays. All of these features are common with motor controllers of all types.

2

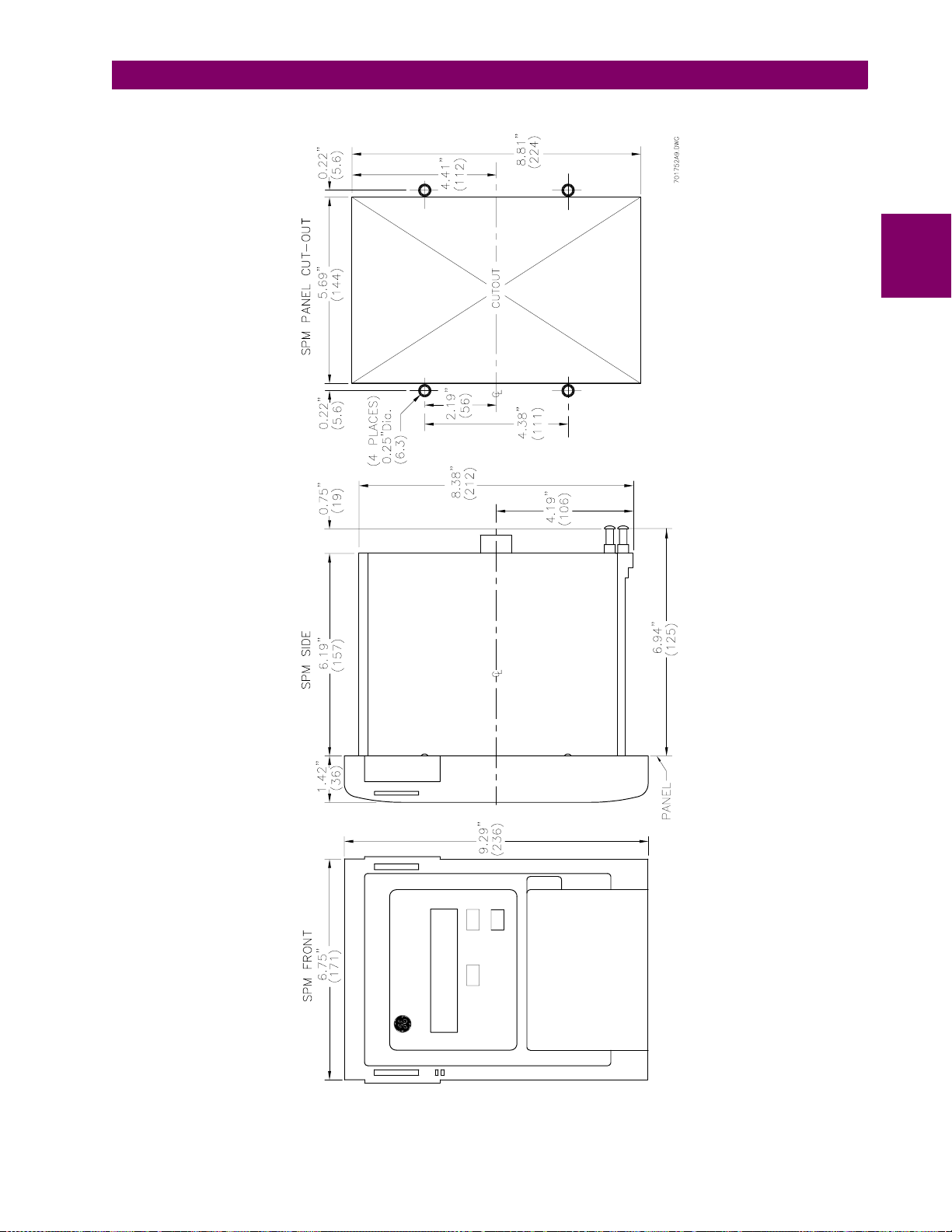

Figure 2–1: EXPLODED VIEW OF THE SPM

GE Power Management SPM Synchronous Motor Protection & Control 2-

1

Page 16

2.2 MECHANICAL INSTALLATION 2 INSTALLATION

2.2 MECHANICAL INSTALLATION 2.2.1 UNPACKING THE SPM

When the SPM is shipped separately, carefully unpack the module and report any observable damage or missing components to the c arrier and to GE Power Management. All inc luded parts are shown in Figure 2–1:

EXPLODED VIEW OF THE SPM on page 2–1.

2.2.2 REMOVING THE DRAWOUT RELAY

2

1. Remove the faceplate as sembl y care fully by pus hing i n on t he qui ck rel ease tab s on t he fro nt of th e SP M

and pulling the faceplate assembly forward. Once the faceplate has pivoted forward, gently lower the faceplate so that it clears the tabs on the bottom of the frame.

DO NOT let the faceplate assembly dangle from the connecting wires.

NOTE

2. Carefully disconnect the ribbon cable from the cradle assembly.

3. Remove the paddle and open the top and bottom lock ing tabs. The relay can n ow be removed from th e

case.

2.2.3 INSERTING THE DRAWOUT RELAY

1. Slide the relay into the case and close the top and bottom locking tabs.

2. Insert the paddle into the opening at the bottom of the relay.

3. Carefully re-connect the ribbon cable to the cradle assembly.

DO NOT shift or skew the ribbon connector.

NOTE

4. Re-mount the faceplate assembly to the case from the front panel. Slide the faceplate onto the tabs on the

bottom of the frame a nd then pivot it up into pos ition over the quick release tabs. The faceplate shoul d

gently snap into place.

2.2.4 MOUNTING THE SPM

Mounting the SPM requires careful attention to the following instructions.

DE-ENERGIZE ALL EXISTING EQUIPMENT BEFORE INSTALLING NEW EQUIPMENT.

CAUTION

1. Remove the relay from the case.

2. Prepare the mounting hole in the panel to dimensions shown in Figure 2–2: PHYSICAL DIMENSIONS.

3. Slide the case into the panel from the front.

4. Install the four mounting scr ews from the re ar of the pane l. The case is now secur ely mounte d and ready

for panel wiring.

2.2.5 SPM MOUNTING ACCESSORIES

See Chapter 8: ACCESSORIES for physical dimensions and mounting requirements.

2-

2

SPM Synchronous Motor Protection & Control GE Power Management

Page 17

2 INSTALLATION 2.2 MECHANICAL INSTALLATION

2

SPM Sync. Protection/Control

Figure 2–2: PHYSICAL DIMENSIONS

GE Power Management SPM Synchronous Motor Protection & Control 2-

3

Page 18

2.3 ELECTRICAL INSTALLATION 2 INSTALLATION

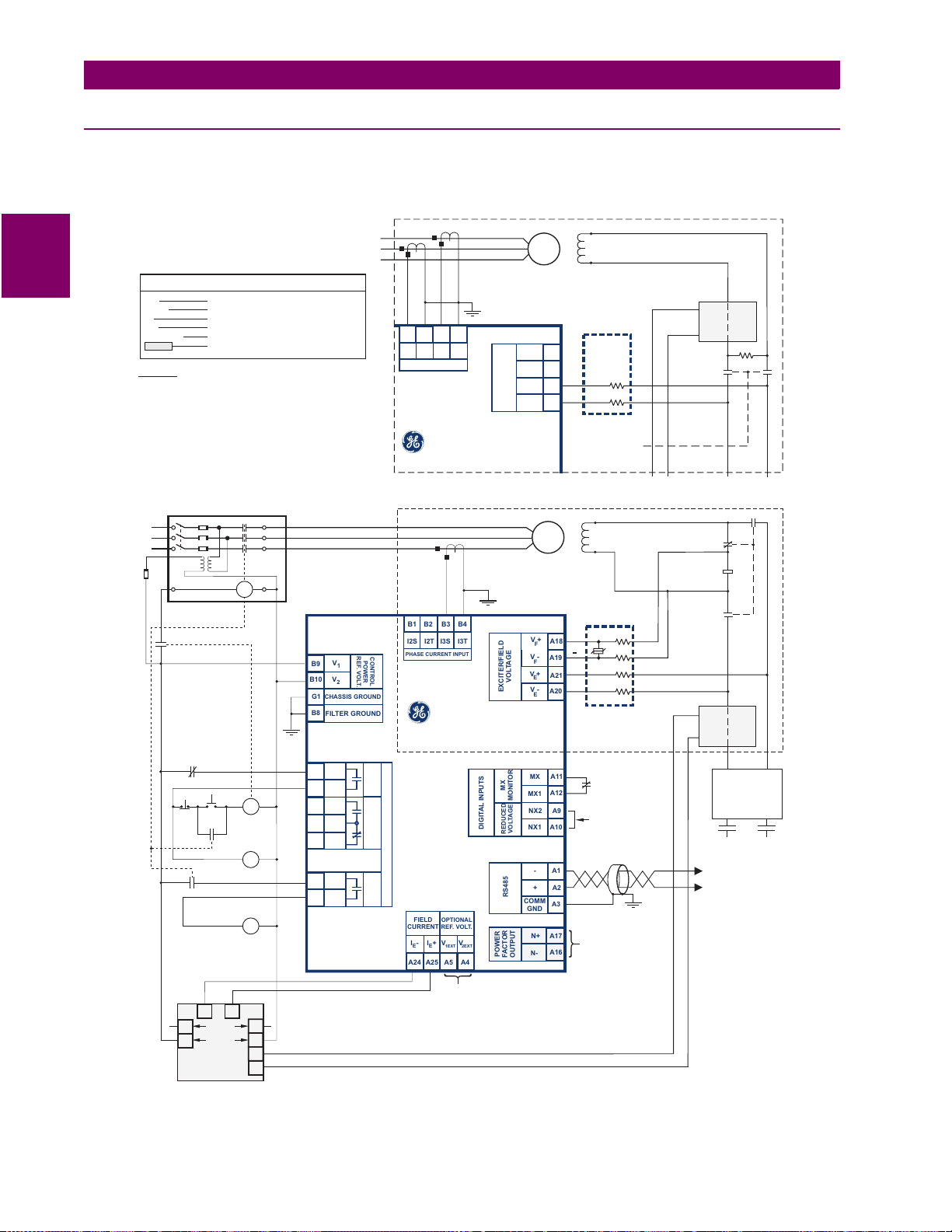

2.3 ELECTRICAL INSTALLATION 2.3.1 DESCRIPTION

Wire the SPM using one of the following wiring diagrams (one each for brushless, collector ring, and brushless

and collector ring). Pay particular attention to the CT and PT inputs. These inputs must be connected as shown

below for proper power factor protection.

2

NOMENCLATURE

CM

DCCT

M

OL

T1, T2, T3

FIELD CURRENT CALIBRATION MODULE

DIRECT CURRENT CT

MAIN CONTACTOR

OVERLOAD RELAY

MOTOR TERMINALS

OPTIONAL ACCESSORIES

NOTES:

1) Relays shown with no control power applied to relay

*

2) Trip Relay closed during normal operation

TYPICAL BRUSHLESS MOTOR CONNECTION

A

B

C

B1

I2S

PHASE CURRENT INPUT

B2

B3

B4

I3T

I3S

I2T

T1

T2

SYNC

MOTOR

T3

V+

F

V-

F

V+

E

VOLTAGE

V-

EXCITER/FIELD

E

A18

A19

A21

A20

EF1

FIELD

EF2

VOLTAGEDIVIDER

NETWORK (VDN)

(E+)

(E-)

DCCT

(V+)

(V-)

FC FC

R

SUPPLY

A

B

C

STOP

OL

M

START

M

EXCITER

CONTACTOR

FIELD

CONTACTOR

M

MX

MAIN

AUXILIARY

RM

FC

V

B9

1

V

B10

2

G1

CHASSIS GROUND

B8

FILTER GROUND

A23

TRIP1

A22

TRIP2

FCX

A13

N/O

A14

COM

FCX

A15

N/C

FAR 1

A7

FAR 2

A6

GE POWER MANAGEMENT

SPM

TYPICAL COLLECTOR RING MOTOR CONNECTION

T1

T2

SYNC

MOTOR

T3

V+

F

V-

F

V+

E

VOLTAGE

V-

EXCITER/FIELD

E

A18

A19

A21

A20

REF.VOLT.

CONTROL

POWER

PHASE C

B1

B2B4B3

I2S

I3S

I2T

PHASE CURRENT INPUT

GE POWER MANAGEMENT

I3T

SPM

*

(FAR)

(FCX)

TRIP

CONTACTOR AUX.

APPLICATION

FIELD

FIELD

OUTPUT RELAYS

DIGITAL INPUTS

FIELD

OPTIONAL

REF.VOLT.

CURRENT

I+

V

I-

A24

A25

V

2EXT

1EXT

EE

A5

POWER

A4

MX

MONITOR

VOLTAGE

REDUCED

RS485

COMM

FACTOR

OUTPUT

MX

MX1

NX2

NX1

GND

N-

A11

A12

A9

A10

A1

-

+

A2

A3

A17

N+

A16

FIELD CONTACTOR

F1

FIELD

F2

VOLTAGE DIVIDER

NETWORK (VDN)

(+)

()

(E+)

(E-)

M

ON REDUCED VOLTAGE

STARTERS, REMOVE

JUMPER AND CONNECT

A NO. AUX CONTACT

FROM THE FINAL STEP

CONTACTOR HERE.

PF ANALOG OUTPUT OR

PF REG CONTROL SIG

OUTPUT (IF PF

REGULATOR OPTION)

(V+)

(V-)

(R1)

(F2)

7

CM8CM

DISCHARGE

RESISTOR

CONTACTOR

FIELD

FIELD

+

-

DCCTDCCT

EXCITER

V-

FC

FC

V-V-

EXCITER

RM

TO EXCITER

POWER SUPPLY

TO PLC

OR COMPUTER

EXCITER

FC

V+V+

V+

2-

USED FOR SEPARATELY

SUPPLIED POWER FACTOR

65

240 VAC

1

120 VAC

3

FIELD CURRENT

CALIBRATION

MODULE (CM)

2

4

7

8

REFERENCE VOLTAGE

(OPTIONAL CONNECTION)

BRUSHLESS & COLLECTOR RING - 701756AN.CDR

COLLECTOR RING - 701751.DWG

BRUSHLESS - 701753.DWG

Figure 2–3: TYPICAL WIRING DIAGRAM

4

SPM Synchronous Motor Protection & Control GE Power Management

Page 19

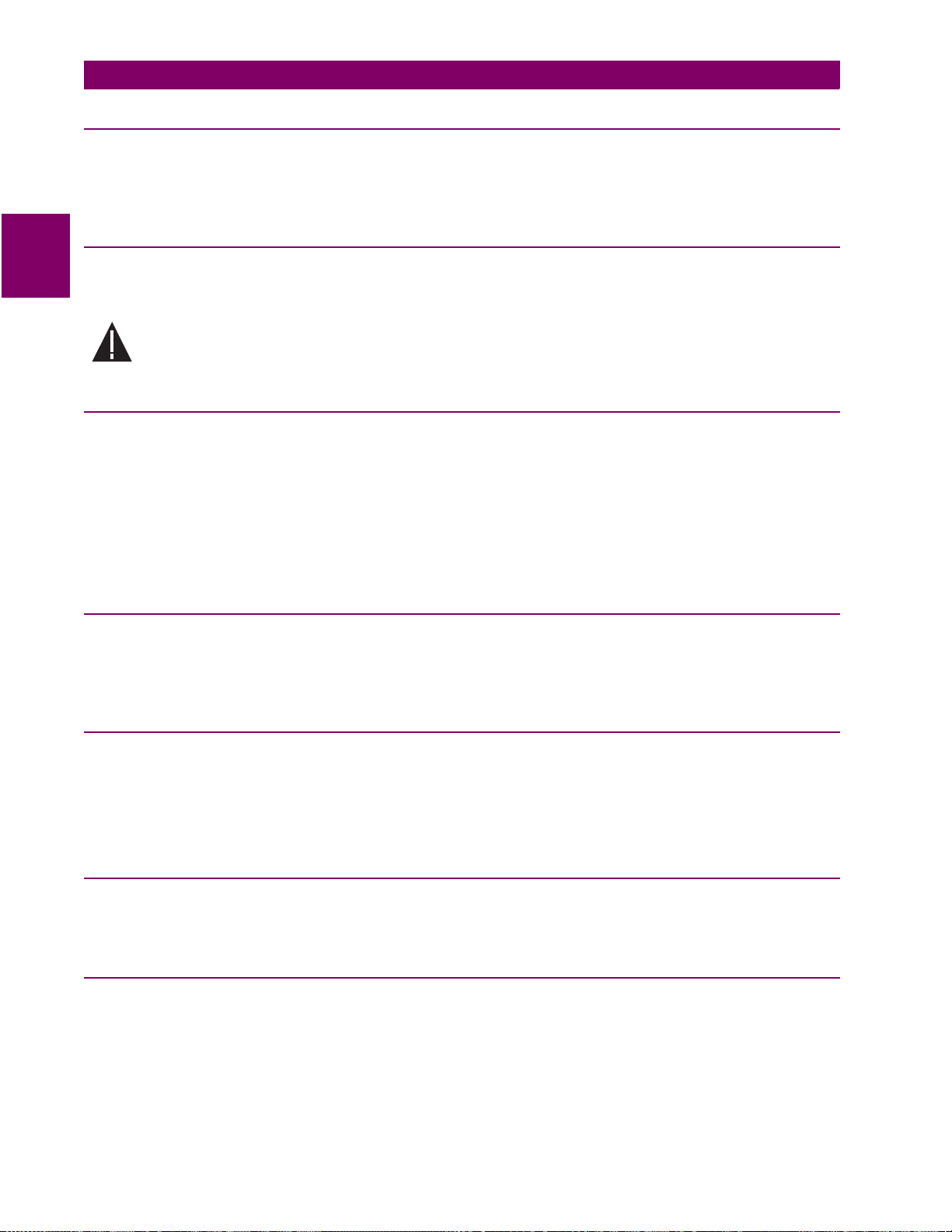

2 INSTALLATION 2.3 ELECTRICAL INSTALLATION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

FRONT VIEW

QUICK RELEASE TABS

Used to remove display for easy

GE KEY

Used to enter or exit the different

modes of the SPM. These are

Standby, Test, Statistics and

Programming modes.

LOCKING PROVISION

A wire lead seal can be used to

prevent unauthorized removal

of relay.

ENTER KEY

Used to make a selection or acts

as an enter key.

DISPLAY FUNCTION MENU

Menu of all accessible setpoints

and actual values for easy reference.

SPM Sync. Protection/Control

ENTER

DISPLAY FUNCTIONS

Items in and white come standard.green

Items in yellow are optional.

Items in green are motor type dependent.

DISPLAY SCROLL SETPOINT SCROLL

AC Amps

Power Factor

DC Amps

DC Volts

(Exciter) Field Ohms

Power Factor Trip

Power Factor Trip Delay

Power Factor Suppression

Power Factor Mode

FAR Delay

FCX Delay

SCROLL

CONTRAST

access to drawout.

LCD DISPLAY

Back lit 32 character display for

setpoints, actual values and status.

Programmable auto scan sequence

for unattended operation.

SCROLL KEYS

Used to scroll through the various

menus and change setpoint

parameter values.

CONTRAST DIAL

Lightens or darkens display.

2

S1 CASE

Compact S1 rugged metal/bakelite

case. Fits standard cutout.

STATSCROLL

Motor Hours

ISP Trip Ctr

FLP Trip Ctr

PO Trip Ctr

Resync Ctr

NO V Trp Ctr

Exc Trip Ctr

PF Trip Ctr

SCP Trip Ctr

FOT Trip Ctr

AC CT Rating

Full Load Amps

Locked Rotor Amps

Sync. Slip

Stall Time

Run Time

DC CT Primary

High (Exciter) Field Ohms

(Exciter) Field Amps

(Exciter) Field Volts

Incomplete Sequence Delay

Regulator Power Factor

Regulator Gain

Regulator Stability

Regulator Output

Regulator Floor Volts

REAR VIEW

F

FCX COM

E

FCX N/C

15

16

TRP1

V+

I+

V-

V+

19

21

23

25

20

22

24

E

E

F

I-

V-

TRP2

FILTER

GND

N+

17

18

N-

1

1

RS485-

2

1EXT

MX

FCX N/O

FAR1

RS485 GND

NX2

V

3

5

7

9

11

4

13

6

8

10

12

14

A

2345678910111213141516171819202122232425262728

NC

A

RS485+

I2S I2T I3S I3T

B

1 23 4 5678910

NX1

2EXT

V

MX1

FAR2

PULLDOWN DOOR

Hides menu when not in use.

TERMINAL BLOCK A

RELAYS

INPUTS

E

NC

27

26

28

NC

NC

V

V

1

2

OUTPUTS

TRIP: Normally open,

failsafe trip relay.

FAR: Field application

relay.

FCX: Autoloading of the

motor.

EXCITER: Exciter voltage

inputs. Connected via

DCCT and CM.

FIELD: DC field voltage

input.

REDUCED VOLTAGE:

Contact input for

reduced voltage starting.

Motor "ON" input.

Exciter current input.

Power Factor reference

voltage (for seperately

powered option).

POWER FACTOR:

0-10VDC analog signal.

MOTOR LINE CURRENT

2 Phase current inputs.

Accept #8 wire.

CONTROL POWER

85 to 265VAC.

701750AF.CDR

Figure 2–4: PANEL AND TERMINAL LAYOUT

GE Power Management SPM Synchronous Motor Protection & Control 2-

5

Page 20

2.3 ELECTRICAL INSTALLATION 2 INSTALLATION

2.3.2 GROUNDING

The SPM relay must be sol idly gro unded to a su itable syste m ground. Ex tensi ve filt ering and tr ansie nt protection has been built into the SPM to ensure proper and reliable operation in harsh industrial environme nts.

Proper grounding of the chassis ground terminal is critical to en-sure safety and filtering.

2.3.3 FIELD AND EXCITER VOLTAGE INPUTS

2

The field voltage i nputs (V

via the supplied voltage divider network (VDN).

DO NOT ATTEMPT TO START THE MOTOR WITHOUT THE EXTERNAL RESISTOR ASSEMBLY

WIRED. SEVERE DAMAGE TO THE SPM MAY RESULT IF THE EXTERNAL RESISTOR ASSEM-

CAUTION

The following is a description of the relay outputs.

1. TRIP: Trip Relay. This relay is normally energized and drops out on loss of power or when the modul e

2. FAR: Field Application Relay. This relay picks up at the proper time to apply DC to the motor field.

BLY IS NOT PROPERLY CONNECTED.

senses an abnormal condition.

+ and VF–) and exciter v oltage in puts (VE+ and VE–) are connected to t he relay

F

2.3.4 RELAY OUTPUTS

3. FCX: Loading Relay. This relay picks up when the motor is fully synchronized and ready to be loaded. It is

controlled by the "FCX Delay" programmable setpoint.

2.3.5 CURRENT TRANSFORMER INPUT

The SPM is designe d to work fro m a fiv e a mpe re (5 A) current trans forme r ( CT) s econdary. The current transformer must be connected i n the prope r motor ph ase. Se e Figur e 2–3: TYP ICAL WI RING DIAGRA M on pag e

2–4 to determine proper phase. For brushless applications, the SPM requires inputs from two motor phases.

2.3.6 POWER FACTOR OUTPUT

This output is a 0 to 10 V DC signal that corresponds linearly to phase shift, and sinusoidal to motor power factor. 0 V is zero lagging power factor, 5 V is unity power factor, and 10 V is zero leading power factor.

Calibration: 1 volt change corresponds to an 18° phase shift (not available with power factor regulation). Do not

connect less than 1000 Ω to this output.

2.3.7 DC FIELD CURRENT INPUT

DC field input must be sensed from a separately purchased DCCT (Direct Current, Current Transformer) and

CM (Calibration Module).

2.3.8 EXCITER VOLTAGE OUTPUT MONITOR

The output of the field exciter must be connected to the SPM through a separate resistor when exciter voltage

failure protection and/or exciter voltage display is required.

2-

6

SPM Synchronous Motor Protection & Control GE Power Management

Page 21

2 INSTALLATION 2.3 ELECTRICAL INSTALLATION

2.3.9 POWER FACTOR REGULATION OUTPUT

This optional output replaces the power factor analog signal output. It consists of a 0 to 10 V DC control signal

which is used to control an SCR Variable Exciter output to obtain motor power factor regulation.

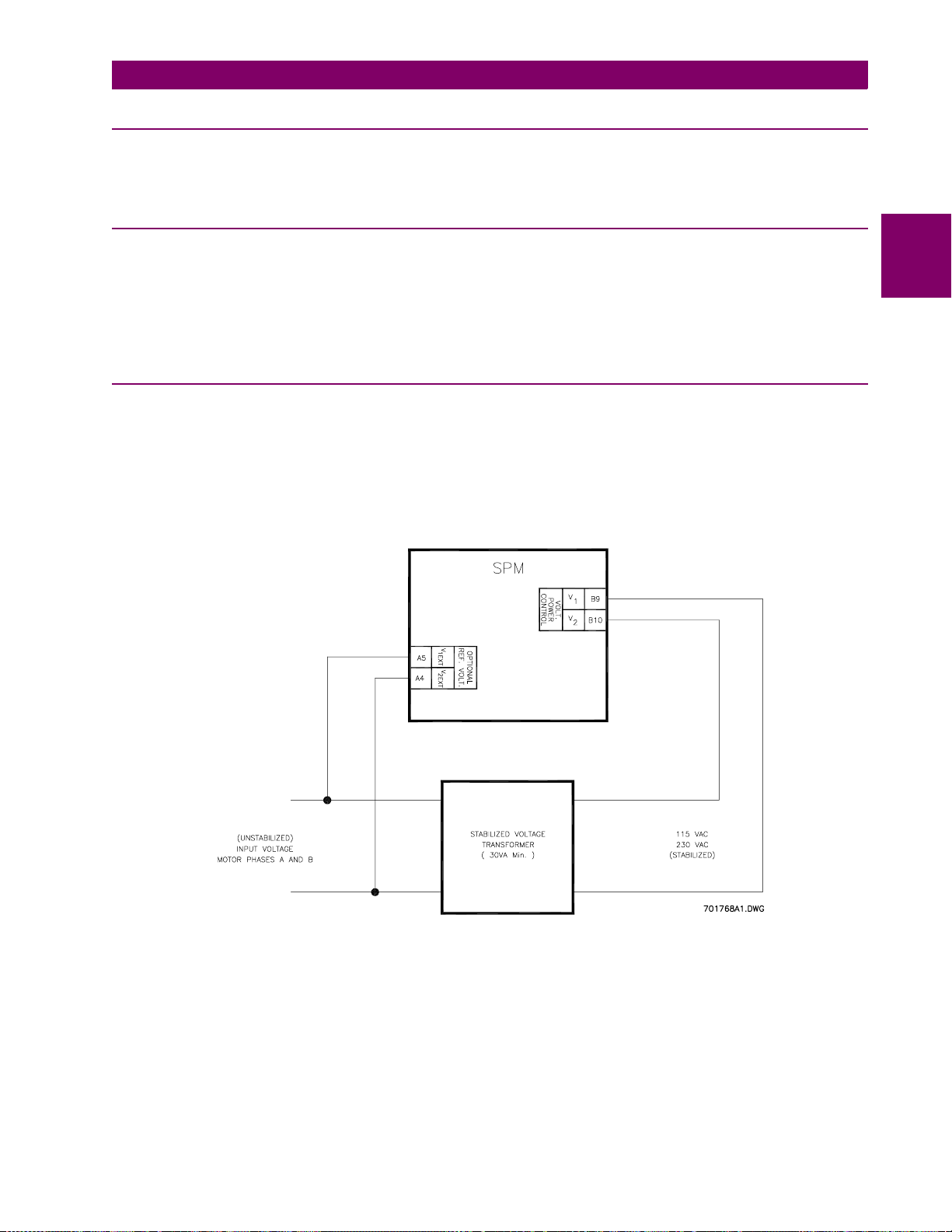

2.3.10 CONTROL VOLTAGE

If control voltage ex cursions occur ou tside the r ange of 85 to 265 VAC, a p rovision is avai lable that will allow

the user to connect a n external stabilizing transf ormer for operation with sev ere control power voltage di ps.

The SPM has separate inputs for control power and power factor reference voltage. This allows connection for

control power from a stabi lized vol tage sour ce of 115 V AC or 230 V AC . Terminal points "V

1EXT

" and "V

2EXT

have been added to accommodate the separate PF reference voltage.

2.3.11 EXTERNAL VOLTAGE PF REFERENCE

When terminal poi nts "V

1EXT

" and "V

" are used to accommod ate a separate PF reference voltage, as

2EXT

described above, a s tandard p rotective function wil l alert the user sho uld this external voltage d rop below th e

acceptable limits for the SP M power s upply. This protection will not allow th e motor t o start while the external

voltage is missin g, bu t the SP M will no t re qui re a r es et befo re the moto r can be restarted. If the exter nal refer ence voltage is lost while the moto r is running, the SPM will trip the motor and will require a r eset before the

motor can be restarted. "MISSING VOLTAGE!" will be displayed until reset.

2

"

Figure 2–5: REFERENCE VOLTAGE INPUT CONNECTIONS

GE Power Management SPM Synchronous Motor Protection & Control 2-

7

Page 22

2.3 ELECTRICAL INSTALLATION 2 INSTALLATION

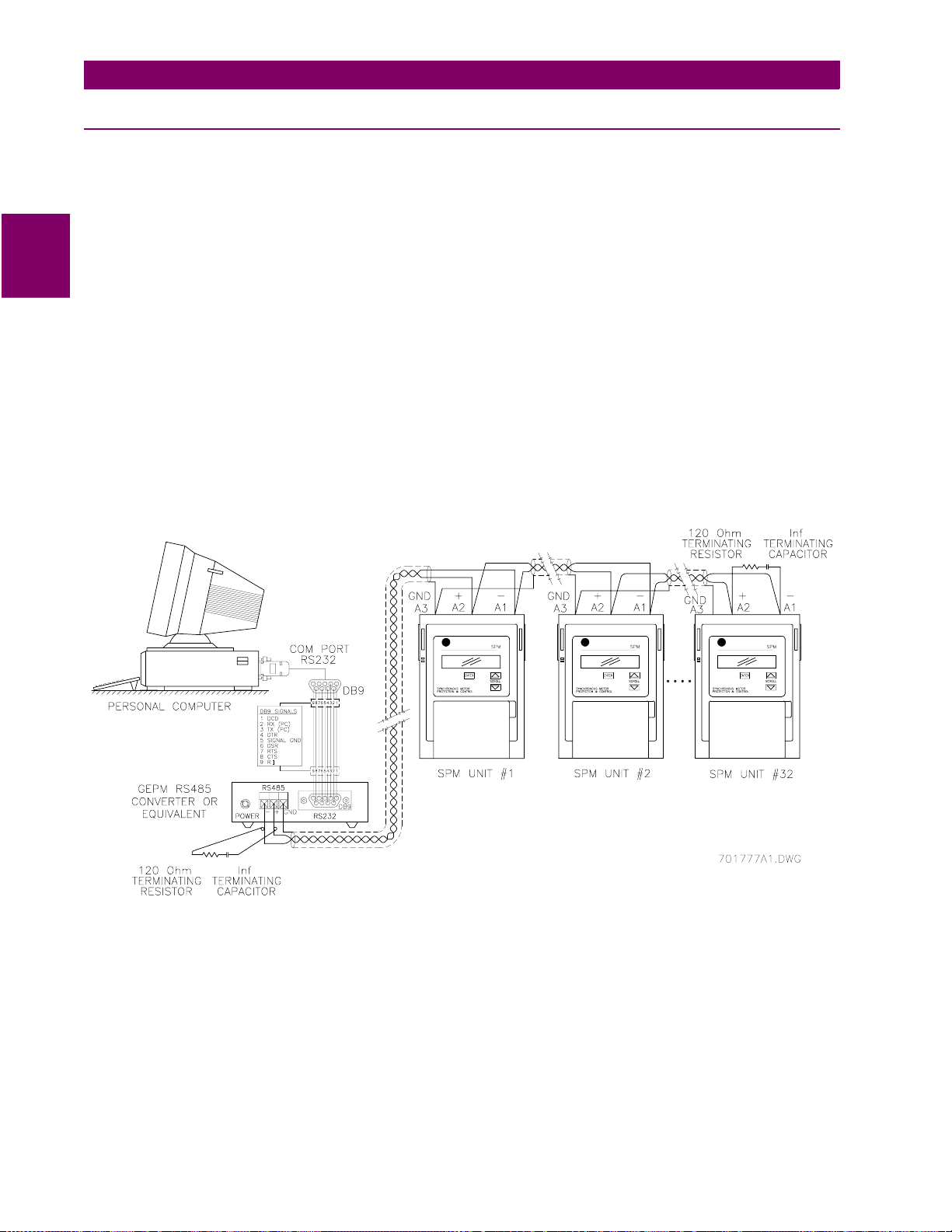

2.3.12 RS485 COMMUNICATIONS PORT

One two-wire RS485 po rt is provided. Up to 32 SPMs can be da isy-chained together on a communica tion

channel without excee ding the driv er ca pabil ity. For larger systems, additiona l serial channels mu st be added.

It is also possible to use commercially available repeaters to increase the number of relays on a single channel

to more than 32. Suitable cable should hav e character istic impe dance o f 120Ω (e.g. Belden #9841) and total

wire length should no t exceed 400 0 ft. Commercial ly available repeaters wil l allow for trans mission distanc es

greater than 4000 ft.

2

Voltage differences between remote ends of the communication link are not uncommon. For this reason, surge

protection device s are internally install ed across all RS485 term inals. Internally an iso lated power supply is

used to prevent noise coupling. To ensure that all devices in a daisy-chain are at the same potential, it is imperative that the common ter minal s of eac h RS485 por t are tied to get her and gr ounded only once , at the ma ste r.

Failure to do so may result in intermittent or failed communications. The source computer/PLC/SCADA system

should have similar tr ansient protection devices insta lled, either internally or externally, to ensure maximum

reliability. To avoid ground loops, ground the shield at one point only as shown below.

Correct polarity is also essential. SPMs must be wired with all '+' terminals connected together, and all '–' terminals connected together. Each relay must b e dai sy -ch ain ed to th e next on e. Avoid star or st ub c onne ct ed c onfigurations. The last device at each end of the daisy chain should be terminated with a 120Ω, ¼ watt resistor in

series with a 1 nF capacitor across the '+' and '–' termi nals . Observi ng thes e guidel ines will res ult in a r eli able

communication system immune to system transients.

2-

Figure 2–6: RS485 WIRING

8

SPM Synchronous Motor Protection & Control GE Power Management

Page 23

3 SYNCHRONOUS MOTOR APPLICATIONS 3.1 OVERVIEW

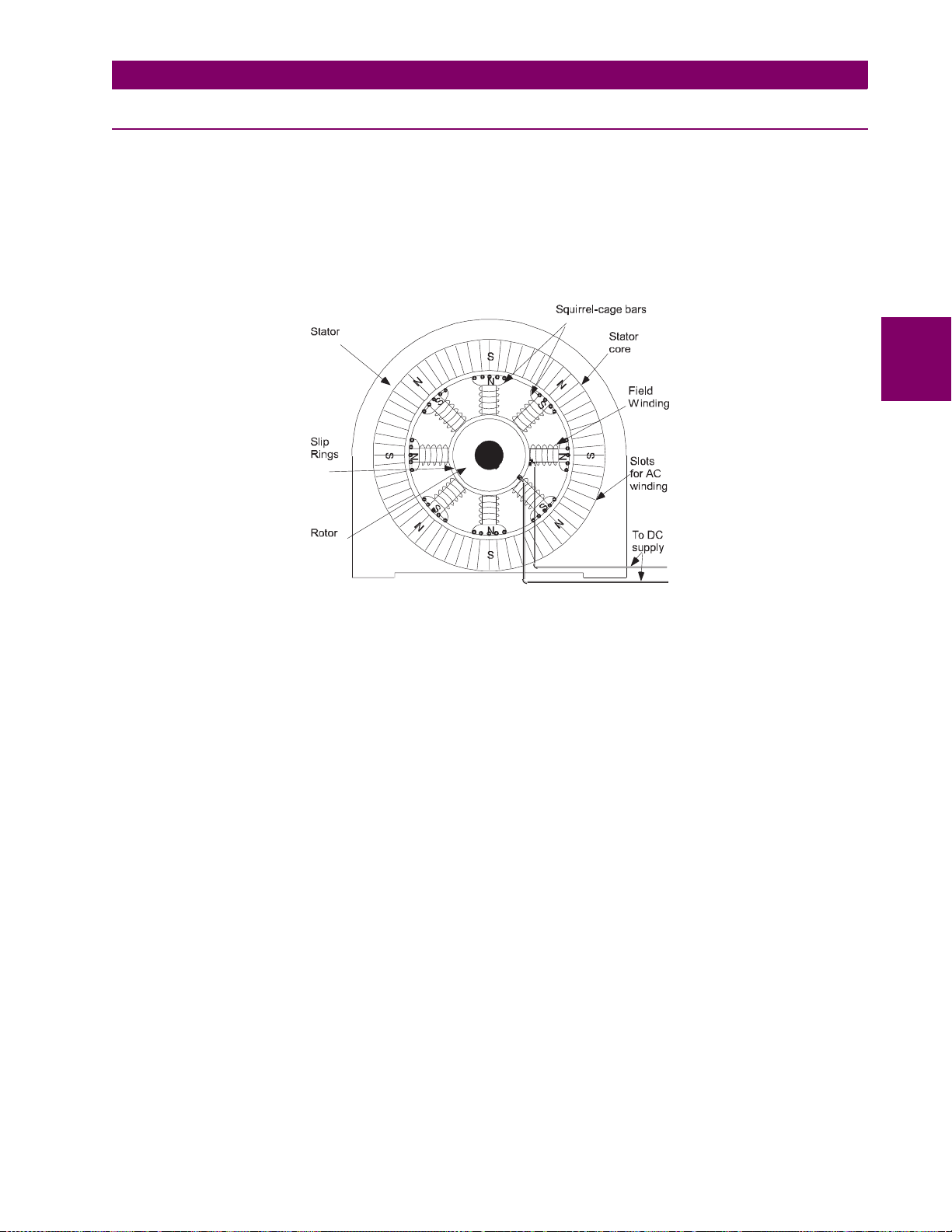

3 SYNCHRONOUS MOTOR APPLICATIONS 3.1 OVERVIEW 3.1.1 GENERAL

The most attractive and widely applied method of starting a synchronous motor is to utilize squirrel cage windings in the pole faces of the synchronous motor rotor. The presence of these windings allows for a reaction (or

acceleration) torque to be dev eloped in the rotor as the AC excited stator windings induc e current into the

squirrel cage windings . Thus, the synchronous motor starts as an induction motor. These rotor windings are

frequently referred to as damper or amorti sseur windings. The other major function of these winding s is to

dampen power angle oscillations after the motor has sync hronized. Unlike induction motor s, no continuous

squirrel cage torque is developed at normal running speeds. Examine the figure below:

3

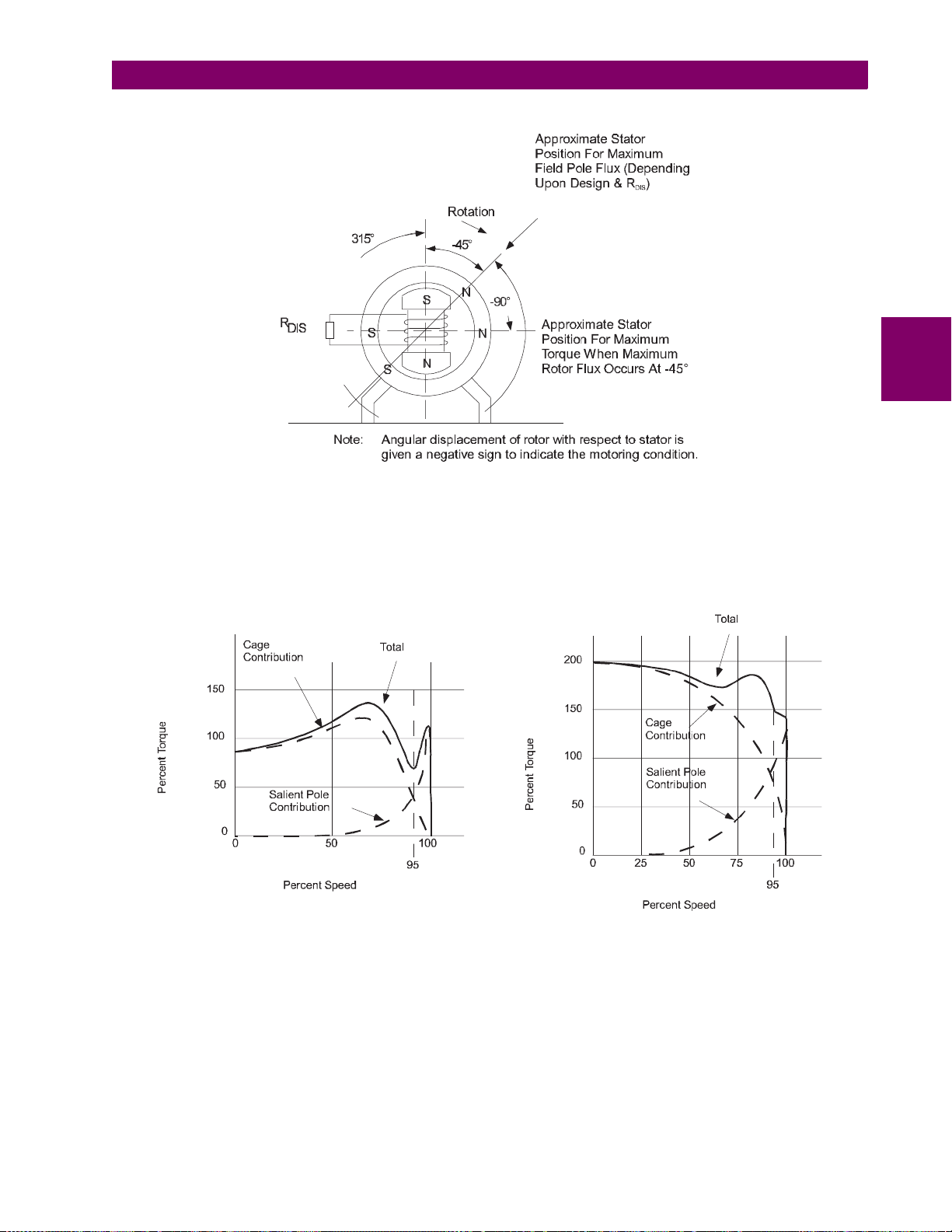

Figure 3–1: SALIENT POLE SYNCHRONOUS MOTOR

When the motor accelerates to near synchronizing speed (about 95% synchronous speed), DC current is introduced into the rotor f ield winding s. This c urrent create s const ant polar ity pole s in the roto r, causing the motor

to operate at synchronous speed as the rotor poles "lock" onto the rotating AC stator poles.

Torque at synchronous speed is derived from the magnetic field produced by the DC field coils on the rotor linking the rotating field produced by the AC currents in the armature windings on the stator.

Magnetic polariza tion of the r otor iron i s due to the rotor ’s physical sha pe and arrang ement and the constant

potential DC in coils looped around the circumference of the rotor.

Synchronous motors possess two general categories of torque characteristics. One characteristic is determined by the squirrel- cage design, which prod uces a torque in rel ation to "slip" (some spe ed other than synchronous speed). The other char acteristic is d etermined by the flux in the s alient field pol es on the roto r as it

runs at synchronous speed. The first characteristic is referred to as

istic is usually referred to as

In starting mode, the syn chronou s motor sali ent pol es are not ex cite d by their external DC sour ce. At temptin g

to start the motor with DC applied to the field does not allow the motor to accelerate. In addition, there is a very

large oscillating to rque component at sl ip frequency, produced by field excitation, wh ich could result in motor

damage if full field curre nt is applied during the entir e starting sequence. Th erefore, application of DC to th e

field is usually delayed until the motor reaches a speed where it can be pulled into synchronism without slip.

At synchronous speed, the ferro-magnetic rotor poles become magnetize d, resulting in a small torque (reluctance torque) which enab les the motor to run at very l ight loads in synchronism without external excitation.

Reluctance torque can also pull the motor into step if it is lightly loaded and coupled to low inertia.

synchronous torque

.

starting torque

, while the second character-

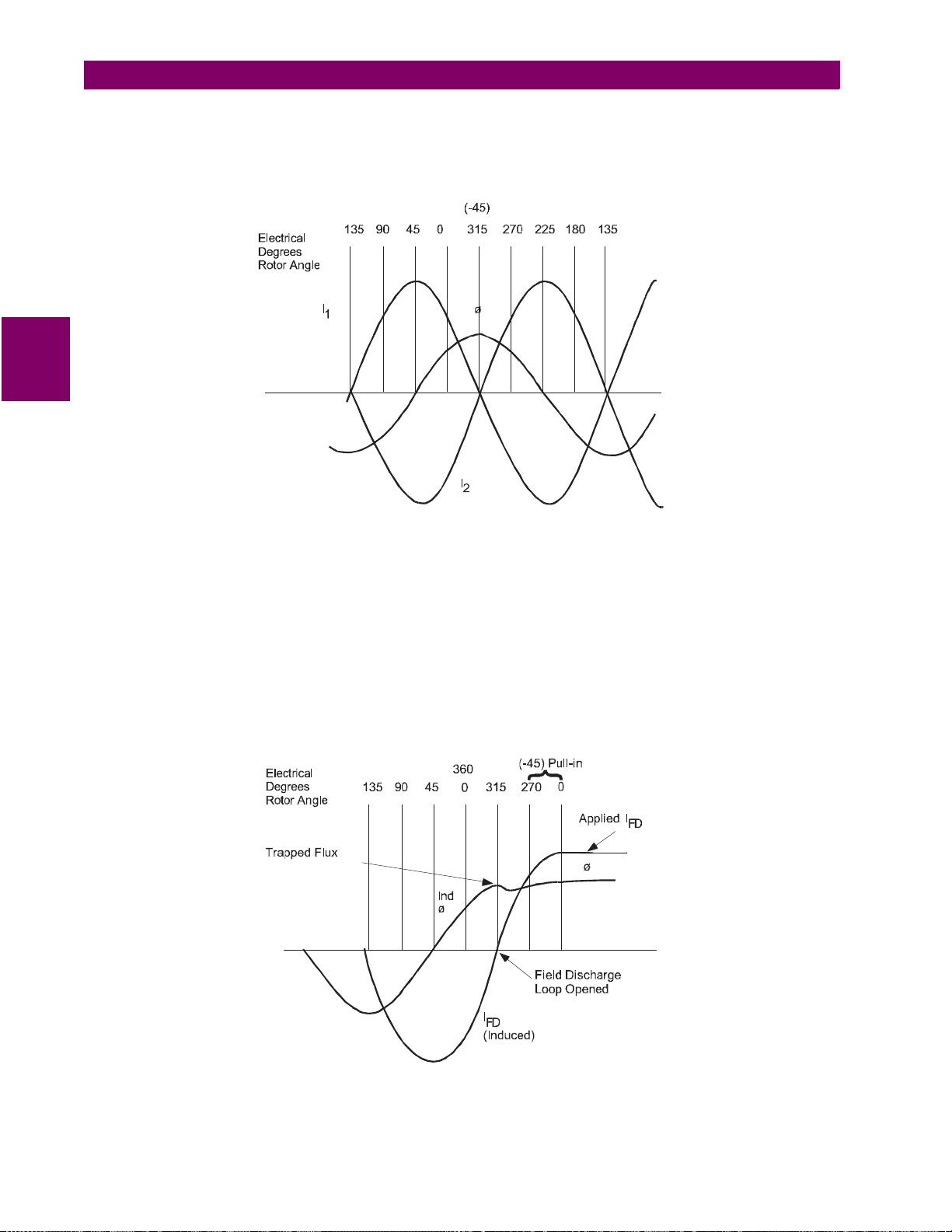

It is convenient to make an analogy of a synchronous motor to a current transformer for the purpose of demonstrating angular relationship of field current and flux with rotor position.

GE Power Management SPM Synchronous Motor Protection & Control 3-

1

Page 24

3.1 OVERVIEW 3 SYNCHRONOUS MOTOR APPLICATIONS

If

I

is an equivalent current in the st ator causi ng the tra nsformer a ction, then

1

I

), and the flux w il l be 90° behind

FD

as the induced field current

rent. See the figure below.

3

I

will be about 180° fr om

I

. Very significantly, then, the poin t of maxim um-i nduce d flux (Ø) oc curs

I

FD

FD

passes through zero from negative to positive; maximum rate of change of cur-

1

I

2

(or

Figure 3–2: TYPICAL TRANSFORMER ROTOR FLUX AND CURENT (CONSTANT SLIP)

The rotor angle at which

I

1

and

I

go through zero depe nds upon the reactance-to -resistanc e ratio in the field

2

circuit. A very high v alue of reactance-to-resistance shifts the angle toward –90°. Re actance is high at low

speed (high frequen cy). At high speed (low slip, l ow frequency), reactance decrease s and the angle shifts

toward 0° if the circuit includes a high value of resistance. As the stator goes beyond –45°, the torque

increases (due to increased stator flux ). At this point,

I

yields a convenient in dicator of maximum flux an d

FD

increasing torque from which excitation is applied for maximum effectiveness.

If the field discharge loop is ope ned at the poi nt of m ax im um flux , thi s f lux is "t rappe d." App ly ing ex ter na l exc i-

tation in correct polarity to increase this trapped flux at this instant makes maximum use of its existence. At this

point the stator p ole ha s jus t mov ed by an d is in po sitio n to pu ll the roto r for ward int o sy nchr onous align ment.

See the figure below.

3-

Figure 3–3: TYPICAL ROTOR FLUX AND CURRENT AT PULL-IN

2

SPM Synchronous Motor Protection & Control GE Power Management

Page 25

3 SYNCHRONOUS MOTOR APPLICATIONS 3.1 OVERVIEW

Figure 3–4: ANGULAR DISPLACEMENT OF ROTOR

It has been established that salient-pole torque near synchronous speed is a function of both slip and field-discharge resistance. The combi ned e ffects of c age to rque and sal ient p ole tor que for a ty pical m otor a re show n

below. The effect of a higher value of discharge resistan ce on a me dium-tor que mot or are sho wn in Figure 3–

6: FIELD DISCHARGE RESISTANCE – MEDIUM STARTING TORQUE. Obviously, without salient-pole torque

the motor would cease to accelerate certain loads at some point on the speed axis.

3

HIGH-STARTING-TORQUE MOTORMEDIUM-STARTING-TORQUE MOTOR

Figure 3–5: MOTOR TORQUE VS. SPEED

The upper limit of t he dischar ge res ista nce i s gover ned b y the other fu nctio n o f the resist or, which is reduc ing

field voltage to saf e le ve ls dur i ng st arti ng. A s the d is ch arge r es i sta nc e in cr ea se s s o d oes the ind uc ed v ol tage ,

and at some poin t this voltage would be damag ing to insula tion o r oth er com pone nts in the fie ld c ircuit. Solidstate excitation a nd control components in the fiel d circuit have had the effect of makin g the disc harge resi stance and its voltage effect mor e signifi cant. There i s a grea ter sens itiv ity to fie ld vol tage to leran ce le vels wit h

solid-state components.

GE Power Management SPM Synchronous Motor Protection & Control 3-

3

Page 26

3.1 OVERVIEW 3 SYNCHRONOUS MOTOR APPLICATIONS

3

Figure 3–6: FIELD DISCHARGE RESISTANCE – MEDIUM STARTING TORQUE

Selection of the value of the field discharge resistance is a decisi on that may r equire judici ous applica tion of

several factors present on a particular drive, such as torque, excitation systems, and control components.

The importance of speed for app lying field cannot be over-emphasized. Rotor and load masses cannot be

accelerated fast enough to allow synchronization, if slip is in excess of ten percent.

Synchronous-motor controllers which can acc urately apply field at an optimum speed and a favor able angle

permit matching the motor to the load with a greater degree of precision than might otherwise be possible. The

increase in load w hich can be pulled in due to preci sion applic ation of fie ld will va ry from one m otor design to

another along with system inertia.

Applying excitation at the point of zero induced current (favorable angle) takes advantage of motor capability in

two ways:

1. It catches (“traps”) salient- pole flux at s ignificant ma gnitude (p rovided ther e is a field di scharge re sistor of

adequate value) and uses it for torque during a 180° acceleration period.

2. It catches the rotor in correct angular position to be pulled forward into step.

In addition to permitting closer matching of motor to load, optimum application of excitation also reduces power

system disturbance w hich o ccurs when th e motor go es thr ough a comp lete sli p cycle with the fi eld en ergized .

If the motor is large relative to the power system, surges transmitted to the system will be at a minimum if field

is applied to prevent slip at pull-in.

3-

4

SPM Synchronous Motor Protection & Control GE Power Management

Page 27

3 SYNCHRONOUS MOTOR APPLICATIONS 3.2 COLLECTOR-RING MOTORS

3.2 COLLECTOR-RING MOTORS 3.2.1 STARTING AND SYNCHRONIZING

Control functions for starting the synchronous motor include the following:

• Applying power to the stator; at full voltage or reduced voltage.

• Shunting the field with a discharge resistor (FDRS).

• Sensing rotor speed.

• Sensing rotor angle.

• Applying excitation at optimum speed and angle.

• Reluctance torque synchronizing.

The first step in starting a synchronous motor is to apply power to the stator by means of a magnetic contactor

or circuit breaker.

Shunting a resistor around the motor field during starting is accomplished with a field contactor. Optimum appli-

cation of excitation (that is, closing the field c ontactor) requires accurate sen sing of motor speed and rotor

angle. This SPM pro vides this functi on. Optimum spee d for pull-in var ies with motor d esign and with the field

discharge resisto r val ue. A dju st men t of the c ontrol to app ly fiel d at v ario us v al ues of mot or spe ed is important.

The correct rotor angle for fiel d application does not vary and is always the po int where induced field cu rrent

passes through zero goi ng f rom ne gative to positive – the poi nt o f ma xi mu m r oto r flux ( see Figure 3–3:: TYPICAL ROTOR FLUX AND CURRENT AT PULL-IN on page 3–2). Maximum utilization of motor pull-in capability

depends upon the degree to which the control can accurately sense speed and rotor angle.

Rotor frequency is th e mo st pos iti ve el ec tr ical parameter available for in dica t ing sp eed , and ca n be s en se d by

detecting the frequency of the voltage across FDRS . Voltage across FDRS is not actually "induced field voltage," but is the volta ge which is essenti ally in time phase relation to the curr ent through the re sistor. That is,

the current goes through zero at the same time the voltage goes through zero.

The SPM detects the proper rotor speed (PRS ) and rotor angle (PRA) signal, implemente d in the Field Programmable Gate Array (FPG A). Outputs fr om the PRS and the circuits are used to de termine the proper time

to close the Field Appli cation Relay (FAR), based on the pe rcent synchrono us slip setpoi nt. When the pro per

rotor speed and the proper rotor angle conditions are met as determined by the FPGA, the CPU delivers a signal to the FAR Relay so it can close its contact FAR1-F AR2. FAR picks up field contactor FC to apply excitation

to the motor field and to o pen the fie ld d isc har ge resi st or loo p. S ee Figu re 2–4 : PANEL AND TERMINAL LAYOUT on page 2–5 for details. The speed at which the motor is to synchronize (PRS) can be programmed from

90 to 99.5% of synchronous speed.

3

GE Power Management SPM Synchronous Motor Protection & Control 3-

5

Page 28

3.2 COLLECTOR-RING MOTORS 3 SYNCHRONOUS MOTOR APPLICATIONS

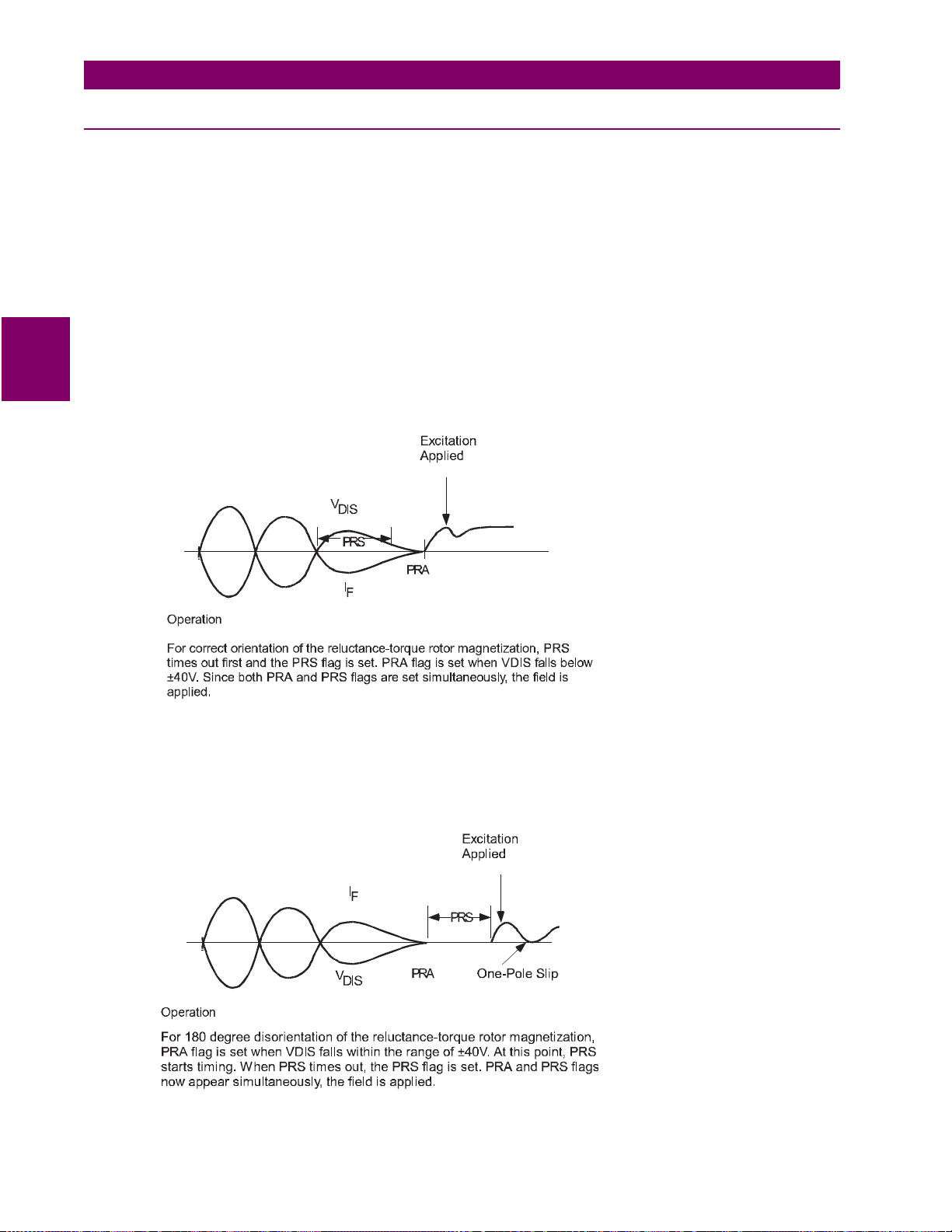

3.2.2 RELUCTANCE TORQUE SYNCHRONIZING

A lightly loaded syn chro nou s m otor c onn ected to a low inertial load may pul l i nto sy nc hroni s m be fore the rotor

poles are externally magnetized. This is commonly known as reluctance torque synchronizing. This magnetization can result in su fficient torque to hol d the salient poles in direct align ment with corr esponding st ator poles

and run the motor at sy nchronous speed. However, when load is applied, th e rotor begins to slip since th e

torque developed is o nly a fraction of rate d torque under sep arate excitation. Fu rthermore, the rotor is polarized by the stat or flux u nder this condition and can therefore be polar ized in a ny direc t axis al ignment; occurring each 180°. External excitation forces pole-to-pole alignment in only one orientation of the direct axis.

Should the rotor pull in to syn chronism 180° away from the normal running al ignment, external ex citation will

build up rotor flux in opposition to the stator flux. As the external excitation builds up, correct alignment of rotor

to stator occurs by slipping one pole and the motor will then run in normal synchronism.

3

The Field Application Control must respond in such a way as to proceed with proper application of excitation in

the event the motor does synchronize on reluctance torque. The following diagram demonstrates how the SPM

automatically responds to reluctance torque synchronizing.

CORRECT

ORIENTATION

180°

DISORIENTATION

3-

Figure 3–7: RELUCTANCE TORQUE MOTOR MAGNETIZATION

6

SPM Synchronous Motor Protection & Control GE Power Management

Page 29

3 SYNCHRONOUS MOTOR APPLICATIONS 3.2 COLLECTOR-RING MOTORS

3.2.3 STARTING PROTECTION

The amortisseur, or cage winding of a synchronous motor, is probably the element most susceptible to thermal

damage. Its function is essen tially operative onl y during starting, a nd there are limitations on sp ace available

for its construction on to the rotor. Hence, it is usually made of lighter material than the cag e winding of an

induction motor. The cage is also vulnerable to overheating should the motor be allowed to run out of synchronism with no excitation. In this case, it runs as an induction motor at some value of slip which will produce cage

current that develops r unning torque . However, the cage of a synchronous m otor is not designed for continuous operation. Theref ore, an important protective function of t he controller is to prevent overheating o f the

cage winding both during starting and running out of synchronism.

Monitoring the starting c ondition of a sync hronous motor can be accom plished by lookin g at the frequency of

induced field current, the same procedure used to ac complish sy nchroniz ing. Motor desig ners always plac e a

limit on the time a particul ar motor can be allowed to remain stalled (" allowable stall time"). An acceler ated

schedule can then be established for the motor in terms of running time at any speed less than synchronous as

a percent of allowab le stall time. Increased air circulation from th e rotor fan reduces the heating rate as the

motor accelerates . Frequency can b e measured d irectly as an indication of s peed, and the des igner's curves

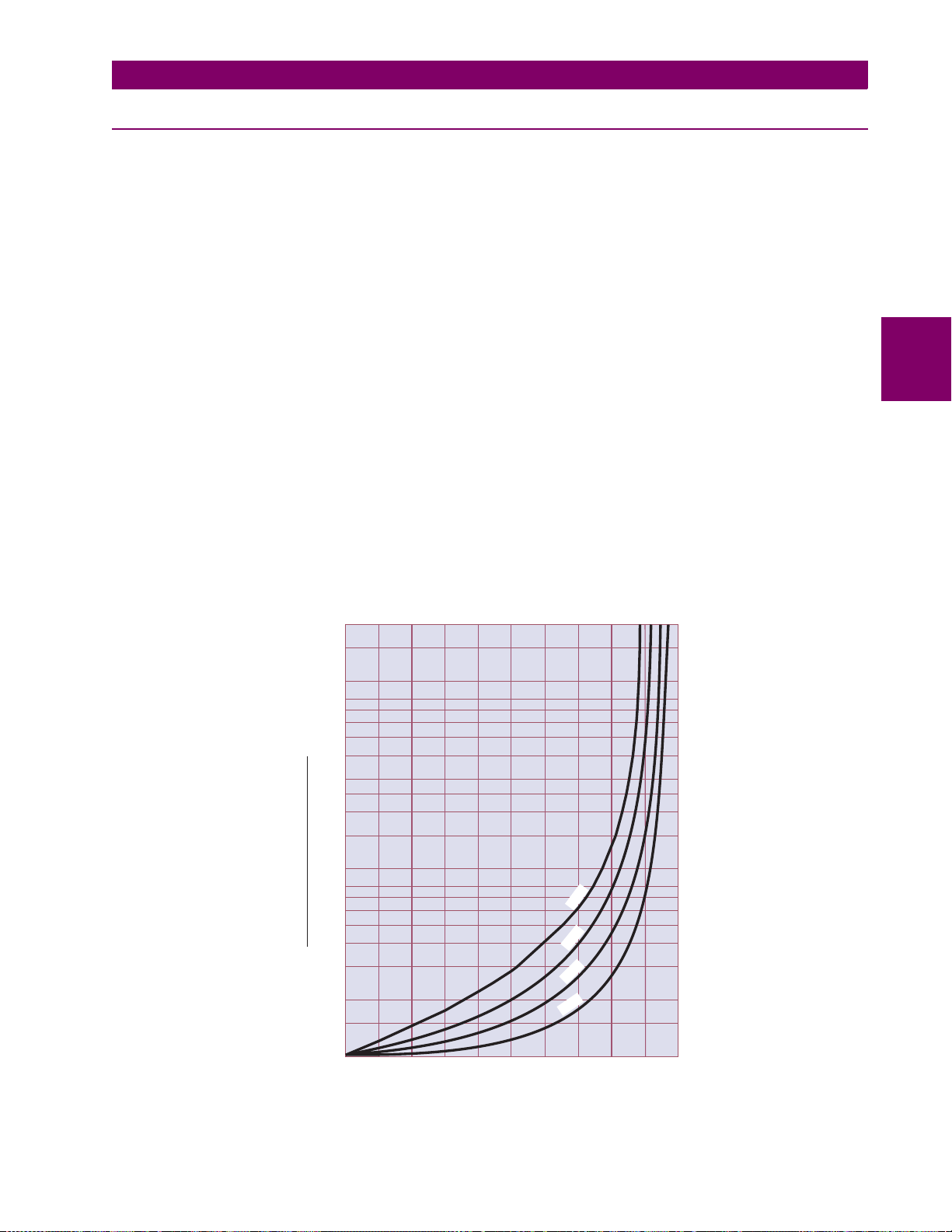

for speed versus time c an be used for protection by softwa re that in tegrates the time-speed function. The figure below shows the typical cage heating protection characteristics during acceleration.

The time-speed functi on show n in belo w is d etermine d inter nally b y SPM s oftwar e. The mo tor spee d is d etermined from the induced field voltage frequency. The programmed values for maximum allowable stall time and

50% speed run time determine which characteristic of protection is required from the family of curves.

3

The SPM will cause a TRIP operation and display "SQL CAGE TRIP" if it calculates that the thermal limit of the

cage winding is reached. The SPM will also p revent an attempted restart if it calculates, from lear ned start

experience, that the cage winding has not had sufficien t cooling time to allow a su ccessful st art. In this case

the message "START INHIBITED! Ready in xxx min" will be displayed

200

150

100

80

60

50

40

30

25

20

15

10

Run Time

Allowable Zero Speed Stall Time

1.5

8

6

5

4

3

2

3

2.05

1.46

1.05

0

0

.

1

0

10 20 60 90 1008070504030

% Synchronous Speed

701761A7.CDR

Figure 3–8: AMORTISSEUR WINDING PROTECTION

GE Power Management SPM Synchronous Motor Protection & Control 3-

7

Page 30

3.2 COLLECTOR-RING MOTORS 3 SYNCHRONOUS MOTOR APPLICATIONS

3.2.4 REDUCED VOLTAGE STARTING

Many synchronous mot or starti ng applications involve either reduced voltage (starting reactor or autotransformer) or part-winding star ting me thods. When these m ethods are use d, the avail able torq ue for ac celera tion

is reduced from the torque that would result from a full-voltage start. Also, the allowable stall time of a motor is

extended during a reduced-voltage start due to the reduced heating-rate resulting from lower inrush currents.

The SPM has the abilit y to take advantage of the motor's extended st all time so that the mot or and load can

accelerate to synchrono us speed in a time period longer than would be allowed with a full volta ge start. The

acceleration torque is reduced as the square of the ratio of reduced voltage to full voltage, and the motor-heating rate is proportional to the square of the starting current. Si nce the motor inr ush current i s reduced p roportionally with the voltage reduction (due to the constant impedance of the synchronous motor at stall) the

following allowable stall time factor applies:

3

2

I

PLR

----------- -

I

MLR

where:

I

= programmed full voltage locked rotor current.

PLR

I

= measured inrush current.

MLR

This ratio can be used as a factor for increasing the stall time above the full voltage allowable stall time for any

given speed. See Figure 19.

The SPM calculates the ratio, squares it, and factors this value into the stall time algorithm approximately onetenth of a second after m otor star ts. When the fin al ste p conta ctor cl oses and appli es ful l voltage to the mo tor

windings, a N.O. interlock from this contactor is wired to the SPM to signal that the motor is now at full voltage.

The correction factor for reduced voltage starts then immediately becomes unity.

If, for any reason, it is not desirable to have this ratio correction factored in , a jumper may be placed ac ross

inputs NX1 and NX2. Conver sely, if the motor is star ted from a weak s ystem, and signific ant vol tage dips are

expected during starting , the factory jumper from NX1 to NX2 may be remove d. The SPM will automatical ly

extend the stall and accelerating time per the reduced voltage factor.

To find the protective characteristic used, plot the programmed value for 50% run time and

draw in the complete curve through the plotted point using the above curves as a guide.

NOTE

The curves shown in the following diagram demonstrate how the trip characteristic of the

amortisseur winding protection is adjusted for reduced voltage starts. For this example, curve

NOTE

1 is taken from one of the family of curves in Figure 3–8: AM ORTISSEUR WINDIN G PROTECTION on page 3–7.

3-

8

SPM Synchronous Motor Protection & Control GE Power Management

Page 31

3 SYNCHRONOUS MOTOR APPLICATIONS 3.2 COLLECTOR-RING MOTORS

200

150

100

80

60

50

40

30

25

20

15

Run Time

10

8

Zero Speed Stall Time

Line

6

Voltage

5

50%

4

3

65%

2

80%

1.5

90%

100%

1

0

10 20 60 90 1008070504030

% Synchronous Speed

701760A7.CDR

3

Figure 3–9: PROTECTION FOR REDUCED VOLTAGE STARTS

GE Power Management SPM Synchronous Motor Protection & Control 3-

9

Page 32

3.2 COLLECTOR-RING MOTORS 3 SYNCHRONOUS MOTOR APPLICATIONS

3.2.5 POWER FACTOR (PULL-OUT) PROTECTION

Synchronous motors are designed to run at constant speed and drive shaft loads from torque derived from the

magnetic poles on thei r roto rs m agnetica lly linking oppos ite s tator pole s. W heneve r the rotor turns a t a spee d

less than that of st ator rotating fi eld, the motor is said to be s lipping poles . Slip can occ ur with the field poles

magnetized while running in synchronism from the following four major causes.

1. A gradual increase in load beyond the pull-out capabilities of the motor.

2. A slow decrease in field current.

3. A sudden large impact load.

4. A system fault or voltage dip lasting long enough to cause pull-out.

Loss of synchronism with field applied will create intense pulsations in torque at the motor shaft each time a

3

stator pole passes a rotor pole. Corresponding pulsations occur in line current. Both types of pulsations can be

damaging. Torque puls ations can break a shaft, coup ling, or other mechanical el ements, and current pulsations can interfere with smooth p ower system o peration. Slip ping pole s with field applied is alwa ys unacce ptable for a synchronous motor, therefore some means must be provided to prevent this condition from

occurring.

One of the most reliable indicators of synchronous and asynchronous (out-of-step) operation is the motor

power factor. Power factor is related to the phase angle between voltage and current. Synchronous motors seldom, if ever, operate continuously at lag ging power factor. Synchronous motors run at either un ity or some

value of leading powe r factor. Lagging power fac tor appears when the motor load angle increas es beyond

rated, becoming almos t fully lag ging (90°) as the motor slips out-of-step. Th erefore, la gging power fa ctor can

be utilized to initiate action to prevent slipping.

Torque and power pulsations during slip can be reduced by removing field current to the rotor poles. The motor

will then run essentially as an induction motor on its amortisseur winding. Slip with the field current removed is

tolerable to the load and power syste m but intolerabl e for any length of time to the motor amortis seur windin g

itself, since the winding is desi gned with limited thermal capab ility and for short-time operatio n. Motor Power

Factor during inductio n motor operat ion (that is with field r emoved) is always laggi ng. However, the degree to

which the current la gs the voltage is less th an at pull-out when fiel d poles are excited. Lagg ing power factor

can again be utilized as an indicator of "slip" during induction motor operation.

For synchronous motors , power-factor monitoring can b e employed to guard against pul l-out or loss of field

conditions.

3-

10

SPM Synchronous Motor Protection & Control GE Power Management

Page 33

3 SYNCHRONOUS MOTOR APPLICATIONS 3.2 COLLECTOR-RING MOTORS

3.2.6 POWER FACTOR OPERATION

Motor pull-out pro tection is provid ed by a circui t which monitors po wer factor and has a built-in t ime delay to

prevent inadvertent tripping on transients. The SPM sens es power factor by monitoring the voltage across

motor Phases One and Two and the current in Phase Three. Figure 20 is a phasor diagram depicting the relationship of voltage and current for various power factors.

The SPM automatically suppresses power factor protecti on until the programmed setpoin t "FCX" times out.

The SPM can be programmed to suppress power factor trip action if the line current is less than 6 percent or 50

percent of the rated full load current via the PF Suppression setpoint. Selecting the "Ridethru" mode for the PF

Mode setpoint places the SPM into ride-through mode. Selecting the "Re-sync" mode for the PF Mode setpoint

places the SPM into resync mode. These modes are described in the next section.

3

Figure 3–10: POWER FACTOR SENSING EXAMPLE

GE Power Management SPM Synchronous Motor Protection & Control 3-

11

Page 34

3.2 COLLECTOR-RING MOTORS 3 SYNCHRONOUS MOTOR APPLICATIONS

3.2.7 CONTROLLER ACTION DURING PULL-OUT

If excessive mechani cal load is applied to the mo tor shaft dur ing normal ru nning of the moto r in synchr onism,

the resulting lagging pow er fact or and/or l ine current surge will be detec ted by the S PM. Two forms of pull-out

protection are available. They are as follows

a) RESYNC MODE

Resync mode operation ca uses the Field Appli cation Relay, FAR, to remov e the motor-field ex citation. Actio n

will occur from either lagging power factor below the programmed setpoint or a line current surge above

approximately four times motor full-load current.

Relay FCX drops out at the same time as FAR. Load is removed if an automatic loader is connected.

The motor will continue to r un with field removed for the programmed power factor dela y time, and if resyn-

3

chronization does not occur within this time, the TRIP relay will operate and the motor will stop.

The display will indicate "FAIL TO RESYNC!"

b) RIDE-THRU MODE

If the alternate "ride-thru" mode is selected, the field is not removed immediately as in the resync mode.

Instead, if the power factor dips below the trip point and persists for the PF time delay, the TRIP relay will oper-

ate and the motor will sto p. A l so, a li ne cu rren t s ur ge grea ter th an appr oxi mate ly fo ur ti mes m oto r ful l loa d will

cause TRIP operation i f the PF time delay is exceeded. Power fac tor trips are indicated by "PW R FACTOR

TRIP!" in the displ ay. Line current surges greater than four tim es rated line current are indicated by "PULLOUT TRIP!".

3-

12

SPM Synchronous Motor Protection & Control GE Power Management

Page 35

3 SYNCHRONOUS MOTOR APPLICATIONS 3.2 COLLECTOR-RING MOTORS

3.2.8 EFFECT OF VOLTAGE DIPS ON MOTOR POWER FACTOR

Solid-state excitation systems have an effect on the way motor power factor responds to line voltage dips. The

effect may be to cause a power-factor relay to operate ina dvertently. This causes the motor to trip on laggin g

power factor caused by a transient condition which is not an actual pull-out condition.

A solid-state ex ci ter d iffers fr om a r otat ing ex cite r in th e wa y it responds to vo lta ge di ps. T he r ota ting i ner tia of

a Motor-Generator set may maintain excitation voltage relatively constant for several seconds, but a solid-state

exciter has practically no built-in delay in the way it responds to line voltage. Therefore, any delay in change of

motor-rotor flux fo llowing an excitation voltage cha nge is determined by the tim e constant of the rotor field

poles themselves. This is usually 0.5 to 1.0 seconds.

The sequence of even ts transpiring during a voltage dip with a solid-state exciter is show n in Figure 3–11:

POWER FACTOR RESPONSE TO LINE VARIANCE on page 3–14.

Assuming the cond ition of a line voltage decrease o f 15% with the motor initially a t unity power factor, the

power factor w ill swing leading momentarily because the generat ed EMF d oes not c hange unti l the rot or flux