GE Smart Water PNRV18ZWH01, Smart Water PNRV18ZBB01, Smart Water PNRV18ZWW01, Smart Water PNRV18ZBL01 Installation Instructions Manual

Page 1

GE SmartWater

™

Profile Performance Reverse Osmosis Filtration System

INSTALLATION INSTRUCTIONS

PNRV18ZBB01, PNRV18ZBL01, PNRV18ZWW01, PNRV18ZWH01

TABLE OF CONTENTS: Page #

Important Installation Recommendations 1

Product Specifications 2

Tools and Materials Required for Installation 2

Things to Check Before Installation 3

Step-by-Step Installation Instructions

— Feed water supply 4

—Drain connection installation 5

—Electronic faucet installation 6

—Tubing and electronics connection 7

— Reverse Osmosis assembly and storage tank installation 8

Sanitizing the Reverse Osmosis System 8

Installation Checklist 9

What the Reverse Osmosis System Does 9

Parts List 10, 11

IMPORTANT INSTALLATION RECOMMENDATIONS

Read entire manual. Failure to follow all guides and rules could cause personal injury or property damage.

• BE SURE TO FOLLOW ALL APPLICABLE STATE AND LOCAL CODES.

• Use a qualified installer.

• Do not install the Reverse Osmosis system outside or in extreme hot or cold temperatures. DO NOT INSTALL ON HOT WATER.

• Recommended installation is under the sink. However, the unit can be installed in a remote location, up to 30 feet away from the sink.

Additional installation materials may be required.

• If unit is installed in basement, with faucet on 1st floor, some capacity loss may be experienced. RVTNK1 can be purchased to provide

additional capacity.

• If Reverse Osmosis system is connected to a refrigerator icemaker, a special icemaker connection kit is required (RVKIT). Do not use

copper tubing for the connection between the Reverse Osmosis system and the refrigerator.

• Be sure the water supply conforms to the specifications on page 2. If water supply conditions are unknown, contact your municipal

water company or your local health department for a list of contaminants in your area and a list of laboratories certified by your state

to analyze drinking water.

WARNING: Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before

or after the system. Systems certified for cyst reduction may be used on disinfected water that may contain filterable cysts. This

Reverse Osmosis system contains a replaceable treatment membrane cartridge critical for effective reduction of Total Dissolved

Solids. The water should be tested periodically to verify that the system is performing satisfactorily. This system is acceptable for

treatment of influent concentrations of no more than 27 mg/L nitrate and 3 mg/L nitrite in combination measured as N and is

certified for nitrate/nitrite reduction only for water supplies with a pressure of 280kPa (40 psig) or greater. Small parts remaining

after the installation could be a choke hazard. Discard safely.

7178993 (7-00 JR) 215C1001P005-6 For Use and Care questions call: GE Answer Center® 800.626.2000

Pub. No. 49-5807-6 GENERAL ELECTRIC COMPANY, Appliance Park, Louisville, KY 40225

1

The GE RO PNRV18Z Model

Series is

Tested and Certified

to ANSI/NSF

Standard 58 for

TDS and Cyst reduction.

Page 2

MODEL PNRV18Z PRODUCT SPECIFICATIONS

Feed water pressure limits—pounds per square inch (psi) 40–125

c

Feed water temperature limits—minimum/maximum degrees F 40–100

Maximum Total Dissolved Solids (TDS)—parts per million (ppm) 2000

Maximum water hardness @ 6.9 pH—grains per gallon (gpg) 10

Maximum iron, manganese, hydrogen sulfide (ppm) <0.1

Chlorine in water supply allowable

b

Feed water pH limits (pH) 4–10

Product (quality) water, 24 hours—gallons 18.0

a

Process water per gallon of product water, 24 hours—gallons 4

a

Percent rejection of TDS (new membrane) 92

a

Cyst reduction 99.95%

Storage tank capacity—gallons 1.9

Automatic shutoff control yes

Prefilter and postfilter (# FX18P) Carbon block and granular activated carbon

Reverse Osmosis membrane (# FX18M) Thin film polyamid

Dimensions (inches) Height Width Depth

21 8 10

a. As tested by Water Quality Association standard “S-300.” Output according to ANSI/NSF Standard 58 is 10.9 gallons per day for the

Reverse Osmosis 18 model. Feed water at 50 psig and 77 °F with 750 parts per million sodium chloride. Quality water production,

amount of waste water and percent rejection all vary with changes in pressure, temperature, and Total Dissolved Solids.

b. Removed (maximum of 2.0 ppm) by the Reverse Osmosis prefilter. REGULAR MAINTENANCE IS REQUIRED. Chlorine will

destroy the Reverse Osmosis membrane.

c. If house water pressure is over 125 psi, install a pressure reducing valve in the water supply line.

If house water pressure is under 40 psi, install a Reverse Osmosis booster pump (contact your local plumbing supply company).

TOOLS AND MATERIALS REQUIRED FOR INSTALLATION

• Cordless Drill

• 1⁄4″Drill Bit

• 1-1⁄4″Carbide Hole Saw (if needed—see page 6)

• Adjustable Open-End Wrenches

• Phillips and Straight Screw Drivers

• Utility Knife

• Teflon Tape

TM

• Contents Included with the Product:

— Reverse Osmosis Assembly

— Product Literature (Installation Instructions, Owner’s Manual, Performance Data Sheet, and Owner Registration Card)

— Faucet Base Parts Bag

— Battery and Holder Parts Bag

— Water Supply Valve Parts Bag

— Drain Line Adapter

—27″Length of 3 ⁄8 ″Tubing

INSTALLER RESPONSIBILITY: The water supply valve (page 4) is included for use in areas where codes permit. Installer must comply

with state and/or local codes. If not, the installer must provide fittings to tap the cold water pipe for a feed water source to the Reverse

Osmosis system (must adapt to 1/4″OD tubing).

2

Page 3

THINGS TO CHECK BEFORE BEGINNING INSTALLATION

FEED WATER—The water supply to the undercounter Reverse Osmosis system must

have the qualities listed in the specifications (see page 2). Municipal water supplies most

often will have these qualities. Well water may need conditioning—have the water tested

by a water analysis laboratory and get their recommendations for treatment.

CAUTION: For water with hardness greater than 10 grains (at 6.9 pH), the use

of

a softener is recommended. Failure to install a softener will reduce the life of

the Reverse

Osmosis membrane. See Fig. 1A for additional information on the

possible need for a softener.

DRAIN POINT*—A suitable drain point and air gap (check your local codes) are

needed for reject water from the Reverse Osmosis membrane cartridge.

RO FAUCET—The RO product water faucet installs on the sink or on the countertop

next to the sink. Often, it is installed in an existing sink spray attachment hole. Space is

required underneath for tubing to and from the faucet, and for securing the faucet in

place. All faucet connections and installation procedures are done on or above the sink

or countertop. Refer to

Electronic Faucet Installation

section.

BASEMENT INSTALLATION—If installing in a basement, leave enough tubing in

place during installation to be able to move unit to floor for ease of servicing and making

filter/membrane changes.

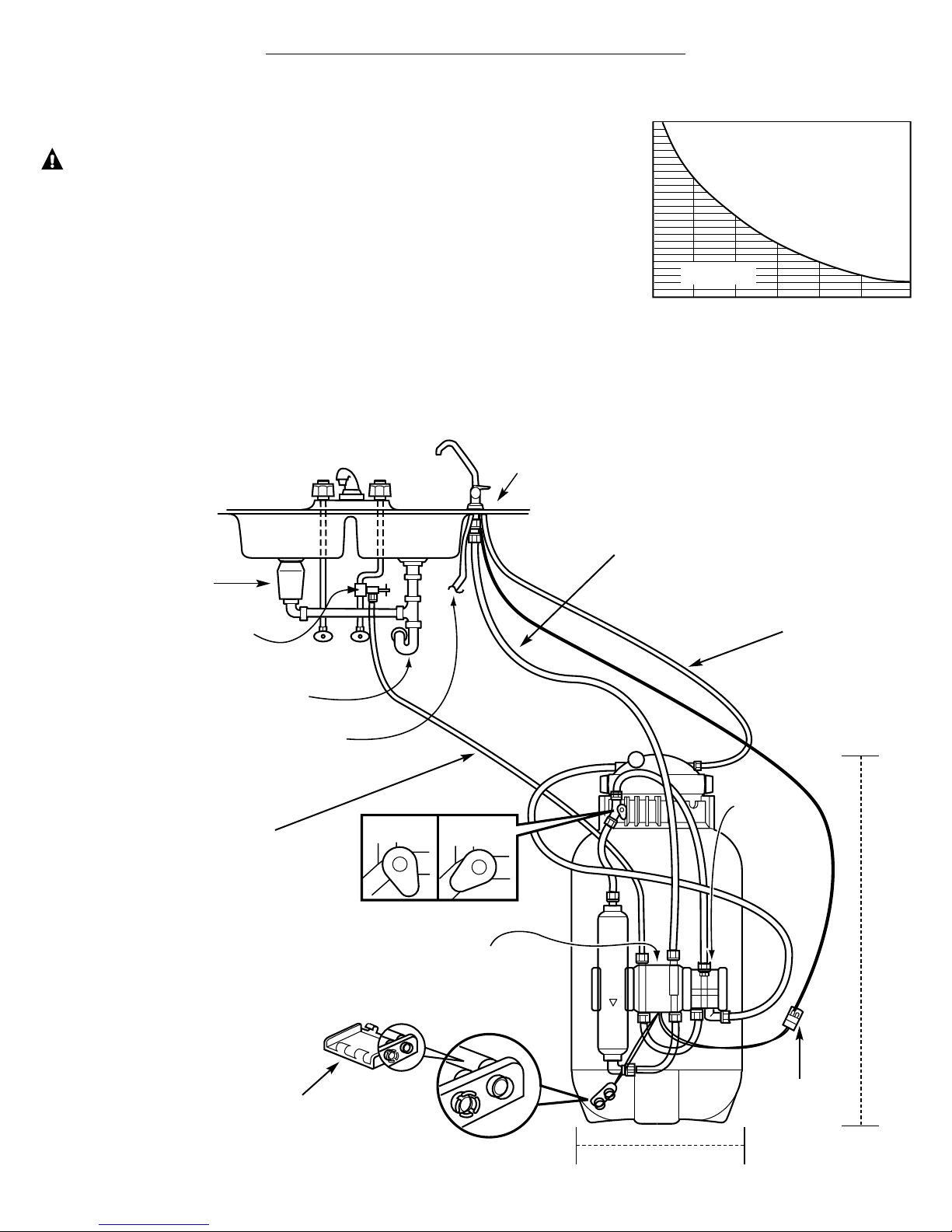

INSTALLATION OVERVIEW

RO product

water faucet

1/4″tubing, marked

WATER SUPPLY

Air gap device

inside faucet

Battery pack

Water supply valve

or compression fitting

Sink

p-trap

Drain

line*

Disposer

Leadwires

Automatic

shutoff

assembly

1/4″tubing,

marked

1/4″BARB

into air gap

device

3/8″tubing, marked FAUCET

Electronics

box

21″

OPEN

CLOSED

Tank shutoff valve

Flow

*For Drain line options refer to

Drain Connection Installation

section.

10″

overall width

including filter system

3

Fig. 1B.

Fig. 1A.

8

7.5

7

6.5

Incoming Water pH

6

WATER SOFTENER RECOMMENDED

Water Softener

not required

30

2010

INCOMING WATER HARDNESS (GPG)

50

40

60

FLOW

Page 4

STEP-BY-STEP INSTALLATION INSTRUCTIONS

FEED WATER SUPPLY

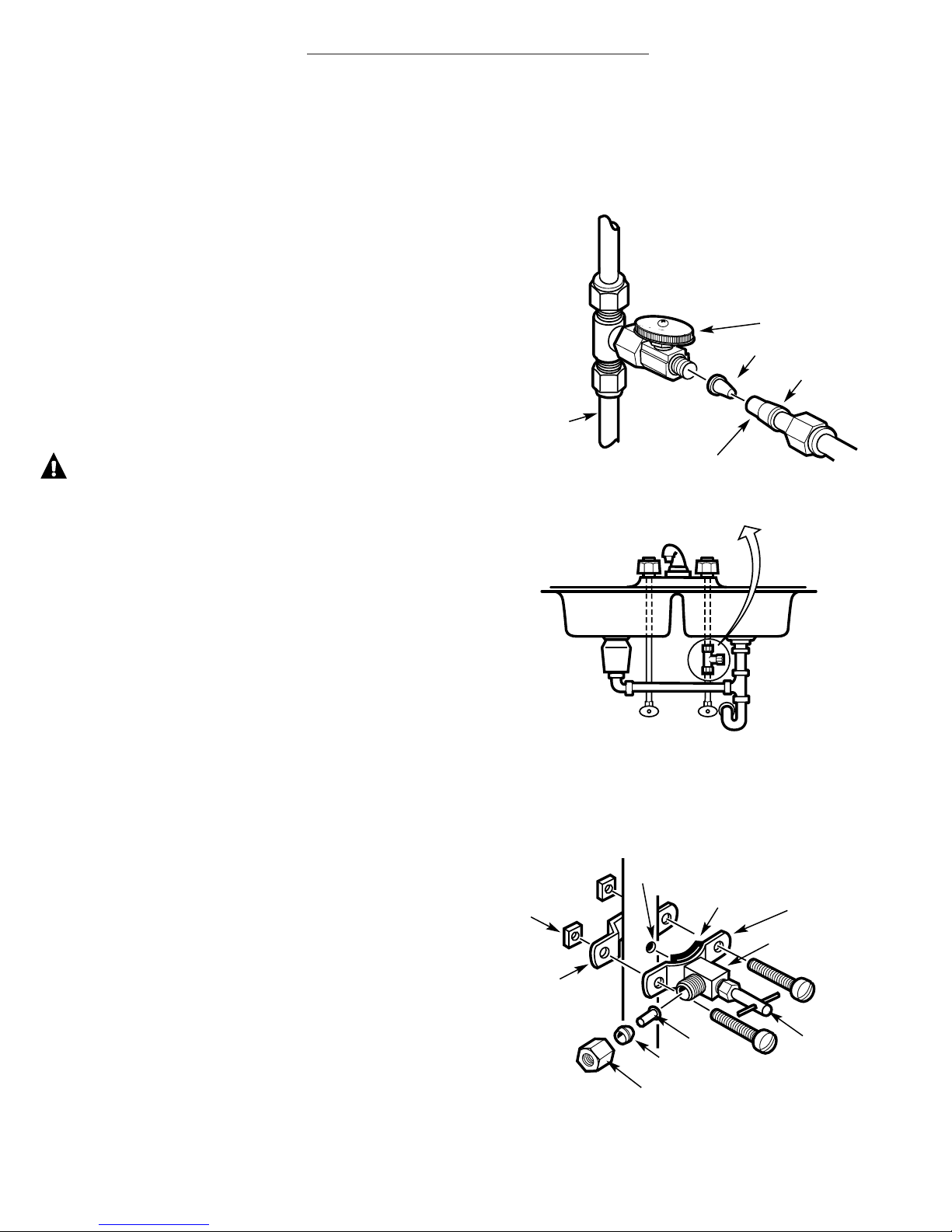

Check and comply with local plumbing codes as you plan, then install a cold feed water supply fitting. For new home installation using

standard plumbing fittings, see Fig. 2A below. A typical installation for existing homes using the saddle valve is shown in Fig. 2B below.

A. PREFERRED INSTALLATION

1. Turn off the cold water supply.

2. Complying with plumbing codes, install a fitting on the cold

water pipe to adapt 1 ⁄4 ″OD tubing. A typical connection is

shown in Fig. 2A (parts not included). Make sure a water

supply valve is used.

B. OPTIONAL INSTALLATION

Where codes permit

NOTE: Codes in the state of Massachusetts require installation

by a licensed plumber and do not permit the use of the saddle

valve. For installation, use plumbing code 248-CMR of the

Commonwealth of Massachusetts.

1. Turn off the cold water supply and attach saddle valve as

shown in Fig. 2B.

DANGER: To protect yourself from serious injury or

fatal shock, use a battery powered hand drill only to make

the hole. Do not use an electric drill.

2. Close the water supply valve by turning the handle clockwise.

3. Open the main water supply valve and several house faucets

to purge air from the system. Close faucets when water runs

smoothly.

4

Fig. 2A.

PREFERRED WATER SUPPLY CONNECTION

(using compression fitting)

TYPICAL

LOCATION

OPTIONAL WATER SUPPLY CONNECTION

(using saddle valve)

Pre-drill

1⁄4″ hole

Seal—make sure

the seal is in place

Clamp X

Nut (2)—not

required if

holes in

clamp are

threaded

Valve

Handle

Nut

Cold

water

1⁄4″compression fitting

Insert

Cold

water

pipe

1⁄4″ tubing to Reverse Osmosis

inlet, step 2, on page 7.

Ferrule

Ferrule

Insert

Use to connect

the tubing,

step 2, on page 7.

❵

Clamp Z

Fig. 2B.

Water supply valve

Page 5

5

FILTRATION DRAIN CONNECTION INSTALLATIONS

Check and comply with all state and local plumbing codes as you plan.

CAUTION: The options detailed below are the ONLY approved installation

configurations. Do not use any drain saddle device.

NOTE: Failure to follow these Installation Instructions will void the Warranty, and the

Installer will be responsible for any service, repair, or damages caused thereby.

PREFERRED INSTALLATION OPTIONS

(Options A, B and C)

OPTION A.

BASEMENT ACCESS INSTALLATION (FIG. 3A)

Route the drain line DIRECTLY from the Reverse Osmosis system to a standpipe in

the basement, bypassing the air gap provided in the faucet. The drain line may also

be routed in the basement to a floor drain or washtub, provided that the air gap in the

basement is maintained. Avoid dips, loops or low spots in the drain line. The basement

air gap and drain installation configuration must conform to all local codes. Special air

gap fittings are available to connect the drain line to the top of the standpipe.

OPTION B.

SEPARATE VENT INSTALLATION—2 P-TRAP (DRY-VENTED) (FIG. 3B)

Install a separate dry-vented p-trap under the sink to be used exclusively for the Reverse

Osmosis drain line. A dry-vented p-trap is a p-trap that has its own vent/stack. Attach

the provided drain line adapter to the p-trap and secure it with the slip joint nut and

washer as shown. Route the drain line from the air gap to the drain line adapter

ensuring that there are no dips, loops or low spots in the line, which could result in a

clogged drain line. The drain line adapter should be aligned vertically such that the

hose connection points in a direction 45° of vertical. (See Fig. 3E.) The drain line

MUST be routed through the air gap provided in the RO water faucet.

OPTION C.

SHARED VENT INSTALLATION— 2 P-TRAP (WET-VENTED) (FIG. 3C)

Install a p-trap under the sink to be used exclusively for the Reverse Osmosis drain line.

A wet-vented p-trap is a p-trap that shares a common vent/stack. Attach the provided

drain line adapter to the p-trap and secure it with the slip joint nut and washer as

shown. Route the drain line from the air gap to the drain line adapter ensuring that

there are no dips, loops or low spots in the line, which could result in a clogged drain

line. The drain line adapter should be aligned vertically such that the hose connection

points in a direction 45° of vertical. (See Fig. 3E.) The drain line MUST be routed

through the air gap provided in the RO water faucet. Locate the p-trap as high as

possible (minimum of 4″above horizontal pipe from second sink or disposer).

SECONDARY RECOMMENDATION

(Use only if option A, B or C is not possible.)

OPTION D.

DRAIN LINE ADAPTER INSTALLATION (FIG. 3D)

DO NOT install the drain line DOWNSTREAM OF A DISPOSAL or in a

HORIZONTAL PIPE. Install the provided drain line adapter under the sink as

shown. The baffle-tee or y-connector shown MUST be in place (purchase and install

if necessary) to prevent a clog in the Reverse Osmosis drain line. Route the drain line

from the air gap to the drain line adapter ensuring that there are no dips, loops or low

spots in the line, which could result in a clogged drain line. The drain line adapter

should be aligned vertically so that the hose connection points in a direction 45° off

vertical. (See Fig. 3E.) This installation MAY result in a slight drain noise in the sink

drain when the Reverse Osmosis system is operating. Rotate the Drain Line adapter tee

assembly slowly until noise is minimized. Generally, 180° opposite the existing

horizontal pipe/baffle-tee is a good orientation.

Fig. 3A.

Fig. 3B.

Fig. 3C.

Fig. 3D.

Fig. 3E.

From second sink

or disposer

From second sink or

disposer

From second

sink or disposer

Mandatory baffle-tee

or y-connector

From second

sink or disposer

45°

From

faucet air

gap

Drain line from

Reverse Osmosis

by-passing faucet

air gap

Maintain air gap at

drain point in

basement

From faucet air gap

Drain line

adapter

Drain line adapter

Separate p-trap

Cap (not

included)

Cap (not

included)

4″

Min.

Drain line connection should

be 180° opposite existing

horizontal pipe/baffle-tee as

shown in diagram

From faucet air gap

Drain line adapter

Drain line adapter

Proper drain line adapter orientation.

Page 6

ELECTRONIC FAUCET INSTALLATION

Be sure there is room underneath the sink to make the needed

connections. Select one of the following places to install the faucet:

—IN an existing sink spray attachment or soap dispenser hole

—IN a hole to be drilled in the sink top

—IN a hole to be drilled in the countertop, next to the sink

NOTE: Looking at Fig. 4D, be sure the faucet base will fit flat against the

surface at the selected location so the gasket will seal. The base may

have to be angled sideways or diagonally.

1. If drilling is needed, make a 1-1 ⁄ 4″dia. hole. Be sure to use the

proper procedure for drilling porcelain or stainless steel.

2. Looking at Fig. 4A, insert a screw into the NON-SLOTTED base

mounting hole. Turn a flat nut a few turns onto the screw.

3. Position the base gasket over the mounting hole. Set the base on

the gasket, routing the leadwire through the mounting hole.

Holding the flat nut under the sink with one finger, tighten the

screw until just snug.

4. Turn the remaining flat nut a few turns onto the other screw.

Position the screw in the slotted base mounting hole and tighten

until snug. Make sure the gasket position is properly aligned and

carefully tighten both screws until the base is held firmly in place.

Do not overtighten and break the base.

5. Assemble the top faucet base and hex nut onto the faucet stud

(Fig. 4C). Tighten the nut until snug.

6. Insert washer into tubing adapter. Securely tighten to faucet stud.

7. Take the 27″ length of 3 ⁄ 8″tubing and push one end completely

onto the 3 ⁄8 ″faucet barb fitting (Fig. 4D).

8. Position the Reverse Osmosis system under the sink. Referring to

Fig. 5, page 7, hang the system on cabinet wall.

9. Route the 1 ⁄ 4″tubing (marked “1 ⁄4 ″BARB ON FAUCET”) and

the 3 ⁄8 ″tubing (marked “FAUCET”) up through the mounting

hole and faucet base:

a. Push one end of the 1 ⁄4 ″tubing onto the 1 ⁄4 ″barb on the

faucet.

b. Using the compression nut, fasten the 3 ⁄8 ″tubing to the tubing

adapter and tighten the nut. Make sure the tubing is completely

seated in the adapter.

10. Remove the short shipping tube and insert the spout into the

faucet body.

11. Lower the faucet assembly and lock into place on the faucet base.

6

Fig. 4C.

Fig. 4A.

Fig. 4B.

Fig. 4D.

Faucet

base

Nut (2)

Screw (2)

Washer

Hex nut

Top faucet base

Faucet

Lever

Spout

Faucet base

leadwire

1-1/4″ dia. mounting

hole in sink or

countertop

Gasket

Faucet

base

NOTE: For ease of service and

maintenance, keep tubing

lengths long enough so removal

of the Reverse Osmosis system

from under the sink is possible.

Faucet stud

Compression

nut

Tubing

adapter

3/8″barb

fitting

1/4″tubing marked

1/4″BARB

1/4″barb

fitting

3/8″tubing

marked FAUCET

3/8″tubing,

27″ long

Faucet base

Compression

nut

TOP VIEW

ASSEMBLED

Screw (2)

Nut (2)

From RO

To drain

From RO

Page 7

FLOW

FAUCET DRAIN TUBING, WATER SUPPLY TUBING, AND ELECTRONIC LEADWIRE CONNECTION

If Option A, BASEMENT ACCESS INSTALLATION, from page 5 was used, go to step 2.

1. If Option B, C or D from page 5 was used, connect the faucet

drain tubing by running the 27″ length, 3⁄ 8″tubing from the

3⁄8″faucet barb to the drain fitting (installed on page 5).

Keep this tubing run as short and straight as possible, without

loops, dips, or low-spots. Cut the tubing as needed and insert

into the drain fitting (Fig. 3B, 3C or 3D, page 5).

2. To connect the water supply tubing: Run the 1 ⁄4 ″tubing

(marked “WATER SUPPLY”) from the Reverse Osmosis inlet

to the feed water supply fitting (reference Fig. 2A or 2B, page

4). Connect the tubing as applies (Fig. 2A or 2B, page 4) and

tighten the nut securely (use Teflon Tape™ to prevent leaks).

3. To connect the electronics box:

a. Remove the box’s back cover and fasten the battery

connector to the battery pack (see Fig. 5). Be sure the

batteries are installed correctly. Place the battery pack in

the electronics box and reinstall the back cover.

b. Fasten the electronics box leadwire to the faucet base

leadwire (see Fig. 5). If needed, a 15′ leadwire extension

is available from GE (part #WS07X10009).

7

RO product

water faucet

Air gap device

inside faucet

1/4″tubing, marked

WATER SUPPLY

Battery pack

Water supply valve

or compression fitting

Sink

p-trap

Drain

line*

Disposer

Leadwires

Automatic

shutoff

assembly

1/4″tubing,

marked

1/4″BARB

into air gap

device

3/8″tubing, marked FAUCET

Electronics

box

OPEN

CLOSED

Tank shutoff valve

Flow

*For Drain line options refer to

Drain Connection Installation

section.

Fig. 5.

Page 8

SANITIZING THE REVERSE OSMOSIS SYSTEM

Sanitize upon installation of the Reverse Osmosis system and after servicing inner

parts of the Reverse Osmosis system, including replacement of prefilter, postfilter

and Reverse Osmosis cartridge. It is important to wash hands with anti-bacterial

soap before handling inner parts of the system.

CAUTION: If installing unit in New Construction, ensure house plumbing is flushed

thoroughly before opening the water supply valve. Also, before sanitizing, be sure to

remove all cartridges as follows. Chlorine will destroy the Reverse Osmosis cartridge.

1. Be sure the water supply valve to the Reverse Osmosis system is turned off and the

RO water faucet is open. Allow the system to drain completely (this takes several

minutes).

2. Place a dry towel under unit. Remove the clamp retainers and clamp

sections from top of unit.

3. Lift the Reverse Osmosis cap straight up (a slight resistance is normal) from

the Reverse Osmosis housing (no need to disconnect tubing) and move aside.

NOTE: If the cap o-ring seal remained in the Reverse Osmosis housing,

replace it on the cap.

4. Remove the Reverse Osmosis cartridge and outer prefilter cartridge from

the Reverse Osmosis housing and place in a clean plastic bag. Dispose of

water from the Reverse Osmosis housing.

5. Fill the Reverse Osmosis housing with fresh cold water, to about 1″ from the top.

Add one ounce (2 tablespoons) of ordinary 5.25% household chlorine bleach

and mix into the water. DO NOT ADD CHLORINE FIRST. Concentrated

chlorine may damage plastics.

6. Replace Reverse Osmosis cap, with the o-ring, and install the clamp retainers.

7. Close the red tank shutoff valve and disconnect postfilter at the tank shutoff valve.

Connect the Reverse Osmosis product water tubing (disconnect at electronics box)

directly to the tank shutoff valve, isolating the carbon postfilter as shown in Fig. 6B.

8

. Open the red tank shutoff valve and the water supply valve to the Reverse Osmosis system.

Allow system to fill for one minute. Now open the RO water faucet, locking the lever

upward against the spout.

9. Allow water to flow through the Reverse Osmosis system until all the bleach odor is

gone (approximately 20 minutes).

10. Turn off the water supply valve to the Reverse Osmosis system. Close the RO water

faucet AFTER the water flow stops.

11. Close the red tank shutoff valve. Disconnect the water product line from the red tank

shutoff valve and connect to the electronics box. Reconnect postfilter line to red tank

shutoff valve. Open red tank shutoff valve.

12. a. Repeat steps two and three. Be careful of water in the Reverse Osmosis housing.

Dispose of water.

b. Replace the Reverse Osmosis cartridge with the o-ring seal downward and the

prefilter cartridge with “this side up” facing upward. BE SURE HANDS HAVE

BEEN CLEANED WITH AN ANTI-BACTERIAL SOAP.

c. Repeat step 6.

8

CLOSED OPEN

Tank shutoff valve

Automatic shutoff assembly

Postfilter

Product water

tubing

Red tank

shutoff valve

Clamp sections

(2)

Reverse Osmosis

housing

Bottom

end

Flow

control

Cone screen

Reverse

Osmosis

cap

Green

protective

cap

Vacuum

relief valve

Postfilter

line

Prefilter

cartridge

Reverse Osmosis

cartridge

End with o-ring

seals downward

Clamp retainers

(2)

Fig. 6A.

Fig. 6B.

Connect Reverse

Osmosis water tubing

to tank shutoff valve

Disconnect

postfilter

Postfilter

Electronics

box

UP

FLOW

Page 9

PRESSURE TESTING THE SYSTEM

—DO THE SANITIZING PROCEDURE BEFORE PRESSURE

TESTING—INSTALLATION CHECKLIST

1. Open the water supply valve to the Reverse Osmosis system and

open the storage tank shutoff valve.

2. Check all connections for LEAKS.

3. In about 4 hours, pressure will build in the Reverse Osmosis

system. Carefully recheck all fittings and connections for water

leaks. Correct leaks if any are found.

4. Fill sink(s) 1/2 full of tap water and drain, checking drain

plumbing for leaks.

PURGING THE SYSTEM

1. Wait about 4 hours for the storage tank to fill.

2. Open the RO faucet until the tank is empty and flow stops.

3. Close the RO faucet and repeat these steps three more times.

The system is ready to make product water for use.

WARNING: Initially, the Reverse Osmosis cartridge

contains a food grade preservative that has to be purged

from the system before first use or whenever Reverse

Osmosis cartridge is replaced. The preservative will give

product water an unpleasant taste and odor.

INSTALLATION CHECKLIST

1. Are all tubing connections tightened? Do they run between the

points shown? No leaks!

2. Is the faucet base leadwire connected to the electronics box

leadwire?

3. Is the battery holder connected to the electronics box and are

the batteries installed in the holder correctly?

4. Did you use drain option B, C or D? Make sure the 3 ⁄8 ″drain

tubing, from the faucet to the drain point, is without loops,

dips, or low-spots.

5. Is the tank shutoff valve in the open position?

6. Is the water supply shutoff valve open?

7. Did you sanitize and purge the system?

WHAT THE REVERSE OSMOSIS SYSTEM DOES

Reverse Osmosis removes Total Dissolved Solids (TDS) and

organic matter from water by diffusing it through a special

membrane. The membrane separates minerals and impurities

from the water and they are flushed to the drain. High quality

product water goes directly to the drinking water faucet or to the

storage tank. The system makes a good supply of drinking water

each day (see

Product Specifications

). How much it makes depends

on the feed water supply pressure, temperature, and quality.

The system includes an electronic faucet assembly with an

integrated testing feature. When water is taken from the faucet,

a flashing green indicator light means TDS removal is within

specified limits and that water quality is good.

The prefilter and postfilter are replaceable cartridges. The carbon

prefilter removes chlorine while also filtering sediments. The

postfilter removes any other undesirable tastes and odors before

you use the water.

THE GE ELECTRONIC MONITOR SYSTEM

Indicator lights on the faucet base show Reverse Osmosis

performance when the faucet is open to dispense water.

Flashing Green Light—The Reverse Osmosis system is providing

high quality drinking water.

NOTE: If the Reverse Osmosis system is connected to the

refrigerator, this light will also flash when the icemaker or

dispenser is in use.

The green light may stop flashing when the supply of Reverse

Osmosis water is nearly gone and flow from the RO water faucet

decreases. This is a normal condition.

Flashing Amber “FILT” Light—The prefilter and postfilter cartridges

need replacing. This occurs after 6 months or 900 gallons of

product water use, whichever occurs first. Also, replace the 4 “AA”

alkaline batteries in the electronics box. Good batteries are needed

to ensure correct indicator light operation. Weak batteries may

give a false “RO” light indication. Changing the batteries resets the

6 month or 900 gallon period.

Flashing Amber “RO” Light—The Reverse Osmosis cartridge is no

longer removing at least 75% of the Total Dissolved Solids (TDS)

from the supply water. The Reverse Osmosis cartridge, flow

control, and screen need replacing.

NOTE: Disregard initial or short periods (a few seconds) of the

flashing “RO” light. Long periods of limited or no use can cause

the TDS levels to temporarily change.

9

Flashing amber

“RO” light

Flashing green

“OK” light

Flashing amber

FILTER light

Fig. 7.

Page 10

LITERATURE

10

NOTE: Codes in the state of Massachusetts require installation

by a licensed plumber and do not permit the use of the saddle

valve. For installation, use plumbing code 248-CMR of the

Commonwealth of Massachusetts.

58

999

1

3

4

55

5

41

6

7

8

13

12

9

10

11

35

34

33

14

32

40

39

38

56

43

44

TO

FAUCET

AIR GAP

45

46

31

BOTTOM

10

9

13

12

15

21

22

16

20

19

18

17

23

24

57

29

28

25

27

26

47, 48

49, 50

51

WS15X10014

SHUTOFF ASM.

Page 11

GENERAL ELECTRIC PARTS CATALOG

REF. NO. PART NO. PART DESCRIPTION BB01 BL01 WH01 WW01

0001 WS15X10011 FAUCET BLACK TIP & LEVER 111-

WS15X10013 FAUCET–ALL WHITE ---1

0003 WS10X10008 TOP FAUCET BASE BLACK 1 1 - -

WS10X10010 TOP FAUCET BASE WHITE - - 1 1

0004 WS02X10007 SCREW #6-32 X 1 -3/8″ 2222

0005 WS10X10011 BASE FAUCET BLACK 1 1 - -

WS10X10004 BASE FAUCET WHITE - - 1 1

0006 WS08X10003 GASKET FAUCET 1111

0007 WS02X10008 NUT 2222

0008 WS03X10003 ADAPTER TUBING 1111

0009 WS22X10005 NUT 1/4″ TUBE 8888

0010 WS22X10006 INSERT 1/4″ TUBE 7777

0011 WS15X10004 VALVE SHUTOFF TANK 1111

0012 WS22X10007 INSERT 3/8″ TUBE 5555

0013 WS22X10008 NUT 3/8″ TUBE 3333

0014 FX18L FILTER POST CARBON 1111

0015 WS28X10002 HOLDER FILTER 1111

0016 WS21X10001 BOX ELECTRONICS 1111

0017 WS03X10004 WASHER FLOW 1111

0018 WS01X10001 MAGNET 1111

0019 WS03X10005 SPRING 1111

0020 WS06X10002 HOLDER BATTERY 1111

0021 WS10X10005 VALVE BOTTOM 1111

0022 WS22X10009 DIAPHRAGM 2222

0023 WS22X10010 PLUNGER 1111

0024 WS22X10012 ELBOW 1/8″ NPT X 1/4″ 1111

WS22X10011 ELBOW 1/8″ NPT X 1/4″ 1111

0025 WS22X10013 CONNECTOR W/NUT 1/8 NPT 1111

WS22X10014 CONNECTOR 1/8″ NPT X 1/4 1111

0026 WS10X10006 VALVE TOP 1111

0027 WS10X10007 VALVE CENTER 1111

0028 WS02X10010 SCREW # 10-14 X 1-3/4″ 4444

0029 WS22X10015 CONNECTOR W/NUT 1/4 NPT 1111

WS22X10018 CONNECTOR 1/4 NPT X 1/4 1111

0030 WS20X10001 LINER ASSEMBLY 1111

0031 WS08X10004 O-RING 5/16″X 7/16″ 1111

0032 WS15X10007 VALVE VACUUM RELIEF 1 1 11

0033 WS20X10002 BLADDER 1111

0034 WS35X10004 CHECK KIT BALL 1111

0035 WS20X10003 HOUSING R.O. 1111

0038 WS03X10012 O-RING R.O. CAP 1 111

0039 WS31X10007 CAP R.O. 1 111

0040 WS22X10019 ELBOW 1/4″ NPT X 1/4″1111

0041 WS15X10008 WATER SUPPLY VALVE* 1111

0043 WS03X10015 SCREEN CONE 1111

0044 WS03X10016 CONTROL FLOW 1111

0045 FX18M R.O. CARTRIDGE 1 1 11

0046 FX18F PREFILTER–CARBON 1 1 11

0047 WS07X10005 TUBING 1/4″X 10 FT 1111

0048 WS07X10006 TUBING 1/4″ X 20 FT 1111

0049 WS07X10007 TUBING 3/8″ X 20 FT 1111

0050 WS07X10008 TUBING 3/8″ X 20 FT 1111

0051 WS15X10014 SHUTOFF ASSEMBLY 1111

0055 WS28X10003 RETAINER CLAMP 2222

0056 WS28X10004 CLAMP HOUSING 2222

0057 FLOW RESTRICTER

0058 DRAINLINE ADAPTER

0999 49-5803-3 PM MANUAL USE & CARE 1111

49-5807-3 PM INSTRUCT INSTAL 1111

PERFORMANCE DATA SHEET

PNRV18Z

NOTE: Codes in the state of Massachusetts require installation by a licensed plumber and

do not permit the use of the saddle valve. For installation, use plumbing code 248-CMR of

the Commonwealth of Massachusetts.

11

Page 12

GENERAL ELECTRIC COMPANY, Appliance Park, Louisville, KY 40225

Loading...

Loading...