Page 1

g

SGT5000_030-040_UPS_ GE_01

SG Series 10, 20, 30 and 40 kVA

GE

OPERATING MANUAL

UNINTERRUPTIBLE POWER SUPPLY

Digital Energy

TM

SG Series

10 – 20 – 30 – 40 kVA

Series 0

g

General Electric Company

2500 Discovery Blvd.

Rockwall, TX 75032

Telephone: (972)-290-7400

Fax: (972)-290-7500

SG Series UPS Technology for the digital world

Page 2

g

GE

Model:

Date of issue: 04/15/2003

File name: OPM_SGS_USM_10K_40K_0US_V010

Revision:

Author:

Identification No.:

Up-dating

Revision Concern Date

COPYRIGHT © 2003 by GE

SG Series

1.0

Raimondo Bizzozero

10, 20, 30 and 40 kVA / Series 0

All rights reserved.

The information contained in this publication is intended solely for the purposes indicated.

The present publication and any other documentation supplied with the UPS system is not to be

reproduced, either in part or in its entirety, without the prior written consent of GE.

The illustrations and plans describing the equipment are intended as general reference only and

are not necessarily complete in every detail.

The content of this publication may be subject to modification without prior notice.

OPM_SGS_USM_10K_40K_0US_V010.doc 2/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 3

g

y

s

t

Dear Customer,

We thank you for selecting our products and

are pleased to count you amongst our ver

valued customers at GE.

We trust that the use of the SG Serie

Uninterruptible Power Supply system,

developed and produced to the highes

standards of quality, will give you complete

satisfaction.

Please carefully read the Installation Guide.

It contains all the necessary information

about the installation of the UPS.

GE

Thank you for choosing

START UP AND COMMISSIONING

A GE Global Services Field Engineer must perform start-up and

commissioning of the UPS. Please Contact G.E. Global Services at least two

weeks prior to schedule start-up and commissioning at 1-800-637-1738, or by

E-mail at gedeservices@indsys.ge.com

Manufactured by:

Distributed in the USA by: Your service contact:

GE

!

g

GE

GE DIGITAL ENERGY SA

6595 Riazzino (Locarno)

Switzerland

OPM_SGS_USM_10K_40K_0US_V010.doc 3/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 4

g

GE

Preface

Congratulations on your choice of a SG Series Uninterruptible Power Supply (UPS).

It will help eliminate Load disturbances due to unexpected power problems.

Manual

This

the switches, the meaning of the system events related to the front panel

indication, and provides procedures for starting and stopping the equipment.

Please refer to the accompanying Installations Guide, which describes how to

prepare the installation site, and it provides weight, dimensions and procedures

for moving, installing and connecting the UPS.

While every care has been taken to ensure the completeness and accuracy of this

manual, GE assumes no responsibility or liability for any losses or damages

resulting from the use of the information contained in this document.

WARNING!

SG Series 10, 20, 30 and 40 kVA, is a product that needs to be installed by a

licensed and knowledgeable contractor.

describes the function of the UPS module, the purpose and location of

We recommend that this manual be kept next to the UPS for future references.

If any problems are encountered with the procedures contained in this manual,

please contact your Service Center before you proceed.

This document shall not be copied or reproduced without the permission of GE.

Some of the information contained in this manual may be changed without notice

to reflect technical improvements.

Safety instructions

Read the safety instructions contained on the following pages carefully before the

installation of the UPS, options and

Pay attention to the rectangular boxes included in the text:

They contain important information and warning concerning electrical connections

and personnel safety.

Battery System

.

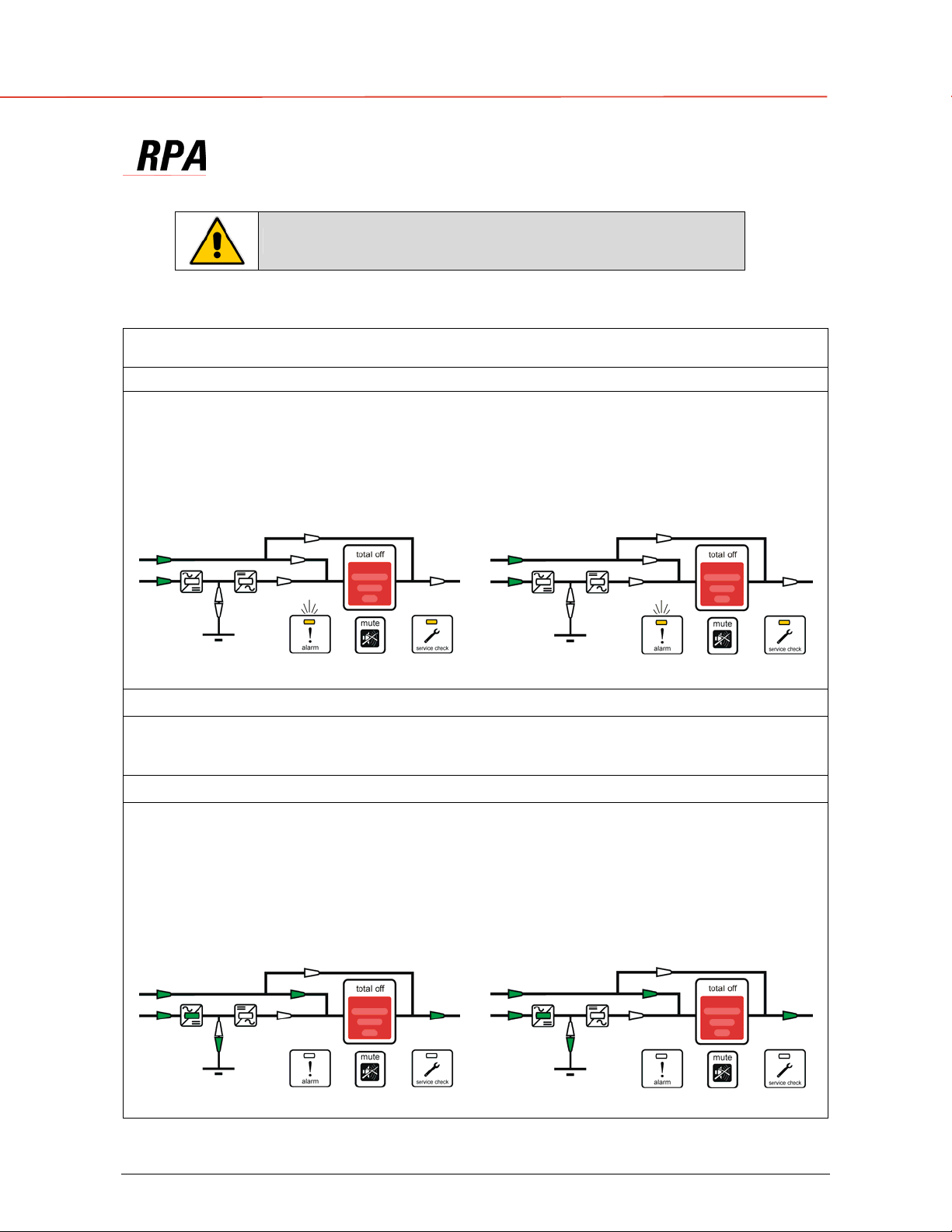

Parallel version secured with RPA

When included in the text, this symbol refers to

operation needed only for parallel system.

OPM_SGS_USM_10K_40K_0US_V010.doc 4/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 5

g

GE

Table of contents Page

1 IMPORTANT SAFETY INSTRUCTIONS .................................................................7

2

INTRODUCTION.....................................................................................................10

3 DESCRIPTION........................................................................................................11

3.1 BLOCK DIAGRAM AND MAIN ELEMENTS..................................................................11

3.2 OPERATION MODES ...................................................................................................12

3.2.1 Normal operation mode.................................................................................................12

3.2.2 Utility failure operation...................................................................................................12

3.2.3 Utility recovery operation...............................................................................................13

3.2.4 Automatic Bypass..........................................................................................................13

3.2.5 Manual Bypass..............................................................................................................13

3.3 PARALLEL SYSTEM OPERATION ..............................................................................14

3.3.1 Introduction to the parallel system.................................................................................14

3.3.2 Features of RPA parallel system...................................................................................15

3.3.3 System control...............................................................................................................15

3.3.4 Synchronization.............................................................................................................15

3.3.5 Load sharing..................................................................................................................15

3.4 RECTIFIERS PARALLELED ON THE SAME BATTERY..............................................16

3.5 RECYCLING AT THE END OF SERVICE LIFE............................................................17

4 LAYOUT .................................................................................................................18

4.1 LAYOUT SG SERIES 10 AND 20 KVA ..............................................................................18

4.2 LAYOUT SG SERIES 30 AND 40 KVA ..............................................................................19

5 CONTROL PANEL .................................................................................................20

5.1 CONTROL PANEL ........................................................................................................20

5.2 TABLE OF FUNCTIONS AND INDICATIONS ON CONTROL PANEL.........................20

6 LCD SCREEN.........................................................................................................22

6.1 METERING MODE........................................................................................................23

6.2 ALARMS........................................................................................................................26

6.3 PARAMETERS..............................................................................................................27

6.4 EDIT MODE ..................................................................................................................29

6.5 USER PARAMETERS...................................................................................................32

6.6 EVENTS (ALARMS AND MESSAGES) ........................................................................35

6.6.1 Alarms list......................................................................................................................35

6.6.2 Messages list.................................................................................................................39

6.6.3 Event report

7

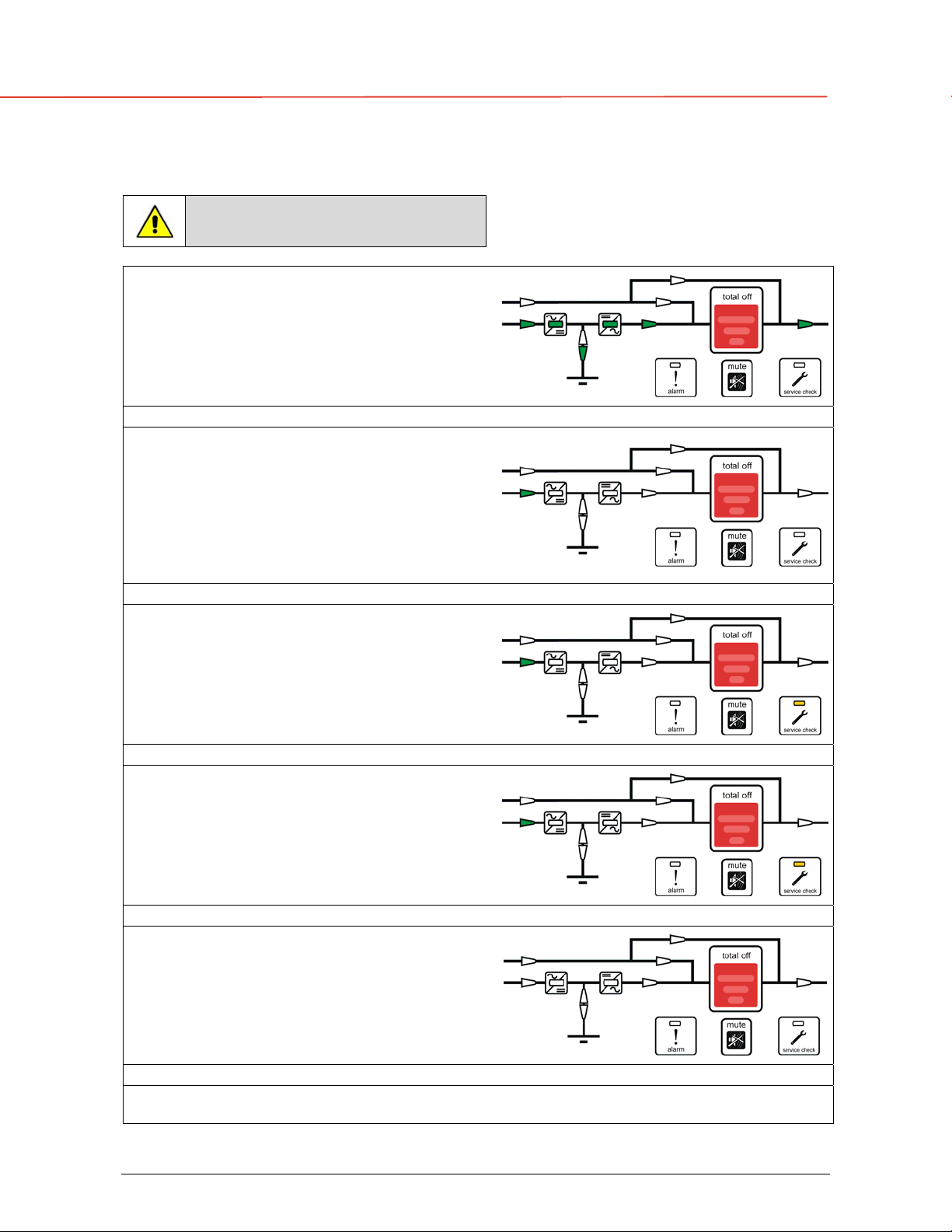

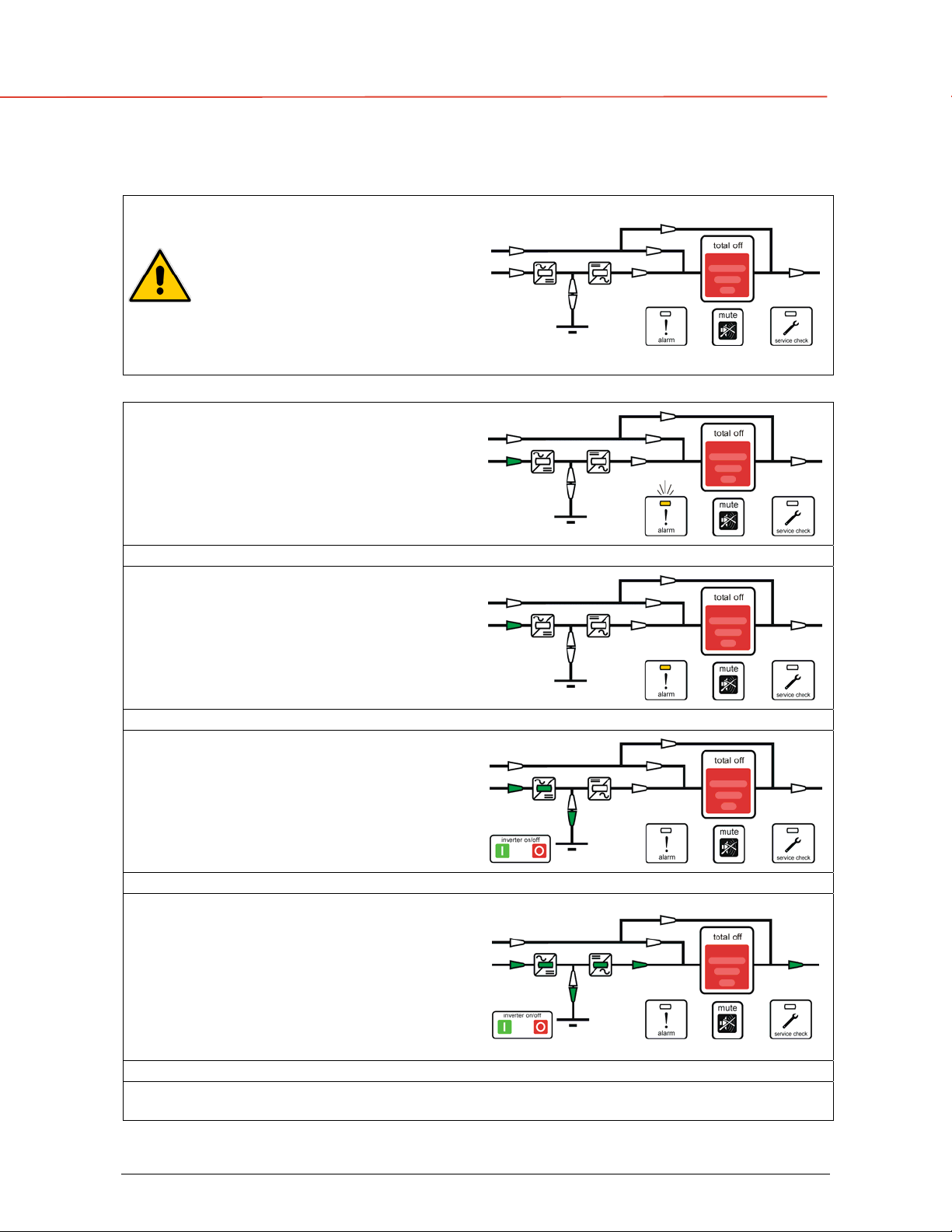

7.1 PROCEDURES FOR SINGLE UPS..............................................................................43

OPM_SGS_USM_10K_40K_0US_V010.doc 5/88 Operating Manual

OPERATION...........................................................................................................42

7.1.1 Start-up of the

7.1.2 Maintenance shutdown (Load on Q2) ...........................................................................44

7.1.3 From Manual Bypass (Q2) to normal function On-line ..................................................45

7.1.4 Complete UPS shutdown (No Load supply)..................................................................46

7.1.5 Restore to normal operation after “total off”...................................................................47

7.1.6 Restore to normal operation after EPO (Emergency Power Off)...................................48

SG Series

.....................................................................................................41

SG Series

..................................................................................................43

SG Series

10, 20, 30 & 40 kVA

Page 6

g

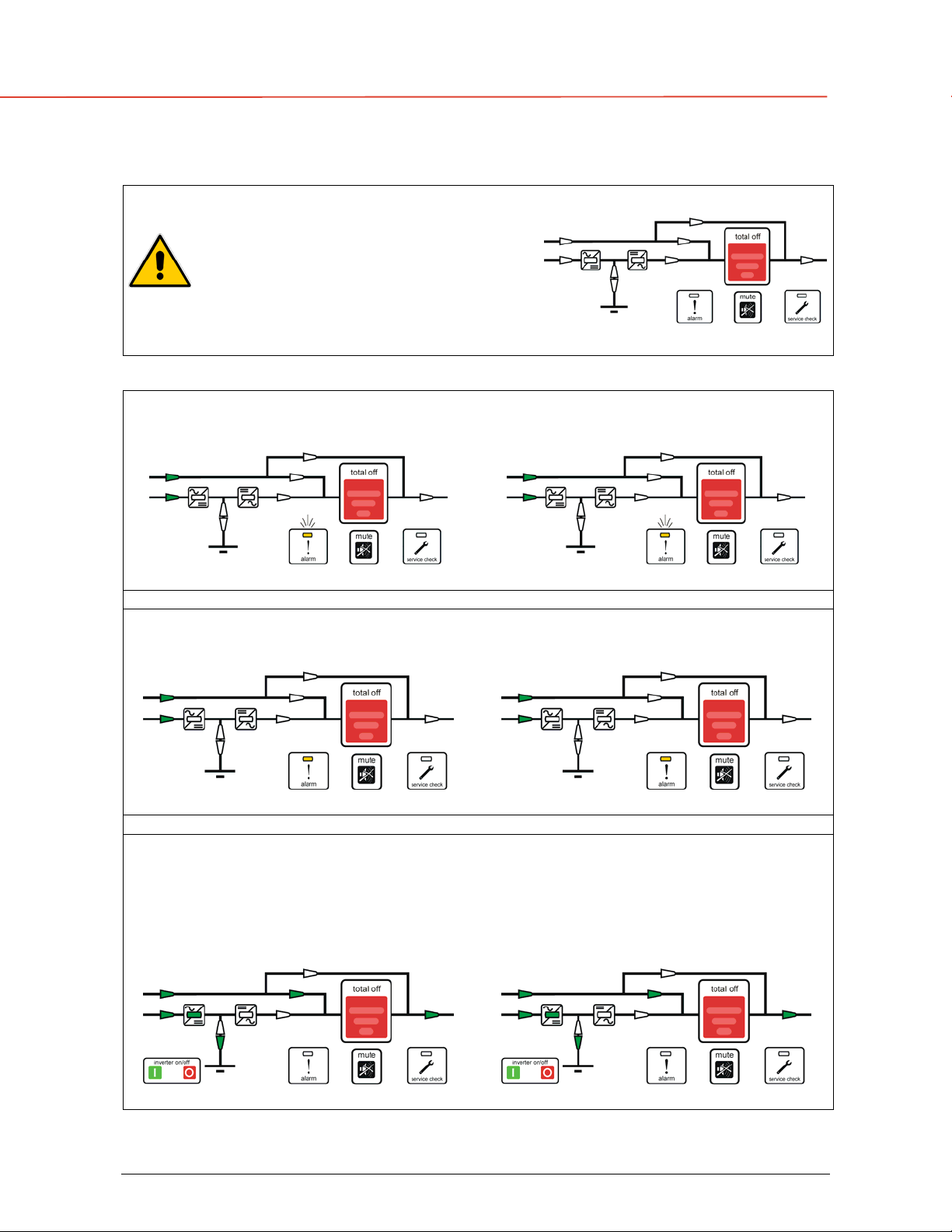

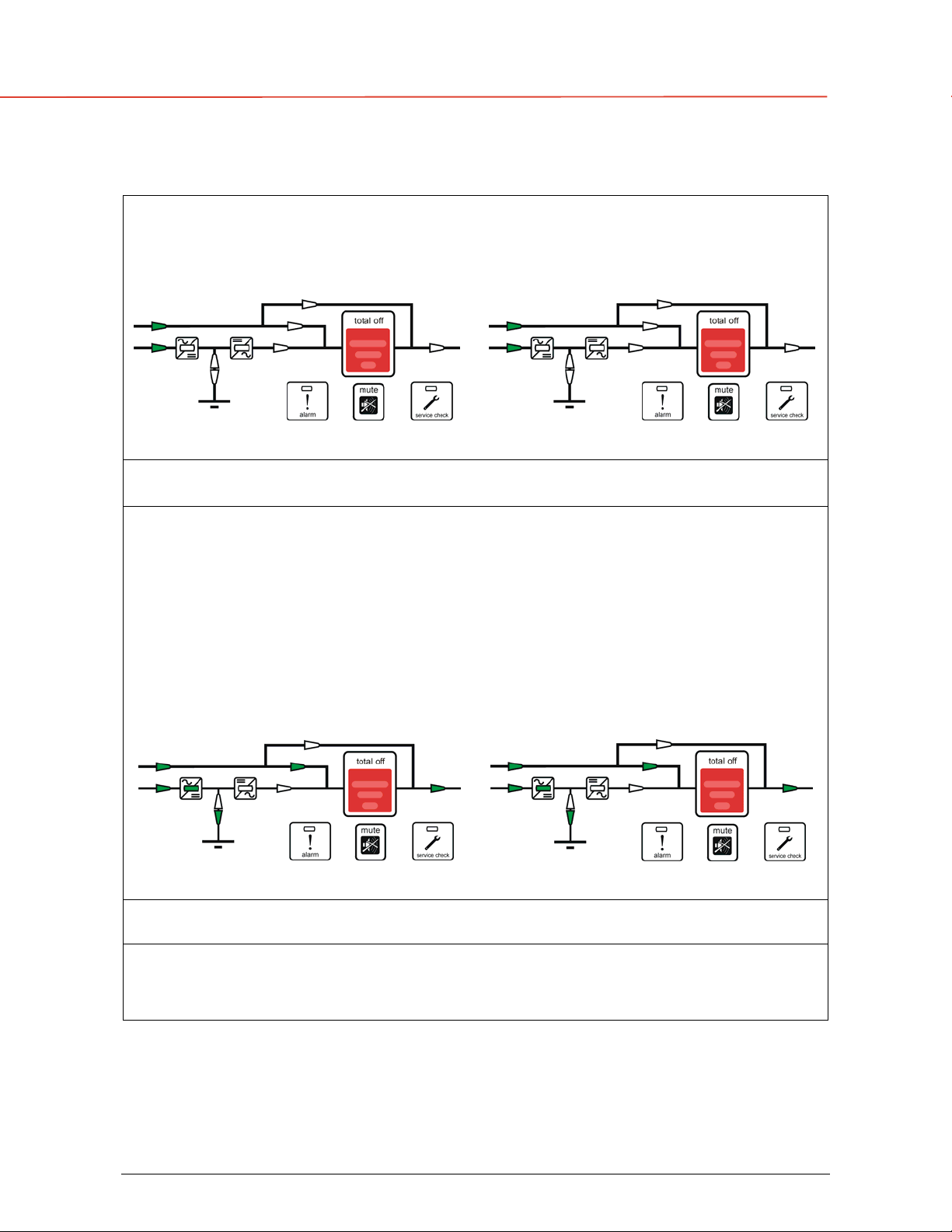

7.2 PROCEDURES FOR UPS FUNCTIONING AS FREQUENCY CONVERTER .............49

7.2.1 Start-up of the SG Series as frequency converter ............................................................49

7.2.2 Complete UPS shutdown (No Load supply)..................................................................50

7.2.3 Restore to normal operation after “total off”...................................................................51

7.2.4 Restore to normal operation after EPO (Emergency Power Off)...................................52

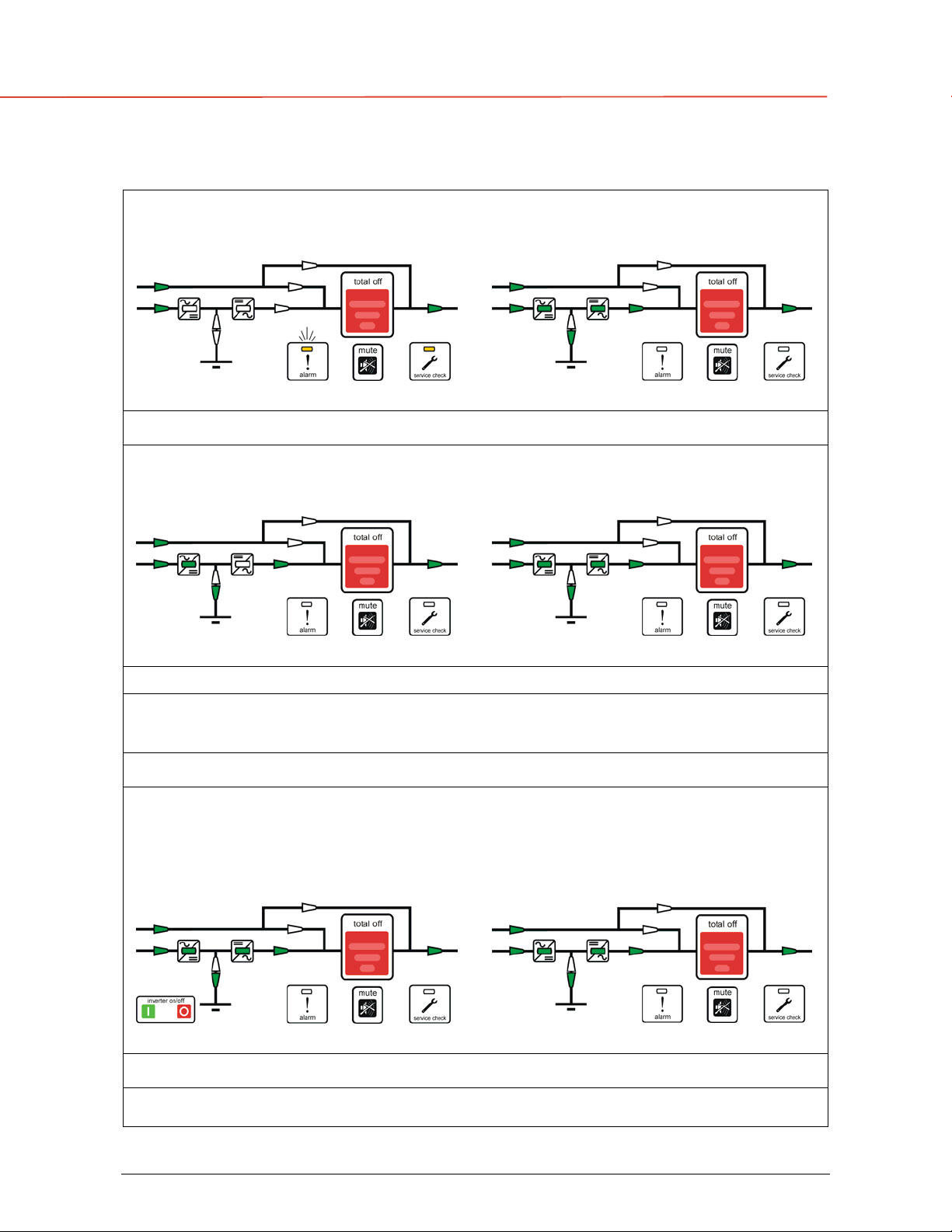

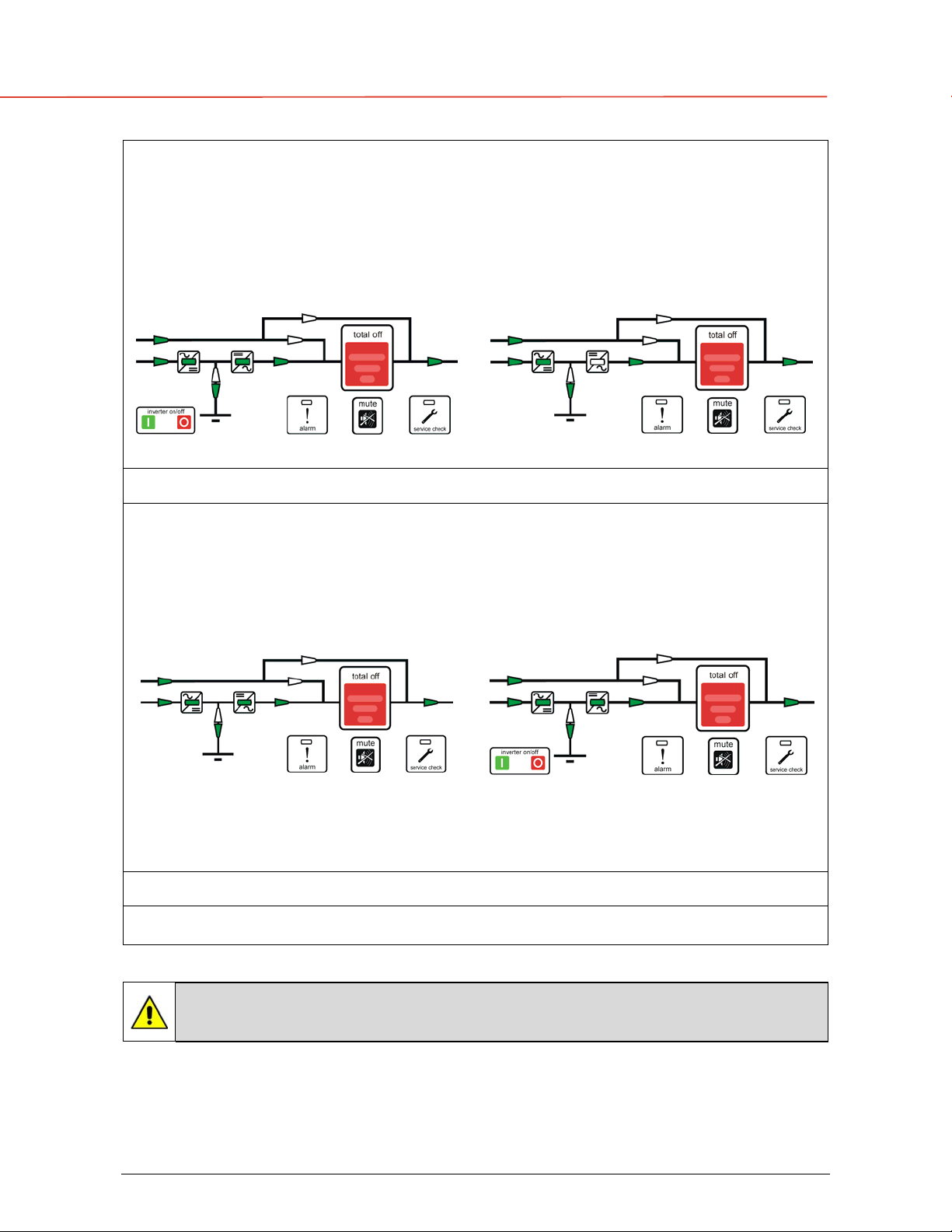

7.3 PROCEDURES FOR PARALLEL SYSTEM..................................................................53

7.3.1 Parallel System start-up ................................................................................................53

7.3.2 Maintenance system shutdown (Load supplied from Q2 on all Units)...........................55

7.3.3 From Manual Bypass (Q2) to normal function On-line ..................................................56

7.3.4 Separate a Unit from the parallel system (System Redundancy)..................................58

7.3.5 Reconnect a Unit to a parallel system ...........................................................................59

7.3.6 Parallel system shutdown (No Load supply) .................................................................60

7.3.7 Restore to normal operation after “total off”...................................................................62

7.3.8 Restore to normal operation after EPO (Emergency Power Off)...................................64

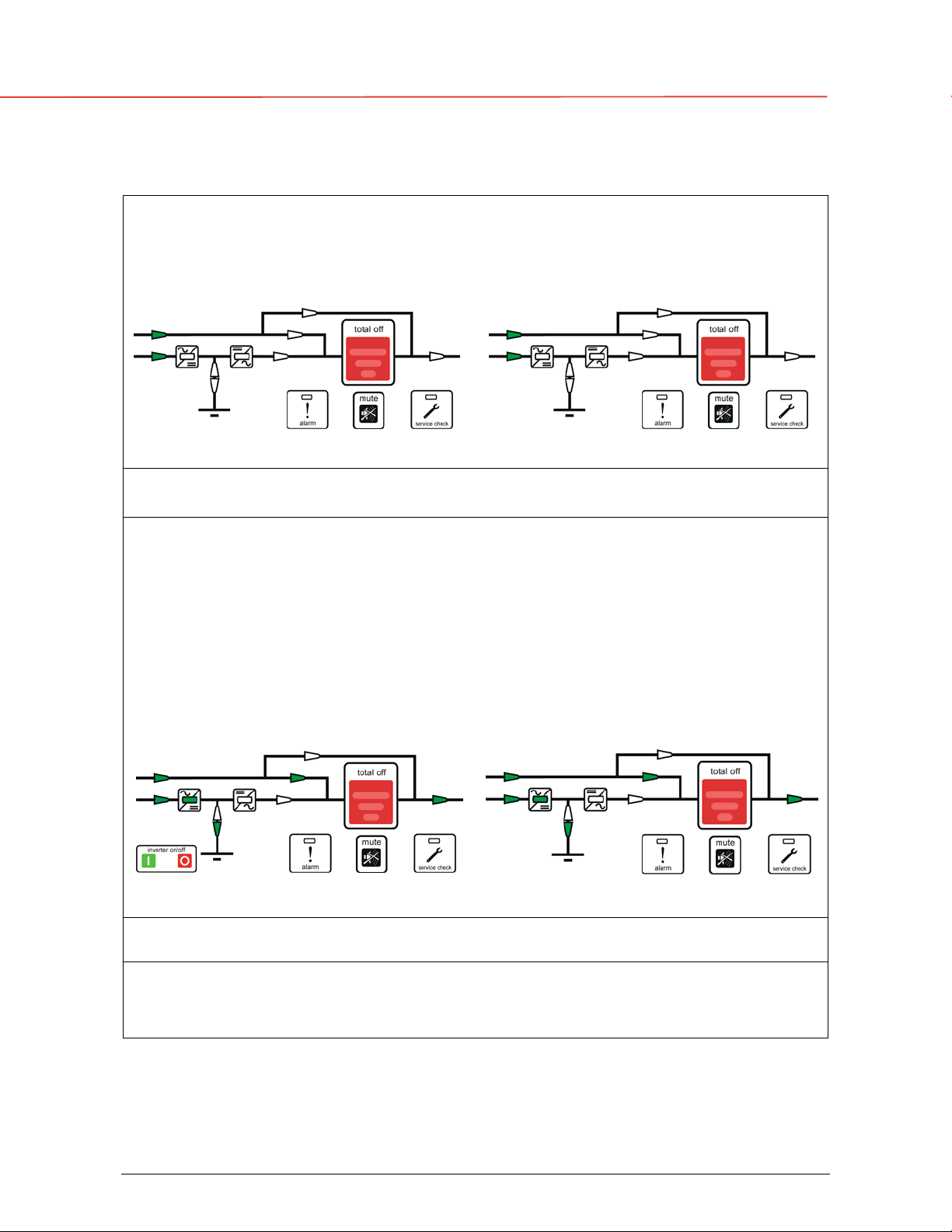

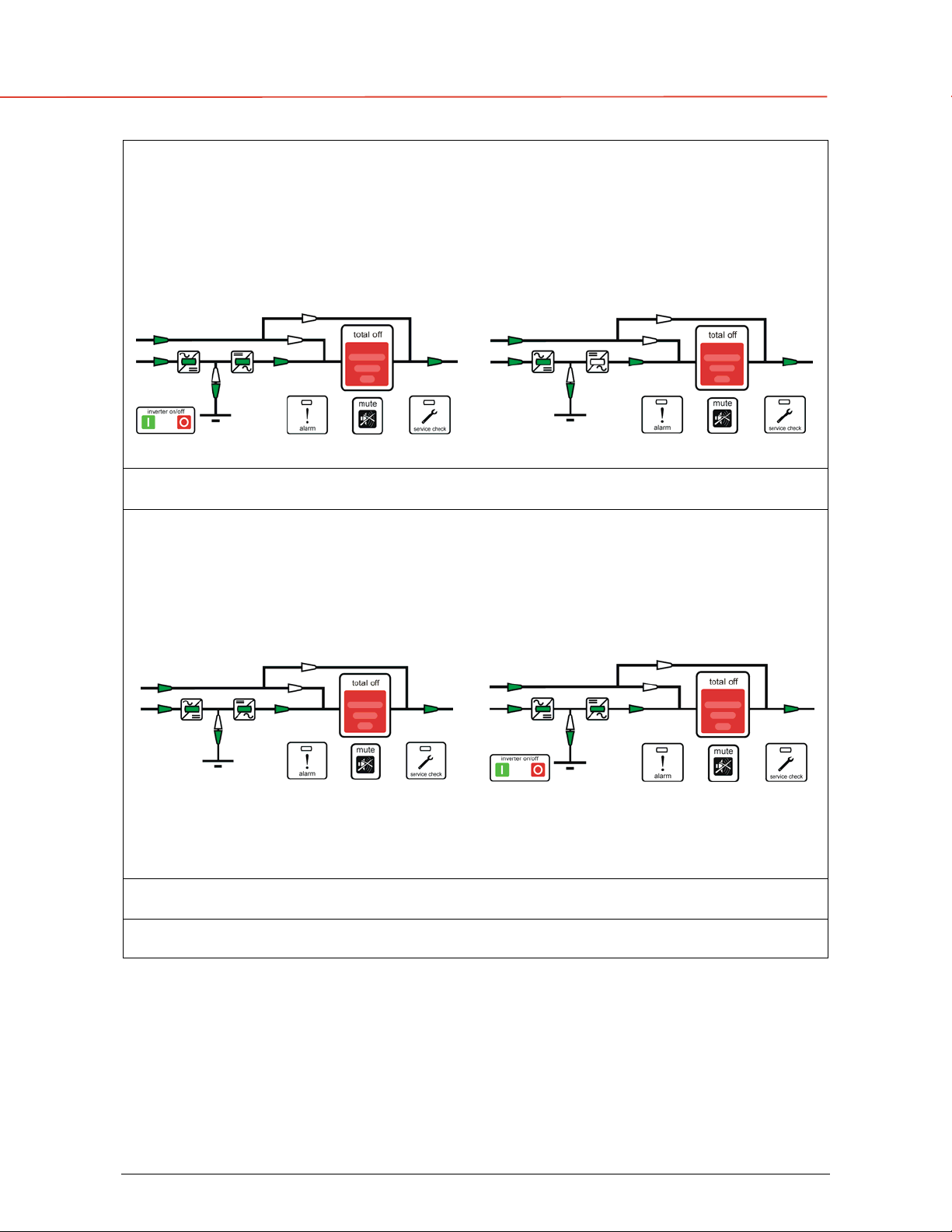

7.4 PROCEDURES FOR PARALLEL SYSTEM WITH COMMON BATTERY ....................66

7.4.1 Parallel System start-up ................................................................................................66

7.4.2 Maintenance system shutdown (Load supplied from Q2 on all Units)...........................68

7.4.3 From Manual Bypass (Q2) to normal function On-line ..................................................69

7.4.4 Separate a Unit from the parallel system (System Redundancy)..................................71

7.4.5 Reconnect a Unit to a parallel system ...........................................................................72

7.4.6 Parallel system shutdown (No Load supply) .................................................................73

7.4.7 Restore to normal operation after “total off”...................................................................75

7.4.8 Restore to normal operation after EPO (Emergency Power Off)...................................77

GE

8 CUSTOMER INTERFACE......................................................................................79

8.1 CUSTOMER INTERFACE ............................................................................................79

8.1.1 Serial Port J3.................................................................................................................80

8.1.2 Output free potential contacts .......................................................................................80

8.1.3 Programmable input free contacts ................................................................................81

8.1.4 Gen Set Signaling (GEN ON)........................................................................................81

8.1.5 AUX external Maintenance Bypass...............................................................................81

8.1.6 Auxiliary Power Supply (APS) 24 VDC / 1A ..................................................................81

8.1.7 EPO (Emergency Power Off) Input contact...................................................................82

9 OPTIONS ................................................................................................................83

9.1 BUILT IN UPS OPTIONS ..............................................................................................83

9.2

9.3 OPTIONS IN UPS CABINET.........................................................................................83

9.4 CONNECTION FOR OPTIONS.....................................................................................84

9.4.1 Remote Signaling Box (RSB) ........................................................................................84

COMMUNICATION OPTIONS ......................................................................................83

10 MAINTENANCE......................................................................................................85

10.1 MAINTENANCE ............................................................................................................85

10.1.1 Service check ................................................................................................................85

10.1.2 Fans and ventilation ......................................................................................................85

10.1.3 Other components with limited lifetime..........................................................................85

10.1.4 Battery ...........................................................................................................................85

10.1.5 Long shut-down periods of the UPS-system .................................................................86

10.1.6 UPS room conditions and temperature .........................................................................86

10.1.7 Long shut-down periods of the UPS-system .................................................................86

11 NOTES....................................................................................................................87

11.1 NOTES FORM ..............................................................................................................87

OPM_SGS_USM_10K_40K_0US_V010.doc 6/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 7

g

1 IMPORTANT SAFETY INSTRUCTIONS

GE

SAVE THESE INSTRUCTIONS

This manual contains important instructions for models SG Series 50 and 80 kVA that should be

followed during installation and maintenance of the UPS and battery.

- Move the UPS in an upright position in its original package to the final destination room.

To lift the cabinets, use a forklift or lifting belts with spreader bars.

- Check for sufficient floor and elevator loading capacity.

- Check the integrity of the UPS equipment carefully.

If you notice visible damage, do not install or start the UPS. Contact the nearest Service Center

immediately.

- WARNING! RISK OF ELECTRICAL SHOCK: Do not remove covers; there are no user serviceable

parts inside.

- All maintenance and service work should be performed by qualified service personnel.

The UPS contains its own energy source (battery).

- The field-wiring terminals may be electrically live, even when the UPS is disconnected from the

utility.

- Dangerous voltages may be present during battery operation.

The battery must be disconnected during maintenance or service work.

- This UPS contains potentially hazardous voltages.

- Be aware that the inverter can restart automatically after the utility voltage is restored.

INSTALLATION

- This UPS must be installed and connected only by trained personnel.

- Verify accurately during Commissioning and Maintenance of the UPS, for the following:

Damaged components, squeezed wires and cables, or not correctly inserted plugs.

- After removing the sidewalls of the UPS, make sure that all earth connections when

reassembling, are correctly reattached

- This UPS is intended for use in a controlled indoor environment free of conductive contaminants

and protected against animals intrusion.

- HIGH GROUND LEAKAGE CURRENT: Ground connection is essential before connecting to AC

input!

- Switching OFF the unit does not isolate the UPS from the utility.

- Do not install the UPS in an excessively humid environment or near water.

- Avoid spilling liquids on or dropping any foreign object into the UPS.

- The unit must be placed in a sufficiently ventilated area; the ambient temperature should not

exceed 104°F (40°C).

- Optimal battery life is obtained if the ambient temperature does not exceed 77°F (25°C).

- It is important that air can move freely around and through the unit. Do not block the air vents.

- Avoid locations in direct sunlight or near heat sources.

- Store the UPS in a dry location; storage temperature must be within -13°F (-25°C)

- If the unit is stored for a period exceeding 3 months, the battery must be recharged periodically

(time depending on storage temperature).

GENERAL

STORAGE

BATTERY

to

131°F (55°C).

- The battery-voltage is dangerous for person’s safety.

- When replacing the battery, use the same number, voltage (V) and capacity (Ah).

-

Proper disposal or recycling of the battery is required.

Refer to your local codes for disposal requirements.

- Never dispose of battery in a fire: They may explode.

- Do not open or mutilate battery: Their contents (electrolyte) may be extremely toxic.

If exposed to electrolyte, wash immediately with plenty of water.

- Avoid charging in a sealed container.

- Never short circuit battery.

When working with battery, remove watches, rings or other metal objects, and only use

insulated tools.

OPM_SGS_USM_10K_40K_0US_V010.doc 7/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 8

g

GE

Safety instructions when working with battery

EXTERNAL BATTERY MUST BE INSTALLED AND CONNECTED TO THE

UPS BY QUALIFIED SERVICE PERSONNEL.

INSTALLATION PERSONNEL MUST READ THIS ENTIRE SECTION AND

REFER TO THE BATTERY MANUFACTURERS INSTALLATION MANUAL

BEFORE HANDLING THE UPS AND BATTERY.

UPS INTENDED TO BE USED WITH A REMOTE BATTERY SUPPLY – ALL MODELS:

“PLEASE REFER TO THE BATTERY MANUFACTURER’S INSTALLATION MANUAL FOR

BATTERY INSTALLATION AND MAINTENANCE INSTRUCTIONS”.

DANGER!

Full voltage and current are always present at the Battery Terminals.

The Battery used in this system can provide dangerous voltages, extremely high currents and a risk of

electric shock.

They may cause severe injury if the terminals are shorted together or to ground.

You must be extremely careful to avoid electric shock and burns caused by contacting Battery

Terminals or shorting terminals during battery installation.

Do not touch un-insulated Battery Terminals.

A qualified service person that is familiar with Battery systems and required precautions must install and

service the Battery.

The installation must conform to national and local codes.

Keep unauthorized personnel away from Battery.

The qualified service person must take these precautions:

1 Wear protective clothing, such as rubber gloves and boots and protective eye wear.

Batteries contain caustic acids and toxic materials and can rupture or leak if mistreated.

Remove rings and metal wristwatches or other metal objects and jewelry.

Do not carry metal objects in your pockets where the objects can fall into the Battery Cabinet.

2 Tools must have insulated handles and must be insulated so that they will not short Battery

Terminals.

Do not allow a tool to short between individual or separate Battery Terminals or to the cabinet or

rack.

Do not lay tools or metal parts on top of the Battery, and do not lay them where they could fall onto

the Battery or into the cabinet.

3 Install the Battery as shown on the drawing provided with the Battery.

When connecting cables, never allow a cable to short across a Battery’s Terminals, the string of

batteries, or to the cabinet or rack.

4 Align the cables on the Battery Terminals so that the cable lug will not contact any part of the

cabinet or rack, even if the Battery is moved.

Keep the cable away from any sharp metal edges.

5 Install the Battery Cables so the UPS or Battery Cabinet Doors cannot pinch them.

6 Do not connect the Battery Terminal to Ground.

If any Battery Terminal is inadvertently grounded, remove the source of the ground.

Contacting any part of a grounded Battery can cause a risk of electric shock.

7 To reduce the risk of fire or electric shock, install the Battery in a temperature and humidity

controlled indoor area, free of contaminants.

8 Battery System Chassis Ground (earth) must be connected to the UPS chassis ground (earth).

If you use conduit, this ground conductor must be routed in the same conduit as the Battery

Conductors.

9 Where conductors may be exposed to physical damage, protect the conductors in accordance with

all applicable codes.

10 If you are replacing Battery or repairing Battery Connections, shut OFF the UPS and remove the

Battery Fuses or open the Battery System disconnect.

OPM_SGS_USM_10K_40K_0US_V010.doc 8/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 9

g

GE

Safety symbols and warnings

Safety warnings

The text of this manual contains some warnings to avoid risk to the persons and to avoid damages

to the UPS system and the supplied critical loads.

The non-observance of the warnings reminding hazardous situations could result in human injury

and equipment damages.

Please pay attention to the meaning of the following warnings and symbols.

Throughout this manual the following symbols are defined:

WARNING, if instruction is not followed injury or serious equipment

damage may occur!

CAUTION, internal parts have dangerous voltage present.

Risk of electric shock!

PE (Earth) – GND (Ground)

PROTECTIVE GROUNDING TERMINAL:

A terminal which must be connected to earth ground prior to making any

other connection to the equipment.

A terminal to which or from which an alternating (sine wave) current or

voltage may be applied or supplied.

A terminal to which or from which a direct current or voltage may be

applied or supplied.

This symbol indicated the word “phase”.

This symbol indicates the principal on/off switch in the on position.

This symbol indicates the principal on/off switch in the off position.

OPM_SGS_USM_10K_40K_0US_V010.doc 9/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 10

g

2 INTRODUCTION

An Uninterruptible Power Supply (UPS) provides the power for critical loads that need a

reliable, continuous, disturbance free supply.

In case the power provided by the Utility Fails, or exceeds the permitted tolerances, the power

to supply the Load is provided by the Battery for the specified time at the rated Load (or longer

at a reduced Load) or until the Utility power returns.

SG Series is a true double conversion On-line UPS system where the Load is continuously

supplied by the Inverter through the Rectifier.

In case of trouble on the Inverter Output Voltage, or when overload or short-circuit on the

output occur, the Load is instantly transferred to the Utility via the Automatic Bypass.

The UPS automatically returns to normal mode when the failure condition is restored.

Key features

• More Critical equipment supported

Rated at 0.8 Power Factor, SG Series delivers more real power than other UPS in the

market.

With today’s trend toward power factor corrected loads, SG Series can support more total

Load than any other UPS available, allowing you to support a greater number of today’s

enterprise computing Power Factor Corrected (PFC) equipment.

• No single point of failure

Redundant Parallel Architecture (RPA) is an exclusive GE technology.

With RPA, SG Series UPS are controlled in a true peer-to-peer configuration where all

critical elements and functions (including Bypass) are redundant.

SG Series is designed to be the most reliable power protection system available on the

market today.

• High Efficiency

Using IGBT technology and Space Vector Modulation (SVM) strategy, SG Series offers low

output voltage distortion and provides efficiencies up to 93%.

• Fully digital

Digital Signal Processor (DSP), Flash memory and SVM strategy, are the technology

corner stones of new age of power quality and power reliability.

• Extremely flexible

Tailor made power protection to meet your individual installation requirements; SG Series

offers various options like input harmonic filters and our comprehensive JUMP software

suite for mission control and data protection to cover all your application needs.

:

GE

OPM_SGS_USM_10K_40K_0US_V010.doc 10/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 11

g

3 DESCRIPTION

3.1 BLOCK DIAGRAM AND MAIN ELEMENTS

GE

The SG Series system can be divided into the following main elements:

Fig. 3.1-1 Block diagram

Control System SG Series is designed with microprocessor-controlled signal

processing circuits. The interface between the operator and the unit is provided by the

monitoring system on the front panel.

This monitoring system consists of an active mimic diagram, a keyboard and a backlit

display.

Rectifier The standard Rectifier consists of a 6-pulse SCR-bridge, which

converts the 3-phase Utility Voltage into a controlled and regulated DC-voltage.

This regulated DC-voltage is used to supply power to the Inverter, and to provide charging

power to the Battery.

Inverter

The Inverter converts the DC voltage into a three-phase ACvoltage with constant amplitude and frequency, which is completely independent and isolated

from the AC-input voltage.

Automatic Bypass The Automatic Bypass consists of a static semiconductor-switch

(SSM: Static Switch Module), used to provide an uninterrupted transfer of the Load from

Inverter to Utility.

Back-feed Protection

All SG Series UPS's are equipped with an automatic system for

the protection against voltage back feeding towards Utility, through the Bypass (Applied

Standard IEC 62040-1).

This protection works automatically by opening contactor K6 and K8 (in series with the

thyristors of the static switch) and eventually K7, and acts in case of internal defects of the

system, or due to wrong manipulations on the Manual Bypass Q2.

Manual Bypass The Manual Bypass consists of a pair of manual switches (Q1

and

Load with power directly from the Utility.

, which removes the UPS from the Load for maintenance, while still supplying the

Q2)

Battery The Battery supplies the DC power to the Inverter when the

Utility is out of accepted tolerances.

OPM_SGS_USM_10K_40K_0US_V010.doc 11/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 12

g

3.2 OPERATION MODES

3.2.1 Normal operation mode

During normal operation, the Rectifier

converts input AC power to DC.

The DC power provides input power for the

Inverter and charging power for the Battery.

The Inverter converts the DC power to

continuous and regulated AC power, which

supplies the critical load.

The control panel reports the Battery charge

status and the expected backup time with the

actual load.

3.2.2 Utility failure operation

When the Utility is no longer within acceptable

tolerances, the Battery will provide the DC

power to the Inverter.

The Inverter will maintain continuous AC

power to the Load until the Battery Voltage

reaches the lower limit of the Inverter

operation capability.

During the discharge, the LCD screen displays

the estimated time the Battery can support the

critical load.

Prior to the Battery completely discharging,

the "stop operation" alarm (shutdown

imminent) warns the operator that the Battery

is almost discharged and the UPS is about to

shut down.

Fig. 3.2.1-1 Block diagram normal operation mode

Fig. 3.2.2-1 Block diagram Utility Failure operation

GE

In case of parallel operation

With a parallel system for power capacity (see Section 3.3)

With the

•

Load to be transferred to Utility (after a selectable time delay).

• With Bypass Utility power not available, a low Battery warning on any unit will start the

“

stop operation

The Load will shut down at the end of the “stop operation” time period.

With a parallel system for redundancy (see Section 3.3)

• When a Battery low warning occurs on a unit not necessary to support the present load, this

unit will shut down after a timeout period (selectable).

The Load is shared between the other units

• As the warning occurs on one unit necessary to support the present load, the system starts

the "

The Load will shut down at the end of the “stop operation” time period.

OPM_SGS_USM_10K_40K_0US_V010.doc 12/88 Operating Manual

Bypass Utility power available,

” timer (adjustable).

stop operation

" timeout (selectable).

a low Battery warning on any unit will cause the

SG Series

10, 20, 30 & 40 kVA

Page 13

g

3.2.3 Utility recovery operation

As soon as the AC input power recovers, the

Rectifier will start automatically,

power to the Inverter and recharging the Battery.

If the Inverter was previously shut down due to low

Battery, the Load will be initially powered by Utility

through the

When the Battery is recharged enough to ensure a

minimum time of operation with the present load,

the Inverter will start automatically and the Load

will be transferred back to the Inverter.

When the AC input power recovers, the Rectifiers will start up sequentially, according to their

number in the parallel system. This minimizes the

The Inverters will start up automatically, but only when the Battery has recharged enough for

a

minimum runtime

When enough Inverters to supply the Load have been restarted, the Load will be transferred

from the Automatic Bypass back to the Inverter output.

Automatic Bypass

In case of parallel operation

with the present load.

supplying DC

.

Fig. 3.2.3-1 Block diagram Utility recovery operation

initial inrush current.

GE

3.2.4 Automatic Bypass

In normal operation, the Load is supplied by the

Inverter.

When the control system detects a fault in the

Inverter, an overload condition or a short-circuit

condition, the Automatic Bypass will transfer the

critical Load to the Utility without interruption.

When the Inverter recovers, or the overload or

short-circuit condition is corrected, the Load will be

automatically transferred back to the Inverter.

If the UPS is unable to return to normal mode

following an automatic transfer to Bypass mode, an

alarm condition will be initiated.

A Manual Bypass (operator initiated) will not be

considered as an alarm condition.

In case of parallel operation

Each unit has it’s own internal Bypass. These units are continuously exchanging information,

enabling all of the internal Bypass circuits in a parallel system to operate simultaneously.

If the Inverter of a unit fails, it’s Bypass circuit remains available to the parallel system.

It is excluded only if the unit is separated from the common bus by opening it’s output switch Q1.

3.2.5 Manual Bypass

FIG. 3.2.4-1 BLOCK DIAGRAM AUTOMATIC

BYPASS

The Manual Bypass circuit consists of Q1 and Q2

manual switches, which permits transfer of the

Load directly to the unconditioned AC power

without interruption, leaving the UPS available for

maintenance.

Fig. 3.2.5-1 Block diagram Manual Bypass

OPM_SGS_USM_10K_40K_0US_V010.doc 13/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 14

g

3.3 PARALLEL SYSTEM OPERATION

3.3.1 Introduction to the parallel system

Two or more equal power units can be paralleled to increase the output power (paralleling for

capacity) or to improve the overall reliability of an UPS system (paralleling for redundancy).

The outputs of parallel units are connected to a common power bus, and in normal operation

the units connected on the parallel bus share the Load equally.

The modular concept of SG Series allows parallel operation of

paralleling switchgear, external bypass circuits or common control circuitry (see Fig. 3.3.1-1).

Parallel units for power capacity

Several units can be paralleled in order to achieve output power greater than the maximum

power of a single unit.

The maximum total power shared between the paralleled units is equal to the total installed

nominal power.

In the event of a failure of one unit, the power supplied by the UPS system becomes

insufficient and the Load will be transferred to the Utility Bypass source.

Parallel units for redundancy

The nominal power rating of the n+1

or greater than the required

The Load will be equally shared by the n

Should one of the n

the load, maintaining conditioned power to the critical load.

From this results higher reliability and security for the Load plus a higher MTBF (Mean

Time Between Failures).

paralleled units trip Off-line, the remaining (n+1) modules will supply

Load

out of n redundant paralleled modules must be equal to

power.

units connected on the output bus.

up to 8 units

, without using

GE

Fig. 3.3.1-1 Block diagram parallel system operation

OPM_SGS_USM_10K_40K_0US_V010.doc 14/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 15

g

3.3.2 Features of RPA parallel system

GE

The SG Series parallel system is designed to provide a complete

Architecture, and is free from common equipment.

Not only the Inverters are redundant, but also the Bypass functions are designed with

redundant modular concept.

When one UPS needs maintenance or service, the Load is powered by the other units

supplying the Load bus.

The redundant communication bus to which all units are connected keeps each unit informed

about the status of all the other units.

The control panel located on each unit allows controlling and monitoring the status of this

unit.

3.3.3 System control

A

high-speed redundant, serial communication

thus the communication between the CPU's of each unit.

Each module controls it's own function and operational status and communicates with all other

modules, in order to act or react if necessary, adapting it to the new conditions.

bus guarantees the exchange of data and

Redundant Parallel

3.3.4 Synchronization

All units are identical, but one unit is arbitrarily selected as the reference and all the other units

synchronize to this unit, which in turn, synchronizes to the Utility Bypass voltage, as long as

the later is within tolerances.

In case of reference failure, another unit in the parallel system is automatically chosen to take

over the reference role.

The Bypass Input for all the units of the parallel system must be supplied from the same AC

source (no phase shift allowed between them).

3.3.5 Load sharing

On each unit of the parallel system, Inverter Output Voltage and Current are measured and

applied to a Load sharing bus.

An eventual difference between the units is therefore automatically equalized.

It is strongly recommended that no transformers, automatic circuit

breakers or fuses should be inserted between the unit’s output and the

Load common bus bars.

However, it is recommended that a disconnect or isolation switch be

inserted.

OPM_SGS_USM_10K_40K_0US_V010.doc 15/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 16

g

3.4 RECTIFIERS PARALLELED ON THE SAME BATTERY

A parallel system with a Common Battery for two or more Rectifiers,

requires a particular installation and adequate setting of some

parameters, (accessible only through password), and can therefore

only be done by a qualified engineer from GE.

Usually each Rectifier-Inverter Unit runs with its own Battery.

In case of parallel units are running with a Common Battery (max. 4 UPS - see Fig 4.12-1), the

sharing circuit between individual Rectifier is integrated in the communication bus of the

system in order to assure an equal sharing of the Rectifiers output currents.

1 –

Rectifier

2 –

Inverter

3 –

Automatic Bypass

4 –

Manual Bypass

5 –

Mains Power

GE

6 –

Load Bus Bar

7 –

External Battery Fuse

8 –

Battery

Fig. 3.4-1 Diagram RPA system with Rectifiers on Common Battery

Pay attention to the following recommendations:

• The units delivered for this functioning mode needs a special parameters setting, so they

must be prepared in advance before the installation.

• The installation must be performed only with the UPS system must be completely shut

down.

• The AC Rectifiers input power (5) must be the same, with clockwise phase rotation for each

unit.

• Each Rectifier must be set for the same floating DC voltage and the same Battery current

limitation.

• It is recommended to install the fuses / MCB (7) on each line connecting the Rectifiers to

the common

• In case one must be powered down for maintenance, switch-OFF the concerned unit before

open the DC fuses / MCB on the Battery line (7).

• It is recommended to connect an external NO free contact “Battery Fuses” to the UPS and

to enable the function by setting the parameter (see Section 7.1).

• If an emergency generator set supply the UPS, and the free contact “Generator ON” is

connected to the Customer interface, connect a separate NO free contact on each parallel

unit.

• The parameters enabling the Battery test, both manual and automatic, must be set in the

same mode on all the units having the Rectifiers on Common Battery.

• Do not connect the temperature sensor for automatic battery floating voltage compensation.

• Do not enable the function Boost charge (parameter 87).

Battery

for maintenance / safety reasons.

OPM_SGS_USM_10K_40K_0US_V010.doc 16/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 17

g

3.5 RECYCLING AT THE END OF SERVICE LIFE

NOTE!

This product has been designed to respect the environment, using

materials and components respecting eco-design rules.

It does not contain CFCs (Carbon Fluor Clorid) or HCFCs (Halogen

Carbon Fluor Clorid).

Packing material recycling

GE, in compliance with environment protection, uses only environmentally

friendly material.

UPS packing materials must be recycled in compliance with all applicable

regulations.

GE

WARNING!

Leads contained in the batteries is a dangerous substance for the

environment, therefore it must be correctly recycled by specialized

companies!

OPM_SGS_USM_10K_40K_0US_V010.doc 17/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 18

g

4 LAYOUT

GE

4.1 LAYOUT

SG Series

10 AND 20 KVA

SGT5000_030-040_UPS_GE_02

FIG. 4.1-1 SG SERIES GENERAL VIEW

SGT5000_010-020_UPS_GE_03

Fig. 4.1-2 SG Series general view with open doors

Fig. 4.1-3 Manual operated switches

Fig. 4.1-4 Control Panel

SNMP

P4

1

2

3

4

1

2

3

4

SGT5000_100-150_Customer interface_03

XA

XB

P4

Q1

Q2

SNMP

XA

Customer Interface Board

UPS output switch

Manual Bypass switch

SNMP Card (option)

Terminals for 24VDC Auxiliary Power Supply connection

Fig. 4.1-5 Connectivity Rack

OPM_SGS_USM_10K_40K_0US_V010.doc 18/88 Operating Manual

XB

Terminals for EPO (Emergency Power Off) connection

SG Series

10, 20, 30 & 40 kVA

Page 19

g

4.2 LAYOUT SG Series 30 AND 40 KVA

GE

SGT5000_030-040_UPS_GE_02

FIG. 4.2-1 SG SERIES GENERAL VIEW

Q1

Q2

ON

ON

OFF

OFF

Fig. 4.2-2 SG Series general view with open doors

SGT5000_030-040_UPS_GE_03

Fig. 4.2-4 Control Panel

Fig. 4.2-3 Manual operated switches

P4 Customer Interface Board

P4

SNMP

1

2

3

4

1

2

3

4

Fig. 4.2-5 Connectivity Rack

SGT5000_100-150_Customer interface_03

XA

XB

Q1

Q2

SNMP

XA

XB

UPS output switch

Manual Bypass switch

SNMP Card (option)

Terminals for 24VDC Auxiliary Power Supply connection

Terminals for EPO (Emergency Power Off) connection

OPM_SGS_USM_10K_40K_0US_V010.doc 19/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 20

g

5 CONTROL PANEL

5.1 CONTROL PANEL

GE

Fig. 5.1-1 Control Panel

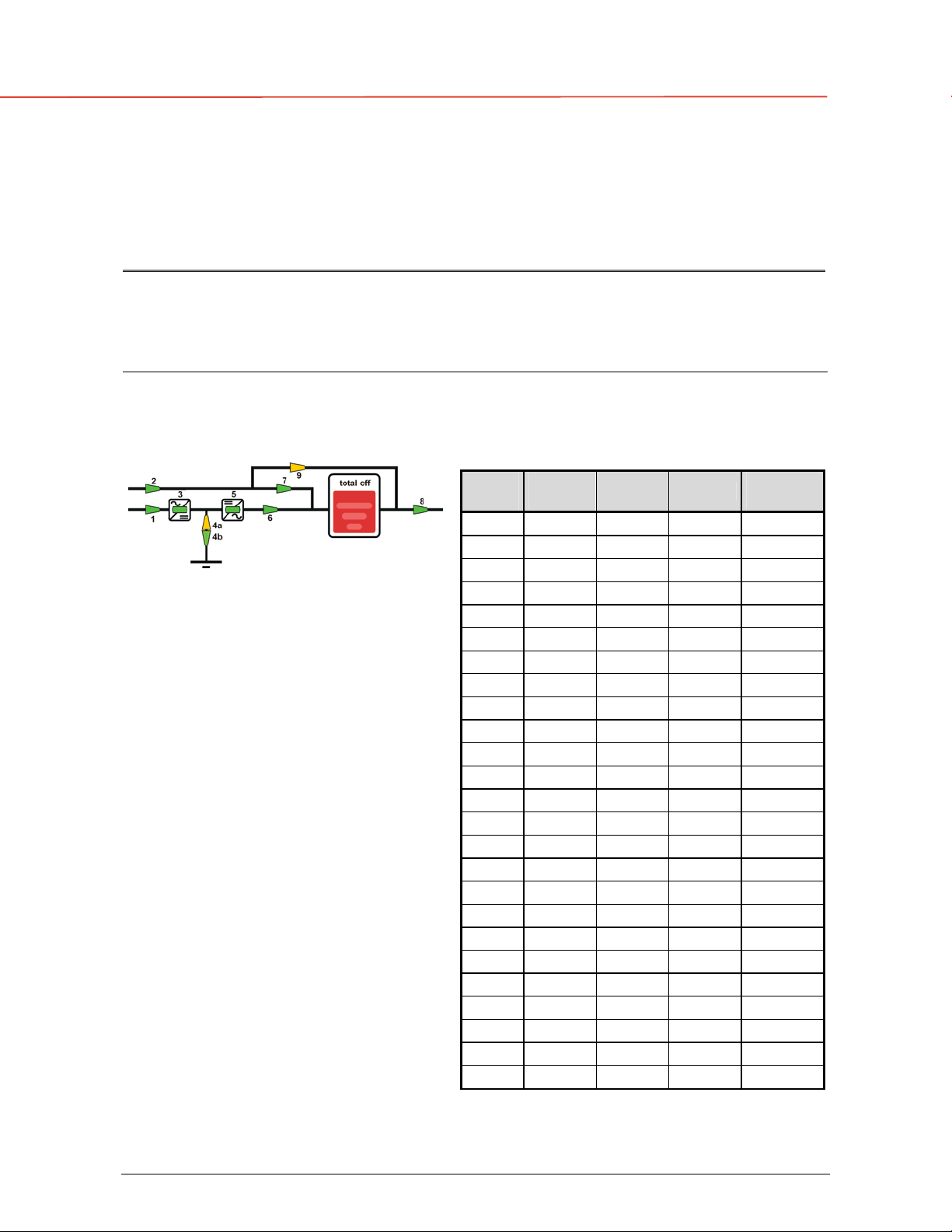

5.2 TABLE OF FUNCTIONS AND INDICATIONS ON CONTROL PANEL

inverter on/off

Key to switch the Inverter ON.

(This key is also used to

off push button).

reset “total off”

if pressed simultaneously with

inverter on/off

Key for Inverter shutdown.

Press key to transfers the

Keep pressed for 5 seconds to shutdown the Inverter.

Load to Utility

.

This key is also used as the EPO (Emergency Power Off) reset.

mute

Key to reset general alarm and buzzer.

test

Key to test the control panel LED’s and buzzer.

(Pressing this key causes all the LED’s to light and the buzzer to

sound 3 times).

The push-button “total off” is protected by a red cover.

By pressing it, you immediately separate the UPS from utility and the Load.

Attention: “total off” cannot disconnect the UPS from the Load with Q2

closed.

To reset “total off”: push and hold the “total off” push-button and the “I” key

(inverter on) simultaneously for some seconds.

total

For parallel system,

pressing “

total off

” on one unit connected on

parallel bus (switch Q1 closed), all the units are separated from the load.

The “

total off” reset

must be done only on one unit connected on the parallel

bus (switch Q1 closed).

Special care must be taken in using this command, in order to

avoid accidental Load disconnection.

OPM_SGS_USM_10K_40K_0US_V010.doc 20/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 21

g

General alarm condition.

It blinks

The LED remains lighted (with alarm condition still present) and the

alarm

service check

Fig. 5.2.1-1 LED’s on synoptic diagram

Fig. 5.2.1-2 LCD screen

buzzer stops as the key “mute” has been pressed.

LED ON indicates that a regular maintenance service is needed.

May be reset by a service technician only.

(See chapter 10 – Maintenance)

THE LED IS ON ALSO WHEN THE OUTPUT SWITCH Q1 IS OPEN,

INDICATING THAT THE INVERTER IS IN

SUPPLYING THE LOAD.

a) LED ON indicates that the Battery reserve lasts for only 3 more

b) LED ON in case of over temperature or overload >125% together with

All LED’s ON indicate that the Battery is fully charged.

LED a Yellow

LED b, c, d

(EACH ONE INDICATING 25 % OF BATTERY BACKUP)

LED’s ON indicate the Load status of the UPS.

LED d red (≥100 % load)

LED c

LED b green (66% load)

LED a

when one or more alarm is activated. The internal buzzer is

minutes

missing

After the timeout the Inverter will shut down.

(selectable).

Utility

.

(Fixed: indicating last 25 % of Battery backup)

(Blinking: indicating Battery backup ≤ 5%)

Green

yellow (100% load)

green (33% load)

ON

SERVICE MODE, NOT

Definition of the LED’s on mimic diagram

LED 1 = Input Utility Rectifier (green)

LED 2 = Input Utility Bypass (green)

LED 3 = Rectifier ON (green)

LED 4a = Discharging (yellow)

LED 4b = Charging (green)

LED 5 = Inverter ON (green)

LED 6 = Load on Inverter (green)

LED 7 = Load on Utility (green)

LED 8

LED 9 = Manual Bypass (Q2) ON (yellow)

User LCD Interface

Consist of a LCD screen, 4 lines with 20

characters each and six keys. It offers:

• UPS operating, AC and DC metering

information.

• History of alarms and events.

• Functionality can be programmed to meet

customer needs by changing parameters.

= Output Load Voltage (green)

GE

.

OPM_SGS_USM_10K_40K_0US_V010.doc 21/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 22

g

–

6 LCD SCREEN

The user interface consists of a back lit LCD screen having:

•

4 lines with 20 characters

And

• 6 keys (the function is described for each operating mode).

The operation is extremely simple and is structured on three important main menus related to

the UPS operation, as follows:

metering A UPS must offer some metering information for the user to be able to

examine the operating status at any time.

alarms In the event of Utility failures or abnormal functioning, the UPS must keep a

history of what has happened as a series of events.

parameters The user must be able to program certain functions of the UPS (user

parameters, accessible without password) to his needs.

LCD screen standard version

metering

alarms

parameters

(standard version for Latin characters).

LCD screen

4 rows x

20 characters

+

ok

GE

The 3 buttons existing on the left side of the screen are used to activate the operating

modes, while the buttons on the right side are used to carry out functions inside these

operating modes.

OPM_SGS_USM_10K_40K_0US_V010.doc 22/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 23

g

6.1 METERING MODE

The metering mode is entered any time the metering button is pressed.

While in this mode the LCD will display a series of screens containing metering information.

In this mode the buttons perform the following functions:

metering

alarms Abandons the metering mode and enters the alarms mode.

parameters Abandons the

+ Scrolls forward to the next screen.

– Scrolls backward to the previous screen.

ok Displays the main screen for this mode.

Main screen

This screen displays the current status of the UPS in a condensed form.

The information offered by this screen consists of:

• The type of the machine: Family name, series number (P + unit number for parallel

• The status of the load.

• The Load amount as a percentage of the nominal Load (referred to the most loaded phase).

• The estimated

Battery data screen

This screen displays:

• The Battery voltage.

• The Battery Current (negative values correspond to the discharge of the Battery).

• The temperature of the Battery (XXX indicates sensor disabled).

• The current charge level.

•

Bypass Utility data screen

This screen refers to the AC source supplying the Bypass. This screen displays:

• The frequency.

• The voltage levels of the three phase voltages.

Scrolls forward to the next screen.

metering mode

and enters the

version from 1 to 8) and power range.

Battery

backup time in minutes with the present load.

metering

alarms

parameters

SG Series S0 30kVA

LOAD ON INVERTER

LOAD = 84%

Autonomie = 12min

The estimated backup time with the present load.

metering

alarms

parameters

metering

alarms

parameters

Ub=540V Ib= + 15A

Battery Temp= + 20°C

Charge Level= 87%

Autonomy = 12min

UT ILIT Y

f = 60.0Hz

U1=276V U2=275V

U3=277V

parameters mode

+

–

ok

.

+

–

ok

+

–

ok

GE

OPM_SGS_USM_10K_40K_0US_V010.doc 23/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 24

g

Rectifier Utility data screen

This screen refers to the AC source supplying the Rectifier.

This screen displays:

• Iout1 = output current Rectifier Bridge.

• Iout2 = output current 2

• The voltage levels between the three phases (line-to-line).

The input frequency of the Rectifier.

•

Inverter data screen

This screen displays:

• The voltage level of the three phase voltages (line-to-neutral).

• The output frequency of the Inverter.

• The synchronization status of the Inverter with respect to Utility.

Status Load screen

This screen displays:

• The Load level in kVA (for RPA: only this unit).

• The Load level as a percentage of the nominal rated Load (for RPA: only this unit).

• The source of the power supplied to the Load.

Load on phases screen 1

This screen displays for each phase:

The output phase voltage and current as RMS values (for RPA: total value of Parallel

•

System).

• The output Load as percent (for RPA: respect to the rated power of Parallel System).

nd

Rectifier Bridge (optional 12 pulse Rectifiers only).

metering

alarms

parameters

metering

alarms

parameters

metering

alarms

parameters

metering

alarms

parameters

U12=481V Iout1 =107A

U23=480V Iout2 = 0A

U31=482V f=60.0Hz

U1=277V I=30A 84%

U2=277V I=26A 73%

U3=277V I=27A 76%

RECTIFIER

INVERTER: U1=277V

U2= 277V U3=277V

Frequency = 60.0Hz

Synchronized

LOAD ON UPS

Load = 25.20kVA

Percentage = 84%

LOAD ON INVERTER

LOAD ON PHASES

+

–

ok

+

–

ok

+

–

ok

+

–

ok

GE

OPM_SGS_USM_10K_40K_0US_V010.doc 24/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 25

g

–

–

–

Load on phases screen 2

This screen displays for each phase:

The Load active power (kW) (for RPA: total value of Parallel System).

•

• The Load apparent power (kVA) (for RPA: total value of Parallel System).

GE

metering

alarms

parameters

LOAD ON PHASES

L1= 6.72kW 8.40kVA

L2= 5.84kW 7.30kVA

L3= 6.08kW 7.60kVA

+

–

ok

Miscellaneous screen

This screen displays:

• The temperature of the Inverter Bridge.

• The total operating time for the UPS (in hours).

• The total operating time for the Inverter (in hours).

metering

alarms

parameters

MISCELLANEOUS

InvHeatsink = 45°C

UpsOperTime= 3125h

InvOperTime = 2135h

+

ok

Utility Faults Statistics screen

This screen displays:

• The total number of minor Utility faults (Bypass Utility out of tolerance faults).

• The total number of major Utility faults (Rectifier Utility out of tolerance faults).

• The total number of detected output overloads.

metering

alarms

parameters

UTILITY FAULTS STAT.

Minor = 43210

Major = 11267

Overloads= 654

+

ok

UPS identification screen

This screen displays:

• The UPS family and the power range.

• The software version.

• The serial number.

metering

alarms

parameters

UPS IDENTIFICATION

SG Series S0 30kVA

SW Version: x.xx

S/N: P0030-2003-0001

+

ok

OPM_SGS_USM_10K_40K_0US_V010.doc 25/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 26

g

–

6.2 ALARMS

The alarms mode is entered any time the

The LCD will display a series of screens corresponding to the last 256 events, one event per

screen.

The buttons perform the following functions:

metering Abandons alarms mode and enters metering mode.

alarms Next screen.

parameters Abandons the alarms mode and enters the parameters mode.

+ Scrolls forward to the next screen.

– Scrolls backward to the previous screen.

ok Display the main screen for this mode.

The events displayed are the standard

(Alarms and Messages)

The information displayed includes:

.

alarms

GE events as described in the Section 6.7 - EVENTS

button is pressed.

GE

• The exact date and time when the event occurred.

• The number of the event, 255 being the most recent event, and 0 the oldest.

• The standard GE code for the event and the machine status word.

An explicit text description of the event.

•

metering

alarms

parameters

The initial screen of this mode is the one showing the most recent event.

01.10.2002 22:11:51

NR=255 Status=4A61

4115:LOW BATTERY

VOLTAGE

+

ok

OPM_SGS_USM_10K_40K_0US_V010.doc 26/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 27

g

–

6.3 PARAMETERS

The parameters mode is entered any time the parameters button is pressed.

The LCD will display a series of screens containing the user parameters, accessible without

password protection.

The buttons perform the following functions:

metering Abandon parameters mode and enter metering mode.

alarms

parameters Scroll forward to the next screen.

+ Scroll forward to the next screen.

– Select from the current screen the parameter to edit.

ok Start the editing for the currently selected parameter.

Example of operation within parameters mode:

Purpose: to correct a wrong telephone number previously stored in Tel2.

1 – entering parameters mode (parameters). The first screen is displayed.

2 – scroll to the next screen (+). The second screen is displayed.

3

4 – move the selection (underscore cursor) to the next parameter in this page (-).

5 – move the selection to the next parameter in page (-).

6

Abandon parameters mode and enter alarms mode.

During parameters mode there is no means to perform scroll back on the

display.

– scroll to the next screen (+). The third screen is displayed.

– enter Edit mode for the currently selected parameter (ok).

metering

1

alarms

parameters

DATE AND TIME

D M Y

Date: 01

Time: 12:45:07

.10.2002

metering

2

alarms

parameters

PROTOCOL SETUP

Modem enabled=N

Init=BEQV1X3&D0S0=2

Alarm= N Delay=22s

+

–

ok

+

ok

GE

OPM_SGS_USM_10K_40K_0US_V010.doc 27/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 28

g

–

–

–

–

3

metering

alarms

parameters

Tel1:002186394567

Tel1 enabled: N

Tel2:004017464340

Tel2 enabled: N

+

ok

GE

4

metering

alarms

parameters

Tel1:002186394567

Tel1 enabled: N

Tel2:004017464340

Tel2 enabled: N

+

ok

5

metering

alarms

parameters

Tel1:002186394567

Tel1 enabled: N

Tel2:0

04017464340

Tel2 enabled: N

+

ok

6

metering

alarms

parameters

EDIT MODE

PHONE NUMBER 2

004017464340

+ SCROLL - CHANGE

+

ok

OPM_SGS_USM_10K_40K_0US_V010.doc 28/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 29

g

6.4 EDIT MODE

The EDIT MODE is entered from the parameters mode when the ok button is pressed.

During this mode the LCD will display a special editing screen for the parameter being edited.

The screen contents during Edit mode is:

• On the first line of the screen it is clearly indicated the special operating mode.

• On the second line you will find the name of the parameter being edited.

• On the third line is displayed the current value of the parameter.

• The fourth line contains a condensed help text.

During the Edit mode the buttons perform the following functions:

metering Exits Edit mode and enters metering mode; any changes are discarded.

alarms Exits Edit mode and enters alarms mode; any changes are discarded.

GE

parameters

Exits Edit mode and enters parameters mode; any changes are discarded.

+ Scroll from editable position to editable position;

– Change the currently selected editable position.

ok Return to parameters mode after saving the changes.

Examples of operation during Edit mode

There are three types of parameters having differences in behavior during Edit mode.

Depending the type of parameters, there are different ways to select and to change the

needed values.

Type 1: Parameters having a large range of values (numeric value).

As continuation of the previous example, the telephone number stored in “Tel2” must be

changed:

1 – move the selection (block cursor) to the next character.

2 – move the selection to the next character (+).

3 – change the selected character (-).

– change the selected character (-).

4

5 – press ok: the screen will return to parameters mode saving the new value.

1

metering

alarms

parameters

004017464340

+ SCROLL - CHANGE

EDIT MODE

PHONE NUMBER 2

+

–

ok

metering

2

alarms

parameters

004017464340

+ SCROLL - CHANGE

EDIT MODE

PHONE NUMBER 2

+

–

ok

OPM_SGS_USM_10K_40K_0US_V010.doc 29/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 30

g

3

4

5

Type 2:

Parameters having a

For example the parameter

9600}.

There is no need to edit this parameter digit by digit.

By pressing the [–] button the next value within the range is automatically provided by the

software.

1 – enter Edit mode for Printer Baud Rate, initial value = 1200.

2 – change to 2400.

3 – change to 4800.

4 – press ok: the screen will return to parameters mode saving the new value.

1

2

metering

alarms

parameters

metering

alarms

parameters

metering

alarms

parameters

005017464340

+ SCROLL - CHANGE

006017464340

+ SCROLL - CHANGE

EDIT MODE

PHONE NUMBER 2

EDIT MODE

PHONE NUMBER 2

Tel1:002186394567

Tel1 enabled: N

Tel2:0

Tel2 enabled: N

limited range of values

Printer Baud Rate

metering

alarms

parameters

metering

alarms

parameters

1200

+ SCROLL - CHANGE

2400

+ SCROLL - CHANGE

EDIT MODE

PRINTER BAUDRATE

EDIT MODE

PRINTER BAUDRATE

+

–

ok

+

–

ok

+

06017464340

–

ok

.

has the range {600, 1200, 2400, 4800 and

+

–

ok

+

–

ok

GE

OPM_SGS_USM_10K_40K_0US_V010.doc 30/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 31

g

3

4

Type 3: Boolean parameters used to simulate command buttons.

The Boolean parameters have a range of Yes/No.

Only the user performs the modification of the value.

These “Type 3” parameters are used to initiate an action. There are two possibilities:

A 1 – the user wants the UPS to start the action => the user sets the parameter to “Yes”.

2 – the UPS finishes the action => the UPS sets the parameter to “No”.

B 1 – the user wants the UPS to start the action => the user sets the parameter to “Yes”.

2 – the user wants to abort the action => the user sets the parameter to “No”.

The actions that can be performed using such software buttons are:

• Print the metering information.

• Print the last 256 events.

• Print the values of the parameters.

• Print all the information obtainable from the UPS.

Returning from the Edit mode

Normally ok button is used to return from the Edit mode.

Then the UPS will perform some validity tests on the new value.

If these tests are successful then the new value is saved and used.

If these tests fail the Edit mode is not exited.

The validity tests performed by the UPS are not exhaustive.

You should not rely exclusively on these tests.

Care should be taken when modifying the values of the parameters.

For all parameters except the LCD Contrast parameter the new value is saved and used

after the ok button was pressed.

In the case of the LCD Contrast parameter the new value is used immediately in order to

obtain a better visual feedback.

metering

alarms

parameters

metering

alarms

parameters

EDIT MODE

PRINTER BAUDRATE

4800

+ SCROLL - CHANGE

PRINTER SETUP

Baud=4

Bits=8 Handshake=XON

Print All = N

800 Parity=O

+

–

ok

+

–

ok

GE

OPM_SGS_USM_10K_40K_0US_V010.doc 31/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 32

g

–

–

6.5 USER PARAMETERS

Pressing the Parameters button displays a series of screens containing the user parameters

on the

LCD panel

This first parameter level in not protected by password, therefore the user can freely adapt

these parameters to their needs.

The meaning of the user parameters and their use is described below (buttons performance is

described to

1. Date and Time set-up

.

Section 6.3

).

GE

metering

alarms

parameters

DATE AND TIME

Date: 01.09.2002

Time: 19:44:07

M Y

D

+

ok

Date You can adjust the date of the real time clock existing in the UPS by the means of this

parameter.

The value you enter is thoroughly checked to be a correct date in the format

“dd.mm.yy”.

Time You can adjust the time of the real time clock existing in the UPS by means of this

parameter.

The value you enter is thoroughly checked to be a correct time in the format

“hh.mm.ss”. The time is specified in 24-hour format.

2. Protocol Set-up

metering

alarms

para me ters

PROTOCOL SETUP

Modem enabled= N

Init= BEQV1X3&D 0S0=2

Alarm=N Delay=22sec

+

ok

Modem enabled You can enable/disable with Y/N the remote control through modem calls

by using this parameter.

Init This parameter presents the modem initialization string.

It can be 39 characters long.

When editing this parameter the UPS considers that a blank character

terminates the string.

If no blank character is found then all 39 characters are used.

Alarm This Y/N parameter controls the automatic events signaling through

modem.

If this parameter is set to Yes the UPS itself will call the remote location

when a new event occurs.

Delay This parameter controls the delay between the occurrence of a new event

and the modem dialing.

It is useful because since the events typically do not occur isolated but in

certain sequences, you can eliminate the need for multiple dial-outs for

such a sequence of events.

OPM_SGS_USM_10K_40K_0US_V010.doc 32/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 33

g

–

3. Telephone numbers

GE

metering

alarms

parameters

Tel1:

Tel1 enabled: N

Tel2:

Tel2 enabled: N

+

ok

Tel1 This parameter specifies a first telephone number to be used for modem

dial-out.

The telephone number has a maximum 39 characters and cannot contain

blanks.

If the desired number is shorter than 39 characters, the string will finish with

blanks.

Tel1 enabled

This parameter

specifies if the

Y/N

telephone number will be used for

first

dial-out.

Tel2 A second dial-out number.

Tel2 enabled This parameter Y/N specifies if the second telephone number will be used

for dial-out.

Tel3 A third dial-out number.

Tel3 enabled This parameter Y/N specifies if the third telephone number will be used for

dial-out.

A

Tel4

fourth

dial-out number.

Tel4 enabled

This parameter

specifies if the

Y/N

telephone number will be used

fourth

for dial-out.

4. LCD Display

metering

alarms

parameters

LCD Display

UPS NAME: Signature

Contrast = 9

Language = ENGLISH

+

–

ok

UPS Name The user can choose the name of the UPS model shown on the main page

(max. 7 characters).

LCD Contrast This parameter controls the contrast of the LCD screen in ten steps.

It can be adapted depending on the room lighting.

LCD Language This parameter allows the choice of language used to display the

information.

Valid choices are English, German, Italian, Spanish, French, Finnish,

Tschech, Slovak, Polish

OPM_SGS_USM_10K_40K_0US_V010.doc 33/88 Operating Manual

and

Portuguese

.

SG Series

10, 20, 30 & 40 kVA

Page 34

g

5. Printer Set-up

The UPS is capable of communicating to a serial printer, to printout disparate information.

Please be sure to have a serial printer, that is a printer with a serial RS232 interface.

This is the

printer-interface supported by the UPS.

only

GE

metering

alarms

parameters

PRINTER SETUP

Baud=24

Bits=8 Handshake=XON

Prin t All = N

00 Parity=O

+

–

ok

Baud Rate This parameter controls the baud rate used for data transmission.

Although different values can be selected, you must select 2400 Baud,

which is the only valid parameter.

Parity This parameter controls the parity used for data transmission.

Odd (O) even (E) and “no parity” (X) can be selected.

Nevertheless the only valid value is NO PARITY (X).

Bits This parameter controls the length of the data word on the serial line during

data transmission 7 or 8 bits are offered as choice.

Please select

, as this is the only valid value.

8 bits

Handshake This parameter is used to determine the communication protocol used when

printing.

Valid values are “XON” standing for the XON/XOFF protocol or “NO”

standing for

any protocol.

Print All This parameter Y/N is used to print all the available information in the

sequence

metering, alarms, user

and

service parameters

.

Please configure your printer with the following parameters: 2400/8/N (2400

bits/sec, 8 bits, no parity).

6. Printer commands

metering

alarms

para me ters

PRINTER COMMANDS

Print Measures = N

Print Alarms = N

Print Parameters = N

Print Measures This Y/N parameter is used to print only the measurement data.

Print Alarms This Y/N parameter is used to print only the sequence of all

Alarms/Events.

Print Parameters This Y/N parameter is used to print only the list of User and Service

Parameters

After each printing command the corresponding parameter will be set again

to N.

OPM_SGS_USM_10K_40K_0US_V010.doc 34/88 Operating Manual

ok

+

–

SG Series

10, 20, 30 & 40 kVA

Page 35

g

6.6 EVENTS (ALARMS AND MESSAGES)

Each of the following listed events can be displayed on the LCD screen or on PC where the

ARGUS/JumpManager - Control Network is installed.

Alarms and Messages are differently specified because the alarms are indicating an

abnormal functioning of the UPS (which are additionally signaled with the LED alarm and

acoustically with the buzzer), while the messages indicate the various states of operation of

the UPS (stored in the events list, but no activating the LED alarm and the buzzer).

When in the alarms mode, the LCD screen displays a time ordered sequence of

screens corresponding to the last 256 alarms and messages, each screen indicating:

The number of the event (255 = the most recent).

The standard code and the status word.

GE

The date and time when the event occurred.

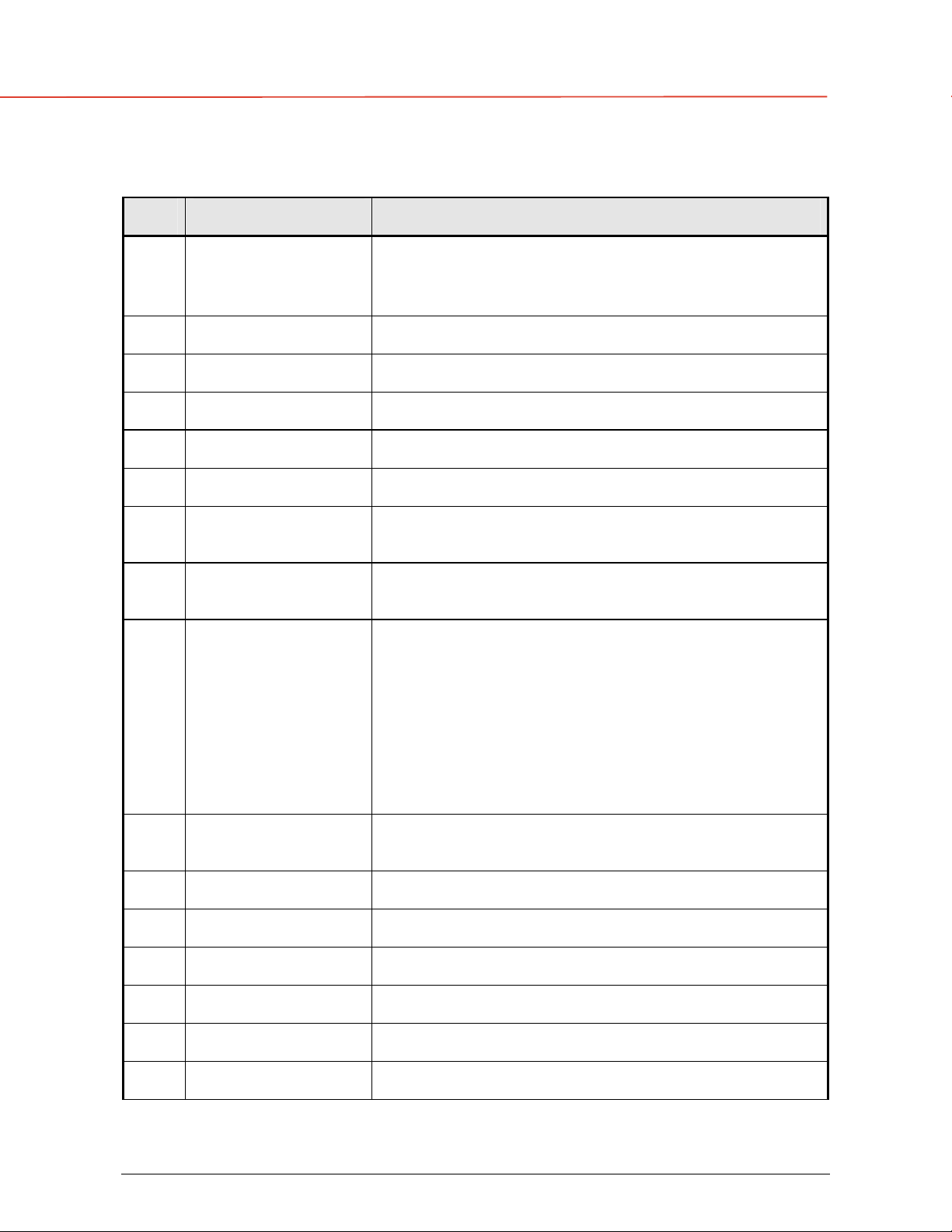

6.6.1 Alarms list

Code Alarms Meaning

Parameters are lost and have been replaced with default

values.

Call nearest Service Center for intervention.

The master unit detected the slave unit missing on the

communication bus even though switch Q1 is still closed.

The u-switch mounted on the Rectifier Input Fuses indicates

a blown fuse, and consequently shut down.

Clearance of this condition allows you to restart the Rectifier.

K4 not closed despite a closing command being issued.

Signaled by auxiliary contact.

Rectifier cannot start.

K4 not open despite an opening command being issued.

Signaled by auxiliary contact.

Utility remains connected to Rectifier bridge.

This function, when enabled on input programmable relays

(password required), warns the user about the external

Battery Fuses failure or MCB opening, signalled by NO free

contact.

Temperature sensor indicates an over temperature on the

Rectifier Bridge

Only alarm is given.

The Rectifier, when in Off state, cannot start as long as this

condition persists.

The temperature sensor inside the input transformer winding

indicates over temperature.

Only the alarm is given.

The Rectifier, when in Off state, cannot start as long as this

condition persists.

Rectifier Input Utility is out of tolerance (voltage, frequency or

phase).

.

4000

4004

4100

4102

4103

4104

4105

4106

4110

SETUP VALUES

LOST

UPS

FAILURE

RECTIFIER FUSES

FAILURE

K4 CLOSING

FAILURE

K4 OPENING

FAILURE

BATTERY

FUSES

RECTIFIER

OVERTEMPERATURE

RECTIFIER

TRANSFORMER

OVERTEMPERATURE

RECTIFIER UTILITY

OUT OF TOLERANCE

An explicit text description of the events.

OPM_SGS_USM_10K_40K_0US_V010.doc 35/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 36

g

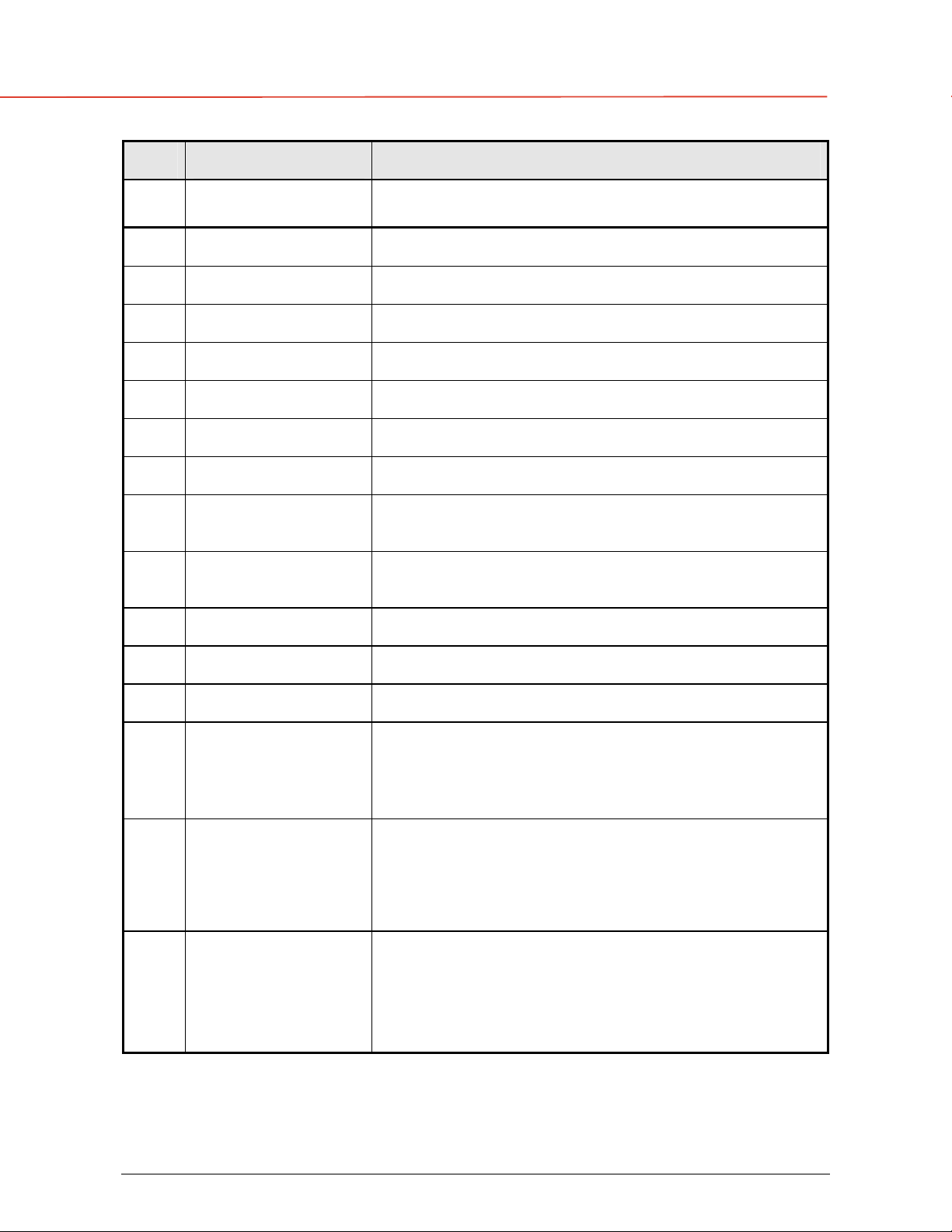

Code Alarms Meaning

The Battery has been discharged and reached “stop

operation” time-out (default 3 minutes), and the Inverter will

be shut down.

It will restart automatically only when the Battery has

recharged enough for a minimum runtime.

Dangerous high DC Voltage caused inverter shutdown.

Inverter restarts automatically after Battery returns to floating

voltage.

A leakage current to earth has been detected on the DC

circuit.

During battery test the voltage falls under the critical level

(depending setting parameters).

Battery test is stopped.

Rectifier and Inverter are OFF.

The DC power supply is discharging the Battery.

Rectifier must be restarted or Battery must be disconnected in

order to avoid damage.

Rectifier Voltage hasn’t reached the set value (probably fault

on regulation loop). LED Rectifier on control panel is blinking.

Inverter Output Fuses

Inverter can be started manually after replacement of the

fuses.

K7 not closed despite a closing command being issued.

Signaled by auxiliary contact.

Load will be supplied by Utility.

K7 not open despite an opening command being issued.

Signaled by auxiliary contact.

Load will be supplied by Utility.

The temperature sensor of the Inverter Transformer indicates

over temperature.

Elapsed “stop operation” time, Inverter shutdown.

With Utility OK, Load is transferred on Utility.

Blown input DC fuse(s) F1 of the Inverter.

Inverter cannot be started as long as present.

An abnormal condition has been detected on one or more

power modules of the Inverter (temperature or over current).

Inverter shutdown and cannot be started as long as the alarm

is present.

Inverter Output Voltage is out of the tolerances (± 10%).

Inverter is switched OFF.

Detection of Inverter Bridge (Is) current limit causing the

Inverter OFF and automatic re-start.

After 3 times the Inverter switches-Off, and it can be restarted

manually.

The “Slave” oscillator is not in synchronized with the Master;

thus causing the shutdown of it’s Inverter.

If after a restart the condition remains, the LED inside the

Inverter symbol on the panel will not light up, indicating that

this Inverter cannot supply the Load anymore.

blown (F5, F6 and F7).

4115

4116

4117

4118

4130

4140

4301

4304

4305

4307

4308

4309

4312

4320

4340

LOW BATTERY

VOLTAGE

HIGH BATTERY

VOLTAGE

BATTERY

EARTH FAULT

BATTERY FAULT

TURN ON RECT.

OR SHUTDOWN UPS

RECTIFIER

CONTROL FAILURE

INVERTER

FUSES FAILURE

K7 CLOSING

FAILURE

K7 OPENING

FAILURE

INVERTER

TRANSFORMER

OVERTEMPERATURE

DC FUSES

FAILURE

DRIVER

FAILURE

INV. VOLTAGE

OUT OF TOLERANCE

ISMAX

DETECTION

INVERTER

CONTROL FAILURE

GE

OPM_SGS_USM_10K_40K_0US_V010.doc 36/88 Operating Manual

SG Series

10, 20, 30 & 40 kVA

Page 37

g

Code Alarms Meaning

GE

4404

4405

4406

4408

4409

4410

4420

4421

4520

4522

4530

4531

4563

4570 OVERLOAD

4571

4581

OPM_SGS_USM_10K_40K_0US_V010.doc 37/88 Operating Manual

K6 CLOSING

FAILURE

K6 OPENING

FAILURE

SSM

FAILURE

K8 CLOSING

FAILURE

K8 OPENING